Smoke generating device for induction heating at front end of cigarette

A smoke generating device and induction heating technology, which is applied in the direction of tobacco, etc., can solve the problems of low heat capacity, peculiar smell of cigarettes, and the inability to install temperature sensors directly, and achieve the effect of high degree of dispersion and high airflow dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

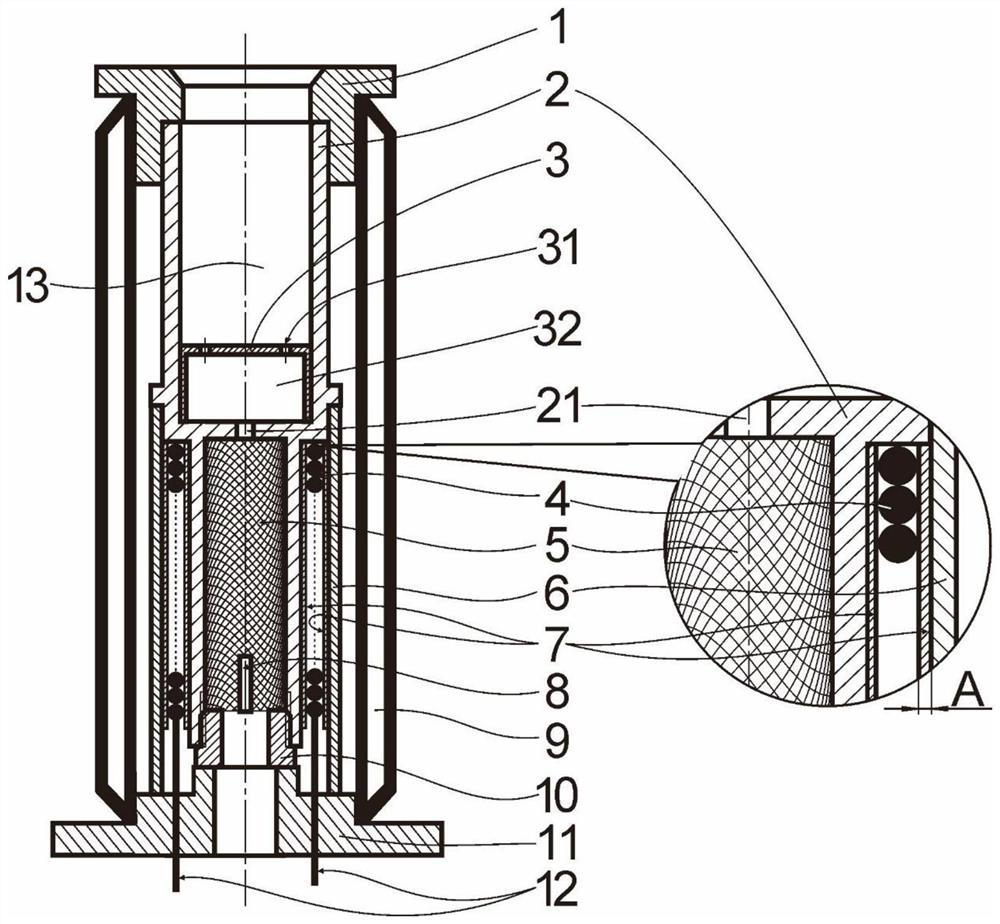

[0064] Such as Figure 1-2 , Embodiment 1 provides a smoking device that is inductively heated at the front end of a cigarette, and the smoking device includes:

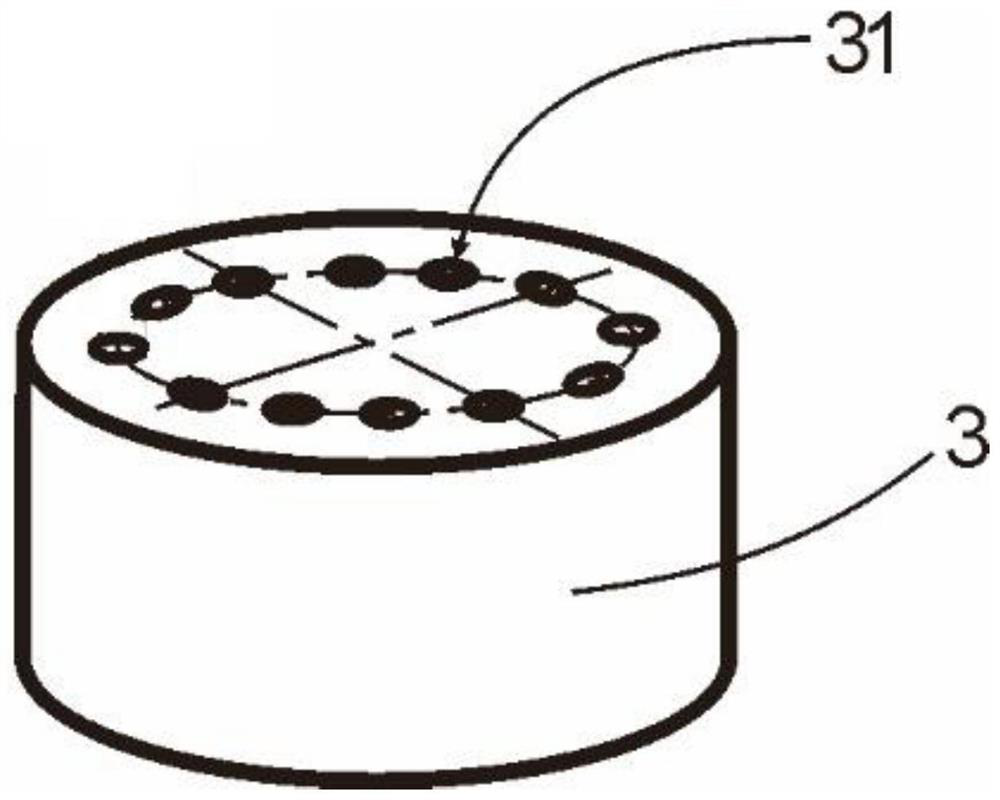

[0065] Socket seat 1, non-metallic hollow heating cup 2, hollow heat spreader 3, induction coil 4, heating element 5, shielding ring 6, heat insulation, insulation isolation layer 7, temperature sensor 8, vacuum insulation tube 9, heat insulation ring 10. Hollow base 11;

[0066] Wherein, the longitudinal section of the heating cup 2 is H-like, and the material is high-precision glass-ceramics, ceramics and other non-metallic materials with high temperature resistance and non-toxicity. The heating cup 2 has an integrated structure, including an upper hollow structure, a lower hollow structure and a baffle between the two, the upper hollow structure includes a cigarette accommodating cavity 13, and the lower hollow structure includes a heating element accommodating cavity, The baffle has a heat collecting hole 21 co...

Embodiment 2

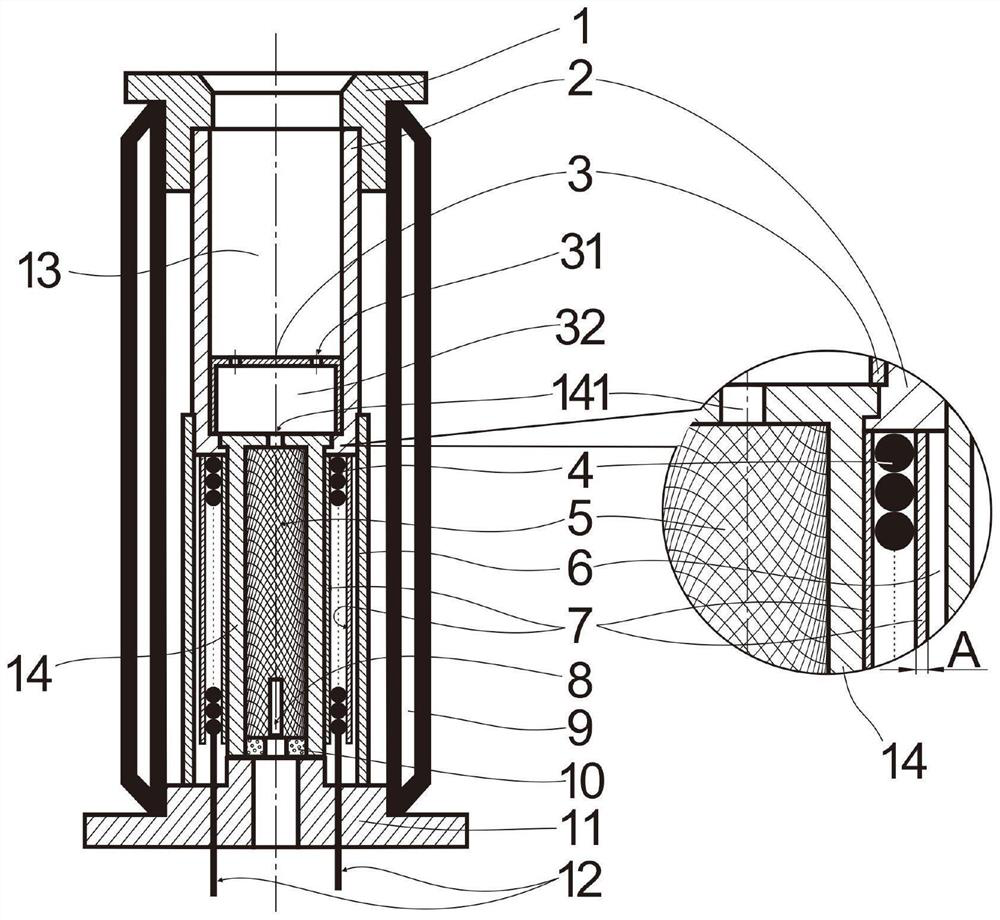

[0082] like image 3 , Embodiment 2 provides a smoking device that is inductively heated at the front end of a cigarette. The difference from Embodiment 1 is that the hollow heating cup 2 is a split structure. The upper part of the hollow heating cup 2 is a hollow tubular structure, and the lower part is a hollow tubular structure 14 with an integrated top plate. thermal hole 21. The upper part and the lower part of the hollow heating cup 2 are clamped.

[0083] The upper hollow tubular structure is made of metal, which is convenient for heat conduction and processing, and the lower hollow tubular structure 14 with a top plate is made of non-metallic material, which is convenient for magnetic conduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com