Bread production line

A production line and bread technology, applied in the fields of machinery for cleaning/greasing the baking surface, baking, food science, etc., can solve problems such as reducing the sticking of bread and bread paper, and incomplete baking at the bottom of the bread, so as to reduce production cost, increased adhesion, increased uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

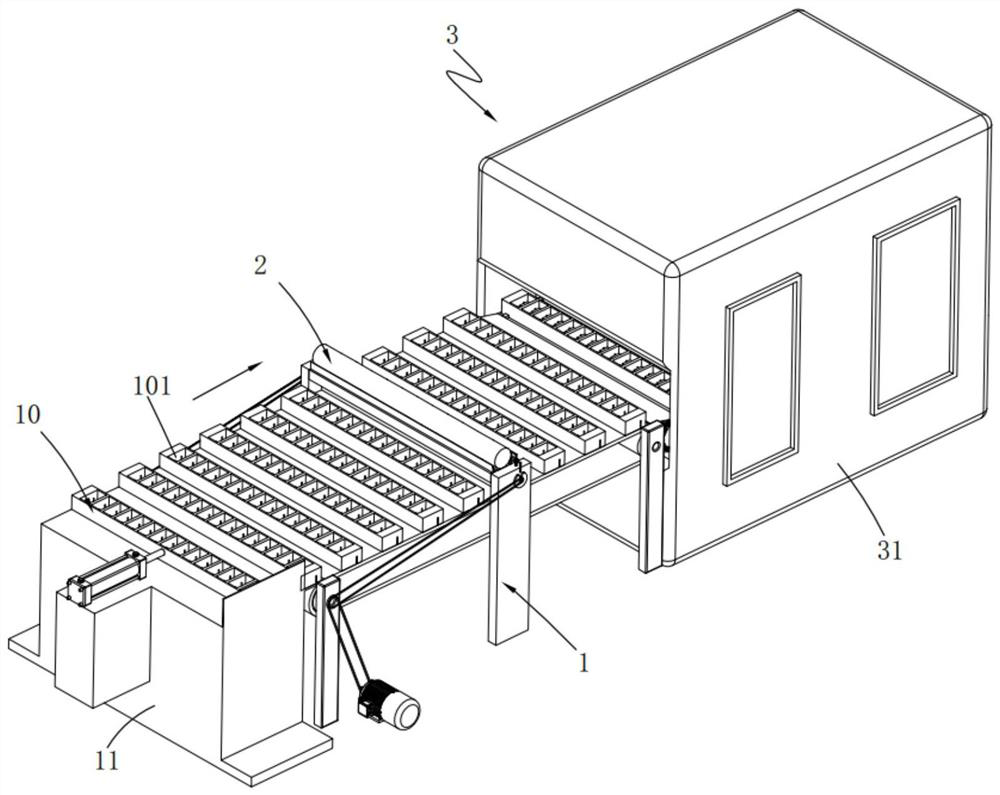

[0096] like figure 1 , 3 Shown in and 4, a kind of bread production line, it comprises:

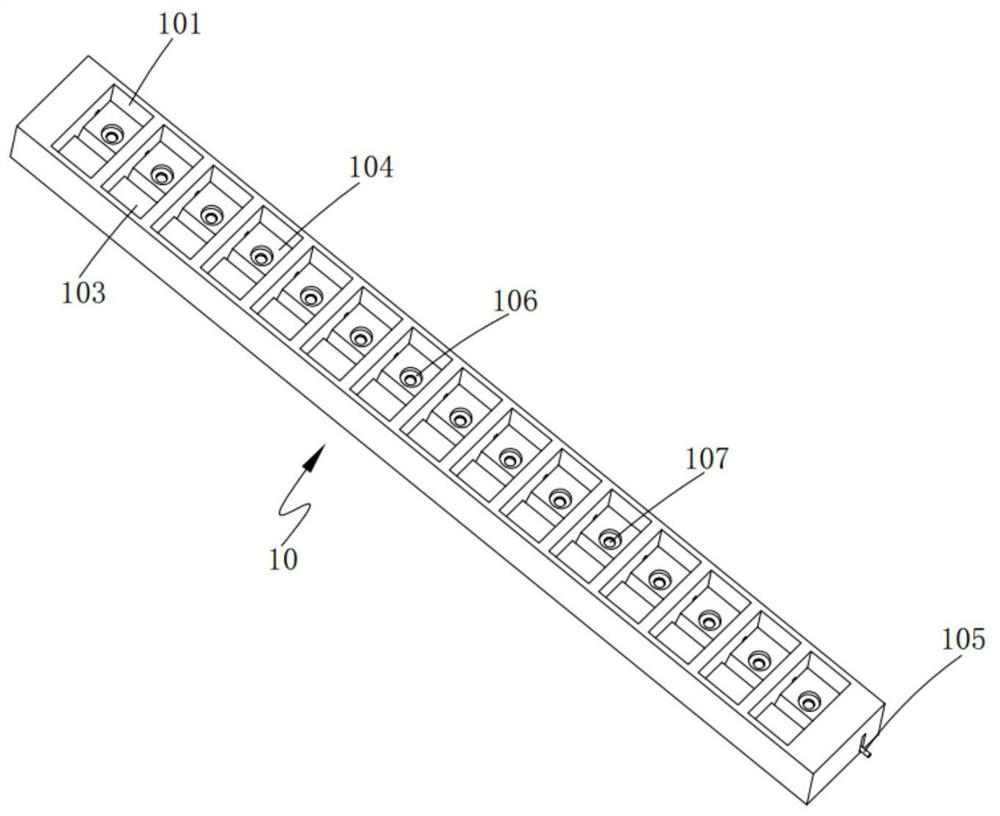

[0097] Conveying mechanism 1, the input end of described conveying mechanism 1 is provided with operation platform 11, and described conveying mechanism 1 transports carrying member 10, and this carrying member 10 is provided with bearing section 101 along its lengthwise array, and the bottom of described carrying member 10 is along Its length direction array is provided with first through holes 102, and the carrying area 101 is set in one-to-one correspondence with the first through holes 102;

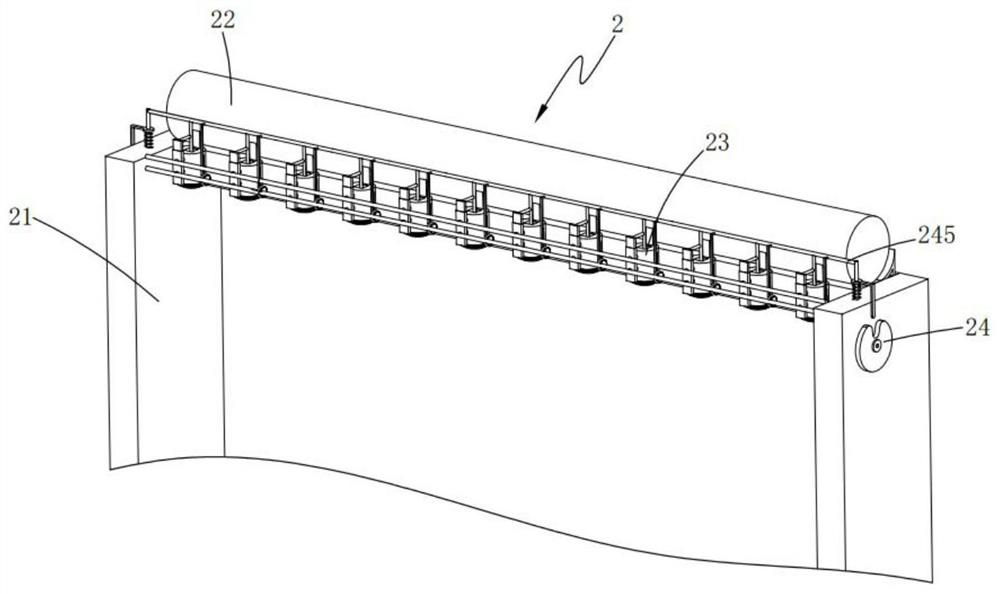

[0098] The material spreading mechanism 2, the material spreading mechanism 2 is arranged in the middle of the conveying mechanism 1 along the conveying direction of the conveying mechanism 1, the material spreading mechanism 2 includes a base 21, a material storage cylinder 22, an oiling assembly 23 and a linkage Assembly 24, the base 21 is symmetrically arranged on both sides of the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com