Patents

Literature

253results about How to "Easy Baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

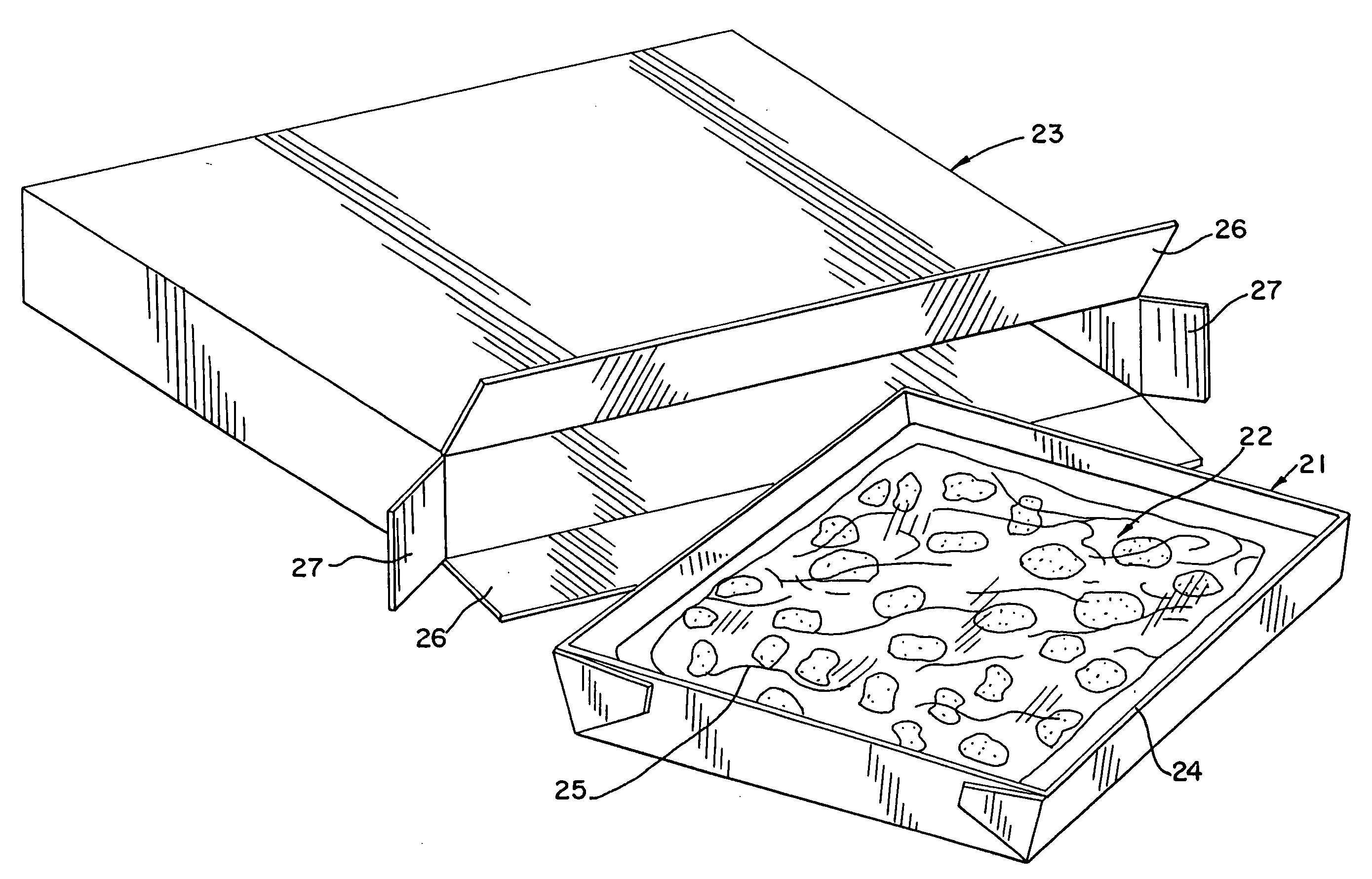

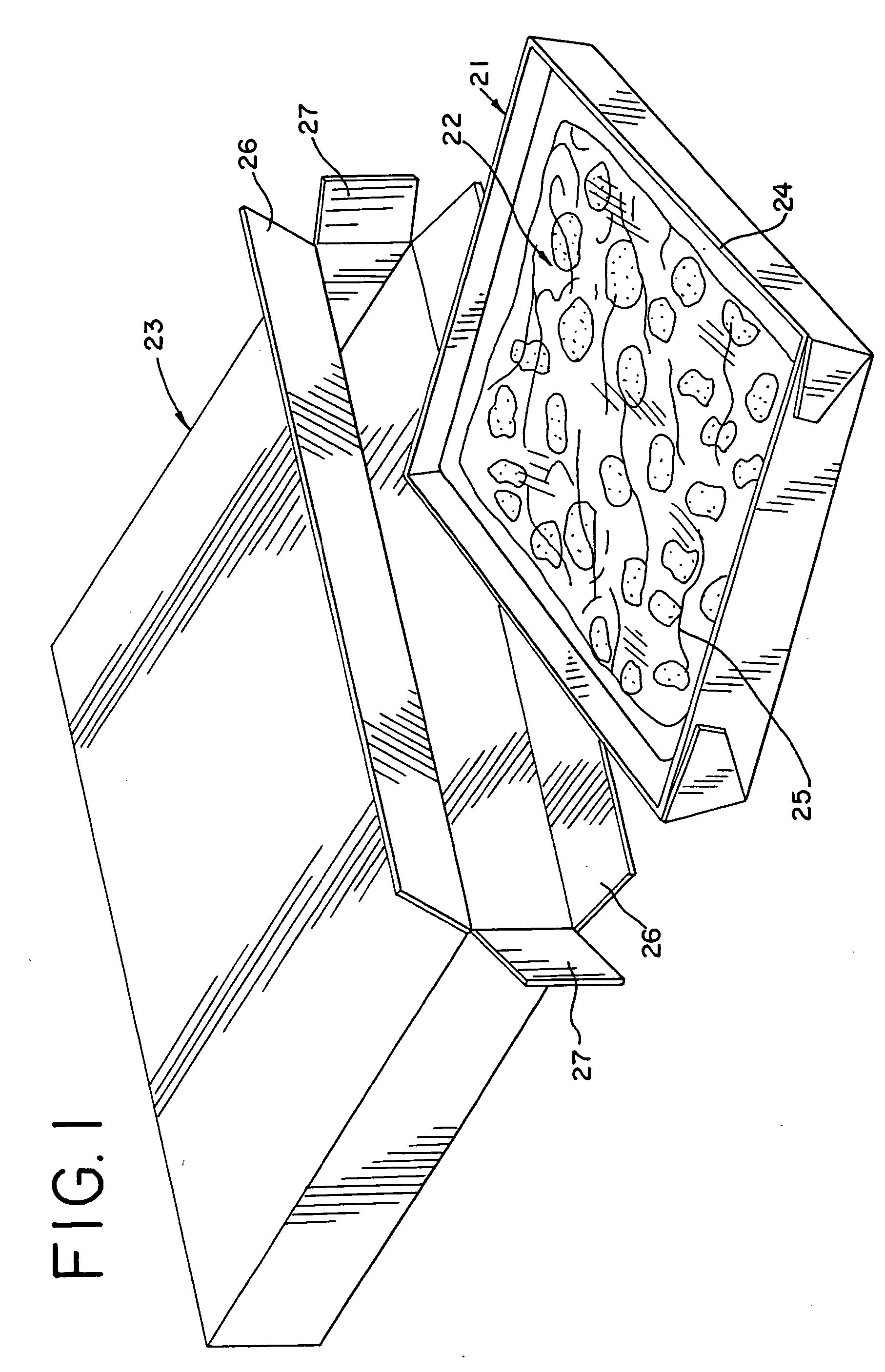

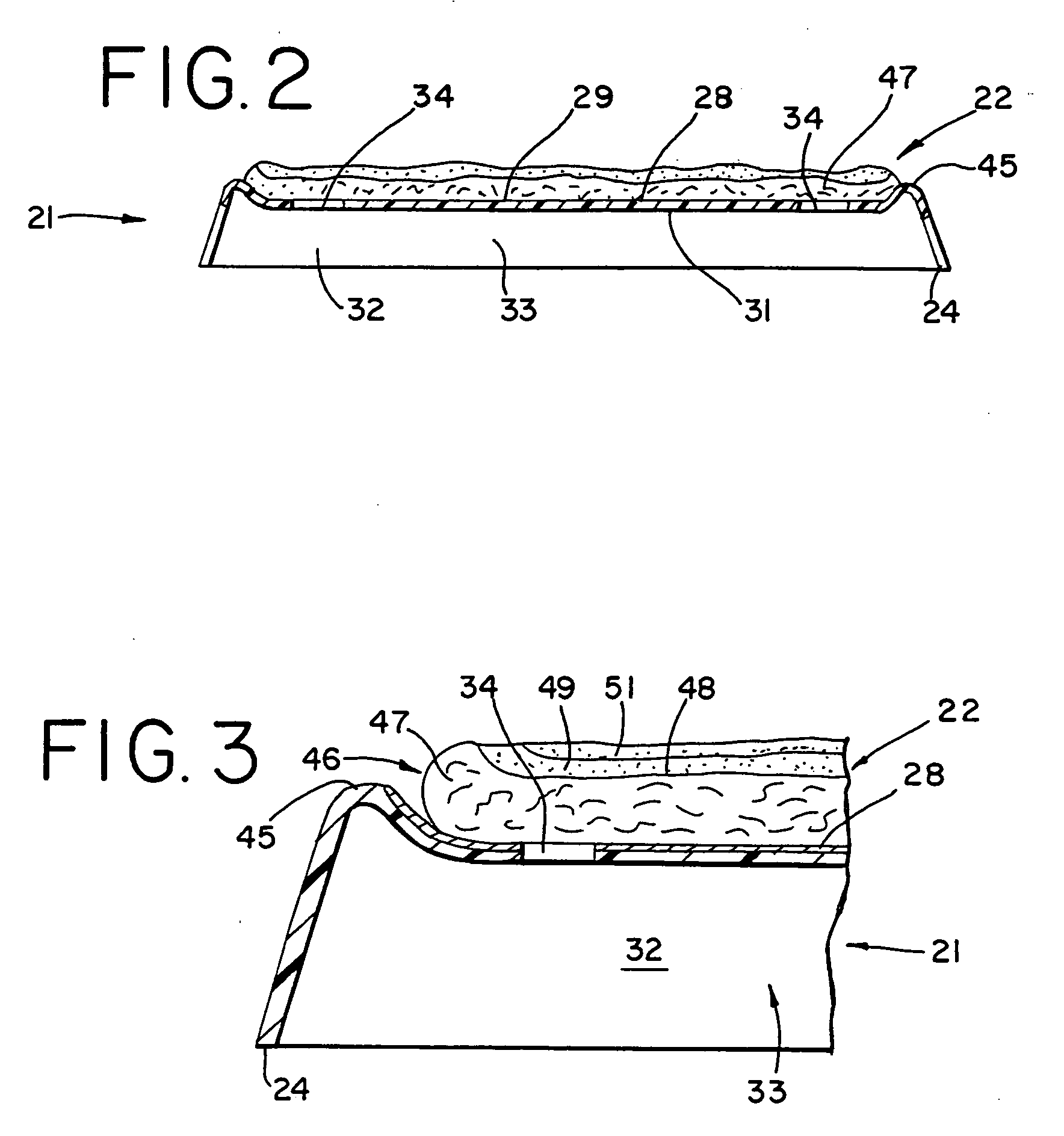

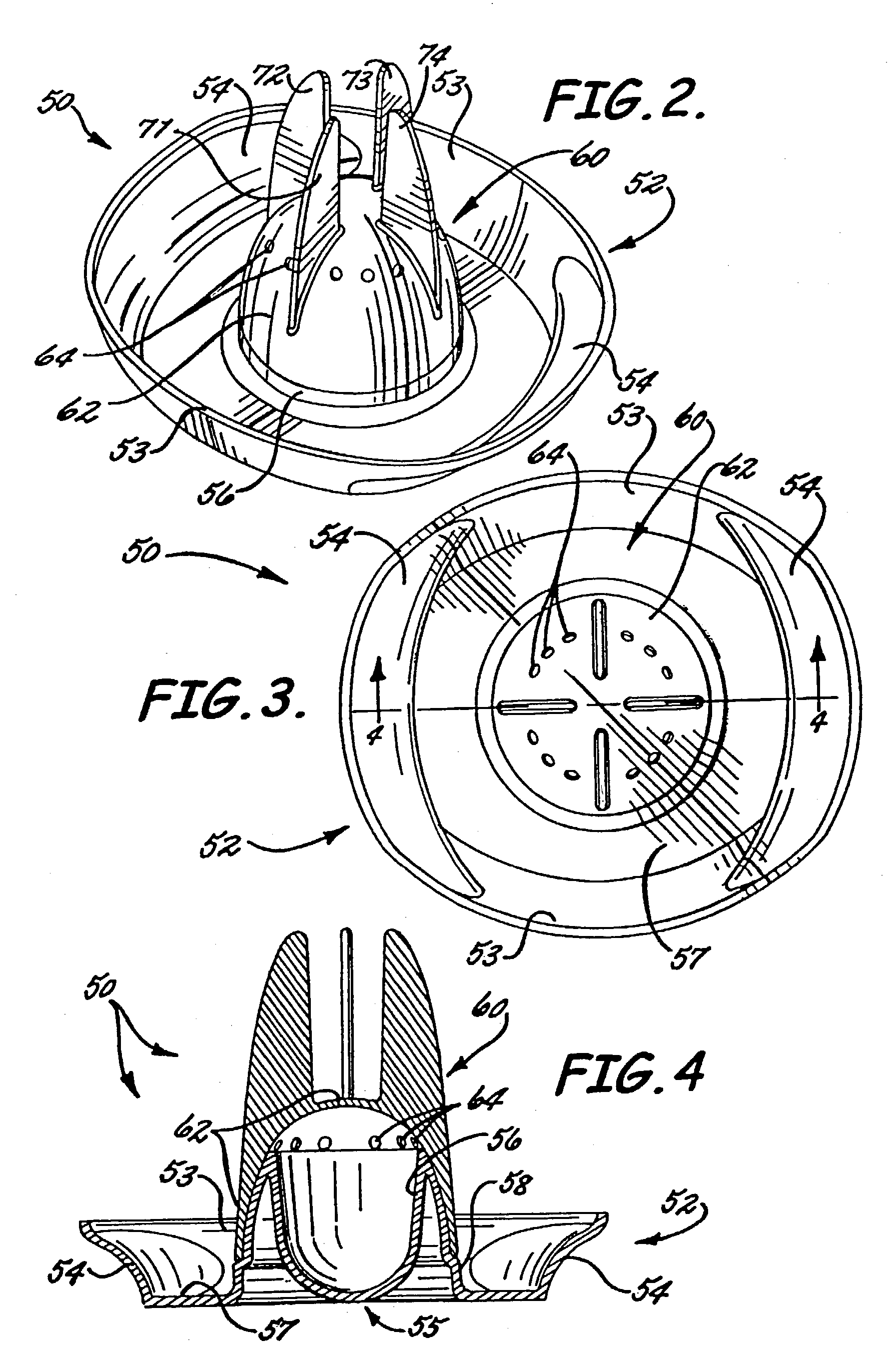

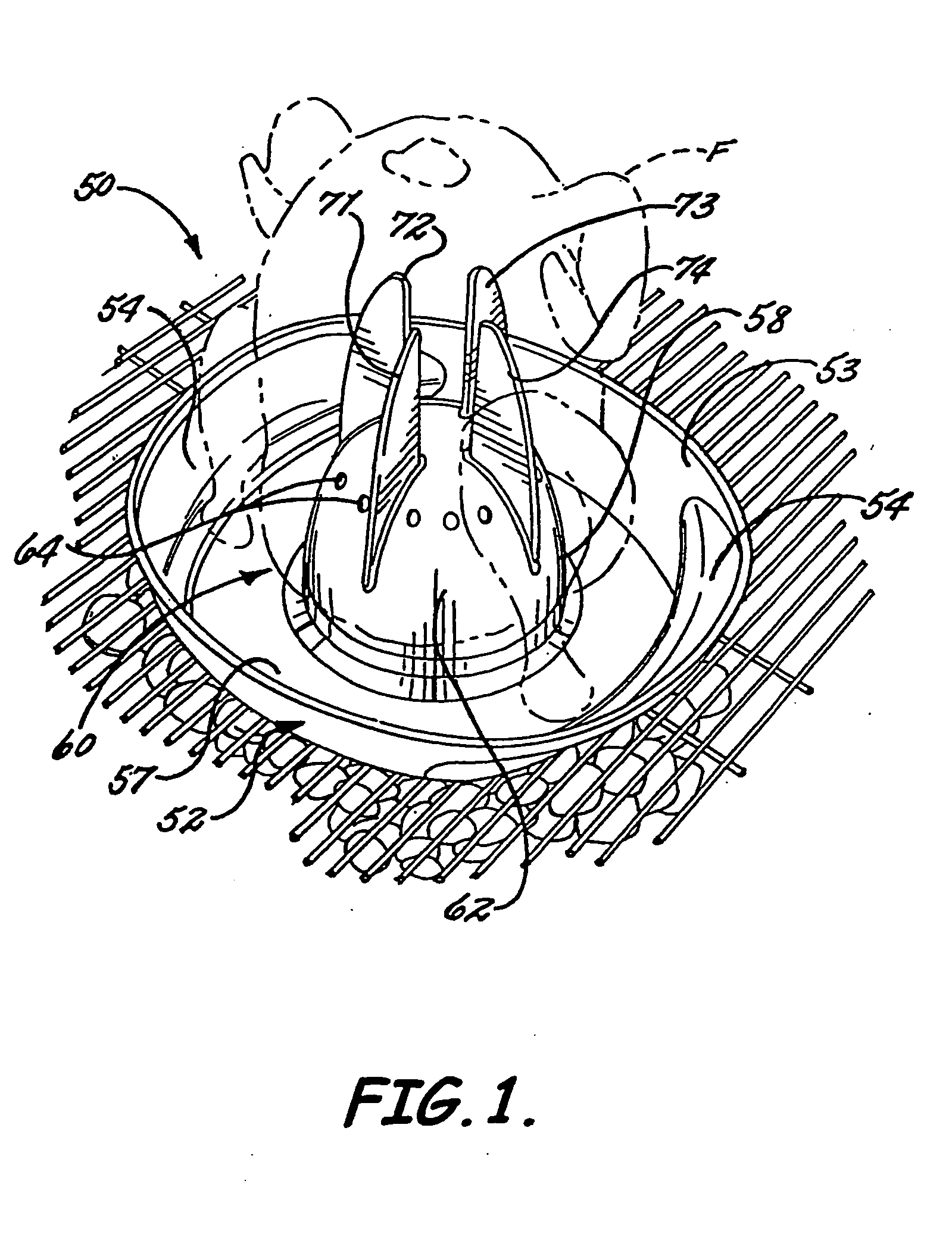

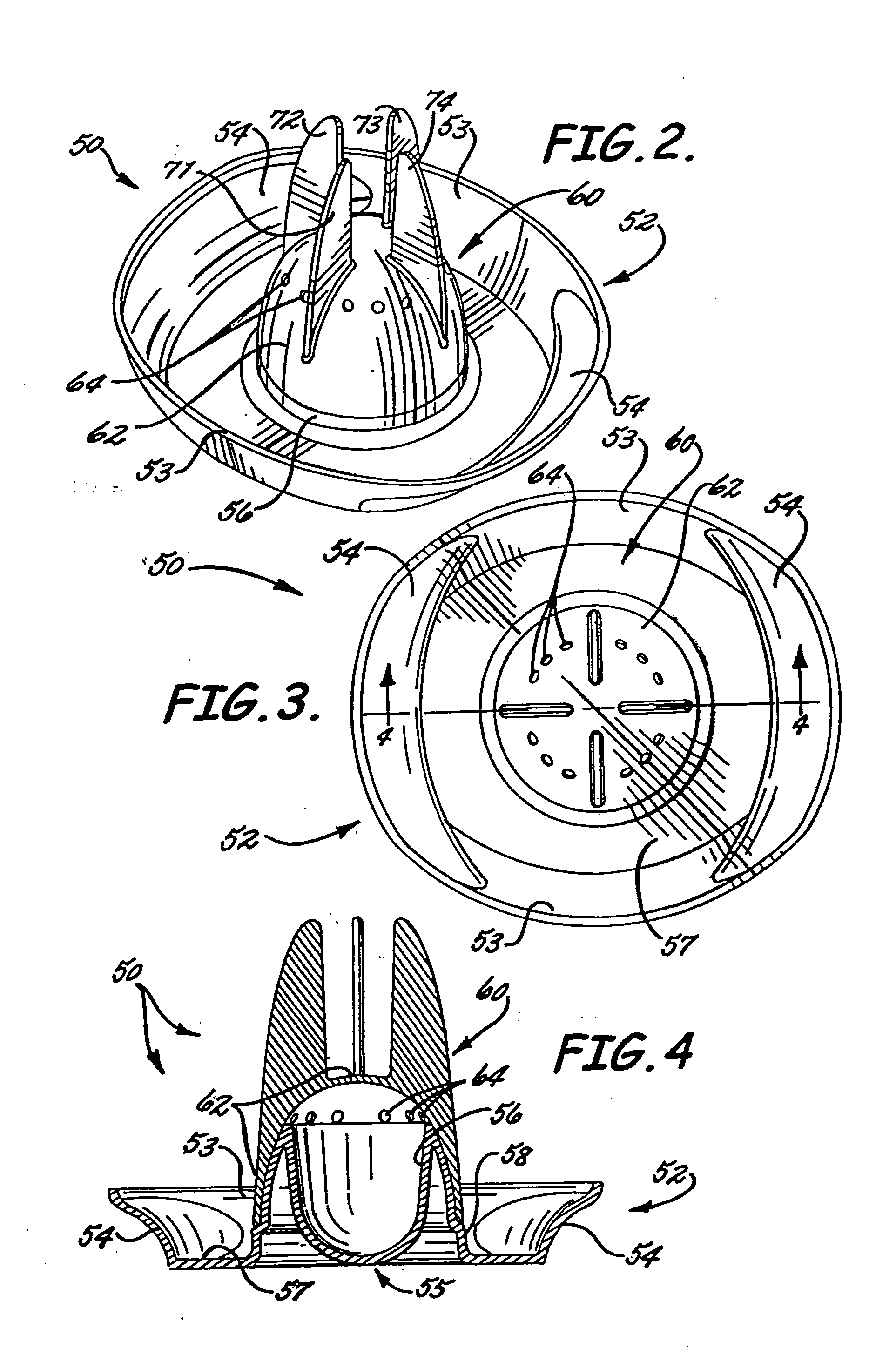

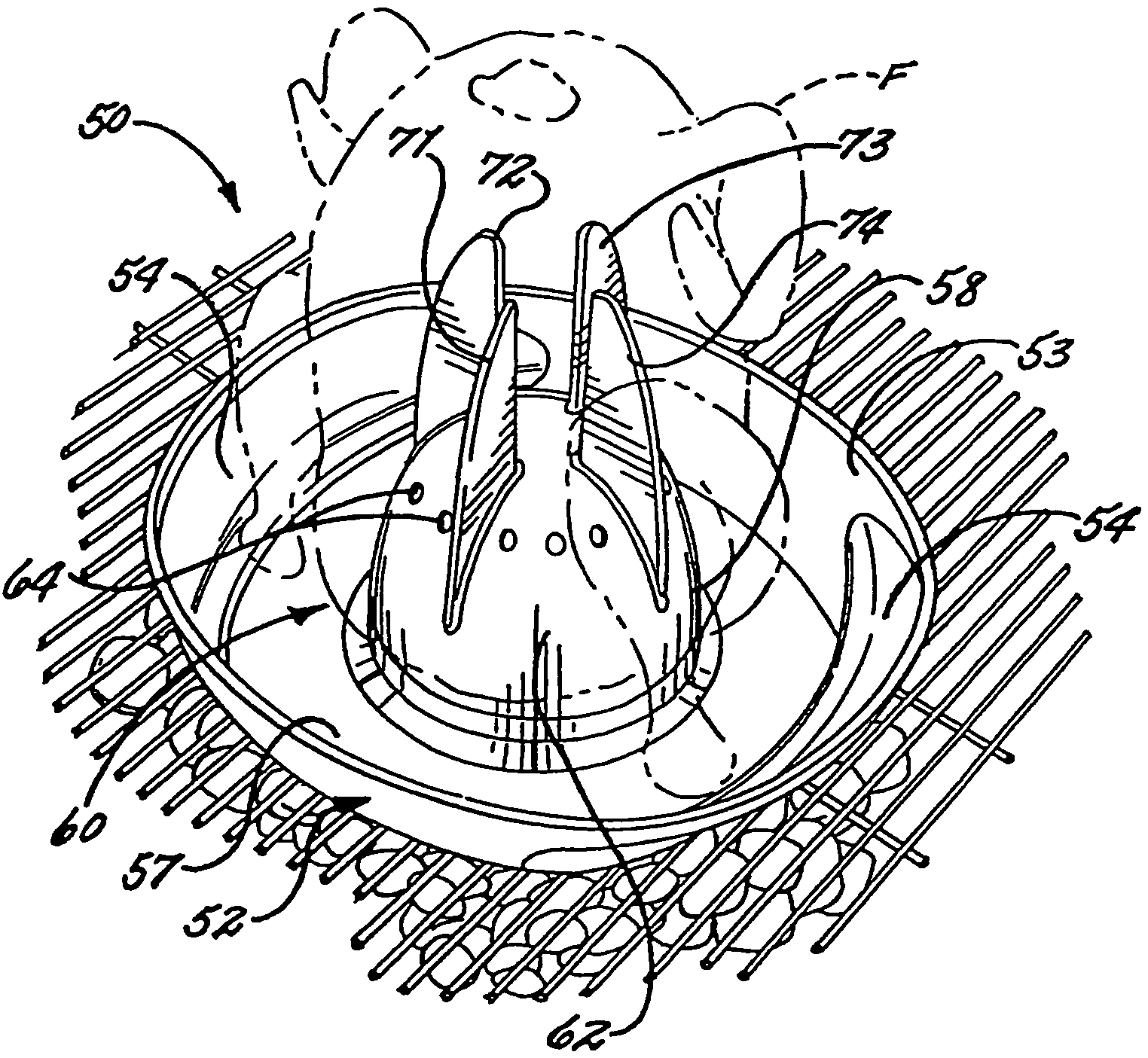

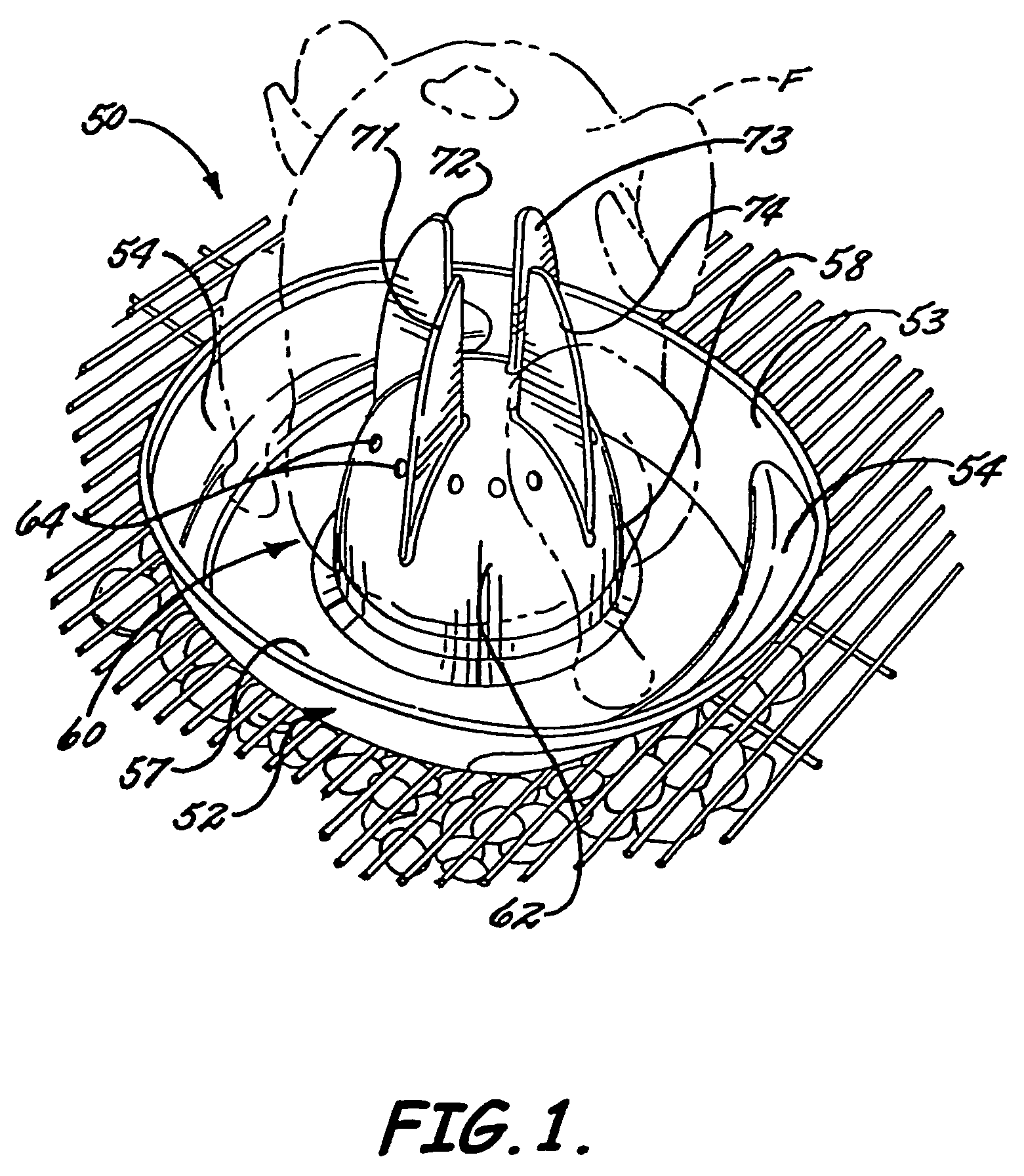

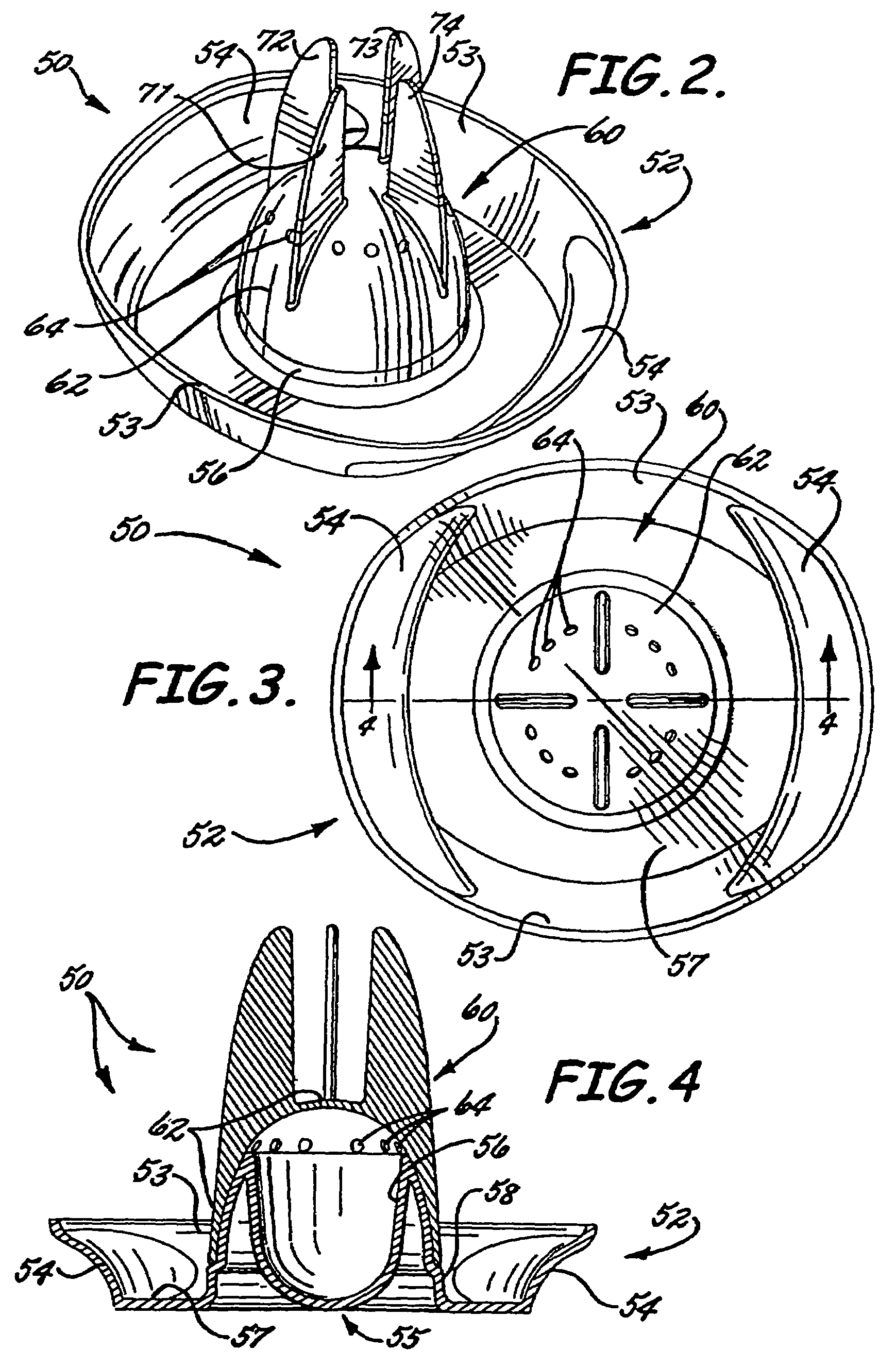

Susceptor cooking trays and kits for microwavable food products

InactiveUS20050184066A1Facilitate product heatingEasy cookingVenting meansContainers for heating foodSusceptorMechanical engineering

A susceptor tray has a susceptor surface of a platform positioned above a downwardly extending portion that has sidewall functions and that traps heated vapor within an open surface defined by the susceptor tray. A kit of the susceptor tray and a dough-containing food product has a storage mode which permits the food product to be stored within the open volume and out of contact with the susceptor surface. The planar portion of the tray includes openings including both a wide-dimensioned opening and a narrow-dimensioned opening in selected respective areas of the susceptor surface.

Owner:KRAFT FOODS GRP BRANDS LLC

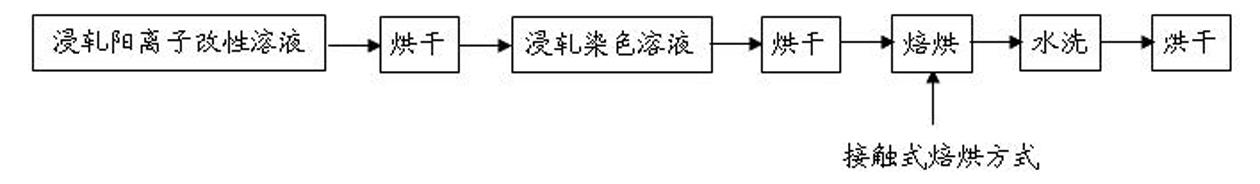

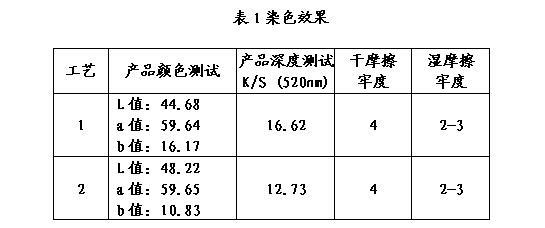

Method for dyeing yarn containing cellulose fiber by reactive dye

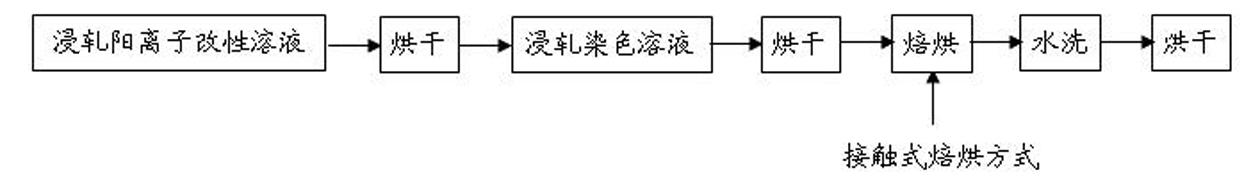

The invention relates to a method for dyeing a yarn containing cellulose fiber by reactive dye. In the method, the following processes are carried out on the yarn which is warped into a beam by a continuous pad dyeing mode: padding with cationic modified solution, drying, padding with staining solution, drying, baking, washing and drying, wherein, a drying cylinder is adopted in the baking process for baking in a contact manner, and the yarn is directly contacted with a high-temperature outer wall of the drying cylinder. By means of the method, continuous pad dyeing of the yarn containing cellulose fiber can be carried out by the reactive dye; the dyeing process has the advantages of relatively low baking temperature, simple baking mode and less broken yarns which are easily handled by an operator; and the adopted dye has the advantages of being free from restriction of K-type reactive dye, comprehensive color spectrum, wide selection range, simple auxiliaries without salt, urea and the like, less dye hydrolysis consumption, low wastewater chromaticity and stable dyeing quality, and deep, medium and light color can be dyed.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

Honey-aroma type congou black tea processing method

ActiveCN104886288AConducive to mutual frictionEasy to convertPre-extraction tea treatmentBlack teaFermentation

The invention discloses a honey-aroma type congou black tea processing method and belongs to the technical field of tea processing. The method includes: firstly, picking fresh leaves of large-leaf tea, and placing the fresh leaves of a tea tree in a withering trough for green leaf cooling; repeatedly subjecting the fresh leaves of the tea tree to rocking process and green leaf cooling for twice, and spreading the obtained rocked leaves in the withering trough for withering processing; twisting the obtained withered leaves heavily and slightly alternatively; sending the obtained twisted leaves to a fermentation chamber for fermentation; subjecting the fermented leaves to drying processing, taking out the fermented leaves for sizing and sending to a dryer for drying process after spreading for cooling; spreading and cooling the dried leaves to obtain the spread and cooled leaves which are sent to a baking machine for aroma extraction to obtain the honey-aroma type congou black tea. Compared with the prior art, the honey-aroma type congou black tea processing method has the advantages that the processed tea leaves are tightly knotted and black, even, fragrant, remarkable in honey aroma, red and bright in soup, rich in taste and bright red in infused leaves.

Owner:贵州怡壶春生态茶业有限公司

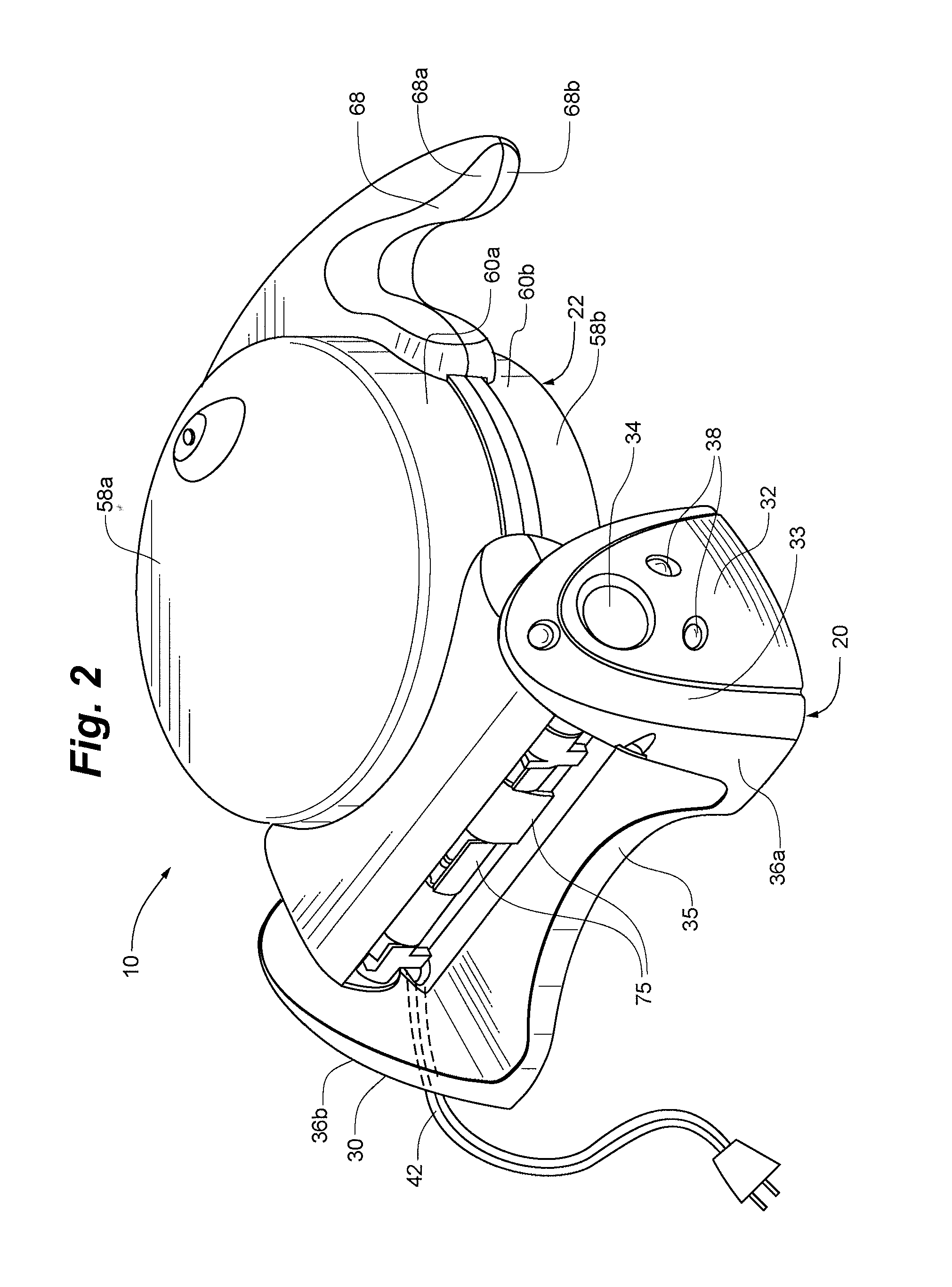

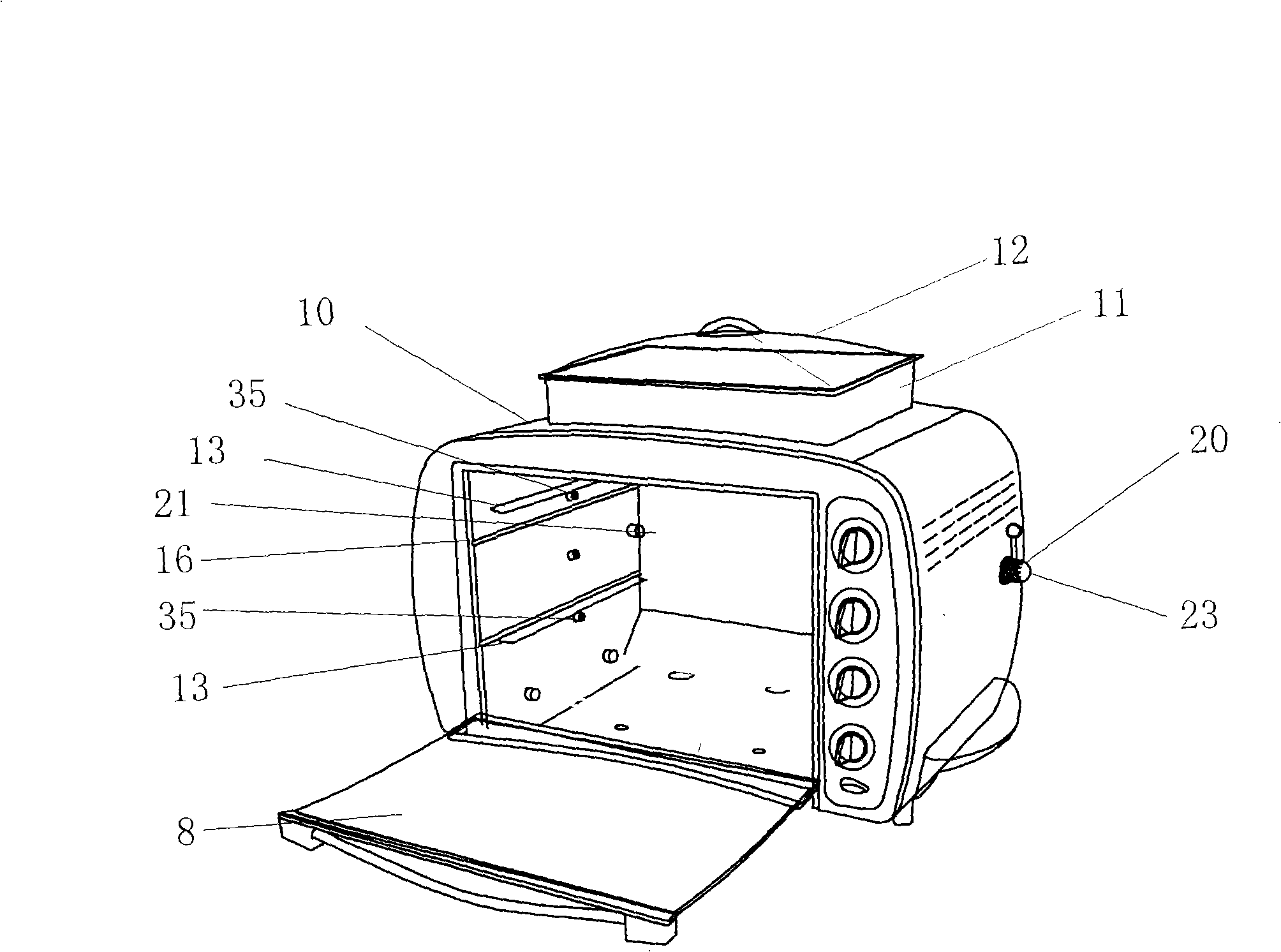

Kitchen electrical appliance

InactiveUS20080257169A1Easy to use and controlMinimum of counter spaceDough treatmentRoasters/grillsEngineeringMechanical engineering

Owner:NATIONAL PRESTO INDUSTRIES

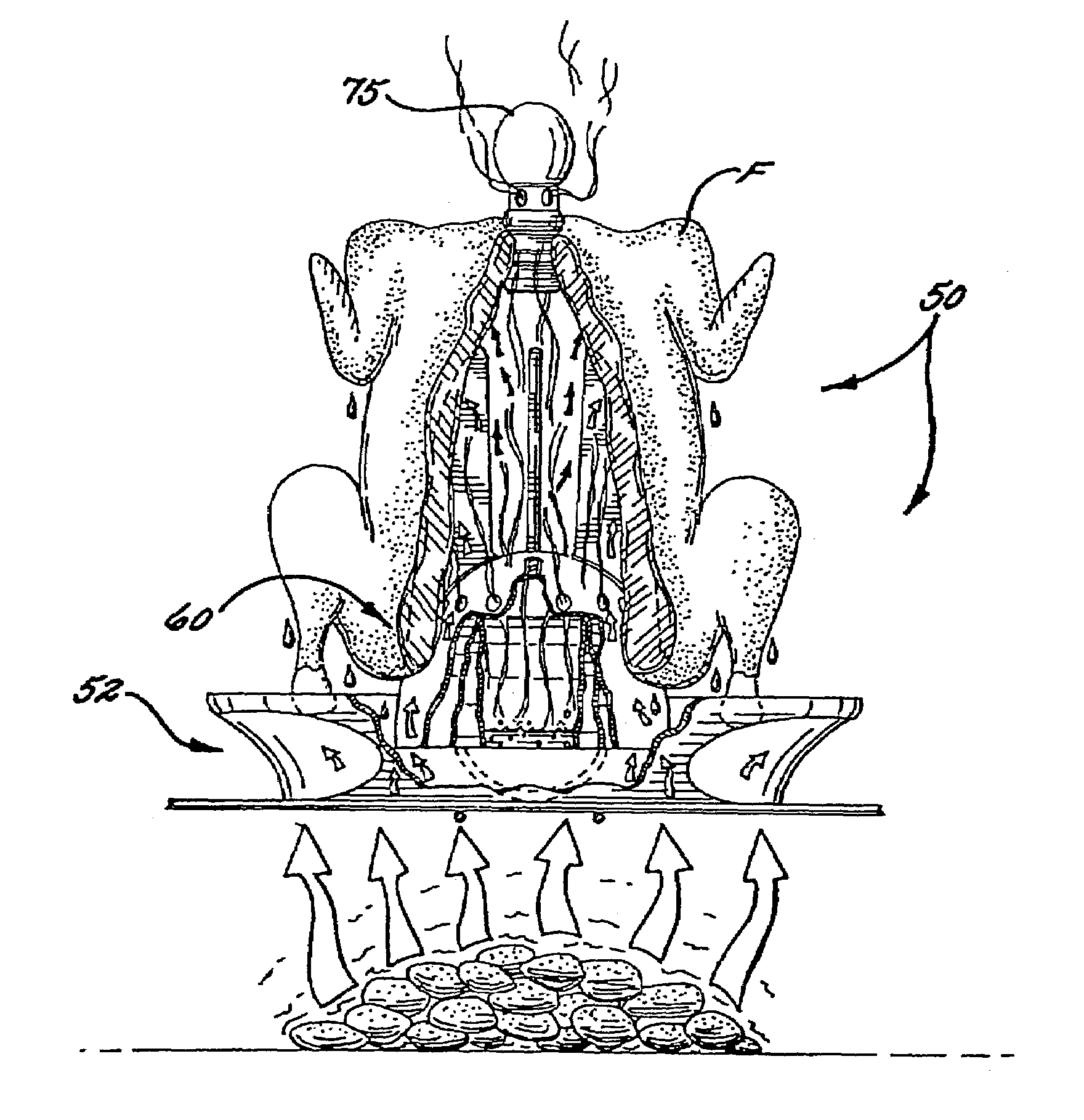

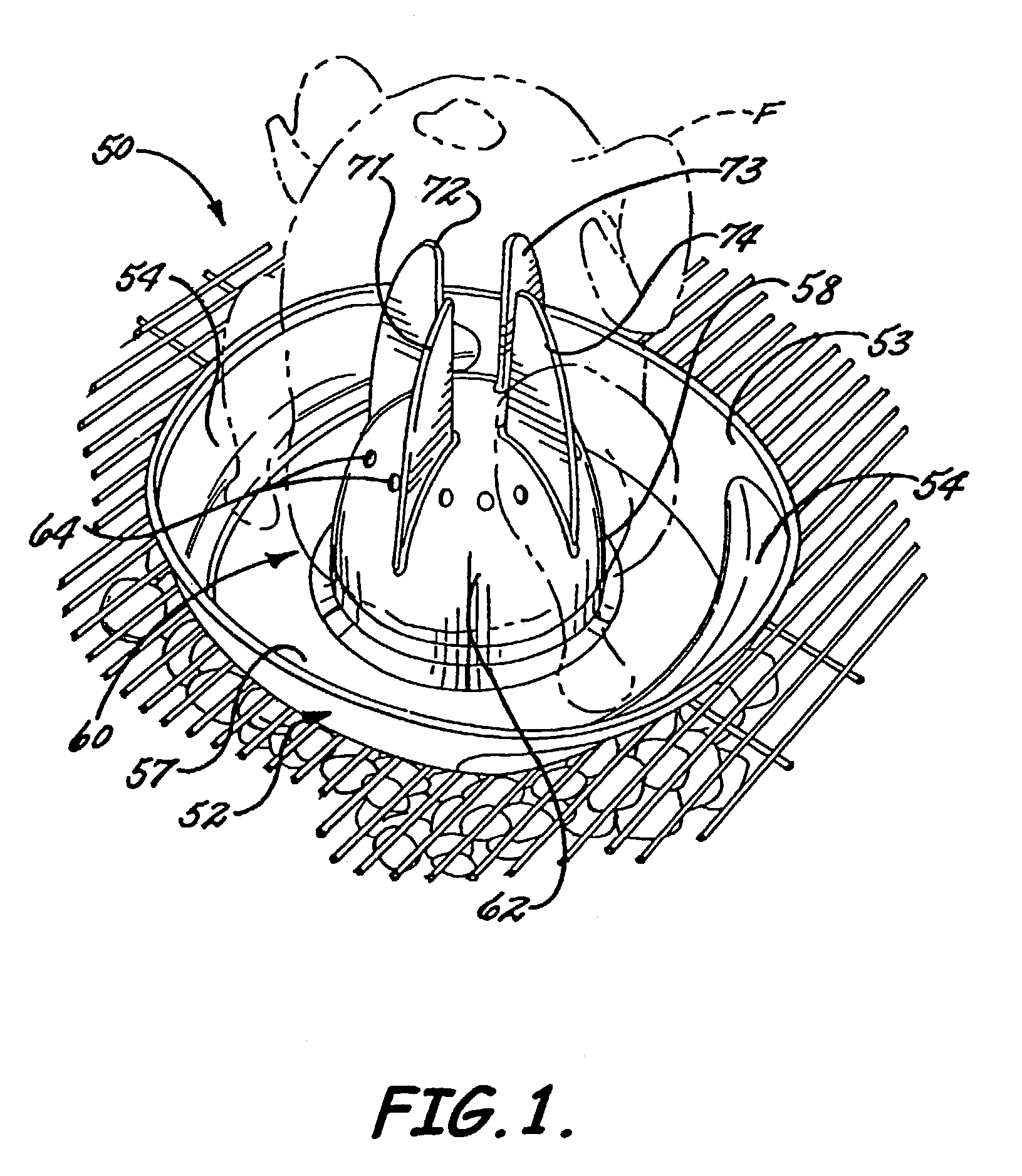

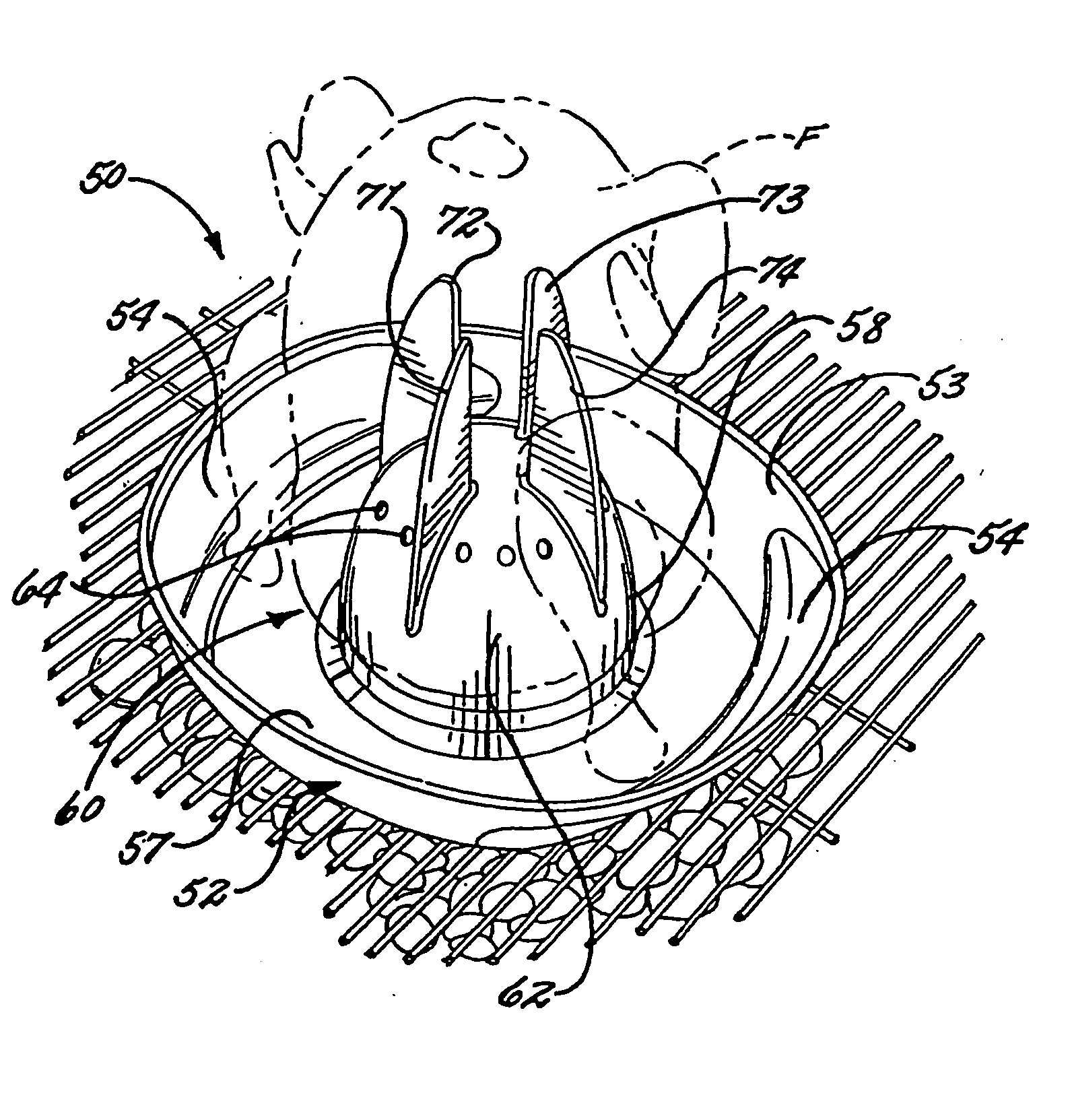

Apparatus for cooking meat and methods of cooking same

InactiveUS7144596B2Increase exposureEnhanced steam absorptionMilk preservationMeat/fish preservation by heatingEngineeringCooking methods

Owner:INNOVATIVE CULINARY CONCEPTS

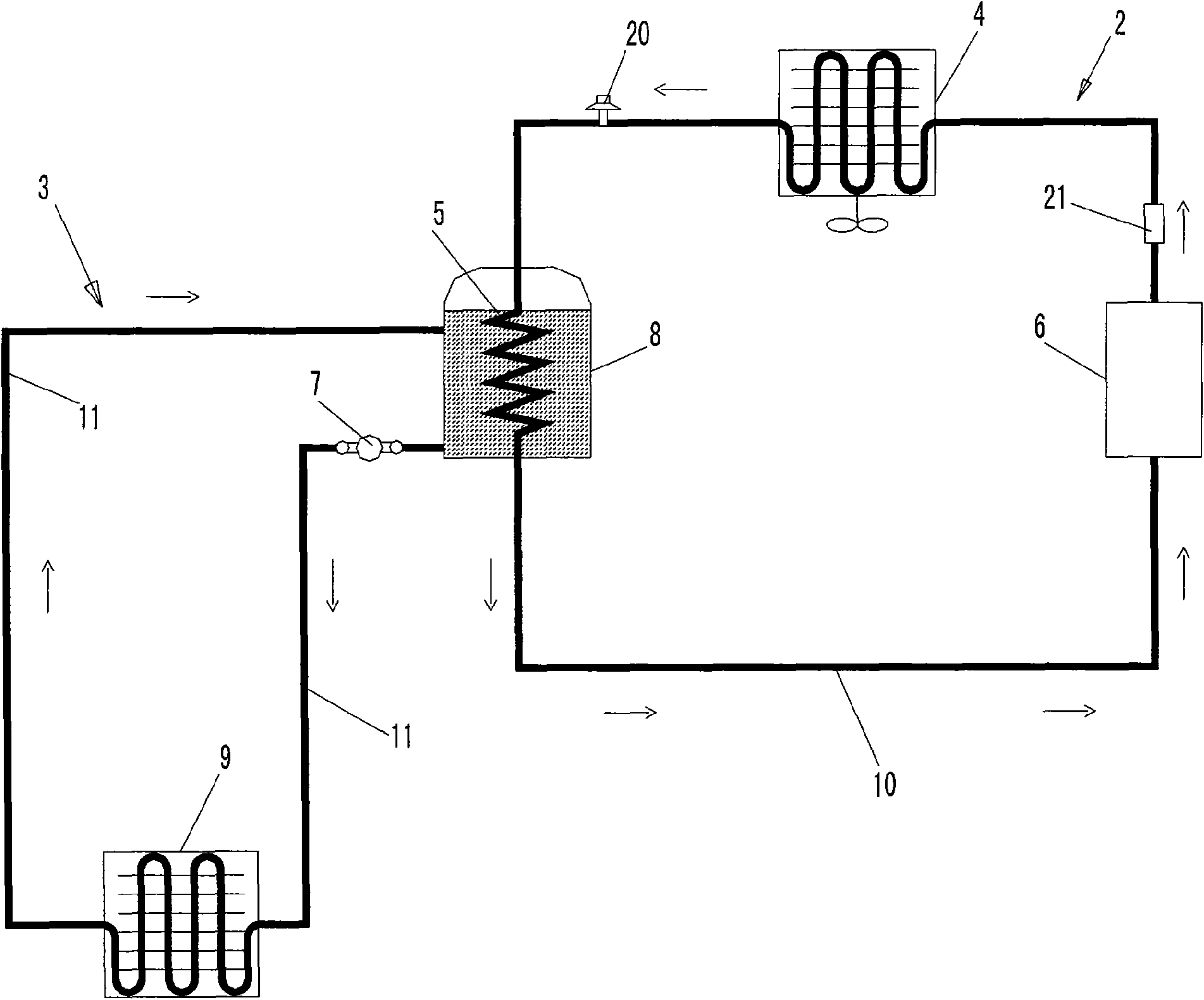

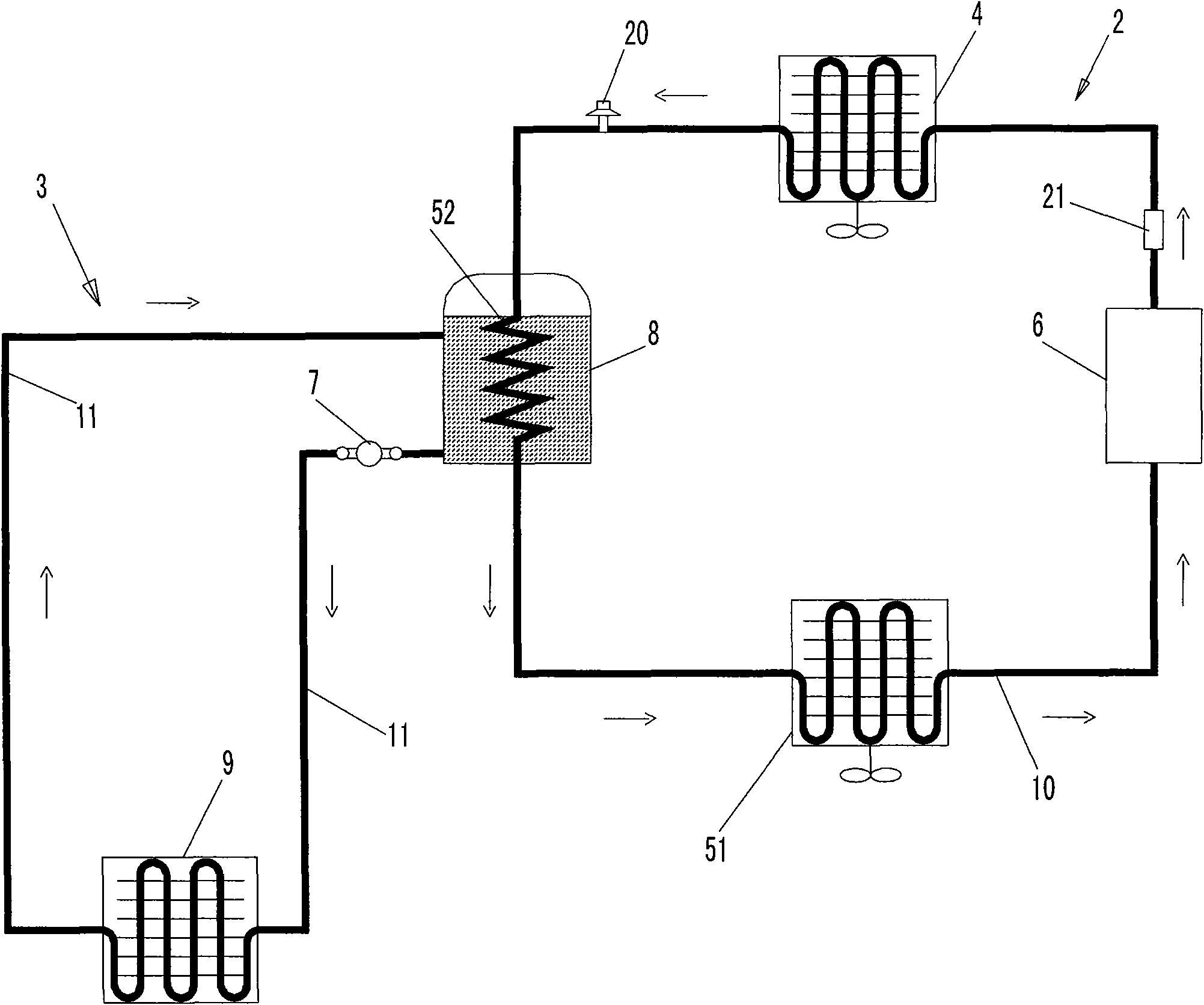

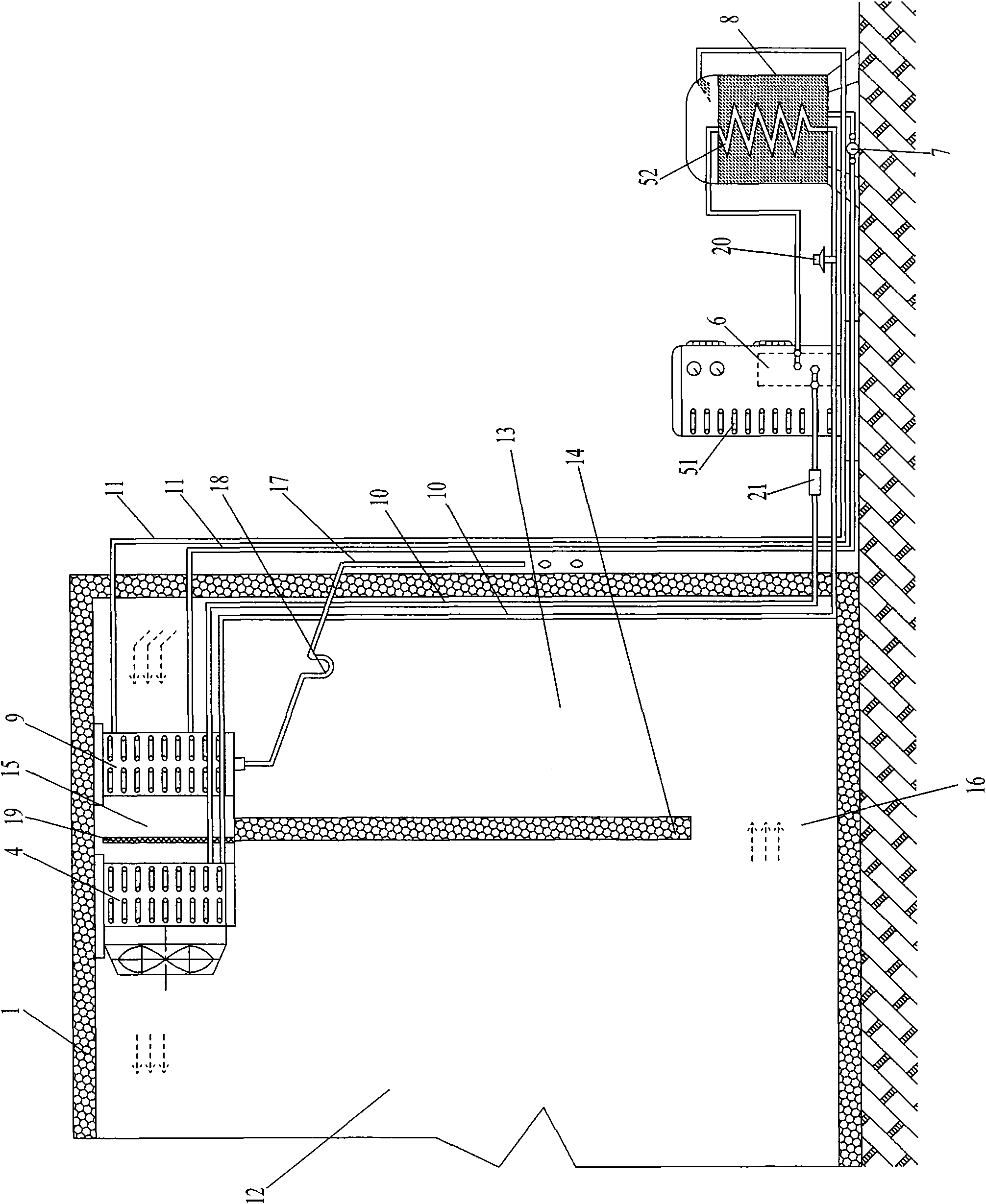

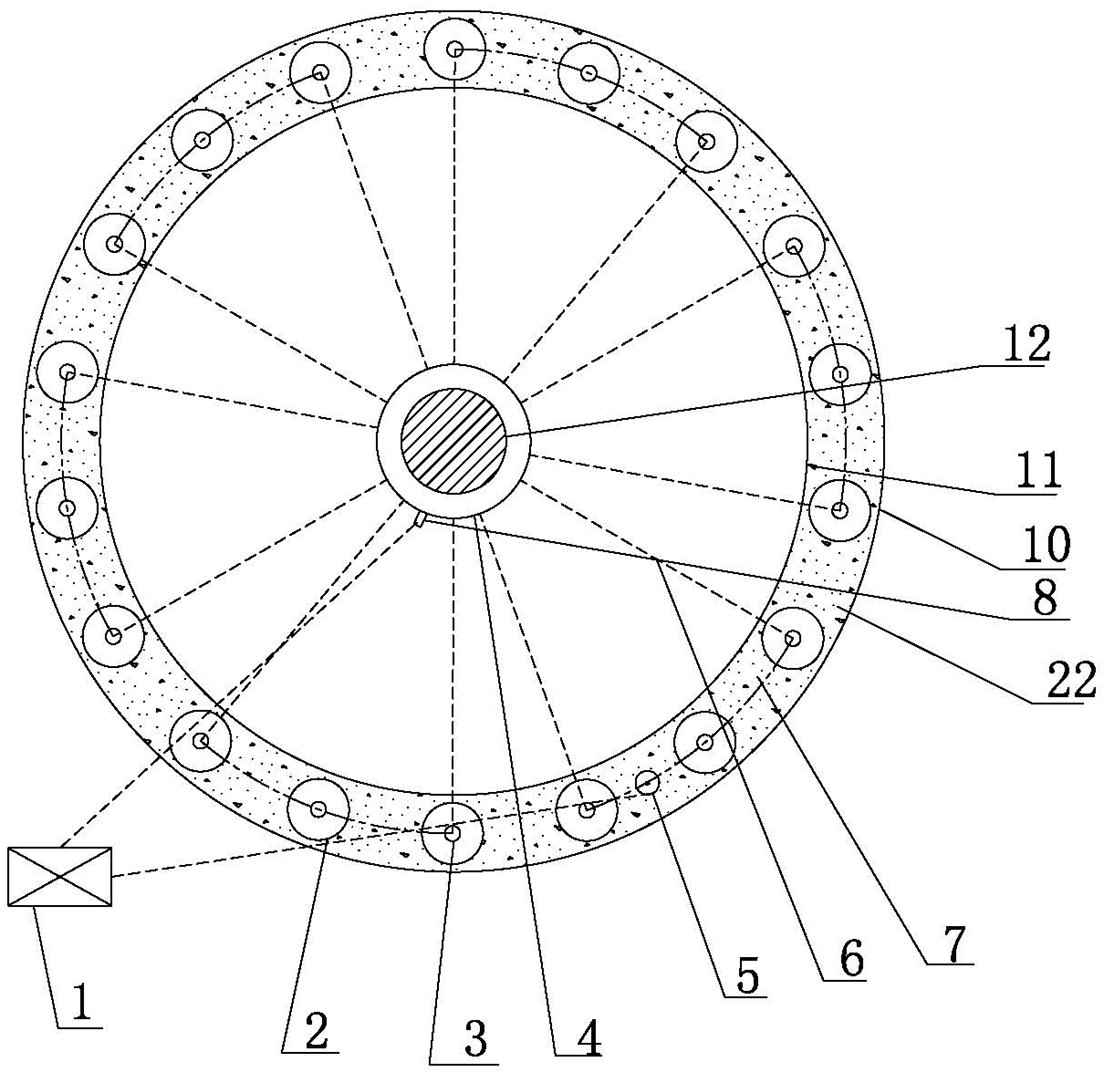

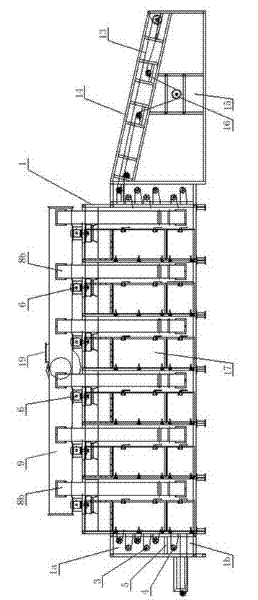

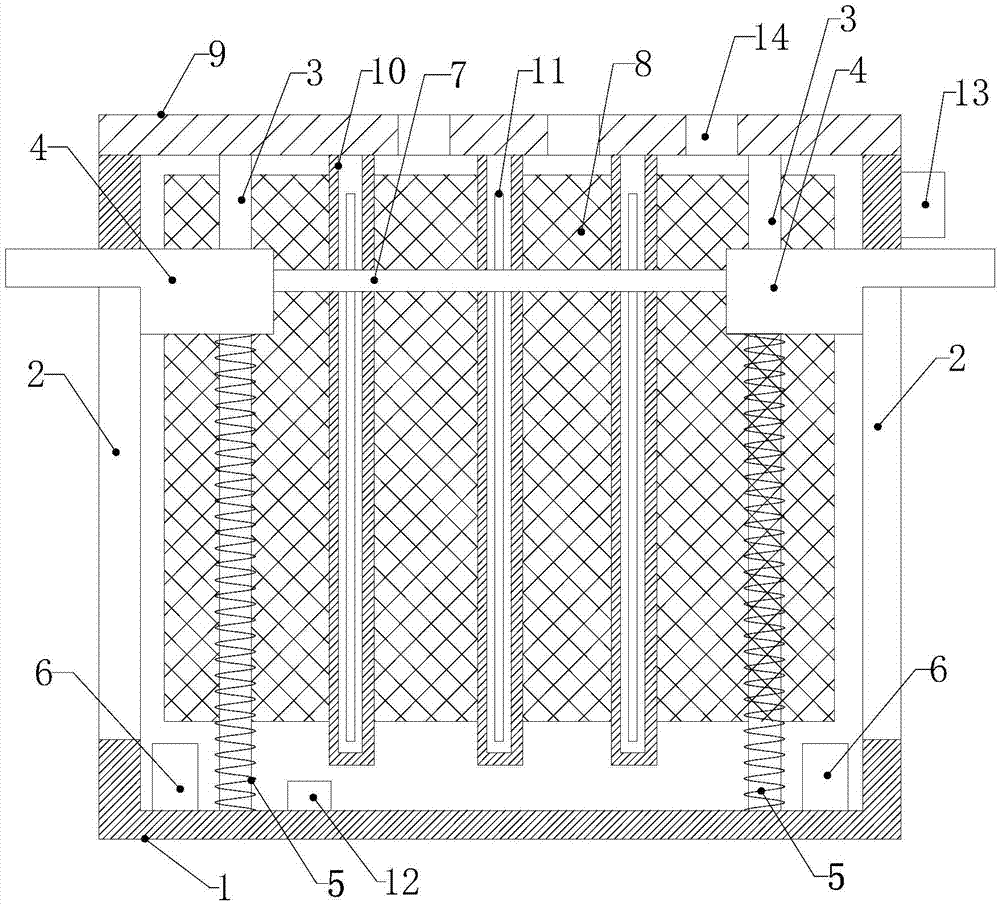

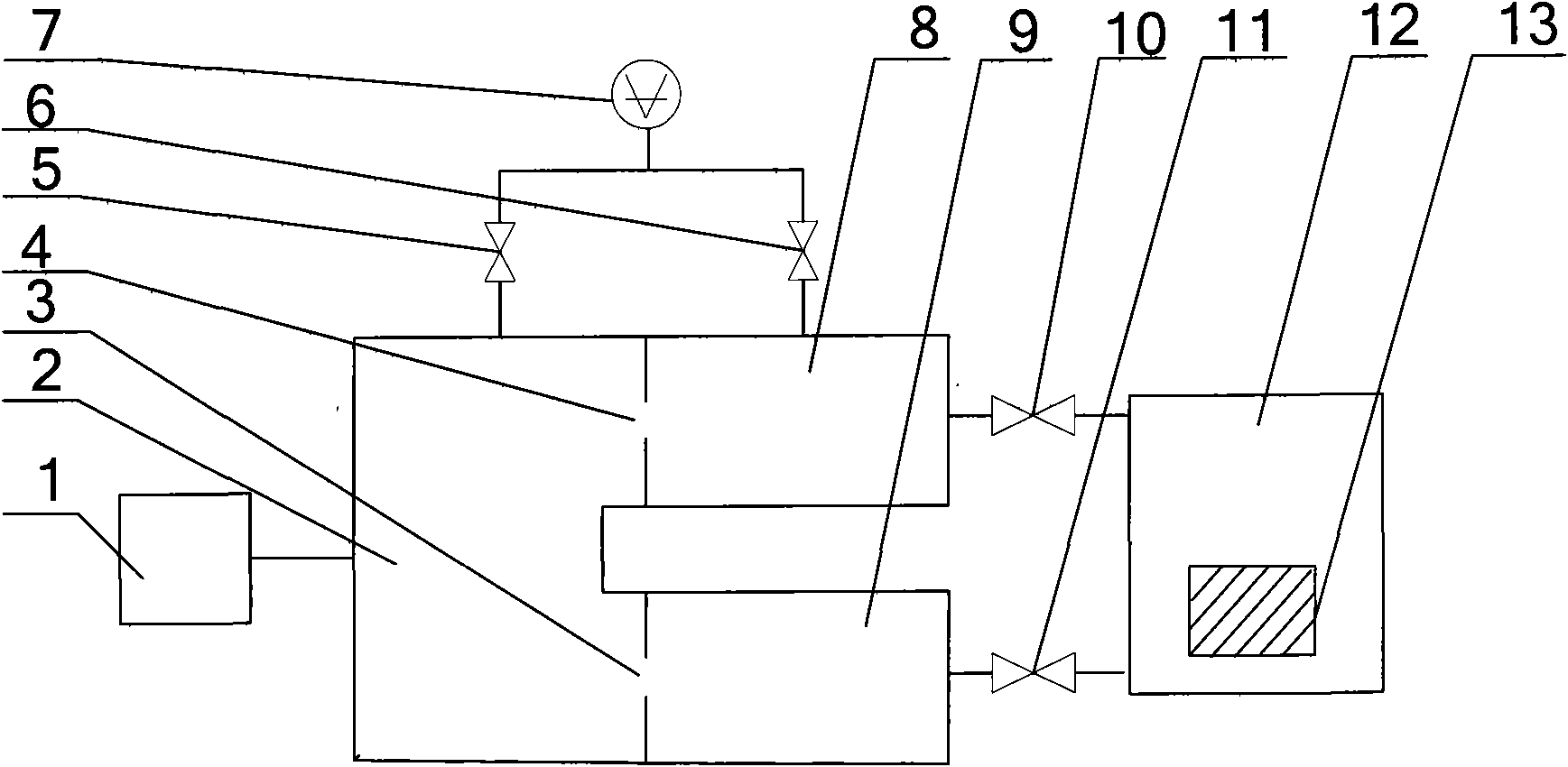

Heat pump cyclic medium dehumidification curing barn

InactiveCN101666576ANo pollutionShorten the timeDrying solid materials with heatDispersed particle separationHigh energyControl system

The invention discloses a heat pump cyclic medium dehumidification curing barn, comprising a heat insulation curing barn body, a control system, a heat pump heating system controlled by the control system, and a dehumidification system. The heat pump heating system comprises a condenser, an evaporator and a compressor which are circularly communicated by a refrigerant circulating pipeline; and thedehumidification system comprises a cold accumulation medium box exchanging heat with the evaporator and a dehumidification condenser circularly communicated with the cold accumulation medium box bya cold accumulation medium circulating pipeline. In the invention, the cold energy when refrigerant evaporates to absorb heat in the heat pump is stored and used for dehumidification work in the curing barn, thereby having good dehumidification effect, low running cost and high energy source use ratio, and being beneficial to energy saving and environment protection.

Owner:宜兴市泽利制冷设备有限公司 +1

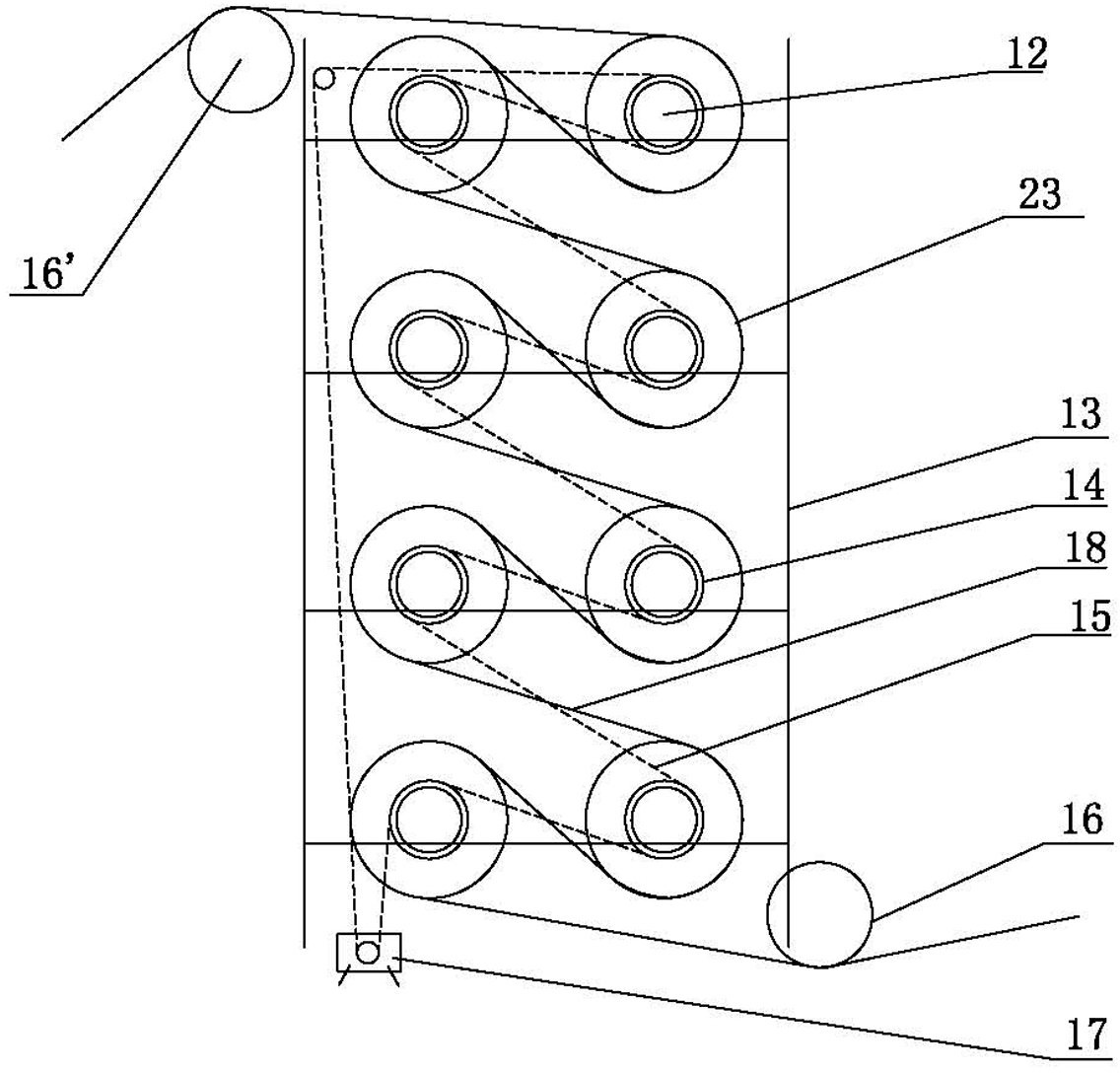

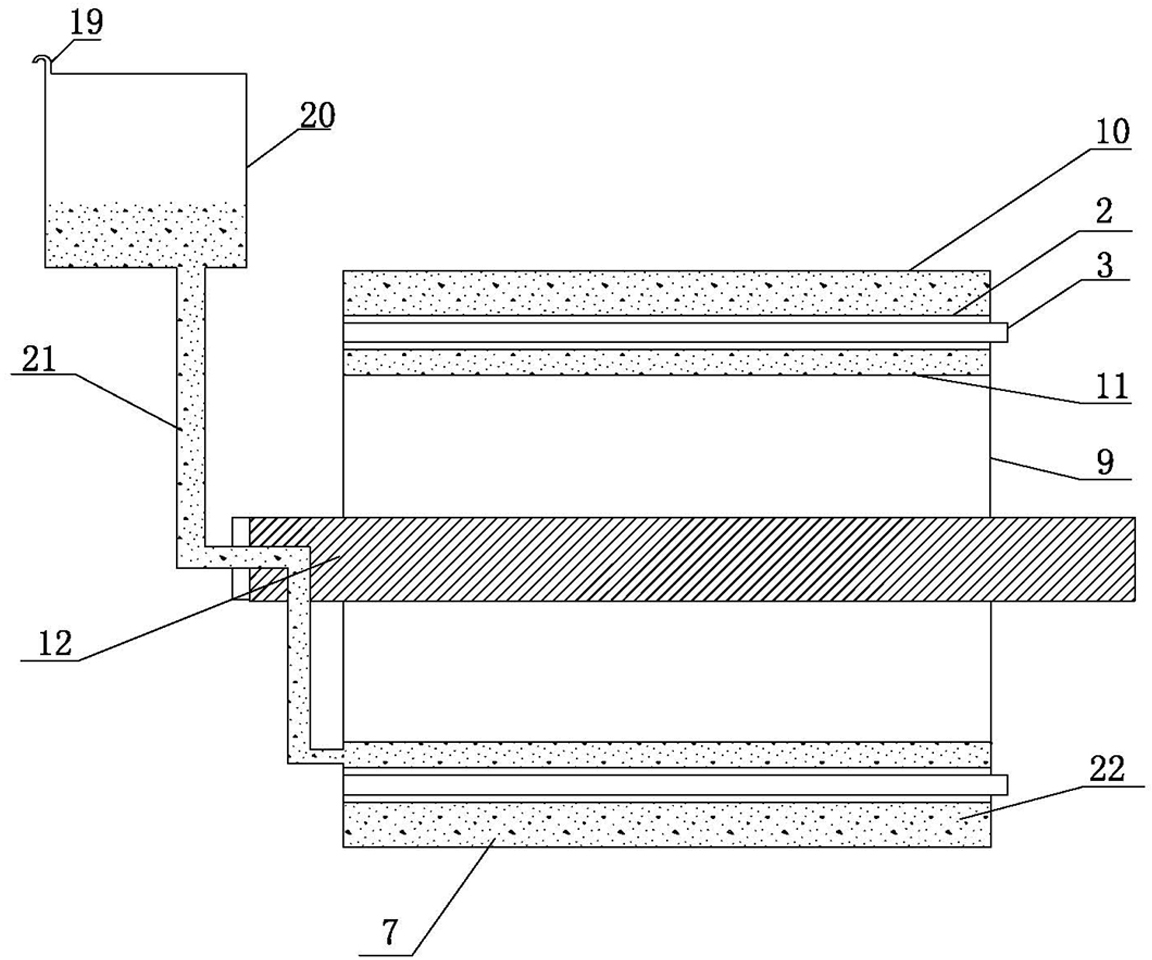

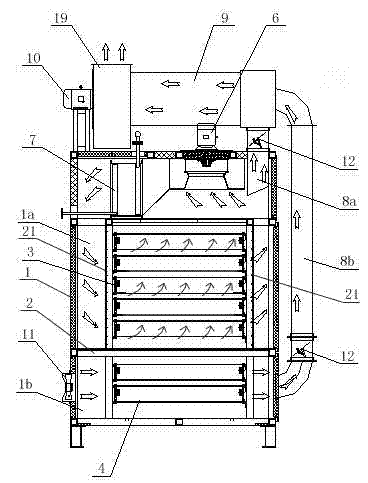

Reactive dyeing equipment for cellulose fibre-contained yarns

ActiveCN101994220AWide selectionReduce hydrolysisLiquid/gas/vapor removalTextile treatment machine arrangementsReactive dyeElectric heating

The invention relates to reactive dyeing equipment for cellulose fibre-contained yarns, comprising a baking device. The baking device comprises a drying drum support, a plurality of rotatable drying drums arranged on the drying drum support, a lead-in yarn guide roller and a lead-out yarn guide roller, wherein each drying drum comprises a drying drum outer wall, a drying drum inner wall and a drying drum side wall; the drying drum outer wall, a closed cavity is encircled by the drying drum inner wall and the drying drum side wall; heat conduction oil is filled in the cavity; an electric heating element used for heating the heat conduction oil is also arranged in the cavity; the drying drums, the lead-in yarn guide roller and the lead-out yarn guide roller synchronously rotate; and when in work, yarns led in by the lead-in yarn guide roller are led out by the lead-out yarn guide roller after bypassing the surface of each drying drum in sequence. Through utilizing the equipment, continuous pad dyeing can be carried out on the cellulose fibre-contained yarns by using reactive dyes, and moreover, in the dyeing process, the baking temperature is relatively low, the baking mode is simple, broken yarns are less and operators are easy to dispose, and therefore, the reactive dyeing equipment is especially suitable for the special requirements on the continuous pad dyeing of the yarn.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

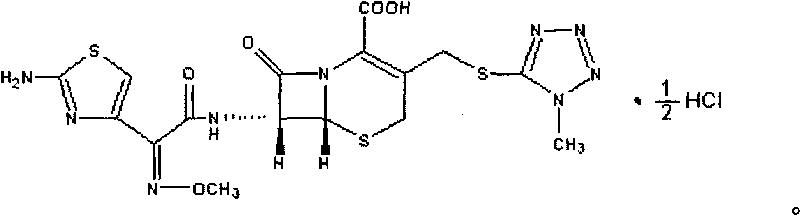

Process for preparing instantly-dissolving cefmenoxime hydrochloride

The invention discloses a process for preparing instantly-dissolving cefmenoxime hydrochloride, which comprises the following steps: 1) adding water into a coarse product of cefmenoxime hydrochloride to prepare a suspension, adding sodium carbonate into the suspension to dissolve the cefmenoxime hydrochloride, and thus obtaining clear liquor; 2), decolorizing the clear liquor by using active carbon, washing the clear liquor and mixing the washing liquor to obtain solution A; 3) adjusting the pH value of the solution A to 0.8 to 1.2 by using hydrochloric acid, filtering the solution A and collecting the filtrate to obtain solution B; and 4), adjusting the pH value of the solution B to 1.3 to 1.75 by using an alkalescent solution, stirring the solution B for crystallization, filtering the solution after the crystallization is finished, washing crystals and drying the crystals under vacuum to obtain the instantly-dissolving cefmenoxime hydrochloride. Compared with the prior art, the method has the advantages that: the pH value is adjusted at two stages and the crystallization is performed under a condition of a pH value of 1.3 to 1.75, so the precipitated crystals have a proper particle size and good dispersibility, can be charged conveniently and separately and can dissolve in a short time; the operation process is simplified; the risks of producing visible foreign matters are reduced greatly; the production efficiency is improved; the cost is reduced; and the clinic use and operation are convenient.

Owner:桂林澳林制药有限责任公司

Tobacco foliage fertilizer

InactiveCN101200388AIncrease the areaIncrease widthMagnesium fertilisersOrganic fertilisersNicotiana tabacumAdditive ingredient

The invention discloses a tobacco foliar fertilizer, which is mainly comprises the ingredients according to the part by weight: zinc sulfate of 30 to 45 parts, boric acid of 5 to 15 parts, potassium bisulfate of 10 to 20 parts, bitter salt of 15 to 25 parts and green copperas of 1 to 6 parts. Since the invention adopts the ingredients to prepare the fertilizer, the area of the upper leaves can be enlarged by fertilizing when the green tips are pruned, and particularly the width of the leaves can be enlarged, and the structure of the upper leaves can be optimized, and the nicotine content in tobacco leaves can be lowered and the potassium content can be increased greatly, thereby the leaves can be thinned and is easy to be roasted, so the quality of tobacco leaves and appearance is improved, and the industrial application is enhanced.

Owner:HENAN AGRICULTURAL UNIVERSITY

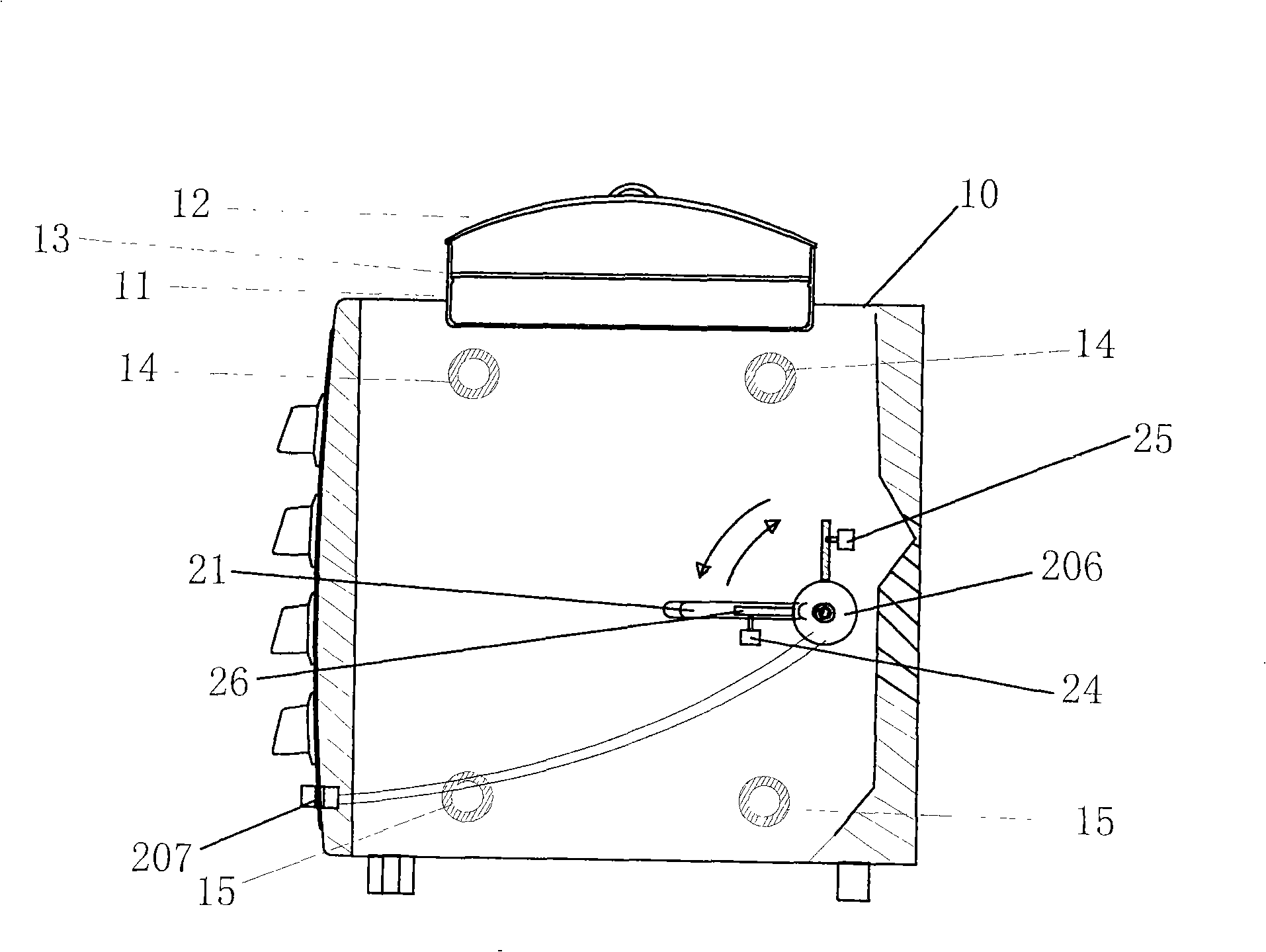

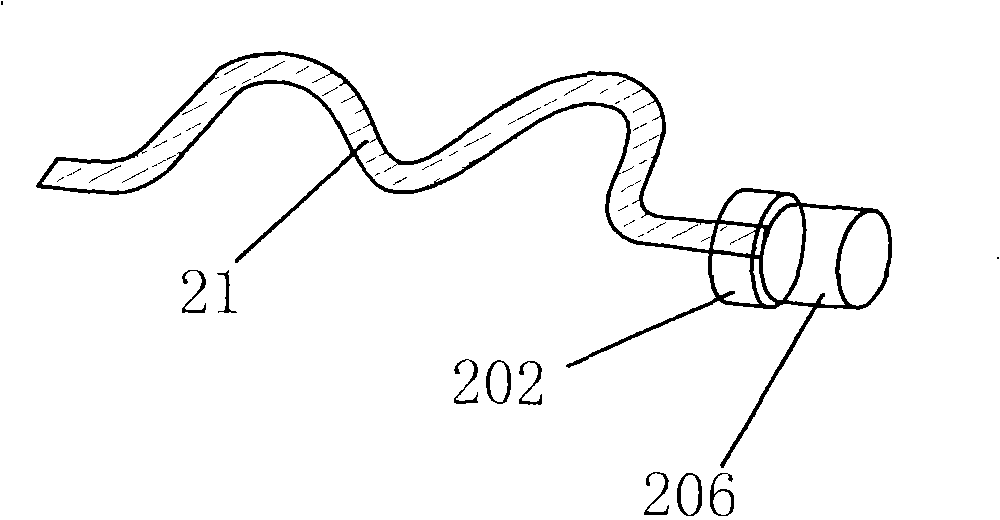

High-efficient energy-saving electric roaster

The present invention relates to a high-efficiency and energy-saving baking oven, which comprises an electric baking oven body, a baking oven gate, a control panel, an upper electrothermal pipe, a lower electrothermal pipe and a rotary electrothermal pipe module. The electrothermal pipe module comprises a rotary electrothermal pipe which can change a frame structure in the position through rotating around the two ends and a synchronous motor; the two ends of the rotary electrothermal pipe horizontally extend out of a left lateral plate and a right lateral plate in the cavity of the electric baking oven body; one end is connected with the synchronous motor through a rotary wheel; a lever is connected with the rotary electrothermal pipe or the rotary wheel; two micro switches are arranged on the two sides of the internal wall of the cavity of the electric baking oven body when the rotary electrothermal pipe rotates at two limit angles; when the lever contacts with the micro switch below, the synchronous motor is off to stop rotating and the rotary electrothermal pipe is on for heating; when the lever contacts the micro switch above, the synchronous motor is off to stop rotating and the spiral electrothermal pipe is off. Due to the structure, the present invention has the characteristics of high baking efficiency and automatic operation of the middle part of the electrothermal pipe.

Owner:李文庆

Meat baking grill for food processing

The invention relates to a grill, in particular to a meat baking grill for food processing. The meat baking grill for food processing can bake meat conveniently and adjust taste of the meat conveniently. In order to solve the technical problem, the meat baking grill for food processing comprises a first support, a second support, a baking plate, a mounting box, an overturning component, a clampingcomponent, a lifting component, a swinging component, a seasoning spreading component and a condiment; and the mounting box is fixedly connected to the first support and the second support, the baking plate is fixedly connected to the inner bottom surface of the mounting box, the overturning component is fixedly connected to the first support and the second support, and the clamping component isin transmission connection with an outputting end of the overturning component. Effects of baking meat conveniently and conveniently adjusting the taste of the meat are achieved.

Owner:杨馨蕊

Method for repairing inner lining of tundish

ActiveCN101214543AHigh turnoverReduce consumptionMelt-holding vesselsCeramic shaping apparatusRepair materialPhosphoric acid

The invention relates to a middle package liner repairing method. The method adopts a hot repairing mode for a the middle package for a lower line; under a temperature of 100 to 140 DEG C, firstly cleans the position of the middle package of a body needed repairing, then spray a phosphoric acid wedding agent uniformly on the position to be repaired; uniformly coats the hot repairing material after mixed on the position to be repaired with a coating thickness of 4 to 6mm higher than the surface of the body. The method directly uses the repairing material with no water to carry through hot repairing on the crack or defective part of the liner for the middle package turning over the lower line, improves the turning over times of the middle package, reduces the consumption of the middle package and has a good repairing effect.

Owner:ANGANG STEEL CO LTD

Method for producing frozen dough

ActiveUS20070160709A1Great tasteUniform crumbReady-for-oven doughsWort preparationCooking & bakingForming gas

The present invention provides a method for producing frozen dough which can be directly transferred from freezer to oven without a proofing or thawing step. The process comprises mixing the dough ingredients, forming gas nucleation sites, exercising the dough by subjecting to cycles of pressure differentials and freezing the dough. The frozen product can be transferred directly from the freezer to an oven for baking.

Owner:RICH PRODUCTS

High-temperature heat-insulation refractory mortar

The invention discloses high-temperature heat-insulation refractory mortar and solves the problem of environmental pollution, short material shelf life, inconvenient construction maintenance or the like due to wrapping of the outer surface of an existing refractory material with a layer of heat preservation material. A preparation method of the high-temperature heat-insulation refractory mortar comprises the following steps: fully mixing aluminum oxide hollow spheres, floating beads, molten quartz powder and bentonite according to a weight part ratio in a sand mixer, adding a proper amount of water, inorganic bonder and foamer, and stirring to obtain the mortar. The high-temperature refractory mortar acts on the surface of the refractory material in a manner of dipping, spraying or coating, and is superior to existing ceramic fibers in linear shrinkage, porosity and thermal conductivity at 1200 DEG C. The high-temperature heat-insulation refractory mortar is simple in preparation process, diverse in construction process, light, environment-friendly and long in shelf life; after acting on the surface of the refractory material, the high-temperature heat-insulation refractory mortar is convenient to maintain, good in heat preservation effect and stable in use performance, and the normal operating temperature exceeds 1200 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

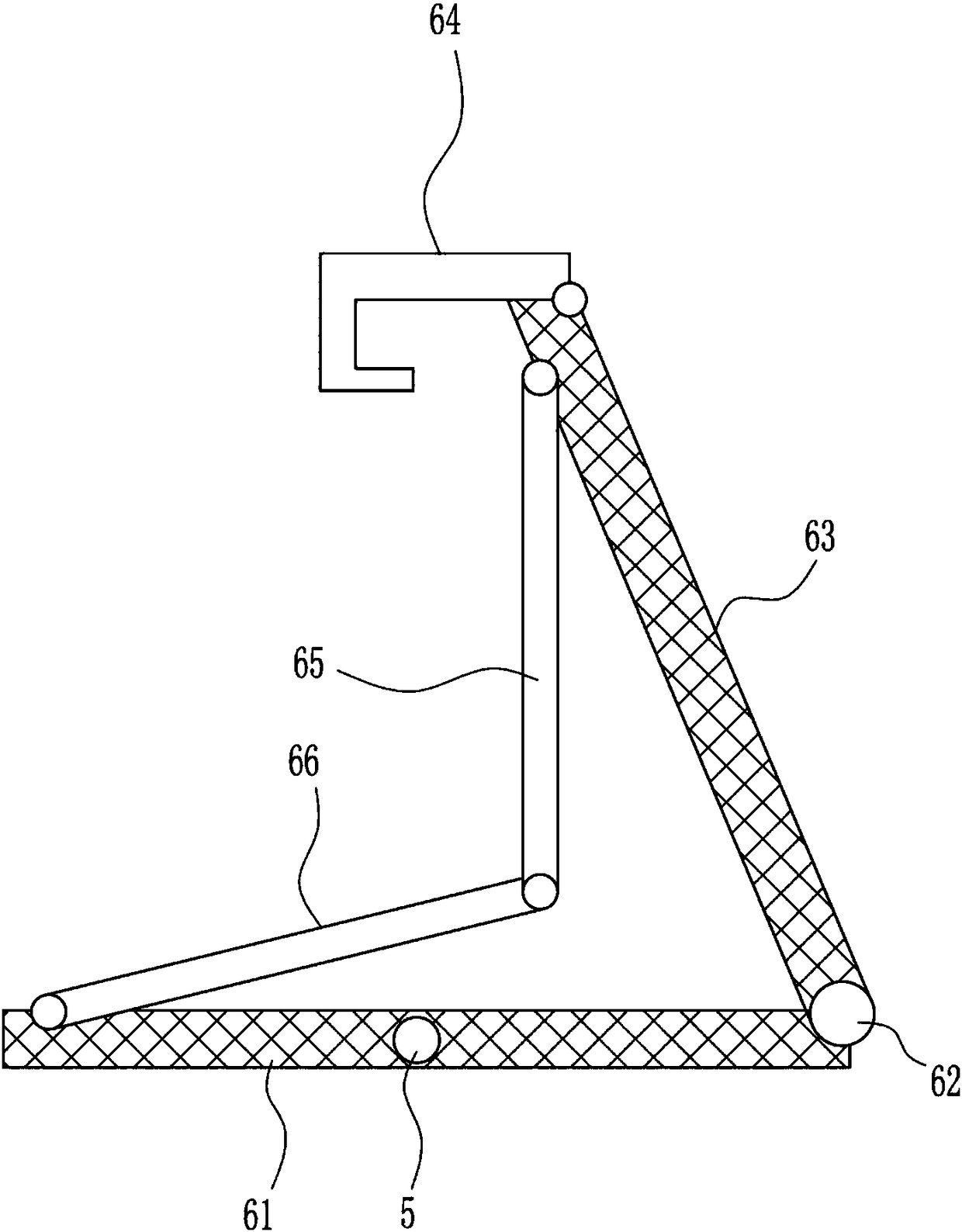

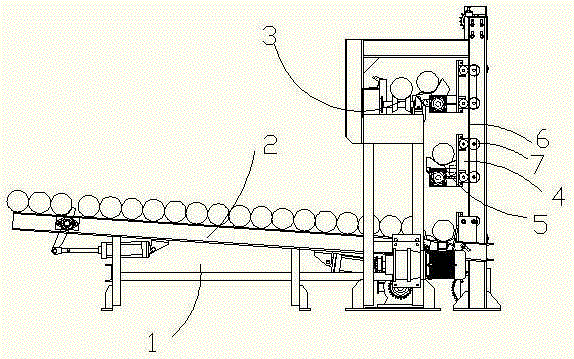

Aluminum bar low-bar-level storage frame

The invention discloses an aluminum bar low-bar-level storage frame. The aluminum bar low-bar-level storage frame comprises a furnace frame. A material frame is obliquely arranged in the furnace frame. A discharge port is formed in the lower end of the material frame. The furnace frame is further provided with an aluminum bar lifting mechanism which is arranged in a sliding manner in the vertical direction. An aluminum bar outlet is formed in the furnace frame and located above the discharging port of the material frame. The aluminum bar outlet is provided with an aluminum bar conveying roller. The aluminum bar lifting mechanism comprises a sliding frame and a V-shaped aluminum bar overturning strip rotationally arranged on the sliding frame. The furnace frame is provided with a guide rail extending in the vertical direction. The sliding frame is rotationally provided with a travelling wheel matched with the guide rail. The travelling wheel is driven by a motor to rotate. Aluminum bars are overturned to the aluminum bar lifting mechanism from the material frame through a bar lifting and overturning mechanism. The aluminum bars needing to be discharged out of a furnace are lifted through the aluminum bar lifting mechanism and then are conveyed to the aluminum bar conveying roller to be discharged out of the furnace. The aluminum bars can be discharged out of the furnace quite conveniently.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

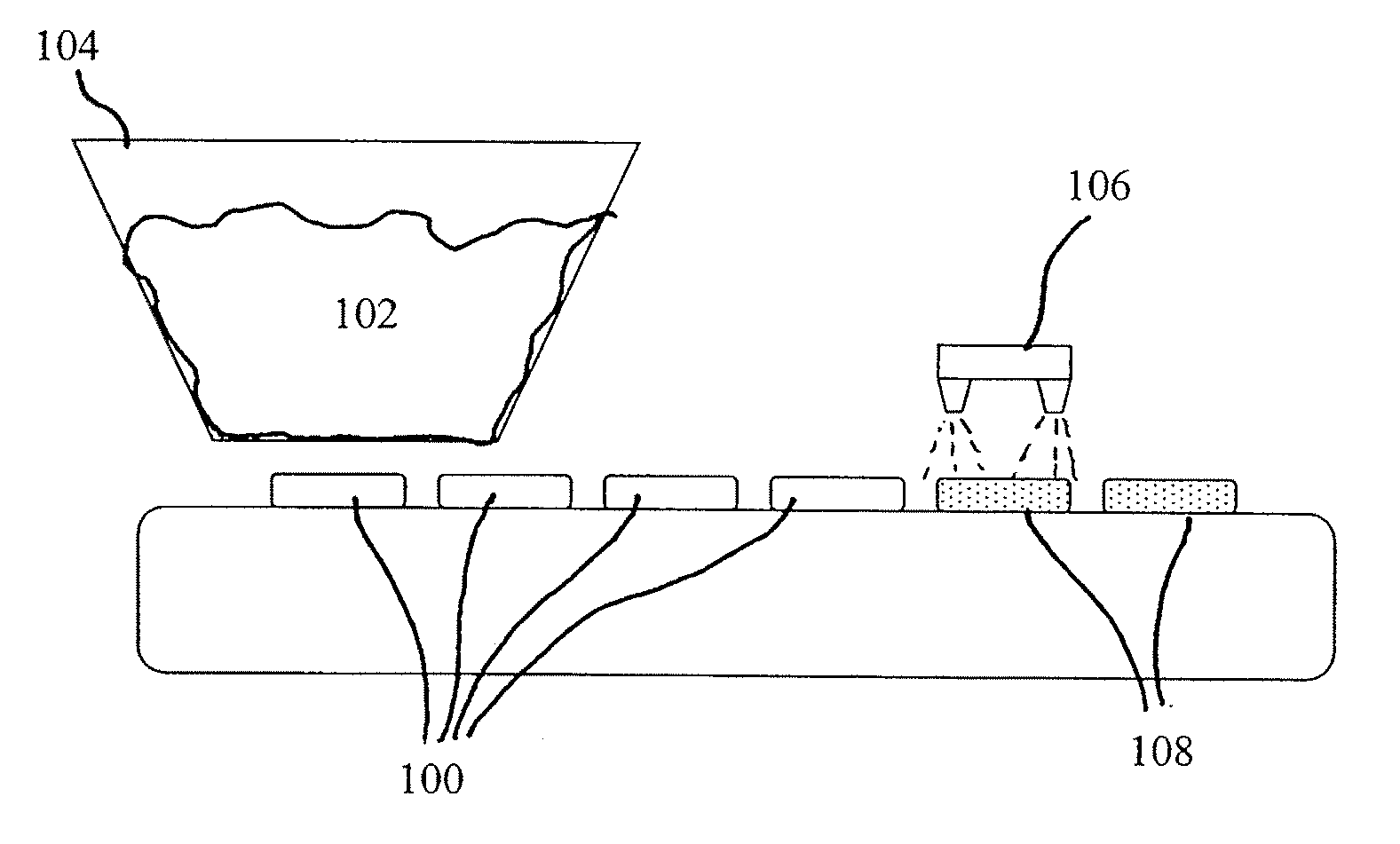

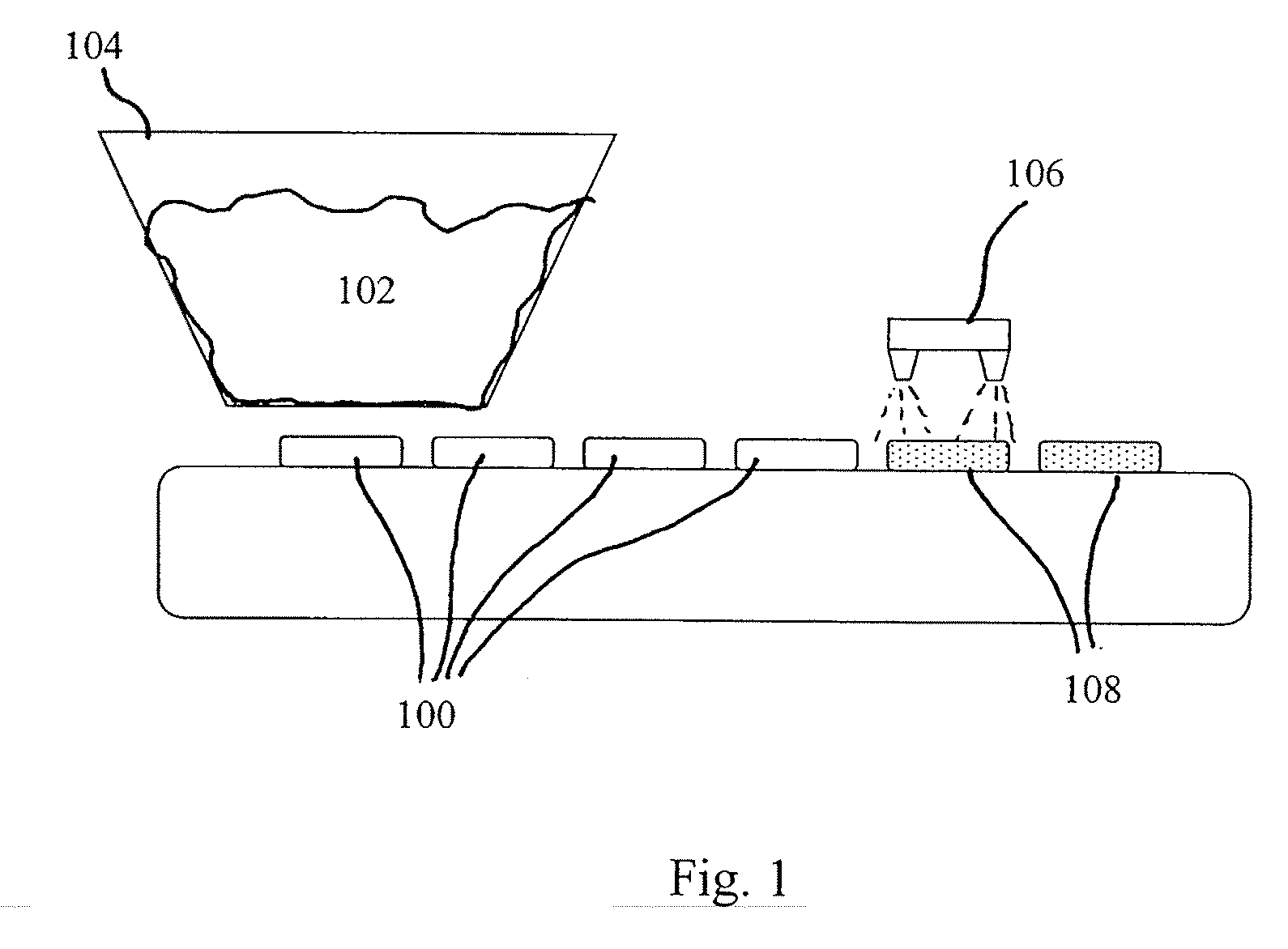

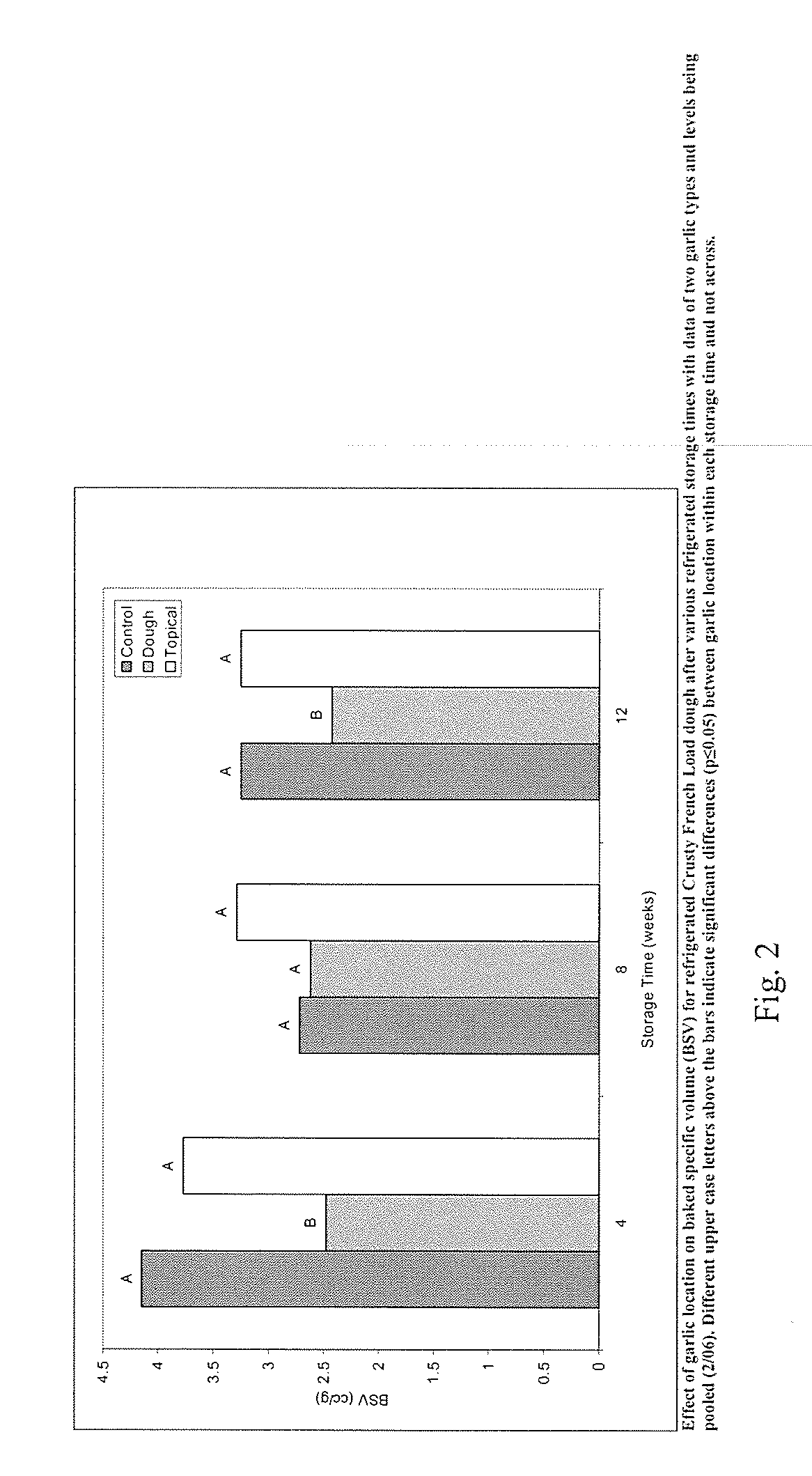

Topically applied garlic on refrigerated dough

InactiveUS20070042098A1Minimal processingEasy BakingBaking mixturesBakery productsCooking & bakingFlavouring agent

Refrigerated, raw dough products having topically applied garlic flavorant. The refrigerated, raw dough products, upon baking, have a higher Baked Specific Volume than comparable, raw dough products having garlic flavorant mixed directly into the dough. The garlic flavorant can be used in a solid form, liquid form or a combination of solid and liquid forms. The refrigerated, raw dough products can be formed from either developed or undeveloped dough. The refrigerated raw dough product can be packaged and stored in a refrigerated environment for a period of about 4 to about 12 weeks while maintaining a satisfactory Baked Specific Volume upon baking. The topically applied garlic flavorant can be present in an amount up to about 5.0% by weight of the raw dough product. A process for forming the refrigerated, raw dough product can include applying the garlic flavorant to an exterior portion of the refrigerated, raw dough product.

Owner:GENERAL MILLS INC

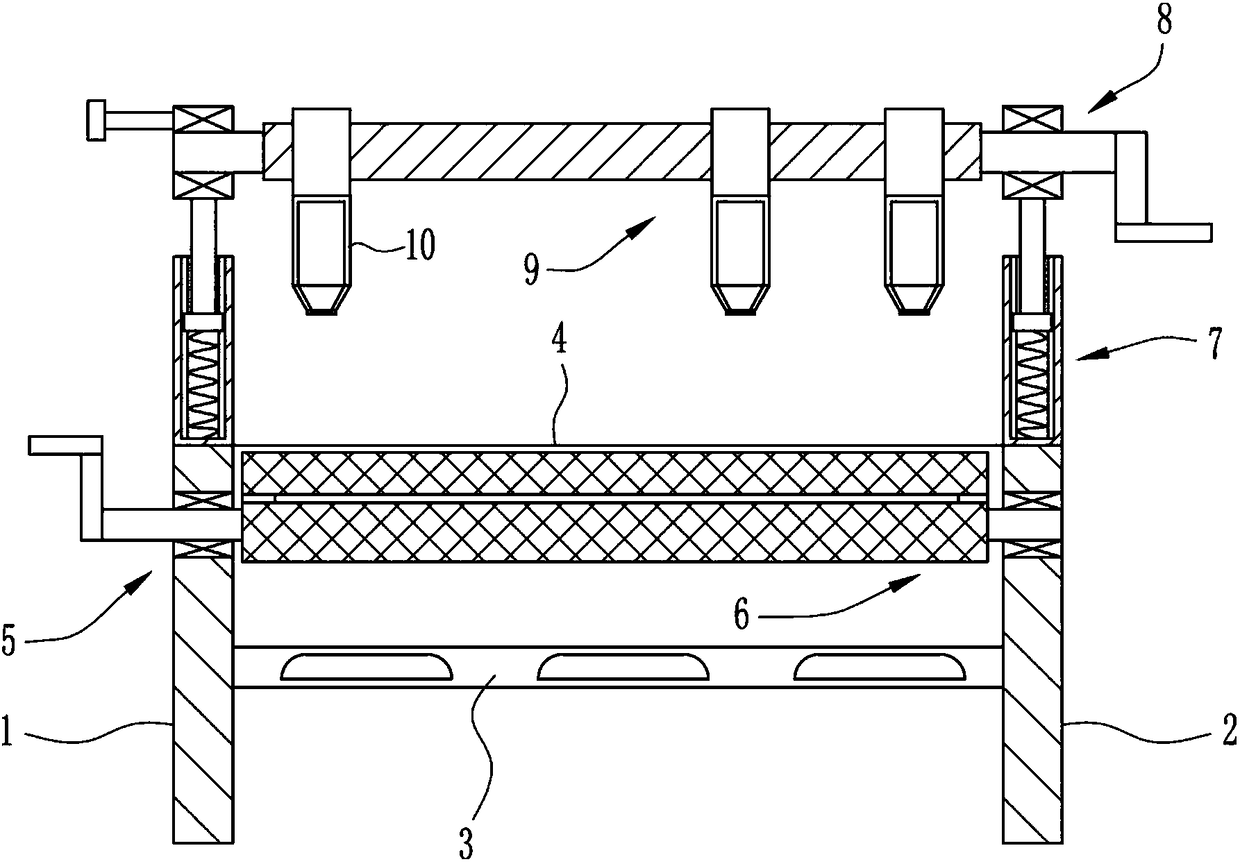

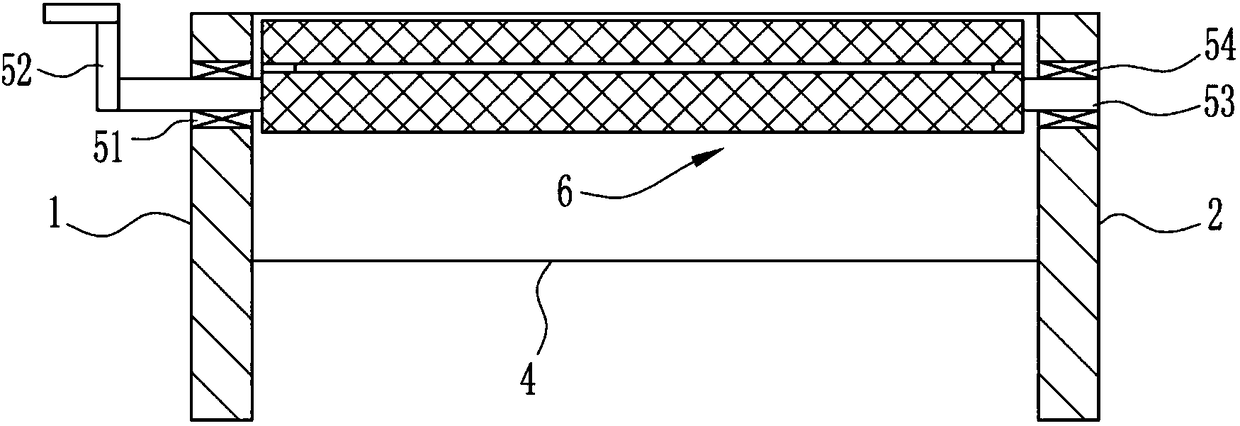

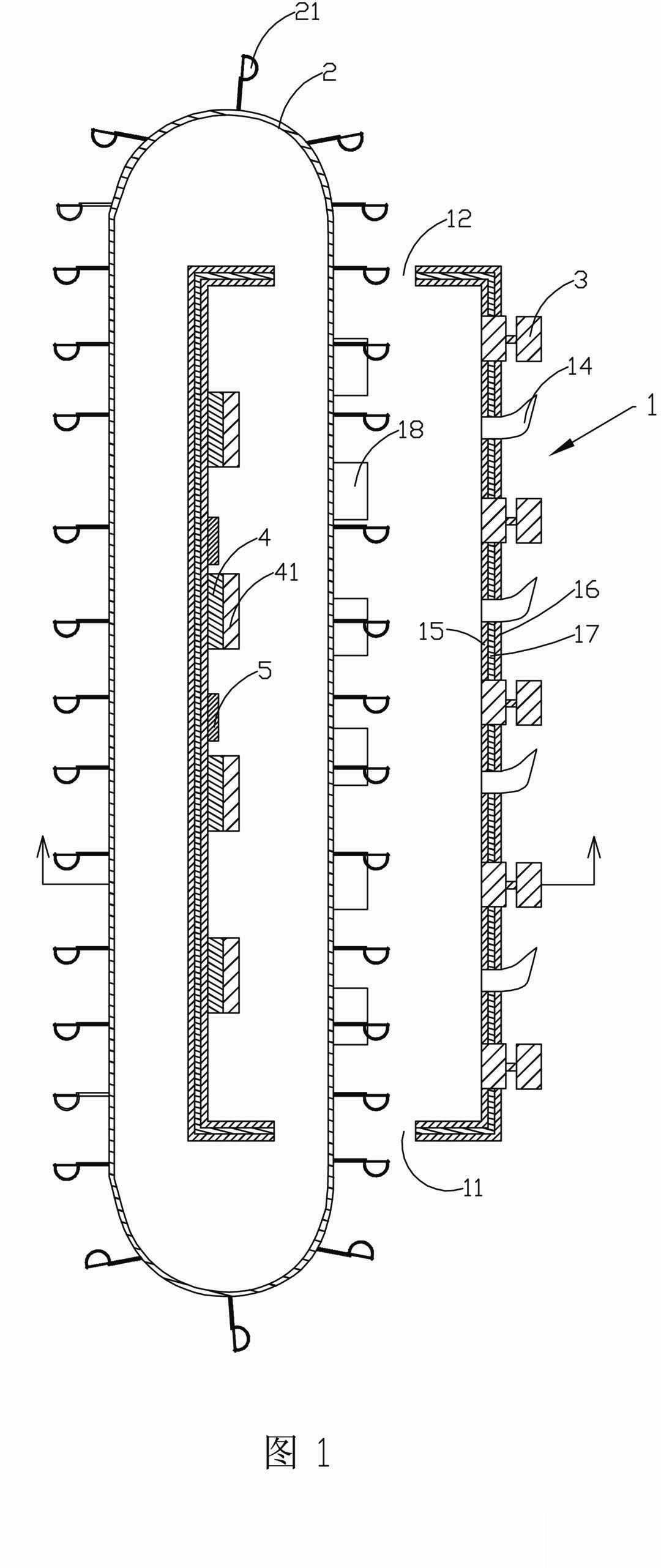

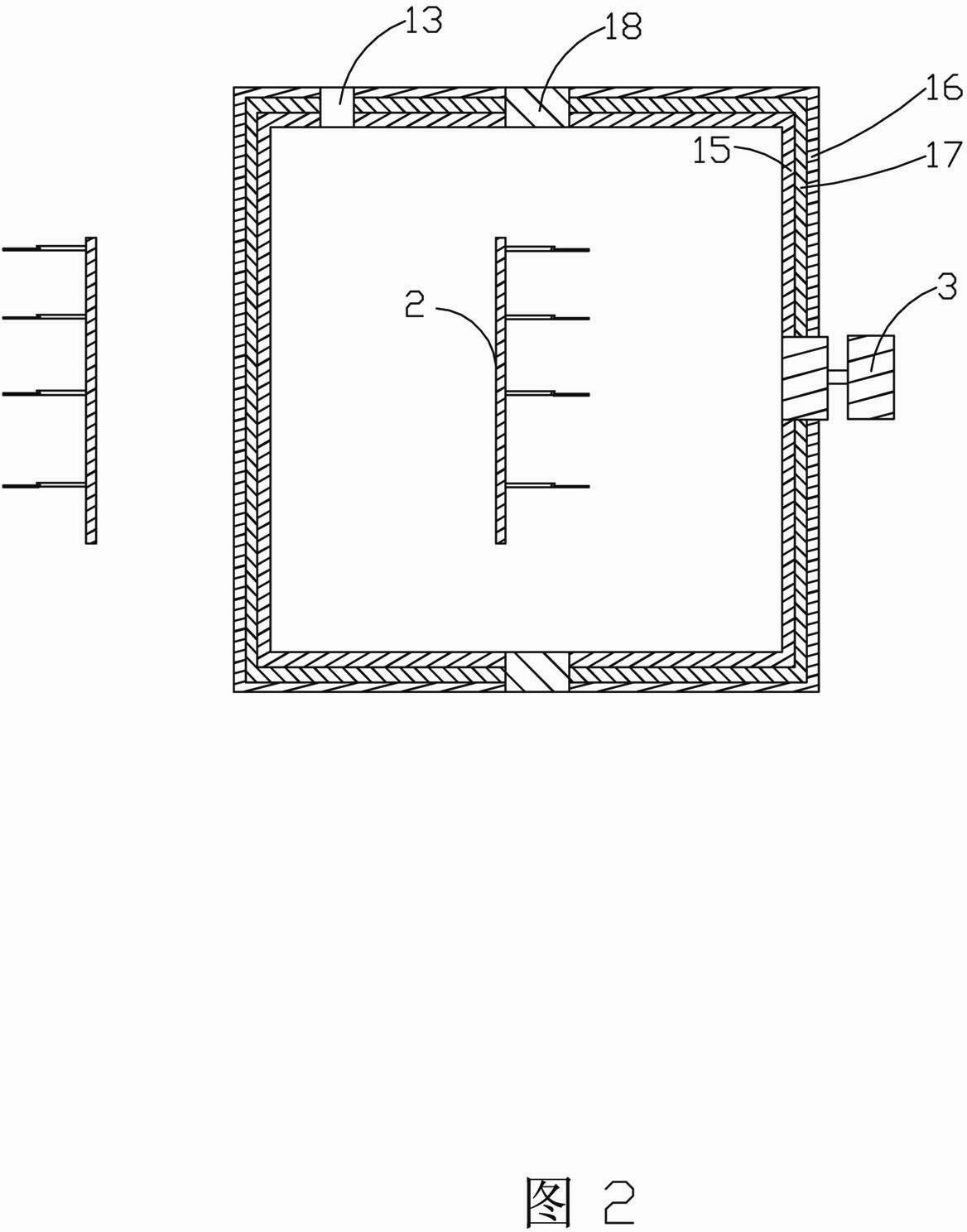

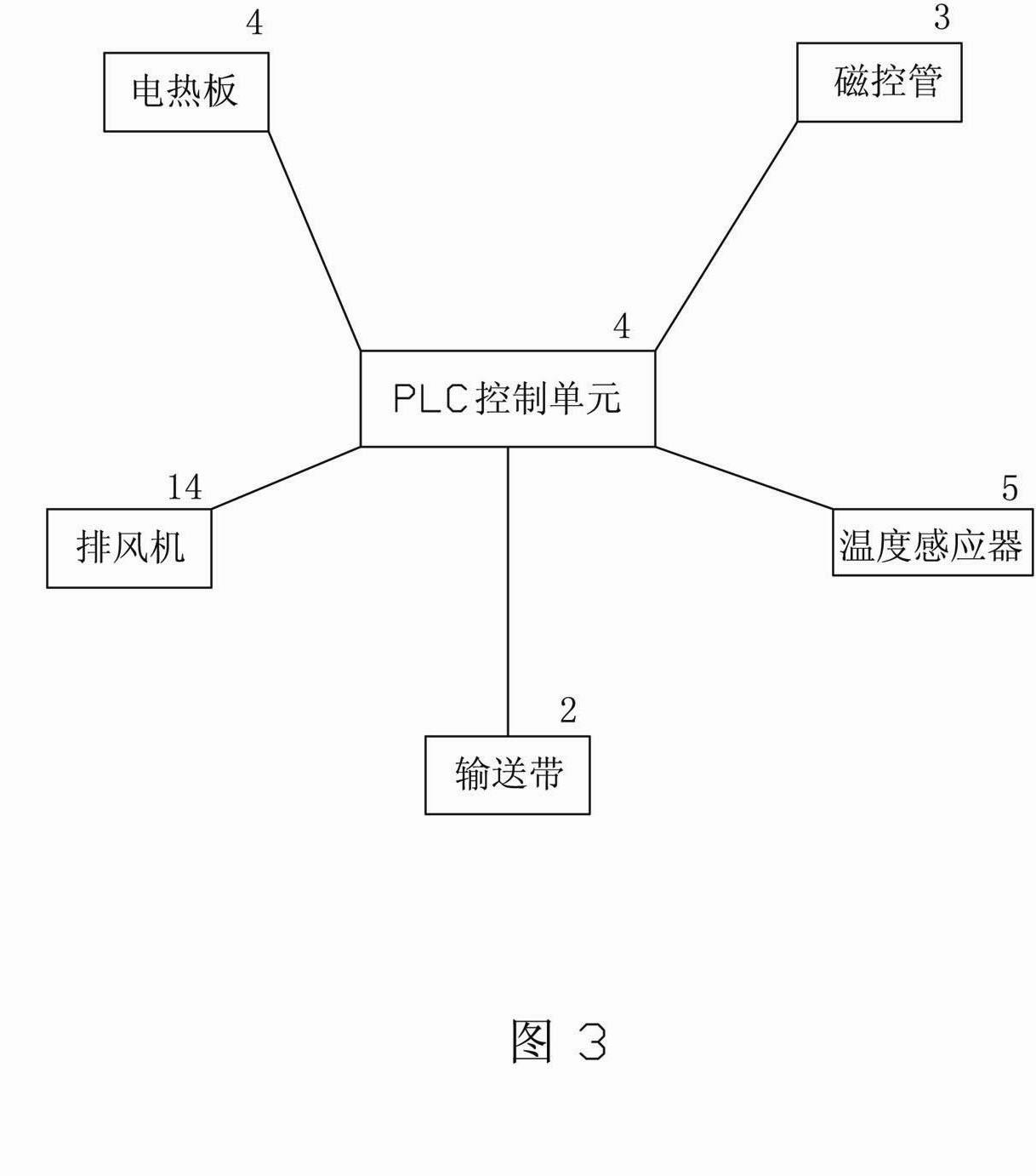

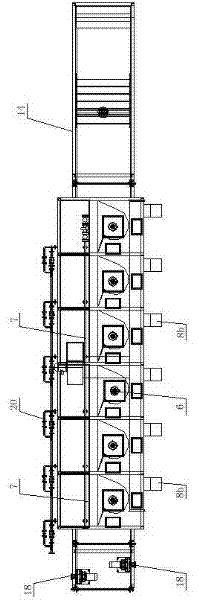

Food baking device

The invention provides a food baking device comprising a food inlet, a food outlet, a superincumbent tunnel type casing body and a conveying belt. The food inlet and the food outlet are respectively arranged at the upper end and the lower end of the food baking device, the conveying belt is arranged in the tunnel type casing body and can convey food to the outlet from the inlet, the conveying belt is provided with a food suspension device, the tunnel type casing body is provided with a wind inlet and a wind exhaust fan, and the tunnel type casing body is at least provided with one of a magnetron and an electric hot plate. With the adoption of the food baking device, the food is baked by hot wind, so that the food is heated more uniformly and the baking quality of the food is ensured. In addition, microwave is generated by the magnetron, so that the food can be better baked and the baking quality of the food is improved.

Owner:林清矫

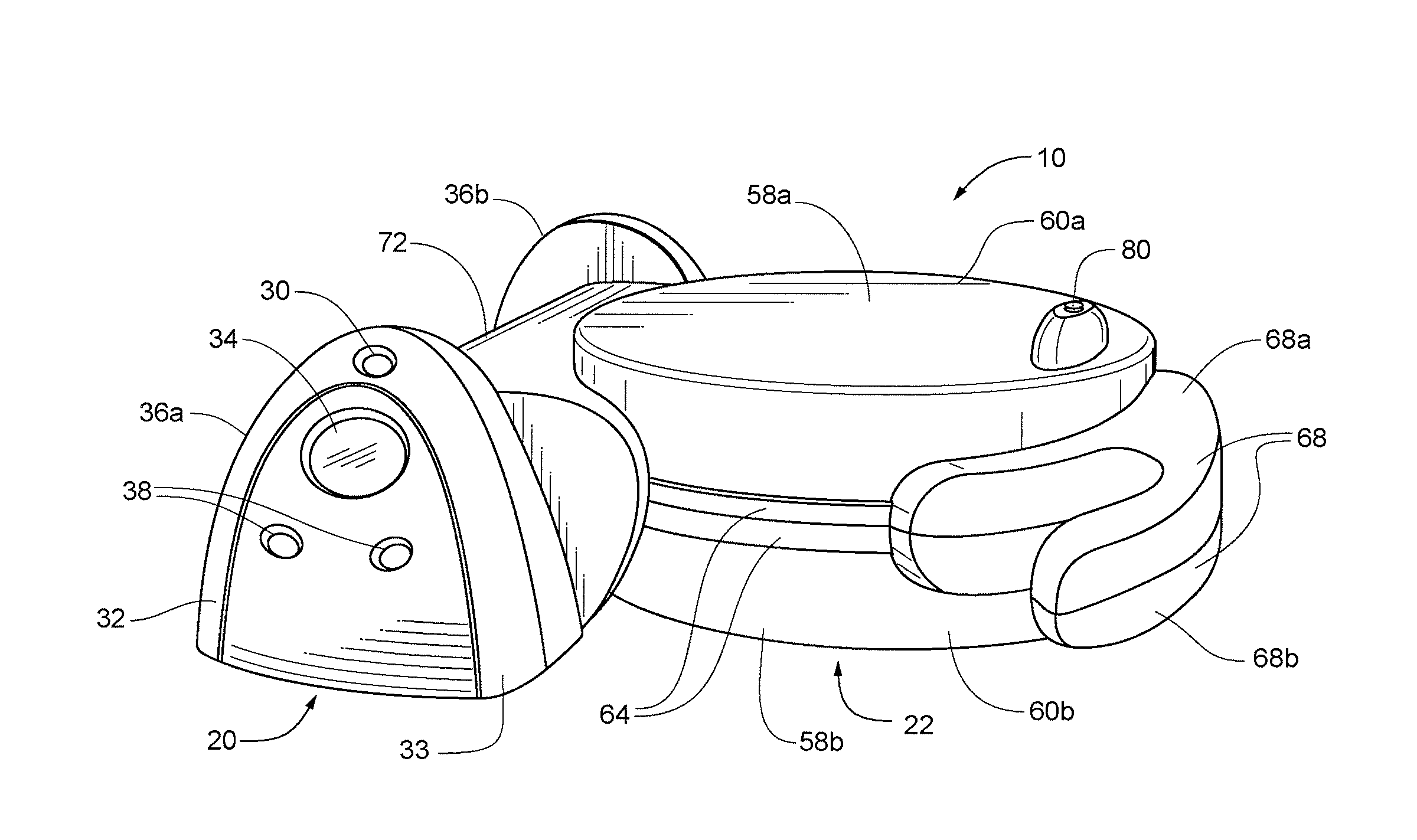

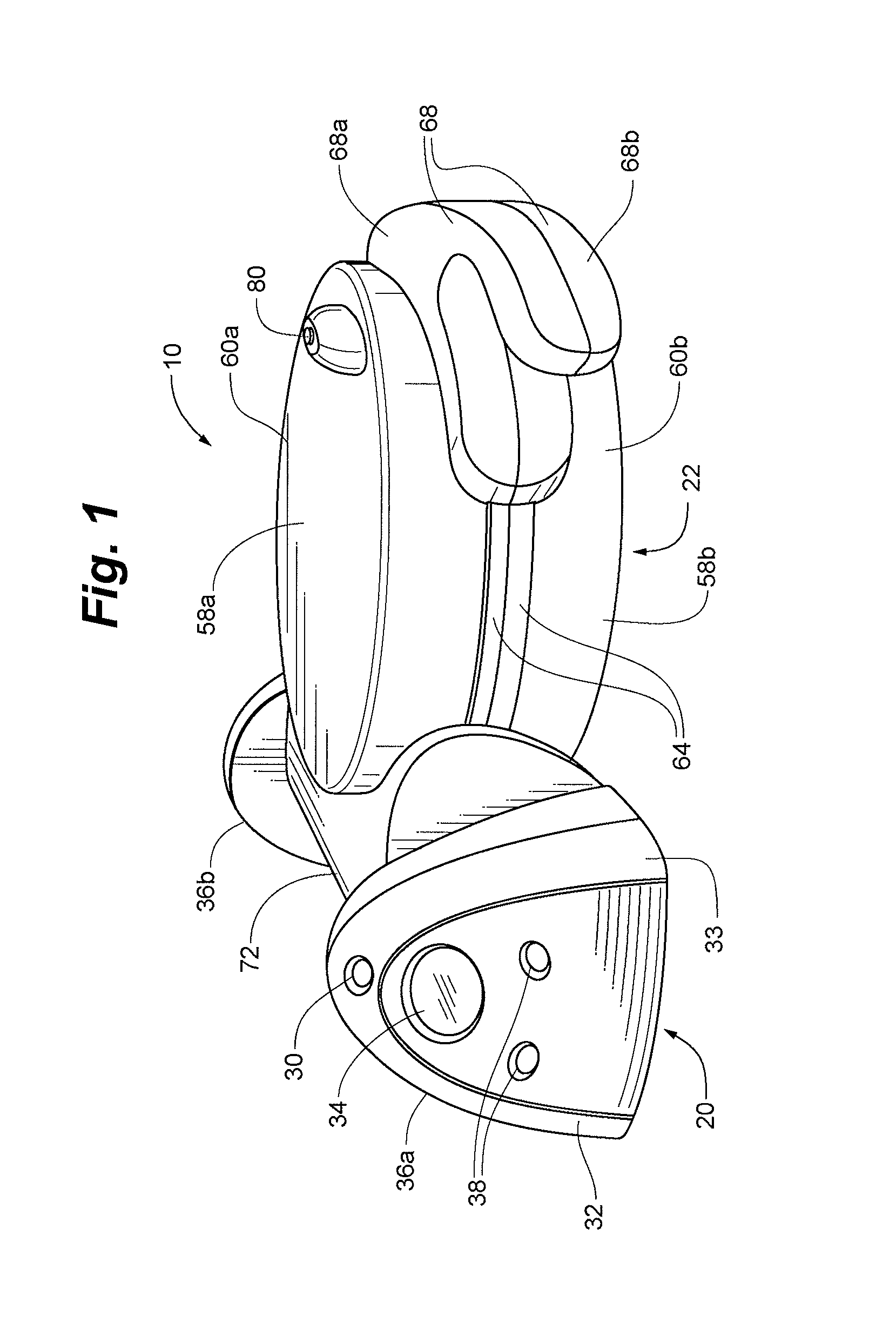

Apparatus for cooking meat

InactiveUS20050039609A1Increase exposureEnhanced steam absorptionCooking vesselsMeat processingEngineeringMechanical engineering

Owner:INNOVATIVE CULINARY CONCEPTS

Apparatus for cooking meat

InactiveUS7146905B2Increase exposureEnhanced steam absorptionMeat processingCooking vesselsEngineeringMechanical engineering

Owner:INNOVATIVE CULINARY CONCEPTS

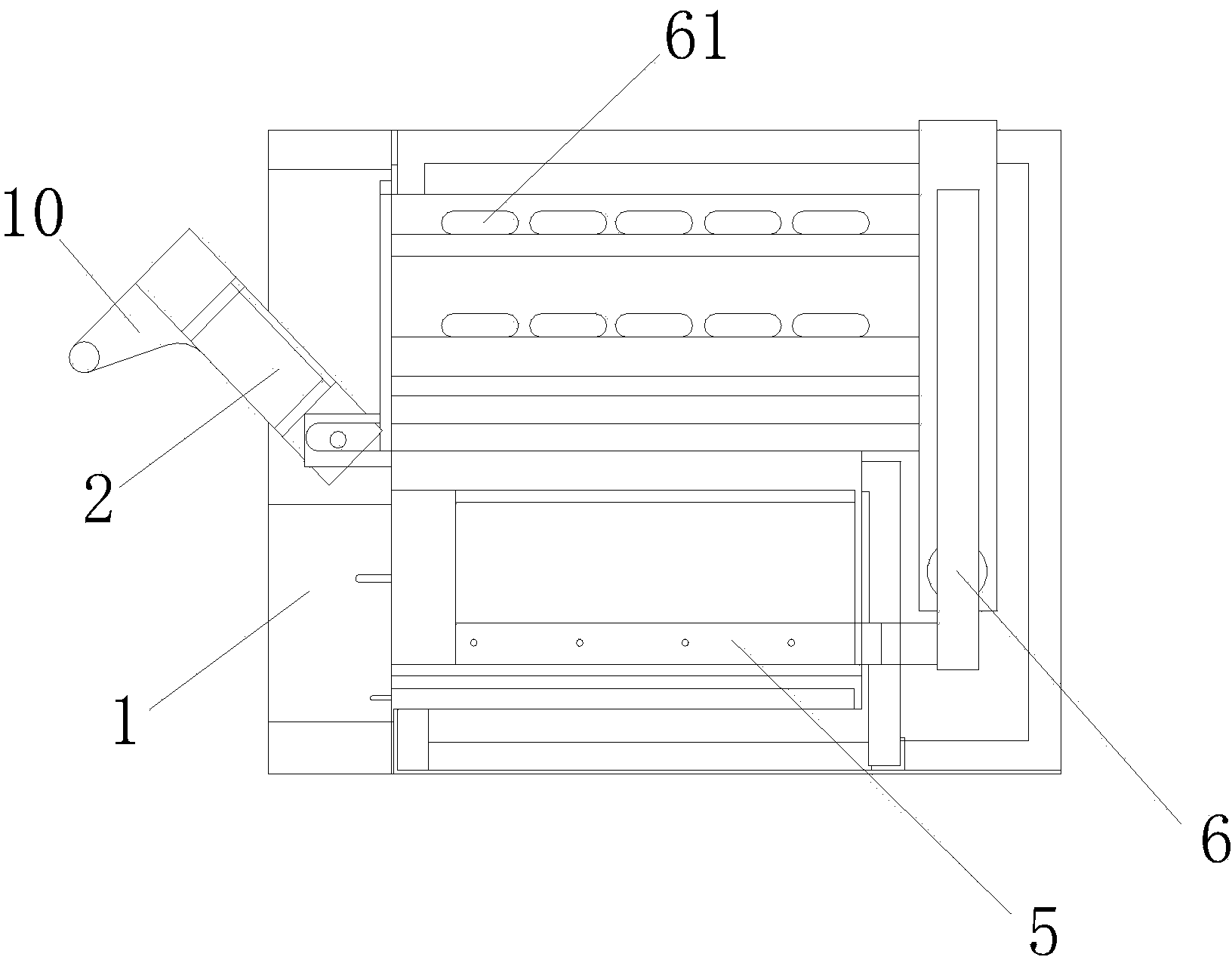

Roasting air cooler

ActiveCN102326594AChange processRealize the function of automatic flippingBaking surface cleaning/greasingEngineeringManufacturing line

The invention discloses a roasting air cooler. The roasting air cooler comprises a box, and the box is internally equipped with an interlayer and is divided into a roasting part and an air-cooling part through the interlayer, wherein, the roasting part is internally equipped with at least one layer of material conveying belt for a roasting section, and the air-cooling part is internally equipped with at least one layer of material conveying belt for an air-cooling section; the discharge end of the material conveying belt for the roasting section is corresponding to the feed end of the material conveying belt for the air-cooling section; the interlayer is correspondingly equipped with a material passing port through which materials enter the feed end of the material conveying belt for the air-cooling section from the discharge end of the material conveying belt for the roasting section; and a roasting mechanism is correspondingly arranged in the roasting part, and an air-cooling mechanism is correspondingly arranged in the air-cooling part. The roasting air cooler has the beneficial effects that by organically combining a roasting process with an air-cooling process, the utilization area of a workshop is increased and meanwhile an automatic production line is realized, thus greatly improving production efficiency and reaching uniform roasting and air-cooling effect; the water content of the roasted materials can be accurately controlled; and the air cooler is simple in operation.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

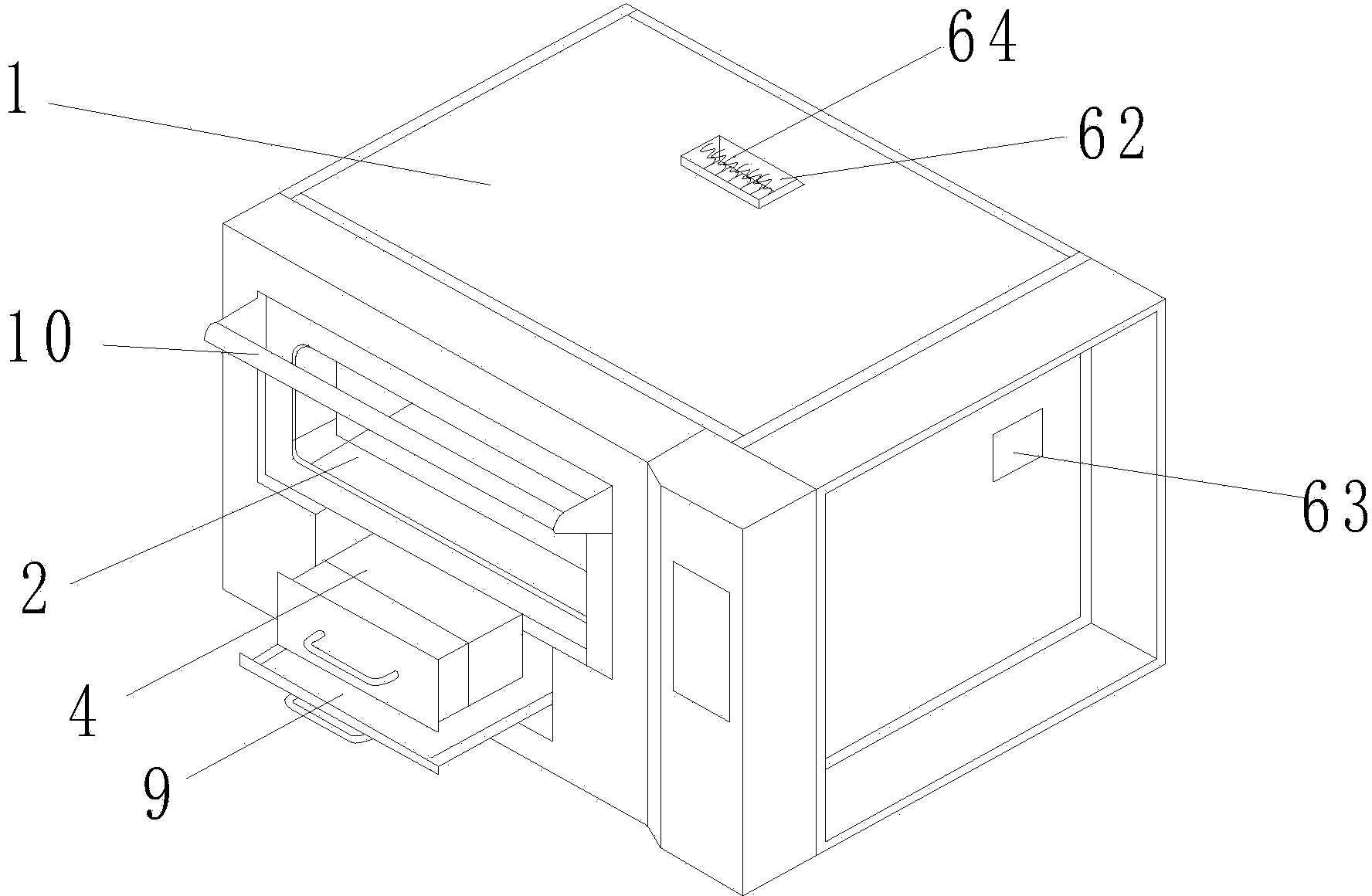

Bread toaster

The invention relates to a toaster that can evenly toast each piece of bread and has a good toasting effect. Support columns are provided respectively, and connectors are arranged on the support columns, and the ends of the connectors pass through the corresponding limit holes. Springs and electromagnets are arranged under the connectors, the springs are sleeved on the support columns, and the electromagnets are fixed on the On the bottom surface of the box body, a supporting plate is arranged between the connectors, and heating resistor screens are respectively arranged on the front and rear sides of the box body, a top cover is fixedly installed at the opening of the box body, and a plurality of The partition, the bottom of the partition passes through the perforation on the supporting plate and protrudes out of the lower surface of the supporting plate. The partition is made of thermally conductive material, a heating device is arranged in the partition, and a temperature sensor is also arranged in the box. A control device is arranged on the outer surface of the box body, and the control device is electrically connected with the electromagnet, the temperature sensor and the heating device respectively.

Owner:李文

Quick-frozen meat pie and preparation method thereof

InactiveCN101889597ARealize automated mass productionEasy BakingBakery productsAssembly lineChemistry

The invention discloses a quick-frozen meat pie. The quick-frozen meat pie comprises a flour wrapper, wherein a stuffing is wrapped in the flour wrapper; the weight ratio of the flour wrapper to the stuffing is 1:1.5-2.5; the weight of the quick-frozen meat pie is 80 to 150 grams; the diameter of a formed green pie body is 70 to 130 mm; and the thickness of the formed green pie body is 12 to 18 mm. The invention also discloses a method for preparing the quick-frozen meat pie. In the method, assembly line automatic batch production of quick-frozen meat pies is realized; the production efficiency and the product quality are improved; the thickness of the flour wrapper of the quick-frozen meat pie is uniform, which contributes to baking the quick-frozen meat pies; and the quick-frozen meat pies can be stored for long time, usually can be stored in cold for more than eight months, which ensures that the quick-frozen meat pies can be transported and sold conveniently at different places.

Owner:王吉山

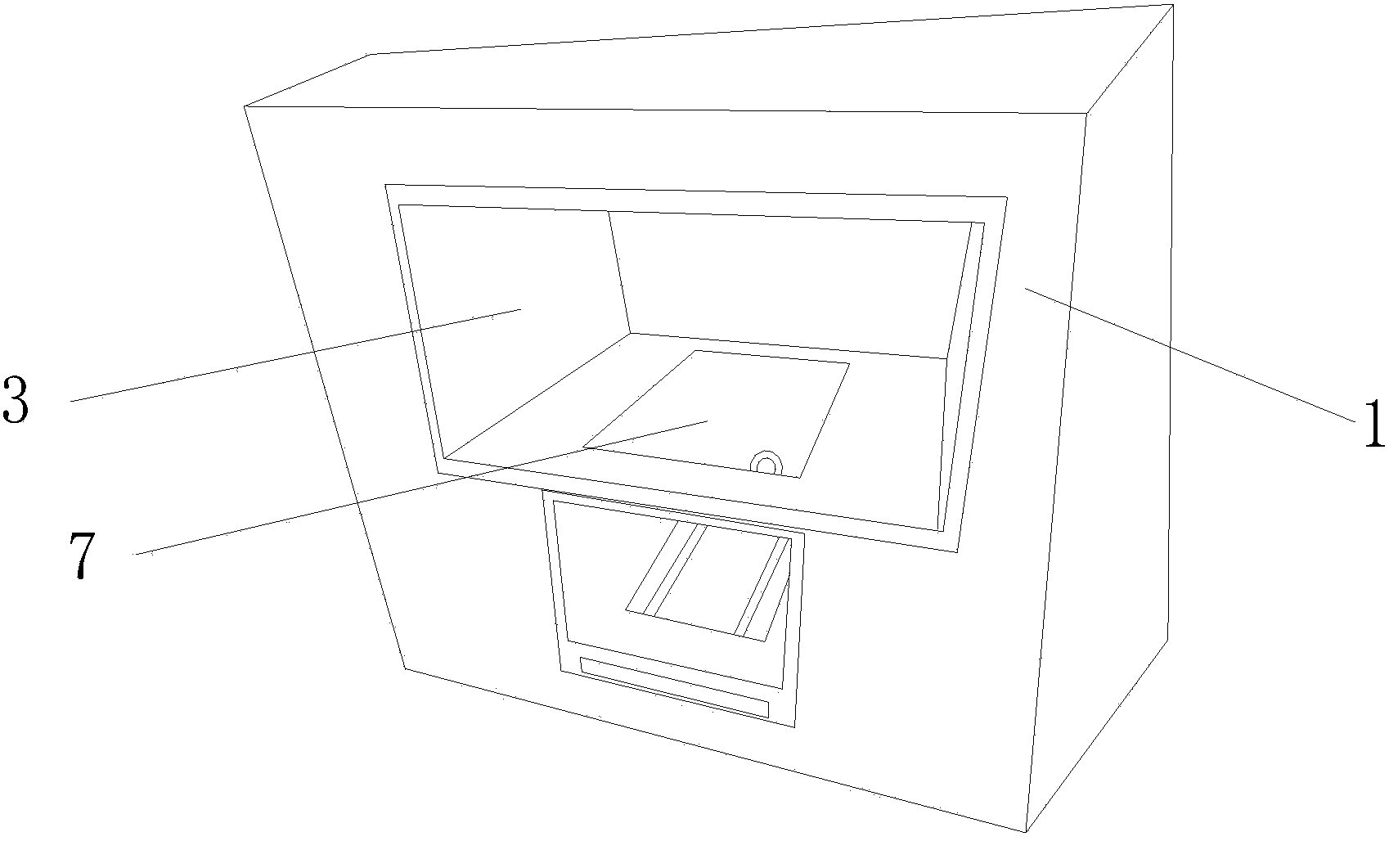

Sesame seed cake oven

The invention relates to the field of food processing, in particular to a sesame seed cake oven. The sesame seed cake oven comprises an oven body and an oven door arranged on the oven body, wherein a chamber for baking foods is arranged in the oven body; a carbon groove is formed below the chamber; a flue gas recovering pipeline is arranged inside the oven body and is communicated with the carbon groove; a vent pipeline is arranged in the carbon groove; the vent pipeline is communicated with the flue gas recovering pipeline arranged in the oven body. According to the sesame seed cake oven, the carbon groove of a unique design is formed in the chamber, so that the amount of carbon ash entering the chamber is reduced, and the sesame seed cake oven is clean and environmentally friendly; moreover, carbon is adopted instead of electricity, so that energy is saved, and environmental protection is facilitated; the flue gas recovering pipeline is arranged in the oven body, so that cold and hot air can be exchanged at any time, a required constant temperature can be reached in the chamber, foods can be baked conveniently and rapidly, and the sesame seed cake oven can be heated uniformly and is sanitary and environmentally friendly.

Owner:杭州吧啦熊自动化科技有限公司

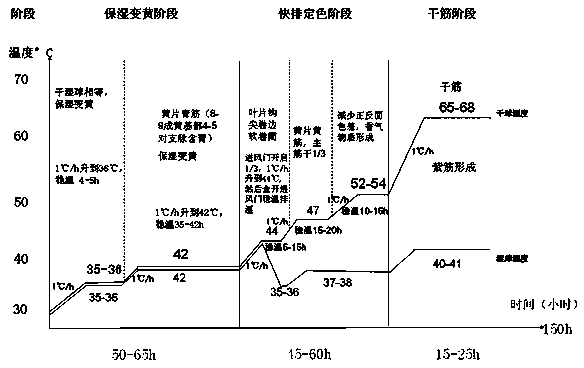

Dual testing room measured material outgassing rate measuring device and method

ActiveCN101696923BDoes not disrupt dynamic balanceEasy BakingPreparing sample for investigationMeasurement testDynamic balance

The invention discloses dual testing room measured material outgassing rate measuring device and method, belonging to the field of vacuum measurement. Symmetric structures of testing rooms are utilized in the device, an extractor guage is in bridge connection at two sides of a small hole, and the backgrounds in the testing rooms are tested in real time by changing flow passages of gas. The methodcomprises the following steps: putting a sample in a high vacuum chamber, baking and degassing while exhausting gas, introducing gas released by the sample in the testing rooms, measuring the pressure difference of two sides of the small hole in a dynamic balance state and obtaining the total outgassing amount through the known conductance of the small hole; introducing the gas released by the sample to the testing rooms, measuring the pressure in the testing rooms and an ultrahigh vacuum chamber in a dynamic balance state, and obtaining the outgassing amount in the testing rooms through the known conductance of the small hole; taking out the sample and obtaining outgassing amount by subtracting each other. The method has convenient operation, measures the backgrounds in the testing roomsin real time and is beneficial to enhancing the measuring accuracy.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

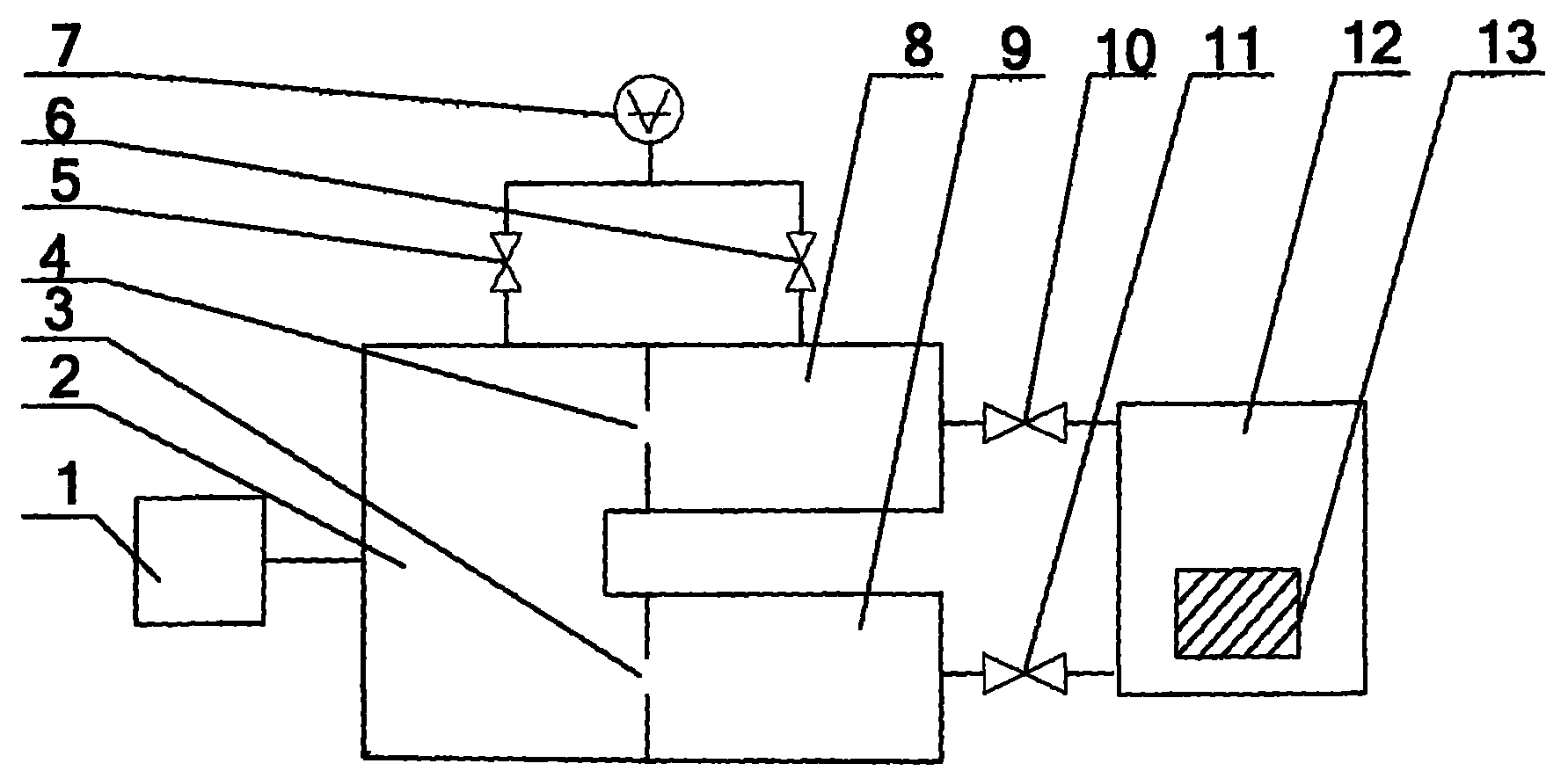

Sugar-free rice flour cake capable improving quality by utilizing sucrose ester and recombined rhizopus chinensis lipase and production method thereof

InactiveCN105230754AWith health functionIncrease in sizeDough treatmentPre-baking dough treatmentSucroseVegetable oil

The invention relates to a sugar-free rice flour cake capable of improving the quality by utilizing sucrose ester and recombined rhizopus chinensis lipase and a production method thereof. The production method adopts the following process steps: adding eggs, xylitol, maltitol, milk, sucrose ester and recombined rhizopus chinensis lipase into an egg beater, and mixing uniformly; then adding vegetable oil and essence, and mixing uniformly; then pouring sieved rice meal, wheat starch and baking powder into the egg beater, continuously stirring until milky-white fluffy paste is formed; pouring an egg paste into a mold, and baking to obtain the sugar-free rice flour cake. According to the sugar-free rice flour cake and the production method thereof, foundation is laid for the production of health and high-quality sugar-free rice flour cake, the sugar-free rice flour cake is prepared by utilizing xylitol and maltitol; meanwhile, through the addition of the bsucrose ester and the recombined rhizopus chinensis lipase, the baking and storing characteristics of egg products can be improved, the prepared sponge cake not only has the health care function of sugar-free food, but also has the characteristics of large volume, moist and flexible taste, difficulty in ageing, high acceptability of consumers in the storage period, and the like.

Owner:JIANGNAN UNIV +1

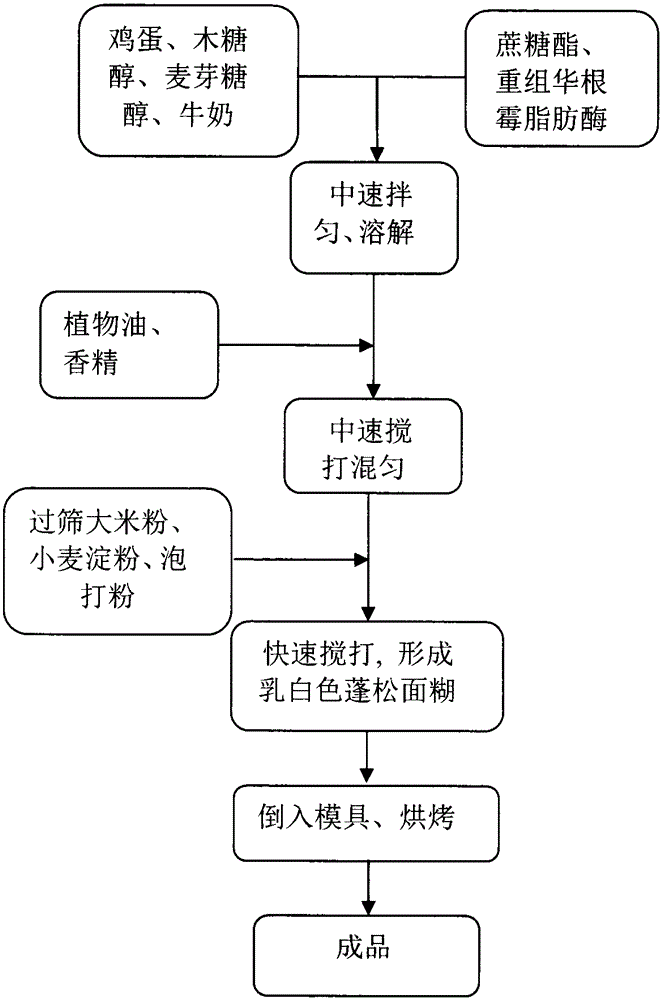

Convenient and efficient bulk curing method for flue-cured tobacco

The invention discloses a convenient and efficient bulk curing method for flue-cured tobacco, and belongs to a curing or preparation method for the flue-cured tobacco. The method comprises the steps of tobacco harvesting, rod tying or tobacco clamping, loading on a heatable brick bed, preparation for curing, yellowing, color fixing and killing-out of a conventional method. The method has the characteristics that tobacco is controlled to be fully yellowed in a high-temperature and high-humidity environment, and is bright in color; main moisture exhaust drying temperature is fixed to be 44 DEG C, and color is fixed under low humidity and high moisture exhaust rate. Compared with the conventional curing method, the method has the advantages that the cured tobacco is bright and shining in color; tobacco with green stems and ash is reduced or eliminated; the tobacco is high in flexibility and softness; tobacco with diseases and special tobacco can also be cured to be yellow and scented; the tobacco of more than two parts and different maturities in the same curing barn can be cured; the curing method is simple, high in operability and easy to master and accept by curing personnel; the curing time is shortened by 10 to 15 hours; the tobacco curing quality and benefits are improved.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

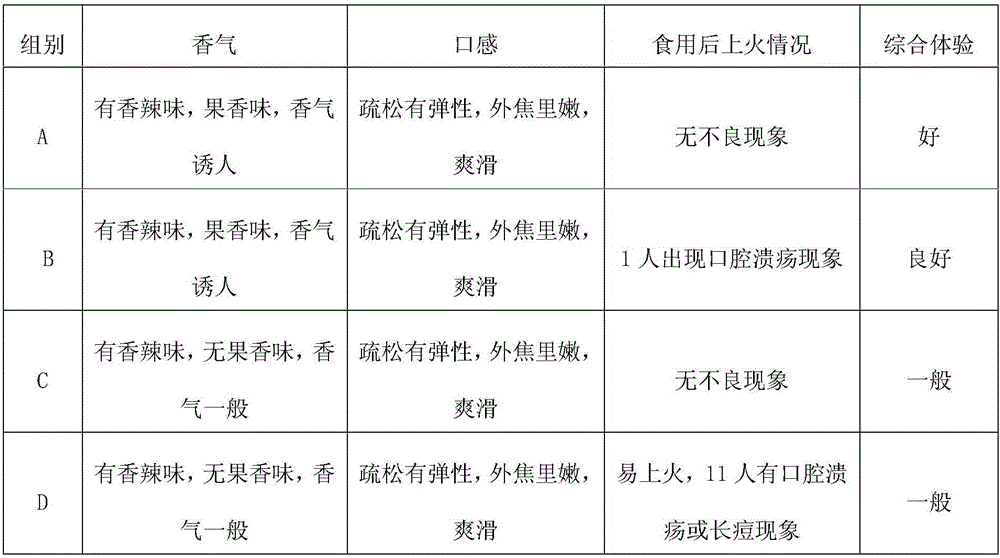

Nutritious beef jerky and preparation method thereof

InactiveCN106579035AHarmonious and pleasant aromaSweet and sour tasteFood sciencePreservativeFood material

The invention provides nutritious beef jerky and a preparation method thereof and relates to the technical field of food processing. The nutritious beef jerky is mainly prepared from, by weight, 150-200 parts of beef, 40-60 parts of curing materials, 20-30 parts of passion fruit, 50-80 parts of Fructus Crataegi, 10-15 parts of Flos Jasmini Sambac, 3-9 parts of Fructus Forsythiae, 3-9 parts of Herba Menthae, 5-10 parts of Herba Rabdosiae Serrae, 1-3 parts of dry red pepper, 2-5 parts of garlic, 2-7 parts of ginger, 5-10 parts of olive oil and an appropriate amount of water. The nutritious beef jerky and the preparation method thereof have the advantages that a specific formula is combined with the special preparation method to make the food materials give maximal play to efficacy, and accordingly the prepared beef jerky exudes a mouthwatering aroma, is fluffy with elasticity, smooth, tender with a crispy crust and delicious, cannot make people get inflamed after being eaten, and is free of harmful substances such as pigments and preservatives, thereby being safe and healthy and worthy of popularization and production.

Owner:GUANGXI UNIV

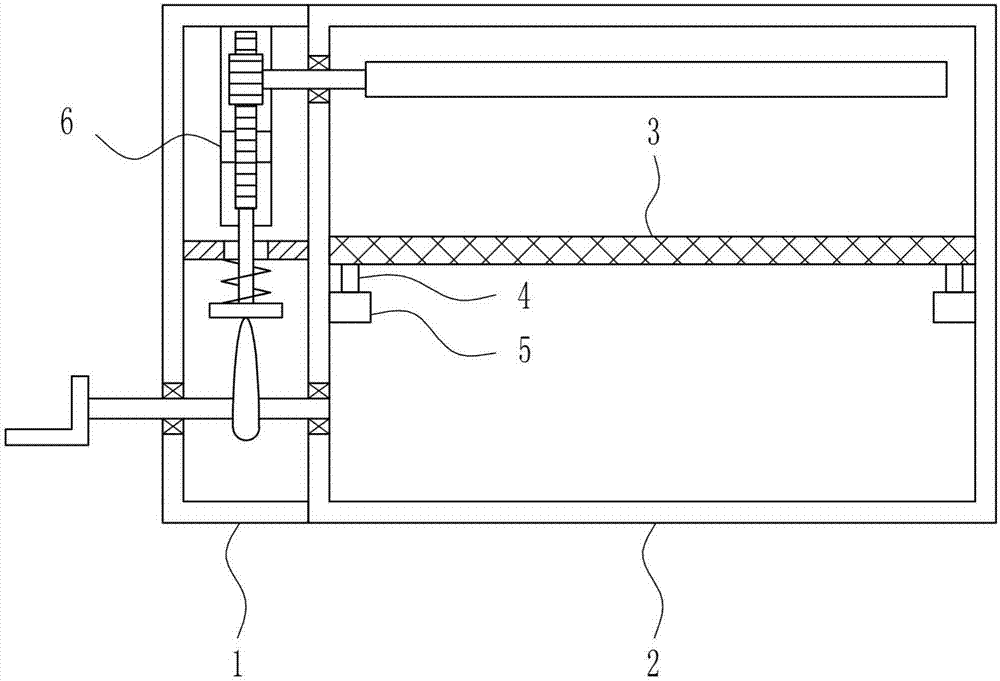

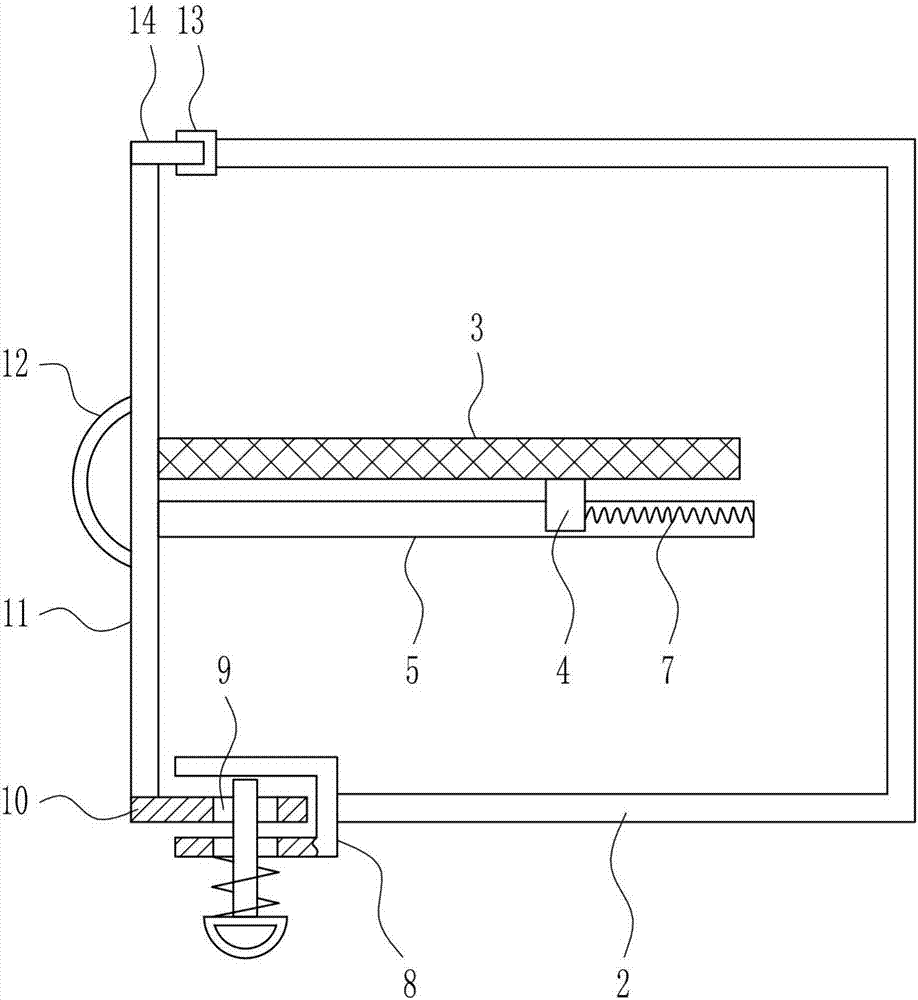

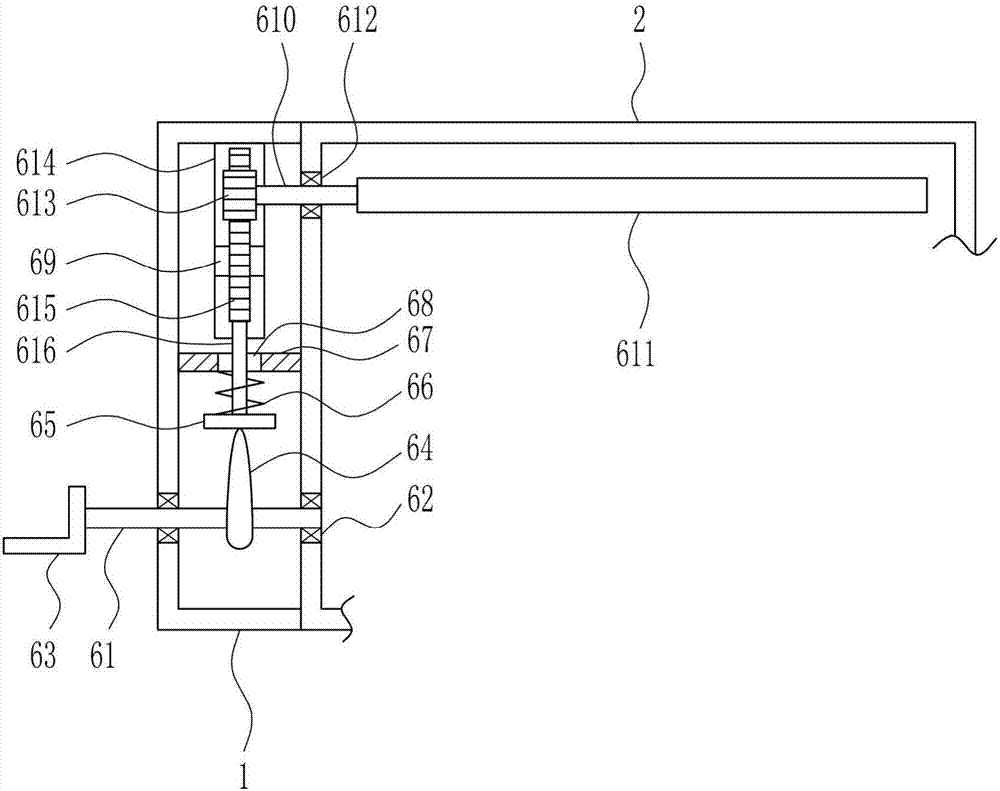

High-efficiency baking and shaping device for vamp

The invention relates to a baking and shaping device, and particularly relates to a high-efficiency baking and shaping device for a vamp. The invention aims at solving the technical problem to provide the high-efficiency baking and shaping device for the vamp; the device has the advantages of quick baking speed and uniform heating. In order to solve the technical problem, the invention provides thesuch a high-efficiency baking and shaping device for the vamp. The high-efficiency baking and shaping device comprises a fixing groove, a working box, a placing net, a first sliding block, first sliding rails, a rocking heating device, a first spring, a fixing device, a fixing rod, a baffle plate, a first pull ring and the like, wherein the left side of the working box is connected with the fixing groove; the rocking heating device is arranged in the fixing groove; the right side of the rocking heating device is connected with the working box; a left wall and a right wall in the working box are symmetrically connected with the first sliding rails. By using the high-efficiency baking and shaping device, the effects that the baking speed is quick and the heating is uniform are achieved; a rotating rod is artificially rocked with a hand to make a heating plate radiate heat to bake and shape the vamp; the fixing device is used for making the baffle plate more stable; meanwhile, an air heater swings upwards, downwards, leftwards and rightwards.

Owner:浙江天宏鞋业有限公司

Using method of barbecuing equipment

InactiveCN108433561AEvenly heatedImprove grilling effectRoasting apparatusRoasters/grillsManufacturing technologyEngineering

The invention belongs to the technical field of barbecuing equipment manufacturing, and relates to a using method of barbecuing equipment. The method comprises the steps that skewers are well fixed and placed through a clamping groove formed in a top fixing plate after a heating source is selected, an outer gear plate is driven to rotate by starting a motor, the outer gear plate is driven to rotate by a driving gear, and a miniature range hood is driven to rotate by starting the motor to absorb lampblack in a carrying box; during the barbecuing process, dropping oil drops move downwards to reach an oil guiding plate along the skewers under the action of gravity, penetrate through the bottom of the oil guiding plate and drop into an oil receiving plate directly, during the barbecuing process, a lower turning door of the carrying box is directly closed to achieve the purpose of heat insulation of a preservation box, after the barbecuing of the skewers is completed, the lower turning doorof the carrying box is opened, and the skewers can be taken out when the motor is stopped or operated. The method has the advantages that the operation is simple and convenient, heat can be distributed uniformly, the barbecuing effect is good, using is safe and convenient, the method is good in environment protection performance and environmentally friendly, and the market prospect is wide.

Owner:王晓珮

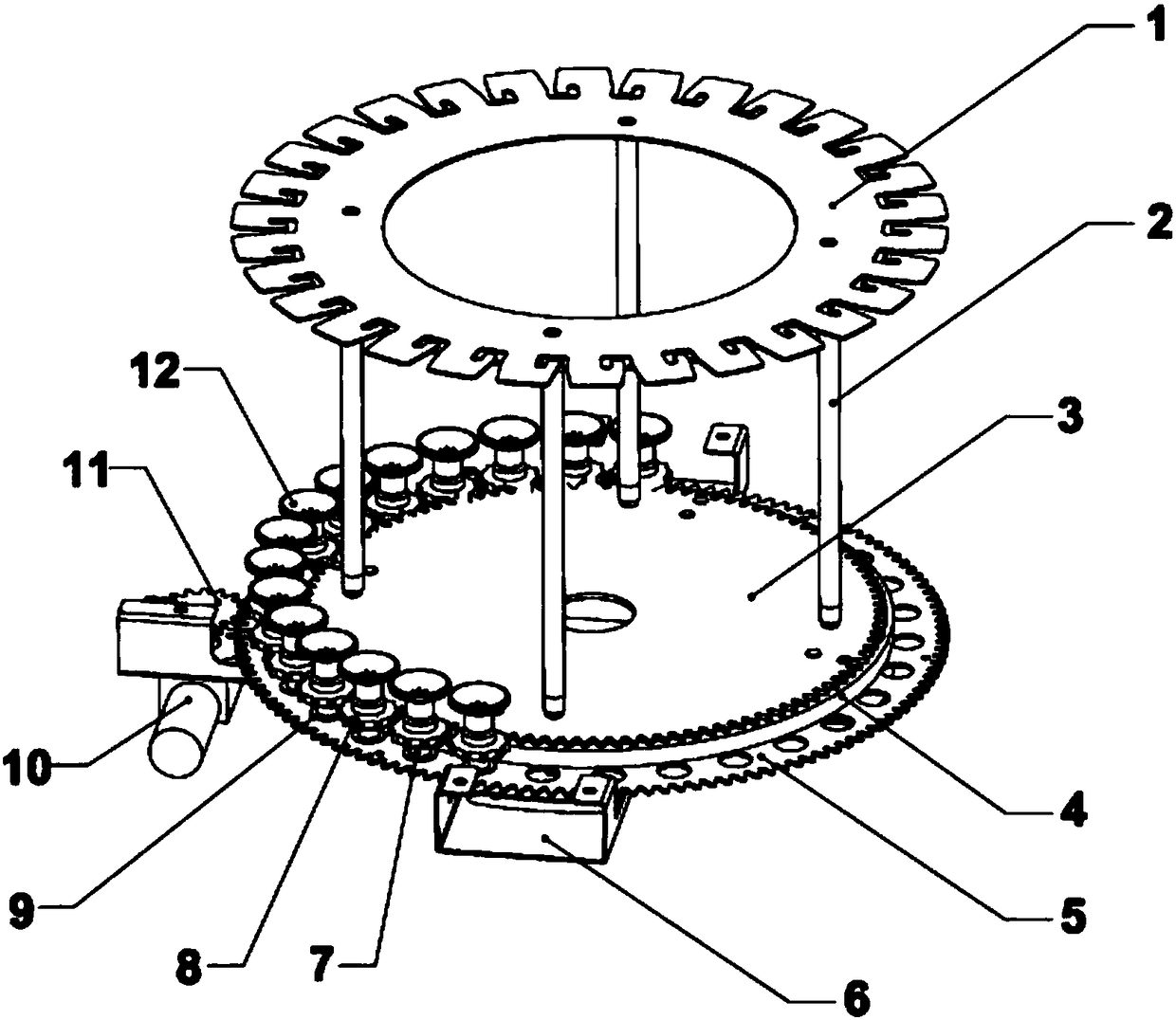

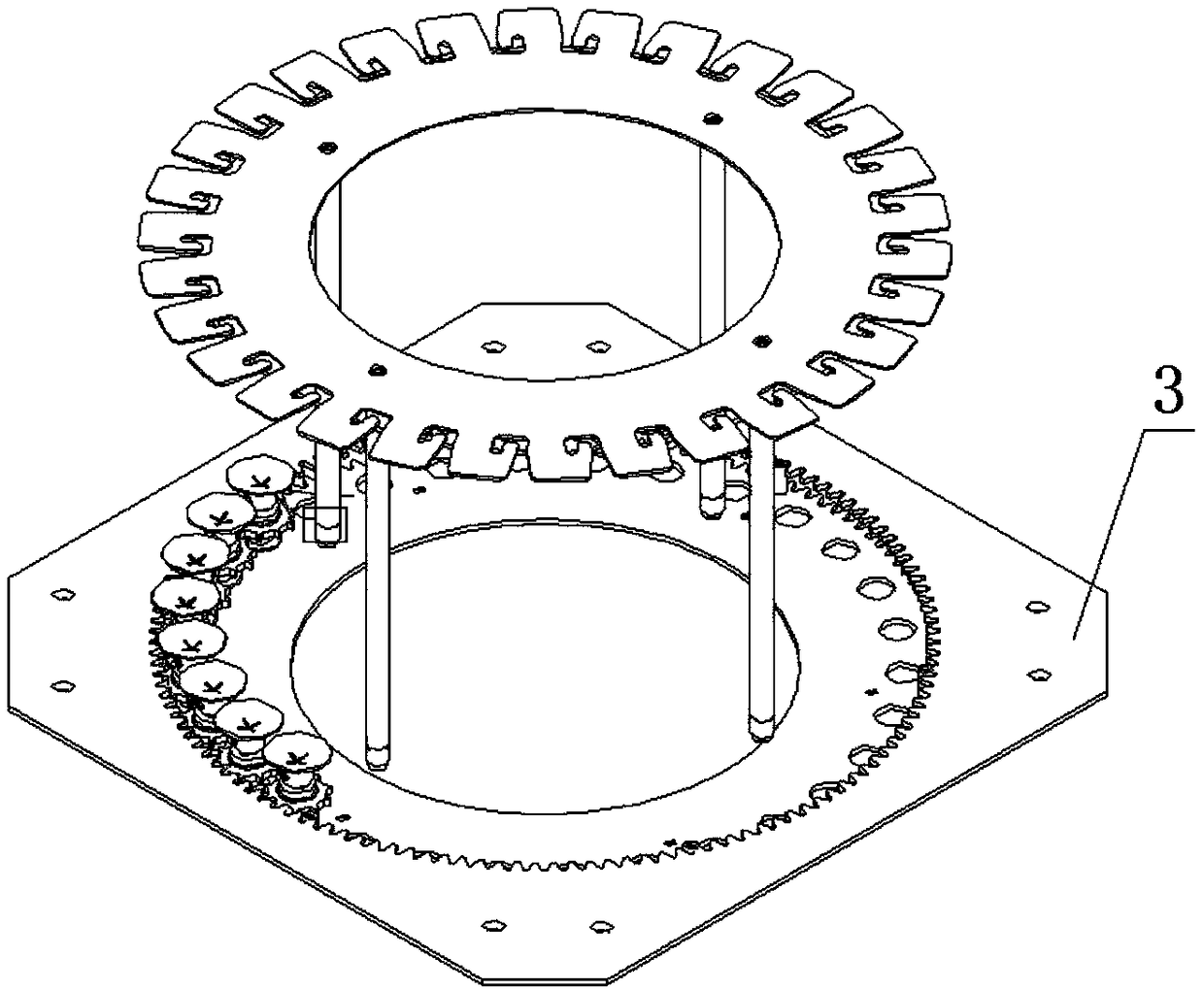

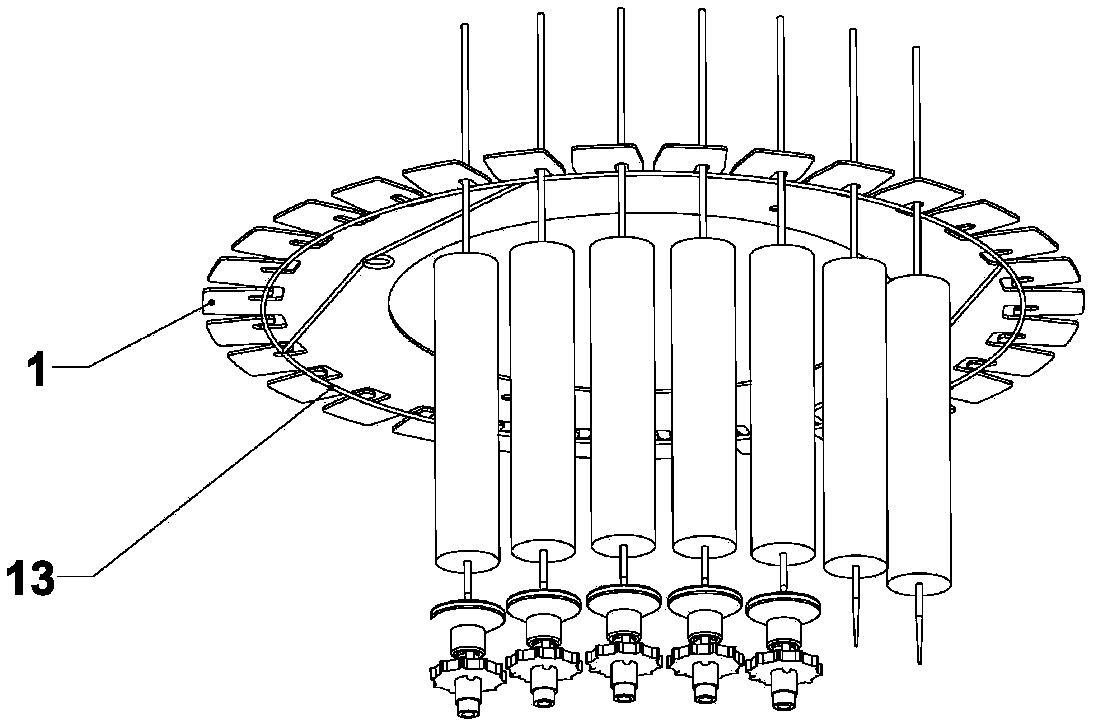

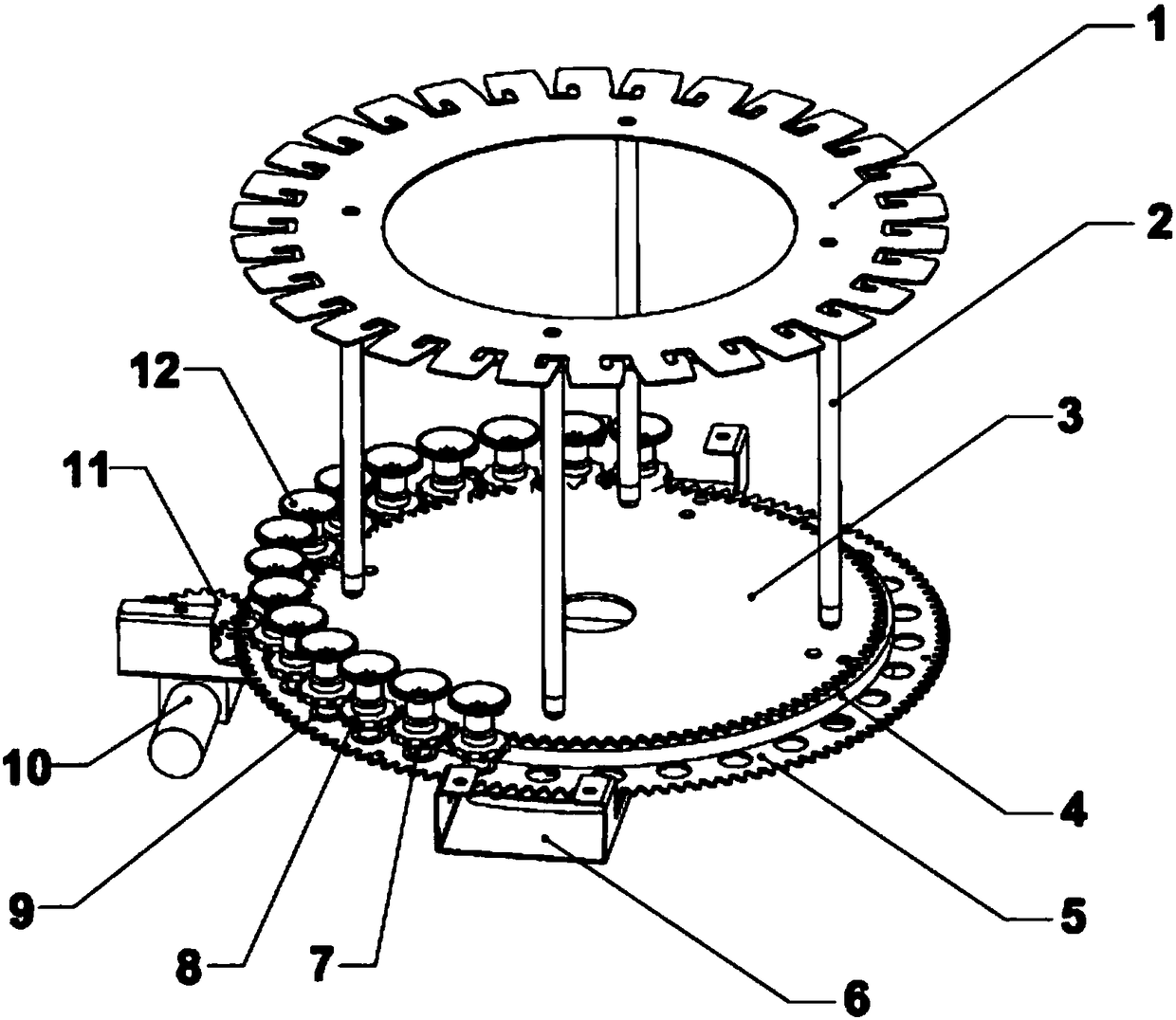

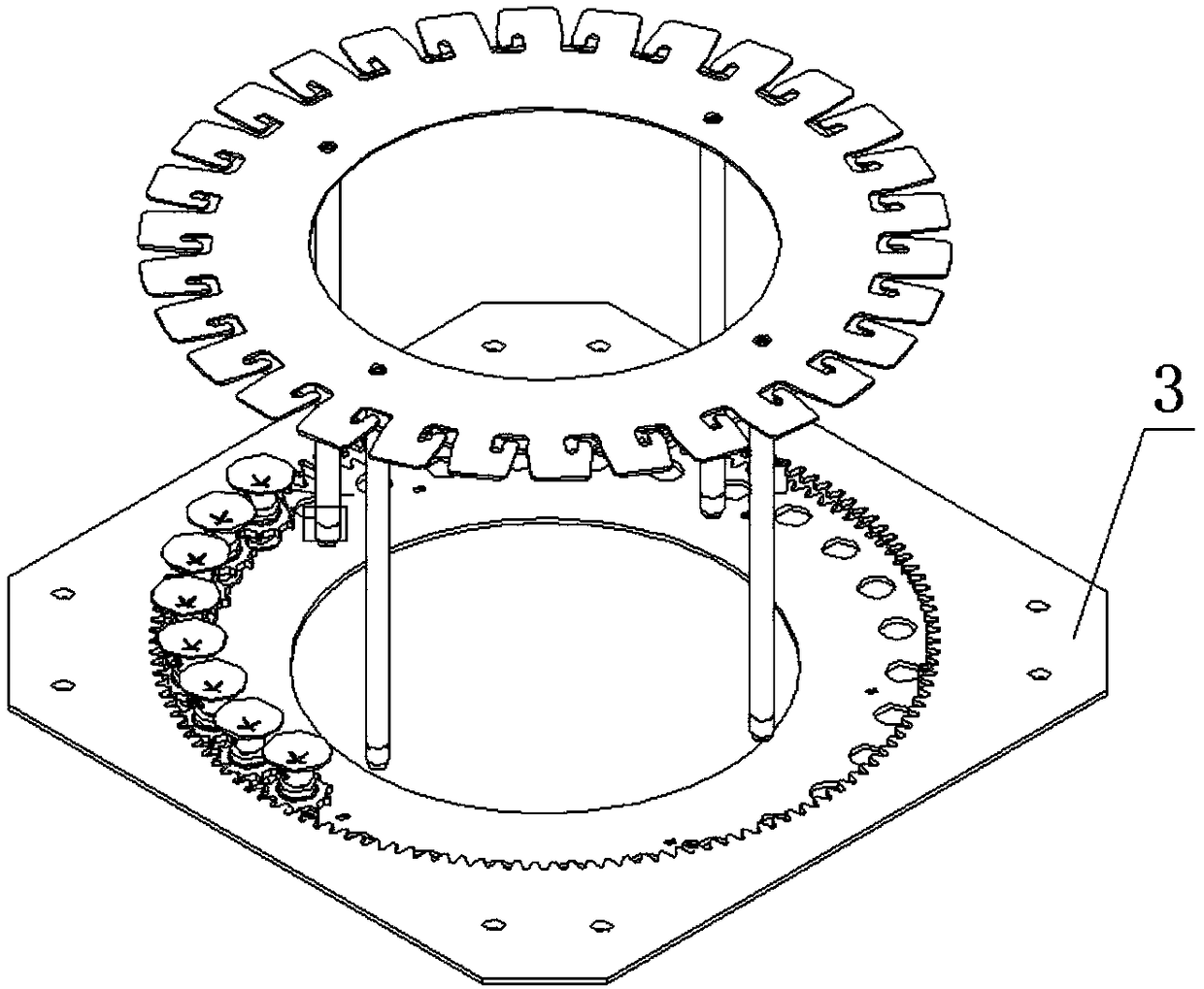

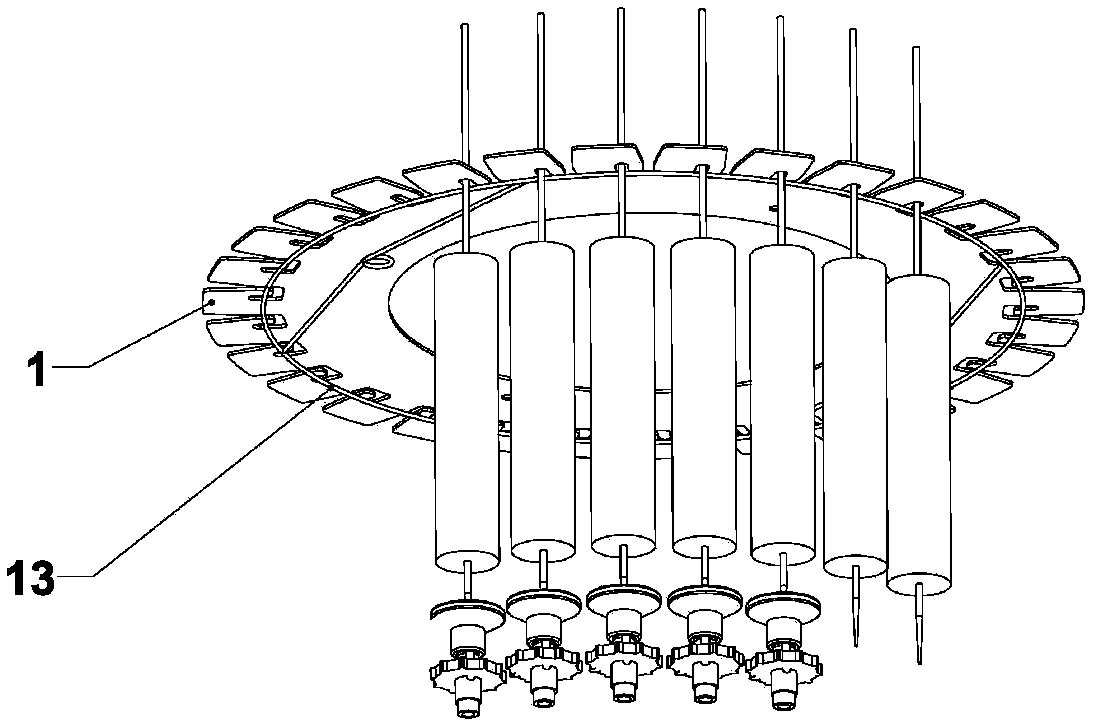

Smokeless automatic barbecue machine

The invention belongs to the technical filed of barbecue equipment manufacturing and particularly relates to a smokeless automatic barbecue machine, an external gear disc is concentrically arranged under a fixed external gear which is arranged horizontally and is in a round disc-shaped structure, the external gear disc is arranged in a manner of capable of rotating around a center shaft, bearingsare arranged on the periphery of the external gear disc, connection shafts which can rotate around the bearings are arranged in the bearings, the middles of the connection shafts are sleeved with driven gears which are meshed with the fixed external gear, oil guide plates which are used for draining oil drops produced during barbecue are fixedly arranged at the upper ends of the connection shafts,the oil guide plates can rotate along the rotation of the connection shafts, a motor which provides power is further arranged on the side surface of the external gear disc, and a motor rotation shaftis connected with a driving gear which is meshed with the external gear disc to transfer power of the motor to the external gear disc and drive the external gear disc to rotate. According to the smokeless automatic barbecue machine, the body structure is simple, the design concept is ingenious, the use is safe and convenient and the environmental protection performance is good, the application isenvironmentally friendly, and the market prospect is wide.

Owner:青岛艺豪机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com