Reactive dyeing equipment for cellulose fibre-contained yarns

A technology of cellulose fiber and reactive dyes, applied in the field of textile printing and dyeing, can solve problems such as unstable quality, excessive dye hydrolysis, and incomplete chromatogram, and achieve the effects of stable dyeing quality, simple baking methods, and a wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

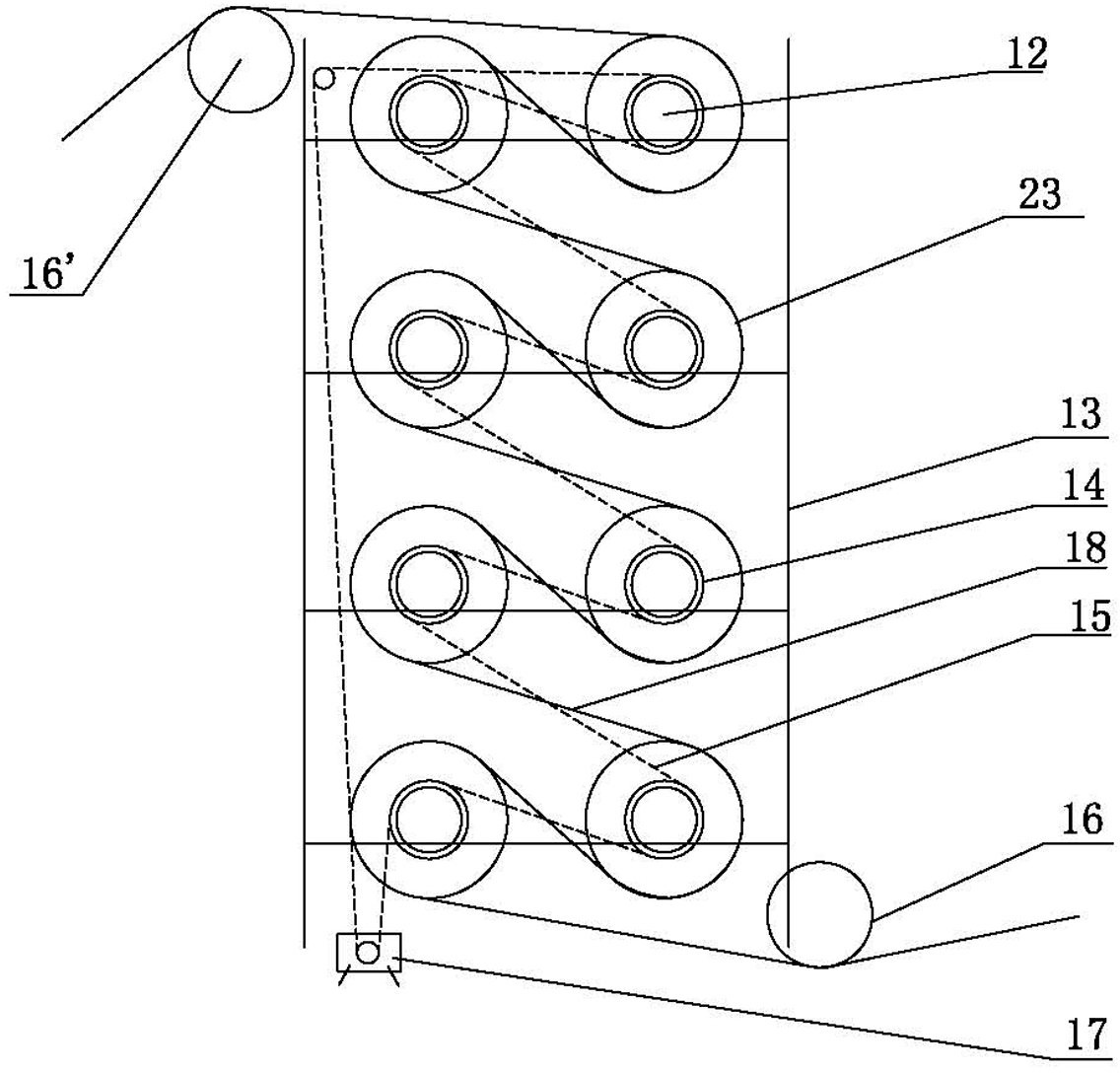

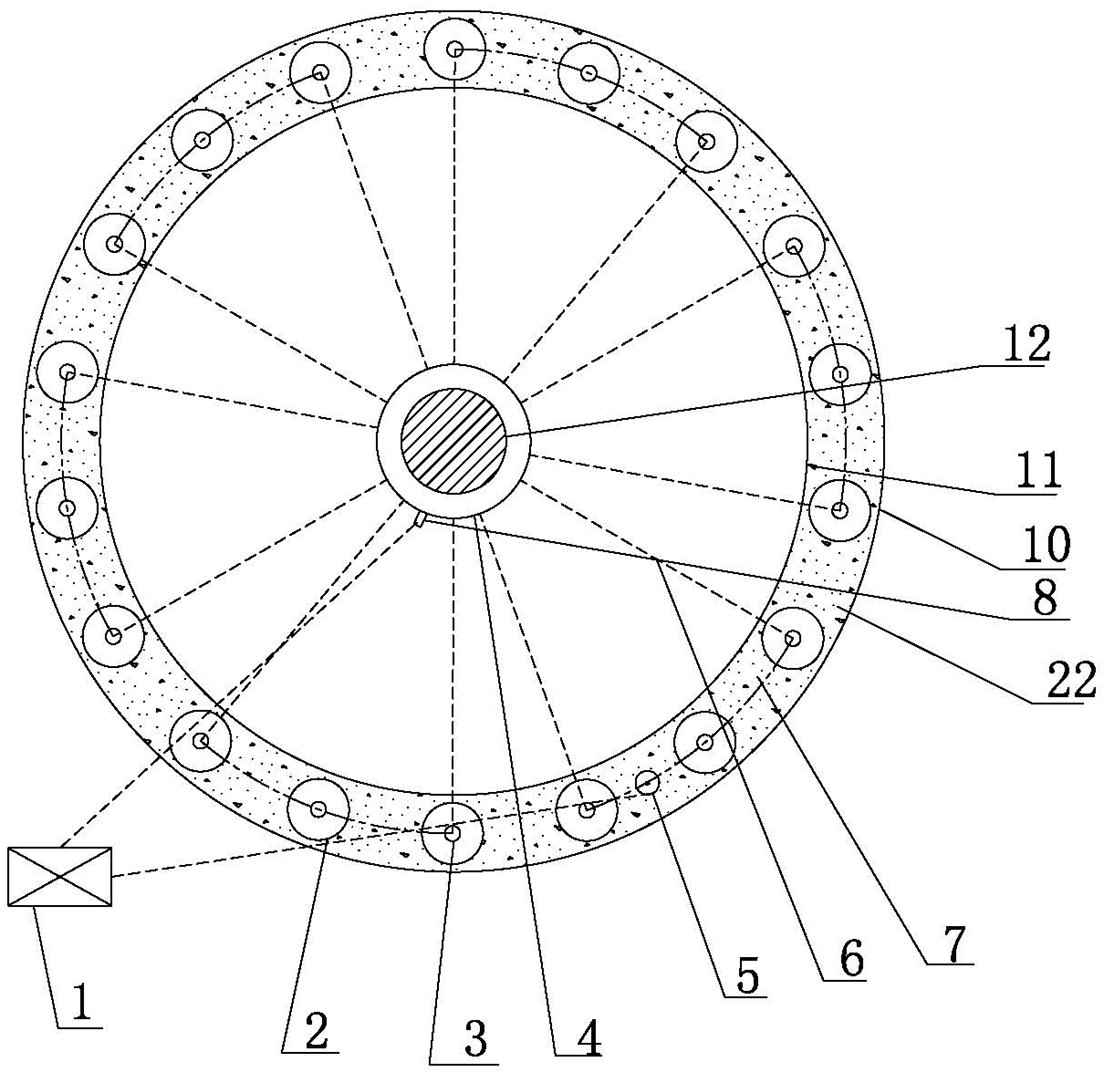

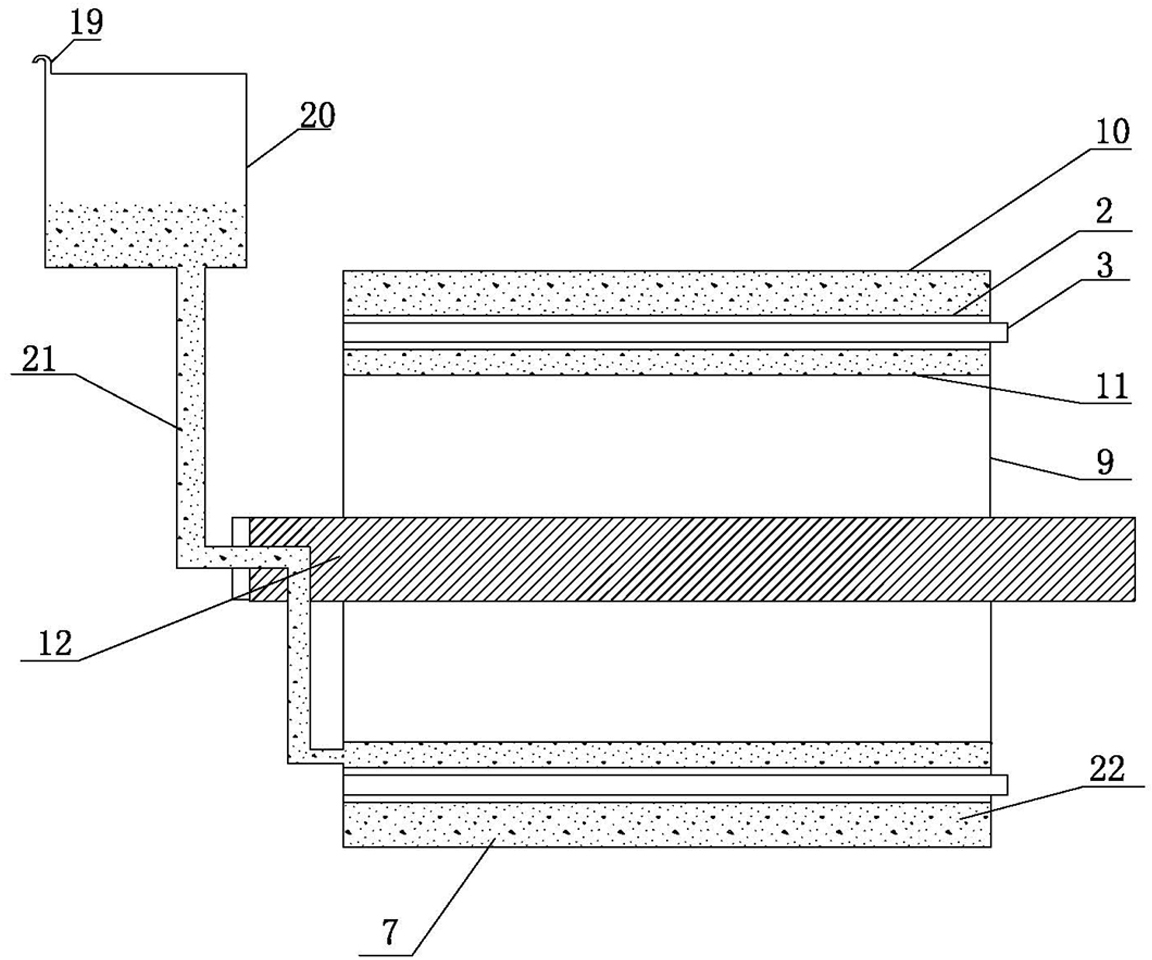

[0016] Below in conjunction with the accompanying drawings, the present invention will be further described through specific embodiments-specific implementation devices and the specific implementation process of reactive dye continuous pad dyeing applied to 32s / 2 pure cotton dyed yarn.

[0017] Such as figure 1 The shown baking device includes a drying cylinder support 13, and eight drying cylinders 23 are arranged on the drying cylinder support 13. These 8 drying drums 23 are rotatable around their own rotating shaft 12 . Two ends of drying cylinder support 13 are provided with import guide roller 16 and export guide roller 16 ', and several drying cylinders 23 rotate synchronously with import guide roller 16 and export yarn guide roller 16 '. The yarn 18 introduced by the guide roller 16 passes around the surface of each drying cylinder 23 in turn, and then is exported by the guide roller 16 ′ to guide the eight drying cylinders 23 to be driven by a driving mechanism to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com