Patents

Literature

634results about How to "Reduce hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

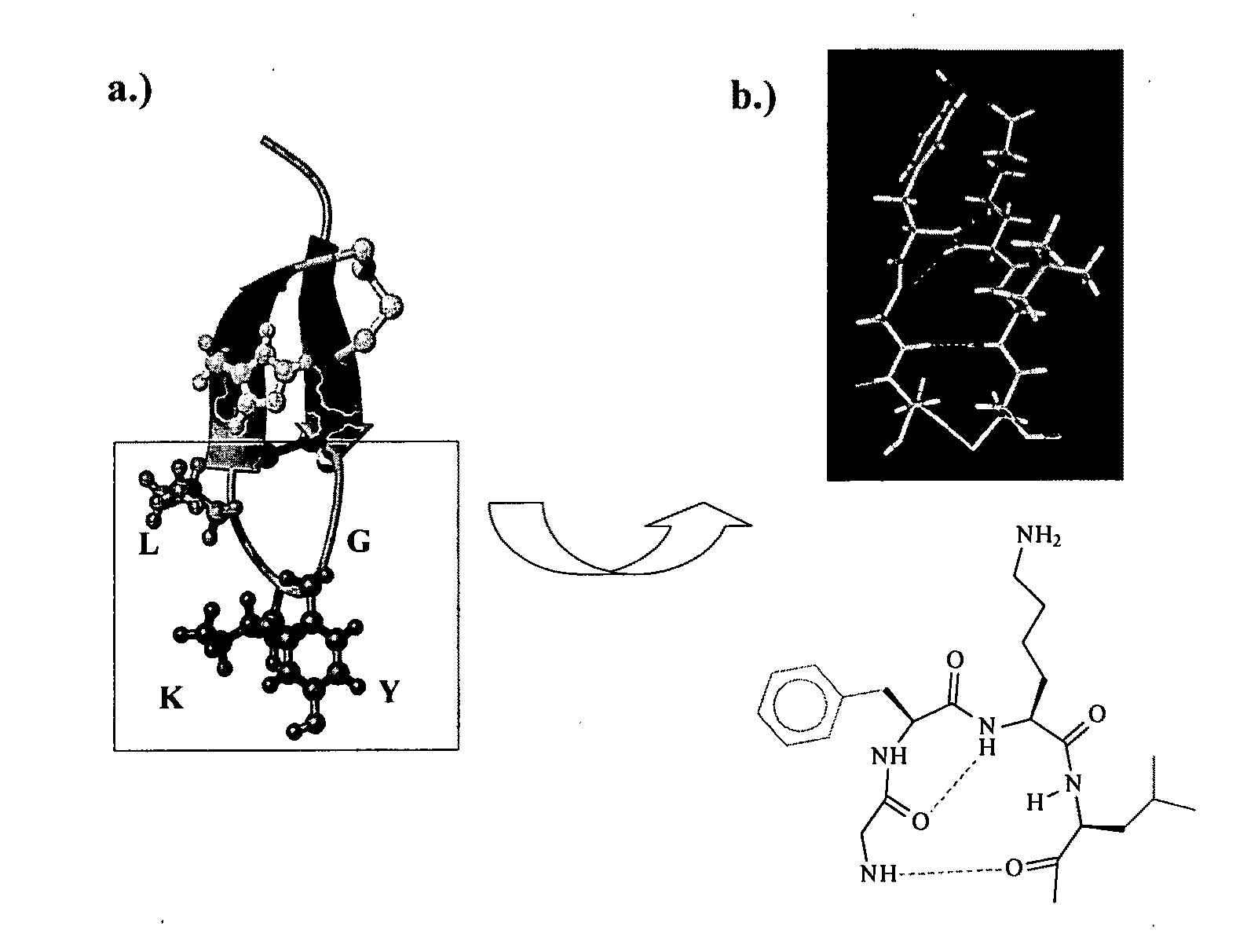

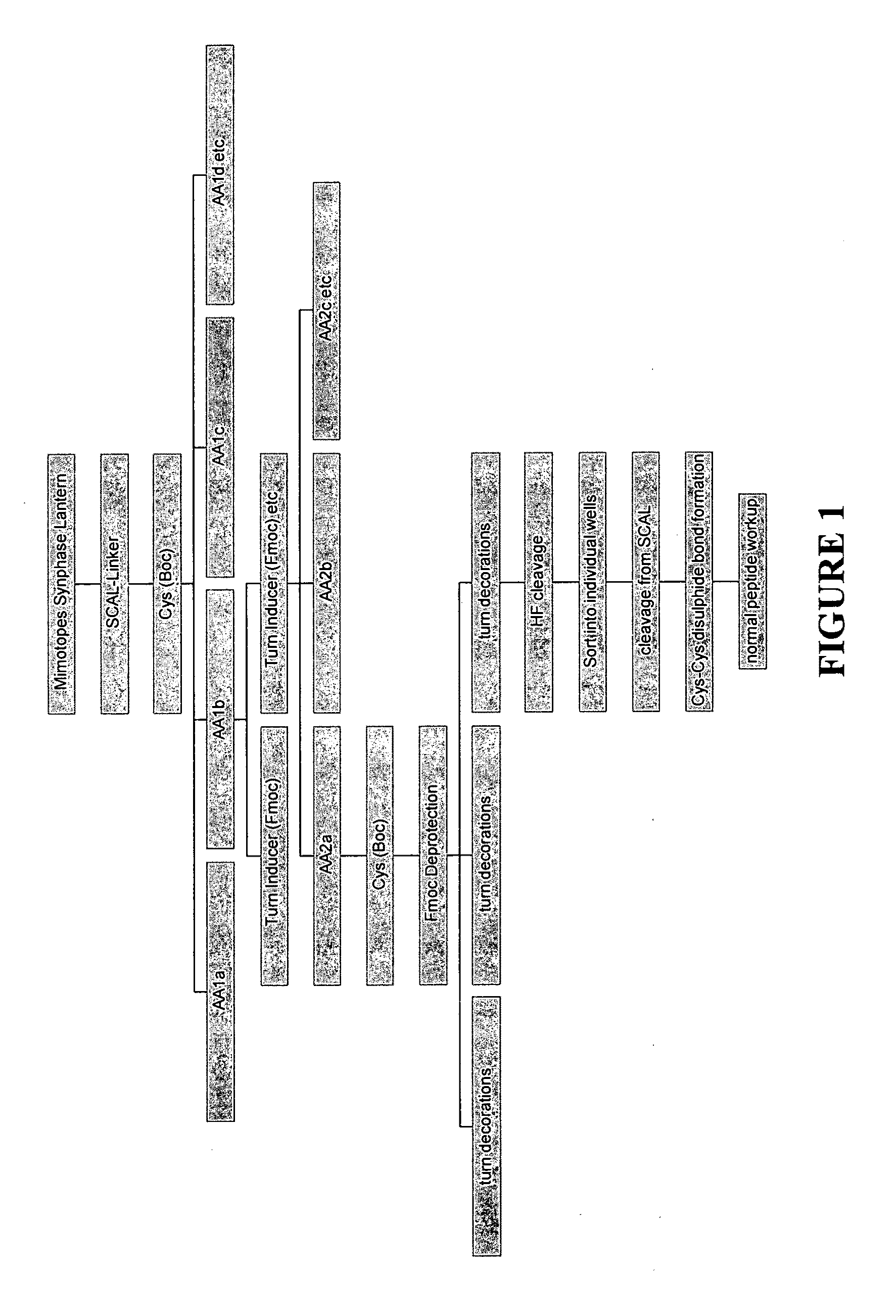

Libraries of peptide conjugates and methods for making them

InactiveUS20110172126A1Reduce hydrolysisReduce degradationPeptide librariesNervous disorderNitrogenInducer

The invention relates to peptide conjugates including at least one turn inducer wherein the turn inducer comprises a 5-7 membered saturated or unsaturated nitrogen containing heterocyclic ring and methods of making the peptides. Libraries of these peptides, methods of making the libraries are also described and methods of screening the libraries for therapeutic activity are also described.

Owner:XENOME

Solvent-free polyurethane adhesive for compound film

ActiveCN101503611ANo pollution in the processImprove securityPolyureas/polyurethane adhesivesPolyesterComposite film

The invention discloses a solvent-free polyurethane adhesive for a composite film, which consists of an A component and a B component, wherein the A component is end-OH polyester polyol, and the B component is end NCO-polyurethane prepolymer; and the A component and the B component are mixed in the molar ratio of functional groups of NCO to OH being 1.2-1.9:1.0. The polyurethane adhesive for the composite film does not need to adopt solvent and has high safety. The adhesive shows low hydroscopic property as well as low hydrolysis and high shock strength due to introducing dimeric dibasic acid, and shows good adhesive property for some substrates which are particularly difficult to adhere and attach. The invention improves the adhesive strength of the composite film through the design of compositions and a molecular structure of the adhesive, the T peeling strength reaches more than 3.8N / 15mm after the plastic films are compounded for 3 to 5 days, and the T peeling strength between the plastic and an aluminum-plating film reaches more than 4.2N / 15mm.

Owner:黄山万丽美油墨科技有限公司

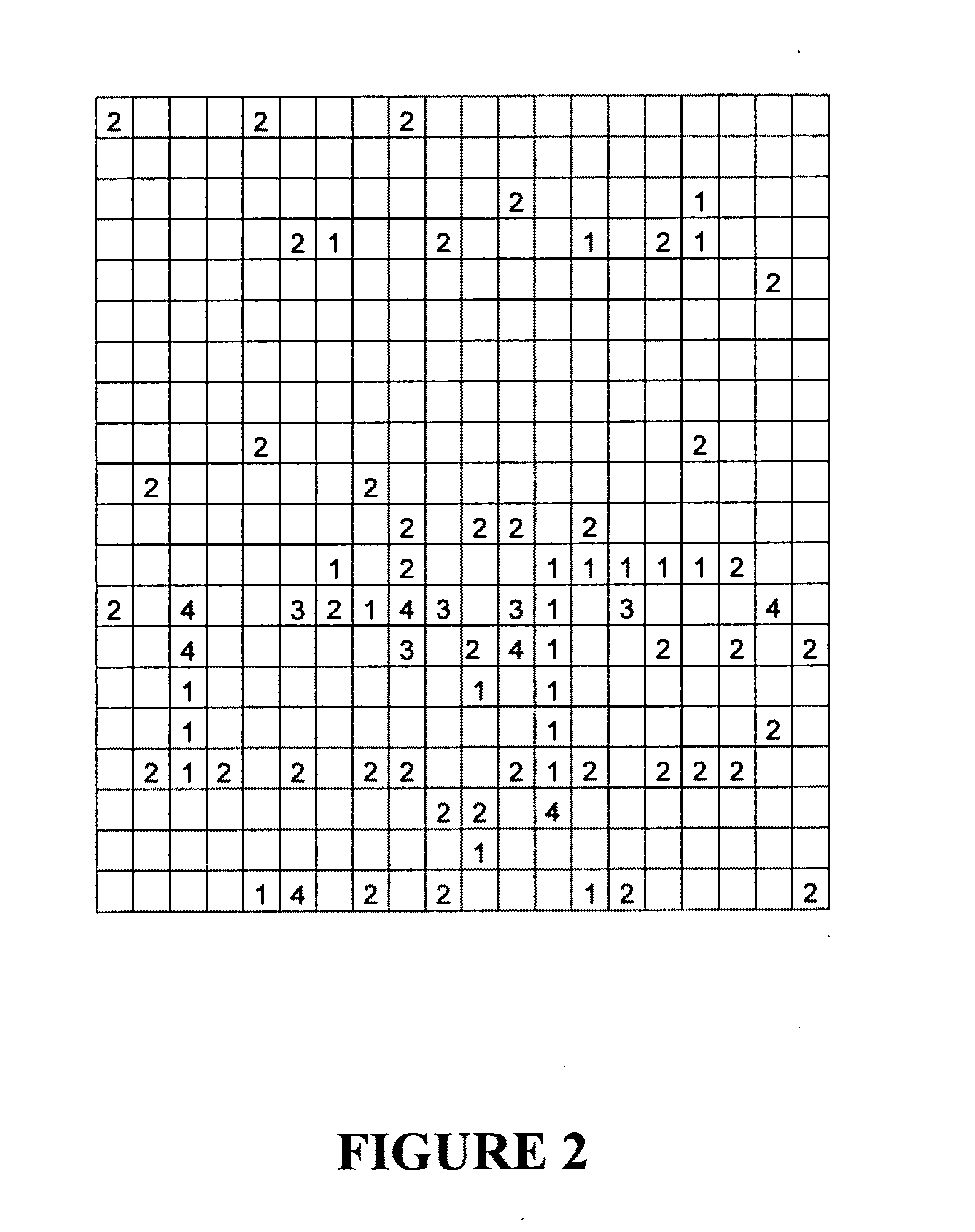

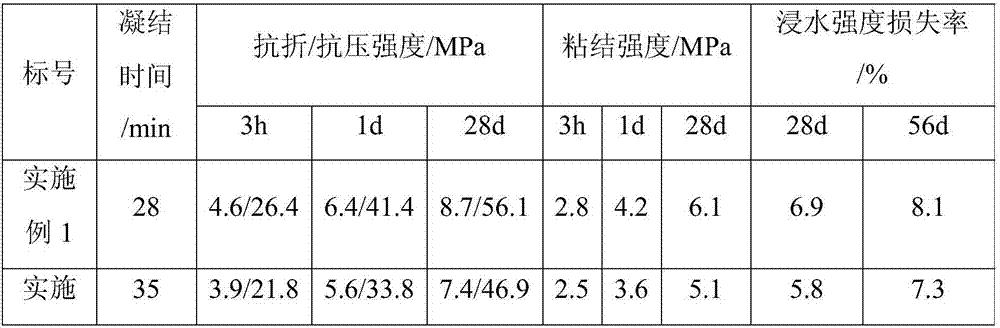

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Solid sandstone dissolver

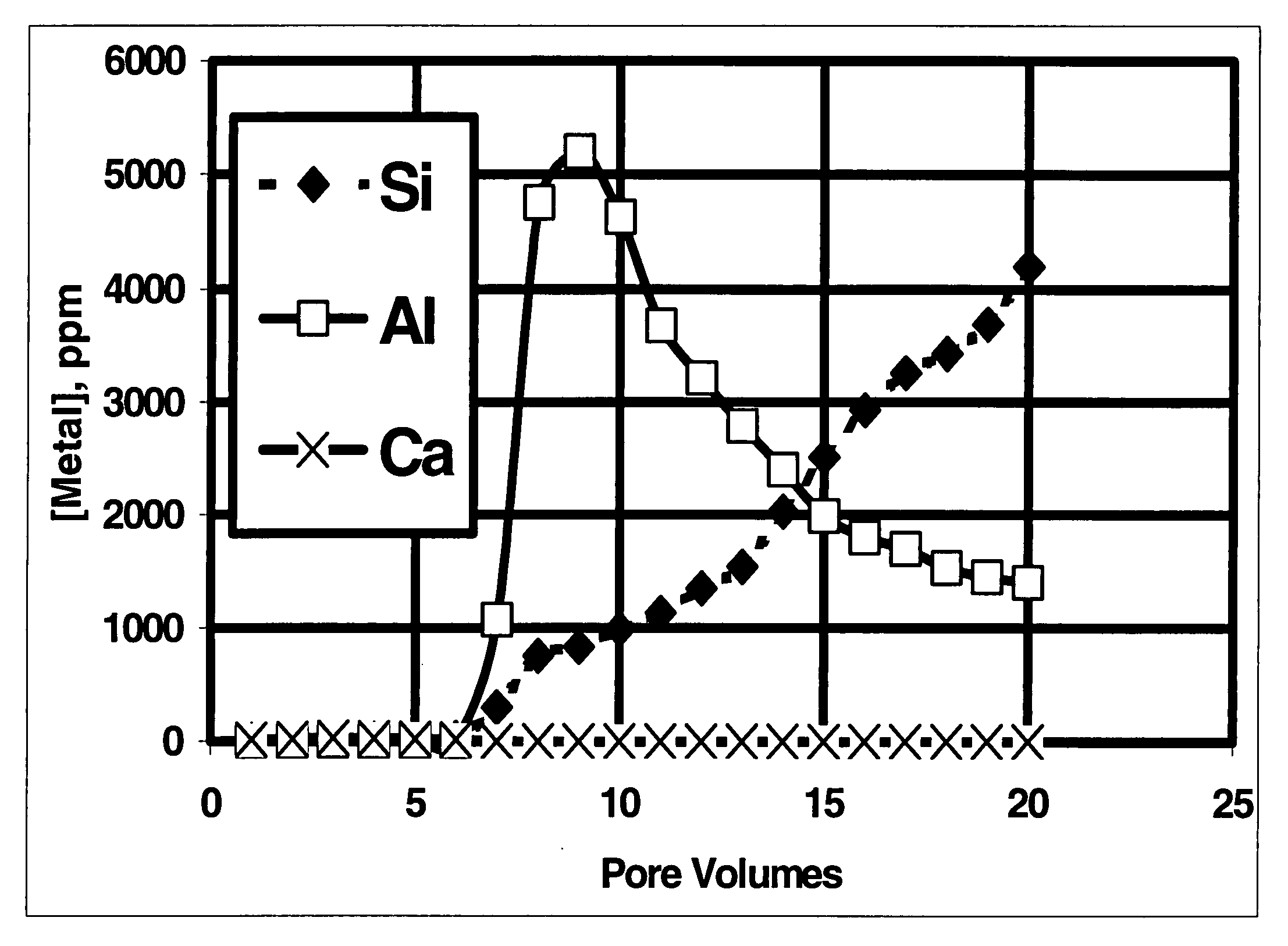

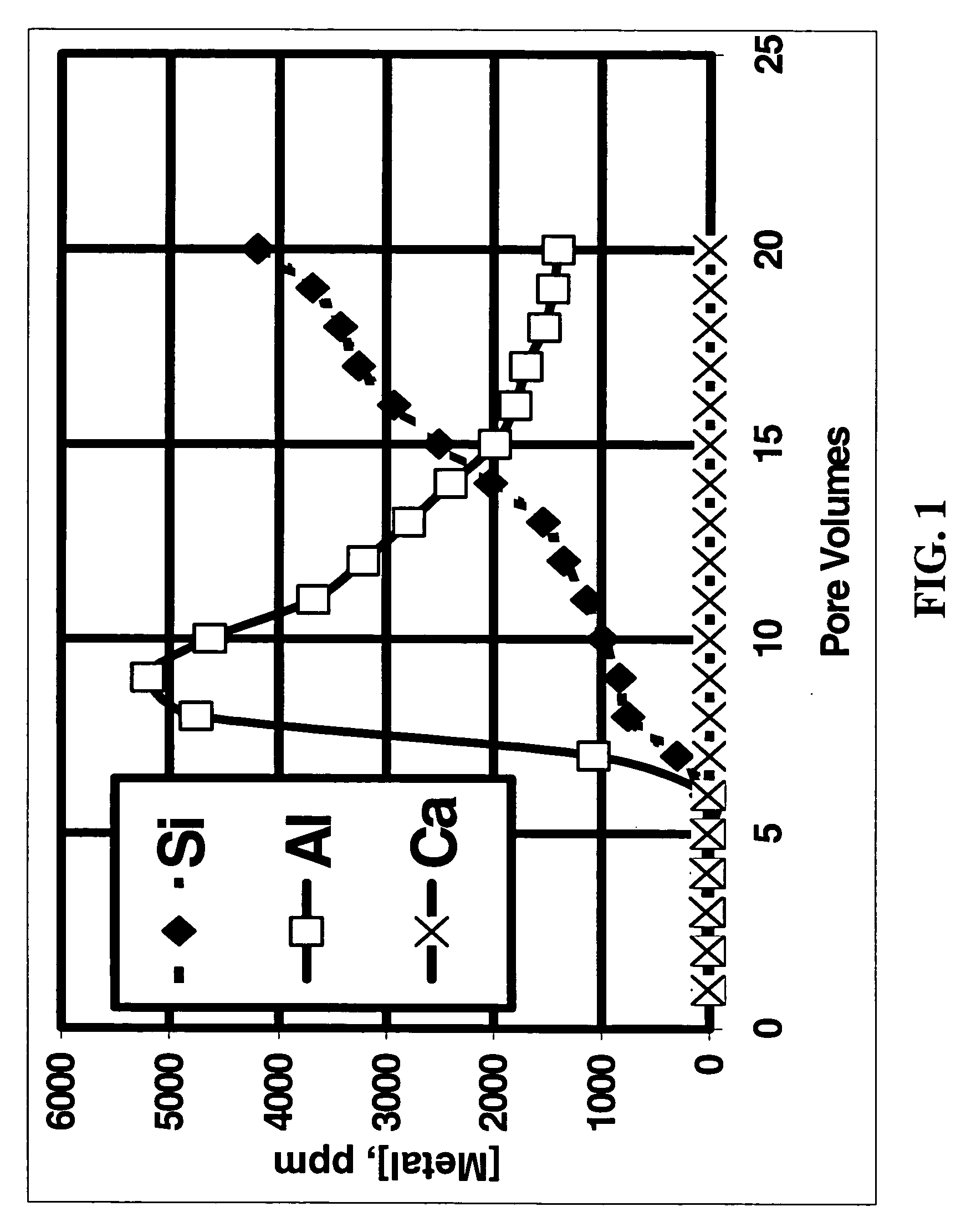

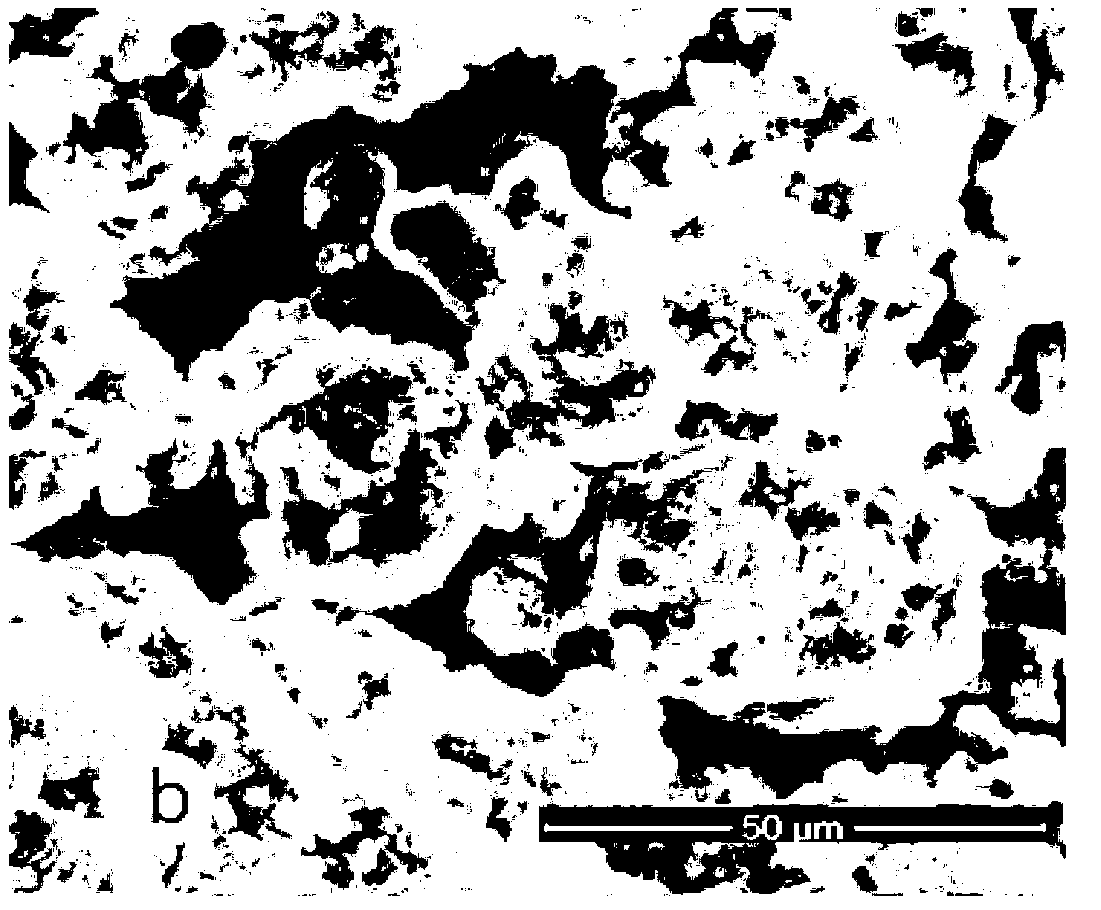

InactiveUS20060054325A1Reduce hydrolysisSlow release of hydrogenFluid removalDrilling compositionChemistryEtching

A dry solid composition is disclosed that, when added to an aqueous liquid, provides a slurry that can be used in sandstone acid fracturing. The slurry generates hydrofluoric acid downhole to etch the sandstone fracture faces created. The chemical and physical properties of the composition result in very uneven etching of the fracture faces, enhancing the fluid conductivity of the final fracture. Optionally, inert masking materials may be included in the dry composition, or added to the slurry, to increase the inhomogeneity of the etching and further increase the fluid conductivity.

Owner:SCHLUMBERGER TECH CORP

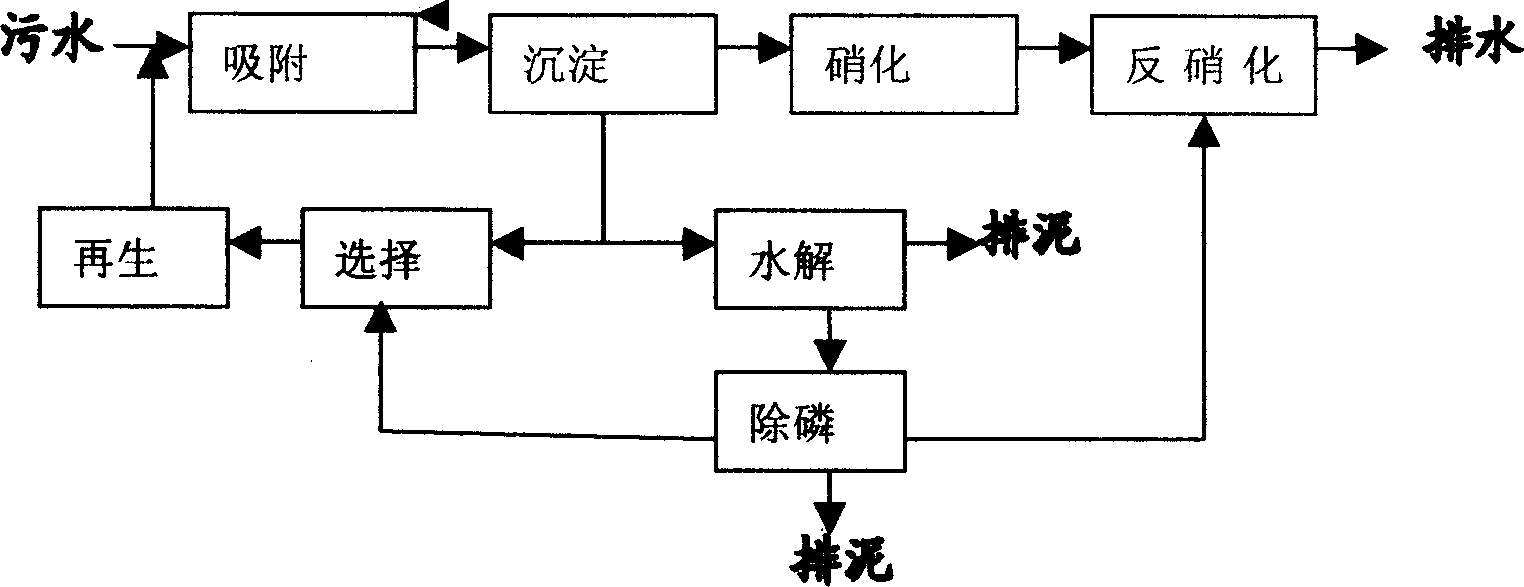

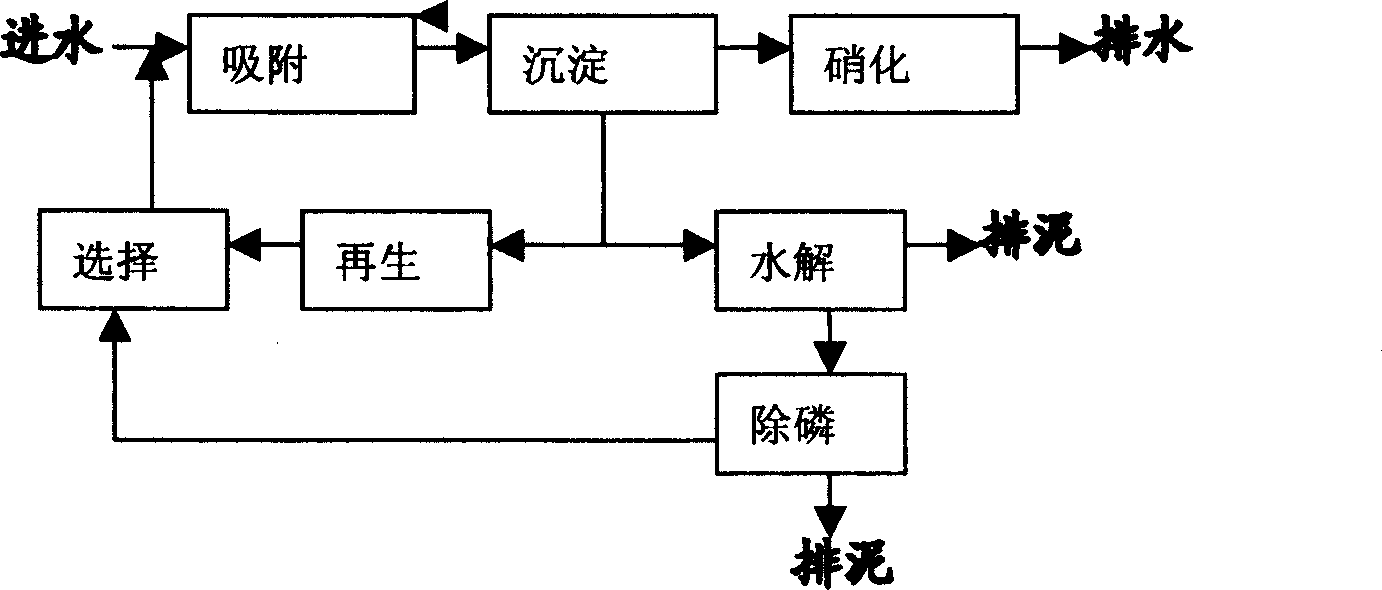

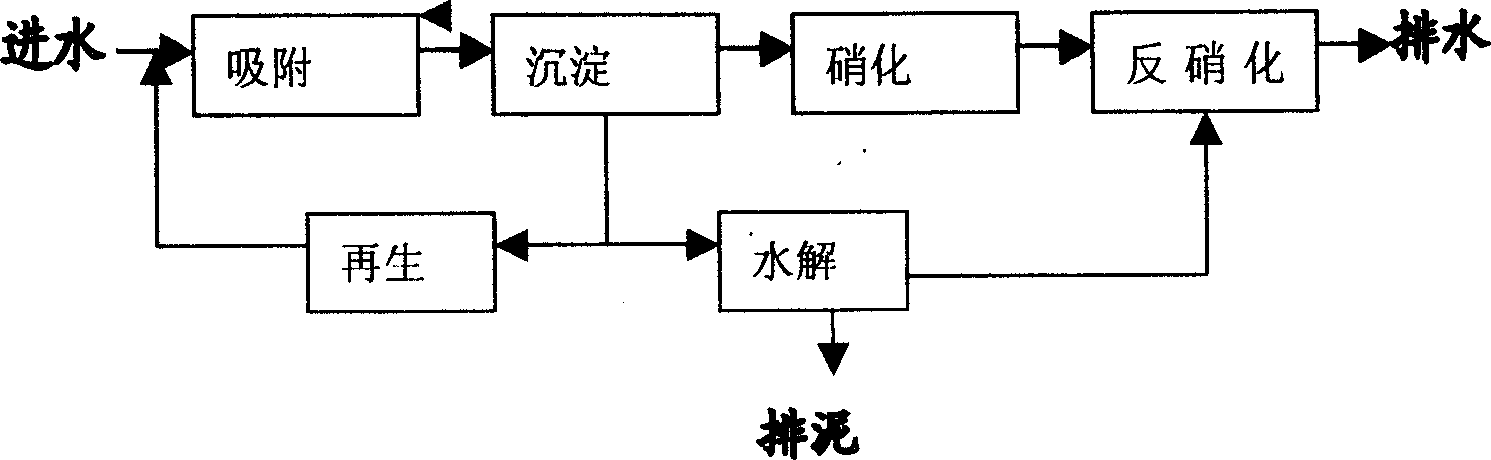

Bio-treatment method for dephosphorization and denitrogenation of sewage

InactiveCN1884151AEasy to degradeAchieve separationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeNitrogen

The invention discloses a sludge dephosphorizing and denitrifying biological disposing method, which comprises the following parts: adsorbing pool, sedimenting pool, regenerating pool, selecting pool, dephosphorizing pool, nitrated pool, denitrifying pool and hydrolytic acidifying pool, wherein the effluent enters in the adsorbing pool firstly to blend with reflux sludge in the selecting pool; the blending liquid is drained from adsorbing pool to sedimenting pool to separate mud from water; the supernatant enters into nitrated pool to denitrify in the denitrifying pool to drain; the sediment part of sludge is proceeded anaerobic hydrolysis in the hydrolytic acidifying pool; the supernatant is inputted into dephosphorizing pool to proceed chemical dephosphorizing; the other part of sediment pool refluxes sludge into selecting pool under anaerobic environment; the composite liquid from selecting pool is input in the regenerating pool; the other part supernatant from dephosphorizing pool is input in the denitrifying pool to accelerate denitrifying action.

Owner:UNIV OF SCI & TECH OF CHINA

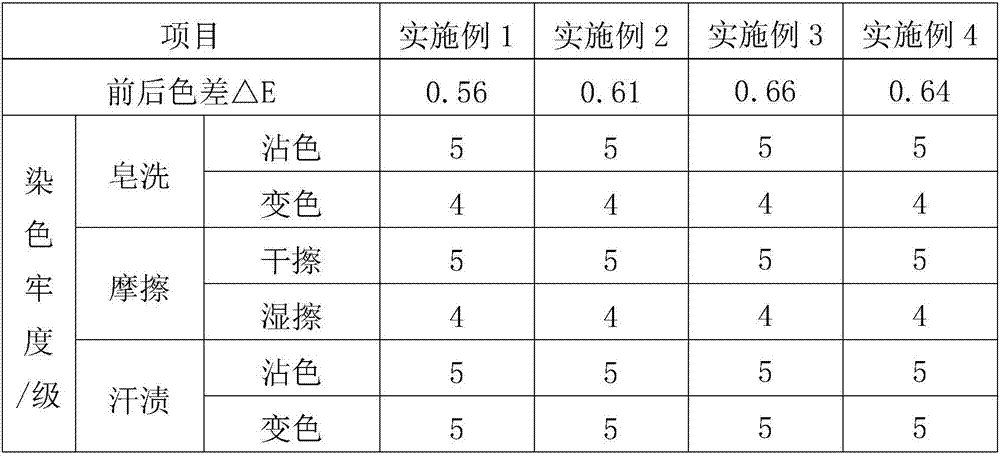

Silicon based non-aqueous medium dyeing method suitable for cheese

ActiveCN107794788AGood dyeing effectMedia is easy to recycleDyeing processPulp and paper industryDyeing wastewater

The invention discloses a silicon based non-aqueous medium dyeing method suitable for cheese, and belongs to the technical field of textile dyeing and finishing. The dyeing method comprises the following steps: (1) preparing a dye solution; (2) dyeing cheese: soaking cheese in a silicon based non-aqueous medium, and adding the dye solution to carry out dyeing in a cheese dyeing facility; and (3) after dyeing, carrying out dehydration, soap washing, water washing, and drying to obtain a finished product. The method has the advantages that only a little amount of water and alkali is needed, other dyeing aids are not needed; the water for dyeing and dyeing wastewater are largely reduced, and dye uptake and fixation rate of cheese dyeing are improved effectively. After dyeing, the silicon based non-aqueous medium can be separated from water and is capable of being used repeatedly. The ecological dyeing of cheese is realized. The shortages of conventional water bath cheese dyeing such as much wastewater, difficulty in wastewater treatment, low dye uptake and fixation rate, and the like, are overcome.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

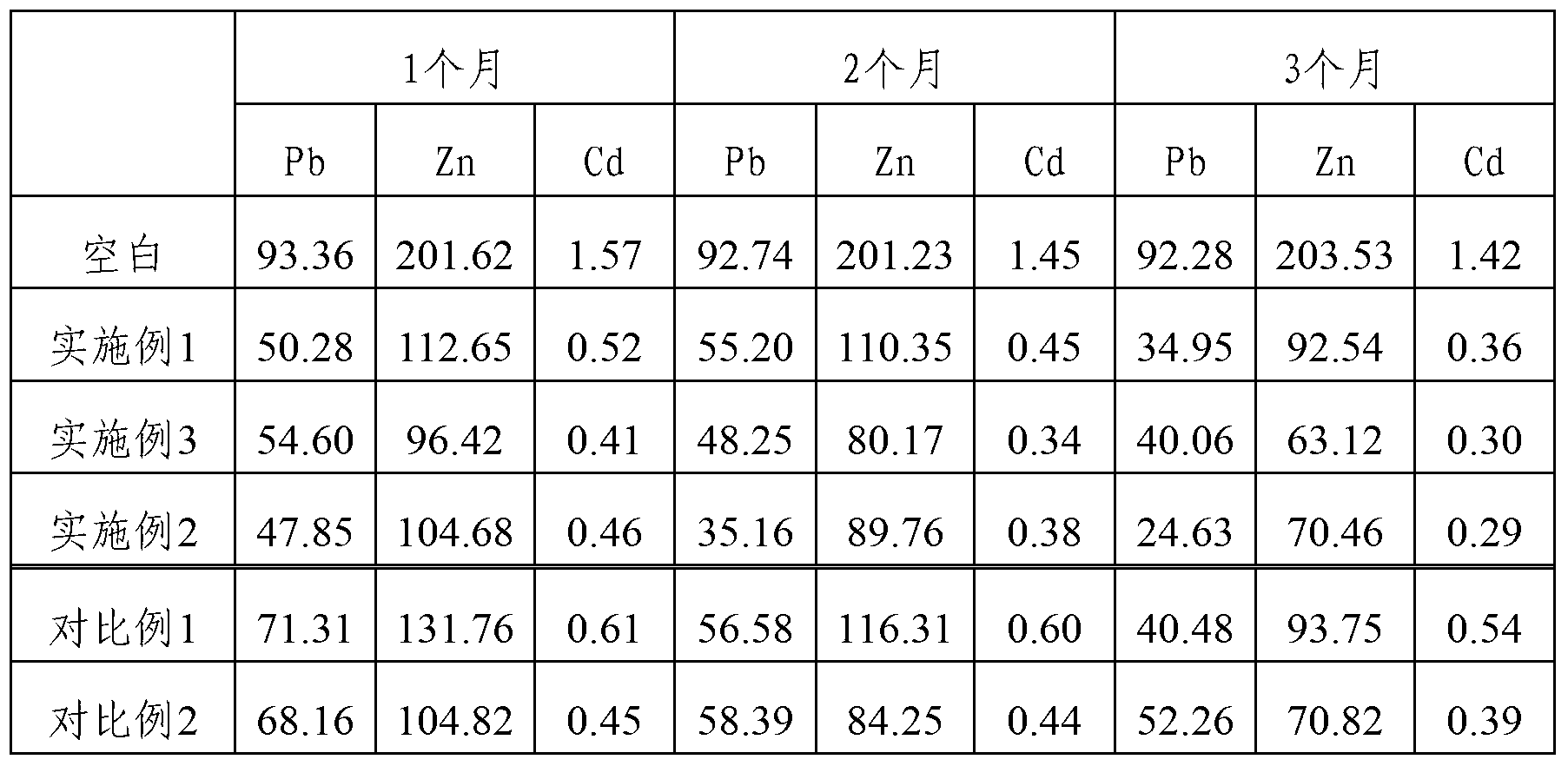

Red mud composite material and repairing method thereof for soil

The invention relates to a red mud composite material which comprises components in parts by weight as follows: 60-78 parts of red mud, 8-12 parts of a cementing material, 8-24 parts of an inorganic addition material, 2-8 parts of a natural fertilizer, water and a pore forming agent, wherein the mass of water is 50%-55% of total weight of the red mud, the cementing material, the inorganic addition material and the natural fertilizer, and use amount of the pore forming agent is 0.1%-0.3% of the mass of water. The invention further relates to a preparation method of the red mud composite material and a repairing method of the red mud composite material for soil polluted by heavy metal. The red mud composite material is simple in preparation process, abundant in raw material source and reasonable in proportion, so that the red mud and agricultural solid wastes are utilized sufficiently, and the comprehensive utilization of resources is achieved.

Owner:长沙天蓝蓝环保科技有限公司

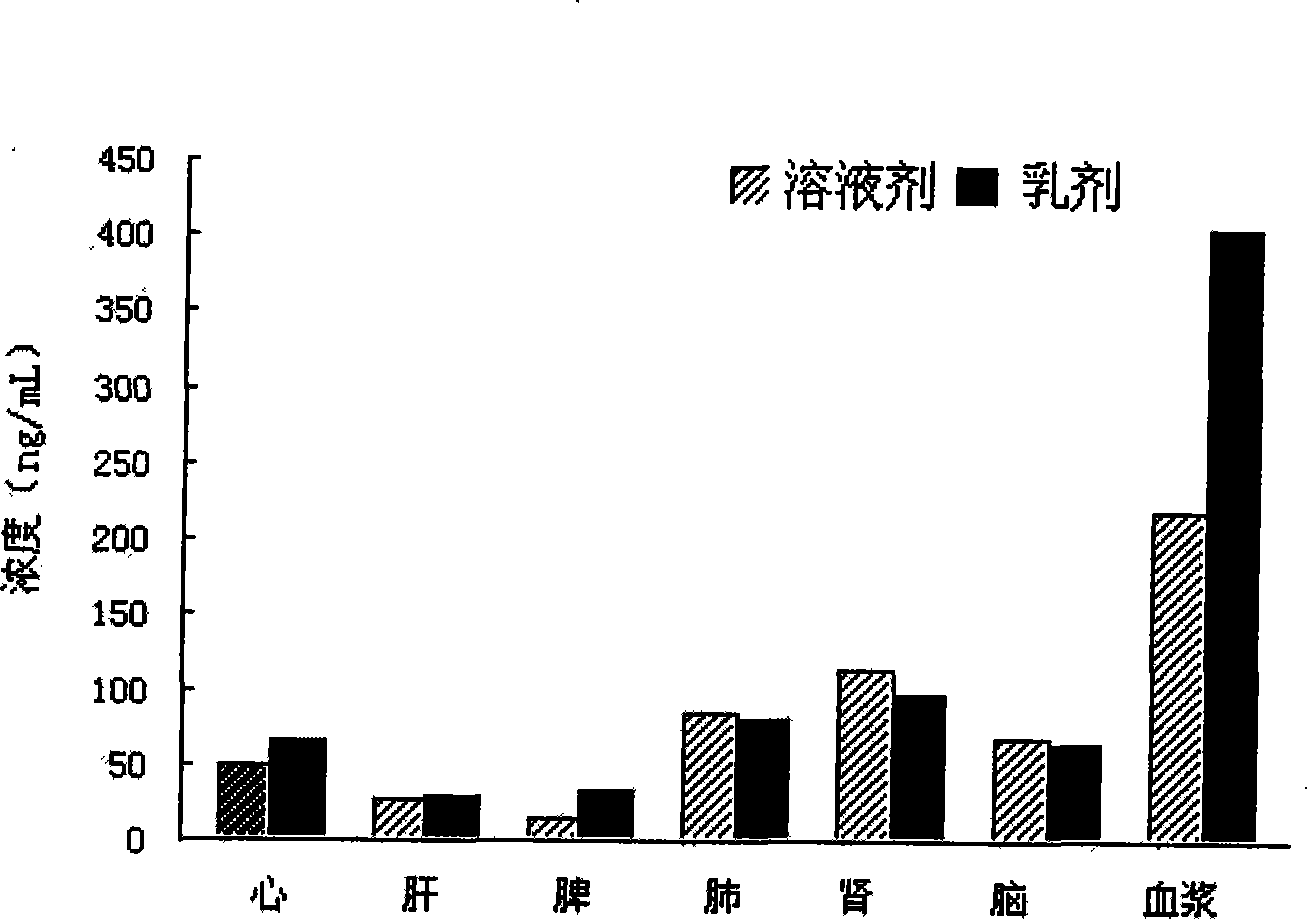

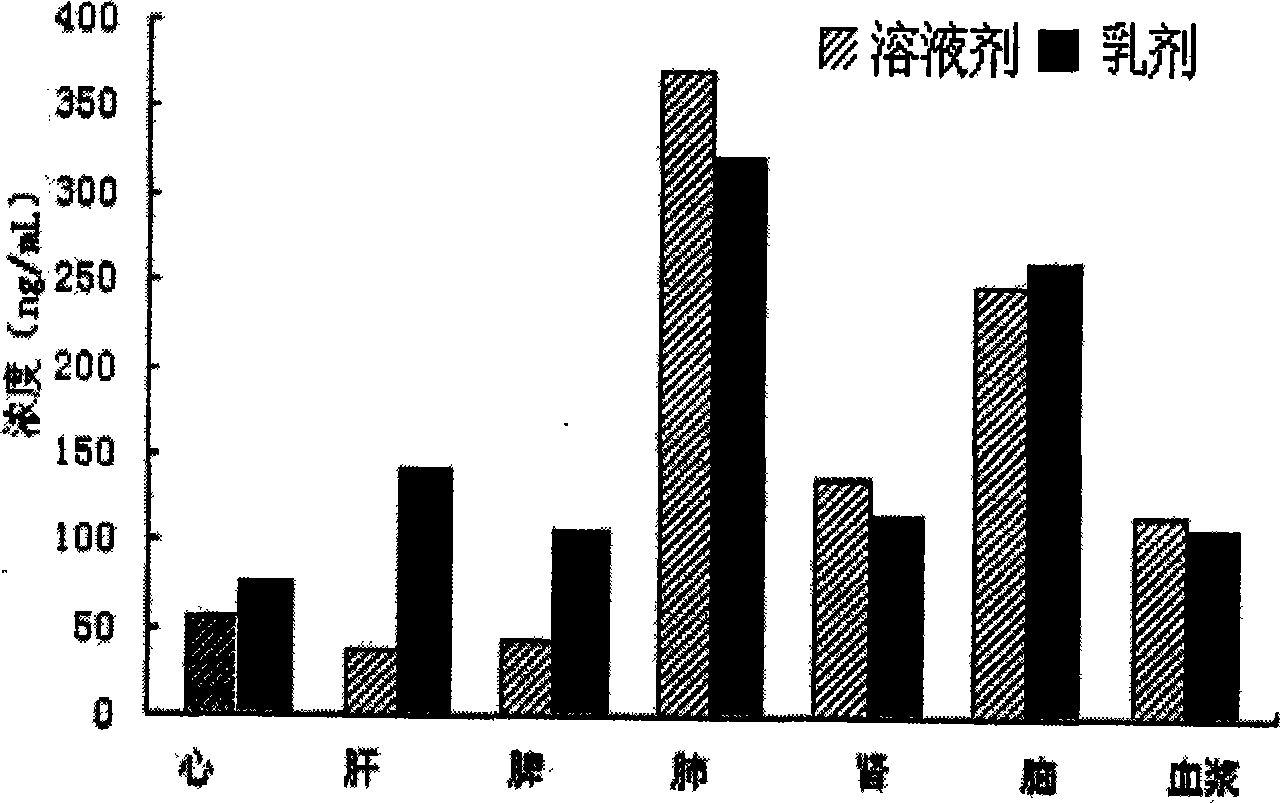

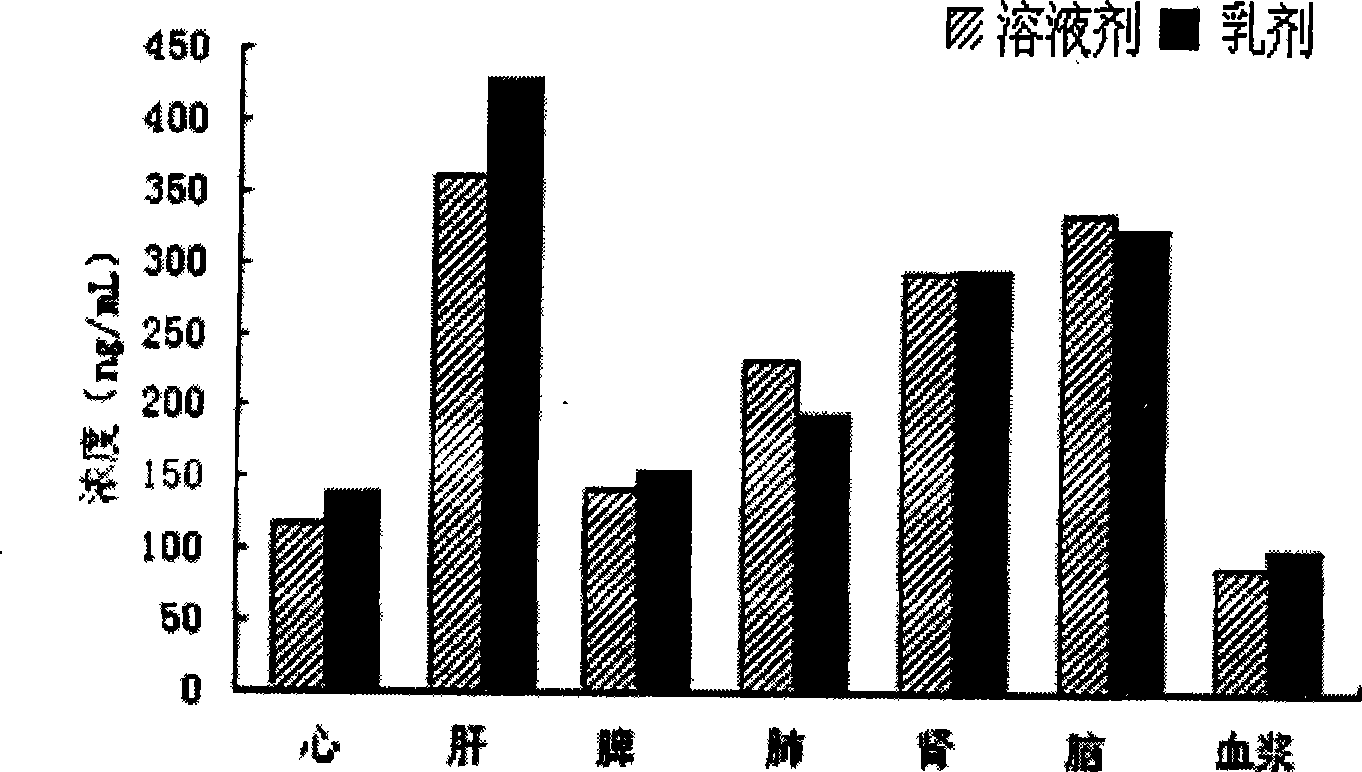

Nimodipine lipid microsphere injection and preparation method thereof

ActiveCN101485632AImprove solubilityImprove stabilityOrganic active ingredientsNervous disorderSolubilityLipid formation

The invention provides a nimodipine lipid microsphere injection, which is prepared from the following components in percentage by weight: 0.08 percent of nimodipine, 0.5 to 2.3 percent of lecithin for injection, 2 to 8 percent of soybean oil for injection, 2 to 8 percent of medium chain fatty acid for injection, 1 to 3 percent of glycerin, 0.1 to 0.2 percent of tween-80, 0.03 to 0.05 percent of sodium oleic acid, and the balance being water for injection. The preparation method comprises steps of preparation of an oil phase, preparation of water phase, preparation of colostrum, homogenization and canning. In the nimodipine lipid microsphere injection, the soybean oil for injection and the medium chain fatty acid for injection are used to prepare the oil phase, the nimodipine is a fat soluble drug and can be better dissolved in the oil phase, the lipid microsphere in which the soybean oil for injection is the main component has solvent characteristics, is non-toxic, and can guide the fat soluble drugs to be dissolved in emulsion particles and perform the metabolism along with lipid oil drops and slowly release, thereby maintaining the effective blood concentration, lowering toxic and side effects of the drugs, increasing the solubility and stability of the nimodipine drug, improving the drug-loading rate and reducing the hydrolysis of the drugs.

Owner:沈阳信康药物研究有限公司

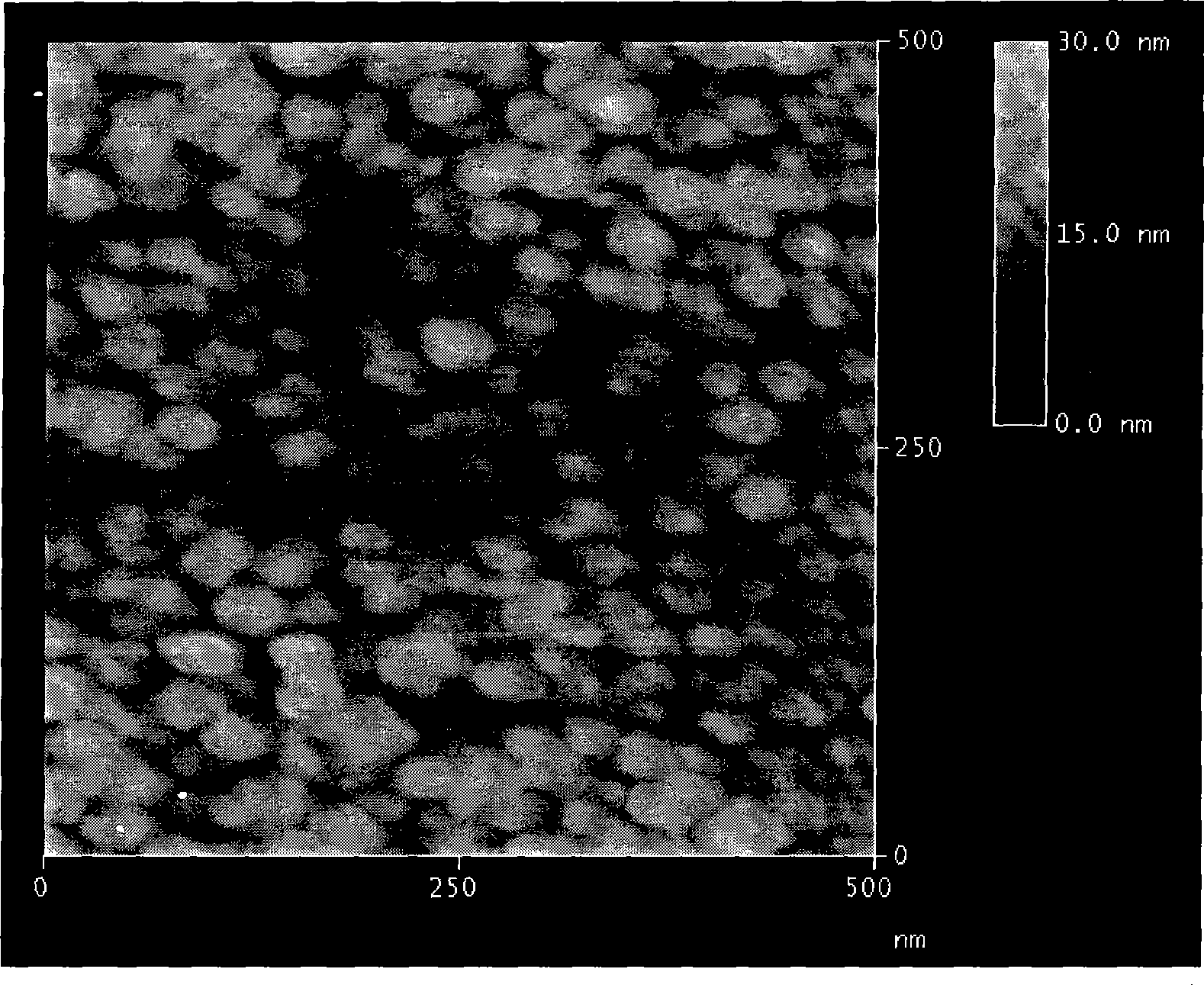

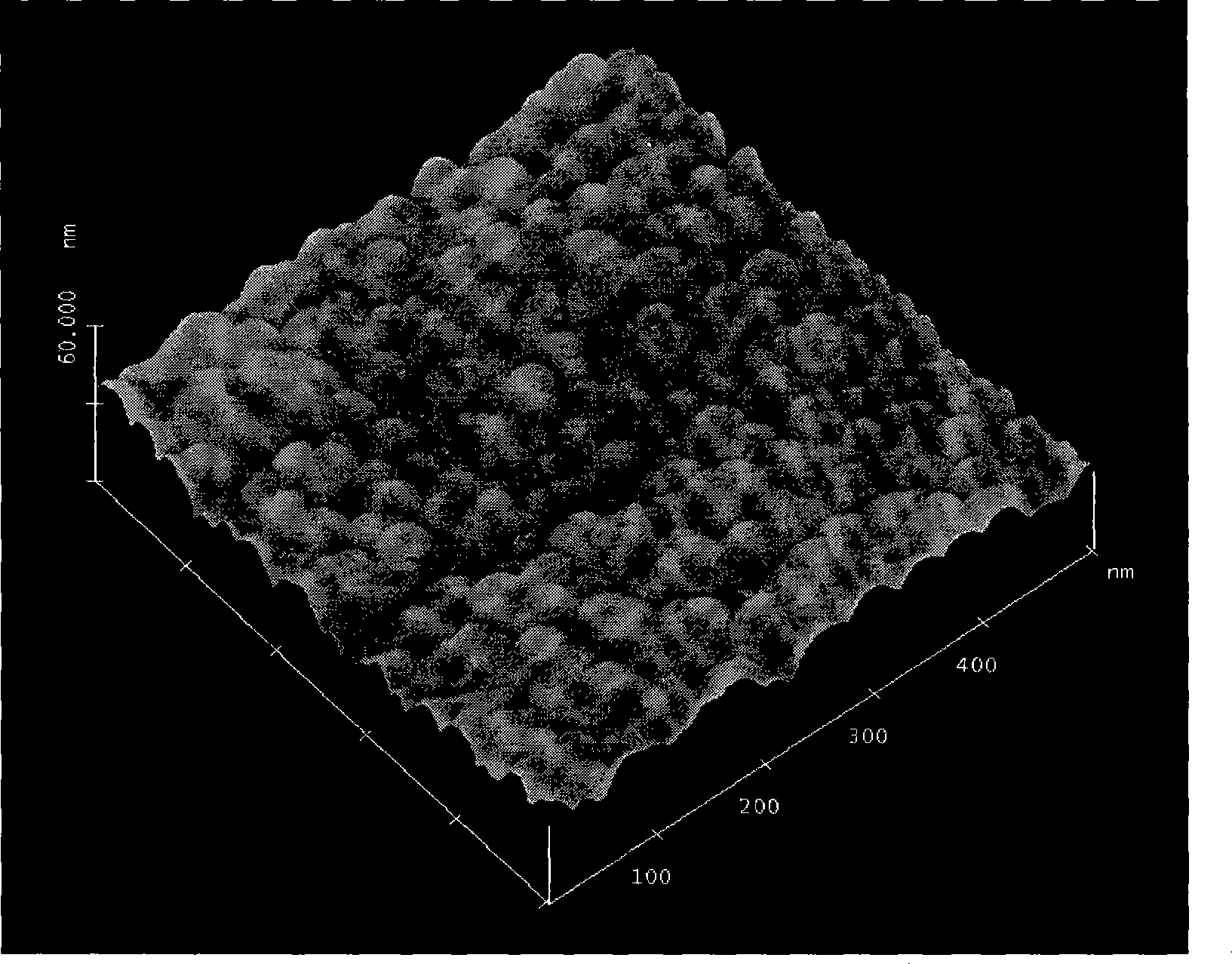

Preparation method for nano-titanium dioxide film photocatalyst

InactiveCN101367035AReduce hydrolysisReduced responsePhysical/chemical process catalystsAlcoholTitanium

The invention relates to the technical field of photocatalyst, and discloses a method for preparing a nanometer titanium dioxide film photocatalyst through a sol gel method on the weak acid condition. The method comprises the following steps of: mixing and stirring the acetate solution of titanium acid dinbutyl phthalate and the alcohol solution of a non-ion type template agent to prepare titanium sol; and dipping and extracting a processed substrate, drying the substrate into a former body film, and calcining the former body film at a high temperature to obtain the nanometer titanium dioxide film photocatalyst. The method has a simple and easily controlled preparation process, the low cost of the preparation technology, little damage to equipment and environment, and no secondary pollution. The nanometer titanium dioxide film photocatalyst which is formed by compact and even nanometer level particles in ordered arrangement has the flat film and high photocatalysis efficiency. The nanometer titanium dioxide film photocatalyst can be repeatedly used with a certain practical application value.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

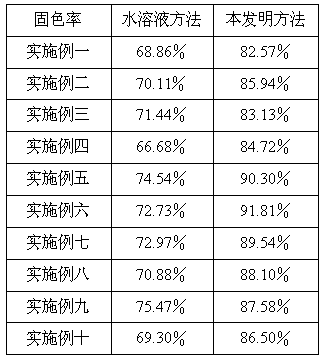

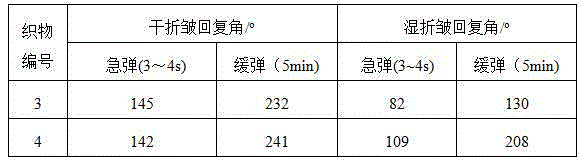

Method for improving pad dyeing fixation rate of textile

The invention relates to a method for improving the pad dyeing fixation rate of a textile, and belongs to the field of textile printing and dyeing processing. According to the method provided by the invention, the proportioning of a dye solution and a fixation solution in a textile pad dyeing process is changed, the textile is pad-dyed and dye-fixed respectively using the dye solution or the fixation solution, which is prepared by mixing an alcohol organic solvent in high proportion, a little water, and a dye or a fixing agent, so that the pad dyeing fixation rate of the textile is improved. By adopting the method for improving the pad dyeing fixation rate of the textile provided by the invention, in the pad dyeing process of the textile, not only can the hydrolysis rate of the dye in the dye solution be reduced to improve the utilization rate, the dye-uptake rate, and the even dyeing rate of the dye and the fixation rate of the textile, but also the problem of high water consumption in the textile pad dyeing process can be greatly reduced, as well as the dosage of an auxiliary can be effectively reduced. The method provided by the invention is simple in process, and low in cost, and the alcohol organic solvent can be recycled, is safe, energy-saving, economic and environment-friendly.

Owner:WUHAN TEXTILE UNIV

Process for producing pulp with a mixture of formic acid and acetic acid as cooking chemical

InactiveCN1299424AReduce hydrolysisImprove propertiesPulping with organic compoundsPulping with acid salts/anhydridesAcetic acidHemicellulose

The invention relates to a process based on formic acid cooking for producing pulp from herbaceous plants and deciduous trees by using acetic acid as an additional cooking chemical. The obtained pulp can be used in fine paper and board production as short-fibred material, for instance. The invention also relates to a process for adjusting the hemicellulose content of the pulp in connection with the formic acid cooking by using acetic acid as an additional cooking chemical.

Owner:CHEMPOLIS OY

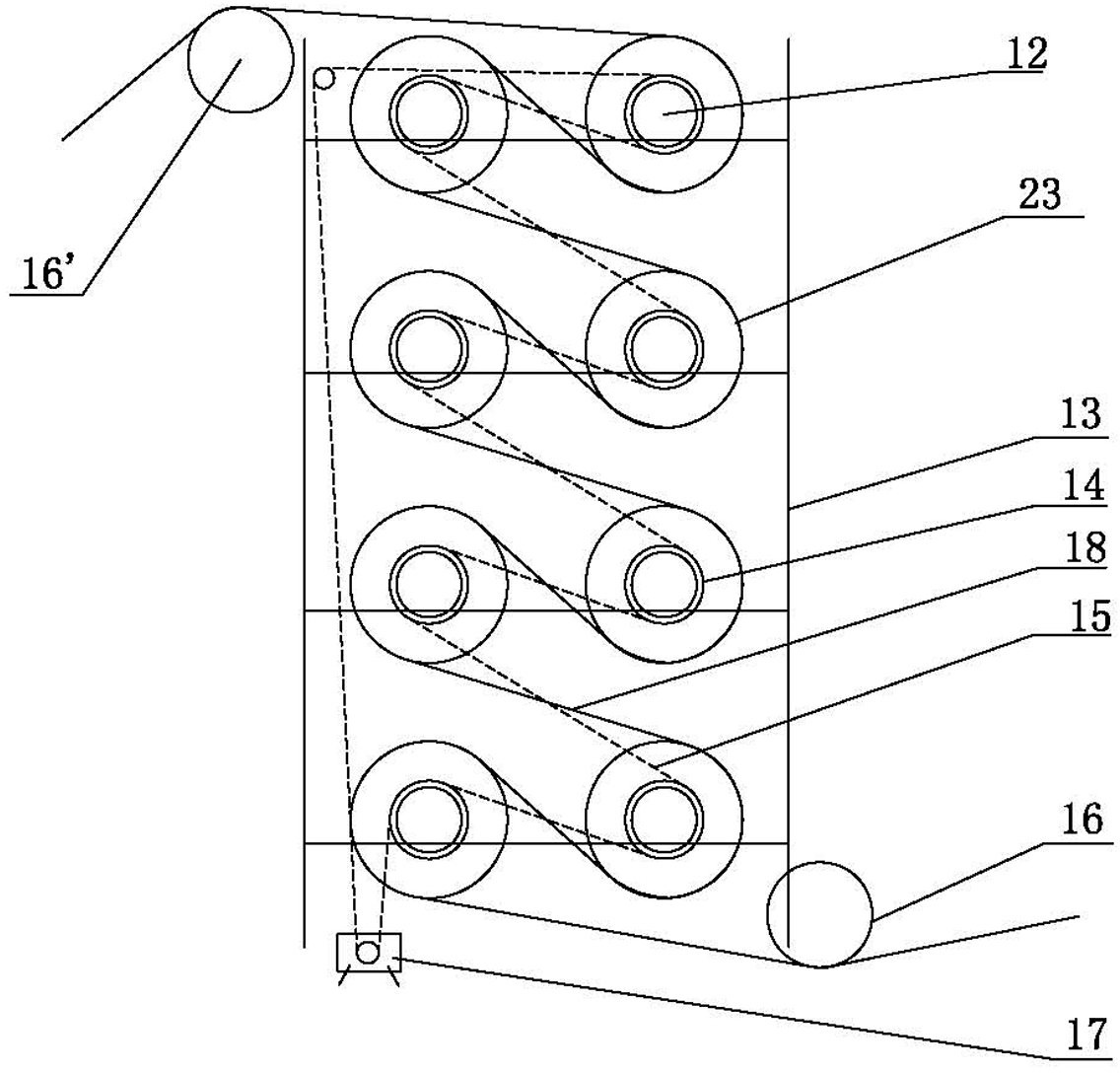

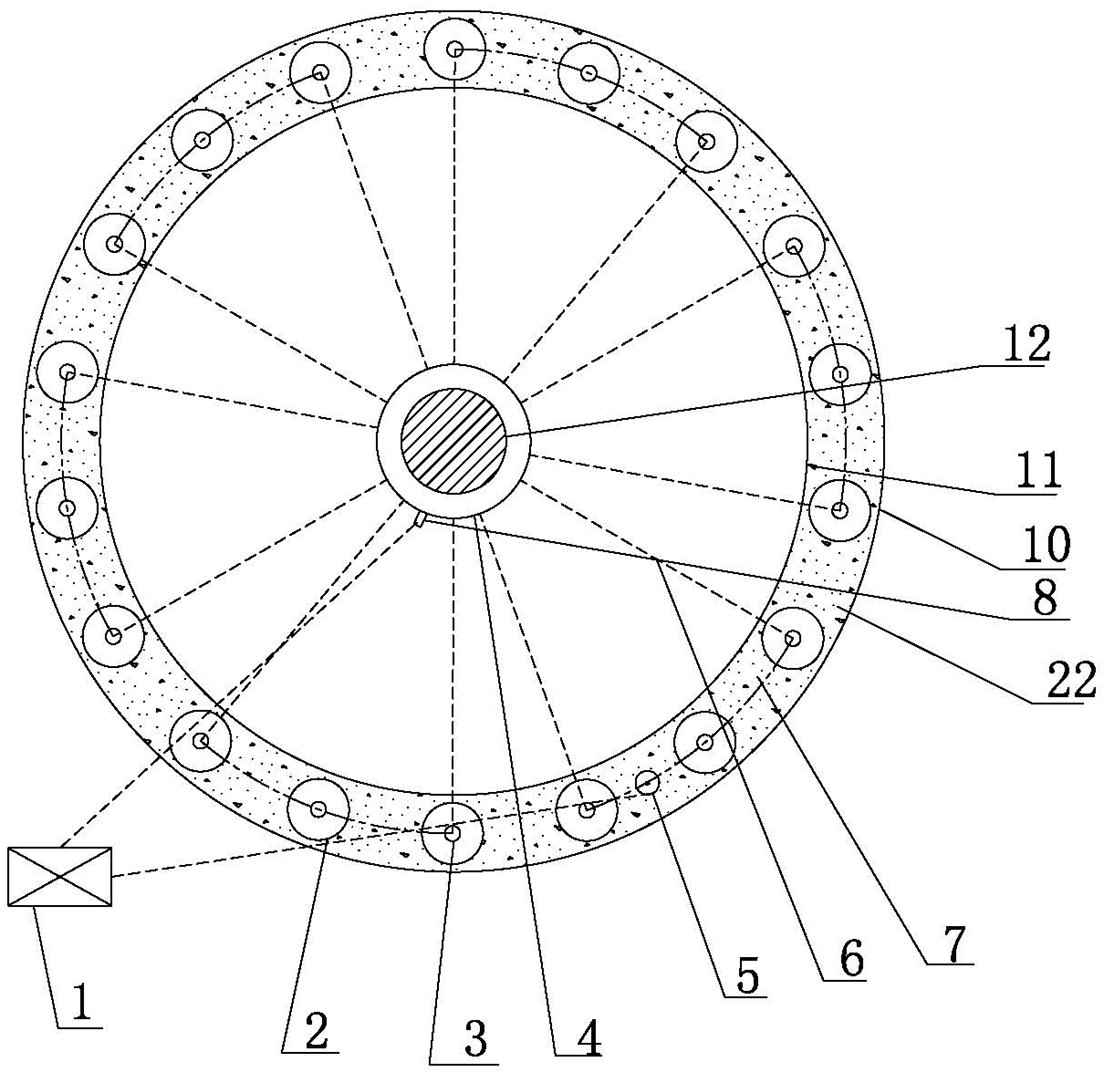

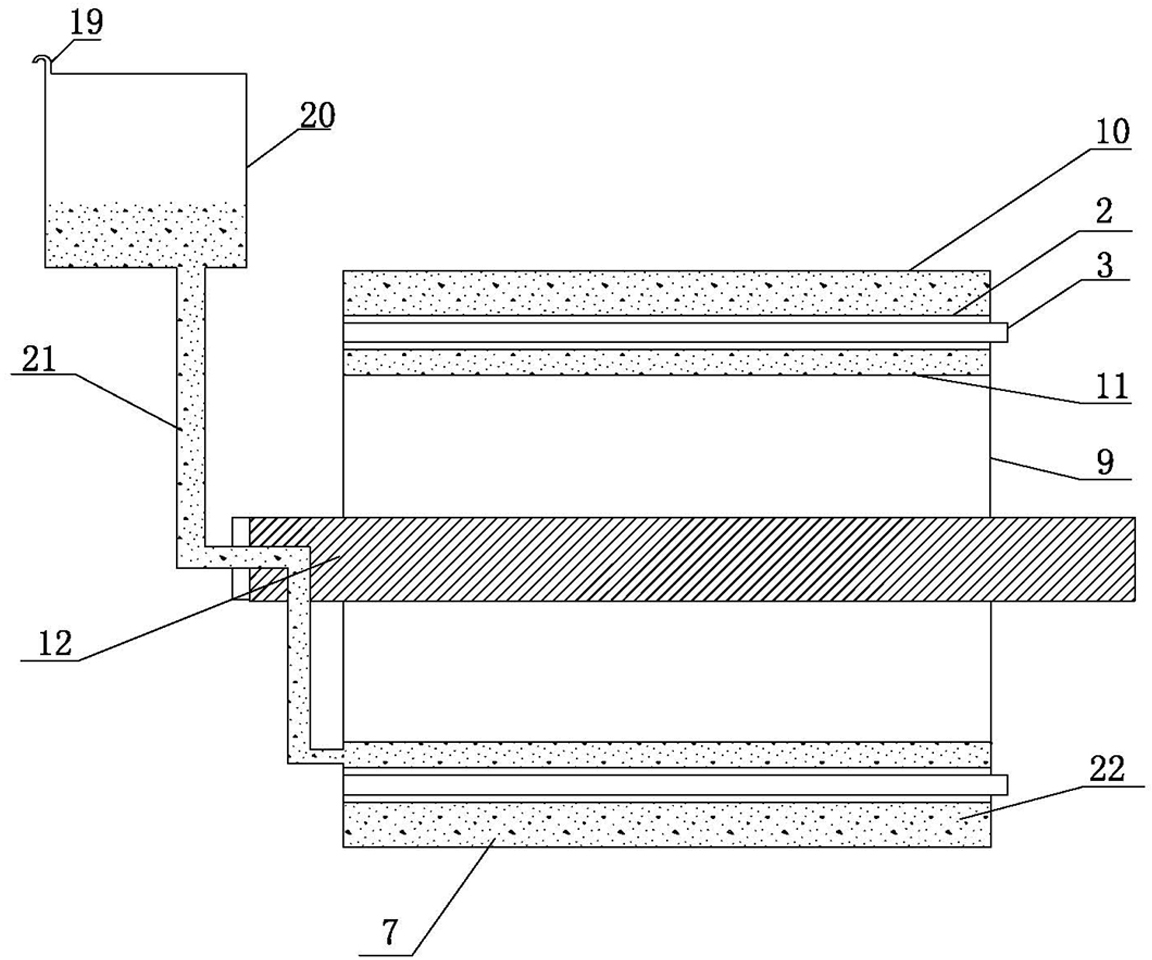

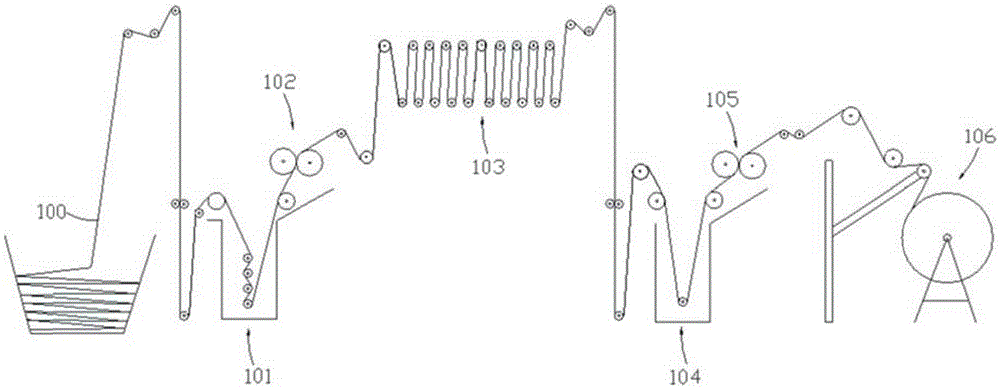

Reactive dyeing equipment for cellulose fibre-contained yarns

ActiveCN101994220AWide selectionReduce hydrolysisLiquid/gas/vapor removalTextile treatment machine arrangementsReactive dyeElectric heating

The invention relates to reactive dyeing equipment for cellulose fibre-contained yarns, comprising a baking device. The baking device comprises a drying drum support, a plurality of rotatable drying drums arranged on the drying drum support, a lead-in yarn guide roller and a lead-out yarn guide roller, wherein each drying drum comprises a drying drum outer wall, a drying drum inner wall and a drying drum side wall; the drying drum outer wall, a closed cavity is encircled by the drying drum inner wall and the drying drum side wall; heat conduction oil is filled in the cavity; an electric heating element used for heating the heat conduction oil is also arranged in the cavity; the drying drums, the lead-in yarn guide roller and the lead-out yarn guide roller synchronously rotate; and when in work, yarns led in by the lead-in yarn guide roller are led out by the lead-out yarn guide roller after bypassing the surface of each drying drum in sequence. Through utilizing the equipment, continuous pad dyeing can be carried out on the cellulose fibre-contained yarns by using reactive dyes, and moreover, in the dyeing process, the baking temperature is relatively low, the baking mode is simple, broken yarns are less and operators are easy to dispose, and therefore, the reactive dyeing equipment is especially suitable for the special requirements on the continuous pad dyeing of the yarn.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

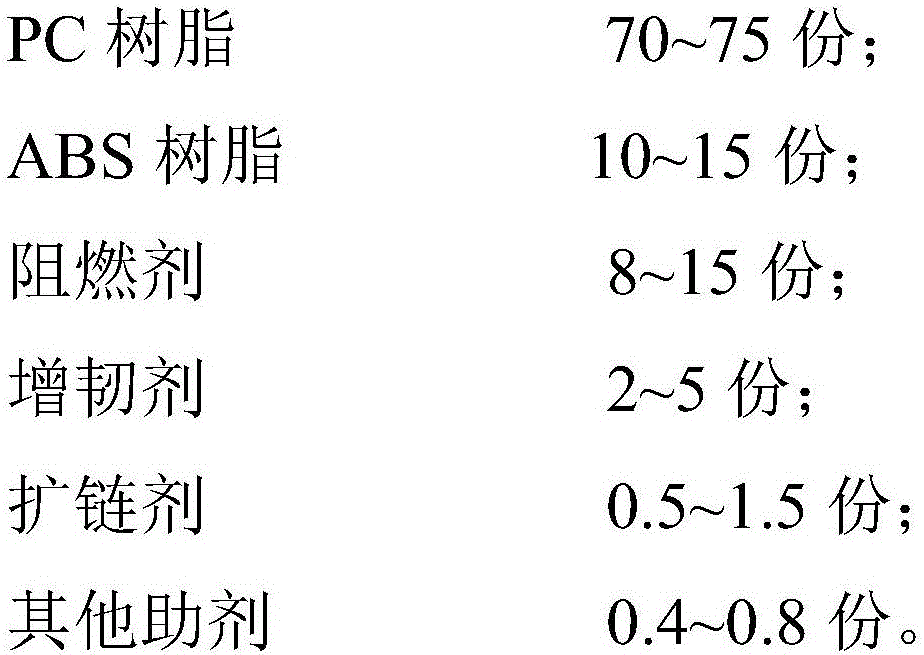

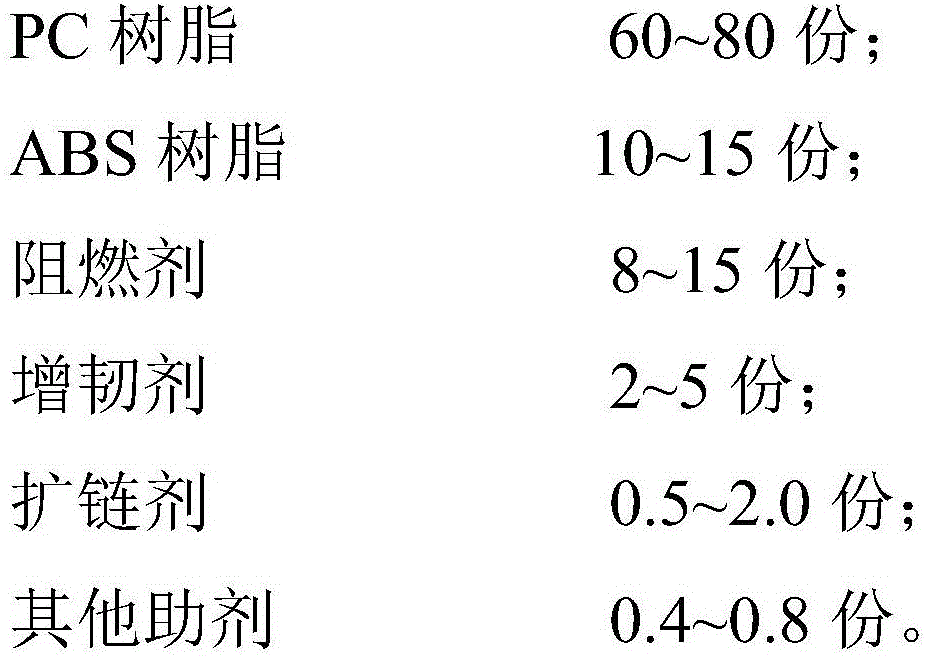

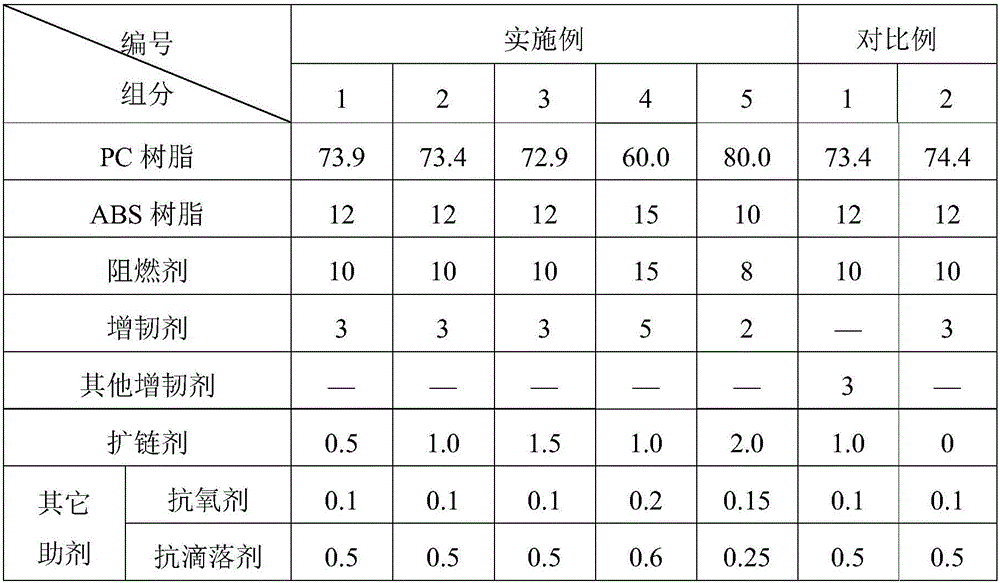

Flame-retardant PC/ABS composite material with high hydrolysis resistance and preparation method thereof

InactiveCN106317821AReduce hydrolysisRetention of mechanical properties and flame retardant propertiesEpoxideFire retardant

The invention discloses a flame-retardant PC / ABS composite material with high hydrolysis resistance and a preparation method thereof. The composite material comprises PC resin, ABS resin, a fire retardant, a flexibilizer, a chain extender and other auxiliaries. According to the composite material, the flexibilizer with specific number-average particle size and specific molecular structure and the chain extender with high epoxide equivalent are selected, the hydrolysis resistance of the flame-retardant PC / ABS composite material can be improved by optimizing the raw materials, and the flame-retardant PC / ABS composite material can have relatively ideal flame retardance and mechanical property after being subjected to long-time high temperature and high humidity treatment and is particularly suitable for the occasions with relatively high requirements for the use environments.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

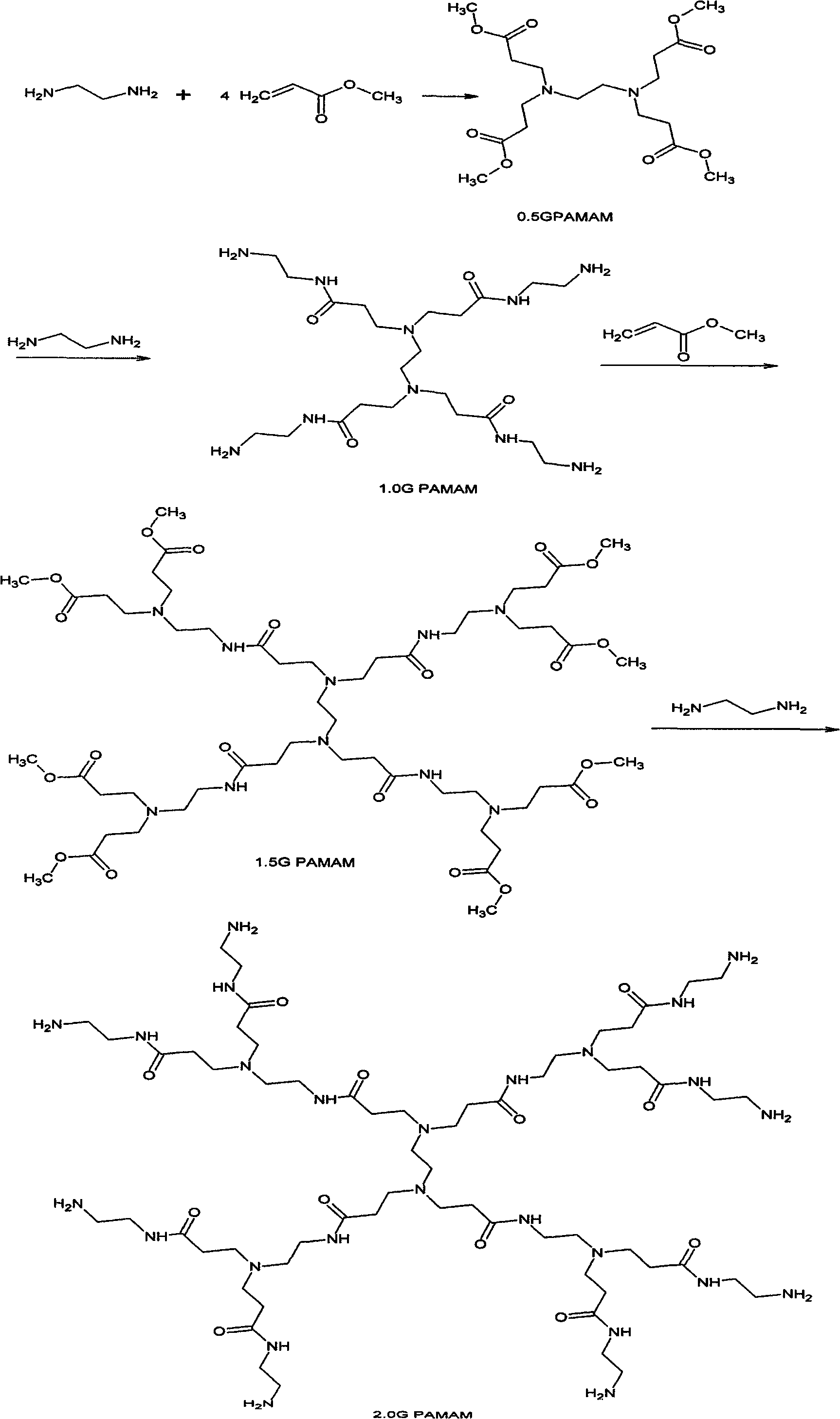

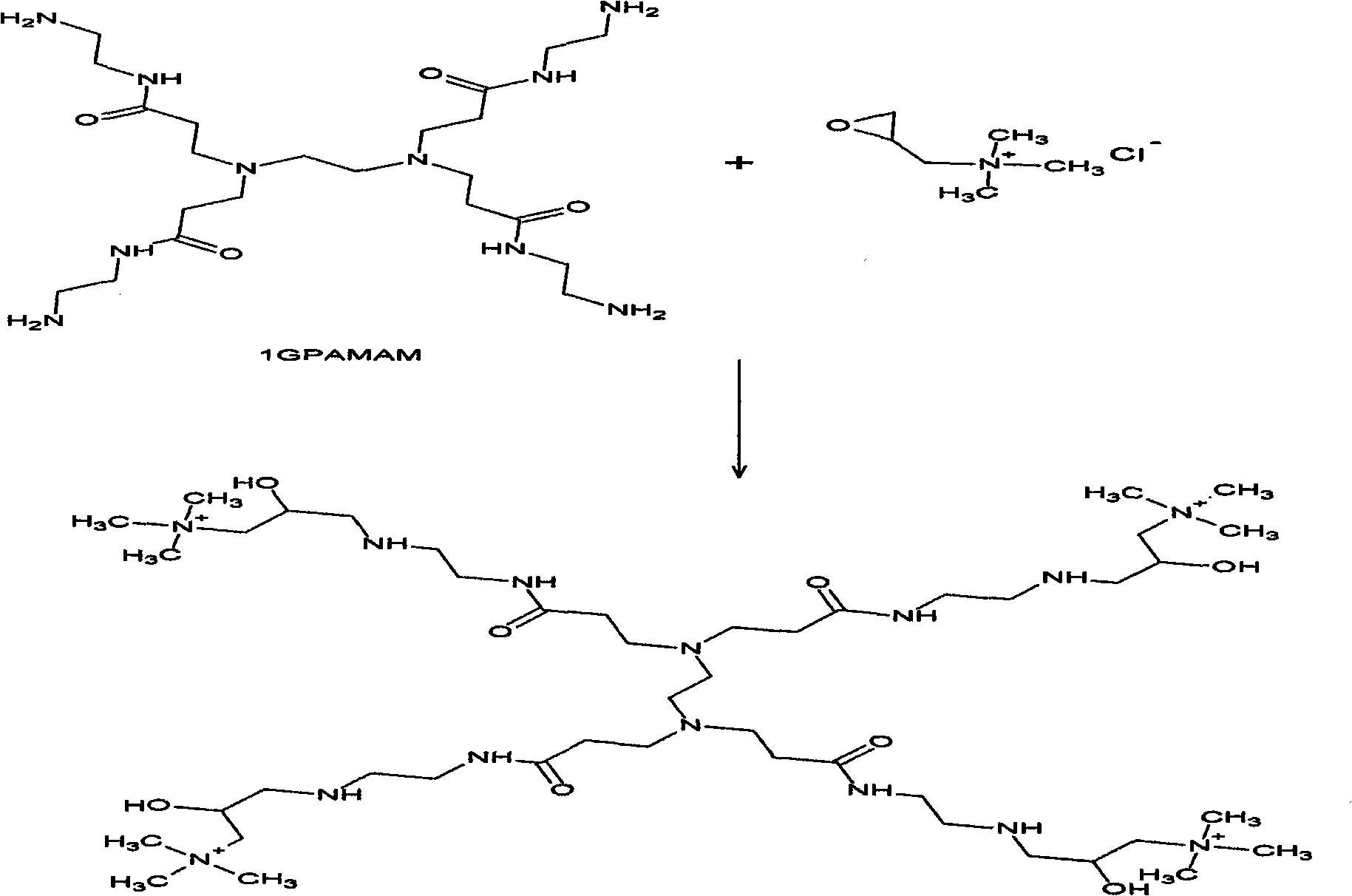

Dendriform cationic leather fixing agent and preparation method thereof

The invention relates to a method for preparing a leather fixing agent, in particular to a dendriform cationic leather fixing agent and a preparation method thereof. To overcome the defects of low activity, high consumption and easily caused grain leather existing in the prior art, the invention adopts a technical scheme that: the method for preparing the dendriform cationic leather fixing agent comprises the following steps: (1) mixing organic amine and acrylic ester, adding a reaction solvent, stirring to react, vacuumizing, distilling by rotating, and removing the solvent and excessive acrylic ester to prepare dendriform PAMAM; and (2) mixing the dendriform PAMAM prepared in the step (1) with a cationic etherifying agent, adding a solvent, adding an extracting agent after reaction, andextracting for multiple times to prepare graft modified dendriform cationic leather fixing agent. Compared with the prior art, the method has the advantages of reducing the hydrolysis effect of dye, improving fastness of leather to wet rubbing, reducing the consumption of the dye, not influencing the hand feeling of the leather, and making the fixing agent biologically degraded easily.

Owner:SHAANXI UNIV OF SCI & TECH

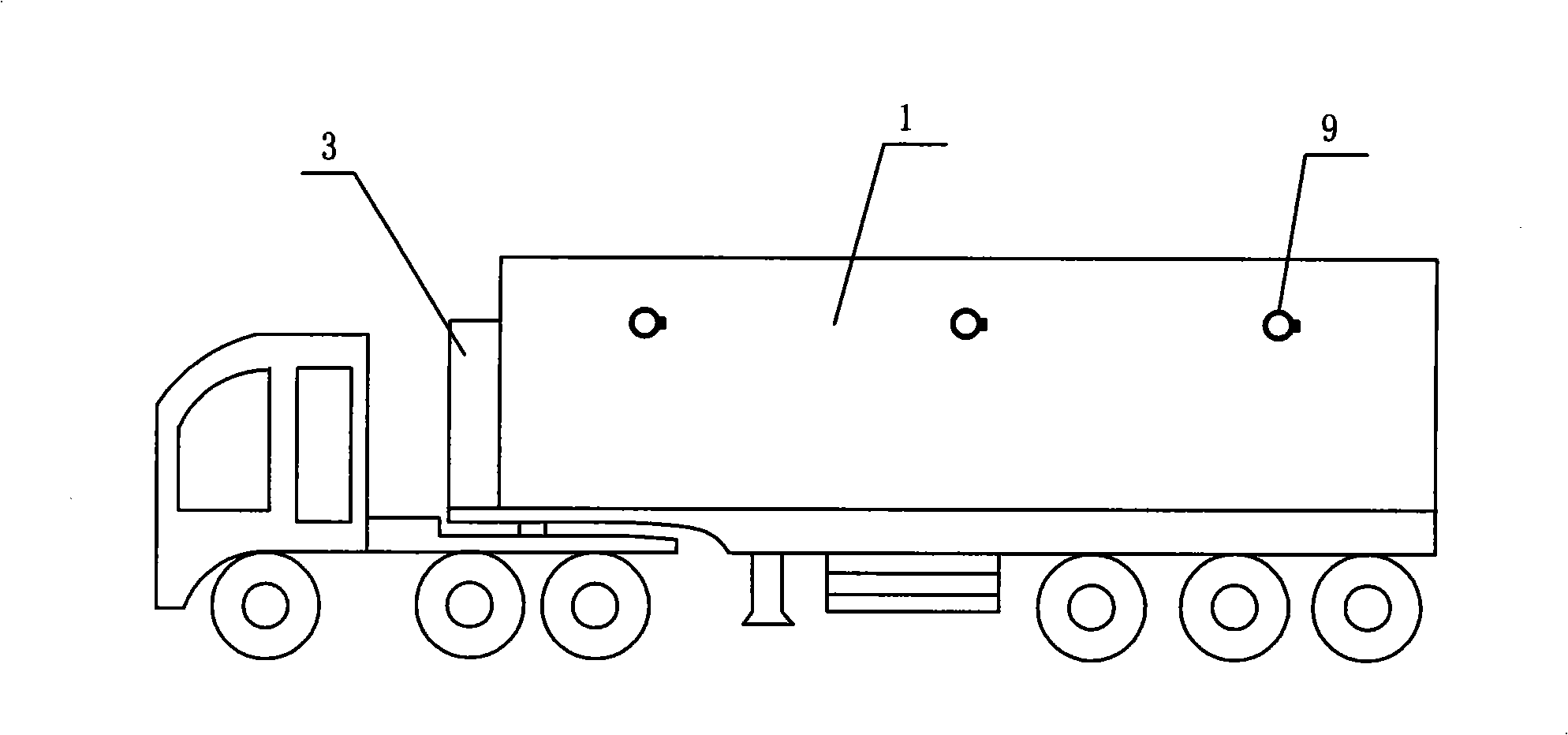

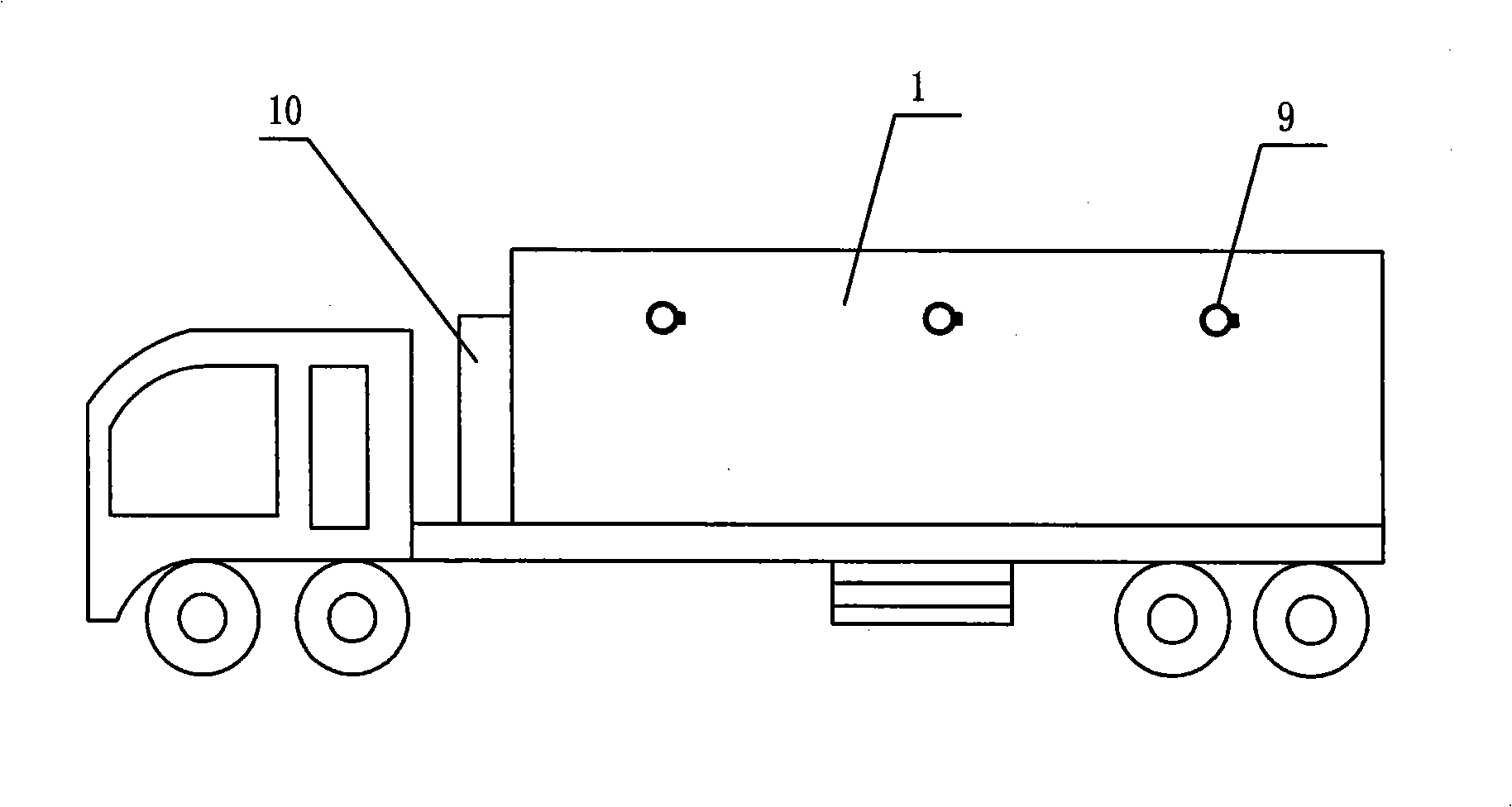

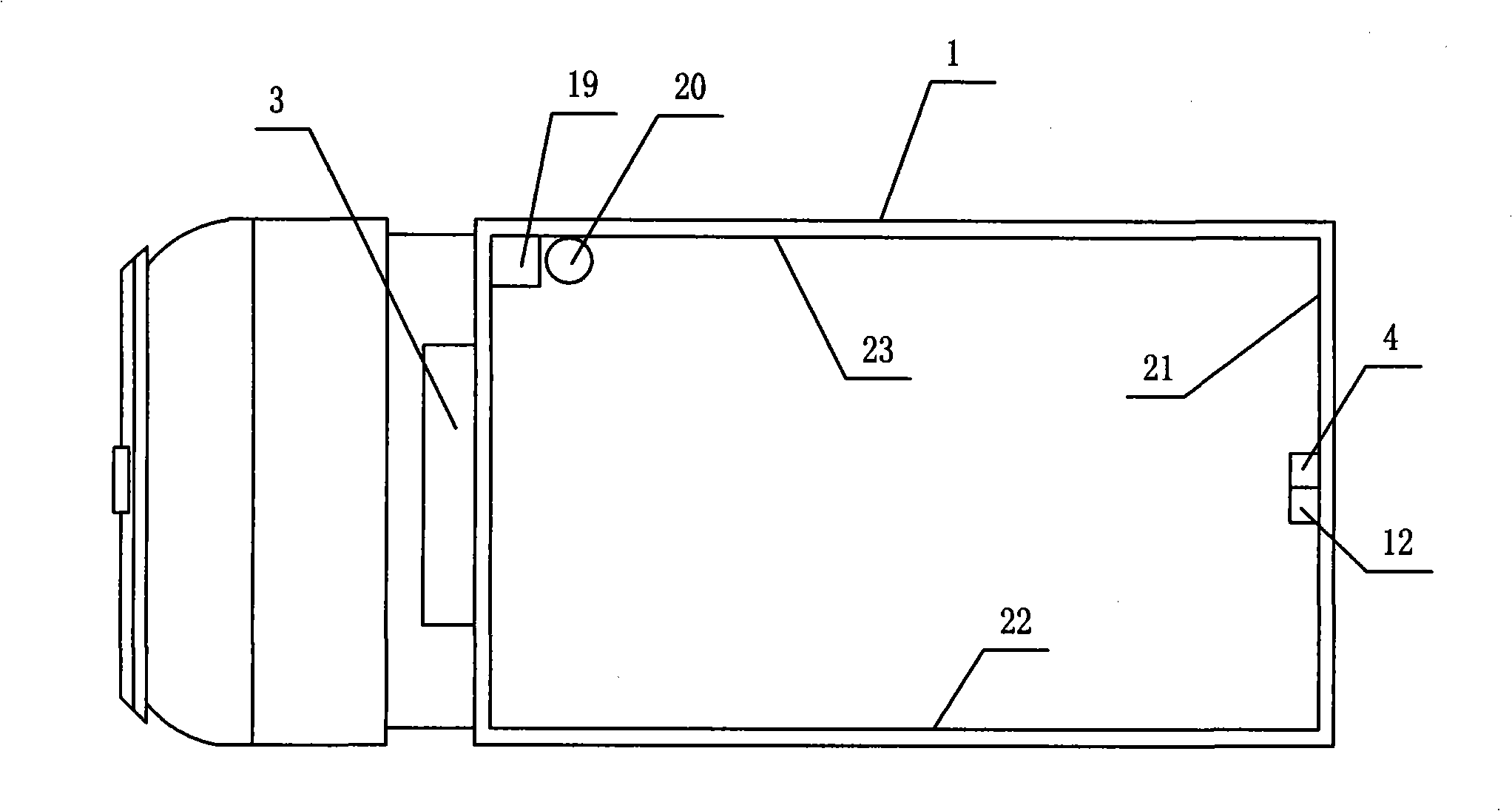

Fruit vegetable transporting and fresh-keeping method and fruit vegetable fresh-keeping carriage as well as fruit vegetable fresh-keeping vehicle

InactiveCN101326927AInhibit metabolismThorough sterilizationFruit and vegetables preservationItem transportation vehiclesVolumetric Mass DensityBiology

The invention relates to a fruit and vegetable transporting and preserving method by using ozone as well as a fruit and vegetable preserving carriage and a fruit and vegetable preserving vehicle. The fruit and vegetable transporting and preserving method is that the ozone is injected into a thermal-insulating fruit and vegetable storage space with a certain shape and volume and not sealed completely; proper ozone density and proper humidity are remained in the space which is not sealed completely, the humidity is maintained at 50-95 percent and the ozone density is maintained at 3ppm-25ppm. The fruit and vegetable preserving carriage comprises a carriage body; a thermal-insulating layer is arranged on the internal surface of the carriage body; the escape pipe of a preserving machine installed on the external wall of the carriage body is communicated with the intake pipe of an ozone delivery pipe network fixed on the inner surface of the roof plate of the carriage; an electric fan and a fine atomizing spray head are also fixed on the inner surface of the roof plate of the carriage; at least one ventilation silicon window communicated with the carriage body is arranged on the flank of the carriage body. The fruit and vegetable preserving vehicle comprises a fruit and vegetable preserving carriage. The invention provides a fruit and vegetable preserving carriage and a fruit and vegetable preserving vehicle with sound preserving effect and low power consumption.

Owner:马献成

Hydrolysis-resistance composition

A composition for forming an article having an improved resistance to hydrolysis is disclosed. The composition comprises a polyalkylene terephthalate and / or polyester thereof, a triglyceride, an epoxy component, and a plasticizer. The polyalkylene terephthalate has terminal carboxyl groups and hydroxyl groups and internal ester linkages. The triglyceride has at least one acid component with 6 to 30 carbon atoms and at least one epoxy group for reacting with the carboxyl groups. The epoxy component has internal aromatic groups and at least one terminal epoxy group for reacting with the carboxyl groups. The plasticizer comprises an esterification product of a polyoxyalkylene glycol with 1 to 20 carbon atoms and an aliphatic carboxylic acid with 1 to 25 carbon atoms for improving melt flow properties and for reducing hydrolysis of the composition.

Owner:BASF CORP

Dyeing and finishing process for polyester interweaved fabric

ActiveCN107059384AGood removal effectHigh whitenessHeat resistant fibresBiochemical treatment with enzymes/microorganismsPhenolsPh buffering

The invention discloses a dyeing and finishing process for polyester interweaved fabric. The dyeing and finishing process comprises the following steps: S1) pre-treating: performing scouring and bleaching and enzyme washing treatment on the polyester interweaved fabric in turn; S2) pre-shaping: performing pre-shaping treatment on the polyester interweaved fabric; S3) dyeing: soaking the polyester interweaved fabric into a dye liquor at a liquor ratio of 1:(10-30), wherein the dye liquor comprises 1-3% of reactive dyes, 2-5% of rare-earth complex micro-encapsulation disperse dyes, 5-15g / L anhydrous sodium sulphate, 1.5-3.5g / L pH buffering agent, 0.1-0.3g / L organic phenol halide and 0.01-0.05g / L organic fluorinated surfactant; and S4) finishing: performing softening and flame-proof treatment on the fabric in turn. The dyeing and finishing process for polyester interweaved fabric, disclosed by the invention, not only can obviously improve the performances, such as, hand feel and elasticity, of the fabric but also can achieve the effects of uniform dyeing, high color fastness and abundant color and luster.

Owner:宣城加特林机械有限公司

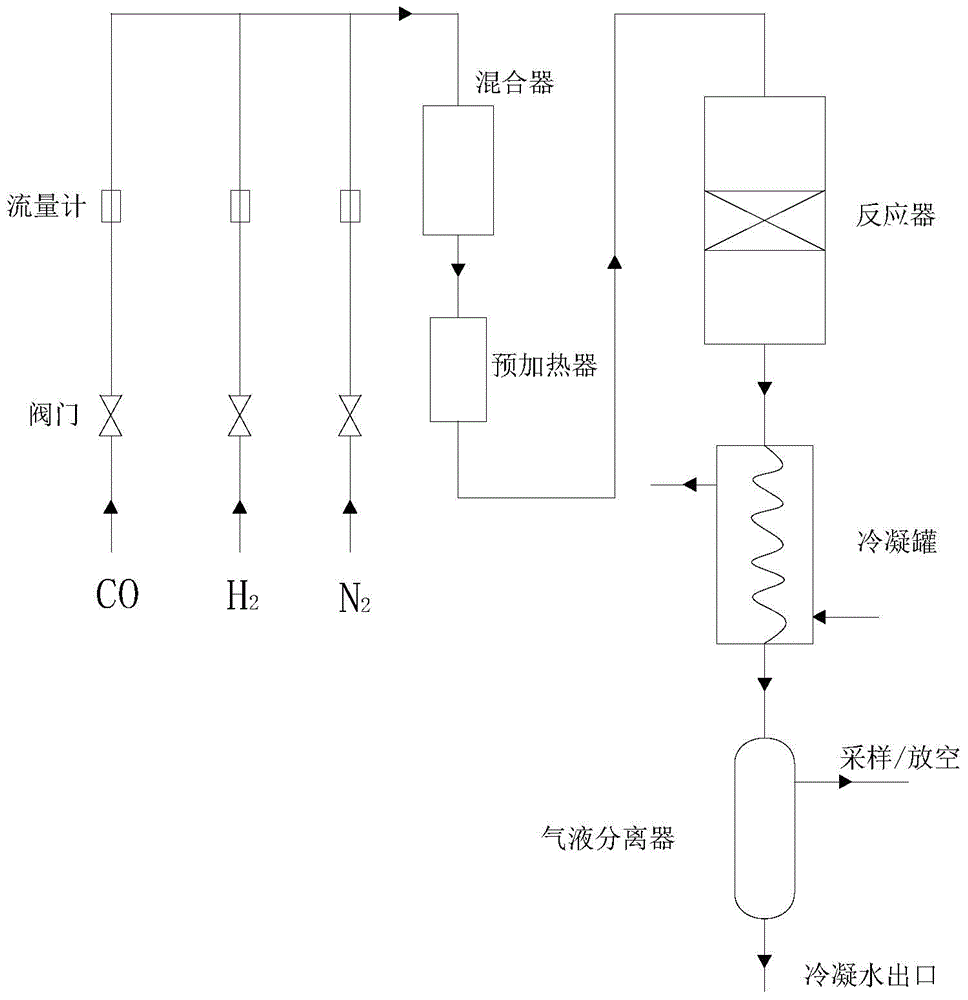

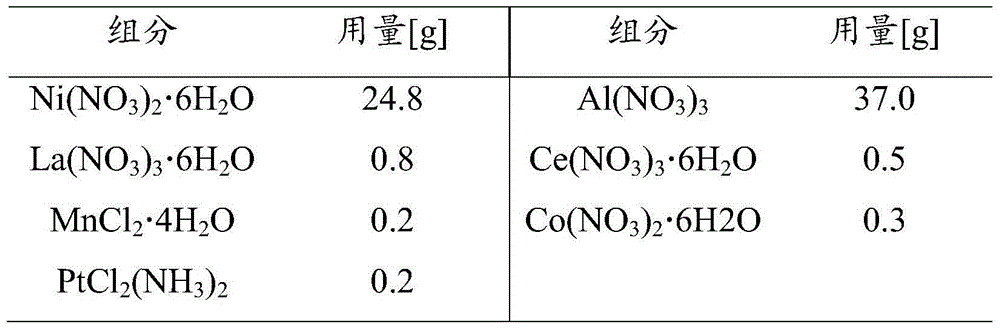

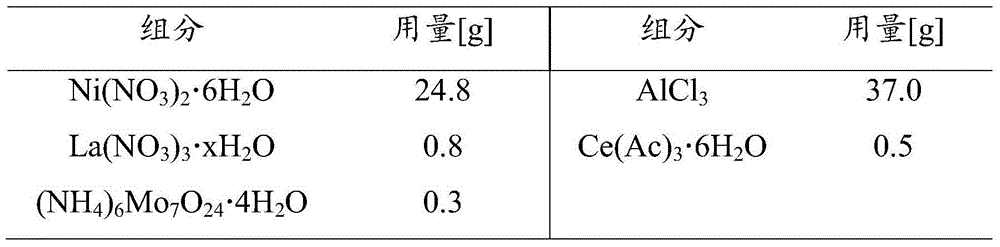

High-temperature-resistant methanation catalyst as well as preparation method thereof

ActiveCN104399491AIncrease active siteLarge specific surface areaHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIncipient wetness impregnationOxide

The invention discloses a high-temperature-resistant methanation catalyst as well as a preparation method thereof. According to the catalyst, Al2O3 is used as a carrier, Ni is used as a primary active component, La and Ce are used as secondary components, and metallic oxides of Mn, Co, Fe, W or Mg are used as other active auxiliaries; the preparation method of the catalyst comprises the following steps: carrying out ultrasonic dispersion and coprecipitation on the primary active component Ni and a PEG (polyethylene glycol)-aqueous solution of a carrier precursor, and separating, drying and roasting to obtain a NiO-Al2O3 catalyst; then, loading the secondary components La and Ce and precursors of the active auxiliaries to the NiO-Al2O3 catalyst by adopting an incipient-wetness impregnation method; finally, roasting and carrying out reduction activation to obtain the high-temperature-resistant methanation catalyst; the catalyst has high specific surface area, and can reduce carbon deposition reaction and improve the selectivity of methane. The high-temperature-resistant methanation catalyst can maintain relatively high methanation catalytic activity for a long time at high temperatures and can be widely applied to a methanation process under a high-temperature environment.

Owner:广东省瀚思尔科技有限公司

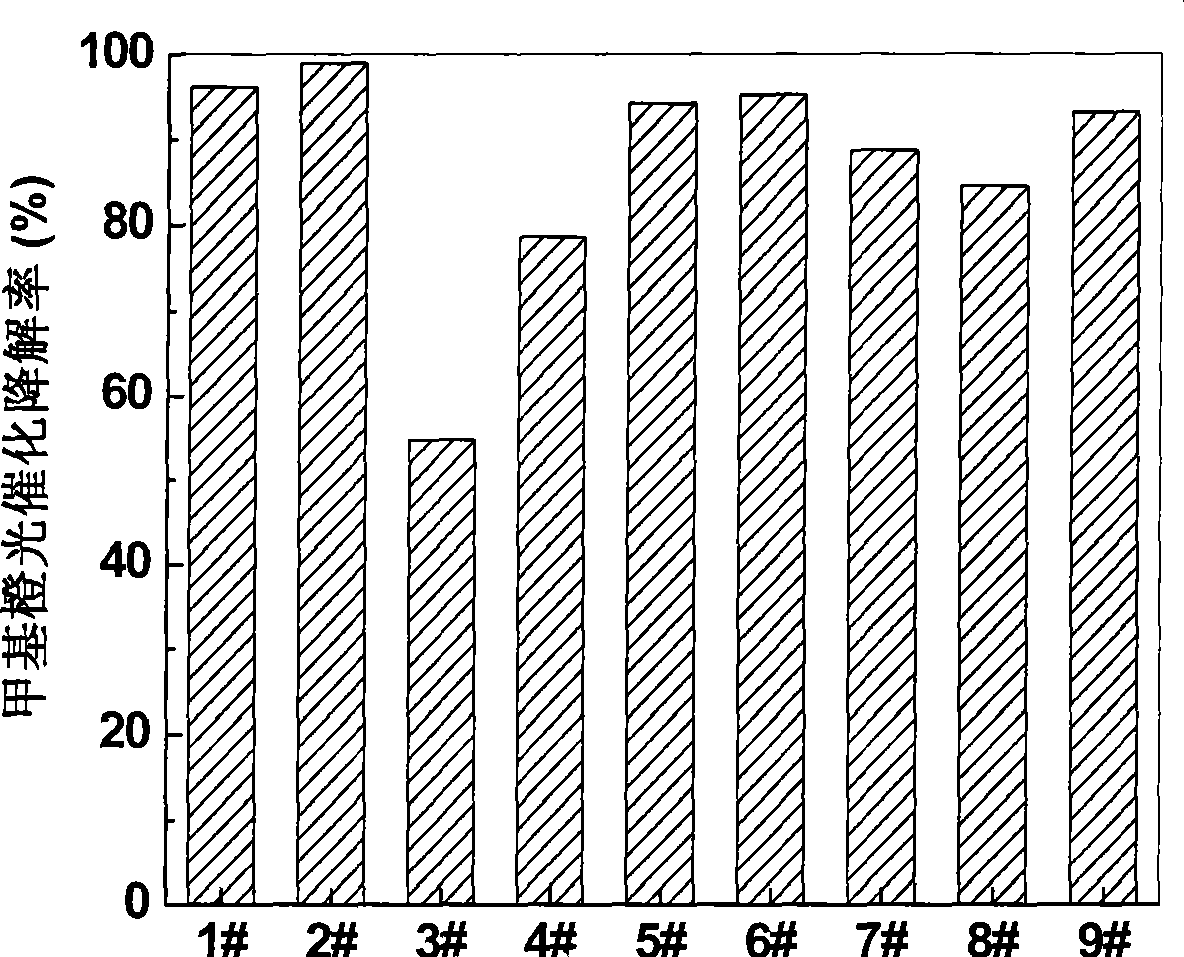

Preparation method and application of general magnetic adsorbent

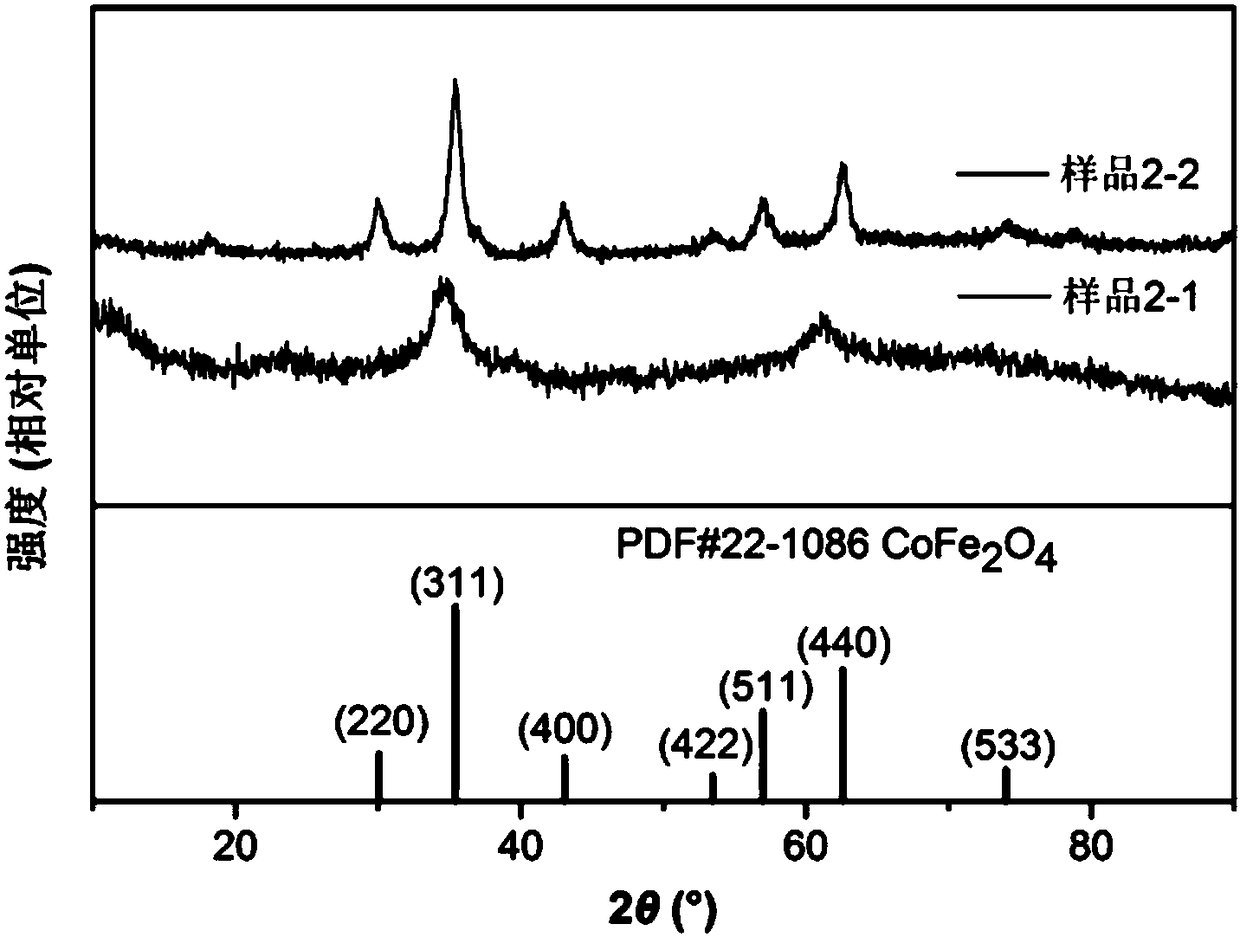

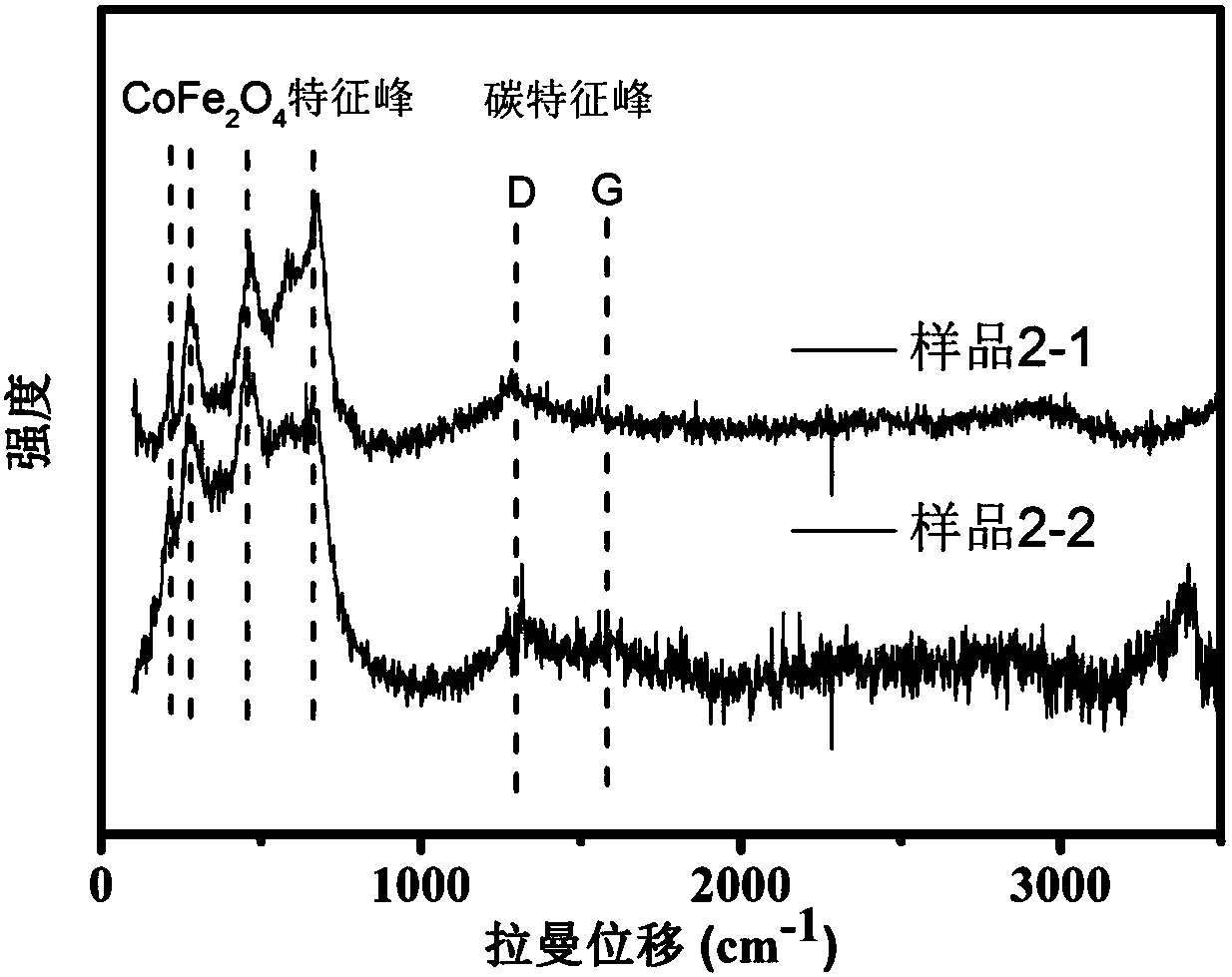

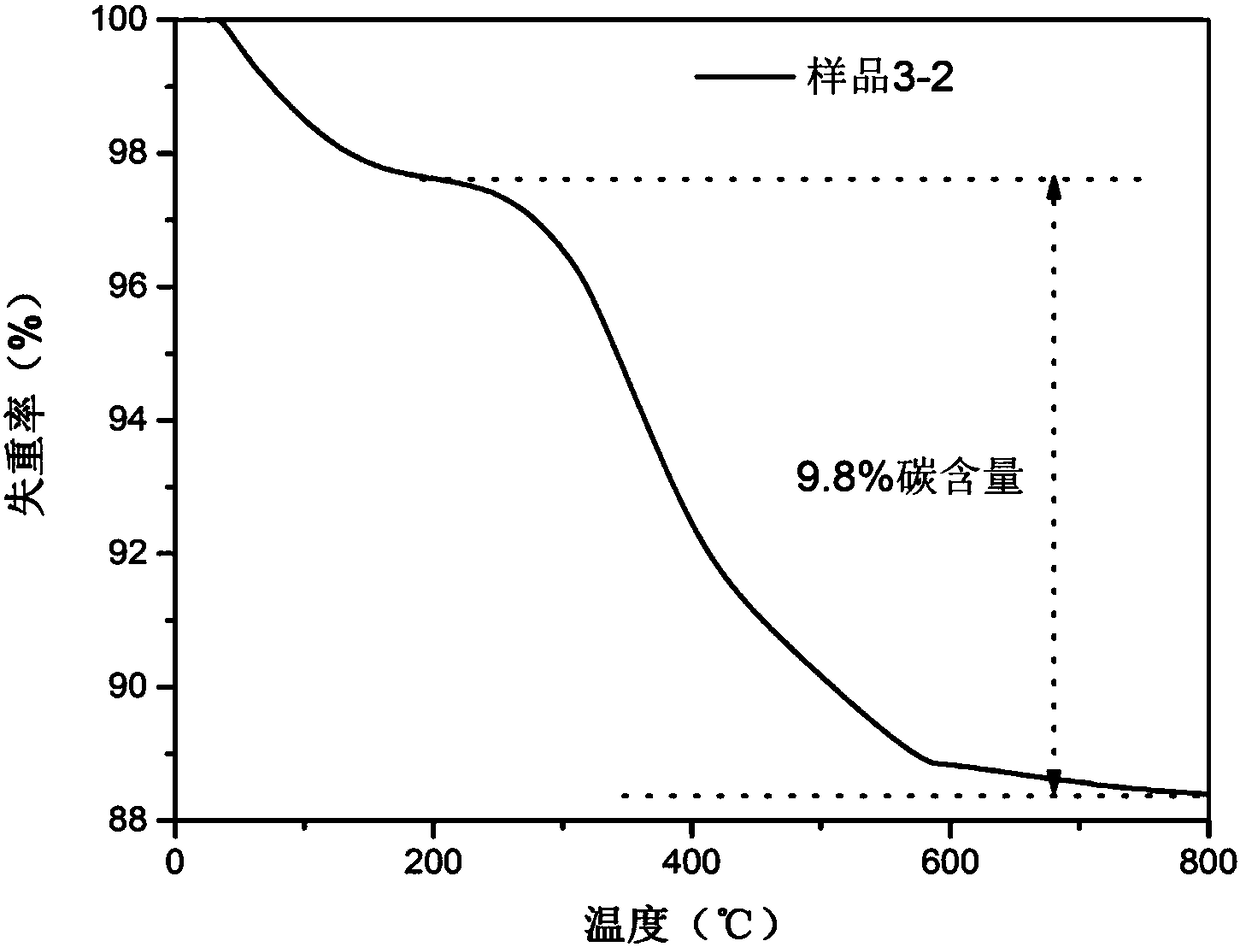

ActiveCN108393073AReduce crystallizationReduce hydrolysisOther chemical processesWater contaminantsSorbentSewage treatment

The invention relates to a preparation method and an application of a universal magnetic adsorbent, belongs to the field of preparation of magnetic porous nanocomposite materials, and concretely relates to a carbon and magnetic spinel ferrite MFe2O4 hybrid nanocomposite MFe2O4 / C synthesized by adopting a solvothermal method, and its application as a dye sewage treatment adsorbent after being calcined. The adsorbent has a good adsorption performance on a cationic dye and an anionic dye in a wide solution pH range of (3.0-11.0), can be quickly separated from an aqueous solution under the actionof an external magnetic field, and is convenient, fast, economical and efficient.

Owner:DALIAN UNIV OF TECH

Corrosion-resistant high-adhesive-force water-based metal paint

InactiveCN104893499AImprove densification performanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsWater basedSilicon oxide

The invention discloses a corrosion-resistant high-adhesive-force water-based metal paint which is prepared from the following raw materials in parts by weight: 20-30 parts of polyorthotoluene glycidol ether, 15-20 parts of bisphenol F epoxy resin, 10-20 parts of polyphenyl glycidyl ether, 20-30 parts of silica sol, 1-3 parts of iron oxide red, 1-2 parts of titanium white, 12-16 parts of mica powder, 15-30 parts of modified wollastonite, 2-6 parts of quartz powder, 1-3 parts of silicon oxide, 1-2 parts of zinc oxide, 5-10 parts of ground calcium carbonate, 1-3 parts of aluminum tripolyphosphate, 5-10 parts of zinc phosphate, 0.2-0.8 part of antimicrobial agent, 1-2 parts of mildew preventive, 1.5-3 parts of leveling agent, 1-2 parts of defoaming agent, 1-2 parts of wetting agent, 1-3 parts of dispersing agent, 2-6 parts of ethylene glycol, 20-30 parts of water and 2-5 parts of film-forming assistant. The metal paint has the advantages of favorable corrosion resistance, high adhesive force and excellent mechanical properties.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Hygroscopic auxiliary material-based solid preparation

InactiveCN101978953AReduce hydrolysisImprove protectionPowder deliveryPill deliveryAdhesiveAntioxidant

Owner:SHANGHAI JIAO TONG UNIV

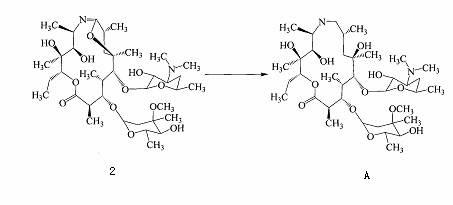

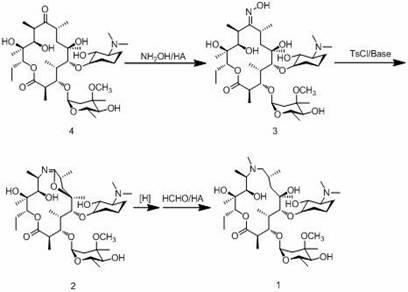

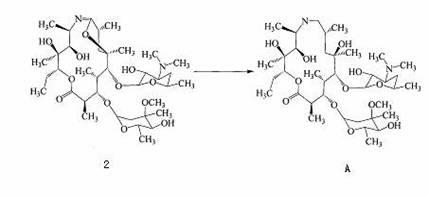

Preparation method of azithromycin intermediate

ActiveCN102127064AHigh yieldReduce manufacturing costOrganic chemistrySaccharic acidChemical synthesis

The invention discloses a preparation method of azithromycin intermediate, in particular to a preparation method of azithromycin intermediate 9- deoxidation-alpha- heterocyclic nitrogen-9a-erythromycin A, belonging to the field of pharmaceutical chemical synthesis. The preparation method comprises the steps of: in acid aqueous solution, under the action of potassium borohydride or sodium borohydride, carrying out reduction reaction on erythromycin A 6, 9-imine ether, adding organic saccharic acid for hydrolysis reaction, and obtaining the 9-deoxidation-alpha-heterocyclic nitrogen-9a-erythromycin A. By adopting the method, the hydrolysis of boric acid ester is thorough, the products of acid degradation are less, the yield is high, the production cost of azithromycin is remarkably reduced, and the industrialized production can be very smoothly carried out.

Owner:KAIFENG PHARMA GRP +1

Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

The invention discloses silicone acrylic emulsion and the application of the silicone acrylic emulsion as a textile finishing agent. The silicone acrylic emulsion is manufactured by the following raw materials in parts by weight: 24-30 parts of butyl acrylate, 6-14 parts of methyl methacrylate, 0.15-1.0 part of initiator, 42.9-67.7 parts of deionized water, 1.2-6 parts of compound emulsifier, 0.3-0.6 part of pH buffer agent, 1-5 parts of vinyltriethoxysilane and 0.1-0.3 part of ammonium hydroxide. The silicone acrylic emulsion of the invention has the advantages that the composition is simple, the consumption of organosilicone monomer is low, the hydrolyzation of siloxane can be efficiently reduced through the matching of the silicone acrylic emulsion and seed emulsion, the polymerization process and the finally obtained emulsion are stable, and the emulsion is high in solid content, low in viscosity and convenient to use; the emulsion is used as the textile finishing agent so as to enable the textile to gain better weight increment and anti-wrinkle performance under the condition of keeping whiteness and intensity, no methyl aldehyde is realized during finishing, preservation and use, and the emulsion has the characteristics of remarkable effect, environmental protection and low cost.

Owner:SUZHOU UNIV

Reactive dye cold pad-batch dyeing equipment and dyeing method

ActiveCN105256485AImprove solubilityIncrease dosageSucessive textile treatmentsTextile treatment machine arrangementsBiochemical engineeringDeoxygenation

The invention relates to the technical field of dyeing and provides reactive dye cold pad-batch dyeing equipment and a dyeing method. The dyeing equipment comprises a first dipping tank, a first padder, a ventilating device, a second dipping tank, a second padder and a rolling and piling device. The dyeing method comprises the following steps of primary padding, wherein fabric sequentially passes through the first dipping tank and the first padder, and the first dipping tank contains reactive dye and deoxygenation enzyme; ventilating treatment for 1-4 minutes; secondary padding, wherein the fabric sequentially passes through the second dipping tank and the second padder, and the second dipping tank contains alkaline agents; aftertreatment. According to the reactive dye cold pad-batch dyeing method, the reactive dye and the alkaline agents are padded in a separated mode, and the problems that because the reactive dye and the alkaline agents react before padding, diffusivity of the reactive dye is decreased, and dyeing is unstable are solved; the selection range of the reactive dye and the color fixing alkaline agents is enlarged, the requirement for the equipment is lowered, a proportioning pump is omitted, and operation is convenient.

Owner:新乡橄榄枝纺织化工有限公司

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

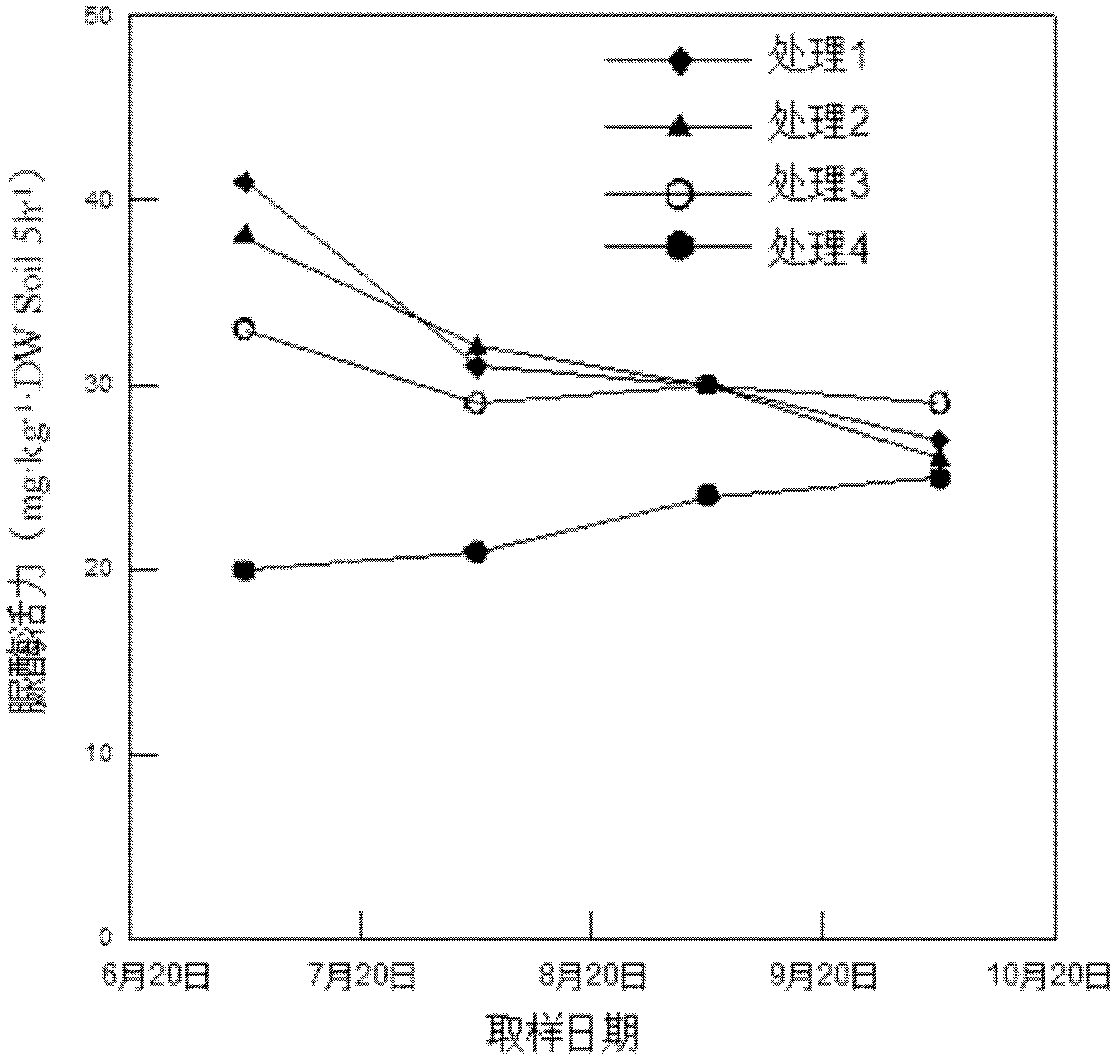

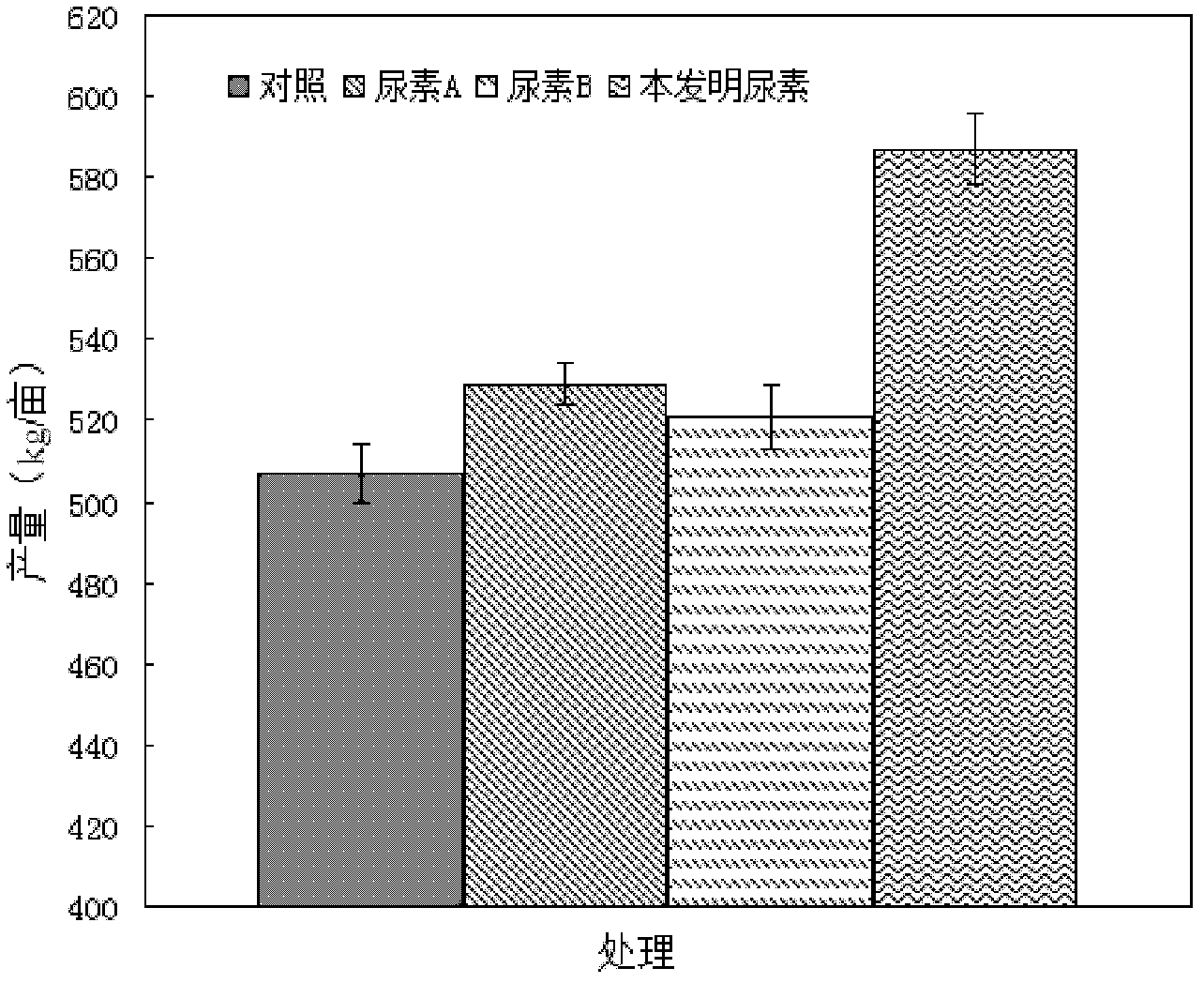

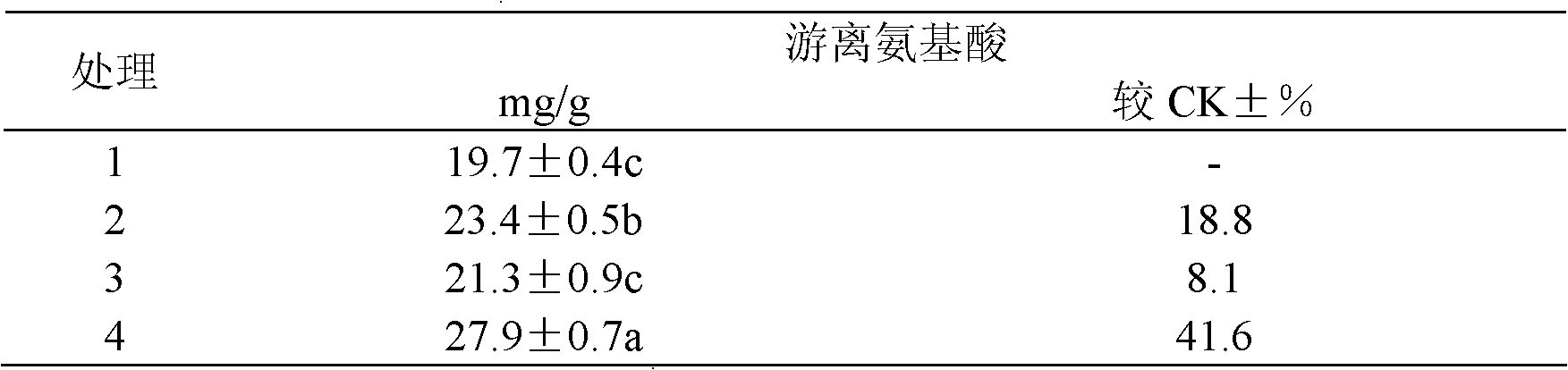

Slow release urea containing gamma-polyglutamic acid and urease inhibitor and preparation method thereof

InactiveCN102584495AEffective absorptionImprove solubilityUrea compound fertilisersFertilizer mixturesUrease InhibitorsGamma-polyglutamic Acid

The invention discloses slow release urea containing gamma-polyglutamic acid and a urease inhibitor. The slow release urea is obtained by spraying a coated slow release solution onto the outer surface of urea particles and drying, wherein the coated slow release solution contains gamma-polyglutamic acid and a urease inhibitor. The invention further discloses a preparation method of the slow release urea. The gamma-polyglutamic acid and the urease inhibitor in the slow release urea have synergic actions, and the gamma-polyglutamic acid can form a layer of protective film on the surfaces of a fertilizer and the urease inhibitor, so that the utilization ratio of the fertilizer is increased, and environmental pollution is lowered.

Owner:NANJING SHINEKING BIOTECH CO LTD +1

Water soluble polyurethane associative thickener, and inverse polymerization method and use thereof

ActiveCN102101909AGood lookingExtended opening hoursCosmetic preparationsTransportation and packagingPolyethylene glycolHydrolysis

The invention discloses a water soluble polyurethane associative thickener, and an inverse polymerization method and use thereof. The method comprises: dehydrating polyethylene glycol by using an organic solvent with a boiling point below 110 DEG C; adding diisocyanate in the protection of an inert gas to perform a reaction; adding fatty alcohol of which the chain is 8 to 22 carbon atoms long as a capping agent for further reaction; adding polyol containing at least three hydroxys as a chain extender to perform an reaction till there are no free isocyanate groups; and adding water, and removing the organic solvent by an azeotropic process to obtain the water soluble polyurethane associative thickener which is white, transparent and sticky fluid. The dehydration temperature of water soluble associative polyurethane is low, so the side reactions are inhibited effectively; and reaction is performed in the organic solvent and catalyst is not required, so cost is reduced and the hydrolysis side reaction of the product due to the catalyst is avoided. Because the polyol is used as a chain extender, the thickener of the invention has a branch structure and high thickening performance.

Owner:GUANGZHOU SHINE POLYMER TECH

Special humic acid fertilizer for sweet potatoes and preparation method of special humic acid fertilizer

ActiveCN104529674AImprove process footprintSimple preparation processAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphateNitrogen

The invention relates to a special humic acid fertilizer for sweet potatoes. The special humic acid fertilizer is shaped like a solid granule, wherein a core raw material comprises the following straight fertilizers in percentage by weight: 10-40% of urea, 5-20% of diammonium phosphate, 15-45% of potassium sulfate and 1-20% of an additive; a binder and a wrapped coating account for 20-40% of the total weight of the fertilizer; nitro humic acid accounts for 30-60% of the total weight of the wrapped coating, ureido humic acid accounts for 10-30% of the total weight of the wrapped coating, and a conditioner accounts for 10-20% of the total weight of the wrapped coating. The special humic acid fertilizer for sweet potatoes contains effective components such as a nitrogen fertilizer, a phosphate fertilizer, a potassium fertilizer and a composite microelement fertilizer special for the sweet potatoes and is prepared by smashing and uniformly mixing nitrogen, phosphorus, potassium and other macroelements and microelements for the growth of the sweet potatoes in a straight fertilizer or formed compound fertilizer way at a proper ratio according to the fertilizer requirement ratio and time of the sweet potatoes; and the added compound nitro humic acid and ureido humic acid have different nitrogen forms, so that the requirements of the sweet potatoes to nitrogen in the whole growth period can be met.

Owner:QINGDAO AGRI UNIV

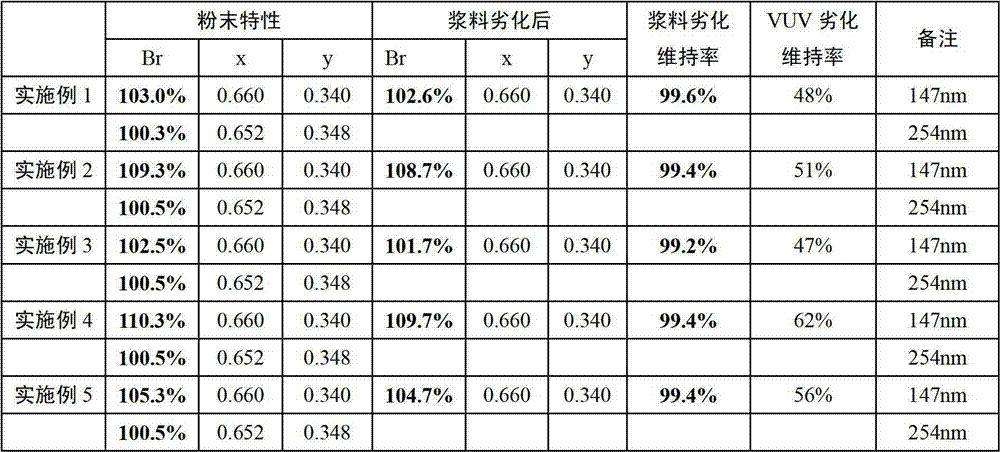

Preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to 3D PDP

InactiveCN102766457AReduce hydrolysisImprove surface integritySolid cathode detailsLuminescent compositionsRare earthYttrium

A preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to a 3D PDP (Plasma Display Panel) comprises the steps as follows: a rare earth oxalate coprecipitation body is prepared by adopting a coprecipitation method, rare earth metal oxide is balanced and dissolved in nitric acid or chlorhydric acid to form a rare earth metal salt solution; an oxalic acid solution or a carbonate solution is prepared and added into the rare earth metal salt solution to obtain rare earth metal oxalate or a carbonate precipitate; the carbonate precipitate is filtered and isolated, dried and burned to obtain a rare earth oxide coprecipitation body; the coprecipitation body is oxidized and burned to form a yttrium gadolinium europium oxide red fluorescent powder burned body; the rare earth oxide coprecipitation body is added with a cosolvent and is loaded in an aluminum oxide crucible and is burned under high temperature in an oxidizing furnace; after burned, the rare earth oxide coprecipitation body is shattered after burning to obtain a yttrium gadolinium europium finished product; and finally, the yttrium gadolinium europium oxide red fluorescent powder is obtained according to a downstream treatment process. The fluorescent powder prepared according to the method has the advantages of high lighting brightness, good color purity, complete crystal morphology, small powder center particle size, simple manufacturing method and low production cost, and is suitable for industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com