Flame-retardant PC/ABS composite material with high hydrolysis resistance and preparation method thereof

A technology of hydrolysis resistance and composite materials, which is applied in the field of PC/ABS composite materials and its preparation, high hydrolysis resistance and flame-retardant PC/ABS composite materials and its preparation, can solve the problem of reducing material fluidity, aggravating PC degradation, and flame retardancy impact and other issues, to achieve the effect of maintaining mechanical properties and flame retardant properties and reducing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

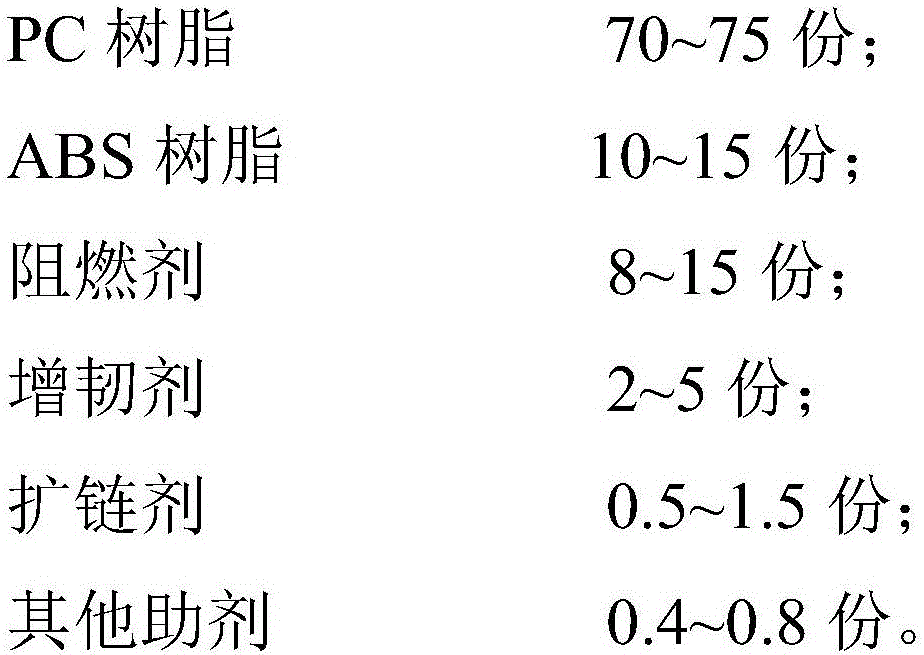

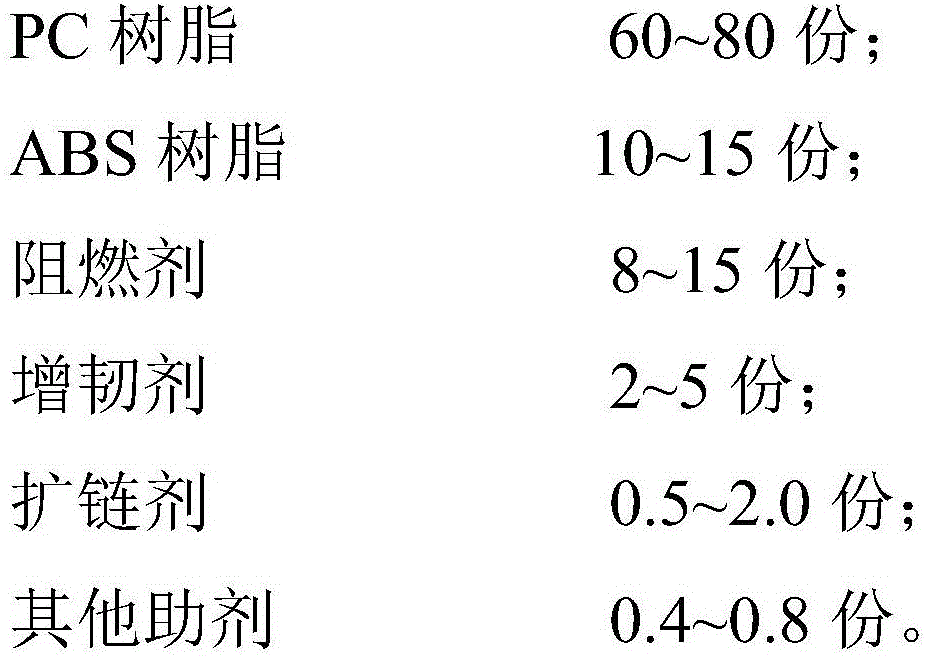

Method used

Image

Examples

Embodiment Construction

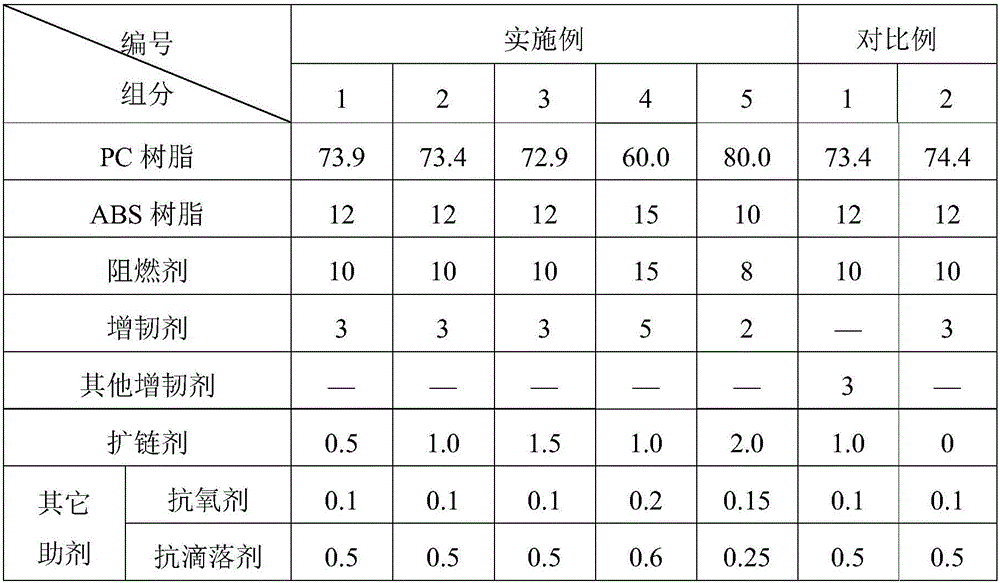

[0028] The present invention will be further described below in conjunction with specific examples and comparative examples. The following specific examples are all preferred embodiments of the present invention, but the embodiments of the present invention are not limited by the following examples, especially not limited to The models of each component raw material used in the following specific examples.

[0029] Selection of raw materials for each component used:

[0030] The PC resin is PC S-2000F (Mitsubishi, Japan) with a viscosity-average molecular weight of 25,000. The ABS resin is ABS 8391 (Gaoqiao Petrochemical) prepared by mass polymerization. The flame retardant is PhireGuard BDP (Jiangsu Yake). The toughening agent is M-732 (Japan Zhongyuan Chemical). Other tougheners are methyl methacrylate-butadiene-styrene M-701 (Japan Zhongyuan Chemical). The chain extender is selected from SAG-008 (Nantong Rizhisheng Company). The antioxidant in other additives is AO1076...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com