Preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to 3D PDP

A technology of red phosphor and yttrium gadolinium europium is applied in the field of preparation of yttrium gadolinium europium oxide red phosphor for 3D PDP, which can solve the problems of poor vacuum ultraviolet maintenance rate and poor luminescence characteristics, and achieves reduced hydrolysis, small central particle size, The effect of enhancing the brightness maintenance ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

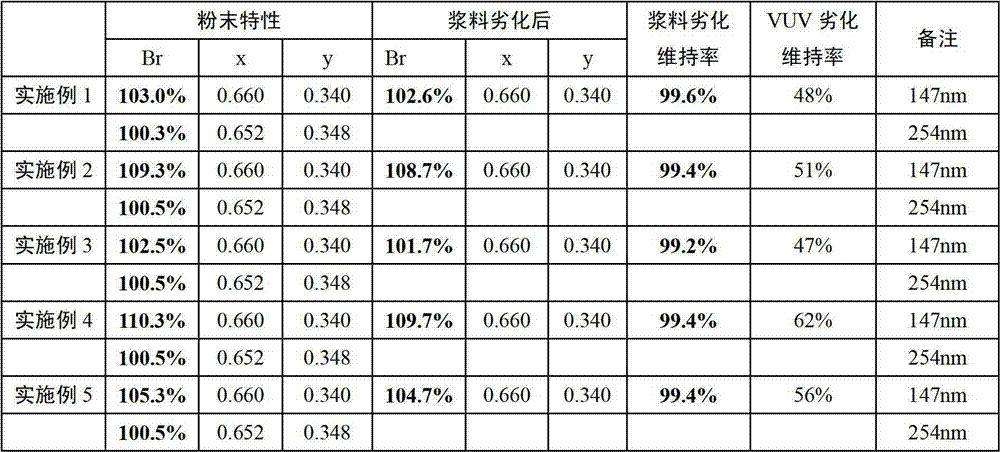

Examples

Embodiment 1

[0026] A kind of preparation method of yttrium oxide gadolinium europium red fluorescent powder for 3D PDP, comprises the following steps:

[0027] The first step, according to the chemical formula (Y 1-x-y Gd y , Eu x ) 2 o 3 For batching, in the chemical formula x=0.06, y=0.27, weigh yttrium oxide, gadolinium oxide and europium oxide respectively, dissolve them in nitric acid with a concentration of 10mol / L, and dilute to 4L to form a rare earth metal salt solution with a concentration of 0.5mol / L ;

[0028] Prepare 4L of oxalic acid solution, the concentration is 0.8mol / L, the pH value of the solution is between 3.0-3.5, heat the rare earth metal salt solution to 80°C while stirring, and add the oxalic acid solution to the rare earth metal salt solution to obtain rare earth metal oxalic acid Salt or carbonate precipitate, the precipitate is fully washed with hot deionized water to pH = 6-7, then the precipitate is filtered and separated, dried at 120°C for 16 hours, an...

Embodiment 2

[0034] A kind of preparation method of yttrium oxide gadolinium europium red fluorescent powder for 3D PDP, comprises the following steps:

[0035] The first step, according to the chemical formula (Y 1-x-y Gd y , Eu x ) 2 o 3For batching, in the chemical formula x=0.06, y=0.27, weigh yttrium oxide, gadolinium oxide and europium oxide respectively, dissolve them in nitric acid with a concentration of 10mol / L, and dilute to 4L to form a rare earth metal salt solution with a concentration of 0.5mol / L ;

[0036] Prepare 4L of oxalic acid solution, the concentration is 0.8mol / L, the pH value of the solution is between 3.0-3.5, heat the rare earth metal salt solution to 80°C while stirring, and add the oxalic acid solution to the rare earth metal salt solution to obtain rare earth metal oxalic acid Salt or carbonate precipitate, the precipitate is fully washed with hot deionized water to pH = 6-7, then the precipitate is filtered and separated, dried at 120°C for 16 hours, and...

Embodiment 3

[0042] A kind of preparation method of yttrium oxide gadolinium europium red fluorescent powder for 3D PDP, comprises the following steps:

[0043] The first step, according to the chemical formula (Y 1-x-y Gd y , Eu x ) 2 o 3 For batching, in the chemical formula x=0.06, y=0.27, weigh yttrium oxide, gadolinium oxide and europium oxide respectively, dissolve them in 10mol / L nitric acid, dilute to 4L to form a rare earth metal salt solution with a concentration of 0.5mol / L ;

[0044] Prepare 4L of oxalic acid solution, the concentration is 0.8mol / L, the pH value of the solution is between 3.0-3.5, heat the rare earth metal salt solution to 80°C while stirring, and add the oxalic acid solution to the rare earth metal salt solution to obtain rare earth metal oxalic acid Salt or carbonate precipitate, the precipitate is fully washed with hot deionized water to pH = 6-7, then the precipitate is filtered and separated, dried at 120°C for 16 hours, and roasted at 1000°C for 5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com