Preparation method and application of general magnetic adsorbent

A magnetic adsorbent and mineralizer technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as complex operation, multiple sets, and poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0051] Weigh 0.946g FeCl 3 ·6H 2 O and 0.346g MnCl 2 4H 2 O was dissolved in 18mL of ethylene glycol and 2mL of absolute ethanol, stirred evenly by magnetic force to form a clear solution, which was designated as solution A. Weigh 1.8g NaAc and add it to the above solution, stir magnetically to form a homogeneous solution and call it solution B, then weigh 0.4g NaAc 3 Cit·2H 2 O and 0.2 g D-Glucose were added to solution B, heated to 60 °C and magnetically stirred to form a homogeneous solution C. Finally, 20 mL of the obtained solution was poured into a 25 mL hydrothermal kettle lined with polytetrafluoroethylene, and reacted at 200° C. for 12 h. Centrifuge, wash and dry the reaction mixture for 6 hours under vacuum at 70°C to obtain MnFe 2 o 4 / C composite material sample 1-1. Under the protection of nitrogen, the heating rate is 5°C / min, keep at 450°C for 1.5h, and cool naturally to obtain MnFe that can be used for adsorption 2 o 4 / C Composite.

preparation Embodiment 2

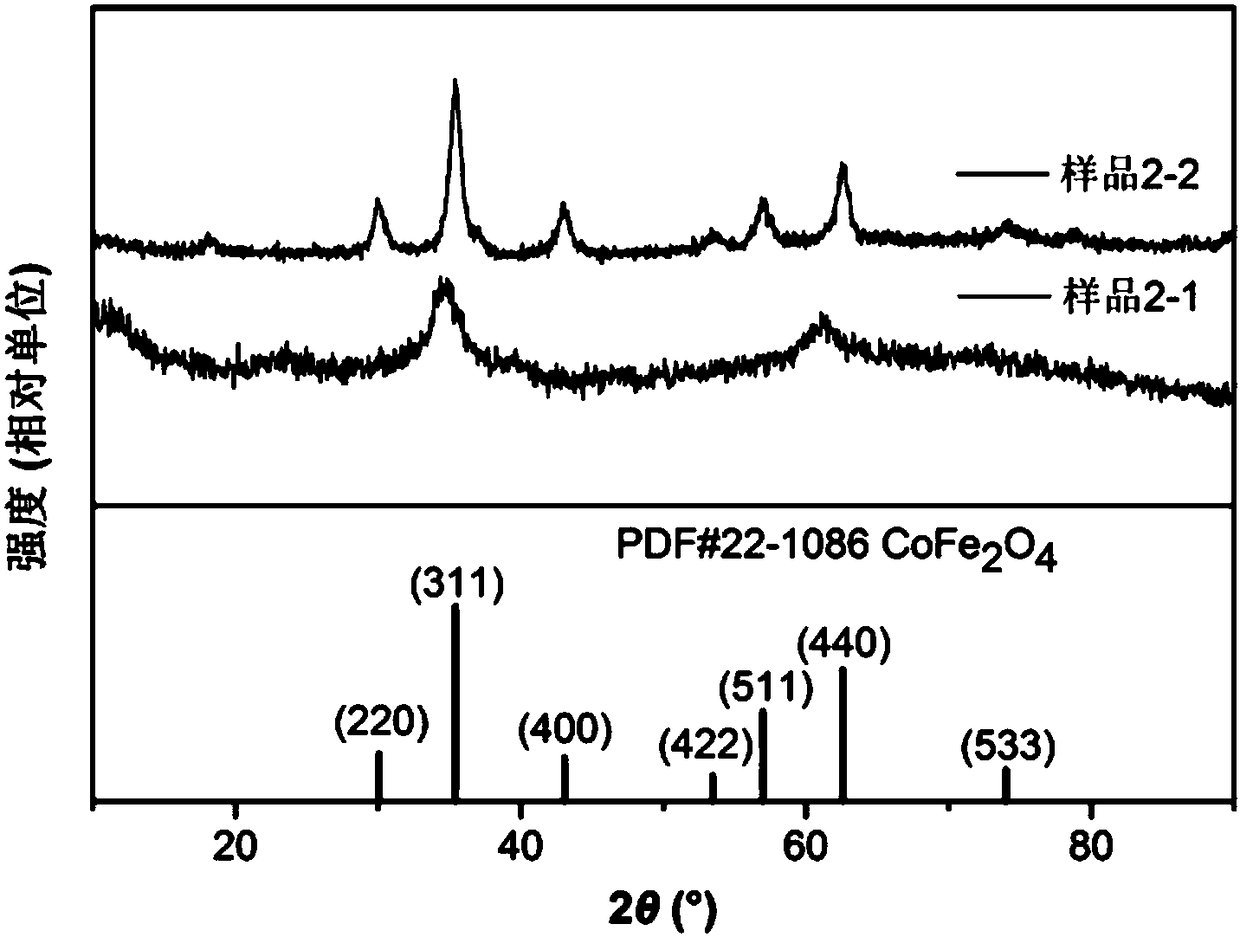

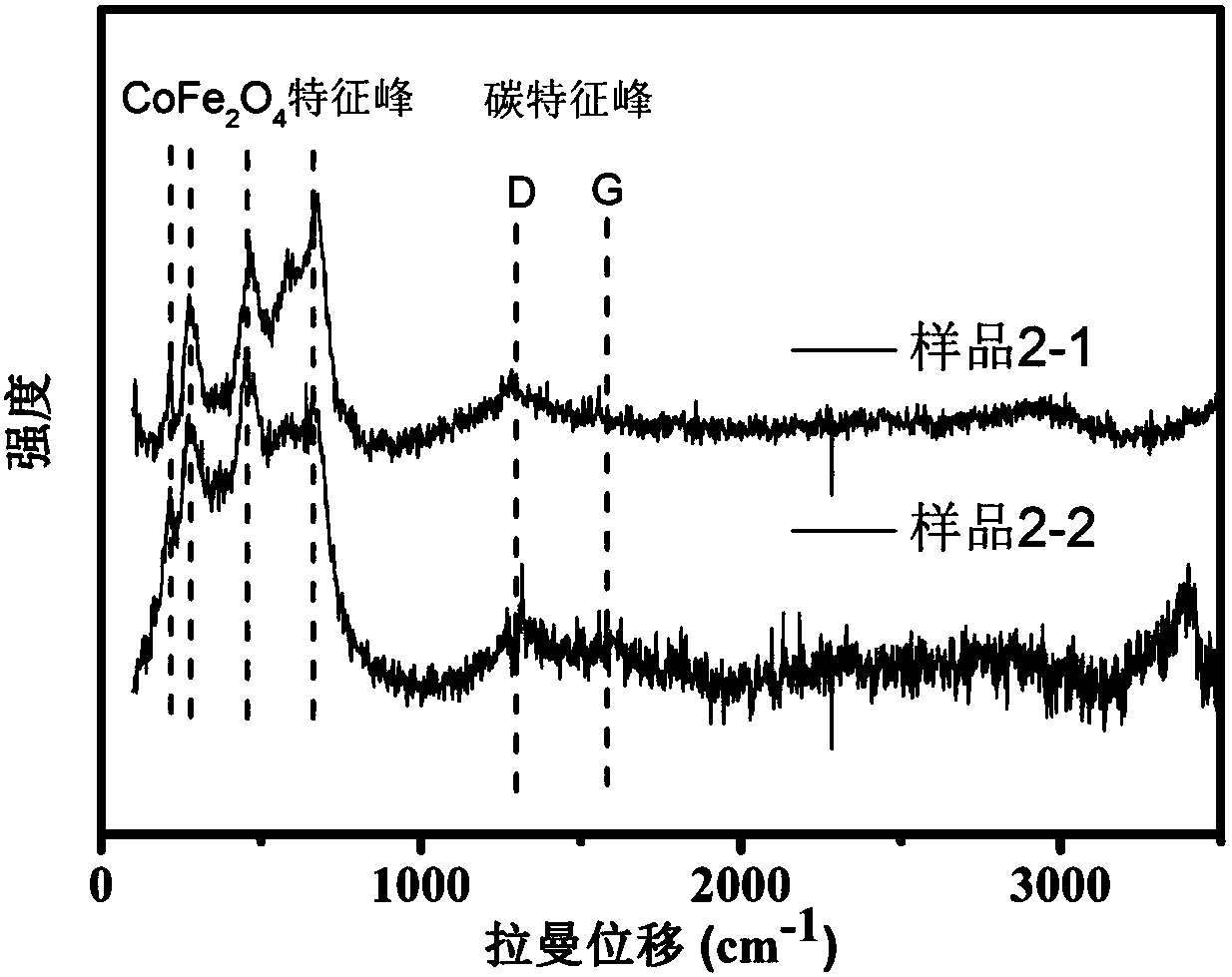

[0053] Weigh 0.946g FeCl 3 ·6H 2 O and 0.416g CoCl 2 4H 2 O was dissolved in 20 mL of ethylene glycol, stirred evenly by magnetic force to form a clear solution, which was designated as solution A. Weigh 1.8g NaAc and add it to the above solution, stir magnetically to form a homogeneous solution and call it solution B, then weigh 0.5g NaAc 3 Cit·2H 2 O and 0.180g D-Glucose were added to solution B, heated to 70°C and magnetically stirred to form a homogeneous solution C. Finally, the obtained solution was poured into a 30 mL hydrothermal kettle lined with polytetrafluoroethylene, and reacted at 200° C. for 16 h. Centrifuge, wash and dry the reaction mixture at 60°C for 12 hours under vacuum conditions to obtain CoFe 2 o4 / C composite material sample 2-1. Under the protection of nitrogen, the heating rate is 8°C / min, and the temperature is maintained at 500°C for 1 hour, and natural cooling is used to obtain CoFe that can be used for adsorption. 2 o 4 / C composite, des...

preparation Embodiment 3

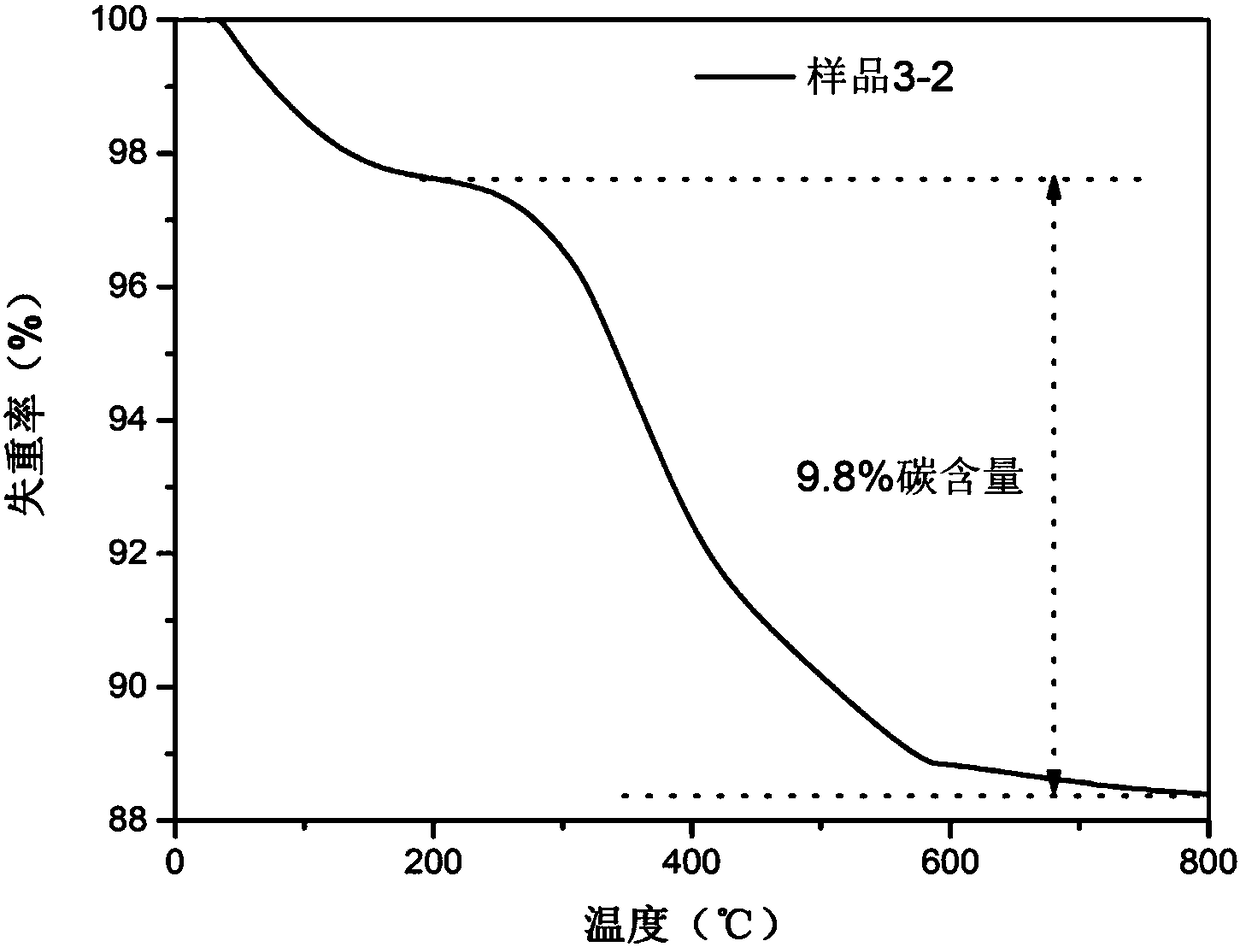

[0055] Weigh 0.946g FeCl 3 ·6H 2 O and 0.238g ZnCl 2 Dissolve in 18mL of ethylene glycol and 2mL of diethylene glycol mixture, and magnetically stir evenly to form a clear solution, which is designated as solution A. Weigh 1.8g NaAc and add it to the above solution, stir magnetically to form a homogeneous solution and call it solution B, then weigh 0.5g NaAc 3 Cit·2H 2 O, 0.2g D-Glucose and 0.1g starch were added to solution B, heated to 70°C and magnetically stirred to form a homogeneous solution C. Finally, the obtained solution was poured into a 25 mL hydrothermal kettle lined with polytetrafluoroethylene, and reacted at 200° C. for 14 h. Centrifuge, wash and dry the reaction mixture for 6 hours at 80°C under vacuum to obtain ZnFe 2 o 4 / C composite material sample 3-1. Under the protection of argon, the heating rate is 10°C / min, and the temperature is kept at 600°C for 1h, and the ZnFe that can be used for adsorption is obtained by natural cooling. 2 o 4 / C compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com