Patents

Literature

48 results about "Post washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

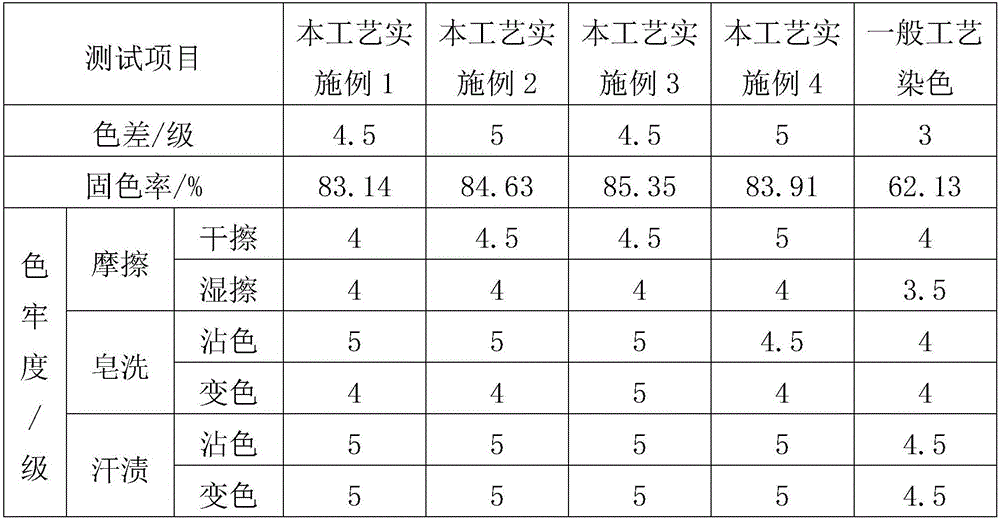

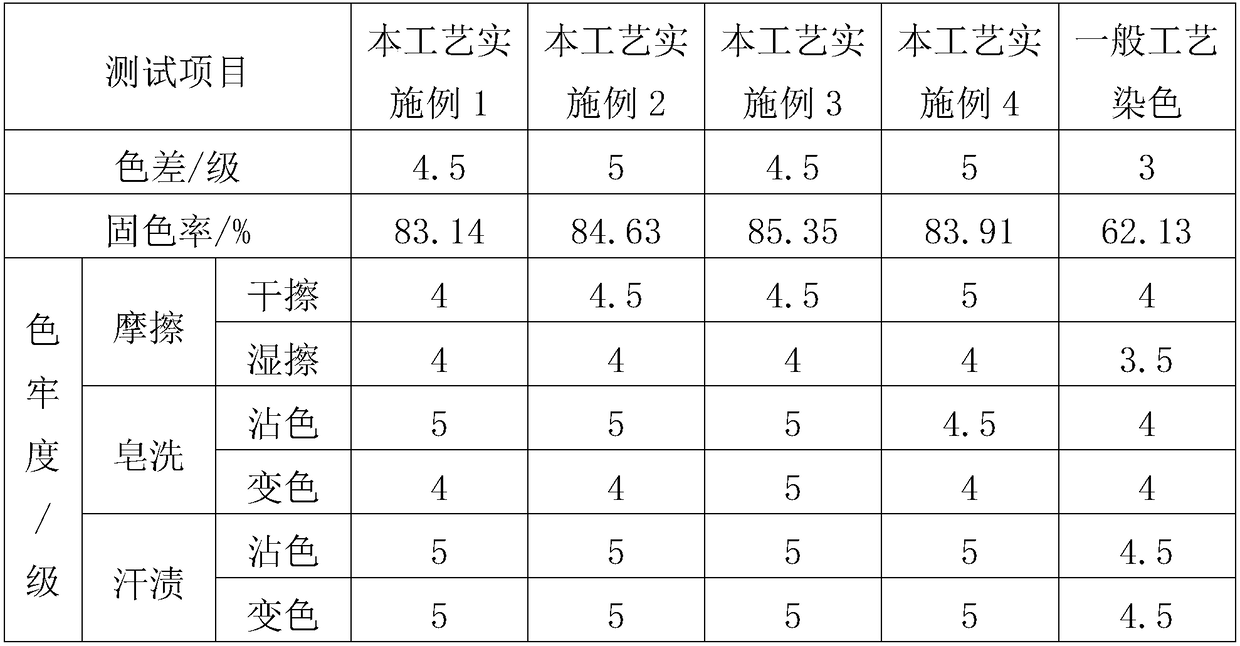

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Microcapsule preparing process utilizing waste beer yeast cell as wall material

InactiveCN1771916AReduce manufacturing costHigh embedding rateMicroballoon preparationMicrocapsulesYeastEmbedding rate

The present invention discloses process of preparing microcapsule with waste beer yeast cell as wall material. Waste beer yeast recovered from fermentation plant is prepared into microcapsule through the steps of washing, sieving, centrifuging, etc. to purify; vacuum drying or spray drying to obtain dry yeast grains of 0.5-2 size and water content of 2 %; adding capsule core material in 1-4 times the dry yeast mass and vibrating at 30-80 deg.c for 4-12 hr to make the capsule core material penetrate into yeast cell; washing and drying. The present invention has the advantages of low cost, high core material embedding rate, fast embedding, and simple post washing and drying.

Owner:TIANJIN UNIV

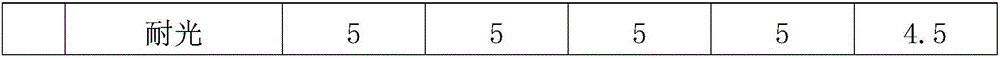

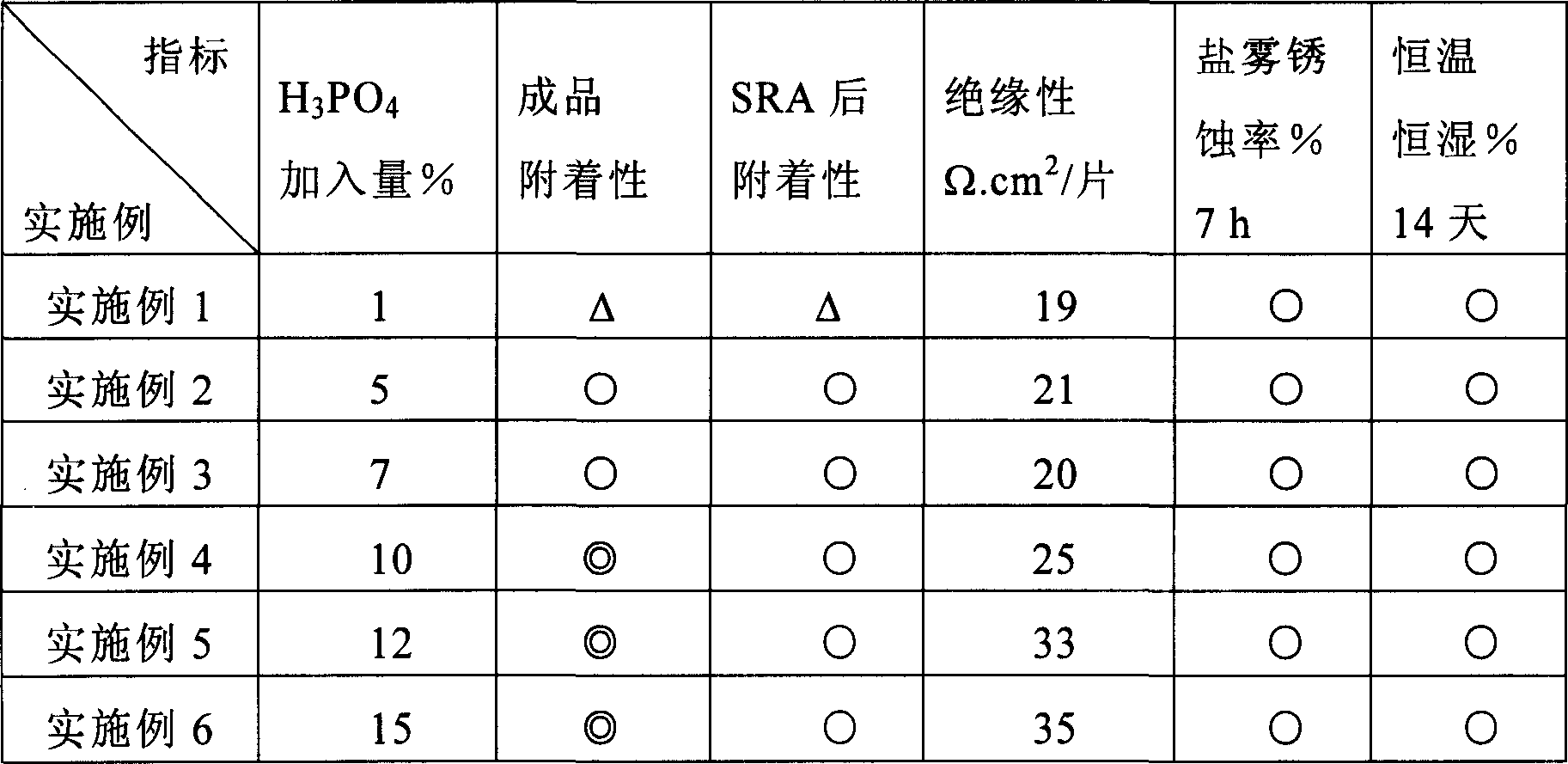

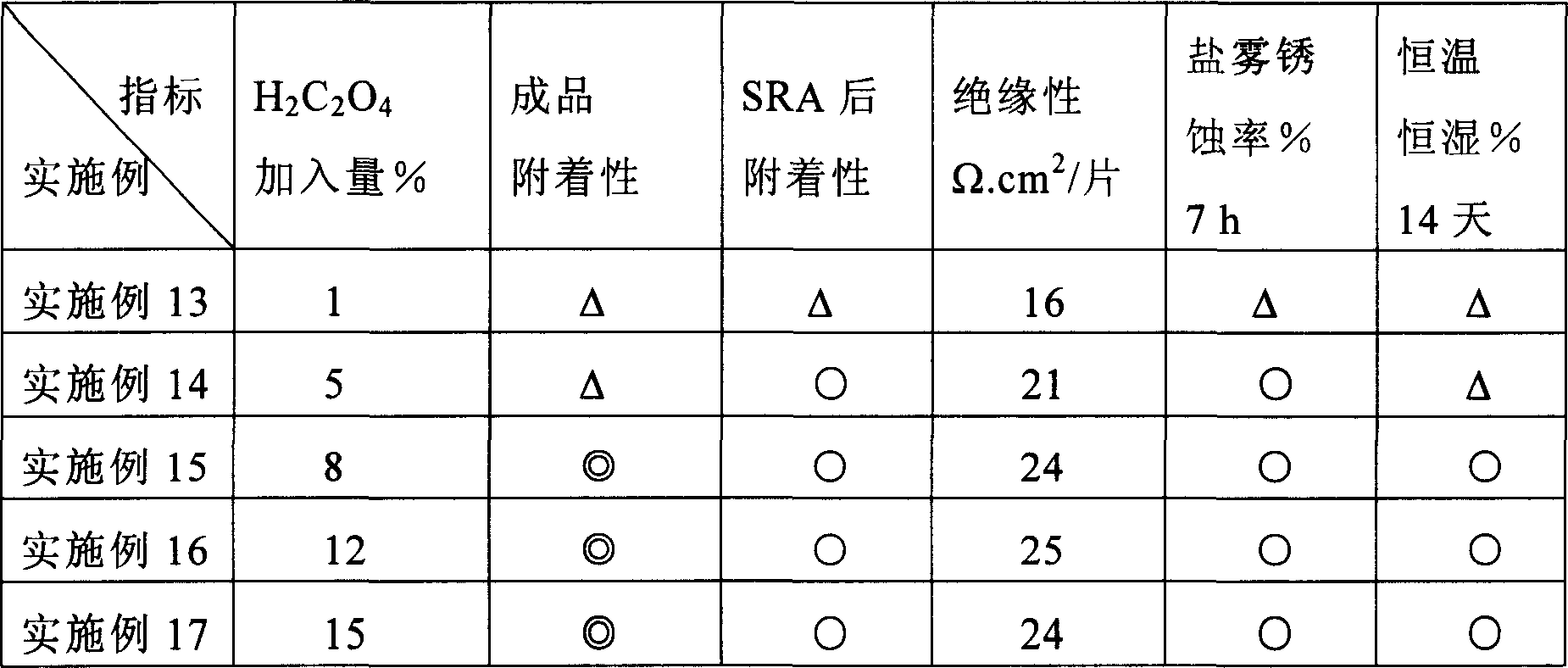

Method for producing non-orientation electric steel plates with insulation coatings

ActiveCN1903498AGood adhesionImprove bindingPretreated surfacesOther manufacturing equipments/toolsSheet steelElectrical steel

A technology for manufacturing the non-orientation electric steel sheet with coated insulating layer includes such steps as rolling, pre-washing, continuous annealing, acid washing, post-washing, coating, drying and winding.

Owner:BAOSHAN IRON & STEEL CO LTD

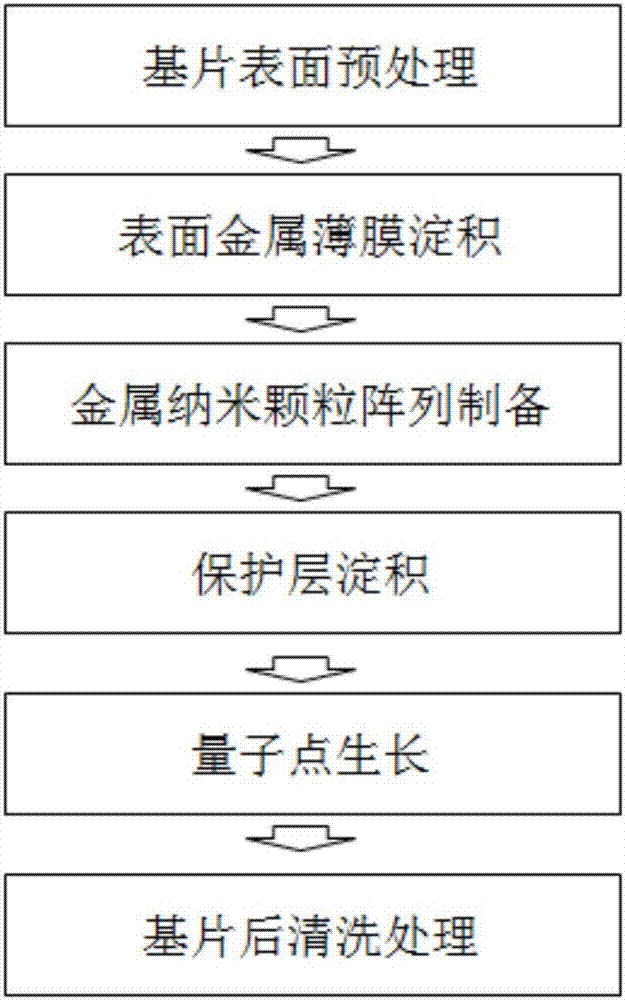

Controllable quantum dot array preparing method based on photo-thermal effect

ActiveCN107993923ASimple processNo damageMaterial nanotechnologySemiconductor/solid-state device manufacturingChemical synthesisThermal effect

The invention discloses a controllable quantum dot array preparing method based on the photo-thermal effect. According to the method, a metal or alloy nanoparticle array serves as a template, the reaction conditions of a quantum dot precursor are controlled through the local surface plasmon thermal effect irritated by a light source, and therefore the preparing site, size and nucleation density ofthe precursor is controlled. The method mainly includes the steps of preprocessing the surface of the substrate, conducting thin-film deposition on surface metal, preparing the metal nanoparticle array, depositing a protecting layer, growing the quantum dot and conducting post-washing on the substrate. The large-area low-cost quantum dot array is prepared through a chemical synthesis method. Themethod can be combined with a semiconductor processing technology, the prepared quantum dot array can be applied for machining and preparing a quantum dot laser device, a single photon light source, asolar cell, a high-efficiency light-emitting diode, a storage and other devices.

Owner:QINGDAO UNIV

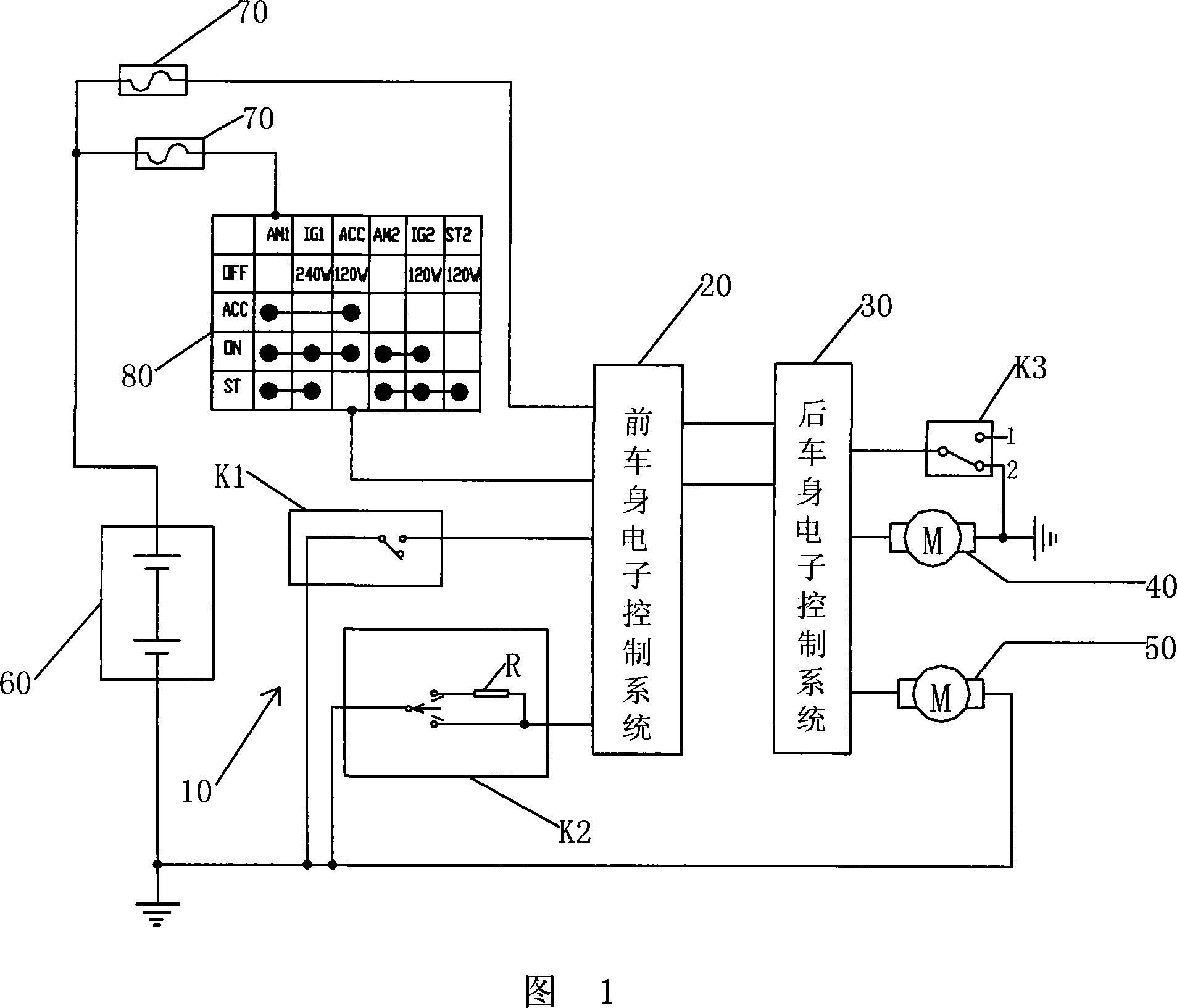

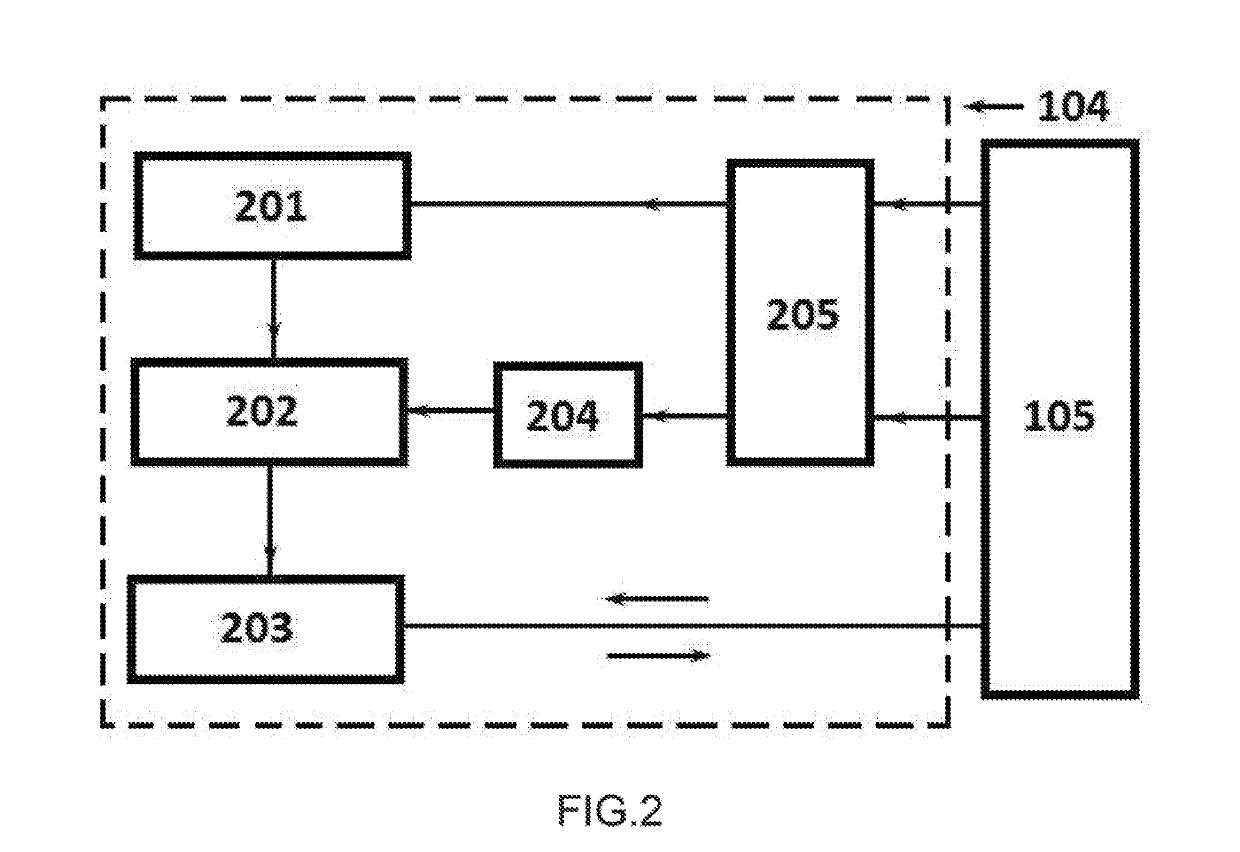

Back rain blowing controlled system

The invention relates to a post wiper control system which includes a control module composed of a switch. An electrical signal outputted by the control module is transmitted to a post wiper motor and / or a post washing motor through a bodywork electrical control system. The invention has the advantages that the invention improves circuit design, simplifies operation steps and meets the comfort requirements of the driver due to the combination of the control module and the bodywork electrical control system to realize the wiping and washing function. In addition, due to the adoption of the bodywork electrical control system, the number of connection wires and electric components is reduced, the space of the entire automobile is saved and the manufacturing, price of the entire automobile is reduced. Meanwhile, by adopting communication diagnosis of the bodywork electrical control system to deal with malfunction, the convenience of maintenance is increased.

Owner:CHERY AUTOMOBILE CO LTD

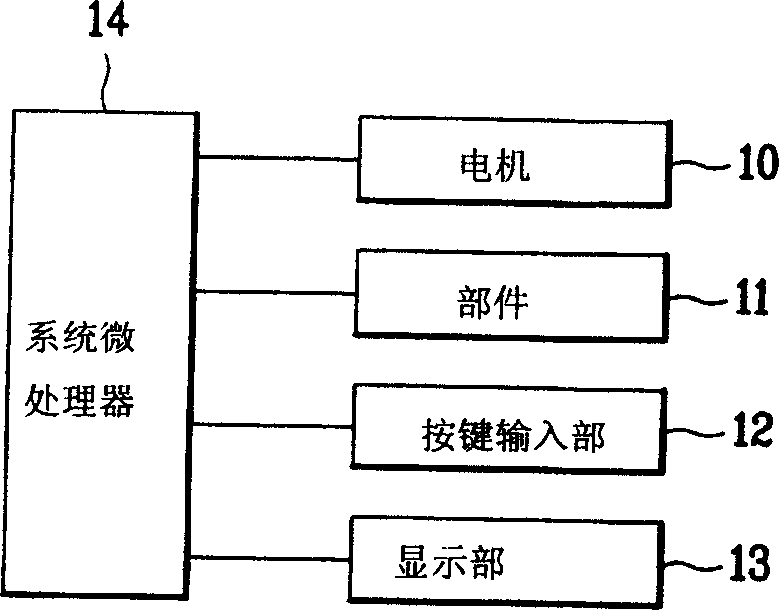

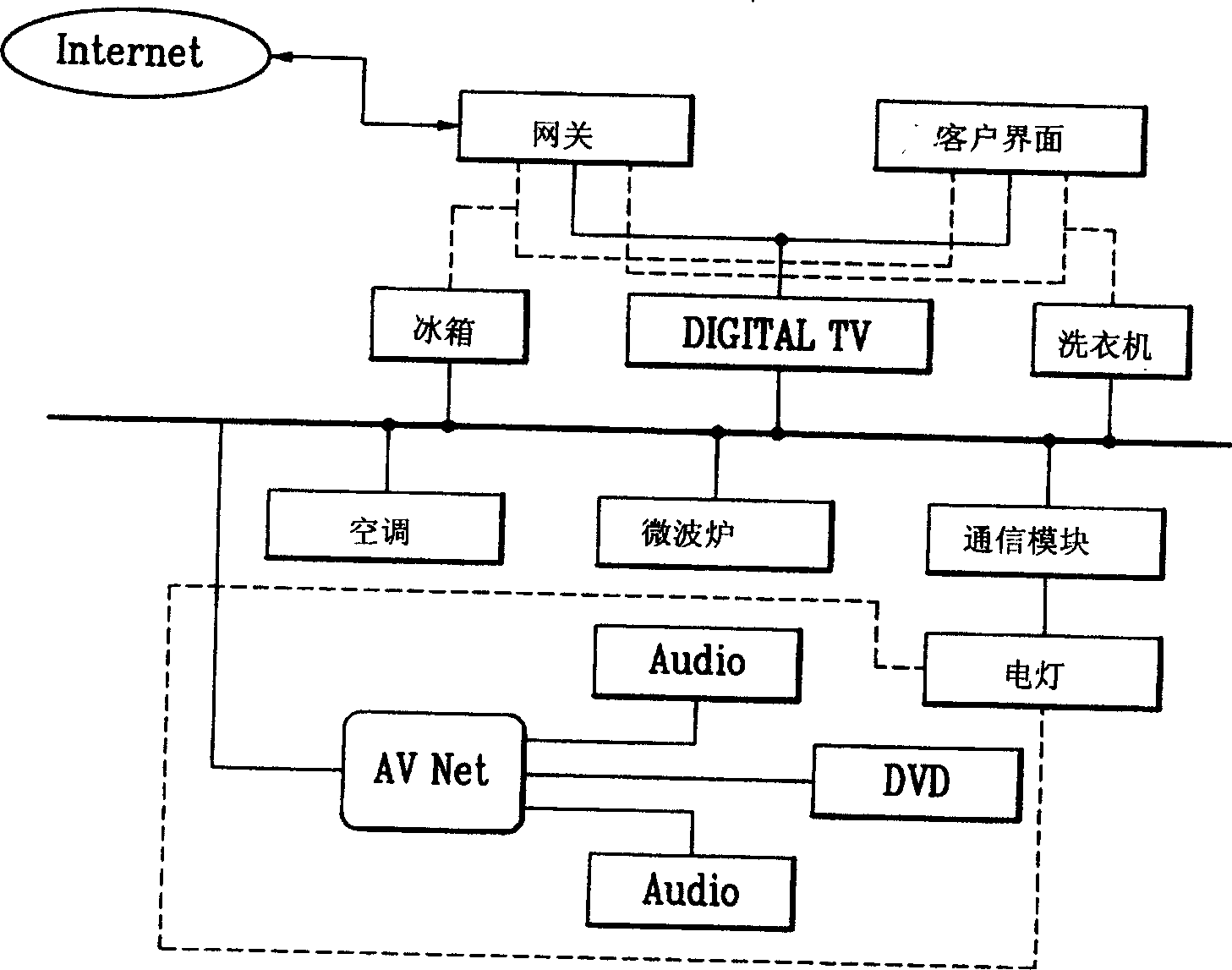

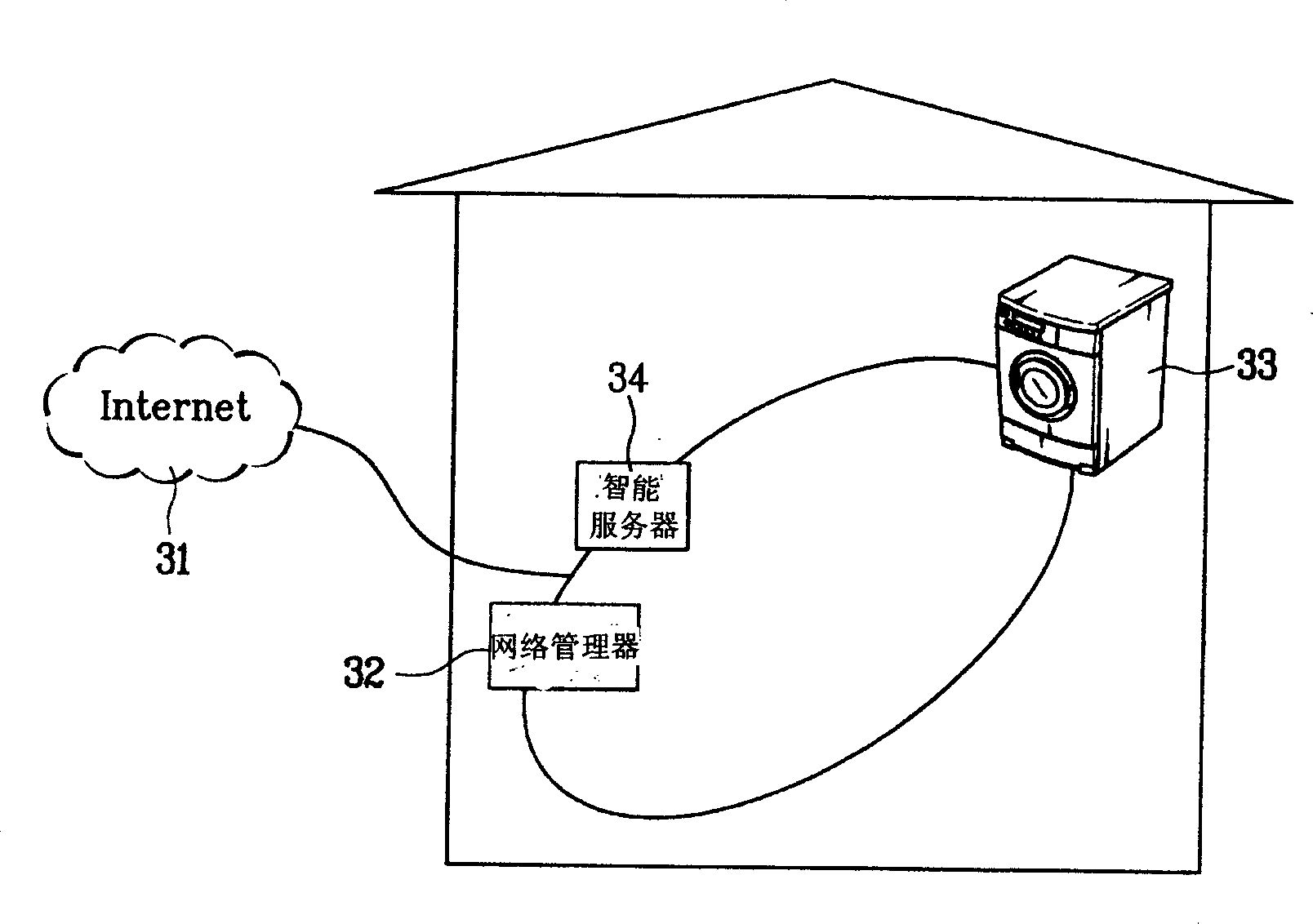

Washing machine control method using intelligent server

InactiveCN1749465AAvoid damageSmart service appropriateControl devices for washing apparatusTextiles and paperMachine controlPost washing

The washing machine control method using intelligent server includes the following stags: the stage for the intelligent server to send request for judging whether to have washed matter inside the washing tub and measuring humidity after the first setting time following the washing operation; the stage for the intelligent server to send washed matter setting information and inquiring information to the user and to inquire whether to have post-treatment based on the measured humidity; and the stage for the intelligent server to send order for the washing machine to complete the post washed matter protecting measures based on the response information from the user and to transmit the said result to the user. The present invention can perform communication for the intelligent server to control the post-washing operation of washing machine.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

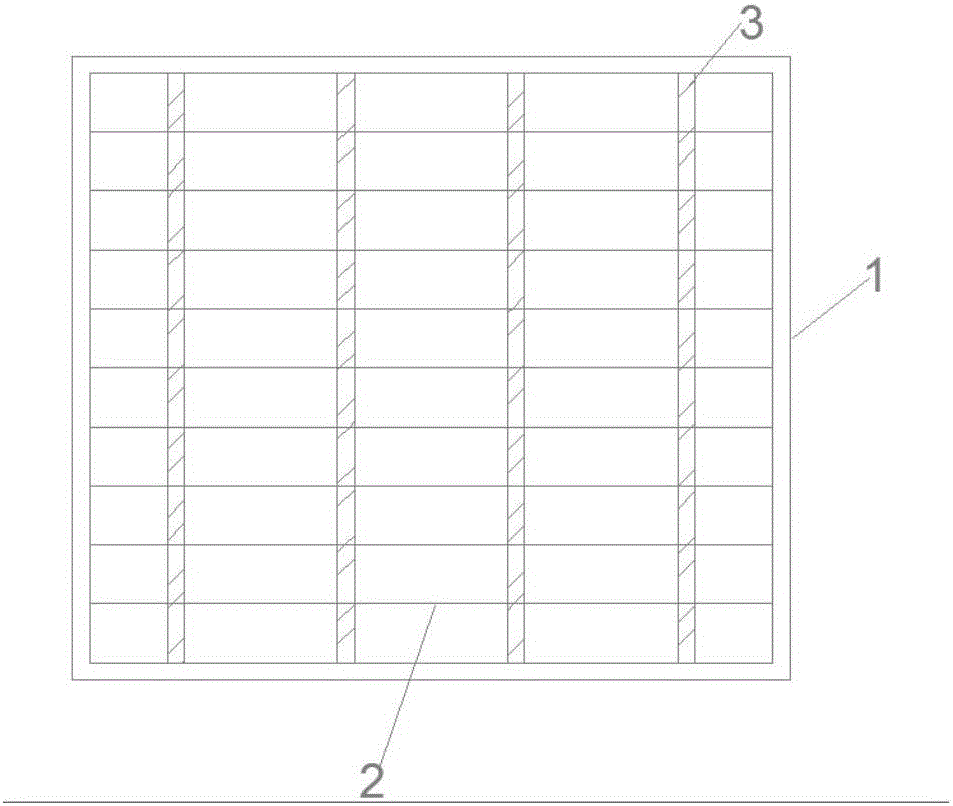

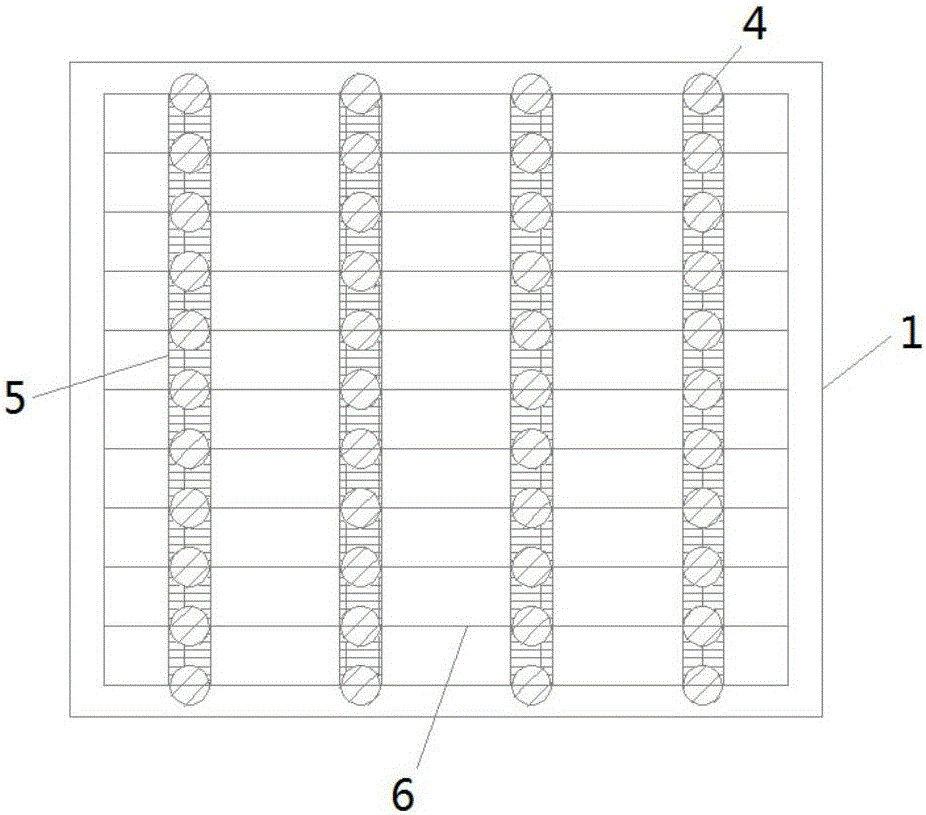

Main grid electrode structure of solar cell and preparation method thereof

ActiveCN105702759AIncrease aspect ratioReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesSilver pasteScreen printing

The invention belongs to the technical field of a solar cell, and particularly relates to a main grid electrode structure of a solar cell and a preparation method thereof. A positive electrode comprises a thin grid silver electrode; metal wires are printed on the metallized thin grid silver electrode; and the metal wires are connected with the silver electrode by adhering points. The preparation method comprises the steps of: by adopting a silk-screen printing process, printing the thin grid silver electrode on the positive surface of a P-type silicon matrix processed by processes of texturing, diffusion, post washing, coating and printing of a back field of a back electrode; and then printing a metal wire main grid electrode on the surface of the metallized silver electrode, wherein the metal wires are connected with the silver electrode together by the adhering points. The main grid electrode structure for the solar cell and the preparation method thereof, which are disclosed by the invention, have the advantages that a copper electrode replaces a positive main grid silver electrode so as to reduce the use quantity of the silver electrode of the positive electrode of the silicon solar cell, thereby reducing production cost of the silicon solar cell; and additionally, the copper electrode is used for replacing burn-through silver paste so as to reduce breakage and replacement of a passive film, improve surface passivation efficiency and improve cell efficiency.

Owner:TAIZHOU LERRISOLAR TECH CO LTD

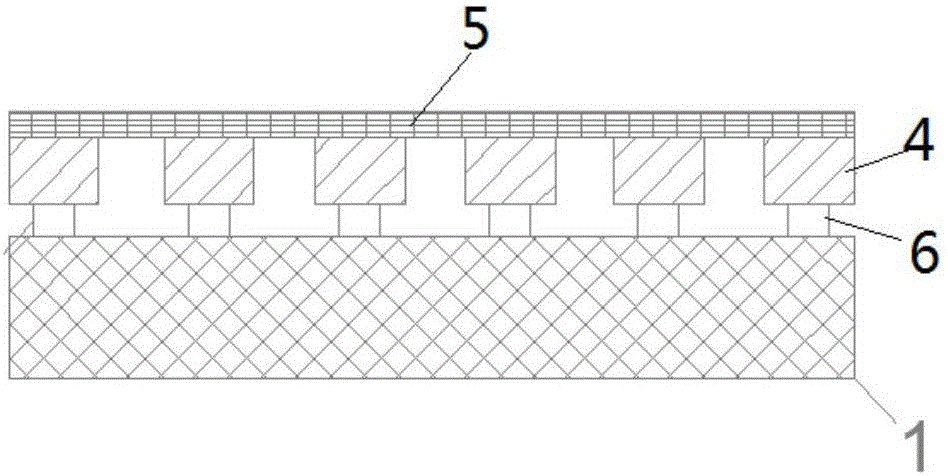

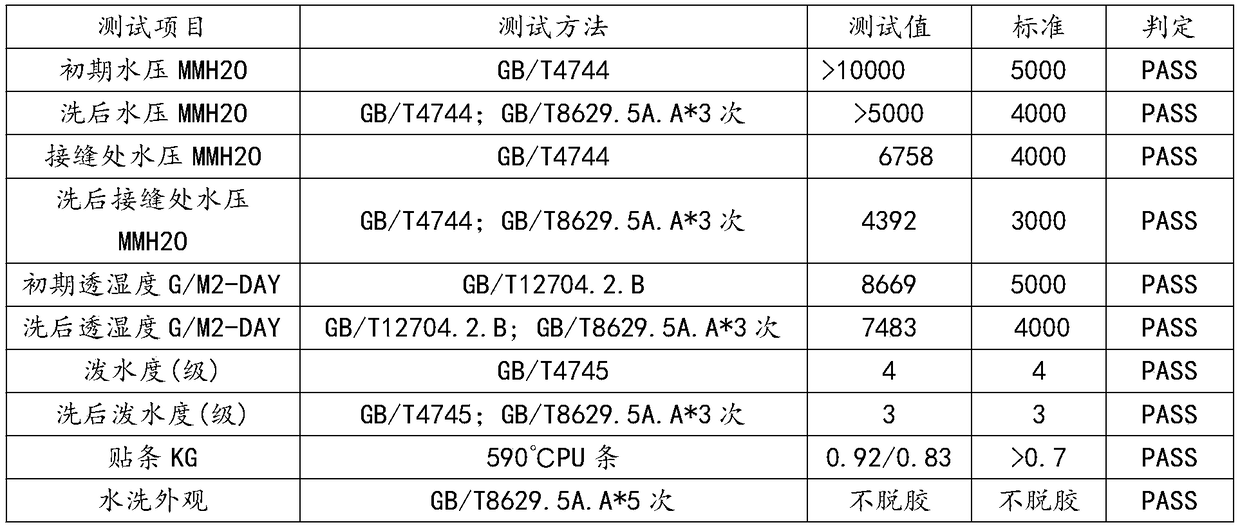

Fabric composite process

ActiveCN109203628AImprove technical gapsIncrease surface tensionFibre typesLaminationPore water pressureNational standard

The invention discloses a fabric composite process comprising the following technological steps: 1) billet adding; 2) desizing; 3) dyeing; 4) drying; 5) press polishing; 6) compositing: compositing afabric with a PU thin film; and 7) single-side water splashing, wherein a formula of a water splashing auxiliary agent comprises 80-100 g / L of an IPA penetrating agent, 7-10 g / L of a bridging agent, 4-6 g / L of a softener, and 90-100 g / L of a water splashing agent; and the water splashing auxiliary agent is splashed to the fabric by a single splashing machine. The fabric composite process innovatively adopts the process of firstly press polishing, then compositing and finally single-face water splashing for operation, and the penetration work of a glue to the fabric surface is ensured, so as toachieve more washability and better connection adhesion; the problems of nylon composite fabrics, such as poor connection adhesion, serious dropping of water pressure after washing and insufficient vehicle sewing water pressure after washing, can be effectively solved, high requirements for fabrics on post-washing performance are facilitated, the performance of interchange jacket products is effectively improved, and the first-class national standard of interchange jackets is met.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH

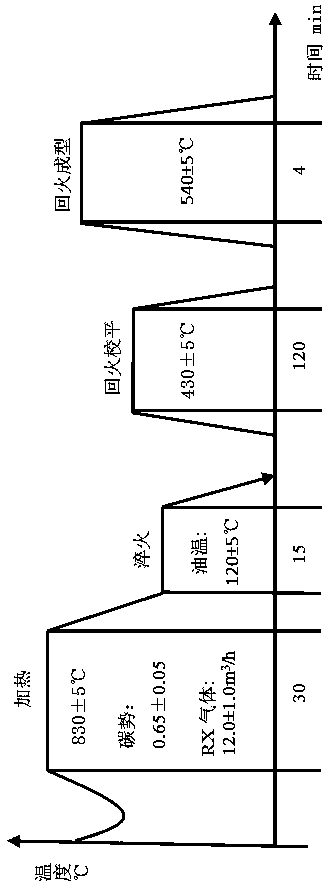

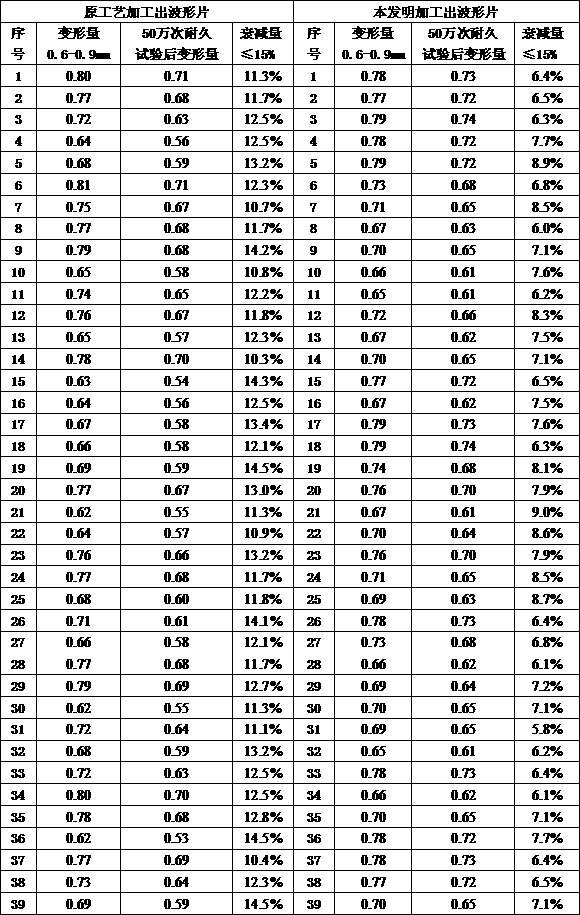

Overall waveform piece machining technology for automobile clutch

The invention relates to an overall waveform piece machining technology for an automobile clutch, and belongs to the technical field of clutch machining. The overall waveform piece machining technology comprises the steps that a 65 Mn steel belt in the spheroidizing annealing state is prepared, and procedures including punching, necking, center hole punching and blanking are carried out; overall waveform piece quenching is carried out, wherein feeding washing, quenching and post washing are carried out; and tempering leveling, tempering molding and anti-rusting treatment are carried out. The overall waveform piece machining technology has the beneficial effects that eight waveforms are formed on a circumference of an overall waveform piece, and the mold height can meet the requirement forcoincidence. Compared with an overall waveform piece machined through original technology by means of axial compression endurance tests, the fatigue decrement is reduced.

Owner:CHANGCHUN YIDONG CLUTCH

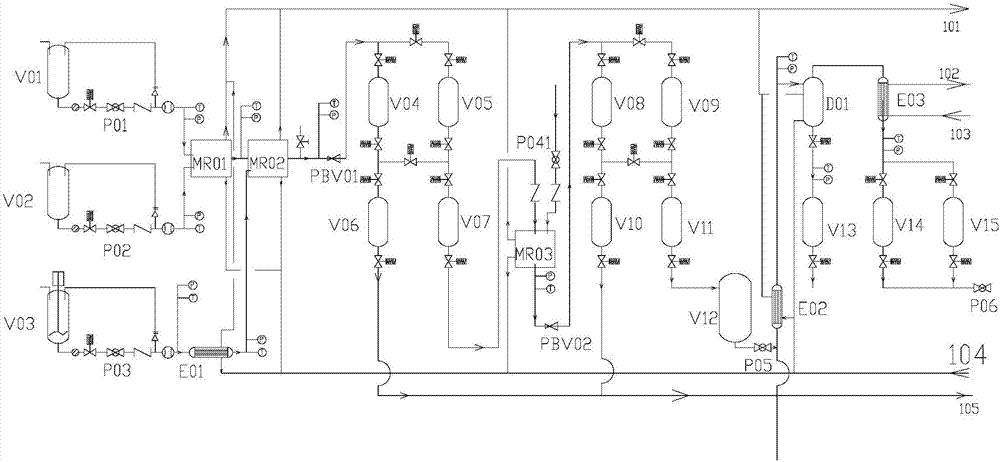

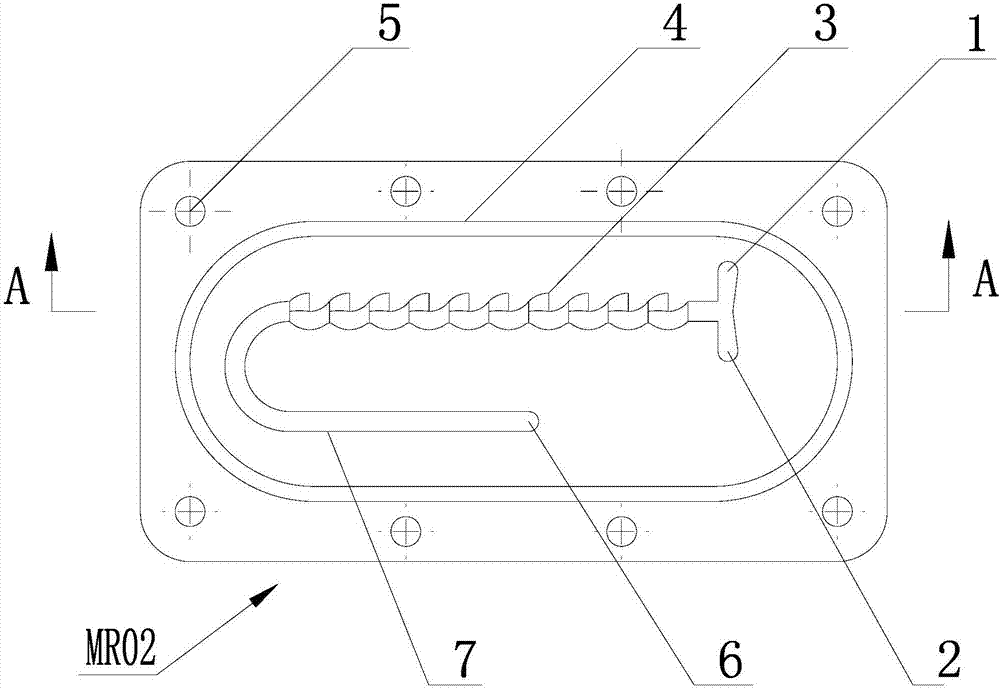

System for producing 2,3,5,6-4-methoxymethyl-tetrafluorobenzyl alcohol

PendingCN107089904AReduce volumeEasy to operateChemical/physical/physico-chemical microreactorsEther preparation by ester reactionsReaction rateBENZYL ALCOHOL/WATER

The invention relates to a system for producing 2,3,5,6-4-methoxymethyl-tetrafluorobenzyl alcohol, which comprises a toluene material storage tank, a dimethyl sulfate material storage tank, a diol-alkali aqueous solution storage tank, a first heat exchanger, a mixer, a microchannel reactor, a first-stage layering tank group, a second-stage layering tank group, a washing mixer, a post-washing reaction liquid receiving tank, a second heat exchanger, a continuous desolventizer, a methylbenzene recovery tank, and a final product tank. A preparation process includes the following steps: a diol-alkali aqueous solution is prepared for later use; the diol-alkali aqueous solution is heated, dimethyl sulfate and toluene are mixed and heated, the diol-alkali aqueous solution and the dimethyl sulfate-toluene solution simultaneously enter the reactor and are mixed to react, reaction liquid undergoes layering and washing treatment, the washed reaction liquid is distilled to recover the toluene, and thereby crude benzyl alcohol is obtained. Continuous production is realized, the reaction rate is higher than the conventional reaction rate, the reaction time is short, the efficiency of production is high, the production of the byproduct diether is reduced, production yield is increased, and consumption in production is reduced.

Owner:中山致安化工科技有限公司

Production method of basic cobalt carbonate

InactiveCN106830103AEasy to operateRapid productionCobalt carbonatesSodium ascorbateReaction temperature

The invention discloses a production method of basic cobalt carbonate. The method realizes efficient pollution-free production of basic cobalt carbonate. The production method comprises the following steps of: a, preparing a Na2CO3 solution; b, synthesizing; c, ageing; d, performing primary filter pressing and washing; e, performing secondary filter pressing and washing; and f, drying. The method is simple in technical process and can be used for quickly producing basic cobalt carbonate; meanwhile, the product quality can be adjusted well by controlling the stirring speed, the reaction temperature and the adding speed of cobalt chloride, an effect of uniform particles is achieved, and the content of cobalt can reach 52%; meanwhile, an additive, namely sodium ascorbate, is added into washing water during reaction to prevent oxidization of the product and is easy for filter pressing; and moreover, the content of impurities in the product is reduced by washing the product with deionized water for many times, and post-washing water can be recycled if being treated. Therefore, the whole production flow is simple in operation and low in cost, the production efficiency is increased while the labor intensity is lowered, and moreover, the method is free of environmental pollution and can be used for large-area popularization.

Owner:赣州逸豪优美科实业有限公司

Method of preparing vanadium pentoxide by using vanadium-containing solution

The invention discloses a method of preparing vanadium pentoxide by using a vanadium-containing solution. The method is characterized in that the method consists of the following steps: a pH value of the vanadium-containing solution is adjusted, magnesium chloride and calcium chloride are added, solid-liquid separation is carried out and silicon-phosphorus residues and a solution are obtained; multistage countercurrent extraction is carried out and a load organic phase and a raffinate phase are obtained; a sodium-containing back-extractant and the load organic phase carry out primary washing, and post-washing liquid and a post-washing organic phase are obtained; and an ammonium-containing back-extractant and the post-washing organic phase carry out primary reextraction, and ammonium-containing vanadium-rich liquid and a half-load organic phase are obtained; the post-washing liquid and the half-load organic phase carry out countercurrent reextraction for many times, and sodium-containing vanadium-rich liquid and a no-load organic phase are obtained; pH values of the ammonium-containing vanadium-rich liquid and the sodium-containing vanadium-rich liquid are adjusted, NH4Cl is added, the solid-liquid separation is carried out and ammonium metavanadate is obtained, and ammonium metavanadate is calcined and then vanadium pentoxide with the grade being greater than or equal to 99.5% and vanadium pentoxide with the grade being 99.9% are obtained. The production operation is simple and feasible, the cost is low, and a recovery rate and the purity are high.

Owner:广东省资源综合利用研究所

Emulsion fabric decontaminating aerosol

InactiveCN101643689AReduce contentEmission reductionOrganic detergent compounding agentsNon-ionic surface-active compoundsAlkaneLaundry

The invention relates to an emulsion fabric decontaminating aerosol, which is particularly suitable for locally decontaminating fabric in the laundry industry and households. The emulsion fabric decontaminating aerosol comprises the following compositions in percentage by weight: a) 5 to 20 percent of nonionic surfactant comprising an alkyl alcohol epoxyethane surfactant and an alkyl phenol epoxyethane surfactant, b) 0.05 to 5 percent of one or more fluorin-containing nonionic surfactants, c) 30 to 40 percent of alkane derived solution, d) 0.1 to 2 percent of defoamer, mainly silicone defoamer, e) 0.1 to 1 percent of compound antirust inhibitor, f) 10 to 30 percent of propane-butane propellant, and g) 30 to 45 percent of water. The emulsion fabric decontaminating aerosol is an emulsifyingsystem product, successfully reduces the content of volatile solvent contained in the product by 30 to 40 percent, reduces the emission of harmful gases, makes post washing treatment easy, reduces consumption of the propellant, reduces resource consumption, and has good economic and social benefits compared with solvent products.

Owner:上海白猫专用化学品有限公司

Protective coating for surface of stainless steel plate and protecting method for stainless steel surface

The invention relates to a protective coating for the surface of a stainless steel plate and a protecting method for the stainless steel surface. The protective coating for the surface of the stainless steel plate comprises 1 to 2 parts of chalk powder and 1 to 3 parts of emulsion paint. The invention provides the temporary protective coating for the surface of the stainless steel plate, which has a simple formula, obvious protection effect and low cost, can effectively reduce labour intensity and difficulties in post washing, acid cleaning and passivation, and is easy to remove. The invention also provides the protective coating-based protecting method.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

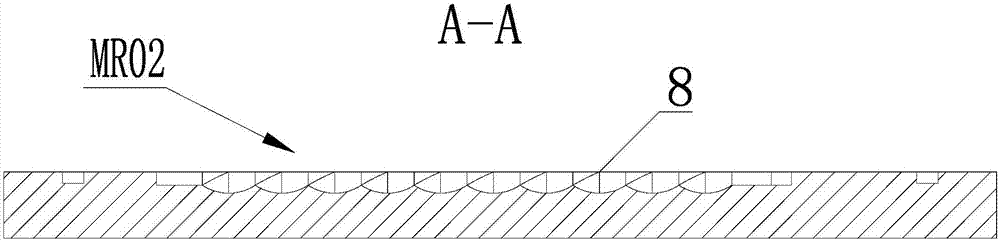

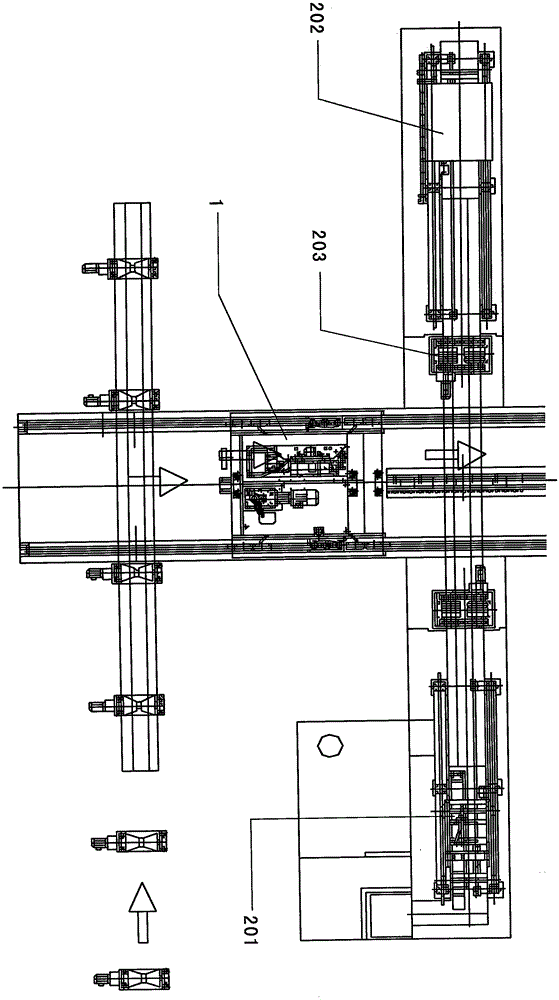

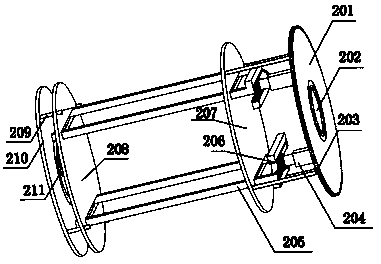

Overall-length diameter-expanding unit for medium-diameter submerged-arc welding pipe

ActiveCN105290242AGuarantee the expansion qualityGuaranteed flushing qualityHollow article cleaningMobile vehiclePre washing

The invention discloses an overall-length diameter-expanding unit for a medium-diameter submerged-arc welding pipe. The overall-length diameter-expanding unit for the medium-diameter submerged-arc welding pipe comprises a diameter-expanding unit body. The diameter-expanding unit body is composed of a steel pipe inlet transverse movement vehicle, a pre-washing station, a diameter expanding station, a post-washing station and a steel pipe outlet transverse moving vehicle. Meanwhile, an independent water way system, a lubricating system, a hydraulic system and an electric system are further arranged. The overall diameter-expanding unit conducts pre-washing, diameter-expanding and post-washing of the inner wall of the steel pipe and steel pipe transferring through electric, hydraulic and mechanical linkage, the diameter-expanding quality, the washing quality and the production efficiency are guaranteed, and a guarantee is provided for later processes.

Owner:SUNYO S&T CO LTD

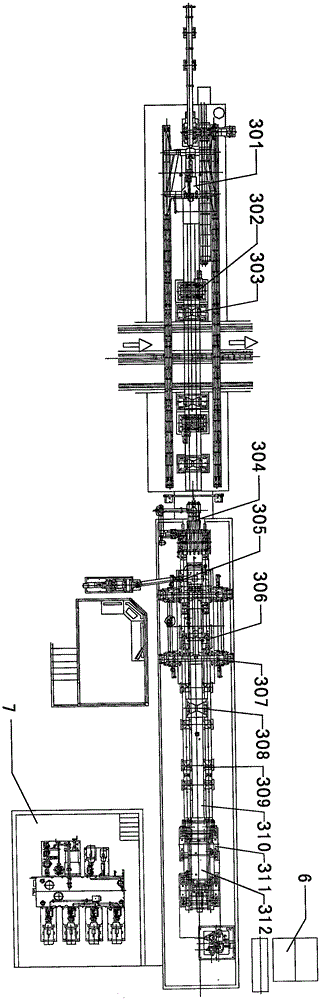

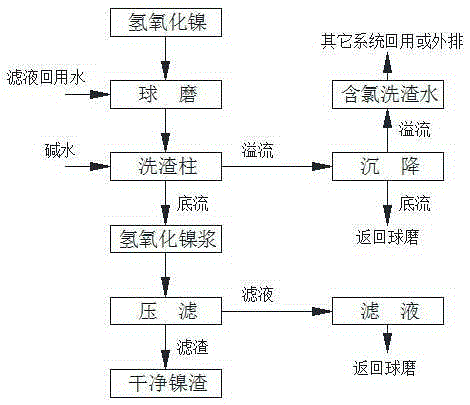

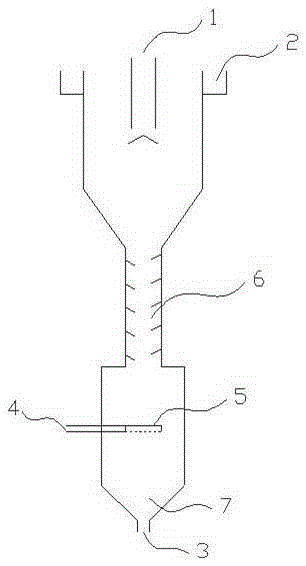

New method for washing chlorine of nickelous hydroxide

InactiveCN105274333AVersatilitySimplify the slag washing processProcess efficiency improvementAlkaline waterSulfate

The invention discloses a new method for washing chlorine of nickelous hydroxide and related equipment of the new method. The method and equipment are used for continuous washing of the nickelous hydroxide and other solid slag. The equipment is cylindrical, a to-be-washed material inlet and a post-washing water overflow outlet are formed in the upper end of the equipment, and a washed material outlet and a washing water inlet are formed in the lower end of the equipment. Materials flow downwards, washing water flows upwards, and then continuous backwashing is achieved. According to the method, the solid nickelous hydroxide is ground and pulpified to be pumped into the to-be-washed material inlet of the slag washing equipment, and meanwhile alkaline water is pumped into the washing water inlet for slag washing. In the existing nickel wet metallurgy, the influence of the electrodeposition of chlorine on nickel sulfate is very large, chlorine can be generated and pollute the environment, and a pole plate can be corroded. Thus, chlorine washing treatment needs to be carried out on the nickelous hydroxide of a finished product with high chlorine content in the front section. According to the new method, the input expense of the equipment can be reduced, the slag washing water amount is reduced, and cost is reduced; and the slag washing effect can be improved, and the nickel-chlorine ratio is increased.

Owner:夏栋

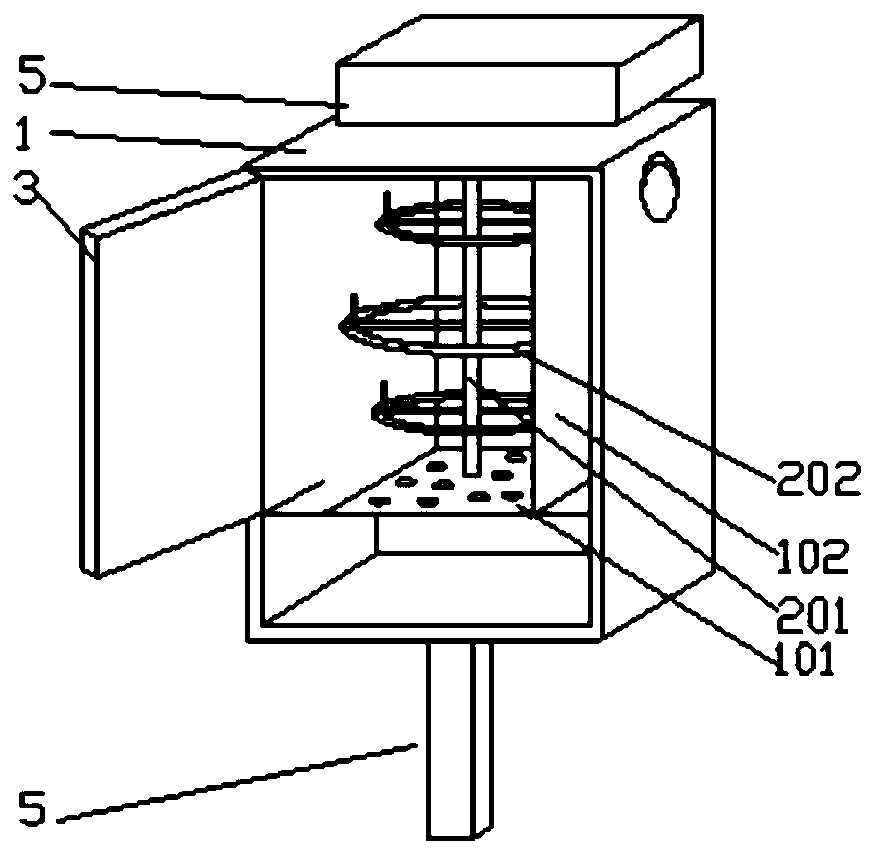

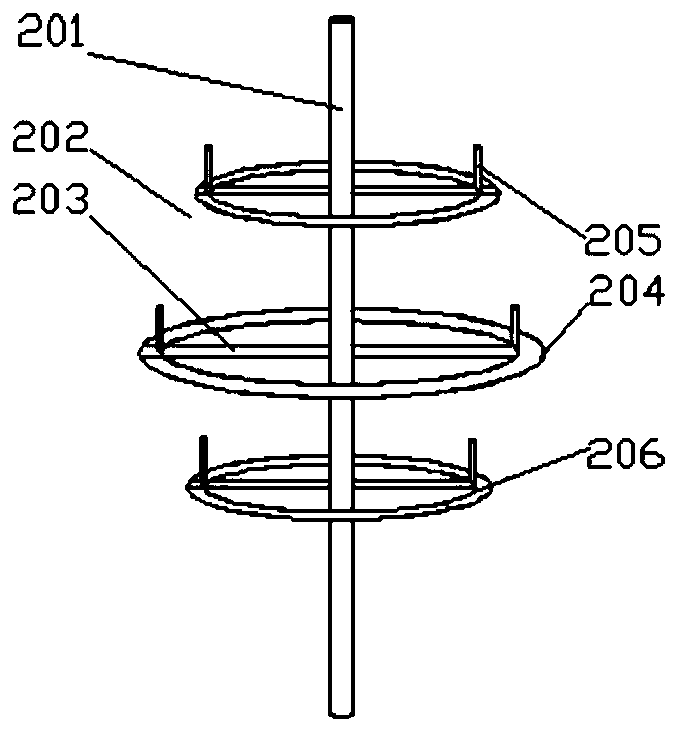

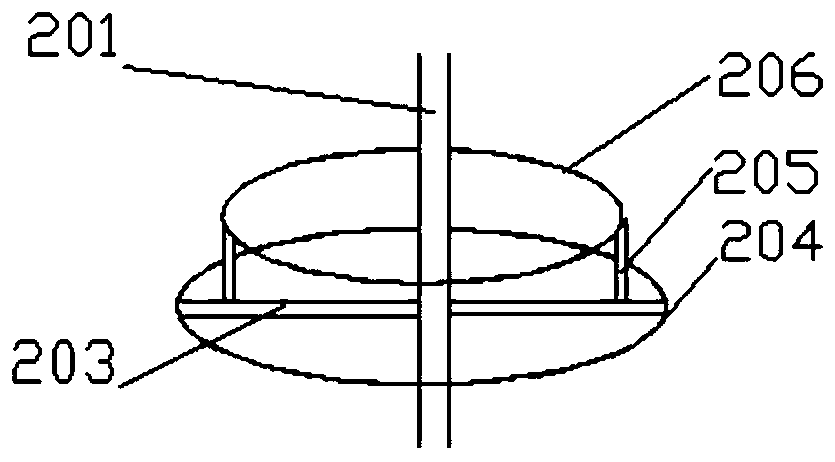

Garment cleaning apparatus with air washing function

ActiveCN110055715AImprove cleanlinessPracticalMechanical cleaningPressure cleaningPost washingMechanical engineering

The invention discloses a garment cleaning apparatus with an air washing function, comprising a housing, a first partition, a second partition, a rotating mechanism and a cover; the first partition divides the housing into an upper space and a lower space; garments in the upper space are separated from water in the lower space, so that the garments are prevented from being wet by the water in thelower space after drying; the rotating mechanism is arranged in the first space and comprises a first rotating shaft and a plurality of ring units; the first rotating shaft drives the ring units to rotate such that the garments are hung to the ring units cycle and are brought to full contact with water and cleaned by friction; during rotating, the garments are spread apart, so that the post-washing airing issue is avoided; any one of the ring units limits the garments between an inner ring and an outer ring, so that the knotting problem of the garments during washing is avoided. The garment cleaning apparatus herein is simple in structure and good in practicality and has good market prospect.

Owner:BEIHAI HUAYUAN ELECTRON CO LTD

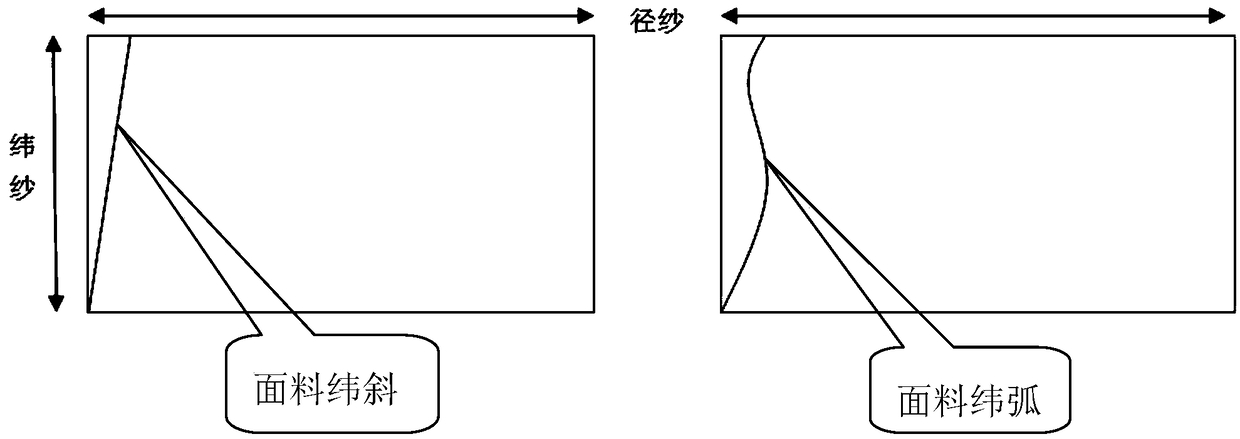

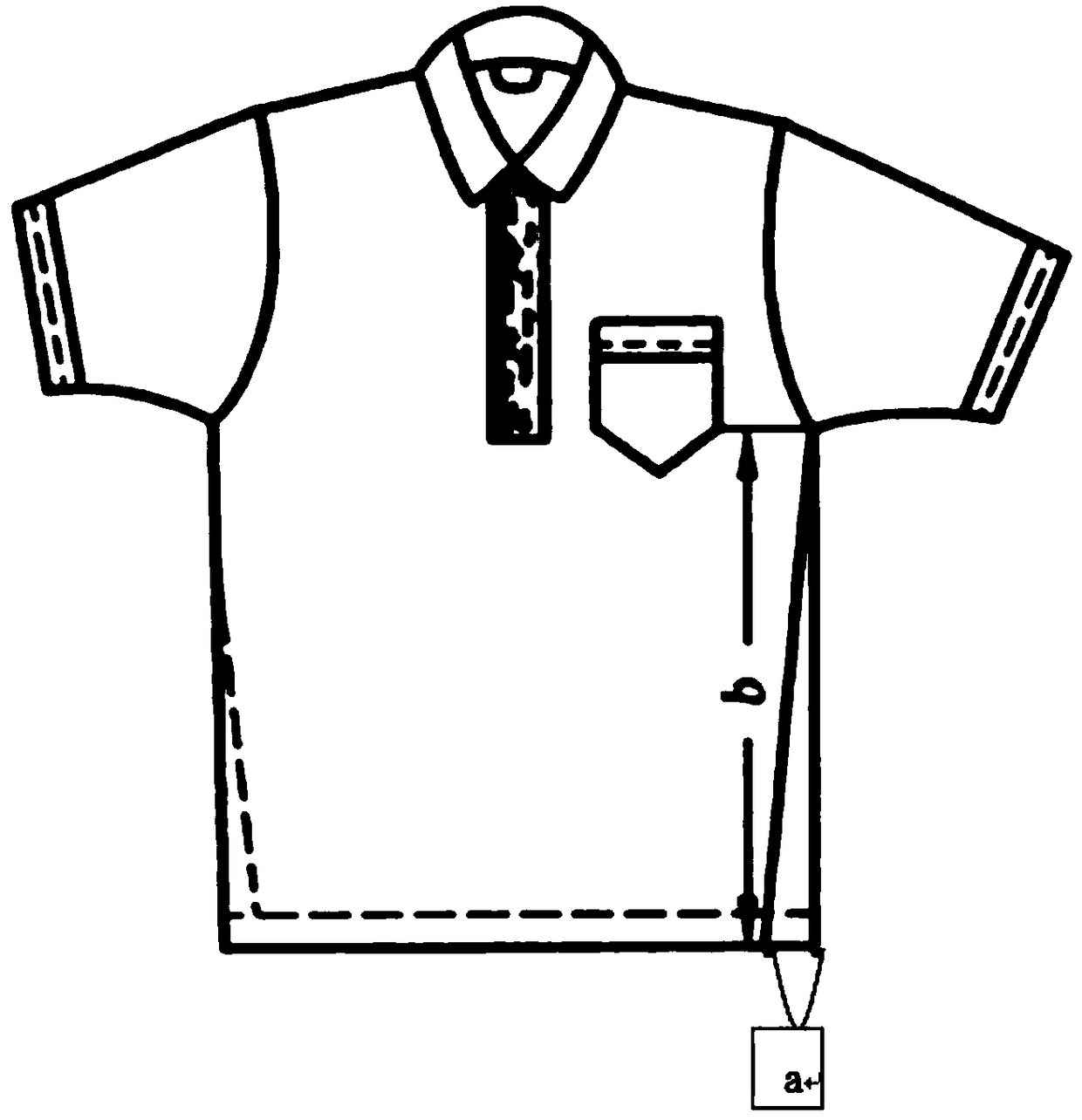

Method for technically controlling washing twisting of garment products due to weft skewing of fabrics

The invention relates to a method for technically controlling washing twisting of garment products due to weft skewing of fabrics. The method includes steps of (1), starting to shear certain portionsof the fabrics, manufacturing a left trouser leg and a right trouser leg with the sizes of 50*50 cm from each fabric, carrying out pre-washing and post-washing tests and recording pre-washing and post-washing sizes; (2), carrying out pre-washing and post-washing twisting rate tests; (3), adjusting twisting angles; (4), carrying out trouser leg tests on bulk products, carrying out summarizing pieceby piece according to different twisting rates, and adjusting the twisting angles of paper patterns for discharging; (5), adjusting grain lines on the paper patterns according to the twisting rates and twisting directions and adjusting pattern grain lines according to twist in the same direction; (6), discharging the bulk products according to new adjusted grain lines. The certain portions, whichare about to be shorn at the step (1), of each fabric are separated from radial yarn plain edges by the breadths of 5-7 cm. The 1 / 2 of the sum of the corresponding twisting rates of each left trouserleg and the corresponding right trouser leg is equal to a twisting degree of the corresponding fabric. The method has the advantages that the problem of twisting of ready-made garments can be solvedby the aid of the method, the production and work efficiency can be enhanced, and fabric test and labor costs can be saved; the appearance quality of products can be enhanced, the brand adhesion degrees can be upgraded, and the brand awareness can be improved.

Owner:ZHEJIANG HAIMING IND CO LTD

Detergent composition and method of regenerating inactivated denitrification catalyst

ActiveCN107126977AHigh removal rateReduce secondary pollutionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemical industryCleansing Agents

The invention relates to the field of chemical industry and discloses a detergent composition and a method of regenerating an inactivated denitrification catalyst; the detergent composition comprises a surfactant, nitric acid, a heavy metal catching agent and an optional flocculant, wherein the weight ratio of the surfactant, the flocculant, the nitric acid and the heavy metal catching agent is (0.002-10):(0.1-50):(0.2-500):1. The detergent composition for removing mercury from the regenerated inactivated denitrification catalyst is more effective in removing heavy metals, such as mercury and arsenic, depositing in the inactivated denitrification catalyst, removing mercury and arsenic ions in post-washing washing solution, and precipitating in washing residue, thereby reducing water pollution.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

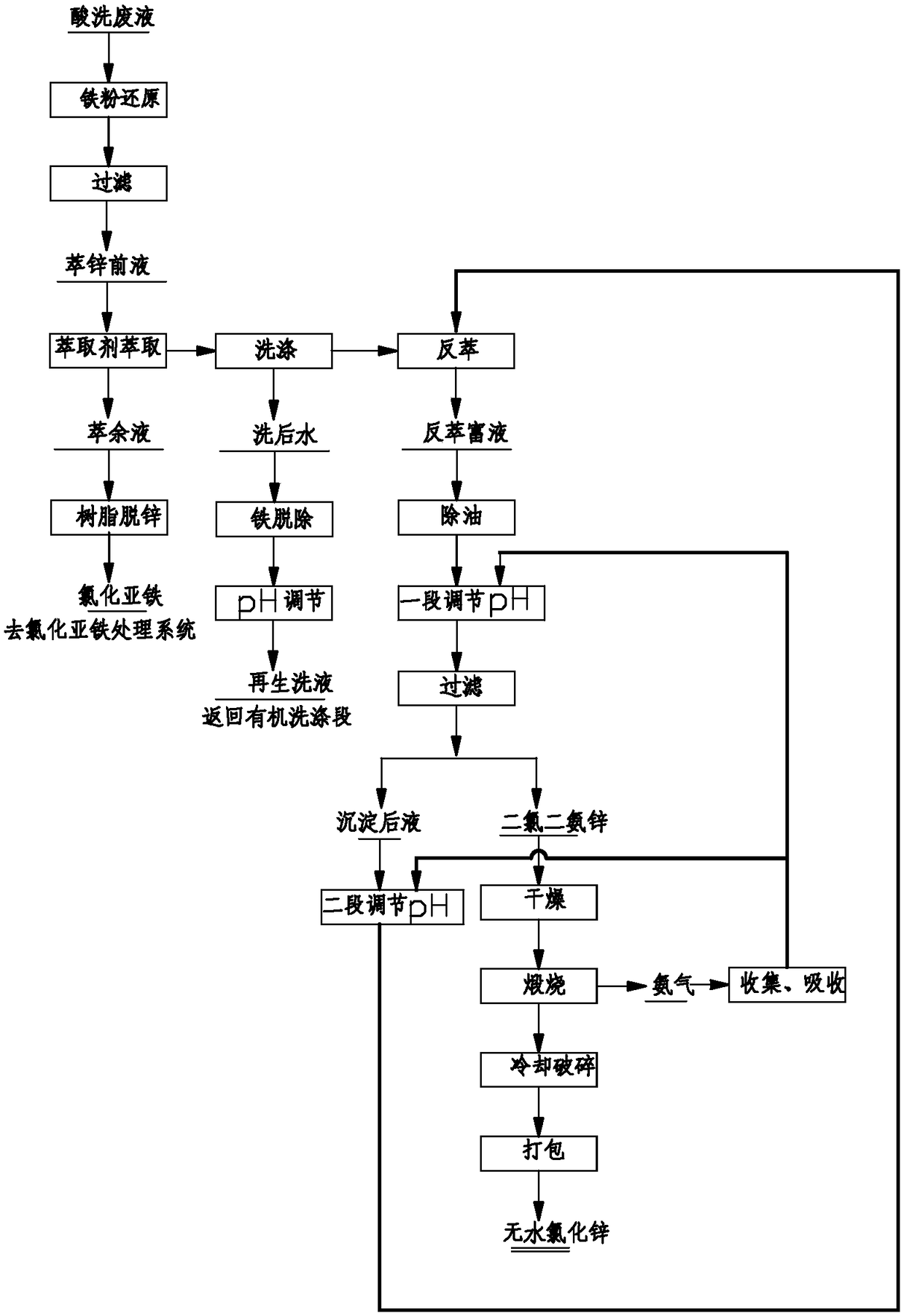

Method for recovering zinc from acid pickling waste liquid by using solvent extraction

InactiveCN109266856ASimple processLess investmentProcess efficiency improvementLiquid wasteIron powder

The invention discloses a method for recovering zinc from acid pickling waste liquid by using solvent extraction, and solves a current problem that a high-quality zinc product cannot be obtained fromhigh-concentration acidic waste liquid containing zinc and iron ions. The method comprises the following steps: firstly reducing the acidic waste liquid containing the zinc and iron ions through ironpowder, and reducing ferric iron in solution; after reduction, filtering the acid pickling waste liquid, to obtain zinc extraction pre-liquid; extracting the zinc extraction pre-liquid, to obtain organic raffinate loaded with zinc chloride; performing impurity washing on the loaded organic, to obtain post-washing organic and post-washing water; performing reverse extraction on the post-washing organic, to obtain regenerated organic and zinc reverse extraction rich solution; deoiling the zinc reverse extraction rich solution, and entering a pH adjusting tank, to obtain a zinc dichlorodiammoniaprecipitate in a section of the pH adjusting tank; filtering, drying, and calcining the zinc dichlorodiammonia precipitate, to obtain high-purity anhydrous zinc chloride, and recovering ammonia. The method is capable of acquiring a high-quality anhydrous zinc chloride product from the acidic waste liquid containing the zinc and iron ions.

Owner:桐乡市思远环保科技有限公司

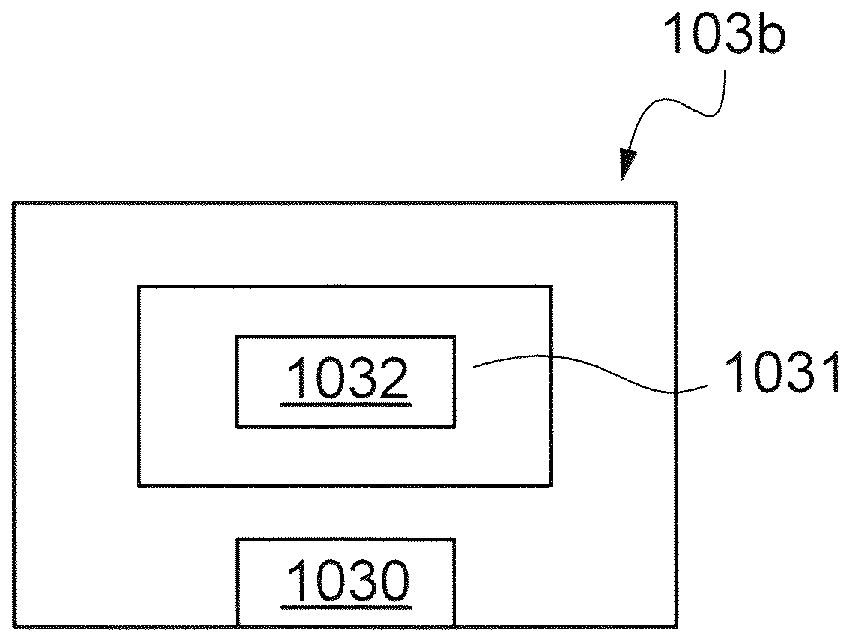

Improved glazing inspection system

InactiveCN110178020AEasy to identifyEasy to checkMaterial analysis by optical meansVisual inspectionEngineering

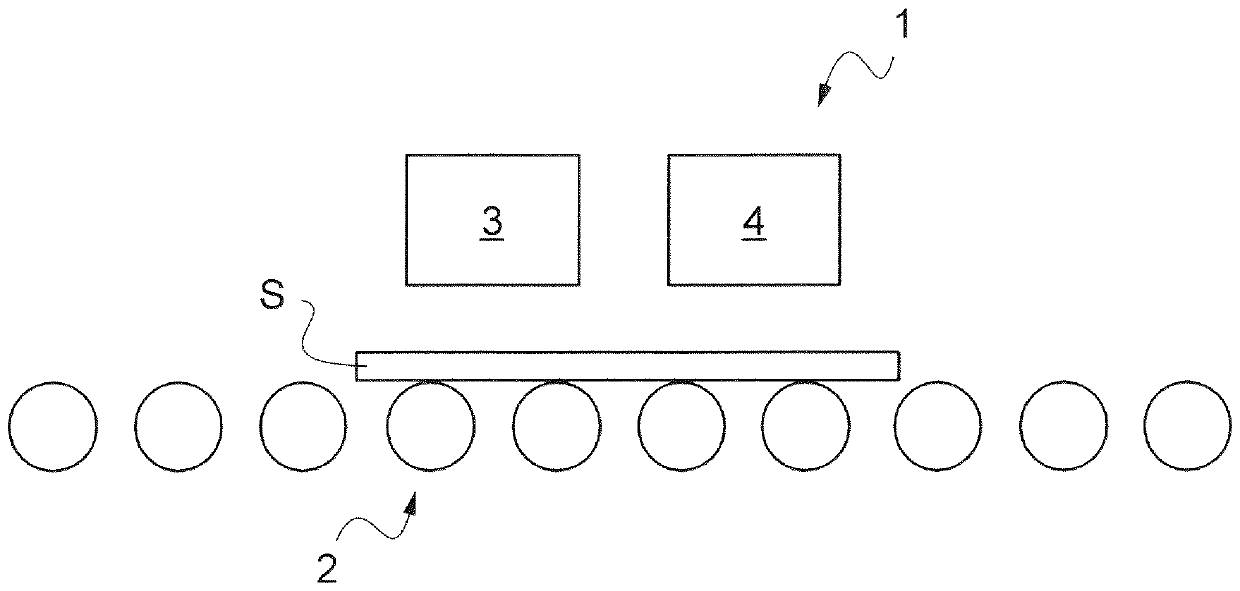

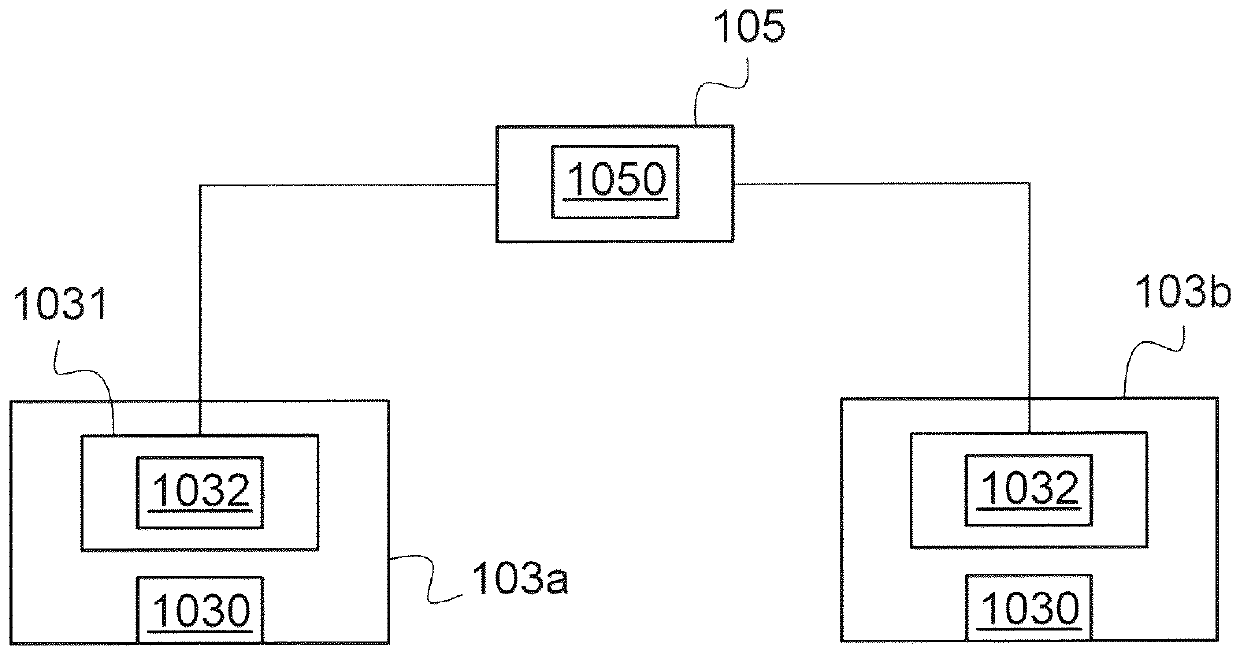

The present invention relates to a system for inspecting (100) a glass substrate (S), comprising conveying means (102) for moving said glass substrate, a cleaning device (104) arranged to clean one orboth faces of the glass substrate, and a first visual control device (103a) which is located downstream of the cleaning device in relation to the direction of travel of the substrate, said first visual control device comprising an optical sensor (1030) arranged to take a post-washing image (IP2) of the cleaned surface or surfaces of the glass substrate, characterized in that said inspection system further comprises a second visual inspection device (103b) located upstream of the cleaning device in relation to the direction of travel of the substrate.

Owner:SAINT-GOBAIN GLASS FRANCE

Towel automatically washing machine

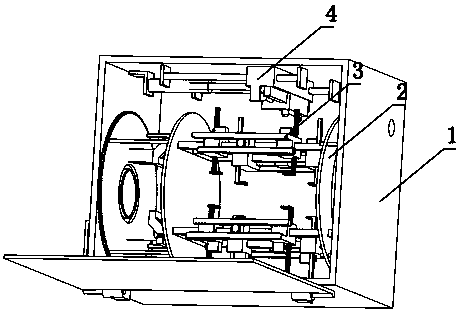

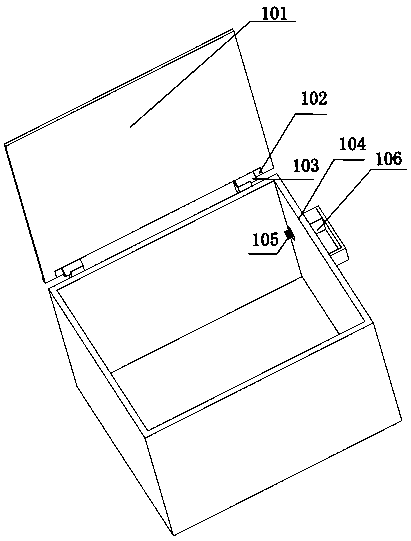

ActiveCN109797517ANo creasesAdjustable sizeWashing receptaclesOther washing machinesHydraulic cylinderGear drive

The invention discloses a towel automatically washing machine. The towel automatically washing machine comprises a housing, a rotating mechanism, a clamping mechanism and a washing drying mechanism, wherein the first bearing inner ring and the second bearing inner ring of the rotating mechanism are fixedly connected with a box body through cylinders; the bottom surface of a third motor of the clamping mechanism is fixedly mounted onto a connecting plate; the connecting plate of the washing drying mechanism is fixedly connected with the box body, and the fixing plate of a second hydraulic cylinder is fixedly connected with the box body; the housing is a sealed waterproof structure with provided with a drainage hole and an openable cover plate; the rotating mechanism drives a first motor onthe housing to drive a first gear to rotate, and the first gear drives a bearing outer ring gear to rotate to drive the rotating mechanism to rotate; the washing drying mechanism is provided with a high-pressure water gun and a drying gun to achieve a washing drying function. Therefore, the towel automatically washing machine achieves a miniature cleaning machine, saves hand washing, avoids towelwrinkling and achieves a practical function of post-washing drying and the like.

Owner:山东省安正安全咨询服务有限公司

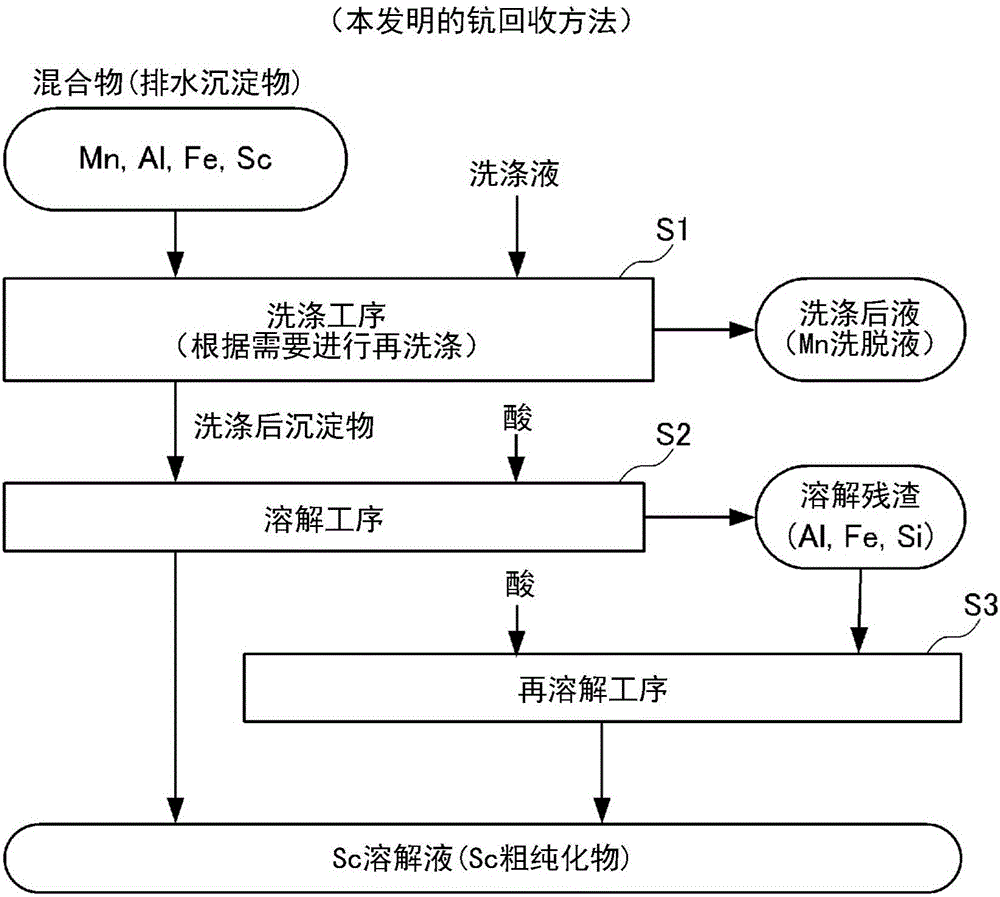

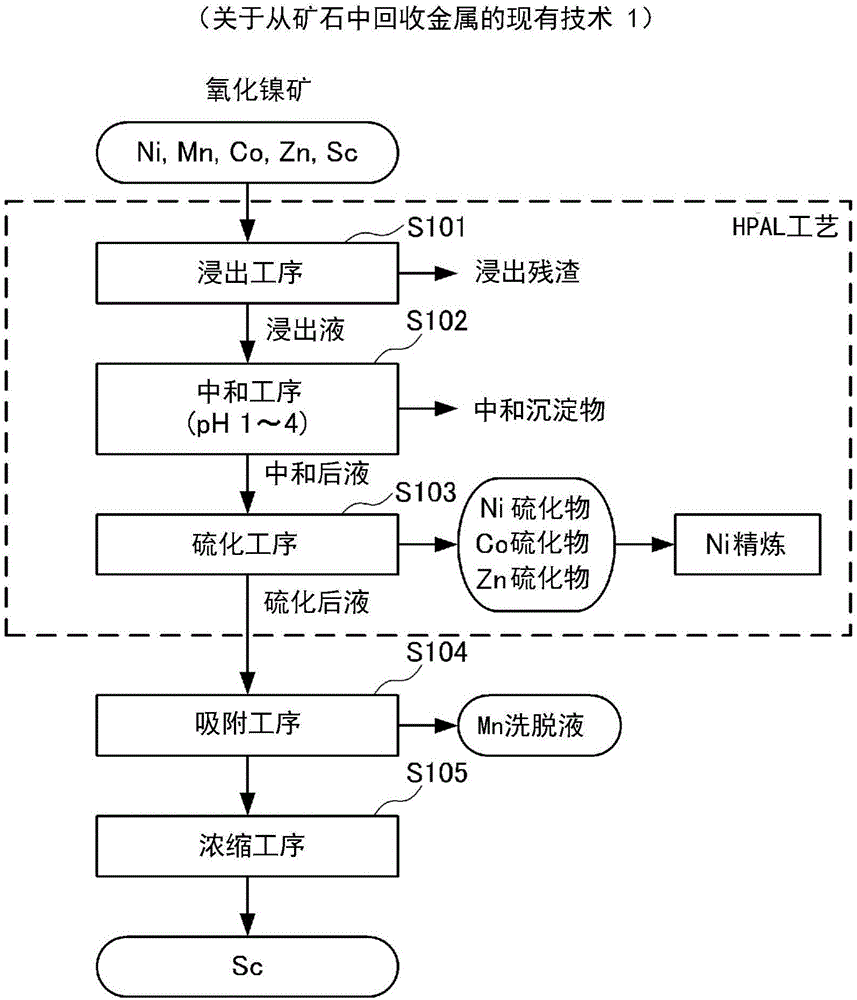

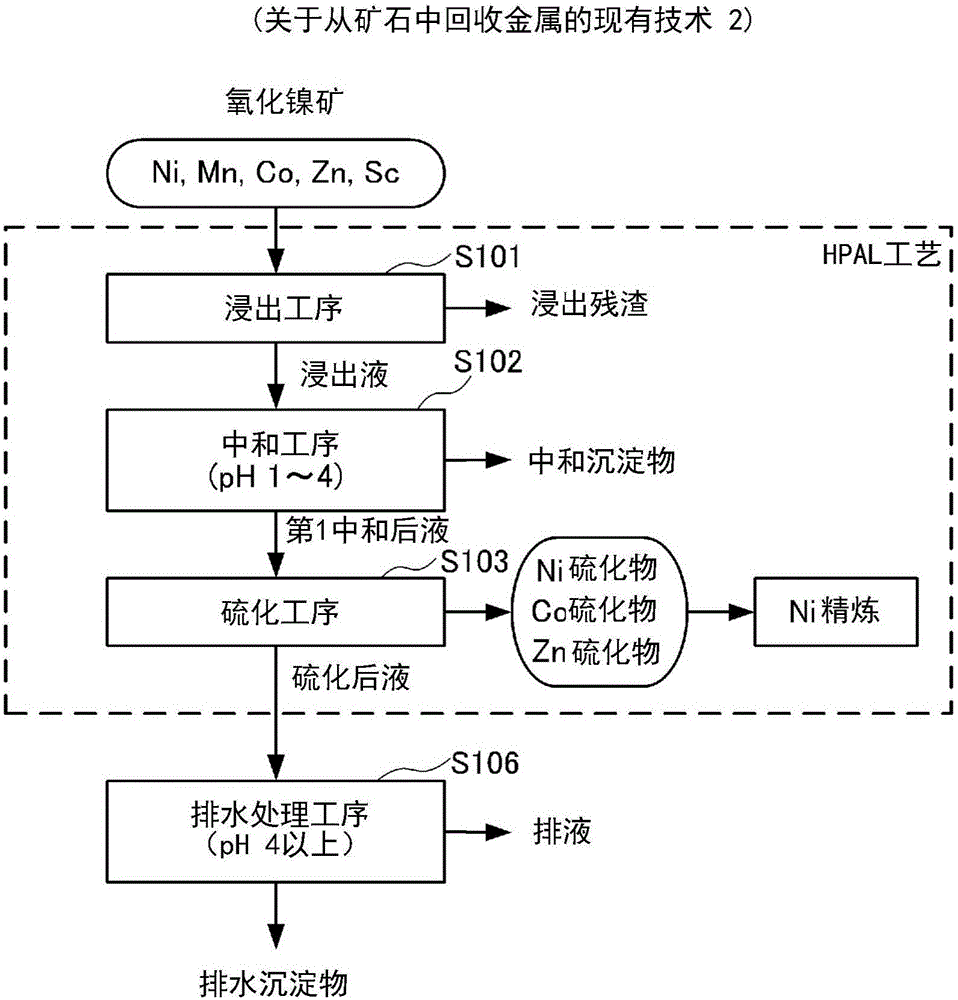

Scandium recovery process

The purpose of the present invention is to recover roughly purified scandium, which is purified to an extent acceptable for a technique for highly purifying scandium, efficiently and without any complicated operation from a neutralization sediment (drainage sediment) generated in neutralizing acid mine drainage which contains a sulfur component. This scandium recovery process includes a washing step (S1) for washing a neutralization sediment (drainage sediment) and a dissolution step (S2) for subjecting the washed sediment obtained in the washing step (S1) to dissolution in an acid. It is preferable that the process further includes a re-dissolution step (S3) for subjecting a dissolution residue which remains after the dissolution in the dissolution step (S2) to dissolution with an acid. In the washing step (S1), it is preferable that the neutralization sediment (drainage sediment) is washed with a washing liquid until the pH of the post-washing liquid generated in the washing step becomes 6 or higher. In the dissolution step (S2), it is preferable that the washed sediment is dissolved in an acid with the system adjusted to pH 1-4.

Owner:SUMITOMO METAL MINING CO LTD

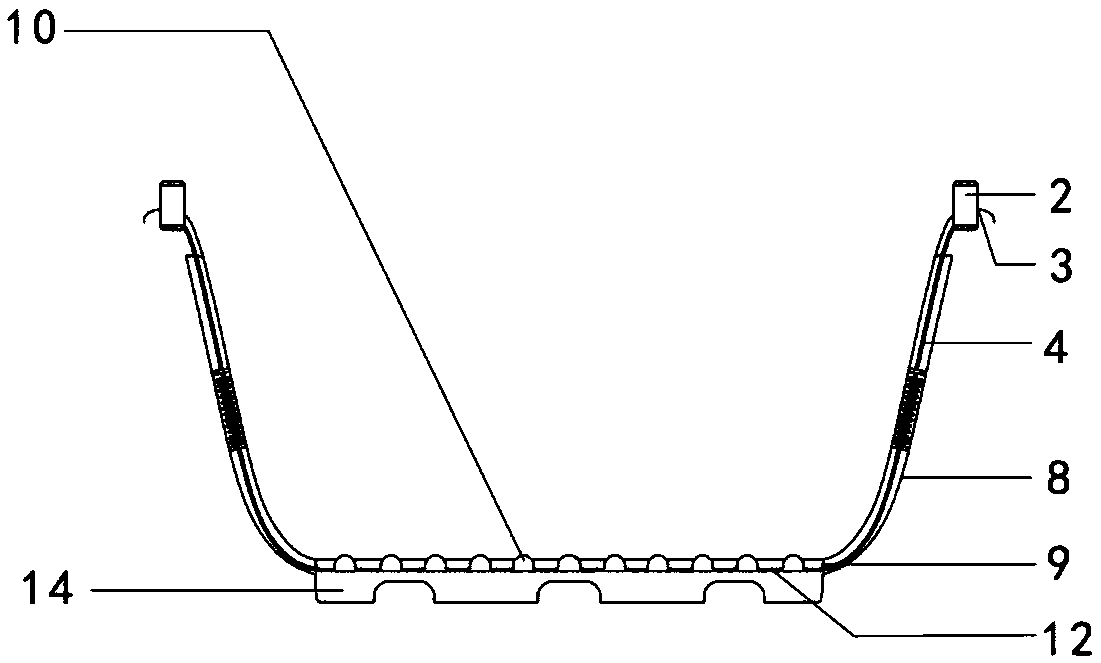

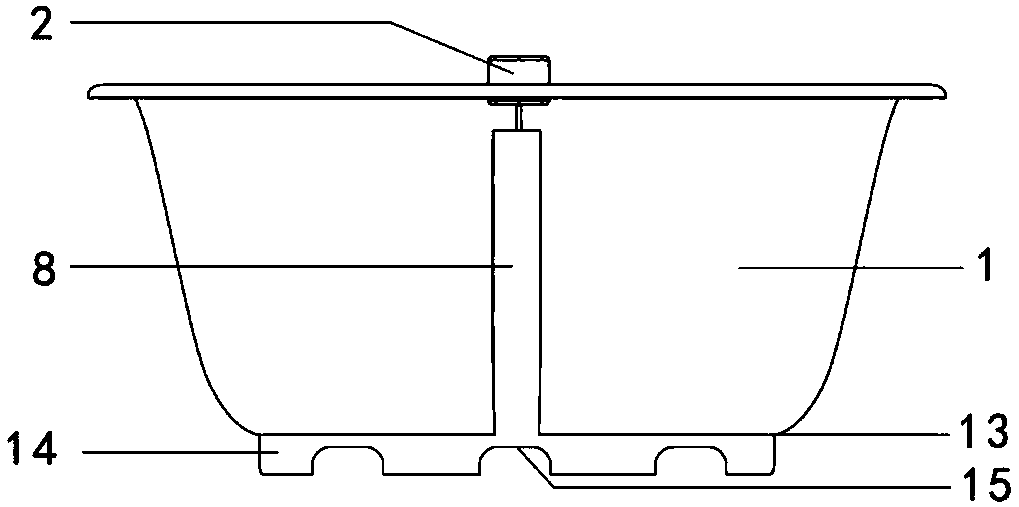

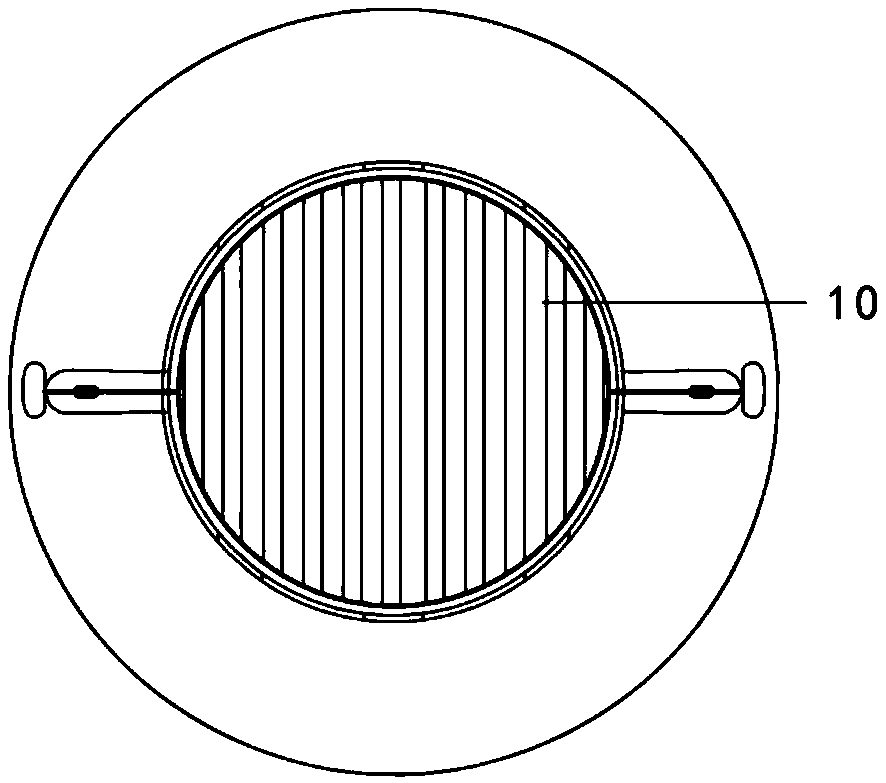

Water basin allowing wastewater to be reused conveniently

ActiveCN109138070AAvoid wastingSave energyIndustrial water supply conservationDomestic plumbingWastewaterEngineering

The invention discloses a water basin allowing wastewater to be reused conveniently. The water basin comprises a basin body, buttons, connection rods, presser plates, elastic parts, holders, a plurality of plug strips, a base, and a basin foot. The two sides of the upper end of the basin body are symmetrically provided with mounting holes; the buttons are fixed in the mounting holes; the lower endof each button is fixed to the upper end of the corresponding connection rod; the presser plates are fixedly connected to the middle of the connection rods; the holder is fixed outside the basin body; the middle of each holder is provided with a through hole; the connection rods are passed through the through holes of the holders; the presser plates are positioned at the upper ends of the holders; the elastic parts are positioned between the presser plates and the holders; the connection rods are passed through the elastic parts; the lower ends of the connection rods are fixedly connected tothe base; the plug strips are fixed on the base; the bottom plate of the basin body is provided with a plurality of filter holes; the plug strips fit the filter holes and seal them; the basin foot isfixed to the bottom of the basin body to raise the bottom of the basin body; the base is positioned within the basin foot; the basin foot is provided with guide holes to guide the connection rod to move. The water basin allows post-washing wastewater to be reused.

Owner:YANGZHOU UNIV

Hydraulic pipe rust prevention process

The invention provides a hydraulic pipe fitting antirust process, comprising the following steps: a. removing impurities, placing the hydraulic pipe fitting in the pretreatment liquid and soaking for 10-30 minutes; b. cleaning, cleaning the hydraulic pipe fitting with warm water at 50-60°C Clean; c, soaking, place the cleaned hydraulic pipe fittings in the anti-rust solution and soak for 1-2 hours; d, cleaning, rinse the hydraulic pipe fittings soaked in the anti-rust liquid with clean water; e, dry, clean them The final hydraulic pipe fittings are dried in a dryer; f, frosting treatment, frosting the outer surface of the dried hydraulic pipe fittings; g, packaging, packaging the frosted hydraulic pipe fittings. The hydraulic pipe fitting antirust process of the present invention has simple process, convenient operation, good antirust effect and long service life of the hydraulic pipe fitting.

Owner:NINGBO YINZHOU LUTONG HYDRAULIC PIPE FITTINGS FACTORY

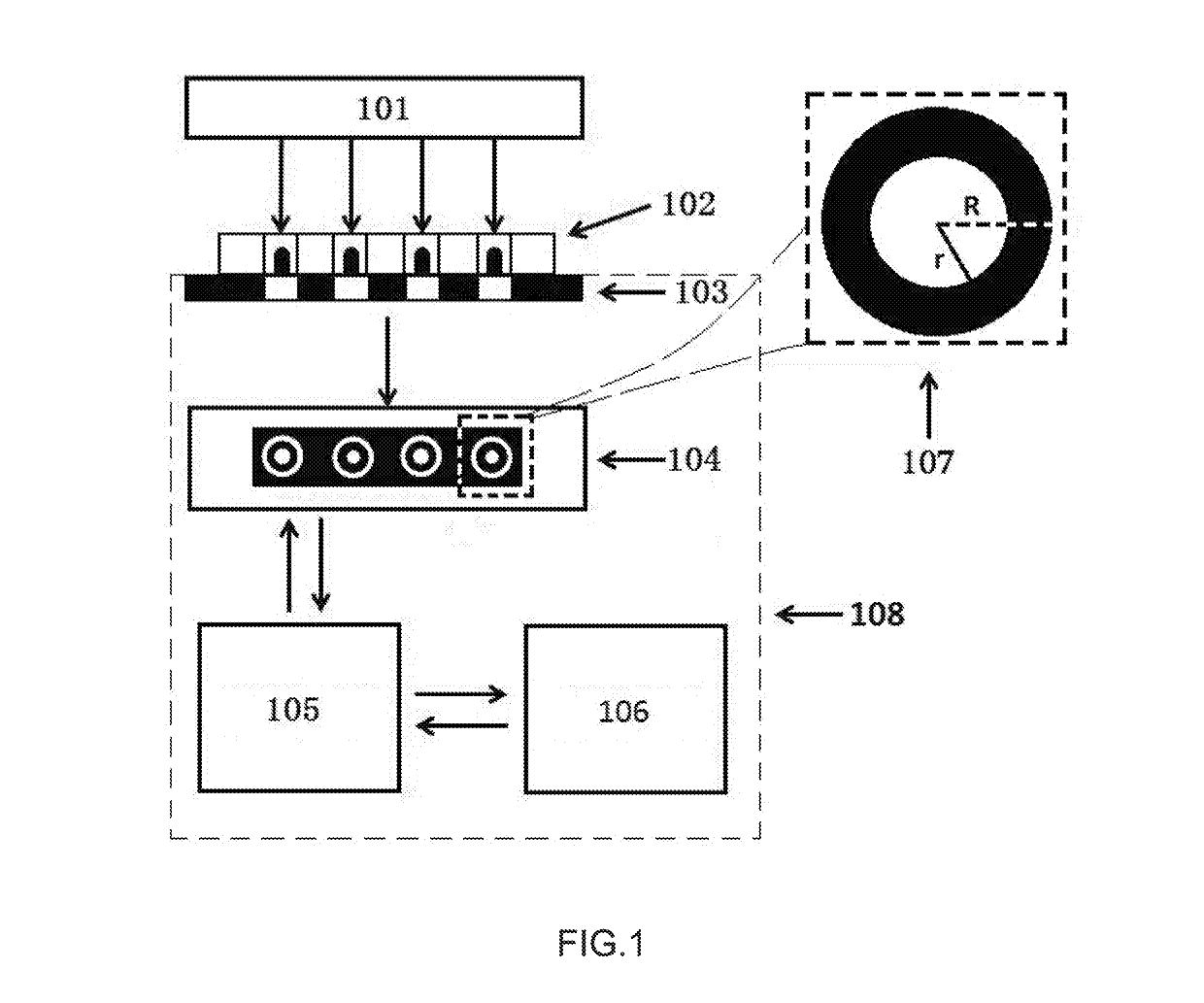

Rapid multi-path micro-lens imaging ultra-micro immunoassay apparatus

InactiveUS20190128876A1Guaranteed uptimeLow costMaterial analysis by observing effect on chemical indicatorChemiluminescene/bioluminescenceRefractive indexTouchscreen

The presently claimed invention applies to an immunoassay apparatus based on micro-lens imaging technique and related product. In a preferred embodiment, the immunoassay apparatus comprises a monochromatic light source module, an intelligent auto-scanning and imaging module, a temperature controlled transparent toughened glass platform, a central control module, and a touchscreen displaying module. By automatically performing scan in focus imaging on the micro-lenses immersing in antigen-antibody solution and analyzing the data of the image, the apparatus can monitor the refractive index change of a sample solution before and after antigen-antibody reaction, so as to determine the concentration of antigen or antibody in the solution without requiring any labeling, expensive enzymes, pre-immobilization / modification, and post-washing. It can detect ultra-micro amount of Ag / Ab (˜pg / mL) in very low sample volume solution (several μL) within 2 minutes. It is of high accuracy and reliability. Moreover, the apparatus is simple and compact, can be portable for on-site immunoassay.

Owner:JINAN UNIVERSITY

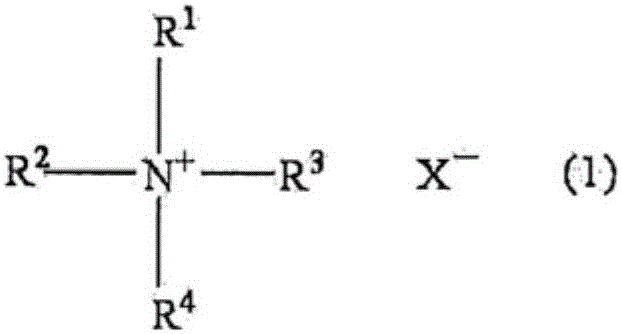

Steel sheet production method

ActiveCN106460200ACationic surface-active compoundsDetergent mixture composition preparationInorganic saltsMetallurgy

The invention discloses a steel sheet production method that includes a washing step (1) wherein a steel sheet that has been cold rolled is washed, a rinsing step (2) wherein the steel plate that has undergone the washing step (1) is rinsed, and a drying step (3) wherein the steel sheet that has undergone the rinsing step (2) is dried. The rinsing step (2) includes one or more rinsing treatments, the final rinsing treatment using a rinsing agent [alpha] that includes a component (a) that is represented by general formula (1) (as shown in the description), the concentration of the component (a) being 150 mg / kg or less of the rinsing agent [alpha]. The rinsing agent [alpha] has an inorganic salt cation concentration of 2.0-18.0 mmol / kg and has a sulfate ion concentration of 0.75 mmol / kg or less. The steel sheet production method has a low waste water treatment load and can reduce energy costs for drying a steel sheet or the like post-washing.

Owner:KAO CORP

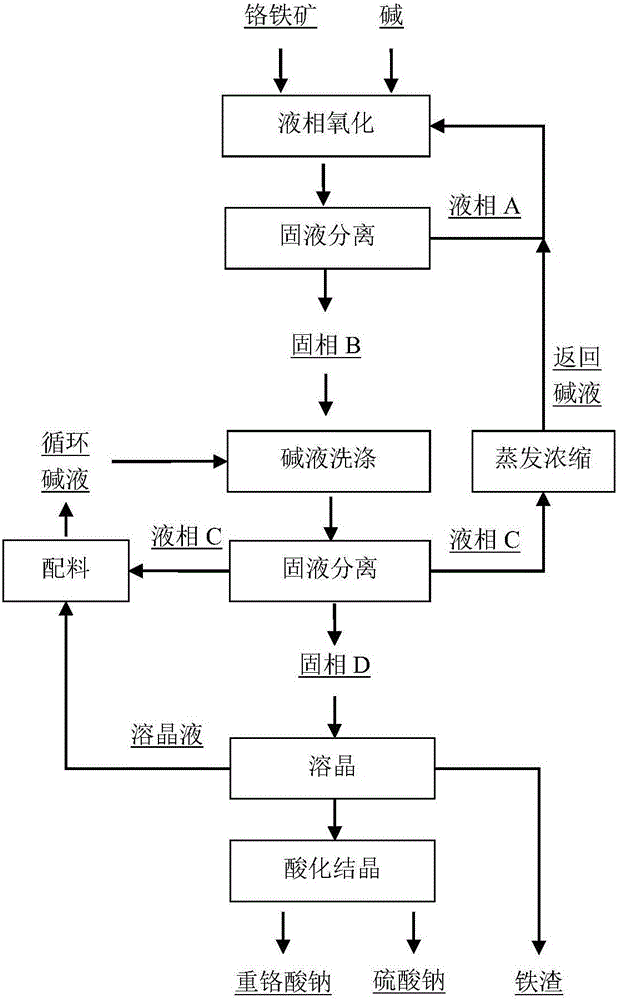

Method of preparing sodium dichromate

ActiveCN106219607ALow costReduce energy consumptionSulfate/bisulfate preparationChromates/bichromatesDissolutionSlurry

The invention discloses a method of preparing sodium dichromate, comprising the steps of (1), subjecting chromite and alkali solution to liquid oxidation, subjecting slurry to solid-liquid separation after reacting to obtain liquid phase A and solid phase B; (2), washing the solid phase B with circulatory alkali liquid, subjecting post-washing slurry to solid-liquid separation to obtain liquid phase C and solid phase D; (3), crystal-dissolving the solid phase D with sodium chromate crystal with water and iron residue washing liquid, carrying out solid-liquid separation to obtain crystal-dissolved liquid and iron residue, washing the iron residue with water, and returning the washing liquid to crystal dissolution; (4), preparing circulatory alkali liquid with the liquid phase C and crystal-dissolved liquid, adding an acid solution to the remaining crystal-dissolved liquid to adjust pH, and carrying out aluminum-silicon removal, acidifying, crystallizing and separating to obtain sodium dichromate and sodium sulfate; preparing. The process of the invention is simple, the flow is short, and the method is highly operable, low in cost and free of wastewater and is an effective way of chromium salt industry to make recycle use and reduce pollution.

Owner:格润过程(北京)科技有限责任公司

One-bath two-step exhaust dyeing method of disperse reactive dyes for polyester-cotton fabrics

ActiveCN106223076BPreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com