Main grid electrode structure of solar cell and preparation method thereof

A solar cell and busbar electrode technology, which is applied in the field of solar cells, can solve the problems of high cost, high price, and the inability to promote silicon solar cells, and achieve the effects of improving efficiency, reducing damage, and improving surface passivation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

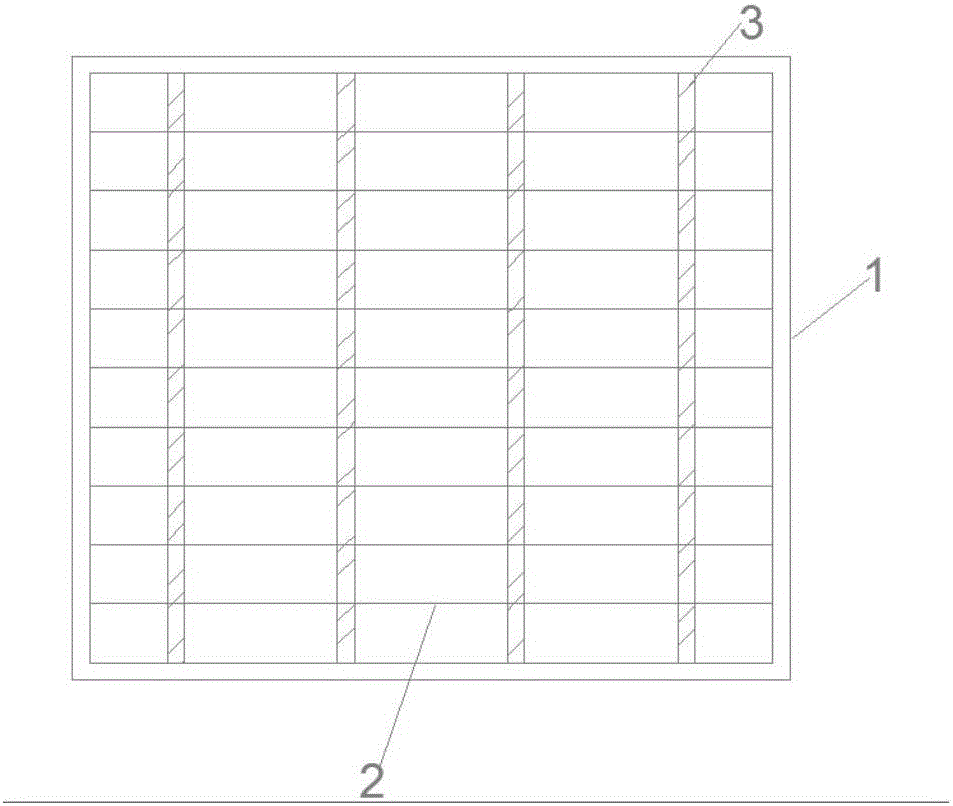

[0028] like figure 1 As shown, the front electrode structure of a conventional battery includes sub-gates 2 arranged on the front surface of a P-type silicon substrate 4 and main gates 3 arranged alternately with the sub-gates 2 .

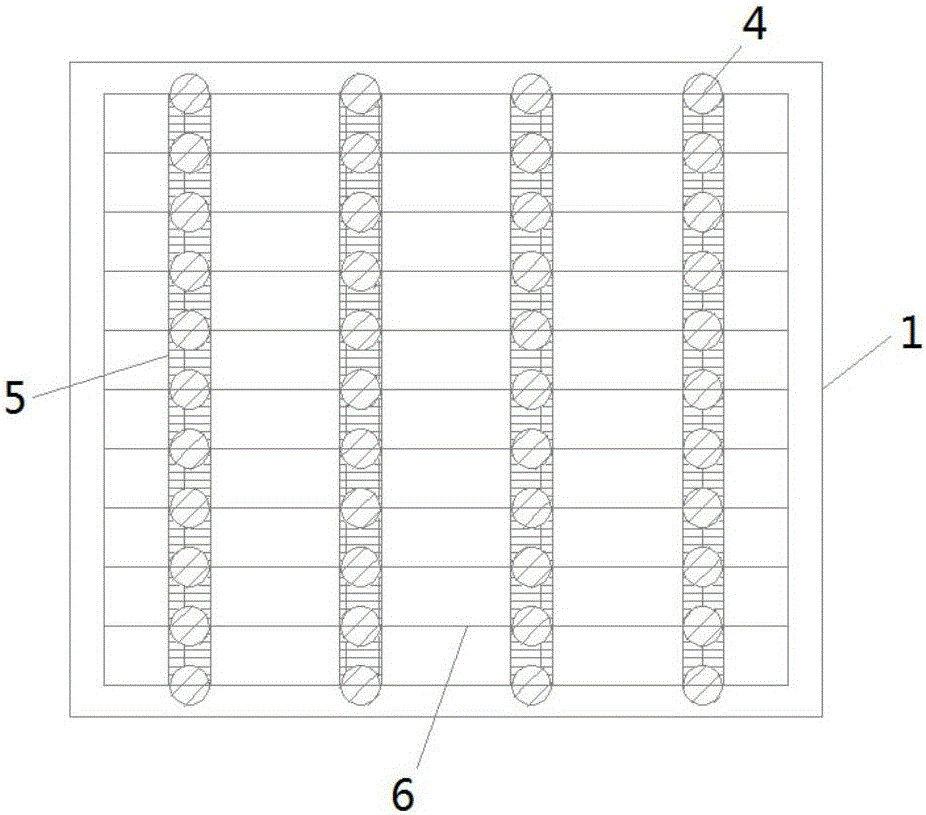

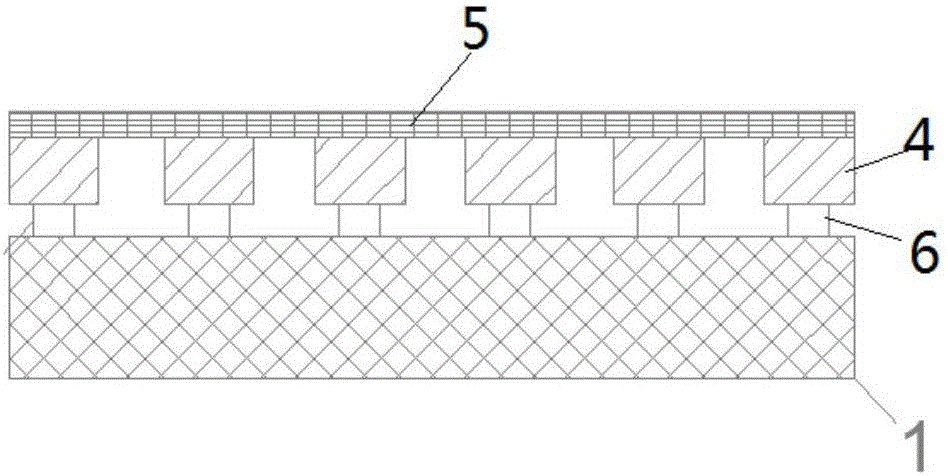

[0029] like figure 2 As shown, the present invention proposes a new front electrode of a silicon solar cell, which includes a P-type silicon base 1, and a layer of width 0.02-0.08mm and thickness 0.005-0.030mm is printed on the front surface of the P-type silicon base 1. mm of silver grid line 6; on the metallized silver grid line 6, print solder paste solder joints (or conductive adhesive) 4 as bonding points by screen printing, and the thickness of solder paste solder joints (or conductive adhesive) 4 0.02 ~ 0.15mm, solder paste solder joints (or conductive adhesive) 4 diameters are 0.02 ~ 0.10mm, the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com