Overall-length diameter-expanding unit for medium-diameter submerged-arc welding pipe

A technology of submerged arc welded pipes and units, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of too much waste of power resources in diameter expansion units, achieve the elimination of messy internal stress, and ensure diameter expansion Quality, the effect of increasing the yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

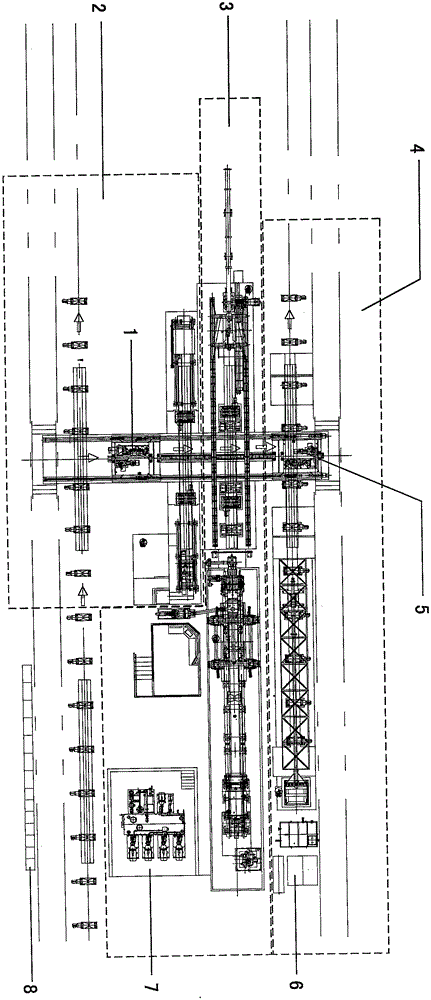

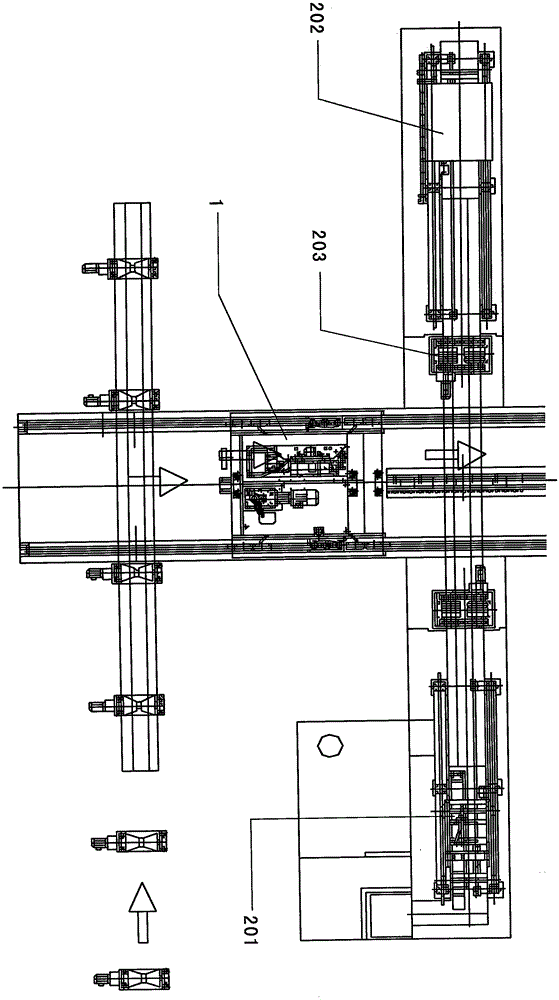

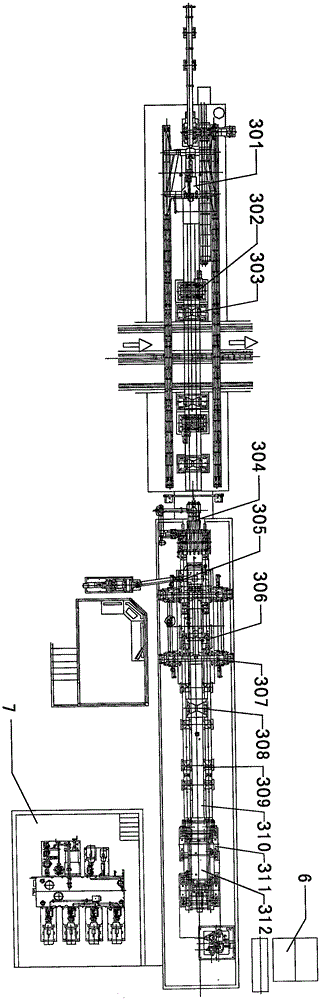

[0035] Such as Figure 1-4 As shown, the present invention discloses a full-length expansion unit for medium-diameter submerged arc welded pipes. The entire expansion unit consists of a steel pipe inlet traverse vehicle 1, a front flushing station 2, a diameter expansion station 3, a rear flushing station 4, Steel pipe export traversing car 5, equipped with independent water system, lubrication system 6, hydraulic system 7, electrical system 8, to achieve the following action control: the mechanism of each station can be fine-tuned by single action; each station can also It can be used as an independent station to work alone; the three stations can also realize fully automatic joint work with the steel pipe inlet traversing car 1 and the steel pipe outlet traversing car 5.

[0036] Steel pipe inlet traversing vehicle 1, steel pipe outlet traversing vehicle 5: The car body is an integral structure, and the car body is equipped with a random hydraulic pump station and an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com