Steam turbine unit oil circulation flushing bearing-bush-turnover-free construction method

A steam turbine unit and construction method technology, applied in the direction of separation methods, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of steam turbine original data changes, bearing bush parts damage, secondary pollution, etc., to reduce labor workload , Reduce flushing cost, increase the effect of flushing oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

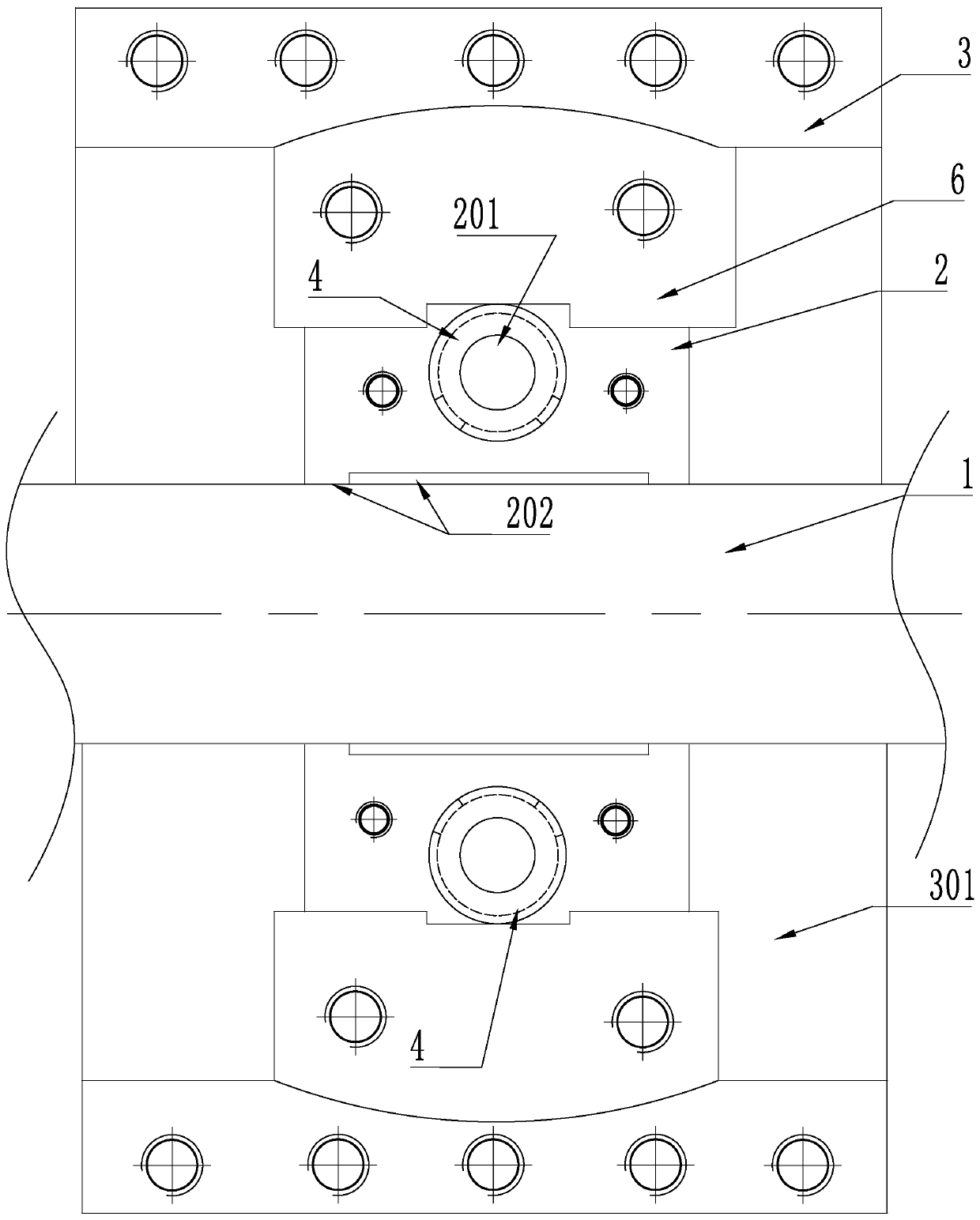

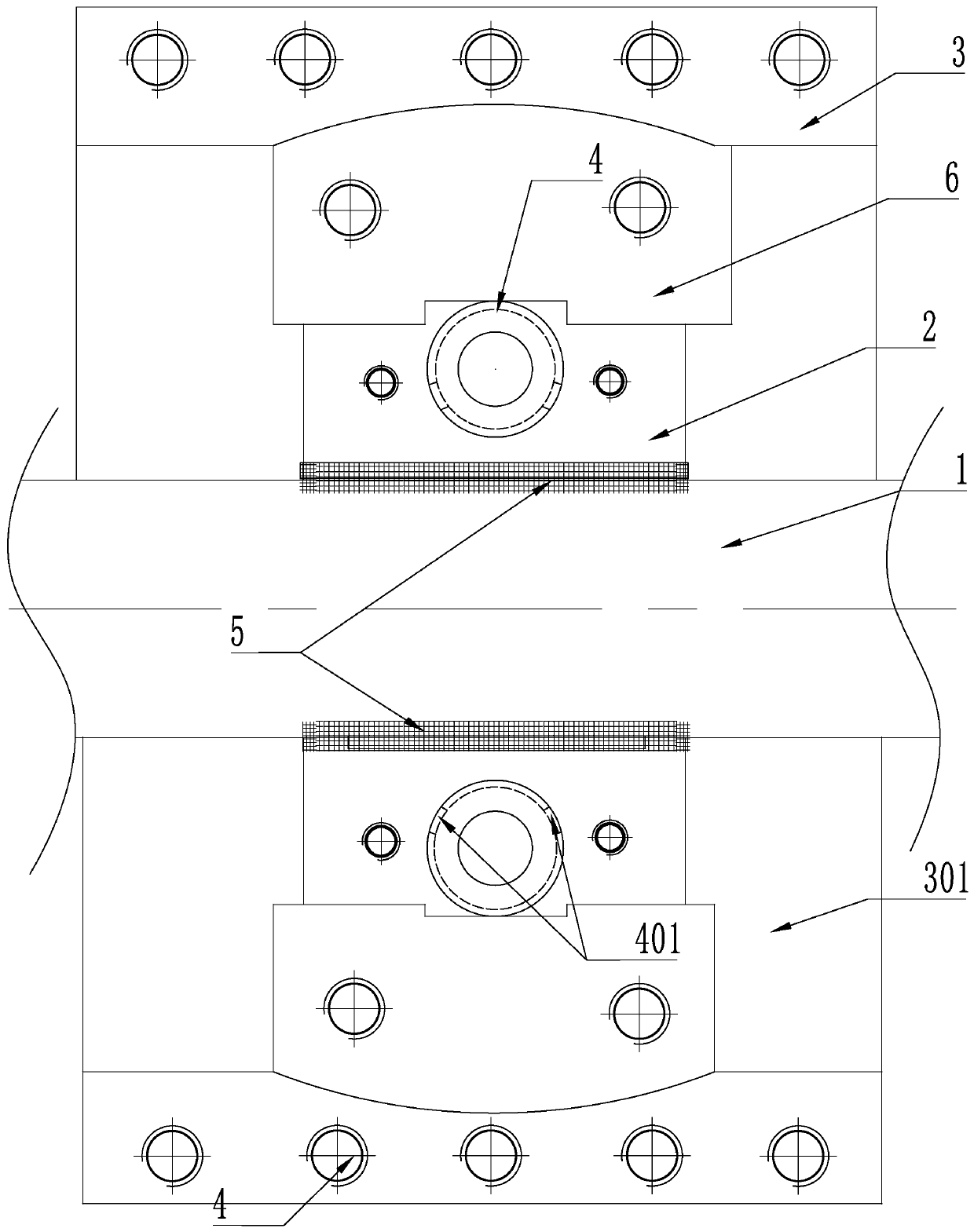

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

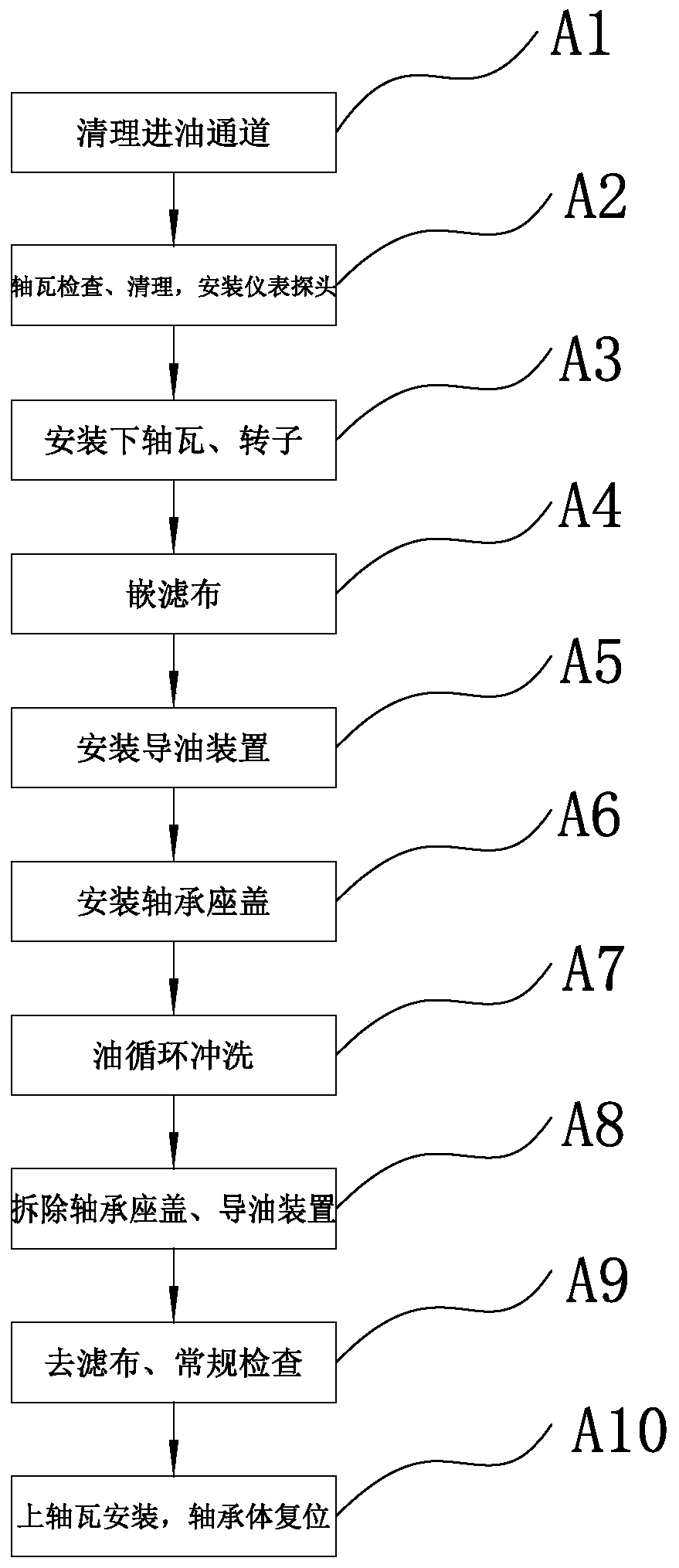

[0034] Such as Figure 1-3 As shown, a construction method for oil circulation flushing of a steam turbine unit without overturning tiles, the process includes the following steps:

[0035] A1: Clean the oil inlet channel of the bearing housing 3;

[0036] A2: Check and clean the bearing bush, and install the instrument probe;

[0037] A3: Install the lower bearing 2, and install the instrument probe on the lower bearing 2 at the same time. At this time, it is more convenient to install the instrument probe, and then install the rotor 1. Therefore, the site construction conditions are better, and the inspection and adjustment of each part of the unit are more convenient and easy to measure. The original data is accurate, and the lower bearing bush 2 and rotor 1 need to be adjusted precisely after installing the rotor 1;

[0038] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com