Low-cost green method for synthesizing Fe-ZSM-5 molecular sieve

A green synthesis, fe-zsm-5 technology, applied in the direction of gallium aluminosilicate/iron aluminosilicate, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., to achieve energy consumption Reduction, reduction of toxic effects, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

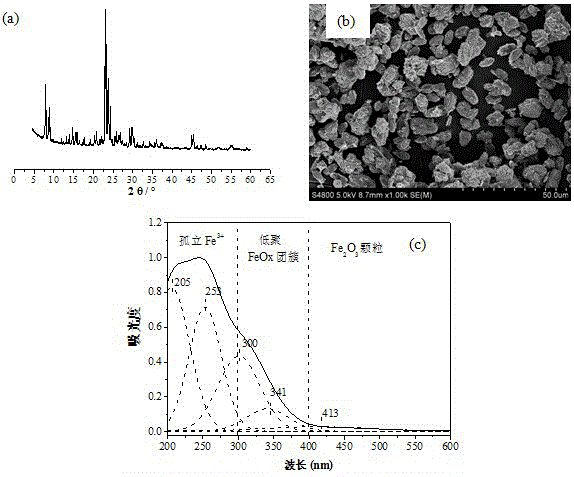

[0036] First, mix the diatomite raw material with a 10% sodium hydroxide solution according to a solid-to-liquid ratio of 1:5 (g / ml), stir evenly, dissolve in alkali at 150°C for 4 hours, and filter with suction to obtain diatomite Alkali-soluble supernatant. Then, add ZSM-5 molecular sieve seed crystals and deionized water to the upper supernatant, and the preparation composition is n(H 2 O) / (SiO 2 )=50, ZSM-5 molecular sieve seed crystal / SiO 2 =6% (mass ratio), the initial gel system with a pH value of 9.5 (adjusted by sulfuric acid), stirred evenly and crystallized at 170° C. for 36 hours. Finally, cool, filter, wash and dry to obtain a crystallized product. According to the XRD analysis, the crystallized product has a typical MFI structure diffraction peak, which proves that the product is a ZSM-5 molecular sieve; it can be seen from the SEM photo that the Fe-ZSM-5 molecular sieve is in the shape of a hexagonal prism; The ZSM-5 molecular sieve framework was formed and ...

Embodiment 2

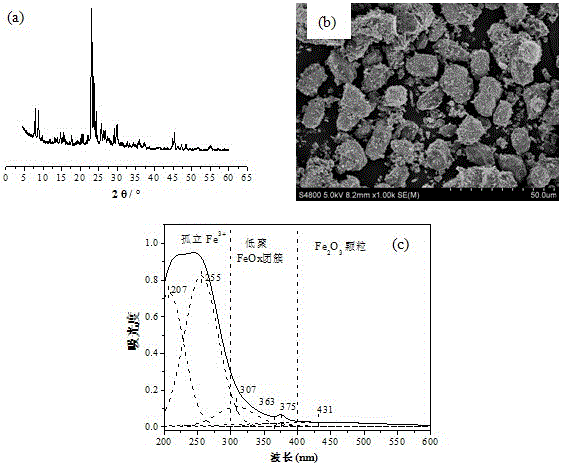

[0039] Firstly, the diatomite raw material is mixed with a 20% sodium hydroxide solution, stirred uniformly and dissolved in alkali at 100° C. for 6 hours, and suction-filtered to obtain a diatomite alkali-dissolved supernatant. Then, NaY molecular sieve seed crystals and deionized water were added to the upper supernatant to prepare n(H 2 O) / (SiO 2 )=40, NaY molecular sieve seed crystal / SiO 2 =8% (mass ratio), the initial gel system with a pH value of 10.5 (adjusted by sulfuric acid), stirred evenly and crystallized at 170° C. for 96 hours. Finally, cool, filter, wash and dry to obtain a crystallized product. According to the XRD analysis, the crystallized product has a typical MFI structure diffraction peak, which proves that the product is a ZSM-5 molecular sieve; it can be seen from the SEM photo that the Fe-ZSM-5 molecular sieve is in the shape of a hexagonal prism; The ZSM-5 molecular sieve framework was formed and mainly existed in the form of isolated trivalent Fe i...

Embodiment 3

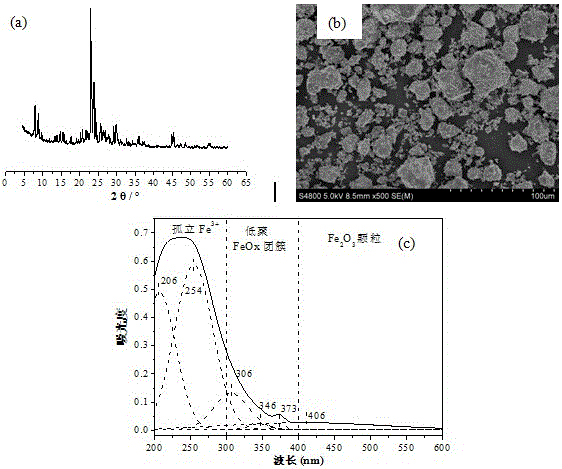

[0043] Firstly, the diatomite raw material is mixed with a 20% sodium hydroxide solution, stirred uniformly and dissolved in alkali at 100° C. for 6 hours, and suction-filtered to obtain a diatomite alkali-dissolved supernatant. Then, add a certain amount of deionized water to the upper supernatant, and prepare the composition as n(H 2 O) / (SiO 2 )=40, ZSM-5 molecular sieve seed crystal / SiO 2 =0% (mass ratio) (note: that is, without adding any seed crystals), the initial gel system with a pH value of 10.5 (adjusted by sulfuric acid), and crystallized at 170° C. for 120 hours after stirring evenly. Finally, cool, filter, wash and dry to obtain a crystallized product. According to the XRD analysis, the crystallized product has a typical MFI structure diffraction peak, which proves that the product is a ZSM-5 molecular sieve; it can be seen from the SEM photo that the Fe-ZSM-5 molecular sieve is in the shape of a hexagonal prism; The ZSM-5 molecular sieve framework was formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com