Method for preparing cathode material of lithium iron phosphate

A technology for lithium iron phosphate and positive electrode materials, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve problems such as poor morphology and poor electrical performance, and achieve low process cost, small particle size distribution, and conductive The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

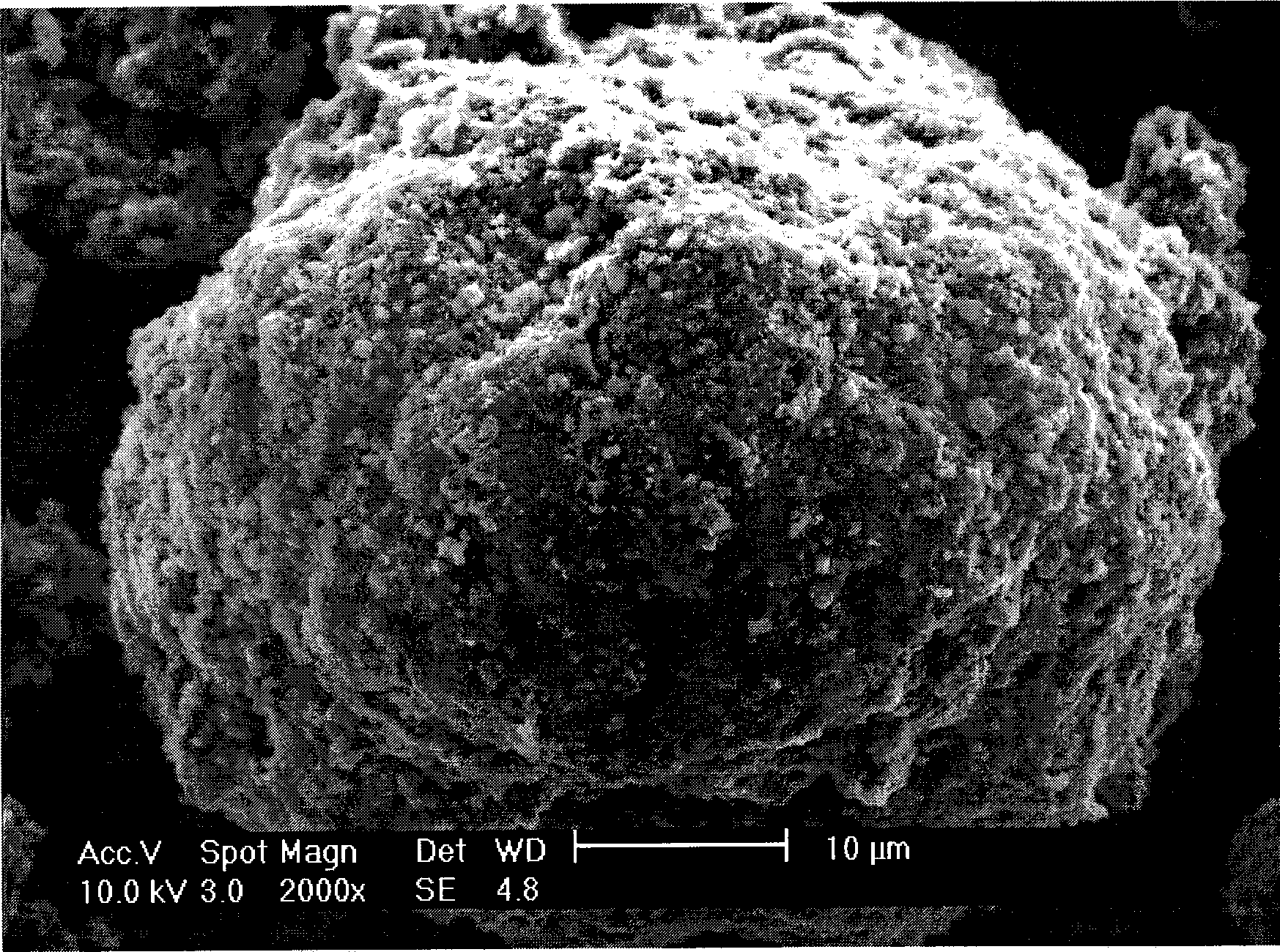

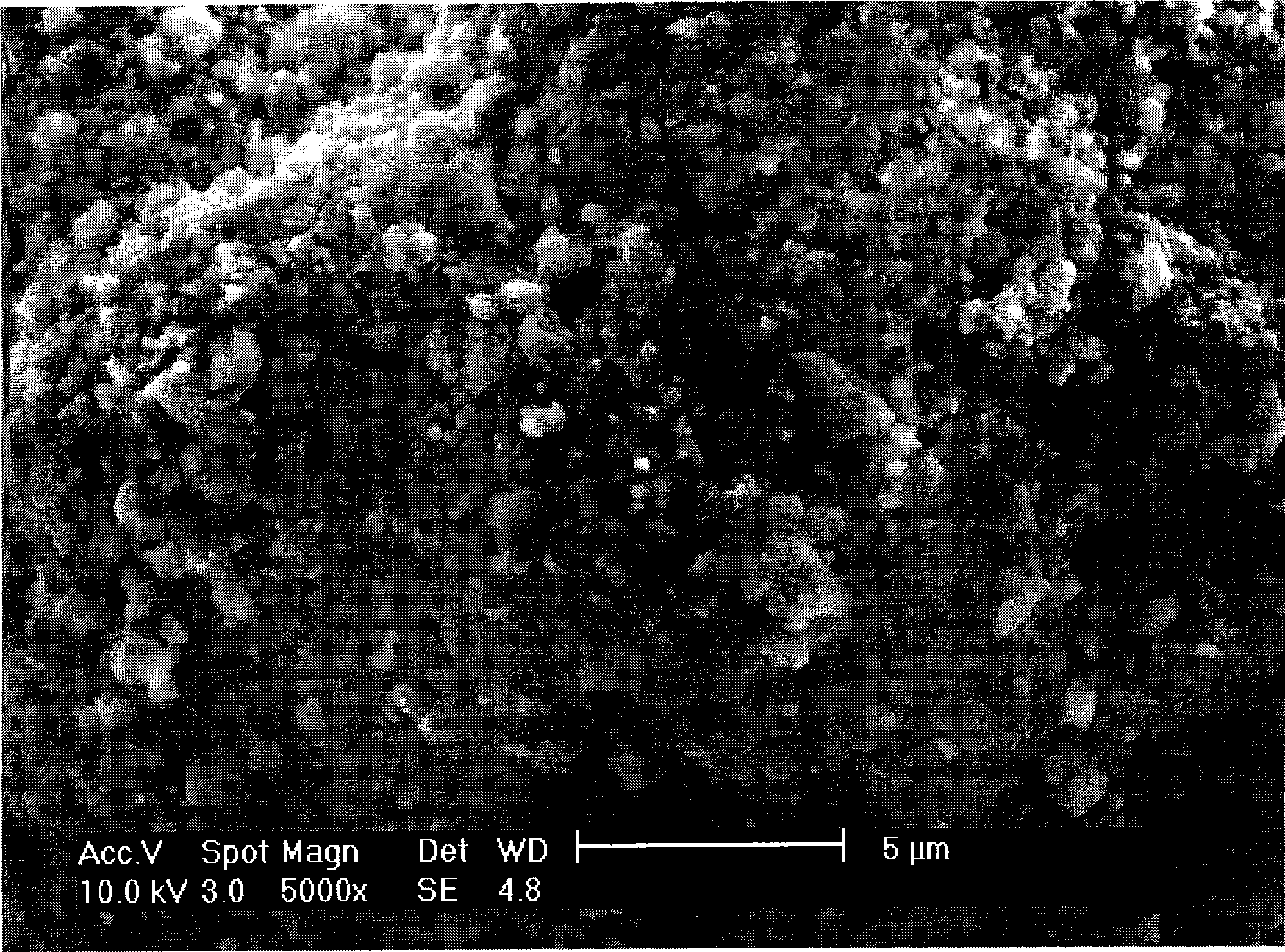

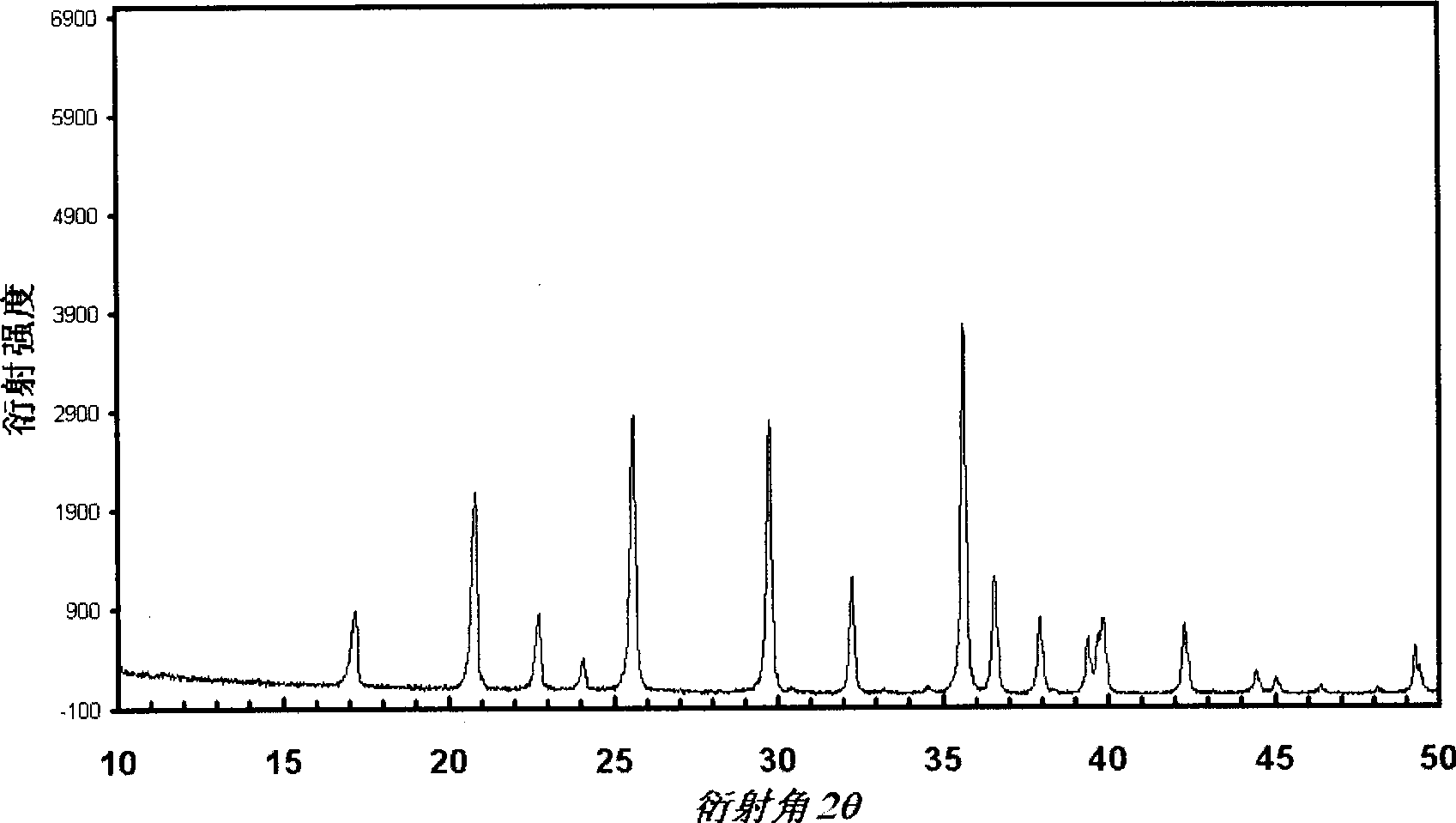

Image

Examples

Embodiment 1

[0035] a. Weighing: Weigh 40000g of lithium dihydrogen phosphate, 1571g of magnesium hydroxide, an ionic compound with good conductivity, 28580g of iron oxide, 1578g of ultrafine carbon powder with a specific surface area between 500-900m2 / g and a specific surface area of 40-100m2 3682g of superfine carbon powder between / g.

[0036] b. Ball milling: Add 500-800kg of 5-10mm zirconia ball milling media into the ball mill, and add 70-100 liters of deionized water, add lithium dihydrogen phosphate and magnesium hydroxide into the ball mill cylinder and stir the ball mill at high speed for 50-70 Minutes, then add iron oxide into the ball mill and stir the ball mill at high speed for 50-70 minutes, then add about 100 liters of deionized water, 3000-4000 ml of absolute ethanol dispersant and two different carbon powders and stir the ball mill at high speed for 30-50 minutes , so as to obtain a homogeneous slurry.

[0037] c, spray drying; by controlling the negative pressure (-60...

Embodiment 2

[0046] Embodiment 2: Take by weighing 40000g of lithium dihydrogen phosphate, 2245g of magnesium hydroxide, an ionic compound with good conductivity, 27660g of iron oxide, 1578g of superfine carbon powder with a specific surface area between 500~900m2 / g and a specific surface area of 40~100m2 3682g of superfine carbon powder between / g. Its specific manufacturing process is consistent with embodiment 1.

Embodiment 3

[0047] Embodiment 3: take by weighing 40000g of lithium dihydrogen phosphate, 449g of magnesium hydroxide, an ionic compound with good conductivity, 30120g of iron oxide, 1578g of superfine carbon powder with a specific surface area between 500~900m2 / g and a specific surface area of 40~100m2 3682g of superfine carbon powder between / g. Its specific manufacturing process is consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com