Patents

Literature

125results about How to "Eliminate bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

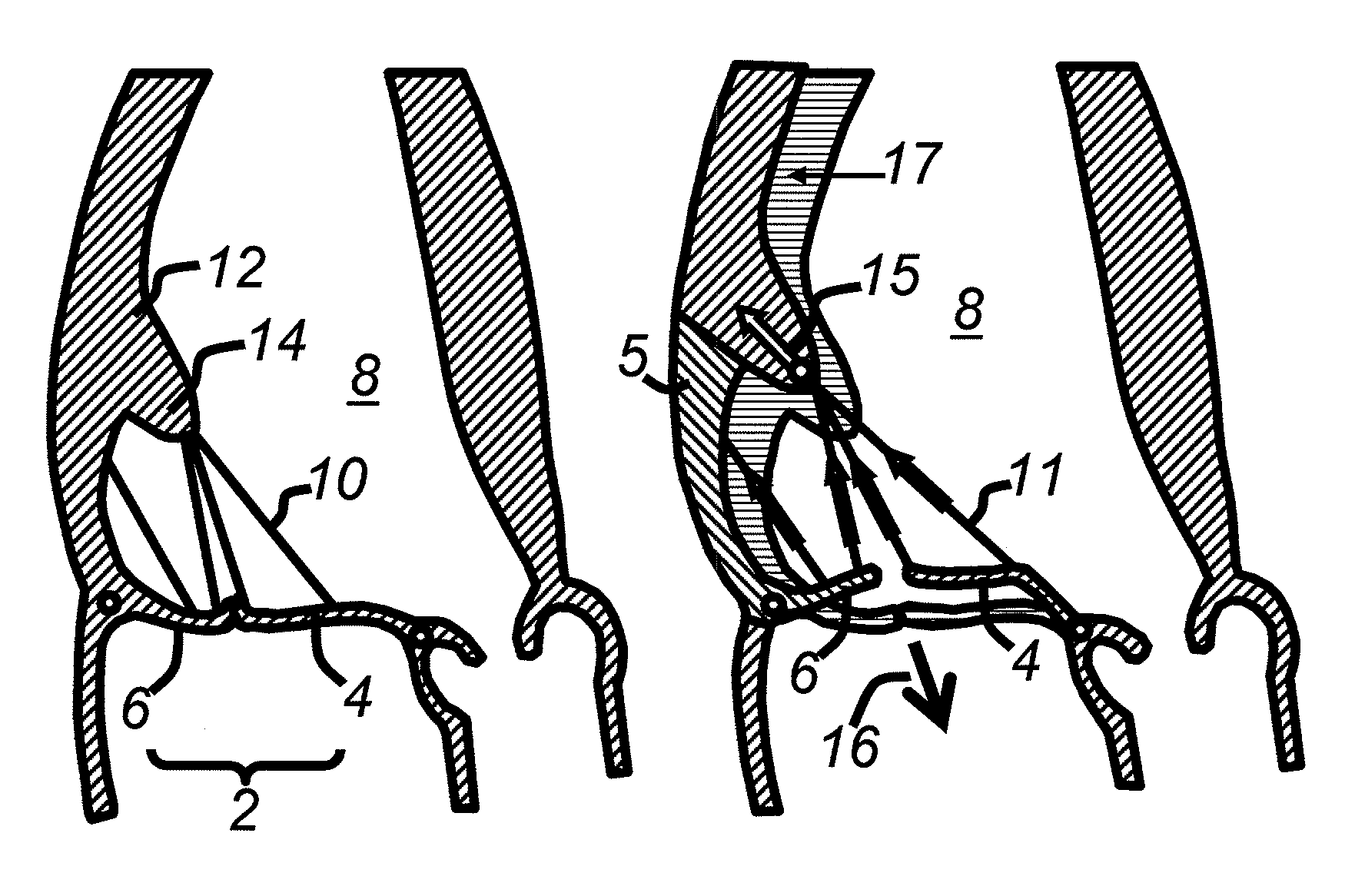

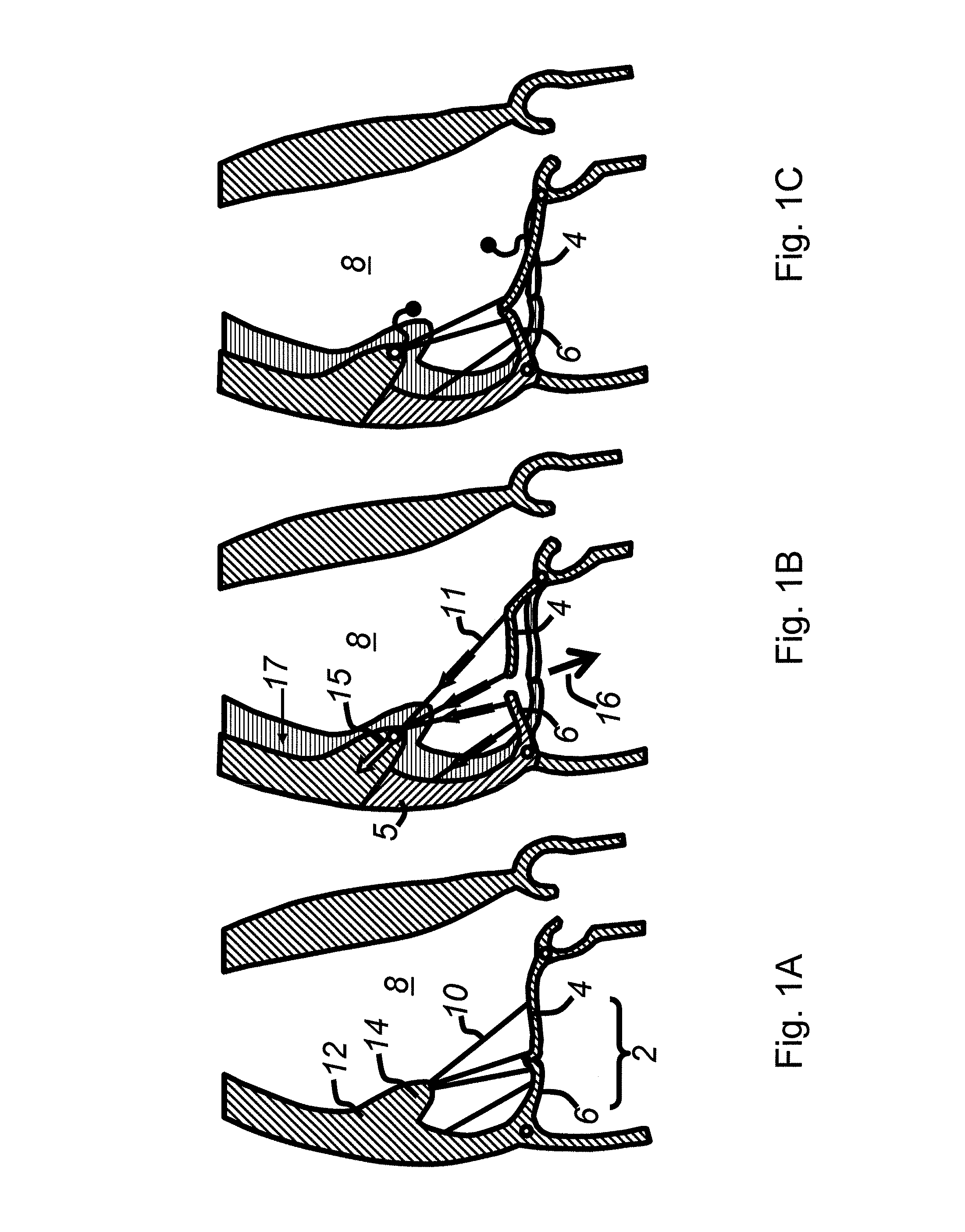

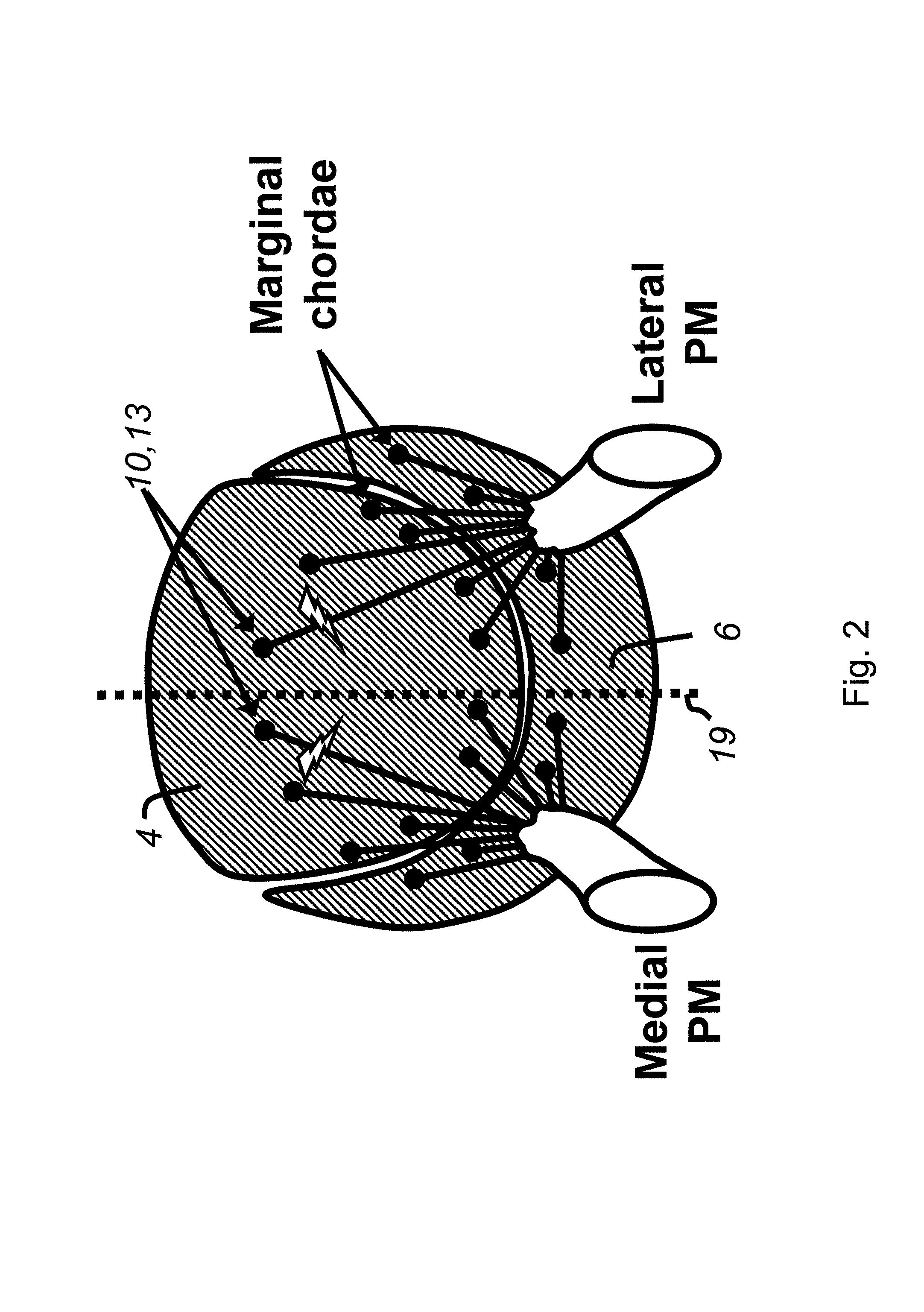

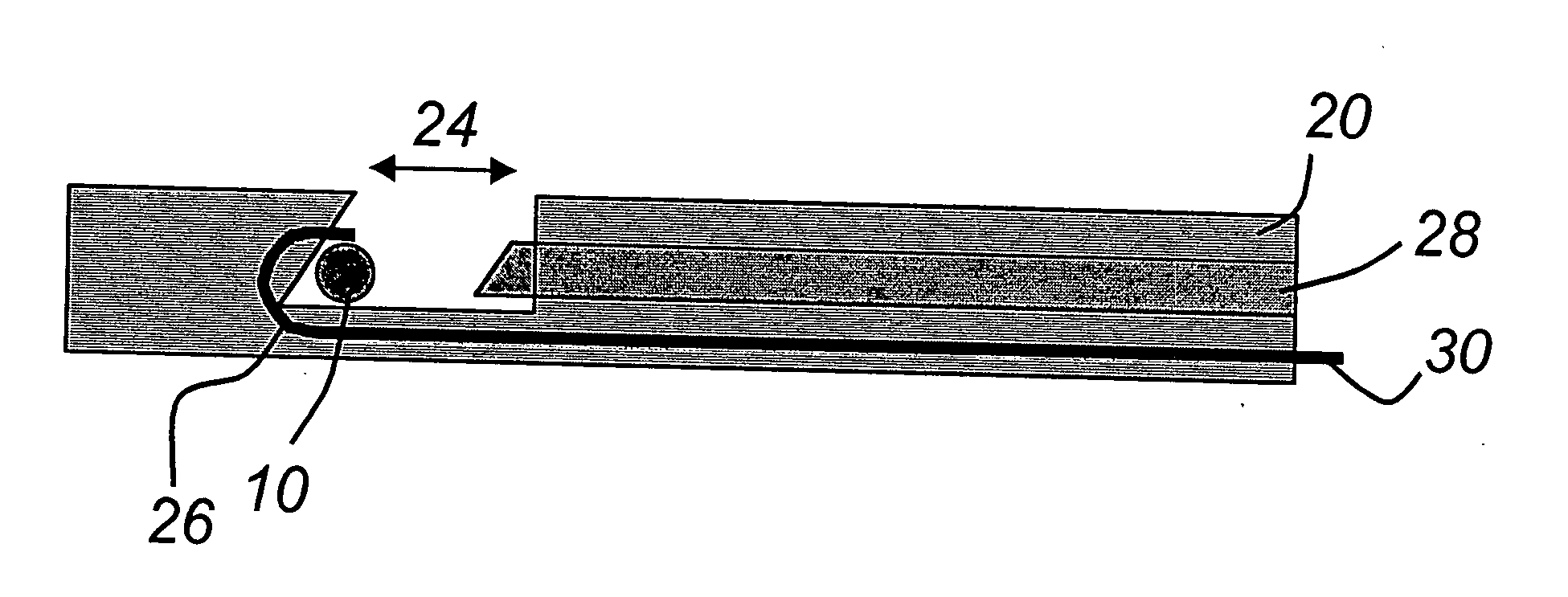

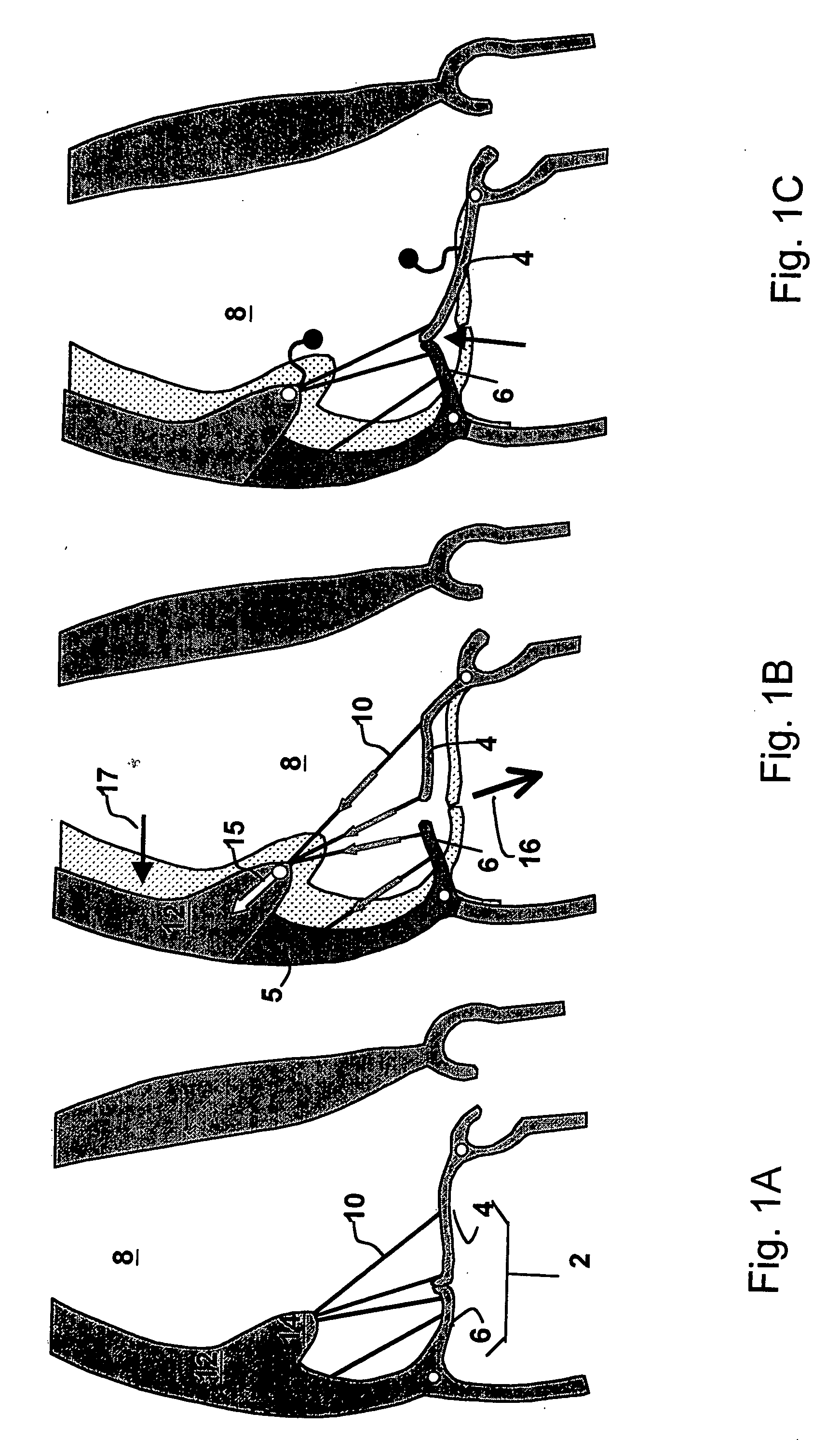

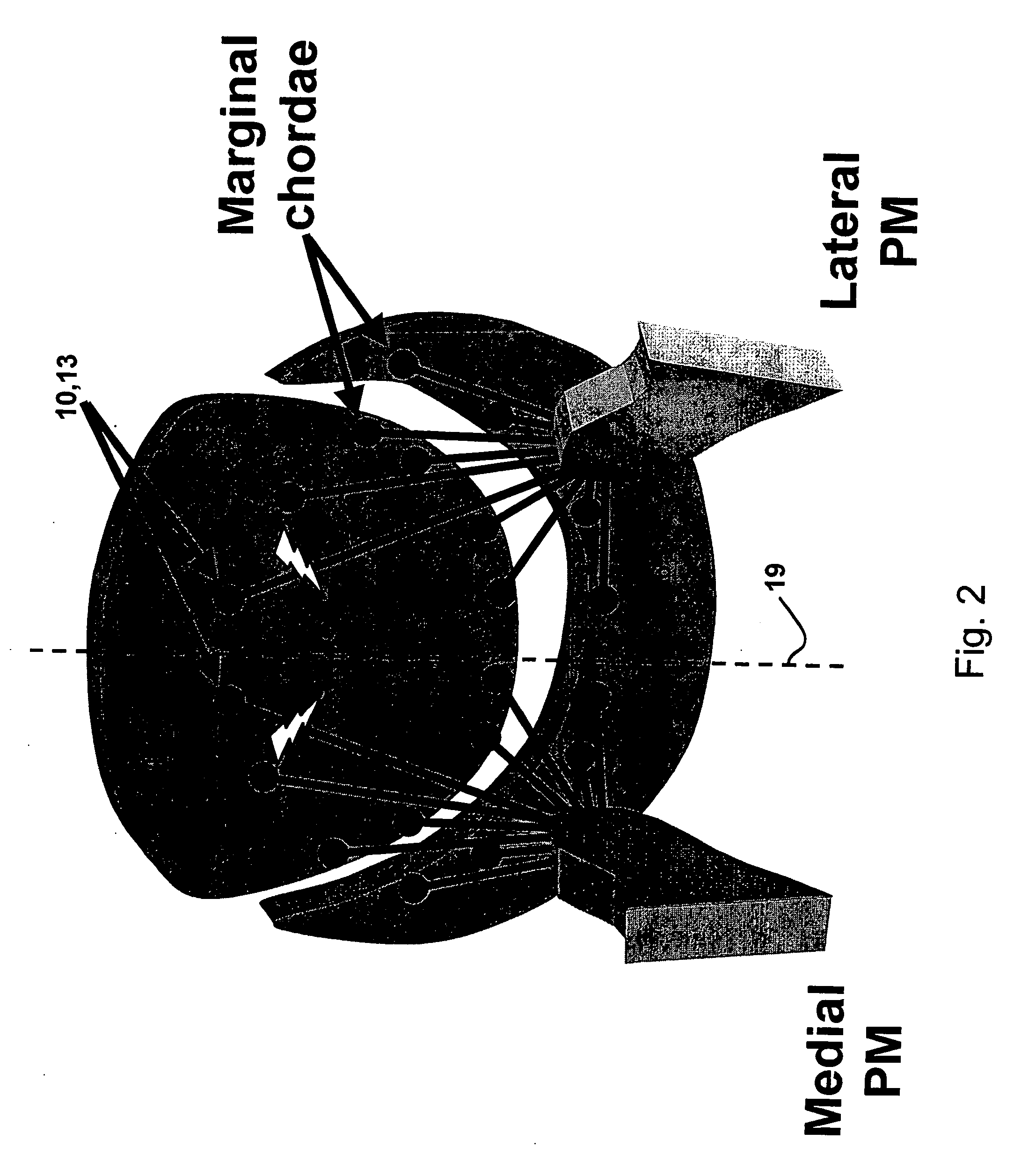

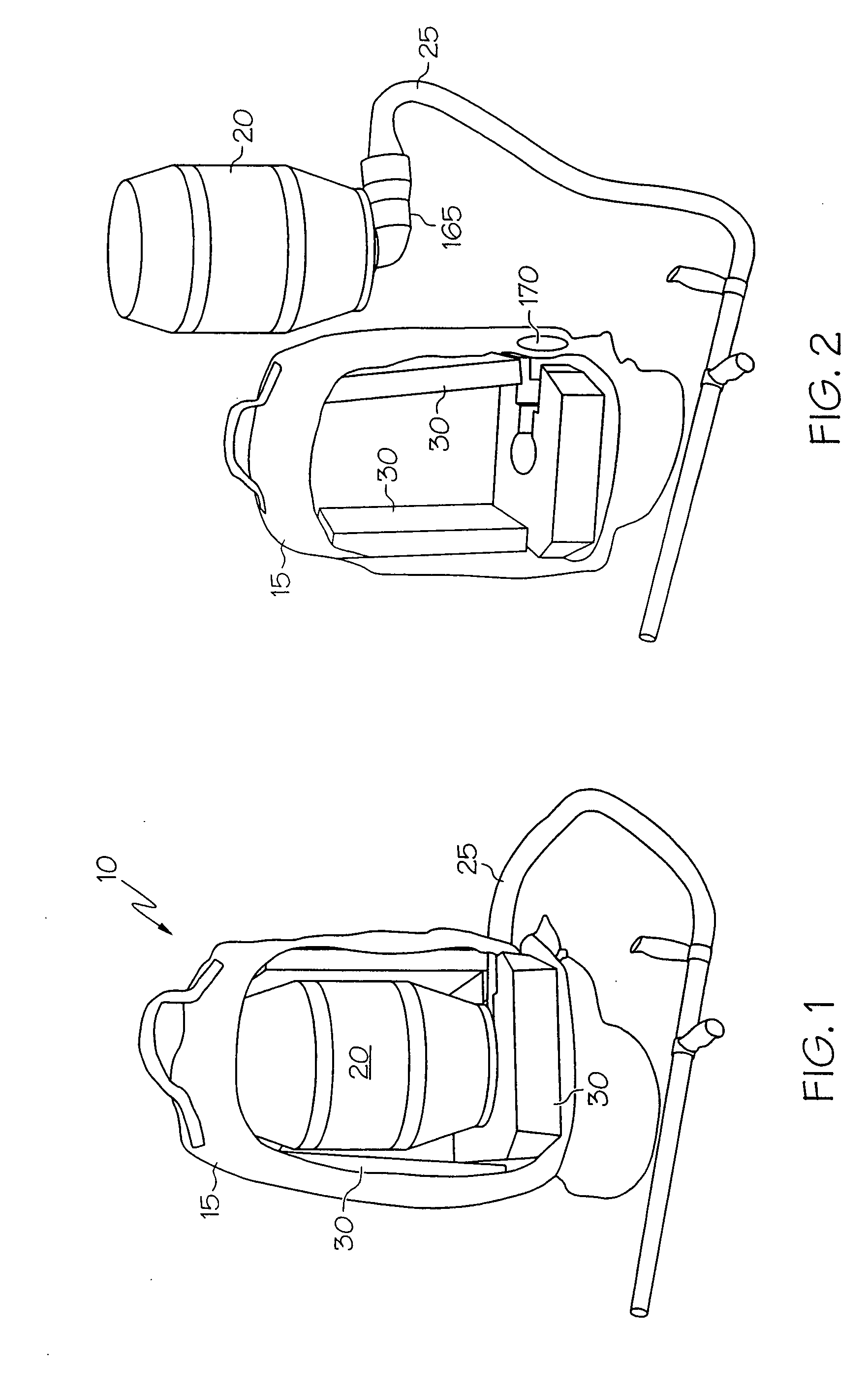

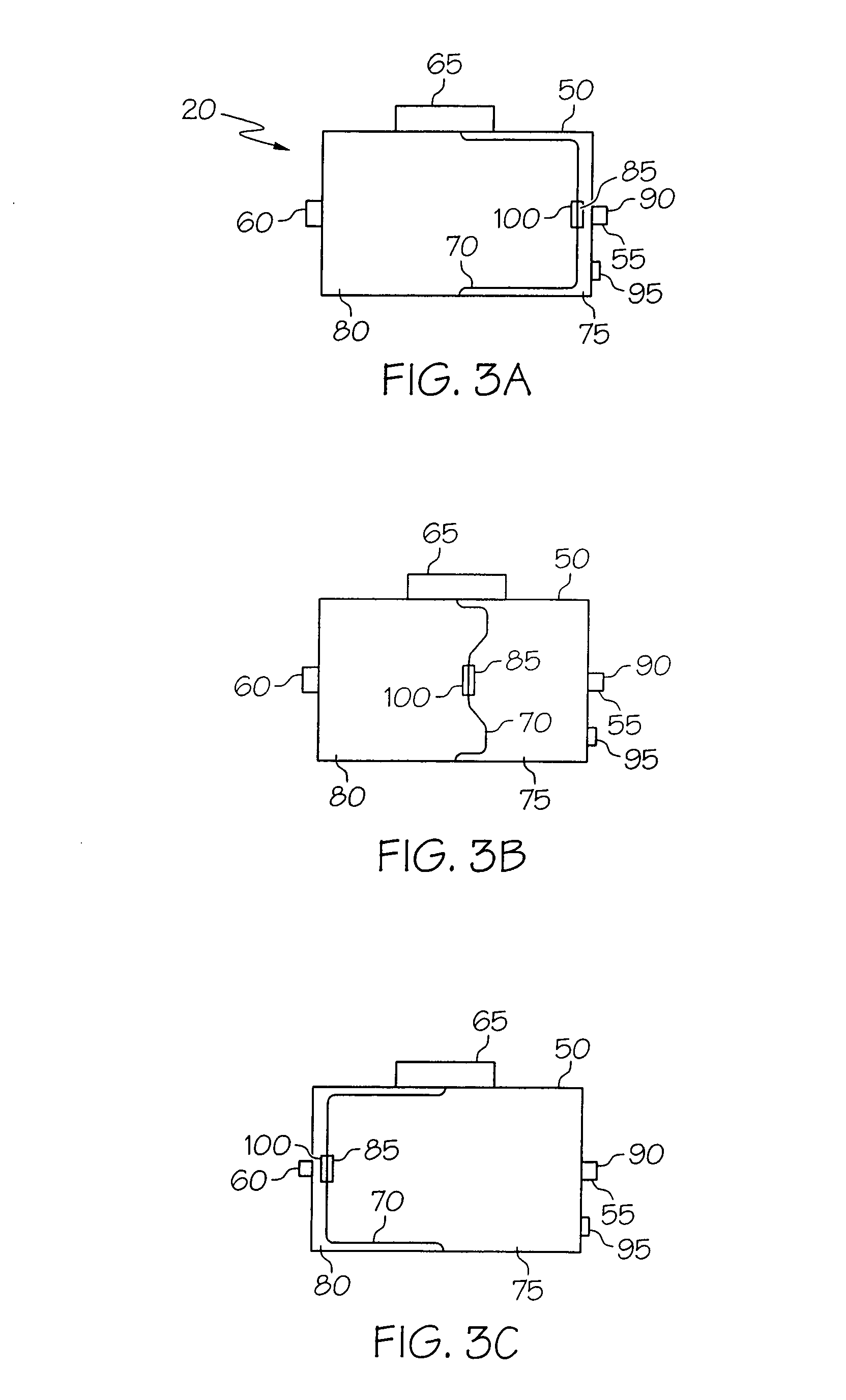

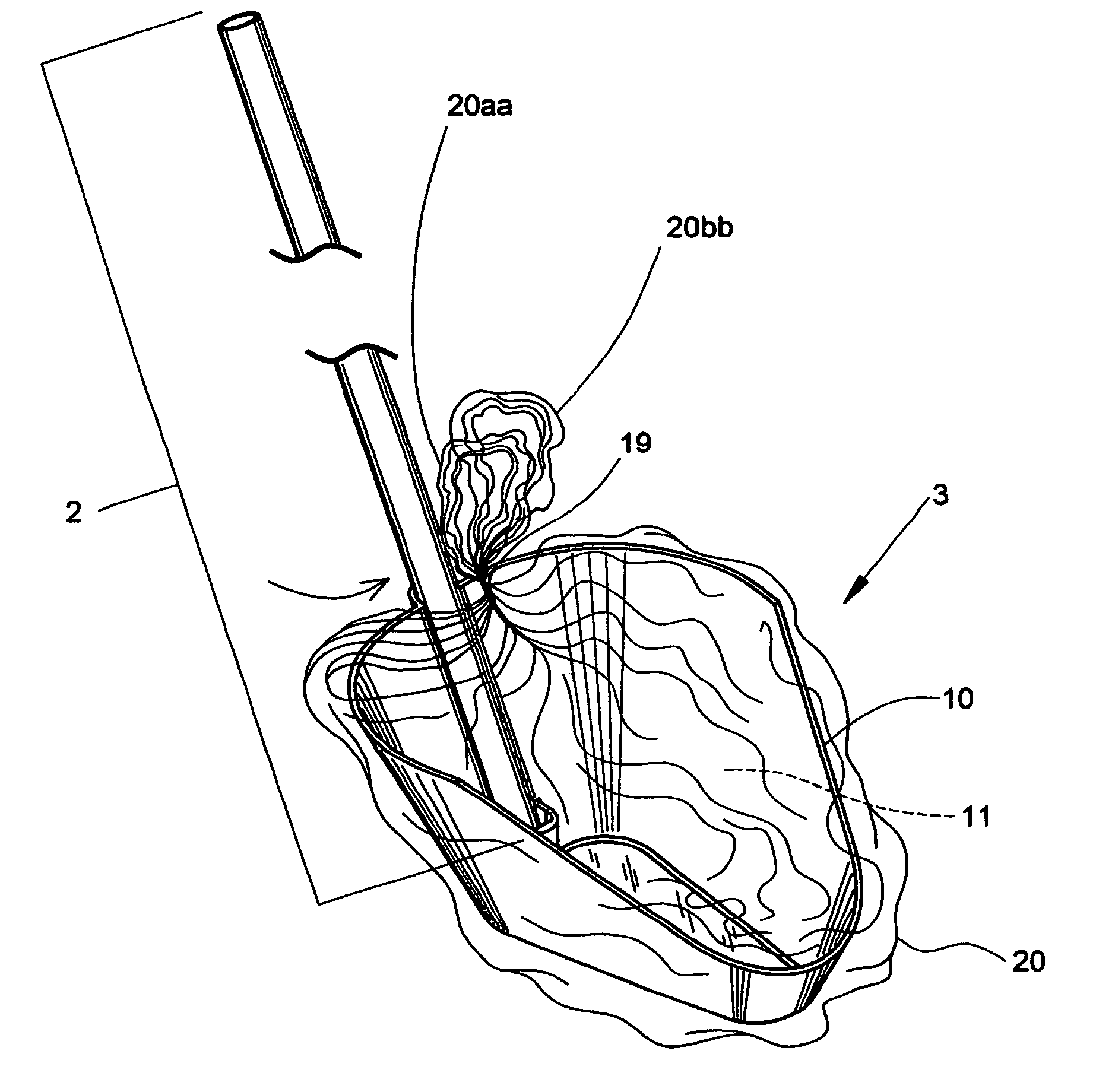

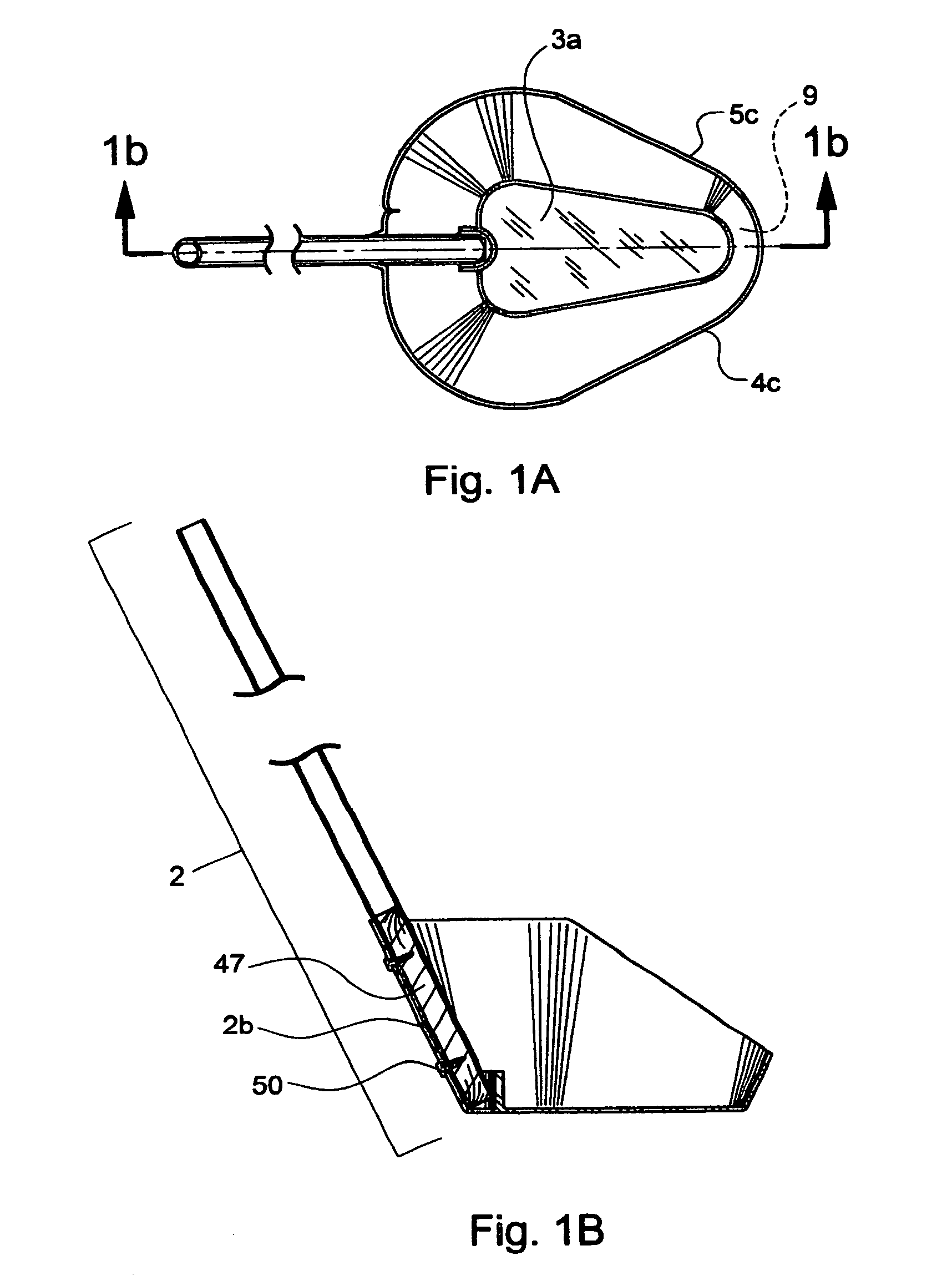

Cardiac devices and methods for minimally invasive repair of ischemic mitral regurgitation

ActiveUS8292884B2Eliminate bendingEffective closureIncision instrumentsDiagnosticsChordae tendineaeAtrial cavity

Novel apparatus and minimally invasive methods to treat atrioventricular valve regurgitation that is a result of tethering of chordae attaching atrioventricular valve leaflets to muscles of the heart, such as papillary muscles and muscles in the heart wall, thereby restricting the closure of the leaflets. Catheter embodiments for delivering and positioning chordal severing and elongating instruments are described.

Owner:THE GENERAL HOSPITAL CORP

Cardiac devices and methods for minimally invasive repair of ischemic mitral regurgitation

ActiveUS20060095025A1Eliminate bendingEffective closureIncision instrumentsHeart valvesChordae tendineaePapillary muscle

Novel apparatus and minimally invasive methods to treat atrioventricular valve regurgitation that is a result of tethering of chordae attaching atrioventricular valve leaflets to muscles of the heart, such as papillary muscles and muscles in the heart wall, thereby restricting the closure of the leaflets. Catheter embodiments for delivering and positioning chordal severing and elongating instruments are described.

Owner:THE GENERAL HOSPITAL CORP

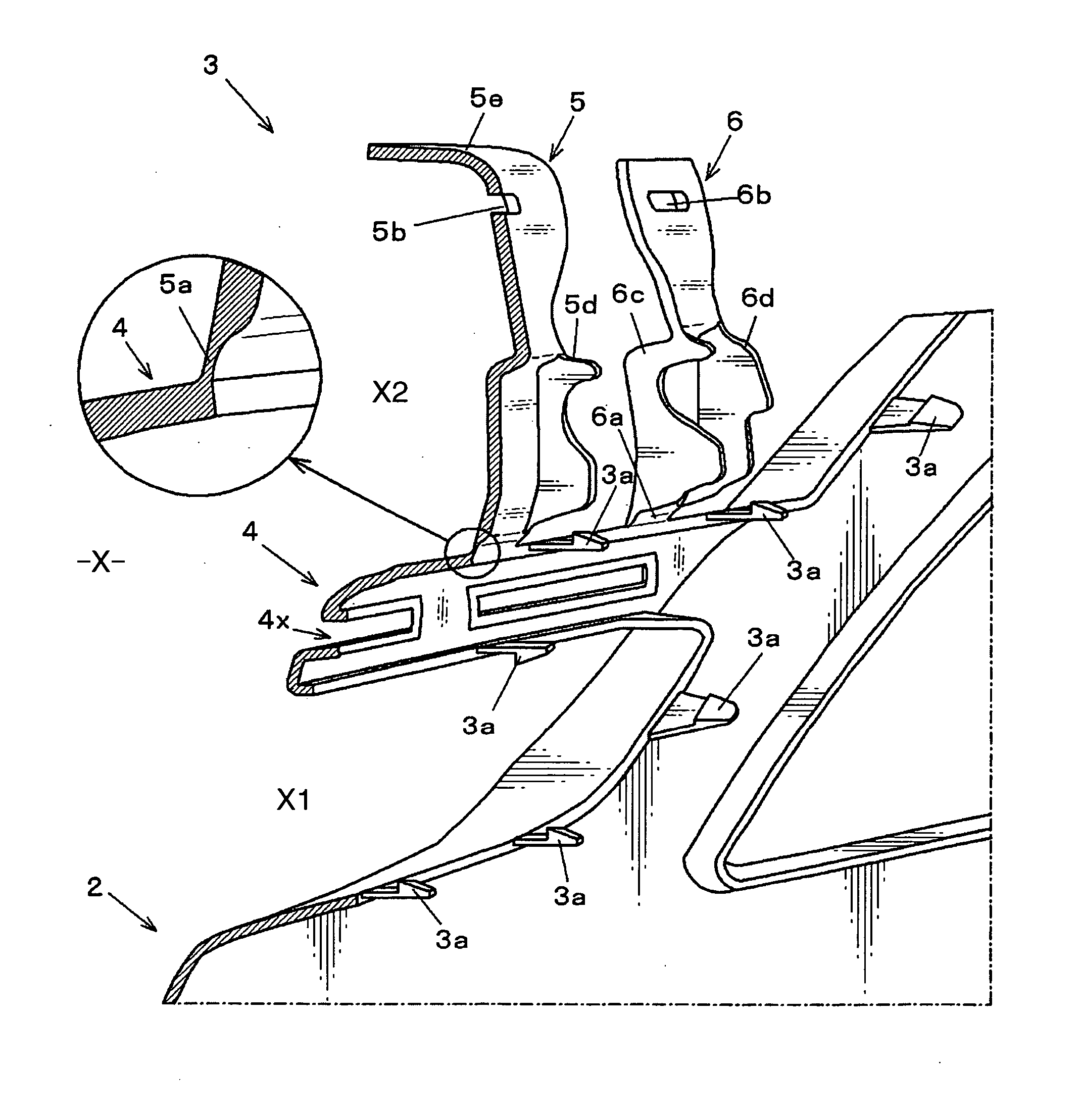

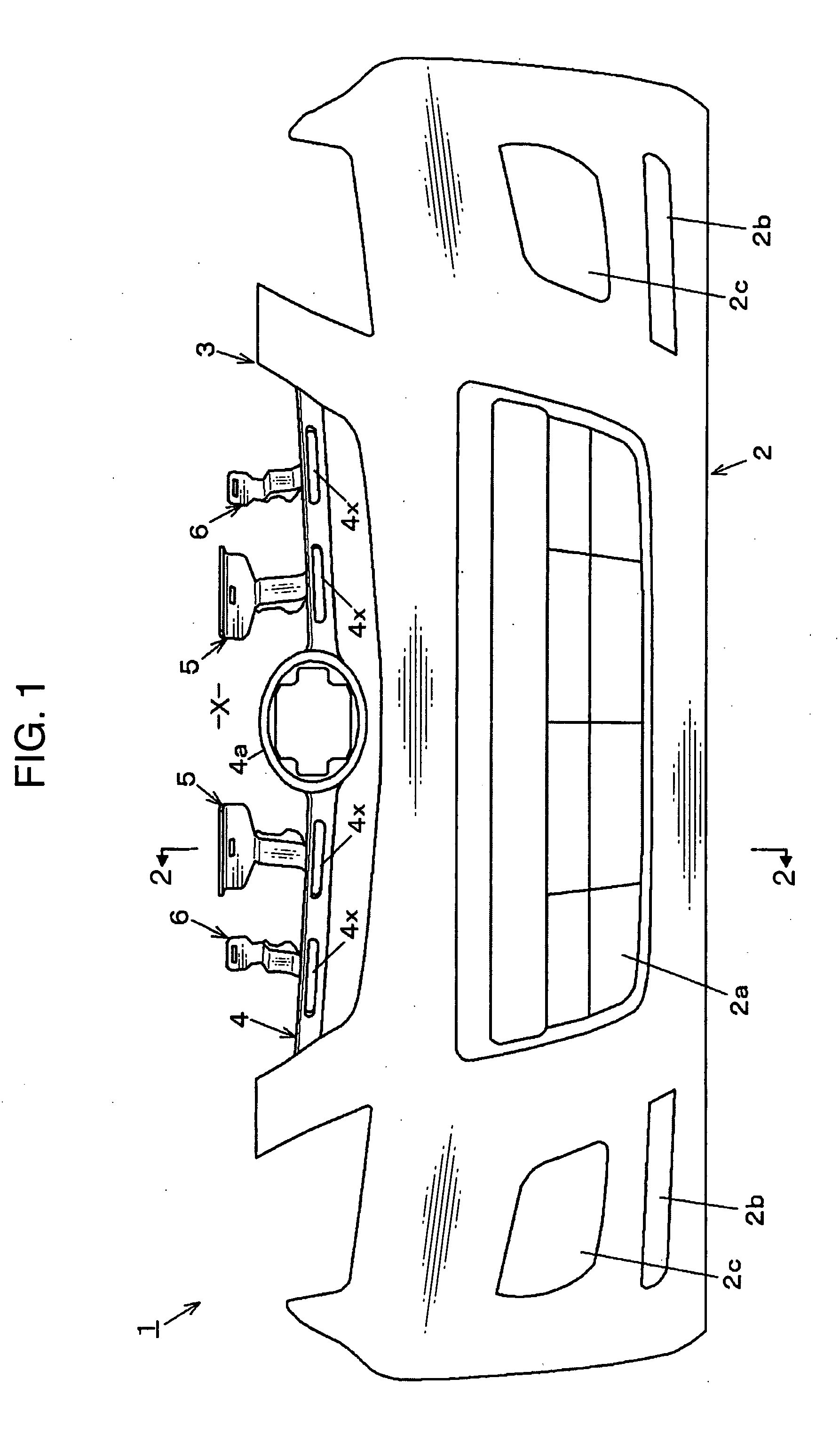

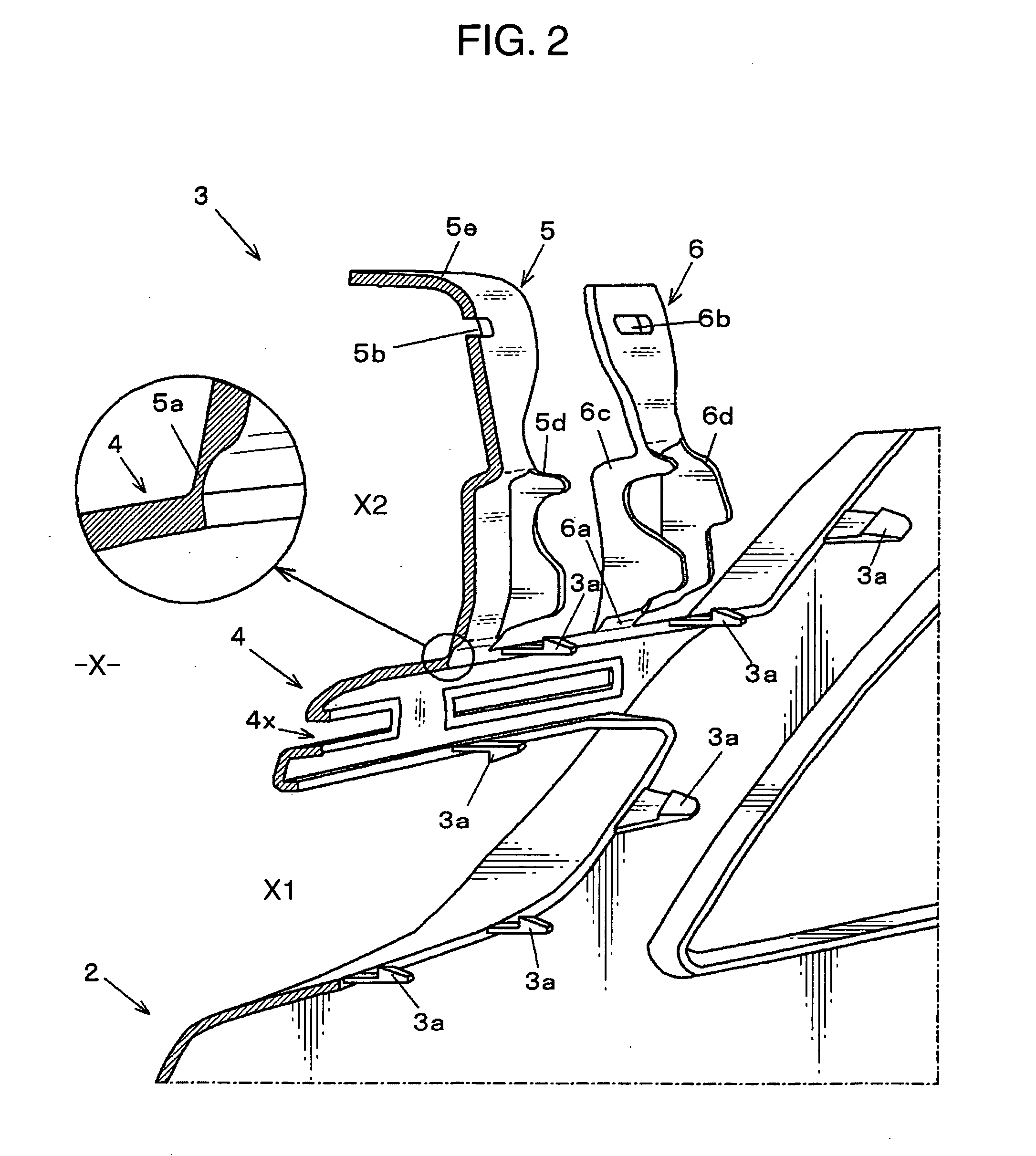

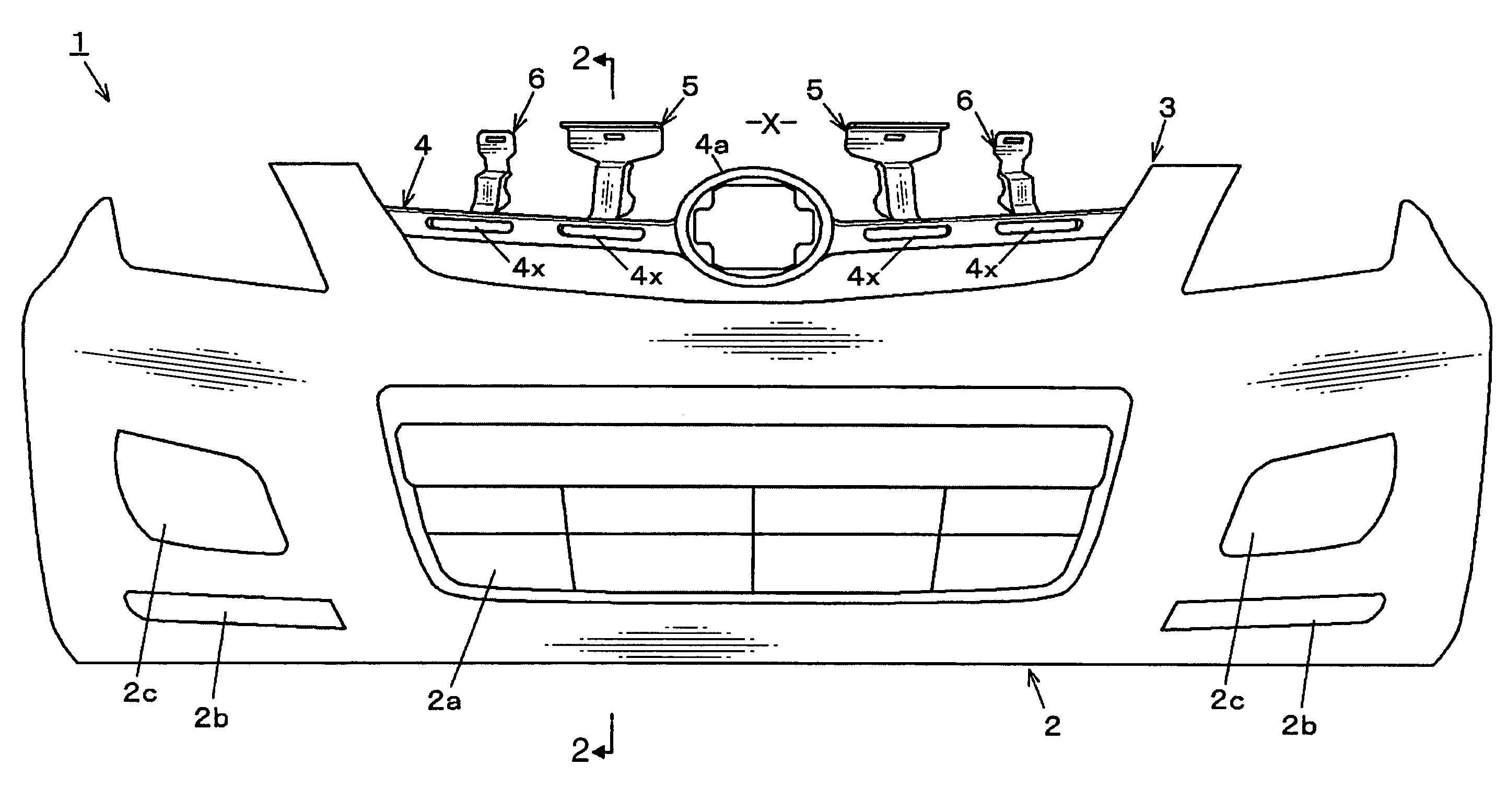

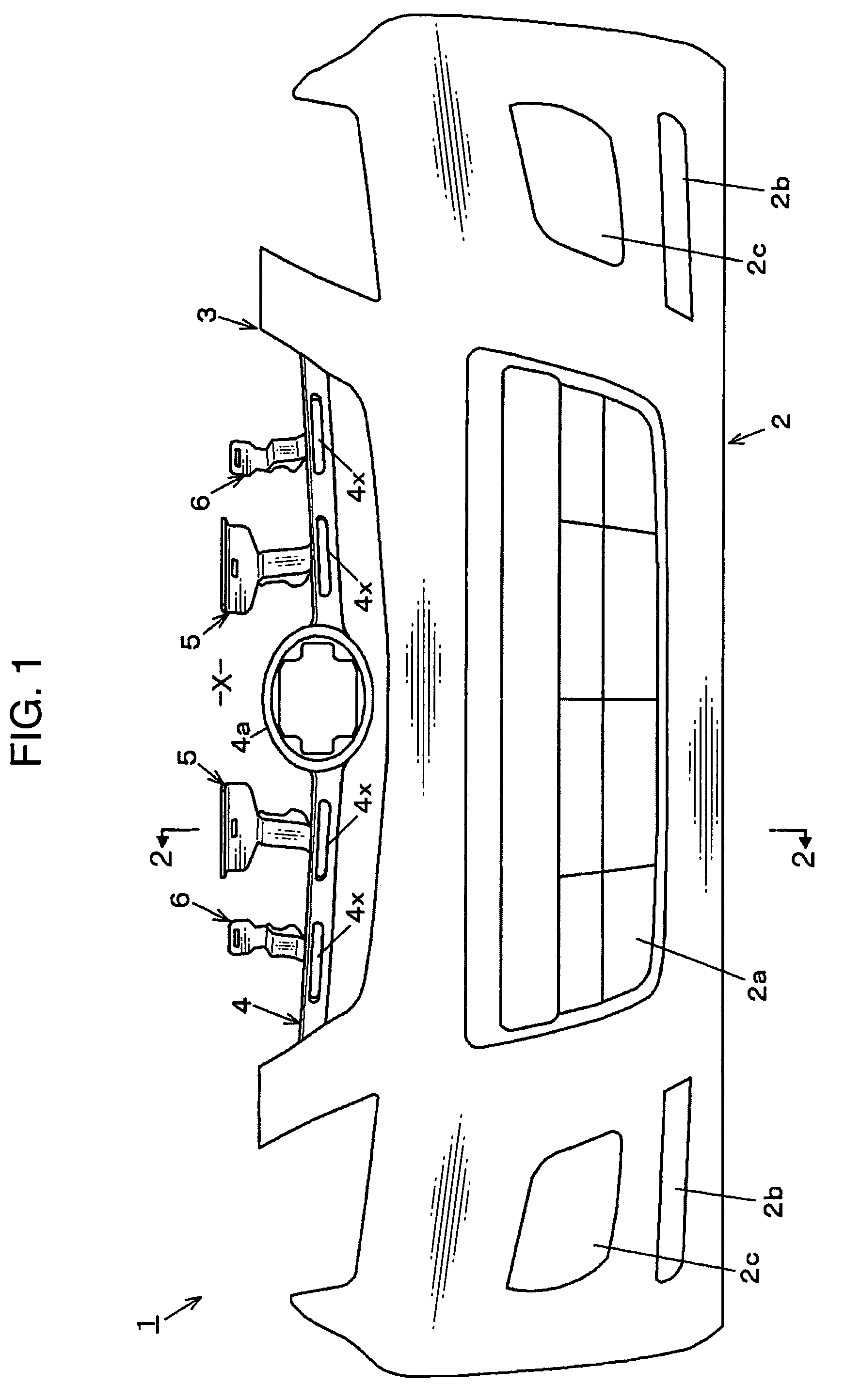

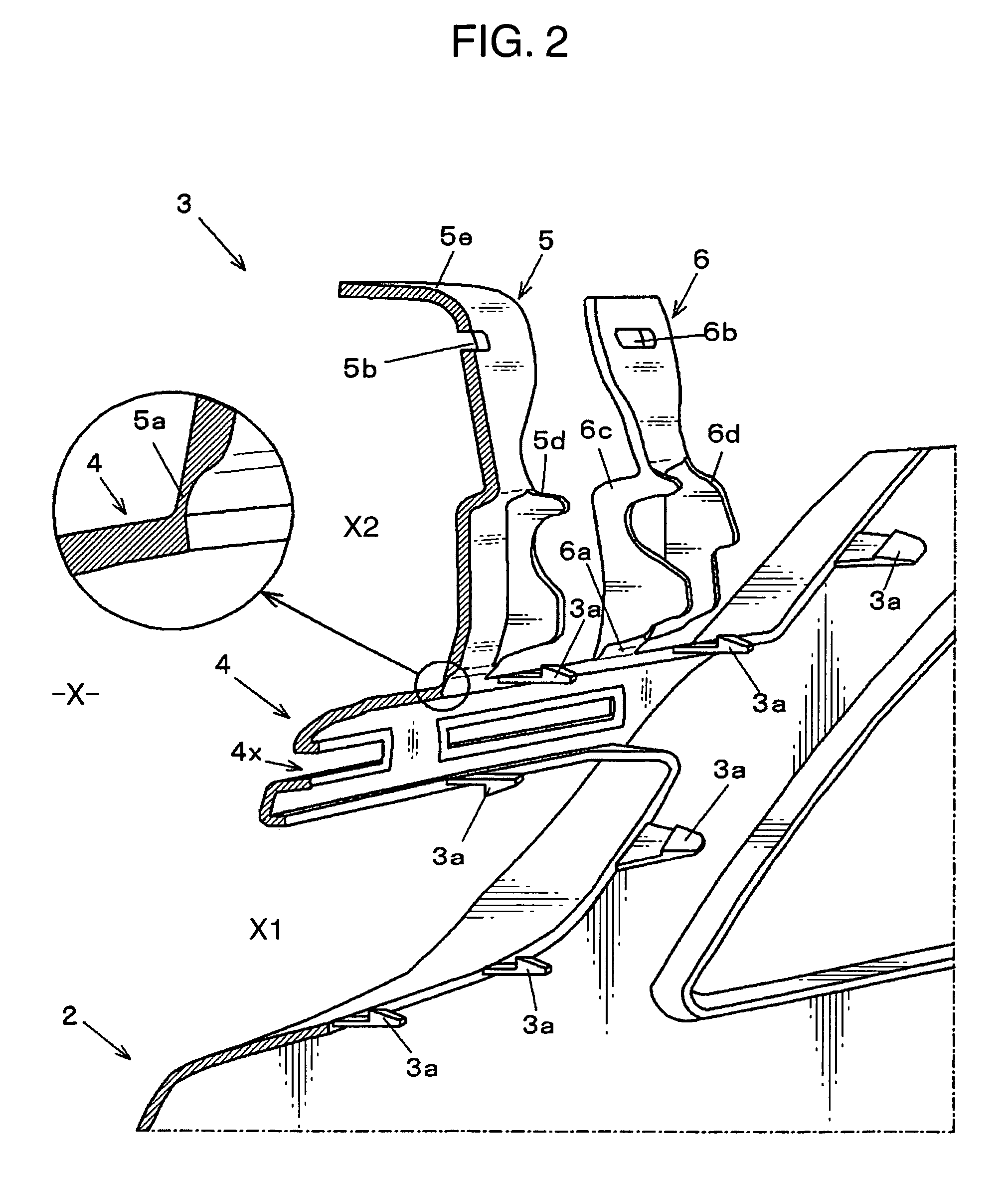

Bumper structure for vehicle

Disclosed is a bumper structure adapted to be attached to a front end of a vehicle, which is capable of preventing a fine member from being bent downward by its own weight after integrally forming a bumper body and a grill portion together, and avoiding a problem about deterioration in appearance of the grill portion which would otherwise be caused by the fin support remaining within the grill portion, so as to provide drastically enhanced appearance of the grill portion. A fin support (5, 5, 6, 6) is formed to allow an distal end thereof to extend toward an open zone on the upper side of an opening (X), and folded about a thin-wall portion (5a, 6a) in such a manner as to be engaged with an engagement pin (3a, - - - , 3a) at an edge of the opening (X) to support the fin member (4). After resin is cooled, thin-wall portion (5a, 6a) is cut off to remove the fin support (5, 5, 6, 6) from the inside of the opening (X).

Owner:MAZDA MOTOR CORP

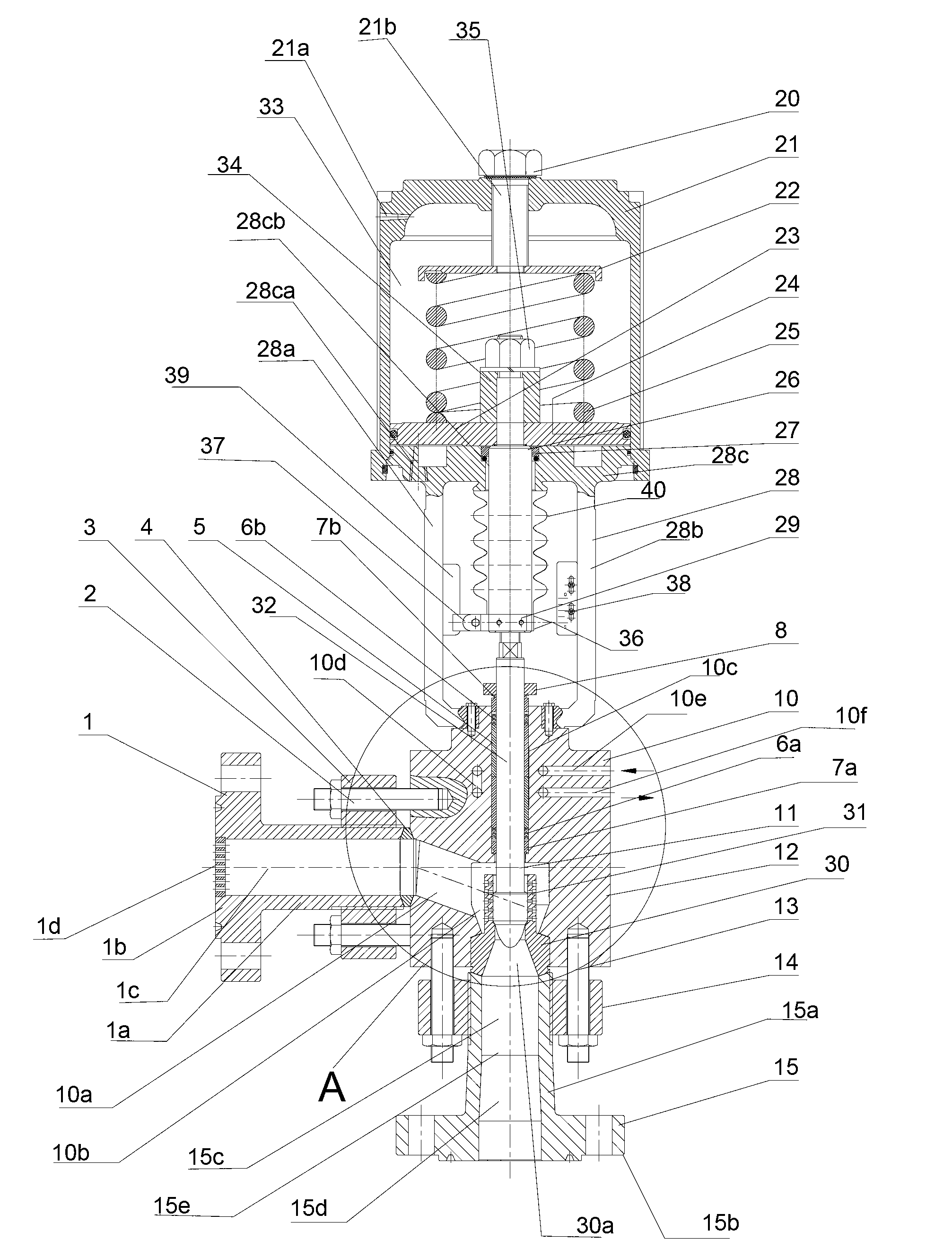

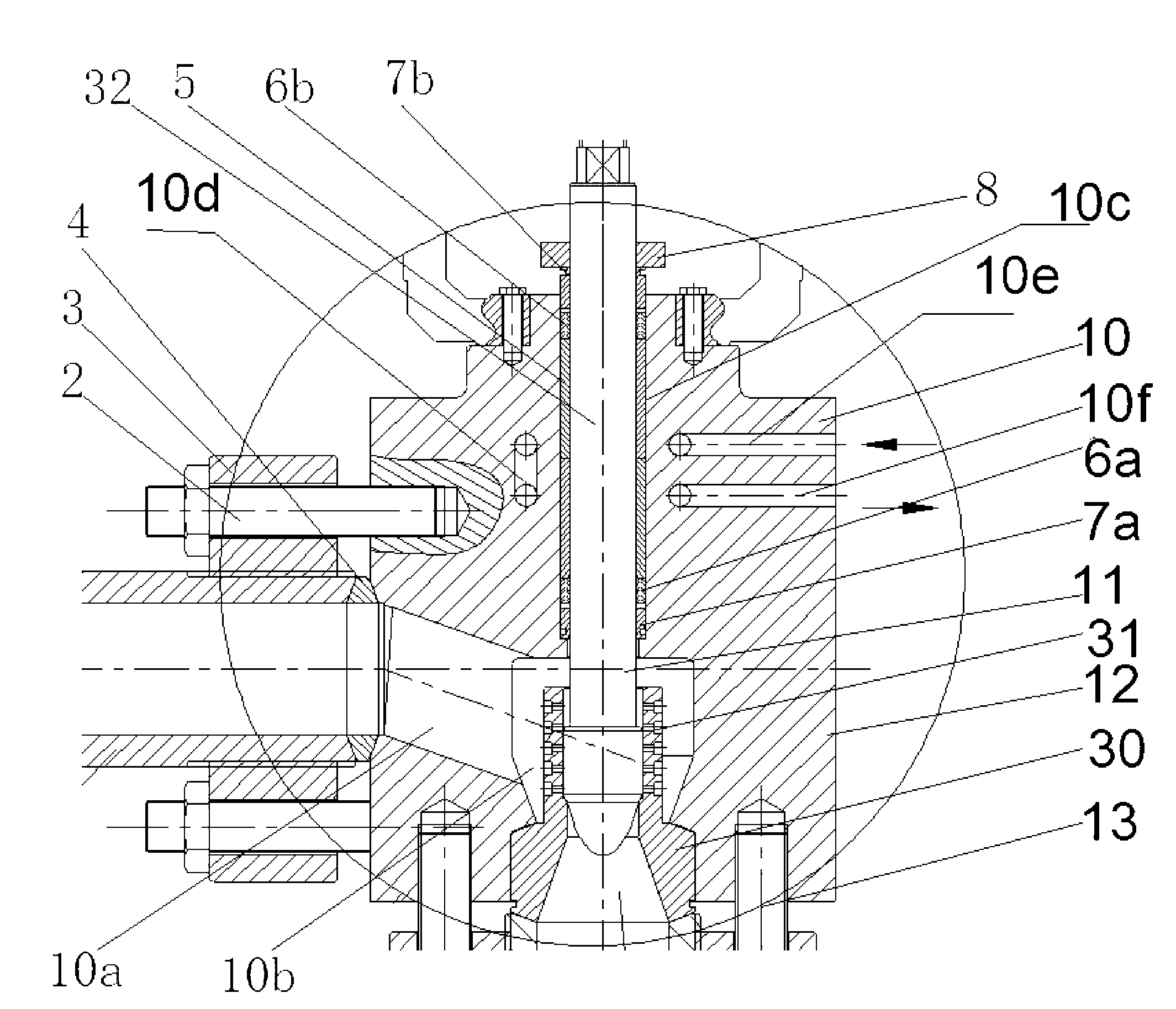

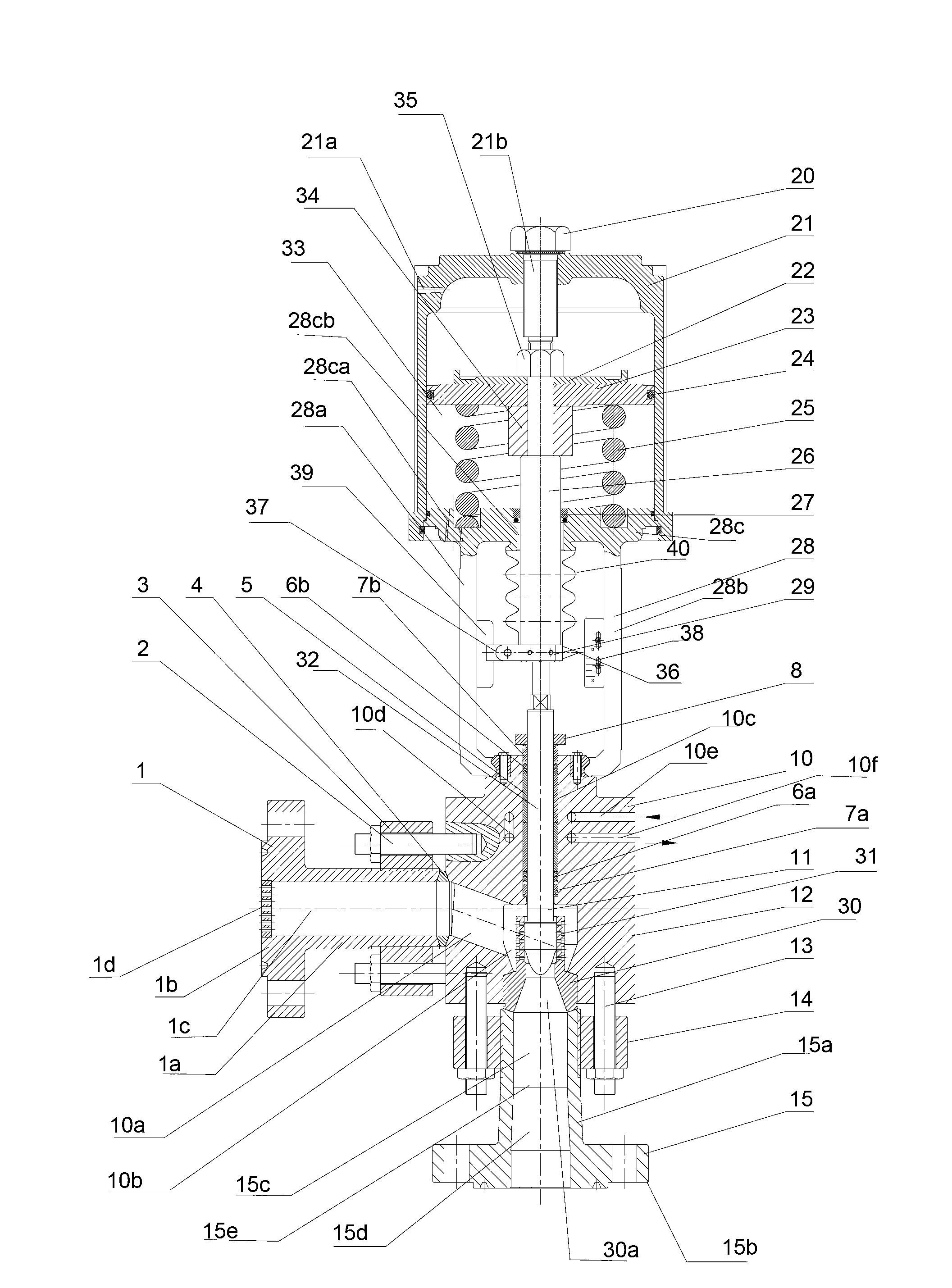

Pneumatic high pressure regulating valve

ActiveCN103016754AReasonable runner designShorten speedSpindle sealingsOperating means/releasing devices for valvesCavitationAutomatic control

The invention discloses a pneumatic high pressure regulating valve. The pneumatic high pressure regulating valve comprises an executing mechanism and a valve part which is arranged under the executing mechanism, wherein the valve part comprises a valve body; an inlet runner and an outlet runner are arranged in the valve body; and an angle formed between the inlet runner and the outlet runner is 120 degrees. The pneumatic high pressure regulating valve disclosed by the invention has the advantages as follows: as the plurality of special structural designs are adopted, applicable pressure difference of the valve is very high and cavitation phenomenon is completely eliminated; sensitive action and high response speed are obtained and the pneumatic high pressure regulating valve can be freely closed and opened and can be tightly closed when meeting very high fluid pressure difference; a side flange and a valve cage of the specially designed valve body can be also used for guiding fluid, buffering fluid pressure and protecting a valve core against being damaged by fluid ablation, flash evaporation and cavitation; meanwhile, noises can be also reduced; simple and rapid maintenance and low cost are also obtained; the service life is obviously prolonged; and the pneumatic high pressure regulating valve is especially suitable for automatically controlling high temperature and high pressure mediums with high pressure differences and is safe and reliable in use. The pneumatic high pressure regulating valve disclosed by the invention is especially incomparable with other valves in advantages when being used for places with high pressure urea and other easily crystallized mediums.

Owner:MAXCO IND TECH (SHANGHAI) CO LTD

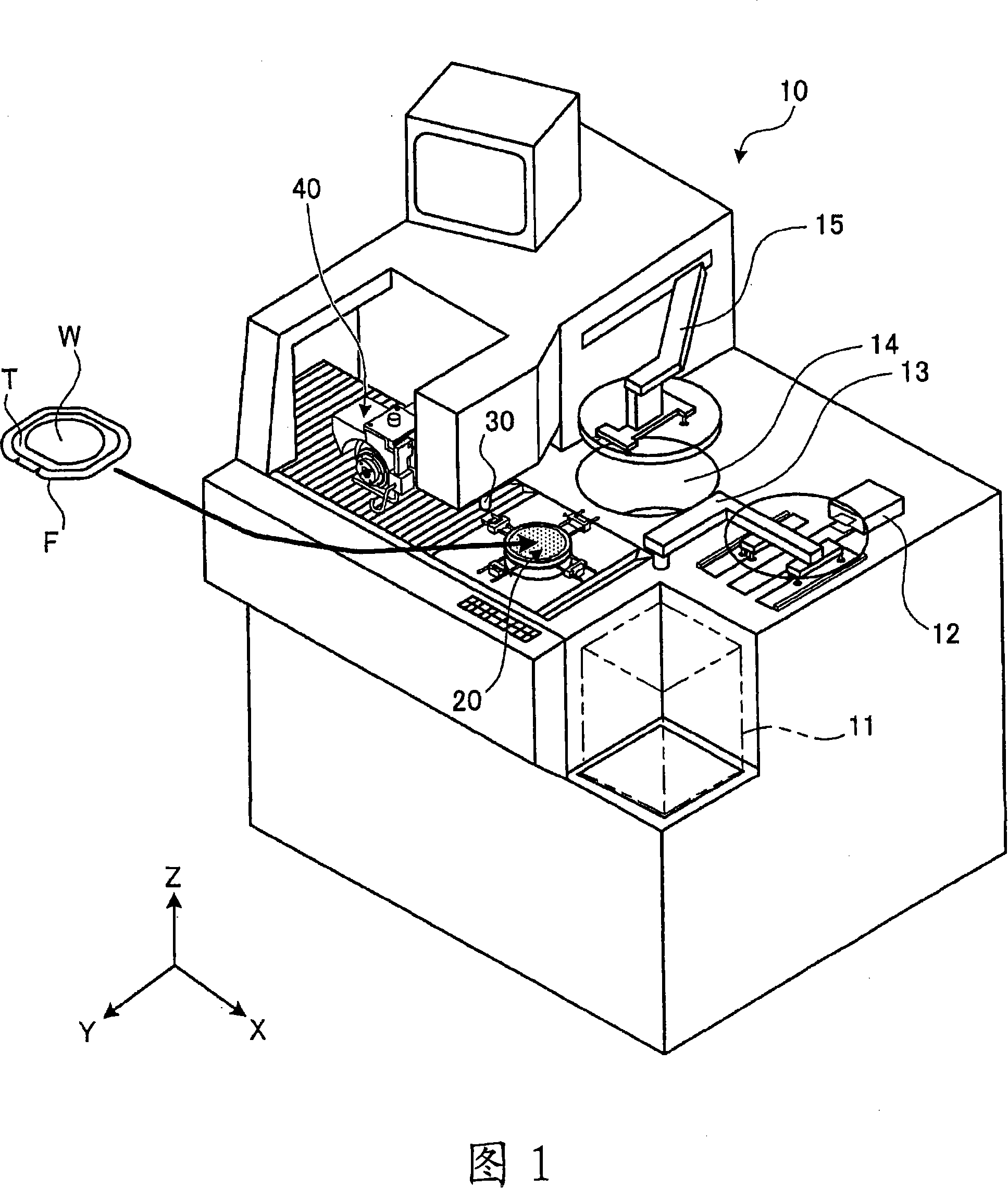

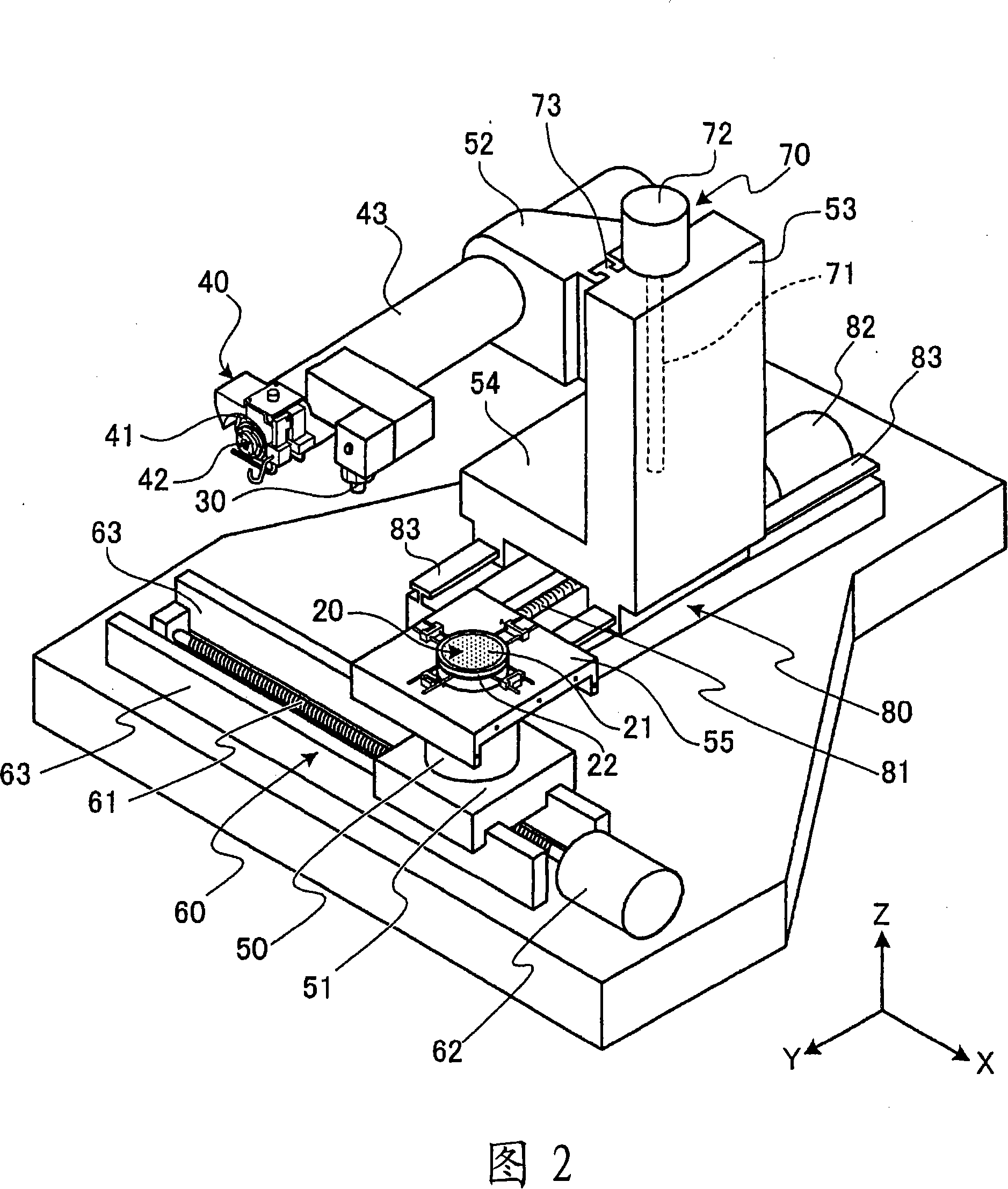

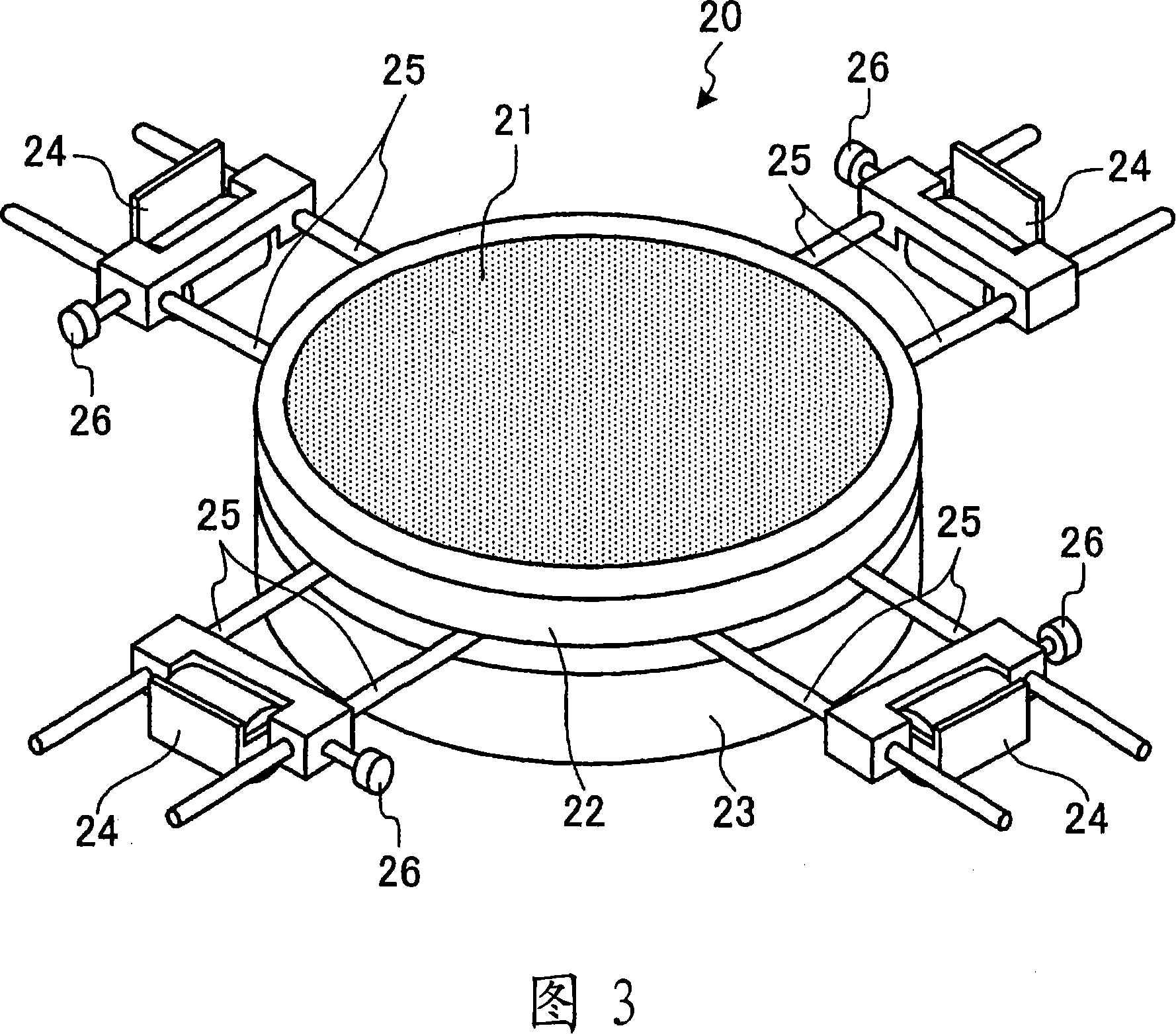

Processing device and suction plate bench

InactiveCN101140892AEliminate bendingDecreased upper surface accuracySemiconductor/solid-state device manufacturingPositioning apparatusThermal expansionTortuous retinal vessels

The present invention provides a processing device and a sucking disc worktable for preventing occurrence of the phenomena such as tortuosity of the sucking disc worktable due to temperature variation, fracture or deviation from frames of aspiration maintenance parts, even in case of realization of major diameter of crystal plates and the sucking disc worktable. The aspiration maintenance part (21) of the sucking disc worktable (20) is made of a porous ceramic whose main component is zirconium oxide having coefficient of linear thermal expansion of 9.0x10 <-6> DEG C approximately similar to that (10.4x10 <-6> DEG C) of stainless steel forming the frame body (22). Therefore, problems such as tortuosity of the sucking disc worktable due to temperature variation, fracture or deviation from the frames of the aspiration maintenance parts can be eliminated; in case of realization of major diameter of crystal plates and the sucking disc worktable, even temperature variation exists, precision drop of supine surfaces of the sucking disc worktable can be restrained, and crystal plates can be processed with high accuracy.

Owner:DISCO CORP

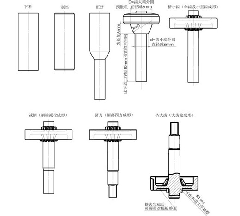

Integral forging near net shaping process for triple gear block, and prepared gear shaft

ActiveCN102189373AGuaranteed coaxialityGuaranteed positionPortable liftingGearing elementsHobbingEngineering

The invention discloses an integral forging near net shaping process for a triple gear block. The process is characterized by comprising the following steps of: blanking and preparing blank; extruding a handle part in a forward direction; pre-upsetting; extruding to obtain a small gear; performing spheroidizing; performing saponification of phosphorus; and extruding to obtain a large gear. The adopted technological scheme has the advantages that: (1) the triple gear block is subjected to integral forging near net shaping; (2) a bevel gear is pre-set, and a material at a tooth space is extruded out, so that the disadvantage of folding caused by pressing a spoke wheel during rear-pass warm forging is avoided; (3) a large straight gear is obtained through cold extrusion, and positioning orientation is adopted, so that the coaxiality and the position of a bevel gear mold and a large straight mold are guaranteed; and by using a lower pressure block, a spoke plate is prevented from being deformed due to gear extrusion, the disadvantages of gear root bending, gear face galling, and damage to a gear mold are eliminated, and in the tooth profile, the undercutting caused by hobbing is avoided.

Owner:JIANGSU CHUANGYI PRECISION FORGING

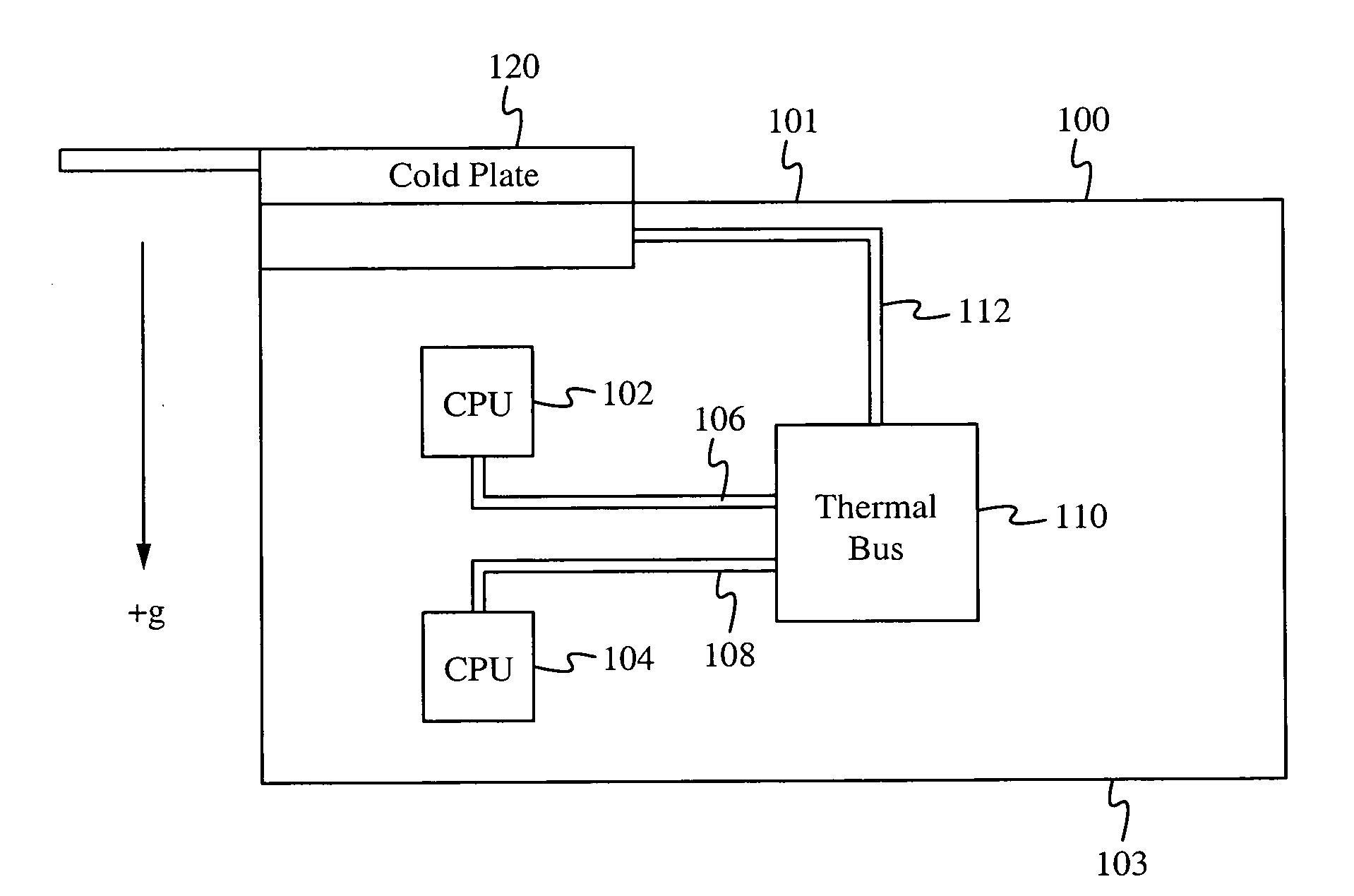

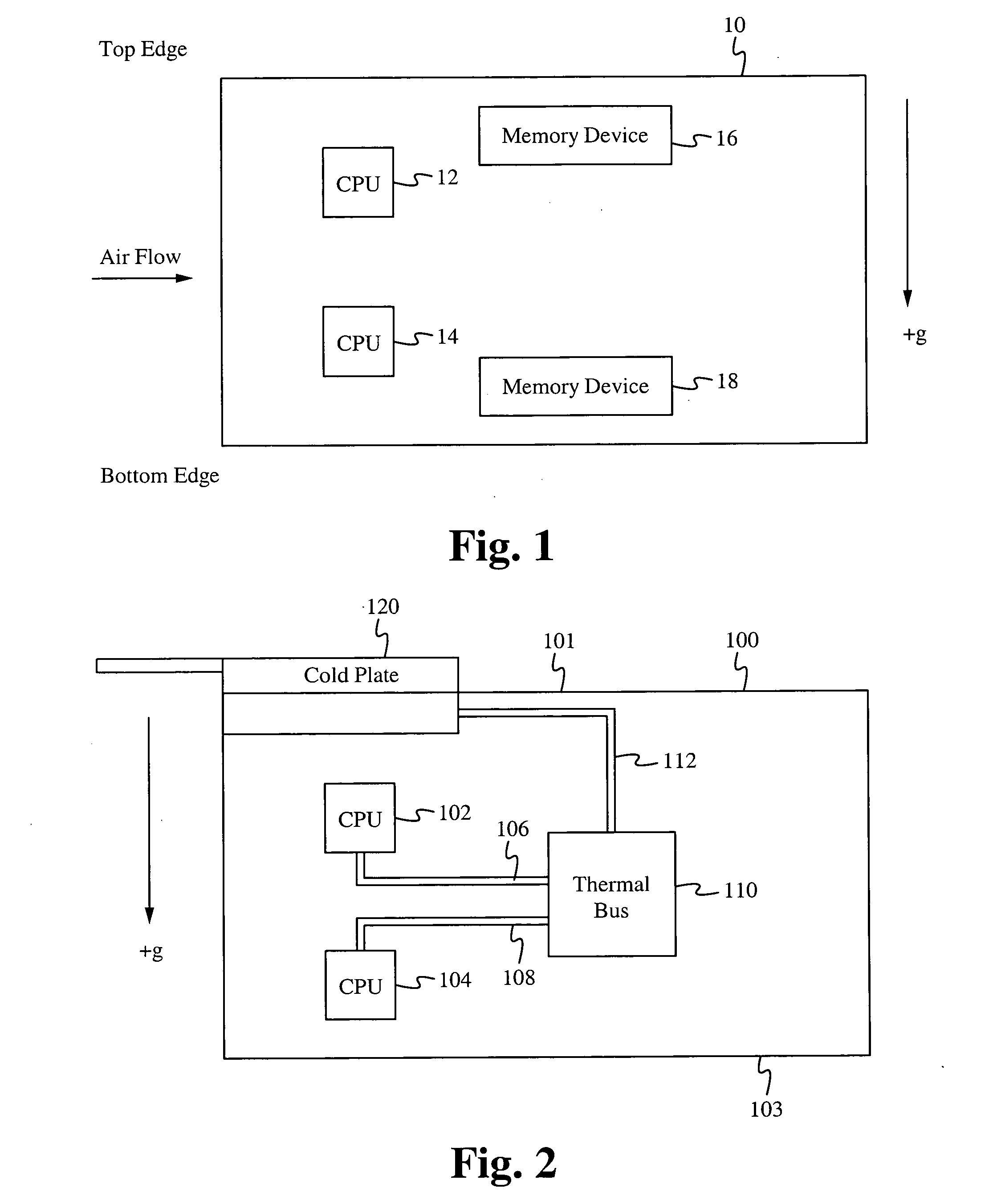

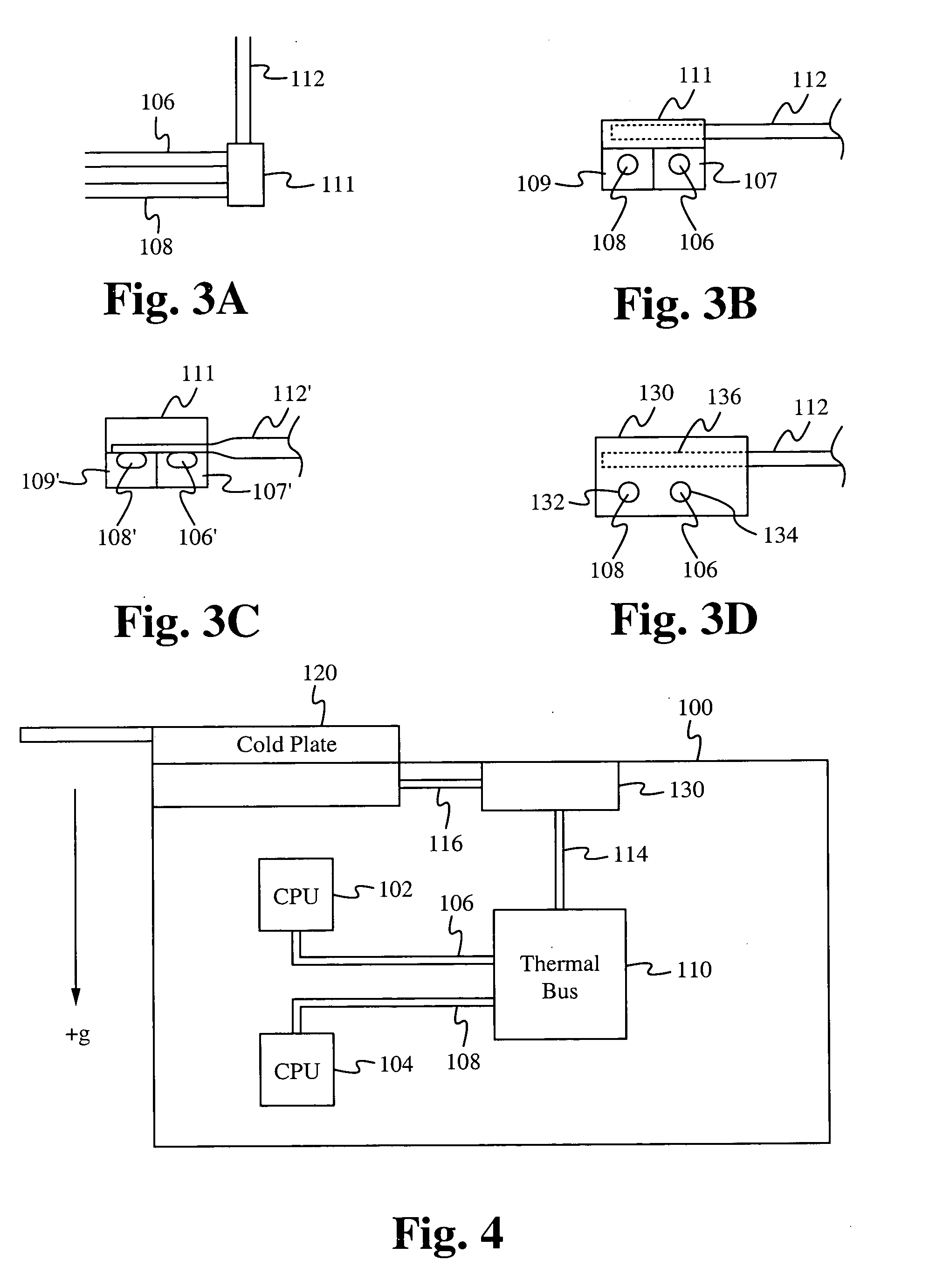

Thermal bus or junction for the removal of heat from electronic components

InactiveUS20090225515A1Shorten the lengthShort strokeWing accessoriesIndirect heat exchangersWorking fluidEngineering

A thermal bus enables the use of multiple separate heat pipe assemblies instead of using a single heat pipe assembly spanning the distance from heat source to cold plate. The use of a thermal bus can decrease the orientation effects as well as decrease the travel length of any single heat pipe assembly. In addition, the use of multiple heat pipe assemblies enables each individual heat pipe assembly to be optimized to meet localized heat transfer characteristics between each heat source, the thermal bus, and the cold plate. Such optimization can include the use of differently sized heat pipes, wick structures within the heat pipe, and working fluid used within the heat pipe. The thermal bus provides an intermediate thermal transfer from one heat pipe assembly serially coupled to another heat pipe assembly, thereby enabling multiple serially coupled heat pipe assemblies to transfer heat from a given heat source to the cold plate at the edge of the electronics board.

Owner:COOLIGY INC

Novel low smoke zero halogen fire resistant armoured cable

InactiveCN1963956ANot subject to crackingEliminate bendingInsulated cablesInsulated conductorsLow smoke zero halogenStress concentration

The related halogenless low-smoke fire retardation armoured cable comprises: between the dual-layer open lapping tape armoring and the halogenless low-smoke fire retarding polyolefin oversheath, arranging a buffer layer as lapping or extruding structure to eliminate stress concentration and prevent the oversheath cracking led by the armoring. This invention has well physical and chemical performances, and can improve cable reliability for long service time.

Owner:JIANGSU HONGTU HIGH TECHNOLOGY STOCK CO LTD

Bumper structure for vehicle

Owner:MAZDA MOTOR CORP

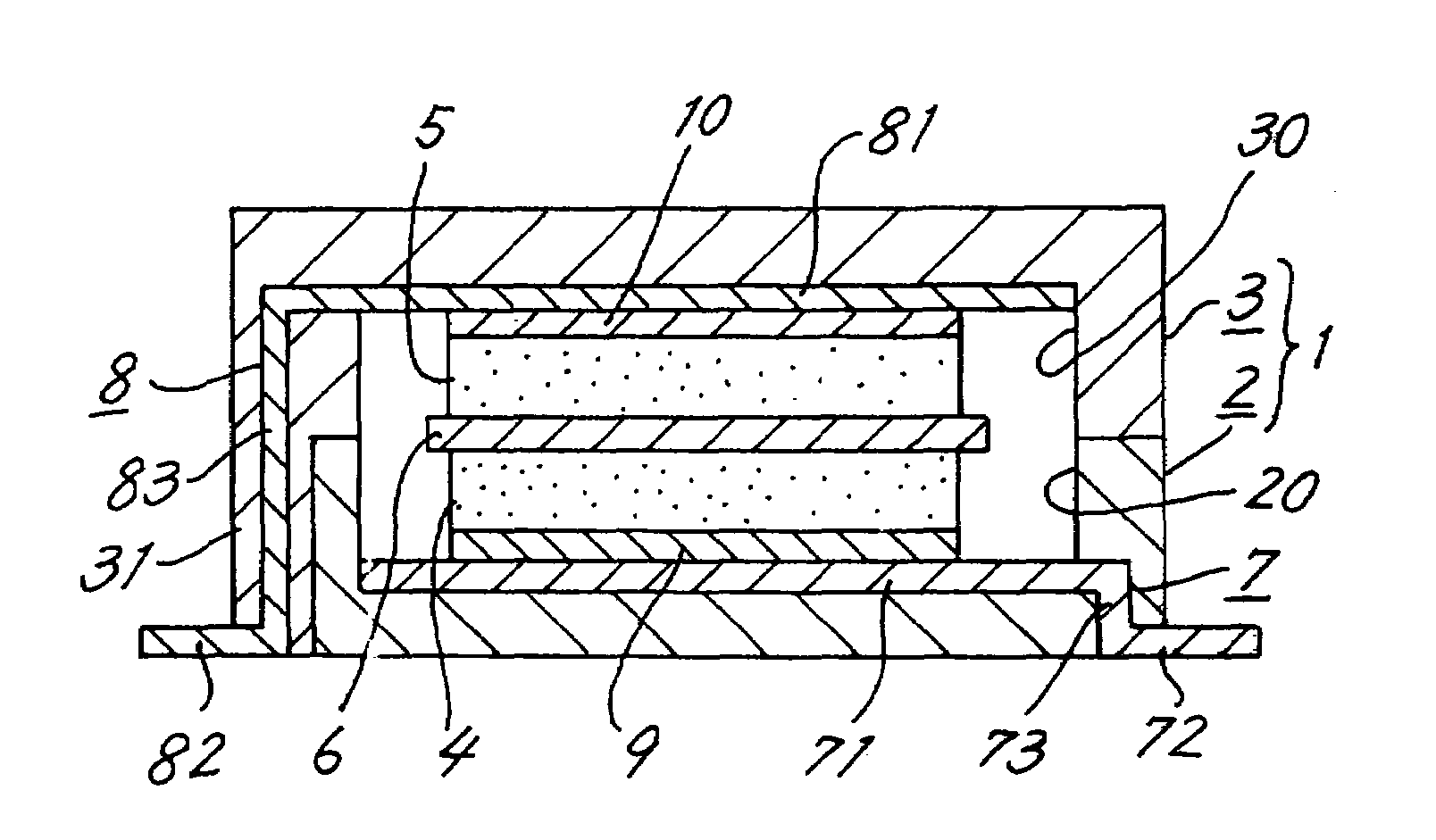

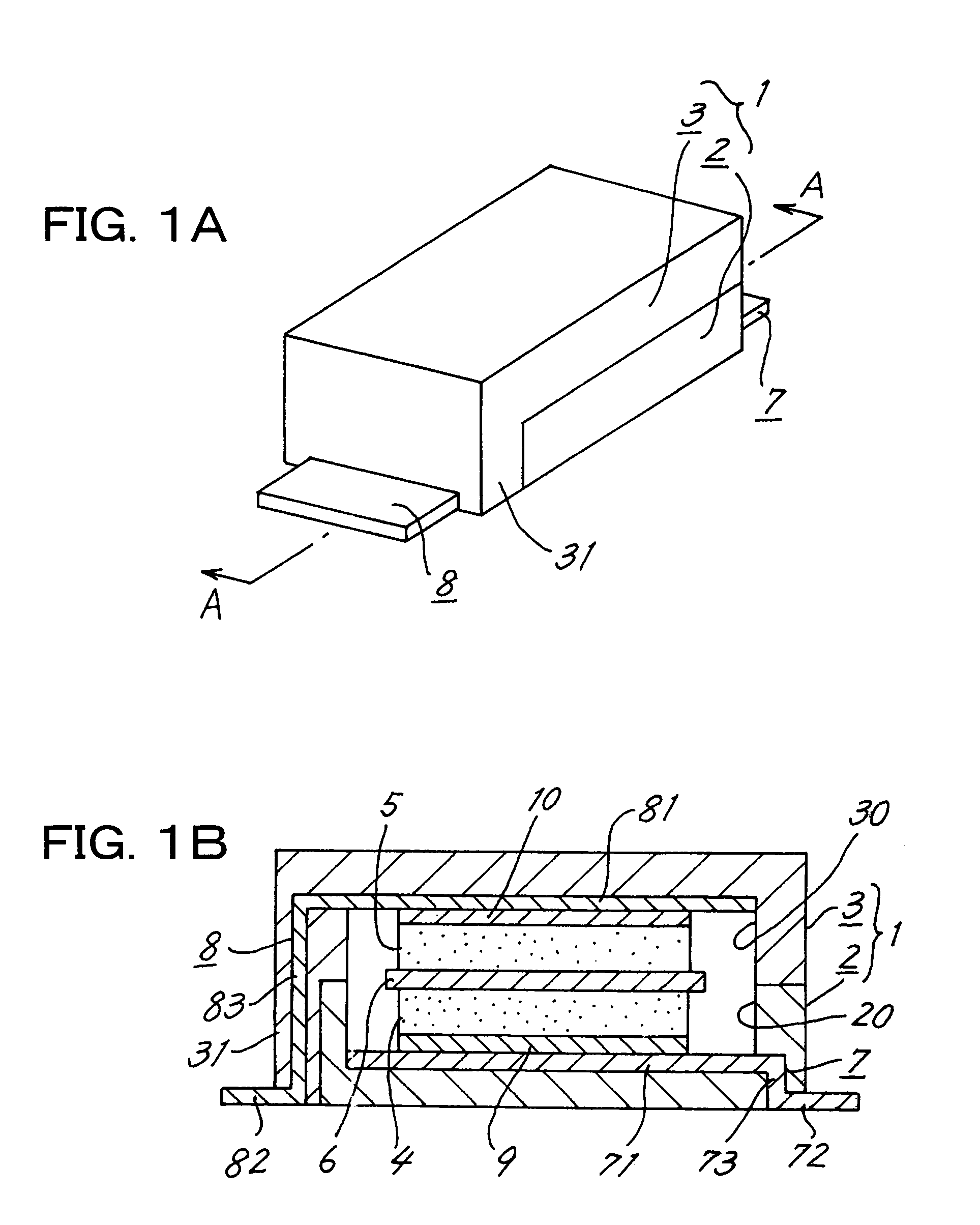

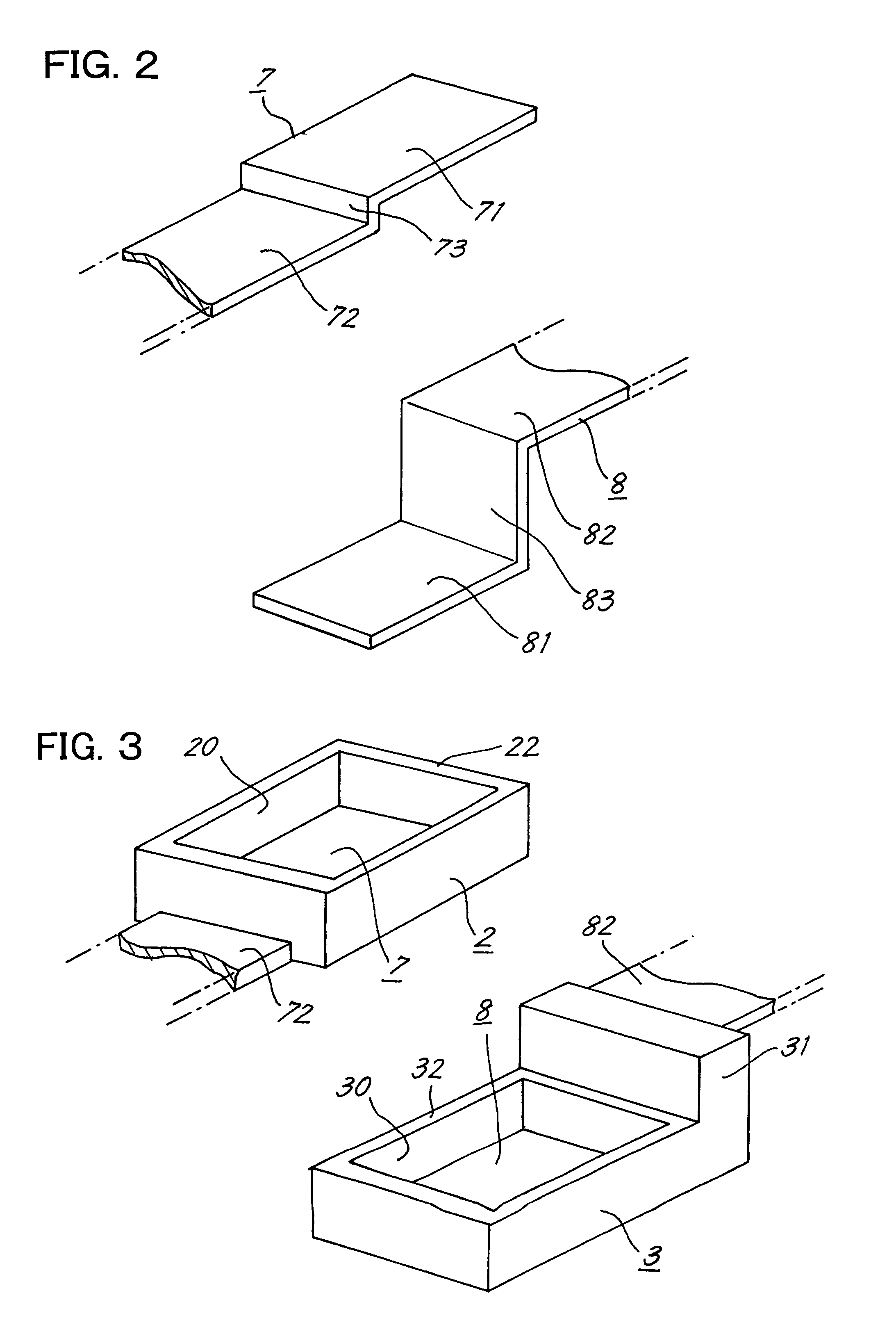

Electric double layer capacitor, electrolytic cell and process for fabricating same

InactiveUS7031140B2Increase the lengthEasy to makeFinal product manufactureDouble layer capacitorsEngineeringMechanical engineering

Owner:SANYO ELECTRIC CO LTD

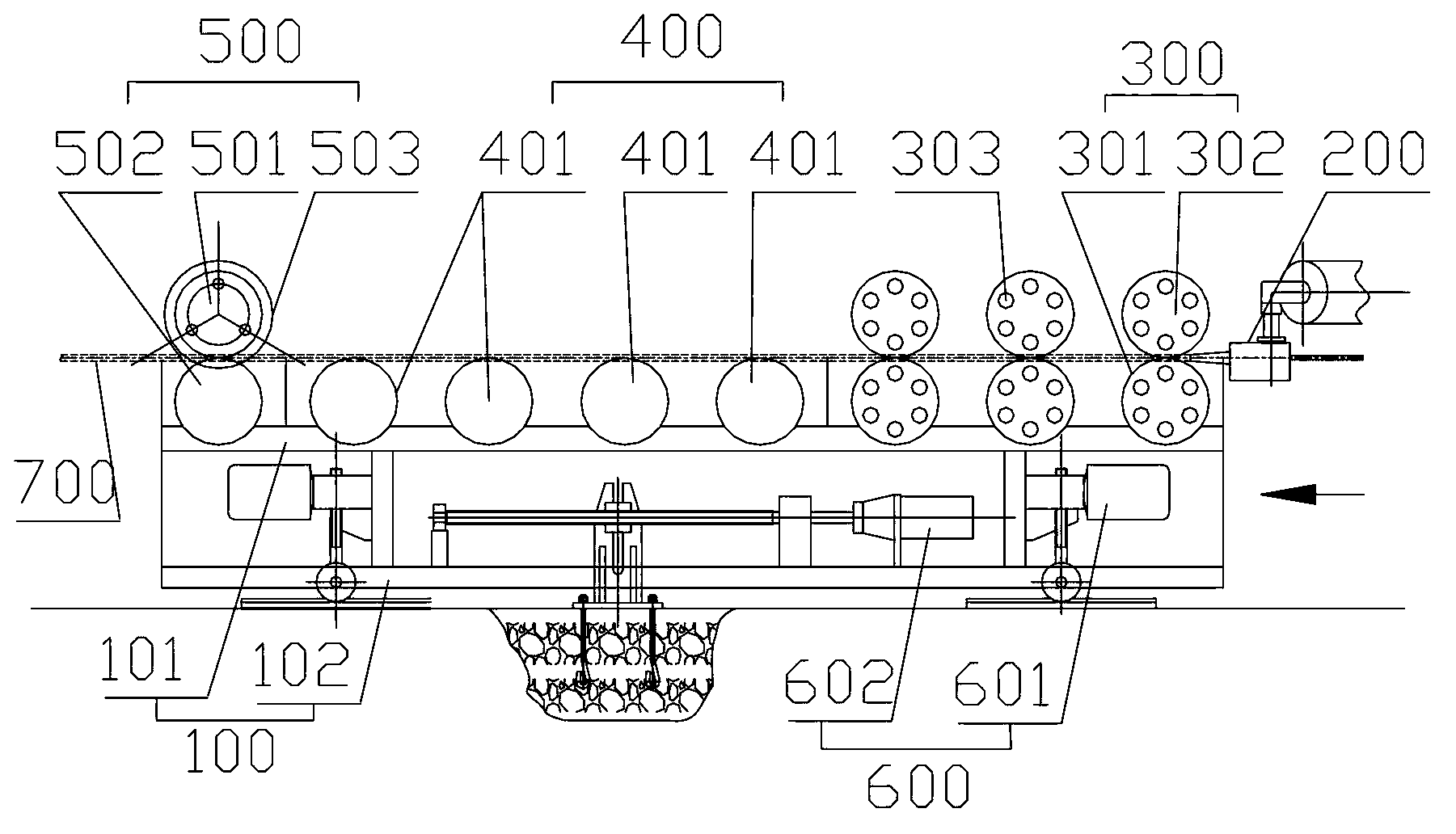

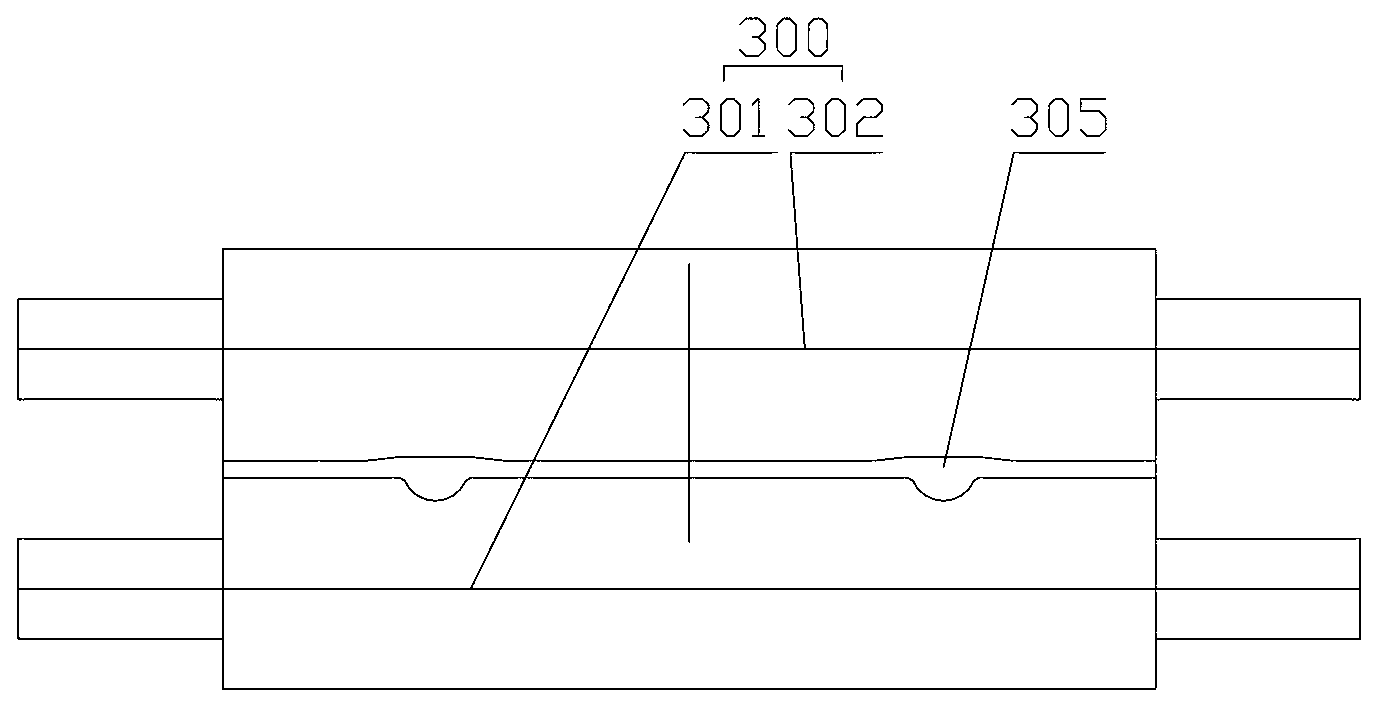

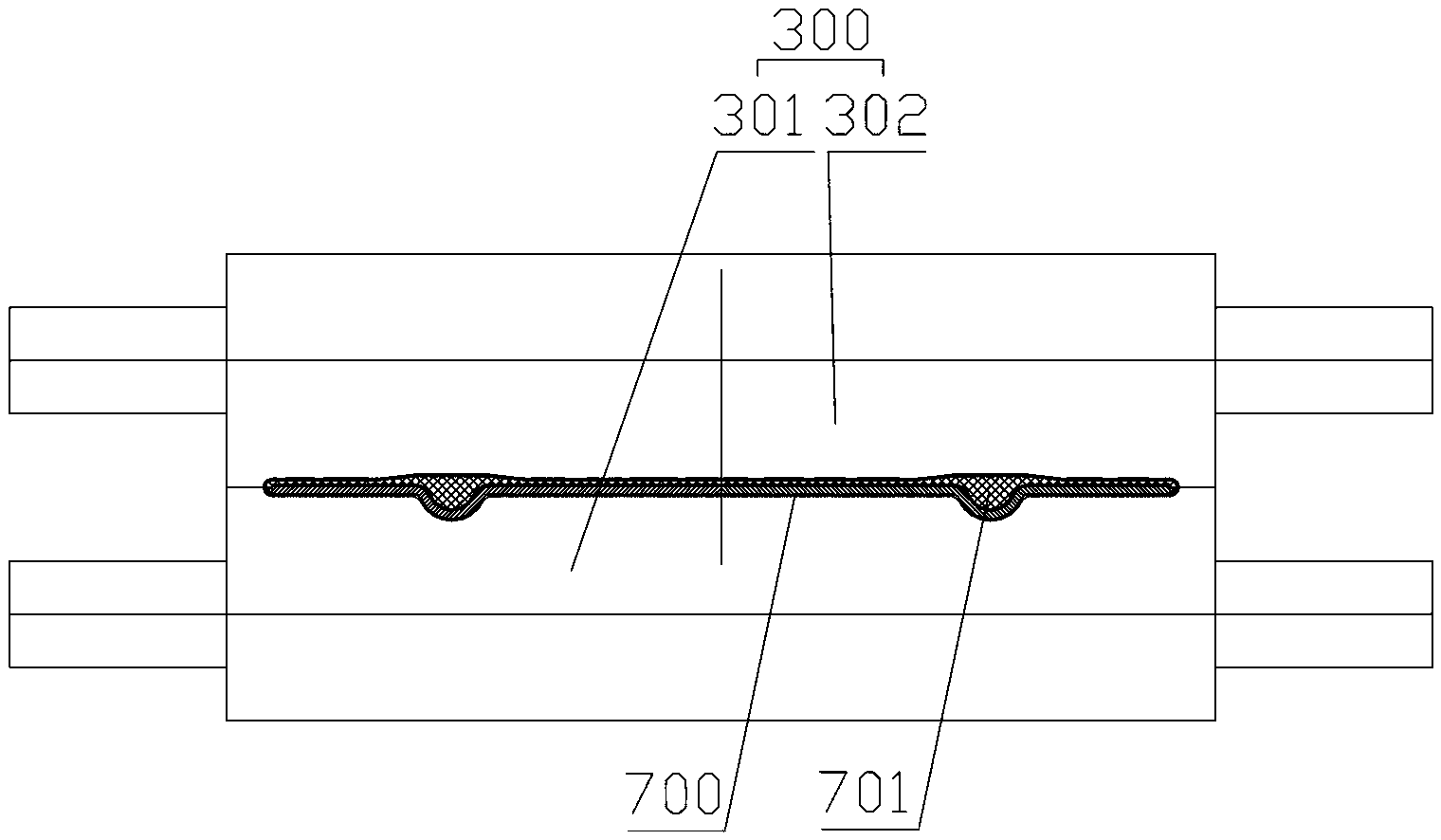

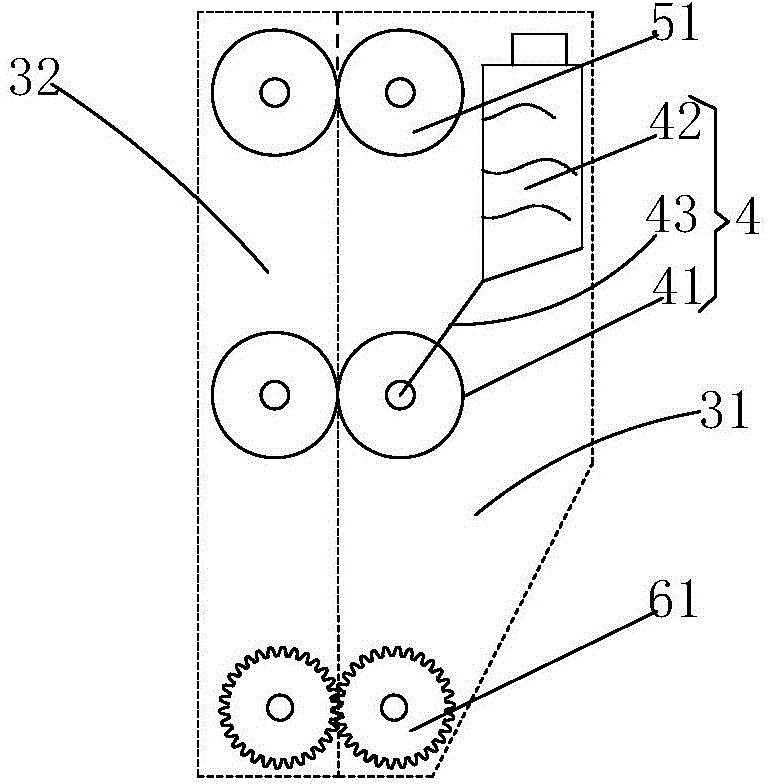

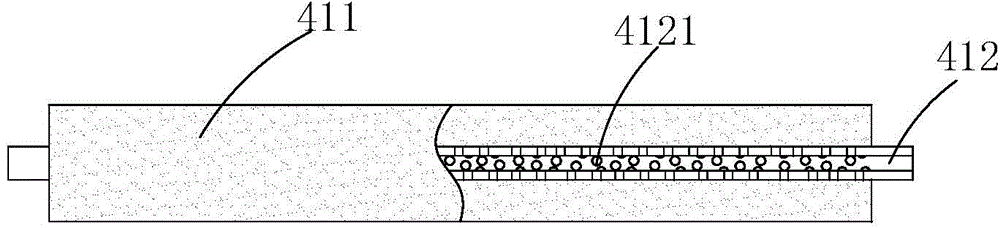

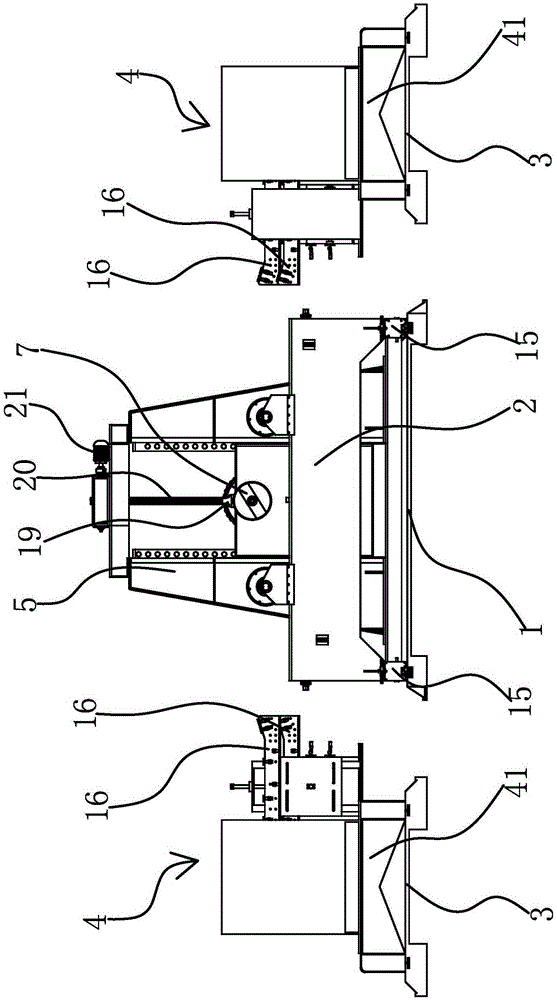

Rolling sizing device

The invention discloses a rolling sizing device comprising a frame. The following components are sequentially arranged on the frame: a rolling roller set used for carrying out drawing and progressive extrusion and sizing upon a strip-shaped thermoplastic composite material, a slow-cooling guide roller set used in further sizing, and an edge-cutting roller set used for trimming the edge of the strip-shaped thermoplastic composite material. The rolling roller set, the slow-cooling guide roller set, and the edge-cutting roller set are linearly arranged. The rolling sizing device also comprise a position adjustment mechanism used for adjusting the relative positions of the rolling roller set, the slow-cooling guide roller set, the edge-cutting roller set, and an extrusion mold. With the strip-shaped thermoplastic composite material rolling sizing device provided by the invention, strip-shaped thermoplastic composite material continuous sizing can be carried out, and the sizing is precise.

Owner:四川江瀚工业股份有限公司

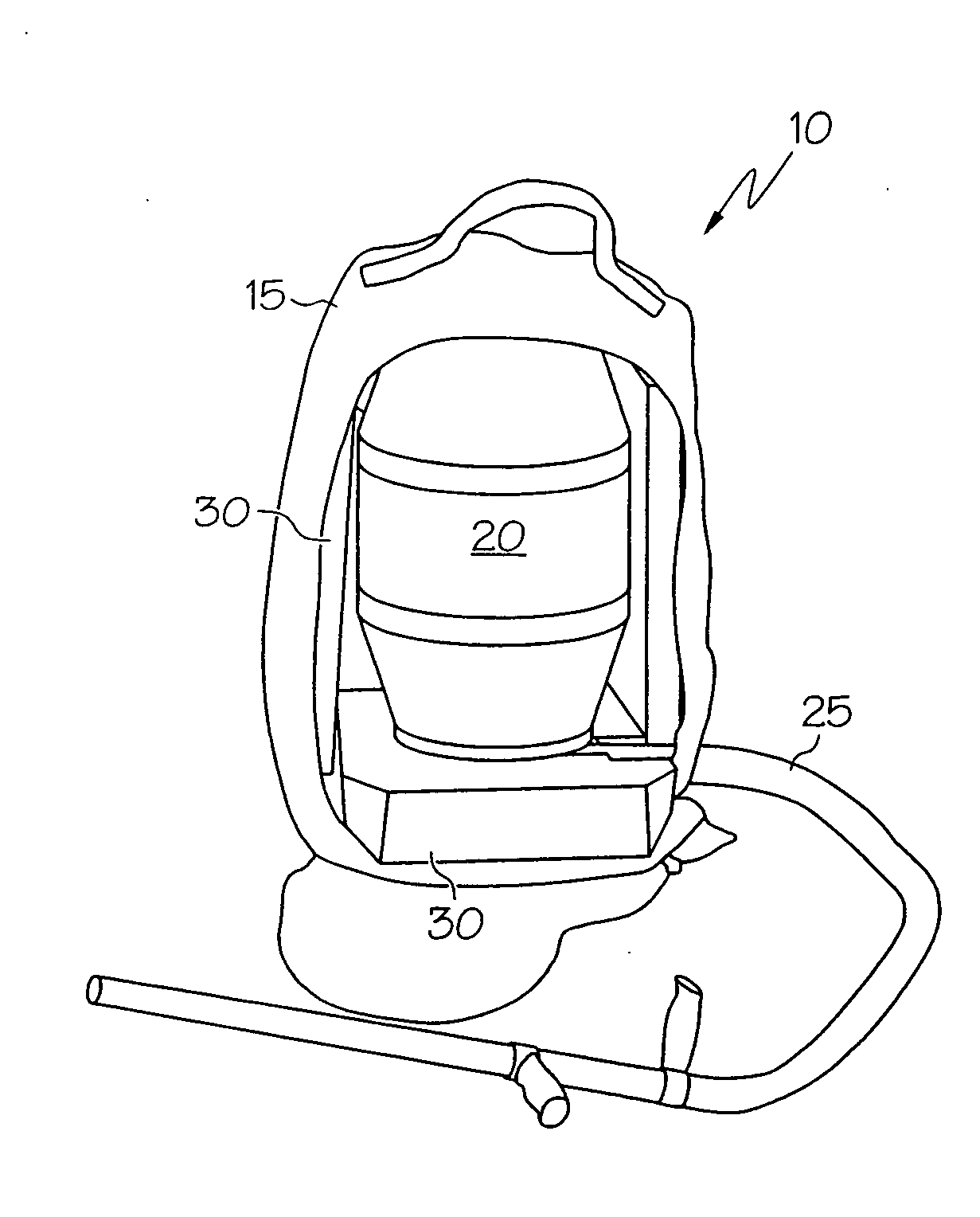

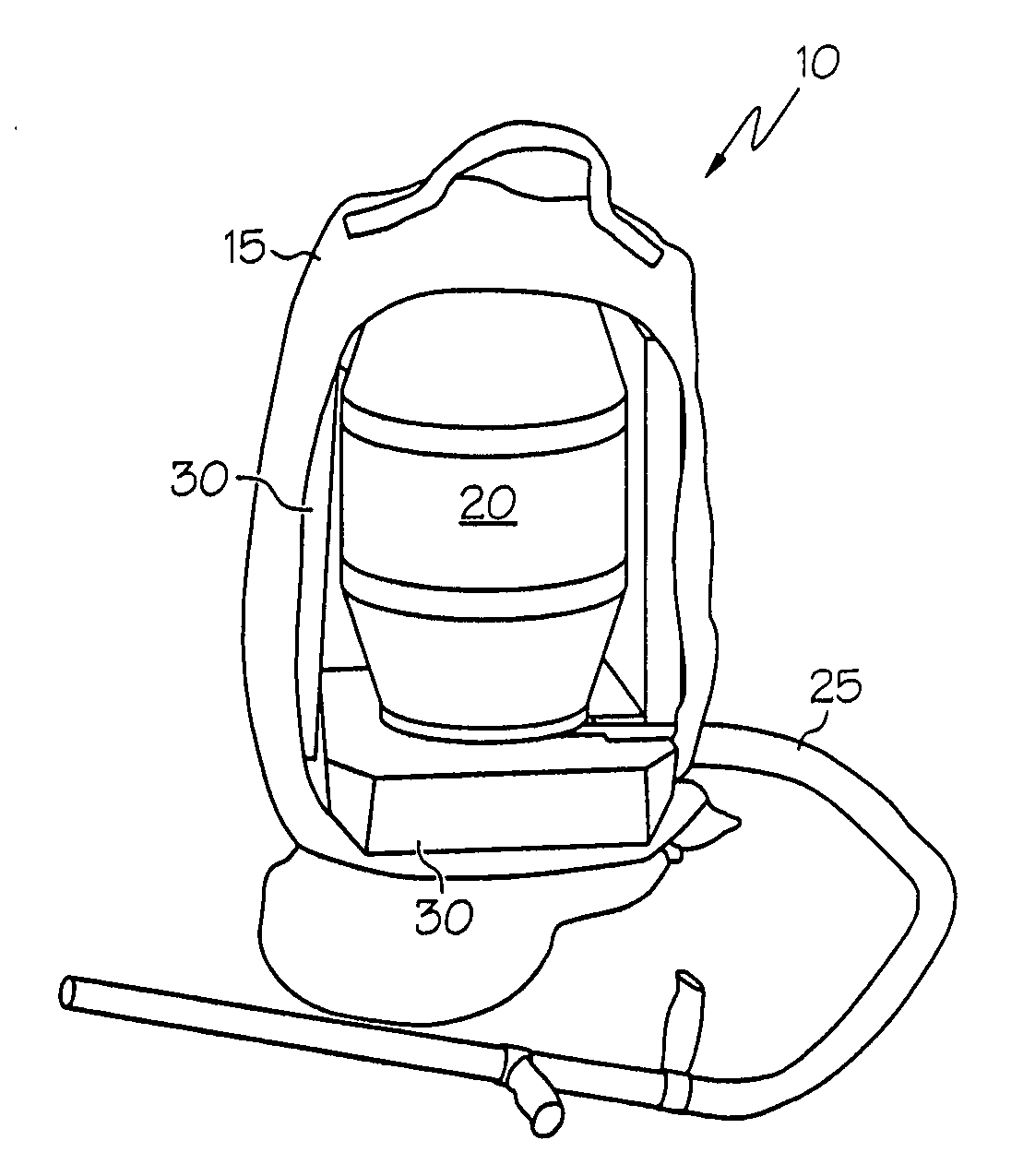

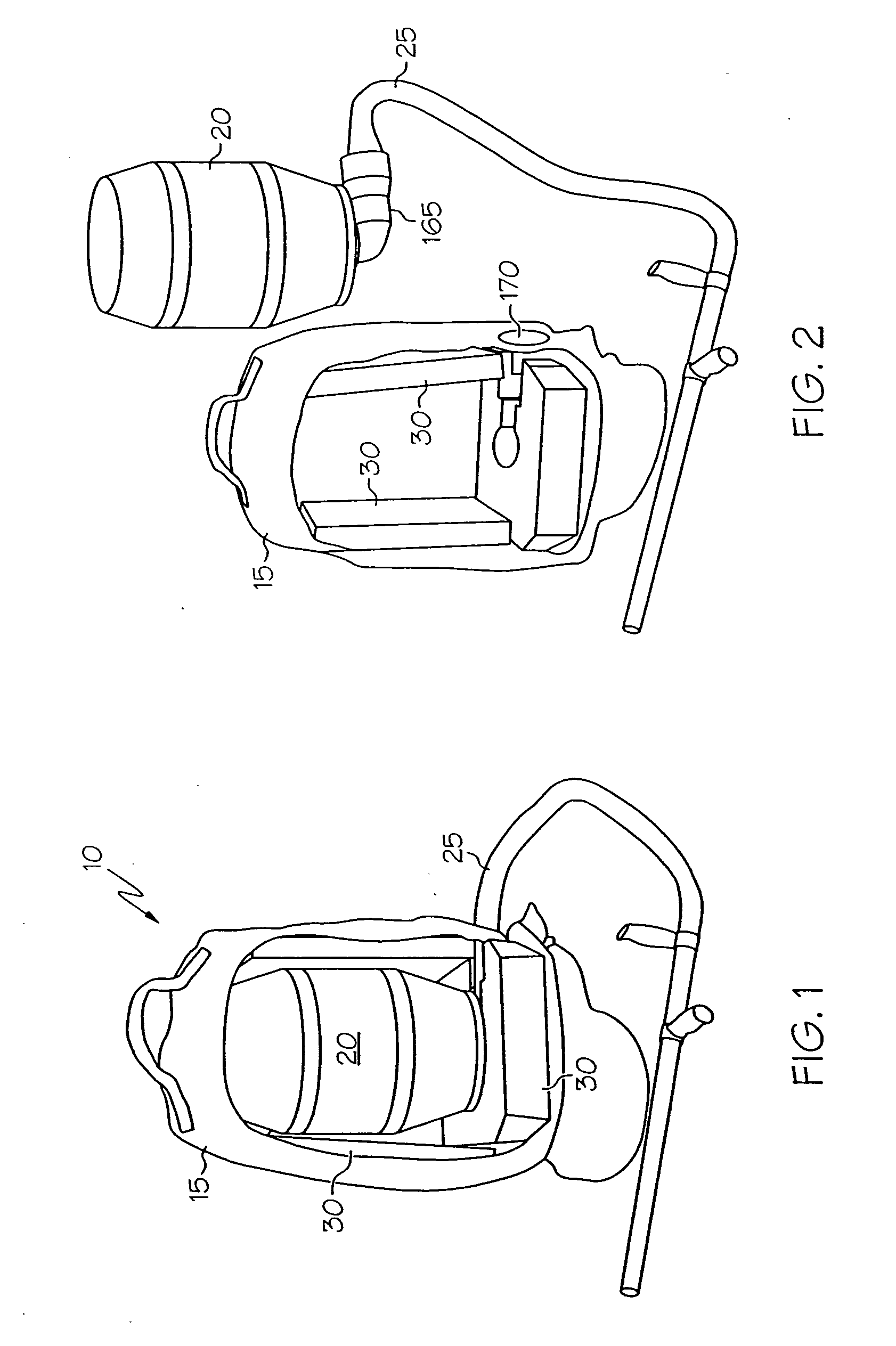

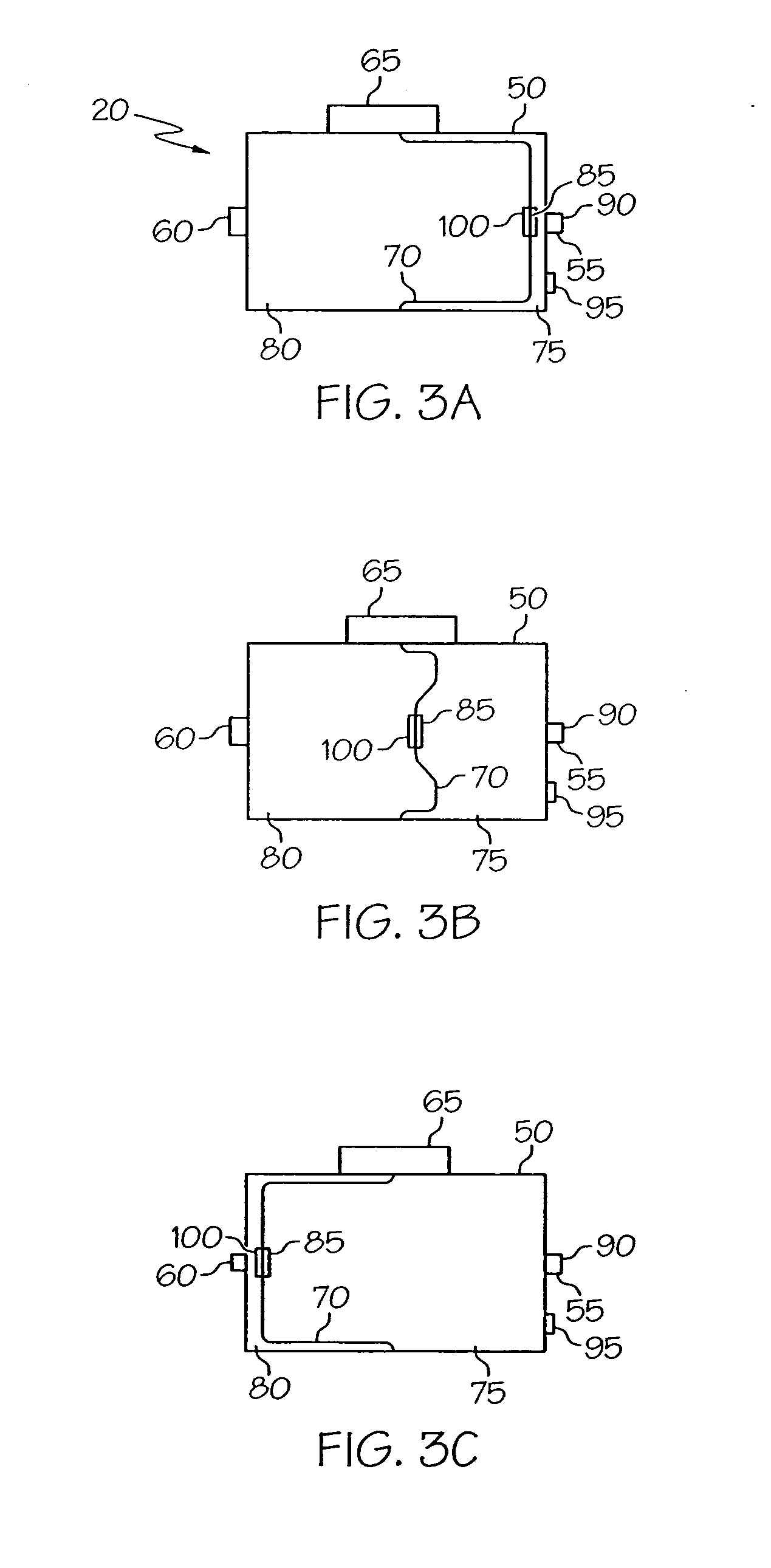

Ergonomic fluid dispenser

InactiveUS20050218157A1Easy to optimizeEliminate bendingLiquid transferring devicesLiquid spraying apparatusEngineeringBiomedical engineering

An ergonomic fluid dispenser. The ergonomic fluid dispenser includes a fluid container, a dispensing assembly, and a carrying case. The ergonomic fluid dispenser allows a user to remain standing during application of the fluid.

Owner:ILLINOIS TOOL WORKS INC

Process for mfg. ferrite rubber-plastic magnetic powder

ActiveCN1724461ACoarse granularityImprove performanceInorganic material magnetismMetallurgyFerrite powder

A process for preparing the magnetic ferrite powder used for rubber or plastic includes such steps as providing SrBa ferrite (SrO1-xBaOx) *nFe2O3 or Sr ferrite SrO*nFe2O3, proportionally mixing raw materials, grinding, adding assistant, pulverizing, granulating, sintering, pulverizing, tempering, water washing, baking, pulverizing and sieving.

Owner:江门江益磁材有限公司

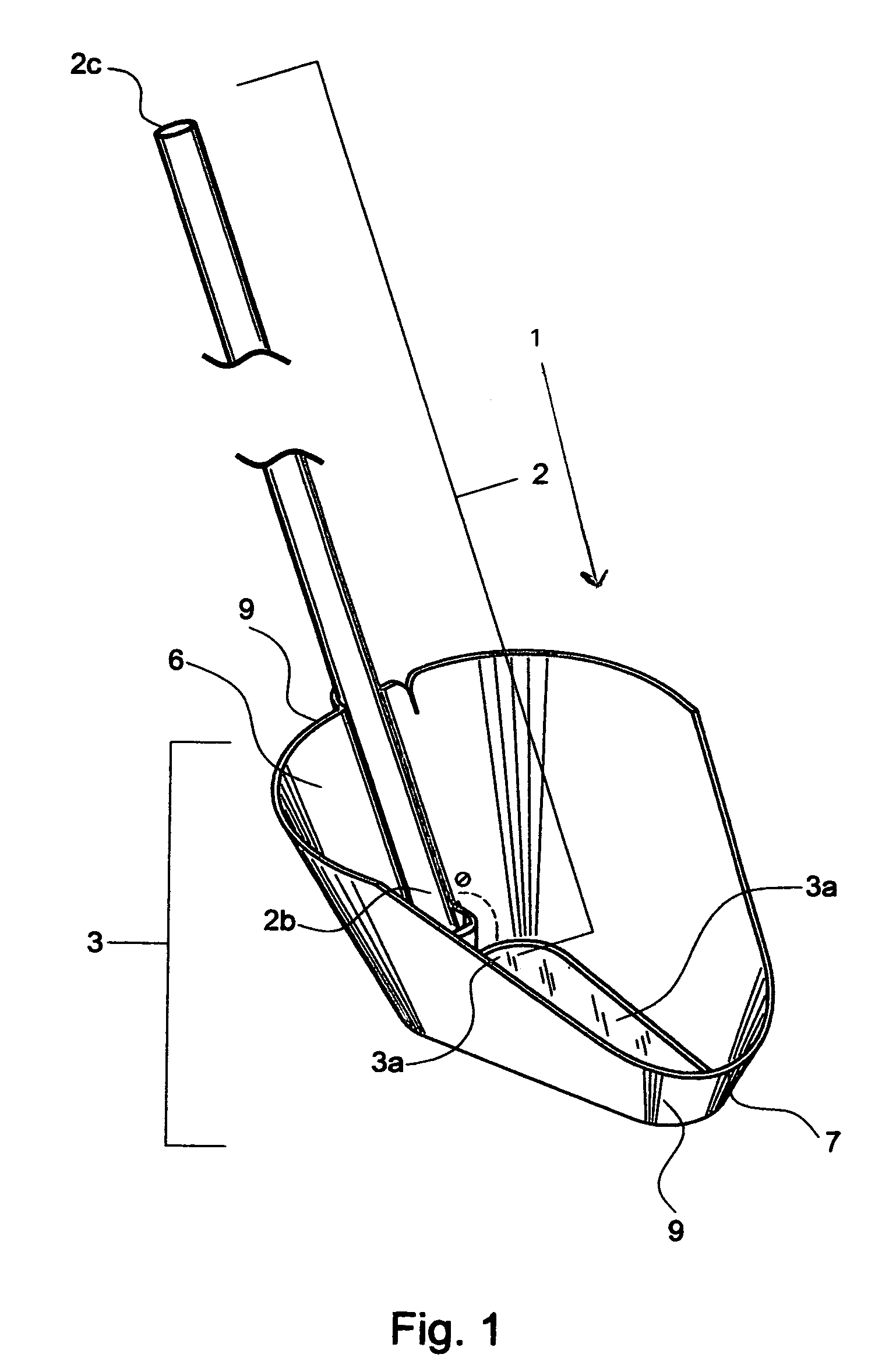

Portable animal waste remover

InactiveUS7431360B1Remove the burdenSufficient clearanceRoad cleaningOther apparatusAnimal wasteIndividual animal

Described herein is a portable animal waste remover with an elongated handle, or two handle components attached to a tapered scoop. The tapered scoop easily fits between an animal's hind legs prior to that animal's defecation. The scoop can contain a notch into which the edges or handles of a disposable bag insert. The bag thereby acts as a liner for the scoop and traps the waste from the animal. The user removes the uppermost edges of the bag from the slot and removes the bag from the curved scoop while retaining the waste within the bag. In other embodiments the elongated handle has an adjustable handle length extension, comprises a wheel, or fits within the user's pocket.

Owner:BIELAK KENNETH

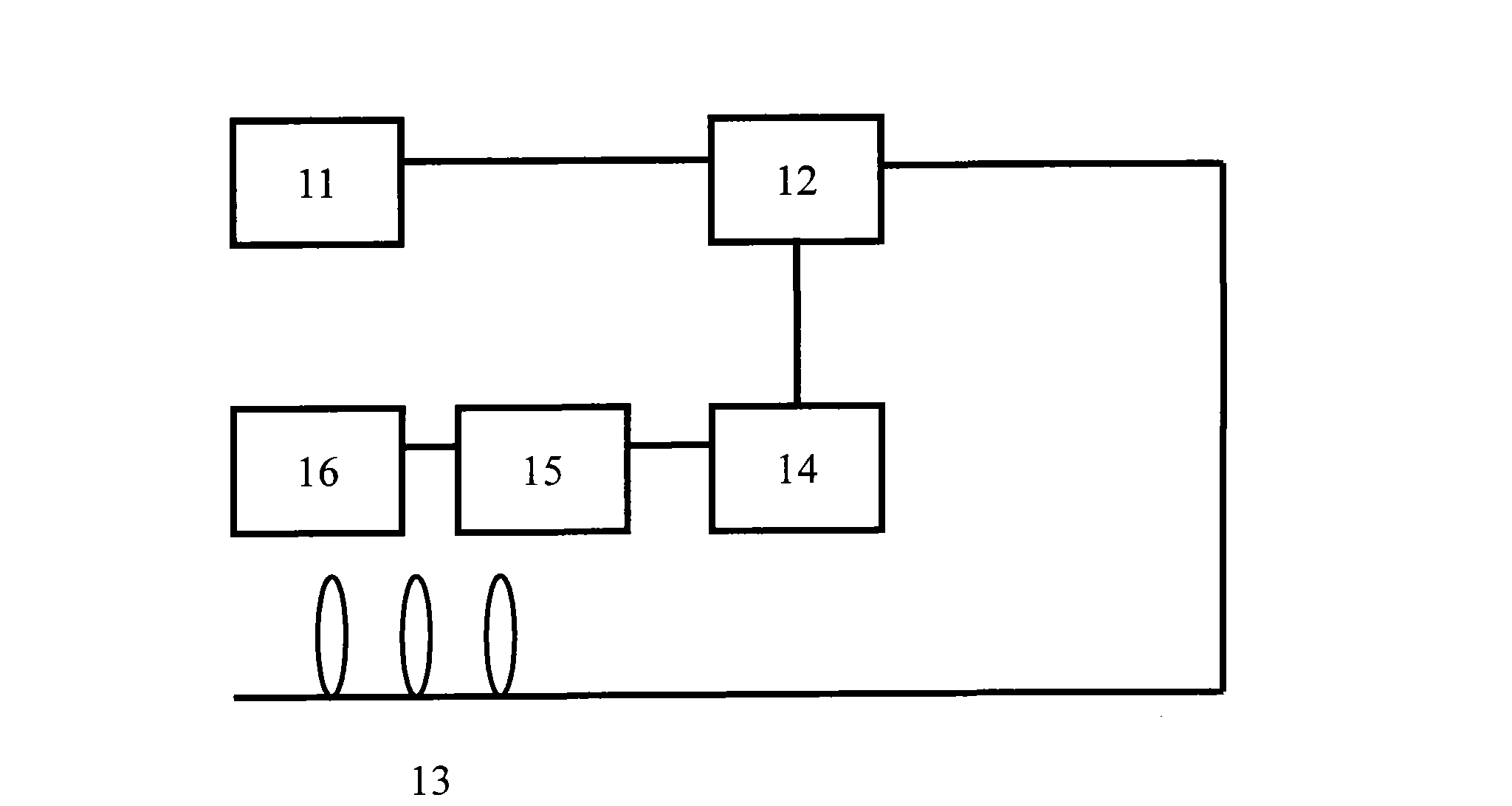

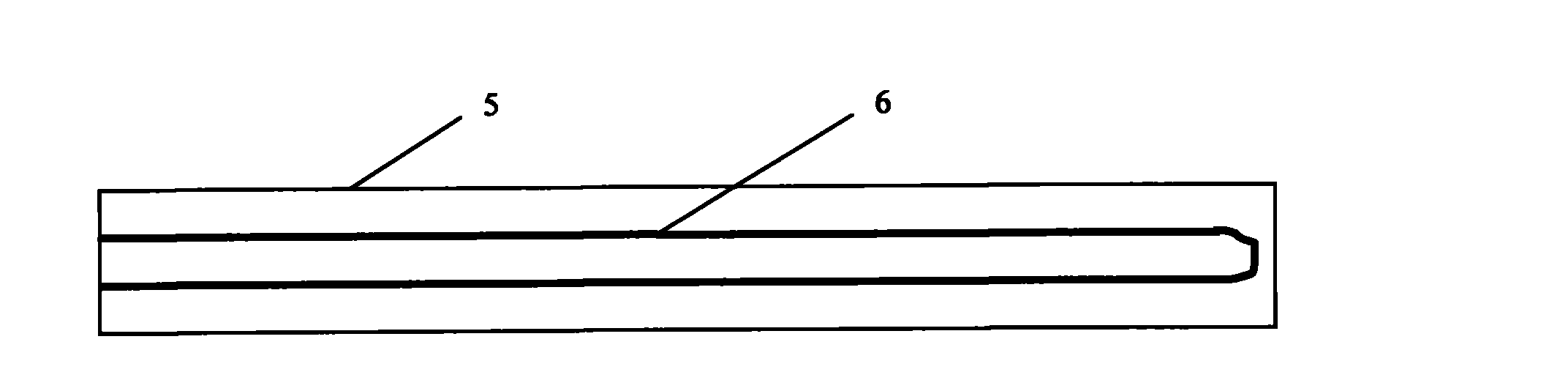

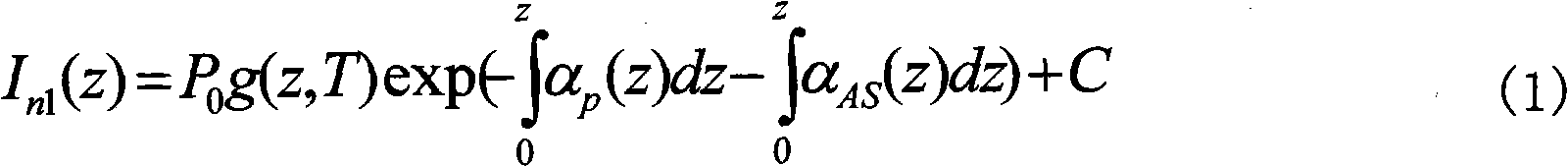

Self-correcting fully-distributed optical fiber Raman scattering sensor

InactiveCN102116684AElimination temperatureElimination speedThermometers using physical/chemical changesThermometer testing/calibrationFiberTransmission loss

The invention discloses a self-correcting fully-distributed optical fiber Raman scattering sensor. In the invention, a duplex fiber cable is utilized as a sensing optical fiber, pump light is divided into a forward beam and a backward beam during the transmission process by welding the tail ends of the duplex fiber cable together so as to obtain two anti-Stokes Raman scattering light beams, and the intensity of the anti-Stokes Raman scattering light beams is measured so as to realize temperature measurement; and the intensity values of the two anti-Stokes Raman scattering light beams can be multiplied so as to achieve the purpose of self-correction of curvature, loss, strain and the like. The sensor disclosed by the invention comprises an optical fiber pulse laser, an optical fiber wavelength division multiplexer (WDM), the duplex fiber cable, a photoelectric receiving module, a digital signal processor (DSP) and a computer. The invention has the advantages that self-correction and temperature measurement can be carried out at the same time only by measuring the intensity of the anti-Stokes Raman scattering spectrums; and the system has a simple structure, and avoids the defects that the traditional measuring system has transmission loss and errors caused by different center wavelength and needs a plurality of photoelectric receivers.

Owner:CHINA JILIANG UNIV

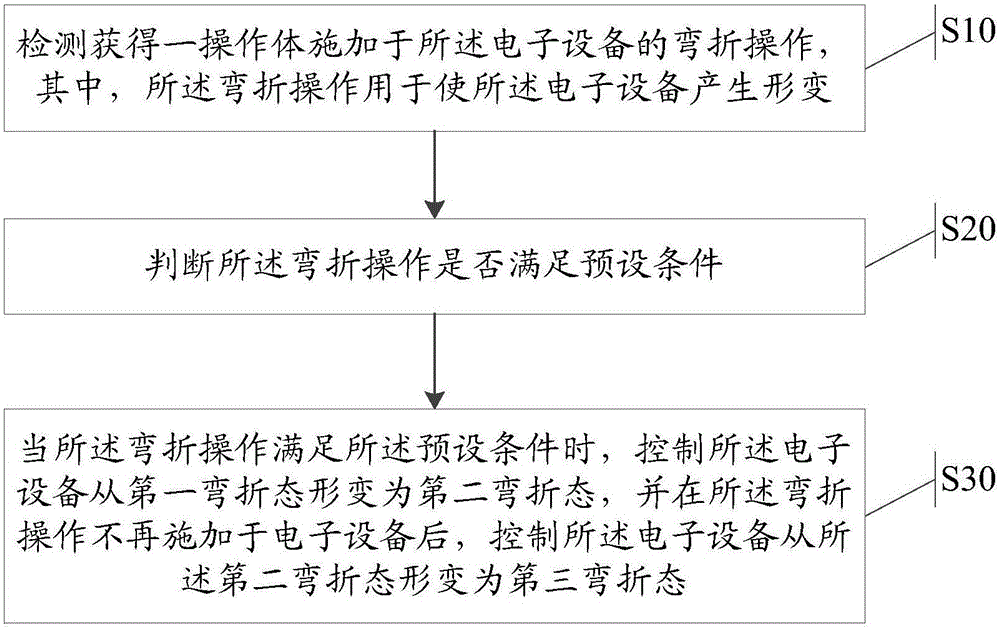

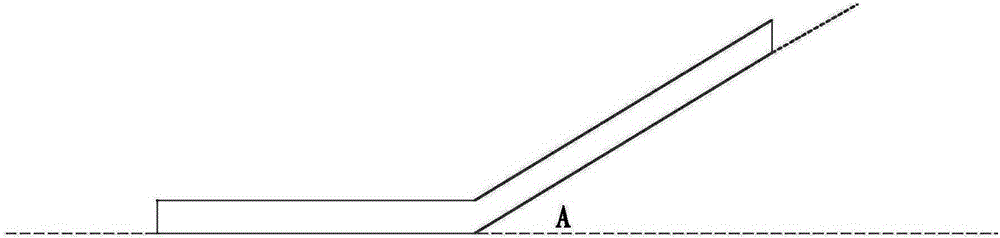

Electronic apparatus control method and electronic apparatus

ActiveCN105138076AControl bend anglePrecise bending angleInput/output for user-computer interactionDetails for portable computersControl theoryElectronic equipment

Owner:LENOVO (BEIJING) LTD

Financial self-service equipment

ActiveCN104616394AEliminate bendingRelieve bending stressCoin/paper handlersSelf-serviceMechanical engineering

Owner:GRG BAKING EQUIP CO LTD

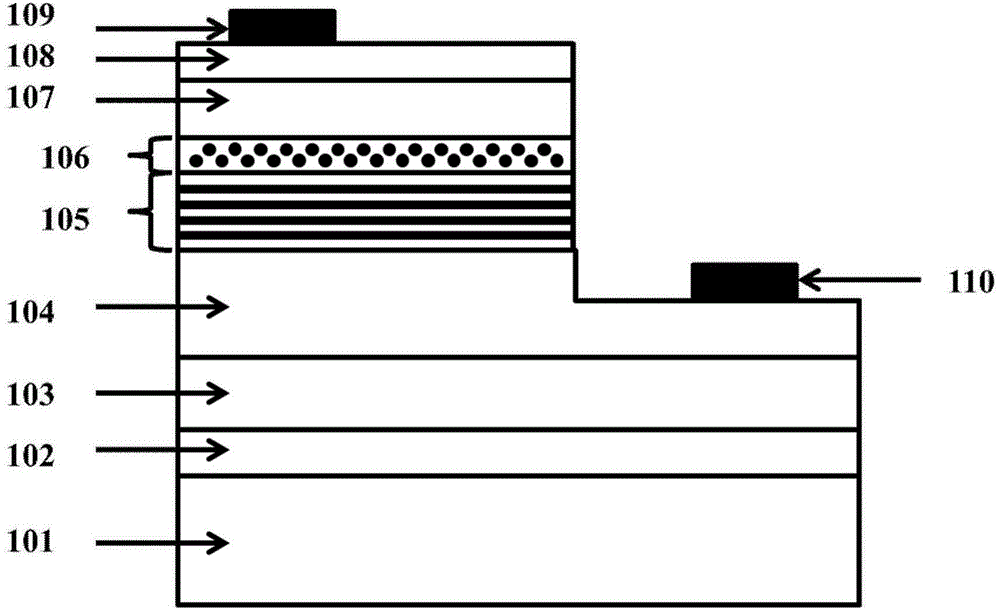

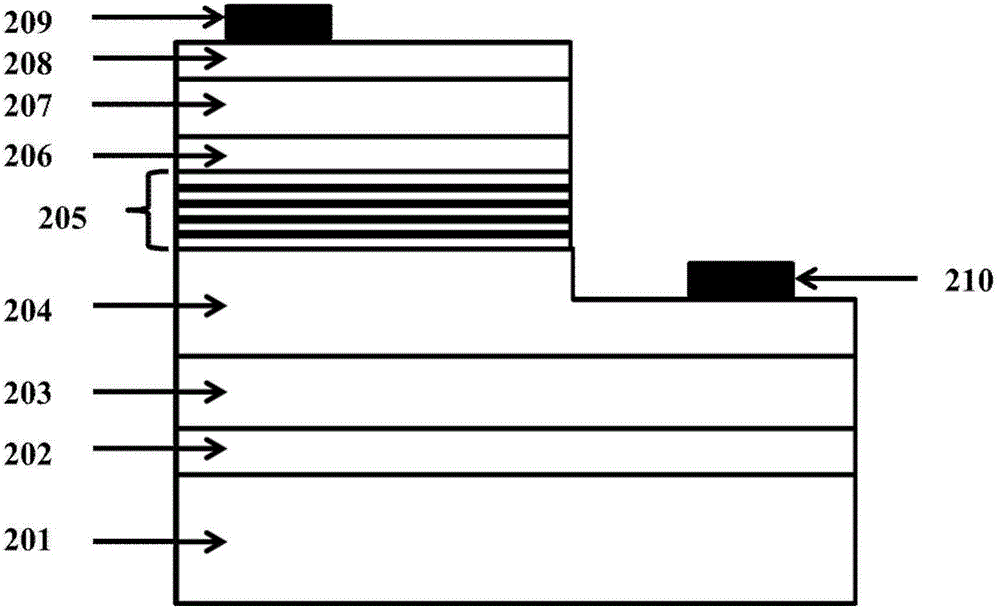

UV-LED with quantum dot structure

ActiveCN104966768ASuppress overflowStrong quantum confinement effectSemiconductor devicesHole injection layerQuantum well

The invention discloses an UV-LED with a quantum dot EBL, comprising a sapphire substrate, an A1N nucleating layer, a non-doped u type A1GaN buffer layer, an n type A1GaN layer, an A1xGa1-xN / A1yGa1-yN quantum well active region, a p type A1N / A1GaN quantum dot EBL, a p type A1GaN layer and an ITO conductive layer. An n type ohmic electrode is lead out on the n type A1GaN layer, and a p type ohmic electrode is lead out on the ITO conductive layer. The UV-LED with a quantum dot EBL employs the p type doping layer of self-assembly A1N / A1GaN quantum dots as the EBL and a hole injection layer, which can effectively inhibit electrons from overflowing out of an active region, enhance the efficiency of hole injection to the active region, and thereby increase the carrier composite efficiency in the active region; in addition, A1N is used as the EBL to replace the A1GaN commonly used in blue LED, which can more effectively reduce UV absorption by the EBL, and increase UV-LED luminous efficiency.

Owner:江西力特康光学有限公司

Ergonomic fluid dispenser

InactiveUS20050230416A1Easy to optimizeReduce torqueOpening closed containersBottle/container closureBiomedical engineering

Owner:ILLINOIS TOOL WORKS INC

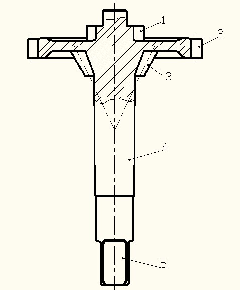

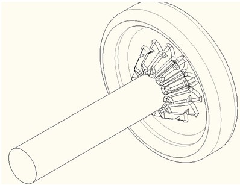

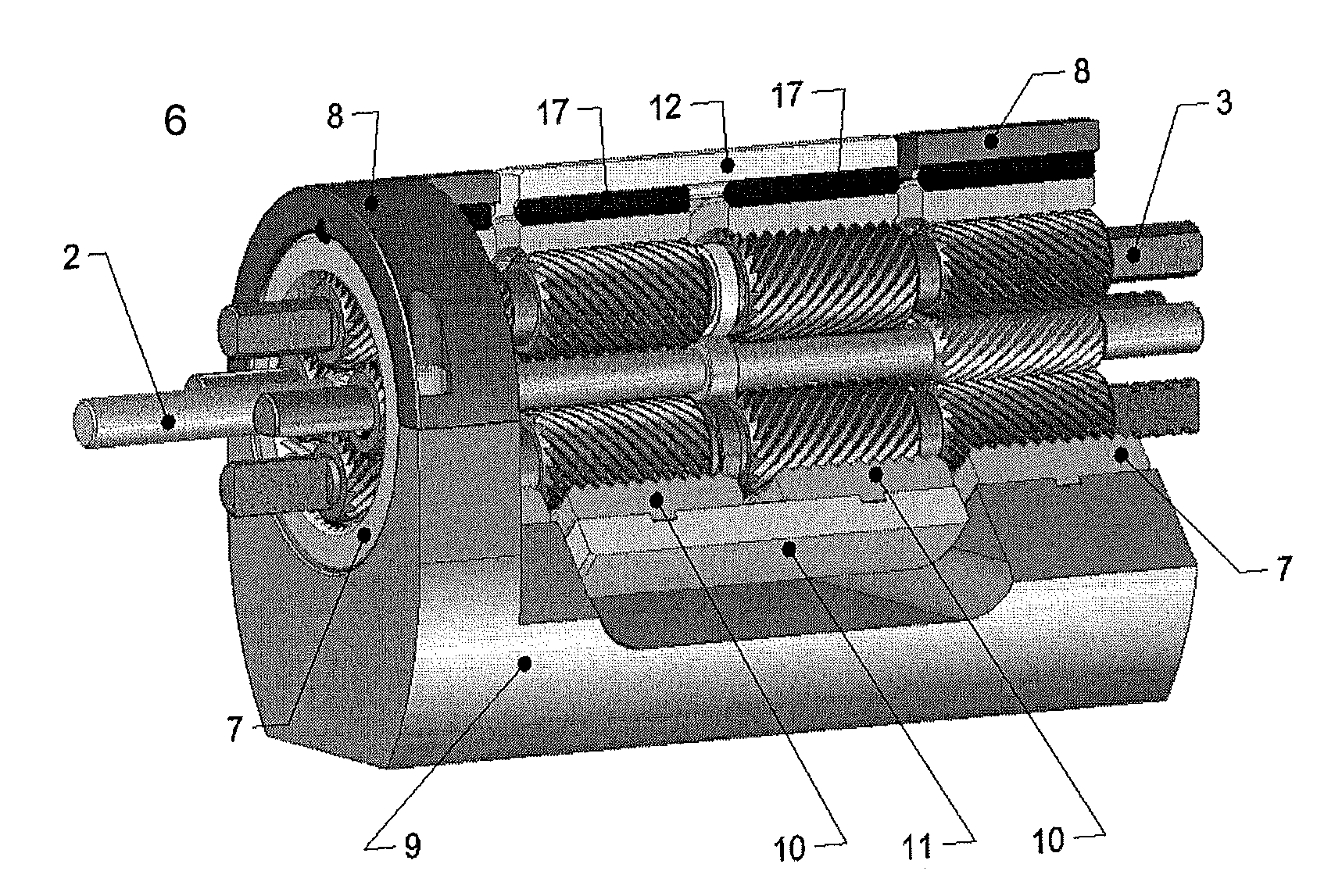

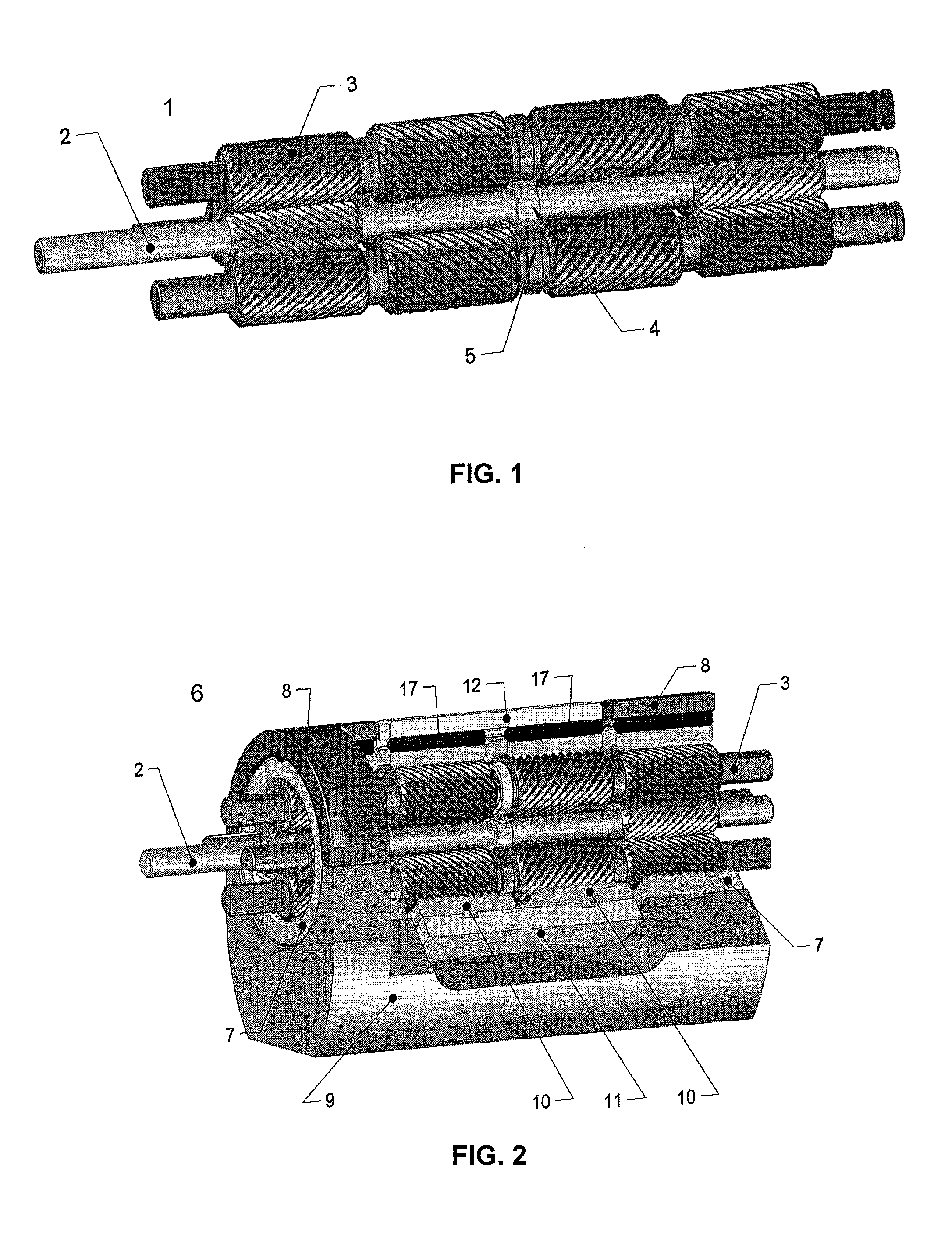

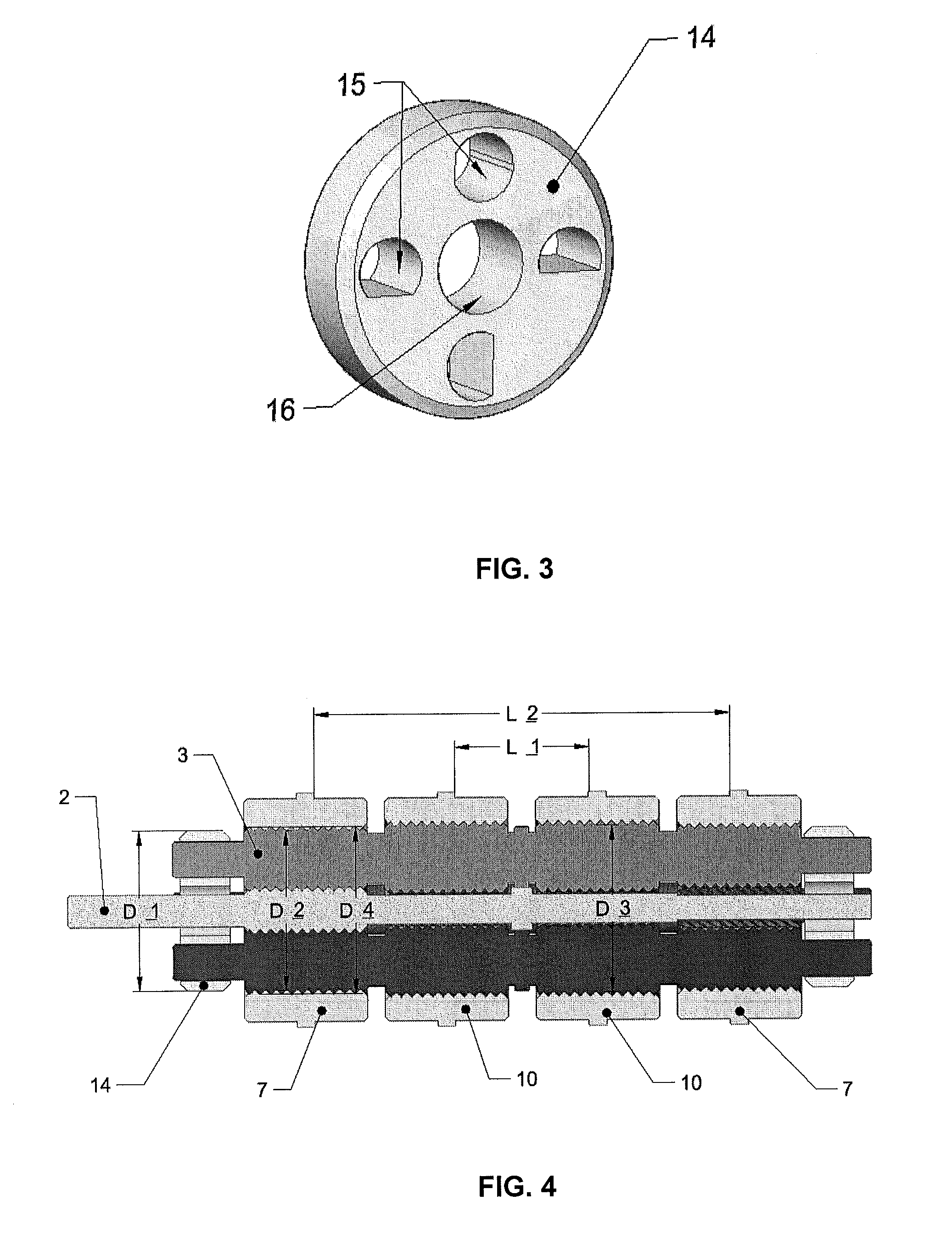

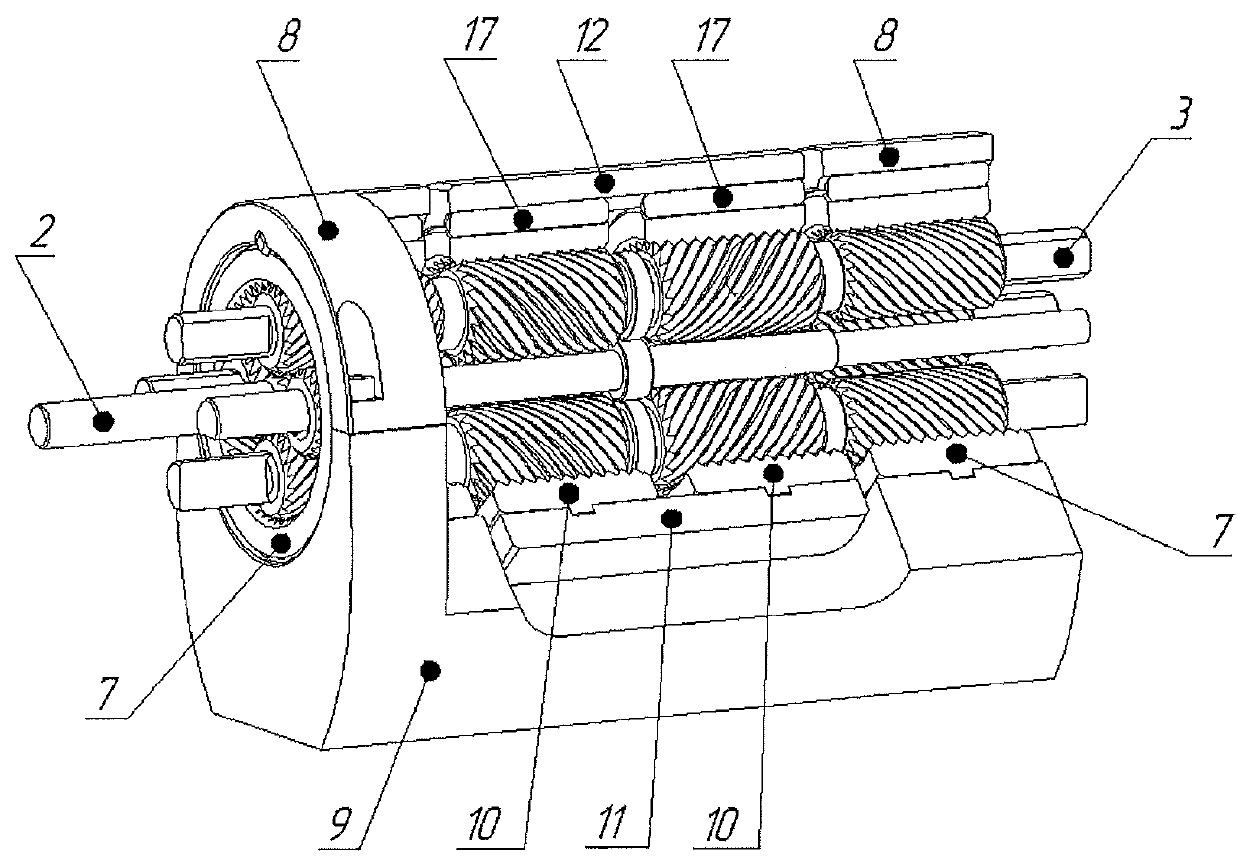

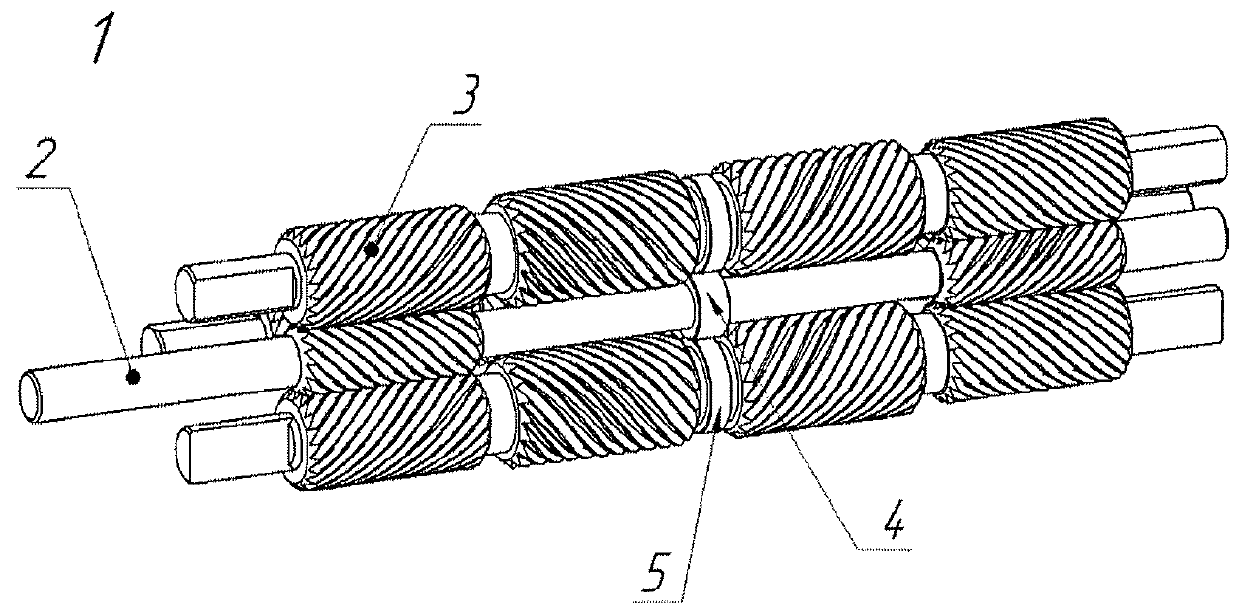

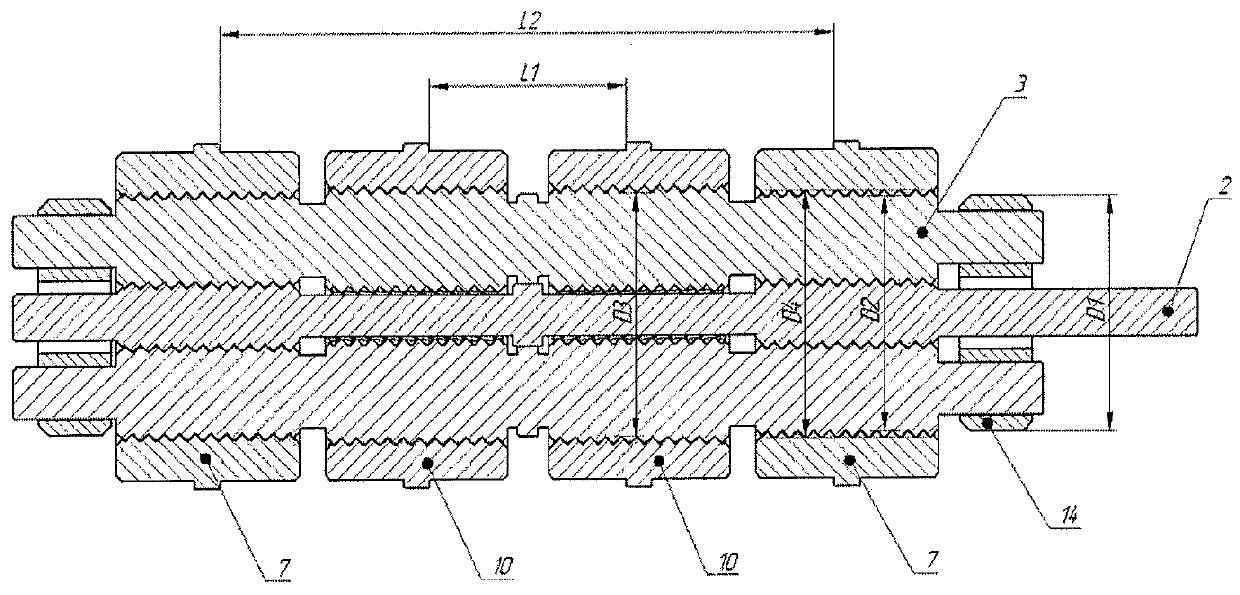

Transmission Gear, Roller Reducer Comprising the Transmission Gear, and Method of Assembly Thereof

ActiveUS20150267776A1Reduce loadImprove efficiencyMetal-working apparatusToothed gearingsEngineeringFlange

The present invention relates to a roller reducer comprising a transmission gear having an externally threaded shaft having at least one left-handed thread portion, at least one right-handed thread portion, and at least one shaft flange ring, and a plurality of rollers, each roller having a plurality of thread portions, comprising at least one left-handed thread portion and at least one right-handed thread portion, each thread portion arranged to engage with the respective thread portions of the shaft, and at least one roller flange ring arranged adjacent to the roller thread portions to rotationally slide against the corresponding at least one flange ring of the shaft.Diameters of the flange rings of the rollers and the flange rings of the shaft are each equal to the respective effective thread diameters of the engaged thread portions of the rollers and the shaft, respectively.

Owner:DIAKONT ADVANCED TECH

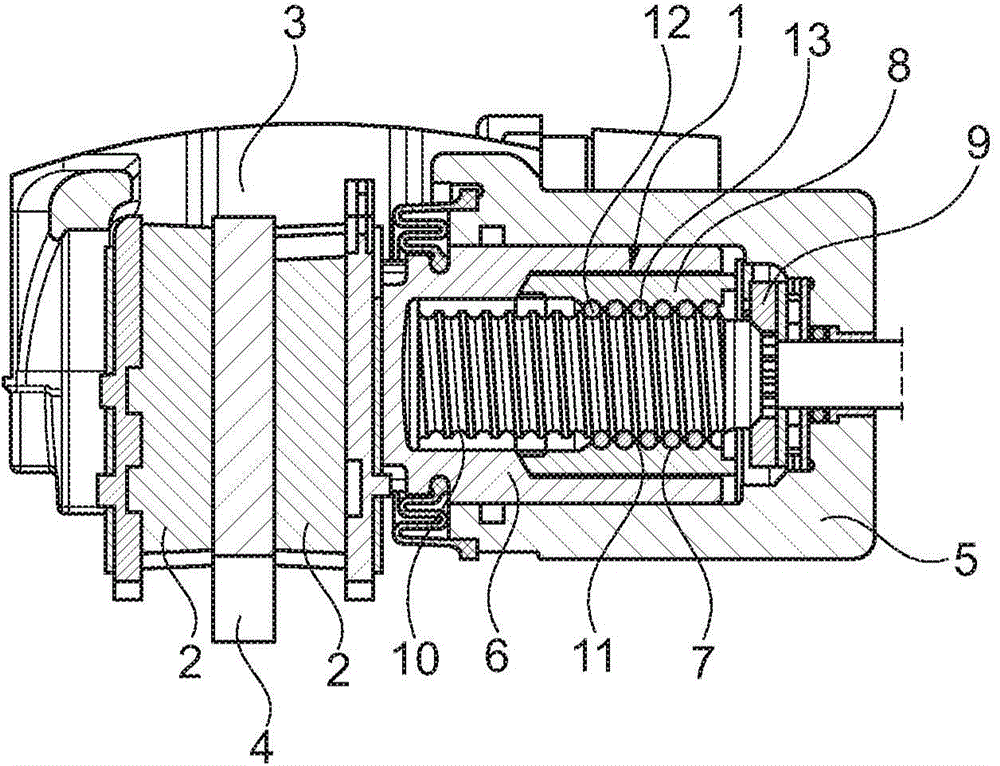

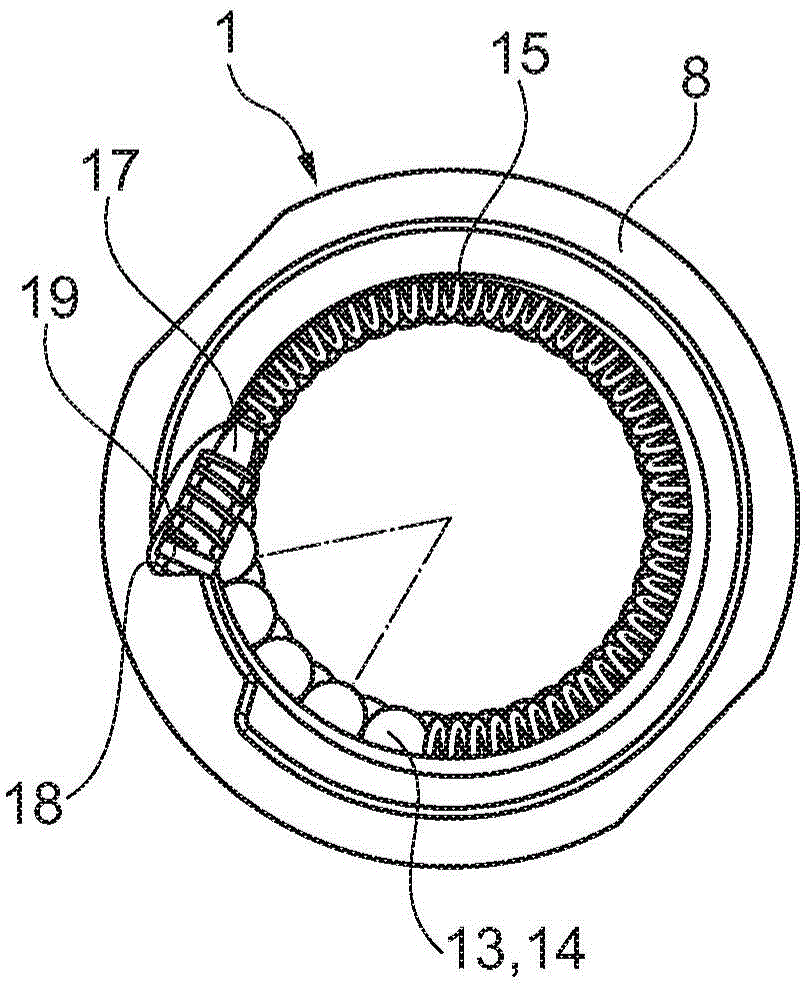

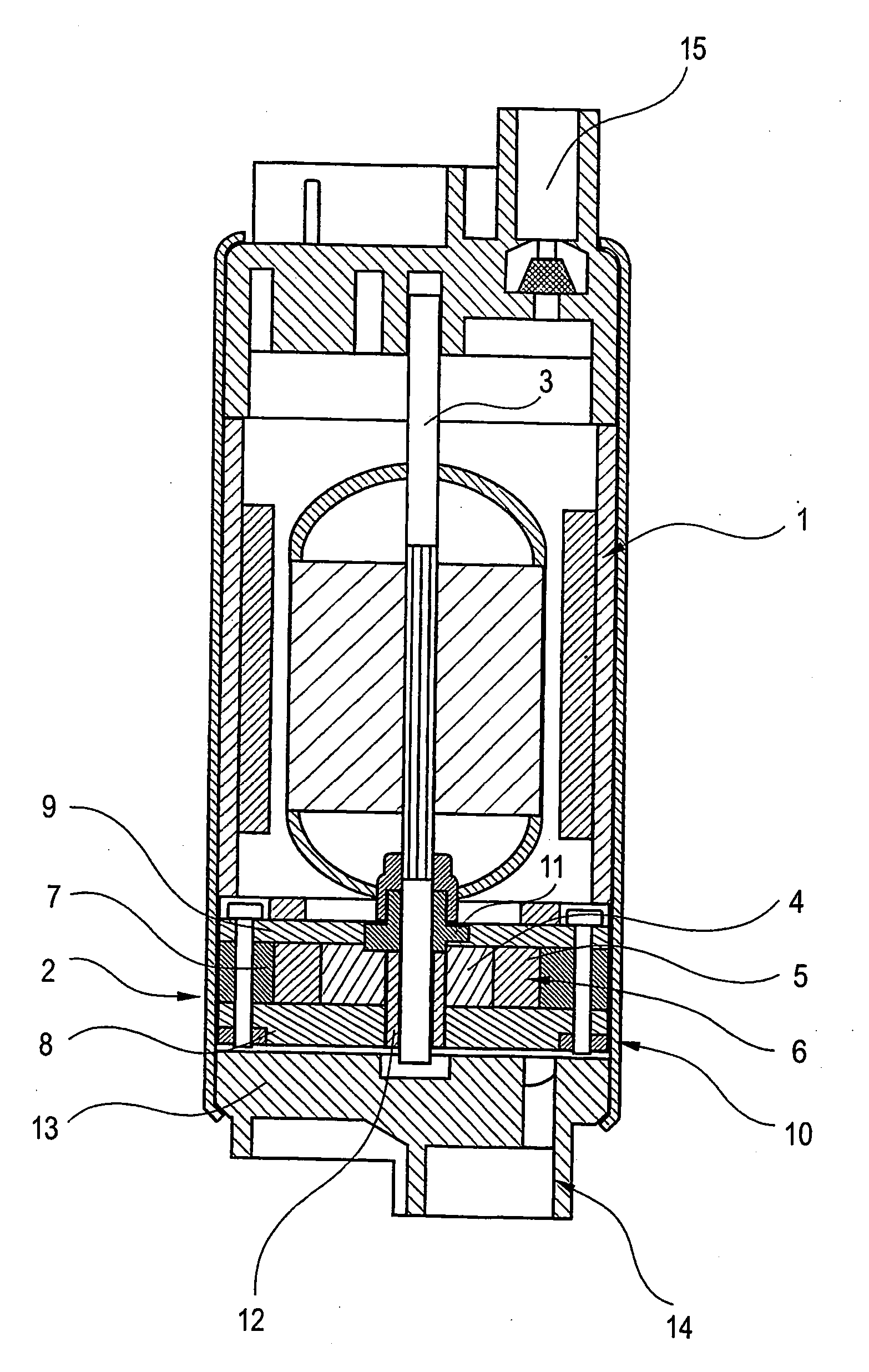

Ball screw drive, in particular for a locking brake of a motor vehicle

InactiveCN104813058AEliminate bendingEasy to bendGearingBrake actuating mechanismsBall screw driveCoil spring

The invention relates to a ball screw drive (1), comprising a spindle nut (8) disposed on a threaded spindle (7) and comprising a helical ball channel (12) which is delimited by ball grooves (10, 11) of the threaded spindle (7) and of the spindle nut (8) and in which a ball row (14) formed of balls (13) is disposed. Said ball screw drive further comprises a helical spring (10) which is disposed along the helical ball channel (12), is supported relative to the spindle nut (8) and is provided for contact on the ball row (14) or on a ball cage (14) which receives the balls (13), wherein a rod (17, 21) provided for stabilising the helical spring (15) engages in the helical spring (15).

Owner:SCHAEFFLER TECH AG & CO KG

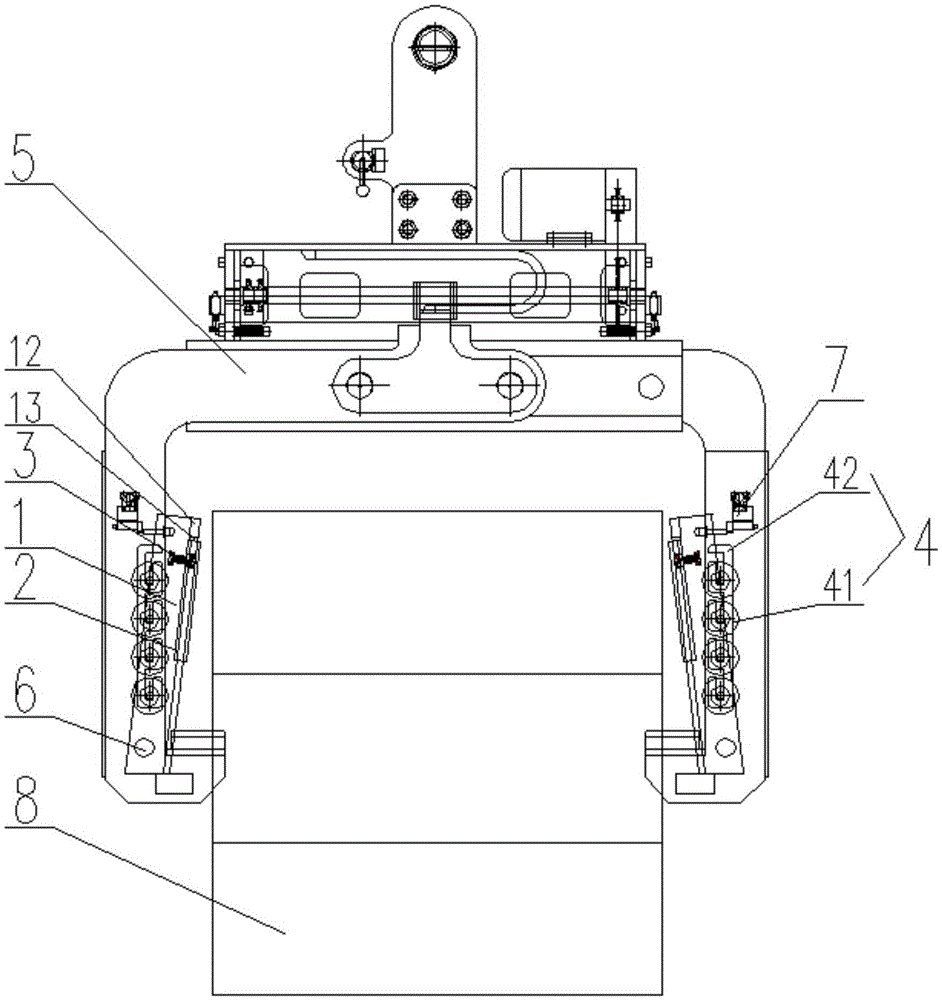

Intelligent fixture clamping protecting device

ActiveCN105645252AEliminate bendingQuality improvementLoad-engaging elementsRolling resistanceSlide plate

The invention discloses an intelligent fixture clamping protecting device comprising a swing frame, a sliding plate, a driving device and a rolling device, wherein the swing frame is hinged to a fixture body; the sliding plate is jogged on the swing frame and can vertically move along the swing frame; the driving device is arranged on the swing frame and is matched with the sliding plate; and the rolling device is matched with the sliding plate and is correspondingly arranged on the fixture body. By using the device, the friction between a steel coil and the fixture body can become rolling friction, so that the steel coil edge bending condition caused by friction generated by the edge of the steel coil and the fixture in the existing device is eliminated, the friction force is effectively reduced, and the edge quality of the steel coil is ensured.

Owner:CISDI ENG CO LTD

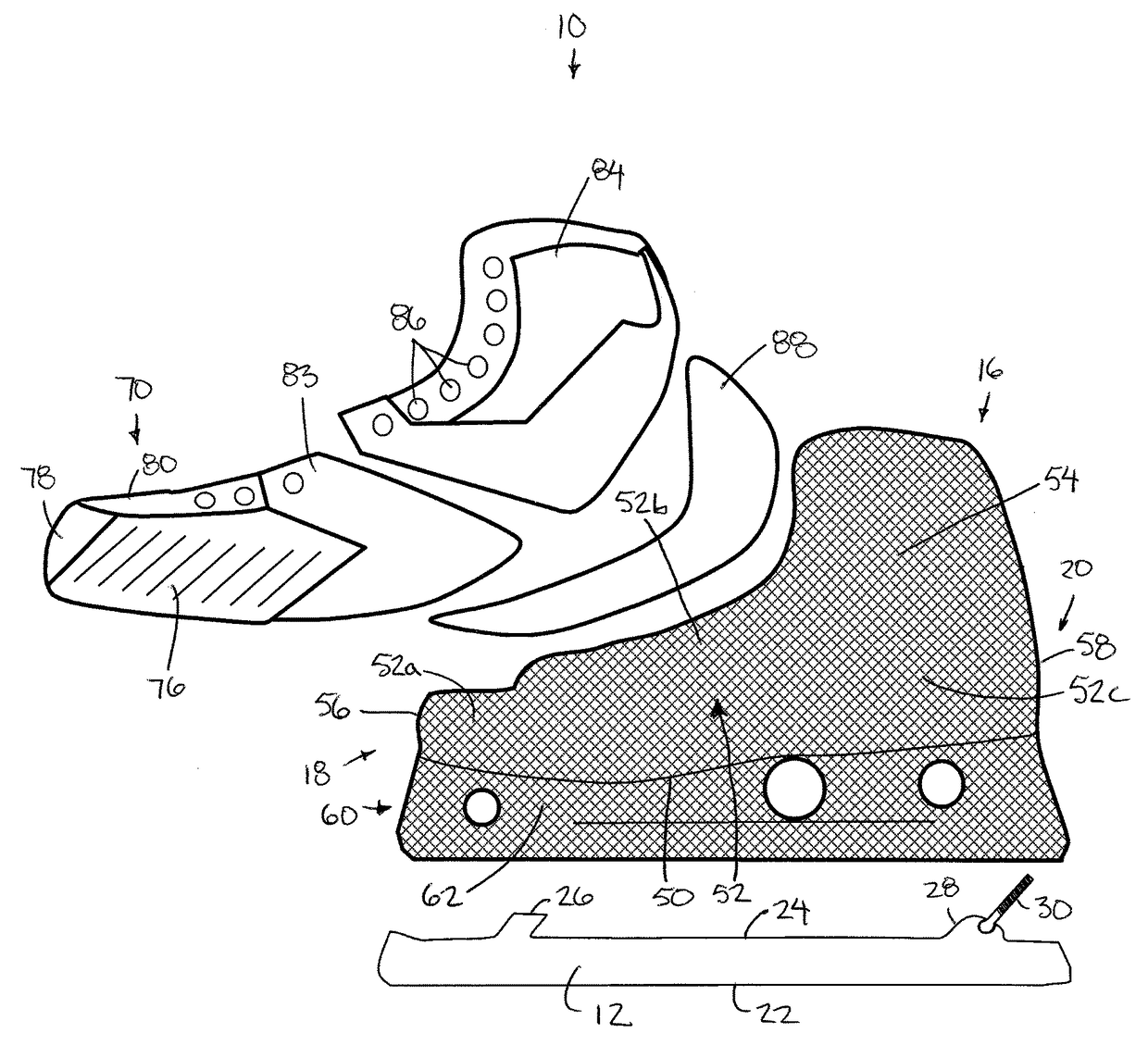

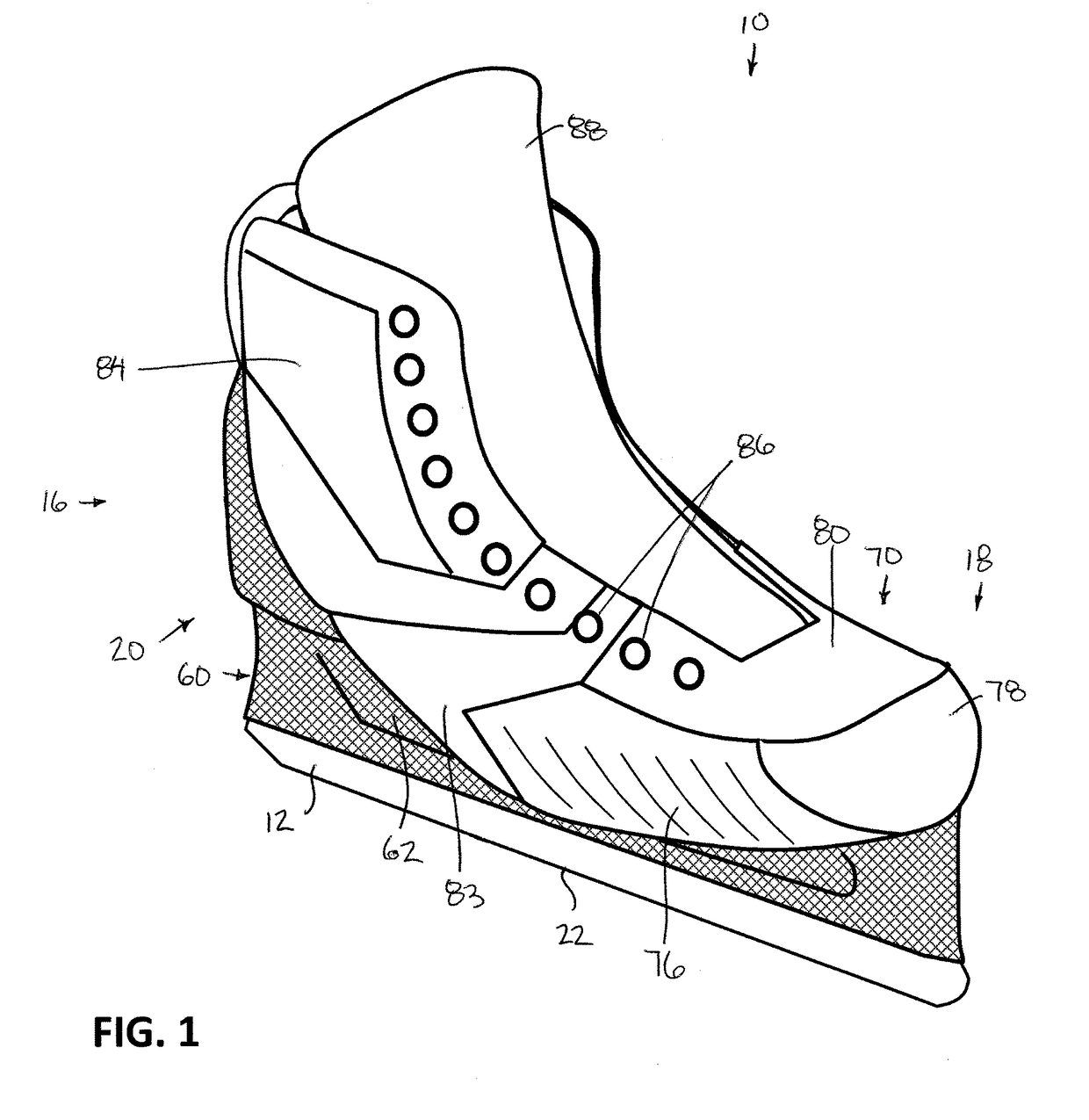

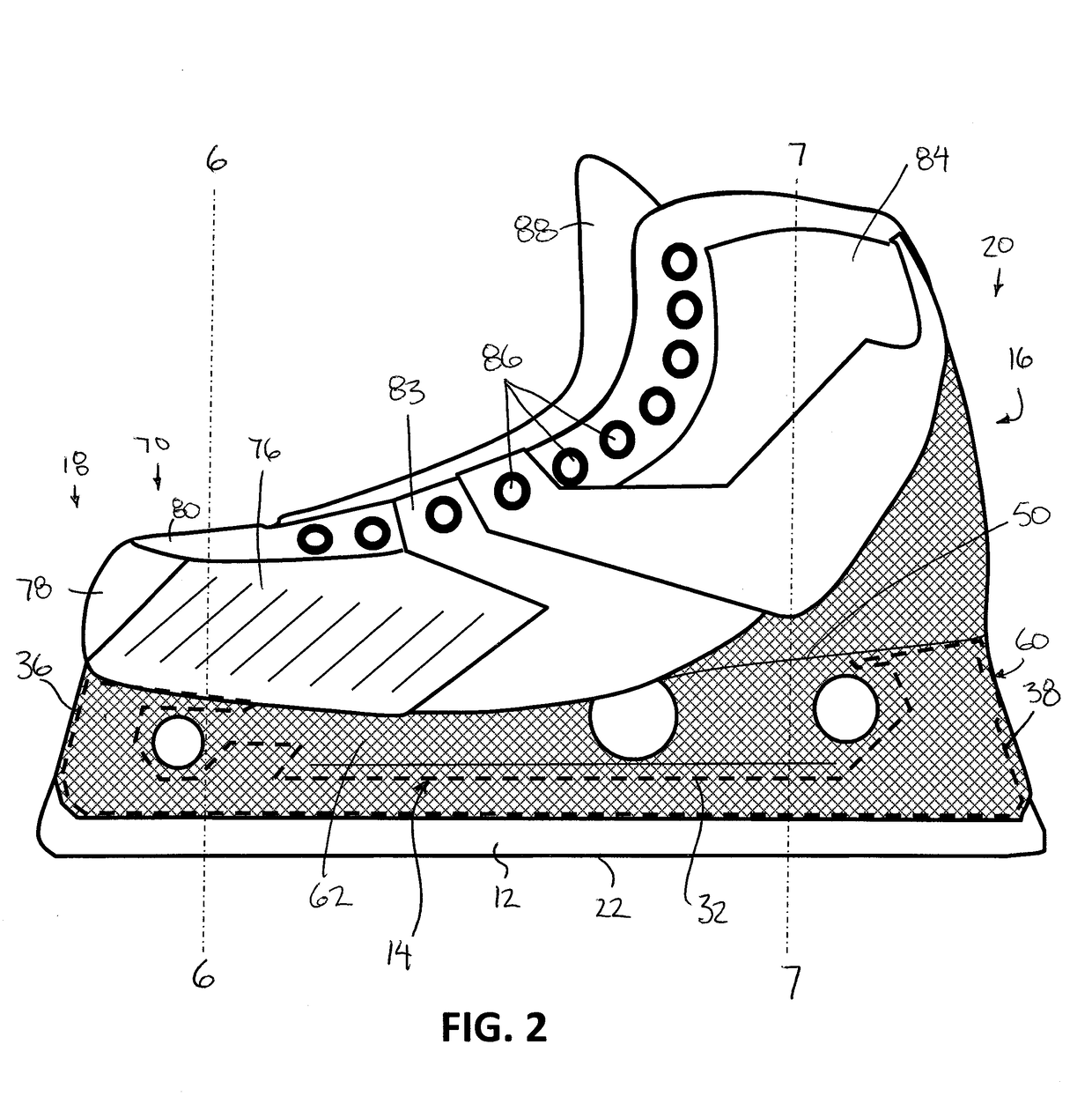

Protective goalie skate boot body with integral blade mounting channel

A goalie skate assembly has i) a plastic blade mounting member adapted to releasably receive a metal skate blade therein, and ii) a monocoque carbon fiber and resin composite skate boot body for receiving a foot of the user therein. The unitary structure of the skate boot body includes i) a sole portion, ii) a heel portion extending upwardly from the sole portion for receiving a heel of the user therein, iii) a pair of side portions extending upwardly from opposing sides of the sole portion, and iv) a lower portion extending downwardly from a bottom side of the sole portion so as to surround at least a portion of the blade mounting member. A toe cap mounted on the skate boot body includes a molded plastic outer shell and a liner formed of a fiber and resin composite material bonded to an inner surface of the outer shell.

Owner:VH FOOTWEAR INC

Transmission gear, roller reducer comprising the transmission gear, and method of assembly thereof

The present invention relates to a roller reducer comprising a transmission gear having an externally threaded shaft having at least one left-handed thread portion, at least one right-handed thread portion, and at least one shaft flange ring, and a plurality of rollers, each roller having a plurality of thread portions, comprising at least one left-handed thread portion and at least one right-handed thread portion, each thread portion arranged to engage with the respective thread portions of the shaft, and at least one roller flange ring arranged adjacent to the roller thread portions to rotationally slide against the corresponding at least one flange ring of the shaft.Diameters of the flange rings of the rollers and the flange rings of the shaft are each equal to the respective effective thread diameters of the engaged thread portions of the rollers and the shaft, respectively.

Owner:DIAKONT ADVANCED TECH

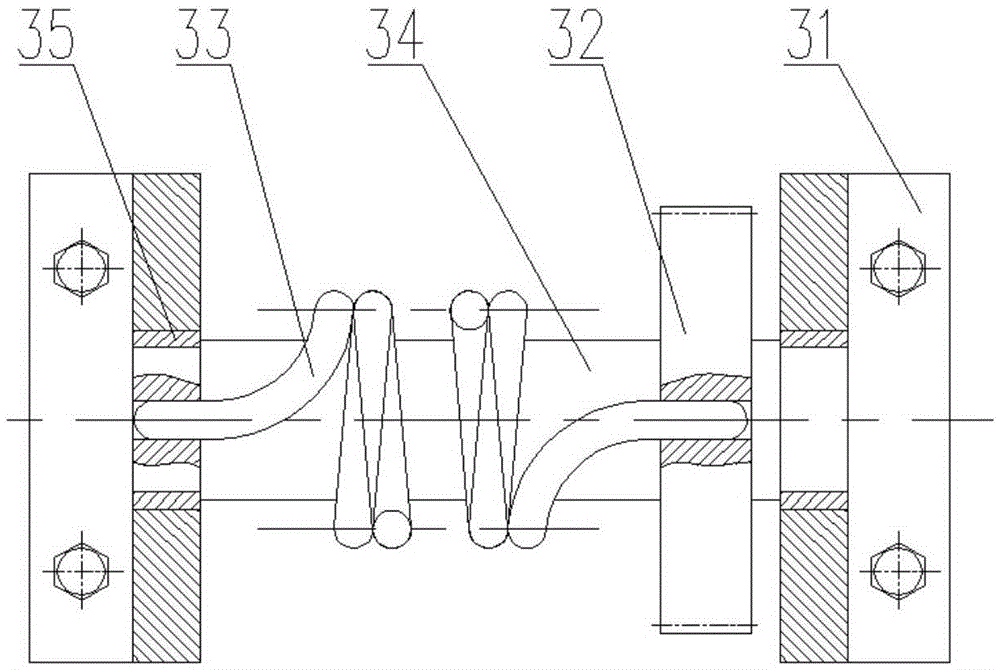

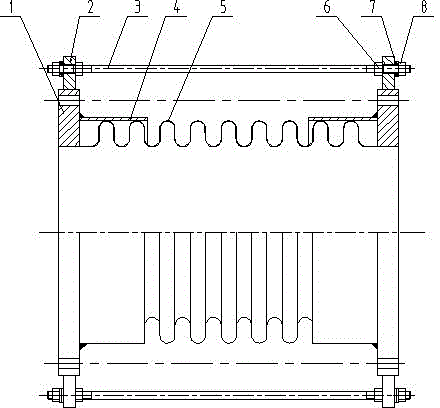

Inlet and outlet damping expansion joint of anti-fatigue type pump

InactiveCN103982735APrevent fatigue failureReduce radial deformationPipeline expansion-compensationCorrosion preventionArchitectural engineeringExpansion joint

The invention discloses an inlet and outlet damping expansion joint of an anti-fatigue type pump. The expansion joint comprises flanges, a limiting protecting sleeve and a corrugated pipe, wherein the flanges are respectively welded at the two ends of the corrugated pipe, the flanges at the two ends are respectively provided with a lug plate, a pull rod penetrates through the lug plates, the two ends of the pull rod are used for connecting the lug plates together through nuts, the inner side end of each lug plate is provided with an adjusting nut, the limiting protecting sleeve is sheathed on the corrugated pipe, the inner wall of the limiting protecting sleeve is in contact with peaks of the corrugated pipe, and one end of the limiting protecting sleeve is fixedly connected with the inner end surface of each flange. The expansion joint has the further improvement that the two limiting protecting sleeves are respectively and fixedly connected with the inner end surfaces of the flanges, the two corrugated pipes are coated by the limiting protecting sleeves, the inner wall of each corrugated pipe is provided with a corrosion-resistant layer, and a spherical spacer and a conical spacer assembly are arranged between each nut and each lug plate. The expansion joint has the advantages that the fatigue failure of the parts at the two ends of the corrugated pipe is effectively prevented, the service life is obviously prolonged, and the corrosion-resistant property is higher.

Owner:江苏苏创管业科技有限公司

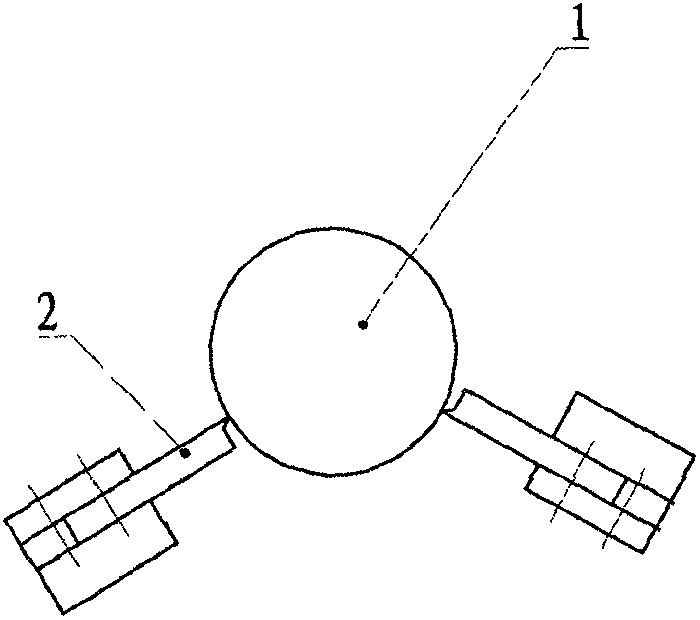

Turning mechanism in machining of large ship propeller shafts

The invention provides a turning mechanism in the machining of large ship propeller shafts, wherein the turning mechanism is provided with two tool holders (2), the feeding directions of turning tools on the two tool holders are oblique and upward relative to a propeller shaft (1), the turning tools are symmetric according to a vertical plane passing the axis, and the two tool holders are mounted on the same axial feed mechanism and respectively provided with a radial feed mechanism. The turning mechanism provided by the invention uses the two turning tools, the feeding directions of the turning tools are oblique and upward relative to the propeller shaft, and the turning tools are symmetrically arranged at both sides of a workpiece. Compared with the prior art, the turning mechanism ensures that the bending effect applied on the shaft by the cutting force of the turning tools and the gravity of the shaft can be dispersed and counteracted, the bending effect applied on the shaft by gravity and cutting force can be eliminated under the condition that the amount of radial feed is controlled, and thereby the turning precision is increased. Meanwhile, under the circumstance of double-tool cutting, the amount of feed of a single turning tool can be reduced, so that the friction and cutting heat of the workpiece can be reduced, and if the amount of feed is controlled at more than half of the ordinary amount of feed, then the turning speed can be increased as well on the basis of heat reduction.

Owner:ZHEJIANG WANLIANDA MACHINERY MFG

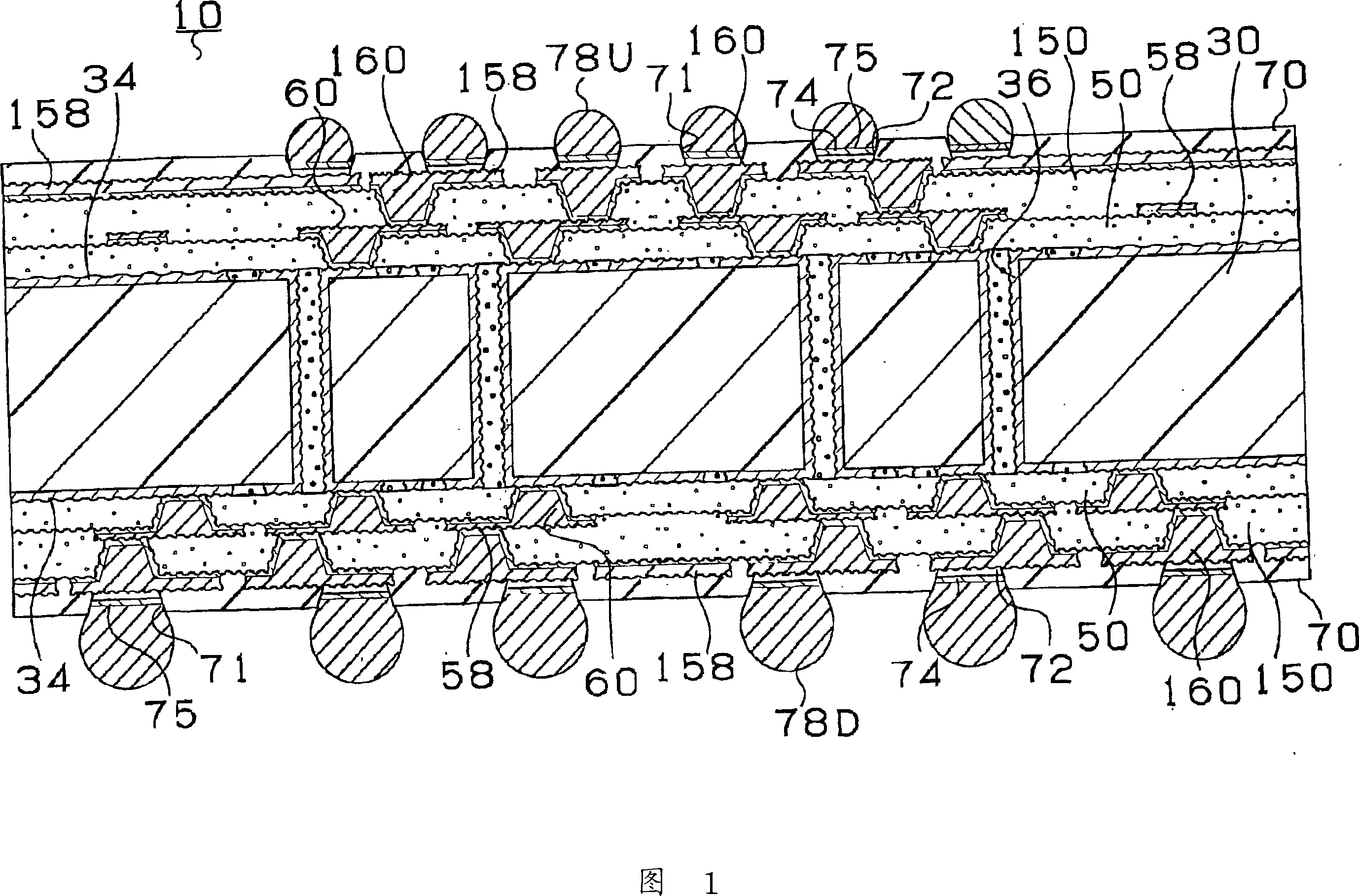

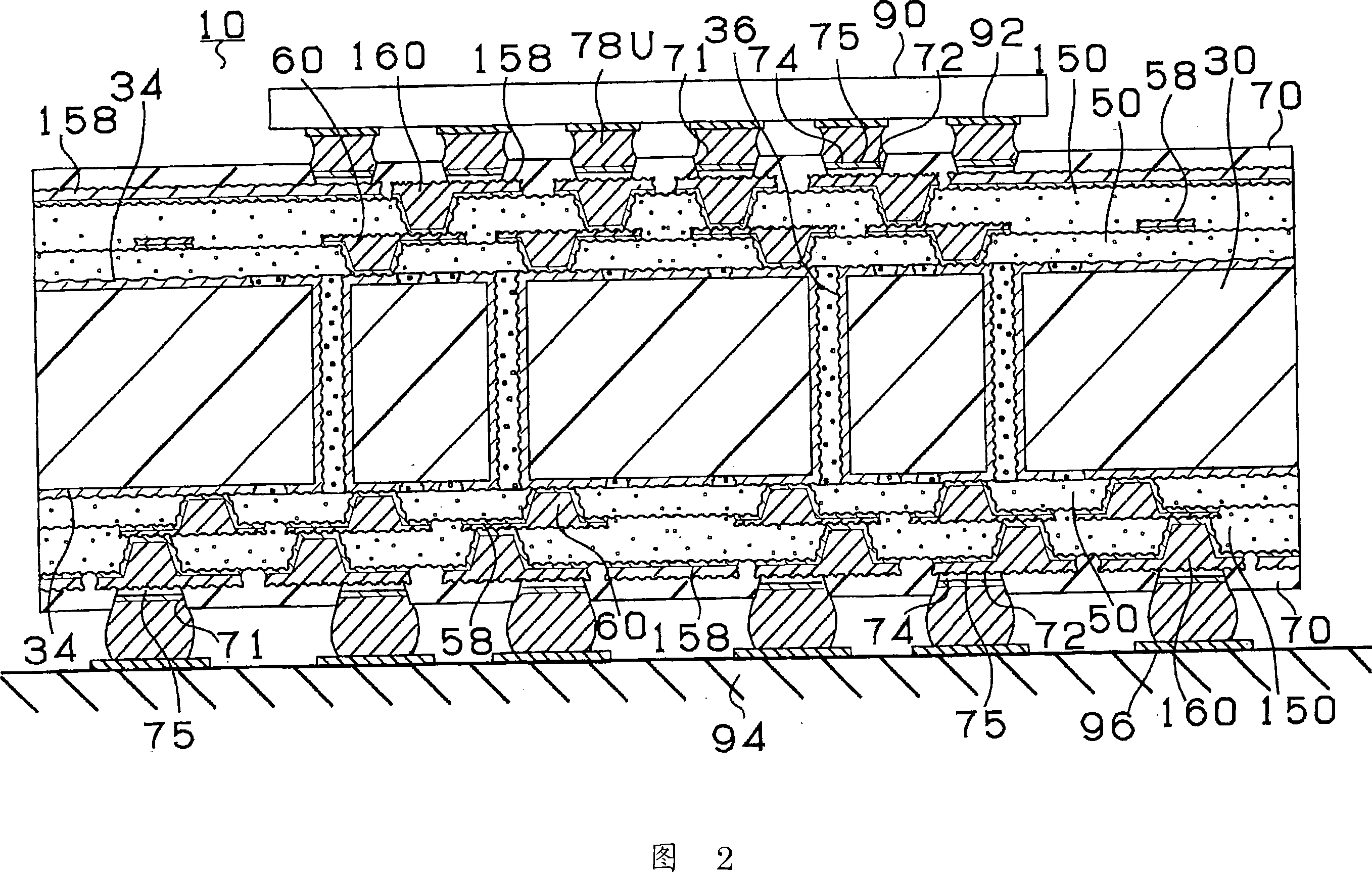

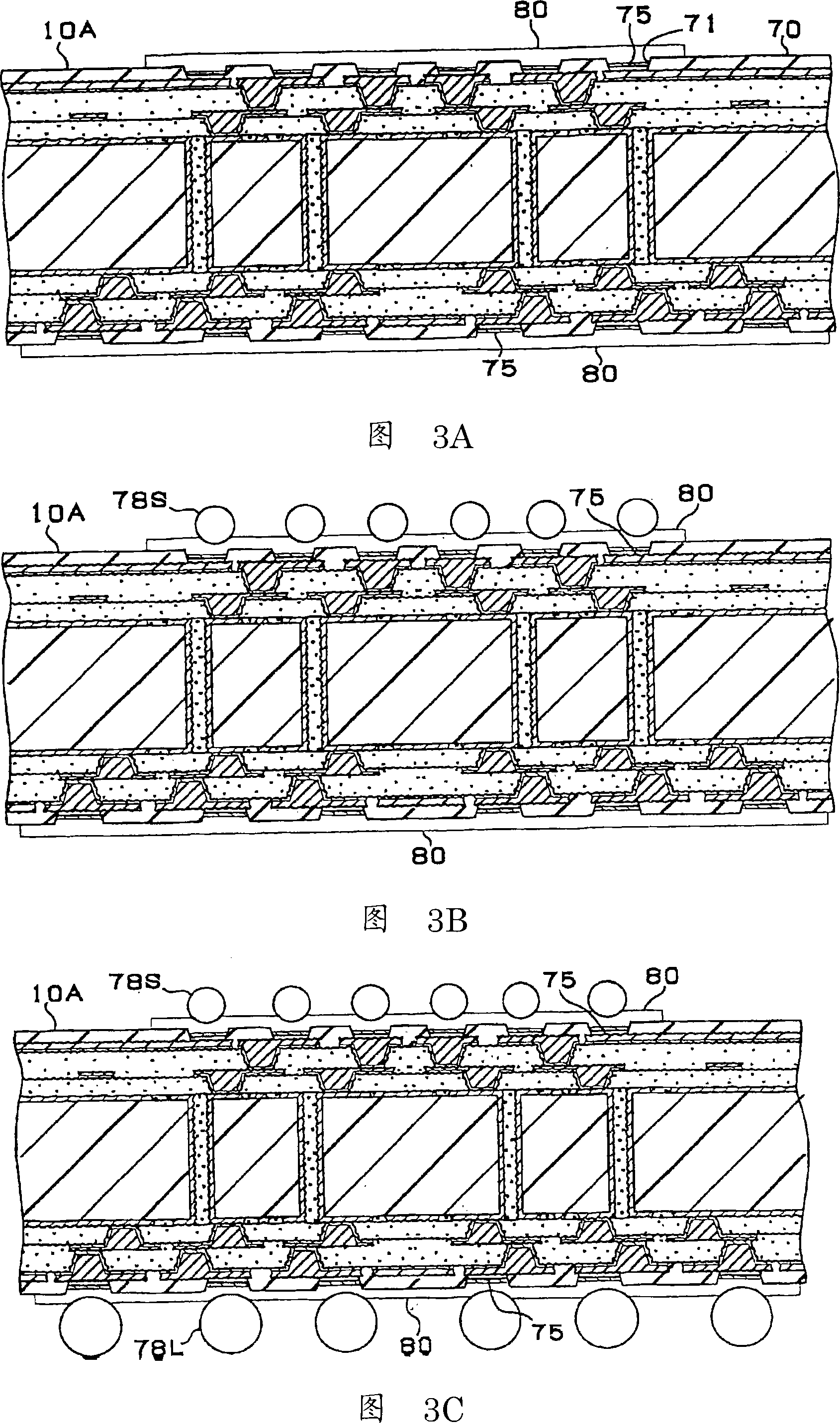

Printed wiring board

ActiveCN101171895APrevent peelingSmall insulation resistancePrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

A printed wiring board comprises a wiring substrate provided with at least one conductor circuit, a solder resist layer provided on the surface of the wiring substrate, at least one conductor pad formed from a part of the conductor circuit exposed from an opening provided in the solder resist layer, and at least one solder bump for mounting electronic parts on the conductor pad. In the printed wiring board, since the at least one conductor pad is aligned at a pitch of 200 µm or less, and a ratio (W / D) of a diameter W of the solder bump to an opening diameter D of the opening formed in the solder resist layer is within a range of 1.05 to 1.7, connection reliability and insulation reliability can be easily improved.

Owner:IBIDEN CO LTD

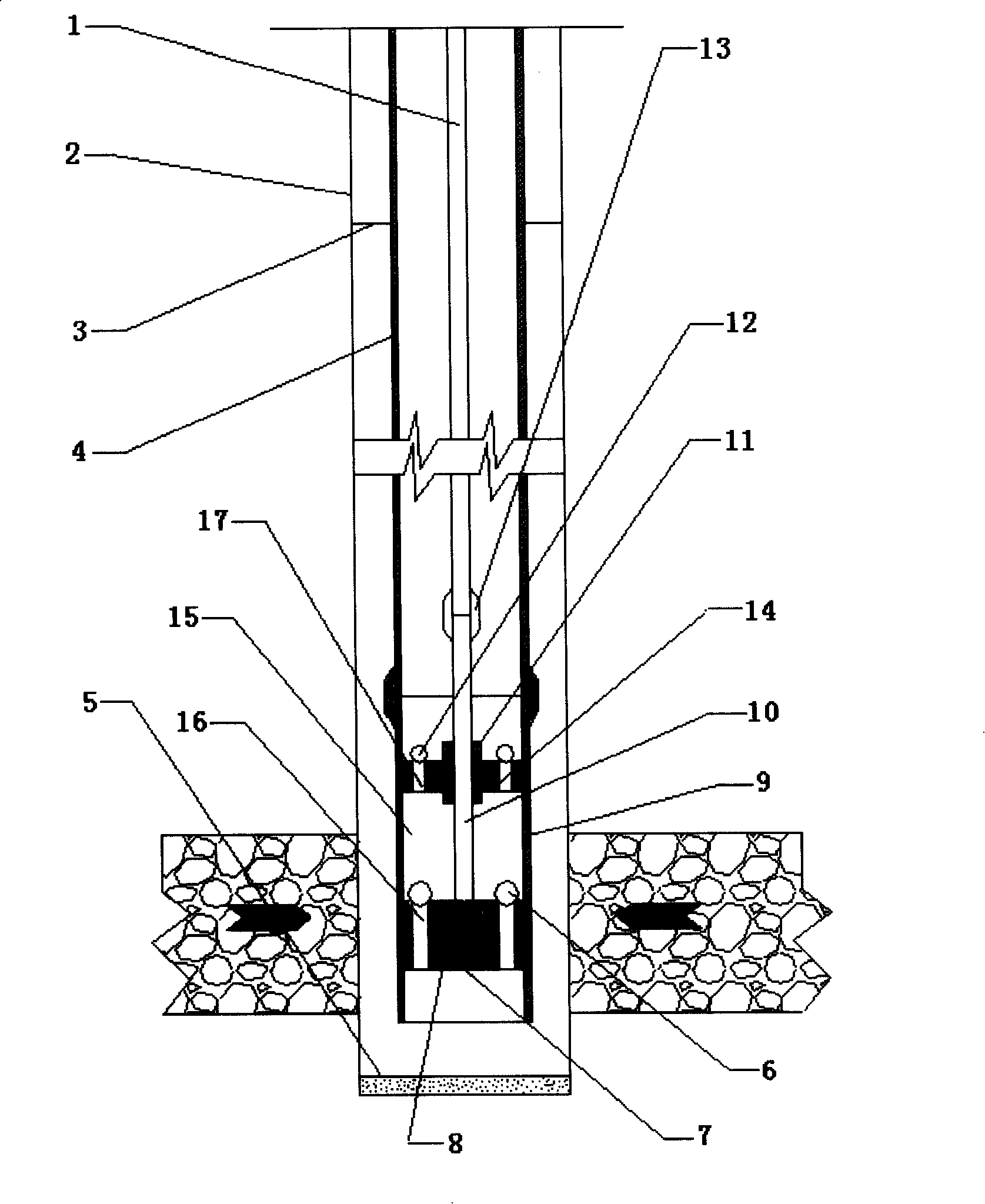

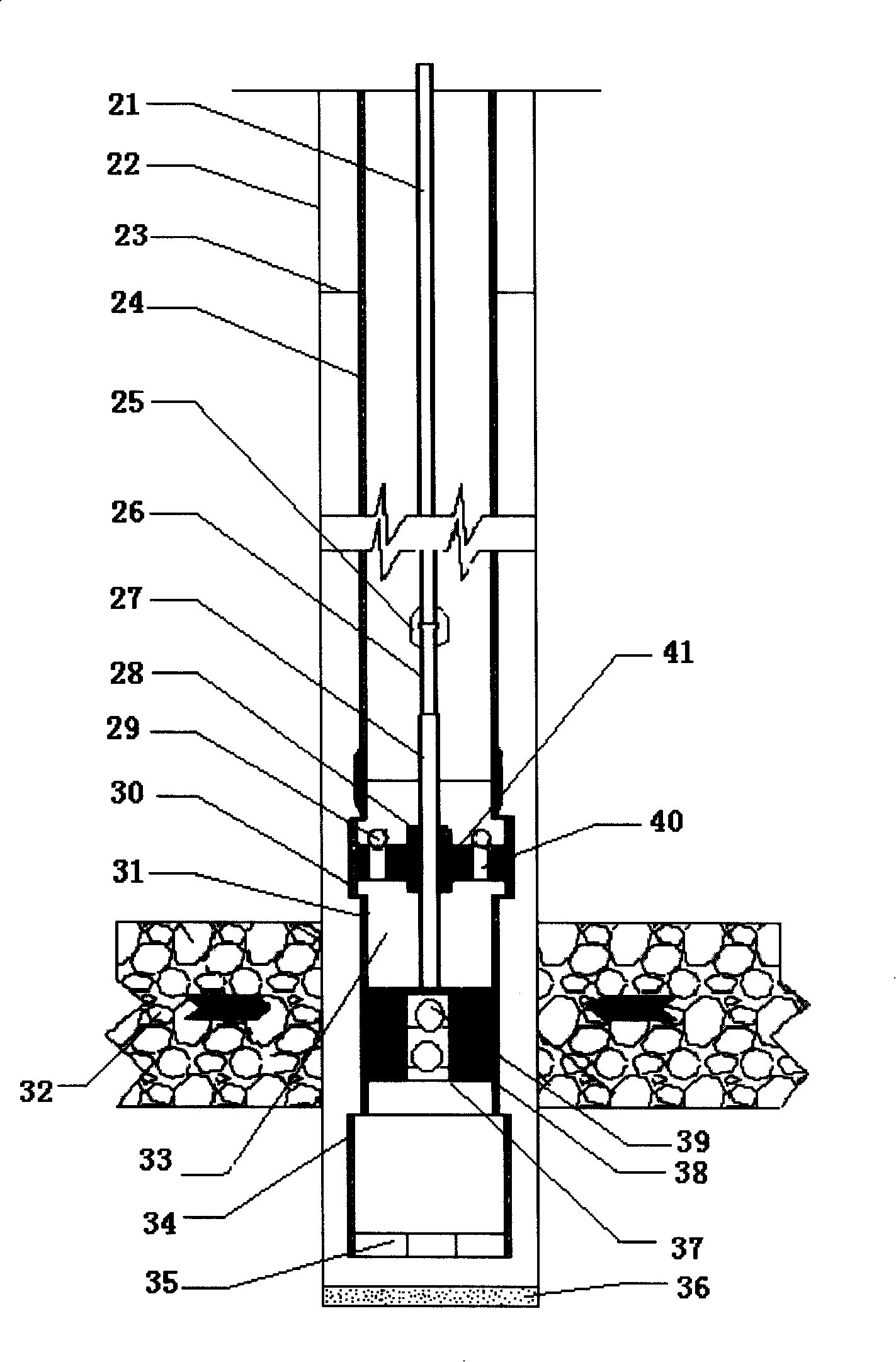

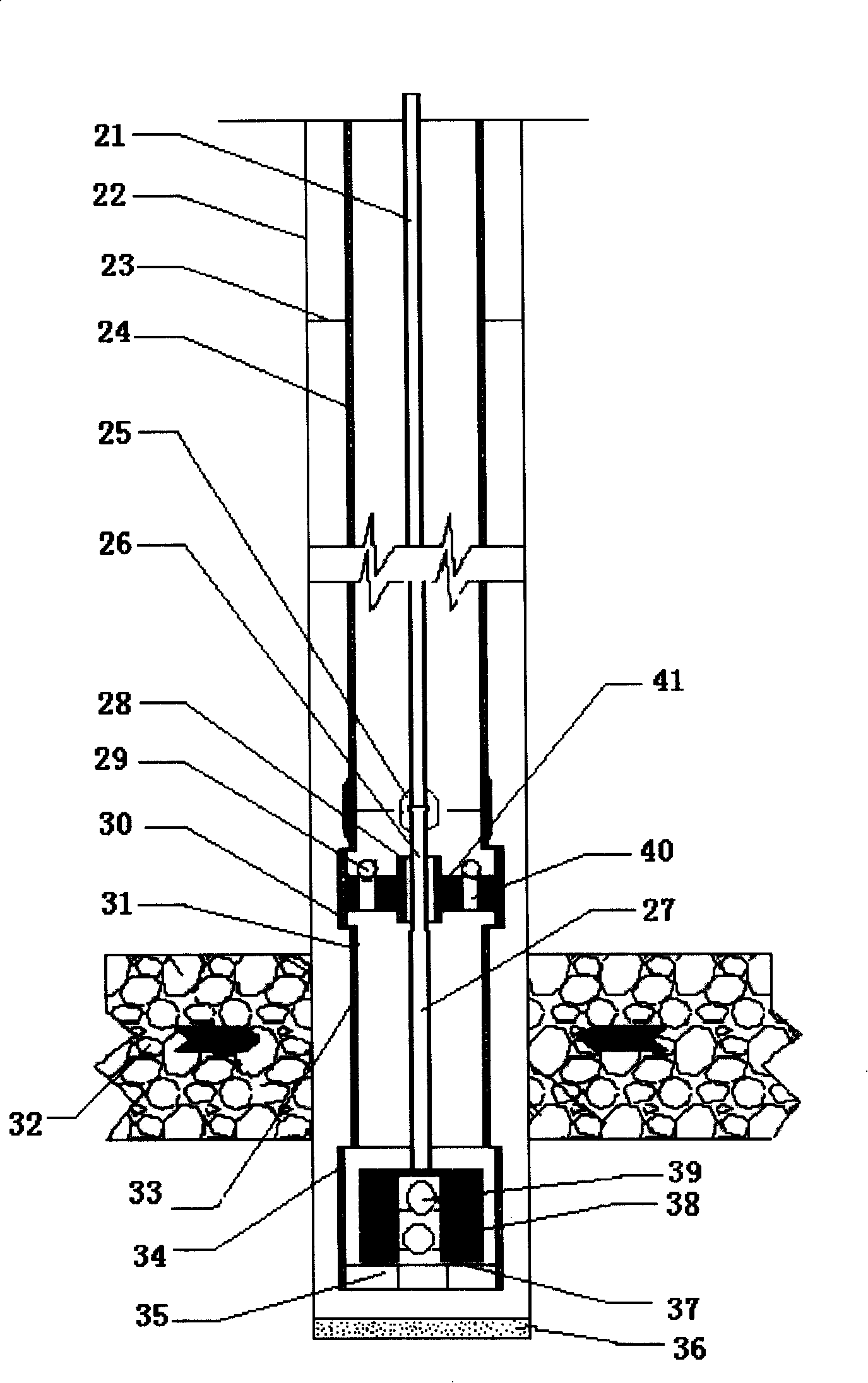

Lever oil pump capable of eliminating eccentric wear and directly flushing well

InactiveCN101220807AEliminate bendingEliminate the situationPositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

The invention discloses a rod-typed oil pump which can eliminate the partial abrasion and has positive well cleanout function, comprising a disconnecting / connecting mechanism, a pulling rod, a long piston, a short pump cylinder, a fixed valve, a fixed valve base expanded pipe, a long pump cylinder, a short piston, a floating valve, a pump cylinder lower expanded pipe, and a short piston supporter with a flow passage. The fixed valve is arranged above the long pump cylinder; the short piston is arranged inside the long pump cylinder and below the fixed valve; the floating valve is arranged on the short piston; the diameter of the pulling rod is less than that of the long piston; the pump cylinder lower expanded pipe is longer than the diameter of the long pump cylinder. The invention can eliminate the partial abrasion of the oil rod and can achieve the positive well cleanout without moving a pipe string.

Owner:凌建军

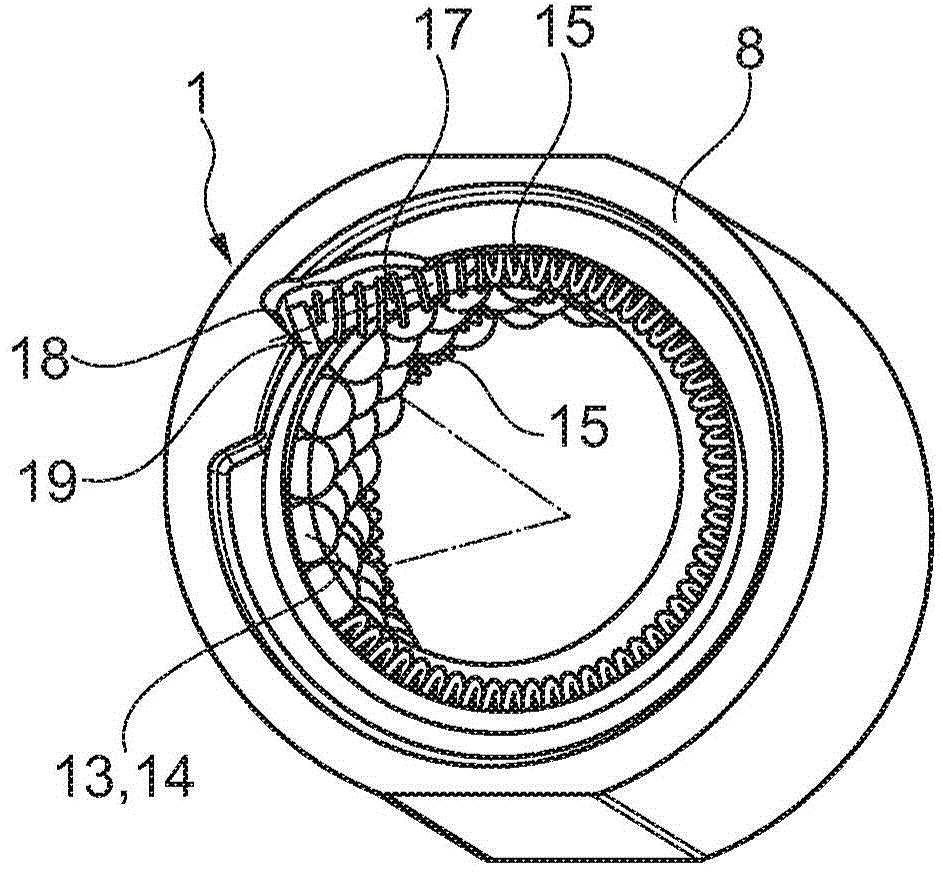

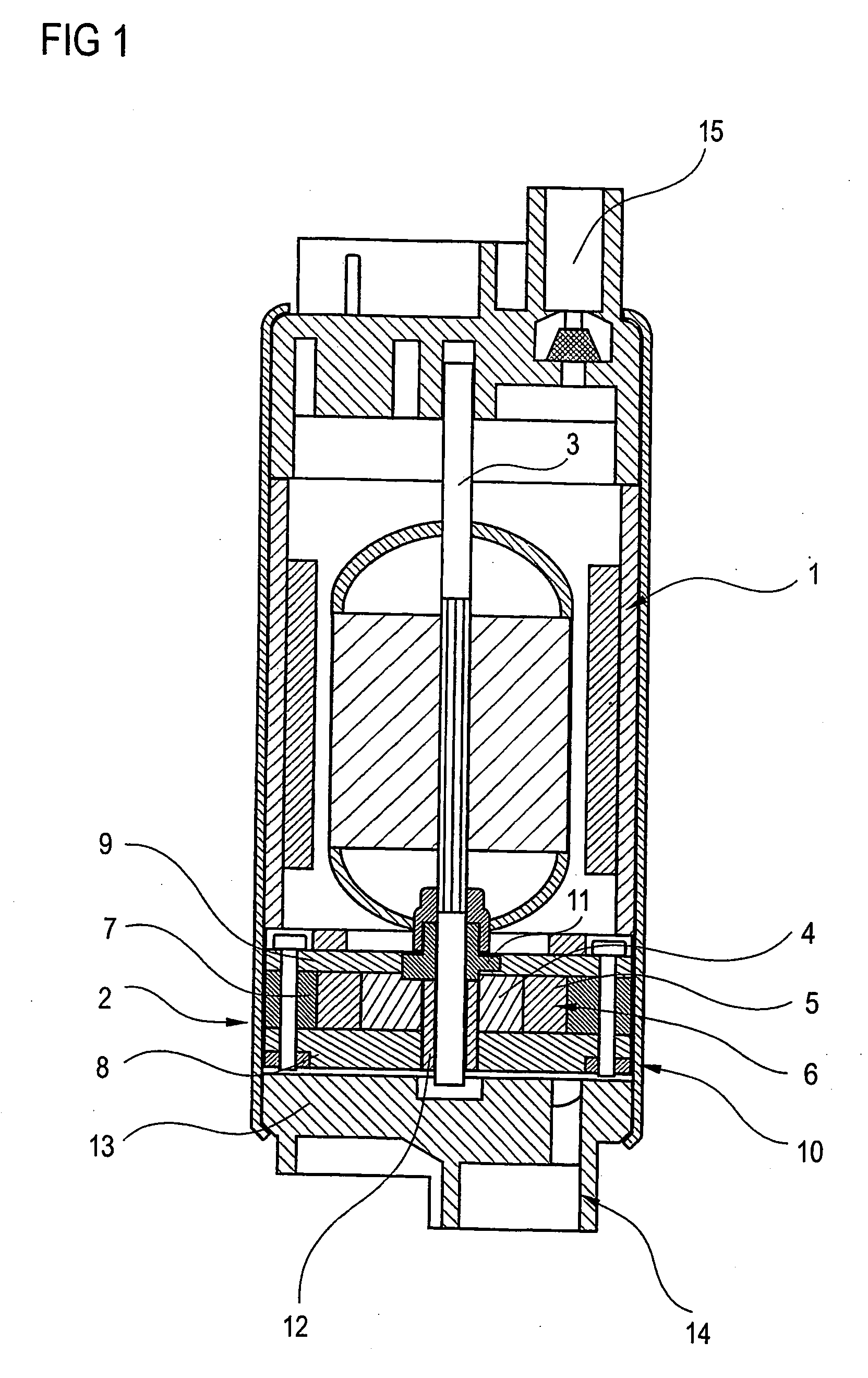

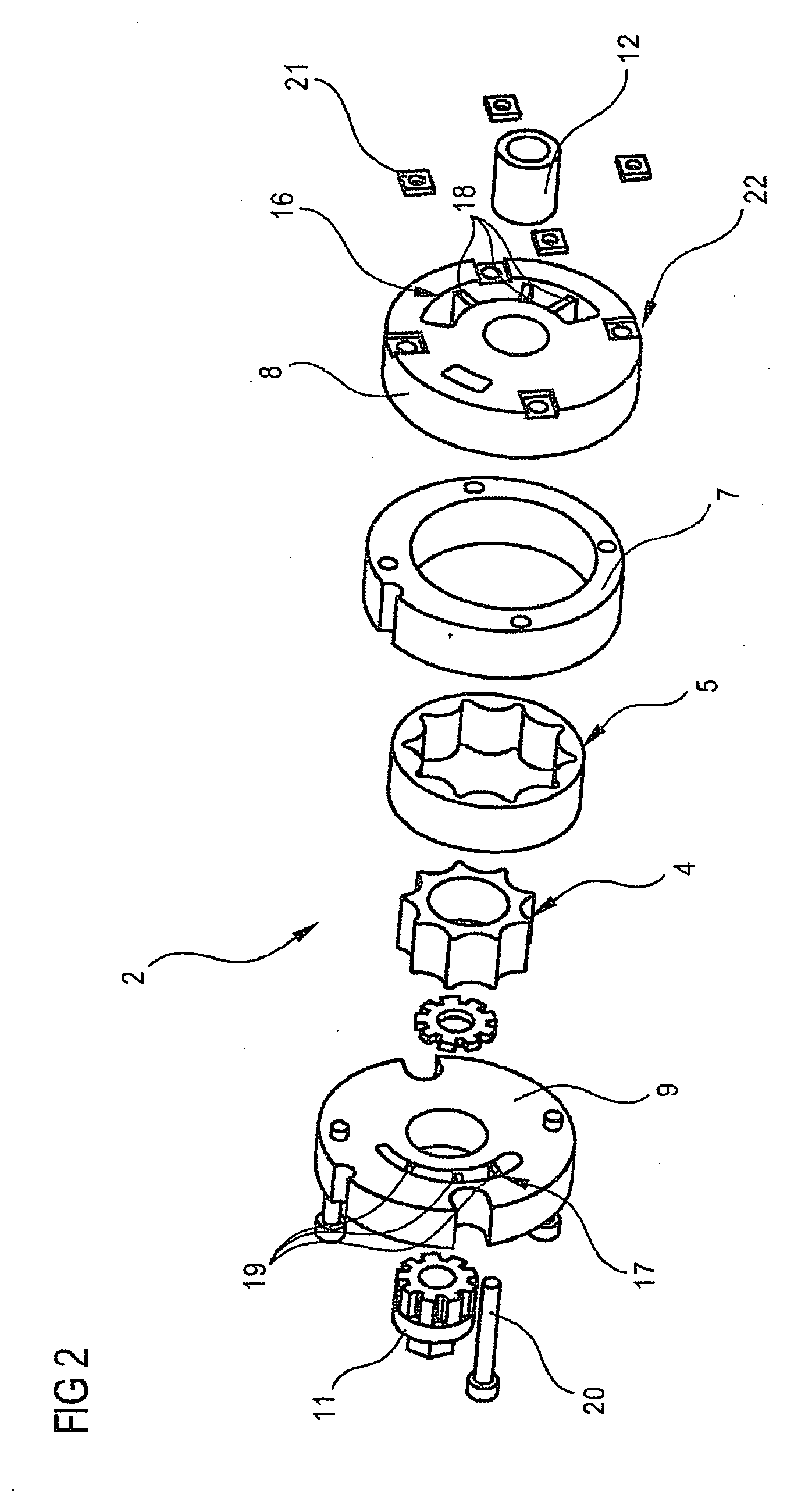

Internal gear-wheel pump comprising reinforced channels

InactiveUS20060153706A1Produced cost-effectivelyReduce intensityPump componentsRotary piston pumpsGear pumpGear wheel

The invention relates to a gerotor fuel pump (2) comprising ribs (18, 19), which are located in channels (16, 17) that are configured as inlets and outlets and that are situated in housing parts (8, 9). The ribs (18, 19) are positioned transversely to the maximal extension of the cross-sections of the channels (16, 17), producing a high degree of stability in the channels (16, 17). The housing parts (8, 9) are composed of plastic.

Owner:CONTINENTAL AUTOMOTIVE GMBH

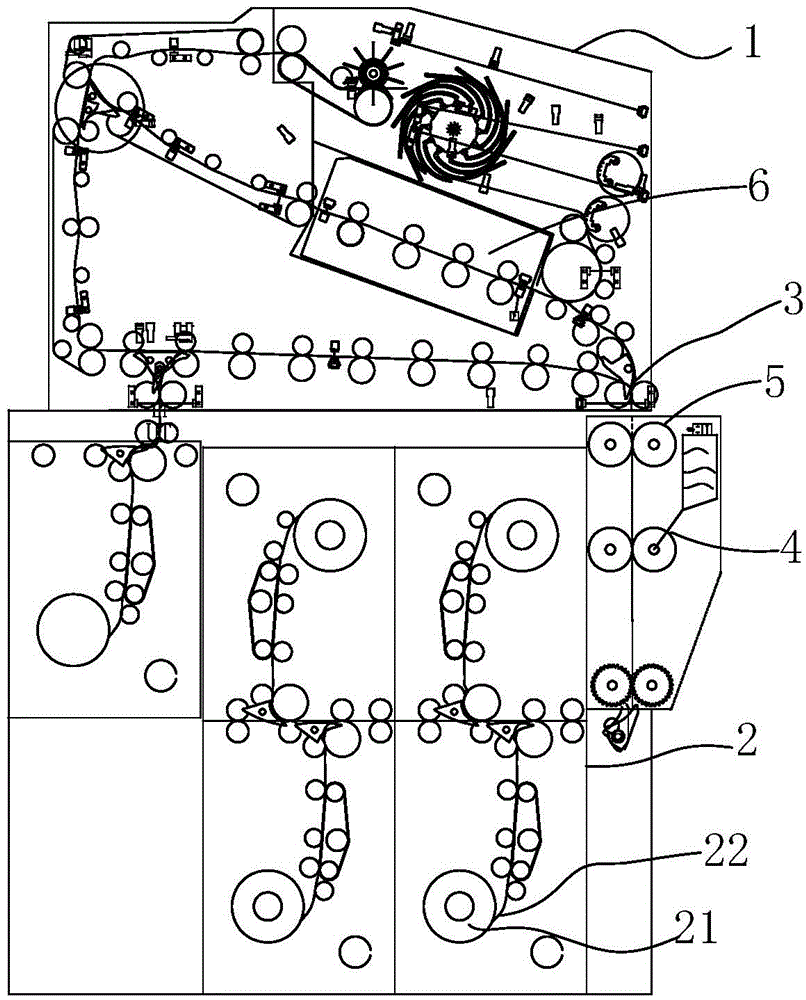

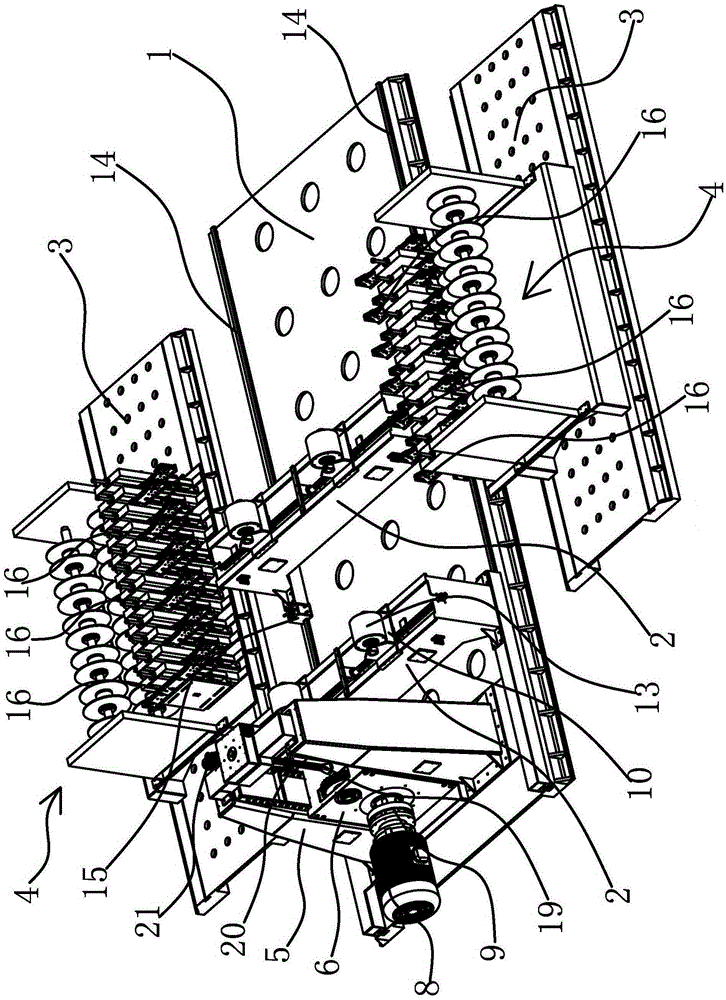

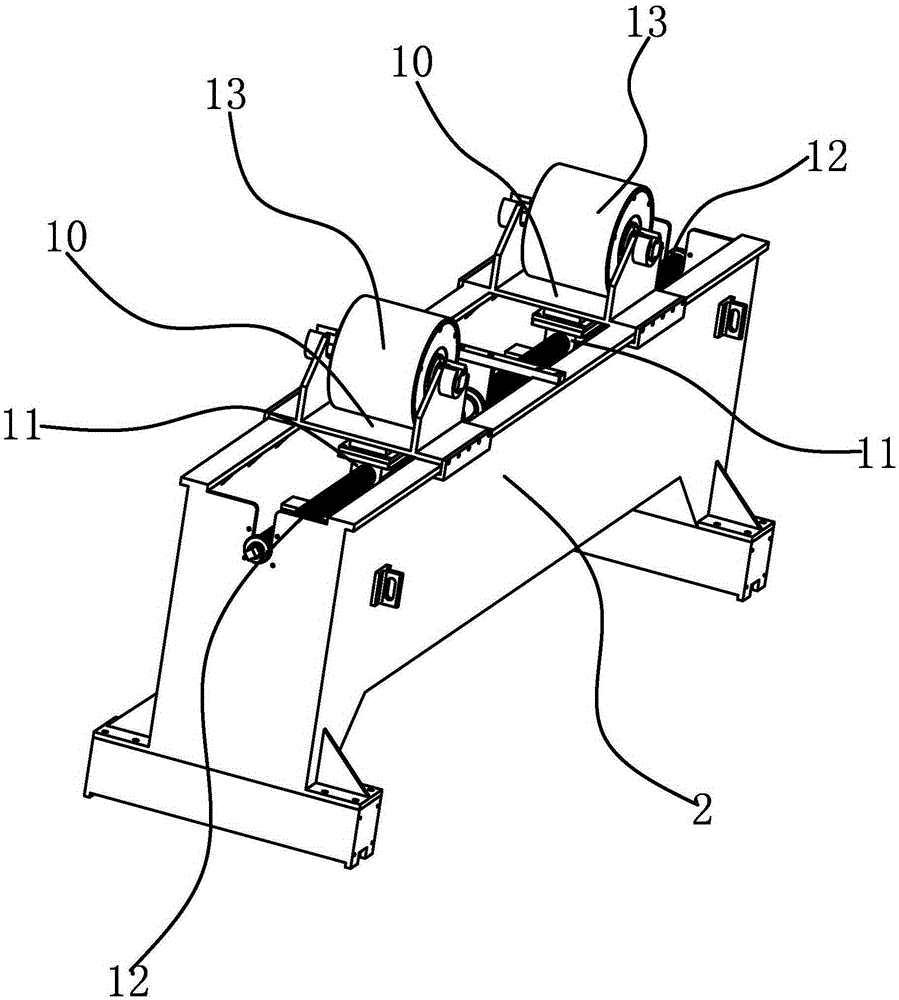

Automatic pipe winder of winding type heat exchanger

ActiveCN105290258AAchieve windingControl volumeMetal-working feeding devicesHeat exchange apparatusPlate heat exchangerMachining

The invention provides an automatic pipe winder of a winding type heat exchanger and belongs to the technical field of machining equipment. The automatic pipe winder of the winding type heat exchanger solves the problem that an existing automatic pipe winder of the winding type heat exchanger is low in production efficiency. The automatic pipe winder of the winding type heat exchanger comprises a main guide rail bottom plate which is provided with at least two supporting bases in the length direction, and the supporting bases are used for supporting core tubes; the two sides of the main guide rail bottom plate are both provided with feeding guide rail bottom plates; each feeding guide rail bottom plate is provided with an automatic correcting pipe conveying mechanism; the automatic correcting pipe conveying mechanisms are located on the sides of the supporting bases and can be aligned with the core tubes located on the supporting bases; and the feeding guide rail bottom plates are further provided with travelling driving mechanisms capable of driving the automatic correcting pipe conveying mechanisms to slide along the feeding guide rail bottom plates. The automatic pipe winder of the winding type heat exchanger can wind a plurality of heat transfer pipes in a multi-layer manner.

Owner:杭州量创科技咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com