Processing device and suction plate bench

A technology of processing device and workbench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, a processing apparatus as a best mode for carrying out the present invention will be described with reference to the drawings.

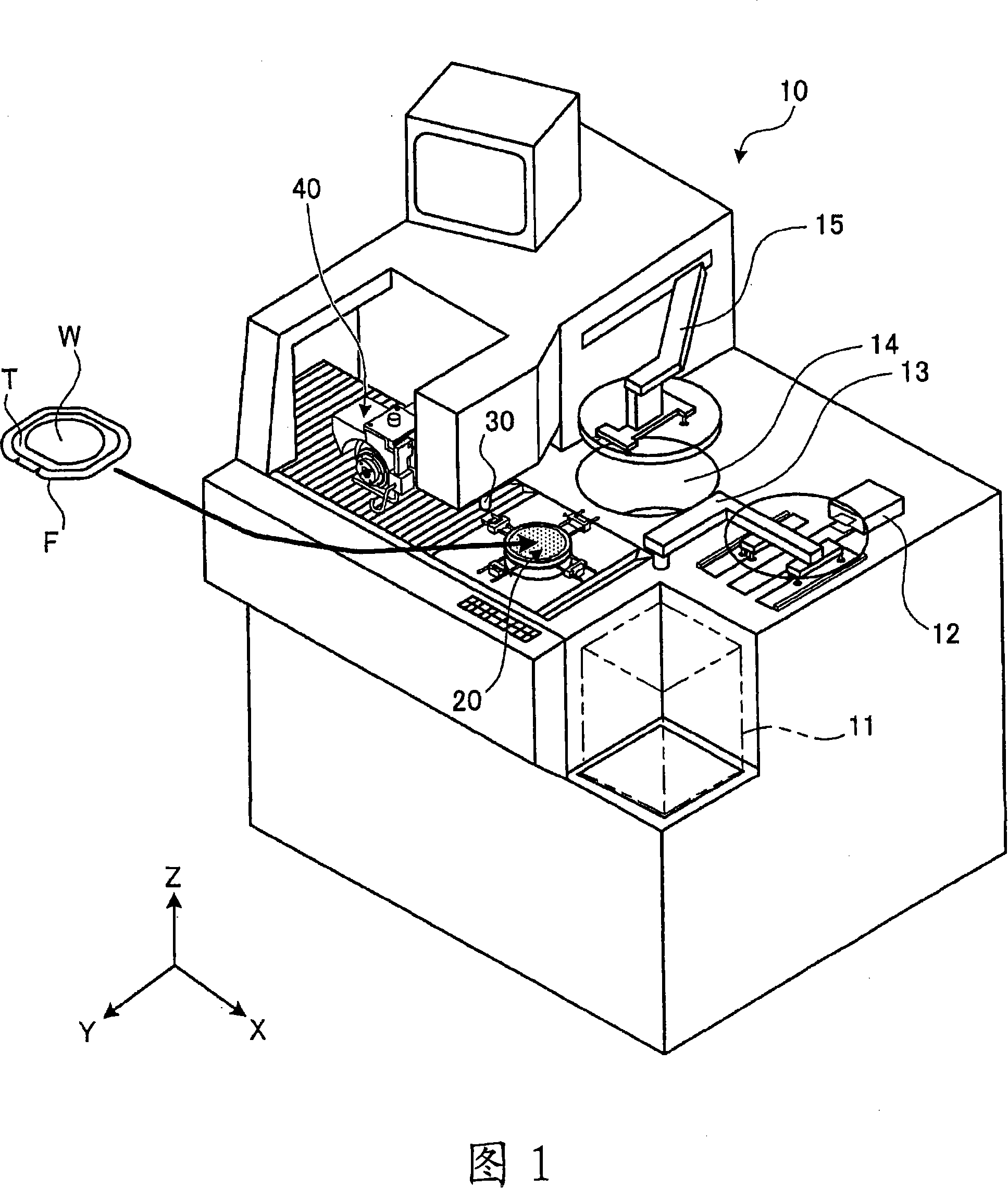

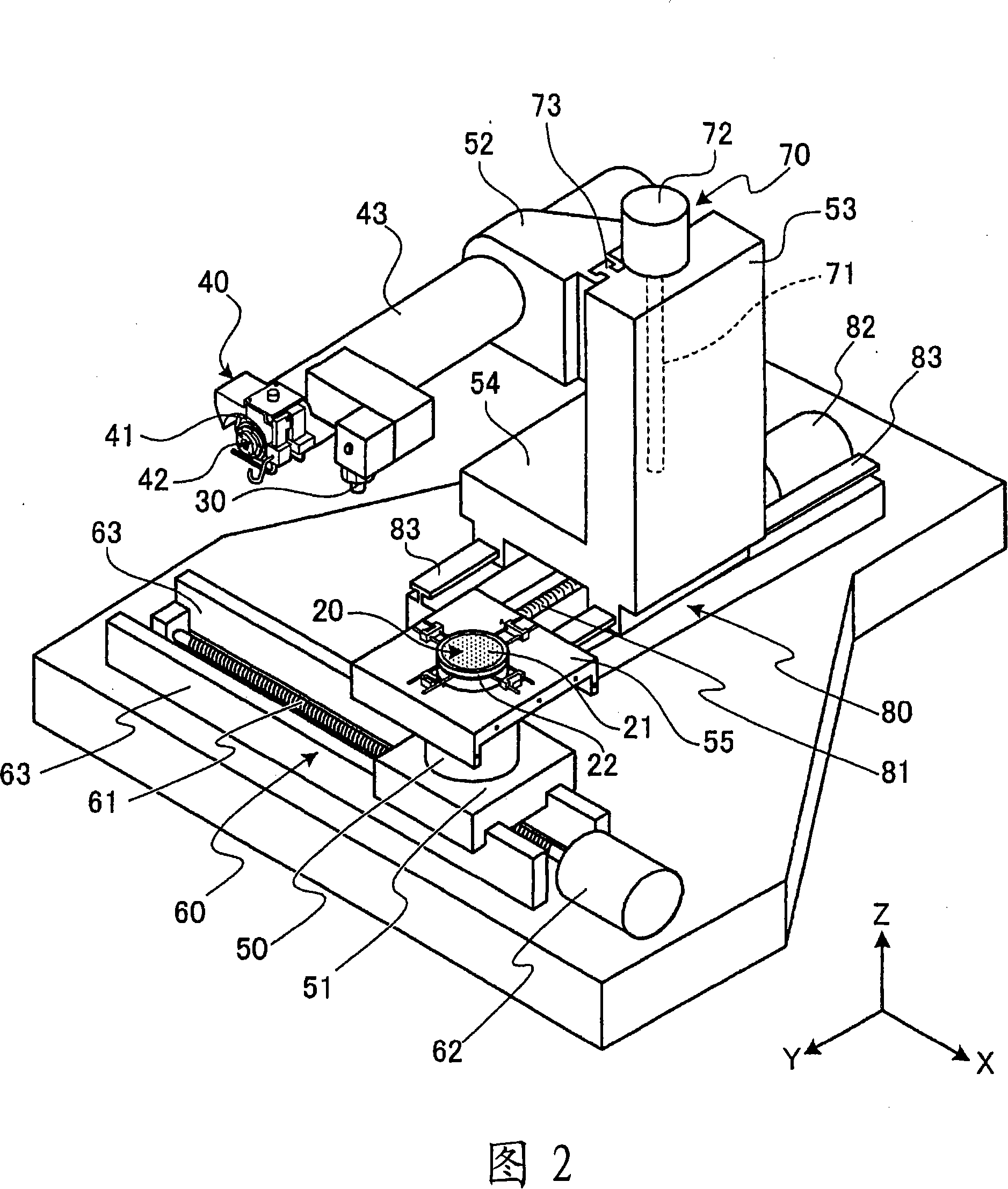

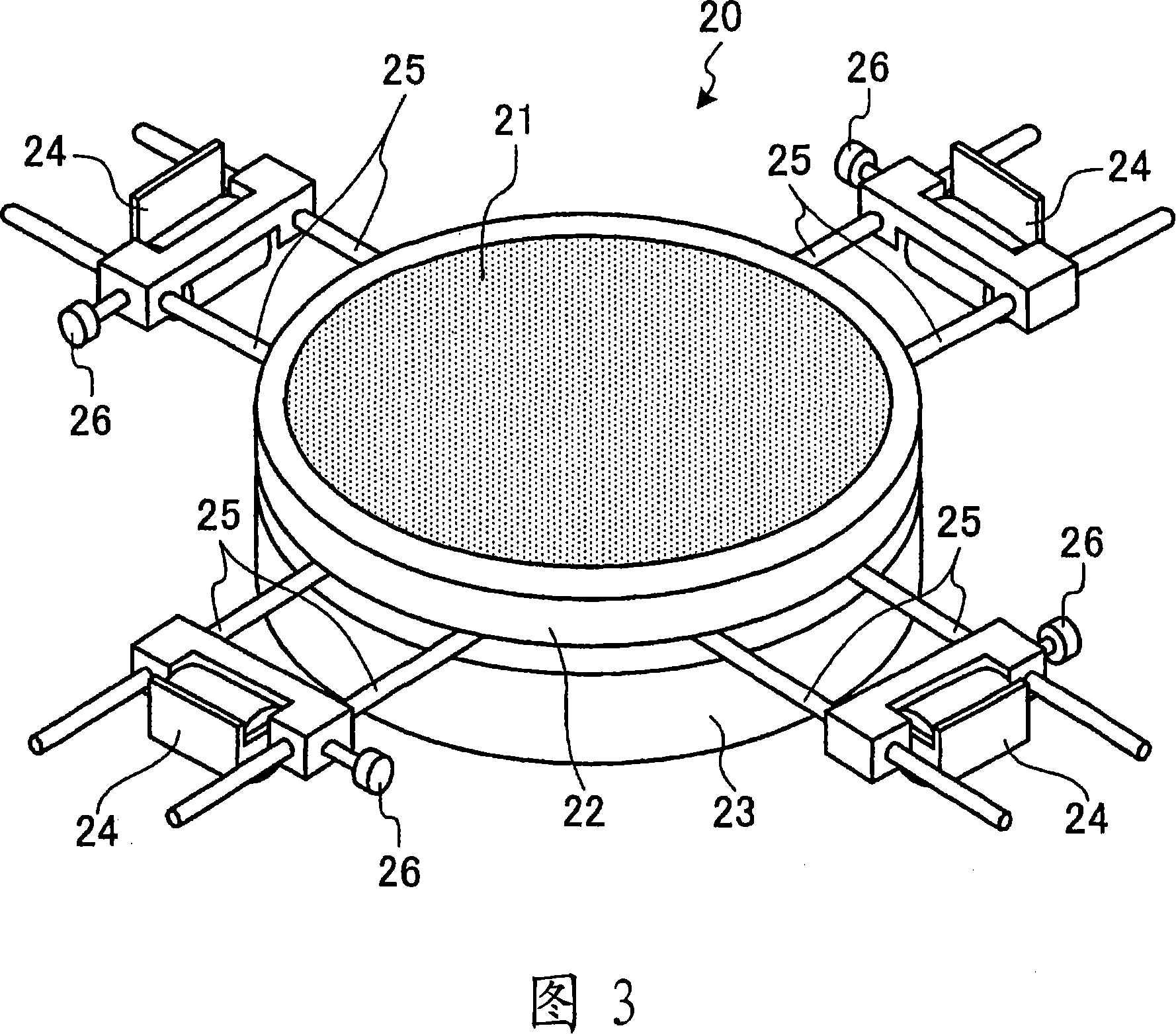

[0026] FIG. 1 is an external perspective view showing an example of a processing device according to an embodiment of the present invention, and FIG. 2 is a perspective view showing the structure around the processing unit extracted. The processing apparatus 10 of this embodiment is applied to a cutting apparatus for cutting a wafer W along a planned dividing line, and as a schematic configuration, as shown in FIG. , the transfer unit 15 and the suction cup table 20 , the camera unit 30 and the processing unit 40 .

[0027] Cassette portion 11 accommodates a plurality of wafers W in a state where wafer W is integrated with frame F via holding tape T. As shown in FIG. The loading and unloading unit 12 unloads the wafer W accommodated in the cassette unit 11 to a loading area where the transfer unit 13 can carry it, and loads the diced wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com