Patents

Literature

357results about How to "High precision machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

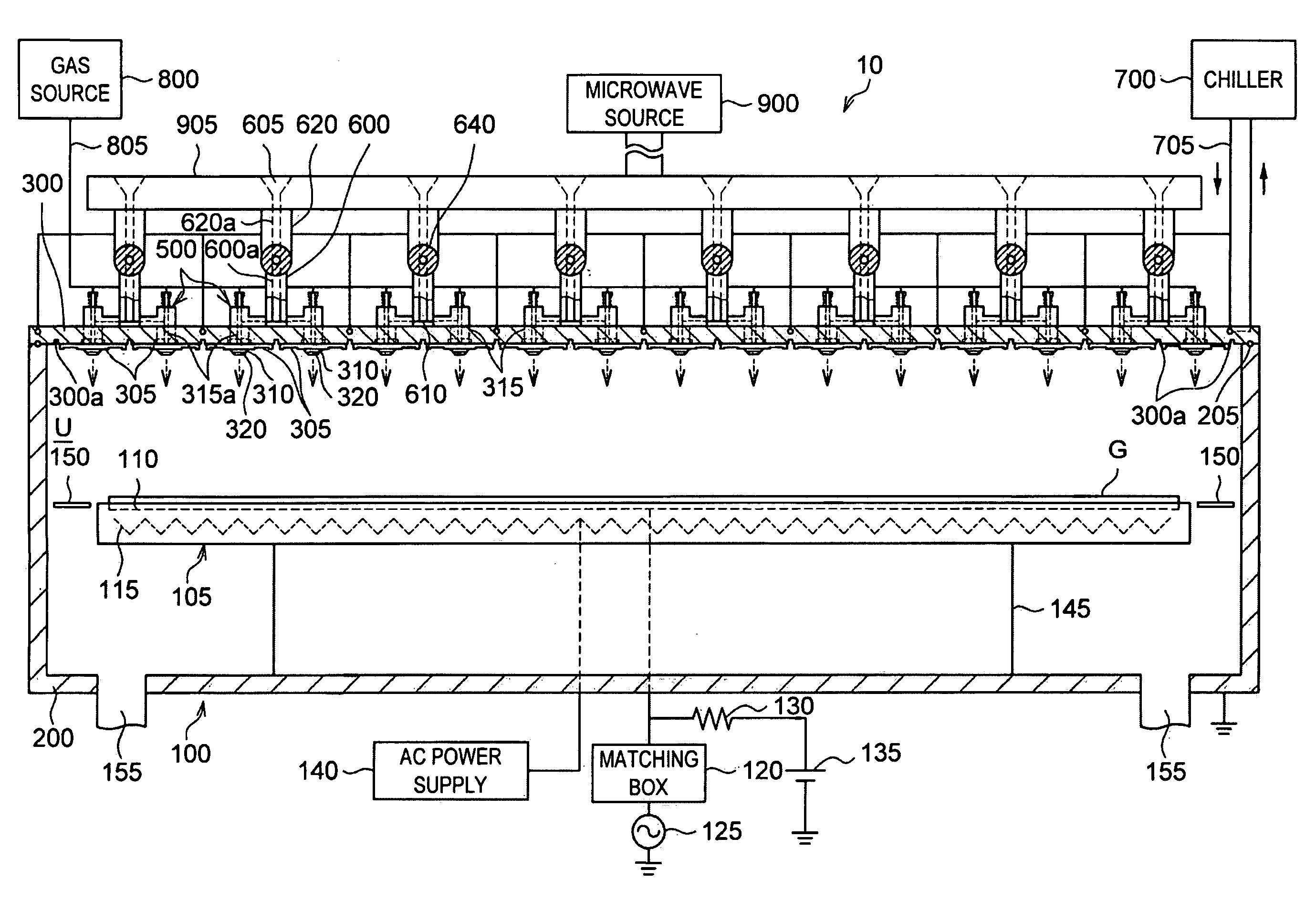

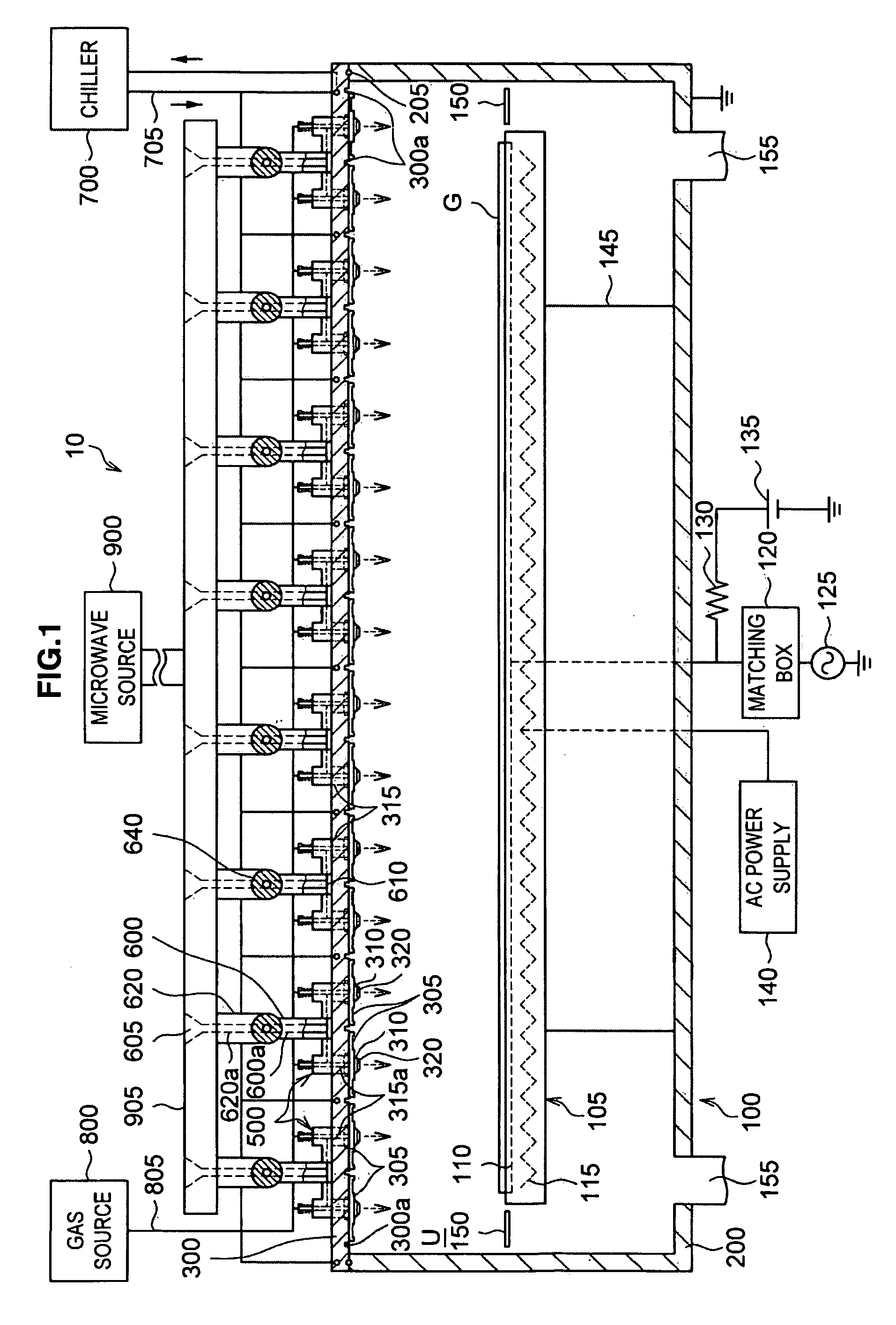

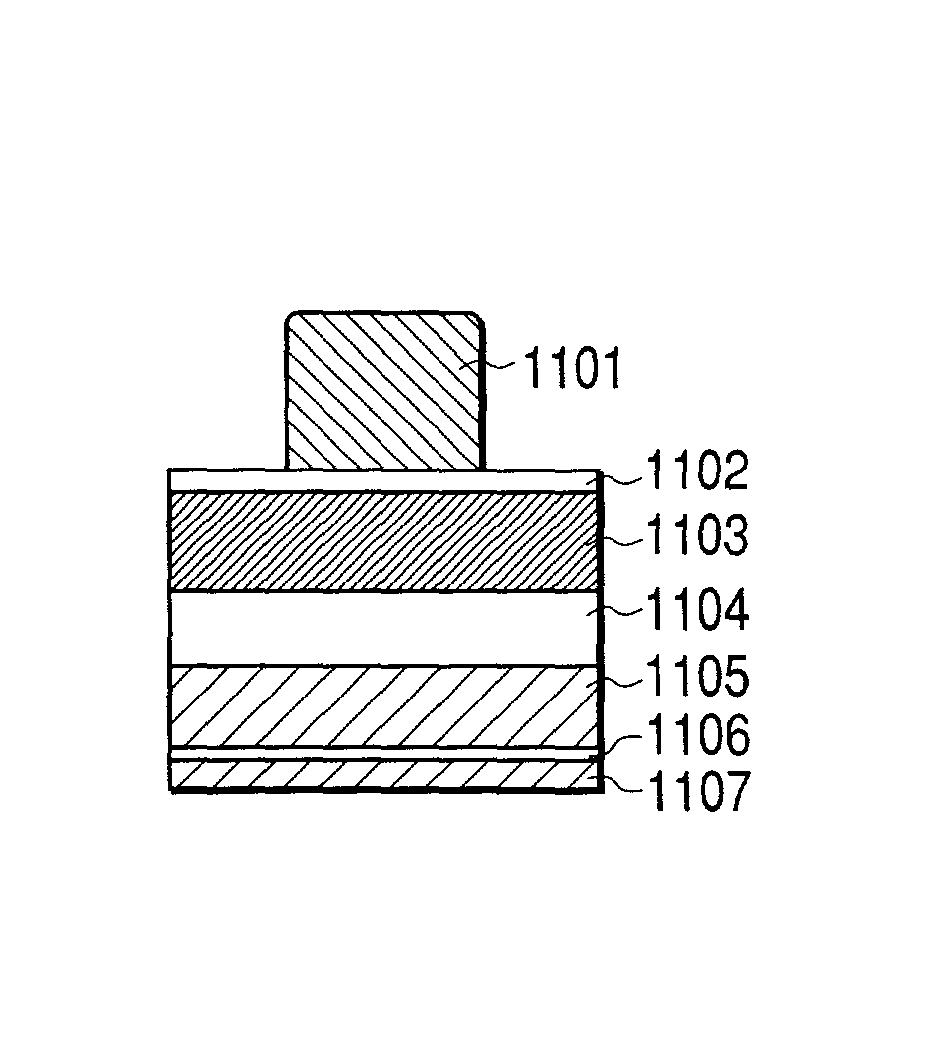

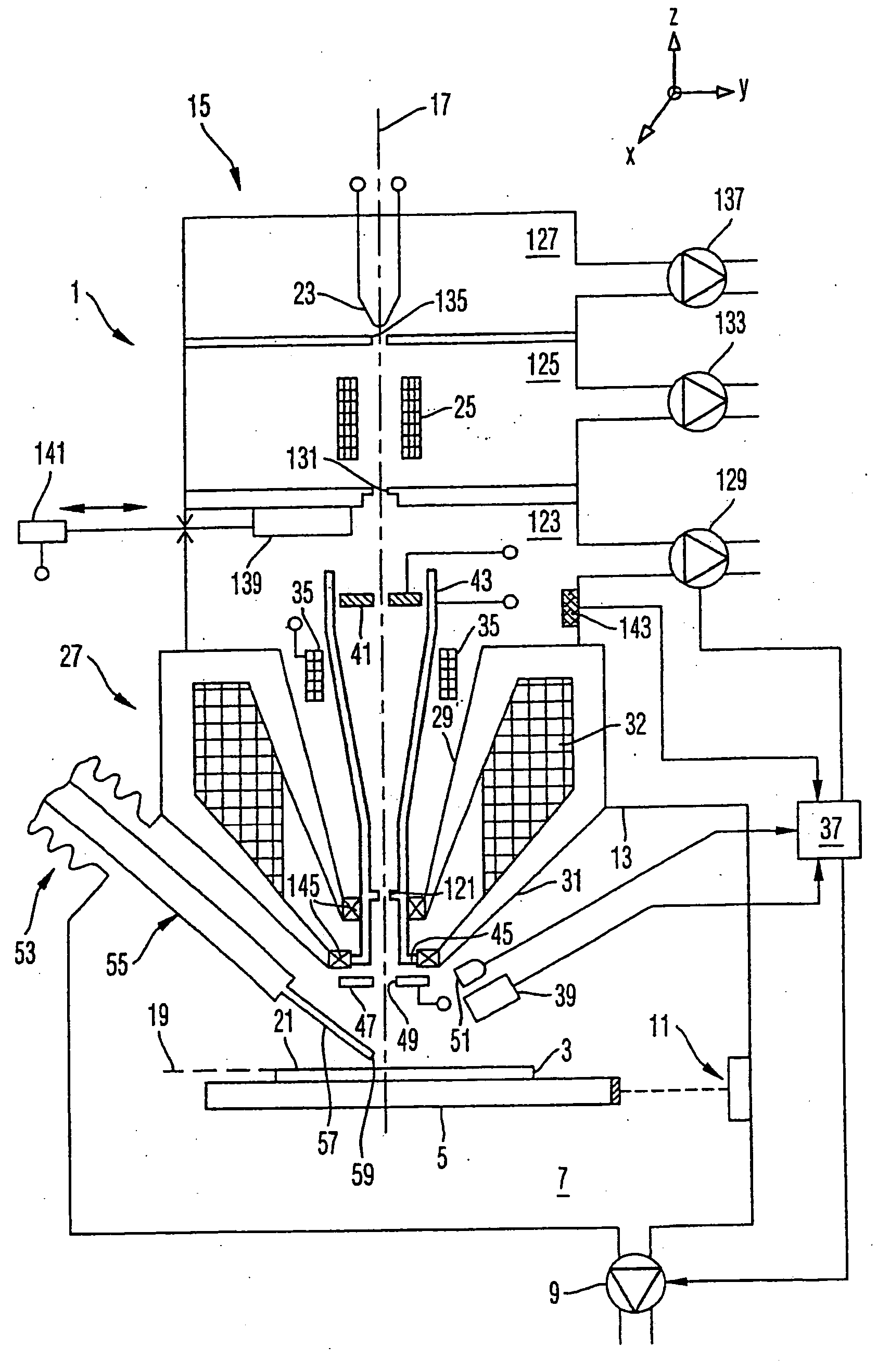

Plasma processing system, antenna, and use of plasma processing system

InactiveUS20080303744A1Reduce the electric fieldImprove uniformityElectric discharge tubesRadiating elements structural formsElectrical conductorDielectric plate

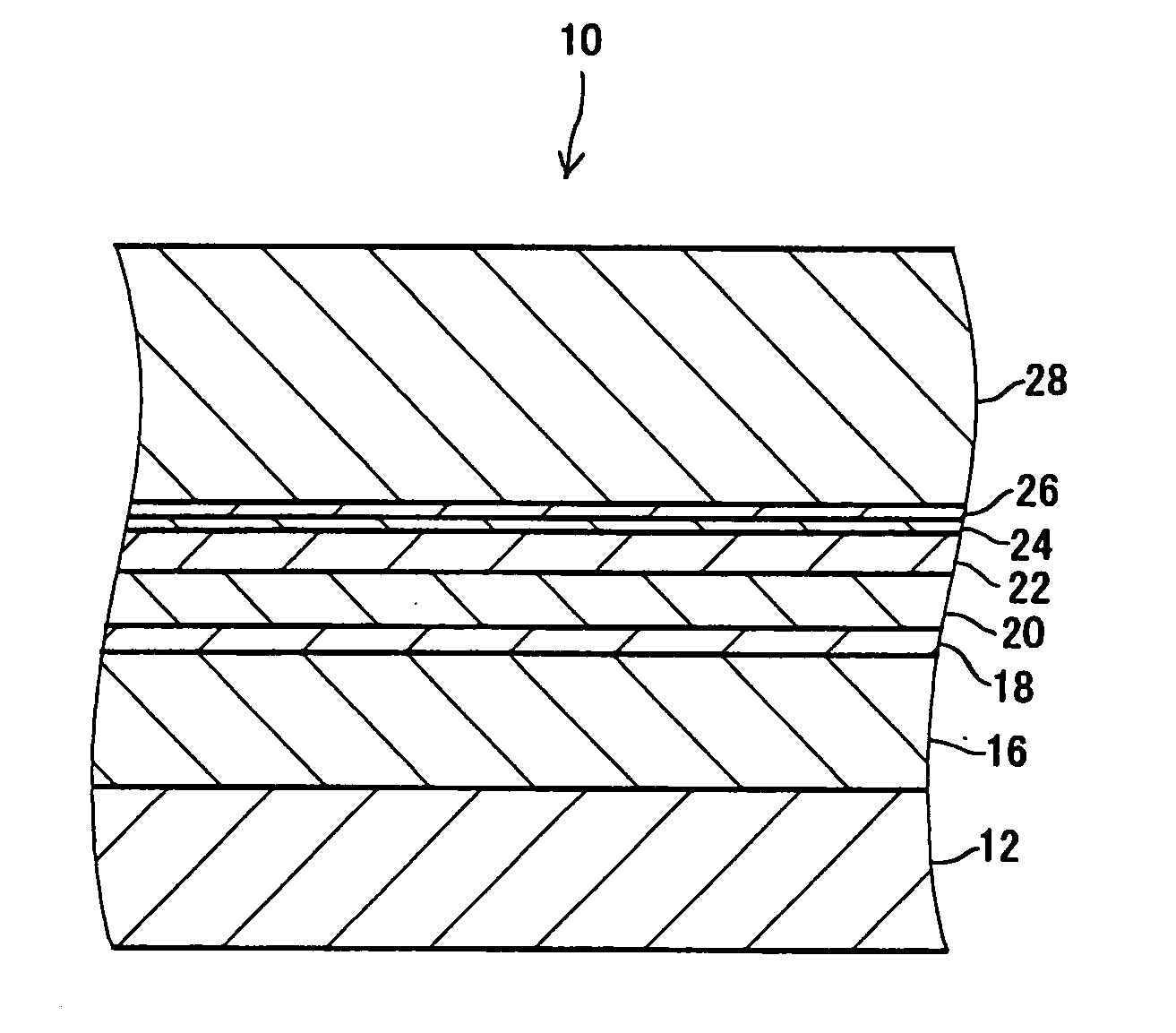

A plasma processing system 10 includes a processing chamber 100, a microwave source 900 that outputs a microwave, an inner conductor of a coaxial waveguide 315a that transfers the microwave, a through-hole 305a, a dielectric plate 305 that transmits the microwave transferred through the inner conductor 315a and discharges it into a processing chamber 100, and a metal electrode 310 that is coupled to the inner conductor 315a via the through-hole 305a, the metal electrode 310 being exposed on the surface of the dielectric plate 305 that faces the substrate with at least a portion of the metal electrode 310 being adjacent to the surface of the dielectric plate 305 that faces the substrate. A surface of the exposed surface of the metal electrode 310 is covered by the dielectric cover 320.

Owner:TOKYO ELECTRON LTD +1

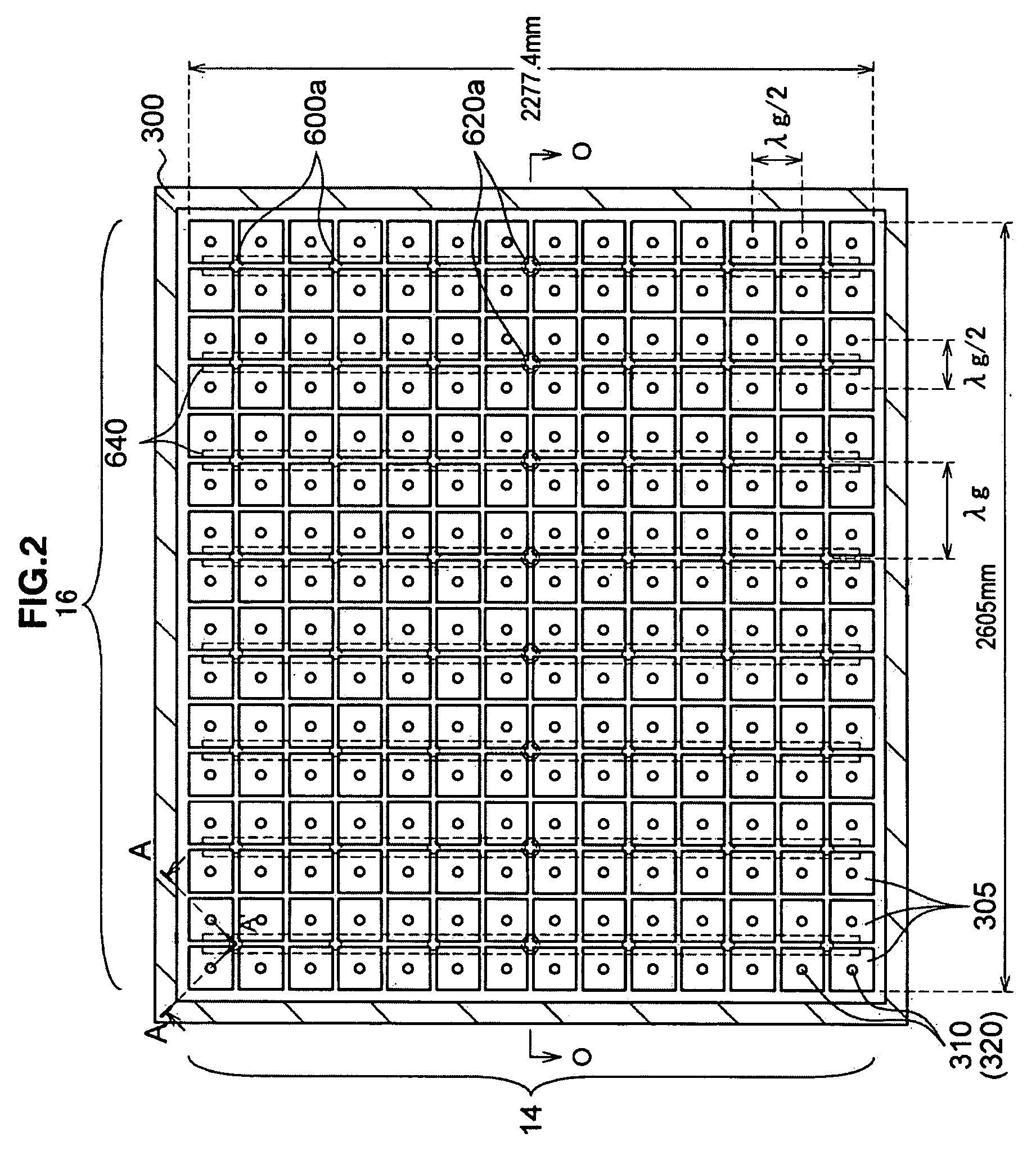

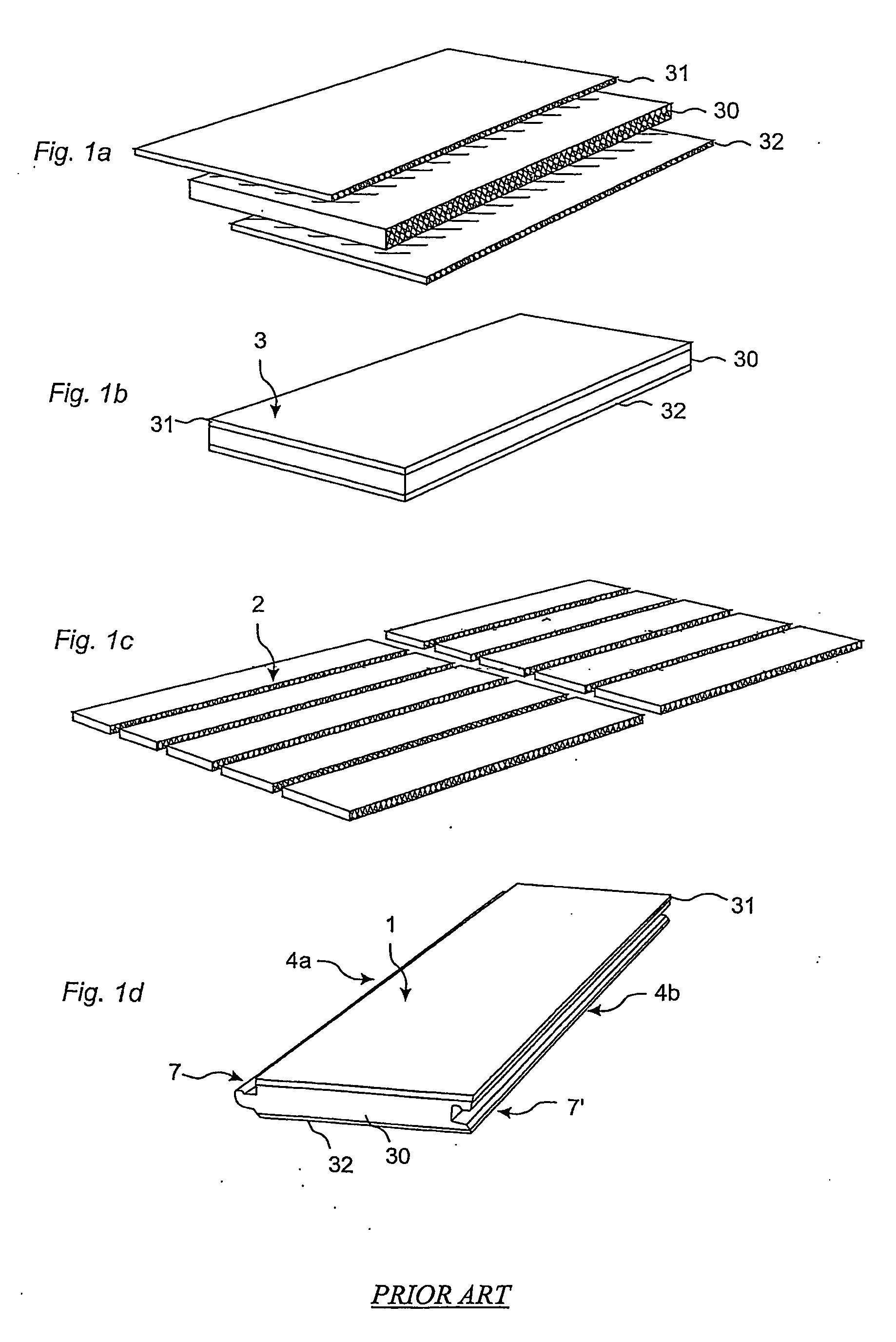

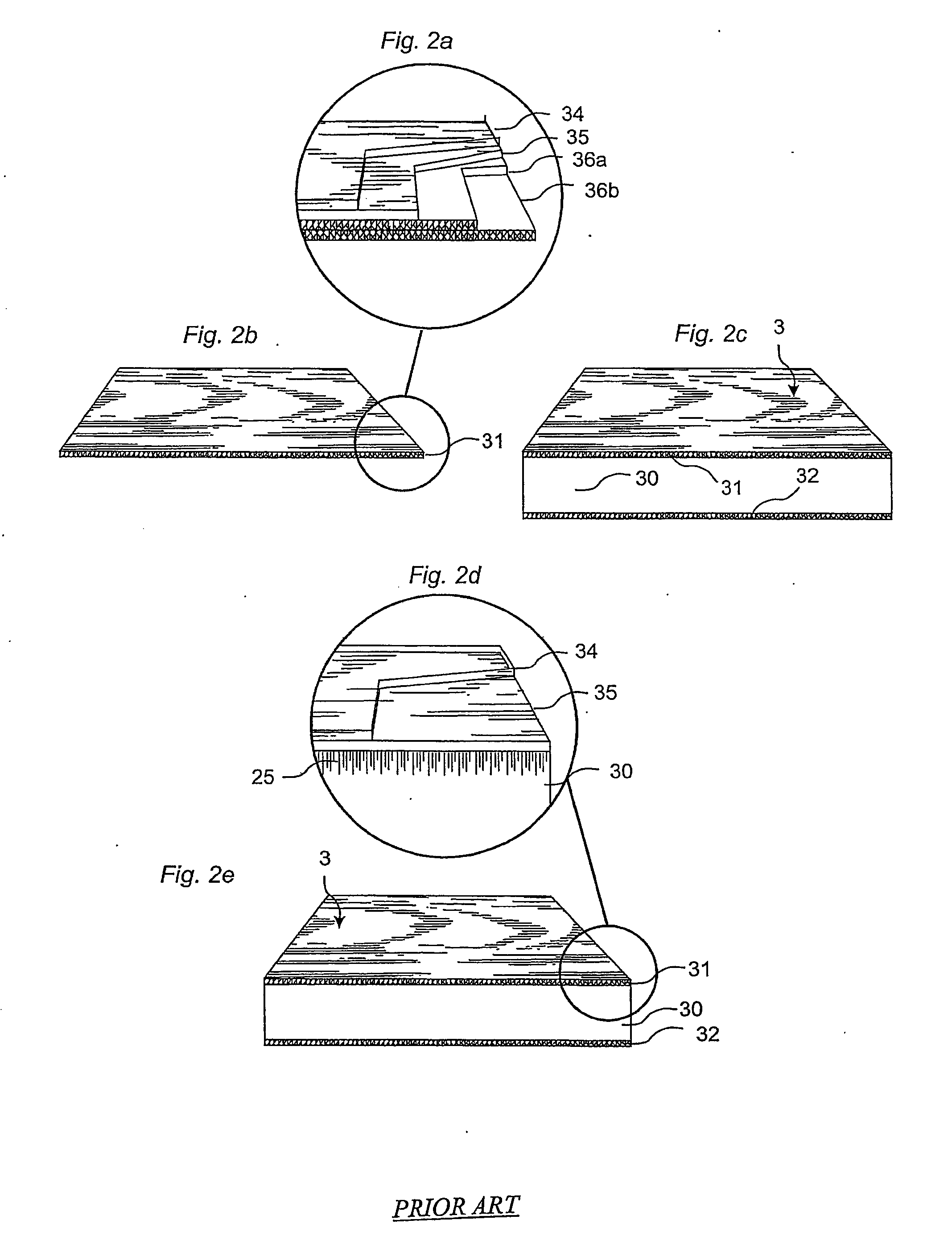

Floorboards with decorative grooves

ActiveUS20060048474A1Rational and cost-efficientEasy to cleanTongue/grooves making apparatusWallsSurface layerEngineering

Floorboards are shown, which consist of a core and a surface layer and are provided with decorative joint edges which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

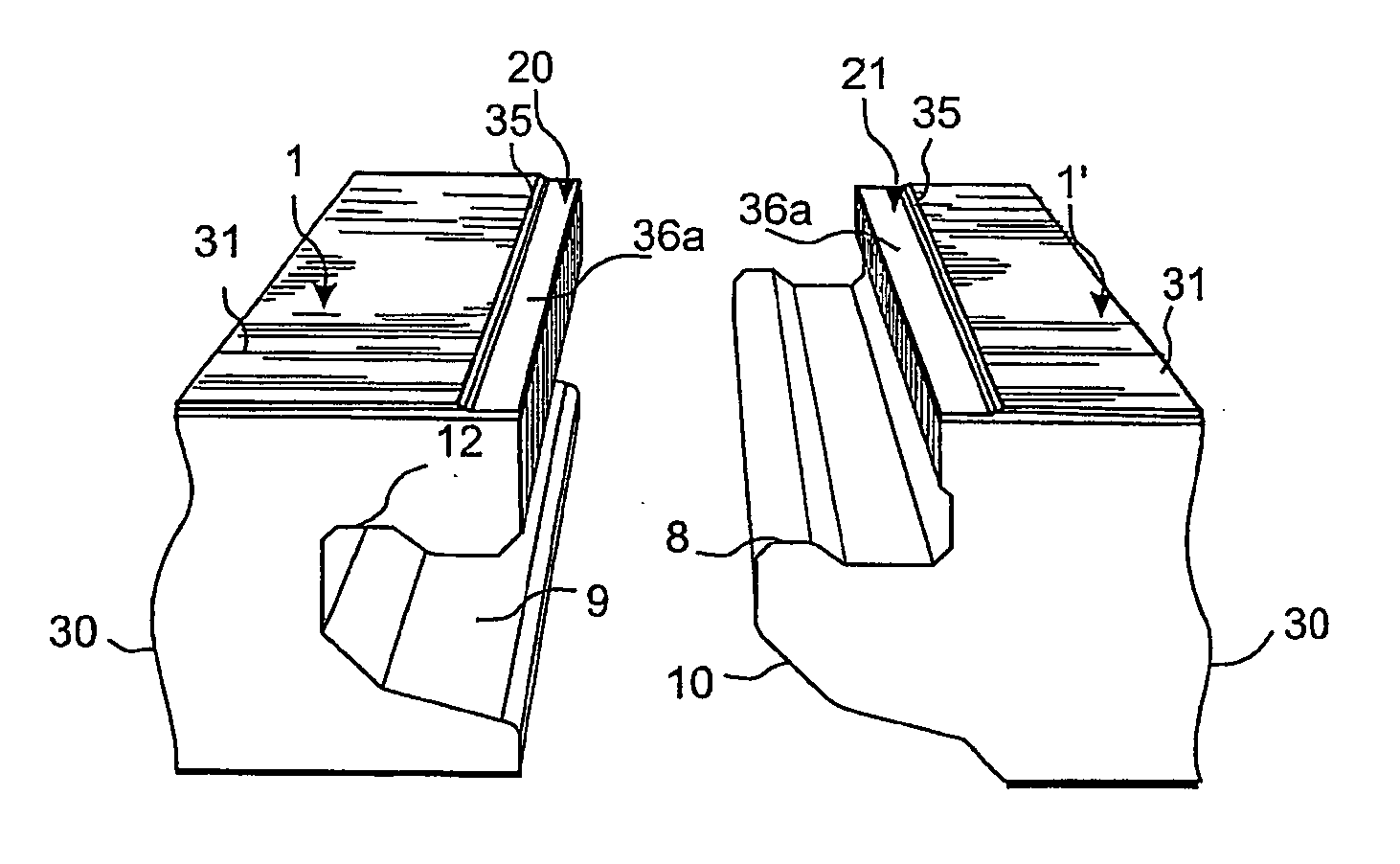

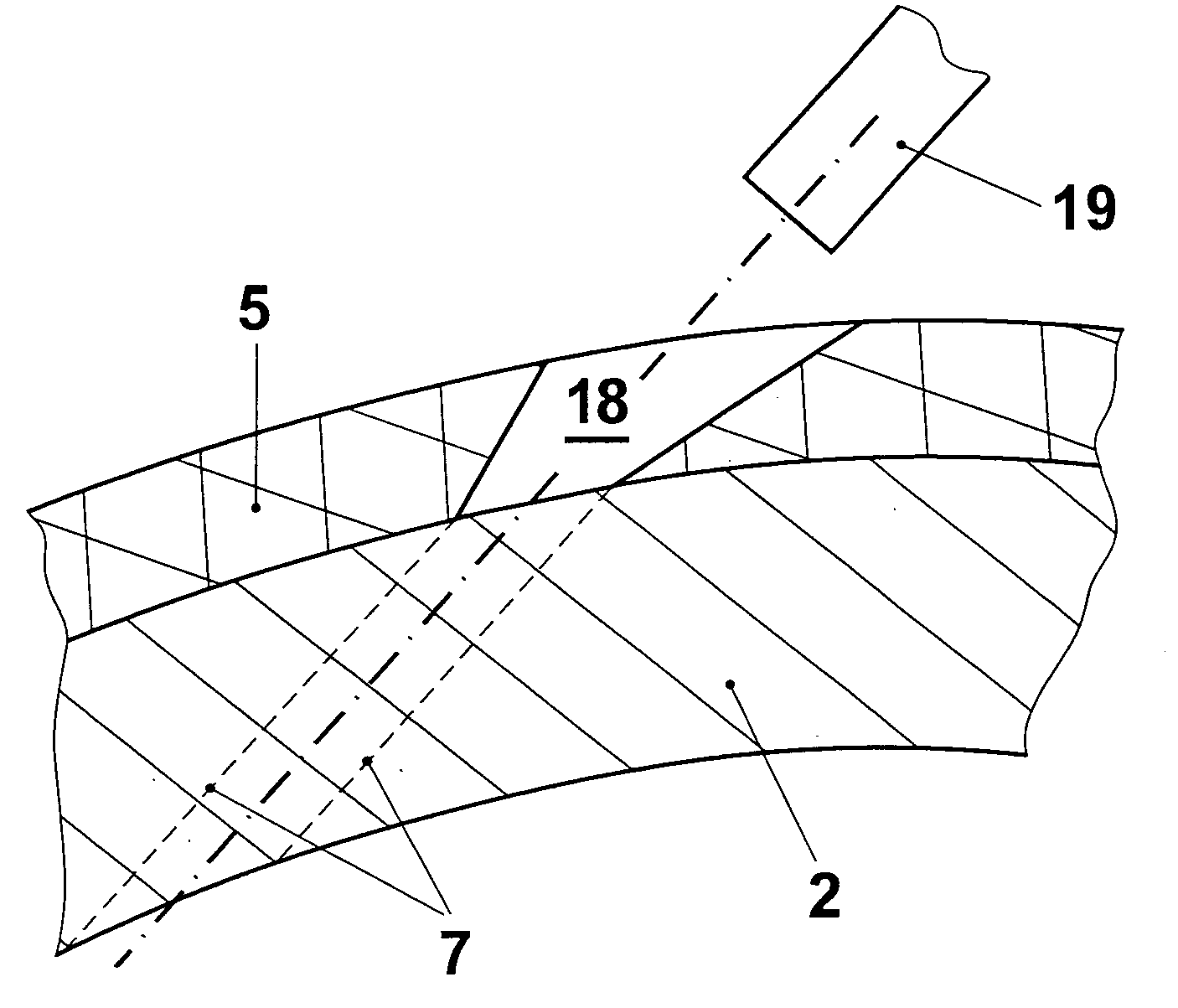

Method of producing a composite component

InactiveUS20050173388A1Enhance utilityLower costTurbinesElectrolysis componentsEngineeringThermal barrier coating

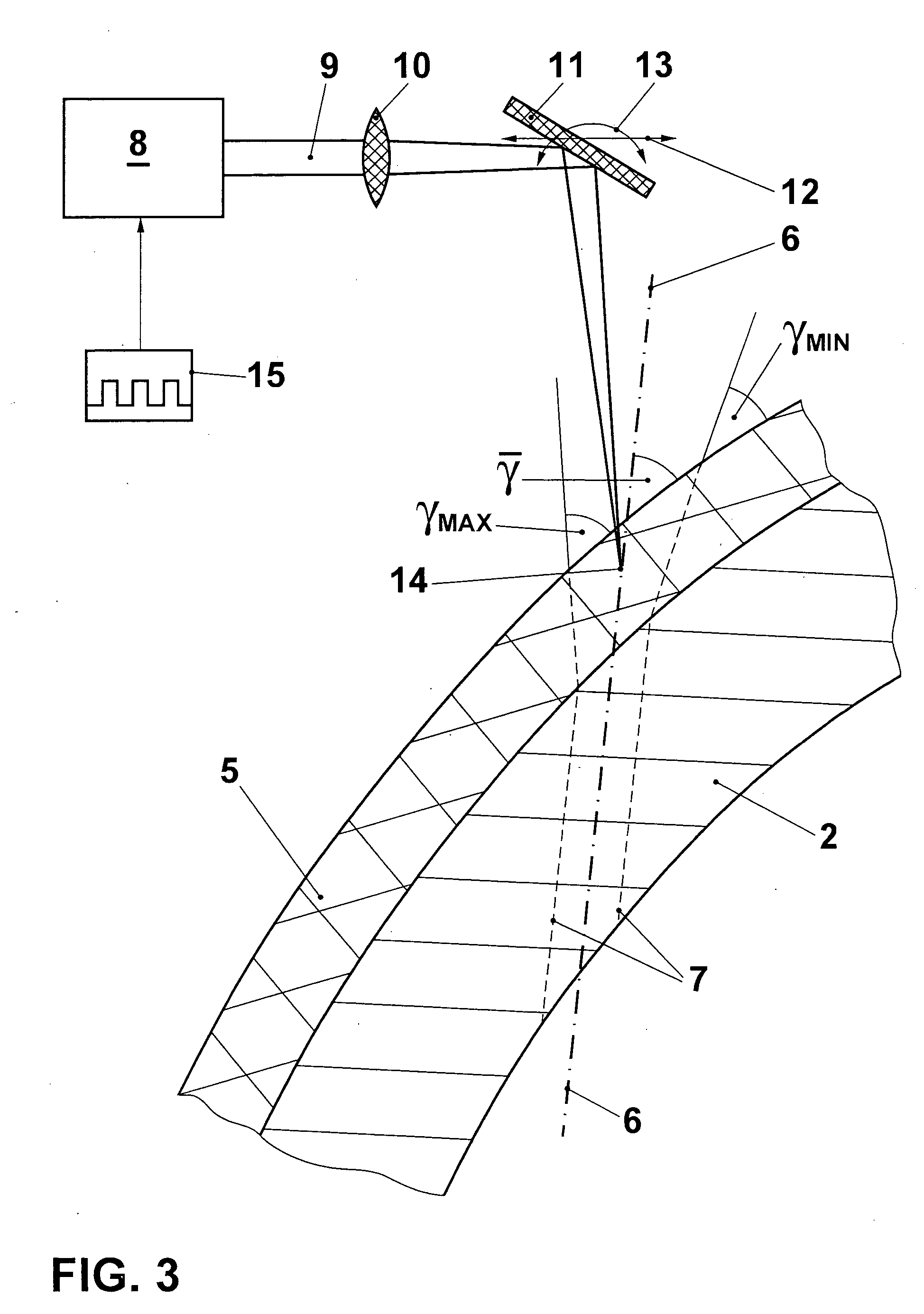

A composite component (1), such as a turbine airfoil, includes a conductive portion (2), and a non-conductive portion (5), such as a thermal barrier coating or a wear protection coating, or both. In machining the component, a laser machining step is applied for machining the non-conductive portion, and an electro-machining step is applied for machining the conductive portion. The laser machining step is performed by applying preferably a high-frequency pulsed laser. The focussed laser beam working diameter (DL) is essentially smaller than the size of the contour (16) to be machined. The contour is scanned by the laser beam (9) along a pre-defined trace (17) thus literally inscribing the desired contour into the workpiece.

Owner:ANSALDO ENERGIA IP UK LTD

Processing apparatus and method of processing and method of making leaf spring

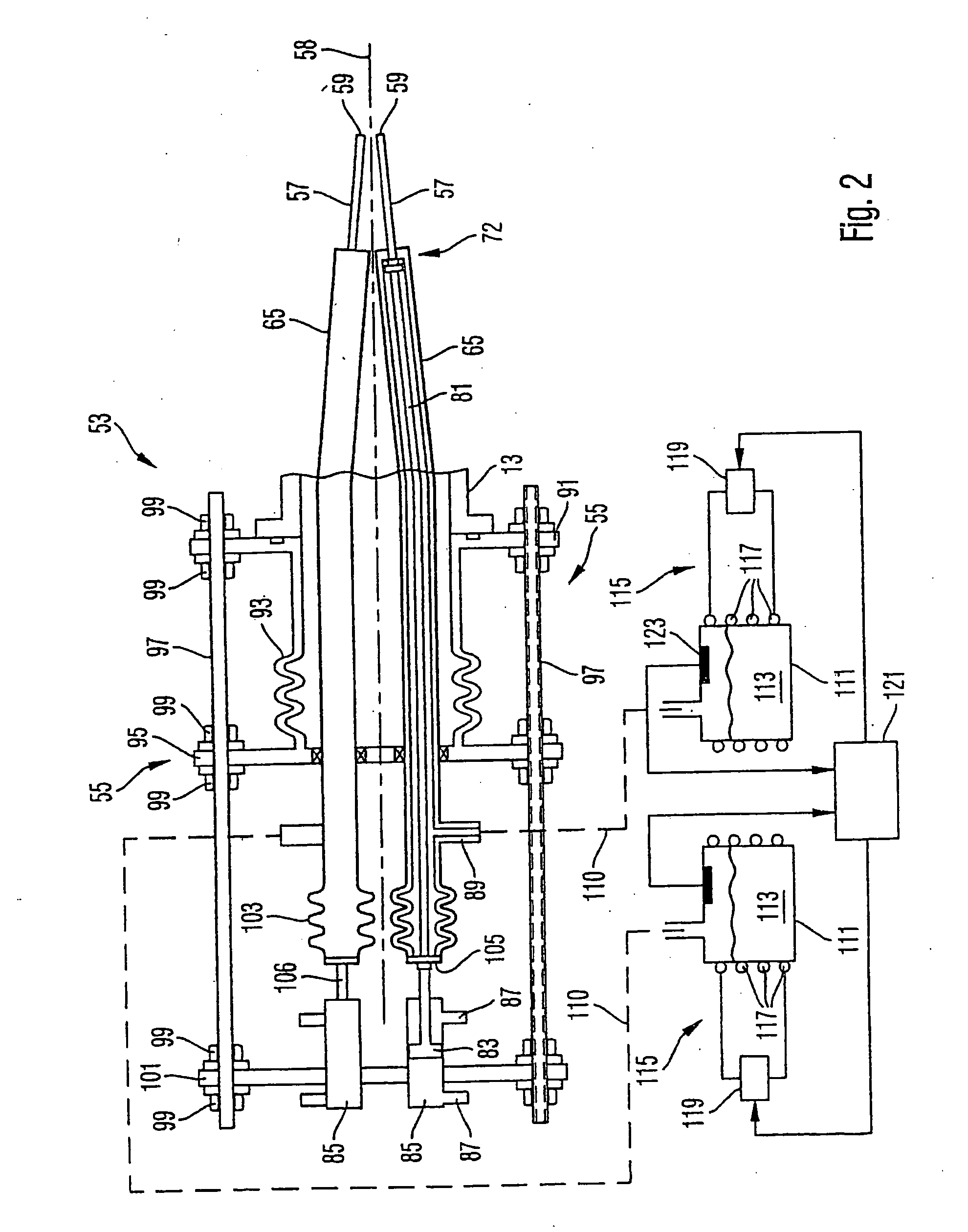

InactiveUS20090103579A1Improve accuracyHigh precision machiningLaser detailsLaser beam welding apparatusVoltage regulationLight beam

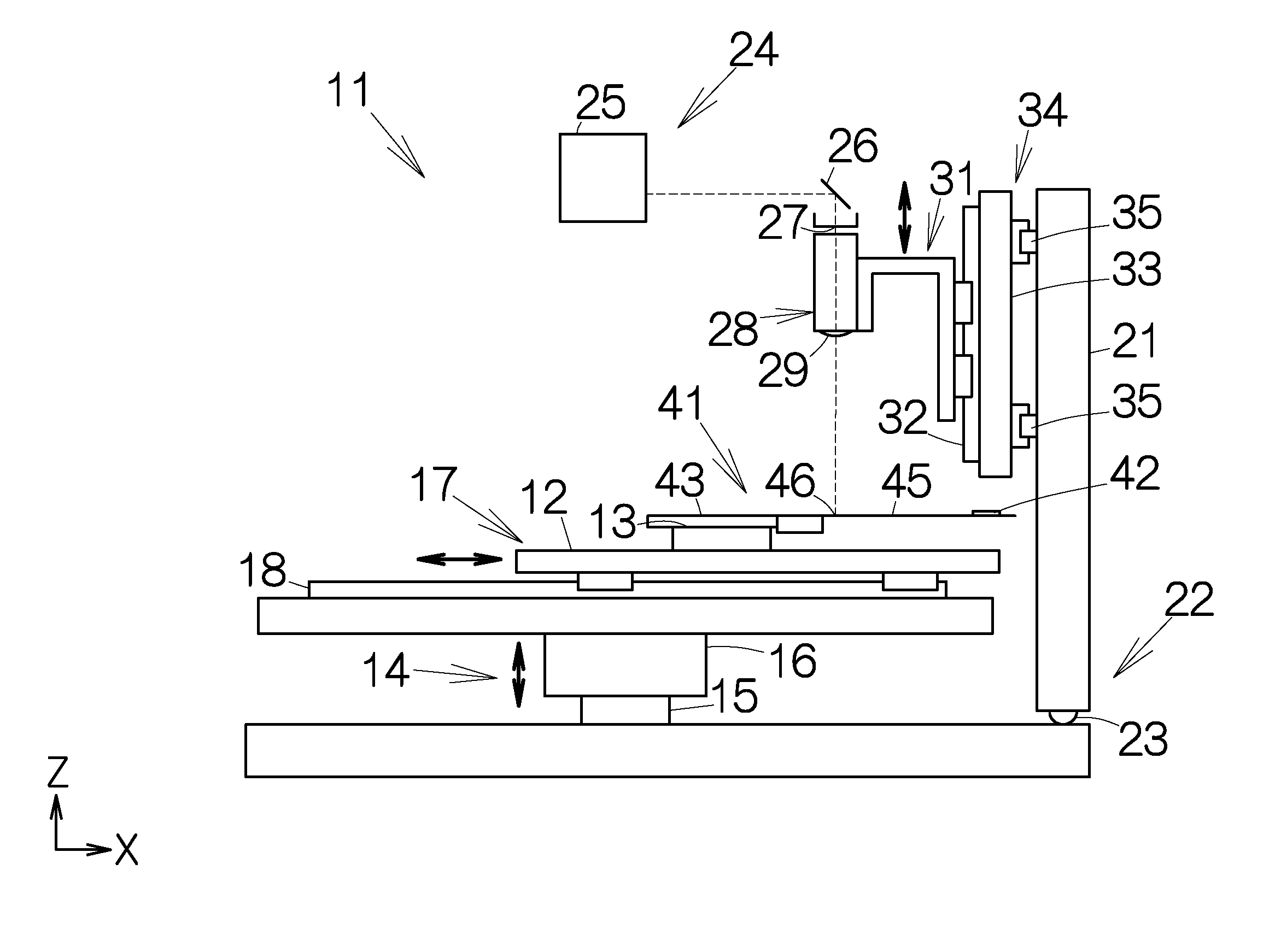

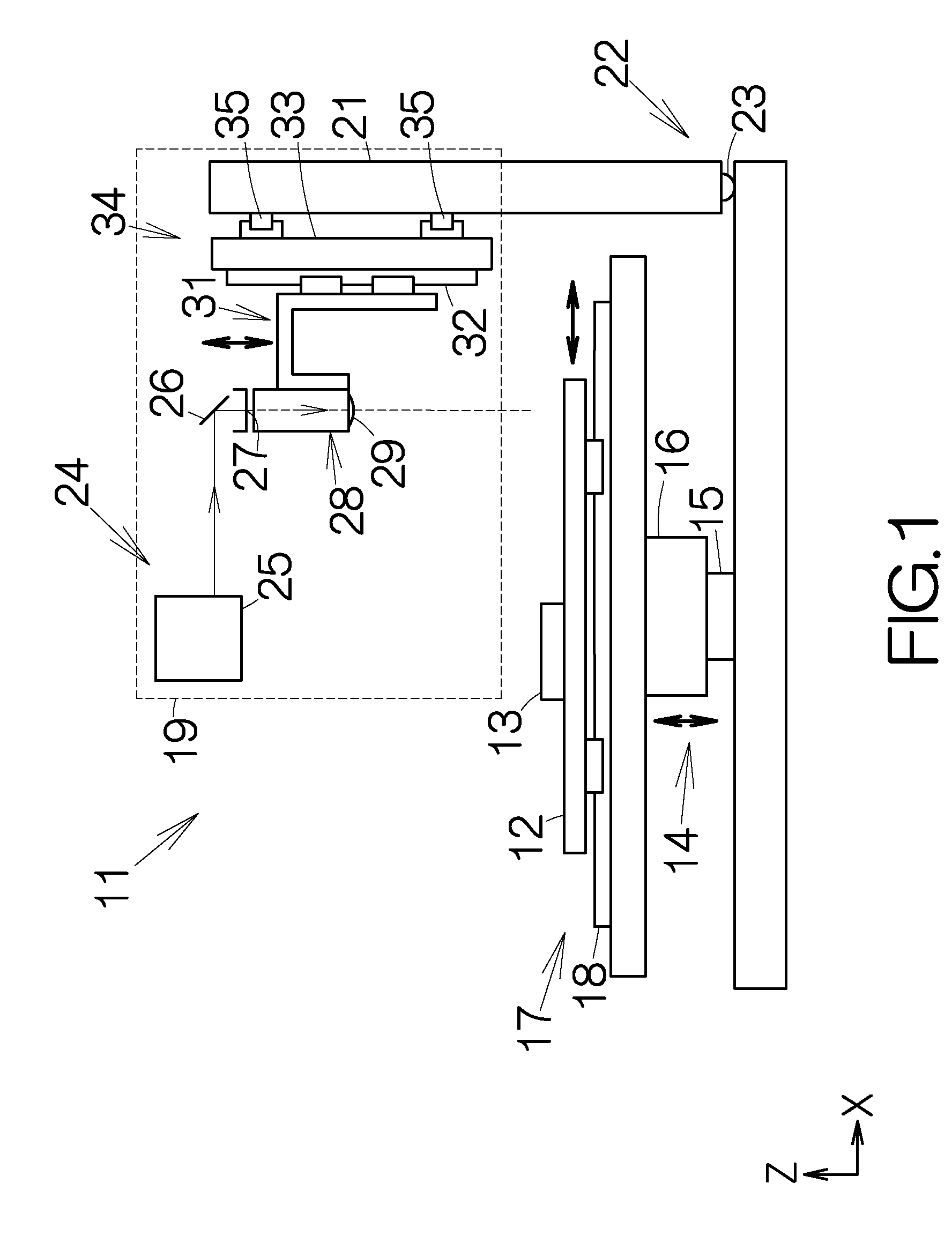

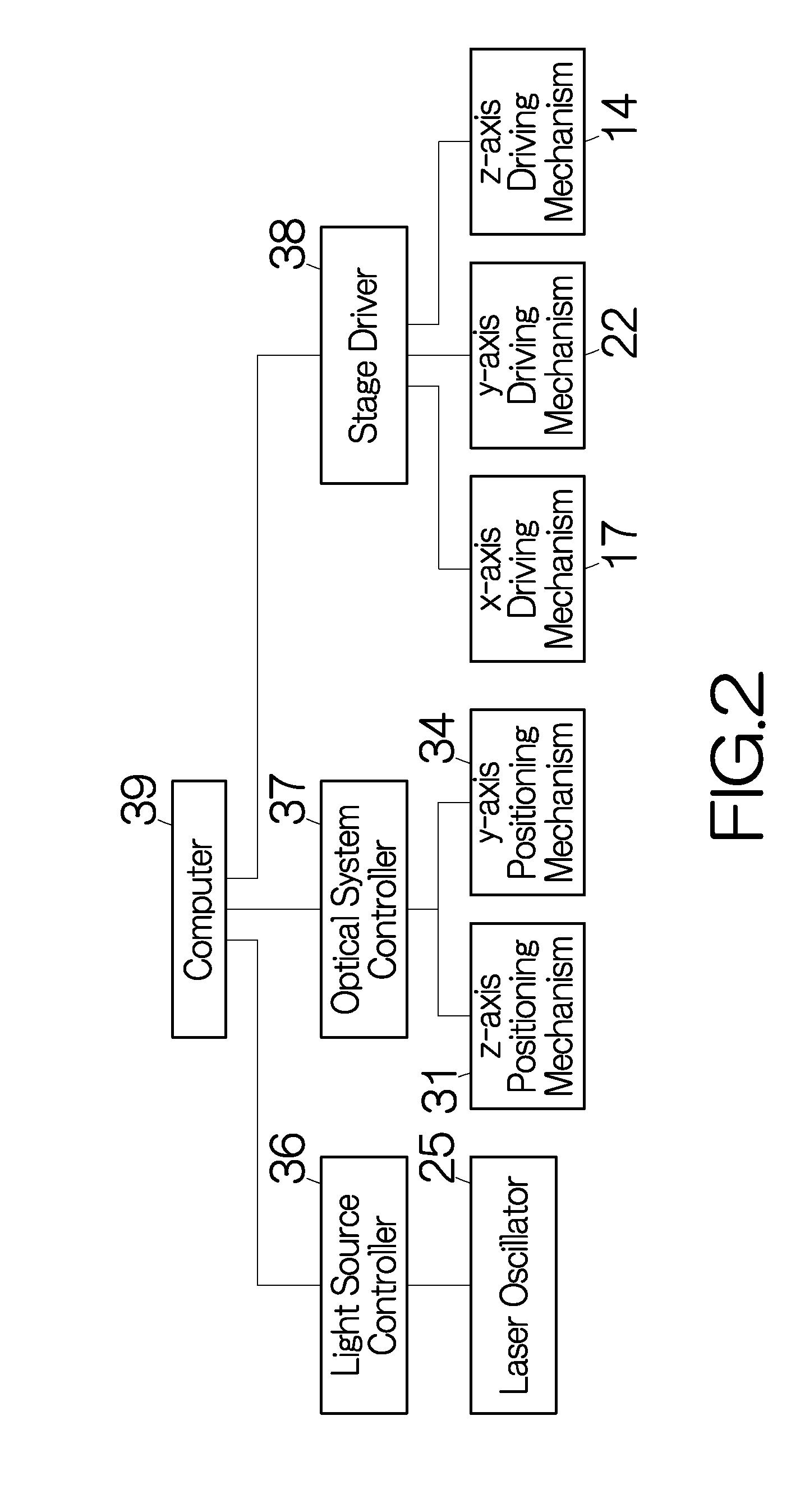

A light source emits a laser beam to the object through an output end. An optical system is placed between the output end and the object. The optical system adjusts the energy of the laser beam emitted, through the output end, onto a unit area for a unit time. The energy of the beam spot on the object enables cutting or bending of the object. The optical system serves to adjust the energy of the laser beam irradiated to the object. The energy of the laser beam instantly changes as compared with the case where the energy of the laser beam is adjusted based on a driving voltage applied to a laser oscillator. The object is thus processed by using the laser beam with high accuracy.

Owner:FUJITSU LTD

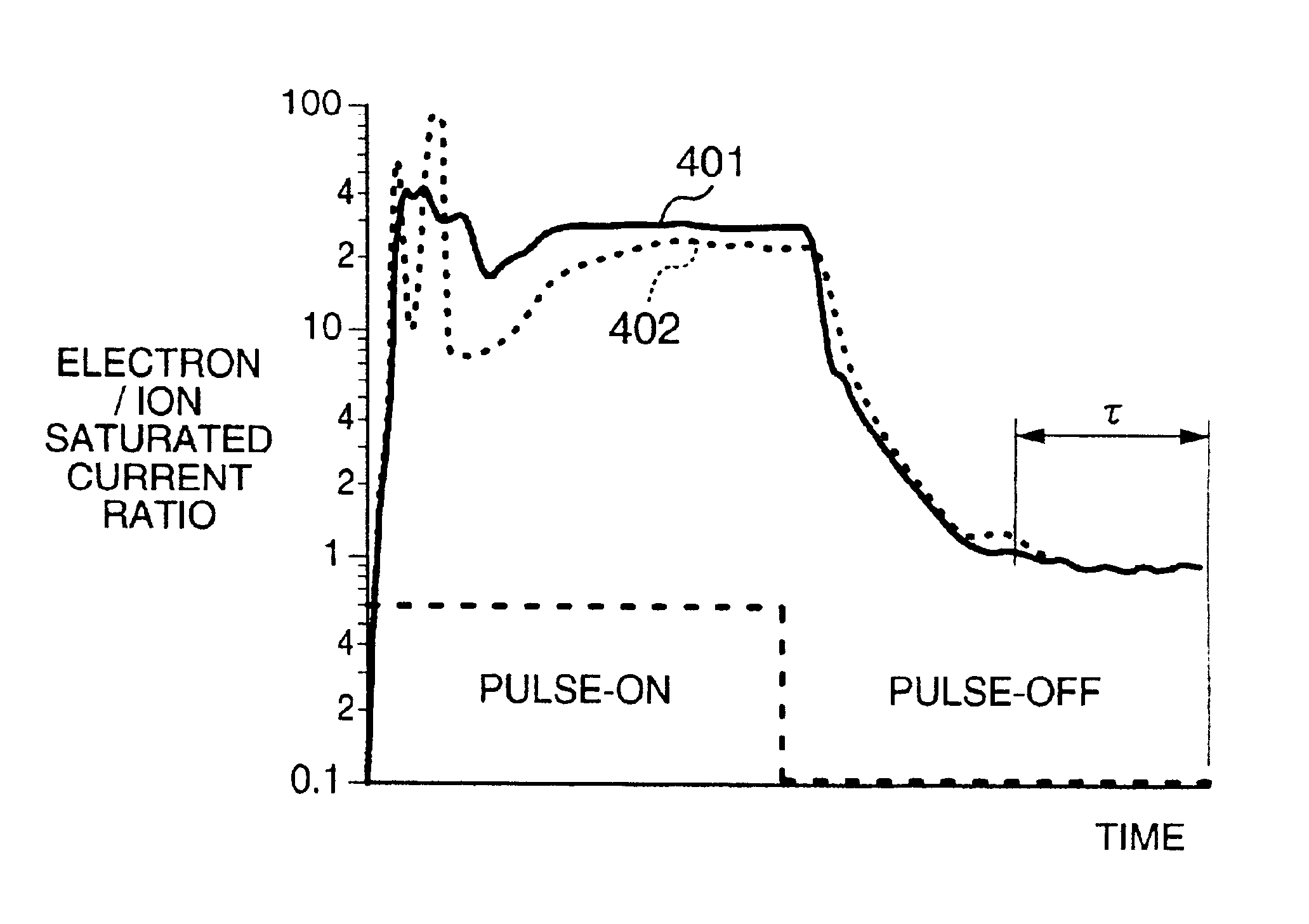

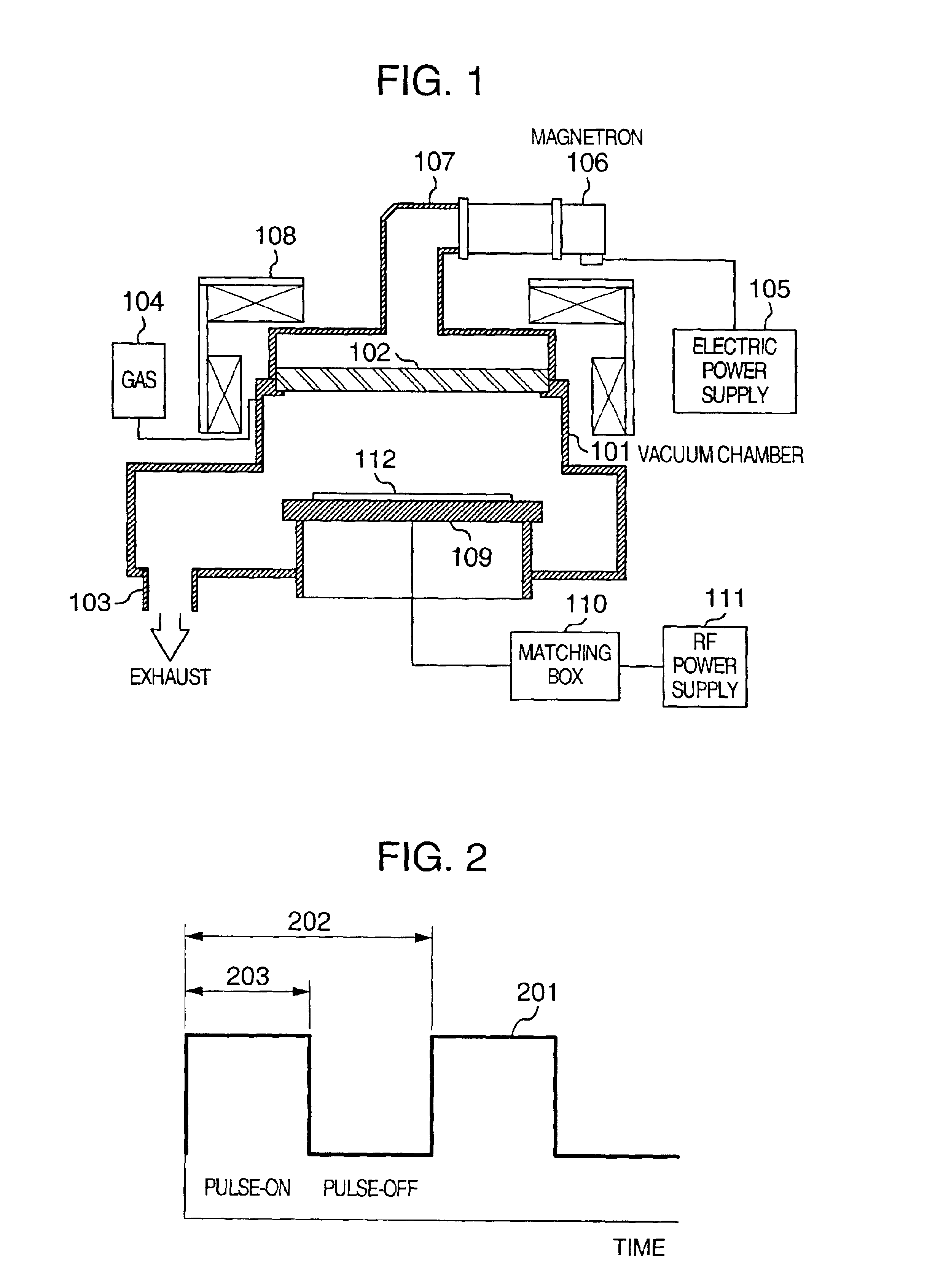

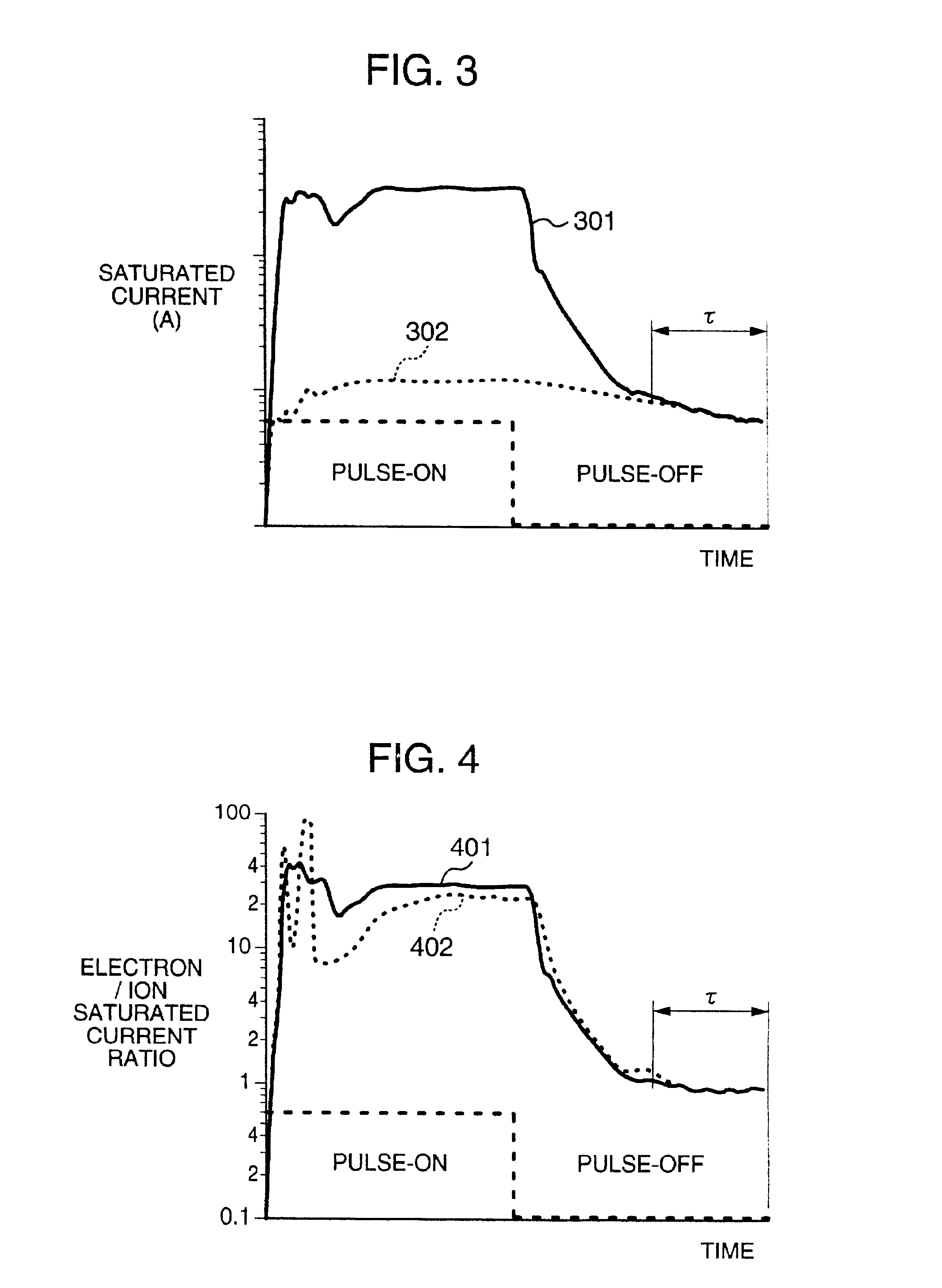

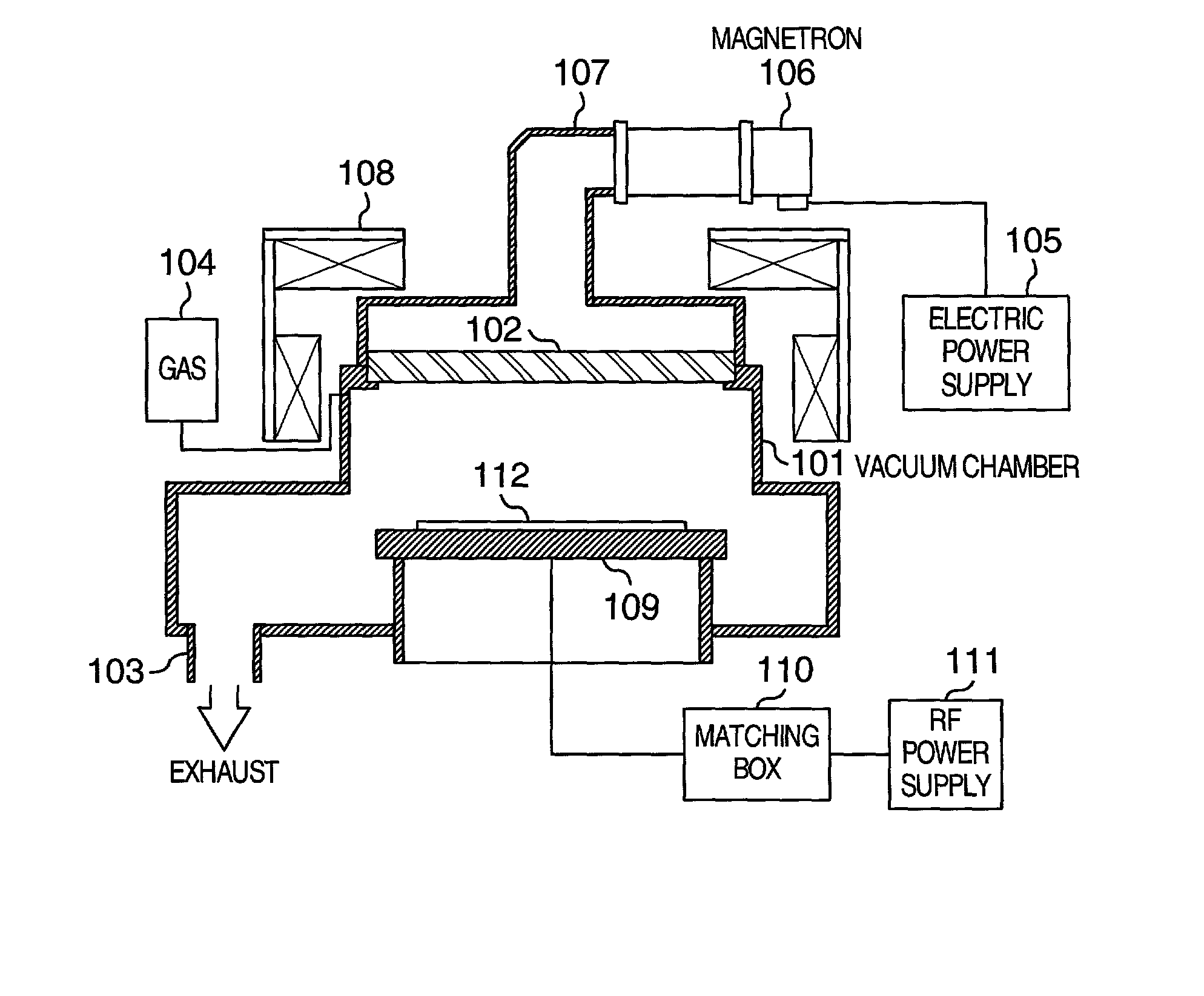

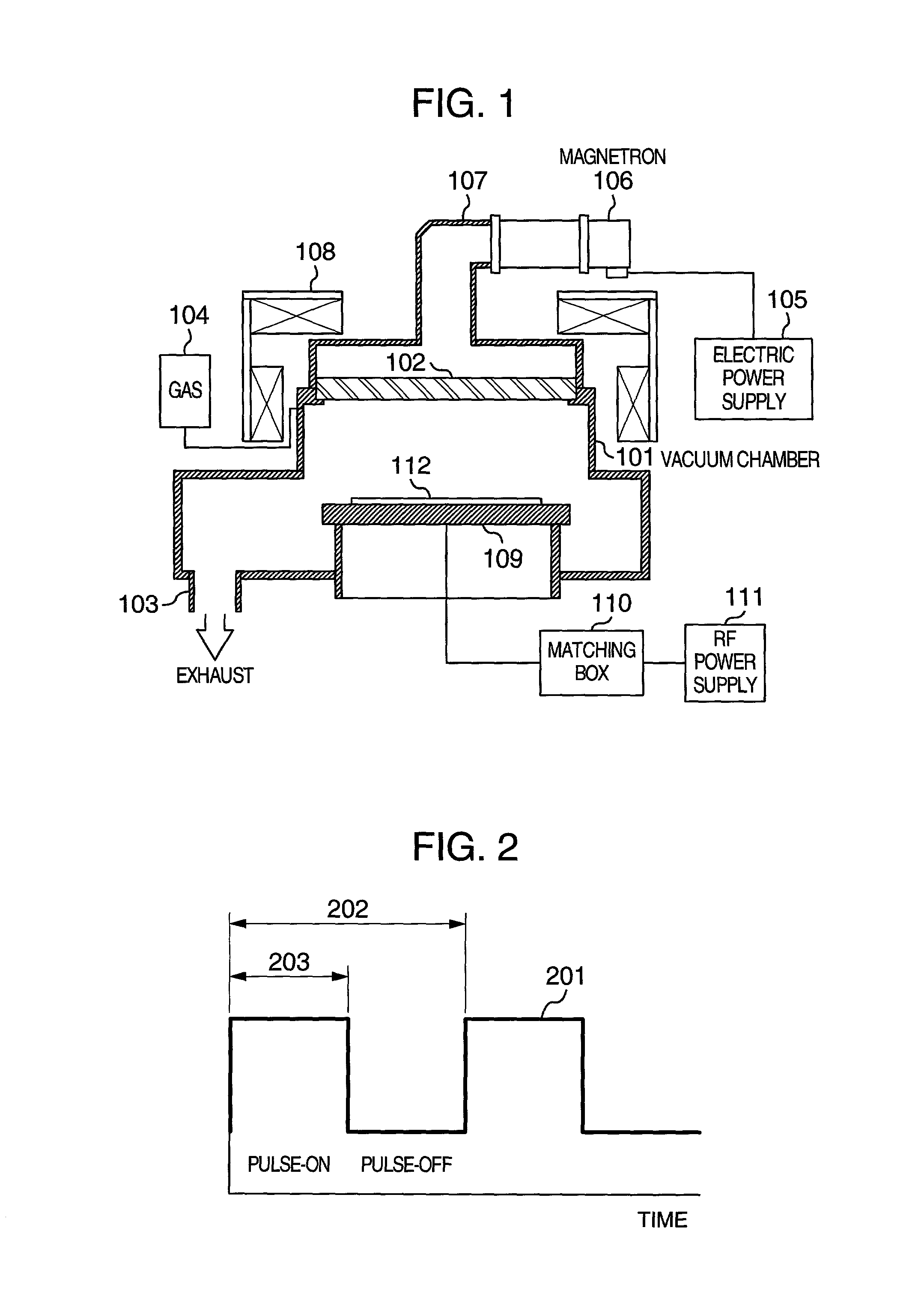

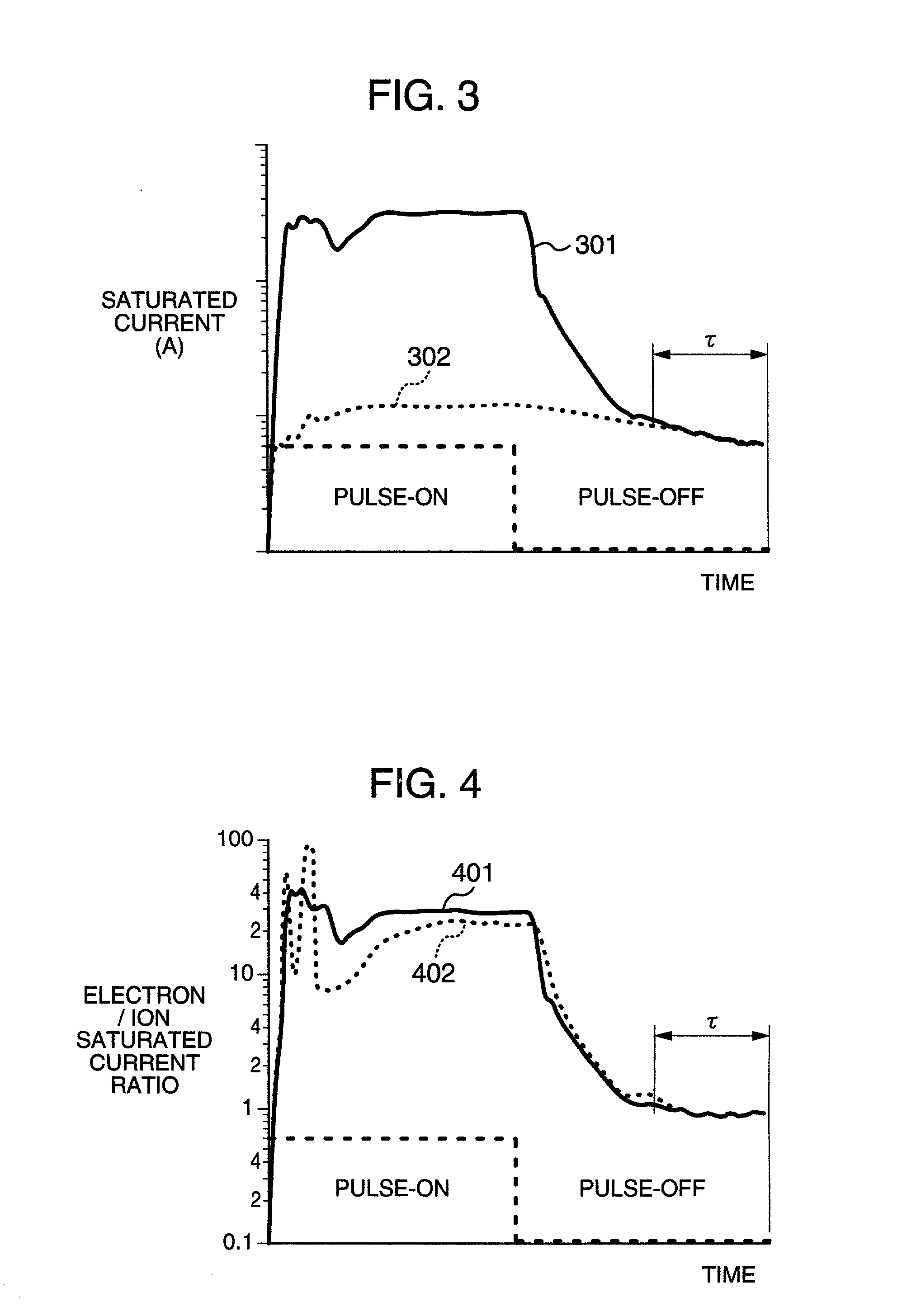

Plasma processing method and apparatus

InactiveUS6777037B2Suppress charging damageImprove accuracyElectric discharge tubesDecorative surface effectsEngineeringGate oxide

A plasma processing method and apparatus are provided for processing the surface of a semiconductor device or the like through the effect of plasma. A pulsed plasma discharge is performed by switching on and off the high frequency electric power for generating the plasma with a specified off period of the plasma generation, to control an inflow amount of positive and negative charges to sparse and dense portions of device patterns and suppress an electric potential on a gate oxide film. Thereby, a highly accurate etching process with no charging damage can be carried out.

Owner:HITACHI LTD

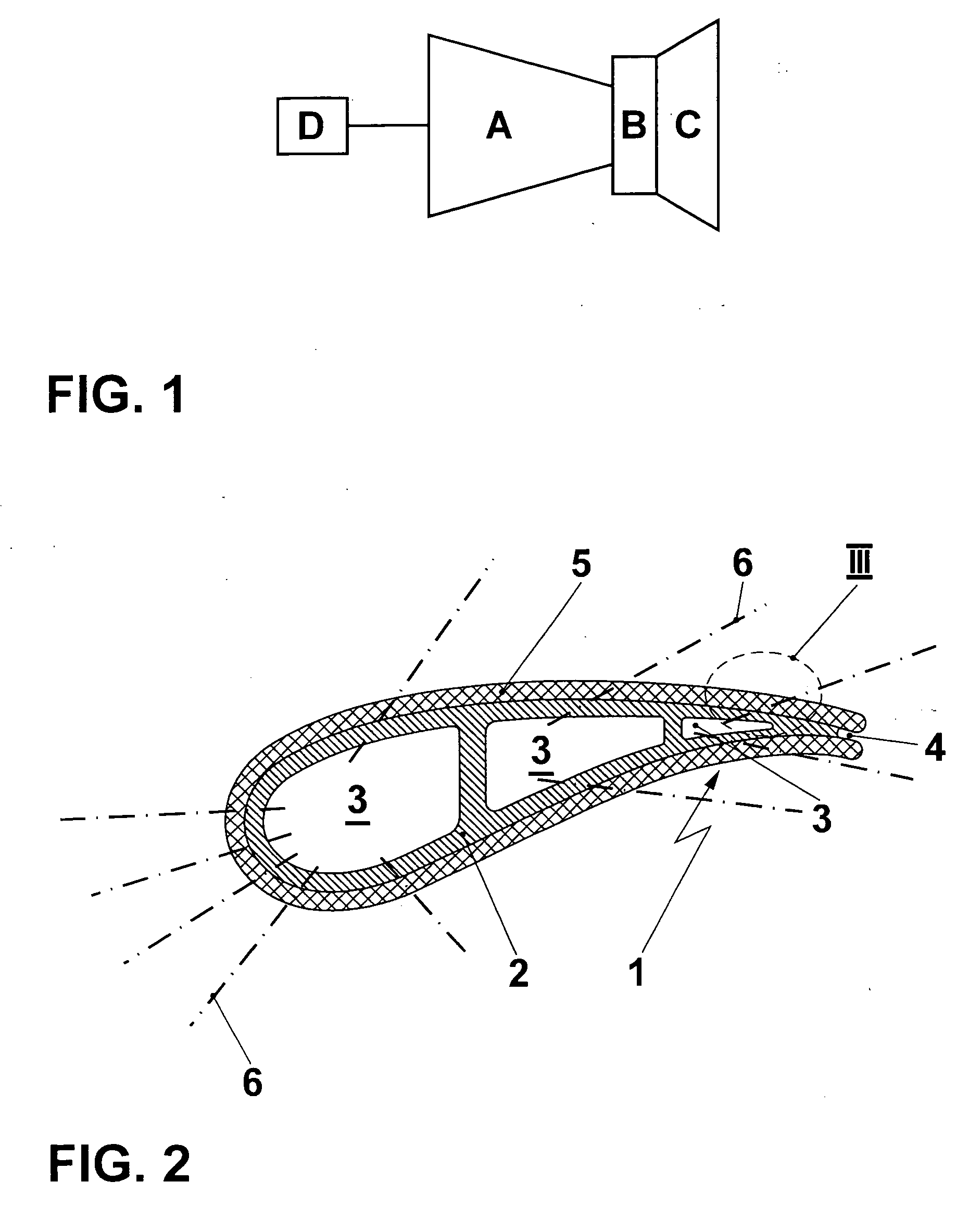

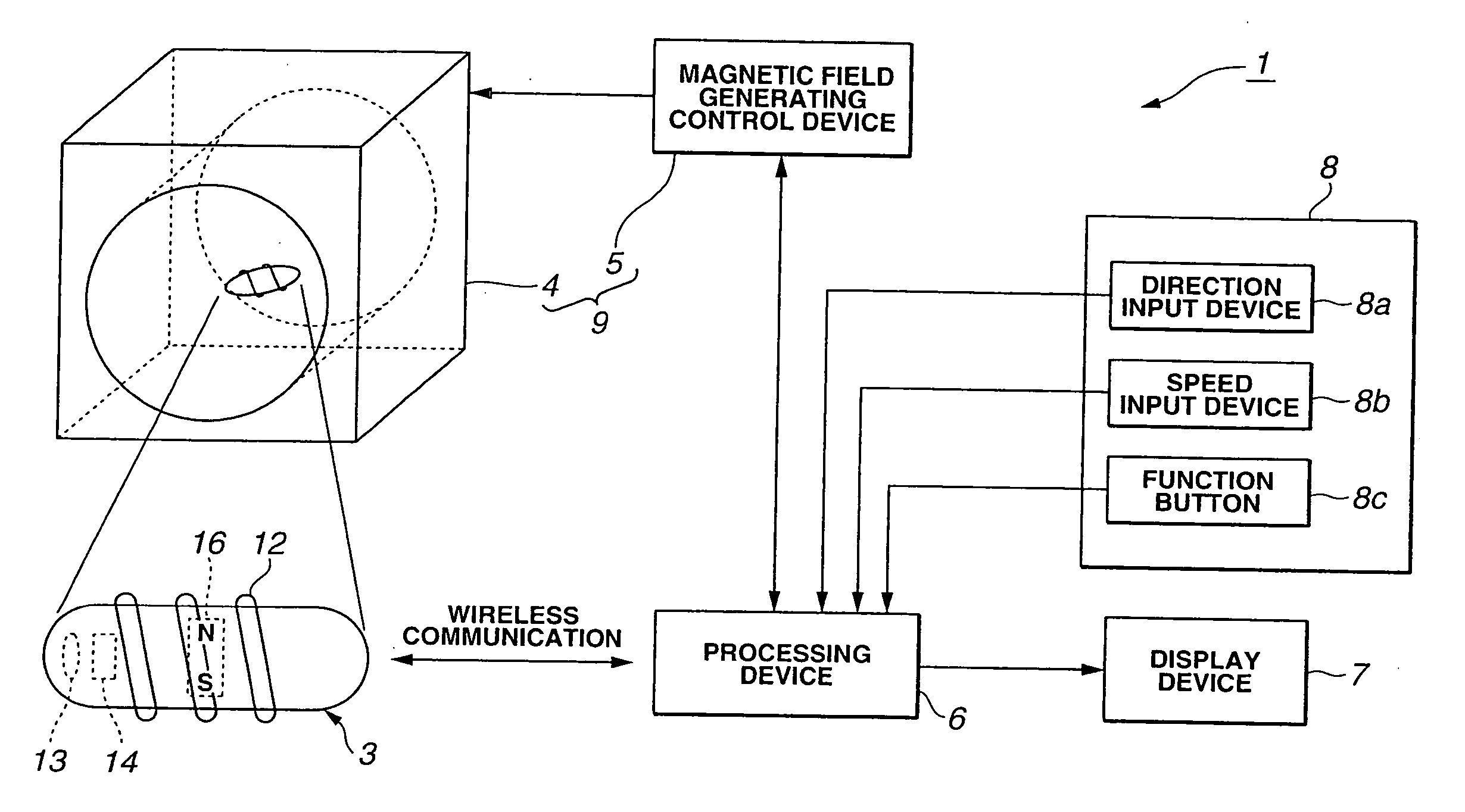

Medical System

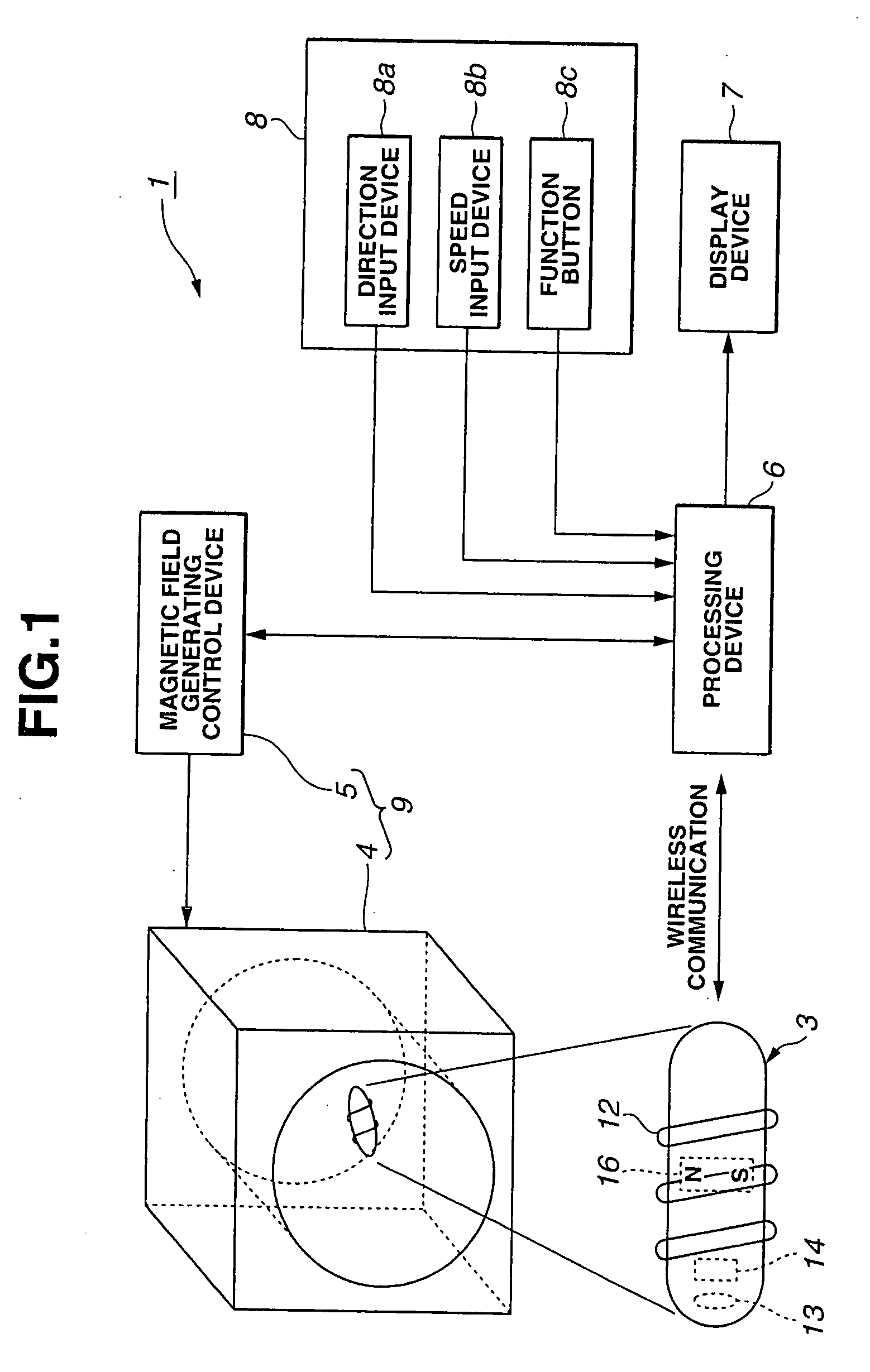

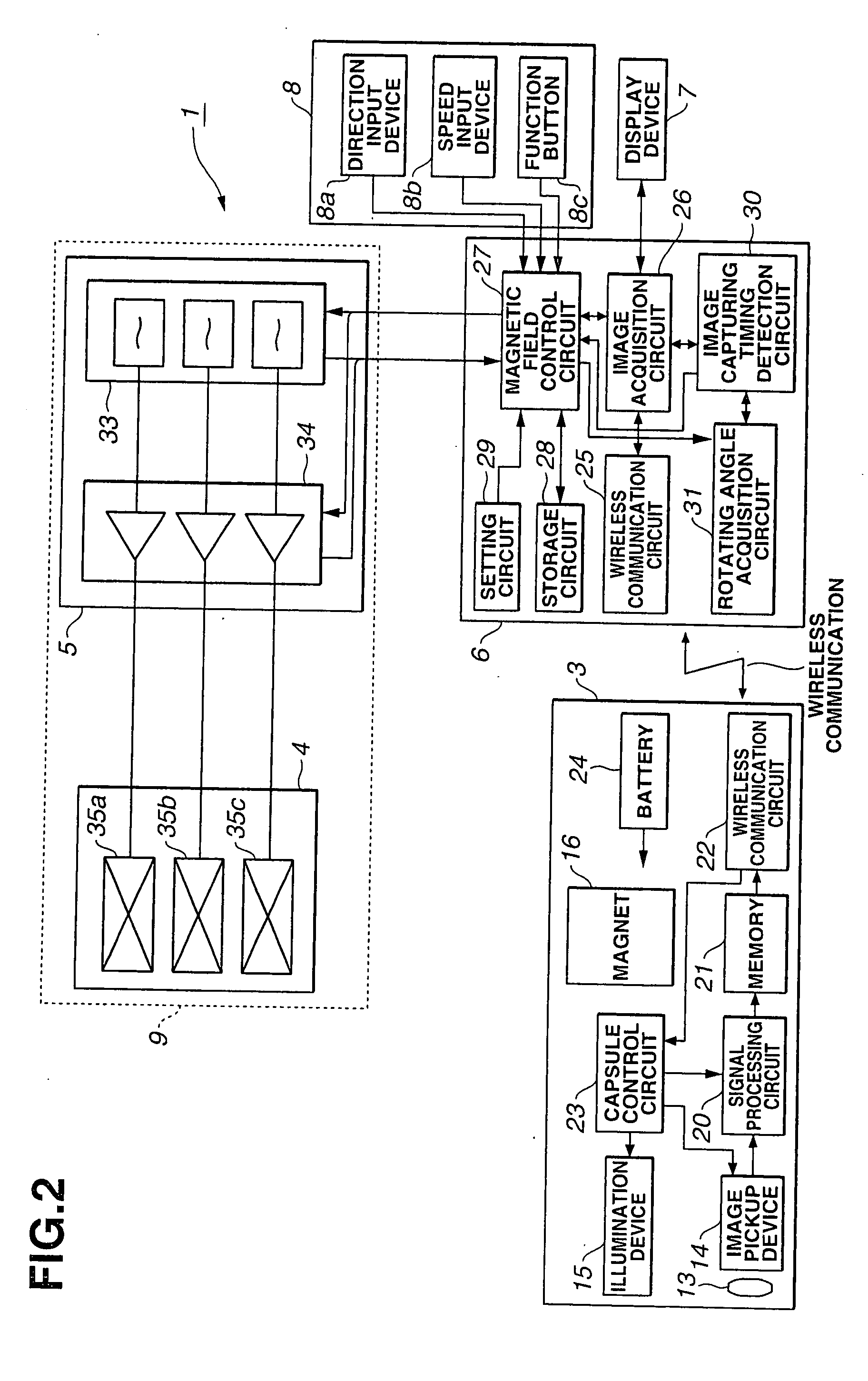

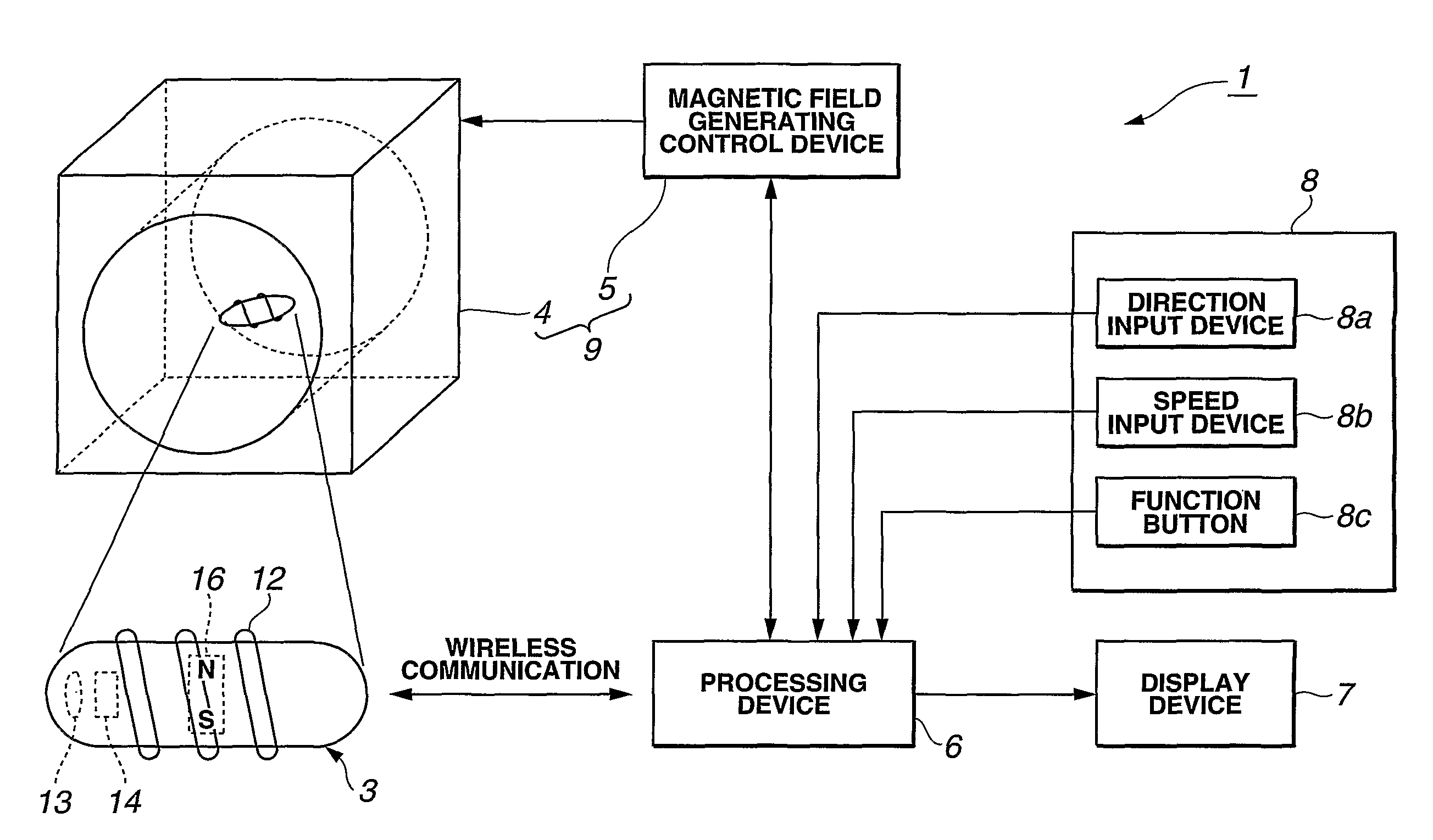

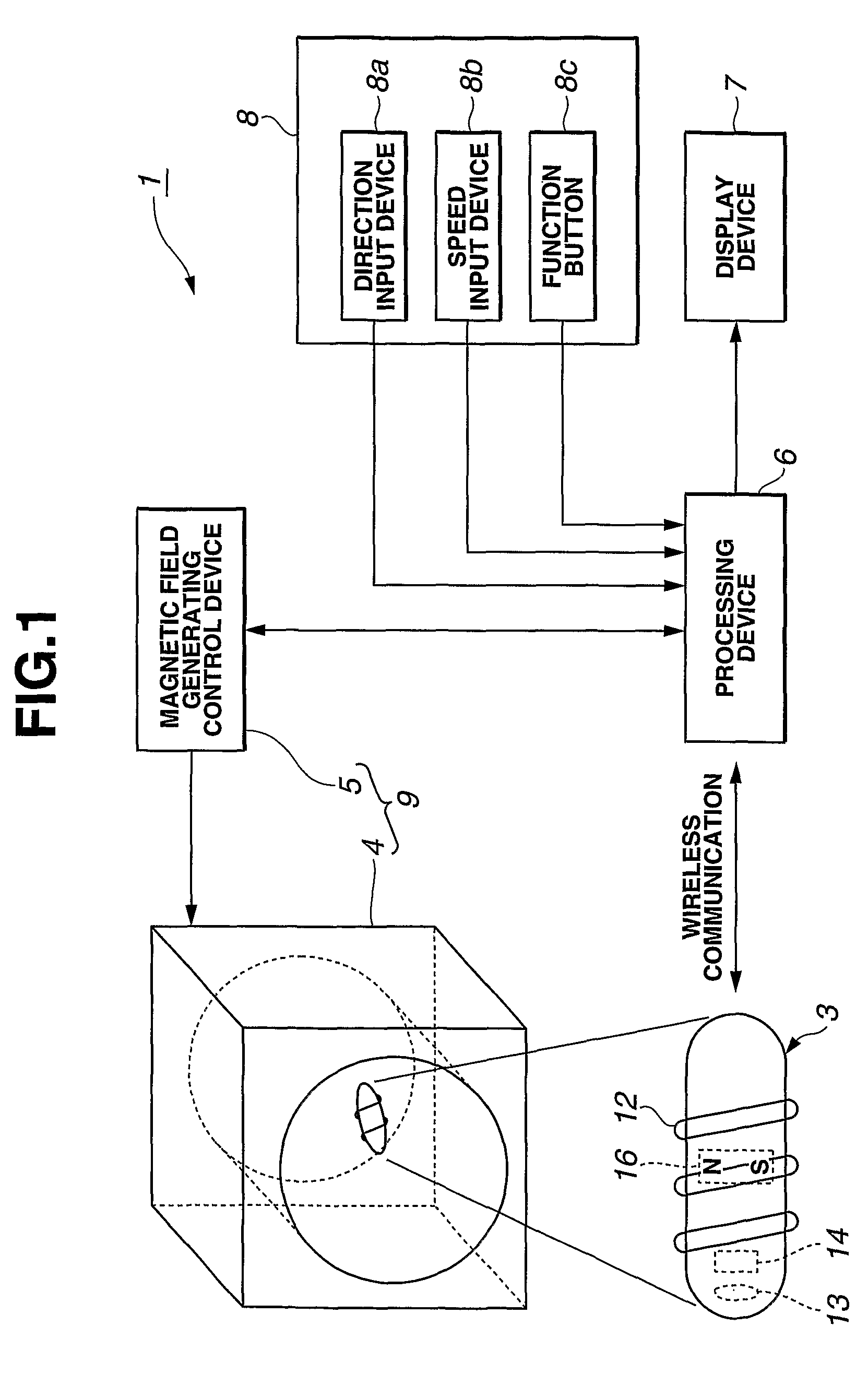

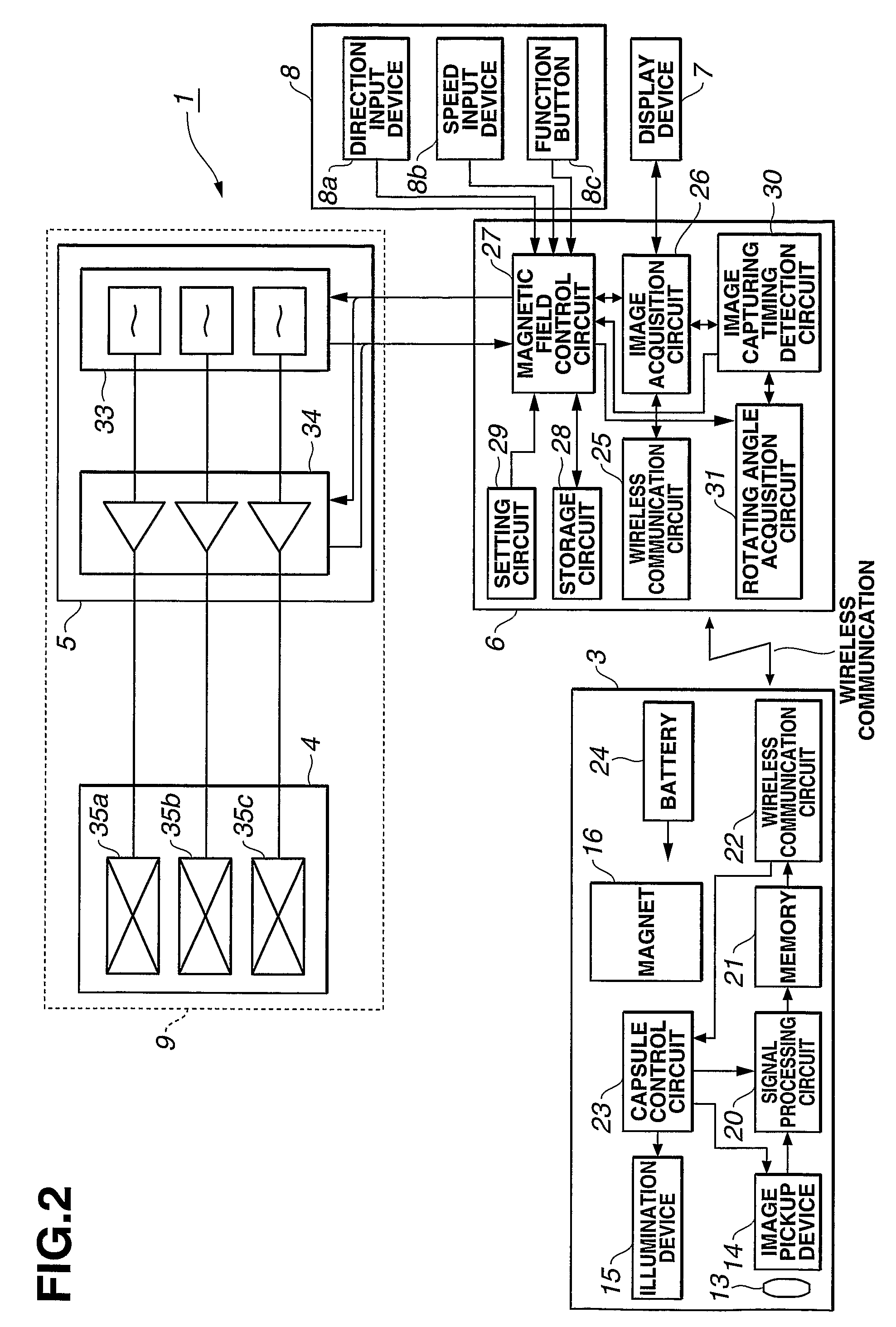

ActiveUS20070299301A1High-precision rotation processingHigh precision machiningGastroscopesOesophagoscopesMedical deviceComputer science

A medical system includes: a medical device to be inserted into the body cavity; a rotating device for the medical device for rotating the medical device around the insertion axis; an image pickup device provided to the medical device; and an image capturing timing detection device for detecting a signal regarding image capturing timing performed by the image pickup device. Furthermore, the medical system includes: a rotating angle acquisition device for acquiring the rotating angle of the rotating device for the medical device regarding the image capturing timing in response to the output of the image capturing timing detection device; and an image acquisition device for performing rotation processing for the image captured by the image pickup device based upon the information regarding the rotating angle acquired by the rotating angle acquisition device, thereby acquiring the image subjected to a rotation processing.

Owner:OLYMPUS CORP

Medical system

Owner:OLYMPUS CORP

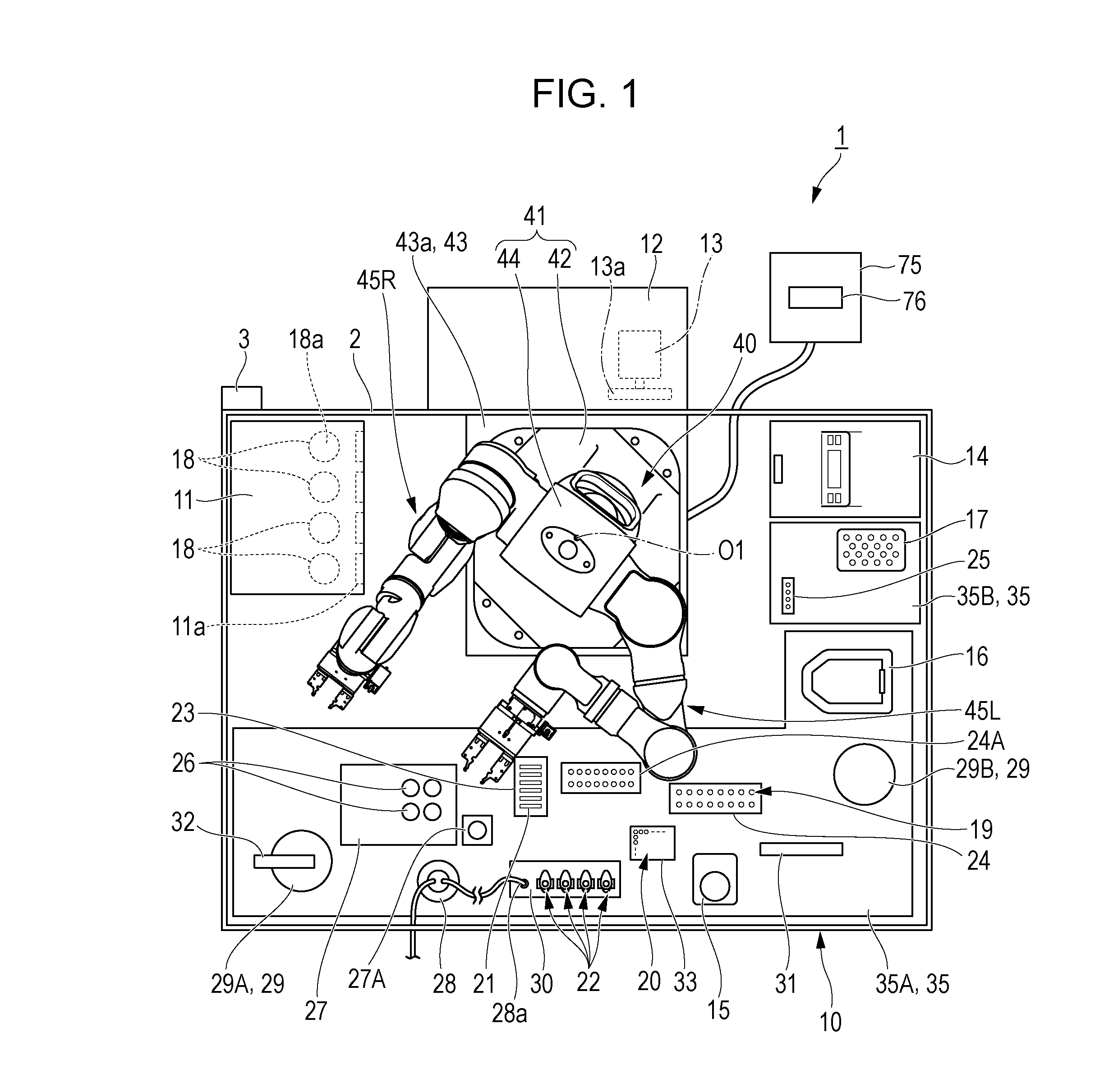

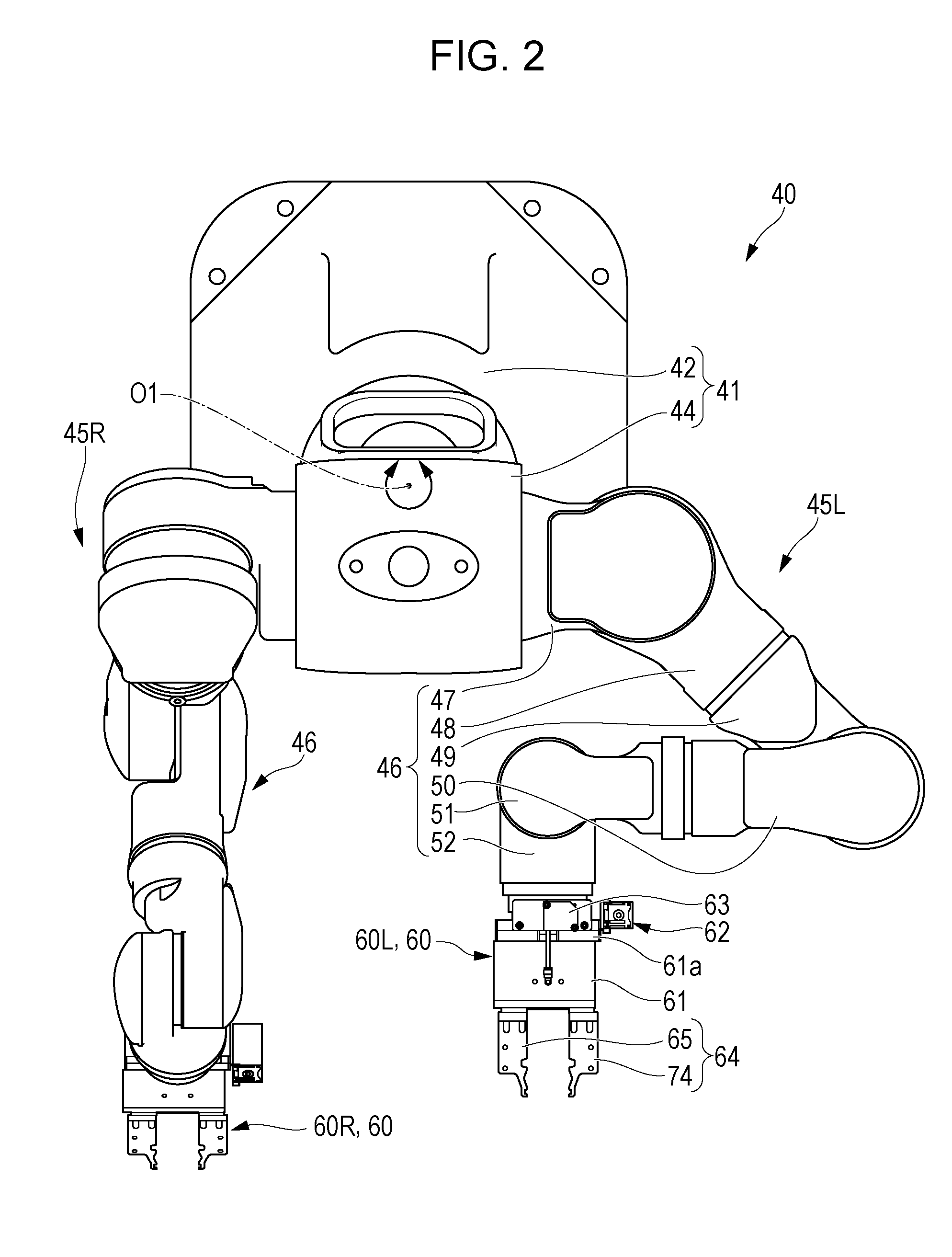

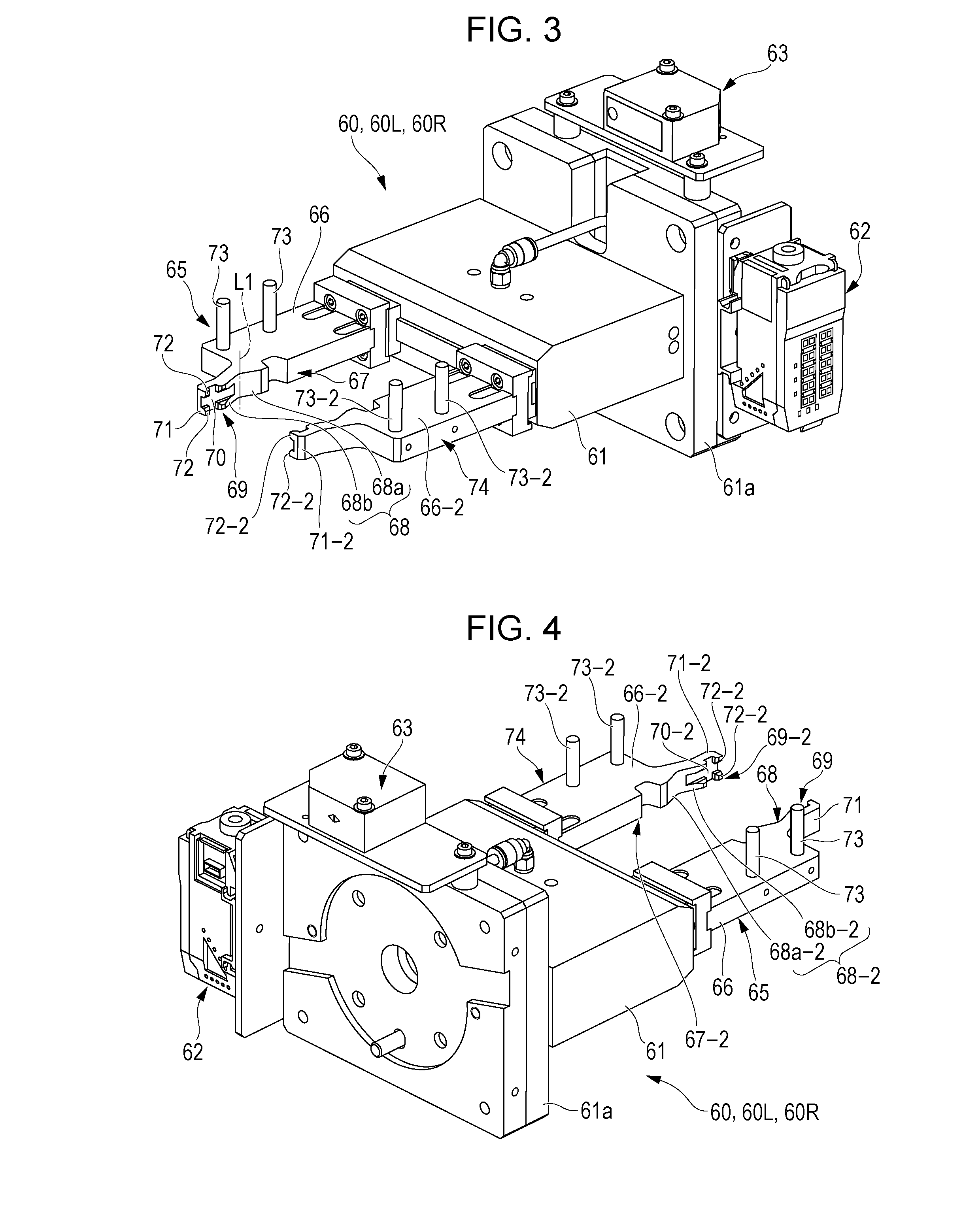

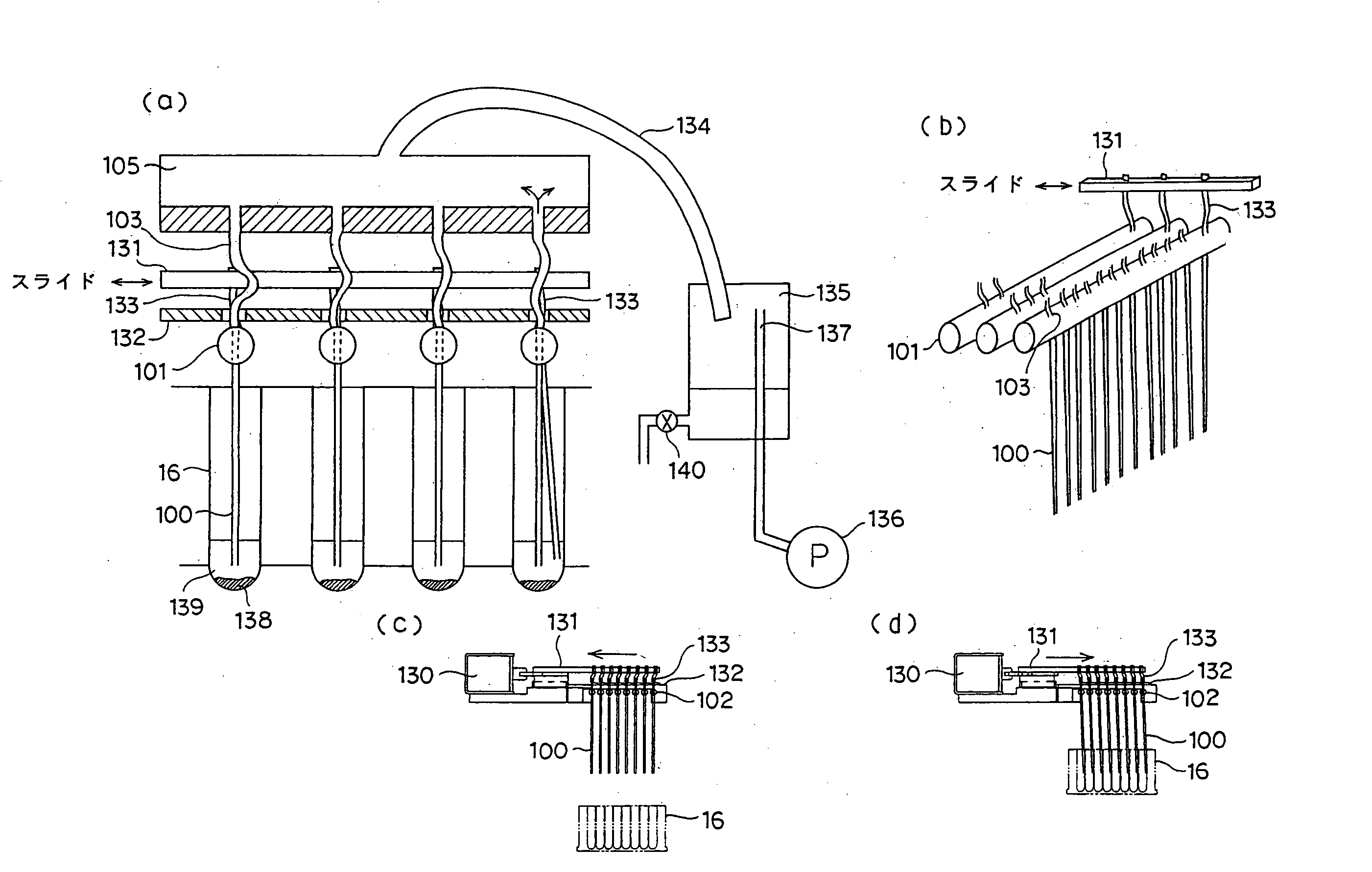

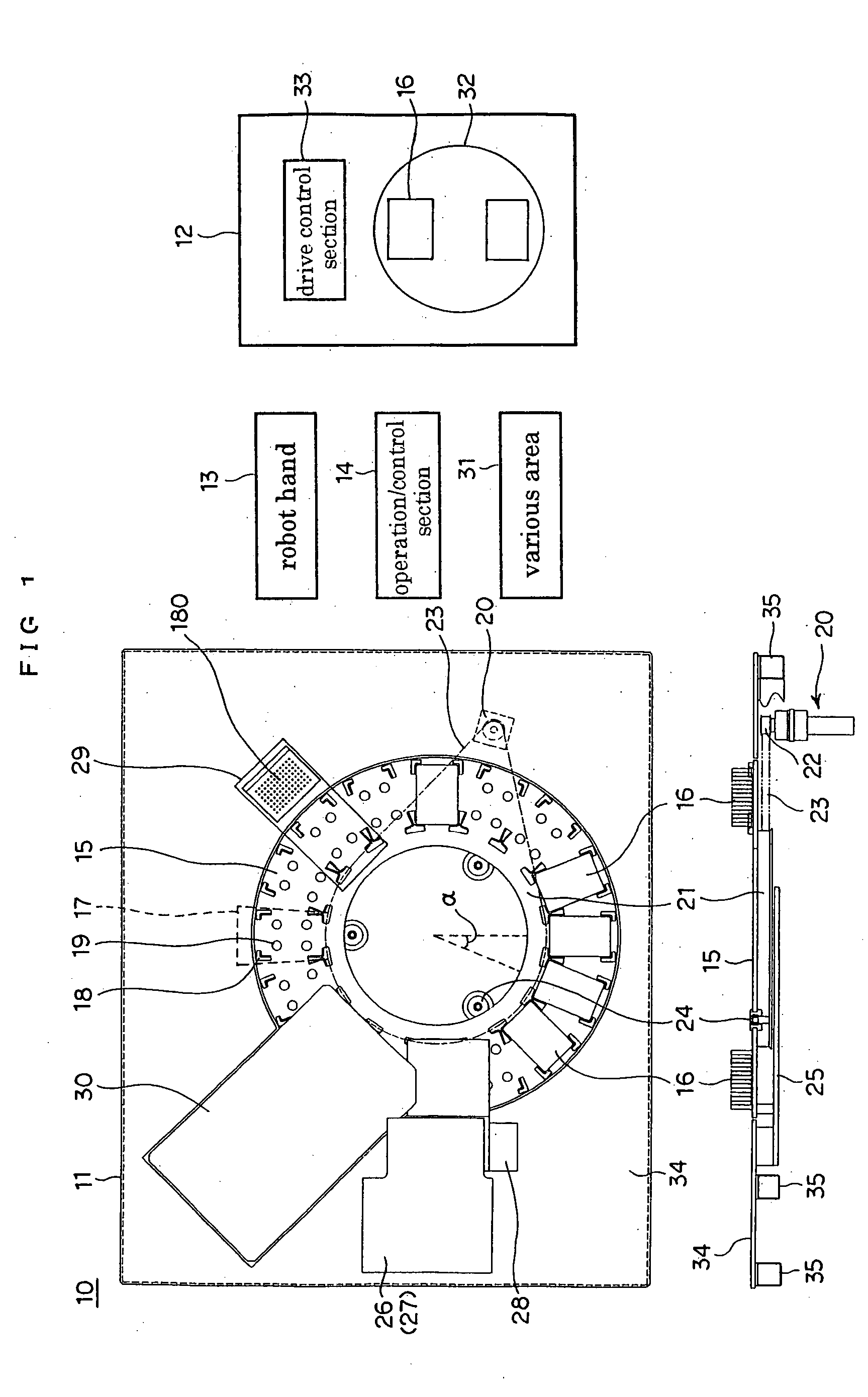

Liquid processing system and liquid processing method

ActiveUS20140106386A1High precision machiningSimple configurationProgramme-controlled manipulatorBioreactor/fermenter combinationsTrunk compartmentEngineering

A liquid processing system to process liquid biological material includes: a trunk provided turnable on an axis, set within a predetermined work space; a first arm provided to the trunk and having at least three degrees of freedom or higher degrees of freedom; a second arm provided to the trunk and having at least three degrees of freedom or higher degrees of freedom; a driving mechanism configured to drive each of the trunk, the first arm, and the second arm; and physiochemical equipment situated within the work space and within the range of movement of at least one of the first and the second arm. The driving mechanism is operated by teaching playback based on the positions and shapes of the physiochemical equipment, and the biological material is processed using the physiochemical equipment.

Owner:YASKAWA DENKI KK

Flattening method and flattening apparatus

ActiveUS20090095712A1Improve flatnessSufficient processing rateDecorative surface effectsSemiconductor/solid-state device manufacturingPlatinumMetal

A flattening method, by utilizing the advantages of the CARE method and making up for the disadvantages, can perform removal processing of a surface of a workpiece at a sufficient processing rate and can provide a processed surface having enhanced flatness without leaving damage in the processed surface. A flattening method comprises at least two surface removal steps and at least two cleaning steps, the final surface removal step being a catalyst-referred etching step comprising immersing a workpiece in a processing solution containing at least one of hydrohalic acid, hydrogen peroxide water and ozone water, and bringing a surface of a catalyst platen into contact with or close proximity to a surface to be processed of the workpiece to process the surface, said catalyst platen having in a surface a catalyst selected from the group consisting of platinum, gold, a ceramic solid catalyst, a transition metal, glass, and an acidic or basic solid catalyst.

Owner:EBARA CORP

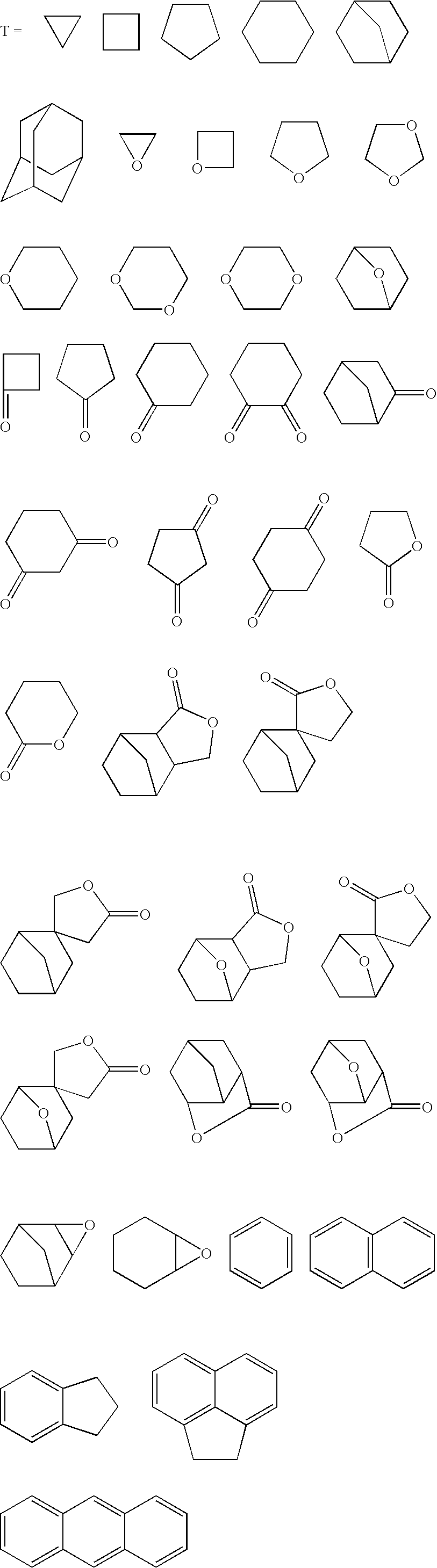

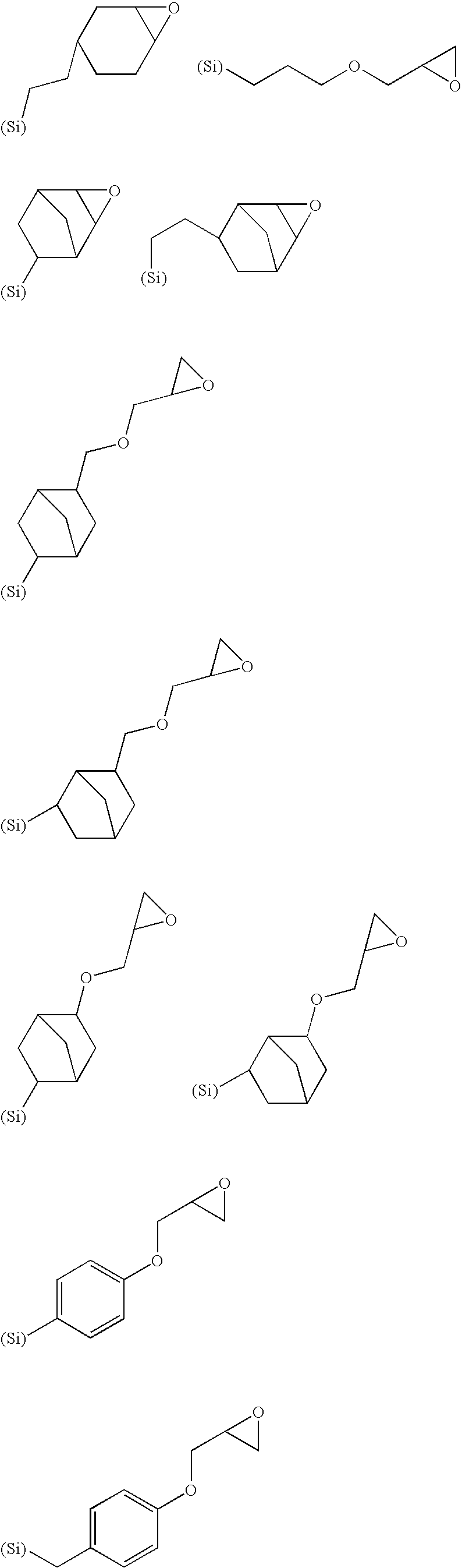

Silicon-containing film-forming composition, silicon-containing film, silicon-containing film-bearing substrate, and patterning method

ActiveUS20080026322A1Sufficient etching resistanceImprove accuracyPhotosensitive materialsSemiconductor/solid-state device manufacturingAmmonium compoundsPtru catalyst

A silicon-containing film is formed from a heat curable composition comprising (A-1) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of an acid catalyst and removing the acid catalyst, (A-2) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of a basic catalyst and removing the basic catalyst, (B) a hydroxide or organic acid salt of lithium, sodium, potassium, rubidium or cesium, or a sulfonium, iodonium or ammonium compound, (C) an organic acid, and (D) an organic solvent. The silicon-containing film allows an overlying photoresist film to be patterned effectively.

Owner:SHIN ETSU CHEM IND CO LTD

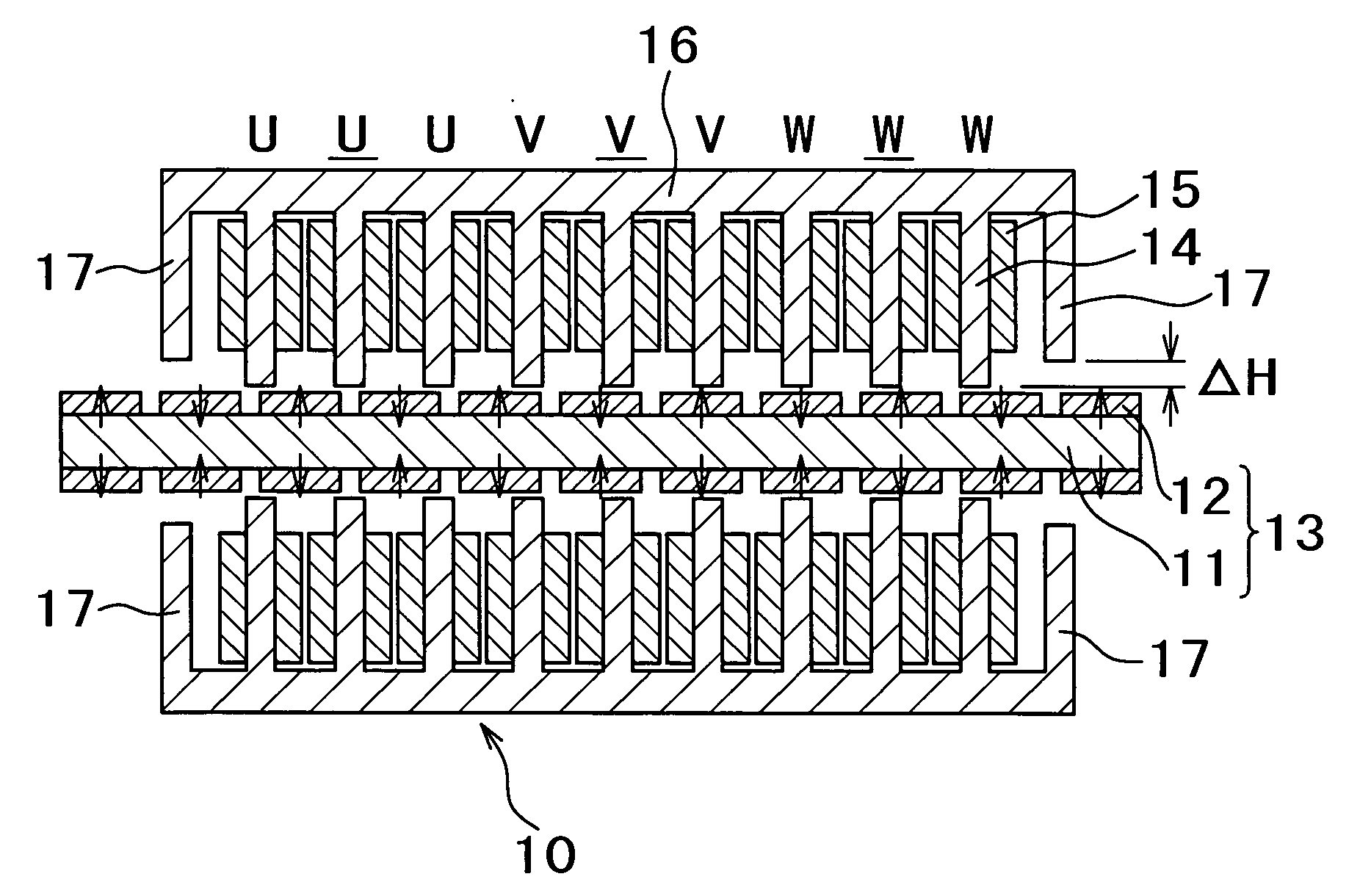

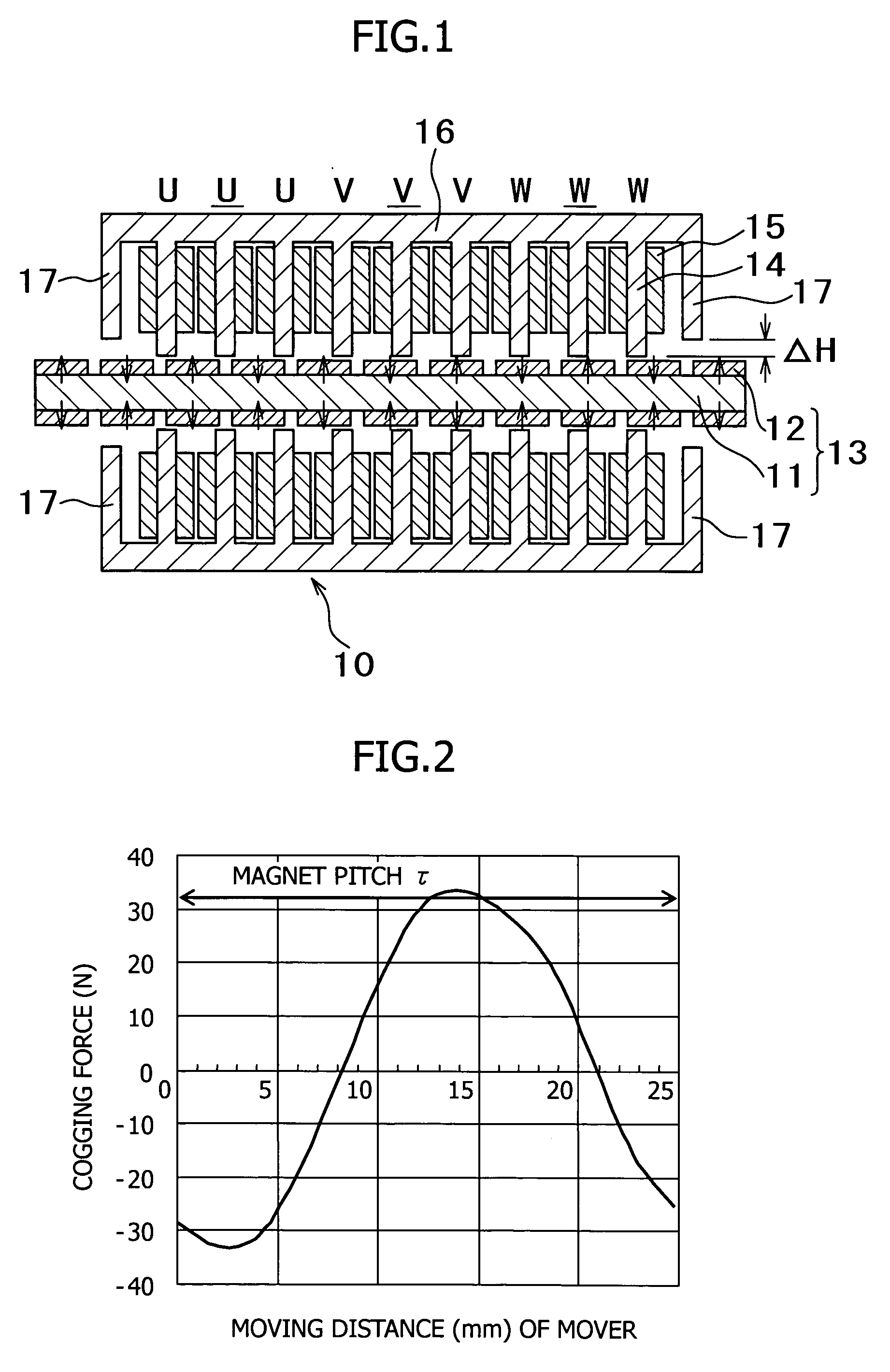

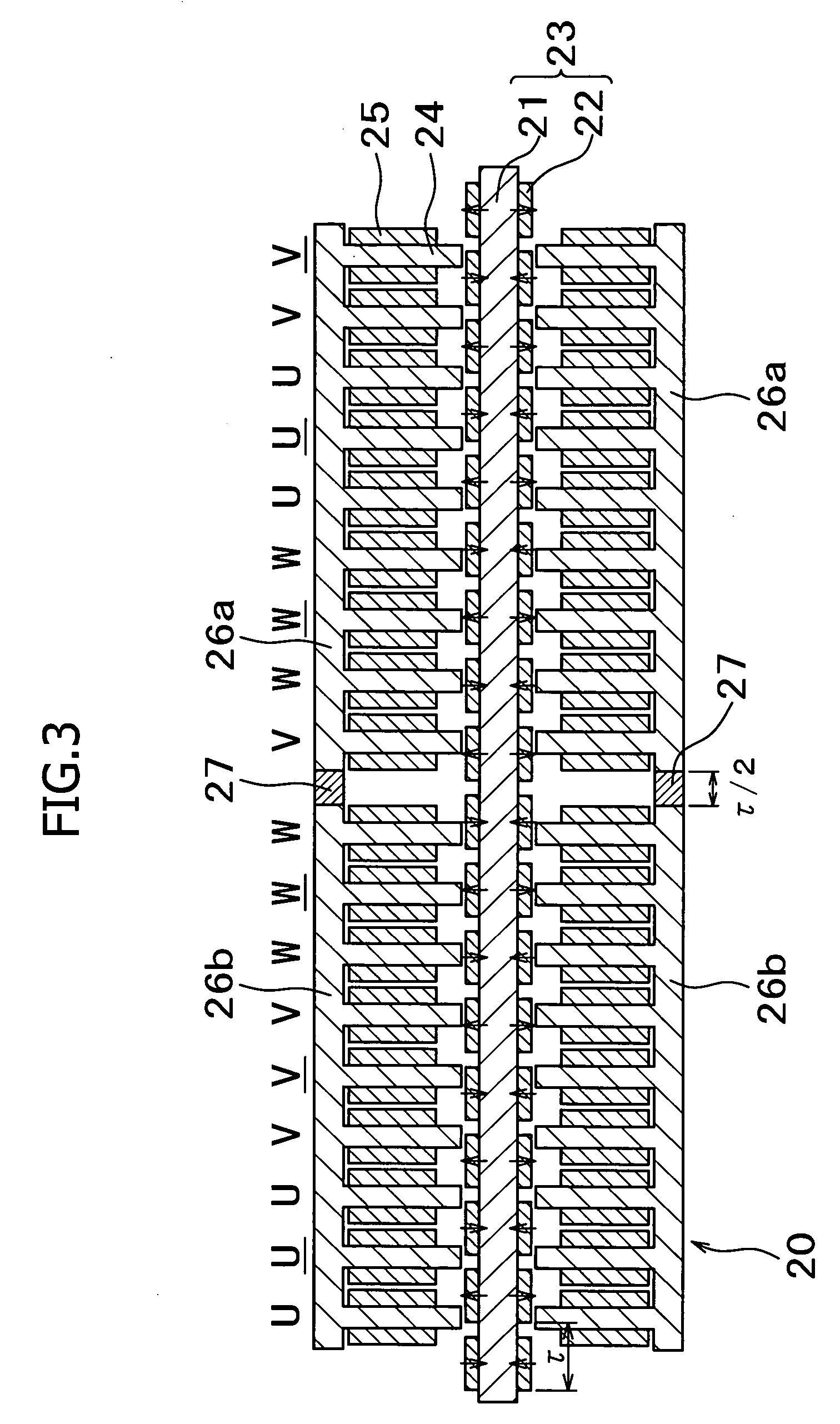

Linear motor for use in machine tool

InactiveUS20060012252A1High precision machiningReduce cogging forceMagnetic circuitMechanical energy handlingLaser processingElectric machine

The invention is a linear motor that improves the processing speed of machine tools is also a linear motor with significantly reduced cogging force, with which high-speed and high-accuracy processing can be realized. More specifically, the invention is a linear motor for use in a machine tool comprising a stator in which a plurality of permanent magnets having the same shape are mounted on both faces of a plate-like yoke at even intervals such that the permanent magnets have polarities being perpendicular to a direction in which a pair of movers move and alternating in the moving direction; the movers in which armature cores wound with armature coils are disposed such that the armature cores are opposed to the rows of the permanent magnets on the both faces of the stator; and magnetic cores that are disposed on both ends of the movers such that the distance between the magnetic cores and the rows of the permanent magnets is longer than that between the armature cores and the rows of the permanent magnets. Moreover, provided is a laser processing machine in which the above-mentioned permanent magnet type linear motor is used for a three-dimensional moving mechanism.

Owner:SHIN ETSU CHEM IND CO LTD

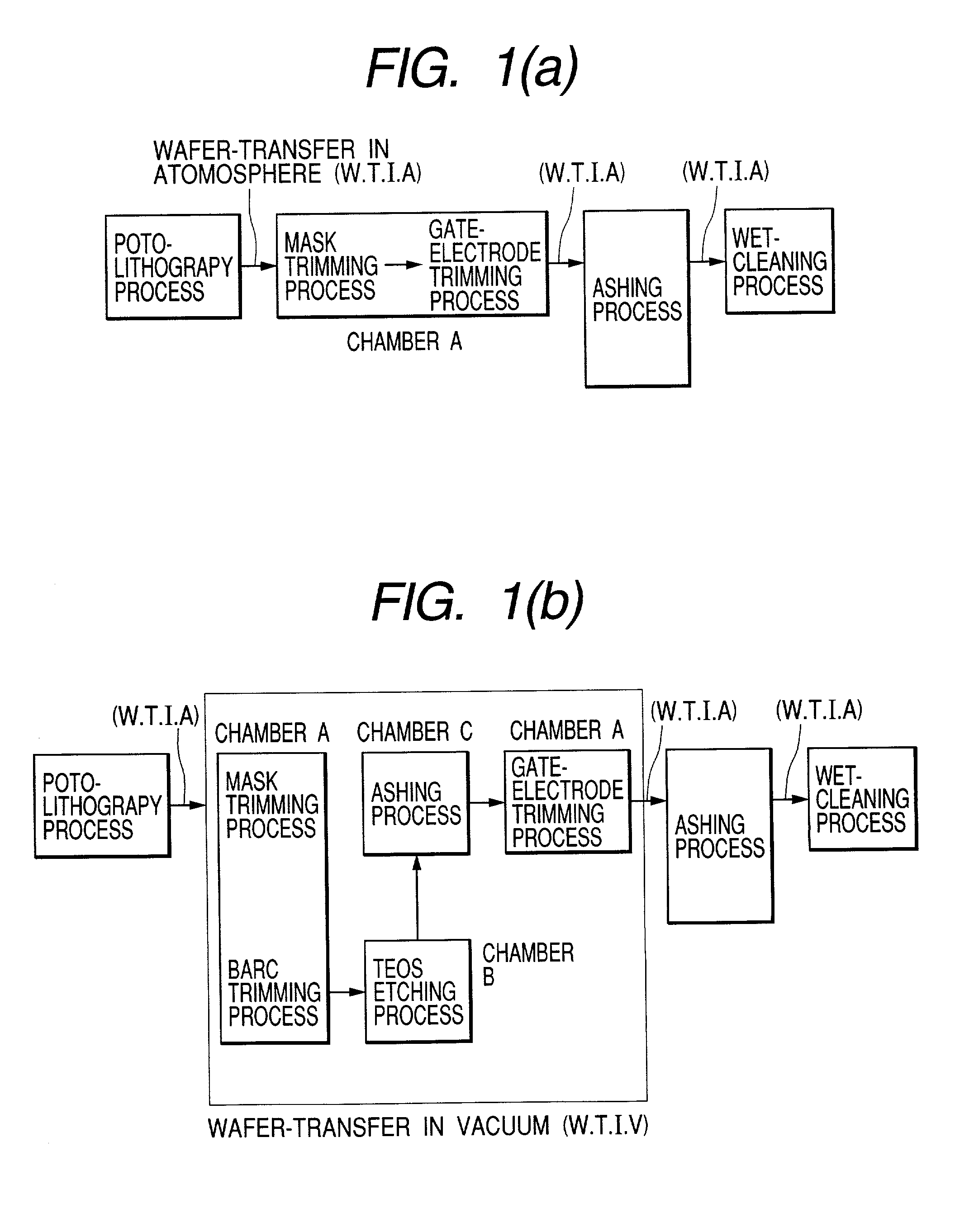

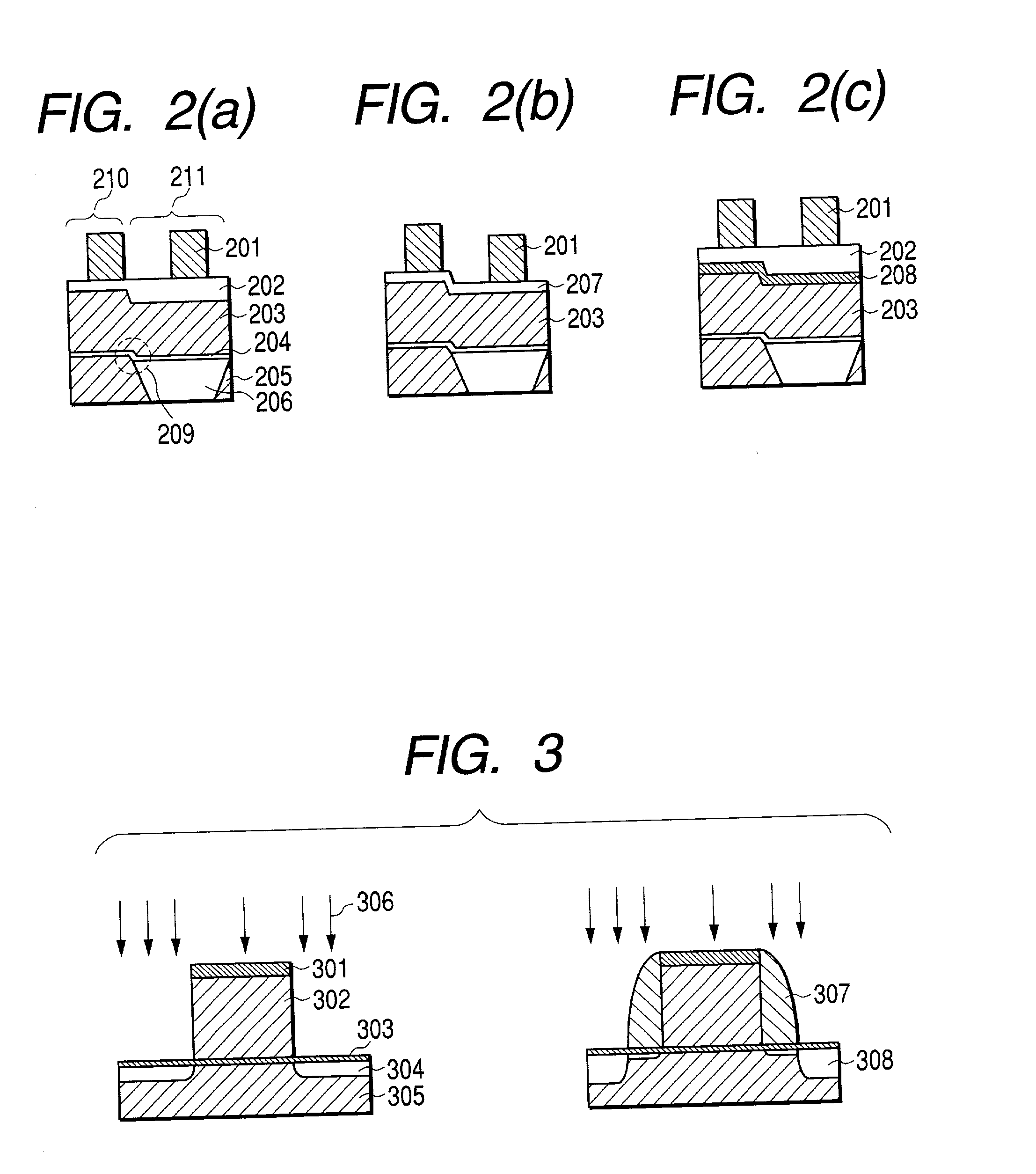

Method of manufacturing semiconductor devices

InactiveUS20030049876A1Reduce variationHigh precision machiningSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

A process for economical and efficient fabrication of gate electrodes no larger than 50 nm, which is beyond the limit of exposure, is characterized by gate-electrode trimming and mask trimming with high resist selectivity which are performed in combination. The process is also preferably characterized by performing trimming and drying cleaning in a vacuum environment and may also include steps of inspecting dimensions and contamination in a vacuum environment. The process can be implemented to provide the effects of forming a gate no longer than 50 nm (beyond the limit of exposure) without restrictions on the resist thickness; reducing contamination resulting from transfer of wafers from one step to next, thereby improving yields; preventing resist from hydrolysis by ArF laser, thereby reducing roughening which adversely affects the gate width; and ensuring stable yields despite variation in dimensions and contamination owing to the additional dry cleaning step and feed-forward control based on CD inspection and contamination inspection.

Owner:HITACHI LTD

Plasma processing method and apparatus

InactiveUS20020114897A1Suppress charging damageImprove accuracyElectric discharge tubesDecorative surface effectsEngineeringGate oxide

A plasma processing method and apparatus are provided for processing the surface of a semiconductor device or the like through the effect of plasma. A pulsed plasma discharge is performed by switching on and off the high frequency electric power for generating the plasma with a specified off period of the plasma generation, to control an inflow amount of positive and negative charges to sparse and dense portions of device patterns and suppress an electric potential on a gate oxide film. Thereby, a highly accurate etching process with no charging damage can be carried out.

Owner:HITACHI LTD

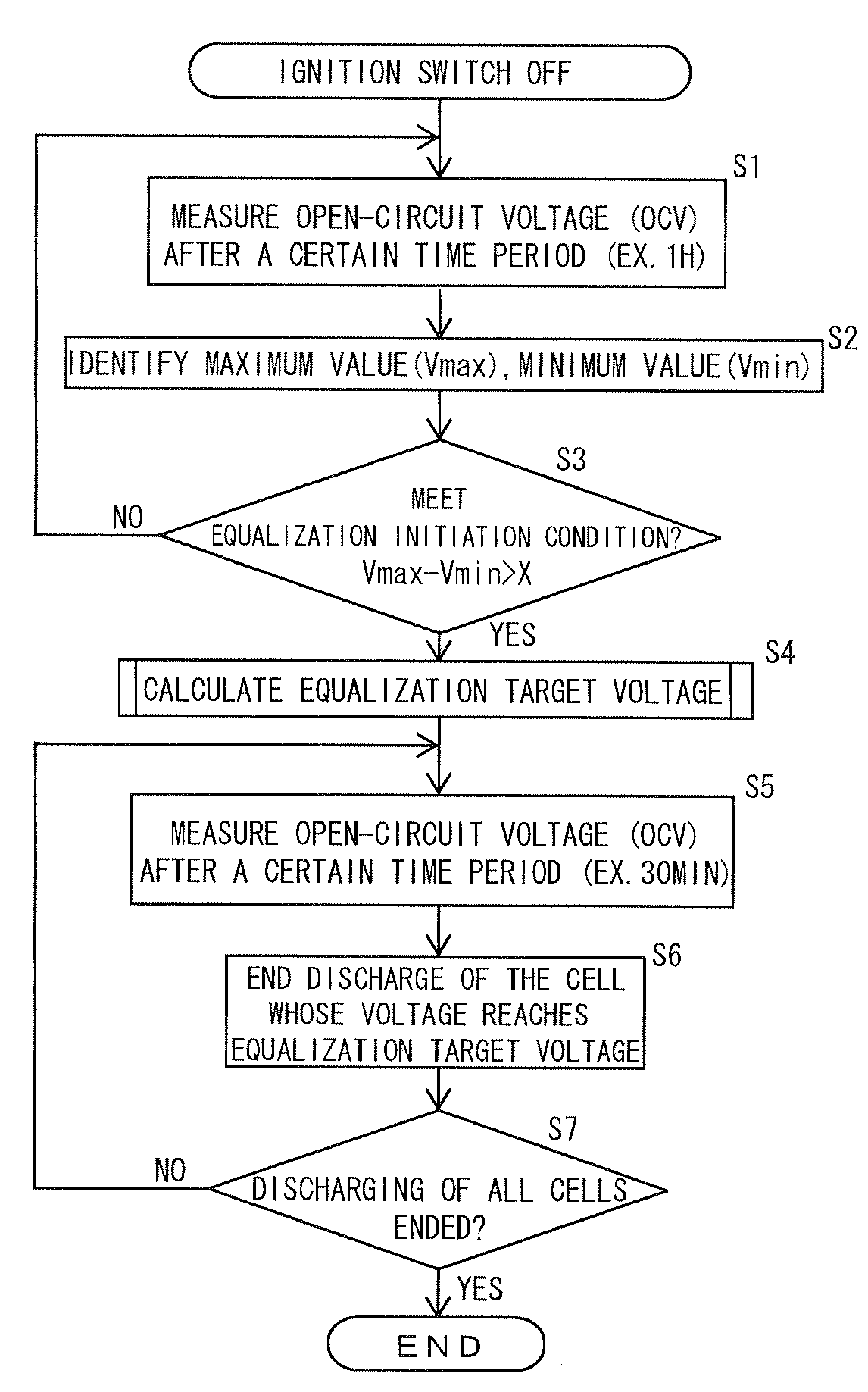

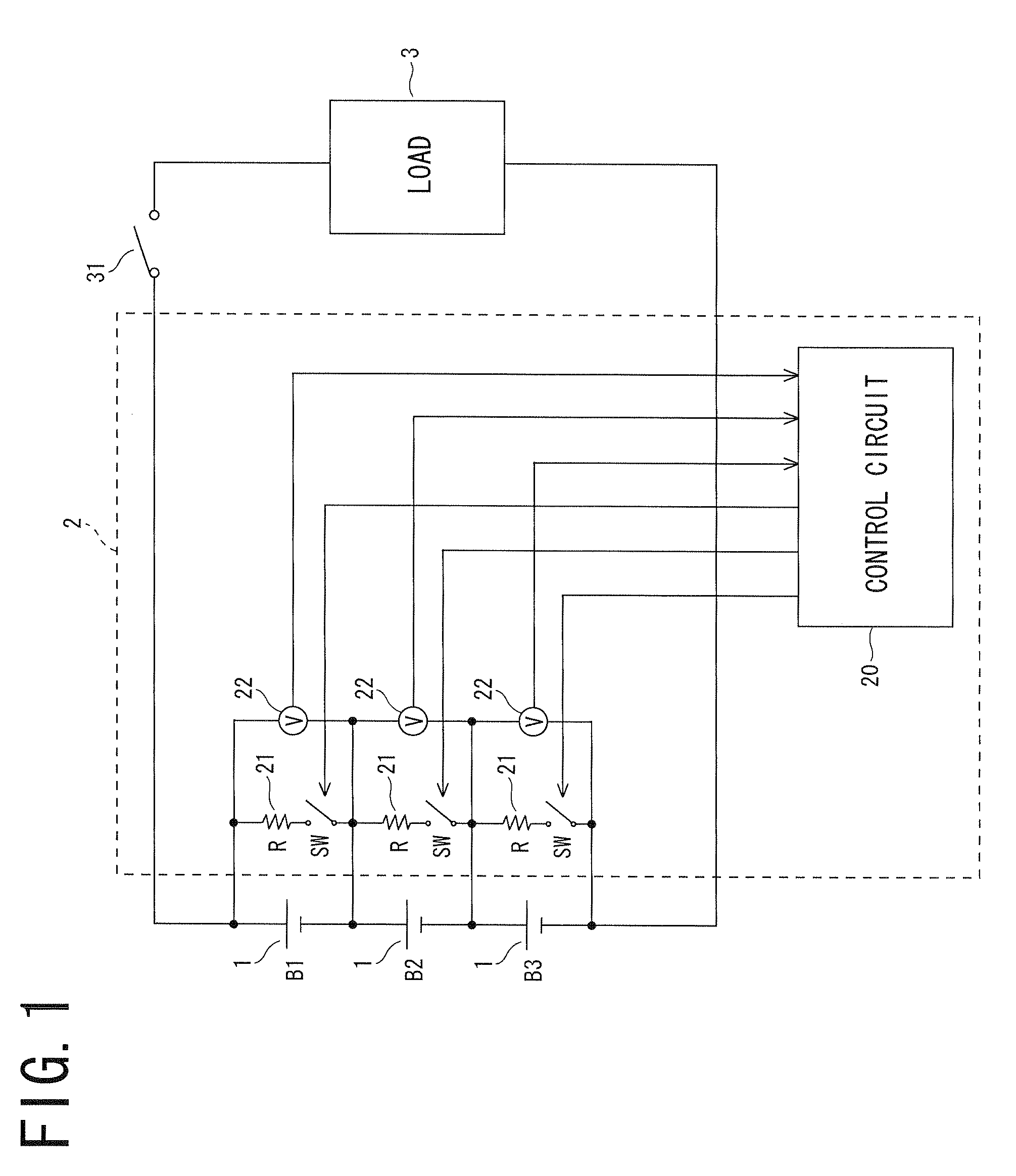

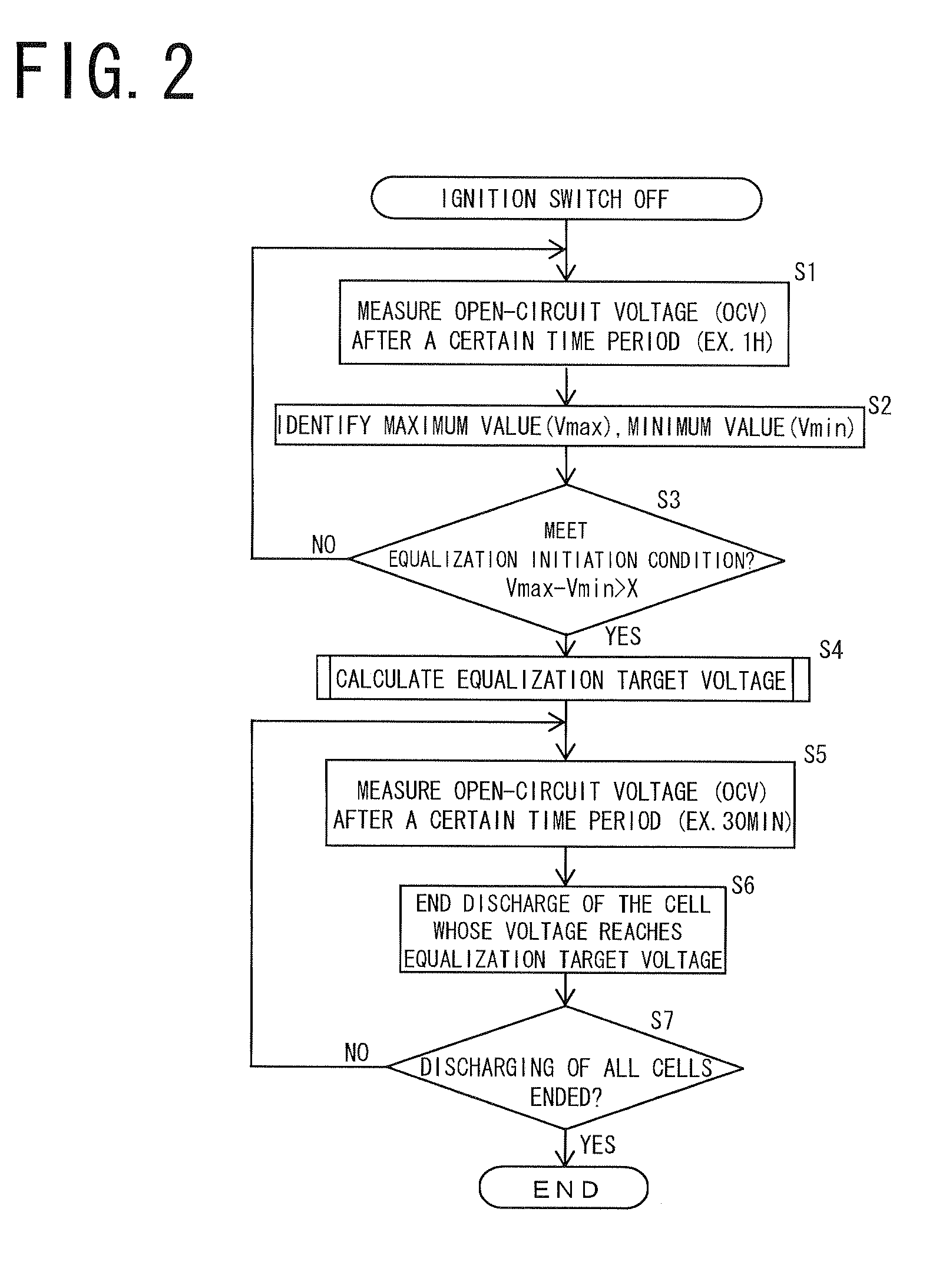

State of Charge Equalizing Device and Assembled Battery System Including Same

ActiveUS20090167248A1Improve accuracyHigh precision machiningDc network circuit arrangementsCharge equalisation circuitState of chargeEngineering

A state-of-charge equalizing device equalizes the state of charge of each of cells connected in series to form an assembled battery, and comprises charging / discharging circuits connected in parallel to the respective cells to discharge and / or charge the respective cells, voltage measurement circuits connected to the respective charging / discharging circuits to measure the voltages across the respective cells, and a control circuit. The control circuit comprises a unit calculating an equalization target voltage based on the measured voltages before the charge or discharge starts, a unit starting discharging / charging the cells having a voltage thereacross different from the target voltage, a unit correcting the target voltage to thereby calculate a corrected equalization target voltage for each of those cells based on the difference between the measured voltages before and at a certain time period after the charging / discharging, and a unit ending the discharging / charging when the measured voltage reaches the corrected target voltage.

Owner:SANYO ELECTRIC CO LTD

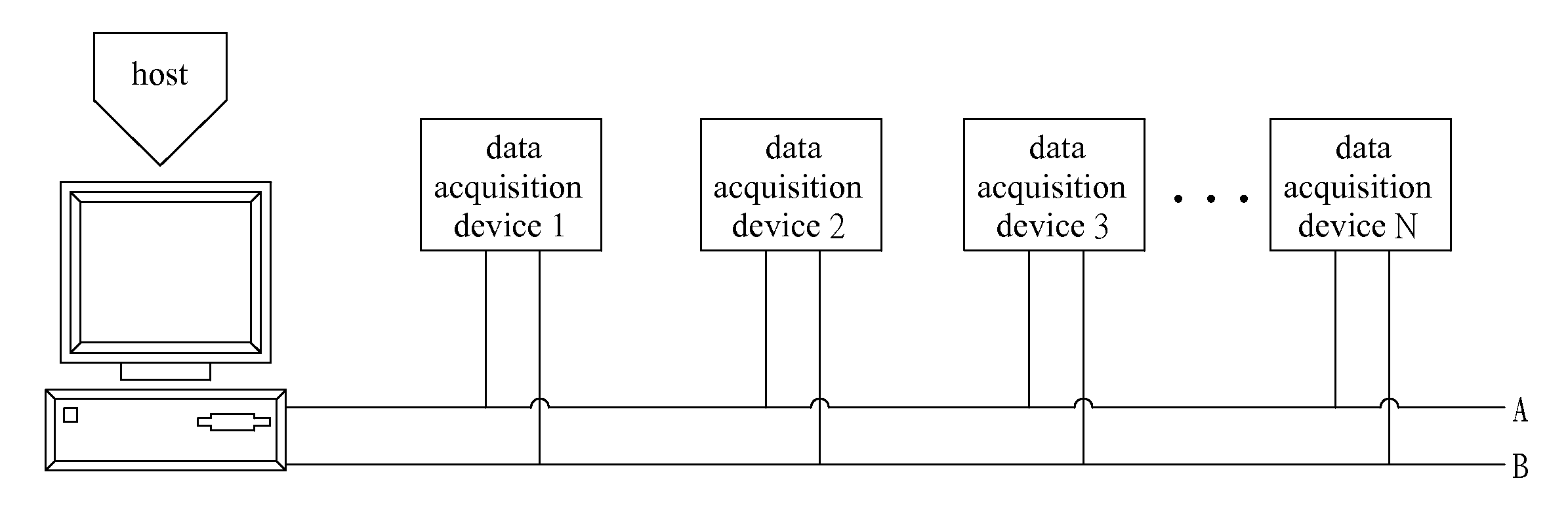

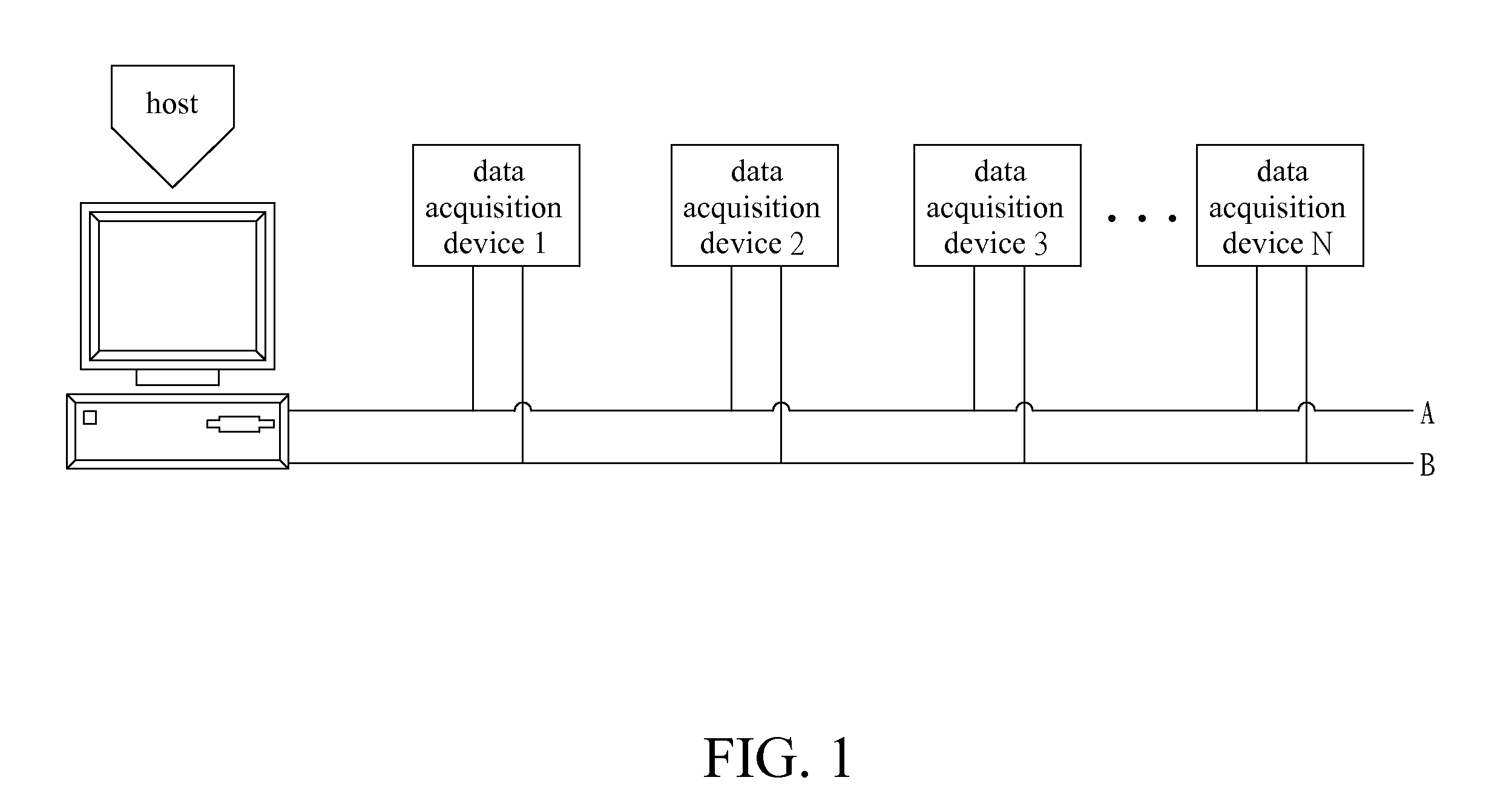

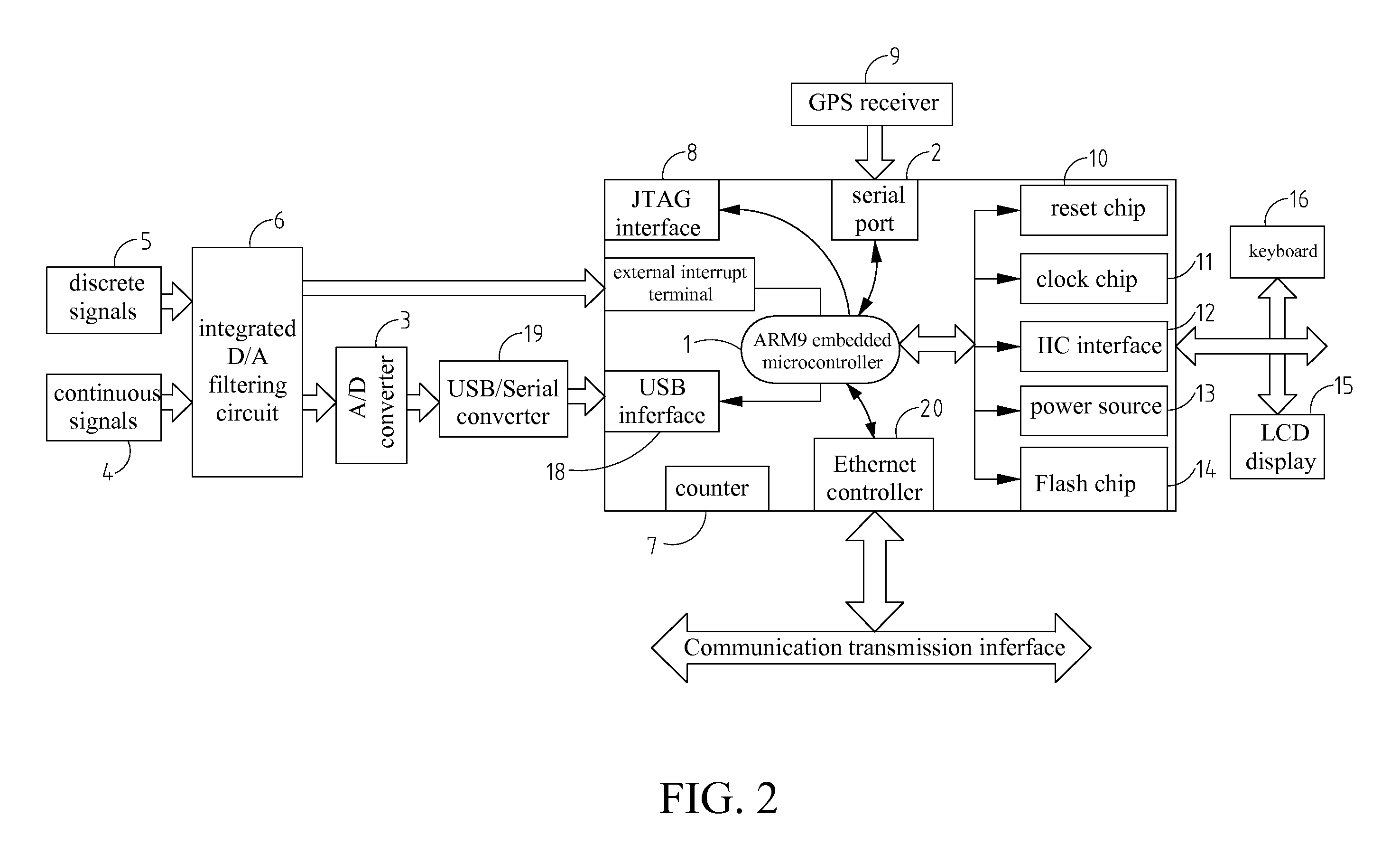

Distributed Networked Data Acquisition Device

InactiveUS20070174451A1Guaranteed synchronizationHigh precision machiningTariff metering apparatusDigital computer detailsGNU/LinuxData acquisition

A distributed networked data acquisition system having distributed networked data acquisition devices based on embedded Linux development platform having an ARM9 CPU is proposed. The system is defined as one or more distributed networked data acquisition devices together with a host. The host could dynamically display data and also coordinate and control the many distributed networked data acquisition devices. Each distributed networked data acquisition device is connected with the host by means of transmission media. The distributed networked data acquisition devices adopts the distributed data acquisition network to implement multi-point data acquisition having many distributed networked data acquisition devices working together and using several UTPs to connect with the distributed networked data acquisition devices in various distribution points. Each distributed networked data acquisition device can connect with different types of sensors, and each sensor can collect different types of continuous signals.

Owner:NORTHEASTERN UNIV

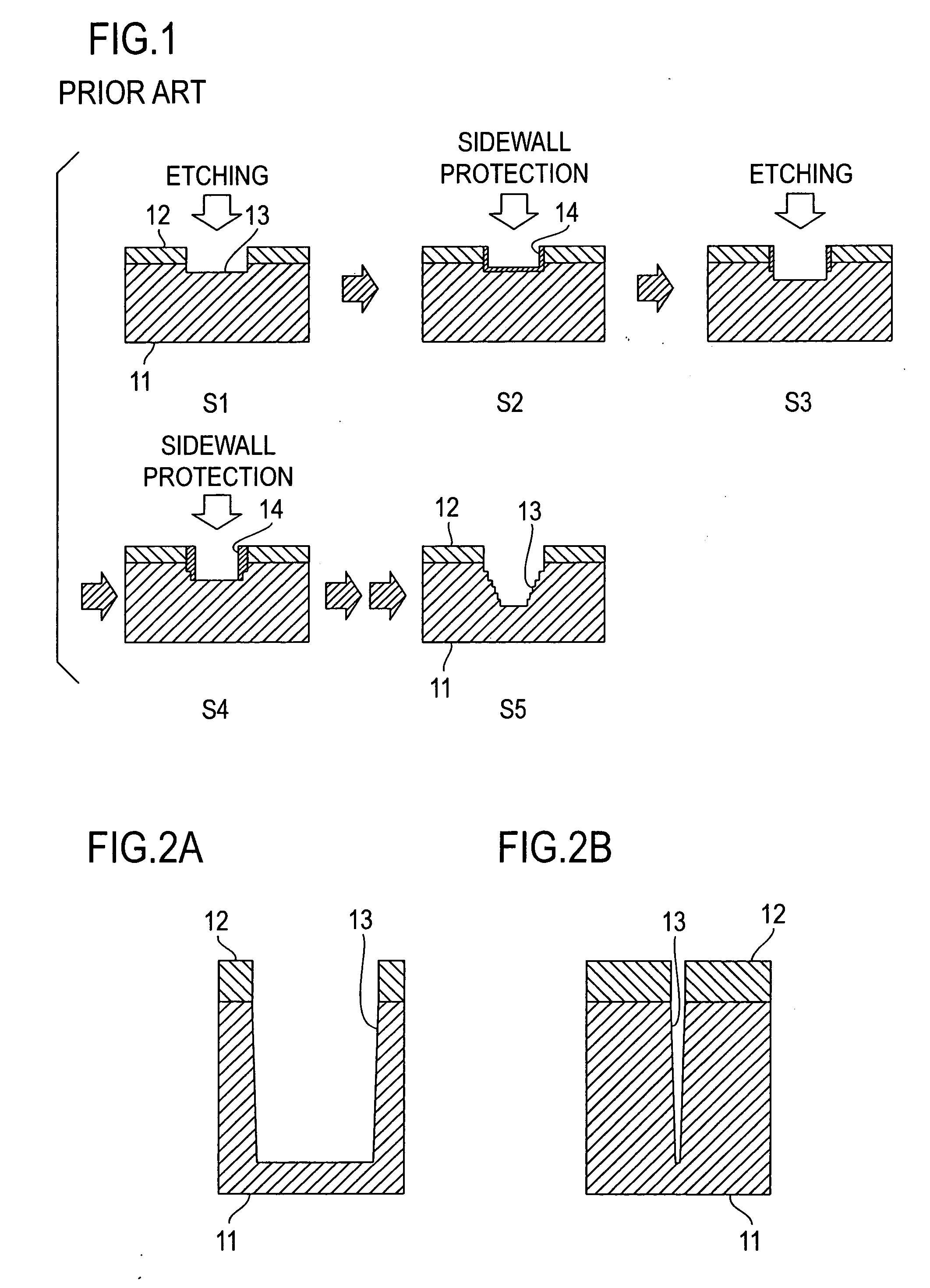

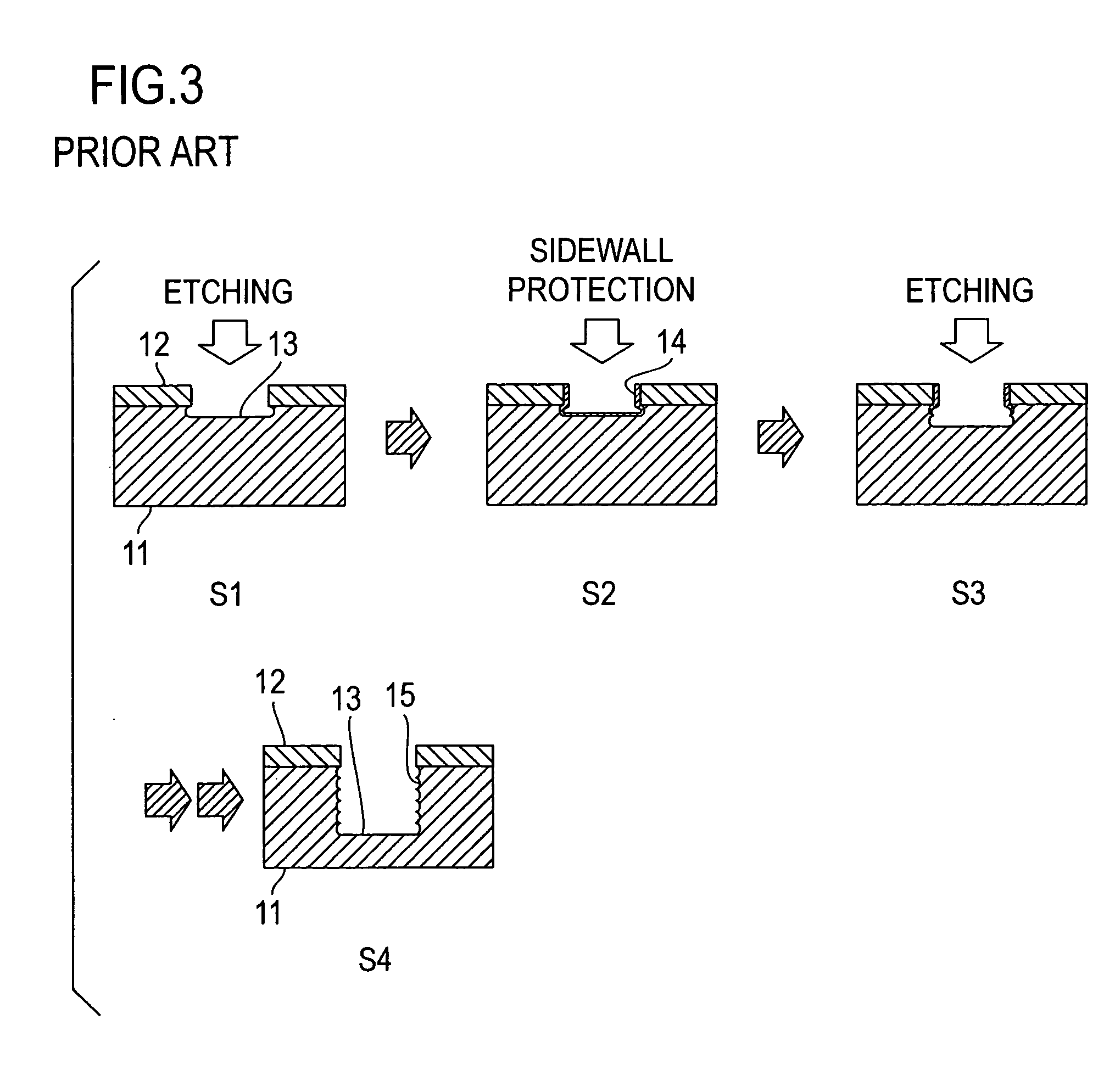

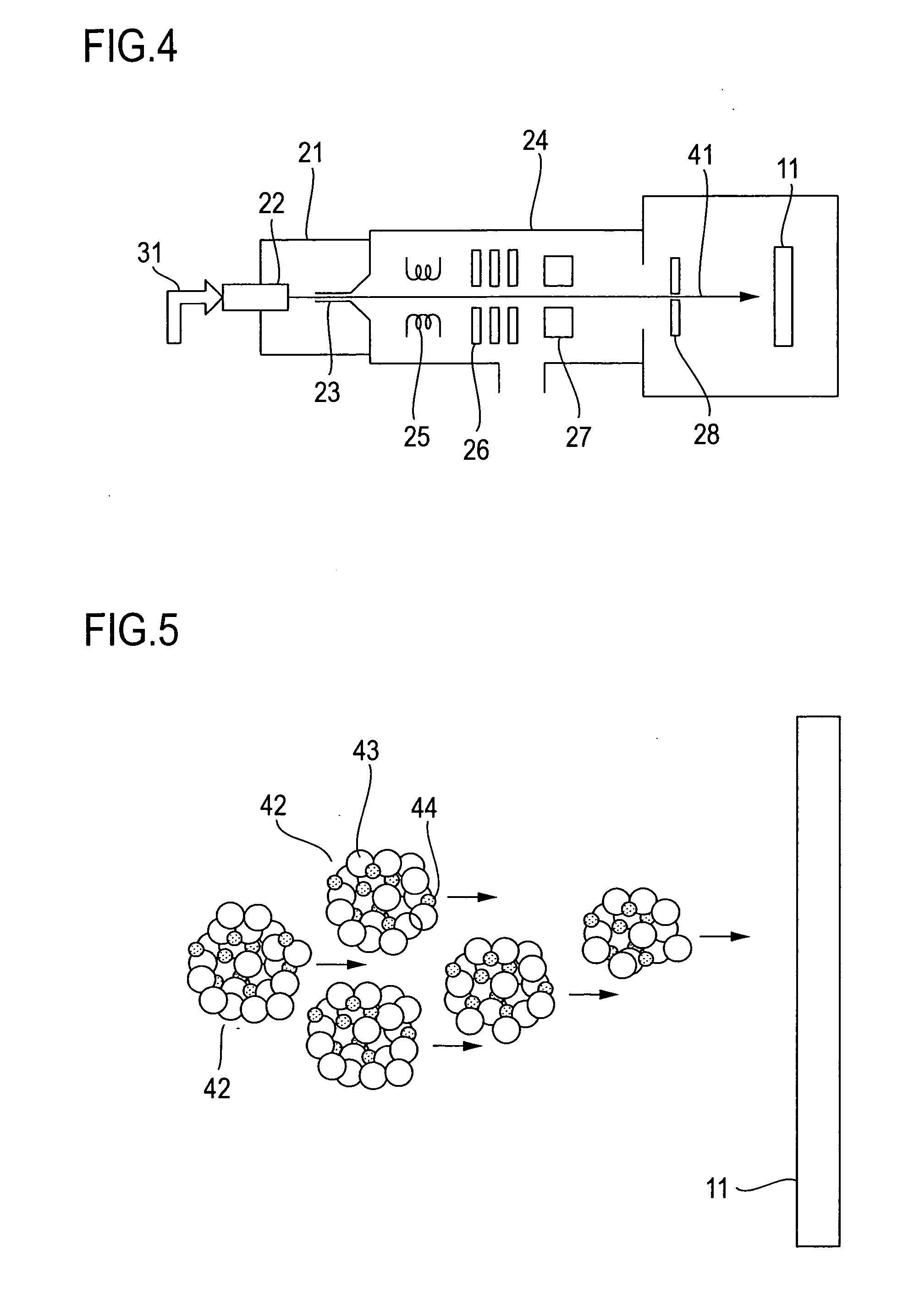

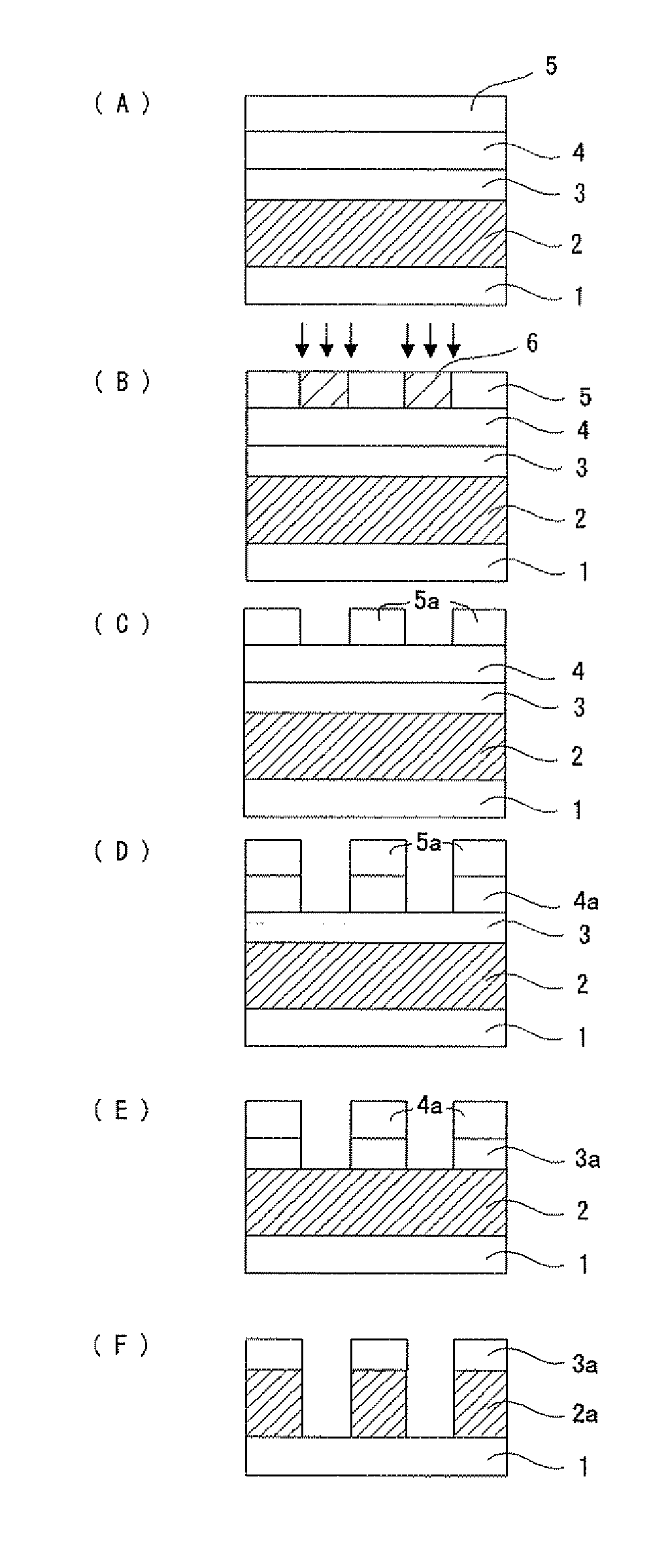

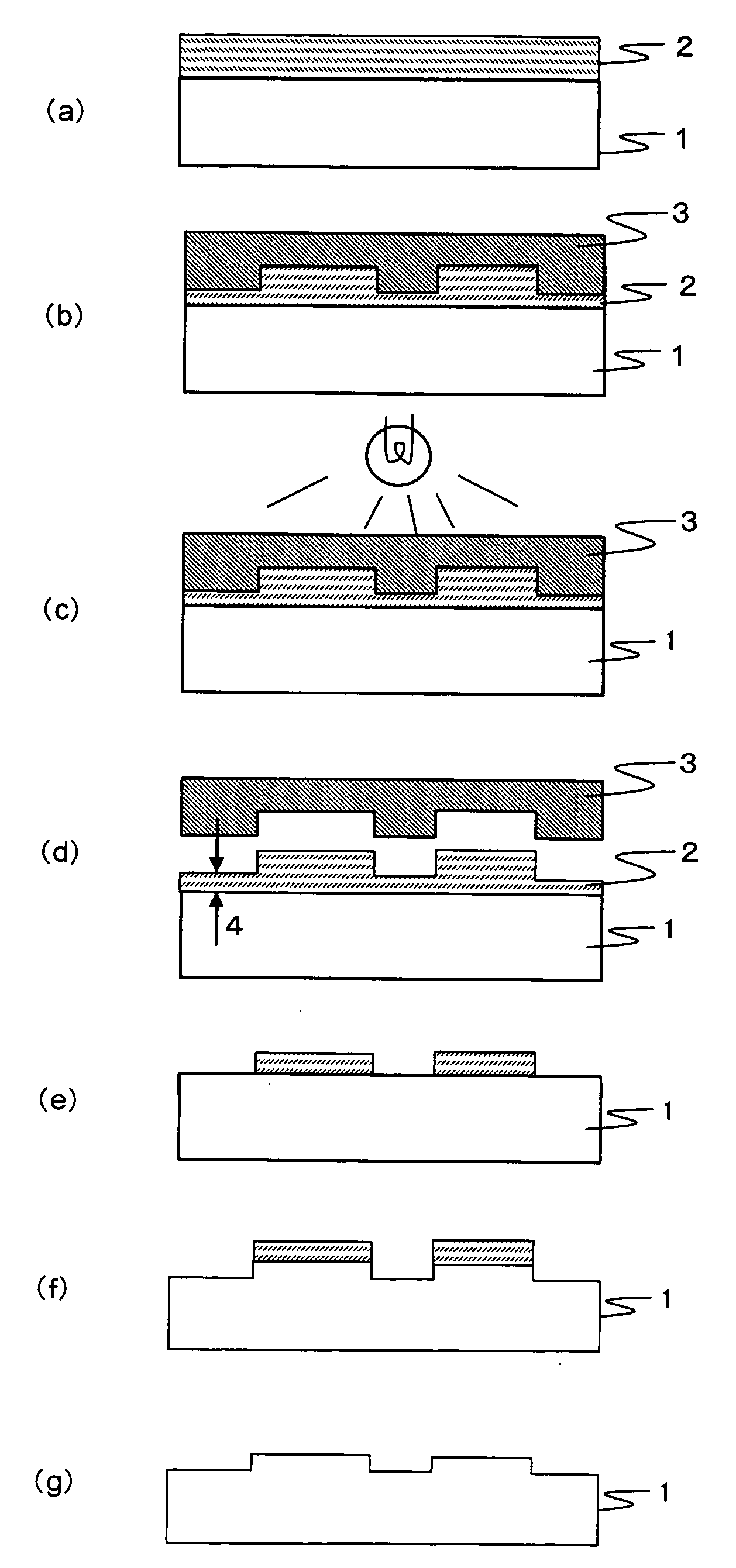

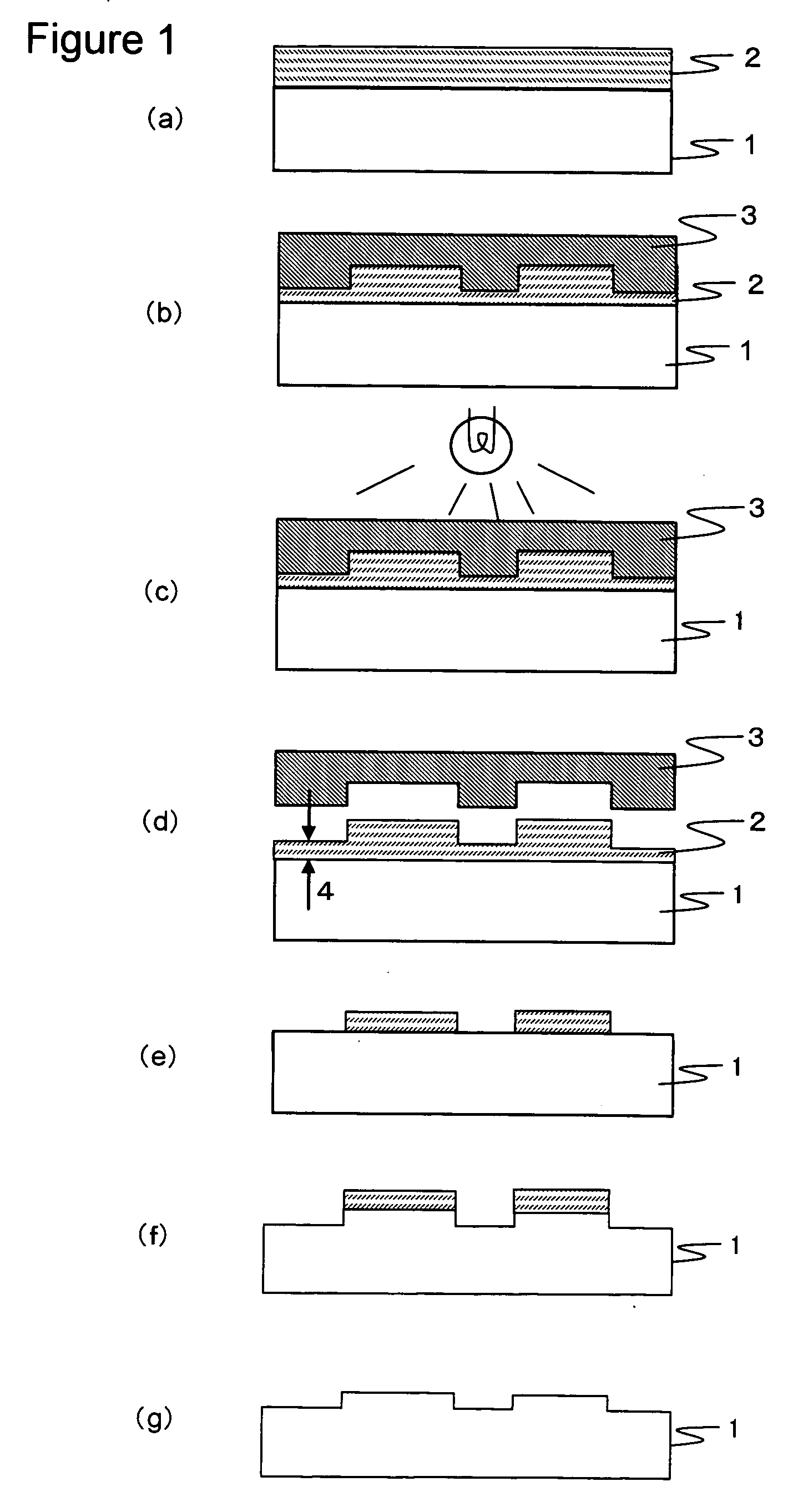

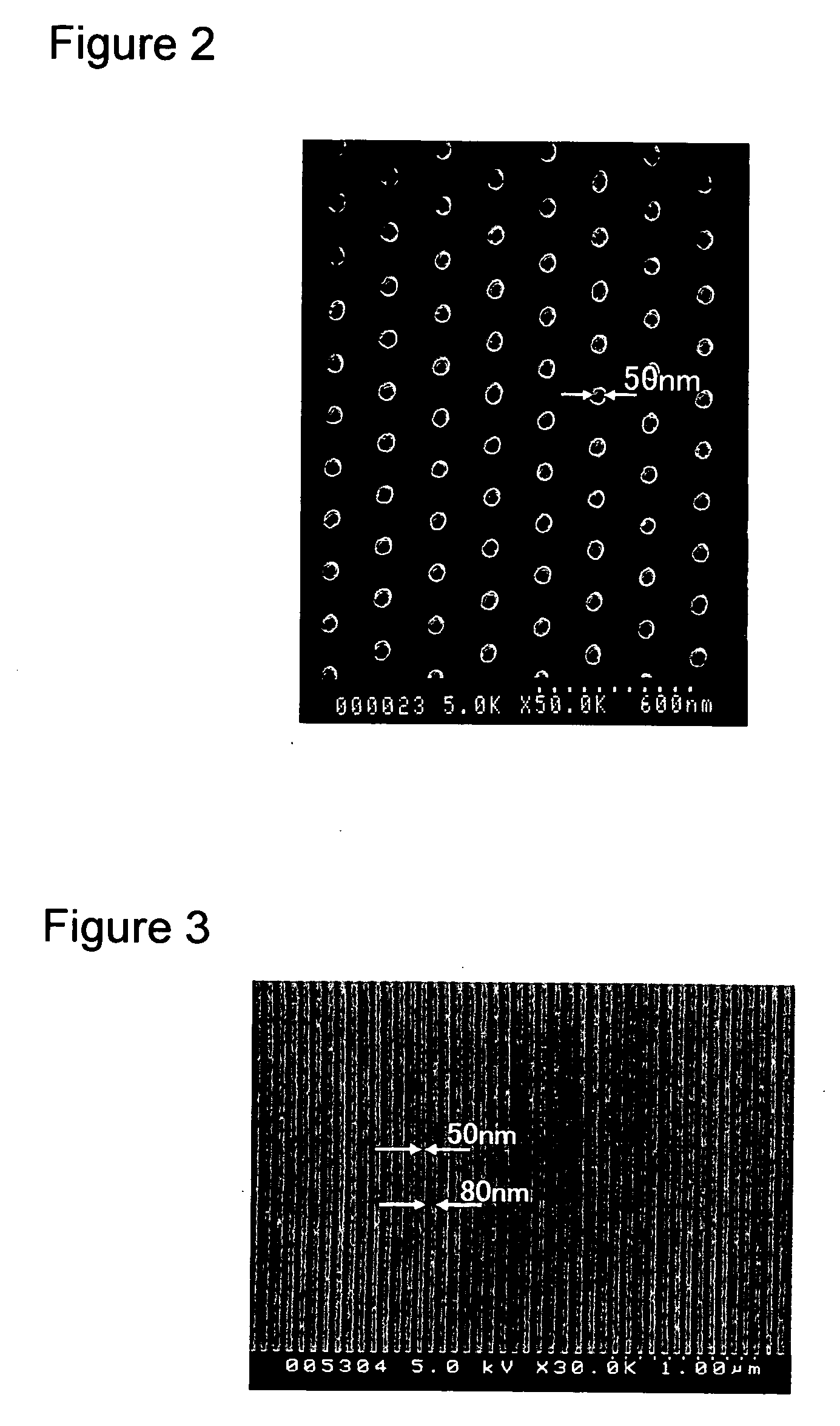

Dry etching method and photonic crystal device fabricated by use of the same

InactiveUS20050155951A1Minimize surface roughnessReduce roughnessElectric discharge tubesDecorative surface effectsKryptonPhotonic crystal

In a dry etching method in which clusters formed by agglomeration of atoms or molecules are ionized and accelerated as a cluster ion beam for irradiation of an object surface to etch away therefrom its constituent atoms, the clusters are mixed clusters 42 formed by agglomeration of two or more kinds of atoms or molecules, and the mixed clusters 42 contain atoms 43 of at least one of argon, neon, xenon and krypton, and a component 44 that is deposited on the object surface to form a thin film by reaction therewith. With this method, it is possible to provide an extremely reduced sidewall surface roughness and high vertical machining accuracy.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

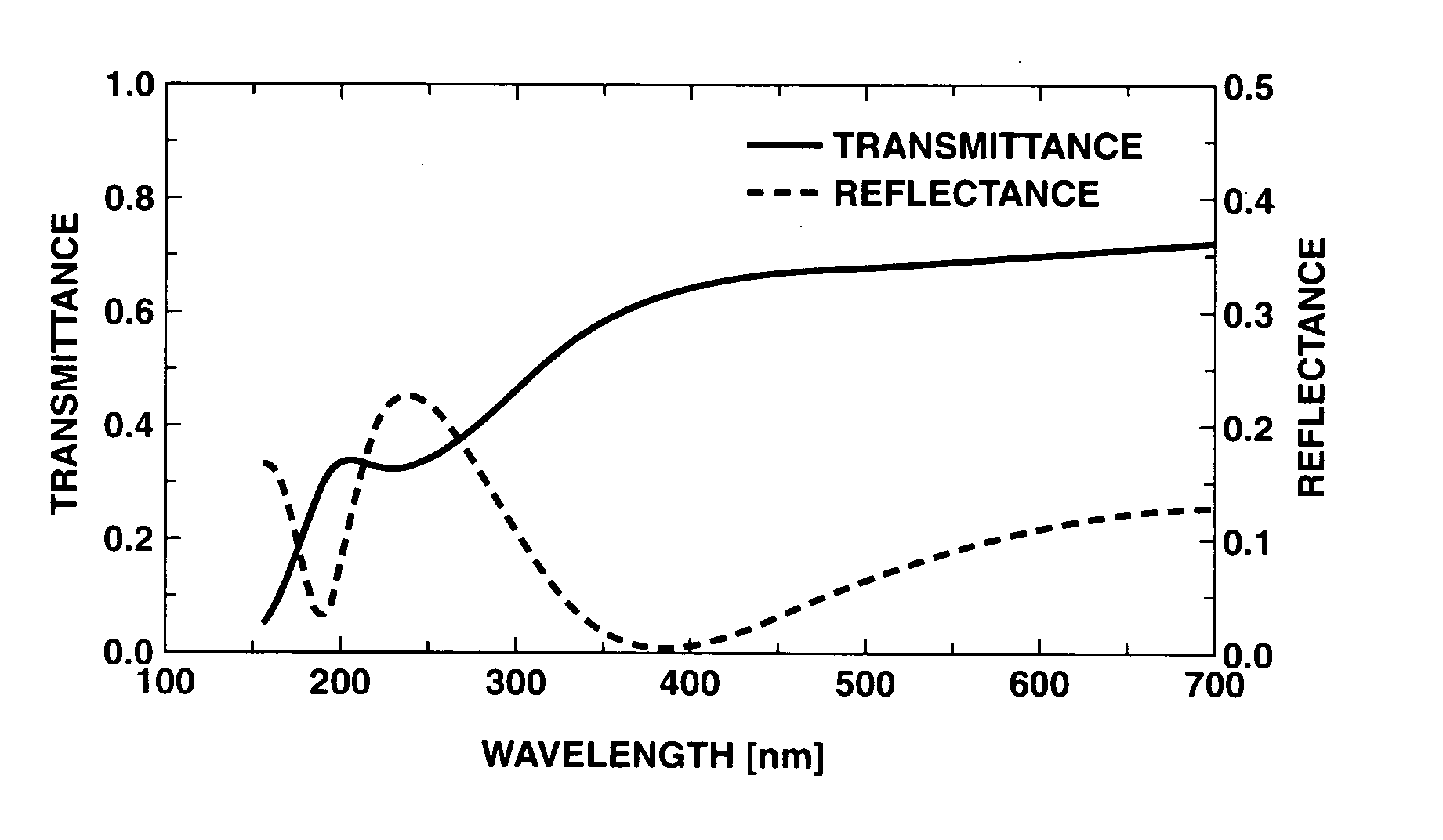

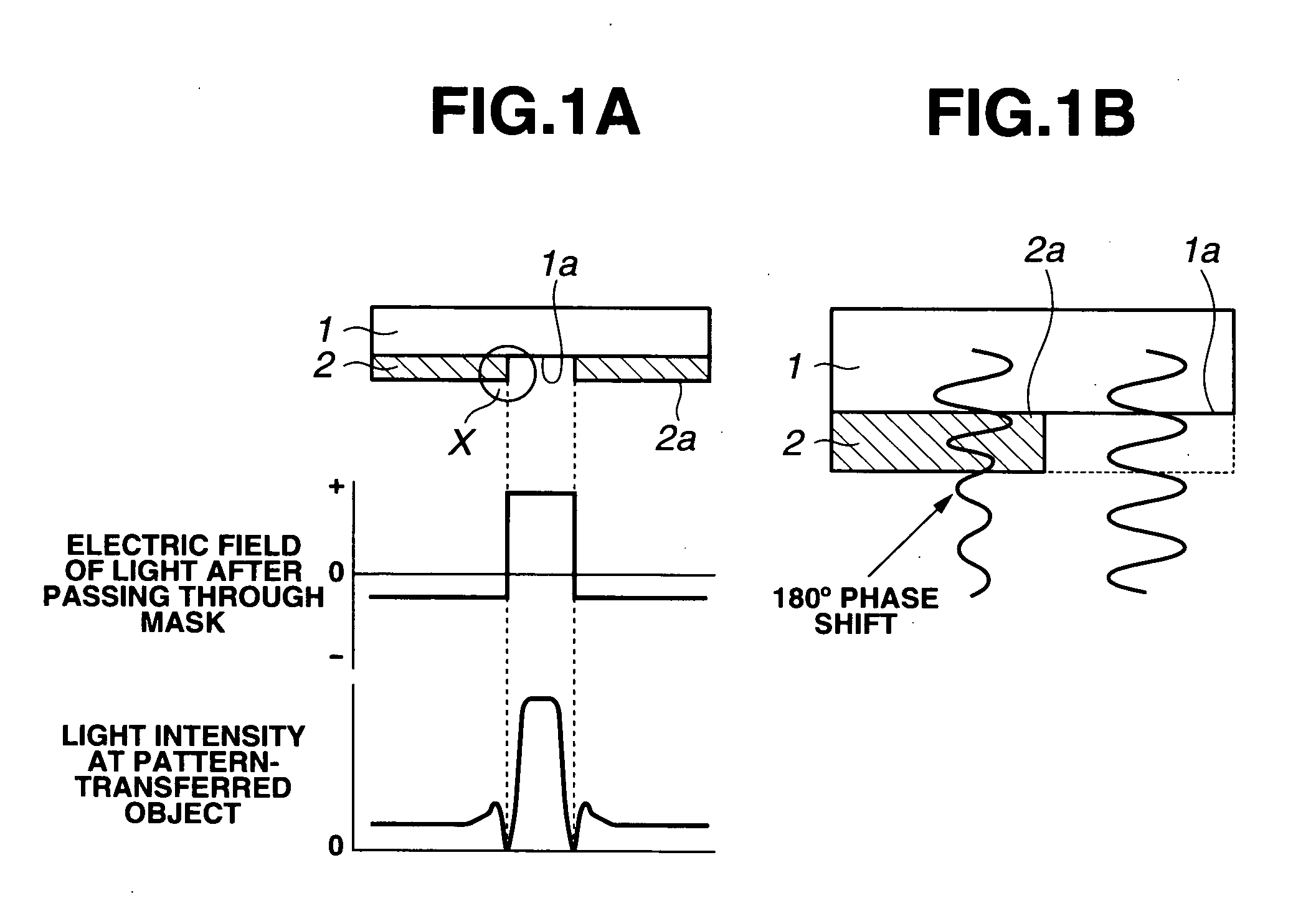

Halftone phase shift mask blank, halftone phase shift mask, and pattern transfer method

ActiveUS20050244722A1Easy to processImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhase shiftedPhase difference

In a halftone phase shift mask blank comprising a substrate, a light absorbing film, and a phase shifter film, the light absorbing film contains a metal element of Group 4A in a distribution having a higher metal element content in an upper region than in a lower region. Also provided is a halftone phase shift mask blank comprising a transparent substrate and a halftone phase shift film of a single layer or multiple layers having a preselected phase difference and transmittance, wherein at least one layer of the halftone phase shift film contains at least 90 atom % of silicon and a plurality of metal elements, typically Mo and Zr or Hf.

Owner:TOPPAN PHOTOMASK CO LTD +1

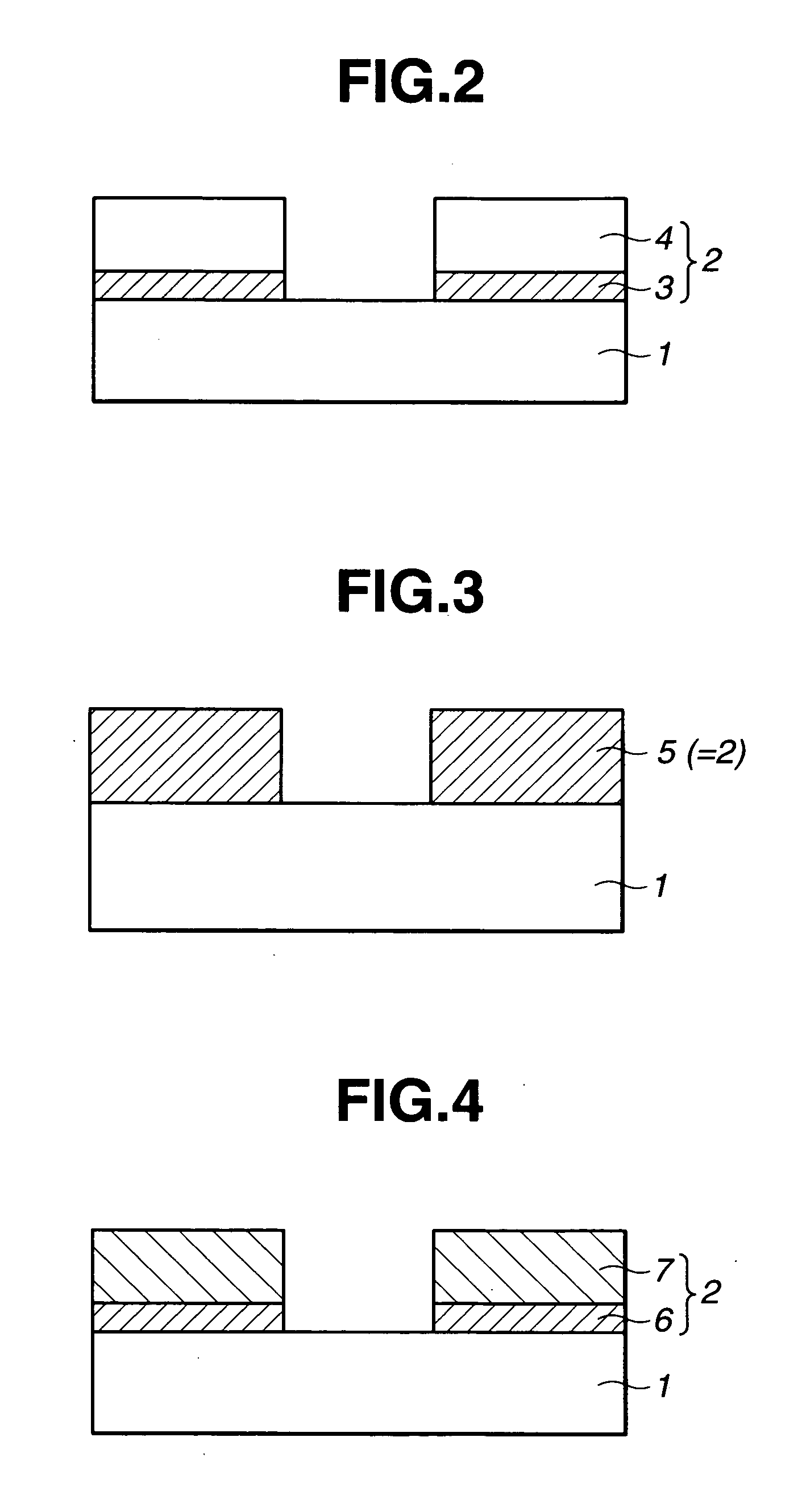

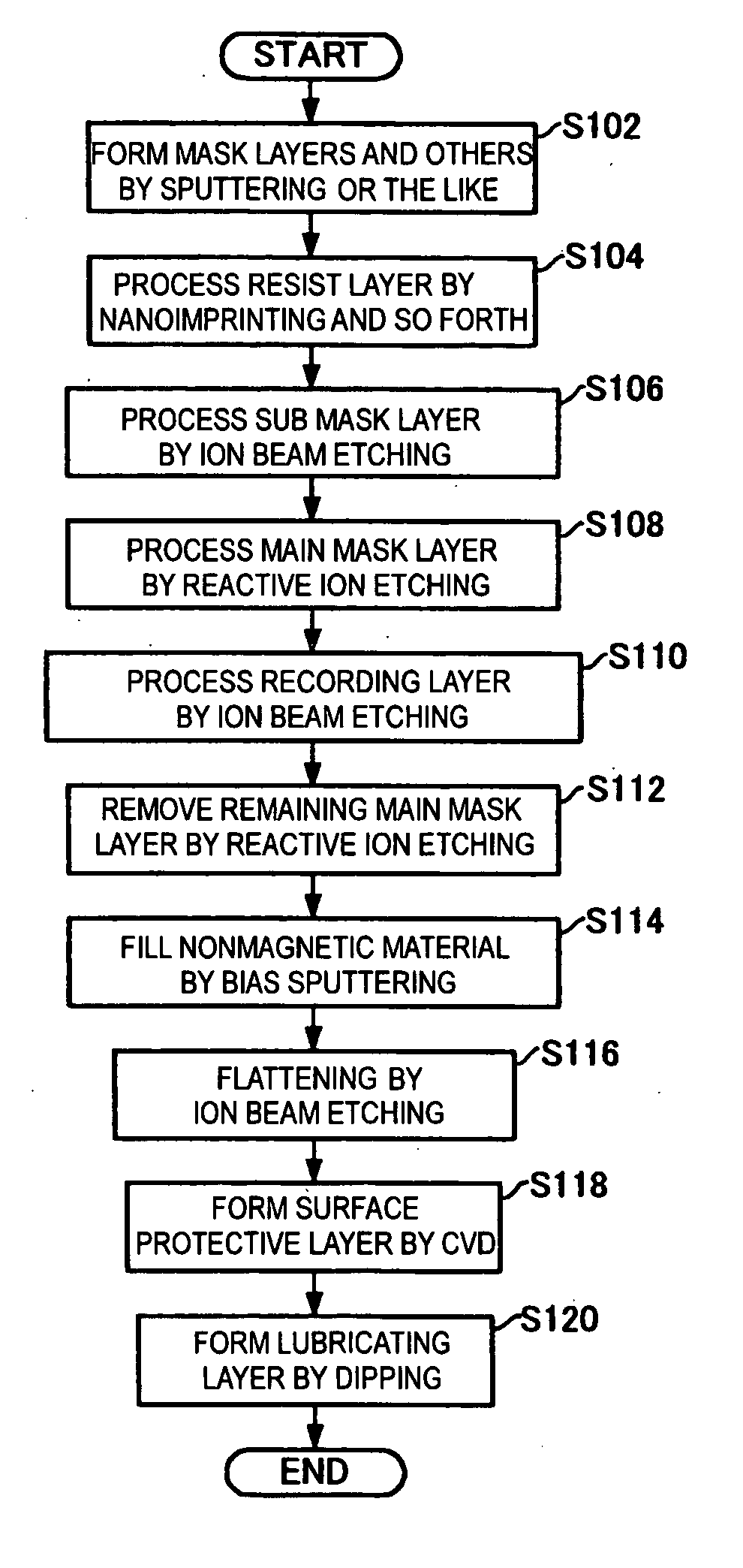

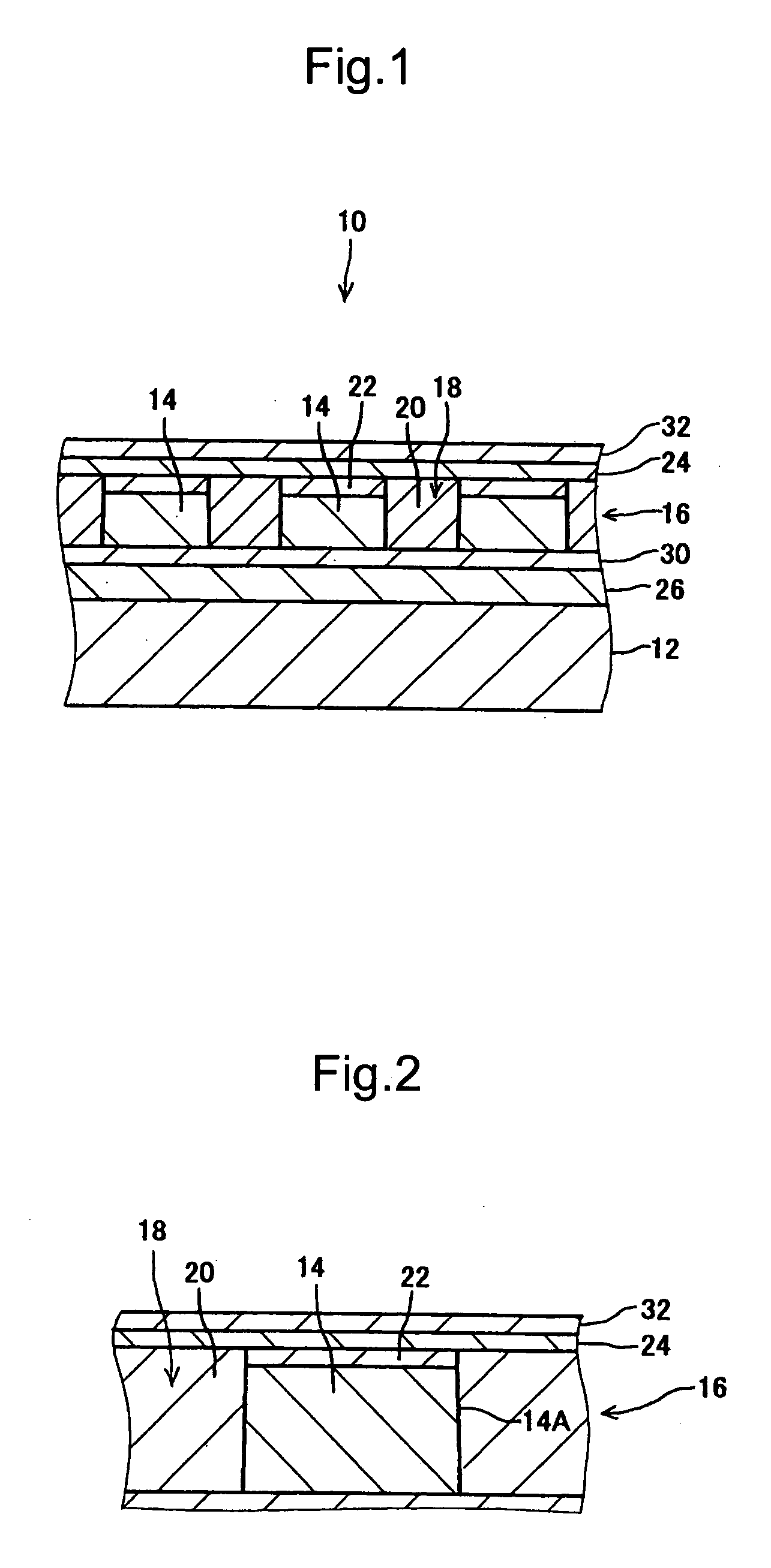

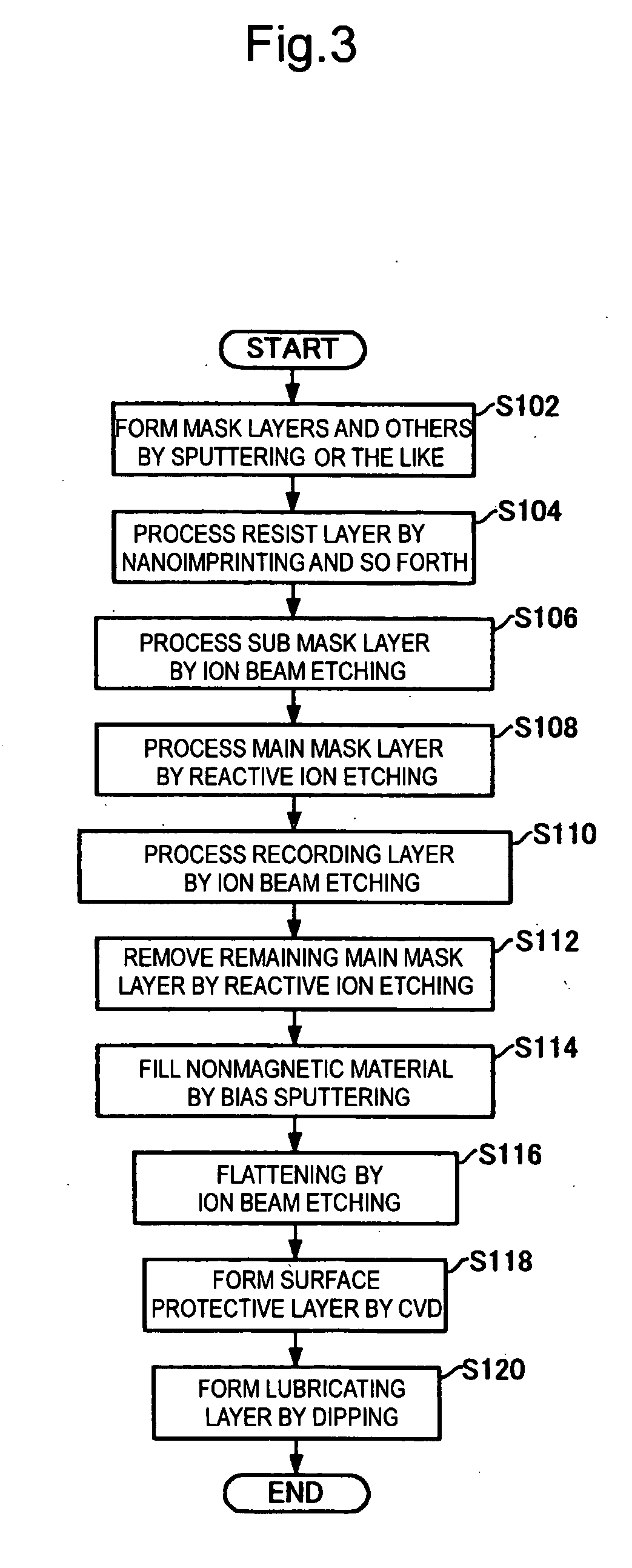

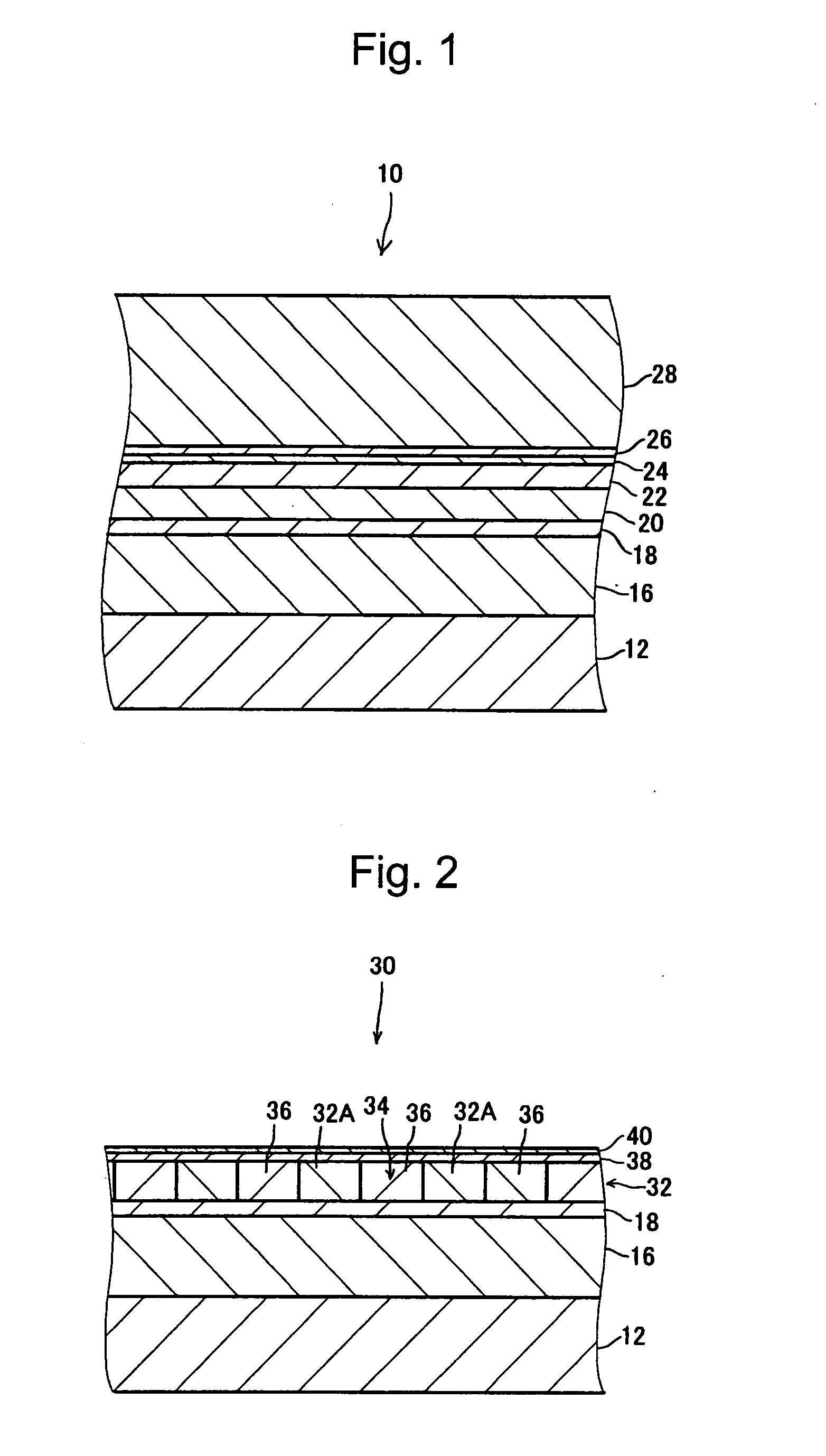

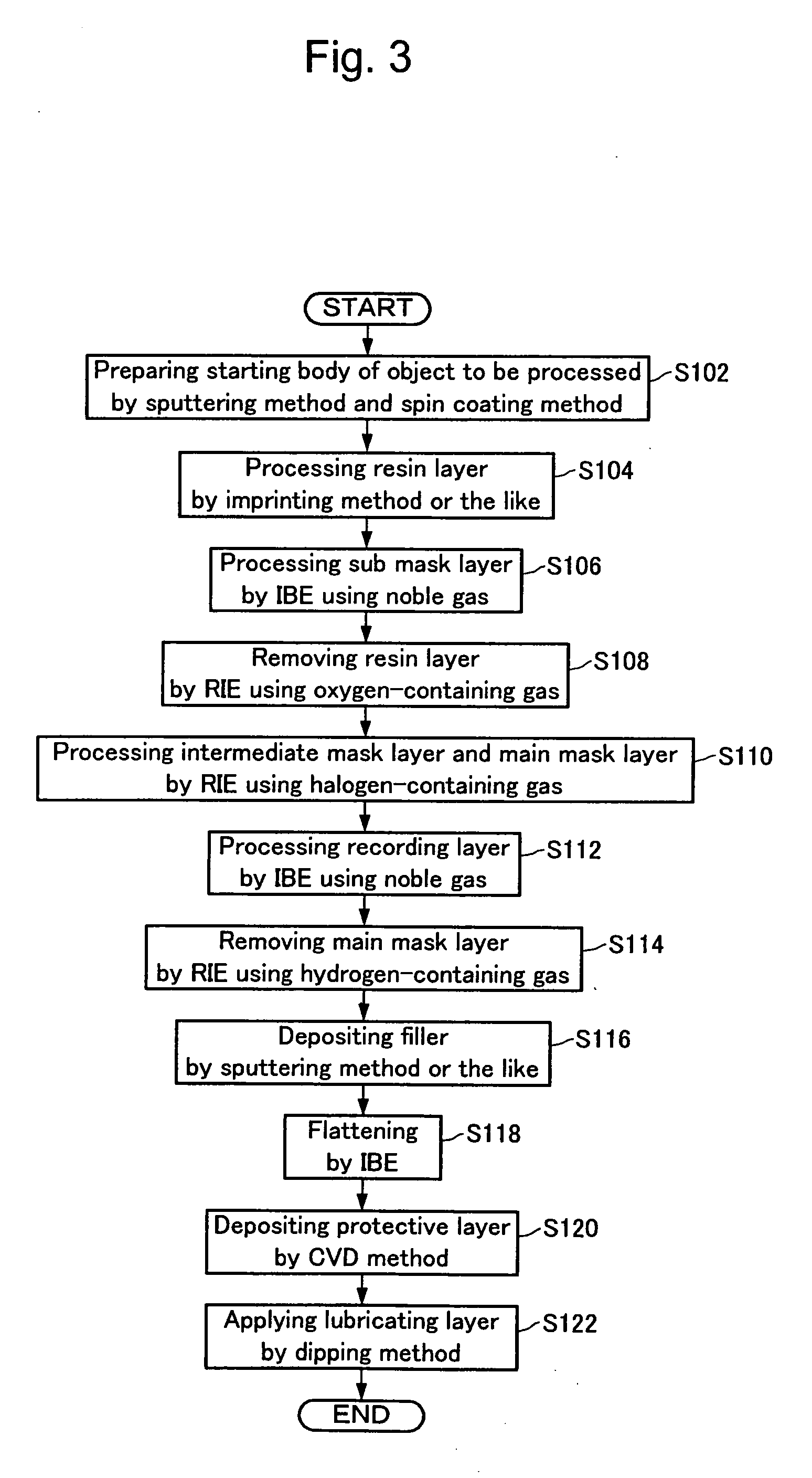

Method of dry etching, method of manufacturing magnetic recording medium, and magnetic recording medium

InactiveUS20050284842A1Excellent magnetic propertiesImprove accuracyBase layers for recording layersDecorative surface effectsReactive gasOptoelectronics

The recording layer (to-be-etched layer), a main mask layer, and a sub mask layer are formed in this order over a substrate, and the sub mask layer is processed into a predetermined concavo-convex pattern. Next, parts of the main mask layer under the concave portions are removed by reactive ion etching using oxygen or ozone as the reactive gas. Parts of the recording layer under the concave portions are also removed by dry etching, whereby the recording layer is shaped into the concavo-convex pattern. The main mask layer is chiefly made of carbon. The sub mask layer is made of a material having an etching rate lower than that of carbon with respect to the reactive ion etching in the step of processing the main mask layer.

Owner:TDK CORPARATION

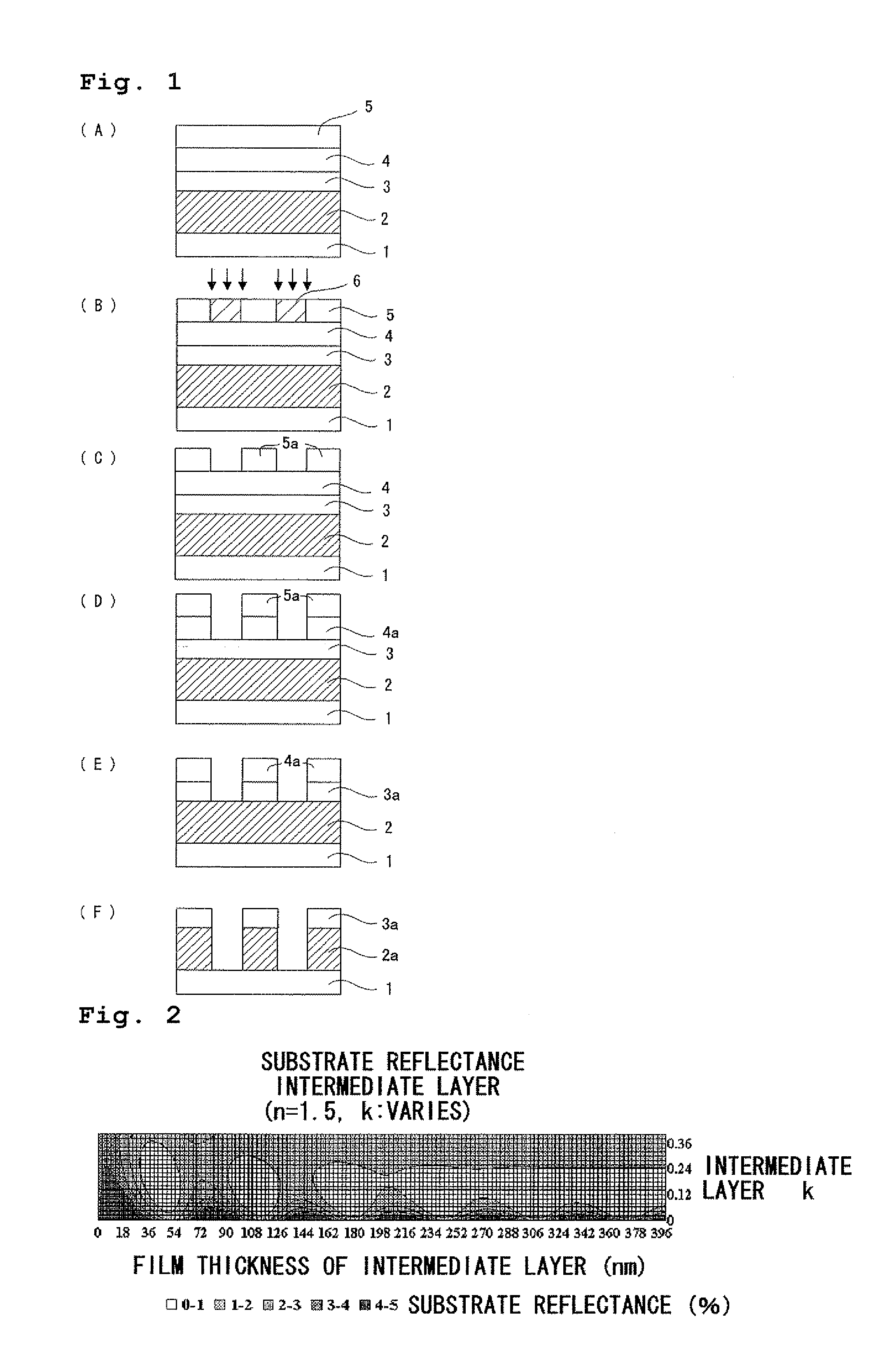

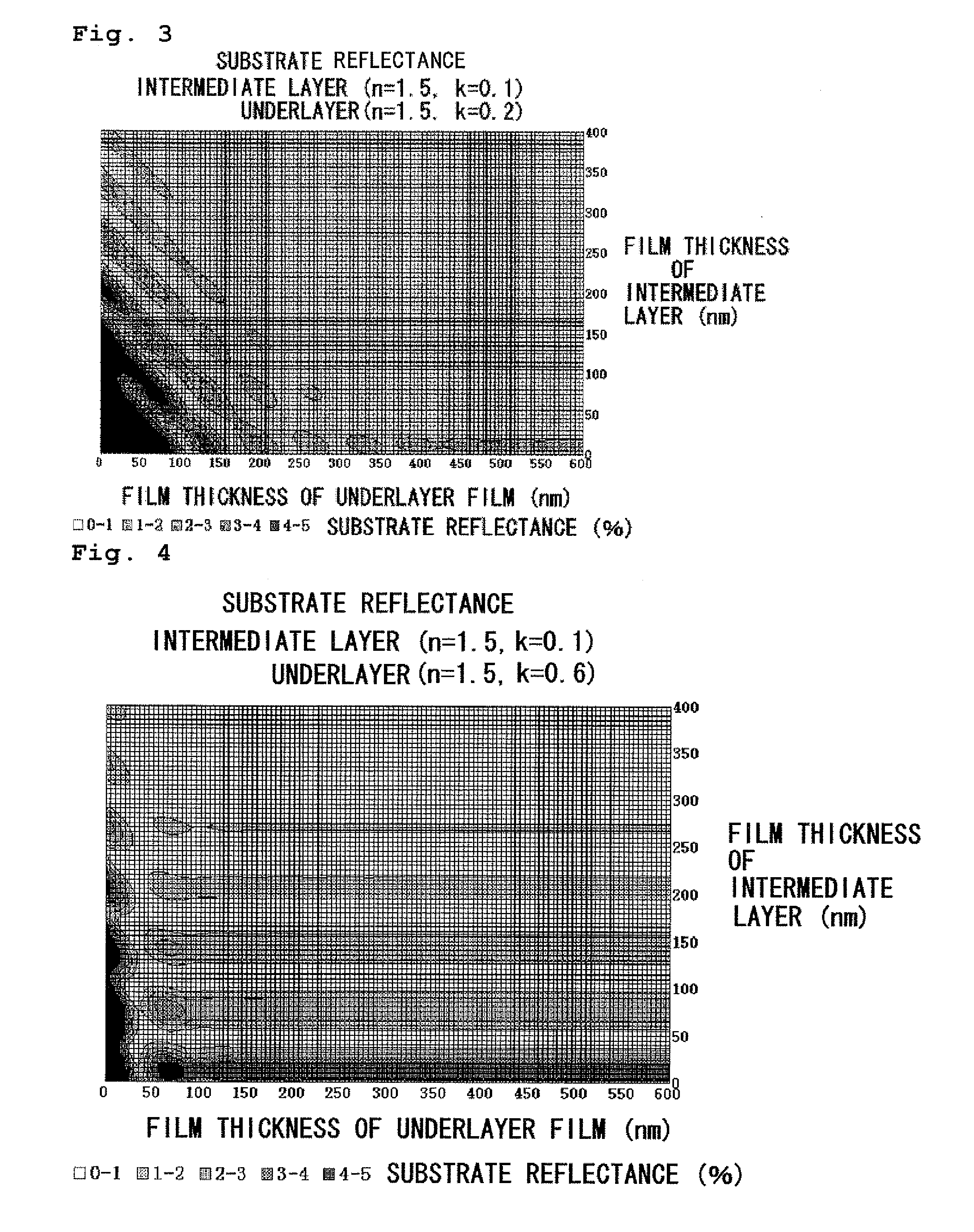

Resist underlayer film composition and patterning process using the same

ActiveUS20120184103A1High precisionExcellent propertyPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistReflectivity

There is disclosed a resist underlayer film composition, wherein the composition contains a polymer obtained by condensation of, at least, one or more compounds represented by the following general formulae (1-1) and / or (1-2), and one or more kinds of compounds, represented by the following general formulae (2-1) and / or (2-2), and / or equivalent bodies thereof. There can be provided an underlayer film composition, especially for a trilayer resist process, that can form an underlayer film having reduced reflectance, (namely, an underlayer film having optimum n-value and k-value as an antireflective film), excellent filling-up properties, high pattern-antibending properties, and not causing line fall or wiggling after etching especially in a high aspect line that is thinner than 60 nm, and a patterning process using the same.

Owner:SHIN ETSU CHEM IND CO LTD

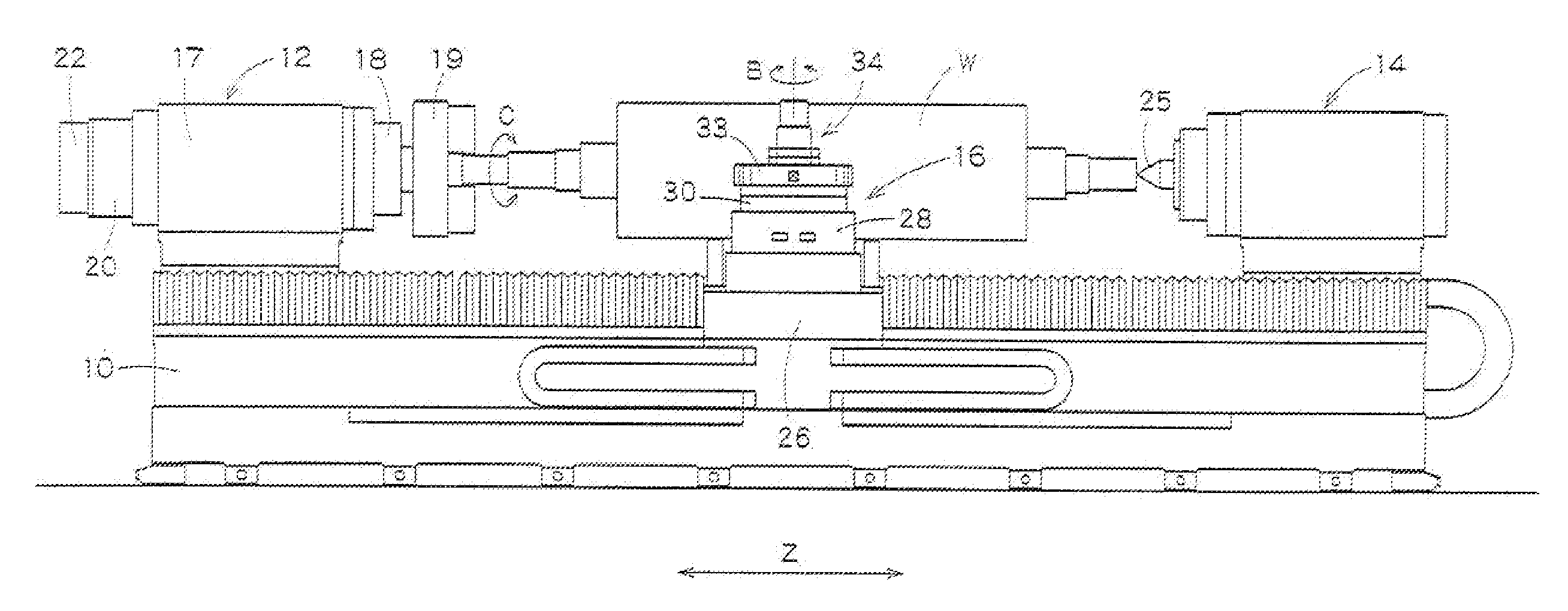

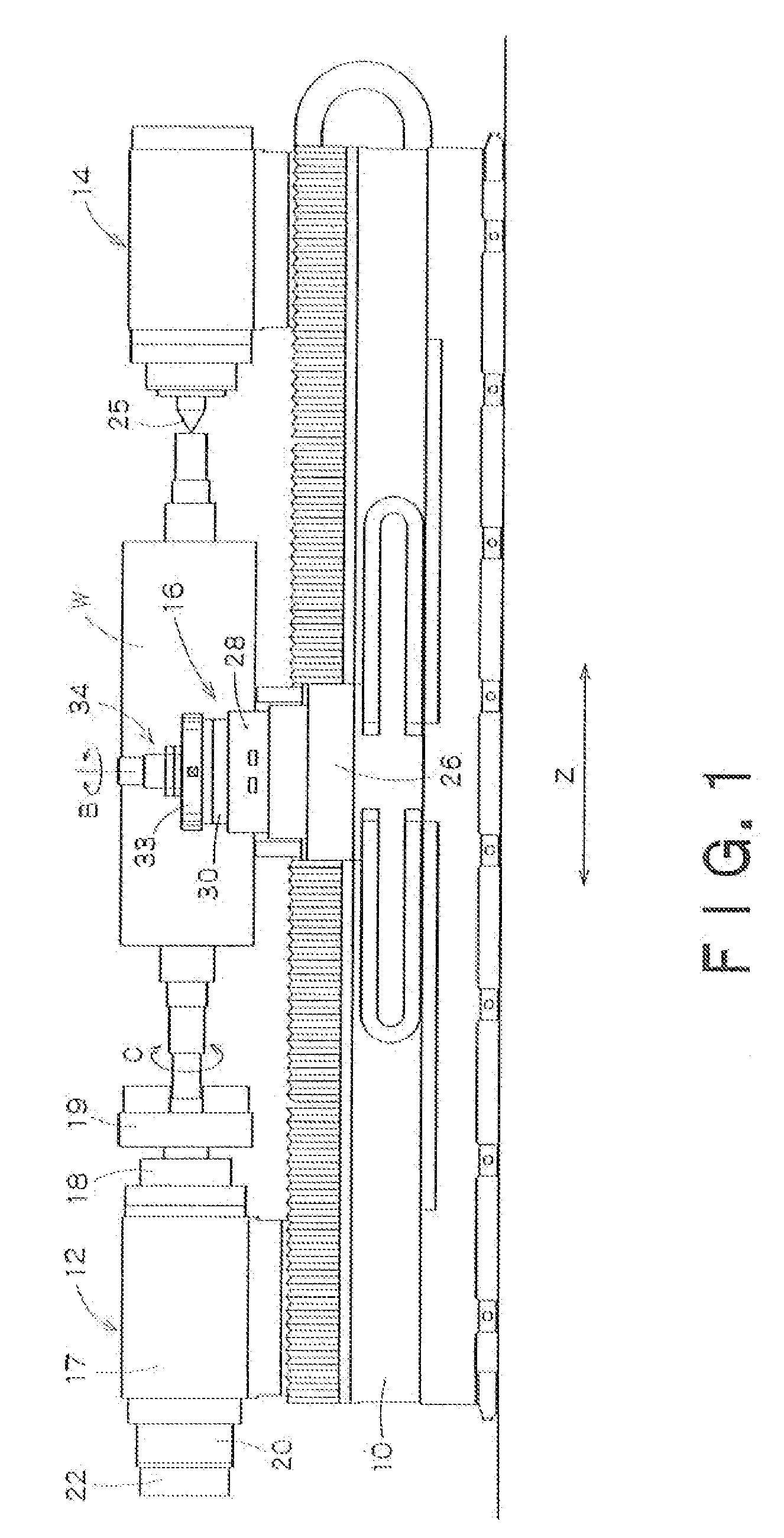

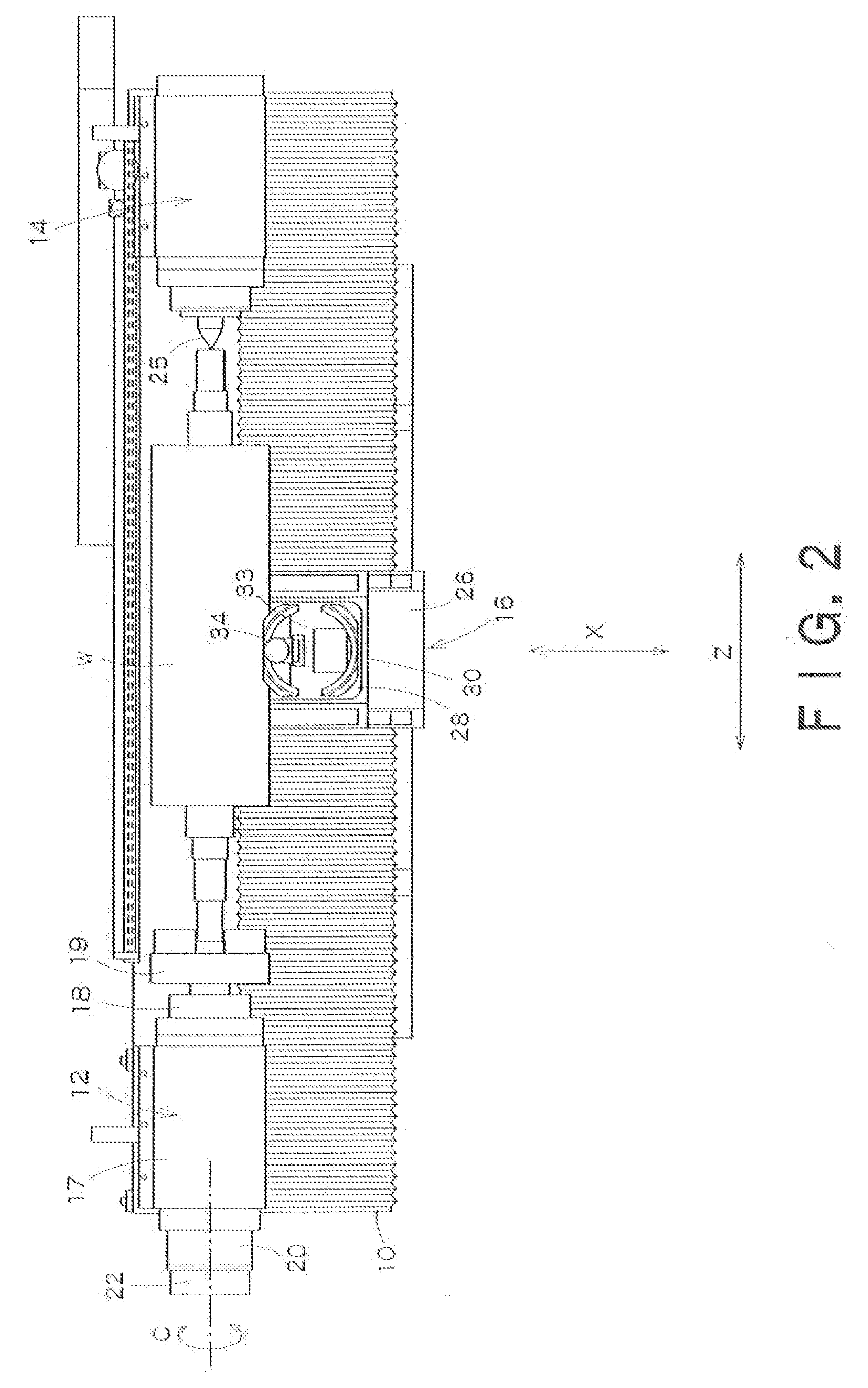

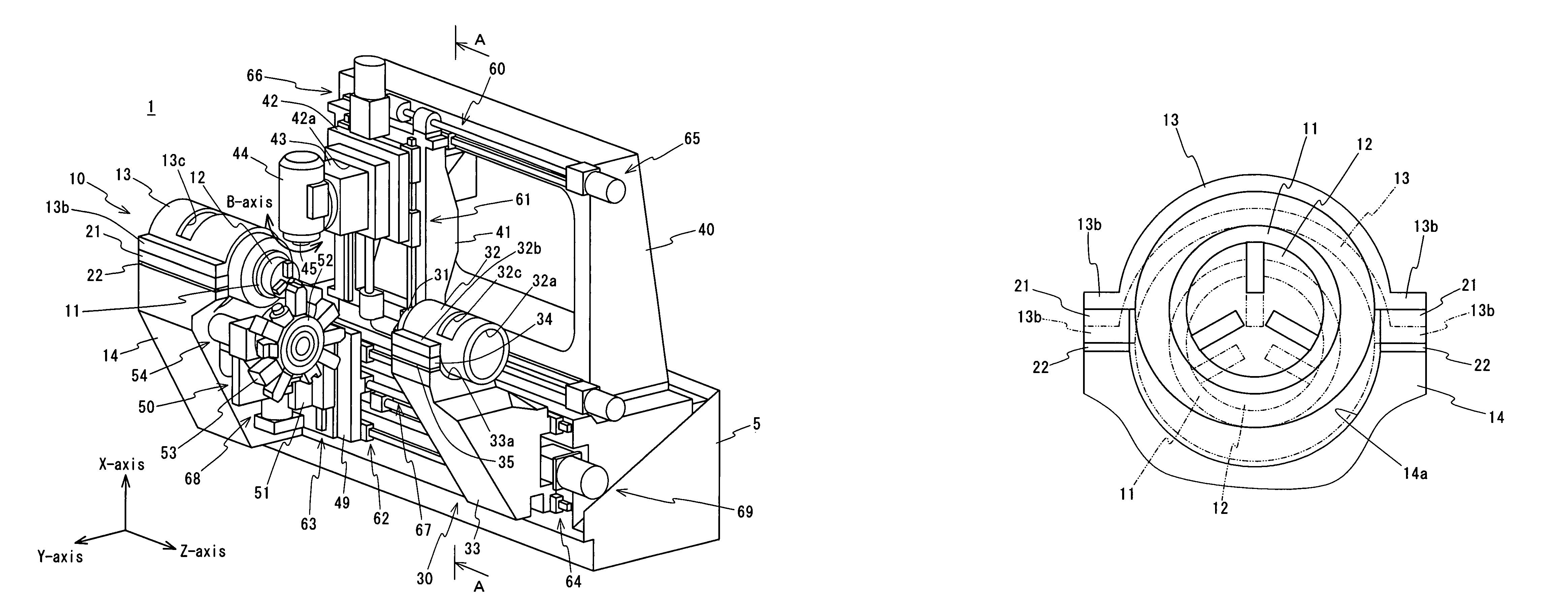

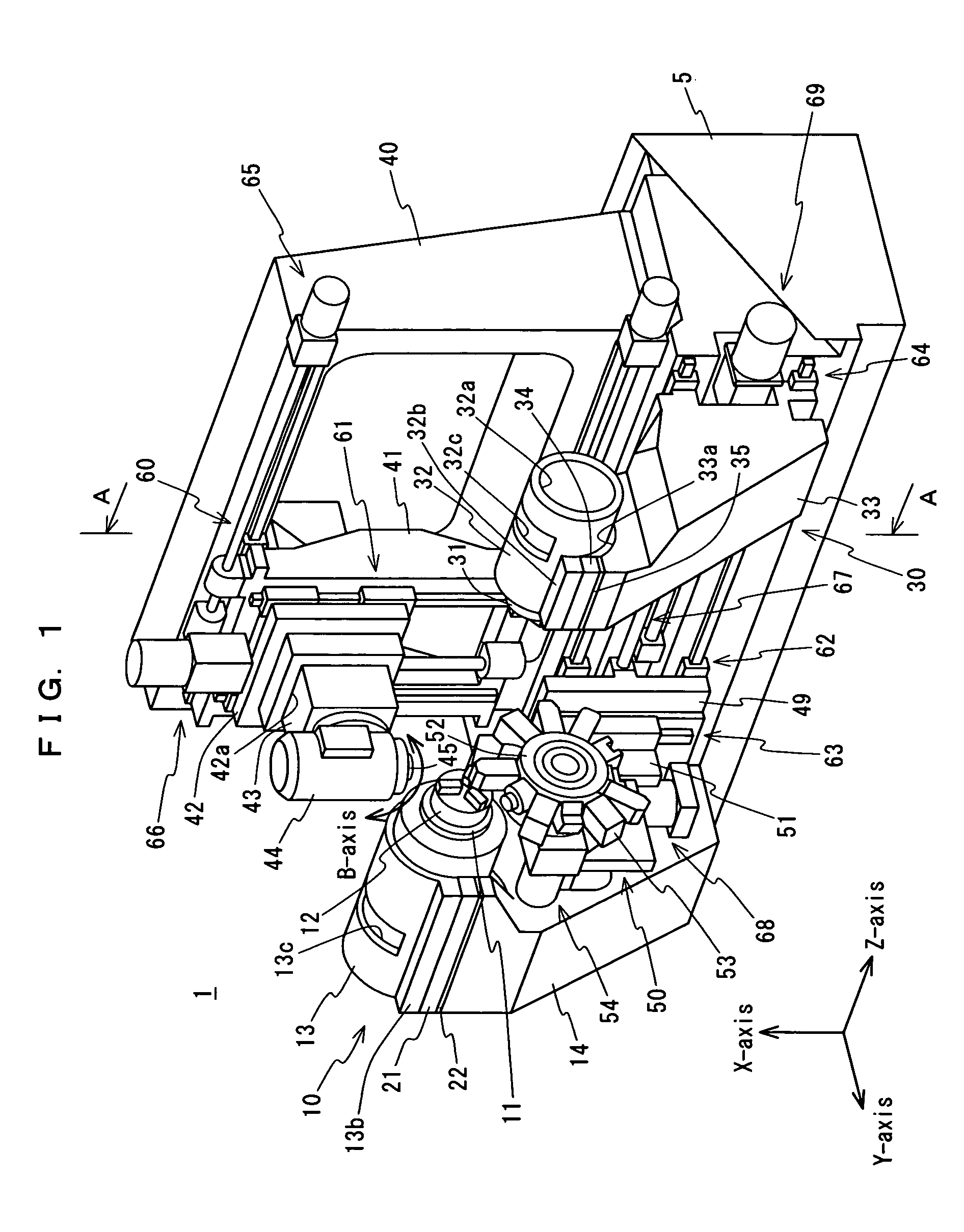

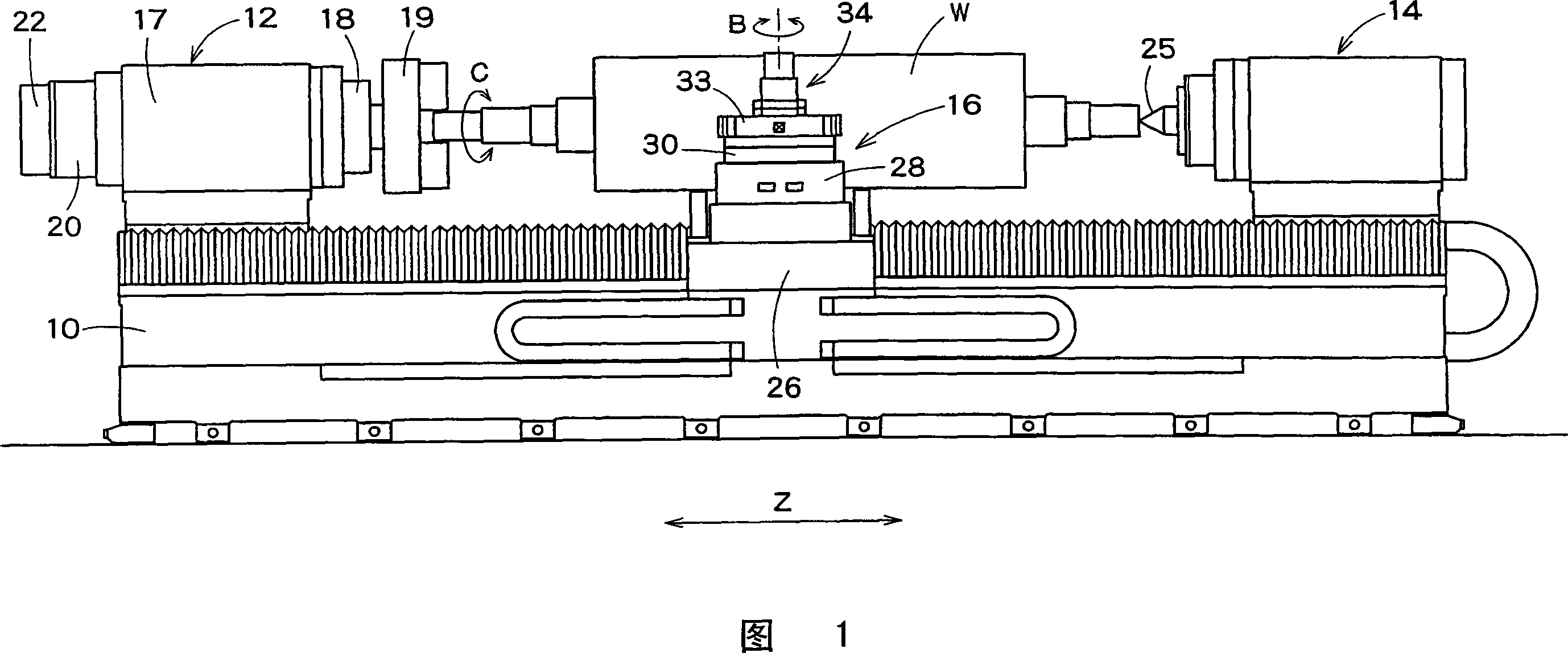

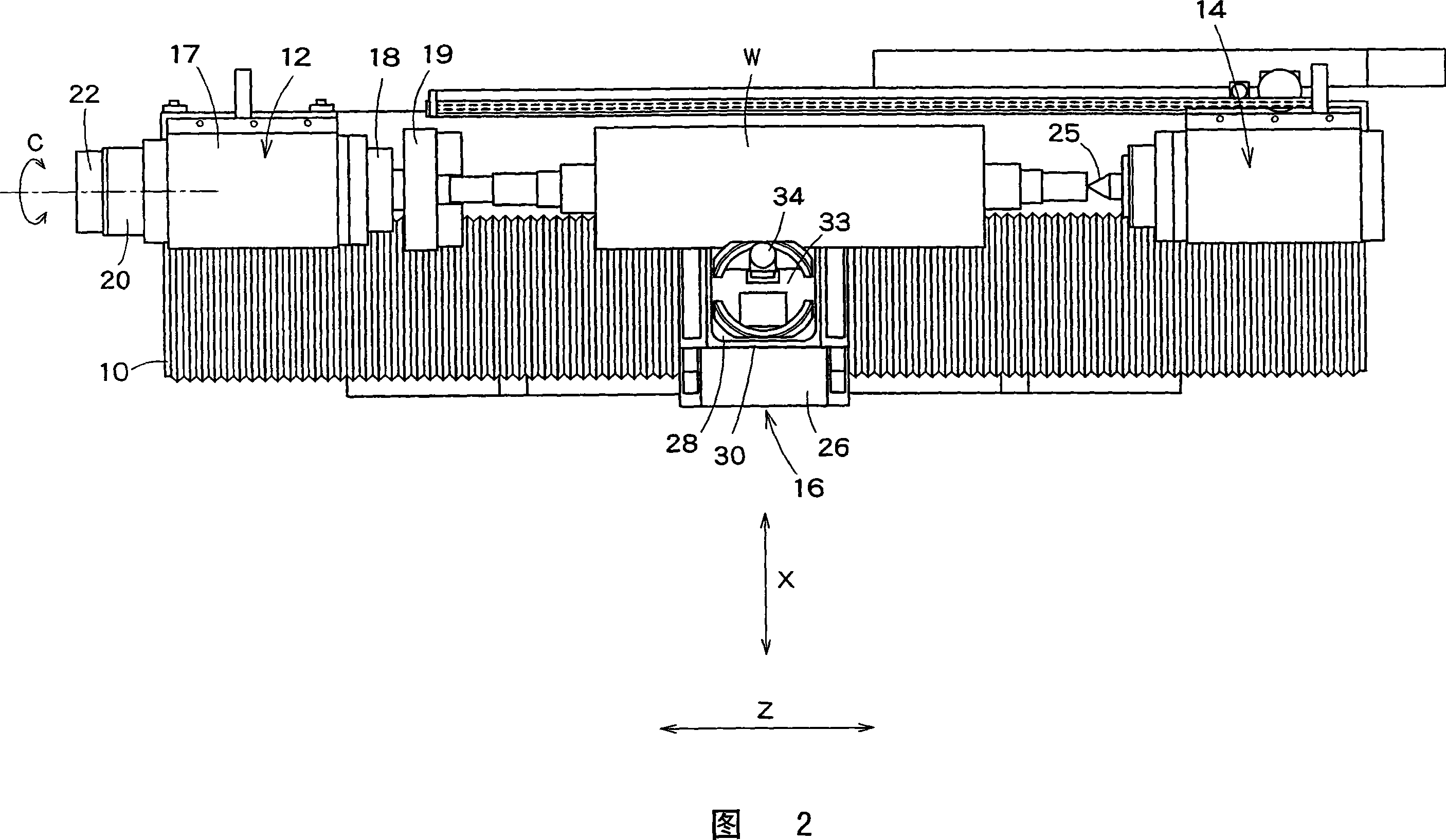

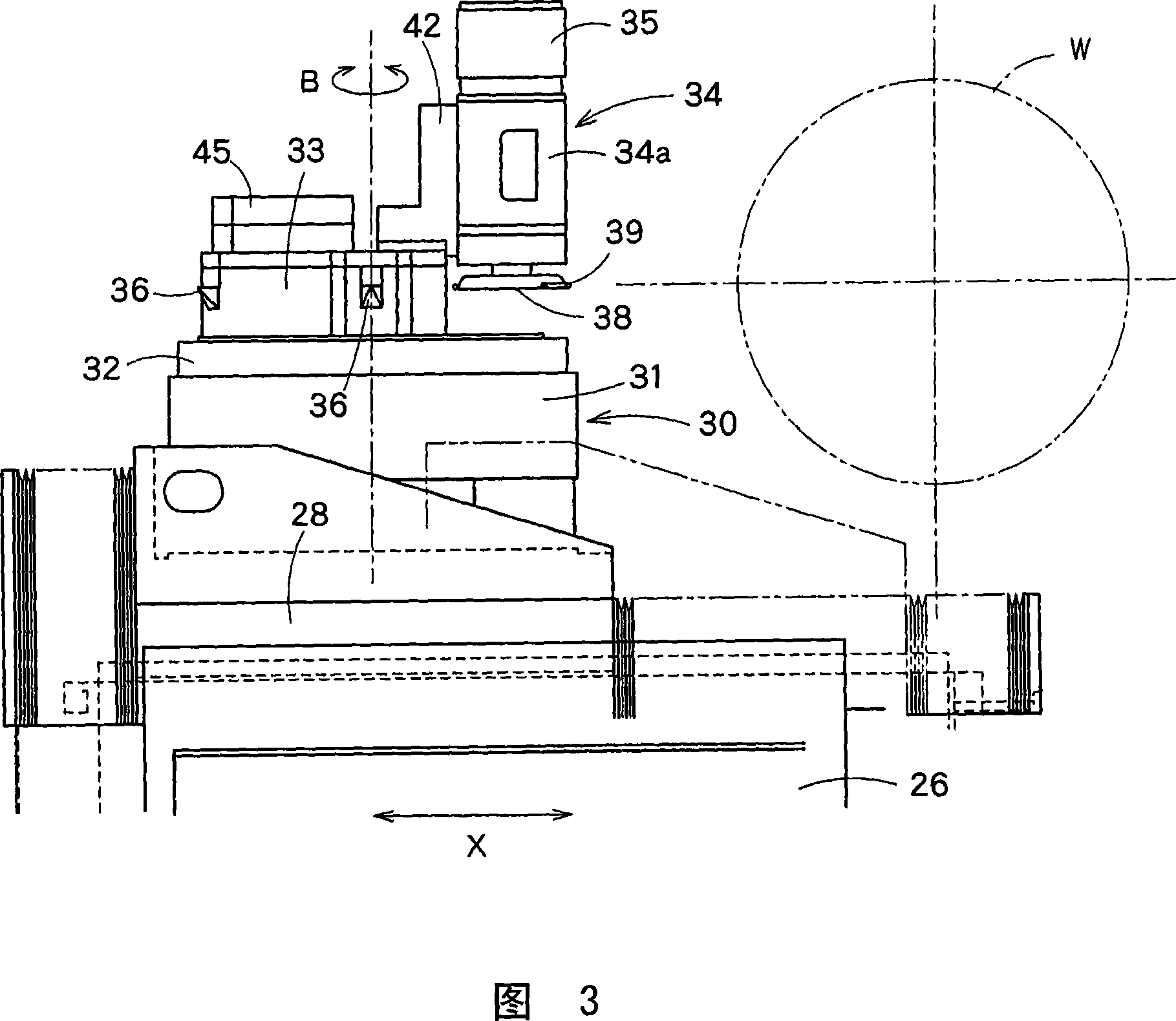

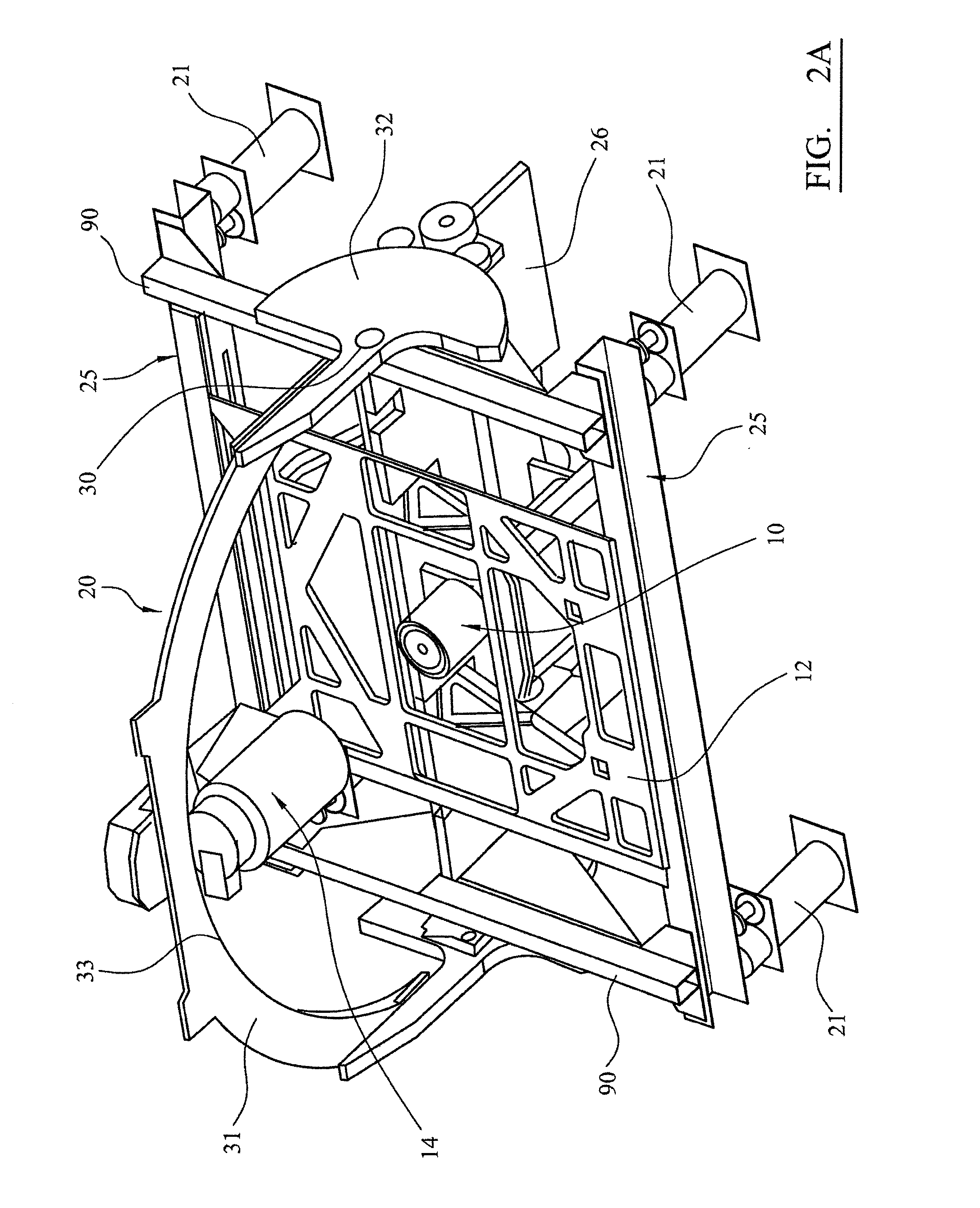

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

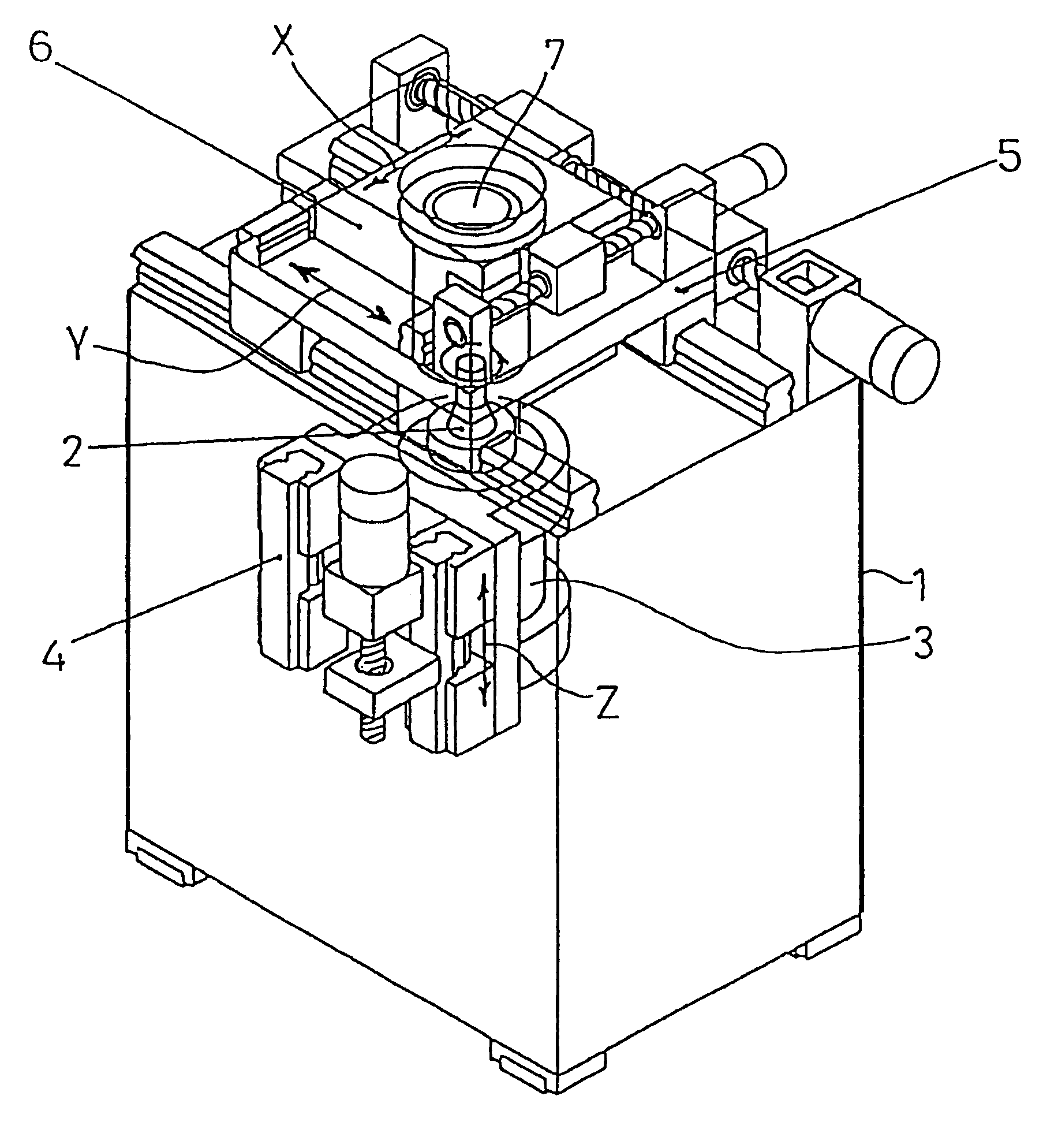

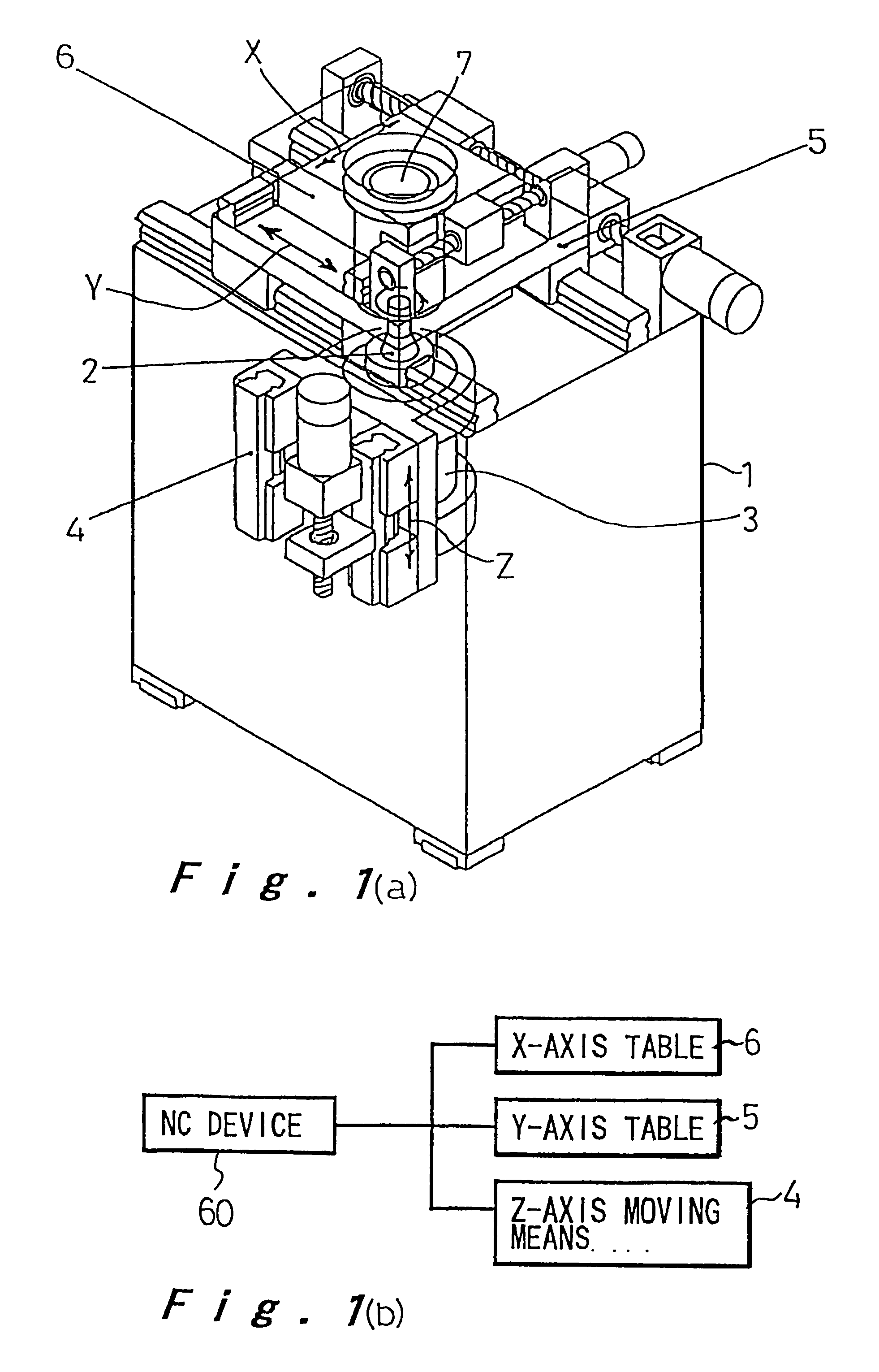

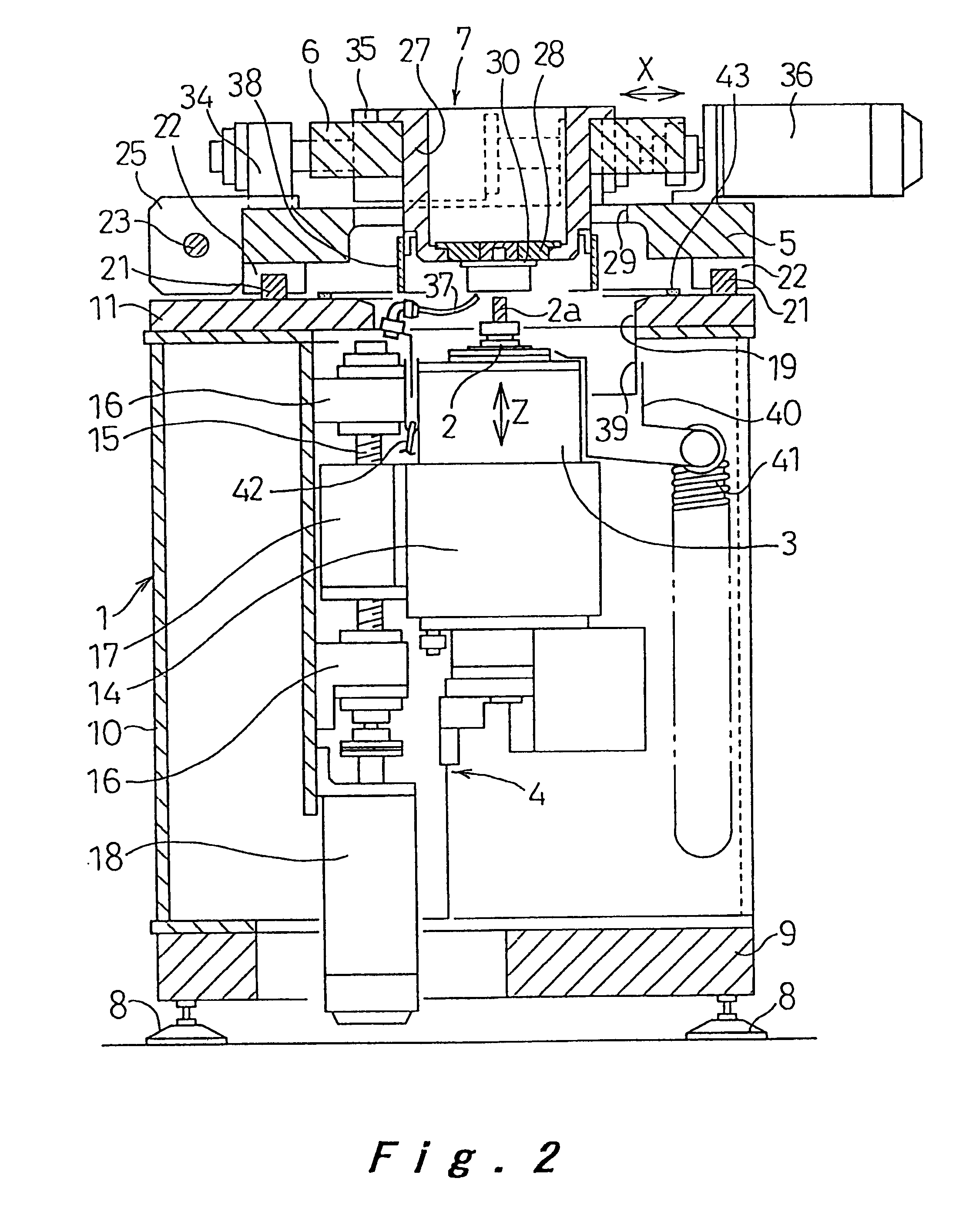

Machine tool

InactiveUS6220799B1Compact structureInhibit bad effectsPlaning/slotting machinesMilling machinesEngineeringMachine tool

A machine tool of small scale, light weight, and low cost, yet accomplishing a high degree of precision in machining. A spindle (2) is encased in a body frame (1) and disposed preferably in such a manner that the spindle (2) is movable along an axial center thereof or Z-axis direction by means of a Z-axis moving means (4). Either Y-axis table (5) or an X-axis table (6), at least being capable of moving along X-axis or Y-axis direction, or both is provided at one end of the spindle (2) on one side of the body frame (1) and arranged to be vertical with respect to the axial center of the spindle (2).

Owner:PANASONIC CORP

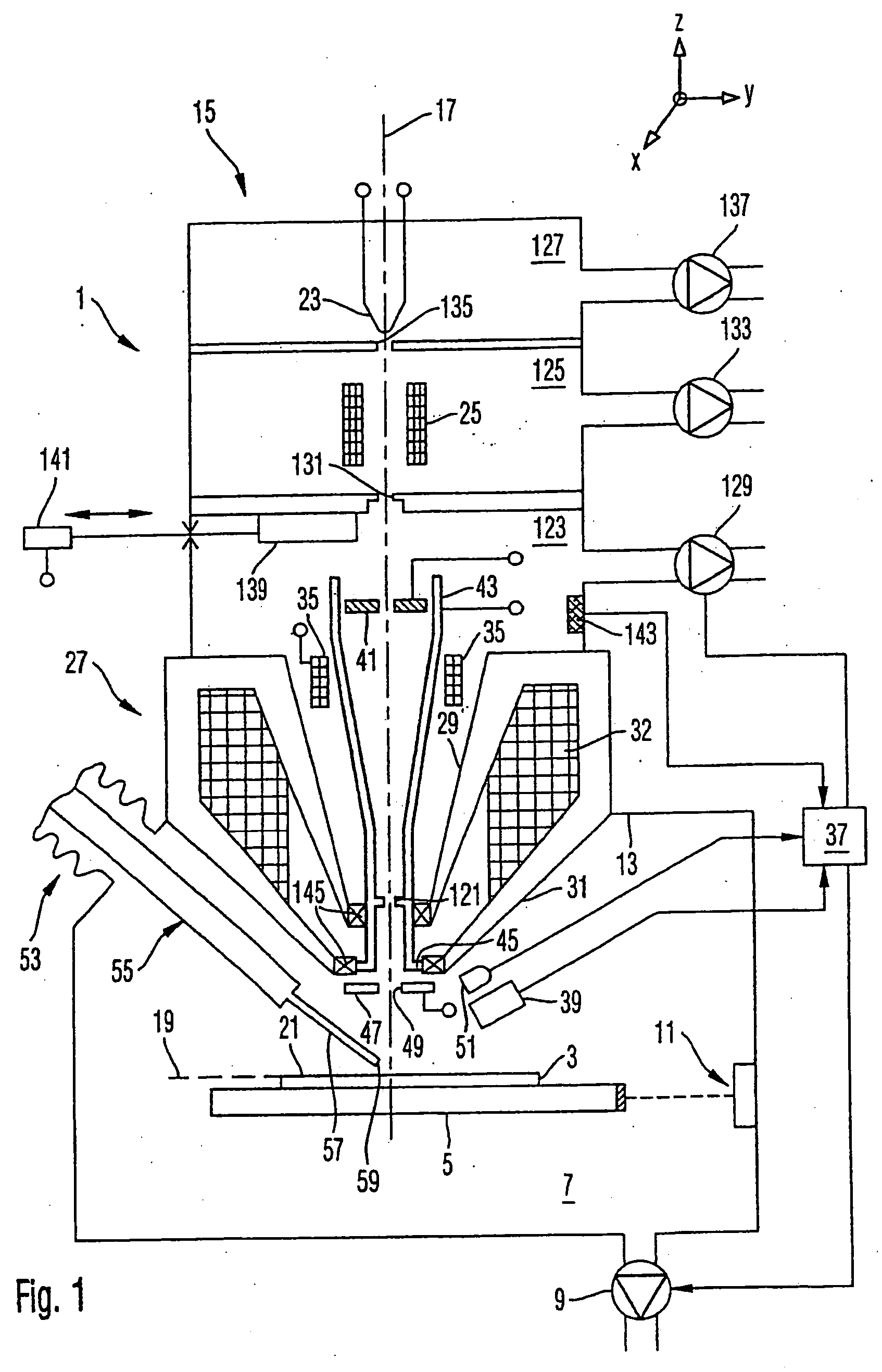

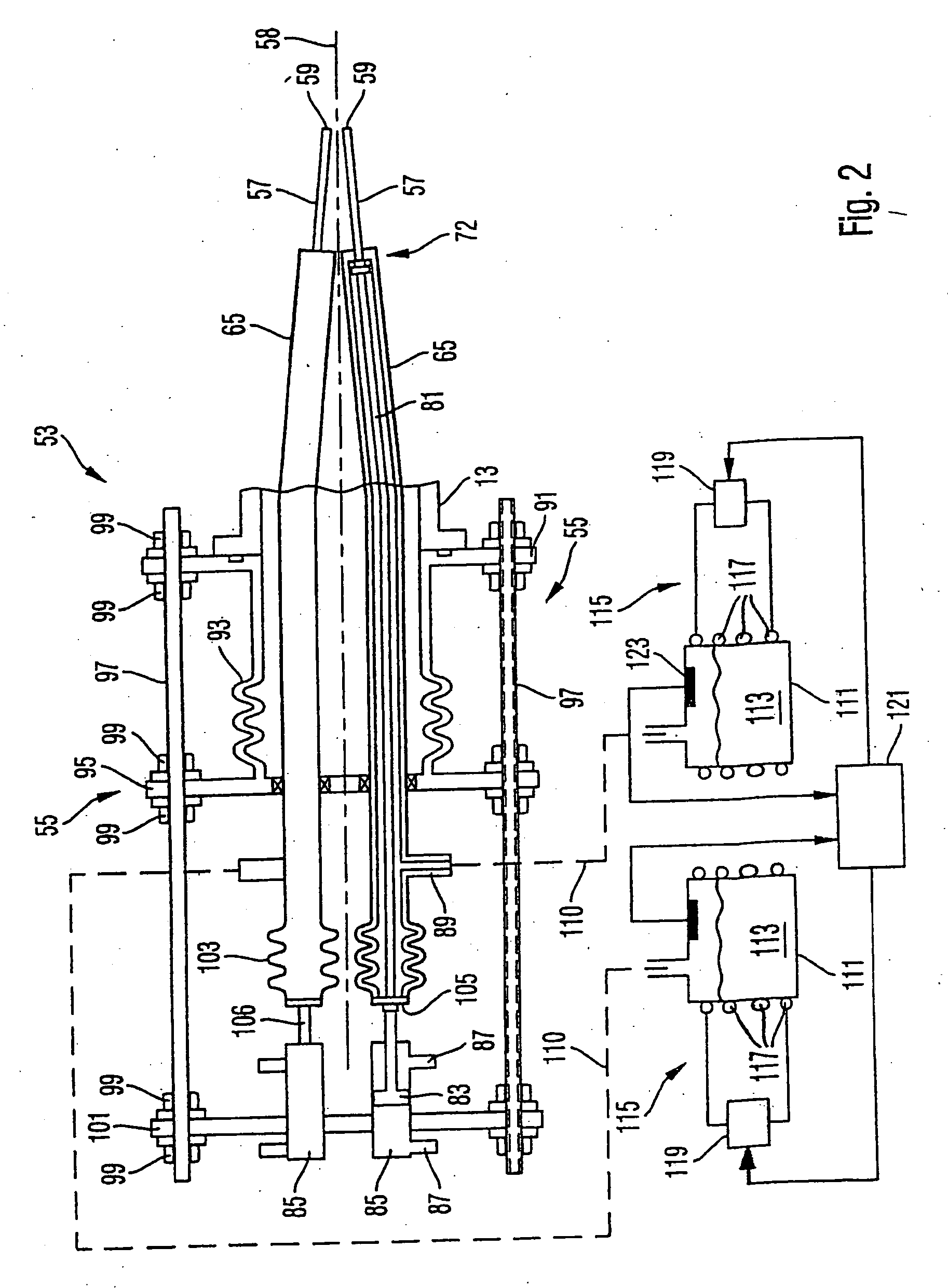

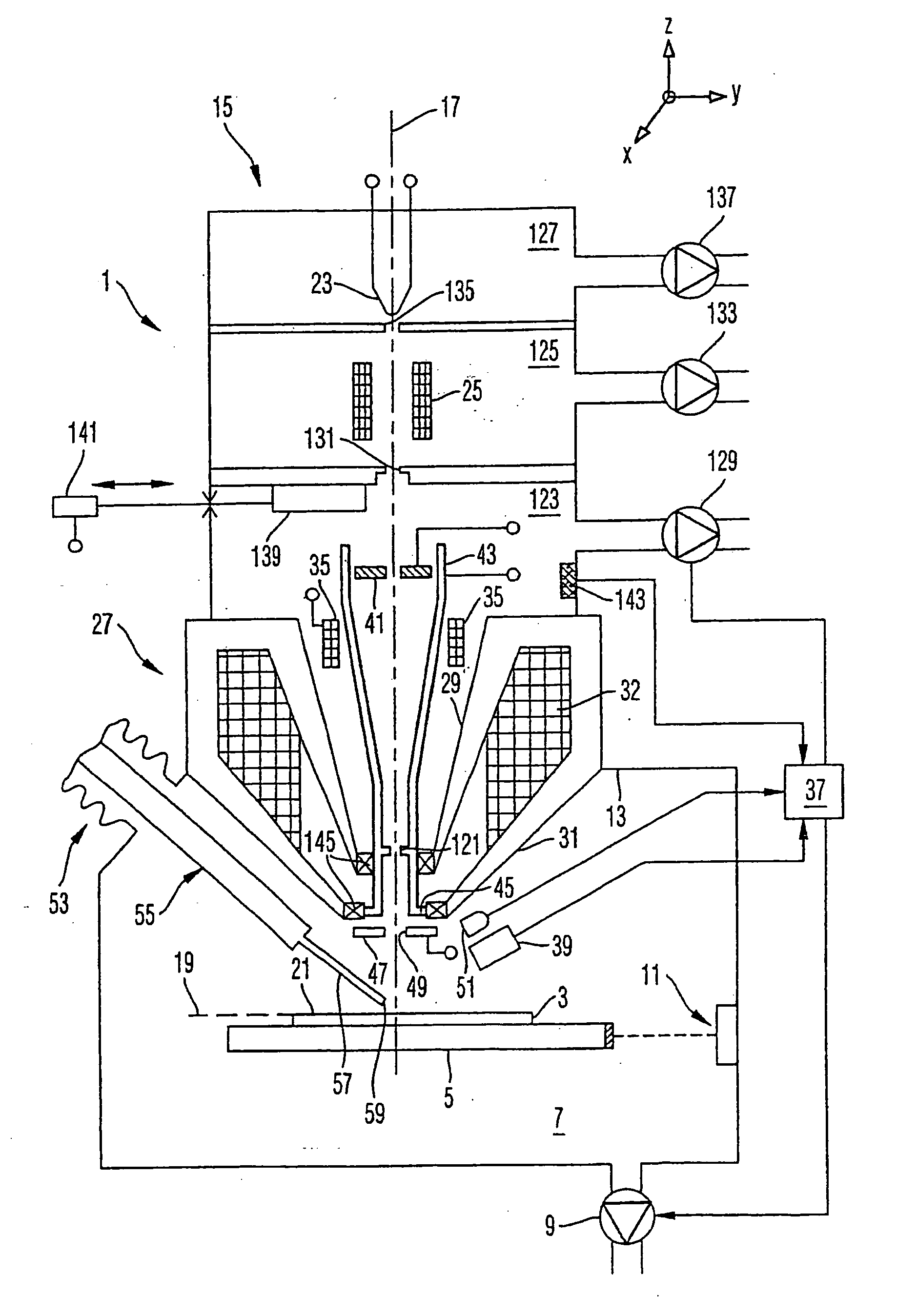

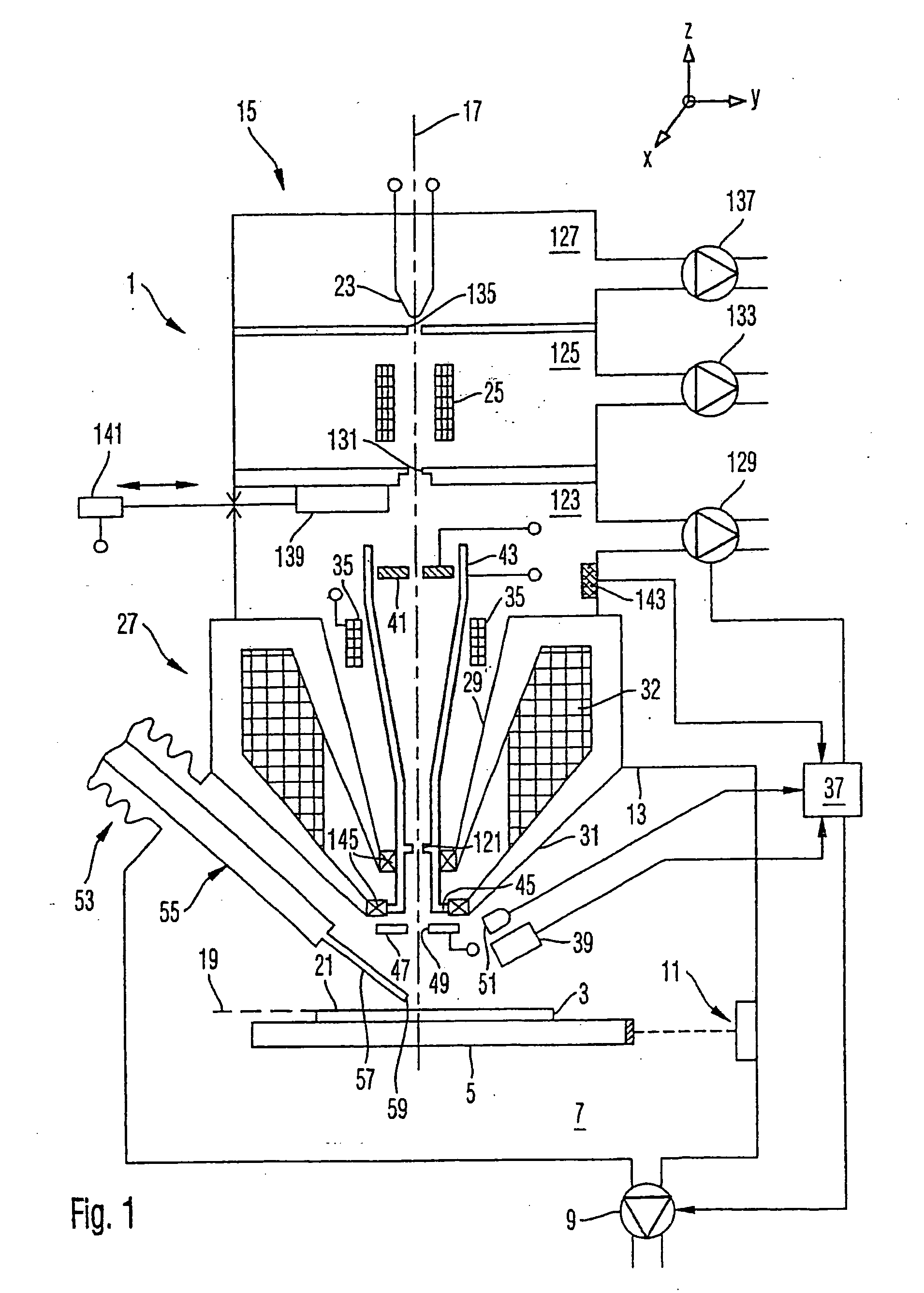

Material processing system and method

InactiveUS20060284090A1Improve accuracyHigh precision machiningMaterial analysis using wave/particle radiationElectric discharge tubesReactive gasElectron microscope

Owner:CARL ZEISS SMT GMBH +1

Material processing system and method

InactiveUS20050103272A1Increase air pressureIncrease vacuumElectric discharge tubesChemical vapor deposition coatingReactive gasElectron microscope

A material processing system for processing a work piece is provided. The material processing is effected by supplying a reactive gas and energetic radiation for activation of the reactive gas to a surrounding of a location of the work piece to be processed. The radiation is preferably provided by an electron microscope. An objective lens of the electron microscope is preferably disposed between a detector of the electron microscope and the work piece. A gas supply arrangement of the material processing system comprises a valve disposed spaced apart from the processing location, a gas volume between the valve and a location of emergence of the reaction gas being small. The gas supply arrangement further comprises a temperature-adjusted, especially cooled reservoir for accommodating a starting material for the reactive gas.

Owner:CARL ZEISS SMT GMBH +1

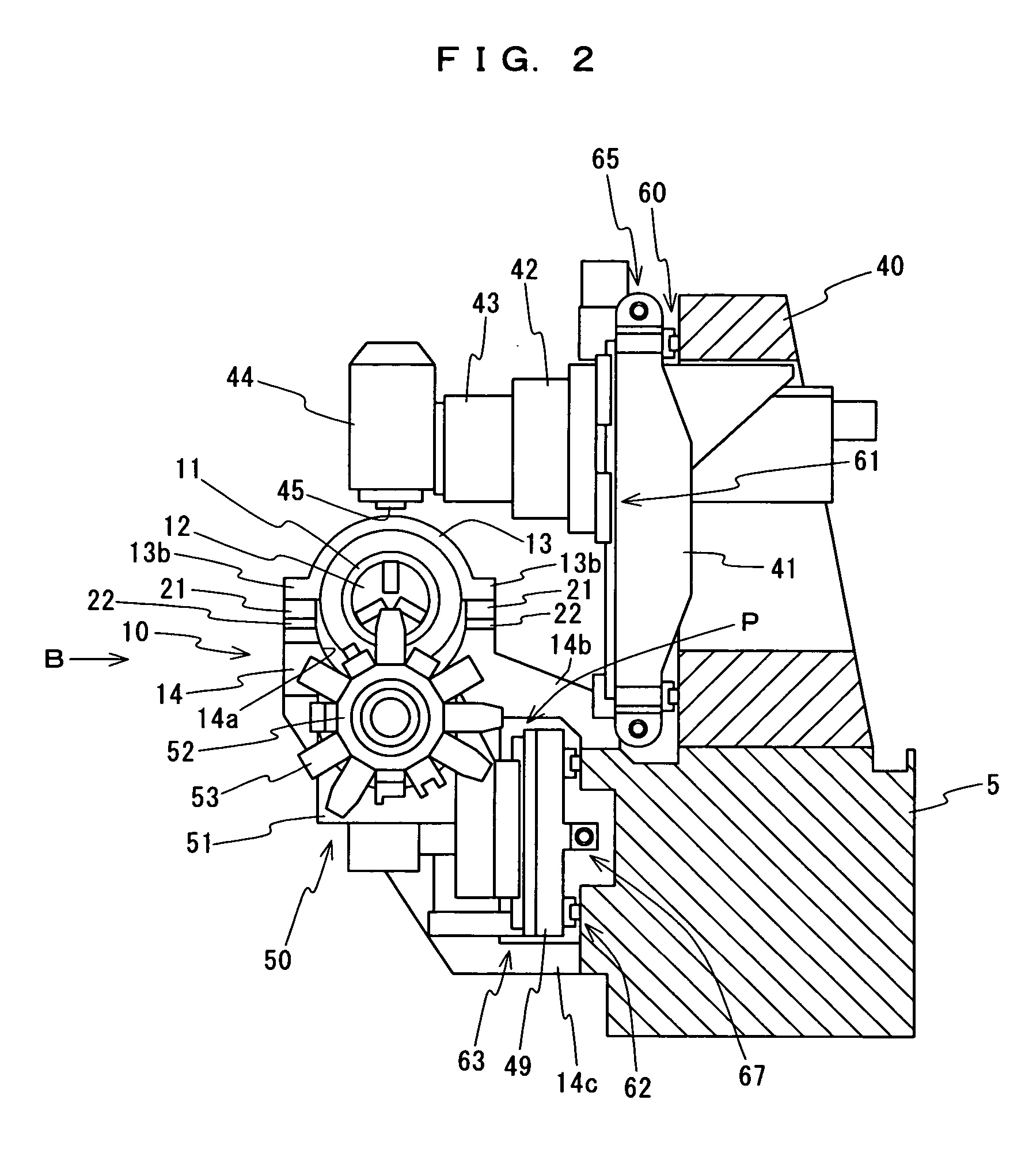

Lathe

InactiveUS7039992B2Improve accuracyHigh precision machiningAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI CO LTD

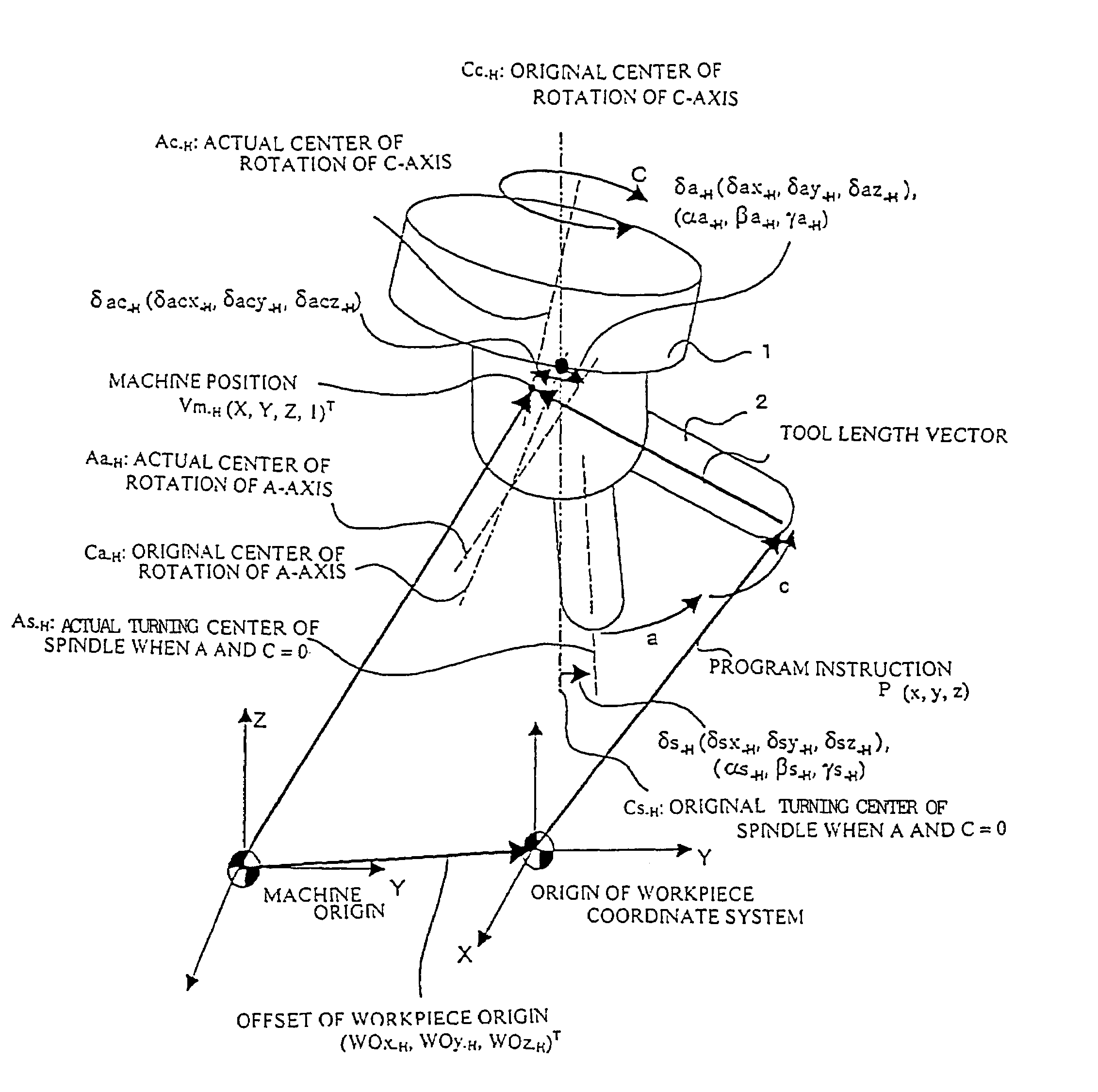

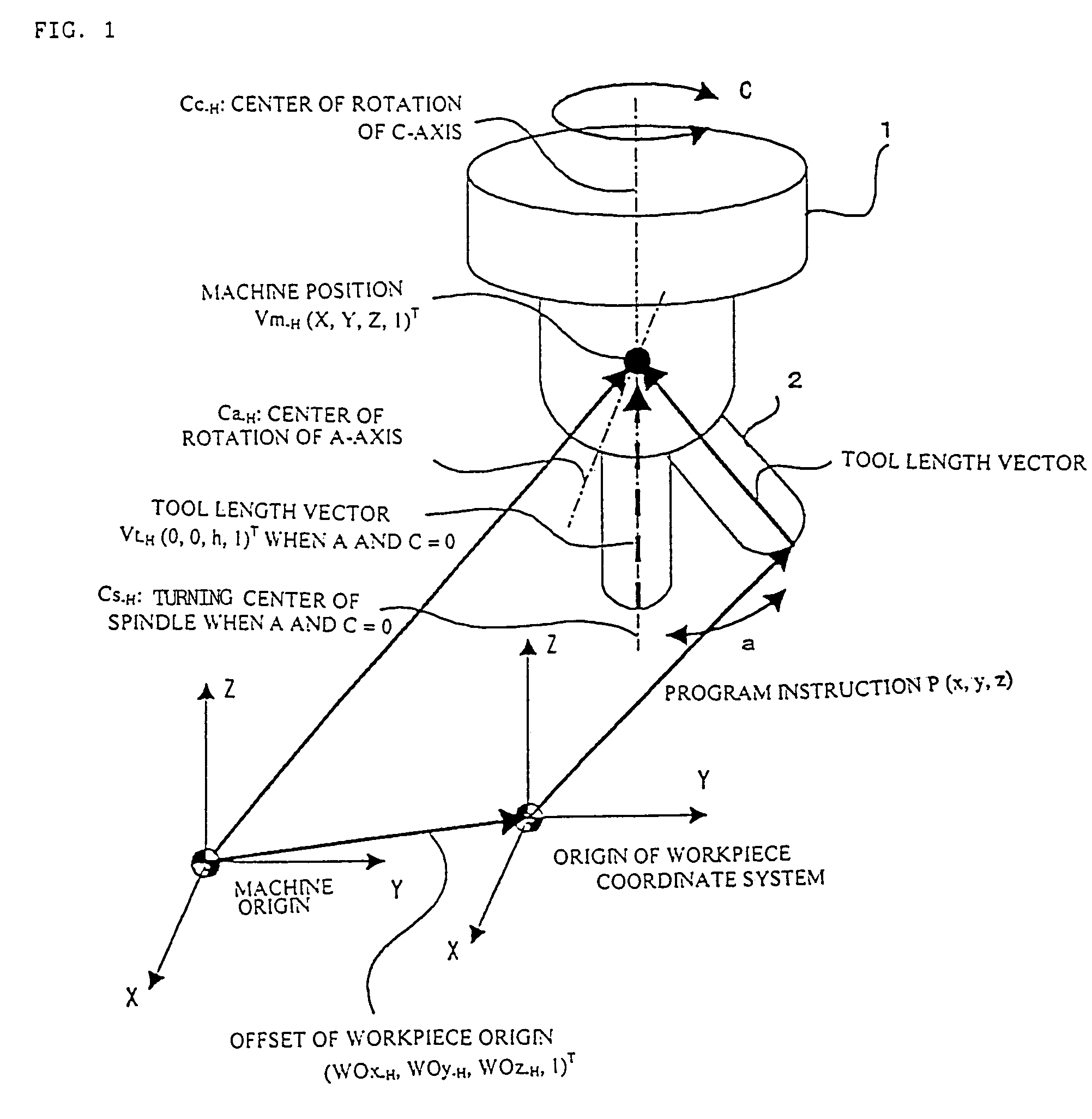

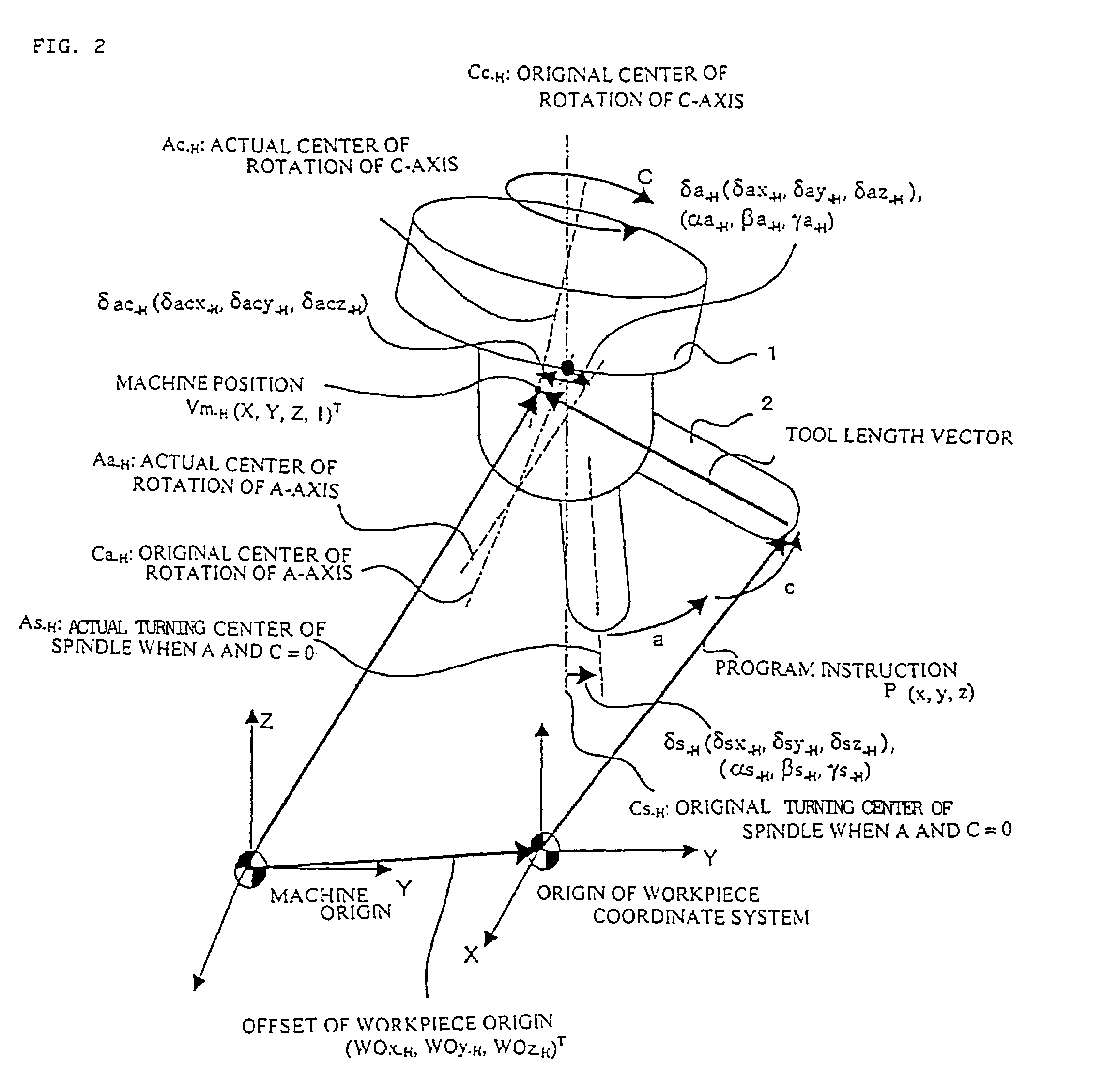

Numerical control device, and numerical control method

ActiveUS7283889B2High precision machiningComputer controlSimulator controlNumerical controlEngineering

A machine has a tool head which rotates on a C-axis (about the Z-axis) and an A-axis (about the X-axis). A tool length vector is multiplied by a matrix whereby a misalignment component δs-H and the incline error (αs-H, βs-H, γs-H) of a spindle are corrected so that the tool length vector due to the misalignment of the spindle is obtained. The vector thus obtained is further multiplied by a transformation matrix that includes a rotation instruction α for the A-axis and misalignments of the A-axis δa-H (αa-H, βa-H, γa-H) to correct the misalignment of the A-axis so that the tool length vector as found when the A-axis has rotated by an equivalent of instruction α is determined. The vector thus determined is further multiplied by a transformation matrix that includes a rotation instruction c for the C-axis and misalignments of the C-axis δac-H (αc-H, βc-H, γc-H) to correct the misalignment of the C-axis, so that a tool length vector as found when the C-axis has rotated by an equivalent of instruction c is determined. The tool length vector thus determined is added to the vector of positional instruction values (x, y, z) and a workpiece origin offset vector Mwo-H, so that the machine position Vm-H′ is obtained.

Owner:FANUC LTD

Method for manufacturing magnetic recording medium

InactiveUS20080078739A1Improve accuracyReliable removalDecorative surface effectsNanoinformaticsHalogenOptoelectronics

A method for manufacturing a magnetic recording medium with excellent production efficiency is provided in which the recording layer can be processed into a desired concavo-convex pattern with high precision and the resin layer can reliably and thoroughly be removed. A sub-mask layer having corrosion resistance against an oxygen-containing gas is provided over a main mask layer composed mainly of carbon. Furthermore, an intermediate mask layer is provided between the main mask layer and the sub-mask layer. The intermediate mask layer has corrosion resistance against the oxygen-containing gas, and its etching rate is higher for a halogen-containing gas than for the oxygen-containing gas. The resin layer removing step is conducted between the sub-mask layer processing step and the intermediate mask layer processing step (the main mask layer processing step). The resin layer removing step uses the oxygen-containing gas, and the intermediate mask layer processing step uses the halogen-containing gas.

Owner:TDK CORPARATION

Precision roll turning lathe

ActiveCN101062543AHigh precision machiningSuppress feverPropelling pencilsWorkpiecesMilling cutterTransverse groove

There is provided a precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 33. The precision roll turning lathe can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface.

Owner:TOSHIBA MASCH CO LTD

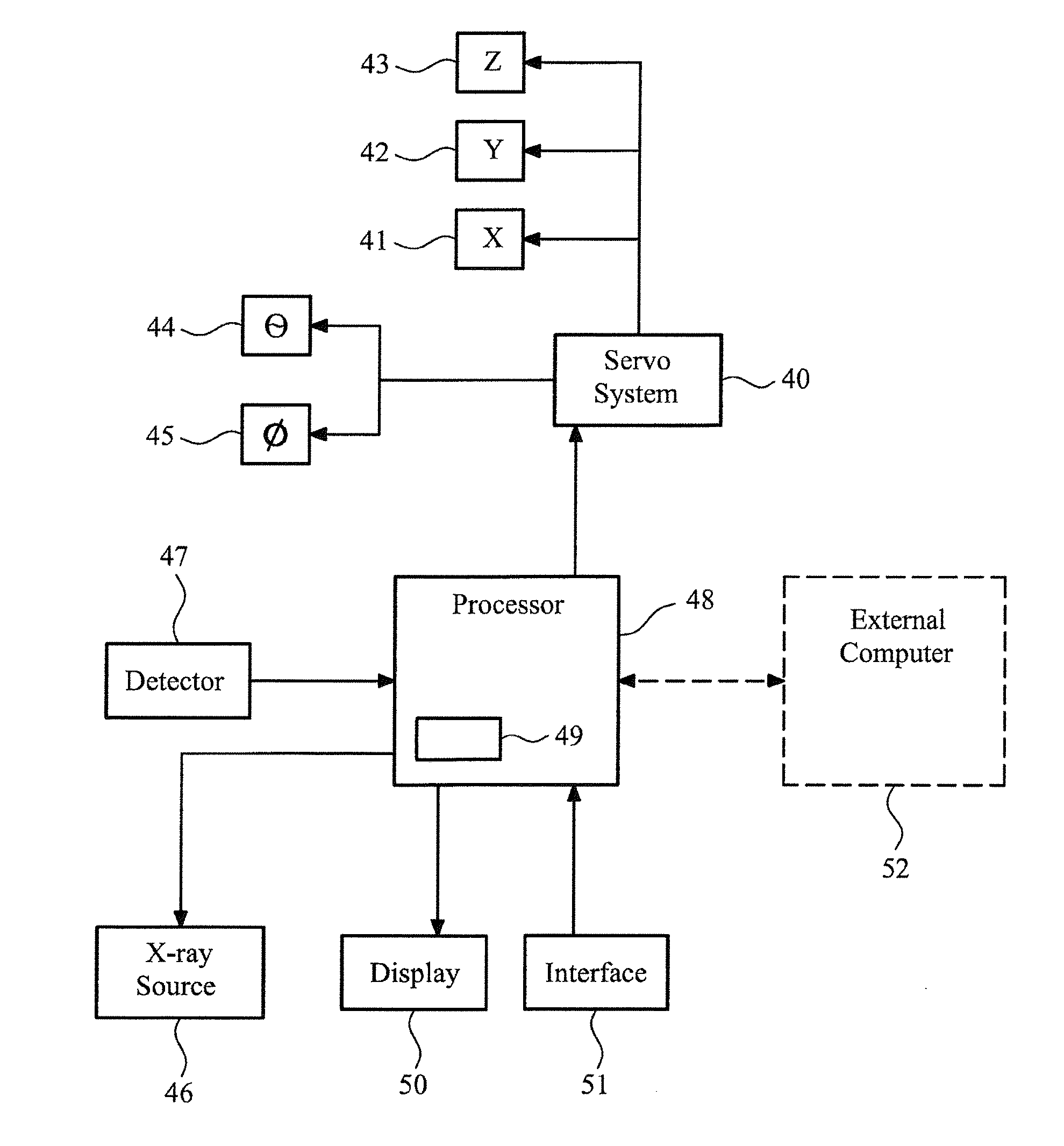

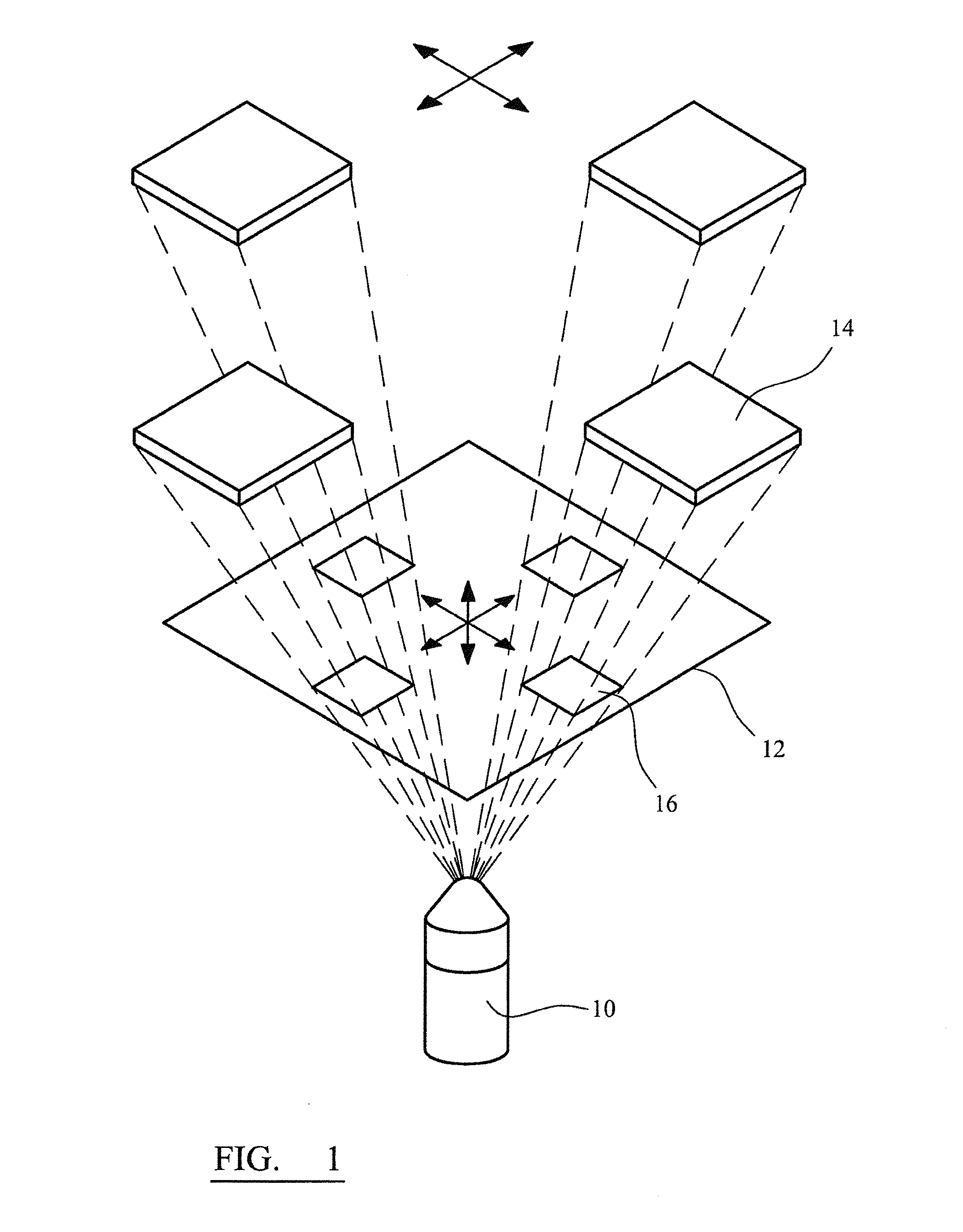

Method and apparatus for generating a three-dimensional model of a region of interest using an imaging system

ActiveUS20130108017A1Inexpensive mechanismQuality improvementImage enhancementReconstruction from projectionX-rayPositioning system

A method of generating a three-dimensional representation of a region of interest on a target object in an x-ray imaging system. The method uses a fiducial marker of known geometry. The region of interest and the fiducial marker are imaged in a plurality of predetermined positions. Expected images of the fiducial marker for each predetermined position are calculated and compared to captured images of the fiducial marker at each predetermined position. The difference between expected and captured imaged is used to generate corrected images of the region of interest for each predetermined position and these corrected images are used to generate a three-dimensional model of the region of interest. The method allows for the generation of useful three-dimensional models of a region of interest in an x-ray imaging system without requiring an expensive mechanical positioning system.

Owner:NORDSON CORP

Photo-curable resin composition and a method for forming a pattern using the same

InactiveUS20070065757A1Low viscosityIncrease resistancePhotosensitive materialsNanoinformaticsMeth-Acrylate ester

Provided is a new photo-curable resin composition which can be used in a photo nanoimprinting technology available for a photo nanoimprinting technology by which a substrate is processed with high accuracy. The photo-curable resin composition contains a photo-curable resin material essentially containing a (meth)acrylate, a reactive diluent, and a photo initiator. Preferably, the (meth)acrylate has a structure containing a benzene ring structure in its skeleton.

Owner:HITACHI CHEM CO LTD

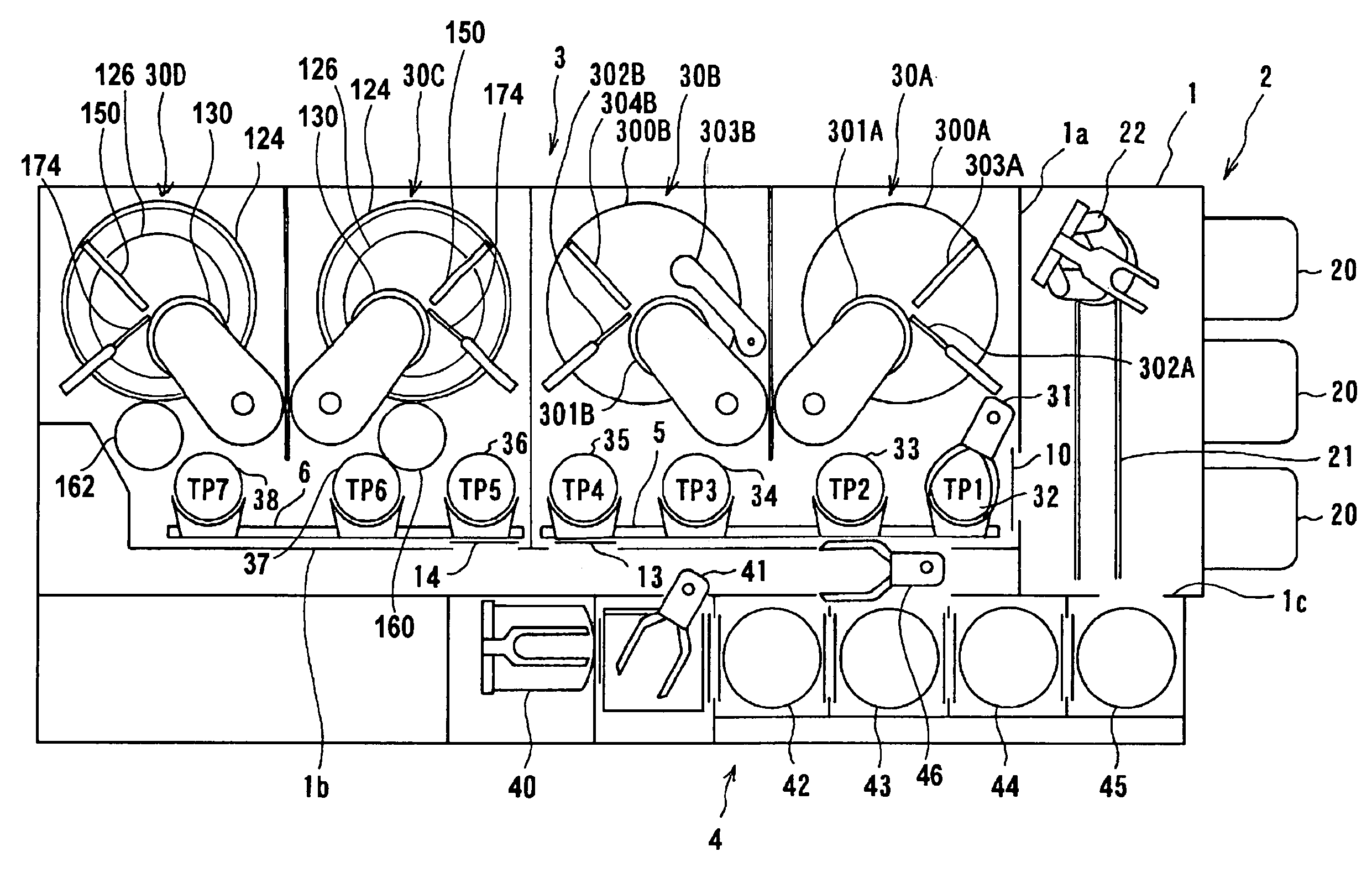

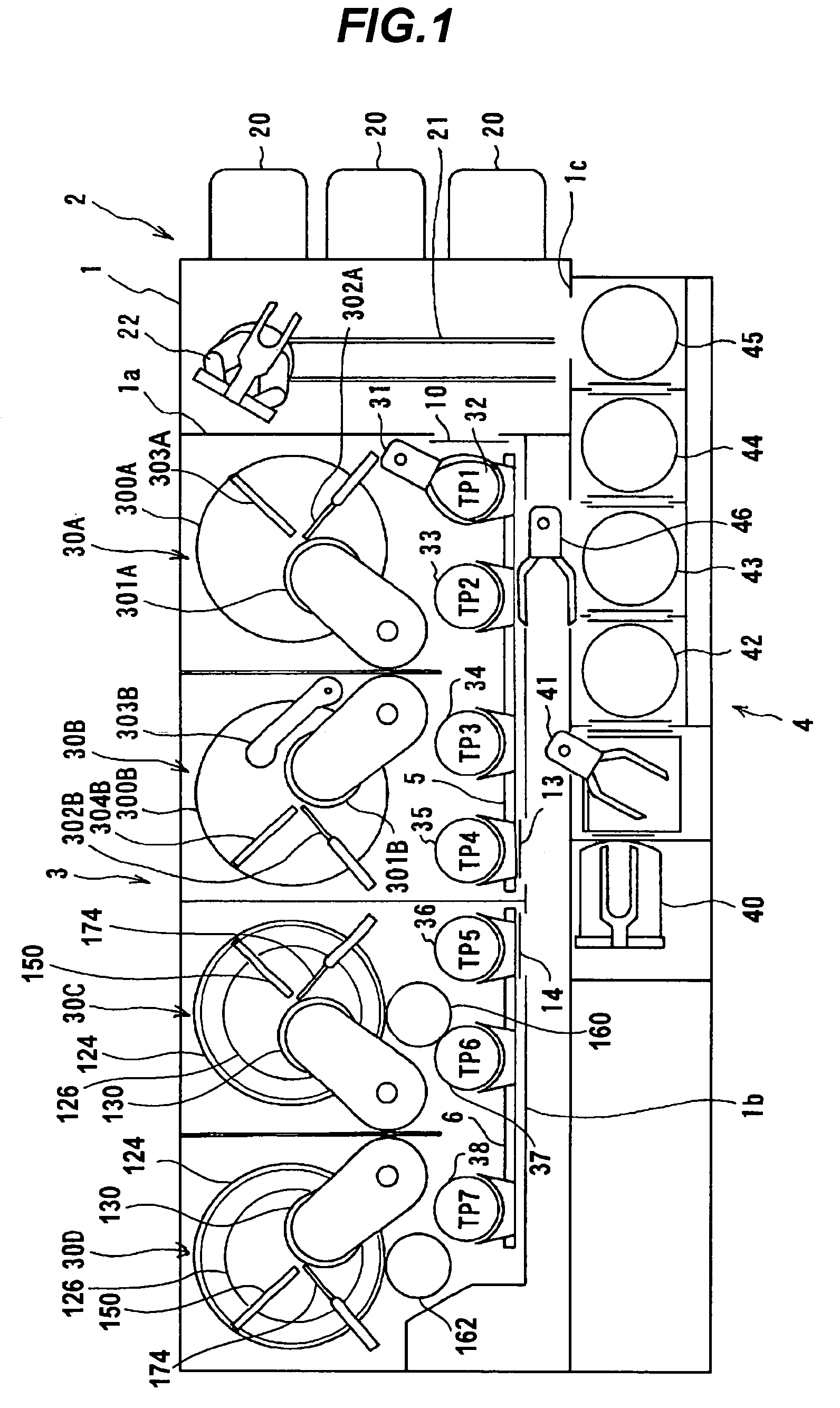

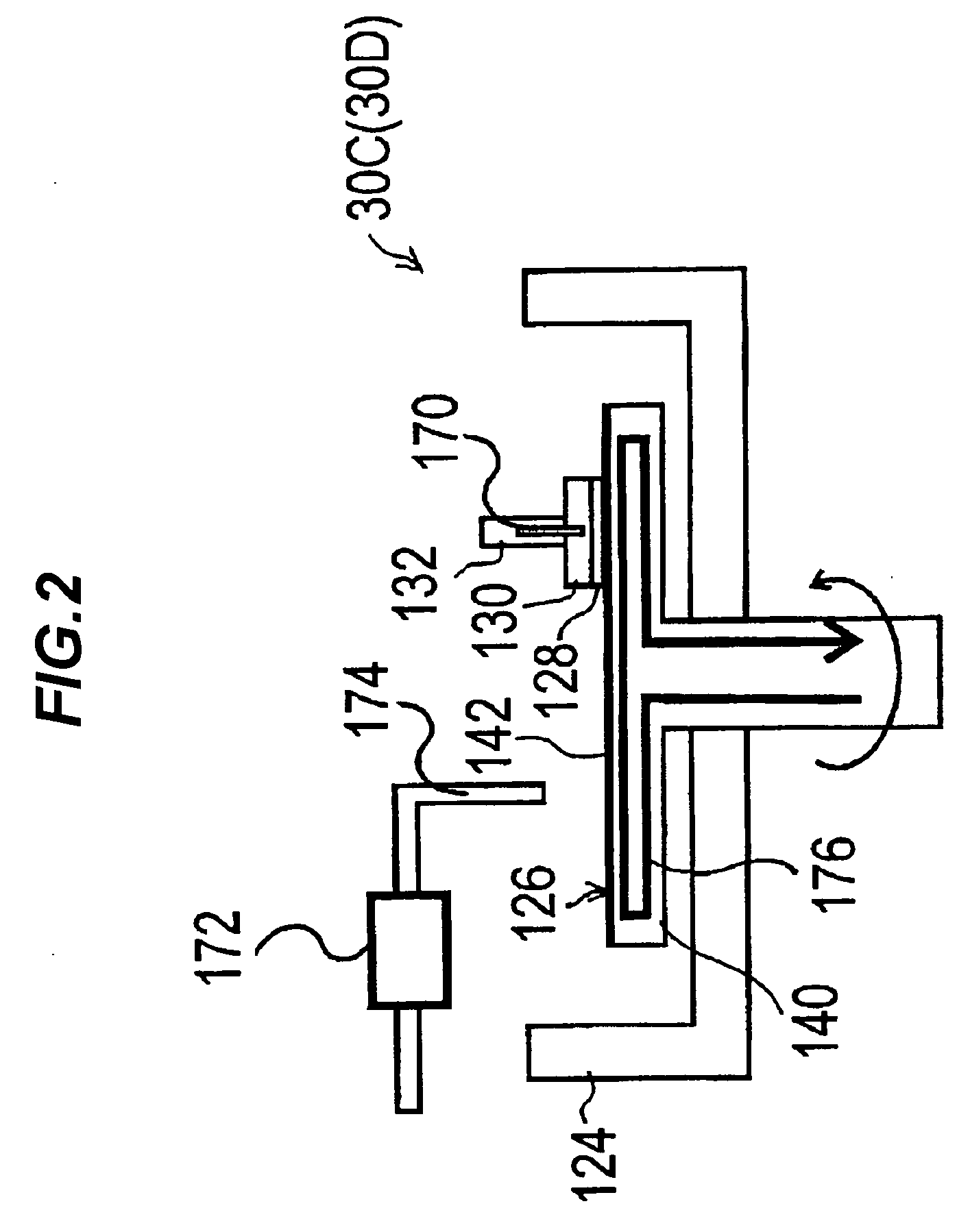

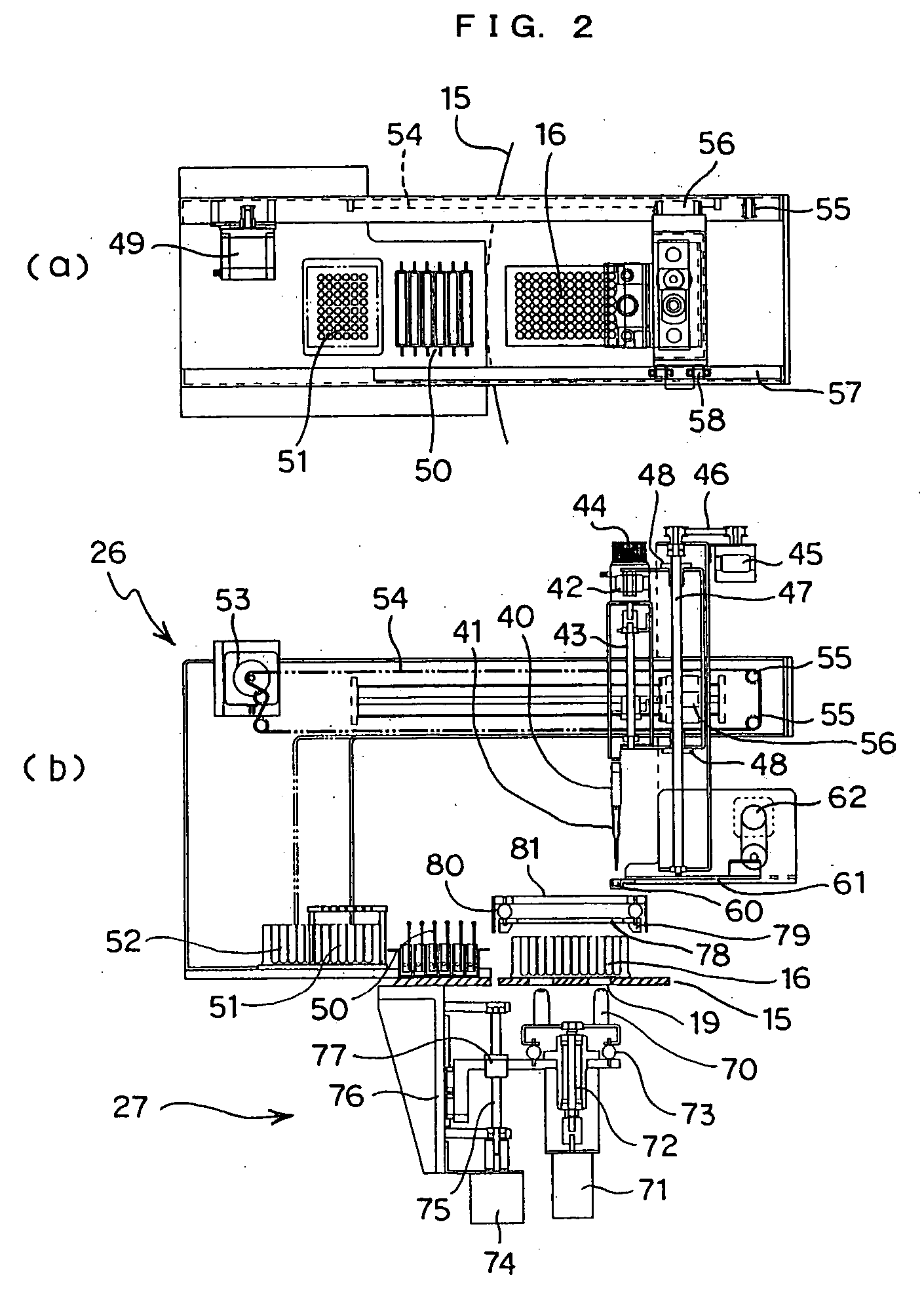

Automatic separator/extractor and method of controlling same

InactiveUS20060110296A1Highly accurate dispensationImprove accuracyAnalysis using chemical indicatorsWithdrawing sample devicesEngineeringHigh velocity

The invention relates to an automatic separator / extractor and a method of controlling same, with the object, particularly in all manner of fields such as medical science, agricultural science, scientific fields, or pharmaceuticals, of being able to achieve at high speed and accuracy, extraction or separation of precipitate or supernatant at a high quality, accuracy and reliability, above that which can be achieved by manual means. The construction has a conveying device for conveying a mounted vessel along a closed path, a dispensing section for dispensing a reagent or the like into the vessel mounted on the conveying device, a liquid processing section for removing and / or extracting liquid other than a precipitate inside the vessel mounted on the conveying device, a separator for performing separation with respect to the contents inside a vessel which is mounted on the conveying device and / or a vessel which is installed away from the conveying device, a vessel moving device for bringing in and taking out the vessel with respect to the conveying device and / or separator, and an operation / control section for performing operation and control with respect to the conveying device, the dispensing section, the liquid processing section, the vessel moving device, and the separator.

Owner:PRECISION SYST SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com