Material processing system and method

a material processing and material technology, applied in the direction of metal material coating process, electric discharge tube, coating, etc., can solve the problems of unsatisfactory accuracy with which the conventional system may be used to process work pieces, and achieve the effect of high vacuum, higher gas pressure, and high gas pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In the exemplary embodiments described below, components that are alike in function and structure are designated as far as possible by alike reference numerals. Therefore, to understand the features of the individual components of a specific embodiment, the descriptions of other embodiments and of the summary of the invention should be referred to.

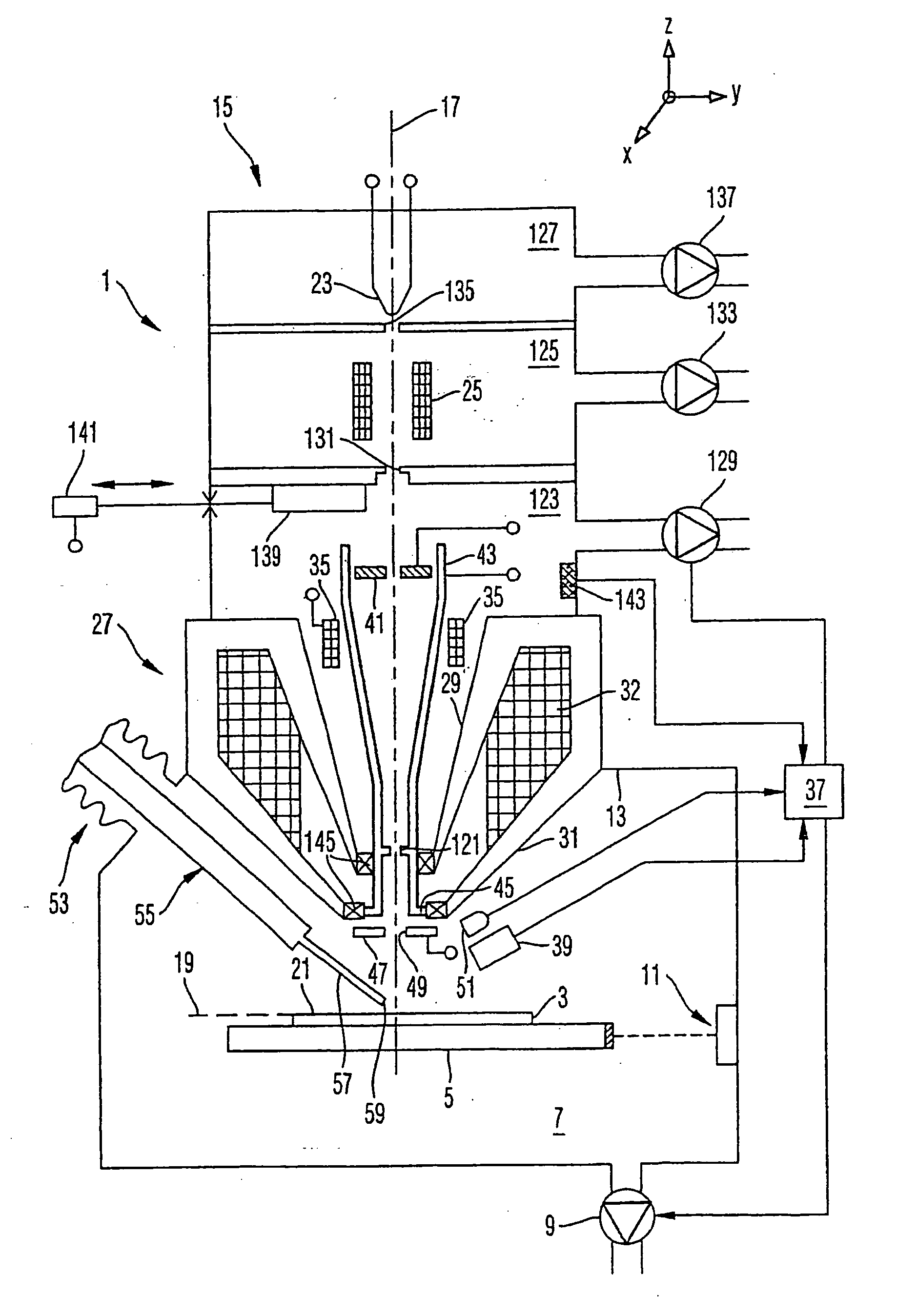

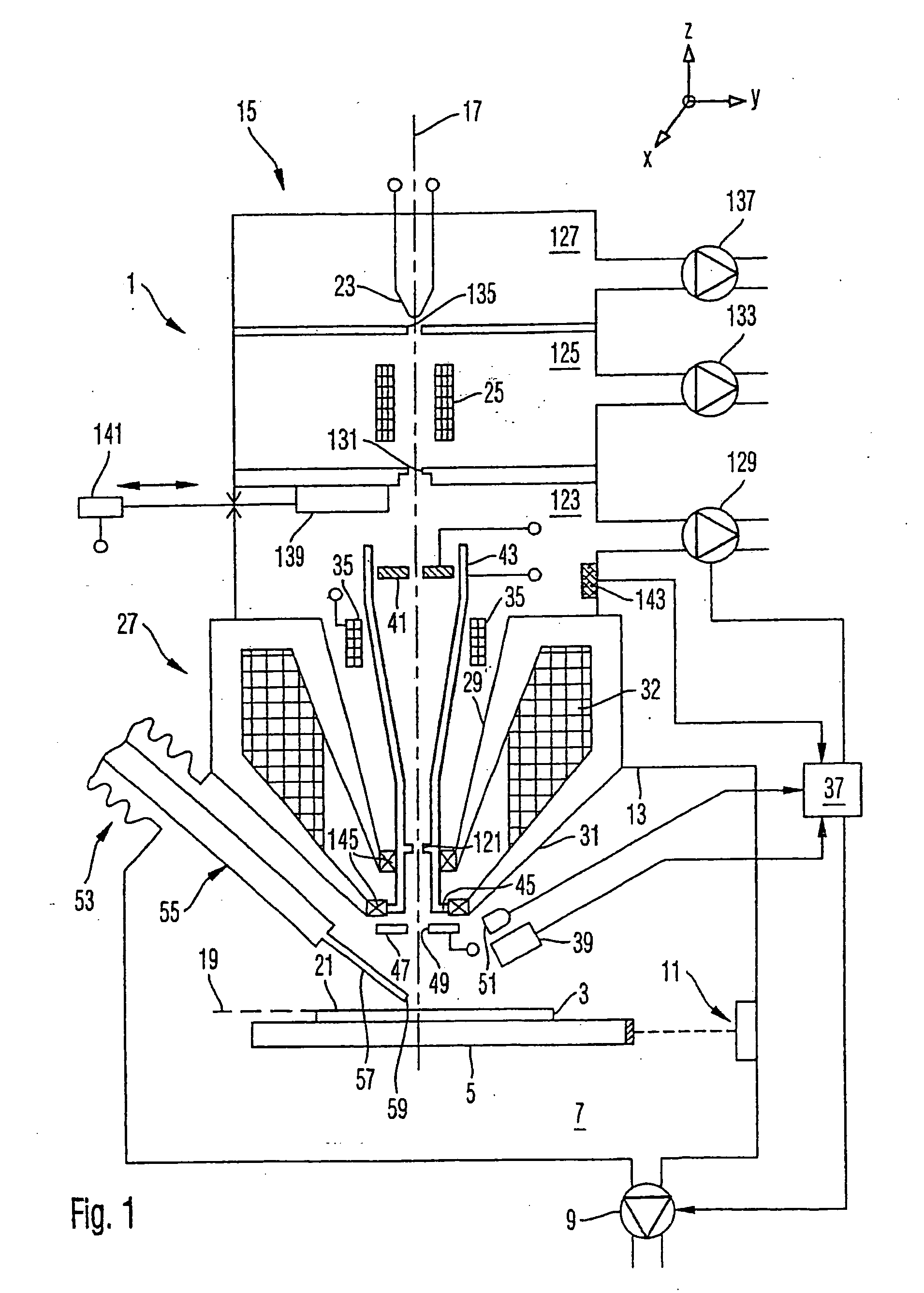

[0063]FIG. 1 schematically illustrates an embodiment of a material processing system 1 according to the invention. This system is used to process a work piece 3, namely a phase mask. This photo mask serves for use in a photolithographic process and carries structures which are photographically transferred to a radiation-sensitive layer (resist) with which a semiconductor substrate (wafer) is coated. In relation to the wavelength of the light used to transfer the structures from the mask to the semiconductor substrate, the critical dimensions of the structures are relatively small. Therefore, the structures on the mask are not merel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com