Precision roll turning lathe

一种轧辊车床、精密的技术,应用在精密车床领域,能够解决切削速度不足、不能够获得等问题,达到防止热变形、抑制发热的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

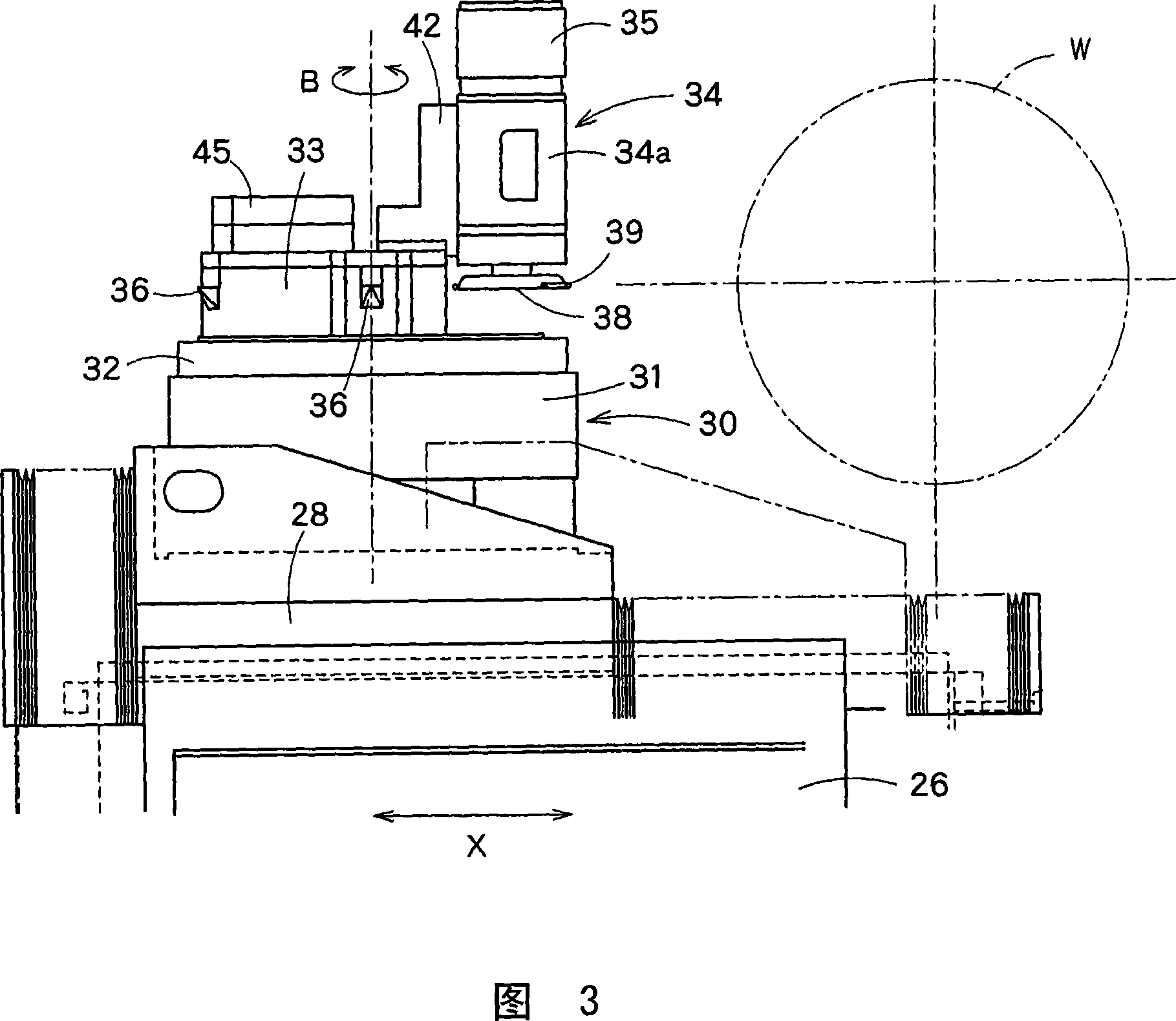

[0024] Hereinafter, one embodiment of the precision roll lathe of the present invention will be described with reference to the drawings.

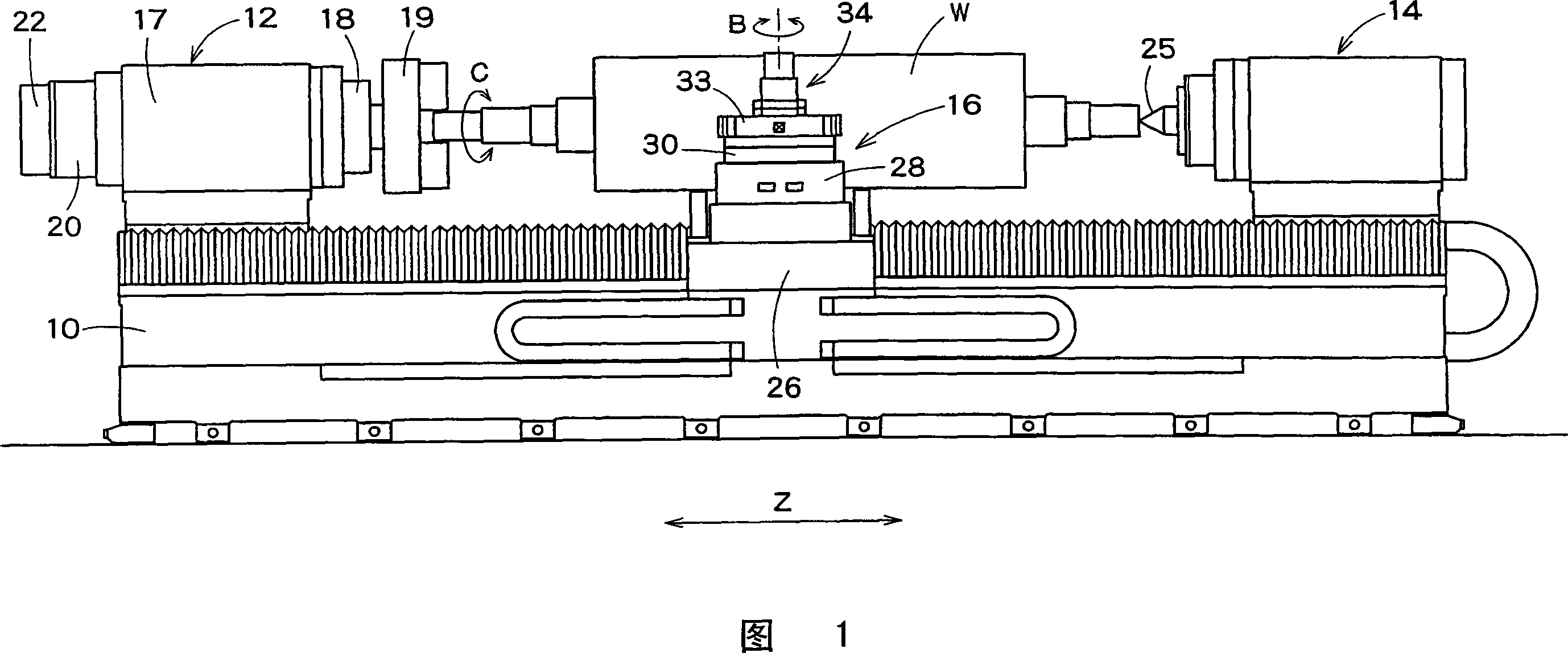

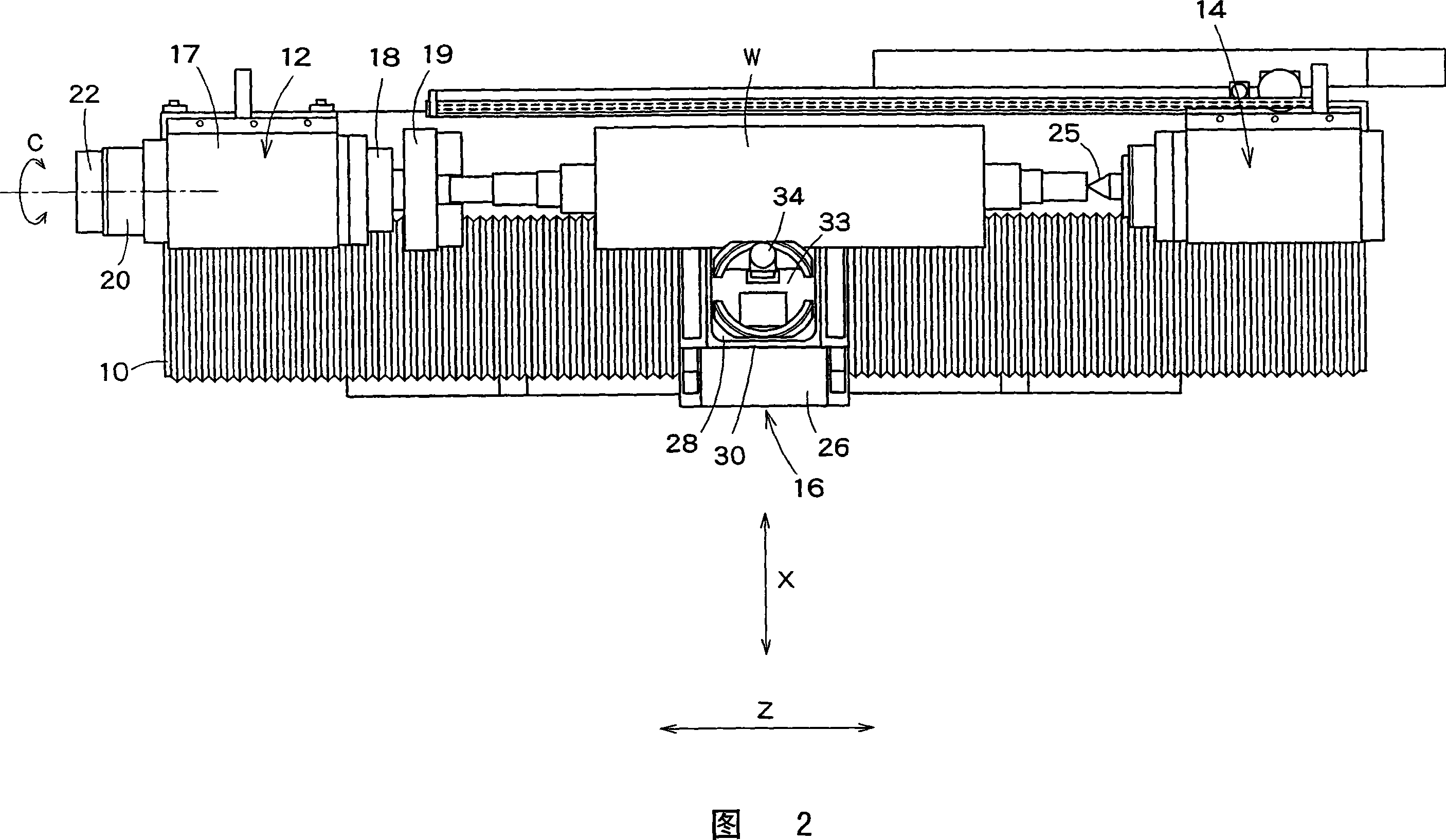

[0025] Fig. 1 is a side view of the precision roll lathe of the present invention, and Fig. 2 is a top view of the precision roll lathe.

[0026] In FIGS. 1 and 2 , reference numeral 10 denotes a base on which a main shaft frame 12 , a tailstock 14 , and a reciprocating frame 16 are disposed. The workpiece is a roll-shaped workpiece W, which is rotatably supported by the headstock 12 and the tailstock 14 .

[0027] The spindle frame 12 is disposed at one end portion of the base 10 in the longitudinal direction. The spindle frame 12 includes a main body 17 , a spindle 18 , a chuck 19 mounted on the front end of the spindle 18 , and a servo motor 20 for driving the spindle 18 . The main shaft 18 is supported by an unillustrated hydrostatic bearing built into the main body 17 . The chuck 19 holds the workpiece W and transmits the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com