Patents

Literature

63results about How to "Avoid low machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

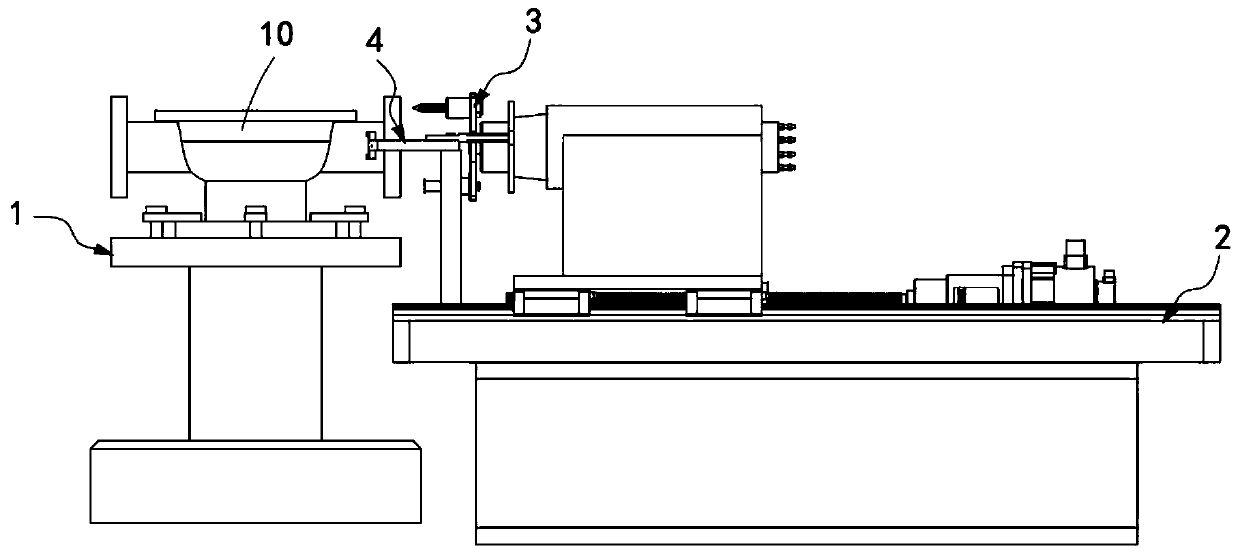

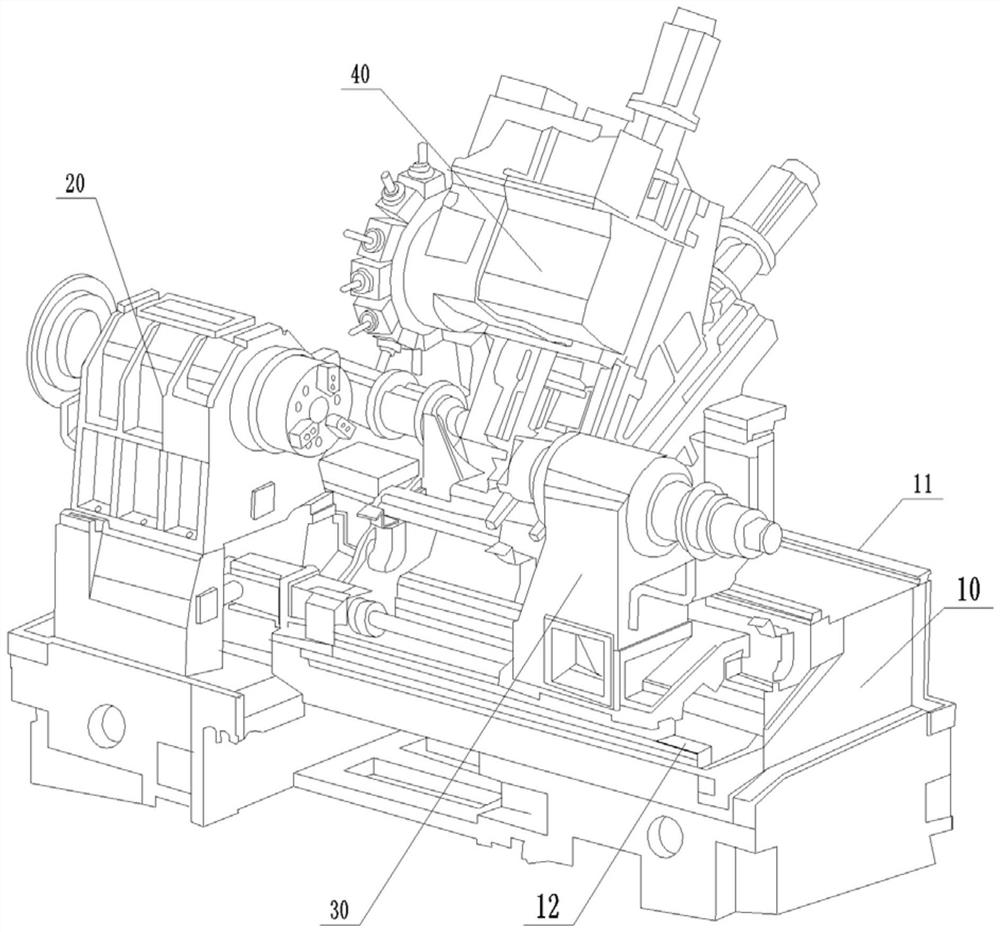

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

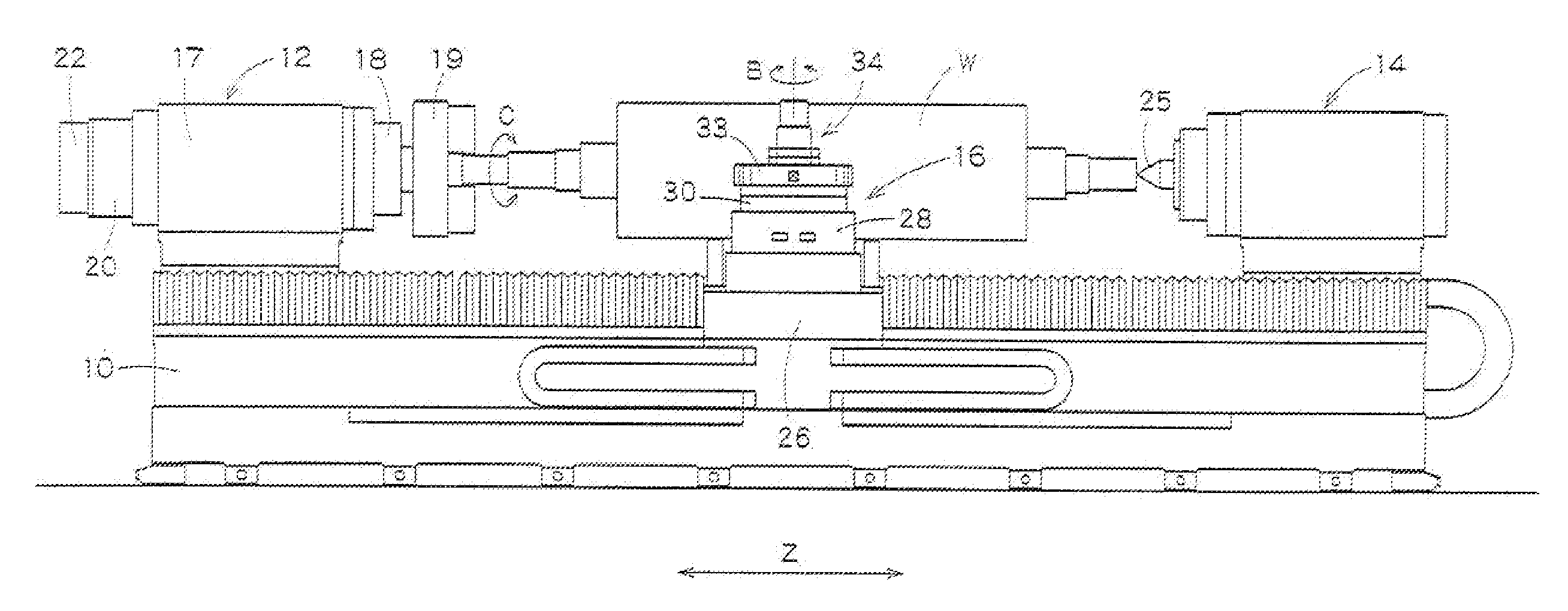

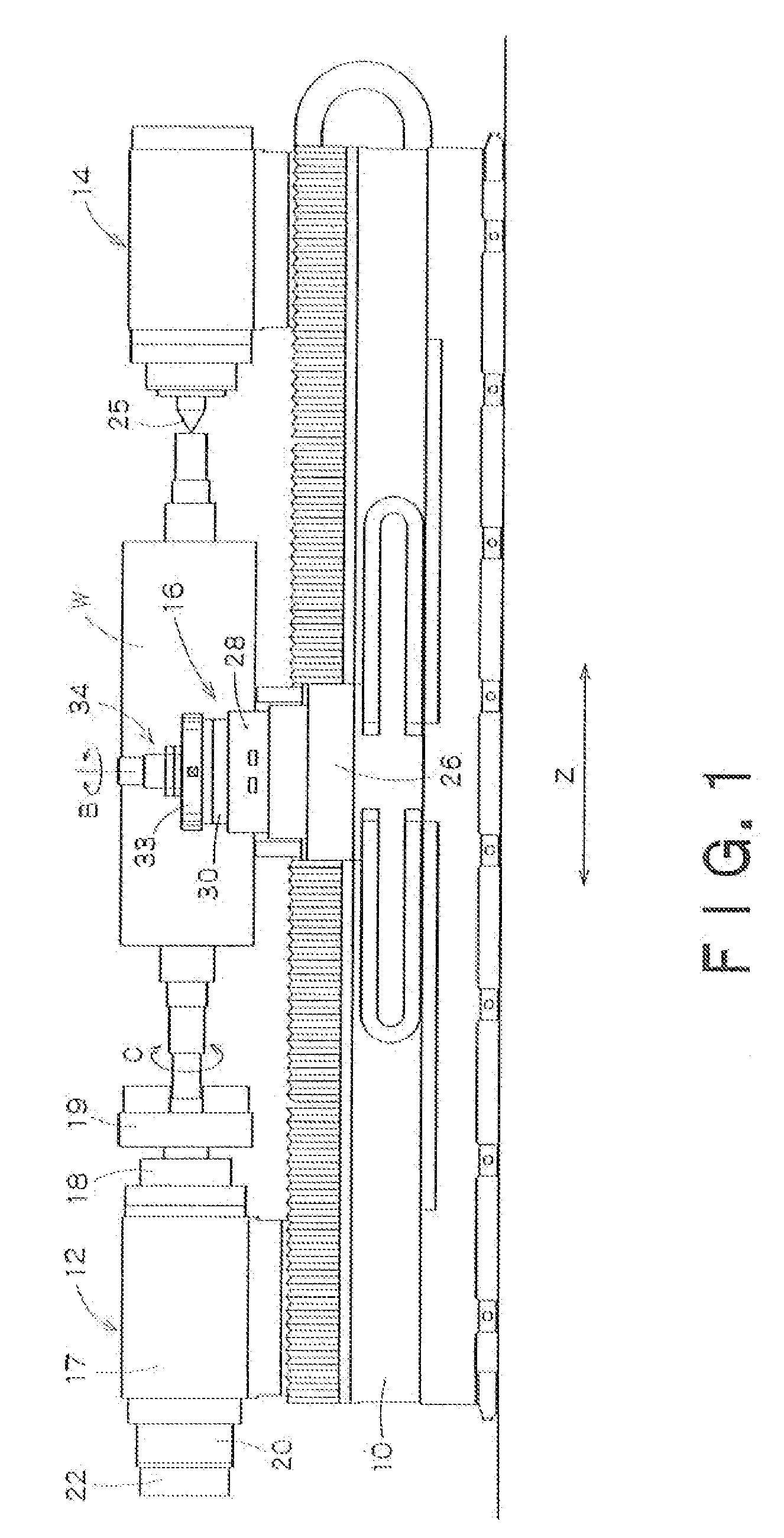

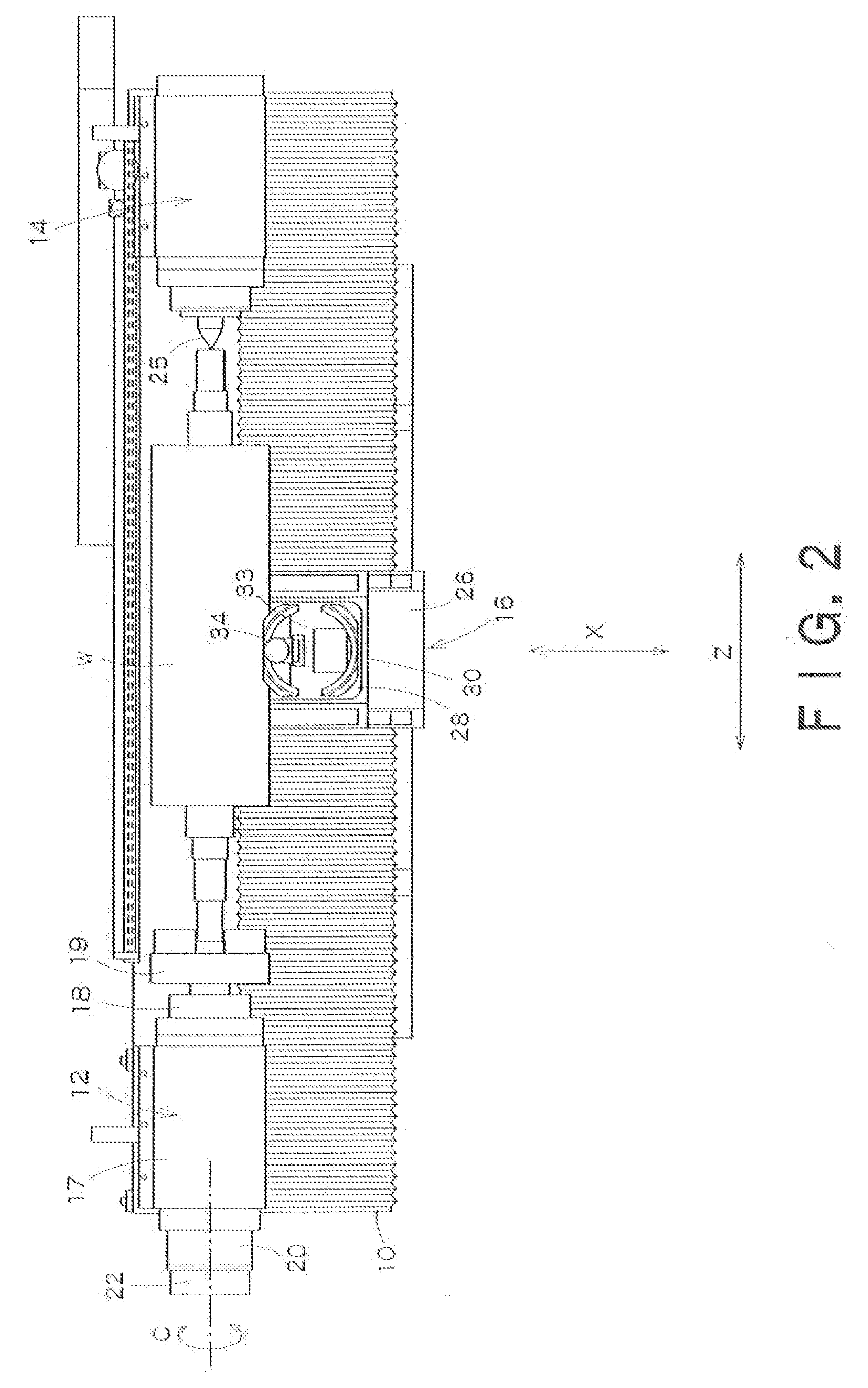

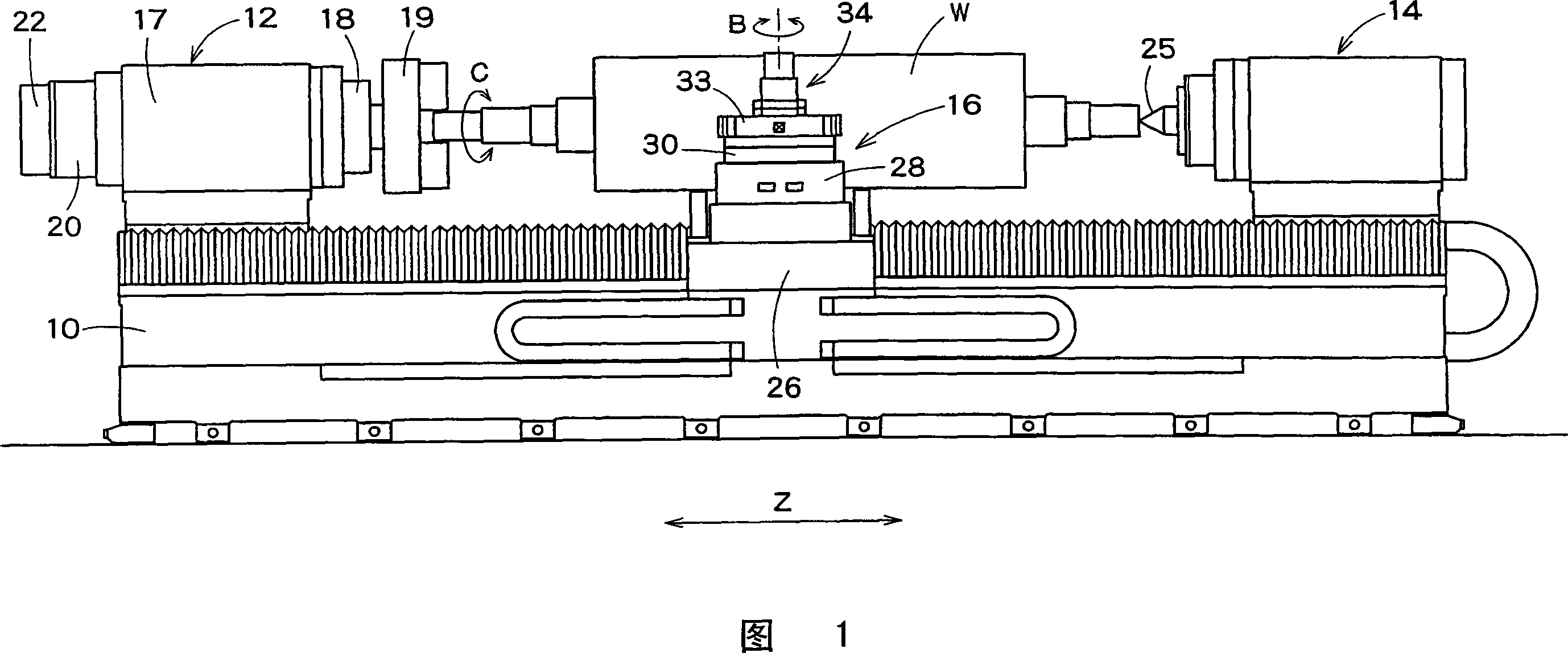

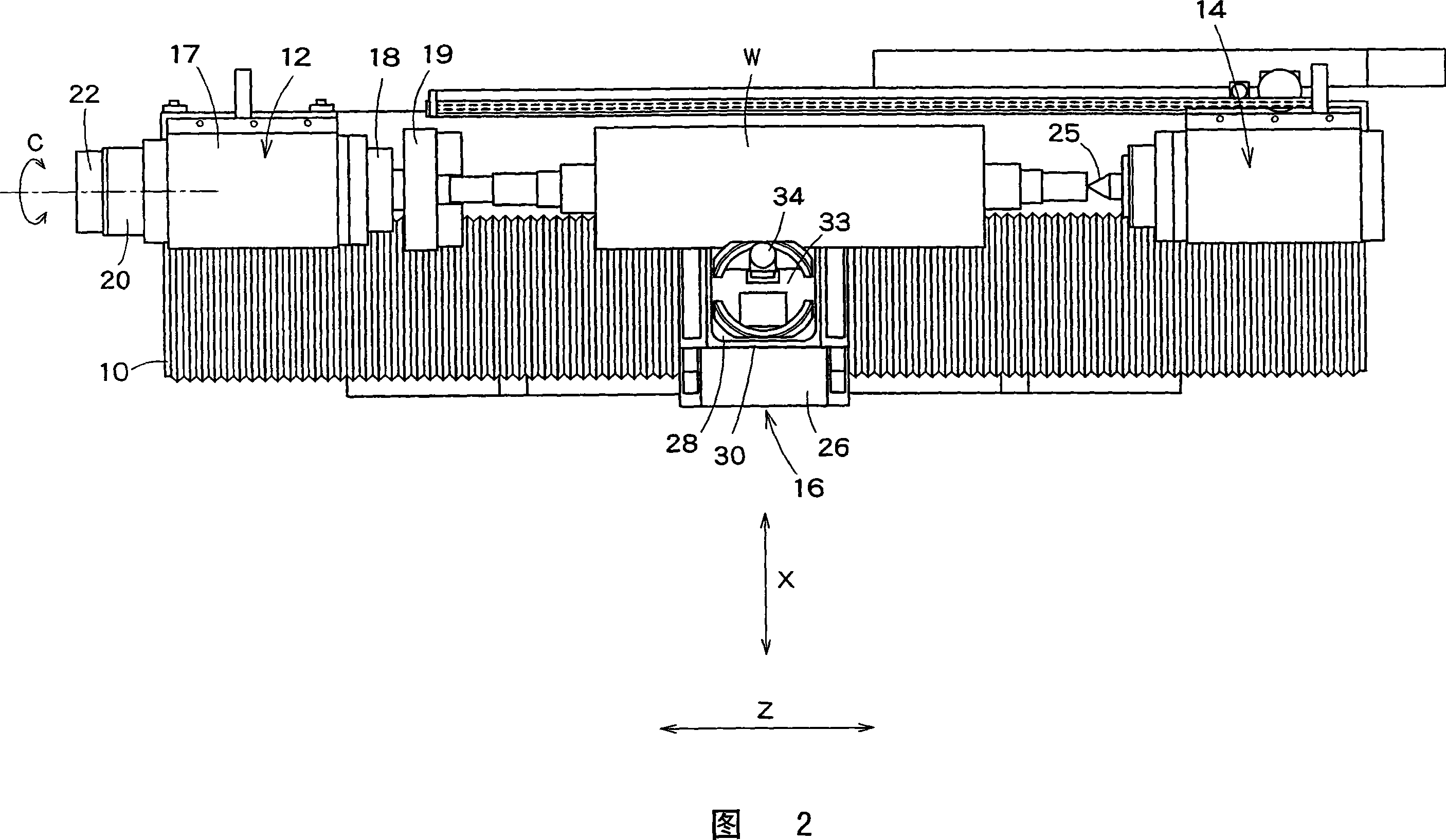

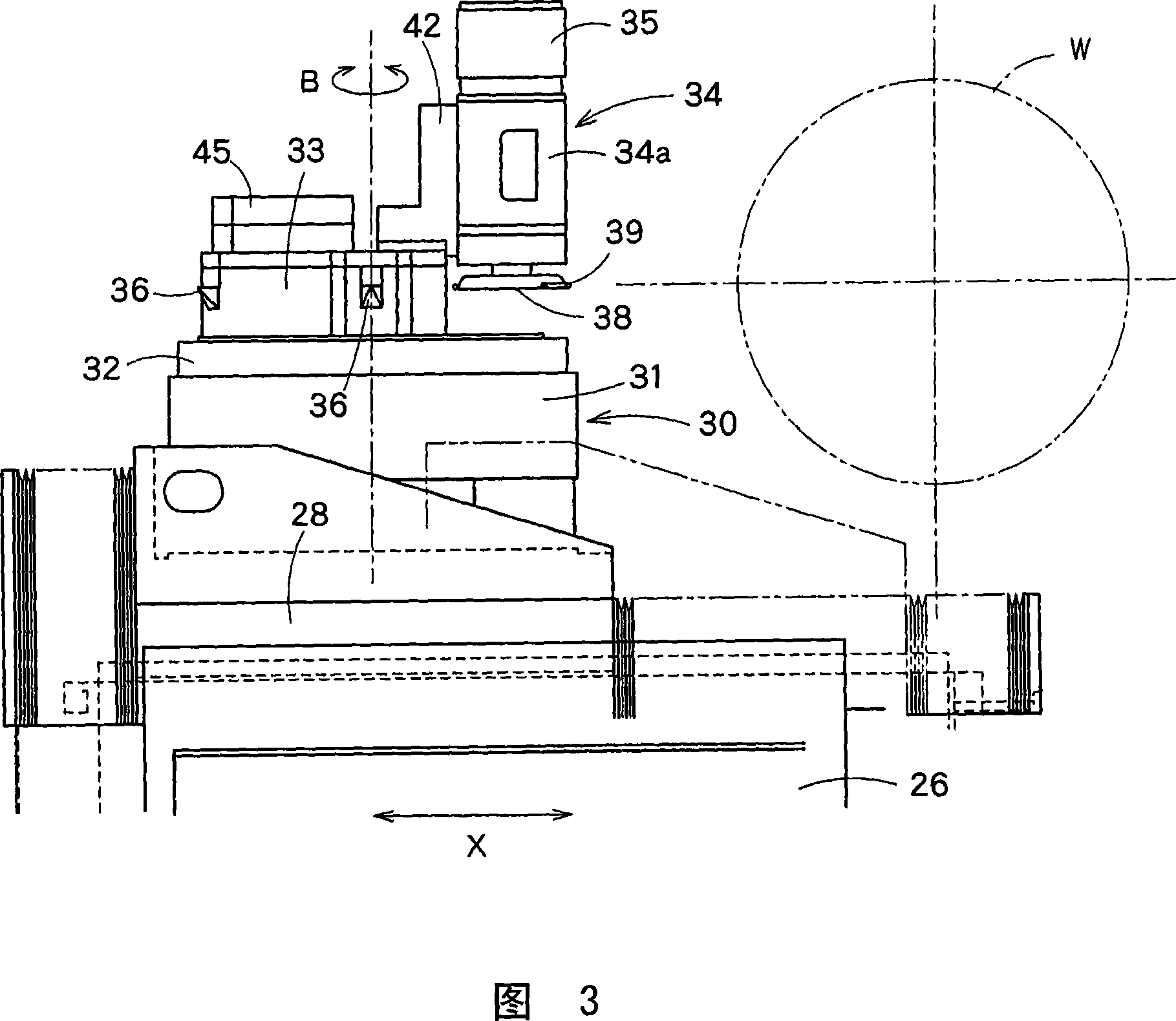

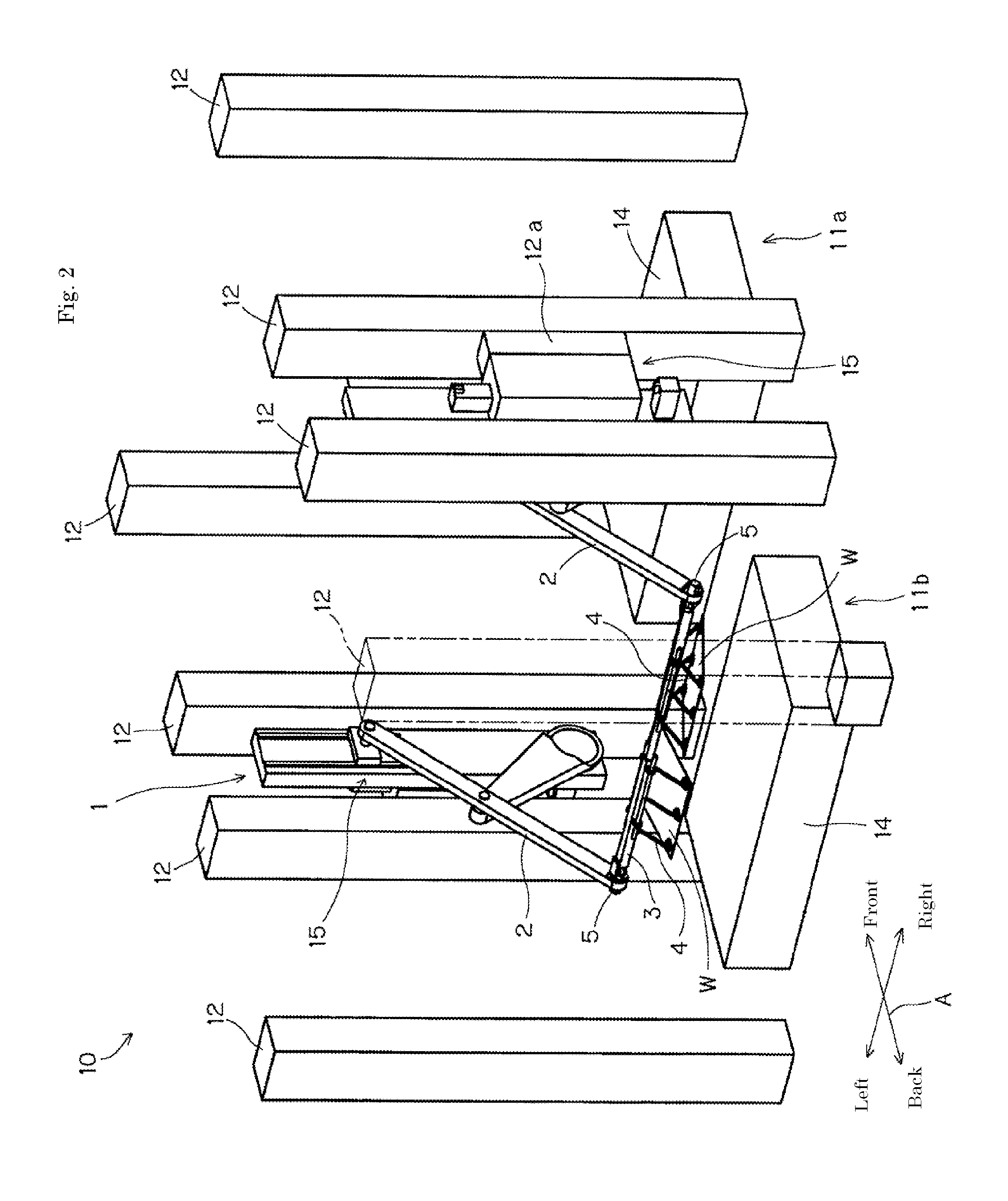

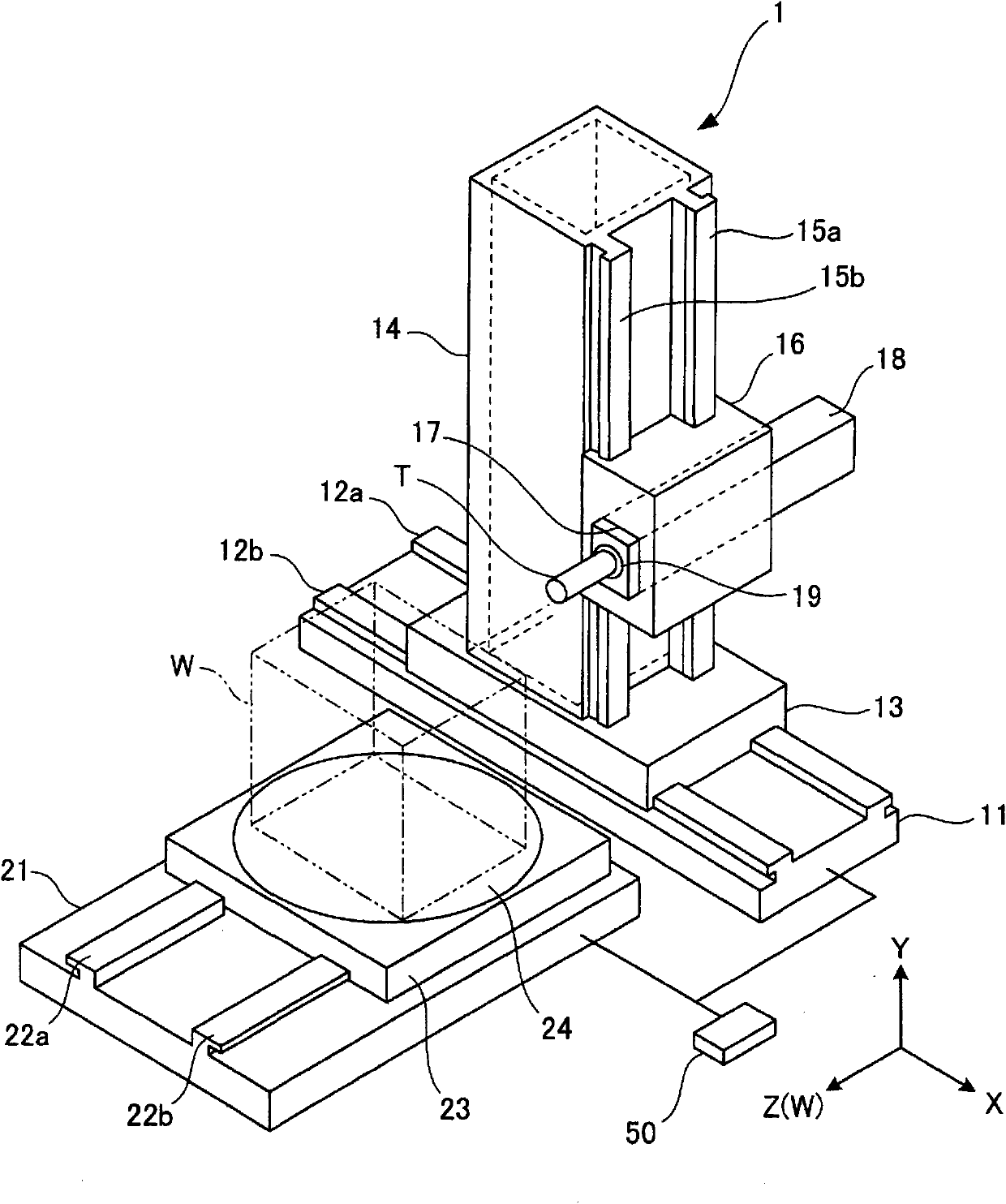

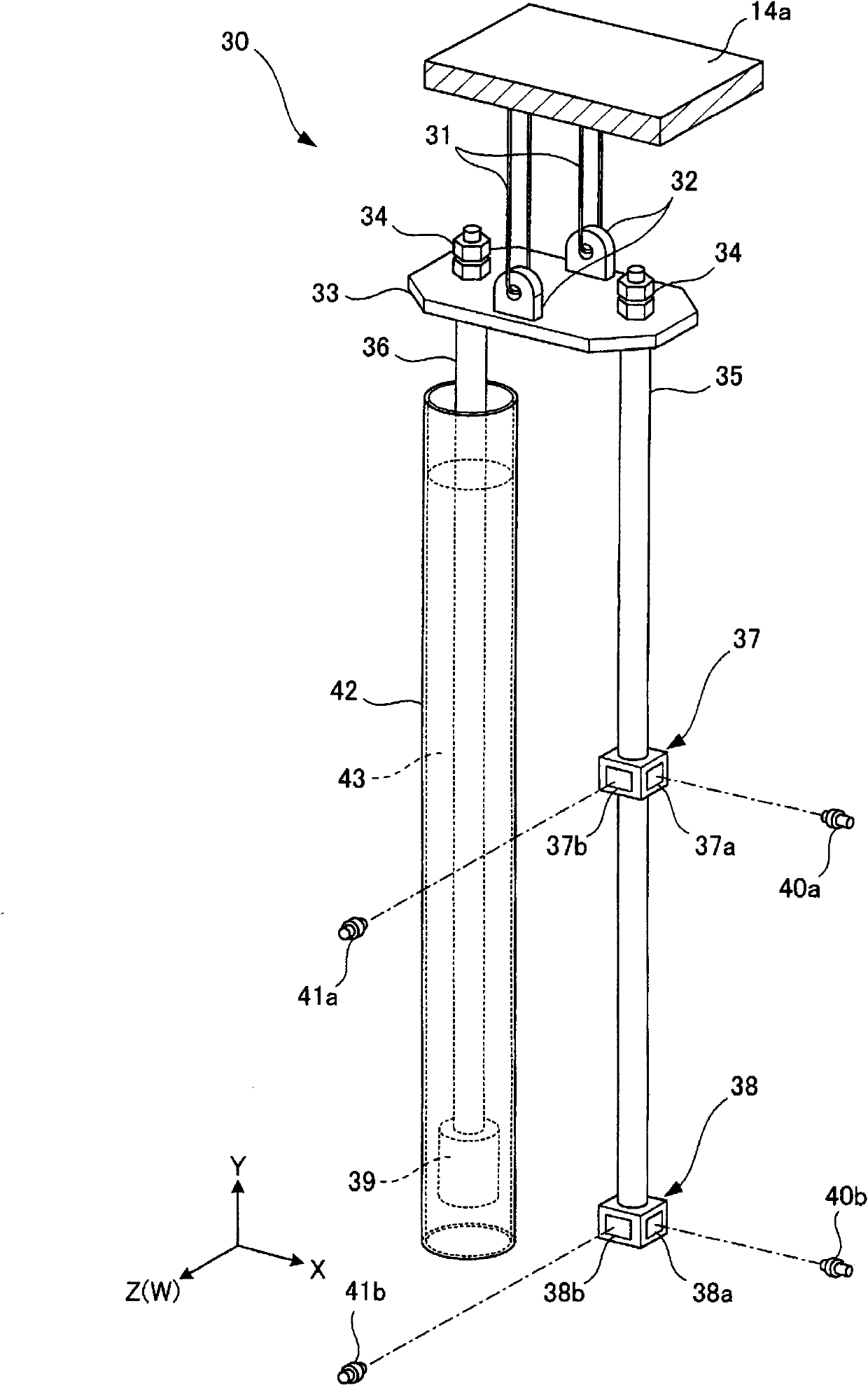

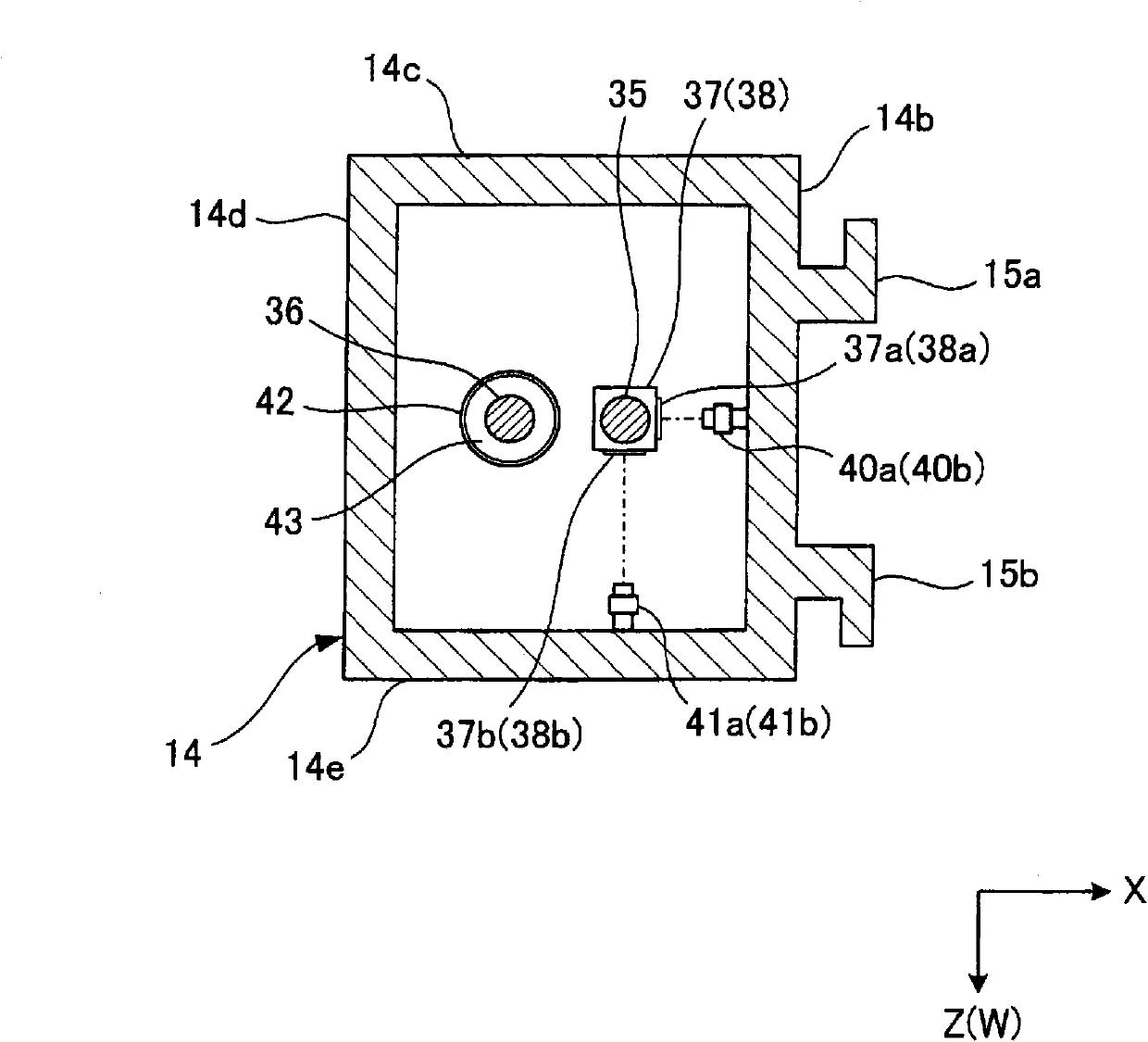

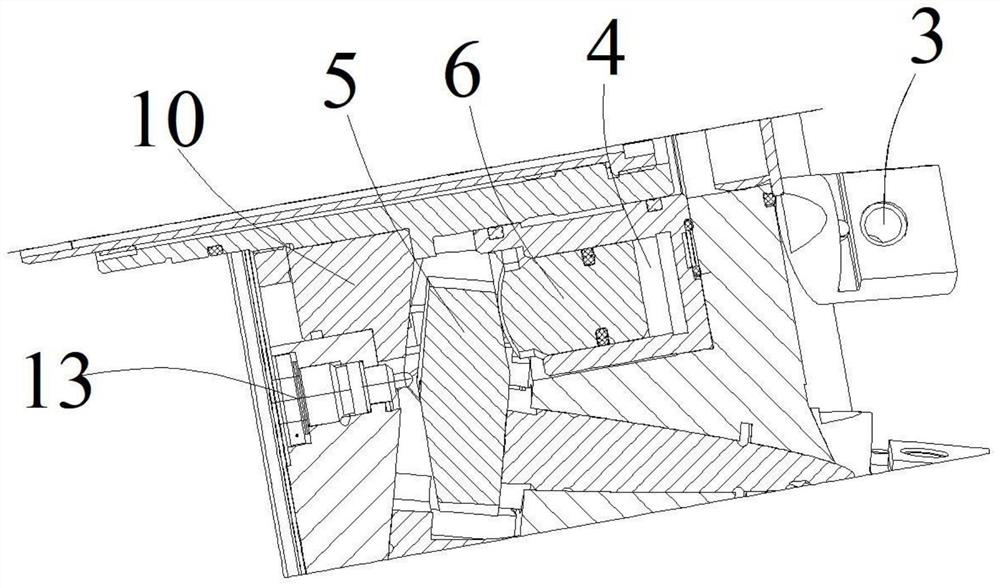

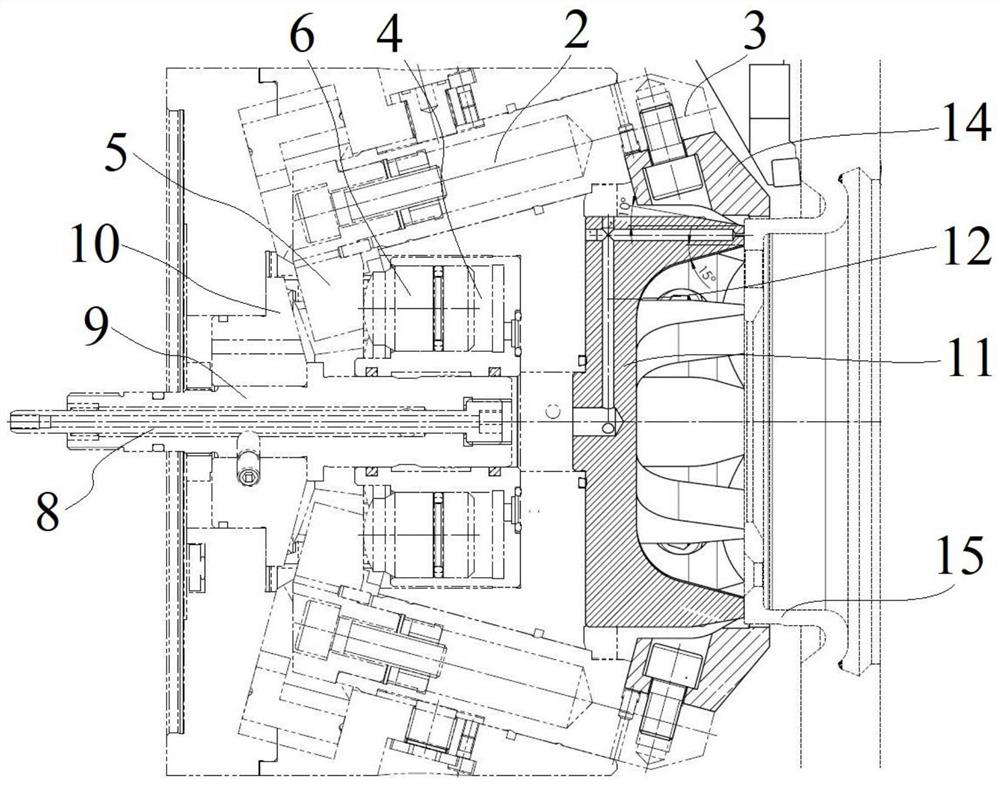

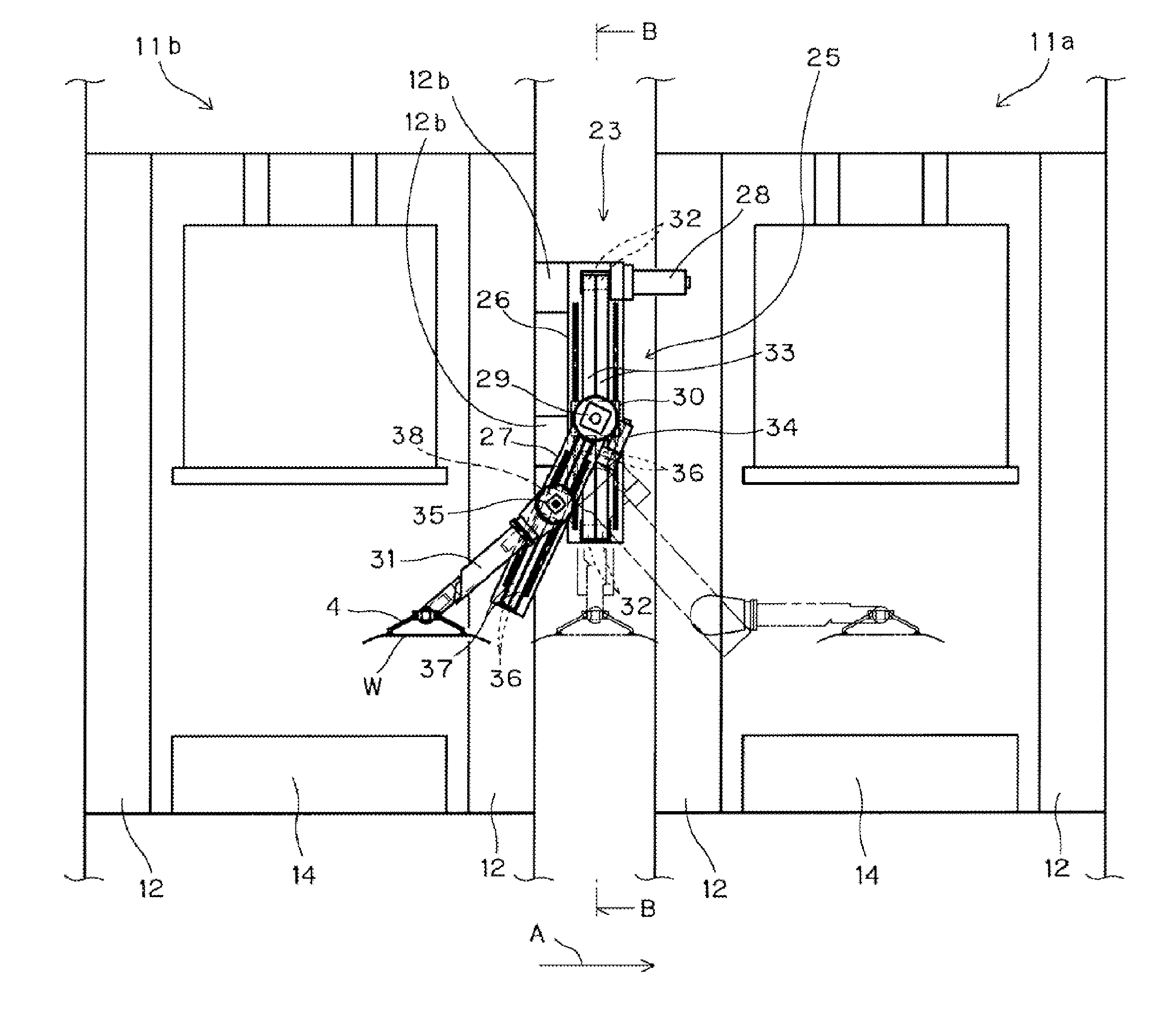

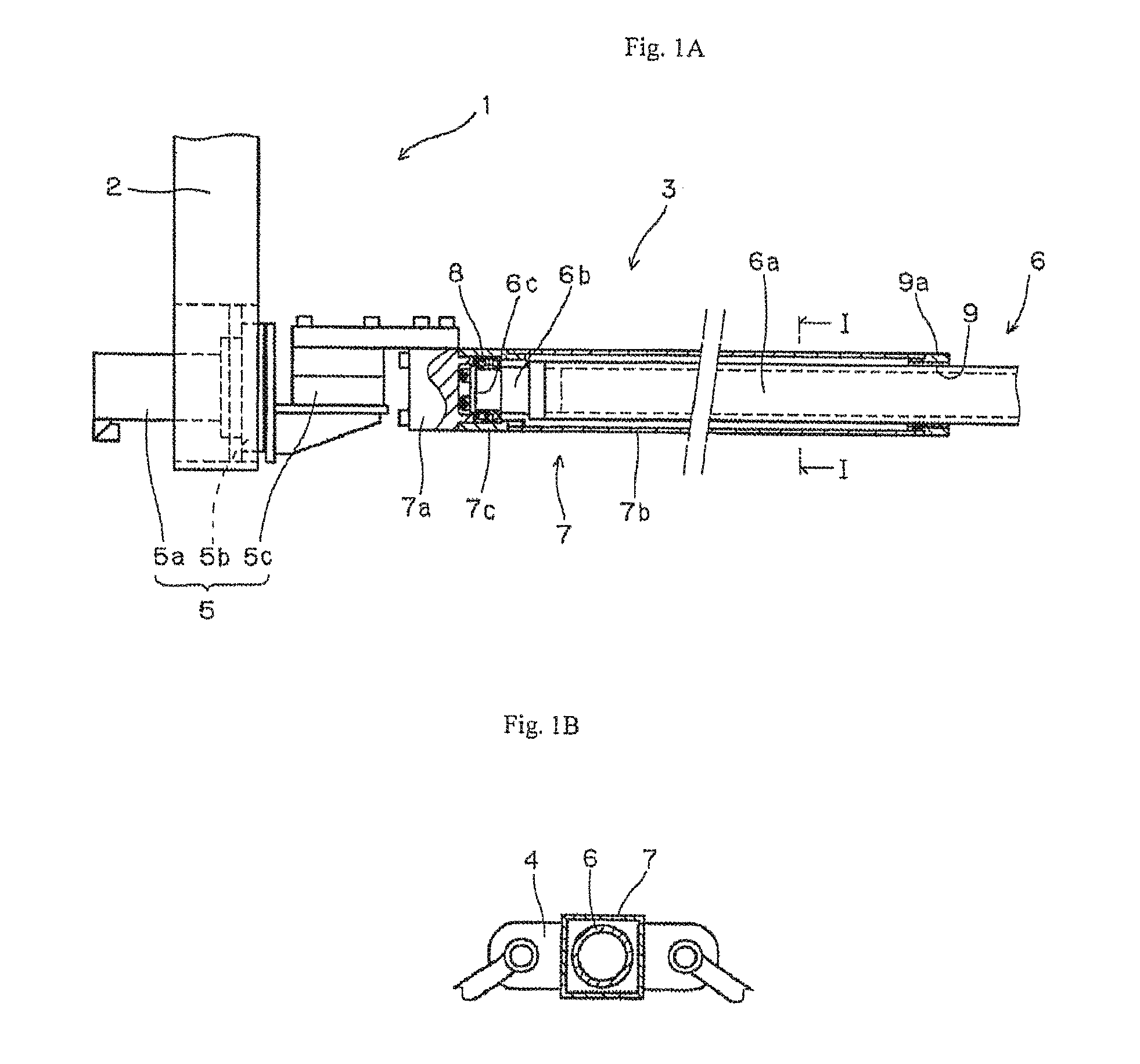

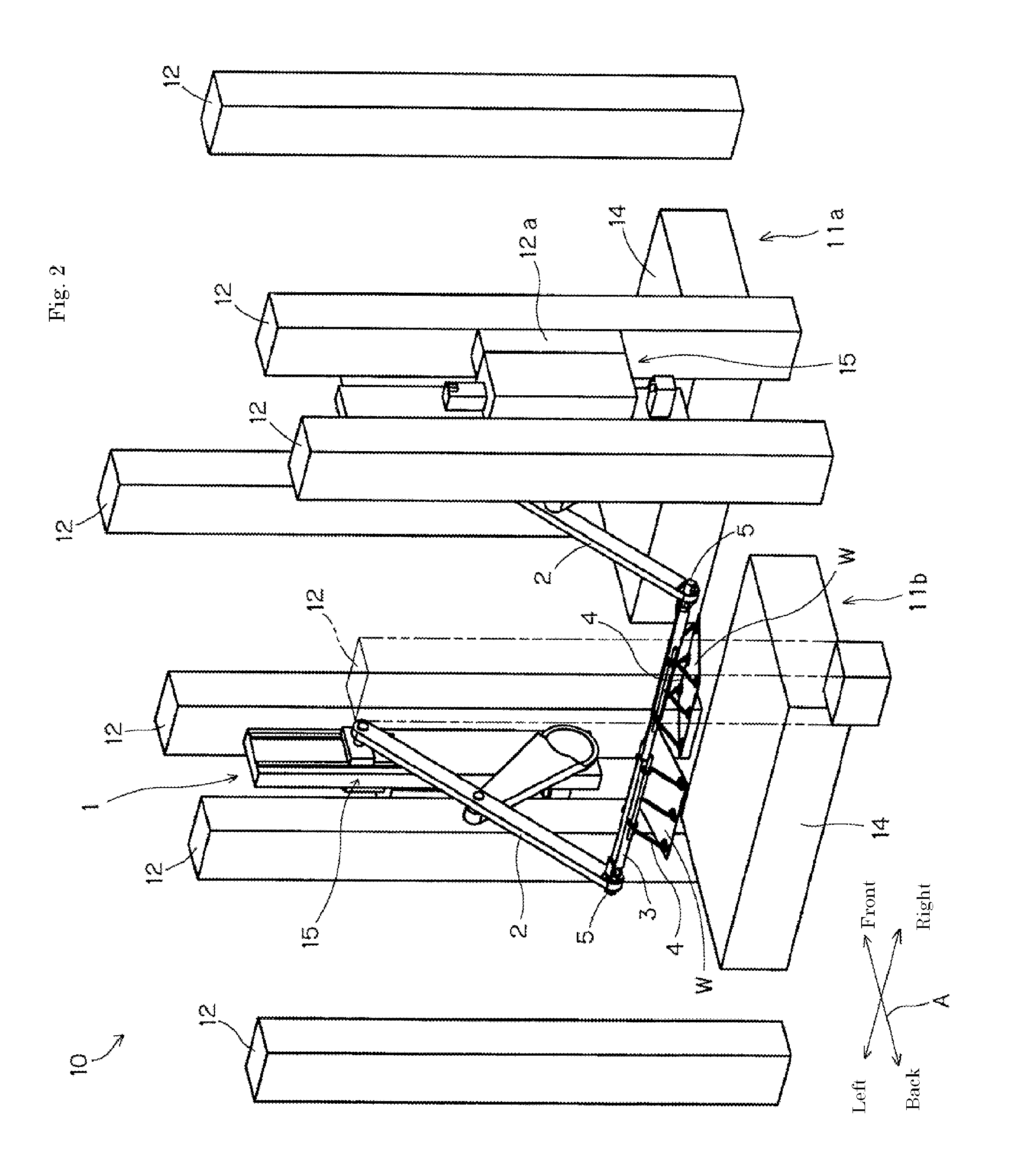

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

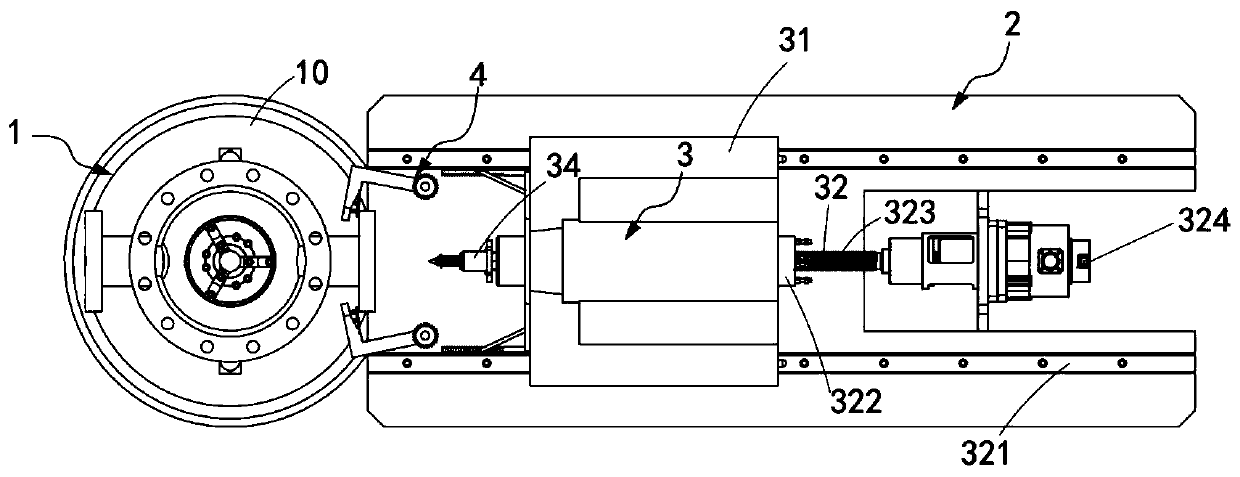

Precision roll turning lathe

ActiveCN101062543AHigh precision machiningSuppress feverPropelling pencilsWorkpiecesMilling cutterTransverse groove

There is provided a precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 33. The precision roll turning lathe can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface.

Owner:TOSHIBA MASCH CO LTD

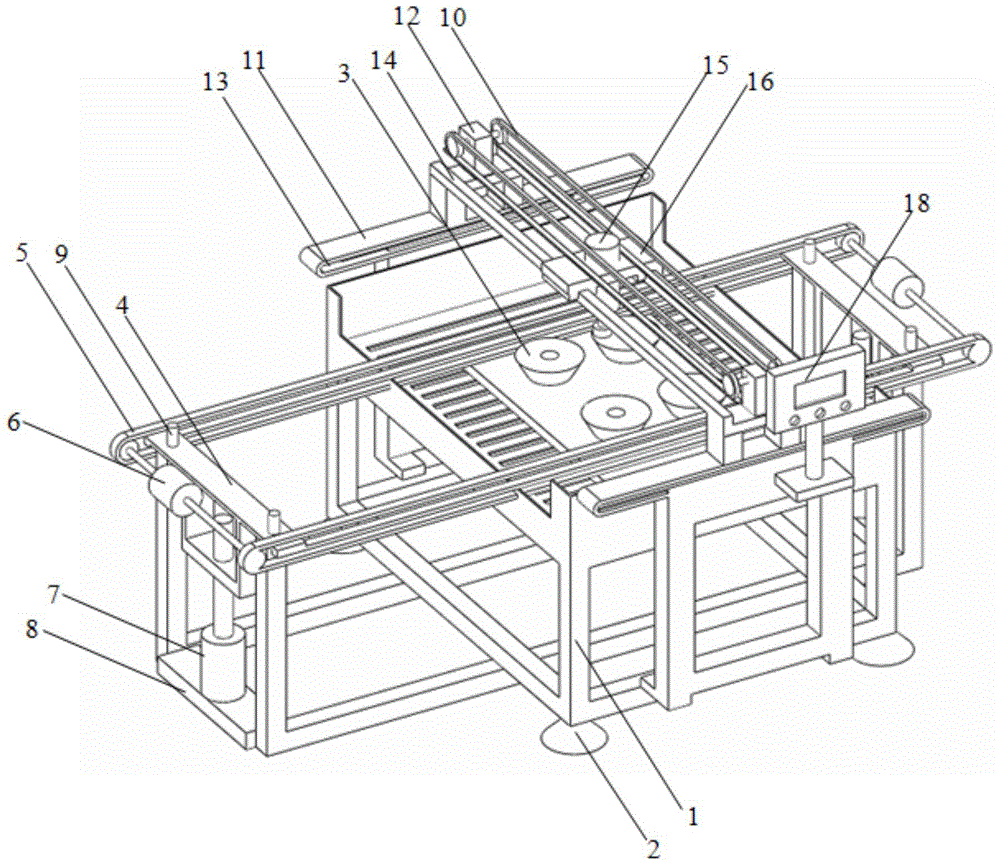

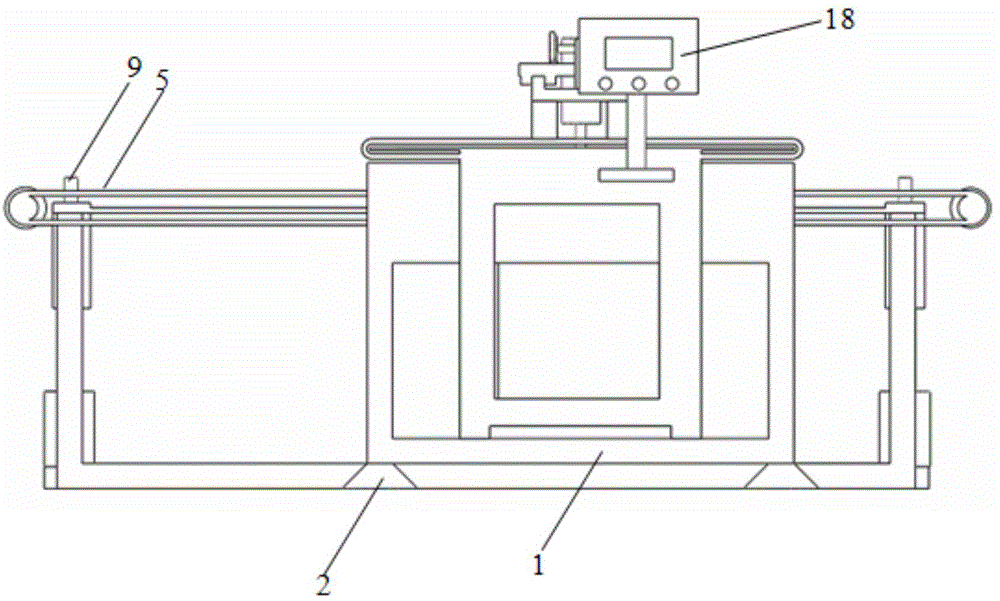

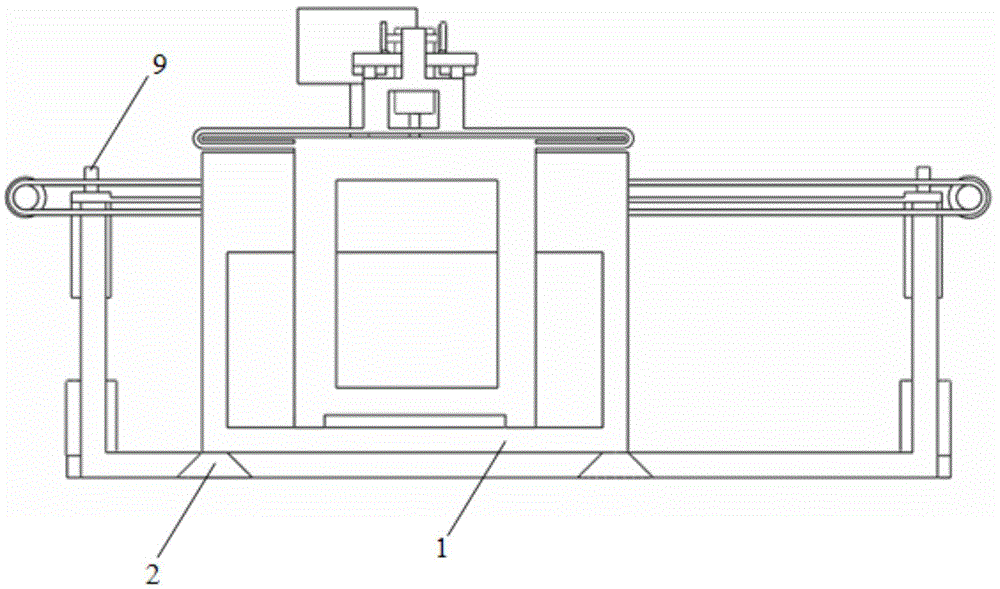

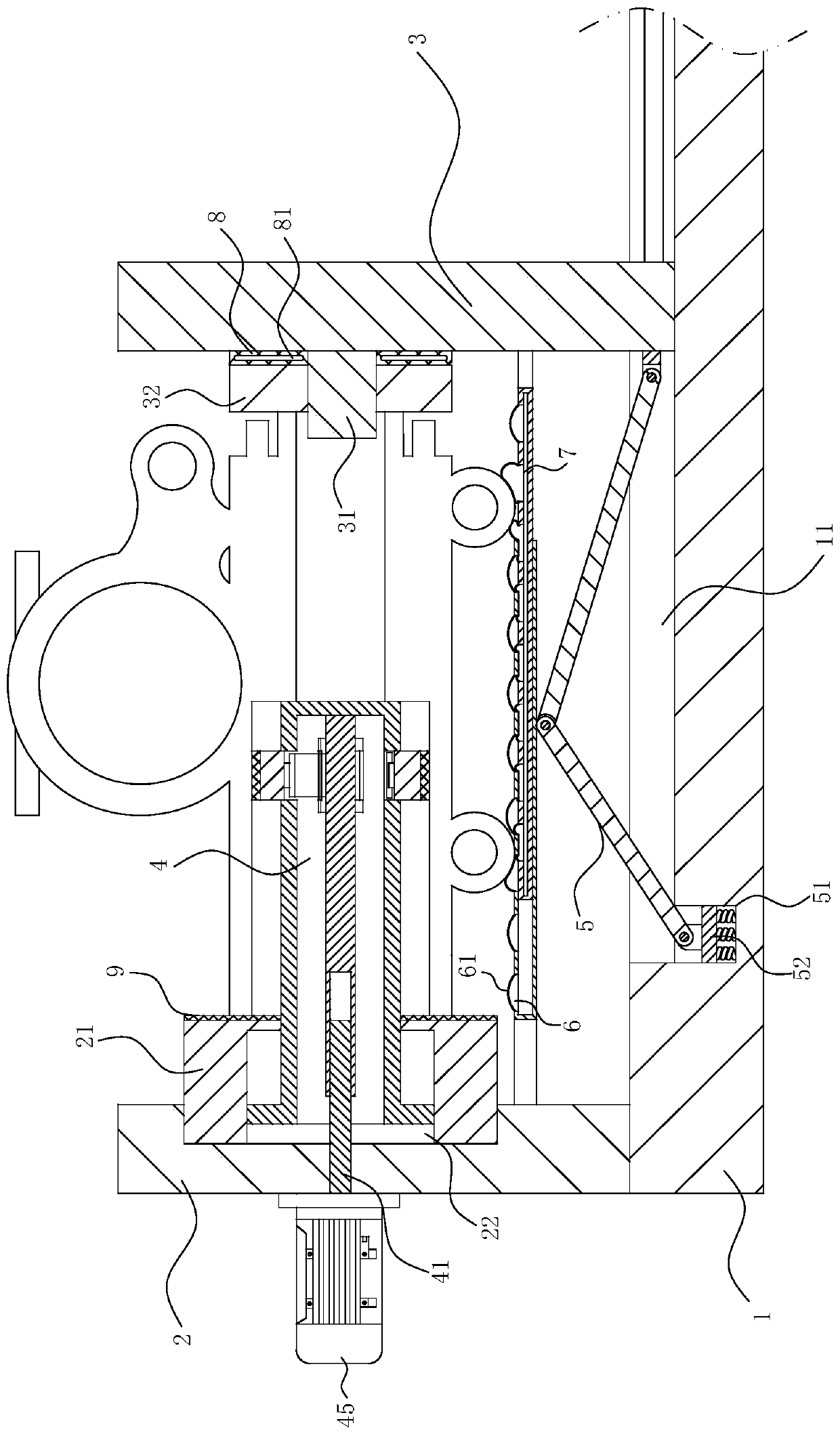

Automatic feeding type glass abnormally-shaped edge grinding mechanism

InactiveCN104816216AAvoid low machining accuracyEdge grinding machinesGrinding feedersElectric controlGrinding wheel

The invention relates to an abnormally-shaped edge grinding machine, in particular to an automatic feeding type glass abnormally-shaped edge grinding mechanism. The automatic feeding type glass abnormally-shaped edge grinding mechanism comprises a machine frame, an automatic feeding mechanism, an automatic edge grinding mechanism and a control mechanism. The machine frame is made of square steel through welding, and self-leveling adjustable suction discs are installed on the four corners of the machine frame. The automatic feeding mechanism comprises an automatic conveying line, an automatic lifting system and suction discs. The automatic conveying line comprises a support, belt lines and stepping motors. The automatic lifting system comprises lead screw stepping motors, motor supports, lead screw nuts, guide pillars and guide sleeves. The suction discs are arranged in the center of the machine frame. The automatic edge grinding mechanism comprises X-axis belt lines, Y-axis belt lines, X-axis stepping motors, Y-axis stepping motors, an X-axis guide rail, a motor head, a motor head support and a grinding wheel. The control mechanism comprises a PLC, a touch screen and pneumatic and stop keys, wherein the PLC, the touch screen and the pneumatic and stop keys are installed in an electric control cabinet. The automatic feeding type glass abnormally-shaped edge grinding mechanism is novel in structure, high in edge grinding speed and high in accuracy, and convenient to operate, and integrates the automatic feeding function and the automatic edge grinding function.

Owner:安徽亚盛技术开发有限责任公司

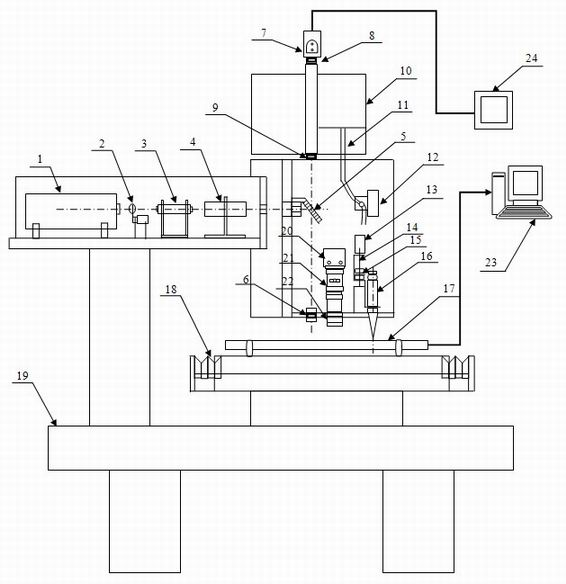

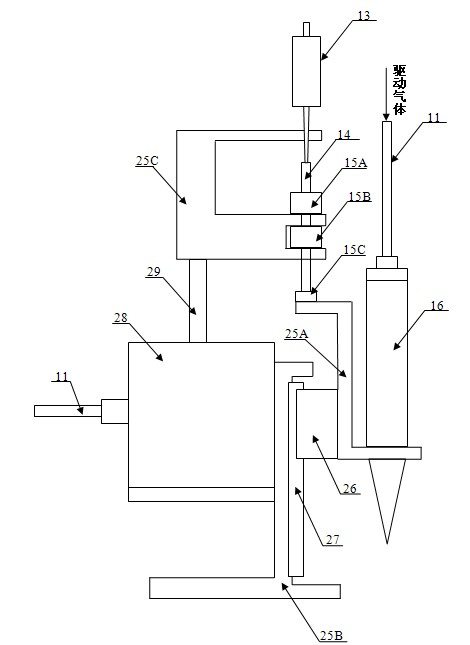

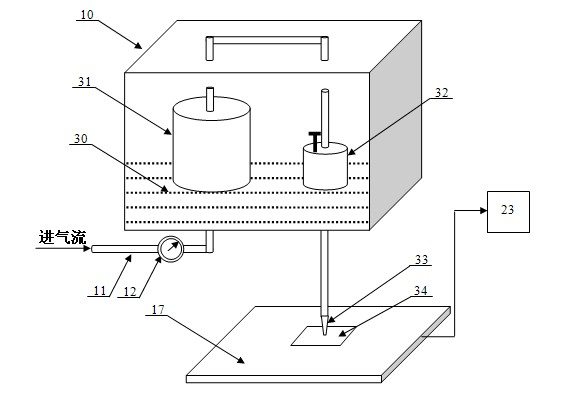

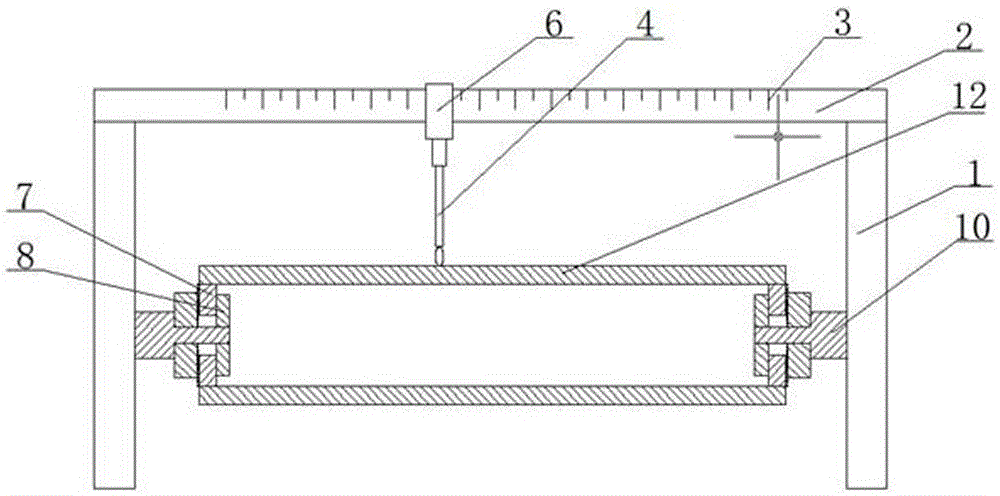

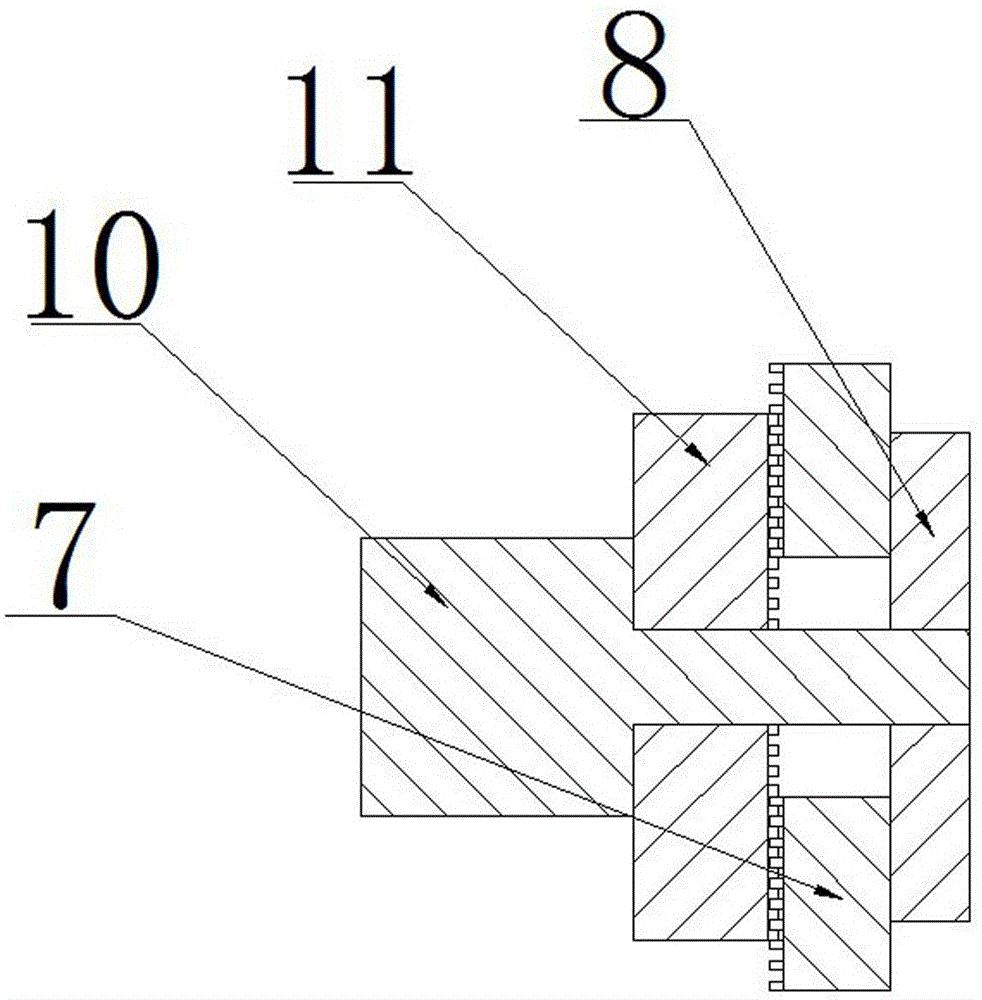

Special equipment for laser micro-cladding

ActiveCN102011123AShorten processing timeGuaranteed accuracyMetallic material coating processesLaser beam welding apparatusOptical pathPhysics

The invention discloses special equipment for laser mirco-cladding. The equipment comprises a workbench, a laser processing system and a control system, and is characterized by also comprising a charge coupled device (CCD) monitoring and positioning system and a direct writing system, wherein the CCD monitoring and positioning system comprises a coaxial CCD sensor, a paraxial CCD sensor, a zoom lens, an imaging eye lens, a zoom optical system, a paraxial imaging object lens and an external monitor; the direct writing system comprises a micro-pen direct writing device and a micro-jet direct writing device; the micro-pen direct writing device comprises a support, a guide rail, a cylinder, a slider, a piston rod, a dial gauge, a micro adjustment nut and a micropen; and the micro-jet direct writing device comprises a water bath kettle, a gas-guide tube, a micro-pressure gauge and a micro-jet tool. In respect of the equipment, a laser optical path and the installation stations and working modes of the micro-jet direct writing device and the micropen are reasonably designed, and laser processing, the micropen and the micro-jet direct writing system are integrated on the same working platform, thereby realizing advantage complementation of various processing methods.

Owner:HUAZHONG UNIV OF SCI & TECH

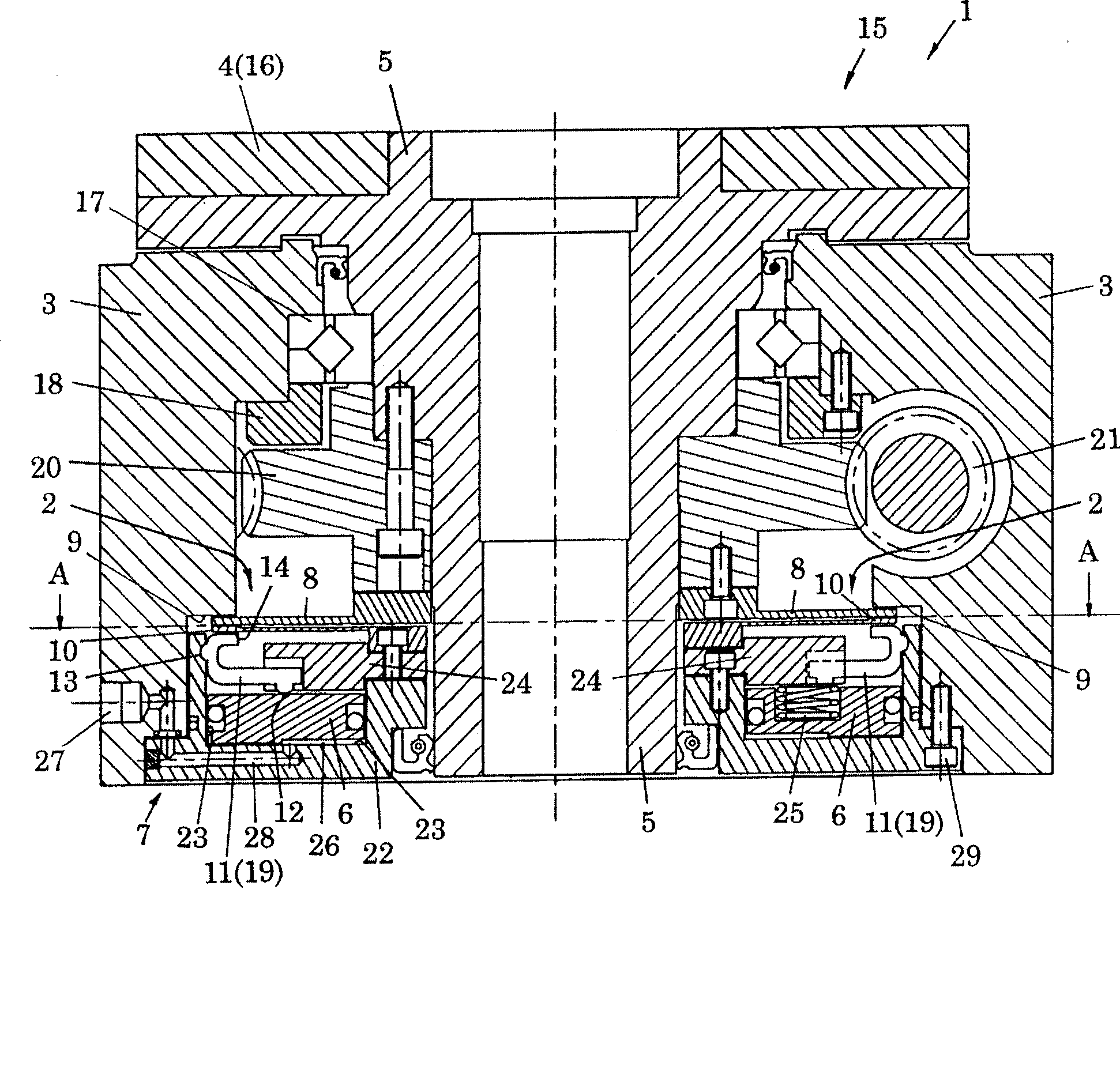

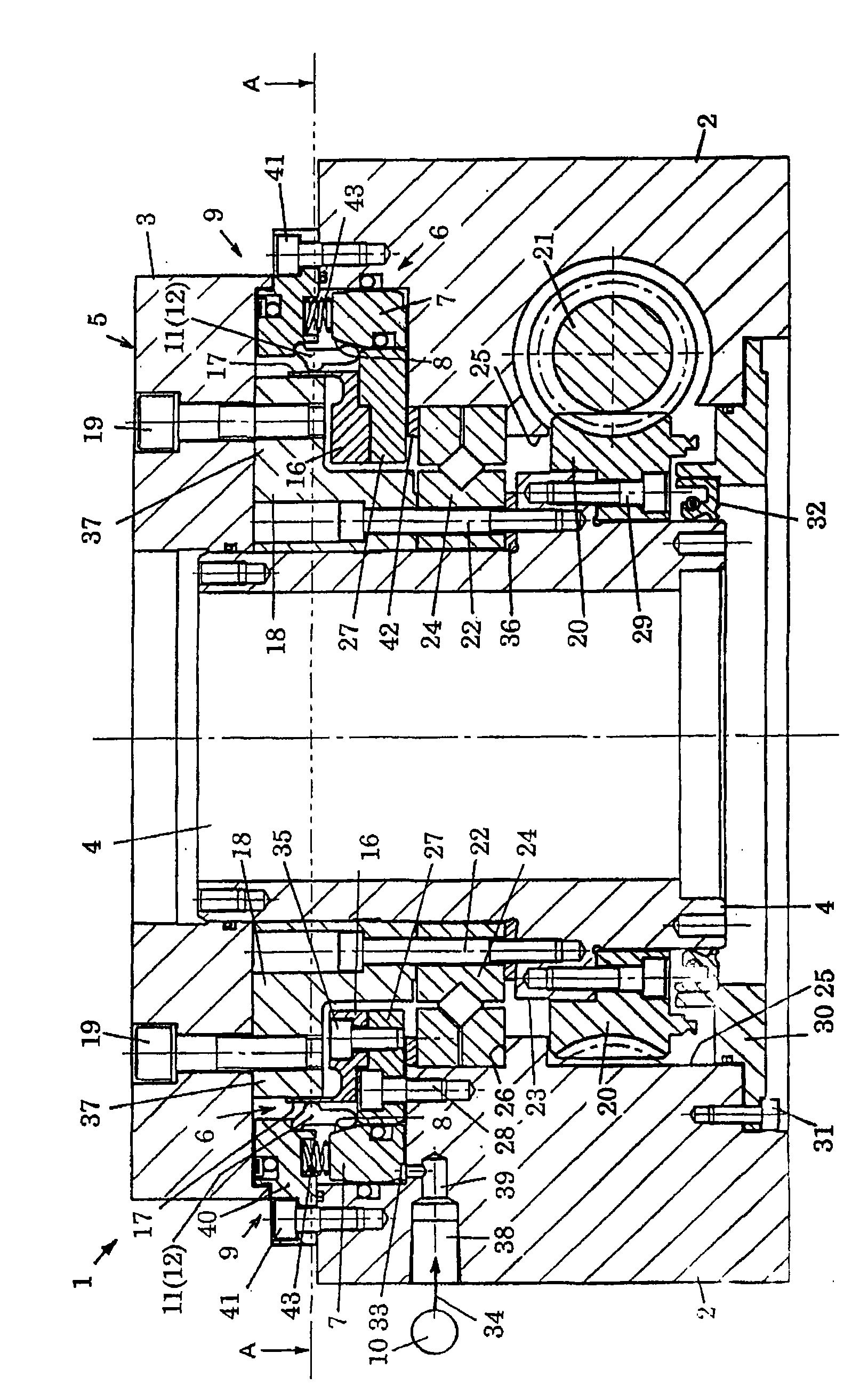

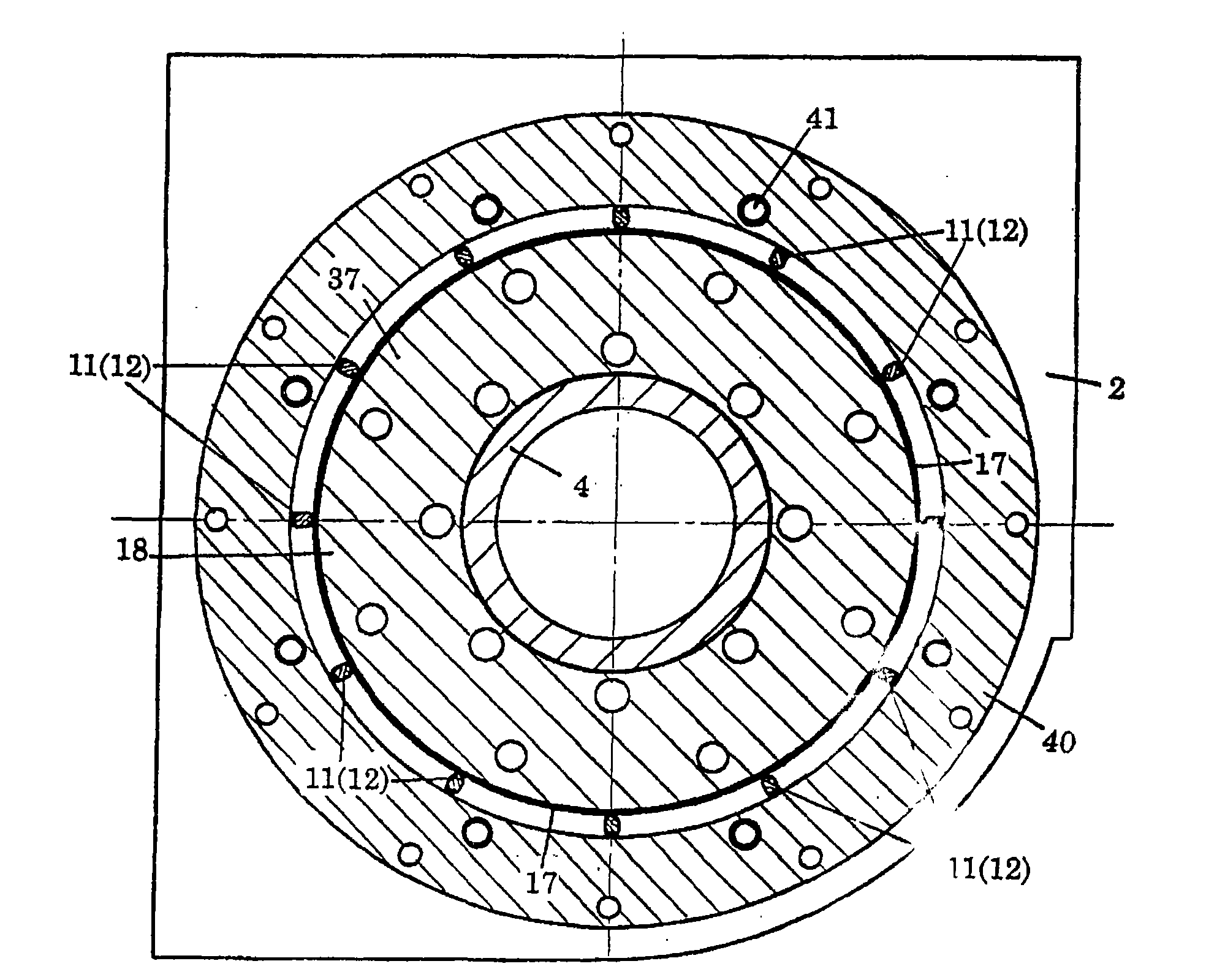

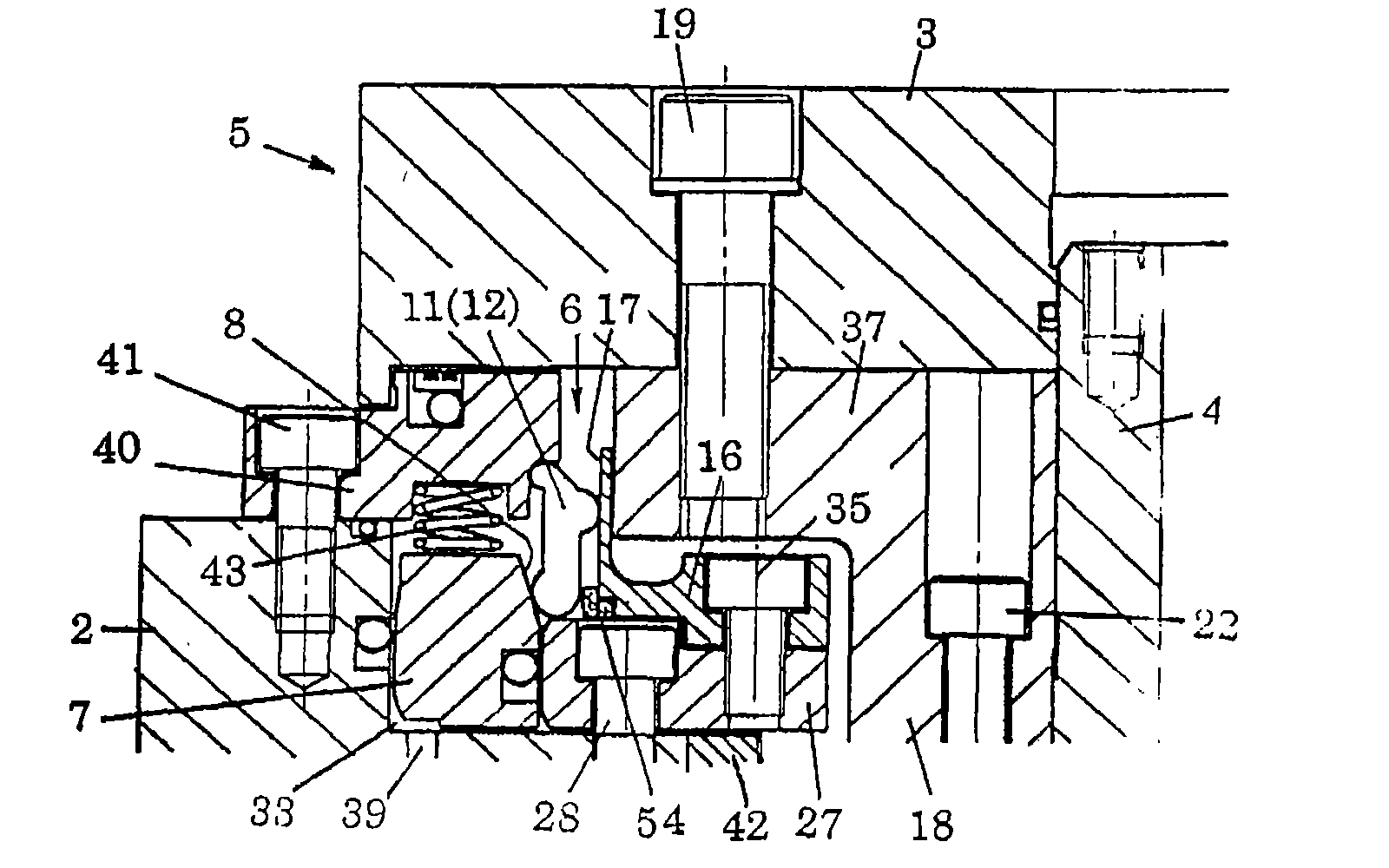

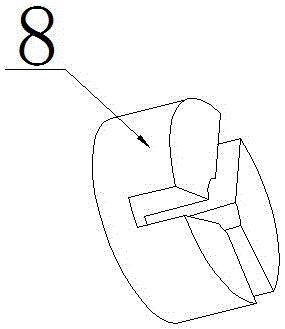

Clamping device for rotation dividing device for machine tool

InactiveCN101396797APrevents reduction in machining accuracyMiniaturizationPrecision positioning equipmentMachine tool componentsPistonRotational axis

The present invention relates to a clamping device of a rotation indexing device used by a machine tool. The invention provides a clamping mechanism which can endure high-load procession and generates enough clamping force in the clamping device of a rotation indexing device used by a machine tool. The clamping device (2) is provided with a clamping mechanism which is set with a mode of extending along a radius direction of rotation axis (5) and is composed of more than three lever components (11) between a clamping disc (8) and a piston component (6). The pulling force of the piston component (6) is increased through a lever principle and is acted on the clamping disc (8).

Owner:TSUDAKOMA KOGYO KK

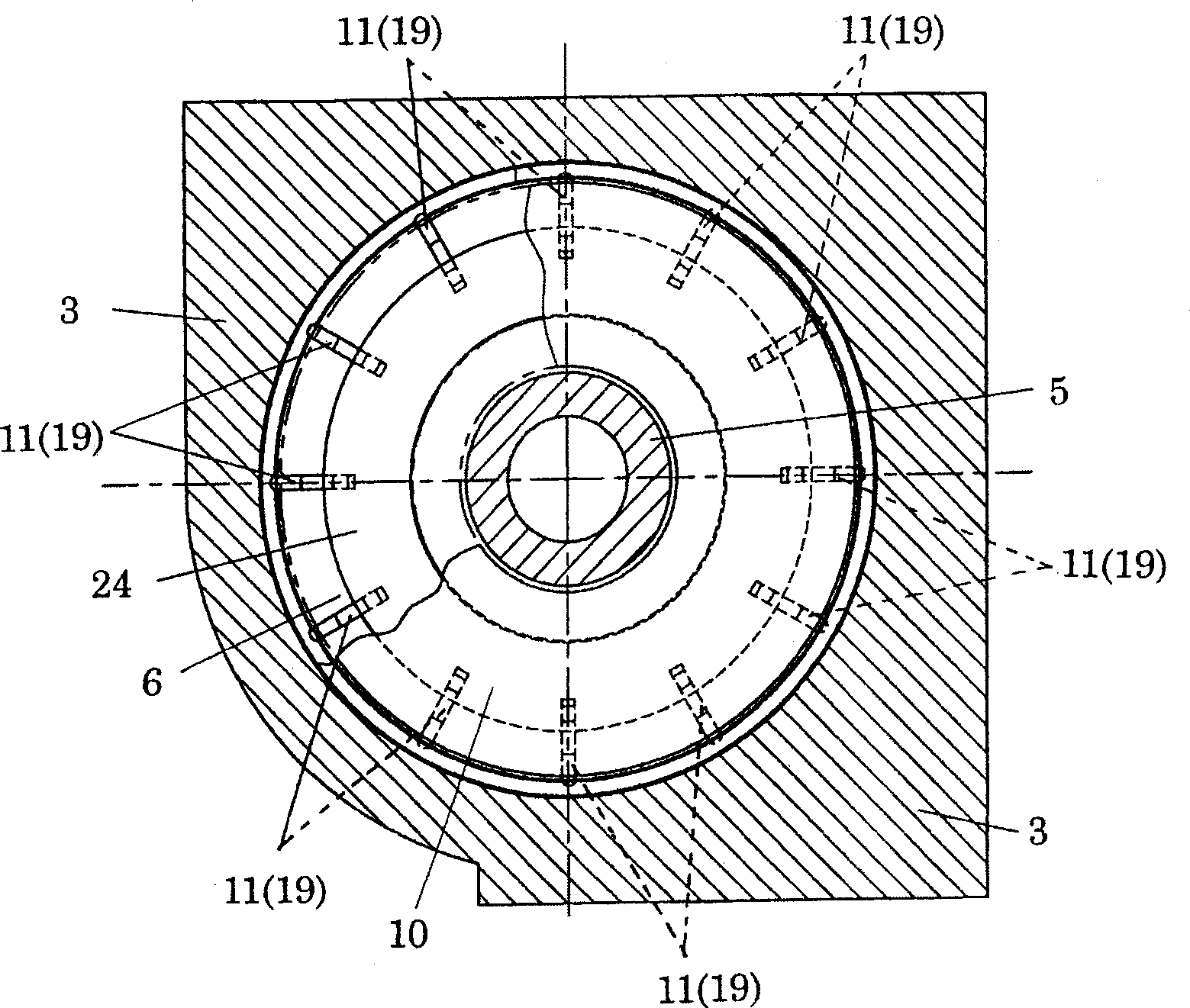

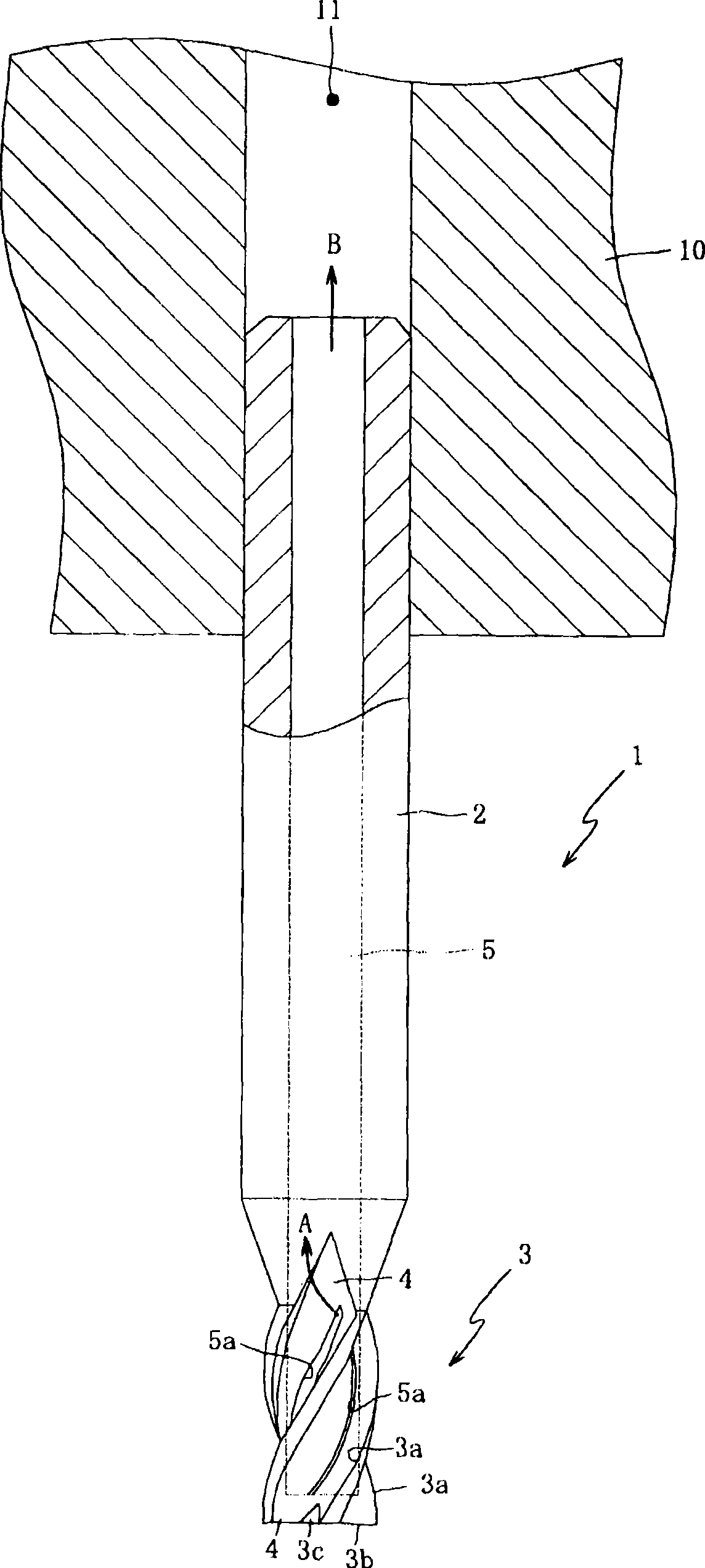

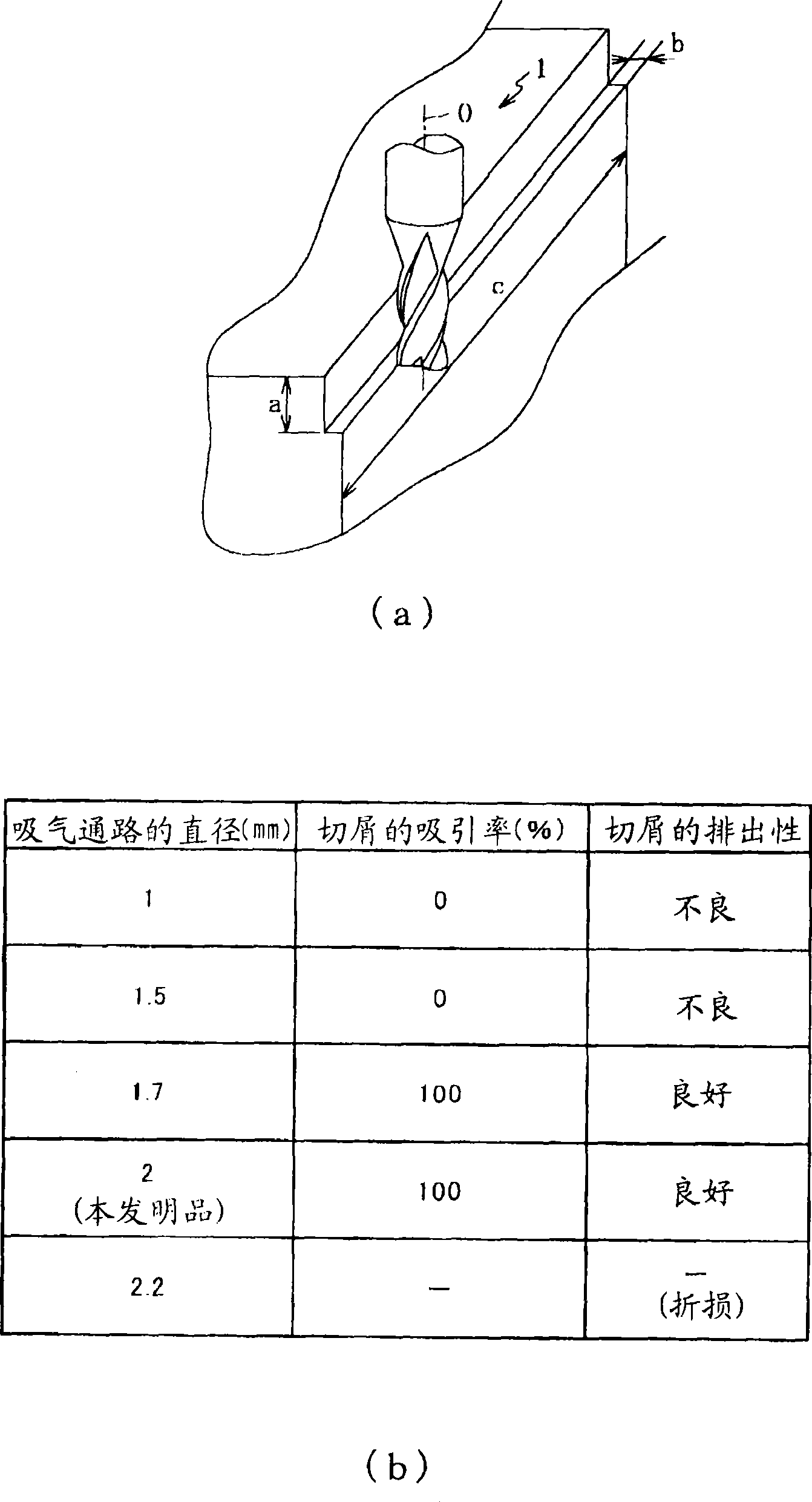

End milling tool

InactiveCN101394962AProhibition of useReduce recycling costsMilling cuttersShaping cuttersFluteMilling cutter

An end mill that realizes prevention of environmental pollution. End mill (1) has aperture (5a) resulting from opening forming along helical flute (4). The aperture (5a) is so structured as to communicate via air suction channel (5) with an opening of the rear end face of shank (2). Accordingly, by air suction through the air suction channel (5), chips generated at cutting processing can be forcibly suctioned from the aperture (5a), and the suctioned chips can be discharged outside from the opening of the rear end face of shank (2). As a result, as compared with conventional products, the use of cutting liquid for eliminating of chips can be suppressed (or rendered unnecessary) to thereby attain prevention of environmental pollution.

Owner:OSG

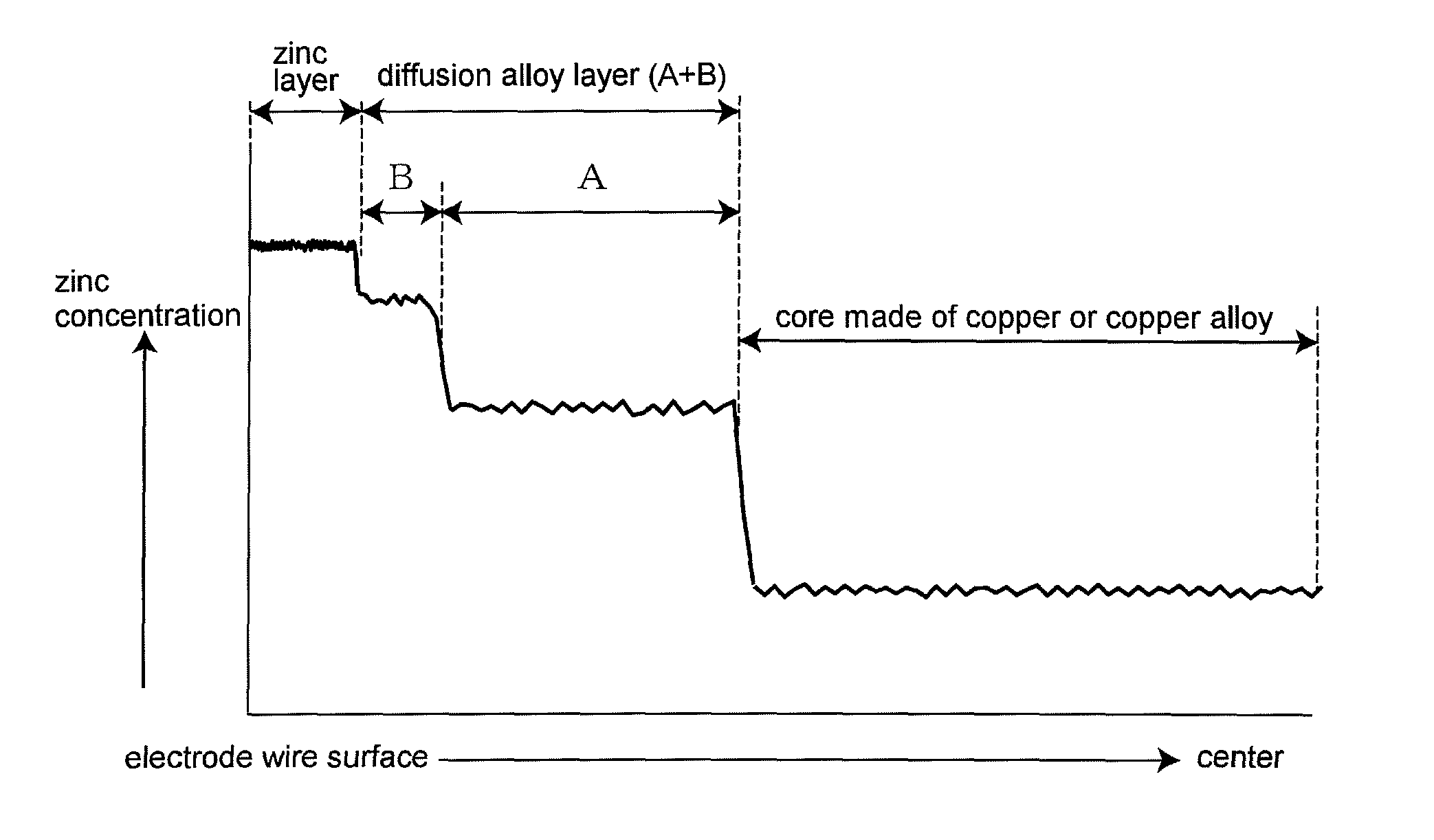

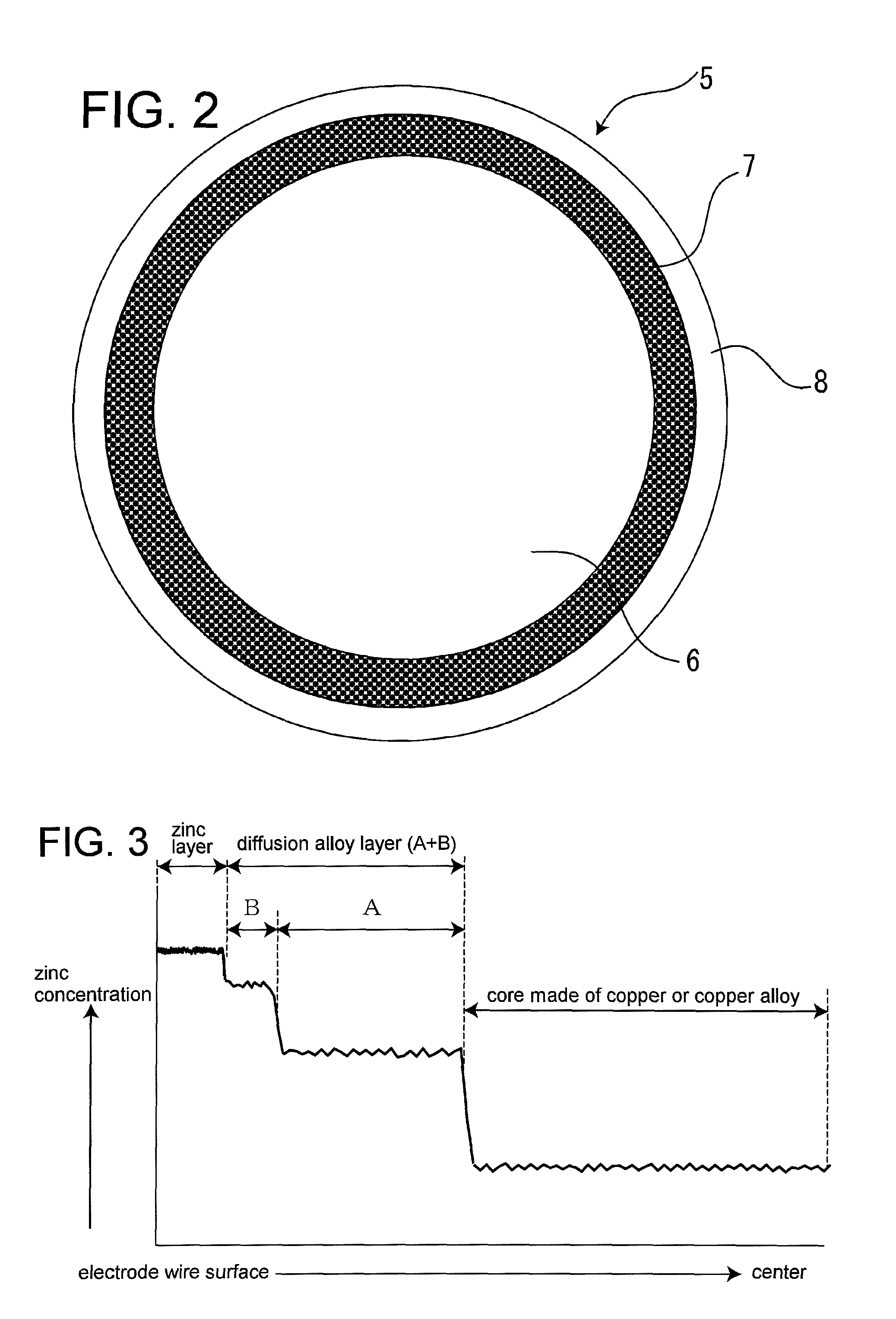

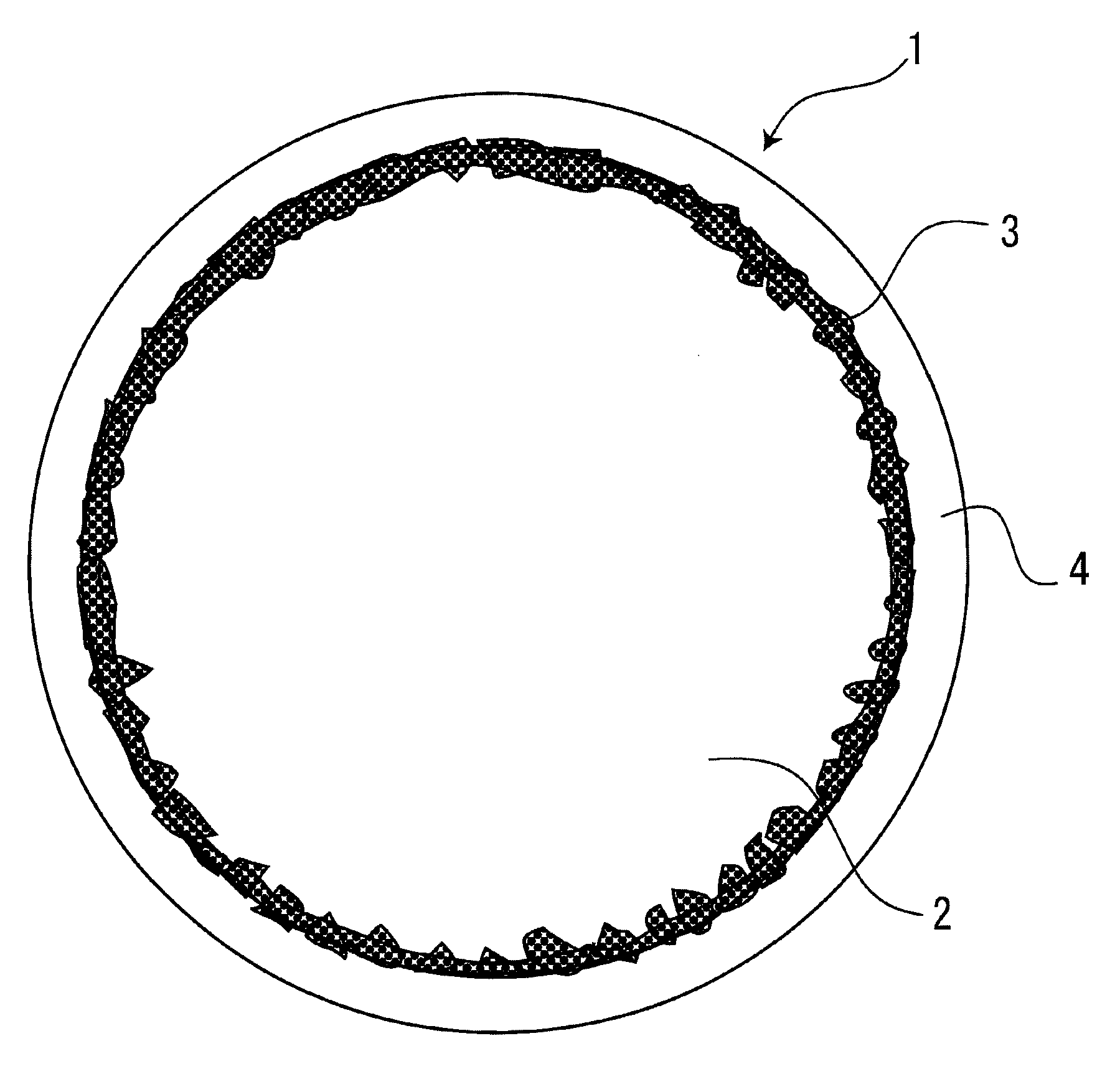

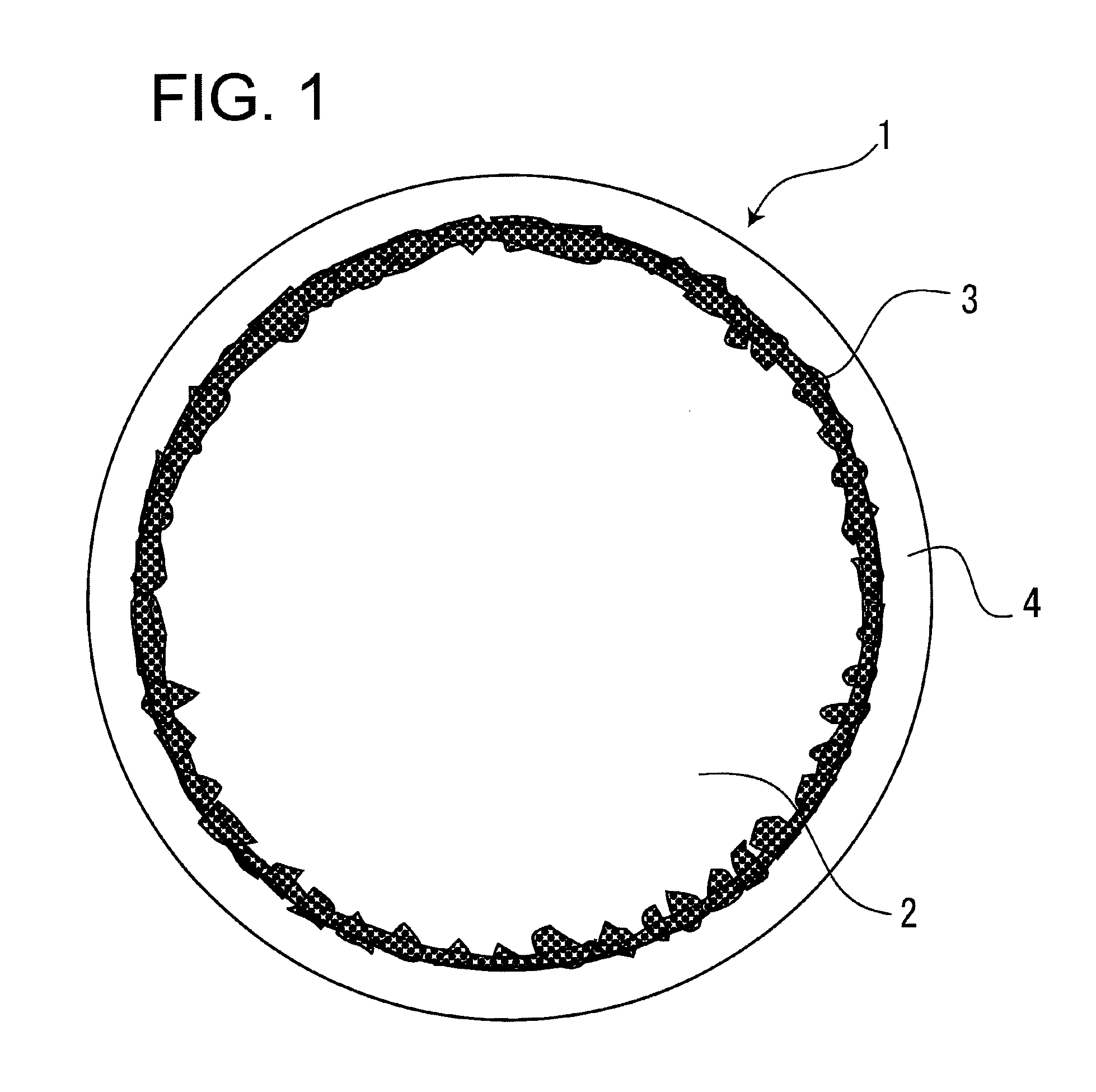

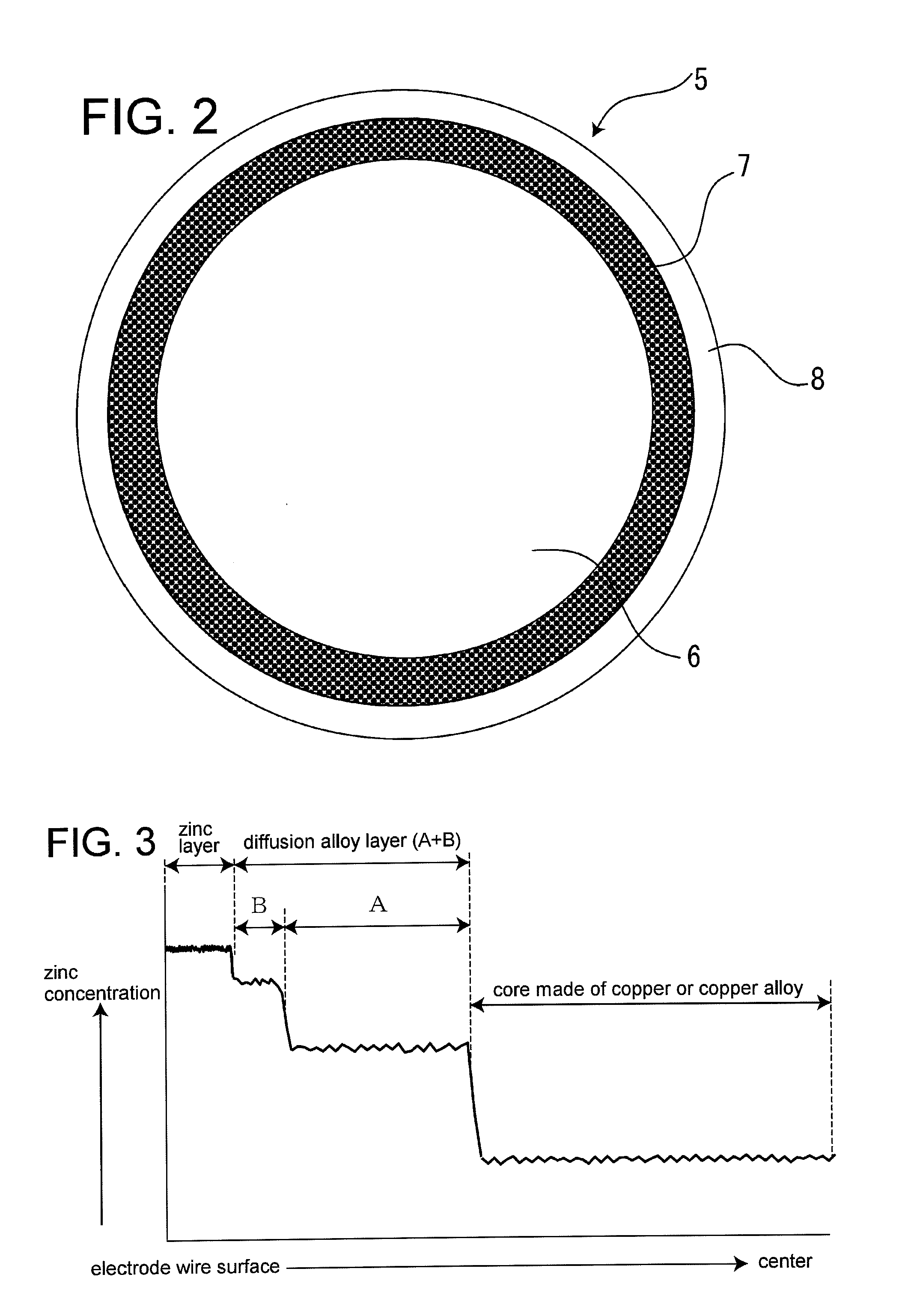

Electrode wire for wire electrical discharge machining, method for manufacturing the same, and method for electrical discharge machining using the same

InactiveUS8445807B2Avoid low machining accuracyImprove abilitiesElectrical-based machining electrodesThin material handlingZinc alloysCopper

A wire material having a copper-zinc alloy layer, which is formed by action of thermal diffusion, and a zinc layer on its circumference surface is subjected to processes, including from a step of drawing the wire material to a step of reducing the diameter of the product, to reliably crash the copper-zinc alloy layer into particles. The particles are embedded in the circumference surface of a core to integrate the diffusion alloy layer and zinc layer with the core and prevent the diffusion alloy layer and zinc layer from falling off from the core. In addition, in order to cover cracks formed in the copper-zinc alloy layer during wire drawing with a zinc thin film, wire drawing is performed at temperatures appropriate for maintaining good malleability and ductility of zinc.

Owner:OKI ELECTRICAL CABLE

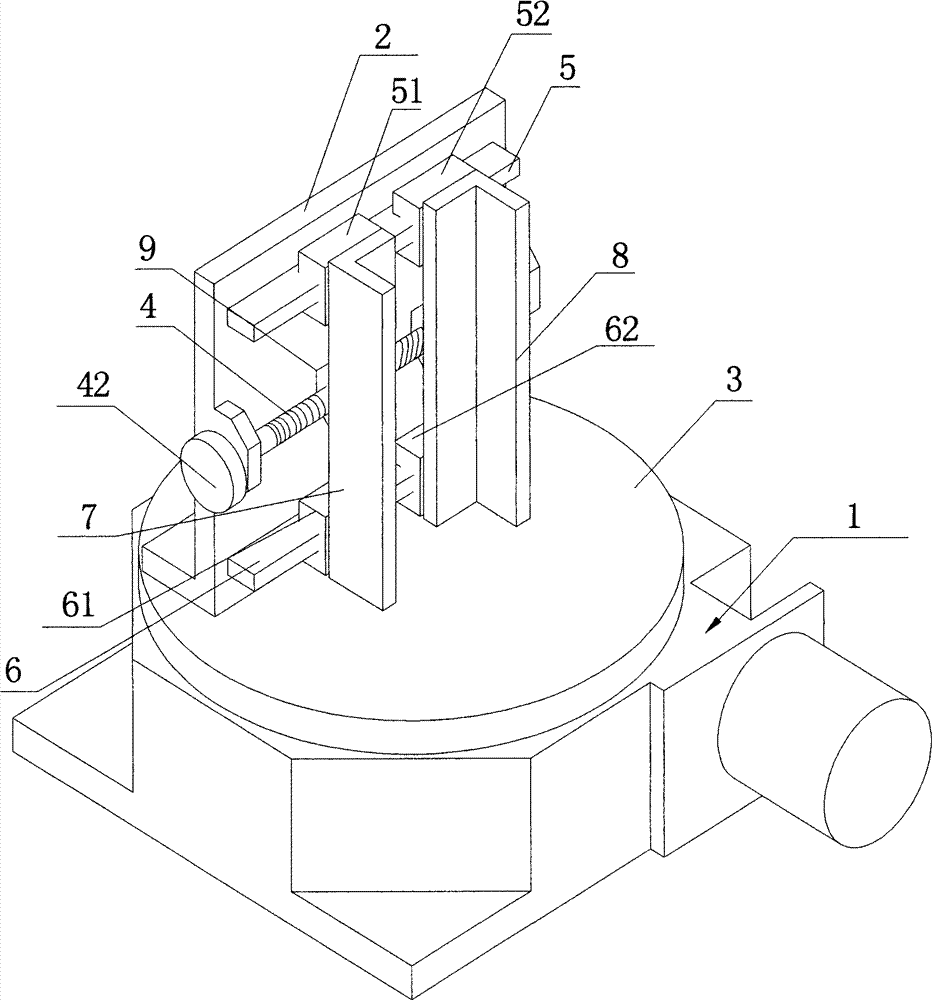

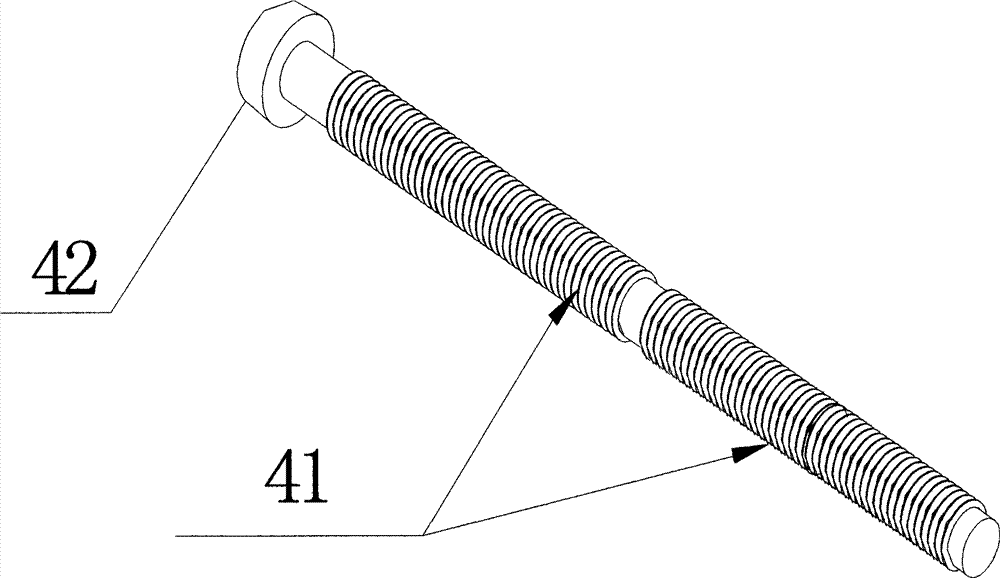

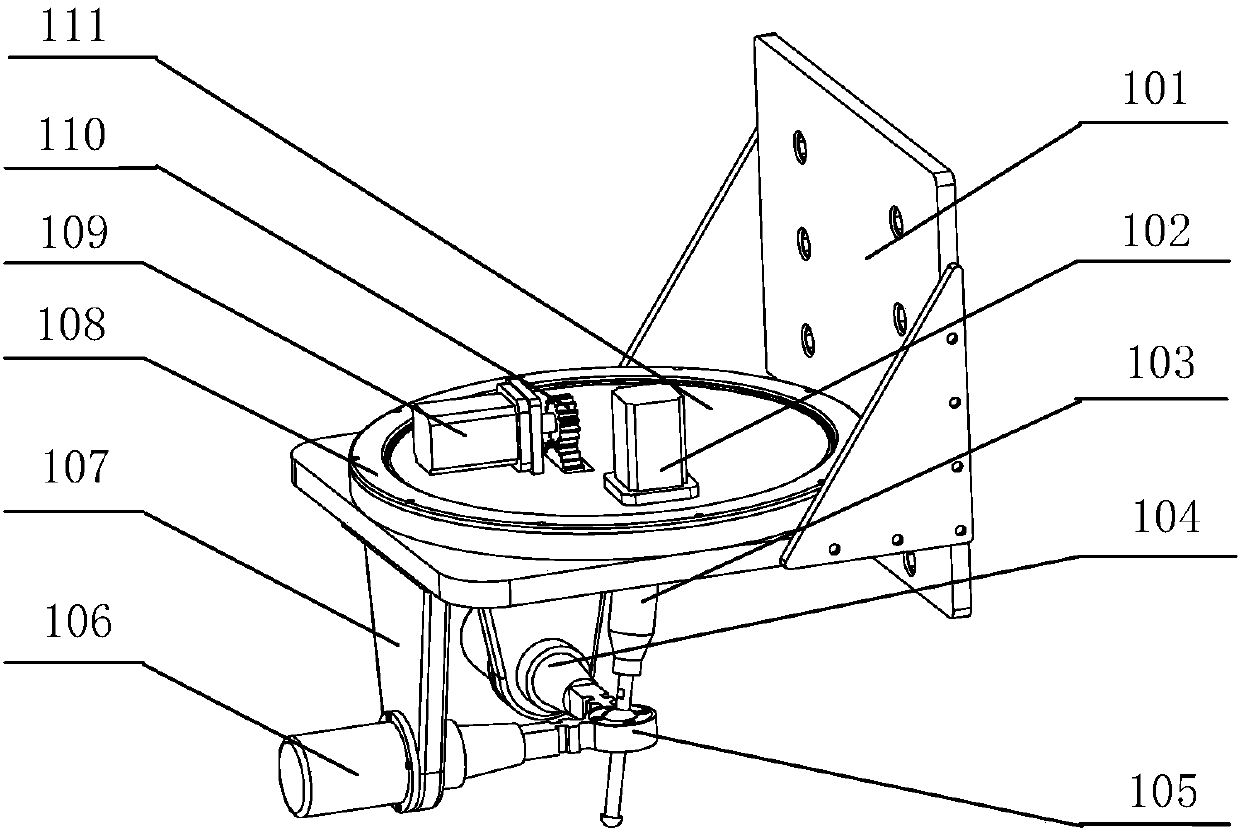

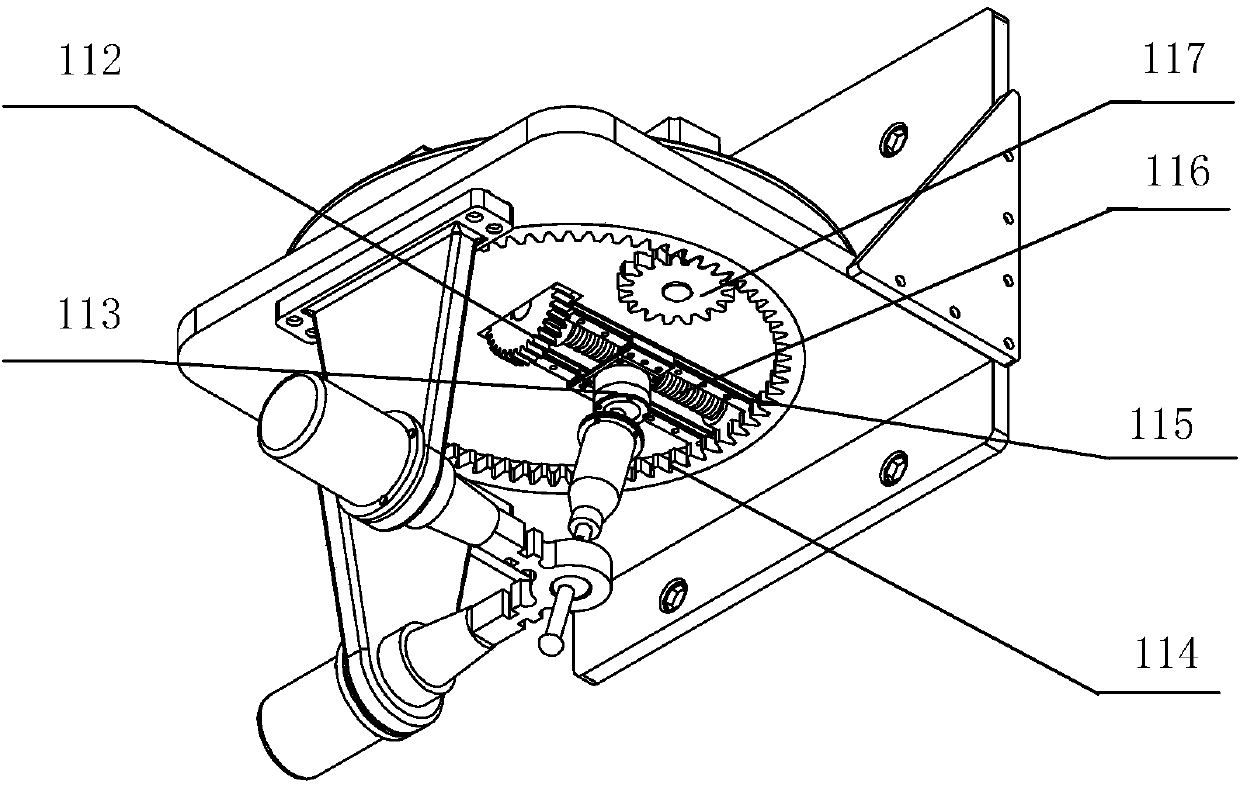

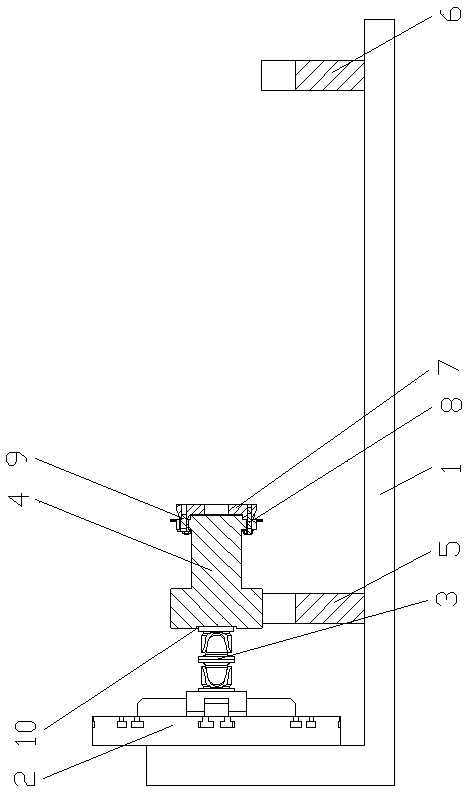

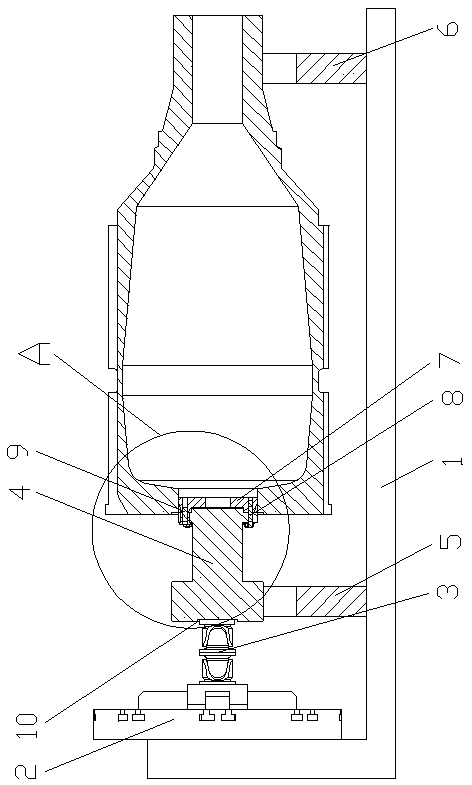

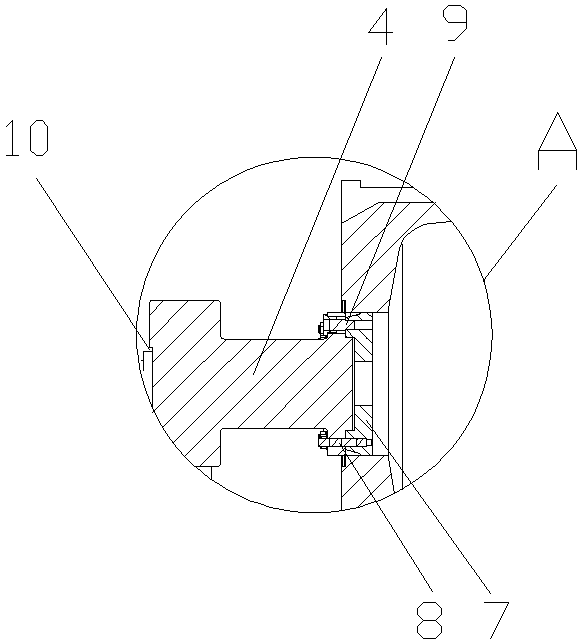

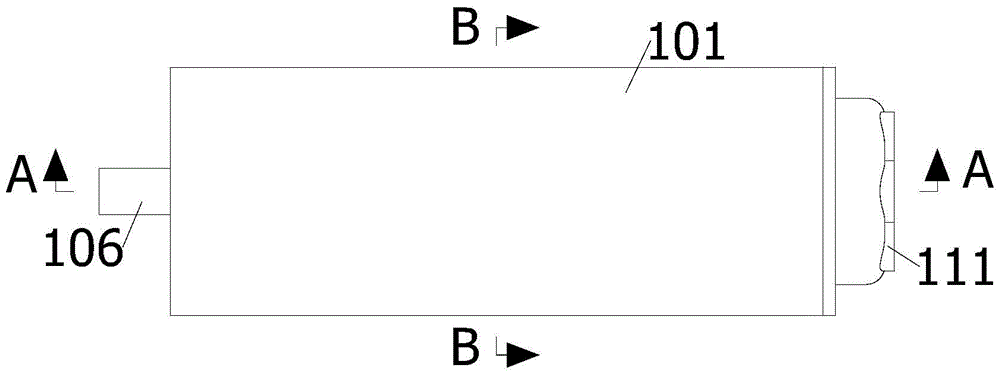

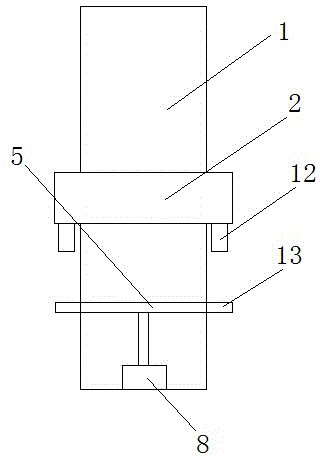

Battery case laser welding clamp

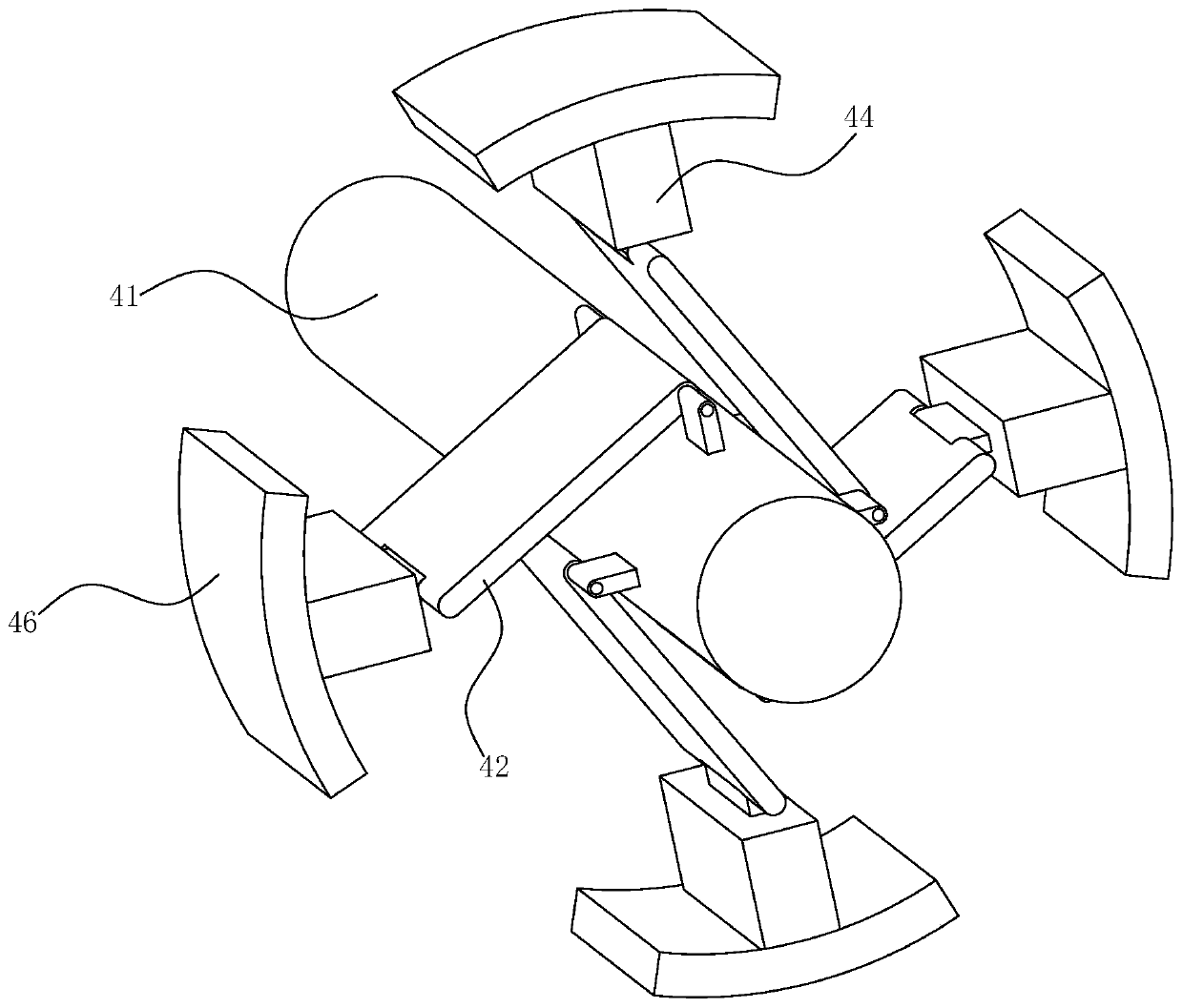

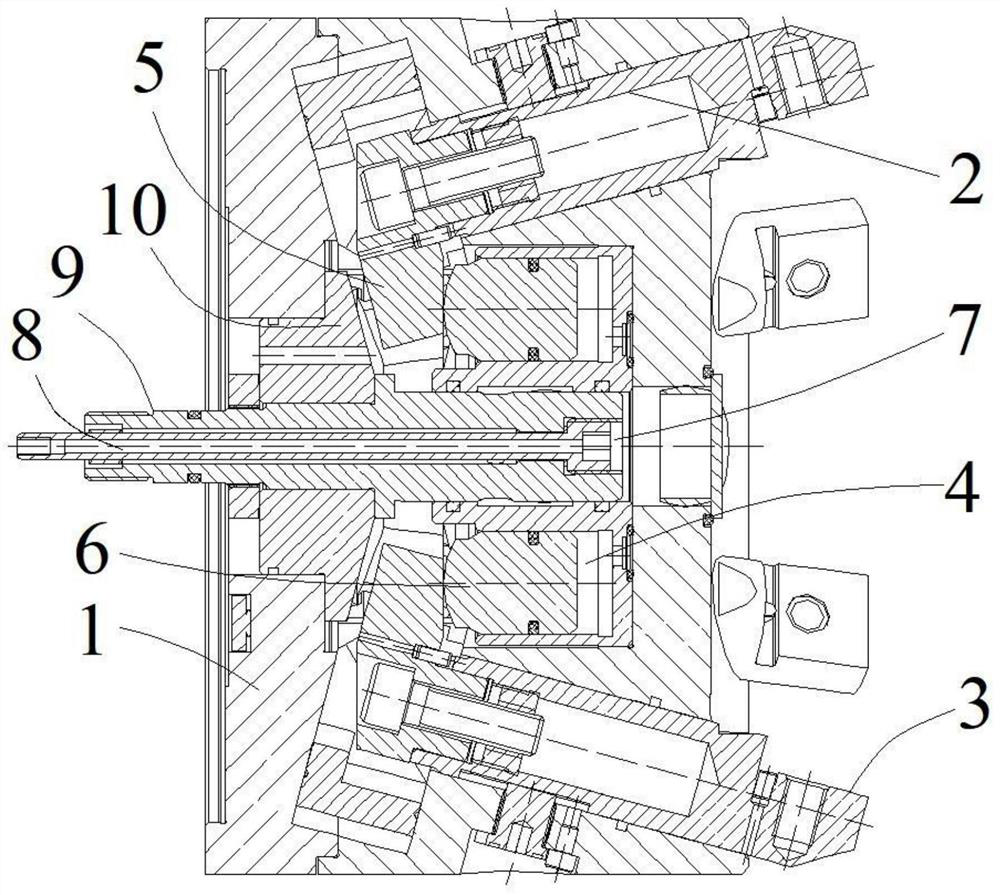

InactiveCN104741804AEnsure consistencyAvoid low machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectrical and Electronics engineering

The invention aims to provide a battery case laser welding clamp. A centering gap adjusting mechanism can guarantee a stable structure, and the consistency of the center of a fixed battery and the center of an indexer disk is good when the type of the battery is replaced, so the product quality is improved. In order to achieve the effect, the battery case laser welding clamp comprises a pedestal and the centering gap adjusting mechanism which is arranged on the pedestal, wherein the centering gap adjusting mechanism comprises a back plate which is arranged on the pedestal; an indexer is arranged between the pedestal and the back plate; an adjusting screw is arranged on the horizontal middle axis of the back plate and penetrates through the nut to be connected with left and right battery clamping plates. Since the technical scheme is adopted, when the type of the battery of the battery case laser welding clamp is replaced, only a spinner is required to be rotated to drive the adjusting screw; the left battery clamping plate and the right battery clamping plate move symmetrically along the longitudinal middle axis of the back plate to guarantee that the consistency of the center of the battery between the left battery clamping plate and the right battery clamping plate and the center of the indexing disk and avoid reduction in machining precision due to replacement of the battery.

Owner:邬汝源

Automobile steering machine shell arm hole boring fixture

InactiveCN111113091AImprove fastnessAvoid low machining accuracyPositioning apparatusBoring/drilling componentsStructural engineeringMachining

The invention belongs to the technical field of machining fixtures, and particularly relates to an automobile steering machine shell arm hole boring fixture. The automobile steering machine shell armhole boring fixture comprises a base, a fixed plate and a moving plate; the fixed plate is fixedly connected to the upper surface of the base; a limiting block is embedded into one side of the fixed plate; a positioning column is slidably connected to the interior of a first sliding groove; the moving plate is installed on the side, far away from the fixed plate, of the upper surface of the base;a guiding rod is fixedly connected to the surface of the side, close to the fixed plate, of the moving plate; an auxiliary ring is slidably connected to the guiding rod; a second sliding groove is formed in the positioning column; a rotating roll is rotatably connected to the interior of the second sliding groove; hinge plates which are evenly arranged are hinged to the surface of the rotating roll; the surface of the positioning column is provided with third sliding grooves which are evenly formed; sliding blocks are slidably connected to the interiors of the third sliding grooves; and the sliding blocks are hinged to the hinge plates. According to the automobile steering machine shell arm hole boring fixture, the positioning column penetrates through a through hole of a steering machineshell and fixes the steering machine shell in the through hole, and then the whole steering machine shell is clamped.

Owner:铜陵市逸欣机械制造有限公司

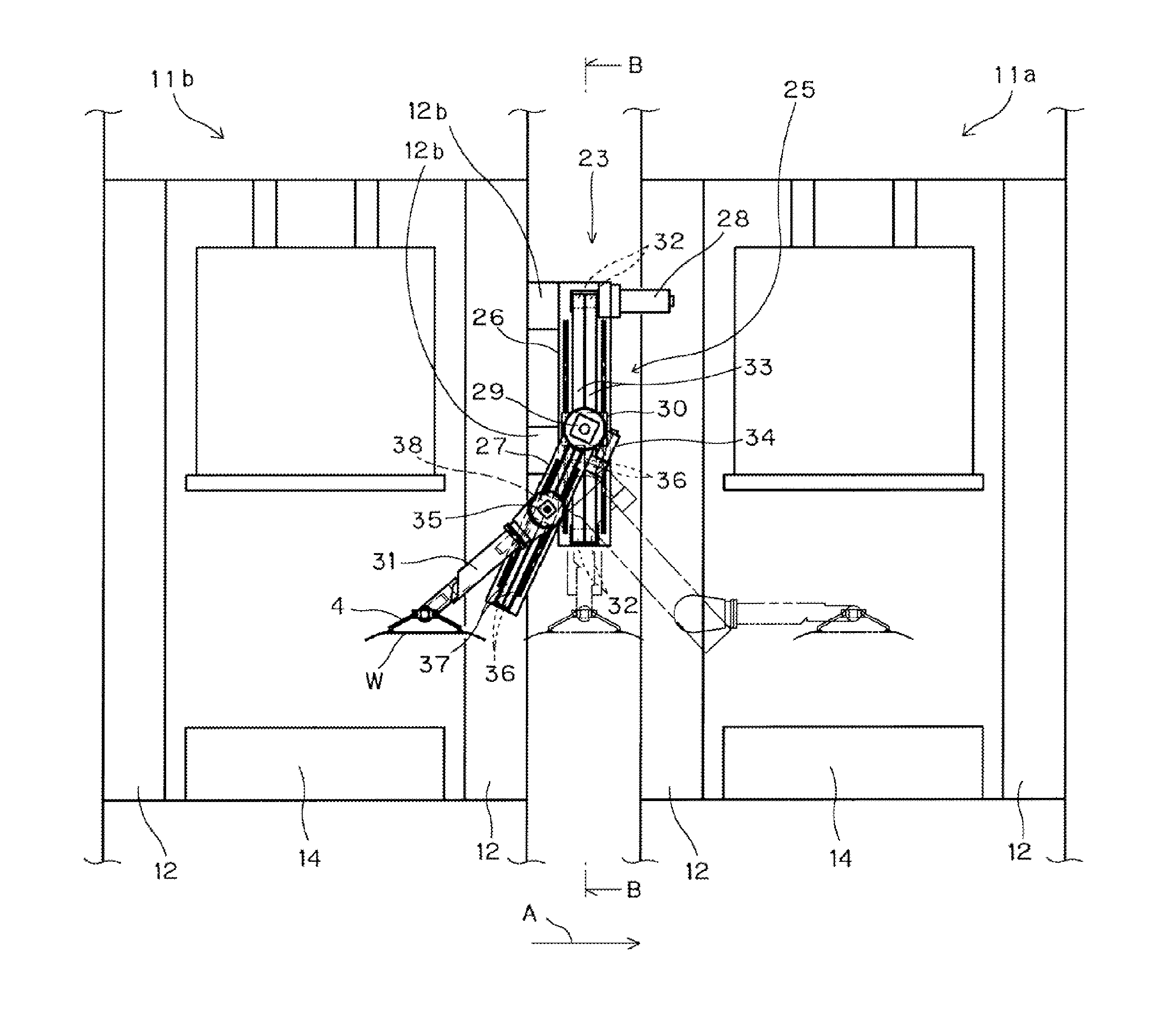

Work transfer apparatus

ActiveUS20130309050A1Easy to disassembleAvoid low machining accuracyMetal-working feeding devicesPositioning devicesEngineeringArm moving

To provide a work transfer apparatus which can transfer works at high speed with controlling respectively the posture of the right and left of works. The work transfer apparatus includes an arm moving back and forth between machines in order to transfer work(s), a crossbar coupled to the arm, and a pair of right and left work holding devices provided at the left and right sides of the crossbar and tilt drive devices being provided on the arm, respectively controlling the work holding devices to rotate around an axis of a longitudinal direction of the crossbar.

Owner:AIDA ENG LTD

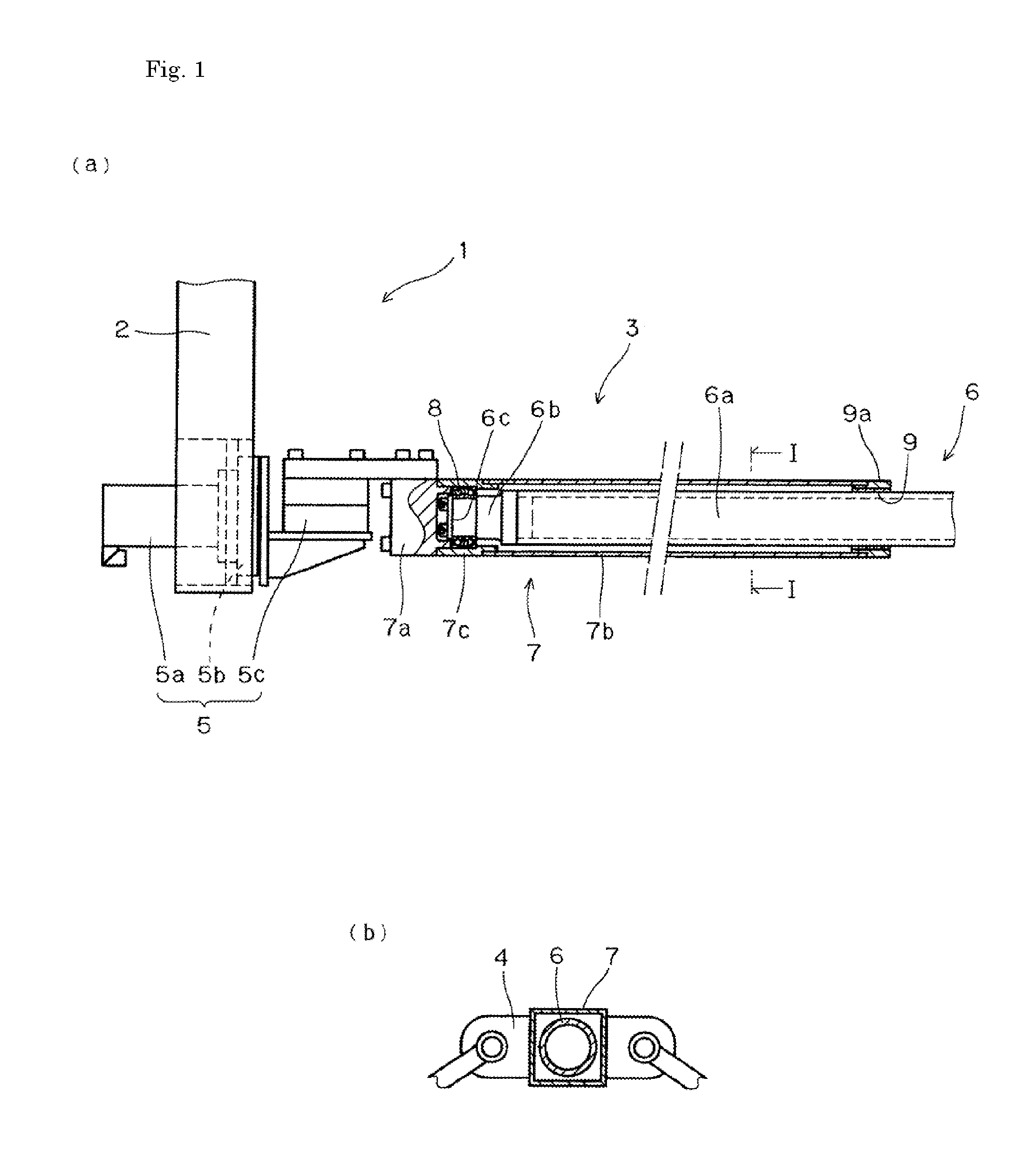

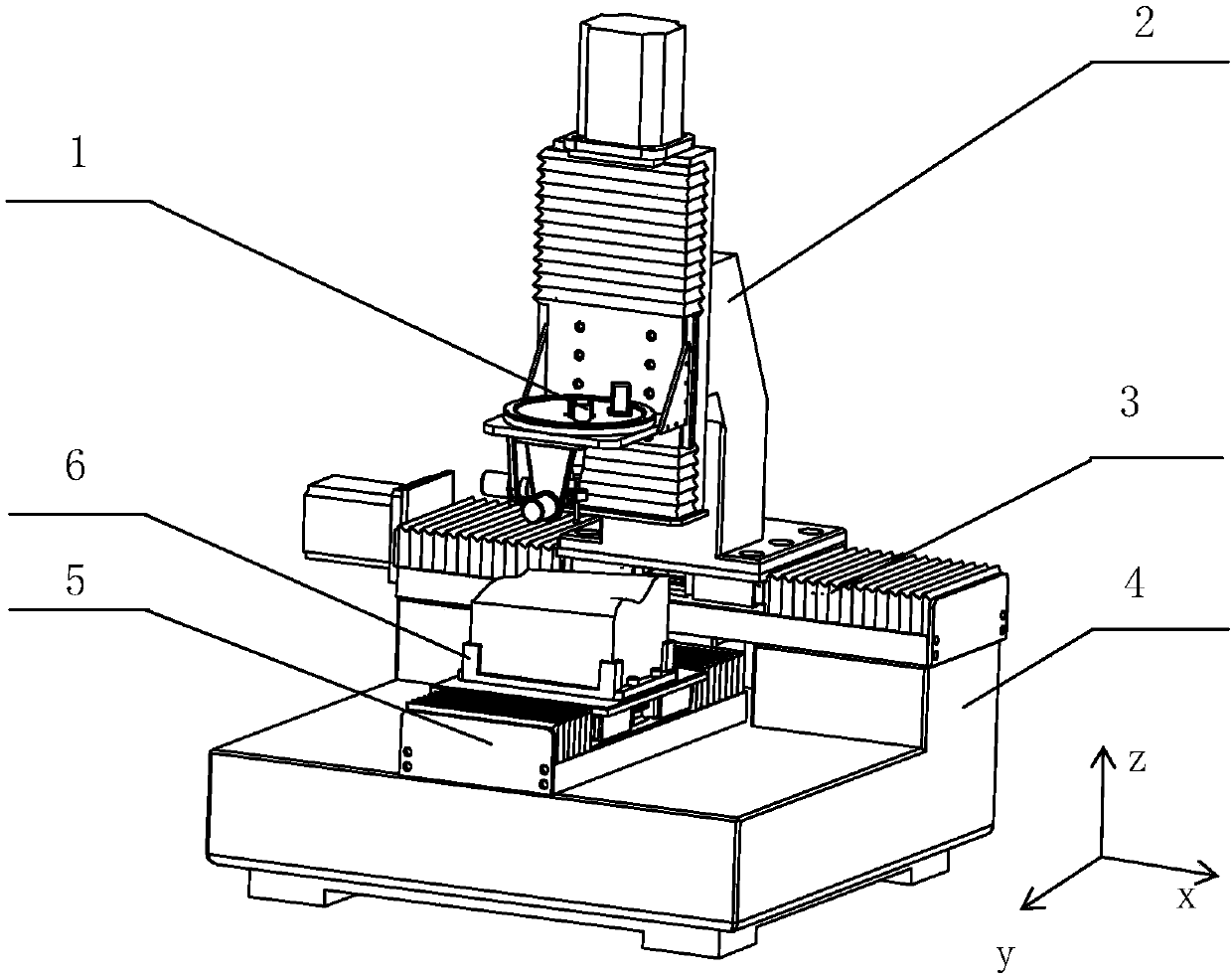

Multi-dimensional ultrasonic tool system with tool head action space being quadric surface and method of multi-dimensional ultrasonic tool system

ActiveCN108406338AVarious motion trajectoriesVarietyAutomatic control devicesFeeding apparatusElectric machineryEngineering

The invention relates to a multi-dimensional ultrasonic tool system with a tool head action space being a quadric surface and a method of the multi-dimensional ultrasonic tool system, and belongs to the field of machine manufacturing. An X-direction movement device is transversely and fixedly arranged on two bosses at the rear of a base; a motor of the X-direction movement device is located on theleft side of an X-direction movement device main body; a Y-direction movement device is longitudinally and fixedly arranged on the base; a motor of the Y-direction movement device is located in a gapbetween the two bosses below the X-direction movement device; a fixture is fixedly arranged on a slide carriage of the Y-direction movement device; a Z-direction movement device is vertically and fixedly arranged on a slide carriage of the X-direction movement device; and an ultrasonic tool head is fixedly arranged on a slide carriage of the Z-direction movement device and is located above the fixture. The multi-dimensional ultrasonic tool system and the method have the advantages that various movement tracks are output by the tool head under the action of an ultrasonic vibrator, so that themachining precision and the machining efficiency are improved, the service life of a cutter is prolonged, and more complex curved surfaces which can not be machined by a traditional machine tool can be machined.

Owner:JILIN UNIV

Electrode wire for wire electrical discharge machining, method for manufacturing the same, and method for electrical discharge machining using the same

InactiveUS20120000889A1Degrade machining accuracyAvoid low machining accuracyWork treatment devicesElectrical-based machining electrodesDuctilityCopper

A wire material having a copper-zinc alloy layer, which is formed by action of thermal diffusion, and a zinc layer on its circumference surface is subjected to processes, including from a step of drawing the wire material to a step of reducing the diameter of the product, to reliably crash the copper-zinc alloy layer into particles. The particles are embedded in the circumference surface of a core to integrate the diffusion alloy layer and zinc layer with the core and prevent the diffusion alloy layer and zinc layer from falling off from the core. In addition, in order to cover cracks formed in the copper-zinc alloy layer during wire drawing with a zinc thin film, wire drawing is performed at temperatures appropriate for maintaining good malleability and ductility of zinc.

Owner:OKI ELECTRICAL CABLE

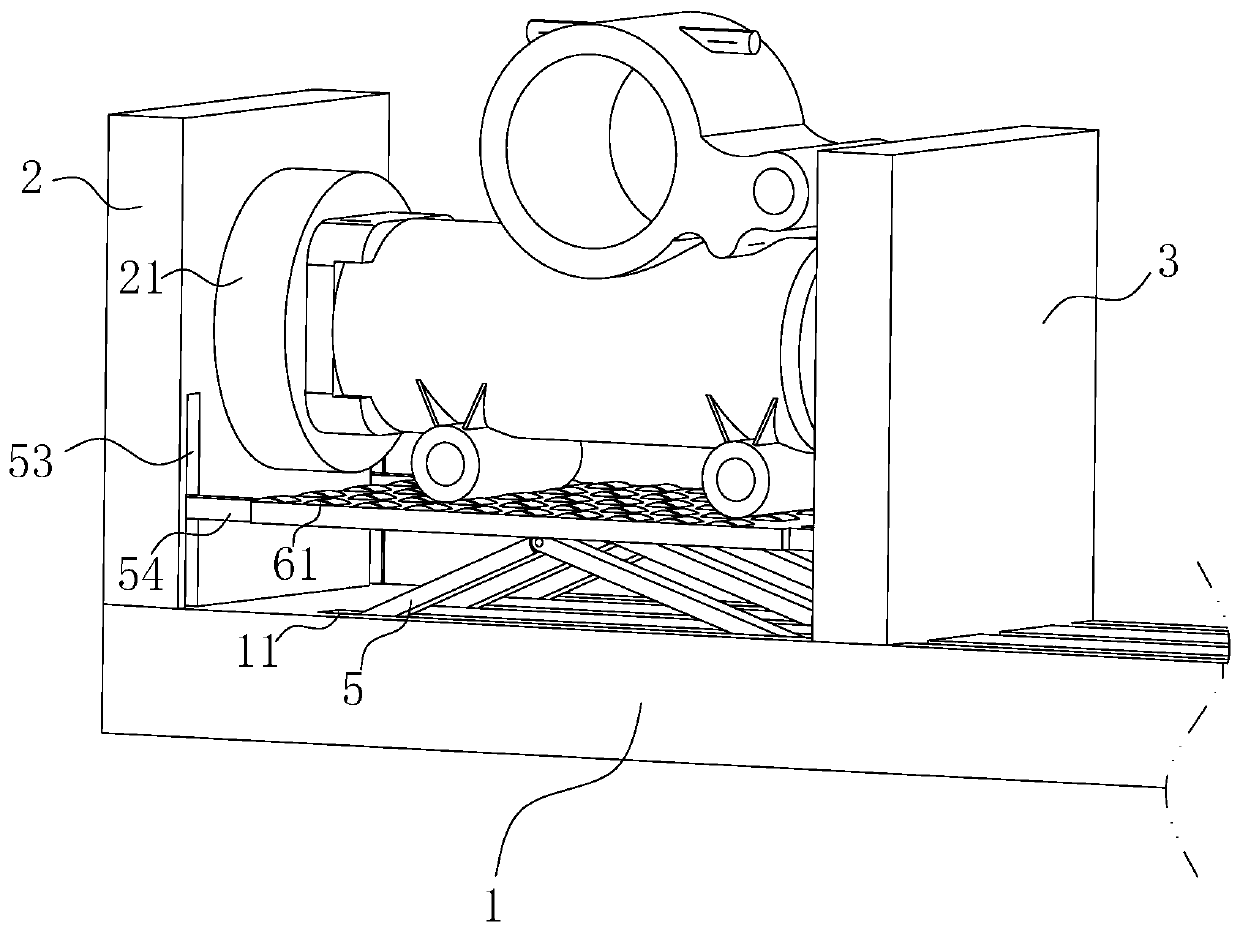

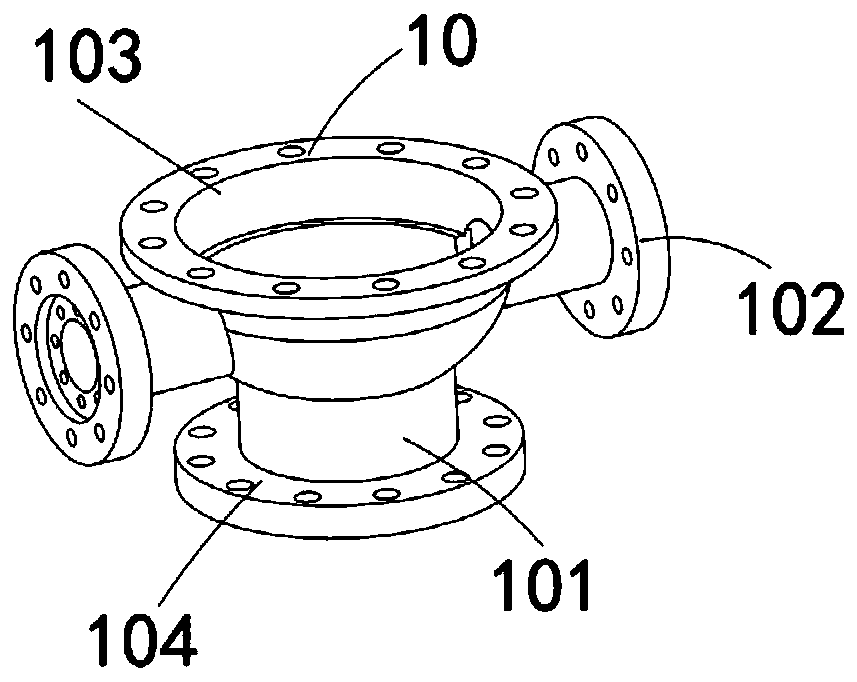

Valve body sunperfinish machining equipment

ActiveCN111375798AImprove machining accuracyGuaranteed stabilityFeeding apparatusOther manufacturing equipments/toolsPhysicsProcessing accuracy

The invention relates to the technical field of valve machining, in particular to valve body sunperfinish machining equipment. The valve body sunperfinish machining equipment comprises a clamping tooling for clamping and installing a valve body, a machining platform arranged to be adjacent to the clamping tooling, a hole drilling mechanism slidably installed on the machining platform and an enclasping mechanism installed on the machining platform and located between the clamping tooling and the hole drilling mechanism. According to the valve body sunperfinish machining equipment, by means of the manner that sliding of the hole drilling mechanism is utilized to drive the enclasping mechanism to enclasp connection mouth ends to be subjected to hole drilling machining, the pressure from holedrilling on the connection mouth ends by the hole drilling mechanism is counteracted, the valve body integrally will not generate a tendency of rotating in the hole drilling process due to the pressure of the hole drilling mechanism, and the technical problem that the machining precision is reduced due to the valve body is subjected to uneven force in hole drilling is solved.

Owner:ZHEJIANG VALOGIN TECH

Rotary index device in machine tool

InactiveCN101687297AAvoid low machining accuracyCorrect clamping stateMechanical apparatusPrecision positioning equipmentRotational axisFree rotation

A rotary index device in which the rotating shaft is held surely and stably after indexing. In the rotary index device of a machine tool comprising a rotating shaft provided rotatably in the housing and having an end portion to which a circular table is secured, and a clamp device for holding the rotational angular position of a body of revolution after indexing by making a pressing force act in the radial direction of the rotating shaft to the body of revolution including the rotating shaft, the clamp device includes a piston member provided displaceably in the axial direction of the rotatingshaft within the housing and having a tapered face formed on the side face, a means interposed between the body of revolution and the piston member, receiving a pressing force in the axial directionof rotation of the rotating shaft from the piston member as it displaces and making the pressing force act on the body of revolution while converting into the radial direction of the rotating shaft, and a means for urging the piston member in the direction for generating the pressing force from the pressing force conversion means.

Owner:TSUDAKOMA KOGYO KK

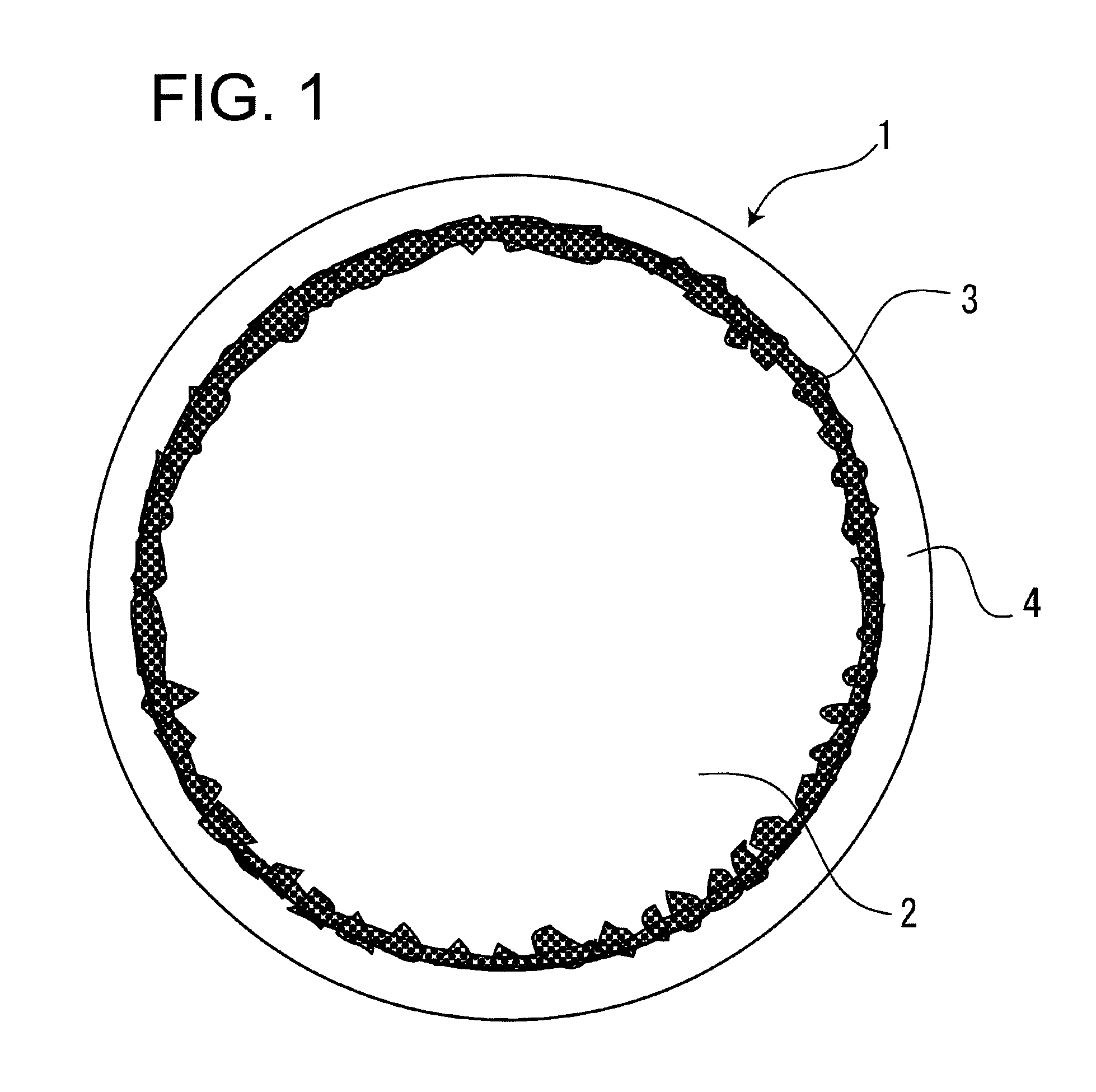

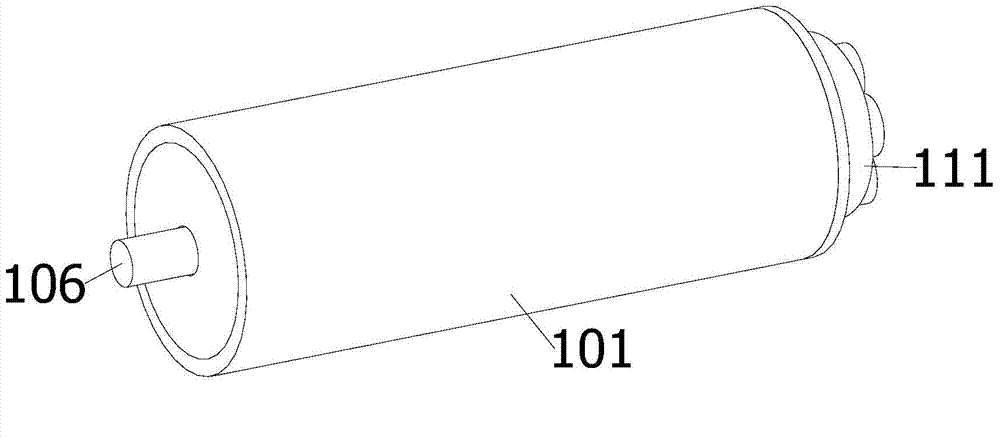

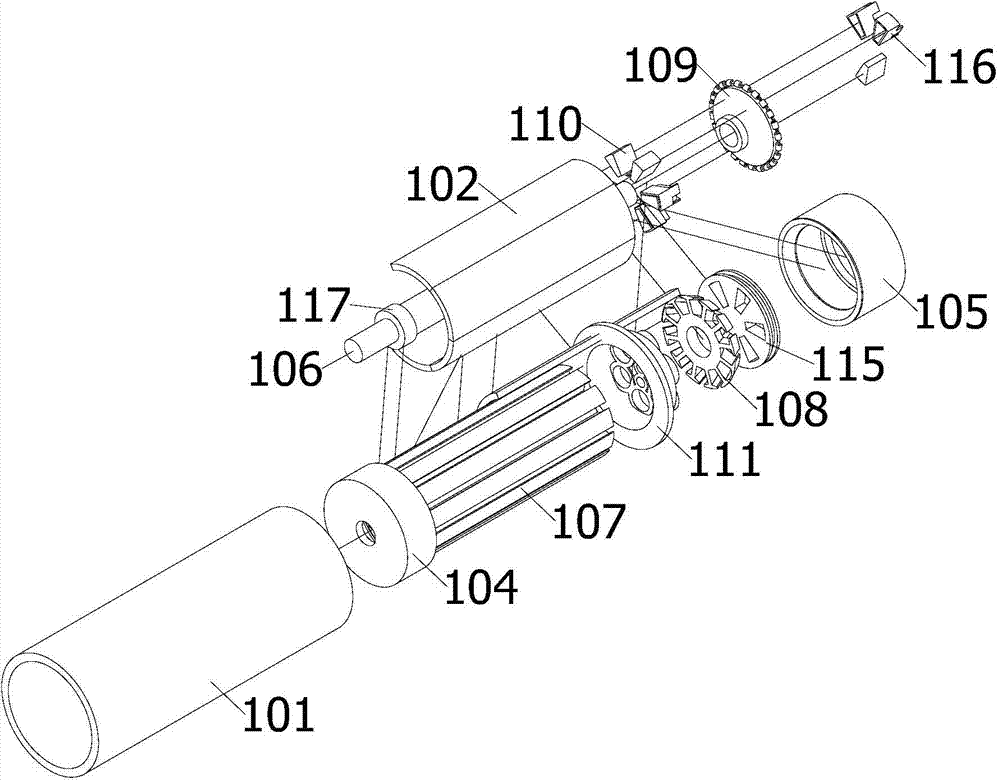

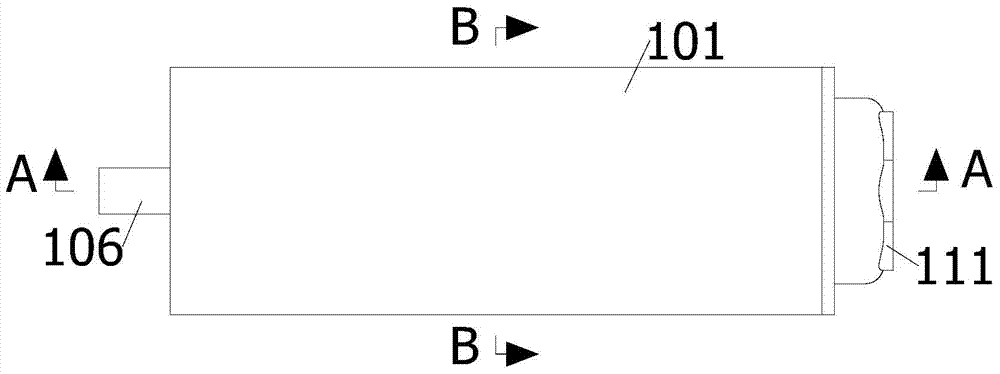

Bearing-free motor

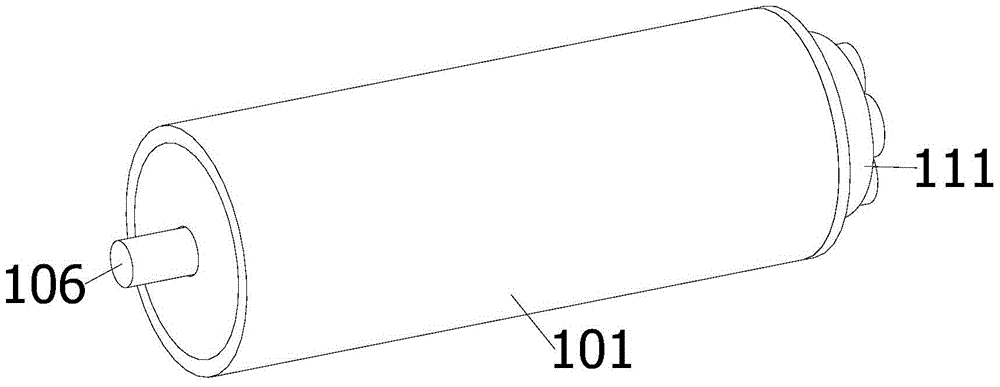

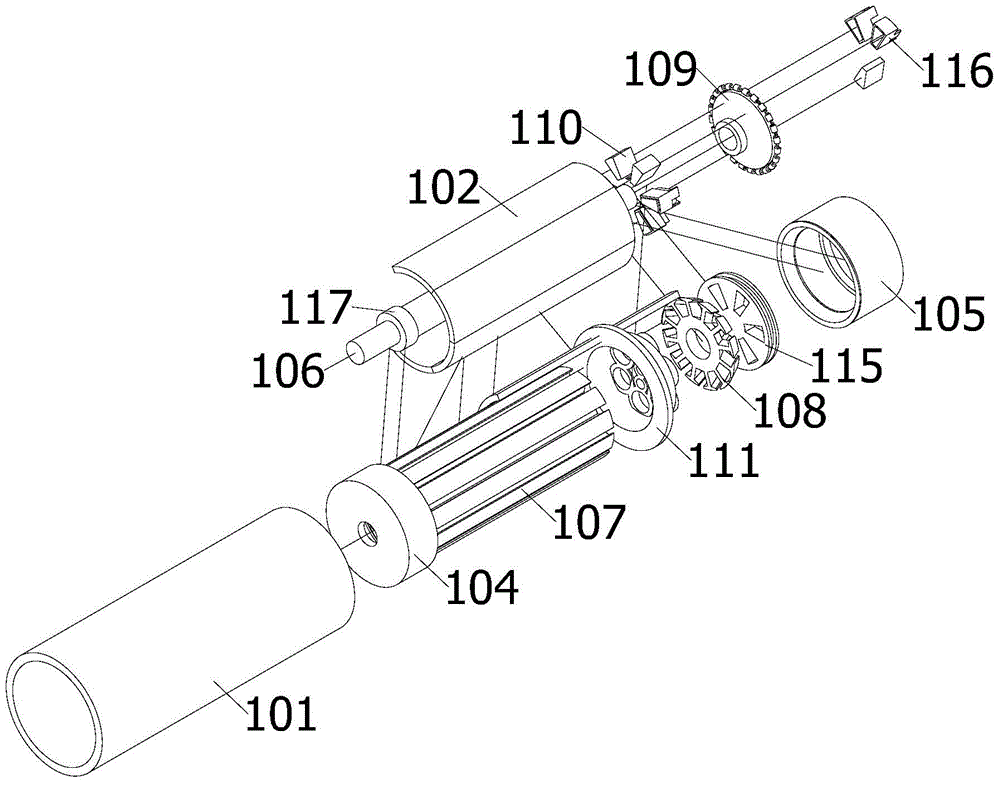

ActiveCN104505981APrecise air gapIncrease speedMechanical energy handlingConductor CoilControl theory

The invention provides a bearing-free motor and belongs to the field of electric motors. The bearing-free motor comprises a machine barrel, magnetic steel, a magnetic ring, a front cover, a rear cover, a rotating shaft, a first iron core, a second iron core, a commutator, a carbon brush holder and a bakelite cover. The first iron core and the second iron core are provided with wire winding grooves, the first iron core is matched with the magnetic steel, the second iron core is matched with the magnetic ring, the first iron core and the second iron core are provided with air gaps, the rotating shaft is suspended under the effect of magnetic force and can rotate around the axis, bearings at two ends of the rotating shaft are omitted, the bearing-free motor does not produce mechanical friction or abrasion and does not lubrication, the rotation speed of the motor can be improved, the efficiency of the motor is improved, the service life of the motor is prolonged, machining accuracy reduction caused by bearing abrasion is avoided, and reliable working of the motor is ensured.

Owner:JIANGXI DONGJIANG ELECTROMECHANICAL

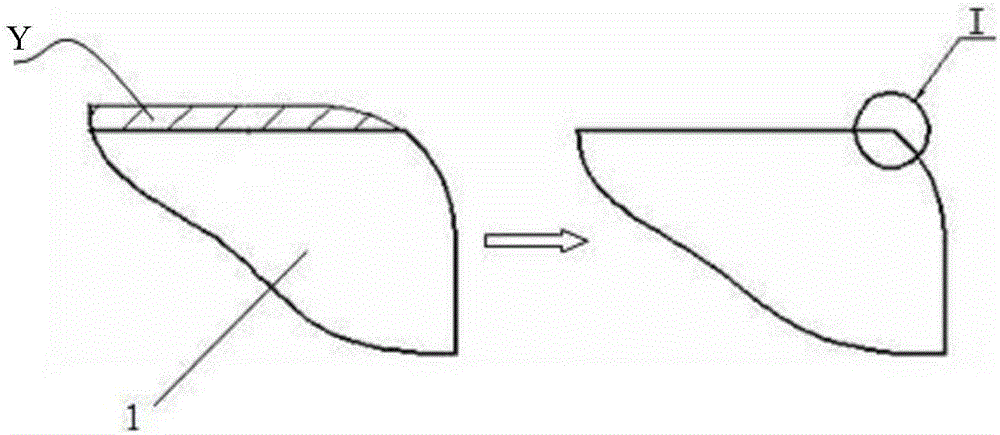

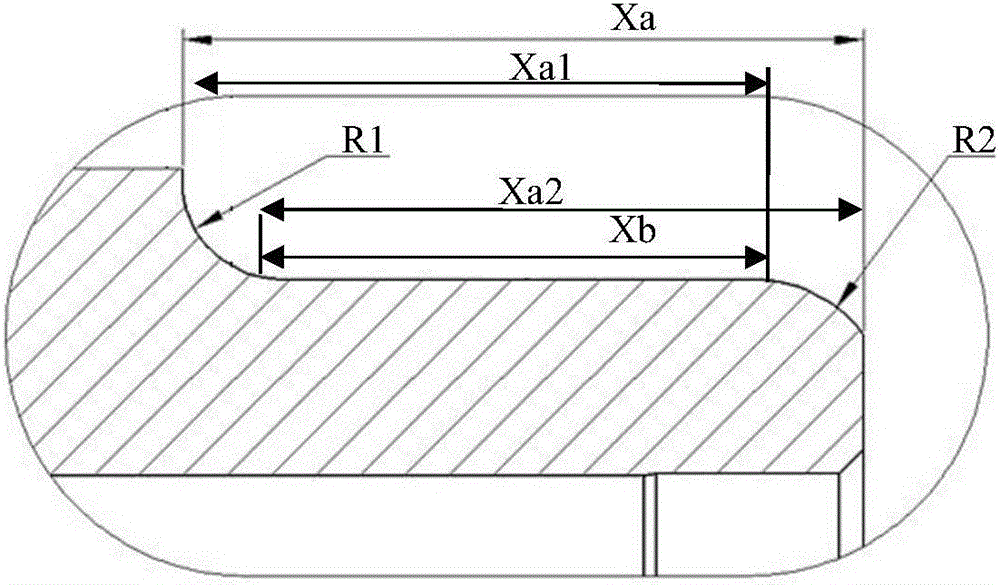

Machining method for numerical control turning of circular arc chamfer on shaft excircle surface

InactiveCN106475576APositive progress effectImprove processing efficiencyTurning toolsTurning machinesNumerical controlEngineering

The invention provides a machining method for numerical control turning of a circular arc chamfer on a shaft excircle surface. The machining method comprises the following steps of: A. carrying out numerical control programming on a machining process in advance according to design requirements, and determining a circular arc chamfer R of a shaft needing to be turned and the shaft excircle surface Xb as a combination curve Xa when a numerical control turning curve graph is determined; B. setting machining parameters of a turning machine as the rotating speed S being 2500r / min and the feeding speed F being 70mm / min; and C. machining the Xa at one time to cause the shaft excircle surface and the circular arc chamfer to be in smooth connection. The machining method has the beneficial effects that the smooth connection of the circular arc chamfer and the shaft excircle surface is ensured; a machining procedure can also be reduced; the operating cost is reduced; the machining accuracy and efficiency are improved; and the machining method has very wide application prospect.

Owner:王爱民

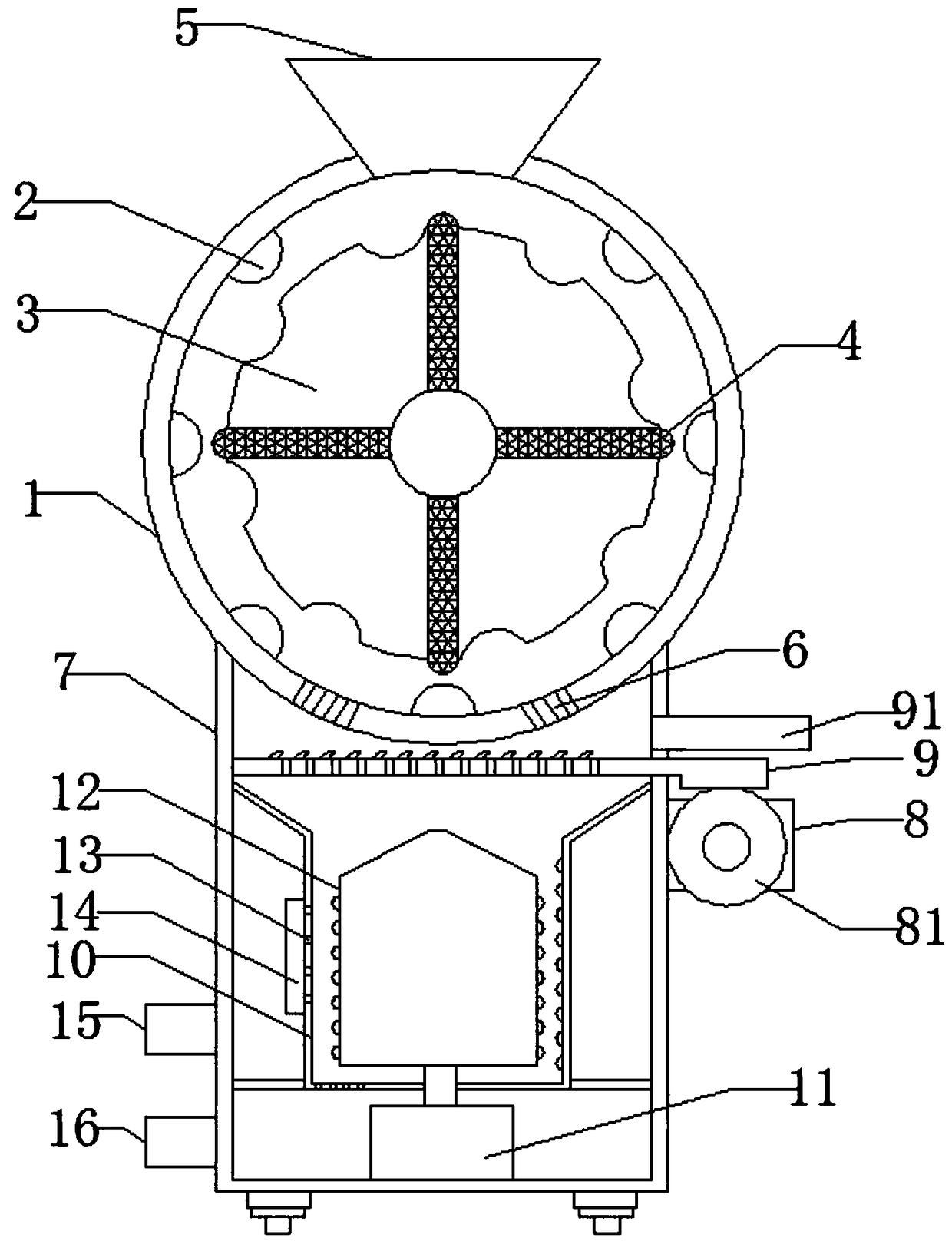

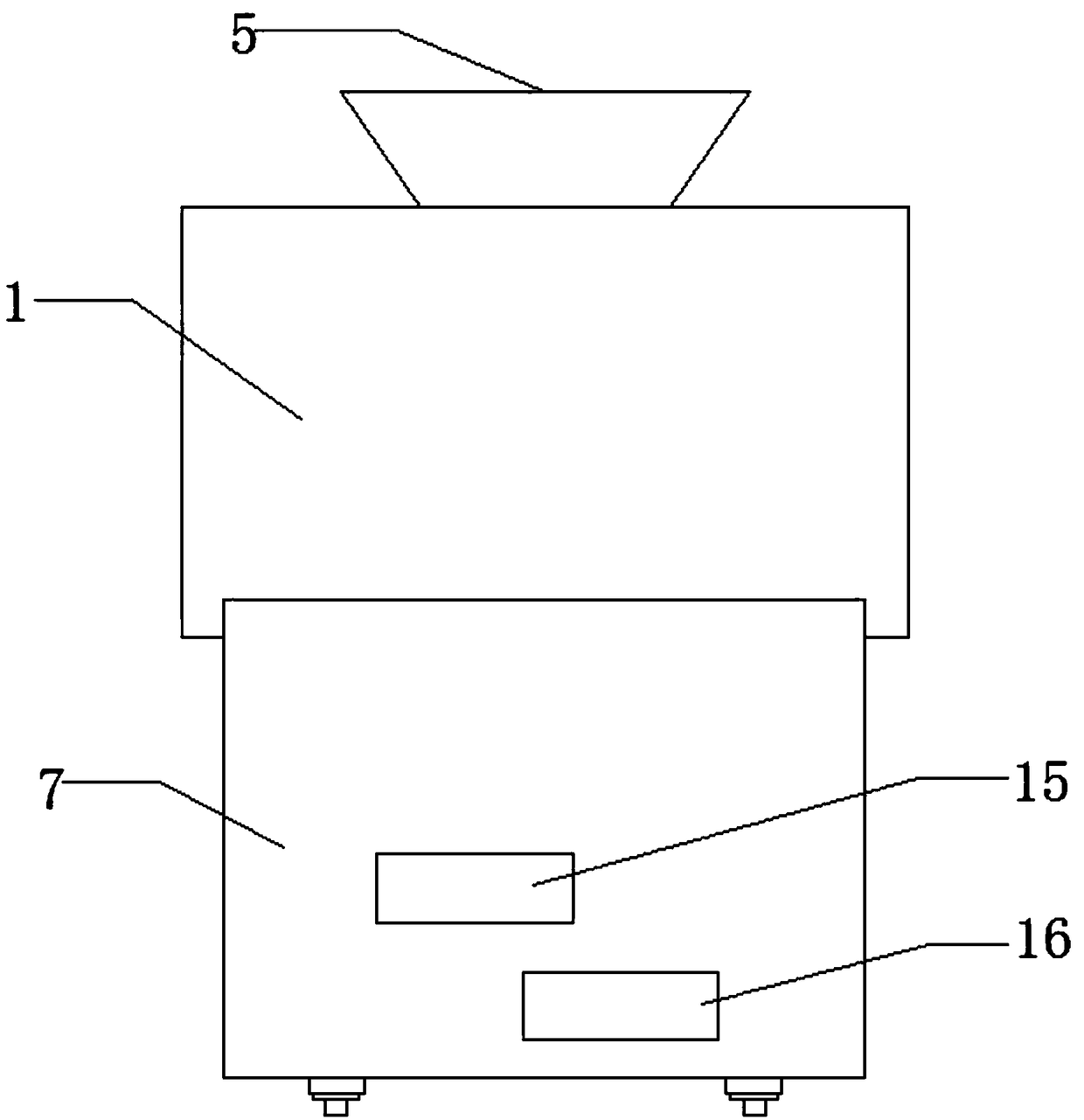

Fine-processing rice shelling equipment

PendingCN108940407AAvoid low machining accuracyImprove machining accuracyGrain huskingGrain polishingFixed frameElectric machinery

The invention discloses fine-processing rice shelling equipment. The fine-processing rice shelling equipment comprises a shelling cylinder, a plurality of protruding blocks are fixedly connected to the inner side surface of the shelling cylinder, a rotating roller is rotationally connected to the middle of the shelling cylinder, a cutter head is fixedly installed on the side surface of the rotating roller, a plurality of first through holes are formed at the lower portion of the shelling cylinder, a box body is fixedly connected to the lower end of the shelling cylinder, a first motor is fixedly installed at the right end of the box body, an output shaft of the first motor is connected with a shelling plate, a first rice chaff outlet is formed at the upper portion of the right end of the box body, a fixing frame is fixedly connected in the box body, a second motor is fixedly installed at the lower end of the fixing frame, the output shaft of the second motor is fixedly connected with ashelling roller, and a second rice chaff outlet and a discharging hole are formed at the left end of the box body. According to the fine-processing rice shelling equipment, the processing precision is greatly improved, so that thorough separation work of the rice and the rice chaff is facilitated, and secondary processing is not required to remove the rice chaff.

Owner:安徽鑫泉米业股份有限公司

Method for machining bottle-shaped shaft of large pumped storage generator motor

ActiveCN111421308AReduce mistakesMeet the requirements of beating high precisionMagnetic circuit rotating partsNumerical controlEngineering

The invention discloses a method for machining a bottle-shaped shaft of a large pumped storage generator motor, and belongs to the technical field of motor shaft machining. The method is characterizedby comprising the following steps of a, boring a matching hole of the center of a large end and a transition connecting plate; b, turning an outer circle and a welding groove of the transition connecting plate, and assembling and welding the transition connecting plate into a shaft center hole in the large end of the bottle-shaped shaft; c, mounting a process dummy shaft at the large end of the bottle-shaped shaft; d, turning the process dummy shaft; e, on a working platform of a numerical control boring machine, erecting and installing the process dummy shaft to be parallel to the numericalcontrol boring machine by using angle iron, pressing a workpiece, checking by using a height gauge according to a line, pressing a gauge on the lower side surface of the machined groove by using a dial gauge, moving the machine tool away along an X axis, checking by using the height gauge according to the line, and machining a magnet yoke key groove to obtain a bottle-shaped shaft finished product. The chuck precision of a horizontal lathe does not affect the rotation center of the bottle-shaped shaft, the machining difficulty is reduced, the machining stability is guaranteed, the machining precision is improved, and machining operation is more convenient.

Owner:DONGFANG ELECTRIC MACHINERY

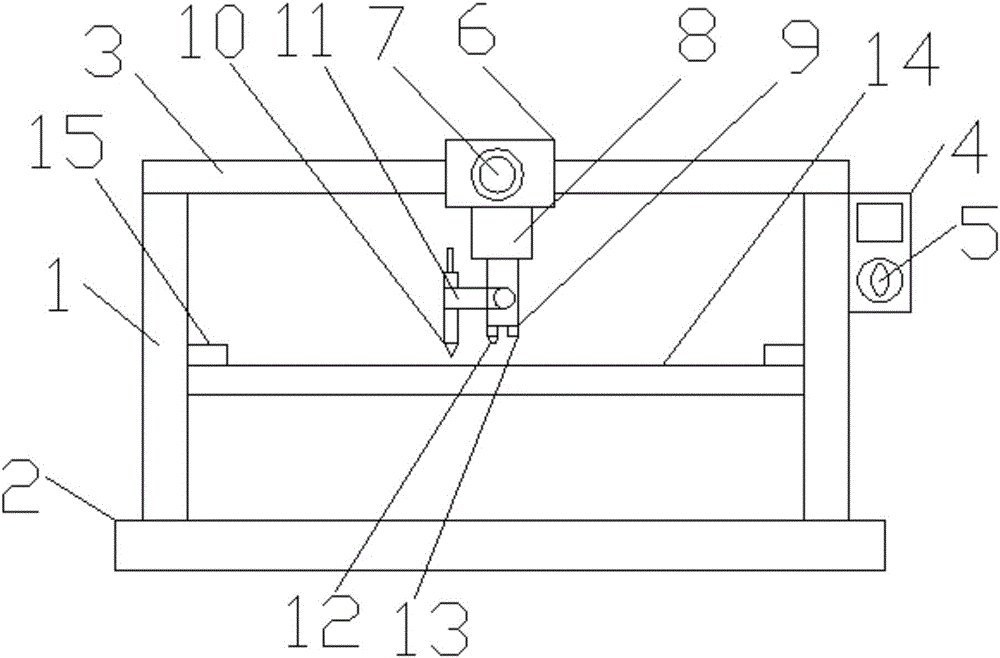

Novel continuous spot welding device

InactiveCN106041282AEasy to operateHigh degree of automationResistance electrode holdersEngineeringSpot welding

The invention discloses a novel continuous spot welding device, which comprises a device main body, a base, a sliding guide rail, a control handle, an operating knob, a sliding device, a clamping knob, a telescopic device, a telescopic rod, a spot welding device, a connecting rod, and an infrared emission device. Device, infrared receiver, workbench and limit baffle, the underside of the main body of the device is provided with a base, the upper side of the main body of the device is provided with a sliding guide rail, the right side of the sliding guide rail is provided with a control handle, and the control handle The lower side is provided with an operating knob, the left side of the control handle is provided with a sliding device, the lower side of the sliding device is provided with a clamping knob, and the lower side of the sliding device is provided with a telescopic device. This new type of continuous spot welding device has the characteristics of simple operation and high degree of automation, which improves the processing accuracy. Infrared equipment is added to detect the placement position of the air-conditioning cover through the infrared equipment, so as to avoid welding work failure and product failure due to welding position deviation. The phenomenon of high production rate and serious waste of raw materials.

Owner:章勤正

Shaft part machining clamp

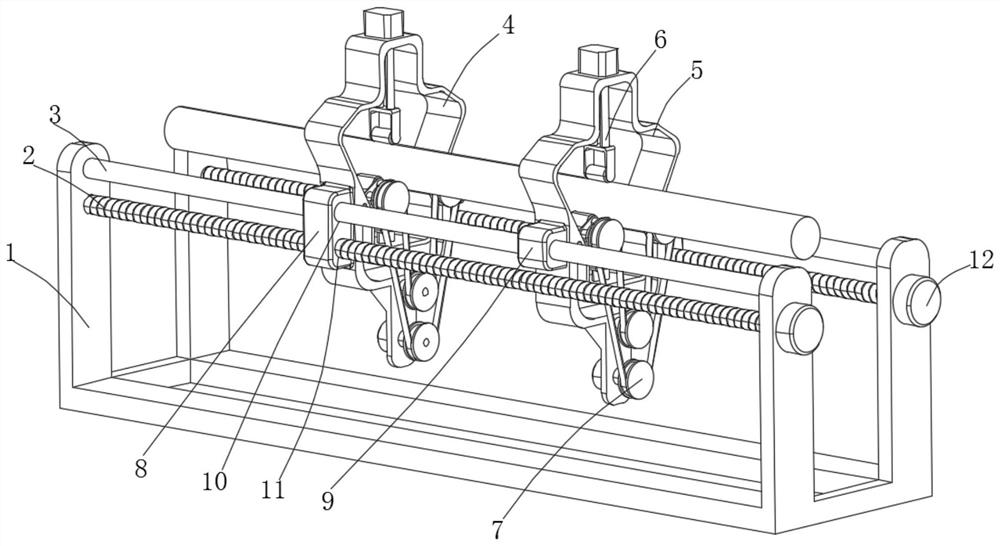

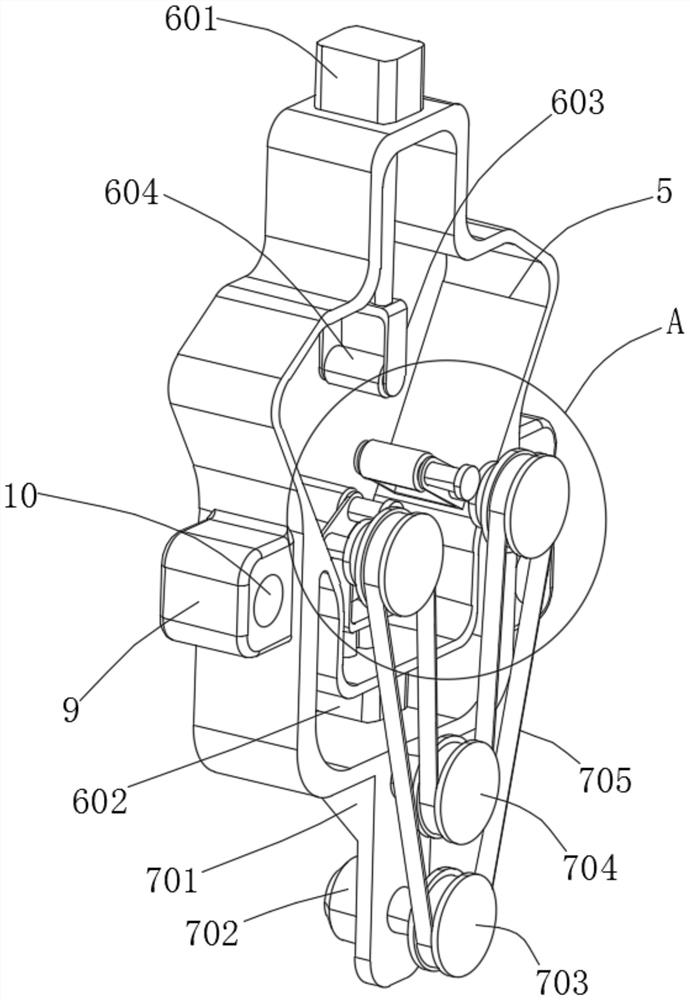

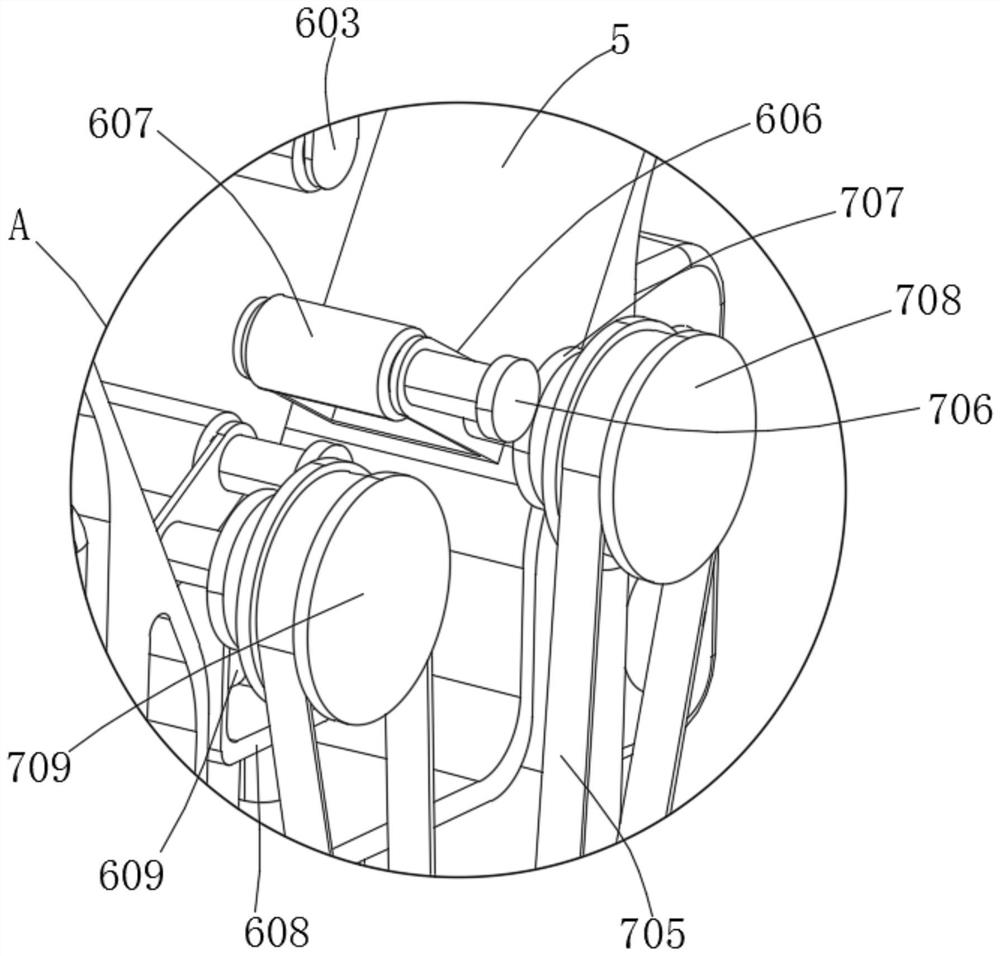

PendingCN113319603AAvoid wasting timeImprove work efficiencyWork clamping meansLarge fixed membersScrew threadIndustrial engineering

The invention discloses a shaft part machining clamp, and relates to the technical field of shaft clamps. The shaft part machining clamp comprises a mounting base, screw rods and polished rods are arranged at the two ends of the inner side of the mounting base, and the mounting base is in threaded connection with a first mounting frame and a second mounting frame through two sets of screw rods respectively. When the shaft part machining clamp is used, two sets of rotary supporting wheels are used for pre-supporting a part, then the supporting wheels are pushed till the supporting wheels make contact with a shaft part, and the supporting wheels are combined with the other two sets of rotary supporting wheels to form a triangular stable structure, so that the shaft part is firmly clamped, when a clamped part needs to be machined, only two sets of mutually matched electric rollers need to be pushed at the same time, the part is supported from the position under the part till the part is completely separated from the two sets of rotary supporting wheels, then the electric rollers are started, the part is driven to move horizontally, and the part is clamped after an original clamping section is exposed, so that time waste caused by re-clamping is avoided.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

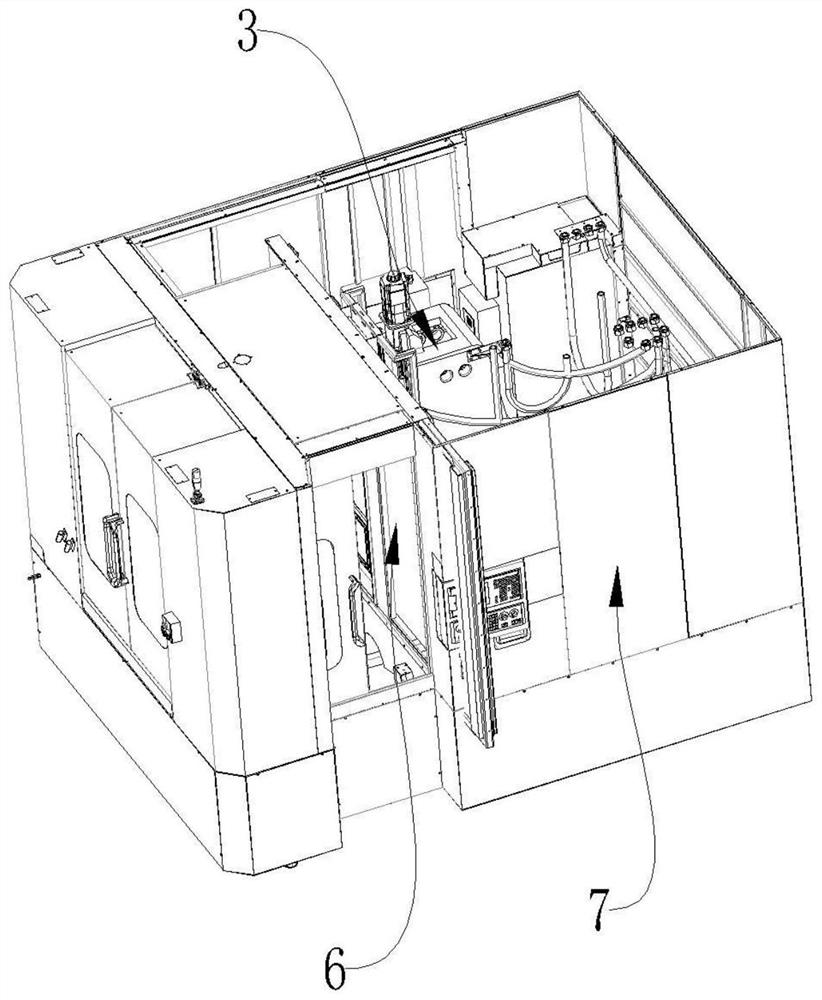

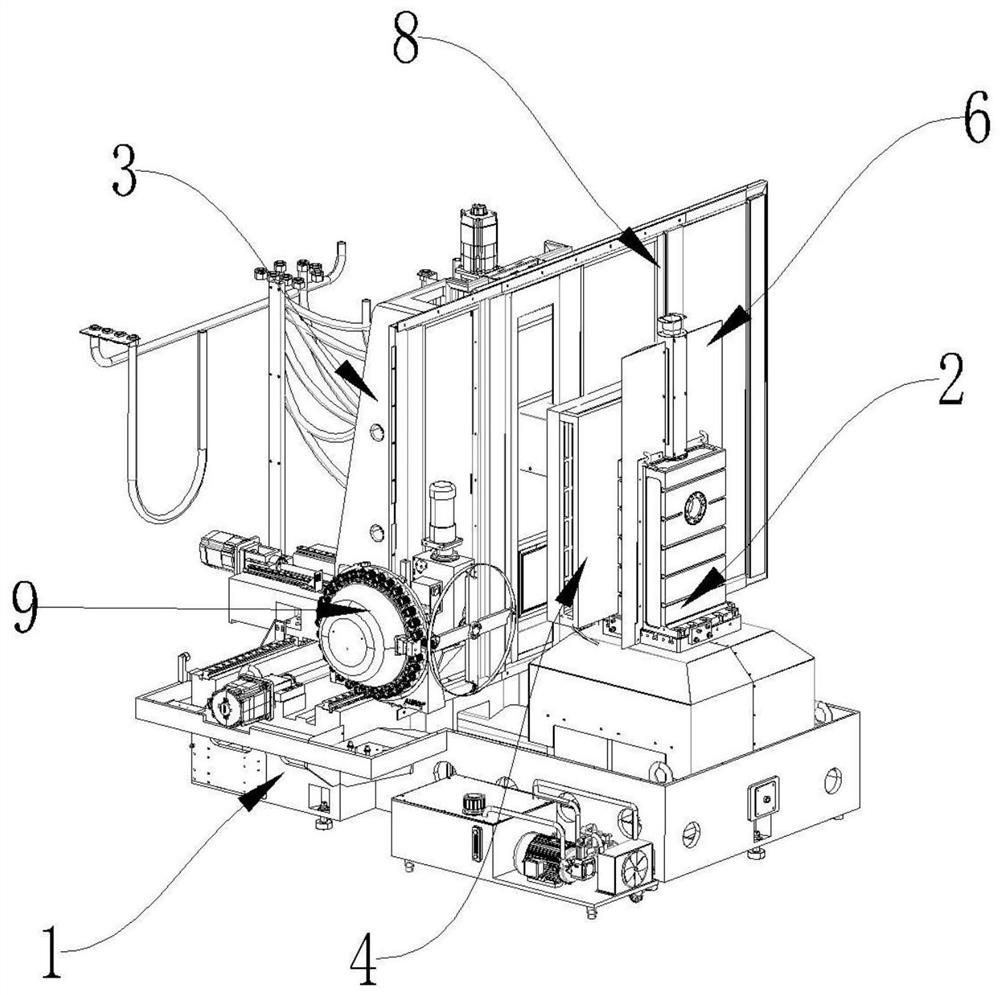

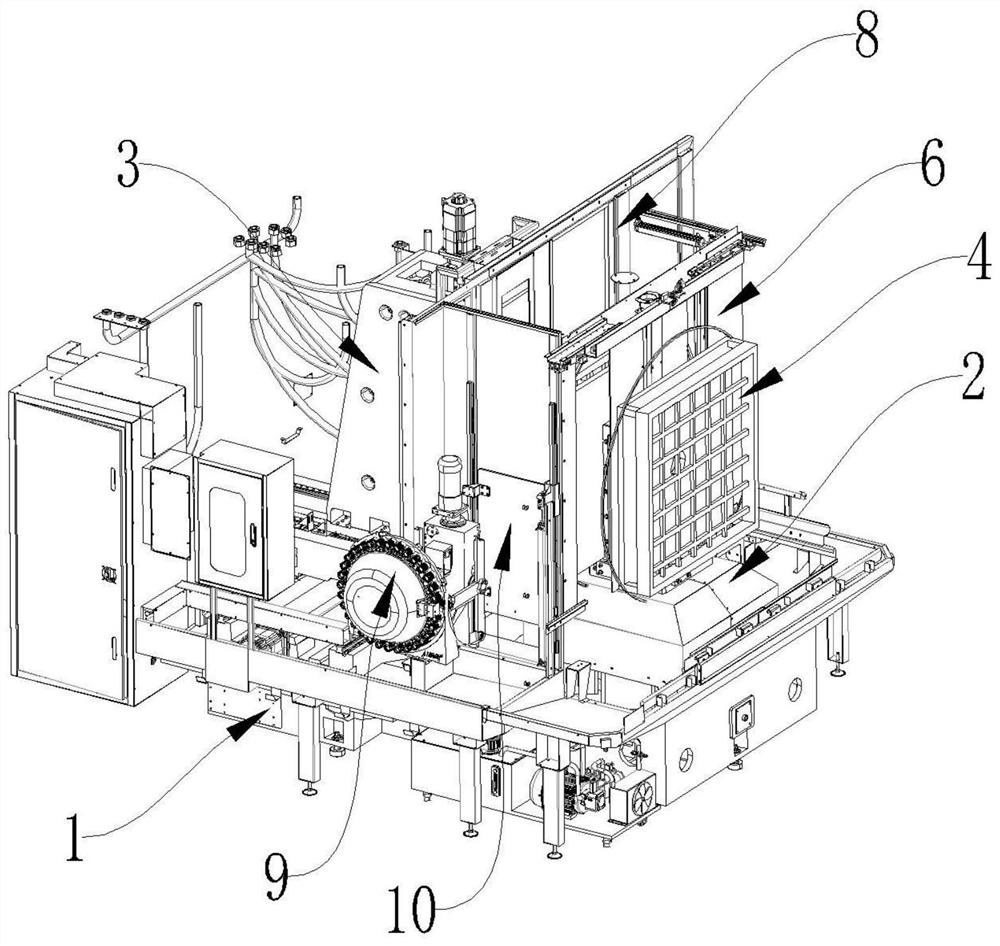

Inclined Bed Double Spindle CNC Lathe

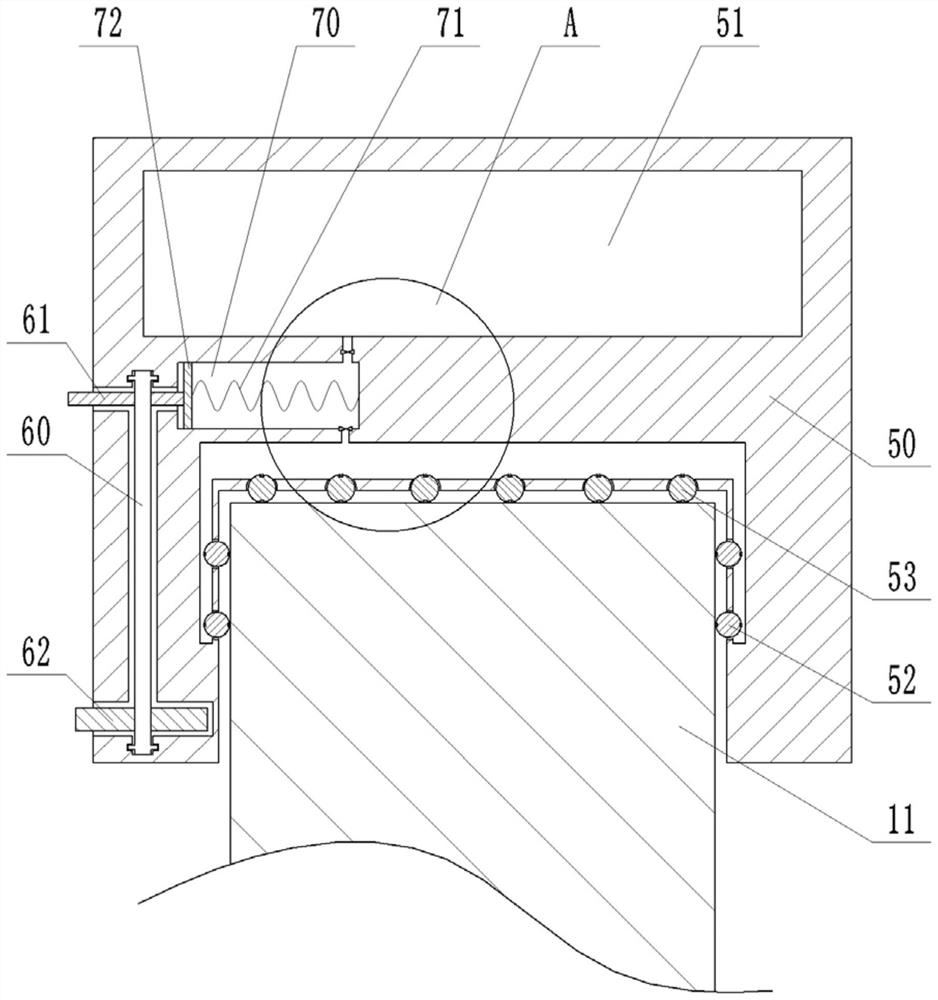

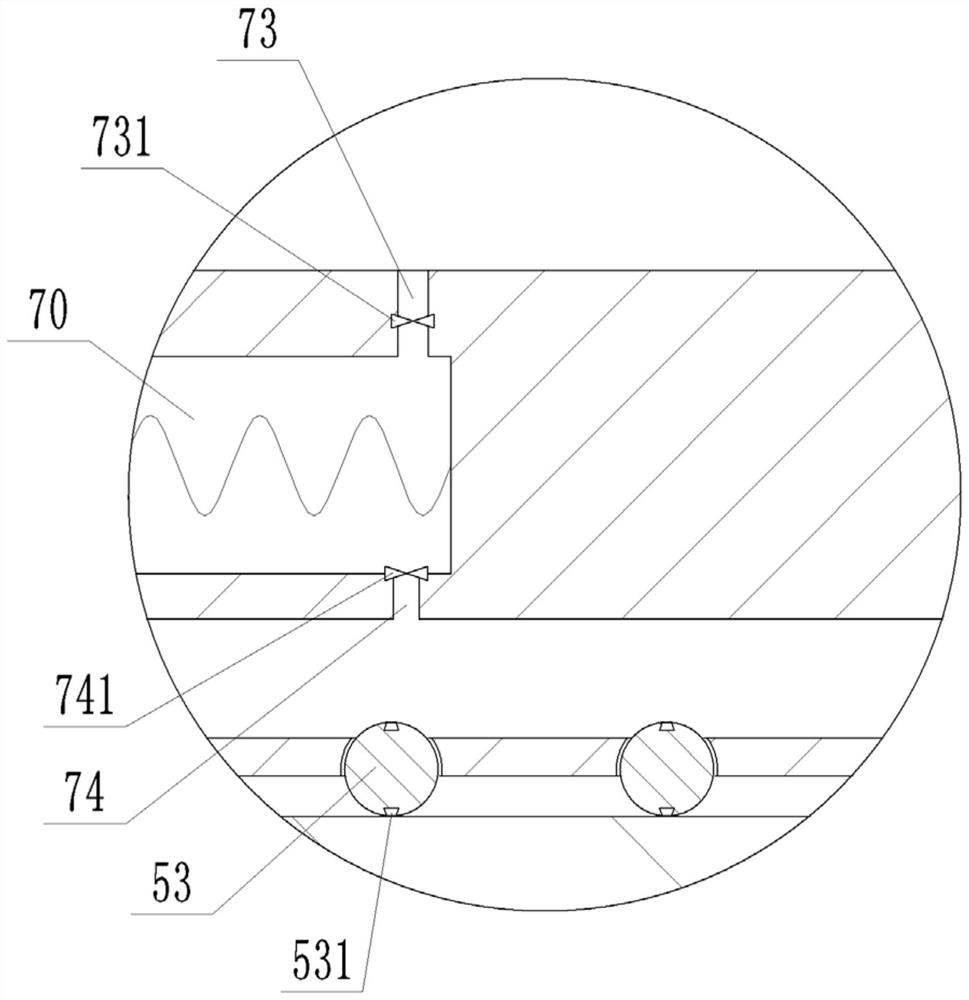

ActiveCN110860701BAvoid low machining accuracyImprove the lubrication effectAuxillary equipmentLarge fixed membersNumerical controlInlet valve

The invention belongs to the technical field of numerically controlled lathes, and particularly relates to a numerically controlled lathe with a slant lathe bed and double spindles. The numerically controlled lathe comprises a protective cover, wherein the slant lathe bed is arranged in the protective cover, and a first spindle assembly and a saddle assembly are arranged on the slant lathe bed; two saddle guide rails and two second spindle guide rails are arranged on a guide rail mounting surface of the slant lathe bed, sliders are connected onto the saddle guide rails and the second spindle guide rails in a sliding manner, and the saddle assembly is connected onto the saddle guide rails through the sliders; a second spindle assembly opposite to the first spindle assembly is connected ontothe second spindle guide rails through the sliders in a sliding manner; and an oil cavity, an oil outlet tube and a power mechanism are arranged in each slider, a piston is connected to inside of theoil outlet tube in a sliding manner, a channel is connected between the oil outlet tube and the oil cavity, a one-way oil inlet valve is arranged on the channel, a one-way oil draining valve is arranged on the oil outlet tube, and multiple oil outlets are formed in the lower part of the slider. According to the numerically controlled lathe in the scheme, machining of two ends of a workpiece can be completed by one-time clamping of the workpiece, and the machining efficiency can be improved.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

Bearingless motor

The invention provides a bearing-free motor and belongs to the field of electric motors. The bearing-free motor comprises a machine barrel, magnetic steel, a magnetic ring, a front cover, a rear cover, a rotating shaft, a first iron core, a second iron core, a commutator, a carbon brush holder and a bakelite cover. The first iron core and the second iron core are provided with wire winding grooves, the first iron core is matched with the magnetic steel, the second iron core is matched with the magnetic ring, the first iron core and the second iron core are provided with air gaps, the rotating shaft is suspended under the effect of magnetic force and can rotate around the axis, bearings at two ends of the rotating shaft are omitted, the bearing-free motor does not produce mechanical friction or abrasion and does not lubrication, the rotation speed of the motor can be improved, the efficiency of the motor is improved, the service life of the motor is prolonged, machining accuracy reduction caused by bearing abrasion is avoided, and reliable working of the motor is ensured.

Owner:JIANGXI DONGJIANG ELECTROMECHANICAL

Numerical control machining center capable of achieving multi-face machining through one-time clamping

PendingCN112720007AImprove practicalityImprove processing productivityPositioning apparatusMaintainance and safety accessoriesNumerical controlRotational axis

The invention relates to the technical field of numerical control machining equipment, in particular to a numerical control machining center capable of achieving multi-face machining through one-time clamping. The numerical control machining center comprises a lathe bed, a multi-station clamp mechanism and a machining mechanism. The multi-station clamp mechanism comprises a B-axis rotary table, a rotary table stand column, a C-axis rotary table and a first clamp fixing base, the B-axis rotary table is installed on the lathe bed, the rotary table stand column is rotatably installed on the B-axis rotary table, the C-axis rotary table is installed on the rotary table stand column, and the first clamp fixing base is rotatably installed on the C-axis rotary table; a rotating shaft of the first clamp fixing base is perpendicular to a rotating shaft of the rotary table stand column; and the machining mechanism is installed on the lathe bed, the machining mechanism comprises a machine tool spindle, and the machine tool spindle corresponds to a clamp installed on the first clamp fixing base. Through rotation of the rotary table stand column and the first clamp fixing base, five faces of a workpiece can be machined by the machine tool spindle under the condition of one-time clamping, and therefore the machining production efficiency is greatly improved, and meanwhile the situation that the machining precision is lower due to multiple times of clamping is avoided.

Owner:FOSHAN PRATIC CNC SCI & TECH

Machine tool

InactiveCN101939134BAvoid low machining accuracyProgramme controlAutomatic control devicesMachine toolEngineering

Owner:MITSUBISHI HEAVY IND LTD

High-precision six-jaw duplex floating type self-centering clamping mechanism and clamping method

PendingCN113770750AStable clampingPrecise gripping methodPositioning apparatusMetal-working holdersThermal deformationEngineering

The invention relates to the technical field of clamp structures, in particular to a high-precision six-jaw duplex floating type self-centering clamping mechanism and a clamping method. The clamping mechanism comprises a clamp body and further comprises at least two sets of clamping jaws, and each set comprises at least three clamping jaws; an inclined mounting groove is formed in the clamp body; each clamping jaw comprises a diagonal draw bar, which is arranged in the mounting groove in a penetrating mode and can move in the length direction of the mounting groove, and a clamping jaw body, which is fixed to the end, extending out of the outer side of the clamp body, of the corresponding diagonal draw bar; plunger cylinders used for driving the diagonal draw bars to move along the mounting groove so as to tighten the clamping jaw bodies to clamp a workpiece are arranged in the clamp body; and the plunger cylinders are in one-to-one correspondence with the diagonal draw bars, the driving speeds of the corresponding plunger cylinders in the same set of clamping jaws are consistent, and the driving speeds of the plunger cylinders in different sets of clamping jaws are different. The clamp is simple in structure and convenient to operate, pre-clamping and pre-positioning of the workpiece are achieved by controlling the clamping speeds of different sets of clamping jaws, the clamping precision of the workpiece is improved, and the technical problem of turning thermal deformation is solved.

Owner:东风汽车动力零部件有限公司

Method and system for forming blind gongs on printed circuit board (PCB) and circuit board

ActiveCN102036483BPrecise control of depthAvoid low machining accuracyPrinted circuit detailsPrinted circuit manufactureEngineeringPrinted circuit board

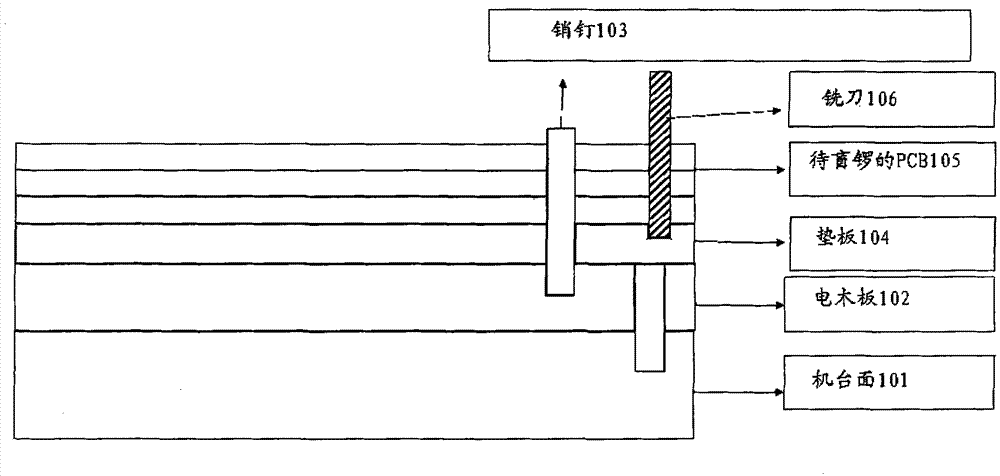

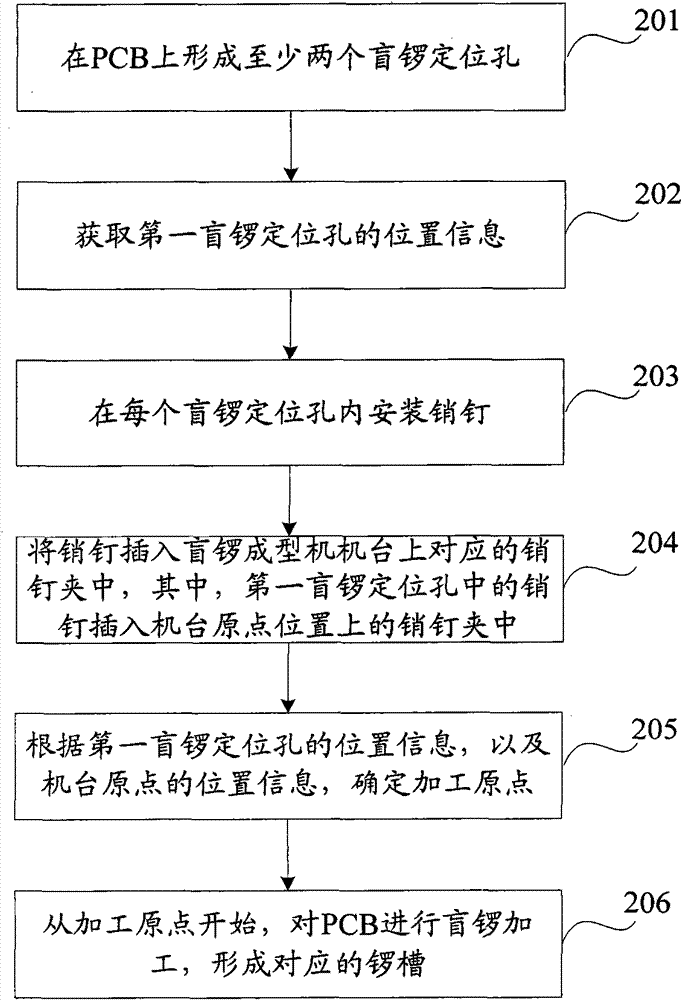

The invention discloses a method and system for forming blind gongs on a printed circuit board (PCB) and a circuit board to improve the precision of machining the blind gongs on the PCB. The method comprises the following steps: forming at least two blind gong locating holes on the PCB and obtaining the location information of the first blind gong locating hole; installing a pin in each blind gong locating hole and inserting each pin into a corresponding pin clip on a bench of a blind gong forming machine, wherein the pin in the first blind gong locating hole is inserted into the pin clip on the location of an origin of the bench; and determining the machining origin according to the location information of the first blind gong locating hole and the origin on the bench and beginning machining the blind gongs on the PCB from the machining origin to form corresponding gong slots.

Owner:CHONGQING FOUNDER HI TECH ELECTRONICS +1

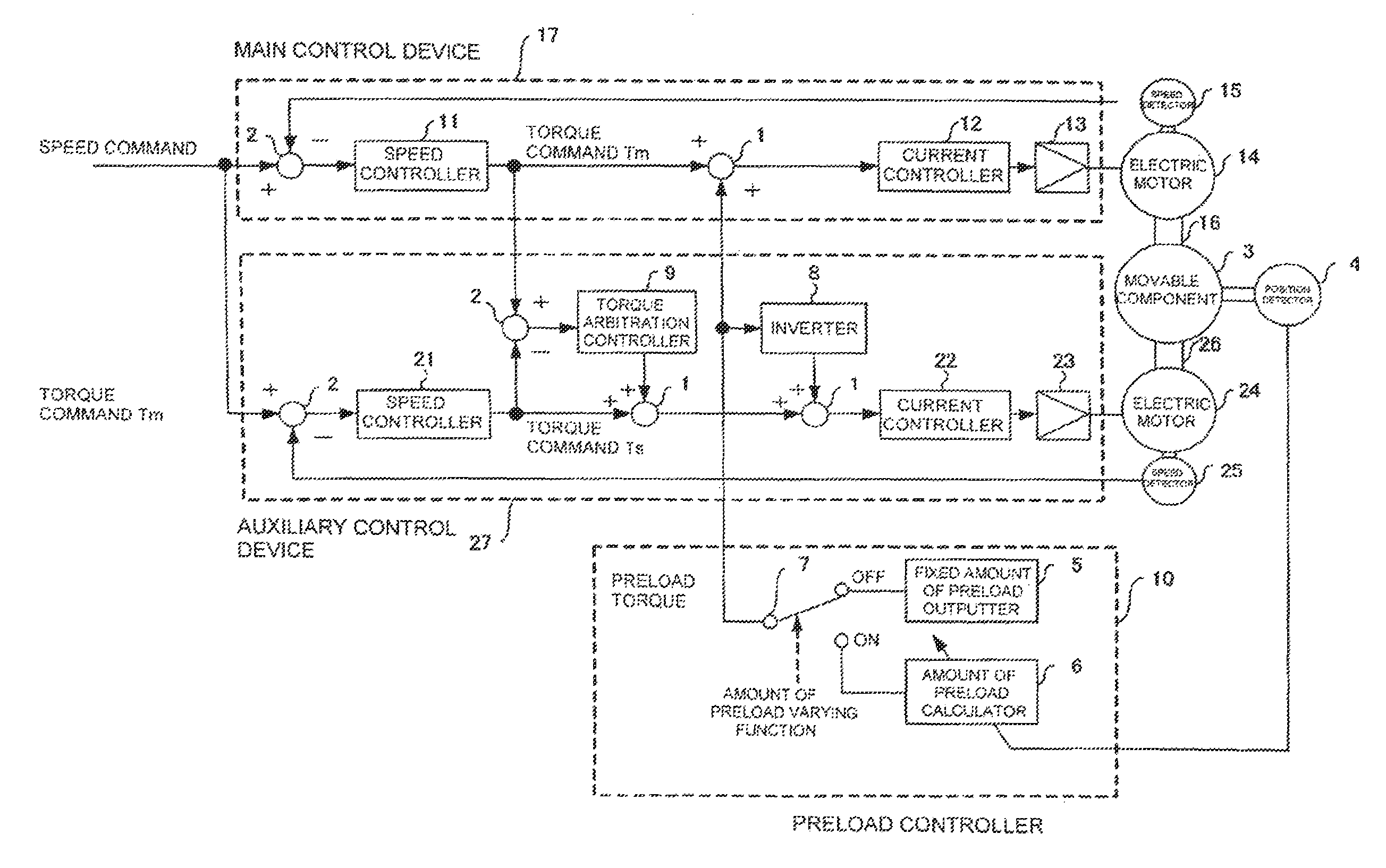

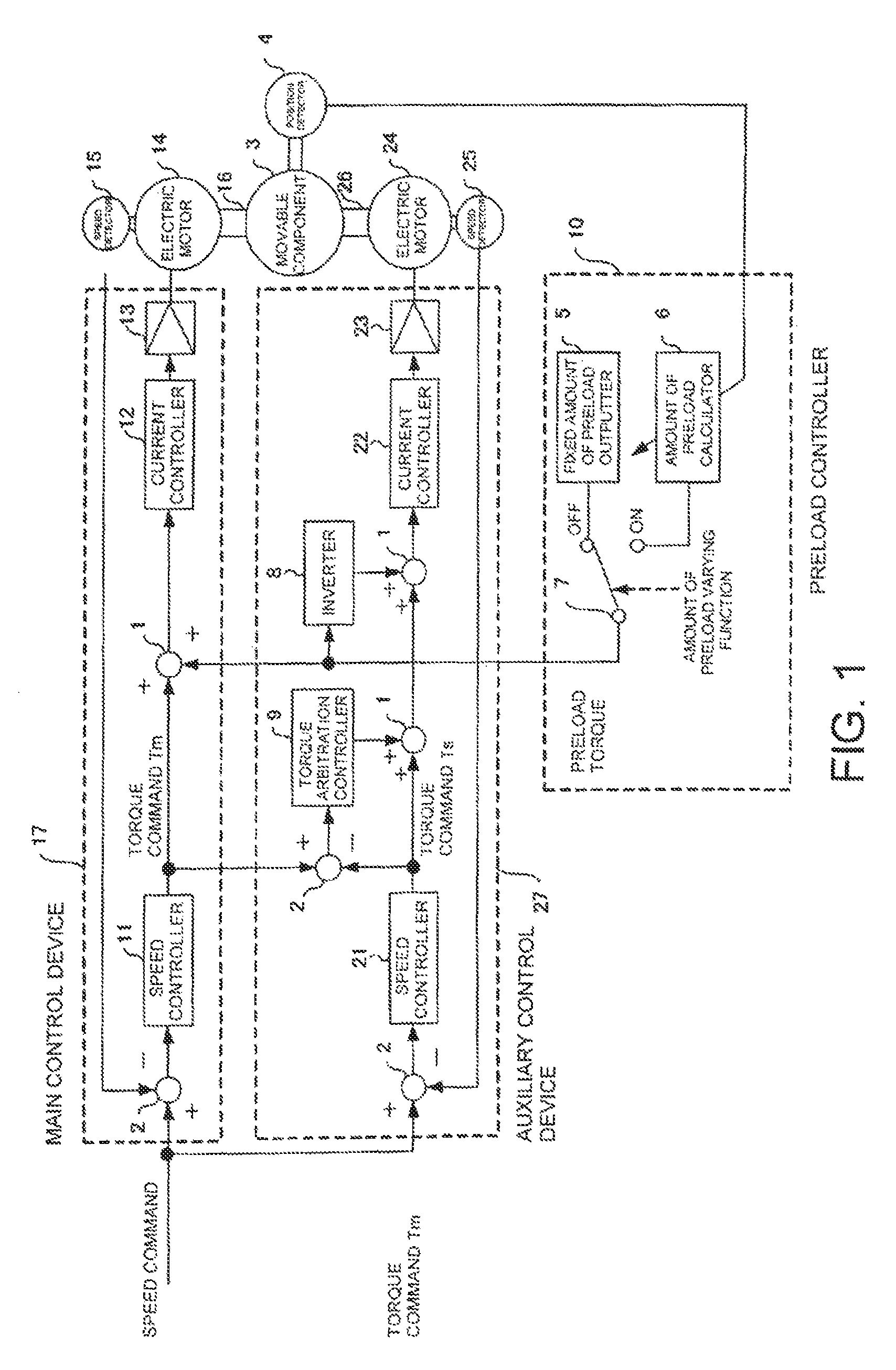

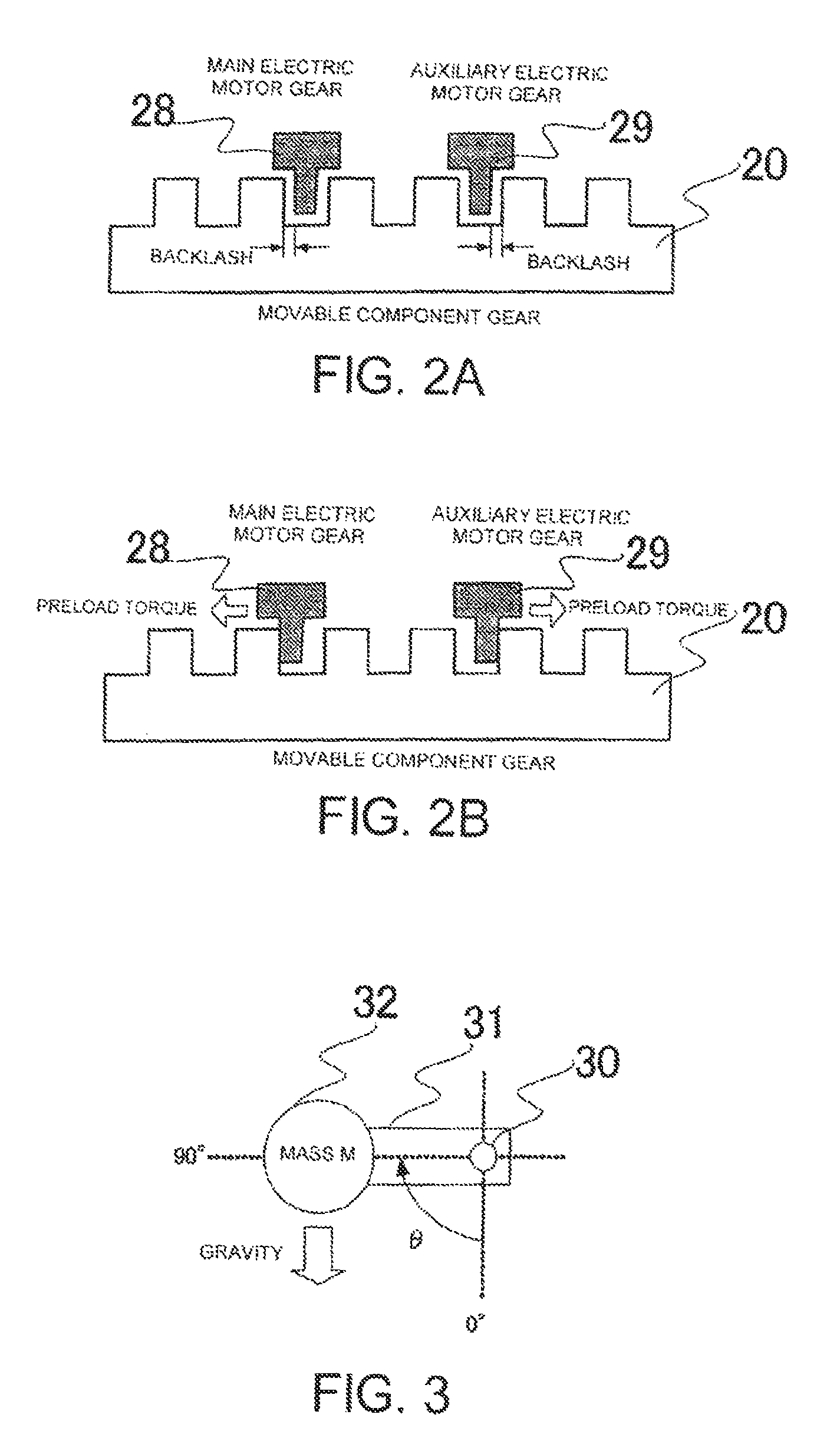

Electric motor control device

ActiveUS9317028B2Displacement minimizationAvoid low machining accuracyProgramme controlMultiple motor speed/torque controlMotor controllerEngineering

An electric motor control device for performing tandem control for driving one movable component includes, for each electric motor, a position controller, a speed controller, and a current controller. Further, each electric motor also has a preload controller for adding a preload torque to a torque command Tm calculated by the speed controller, and to a torque command Ts calculated by the speed controller. The preload controller calculates a minimum necessary preload torque for eliminating backlash in accordance with a position of the movable component.

Owner:OKUMA CORP

Work transfer apparatus

ActiveUS20160167103A1Avoid low machining accuracyReduce imbalanceMetal-working feeding devicesPositioning devicesEngineeringArm moving

To provide a work transfer apparatus which can transfer works at high speed with controlling respectively the posture of the right and left of works. The work transfer apparatus includes an arm moving back and forth between machines in order to transfer work(s), a crossbar coupled to the arm, and a pair of right and left work holding devices provided at the left and right sides of the crossbar and tilt drive devices being provided on the arm, respectively controlling the work holding devices to rotate around an axis of a longitudinal direction of the crossbar.

Owner:AIDA ENG LTD

Rubber cutting machine capable of carrying out precise machining

InactiveCN104162902AAvoid leaningAvoid low machining accuracyMetal working apparatusHydraulic cylinderVertical plane

The invention relates to a rubber cutting machine capable of carrying out precise machining. The rubber cutting machine comprises a rubber guide base used for containing rubber, a rack is arranged in the rubber guide base, the end face, opposite to the rubber guide base, of the rack is provided with a rubber cutter, and the rubber cutter is controlled by a hydraulic cylinder which is arranged on the upper end face of the rack. According to the rubber cutting machine capable of carrying out precise machining, a baffle is arranged between the tail end of the rubber guide base and a vertical plane where the rubber cutter is located, a slide rail is arranged at the joint of the upper end face of the rubber guide base and the side end face of the rubber guide base, and the baffle extends into the sliding rail. By means of the technical scheme, rubber can be fixed to the position where the rubber is machined through the baffle which can carry out precise positioning, and therefore machining precision reducing caused by deviation generated when a worker adjusts the rubber machining position can be avoided; meanwhile, due to elasticity of the baffle, the baffle can prevent the rubber cutter from cutting the rubber obliquely when the rubber makes contact with the rubber cutter.

Owner:ZHANGJIAGANG HONGLI RUBBER & PLASTIC PROD

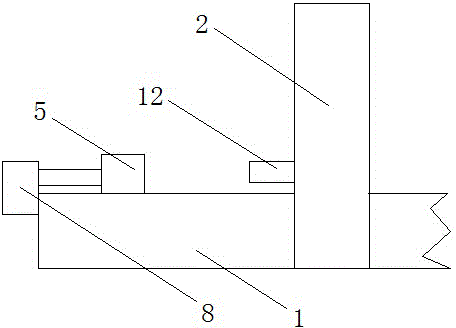

Paper tube clamping dividing and cutting machine

The invention discloses a paper tube clamping dividing and cutting machine comprising a support frame. A sliding rail is arranged at the upper end of the support frame; a dividing ruler is arranged on the sliding rail; and a sliding sleeve is arranged on the sliding rail and is connected with a cutting unit. Rotating shafts are respectively arranged at the two ends of the support frame; connecting shafts are fixedly connected to the tail ends of the rotating shafts; rotating posts and guiding posts sleeve the connecting shafts; the rotating posts are connected with the excircle surfaces of the connecting shafts in a cooperation mode; and the guiding posts are connected with the connecting shafts in a screw-thread fit mode. One end surface of each rotating post cooperates with the tail end of each rotating shaft and threads are arranged at the other end surface. A plurality of grooves are formed in the end surfaces, corresponding to the threaded surfaces of the rotating posts, of the guiding posts, wherein the grooves are distributed uniformly; sliding blocks are installed in the grooves in a cooperation mode and are equipped with tooth bars cooperating with the threads of the rotating posts. With the machine, the working efficiency is improved and the cost is lowered.

Owner:CHENGDU BAOMIHUA INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com