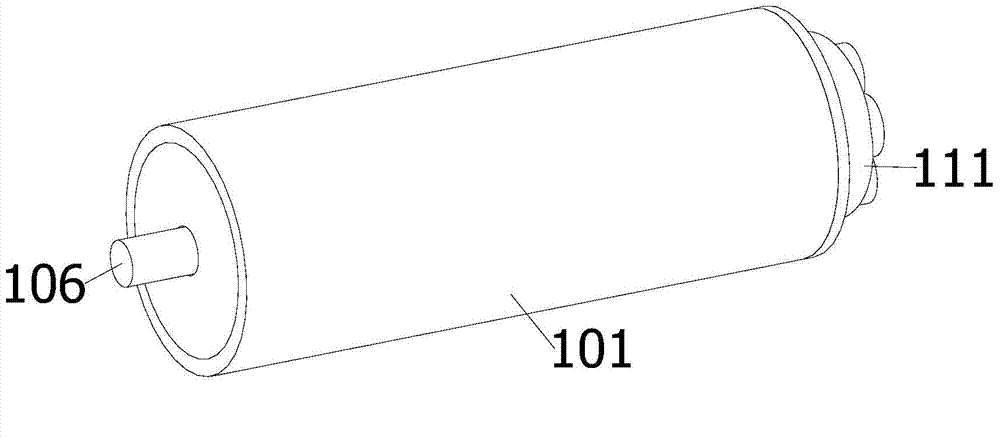

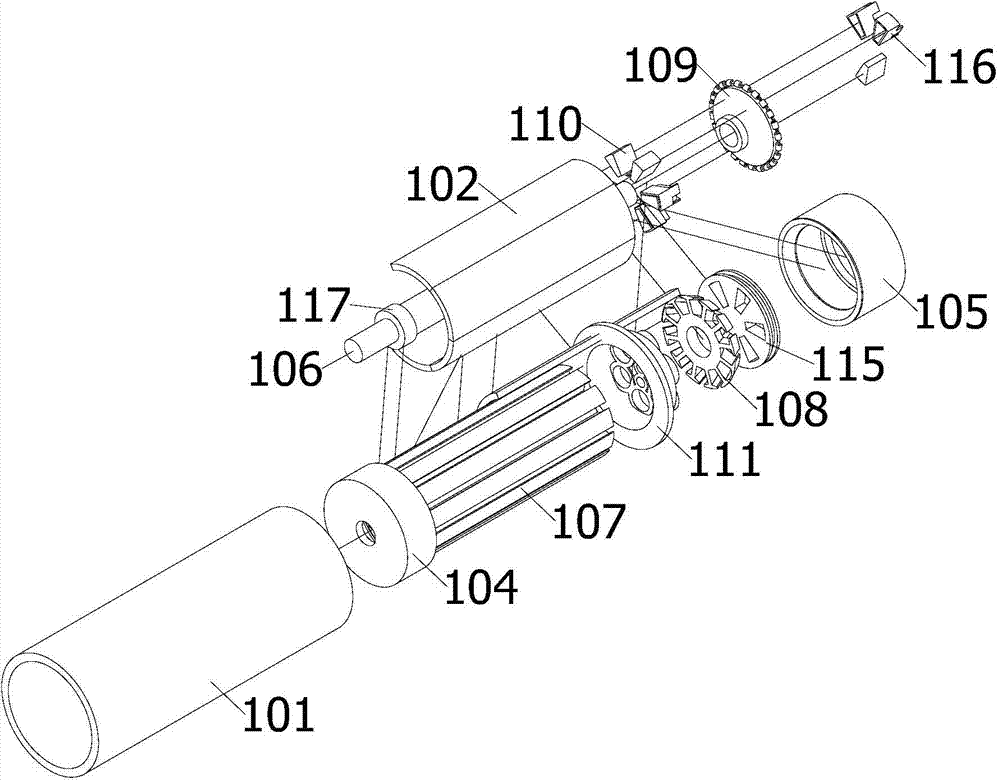

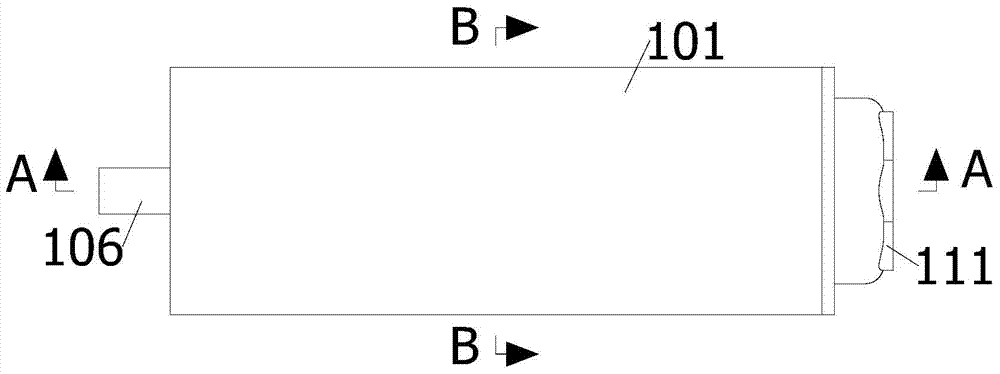

Bearing-free motor

A bearingless motor and machine barrel technology, applied in the field of electric motors, can solve the problems of shortening the service life of bearings and motors, reducing the service life of bearings, increasing the frictional resistance of rotors, etc., achieving the goal of no need for lubrication, prolonging service life and increasing magnetic flux density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The rotor of a traditional motor is supported by two mechanical bearings, so there is mechanical friction during the rotation of the rotor. Mechanical friction not only increases the friction resistance of the rotor, but also wears the bearing and reduces the service life of the bearing. Because in the high-speed running motor, the mechanical The impact force received by the bearing is greater, and the wear of the mechanical bearing is faster, so that the service life of the bearing and the motor is greatly shortened. In addition, due to the high assembly requirements of mechanical bearings, if the mechanical bearings are worn at high speed, the machining accuracy will be affected.

[0042] In order to improve the above problems, the present invention provides a bearingless motor. The rotating shaft of the motor is suspended under the action of a magnetic field and can rotate without mechanical bearings, which reduces wear after mechanical friction and can increase the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com