Machining method for numerical control turning of circular arc chamfer on shaft excircle surface

An external surface, arc chamfering technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of sharp edges and the unsmooth connection of the external surface of the shaft, so as to reduce the processing cost and avoid processing. The effect of low precision and ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

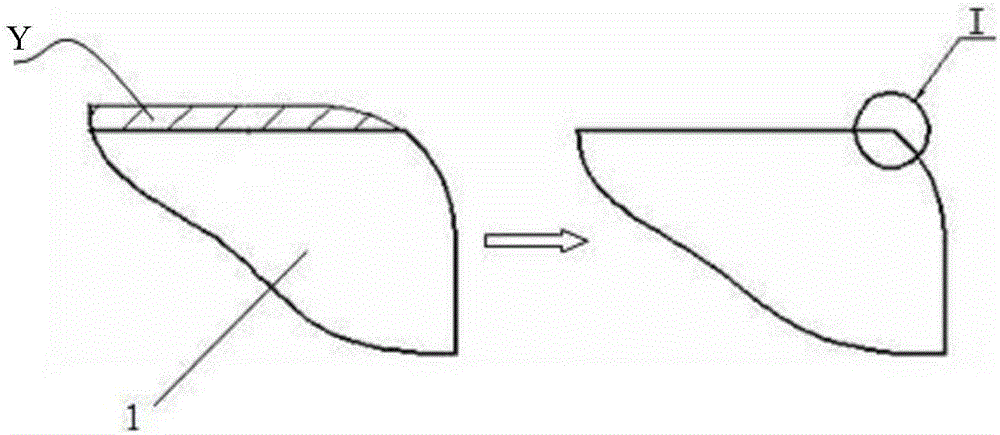

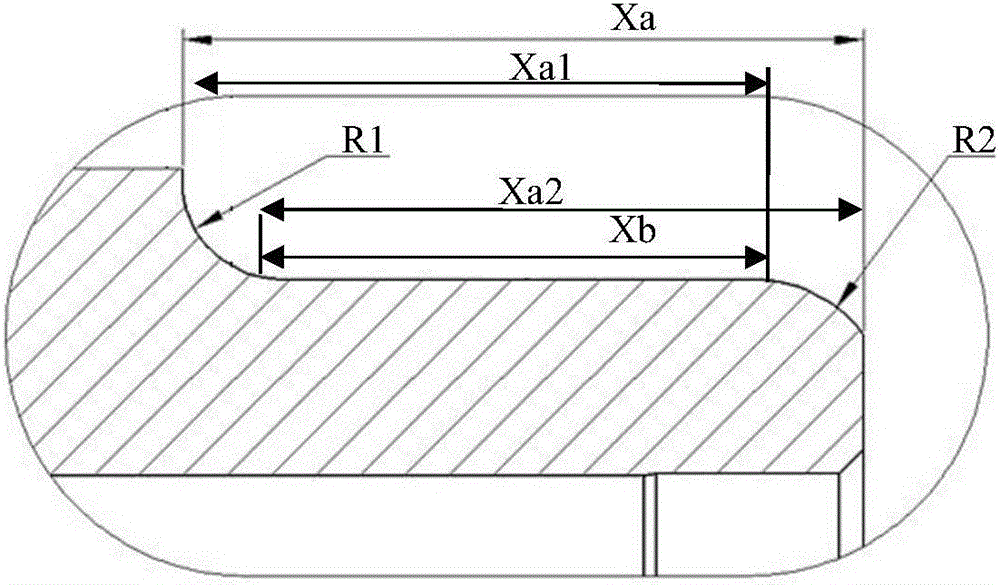

[0023] Such as figure 2 As shown, there is a circular chamfer R2 at the end of axis 1. We set the outer circular surface of the axis as Xb. When processing R2 and Xb at one time, the machining process can be programmed in advance according to the design requirements. After determining the NC turning When drawing the graph, determine the arc chamfering R2 and Xb of the shaft to be turned as a combined curve Xa2, and set the processing parameters of the turning machine tool as S=2500r / min, F=70mm / min. S is the speed, F is the feed rate, and Xa2 is processed at one time, and the outer surface of the shaft is smoothly connected with the arc chamfer.

Embodiment 2

[0025] Such as figure 2 As shown, the neck of shaft 1 has a circular chamfer R1, we set the outer surface of the shaft as Xb, and when processing R1 and Xb at one time, the machining process can be programmed in advance according to the design requirements. When drawing the graph, determine the arc chamfering R1 and Xb of the shaft to be turned as a combined curve Xa1, and set the processing parameters of the turning machine tool as S=2500r / min, F=70mm / min. S is the speed, F is the feed rate, Xa1 is processed at one time, and the outer surface of the shaft is smoothly connected with the arc chamfer.

Embodiment 3

[0027] Such as figure 2 As shown, the neck of shaft 1 has a circular chamfer R1, and the end of shaft 1 has a circular chamfer R2. We set the outer surface of the shaft as Xb. When processing R1, Xb and R2 at one time, it can be processed according to The design requires NC programming in advance for the machining process. When determining the NC turning curve, determine the arc chamfering R1, Xb and R2 of the turning axis as a combined curve Xa, and set the processing parameters of the turning machine tool as S= 2500r / min, F=70mm / min. S is the speed, F is the feed rate, and Xa is processed at one time, and the outer surface of the shaft is smoothly connected with the arc chamfer.

[0028] Preferably, in the above three embodiments, the knives used are all ceramic knives. Because ceramic knives have the advantages of better durability, higher hardness, wear resistance, better anti-sticking properties, and less wear and tear.

[0029] Positive progress effect of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com