Multi-dimensional ultrasonic tool system with tool head action space being quadric surface and method of multi-dimensional ultrasonic tool system

A quadratic surface, ultrasonic tool head technology, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of generating elliptical motion trajectories, small changes in cutting points and cutting force directions, and single motion trajectories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

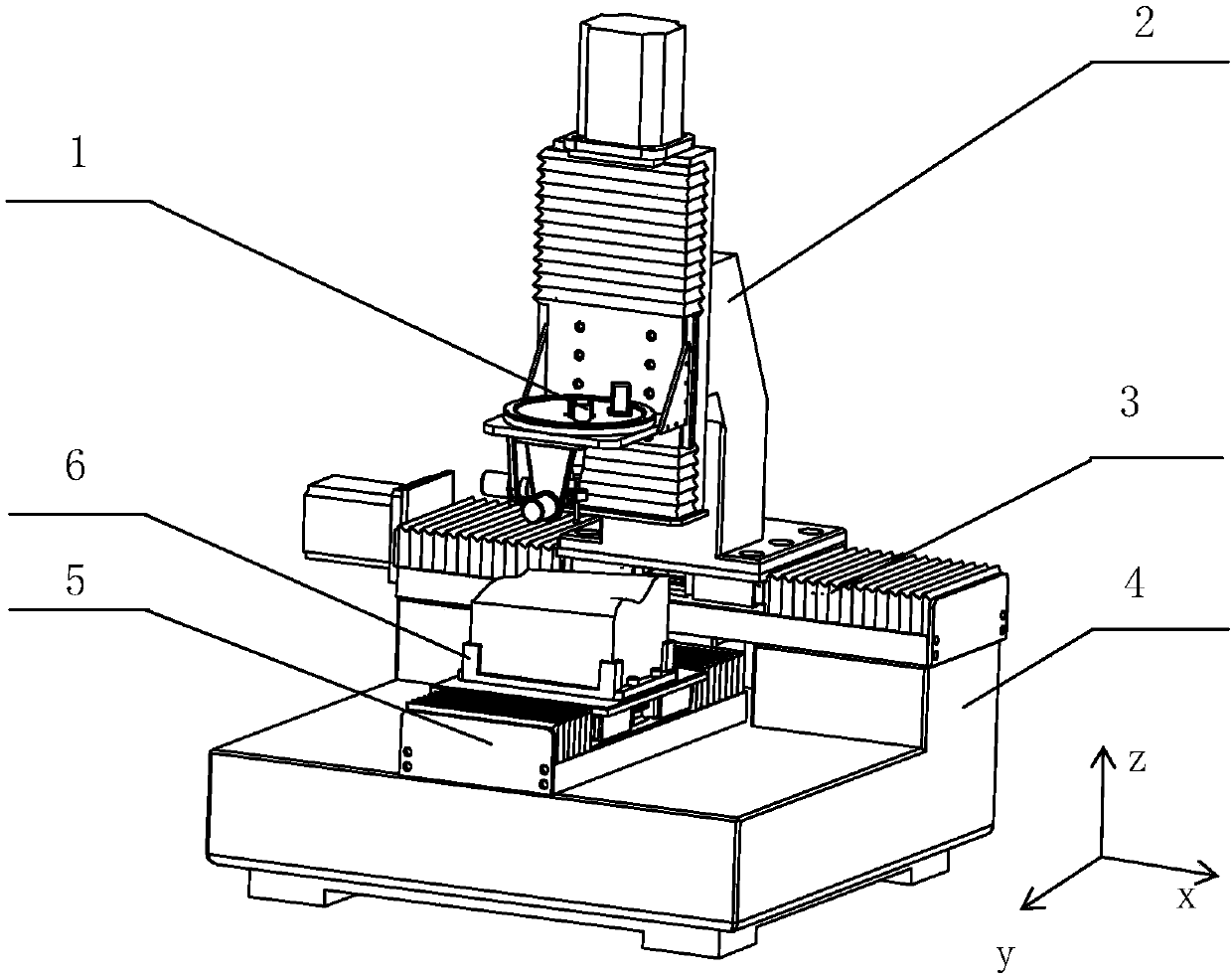

[0068] see figure 1 , including an ultrasonic tool head 1, a Z-direction moving device 2, an X-direction moving device 3, a base 4, a Y-direction moving device 5, and a fixture 6, the X-direction moving device 3 is laterally fixed and installed on the two bosses behind the base 4 , the motor of the X-direction moving device 3 is located on the left side of the main body of the X-direction moving device 3, the Y-direction moving device 5 is longitudinally fixed on the base 4, and the motor of the Y-direction moving device 5 is located in the X-direction moving device 3 In the space between the two bosses below, the fixture 6 is fixedly installed on the slide of the Y-direction moving device 5, and the Z-direction moving device 2 is vertically fixed on the slide of the X-direction moving device 3, so The ultrasonic tool head 1 is fixedly installed on the sliding plate of the Z-direction moving device 2, and the ultrasonic tool head 1 is located above the fixture 6;

[0069] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com