Patents

Literature

36results about How to "Achieve three-dimensional effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

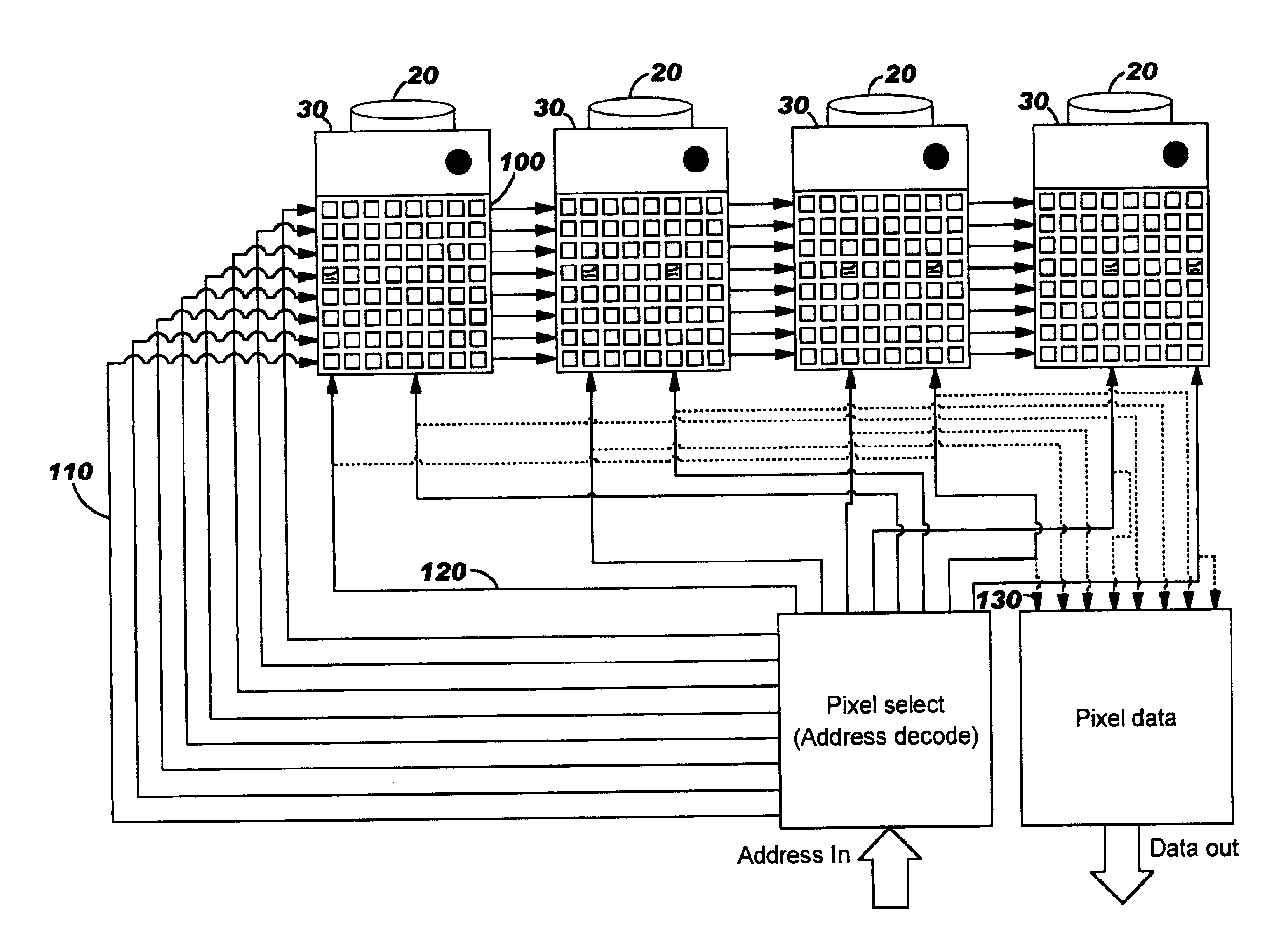

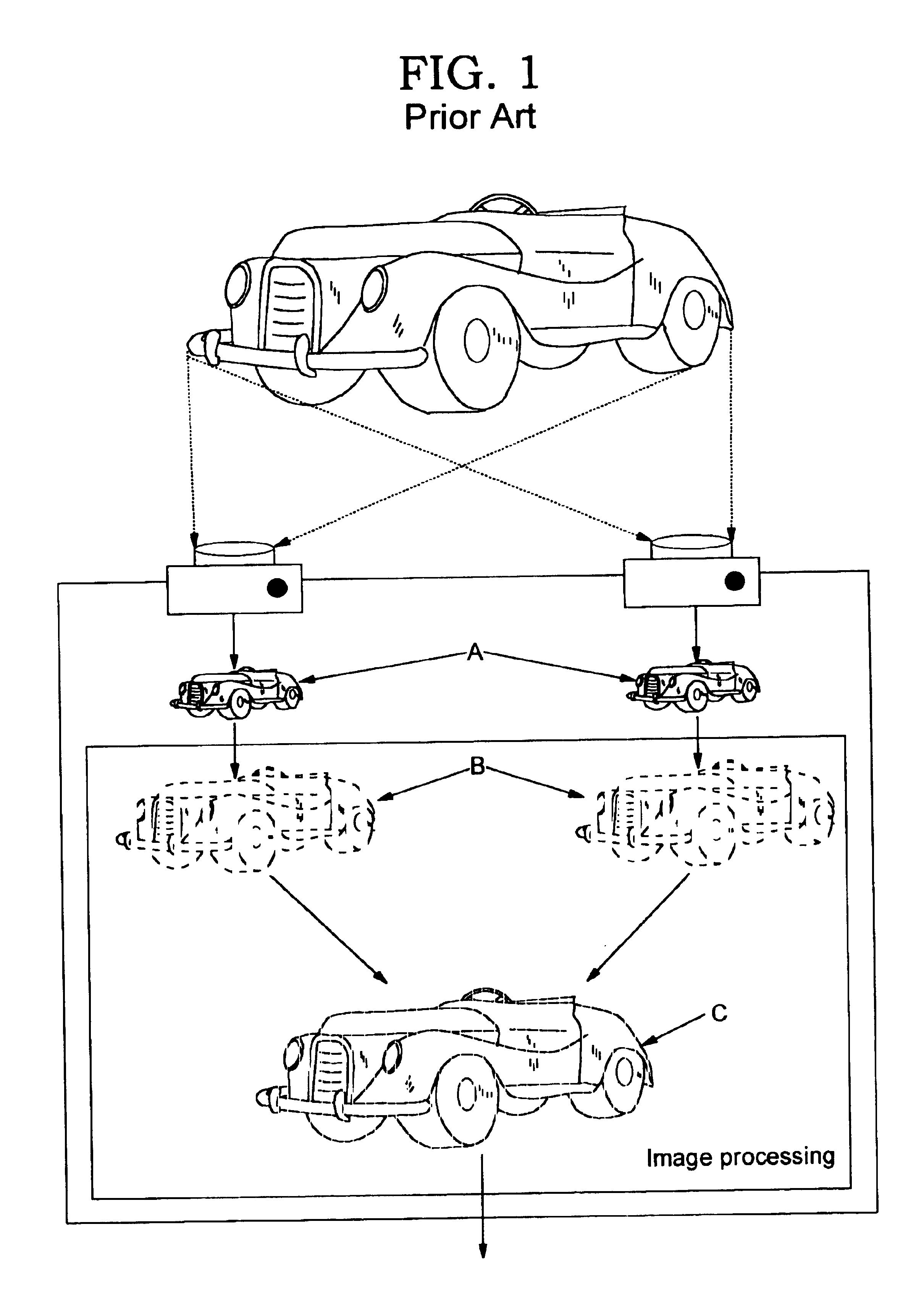

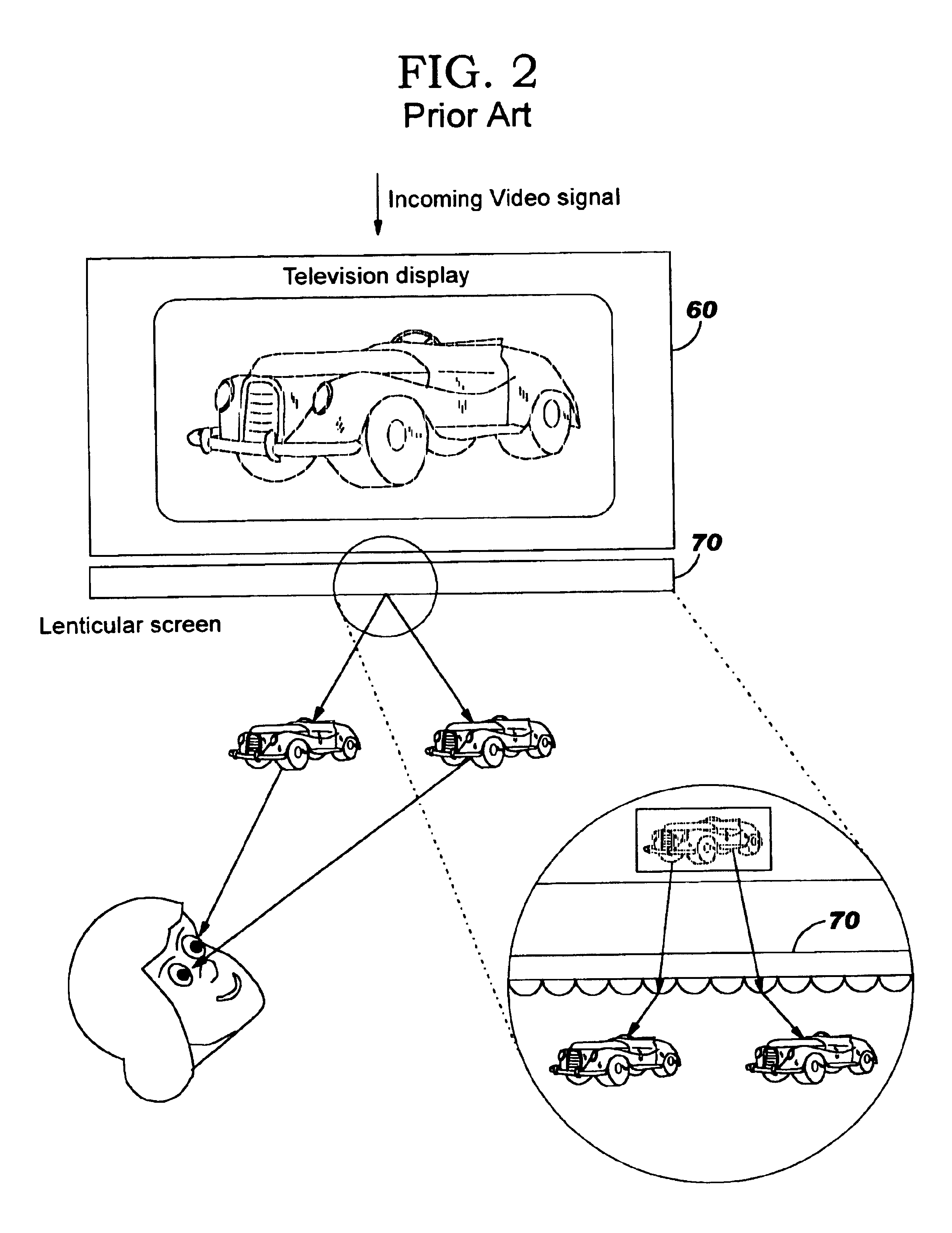

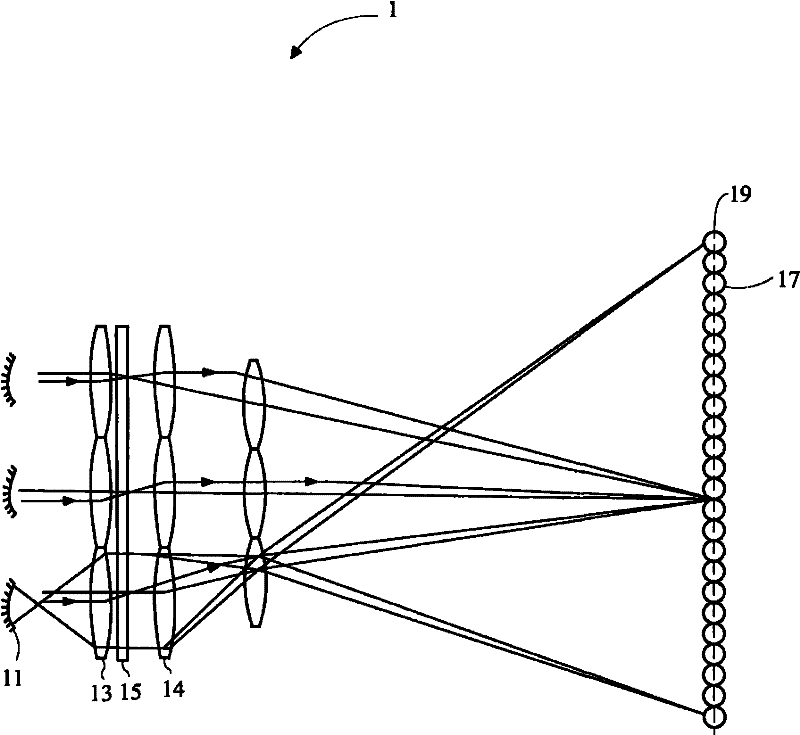

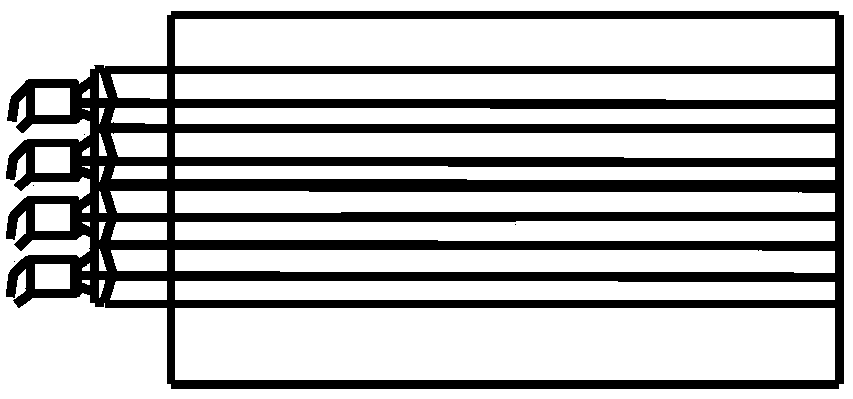

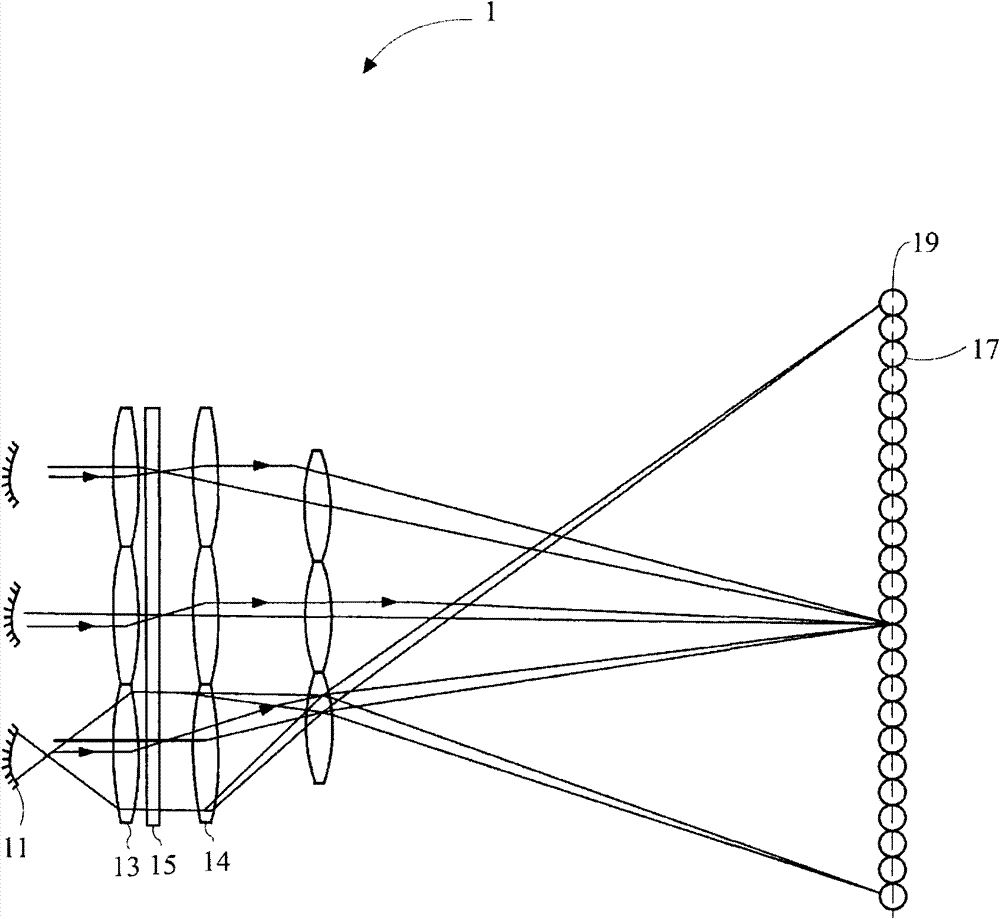

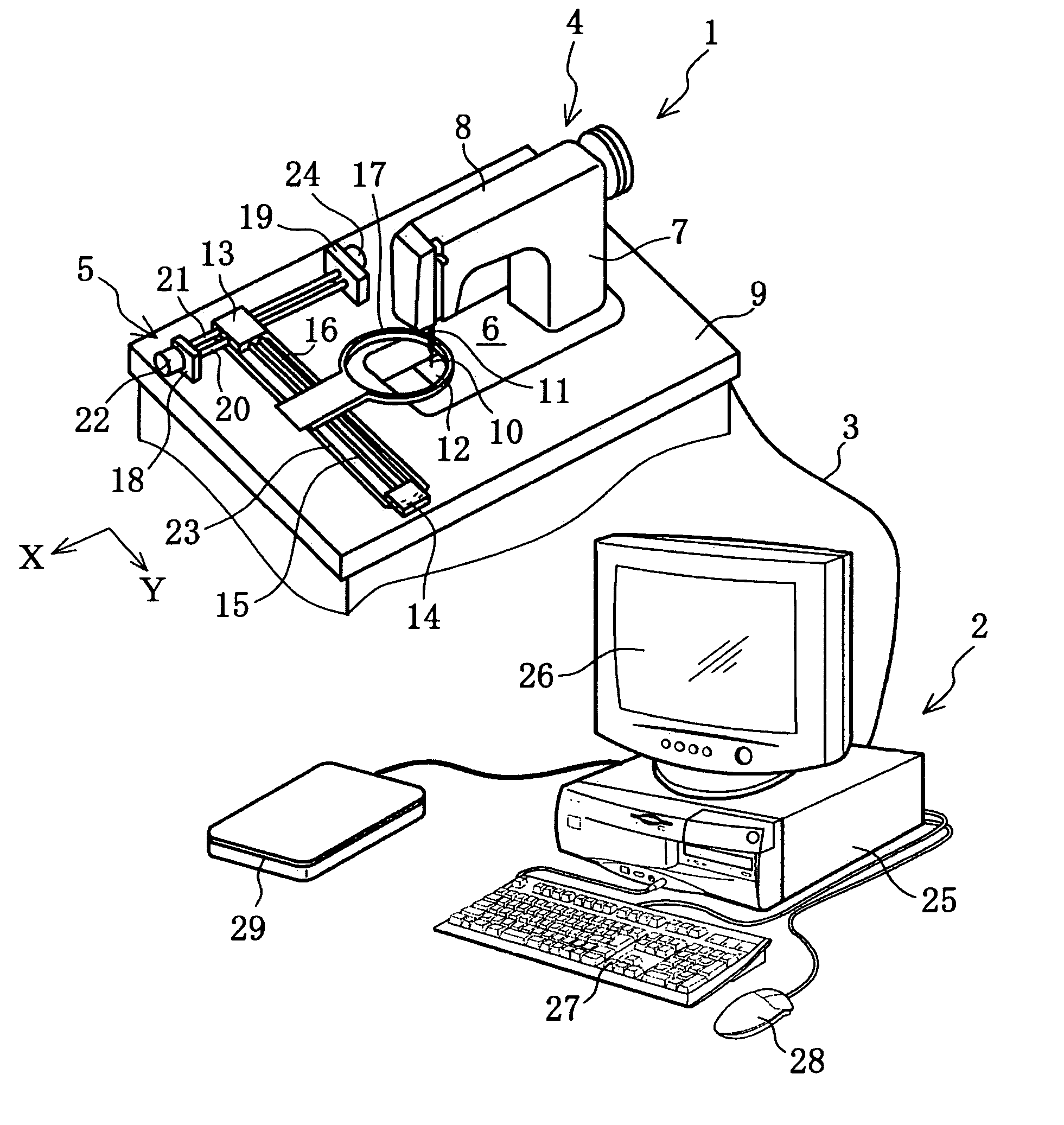

Camera system for three dimensional images and video

InactiveUS6750904B1Achieve three-dimensional effectAvoid the needTelevision system detailsColor television detailsImaging processingComputer graphics (images)

A camera system including a plurality of image capture devices and supporting output of data from data storage arrays of each image capture device in a segment-by-segment manner, with output lines arranged in an interleaved manner so that interleaving is automatically achieved without complex image processing. The interleaved image or video output of such a camera system will appear as a three dimensional image when viewed through a screen of lenticular lenses.

Owner:IBM CORP

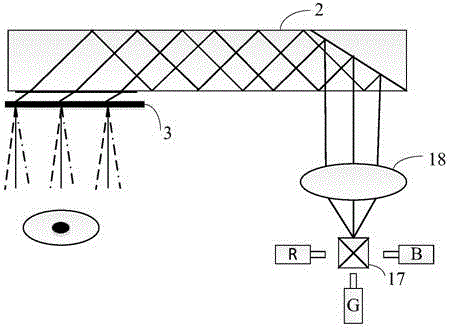

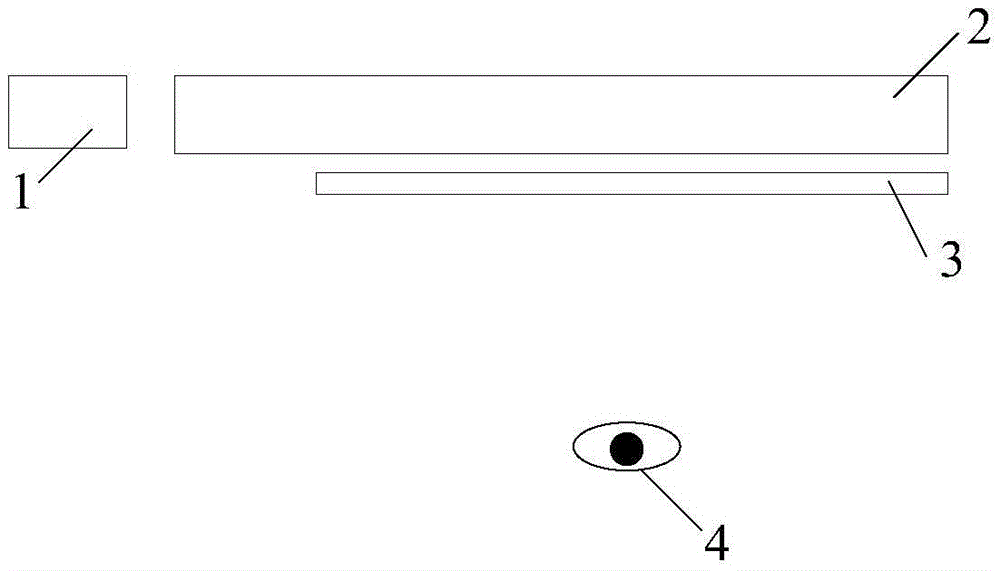

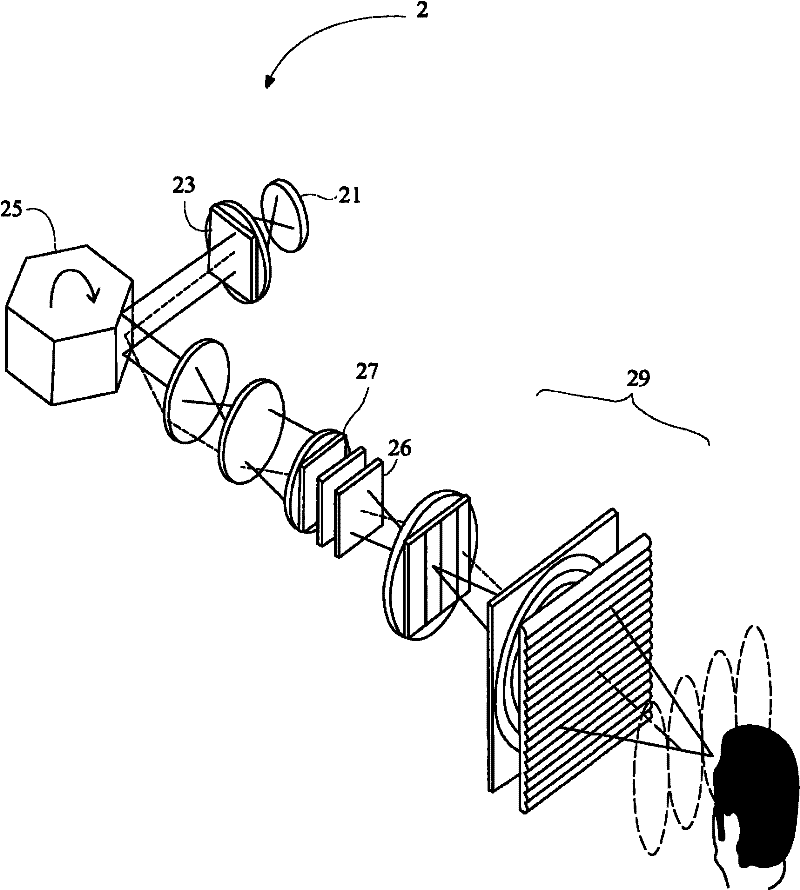

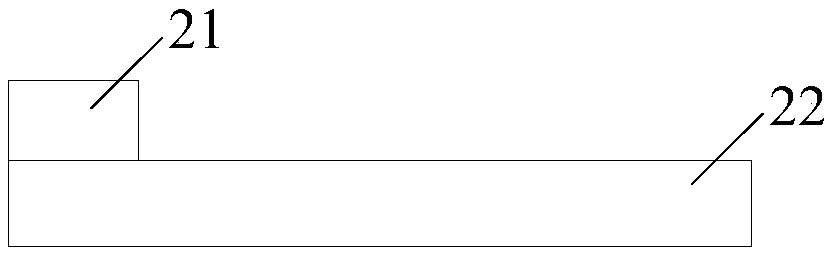

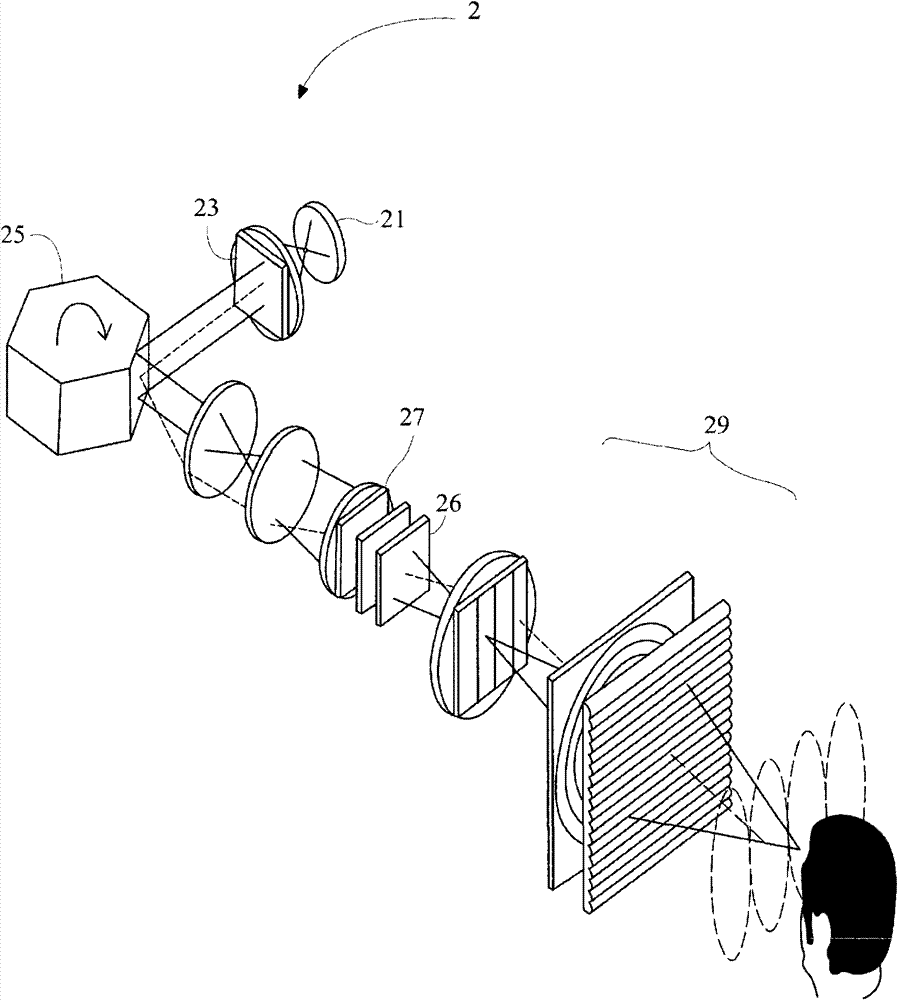

Near-to-eye display system and head-mounted display device

The invention discloses a near-to-eye display system, which comprises a light source system, a light guide system and an image display system, wherein the image display system is used for displaying a hologram; the light source system is used for inputting a lighting beam to the light guide system; and the light guide system is used for carrying out transmission and expansion on the lighting beam and then enabling the beam to irradiate on the hologram displayed by the image display system to activate the hologram in a transmission mode. Correspondingly, the invention also discloses a head-mounted display device. The waveguide light guide technology and the computational holography technology are integrated fully, and thus, the near-to-eye display system is light and delicate, and large-view field display and depth adjustment through computational holography can be realized.

Owner:CHENGDU IDEALSEE TECH

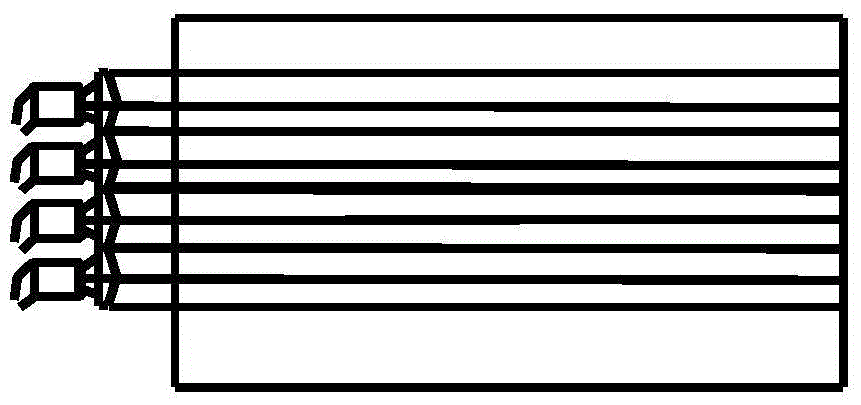

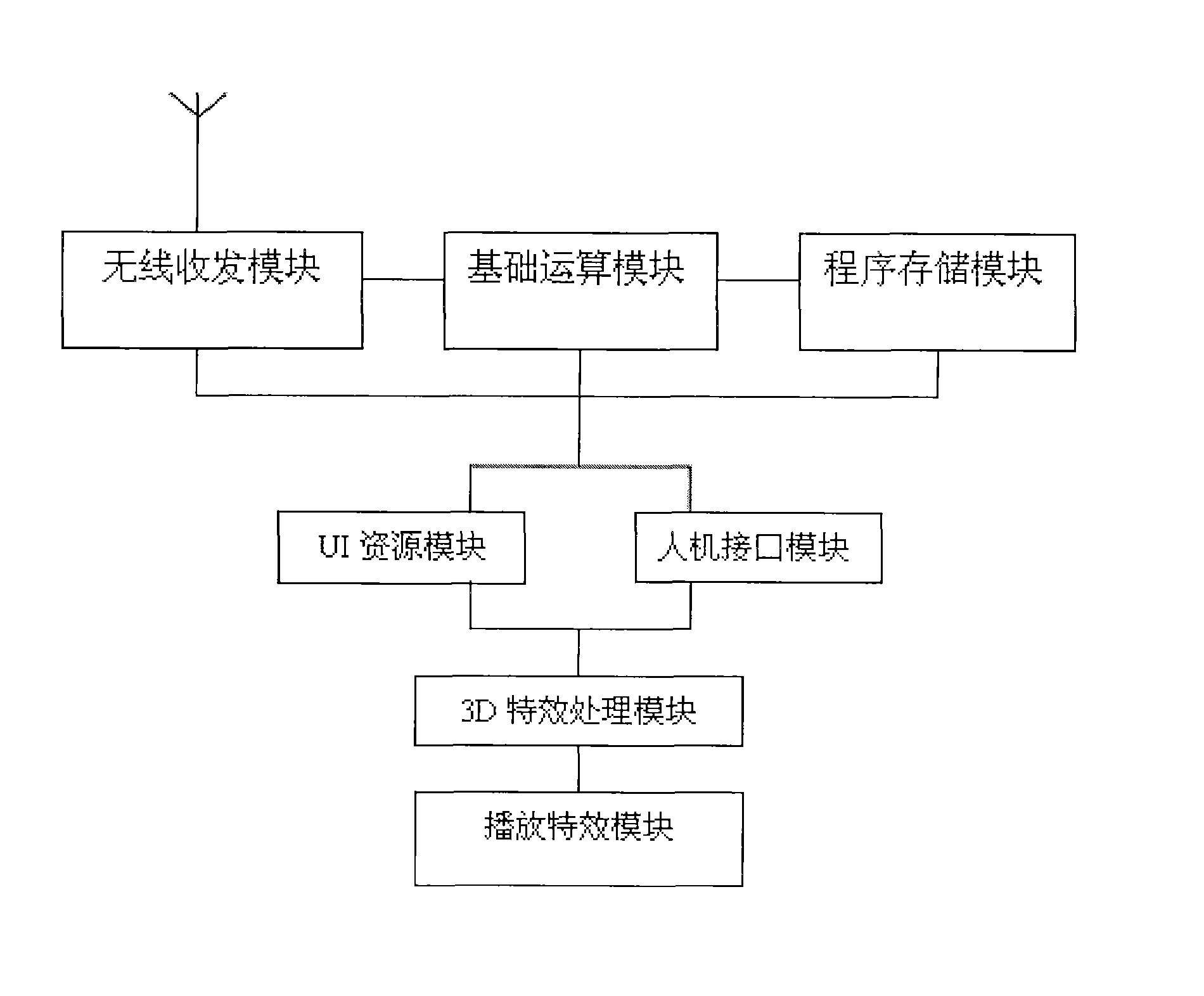

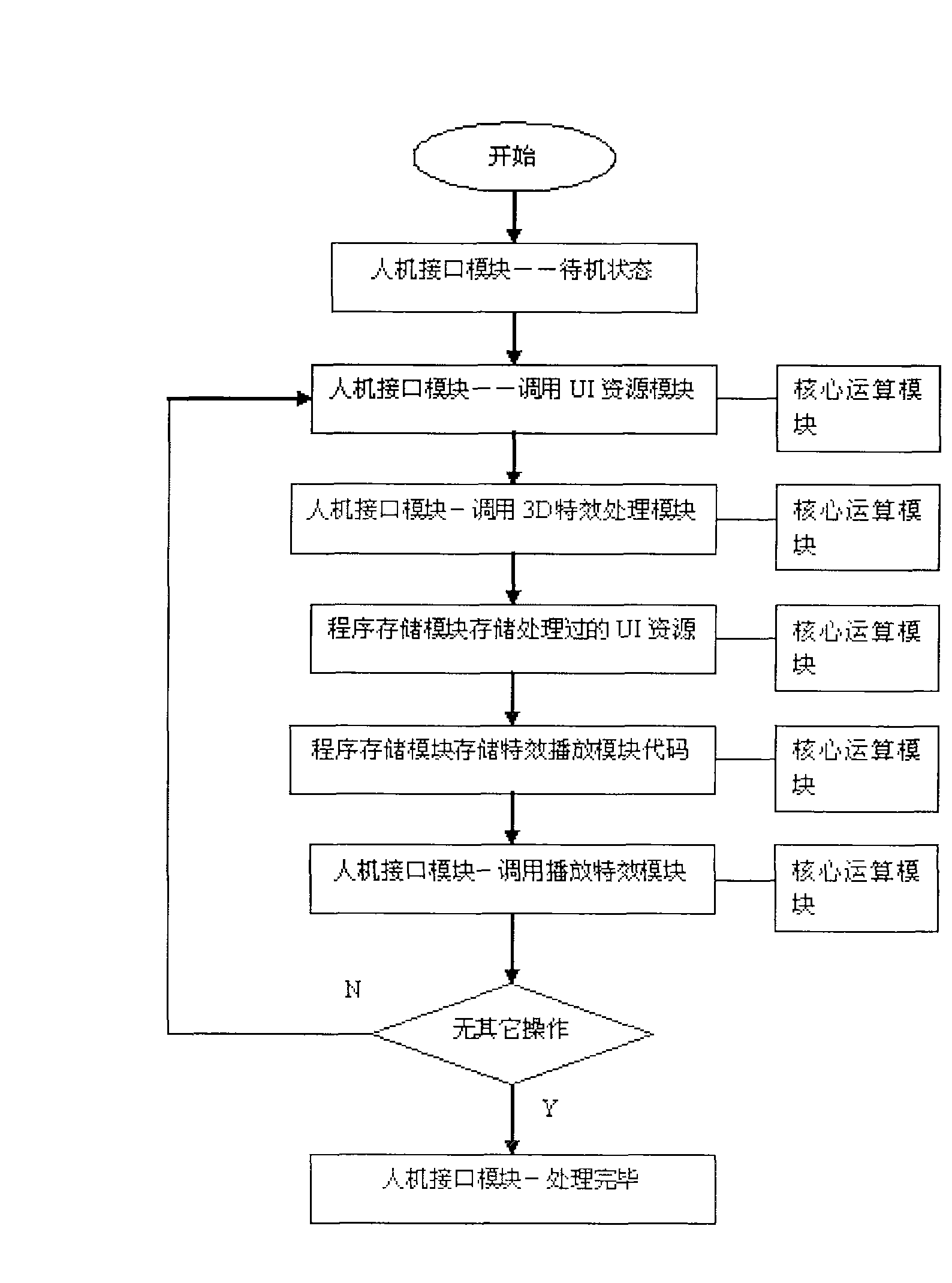

3D special-efficacy graphic user interface system and method of mobile phone

InactiveCN101655989AMeet visual needsAchieve three-dimensional effectSubstation equipmentAnimationGraphicsGraphical user interface

The invention discloses a 3D special-efficacy graphic user interface system and method of mobile phone, comprising a CPU, also comprising a a man-machine interface module for detecting user operationinstruction and calling pictures in user interface resource module; a 3D special efficacy processing module for executing operation processing to the pictures and storing the processed pictures in a memory in logic sequence; a special efficacy playing module for playing the processed pictures in logic sequence. The invention uses the 3D special efficacy processing module to executing operation processing such as turning, distorting, changing color etc. to the user interface resource pictures, then aligns the processed pictures in logic sequence and stored in memory of the mobile phone; when user selects the menu interface, the man-machine interface module calls the pictures in logic sequence to generate three-dimensional overturn special efficacy, thereby achieving three-dimensional effect, generating colorful and variation abundant operation interface on the mobile phone to meet vision requirement of users.

Owner:SHENZHEN GIONEE COMM EQUIP

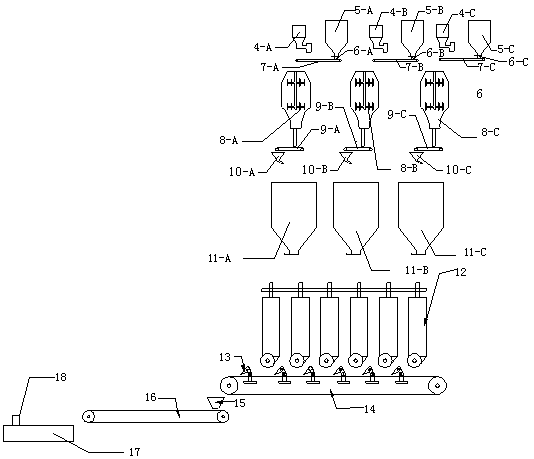

Method for manufacturing glazed tile with glaze three-dimensional effect

InactiveCN103193457AAchieve three-dimensional effectUnique effectDecorative surface effectsClaywaresTexture gradientCeramic glaze

The invention relates to a method for manufacturing a glazed tile with a glaze three-dimensional effect. The method comprises a printing process of printing on an unglazed biscuit through a relief silk screen plate with a certain thickness and a relief roller with a certain depth, so as to form texture patterns with a variable concave-convex effect, and a once-firing process, thus preparing the glazed tile with a glaze three-dimensional effect. The glazed tile manufactured by the invention can generate a concave-convex texture gradient effect, and is good in decoration effect, high in durability, good in antifouling performance, variable in patterns, and can well reflect change of the natural color of stone.

Owner:MONALISA GRP CO LTD

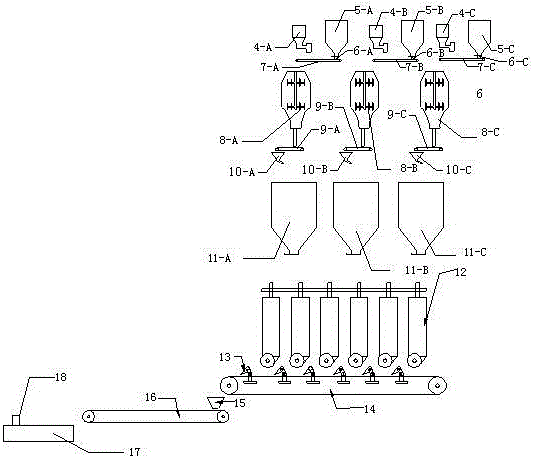

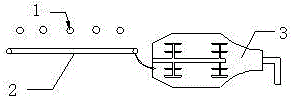

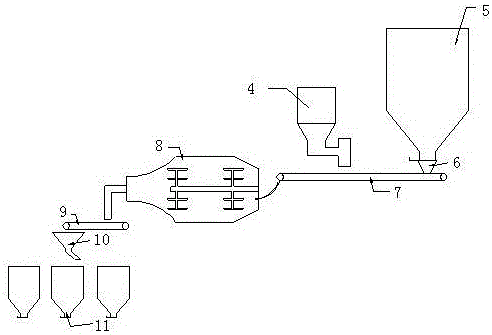

Fully polished glazed ceramic tile with a real stone effect and production process thereof

The invention discloses a fully polished glazed ceramic tile with a real stone effect and a production process thereof. The production process includes the following steps: (A) by means of feed modules, pigments and base adobe powder are mixed into a variety of needed colored adobe powders by a dry mixing method according to needed proportions; (B) by means of a distribution module and a press mechanism, the colored adobe powders are pressed into a fully colored adobe; (C) the fully colored adobe is dried under 120DEG C to 180DEG C for 50 to 100 minutes; (D) the surface of the fully colored adobe is decorated, so that a semifinished product is obtained; (E) the semifinished product is fired once under 1100DEG C to 1250DEG C for 40 to 90 minutes; (F) after the fired product is processed polishing, edging, waxing and filming steps, the finished product is obtained. The invention realizes the representation of the changing colors and texture of natural stone on the ceramic tile, the fully colored adobe can more embody the unique stereoscopic impression of stone, and by means of post-processing processes, such as chamfering and groove broaching, the fully polished glazed ceramic tile can show a full real stone decoration effect.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

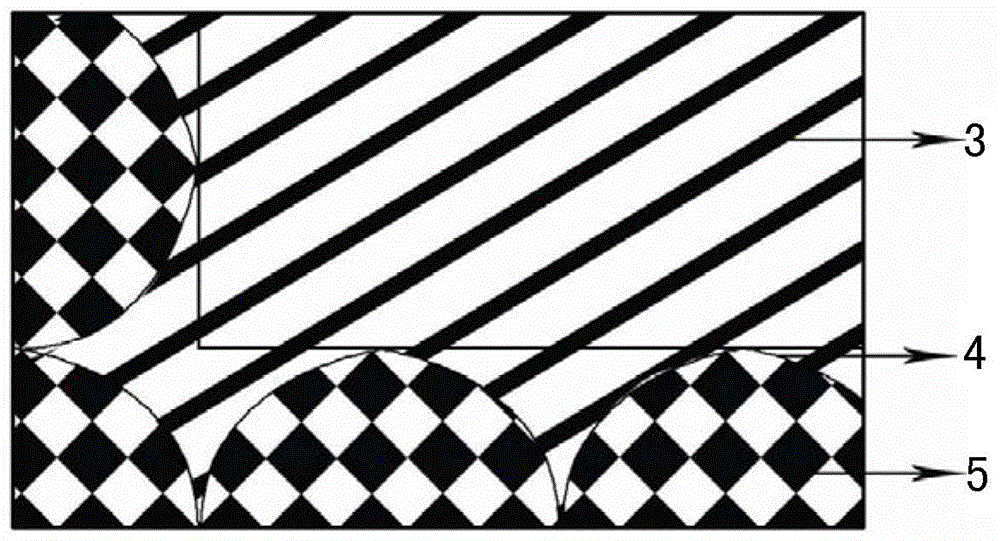

Display device for displaying multi-view images

InactiveCN102262346AAchieve three-dimensional effectIncrease visual brightnessStereoscopic photographySteroscopic systemsCamera lensMultiple perspective

The invention discloses a display apparatus used for displaying multiple perspective images. The display apparatus comprises: a display screen and a plurality of projectors. Each projector includes: at least one light source module, one spatial light modulation component and a lens. The display screen respectively forms imaging of a first visual angle image and a second visual angle image emitted by the each projectors to a first sub-vision field and a second sub-vision field through a first light and a second light provided by the light source module.

Owner:DELTA ELECTRONICS INC

Three-dimensional embossment process for all-polyester cony-hair-like napped surfaces

InactiveCN110219093AAchieve three-dimensional effectStable and mature processPattern makingWarp knittingPolyesterWork in process

The invention discloses a three-dimensional embossment process for all-polyester cony-hair-like napped surfaces. The three-dimensional embossment process includes the steps of 1) weaving, 2) presetting, 3) dyeing, 4) cloth washing and softening, 5) semi-finished product resetting, 6) decoration spraying, 7) shearing, 8) hot blowing, 9) combing, 10) luster finishing, and 11) finished product resetting. The process has the advantages that the process is mature, stable, and convenient to operate; the three-dimensional all-polyester cony-hair-like napped surfaces can be effectively obtained, and an embossment effect can be achieved.

Owner:常熟市易美纺织品有限公司

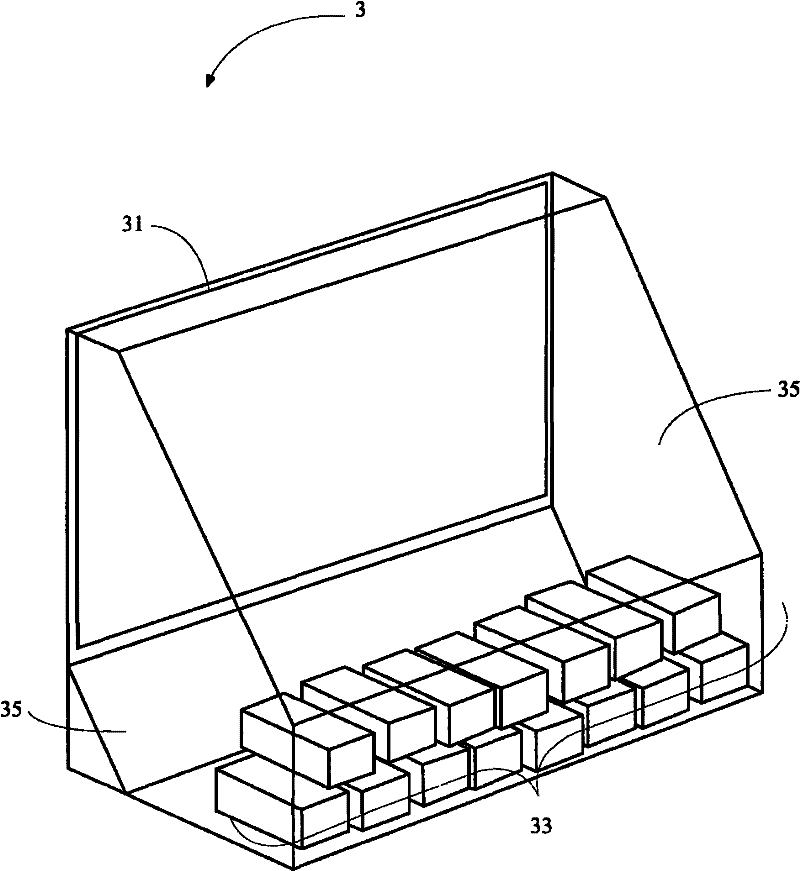

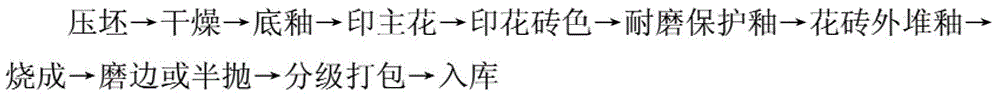

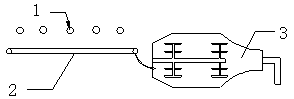

Preparation method for mono-firing embossed ceramic tile

ActiveCN106554156AAchieve three-dimensional effectInsufficient improvementOther printing apparatusSocial benefitsBody Patterning

The invention relates to a preparation method for a mono-firing embossed ceramic tile. The mono-firing embossed ceramic tile comprises a main tile body and an embossed tile body. The preparation method comprises the following steps that (1) a ground coat is applied to a billet; (2) main tile body pattern printing and embossed tile body pattern printing are conducted on the billet coated with the bottom coat, and an embossed tile billet is produced; (3) protective glaze is applied to the main tile billet and the embossed tile billet obtained in the step (2); (4) an embossed material corresponding to an embossed tile pattern is printed on the embossed tile billet obtained in the step (3), so that a three-dimensional layer is formed; and (5), the main tile billet obtained in the step (3) and the embossed tile billet obtained in the step (4) are fired, so that the mono-firing main tile body and the mono-firing embossed tile body are obtained. By adoption of the preparation method for the mono-firing embossed ceramic tile, the three-dimensional effect of a tri-firing product embossed tile is achieved, deficiencies of the tri-firing product are overcome, the durability of the product is enhanced, the energy source is saved, the labor cost is lowered, and good economical and social benefits can be obtained.

Owner:MONALISA GRP CO LTD

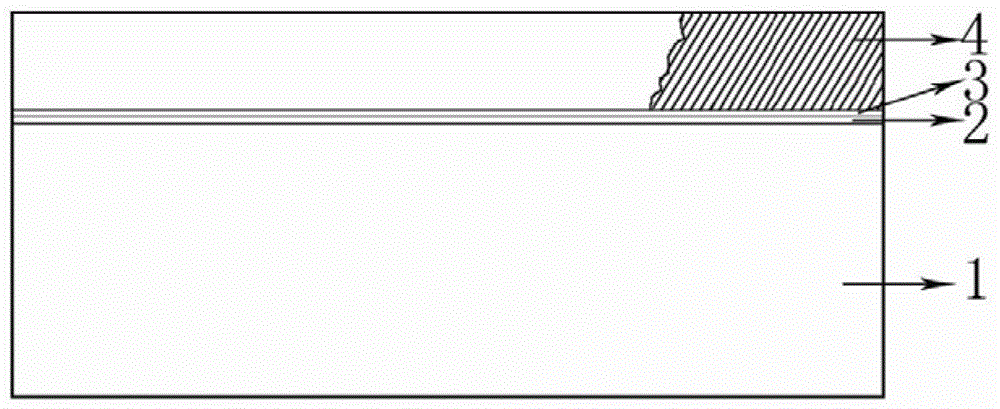

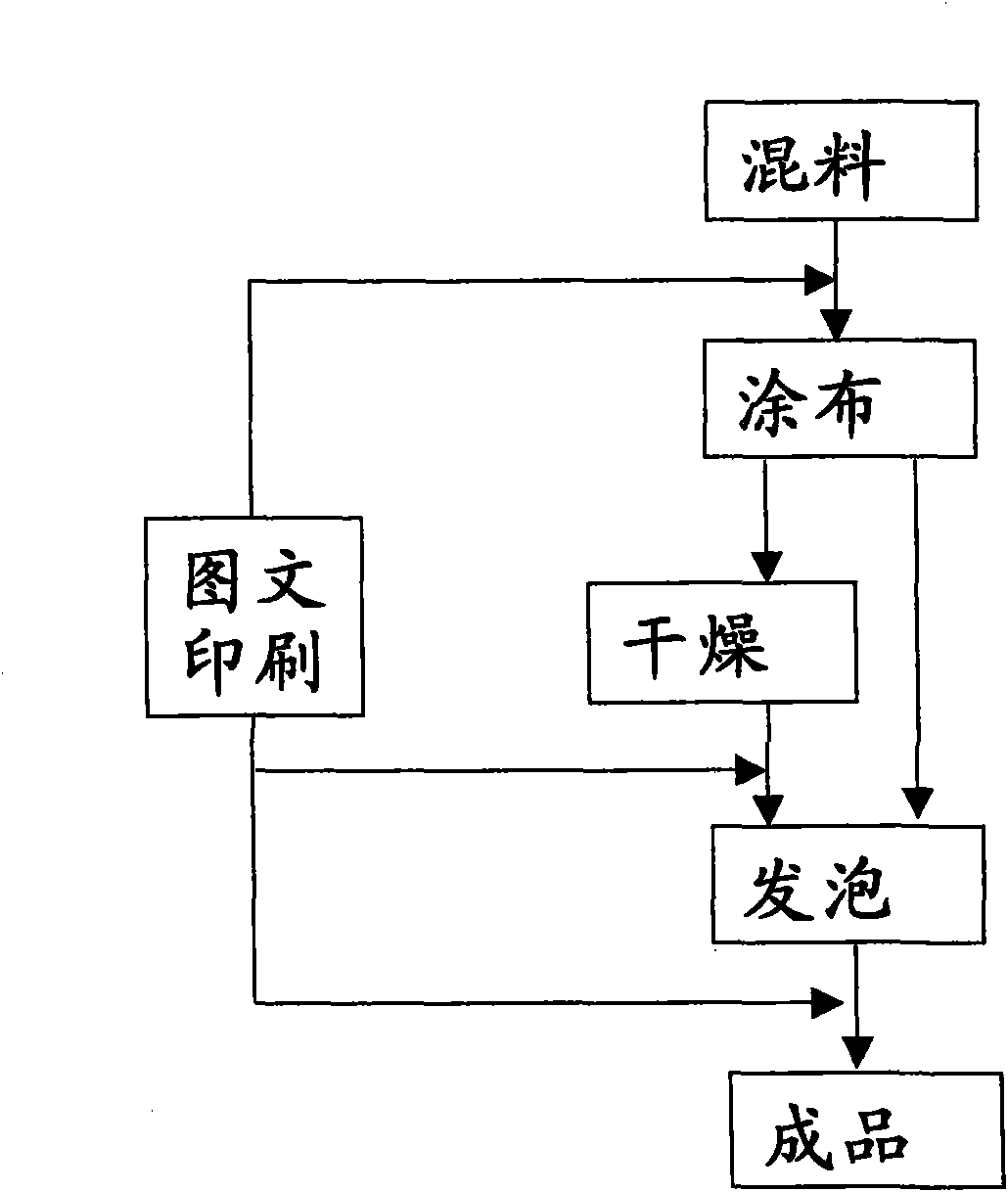

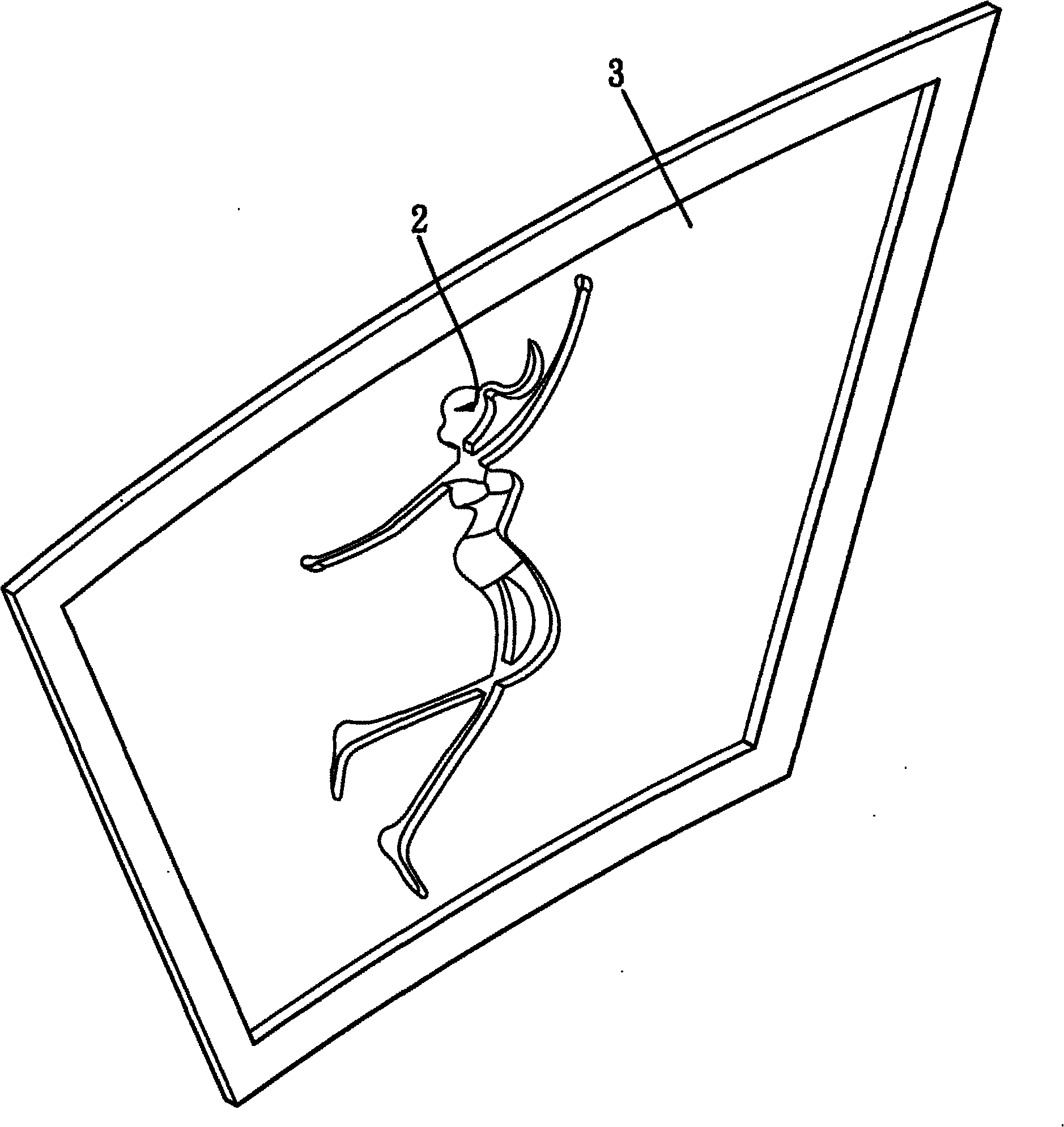

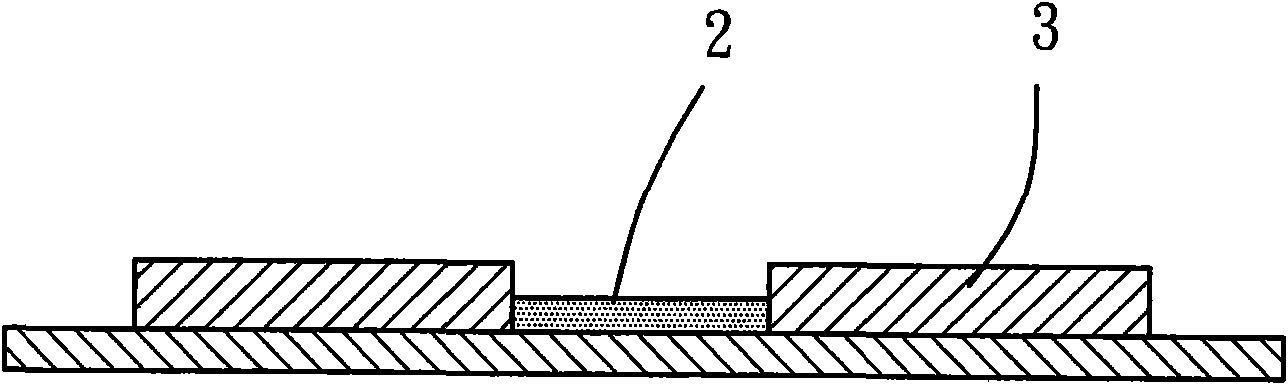

Manufacturing method of container and container manufactured by utilizing method

InactiveCN101875280AAchieve three-dimensional effectDomestic cooling apparatusLighting and heating apparatusHeight differenceMaterials science

The invention discloses a manufacturing method of a container and the container manufactured by utilizing the method, and the manufacturing method comprises the steps of material mixing, coating and foaming and is mainly as follows: forming a foaming layer with a hollow part on the outer surface of a substrate of the container by foaming, at least printing a picture and a text in the hollow part, playing the height difference property of the foaming layer and achieving the three-dimensional effect with the help of the picture and the text which are developed and printed in the hollow part. The container manufactured by the method comprises a body part surrounded by the substrate and a baseplate arranged at the bottom end of the body part.

Owner:RICH CUP BIO CHEM TECH

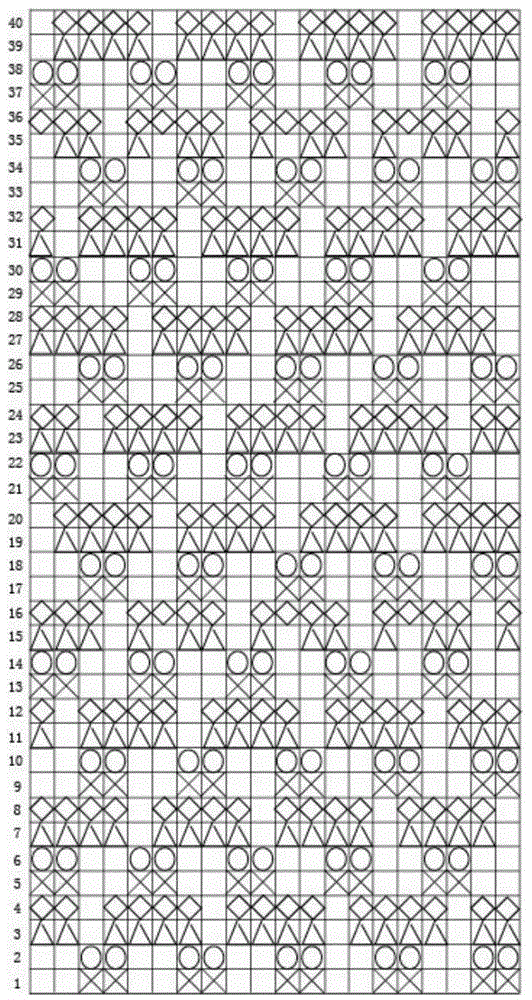

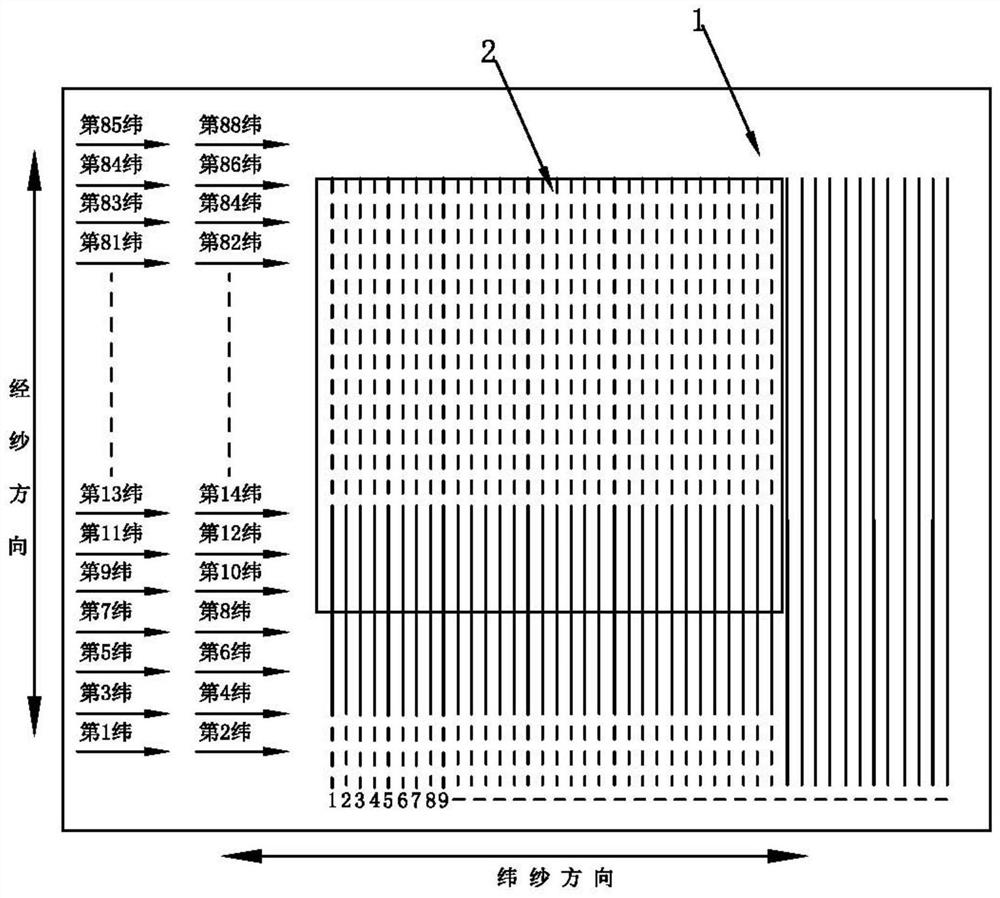

Three-dimensional sketch jacquard satin towel and weaving method thereof

ActiveCN105648624AGuaranteed uptimeStrong noveltyHeating/cooling textile fabricsDomestic applicationsEngineeringWeft yarn

The invention discloses a three-dimensional sketch jacquard satin towel and a weaving method thereof. The towel is formed by weaving ground warp and nap warp and weft yarn, the weft yarn is divided into four layers, the four layers of weft yarn are chosen to be in a white color or chosen to be in four colors of shallow, moderate and deep in the same color system, a jacquard pattern of the towel is at least divided into the several different weave regions of a light part, a dark part, a grey part according to the light and shade change of the pattern, and then the group warp and the nap warp of different weave regions and the yarn of different colors in the weft yarn are woven into a jacquard type having a three-dimensional sketch effect by the adoption of different weaves. The three-dimensional sketch jacquard satin towel is different from a common satin mode, satin weaves, twill weaves, rib weaves and other weaves are matched and matched with the colors of the yarn reasonably in a vitality and reality combination mode, third dimension of a spatial level is stronger, and a more vivid three-dimensional effect is achieved.

Owner:SUNVIM GROUP

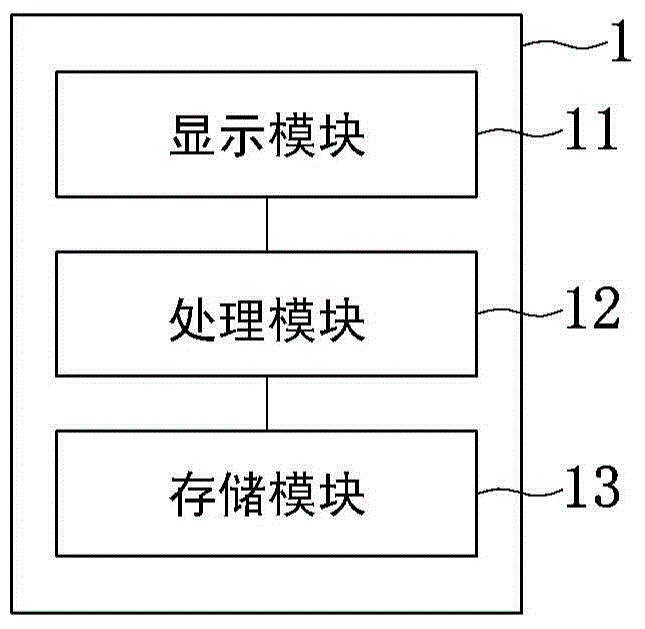

Image processing method and electronic device

InactiveCN105791793AAchieve three-dimensional effectLow costSteroscopic systemsEditing/combining figures or textImaging processingBackground image

The invention provides an image processing method and an electronic device. The image processing method comprises following steps of deciding depth values of multiple objects in original images according to depth images corresponding to the original images, wherein the multiple objects comprise at least one first object and at least one second object, the depth value of the at least one first object is less than that of the at least one second object; obtaining a reference depth value; obtaining at least one first object and a background image according to the original images; keeping the size of the at least one first object or amplifying the at least one first object, wherein the depth value of the at least one first object is less than or equal to the reference depth value; and generating an outline image; and respectively superimposing the at least one first object and the background image before and after the outline image, thus highlighting a target object and realizing a three-dimensional effect.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

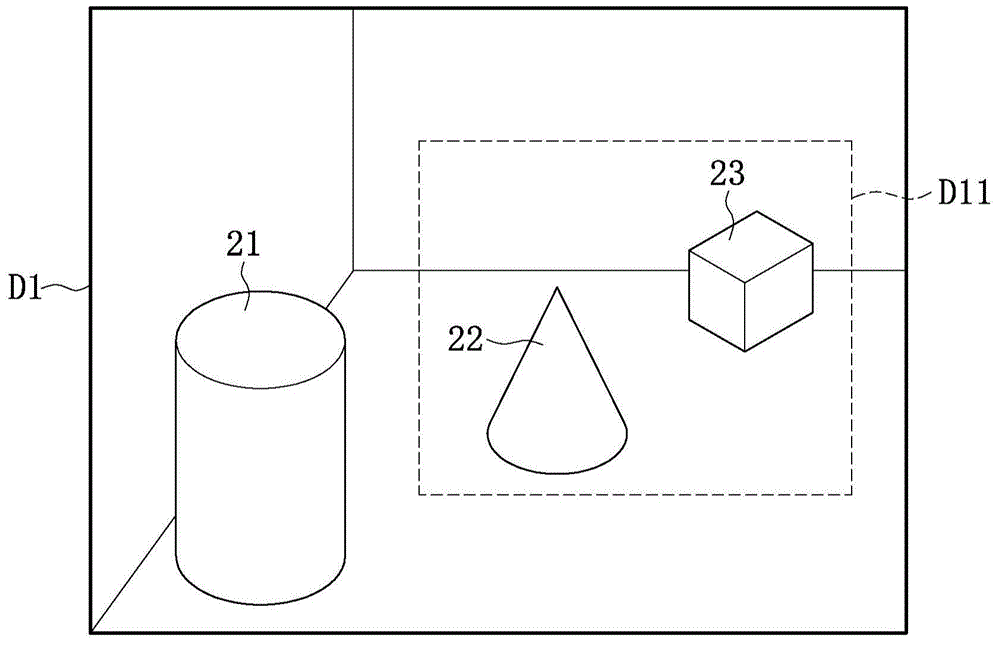

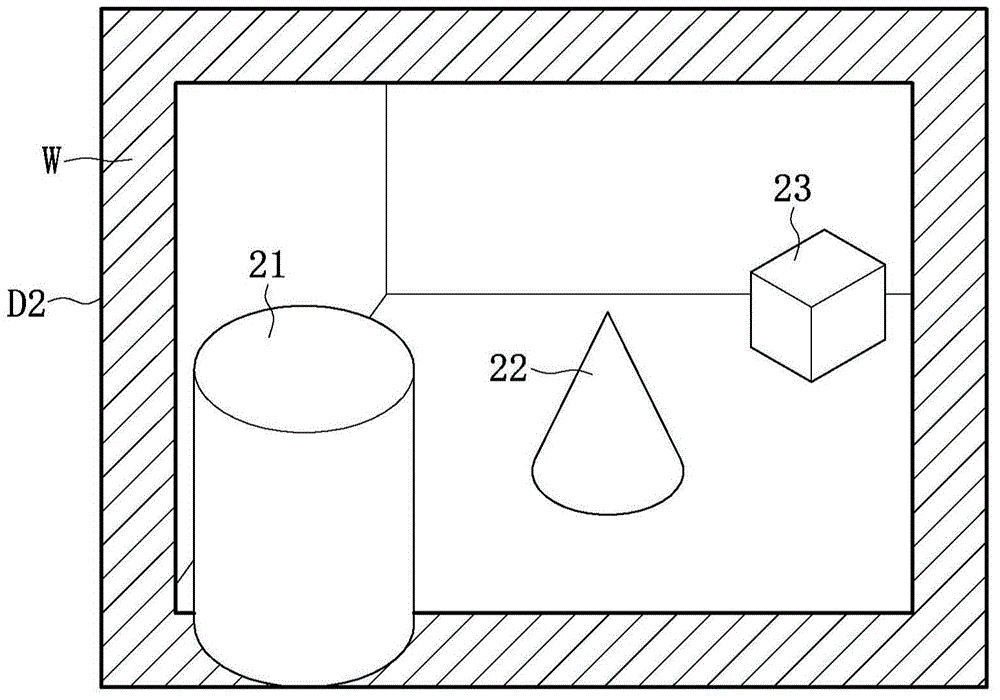

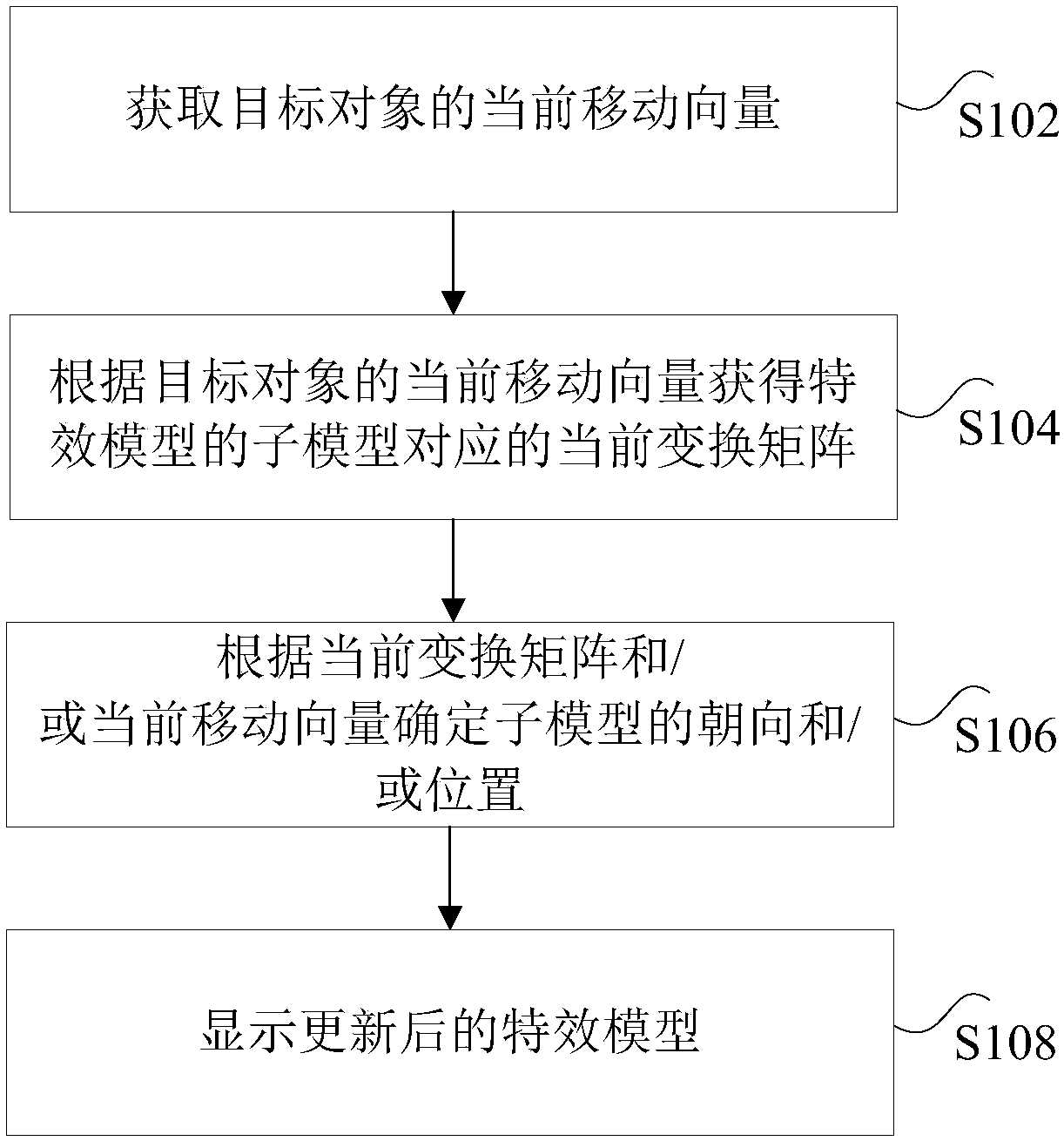

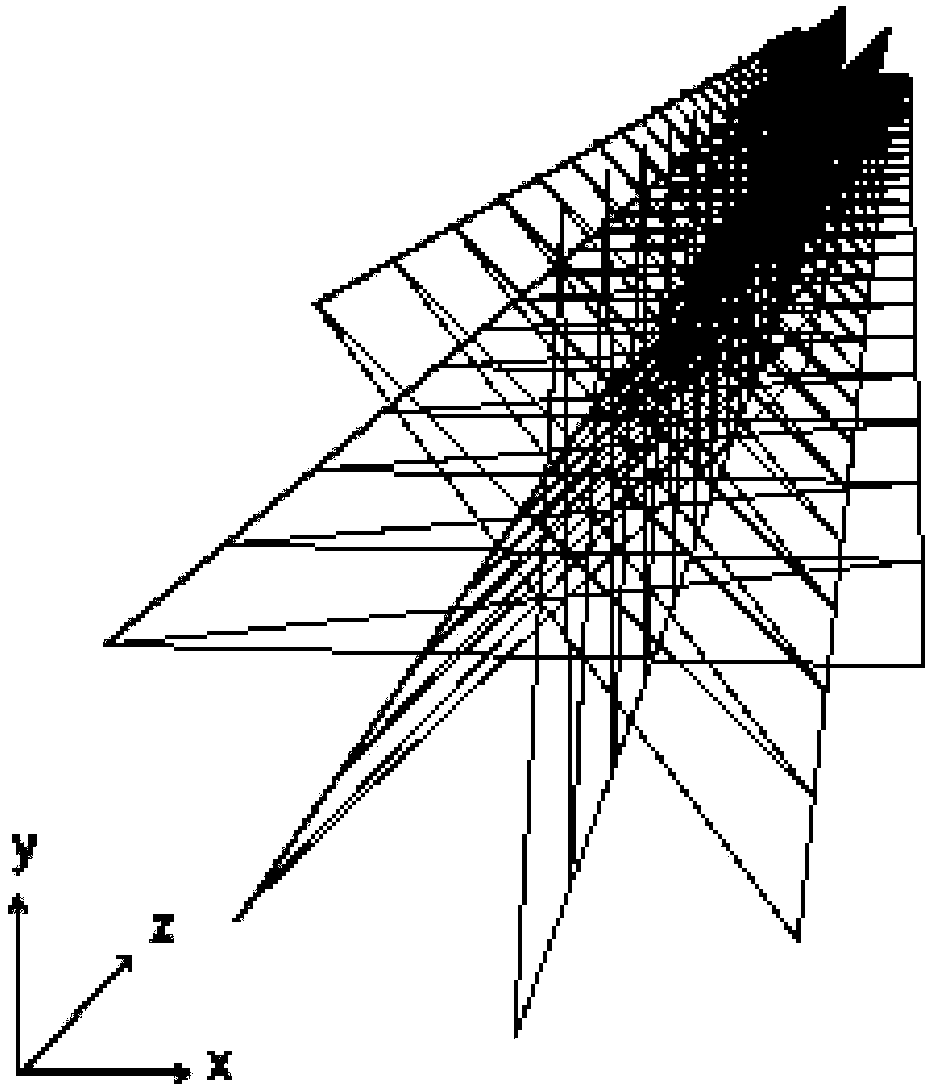

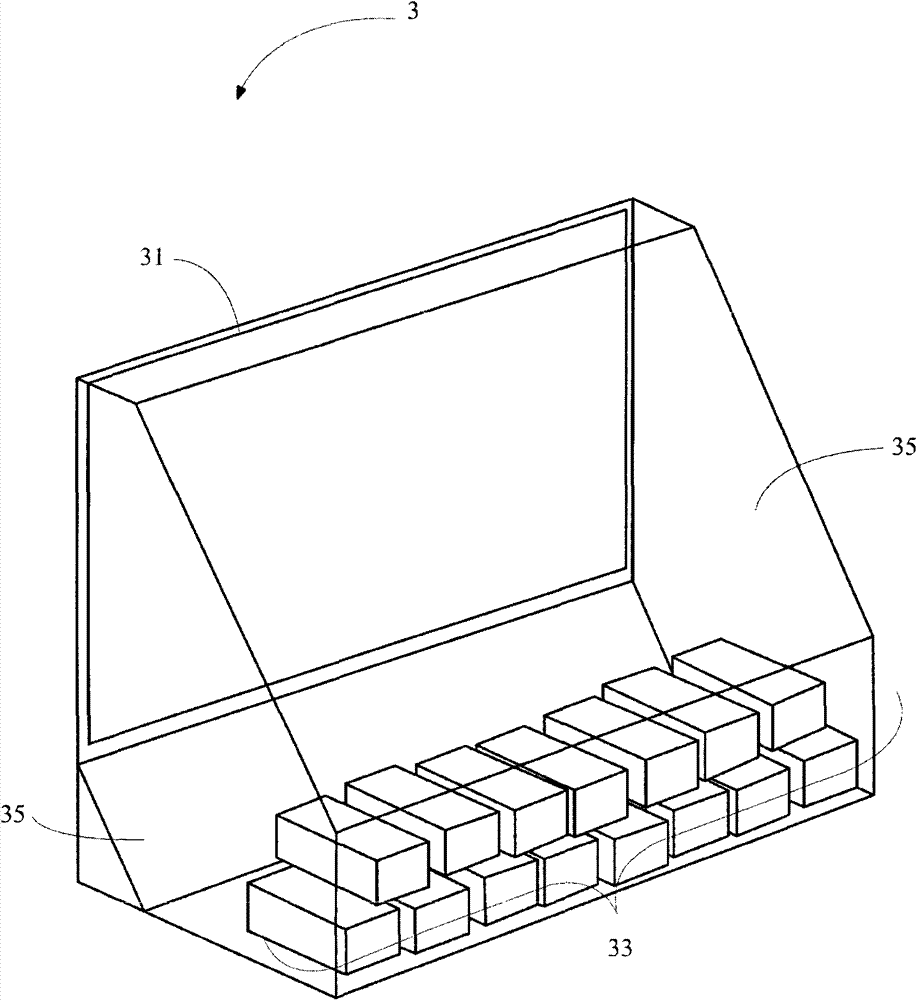

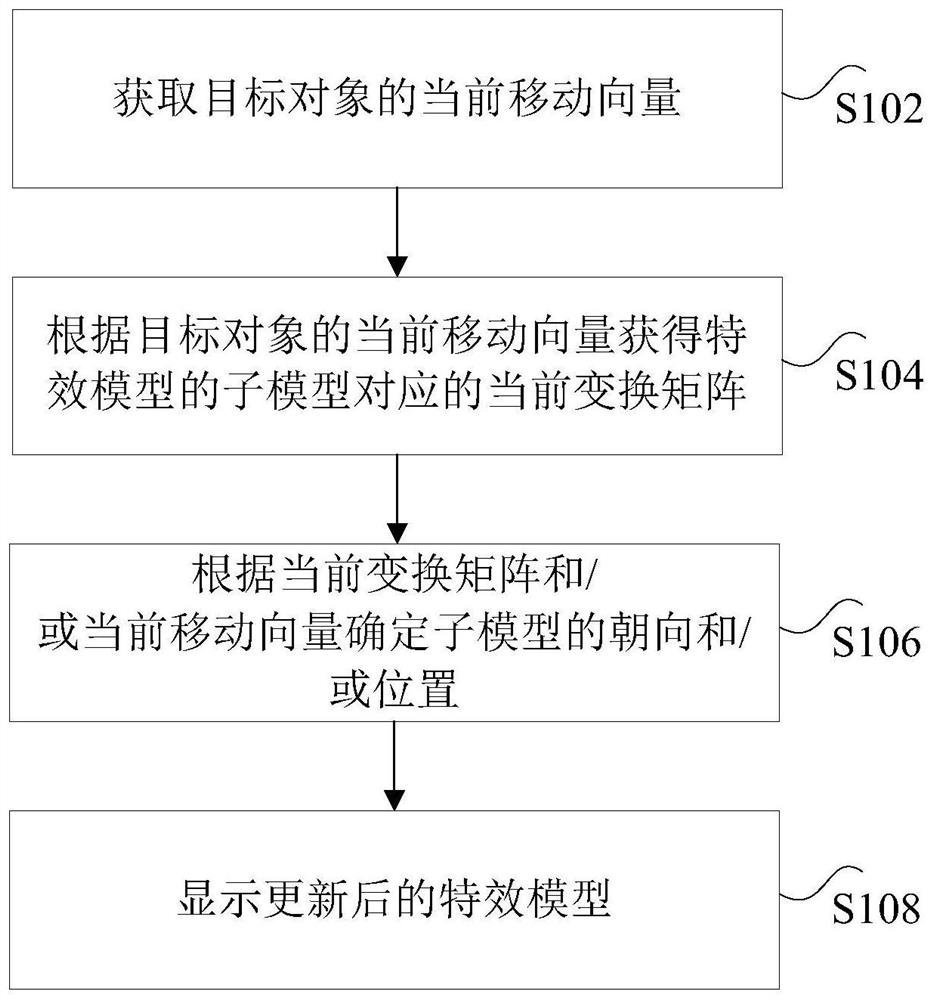

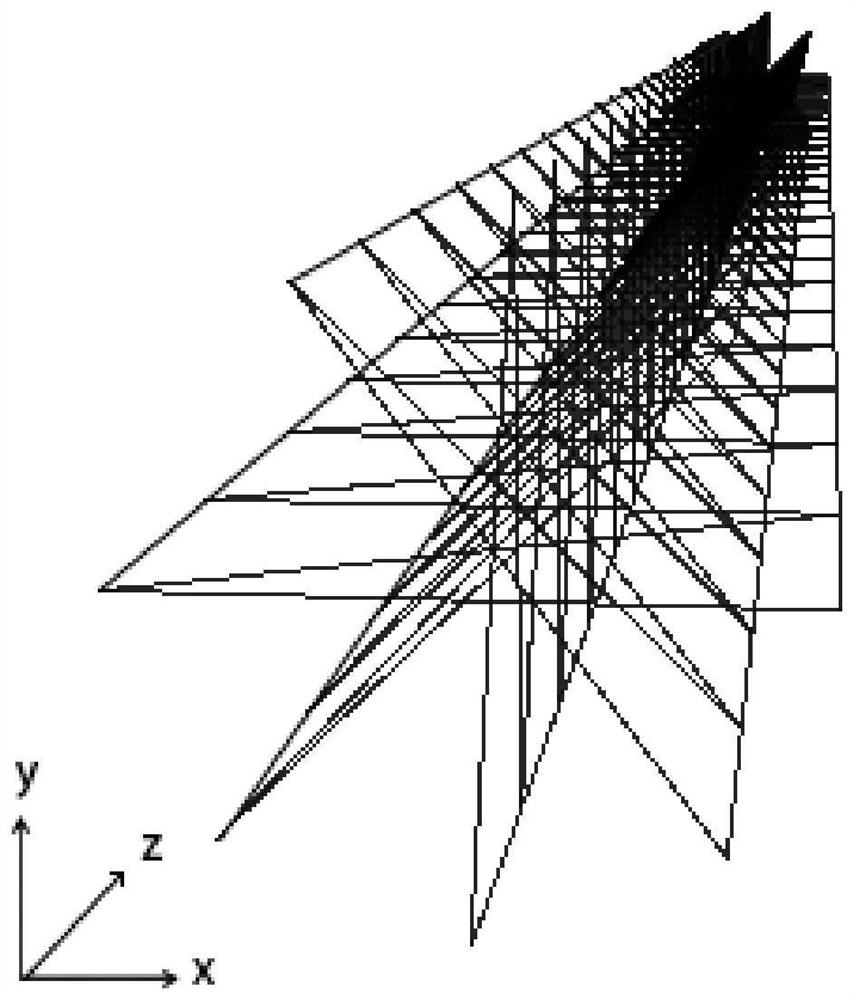

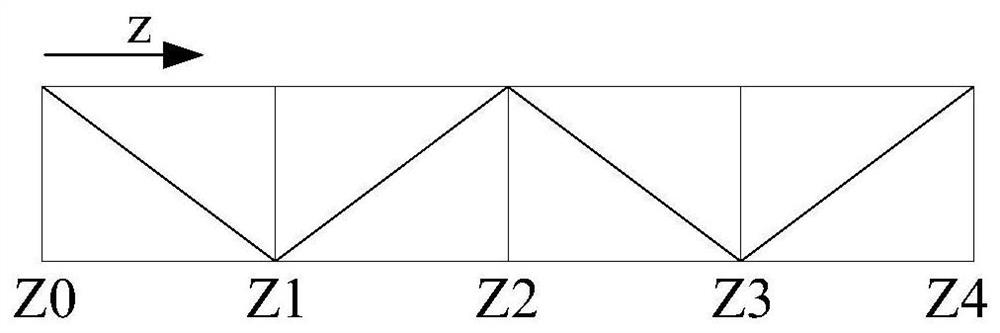

Method, device and terminal for processing game special effects

ActiveCN108379841AImprove the display effectSolve poor display effectVideo gamesSpecial effectsTransformation matrix

The invention discloses a method, a device and a terminal for processing game special effects. The method comprises: acquiring a current motion vector of a target object; obtaining a current transformation matrix corresponding to a sub-model of a special effect model according to the current motion vector of the target object, wherein the special effect model comprises a plurality of intersectingplanes; determining an orientation and / or position of the sub-model according to the current transformation matrix and / or the current motion vector; and displaying the updated special effect model. The invention solves the technical problem of poor tail trace display effect in the prior art.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

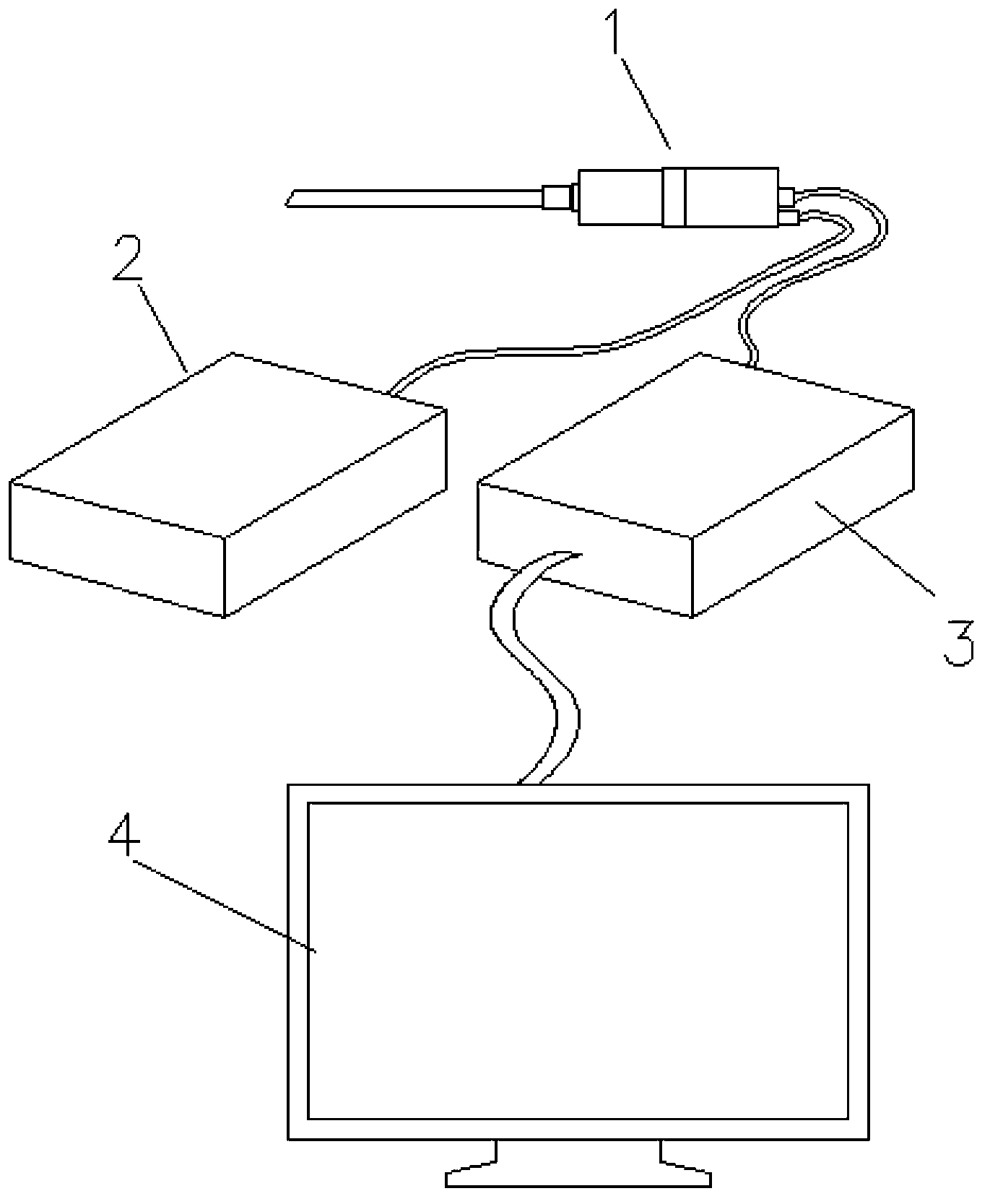

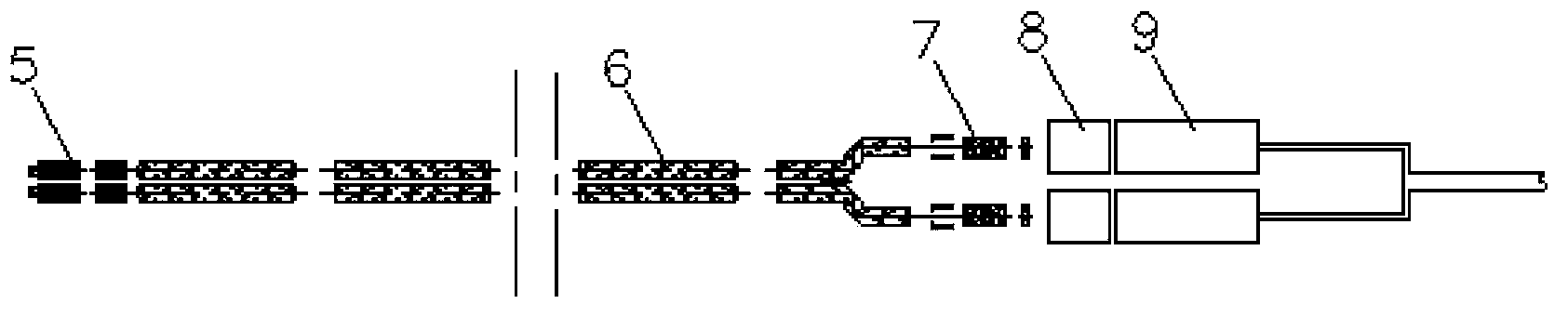

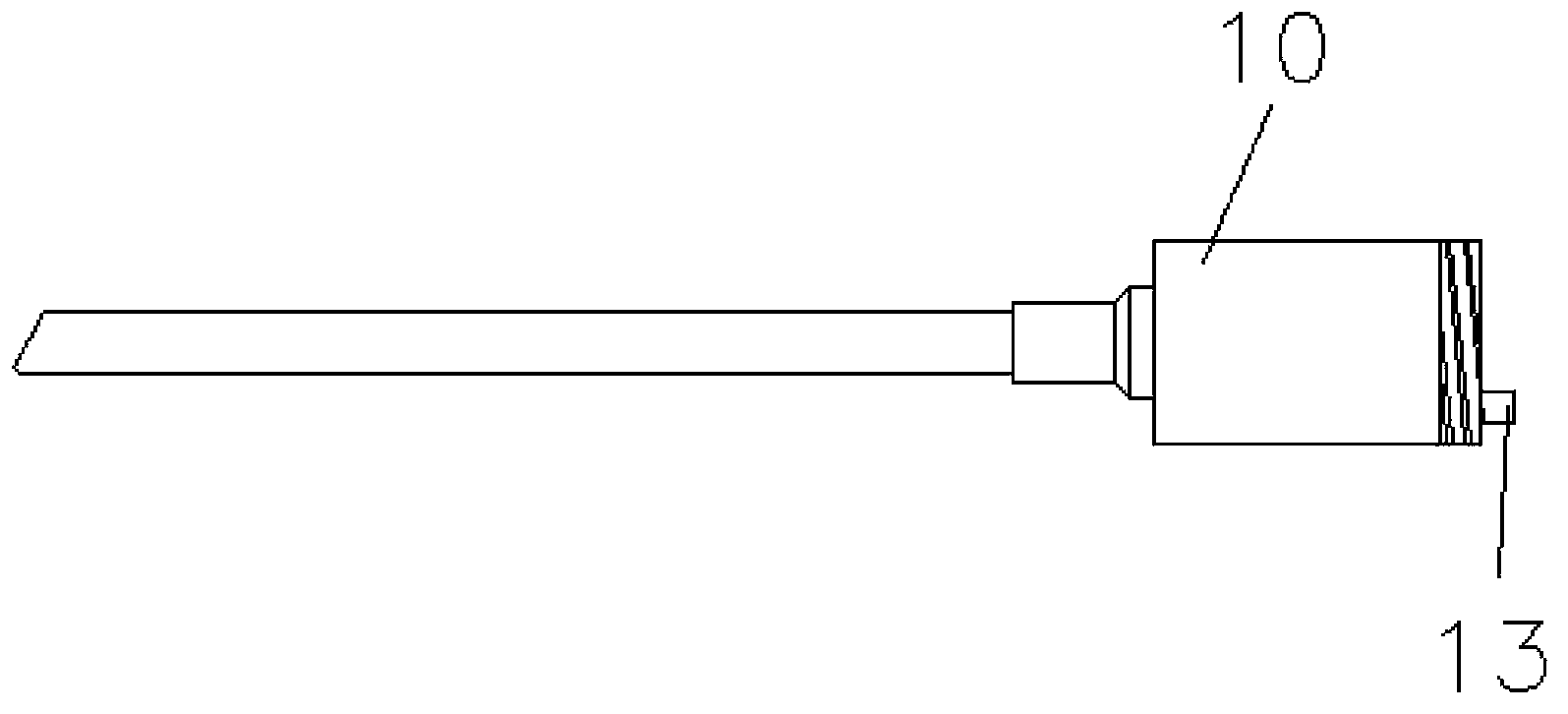

Stereoscopic endoscope system

The invention provides a stereoscopic endoscope system which comprises a stereoscopic endoscope, a light source, an image collecting processor and a 3D displayer. The stereoscopic endoscope is connected with the light source and the image collecting processor, the image collecting processor is connected with the 3D displayer, the stereoscopic endoscope comprises two light paths, an object lens, a rotating mirror, an ocular lens, an adapter and a CCD are fixed to each light path in sequence, cables stretching out of the rear ends of the two CCDs are combined to be one cable and are connected with the image collecting processor, and a cable connected with the light source can be connected fast with a stereoscopic camera shooting part and is guided out of a rear end. The stereoscopic endoscope system has the advantages that the two light paths are adopted in the stereoscopic endoscope system, two sets of images are formed and output, signals are collected and processed, standard 3D digital signals are directly output, and the check and treatment effect of diseases is improved. Light sources and image collecting processors are integrated and optimized in one light source and one image collecting processor from original two sets of light paths respectively, the structure is reduced, and cost is lowered.

Owner:TIANJIN BOLANG SCI TECH DEV

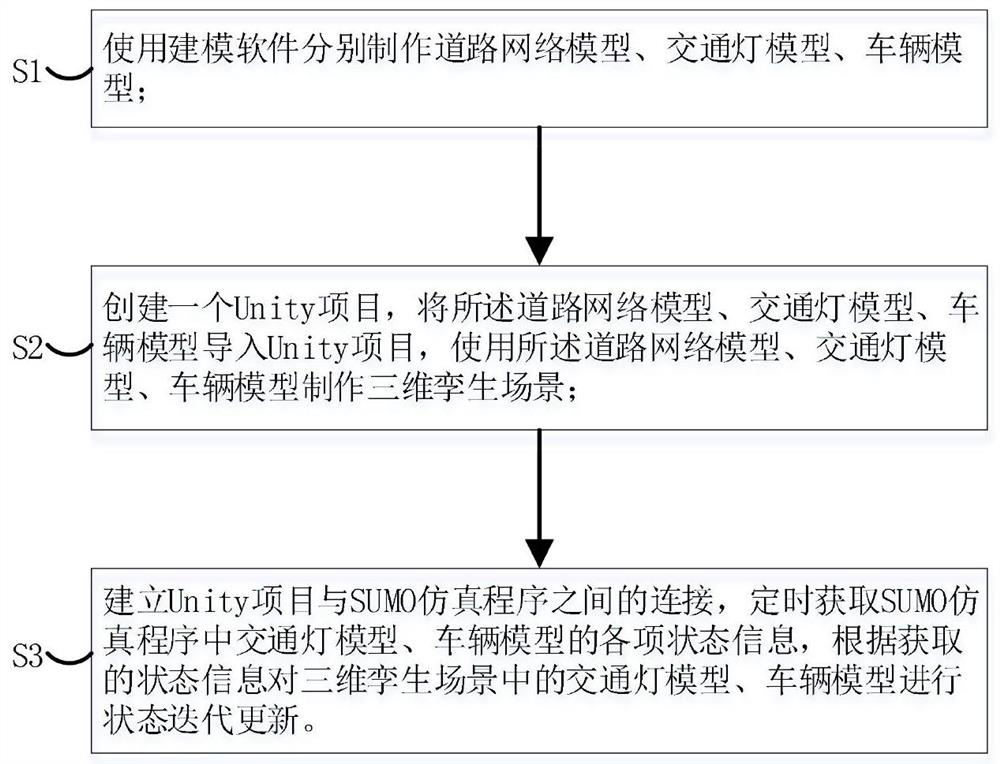

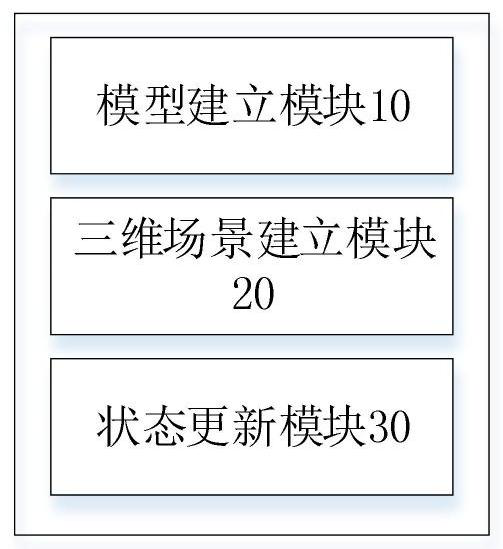

SUMO and UNITY joint simulation traffic network method and system

PendingCN112434412AAchieve three-dimensional effectMake up for the lack of 3D displayDesign optimisation/simulationSpecial data processing applicationsTraffic networkSimulation

The invention discloses an SUMO and UNITY joint simulation traffic network method and system, and the method comprises the steps: building a three-dimensional twin scene corresponding to a road network used by an SUMO simulation program through employing Unity, placing three-dimensional twin vehicles in the scene, and carrying out the call of functions of vehicle positions, attitudes and traffic light states in a function library TraCI.NET in the Unity scene; and updating the phases of the traffic lights and the positions and postures of the three-dimensional twin vehicles in the three-dimensional twin scene by using information returned by the SUMO simulation program, thereby achieving a three-dimensional effect of SUMO traffic simulation. According to the method, Unity is selected to make a three-dimensional twin simulation scene, and the defects of SUMO in the aspect of three-dimensional display are overcome; the powerful three-dimensional graphic function of Unity and the powerfulmicroscopic traffic simulation function of SUMO are combined, microscopic traffic can be conveniently simulated, and the simulation effect can be visually seen.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

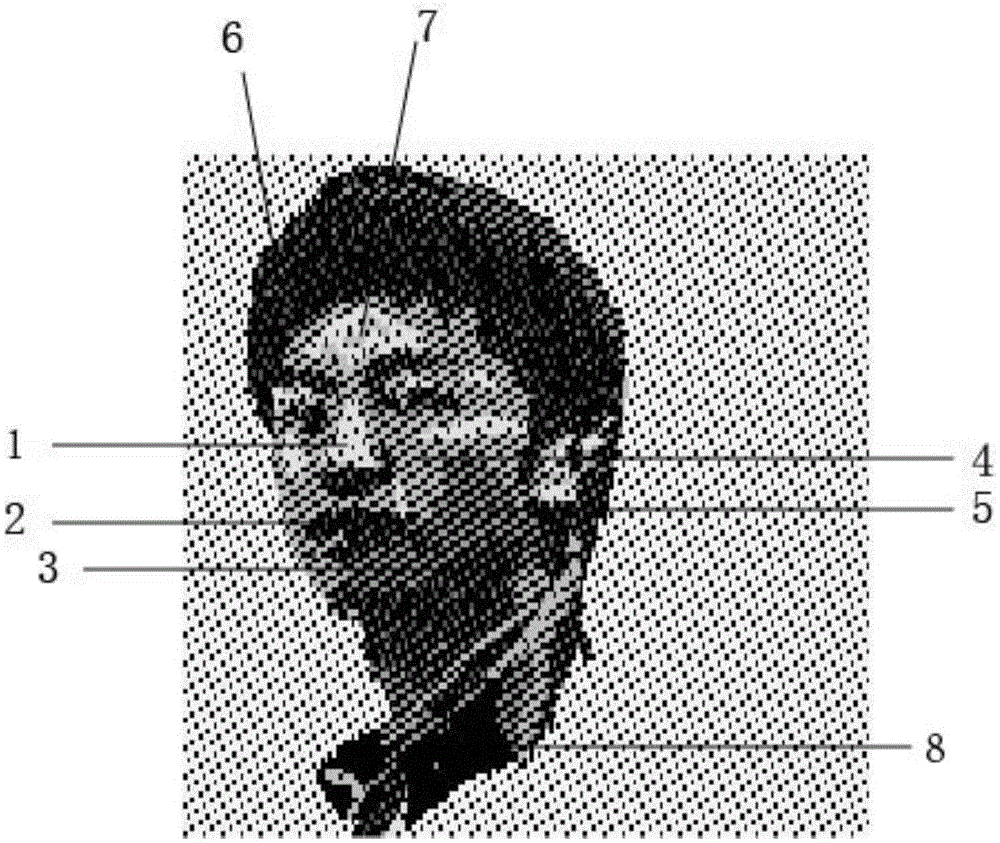

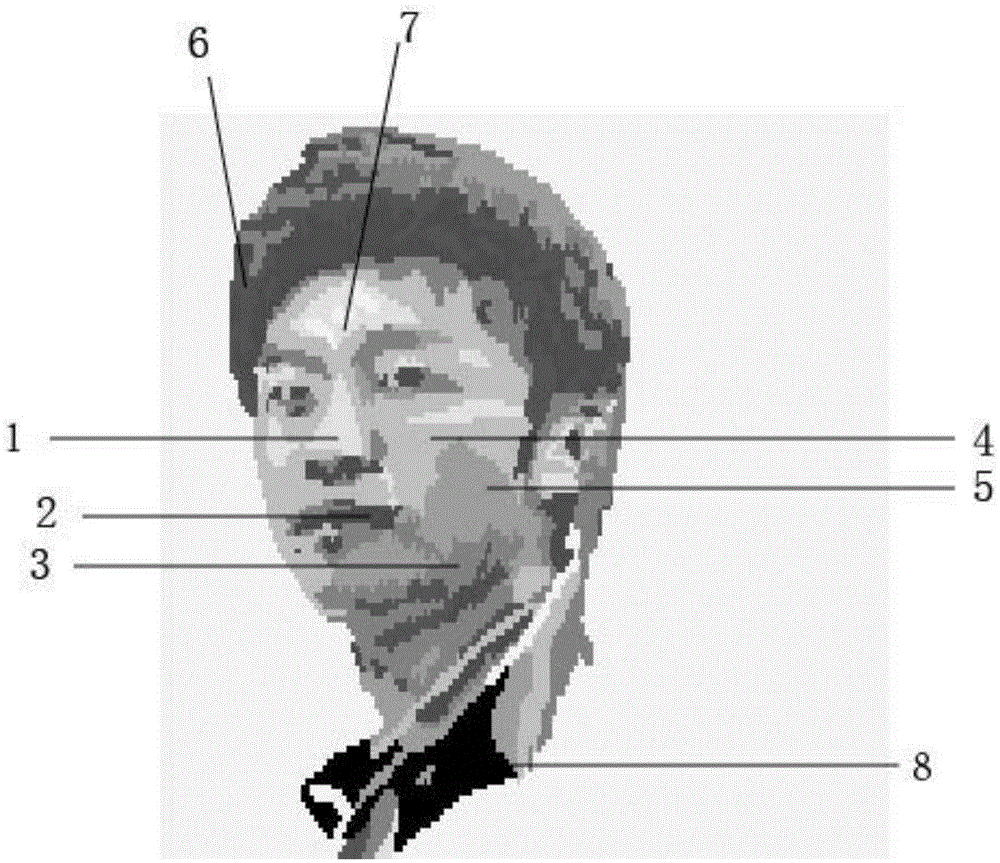

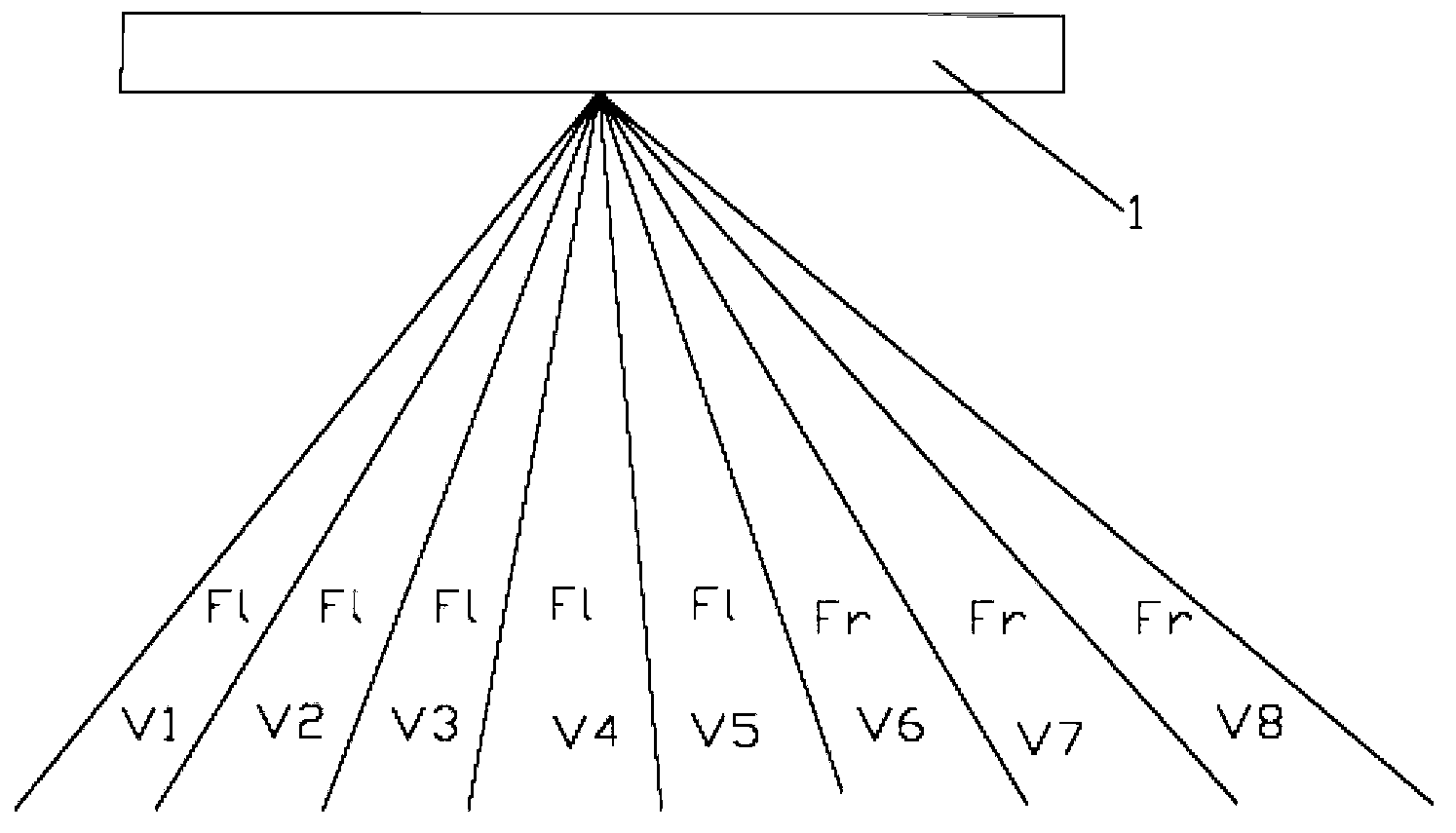

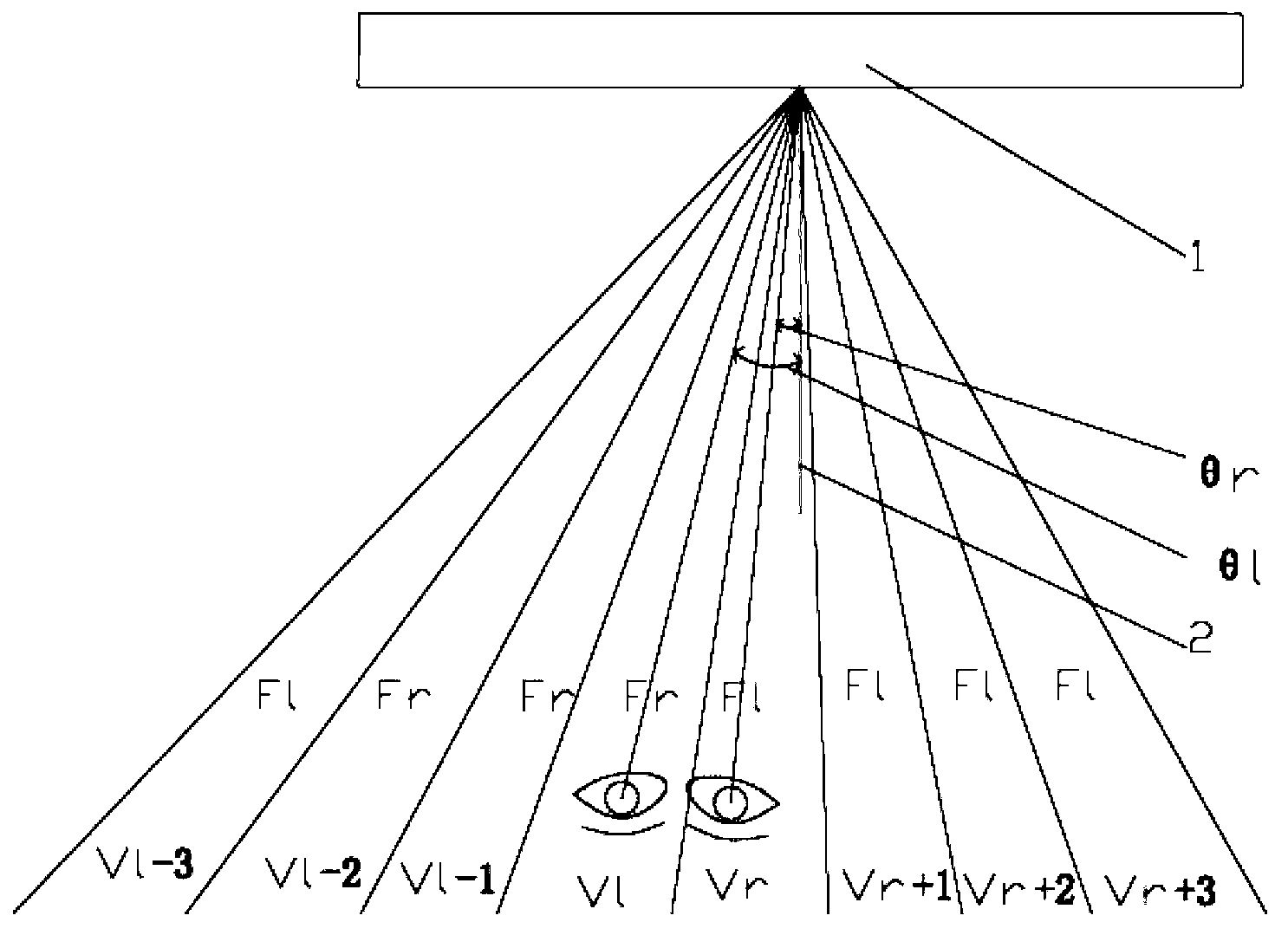

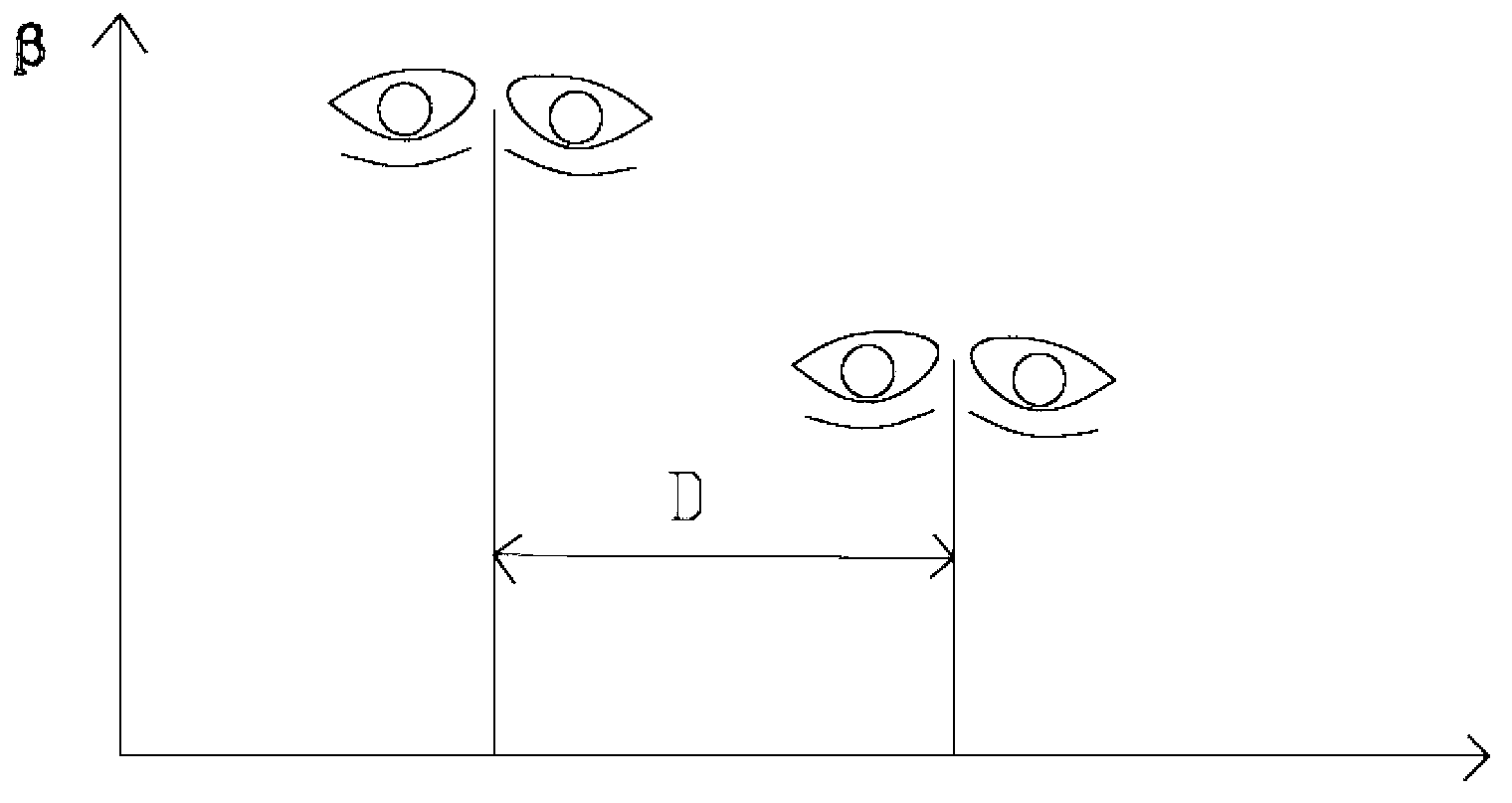

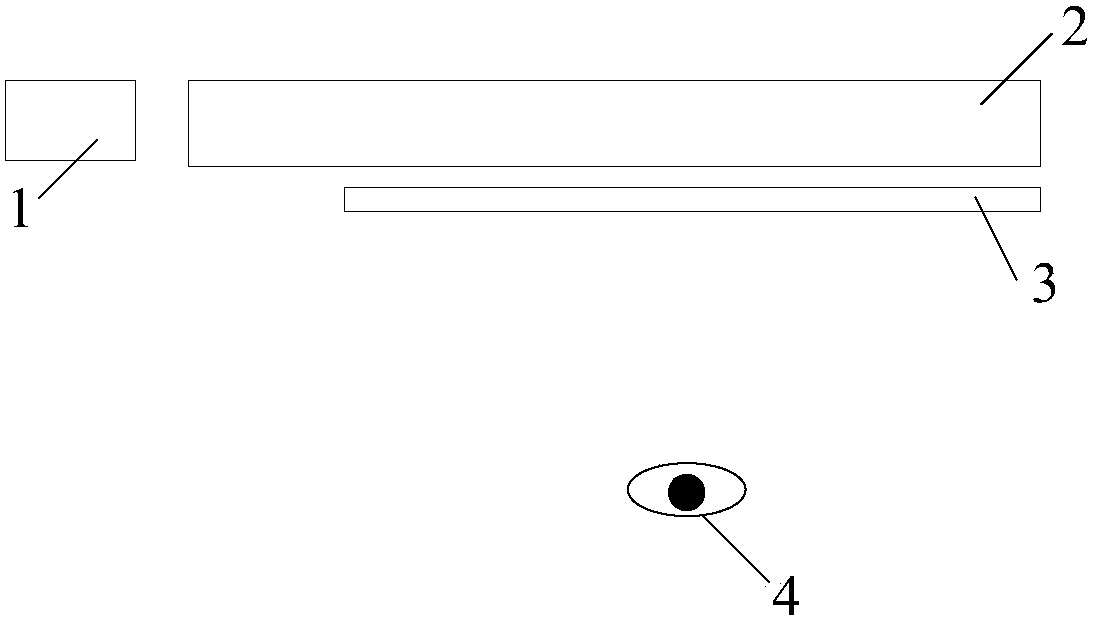

Tracking type multi-angle three-dimensional display image quality improving method

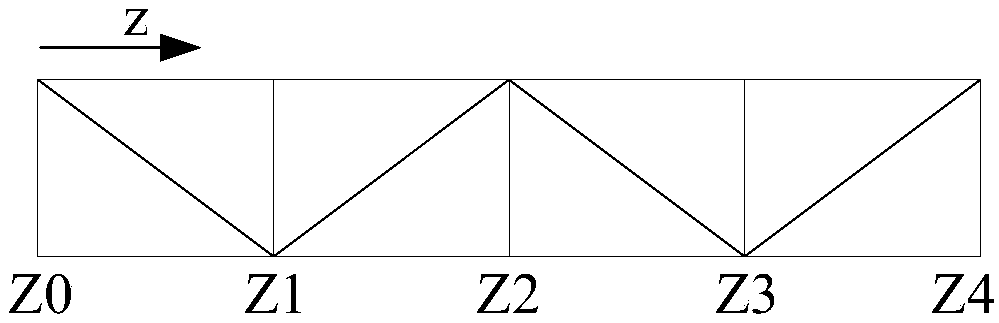

InactiveCN102802000ALow costAchieve three-dimensional effectSteroscopic systemsStereo imageThree dimensional display

The invention discloses a tracking type multi-angle three-dimensional display image quality improving method, which comprises the steps of: obtaining eye images through an image acquiring device and transmitting the eye images to an image processing device, determining positions of eyes by the image processing device according to an iteration algorithm, respectively figuring an included angle theta L between the position of the left eye and the normal of a display and an included angle theta R between the position of the right eye and the normal of the display, transmitting position information of the eyes to an image synthesizing device by the image processing device; and firstly reading a three-dimensional display parameter by the image synthesizing device, and judging the states of the eyes by the image synthesizing device according to the position information of the eyes, and filling corresponding view angle images in corresponding pixel points. According to the invention, a three-dimensional effect can be obtained on a multi-angle three-dimensional screen by only using two two-dimensional three-dimensional images, the hardware cost can be greatly lowered, and by matching with a face tracking system, the three-dimensional effect can be shown in a viewing angle at any moment.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

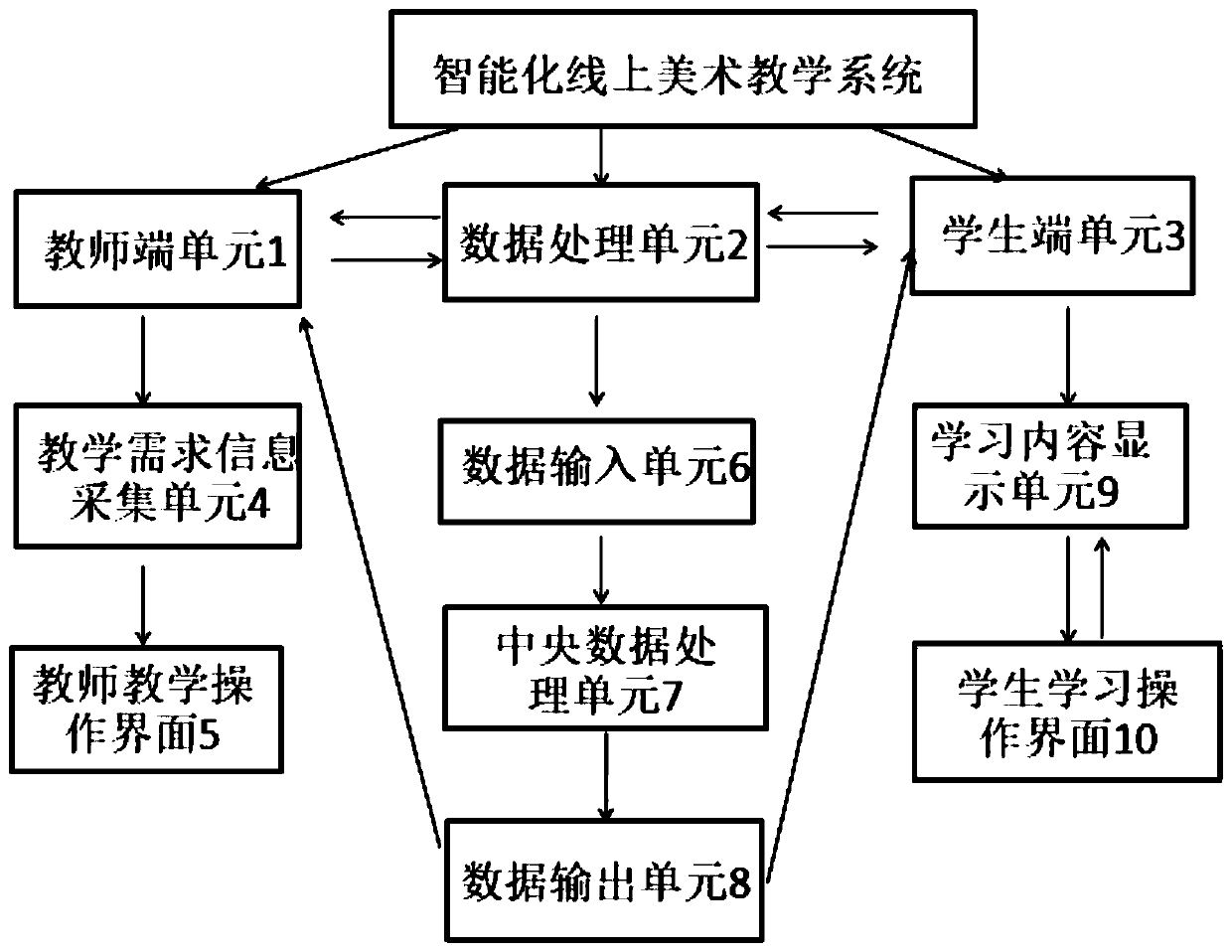

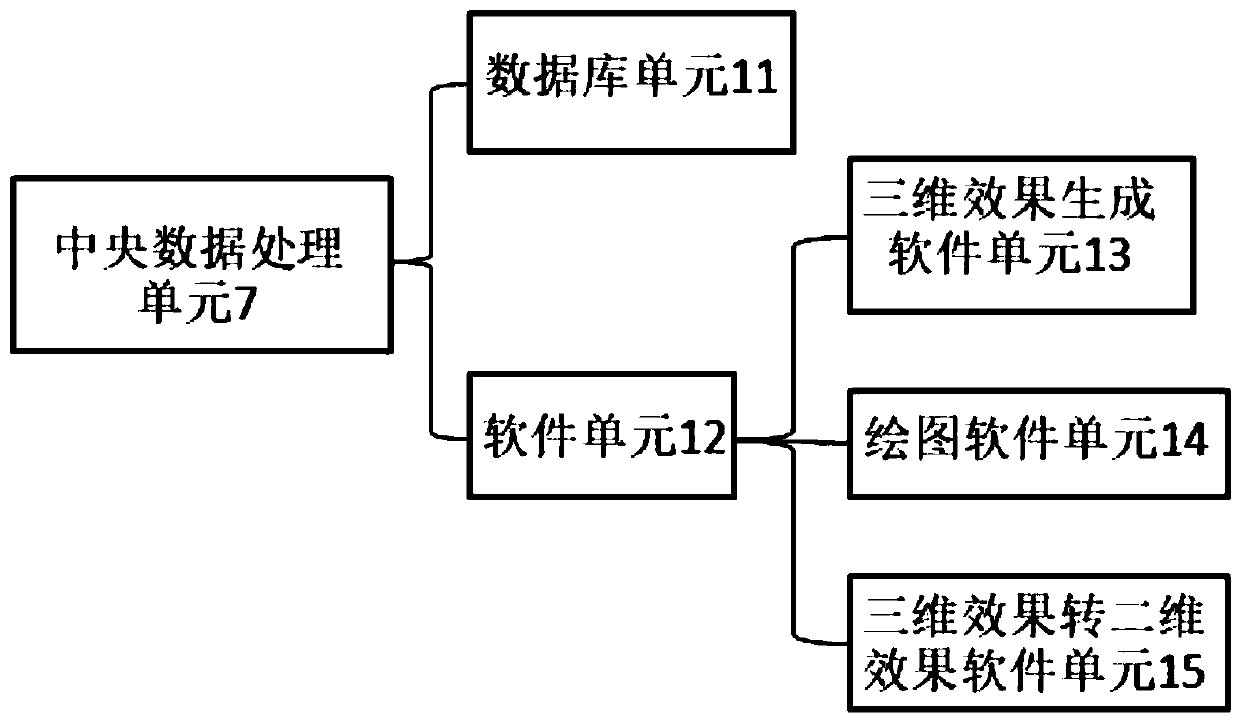

Intelligent online art teaching system

InactiveCN111564068AAchieve three-dimensional effectData processing applicationsElectrical appliancesEngineeringProcessing element

The invention belongs to the field of online art teaching systems, and particularly relates to an intelligent online art teaching system which at least comprises a teacher end unit, a data processingunit and a student end unit. The teacher terminal unit at least comprises a teaching demand information acquisition unit and a teacher teaching operation interface. And the student terminal unit at least comprises a learning content display unit and a student learning operation interface. According to the intelligent online art teaching system provided by the invention, on one hand, from the perspective of student cognition, the three-dimensional art teaching system is provided, so that the problems of information divergence, information loss and the like of three-dimensional art works are effectively solved; on the other hand, the three-dimensional effect can be seen, the three-dimensional effect can be converted into the two-dimensional effect in the learning process, and the two-dimensional effect of artistic creation is achieved.

Owner:上海意存文化传播有限公司

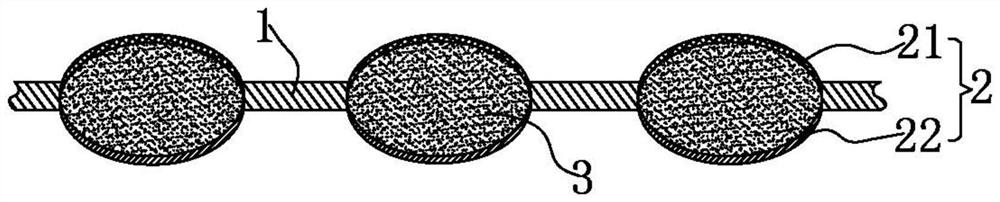

Three-dimensional woven fabric and weaving mode thereof

The invention relates to the technical field of woven fabrics, in particular to a three-dimensional woven fabric. The three-dimensional woven fabric comprises weft yarn groups and warp yarn groups, wherein the weft yarn groups comprise a plurality of first weft yarn groups and a plurality of second weft yarn groups; the warp yarn groups comprise a plurality of first warp yarn groups and a plurality of second warp yarn groups; the weft yarn groups are interwoven with the first warp yarn groups and the second warp yarn groups to form a plurality of single-layer areas; the first weft yarn groups are interwoven with the first warp yarn groups to form a plurality of first woven layers; the second weft yarn groups are interwoven with the second warp yarn groups to form a plurality of second woven layers; the first woven layers and the second woven layers form a plurality of layered areas together; the plurality of single-layer areas and the plurality of layered areas are integrally woven to form the three-dimensional woven fabric; the single-layer areas form bonding parts of the three-dimensional woven fabric; and the layered areas form hollow areas of the three-dimensional woven fabric.

Owner:SINCETECH FUJIAN TECH CO LTD

A near-eye display system and a head-mounted display device

The invention discloses a near-to-eye display system, which comprises a light source system, a light guide system and an image display system, wherein the image display system is used for displaying a hologram; the light source system is used for inputting a lighting beam to the light guide system; and the light guide system is used for carrying out transmission and expansion on the lighting beam and then enabling the beam to irradiate on the hologram displayed by the image display system to activate the hologram in a transmission mode. Correspondingly, the invention also discloses a head-mounted display device. The waveguide light guide technology and the computational holography technology are integrated fully, and thus, the near-to-eye display system is light and delicate, and large-view field display and depth adjustment through computational holography can be realized.

Owner:CHENGDU IDEALSEE TECH

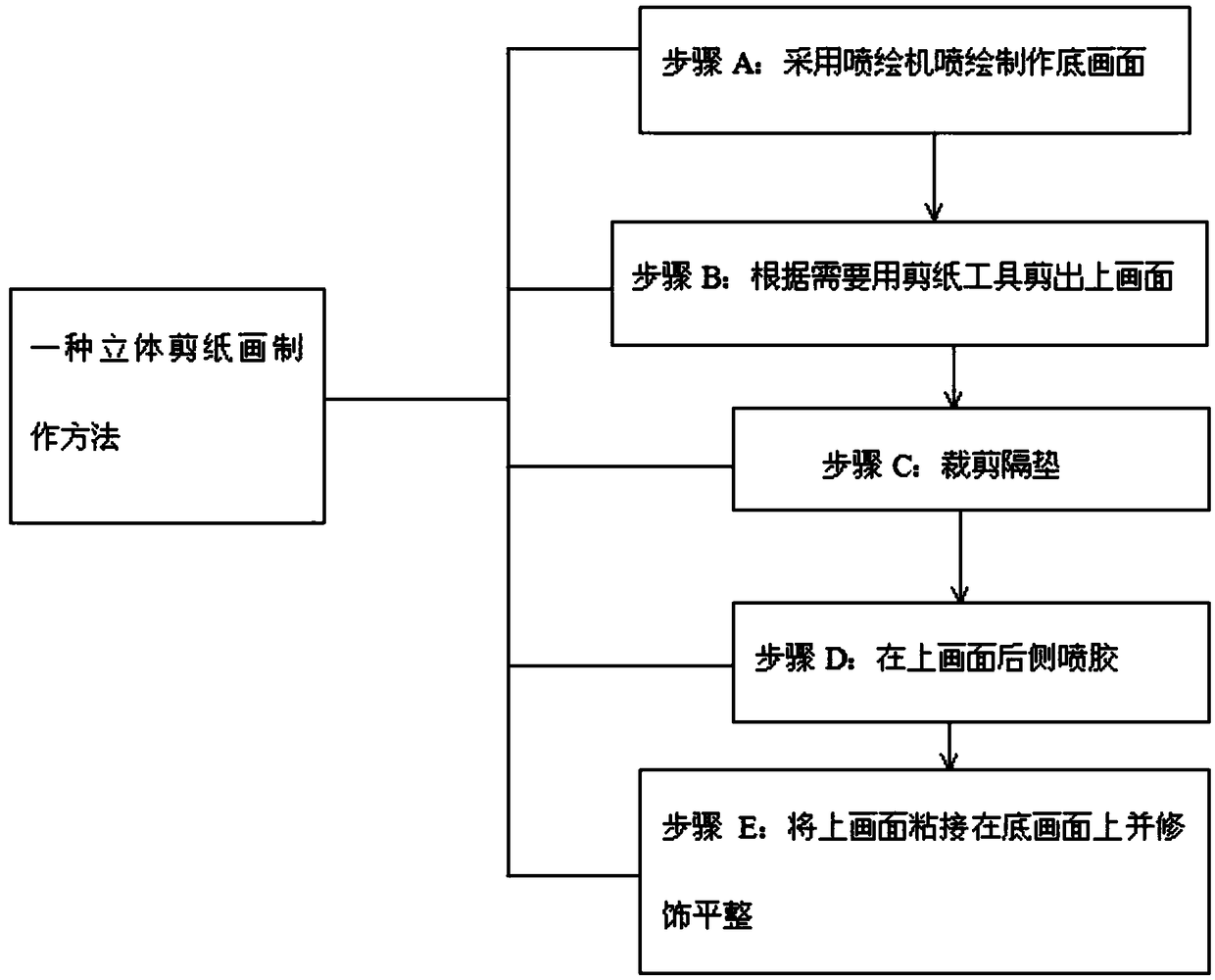

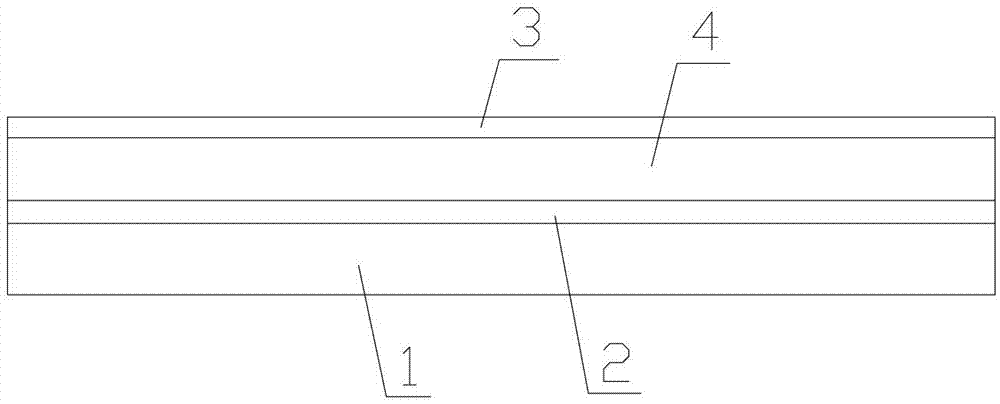

Method for producing three-dimensional paper-cut picture

The invention relates to a method for producing a three-dimensional paper-cut picture. The method comprises the following five processes that step A, an inkjet printer is used for spraying and drawinga bottom picture; step B, an upper picture is cut by a paper cutting tool as required; step C, an insulation pad is cut; step D, glue is sprayed on the rear side of the upper picture; and step E, theupper picture is adhered to the bottom picture, and finishing and leveling are carried out to obtain a three-dimensional paper-cut picture finished product. According to the method, the finished product is produced by combining the traditional Chinese folk art of the paper-cut picture, the display effect of the paper-cut picture is enriched, the production process is simple and effective, and themethod is suitable for industrial large-scale production and suitable for workshop type manual production; and the produced finished product has diversified colors, can achieve a three-dimensional effect on pictures, the appreciation of the paper-cut picture is improved, and better visual enjoyment can be brought to people. Based on the advantages, the method has a good application prospect.

Owner:济南福泉文化创意有限公司

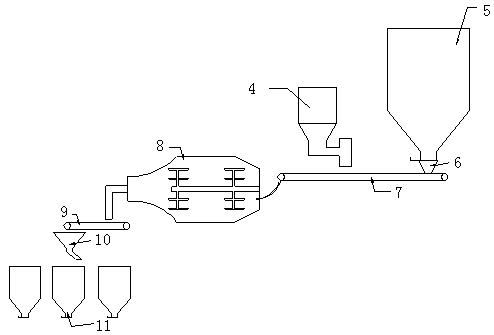

Surface-printed artificial stone and manufacturing method thereof

InactiveCN102935739BAchieve three-dimensional effectAchieve transparencyWater-setting substance layered productEpoxyTextile printer

The invention relates to surface printed artificial stone and a manufacturing method of the surface printed artificial stone. The manufacturing method comprises the steps of (1) mixing epoxy rein and phenolic resin to obtain a raw material A, (2) mixing quartz sand to obtain a raw material B, (3) mixing reflective sand and glass powder to obtain a raw material C, (4) mixing the raw materials A and B and pressing to obtain a D type sand plate, (5) mixing the raw materials A and C and pressing to obtain an E type sand plate, and (6) coating the raw material A on the surfaces of the sand plates and pressing to obtain an integral sand plate, pressing the surface of the E type sand plate to a concave-convex surface and then curing and drying. The artificial stone is formed by the D type sand plate and the E type sand plate; the D type sand plate is formed by the quartz sand and the E type sand plate is formed by the reflective sand and the glass powder; the D type sand plate and the E type sand plate are bonded through a bonder to form the integral sand plate; and the concave-convex surface is arranged on the surface of the E type sand plate. Sand grains and particles with different textures are mixed for forming, so that the third-dimensional, transparent and reflective effects of the artificial stone are realized, the third dimension and the perspective of the painting on the surface of the stone are enriched and the oil painting effect is provided.

Owner:王长兵

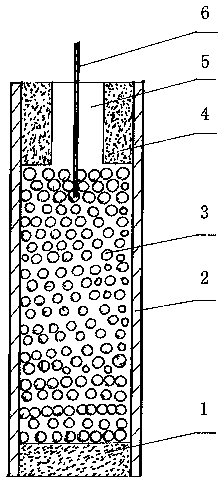

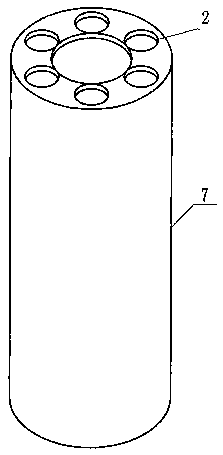

Combined firework without ejecting powder

The invention discloses a combined firework without ejecting powder. The combined firework is characterized by comprising bottom plugs and effect cylinder bodies, wherein the bottom plugs are arrangedat the bottoms of inner cavities of the effect cylinder bodies, fire blasting mud heads are arranged at the upper end parts of the effect cylinder bodies; fire spraying ports are formed in the centers of the fire blasting mud heads, effect bright beads are arranged in cavities between the bottom plugs of the inner cavities of the effect cylinder bodies and the fire blasting mud heads, ignition devices are arranged in the effect bright beads in a penetrating mode from the centers of the fire spraying ports, so that an internal self-ejecting function of a powder structure can be formed throughthe effect bright beads, and a fountain ejecting effect without powder can be achieved; and the bottom plugs are of wood plug structures or mud head structures or dry powder structures, and the ignition devices are leads or electric ignition head devices, the combined fountain ejecting is a combined fountain ejecting body with a free-ejecting-powder structure, and the combined fountain ejecting body is composed of the plurality of effect cylinder bodies arranged in an outer cylinder, and the outer shape of the combined fountain ejecting body is in a circular shape or a suitable geometrical shape. According to the combined firework, the powder composition is simple in structure, and combined assembly is simple and convenient; and the combined firework is capable of meeting the requirementsof new setting-off quality standards of low carbon, safe, environment-friendly and green fountain ejecting.

Owner:浏阳市普迹镇金旺烟花鞭炮厂

Three-dimensional diamond plate and method for manufacturing same

InactiveCN101531487BNo pollution in the processNo smellSolid waste managementPress rollersCelluloseFiber

Owner:胡楼君

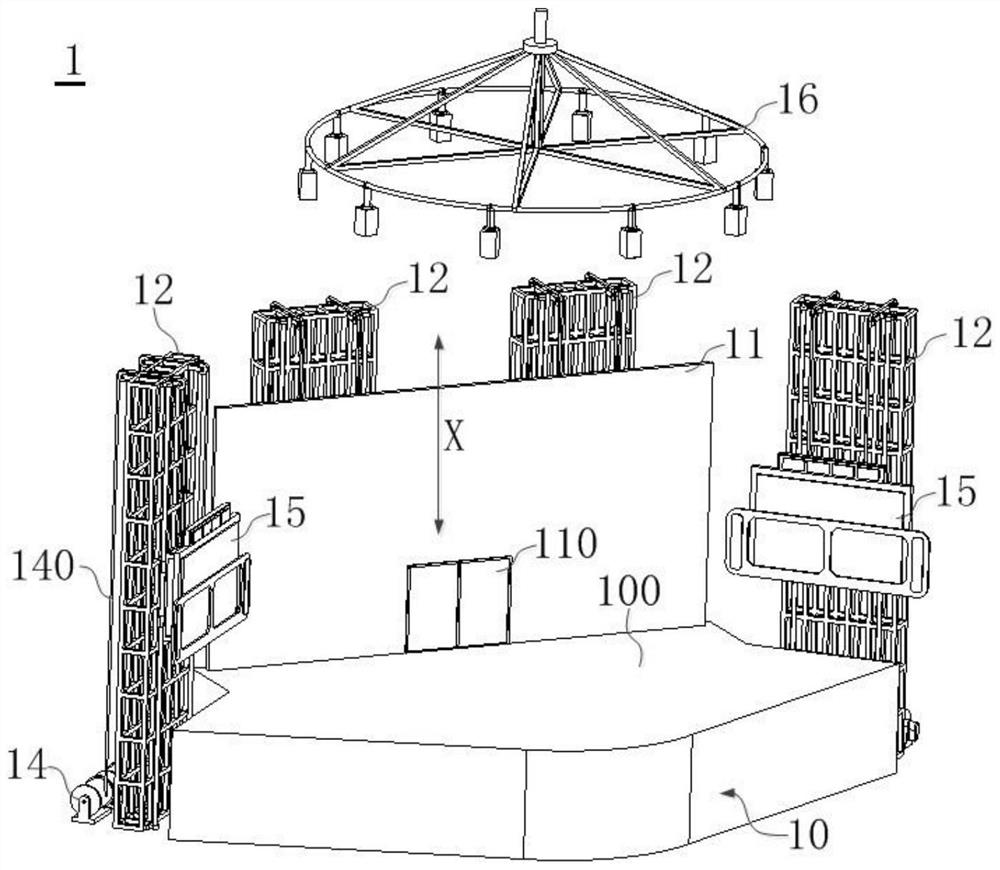

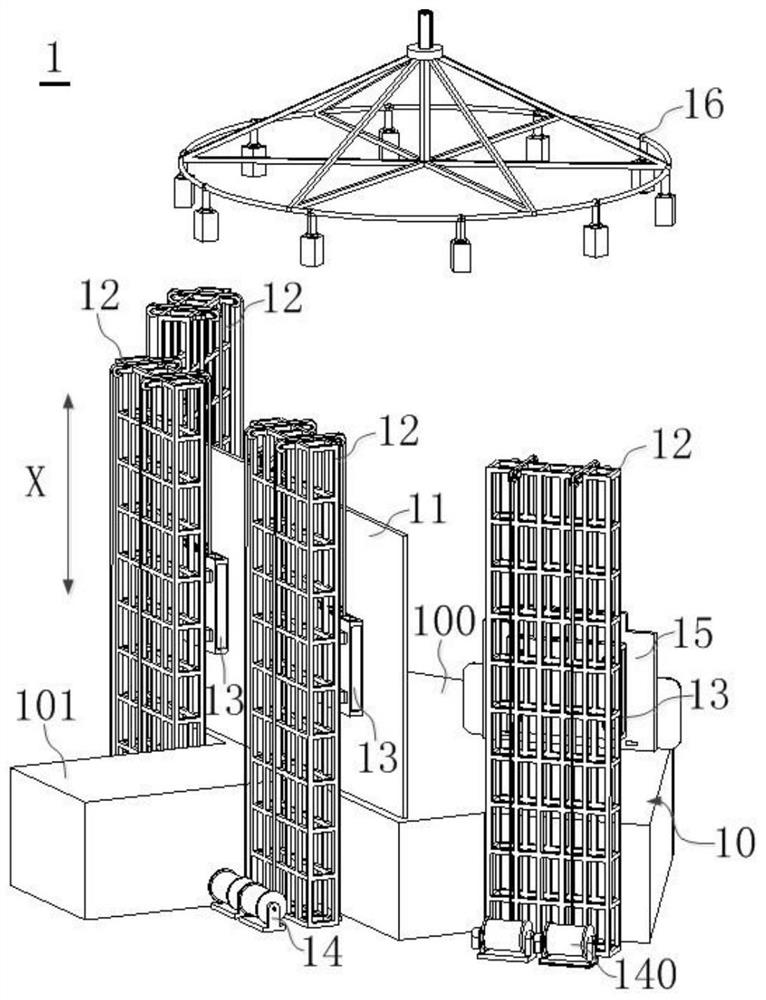

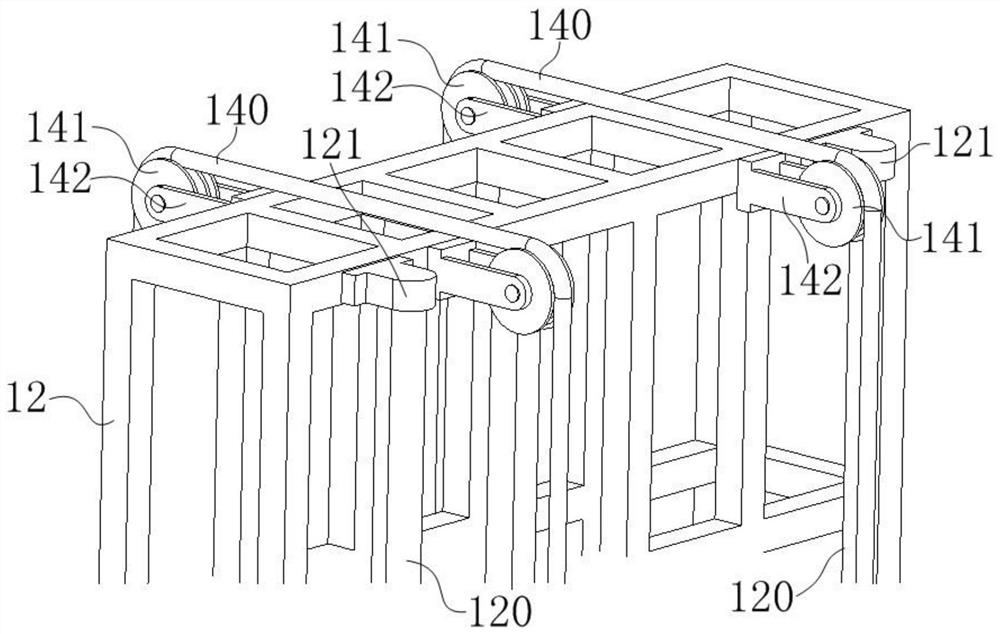

Active stage for showing street dance

PendingCN112627600AIncrease dynamicsGood effectMechanical apparatusLighting support devicesCurtain wallLight fixture

The invention discloses an active stage for showing street dance. The active stage comprises a stage main body, a floating curtain wall, a floating lamp and a main frame, wherein the floating curtain wall and the floating lamp are arranged on the main frame and can move on the main frame; the floating curtain wall divides the stage main body into a main stage and a background; a top lamp is arranged at the top of the main stage; a mounting frame is arranged on the main frame; and the floating curtain wall and the floating lamp are arranged on the main frame through the ascending mounting frame and can be driven by the mounting frame to incline forwards. By the adoption of the technical scheme, the floating curtain wall and the floating lamp are movably arranged on the main frame, so that the floating curtain wall and the floating lamp can float up and down on the main frame, the dynamic sense of the stage can be improved, and the problem of single modeling of the stage curtain wall is solved. The floating curtain wall and the floating lamp incline forwards in the up-and-down floating process, so that the change of the light distance and the stereoscopic impression of the floating stage are realized, and the showing power and the infectivity of the stage are improved.

Owner:上海灿星文化传媒股份有限公司

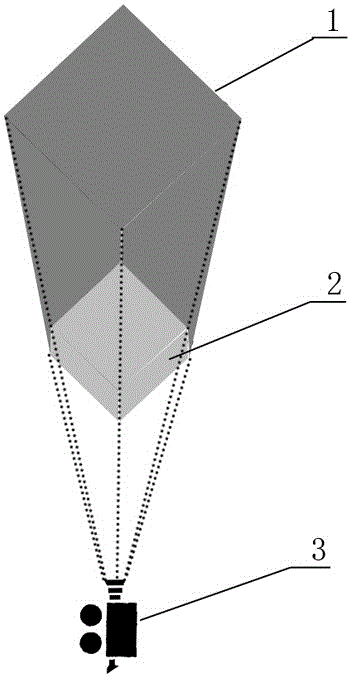

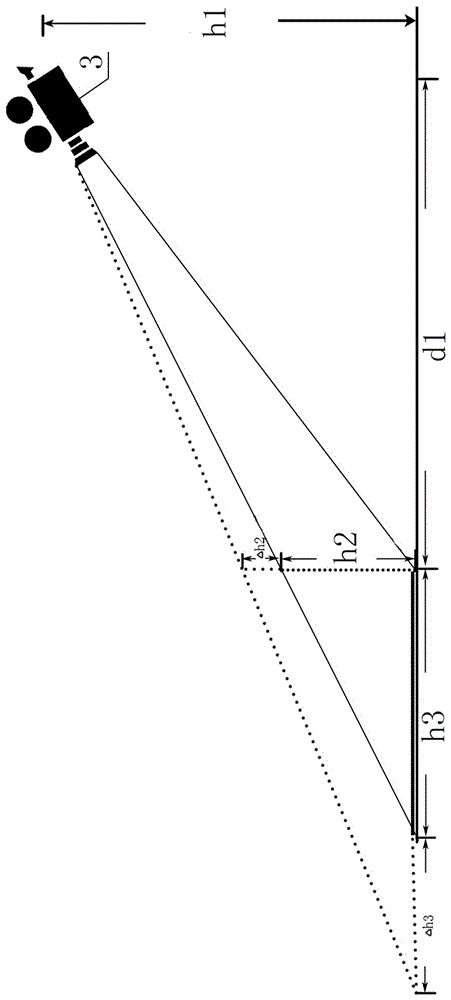

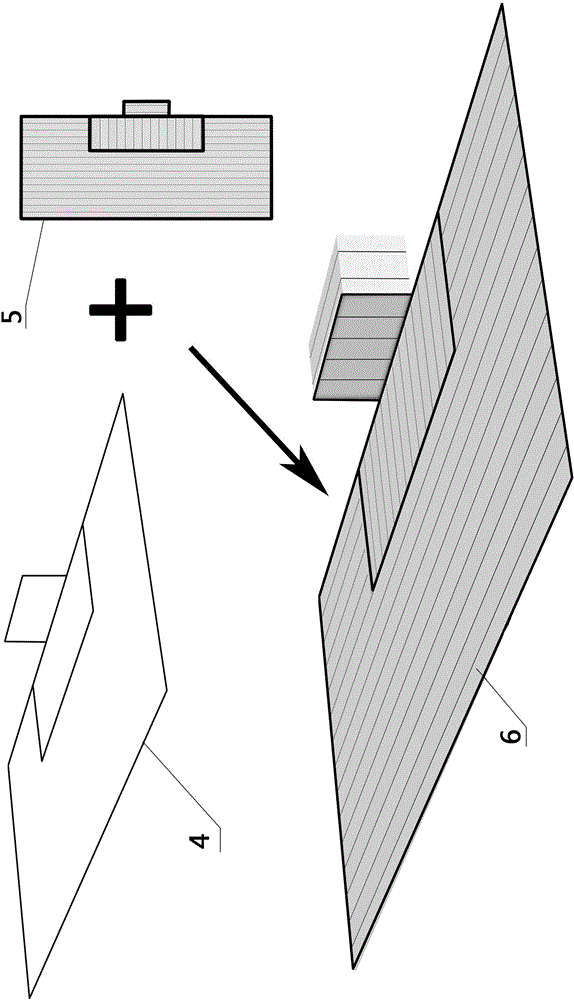

A method for making three-dimensional advertising in a sports field

ActiveCN103413354BAchieve three-dimensional effectEasy to create3D modellingGraphicsComputer graphics (images)

The invention discloses a competition field three-dimensional advertisement manufacturing method. The method includes the steps of simulating the perspective relation similar to a camera by conducting simulation on the camera in a host position in a competition field, then, conducting designing under the perspective relation, accurately manufacturing a final printed draft through stretching and deforming methods after the design is completed, and finally manufacturing a corresponding printed product under the practical situation of the field. By combining computer graphic image software with the camera, the aim of enabling a flat image to present a three-dimensional effect by the camera is achieved. A three-dimensional graph can be conveniently established through two-dimensional software and three-dimensional software, raw materials of mainstream computer formats such as AI, MAX, PSD and JPG are conveniently added to the design content through various methods, and therefore the design efficiency is obviously improved. The effect image of the final pavement position, the final pavement size and the design content can be accurately simulated in advance, the effect images are compatible with the final pavement effect, and therefore accuracy of the design is ensured.

Owner:张瀚宇

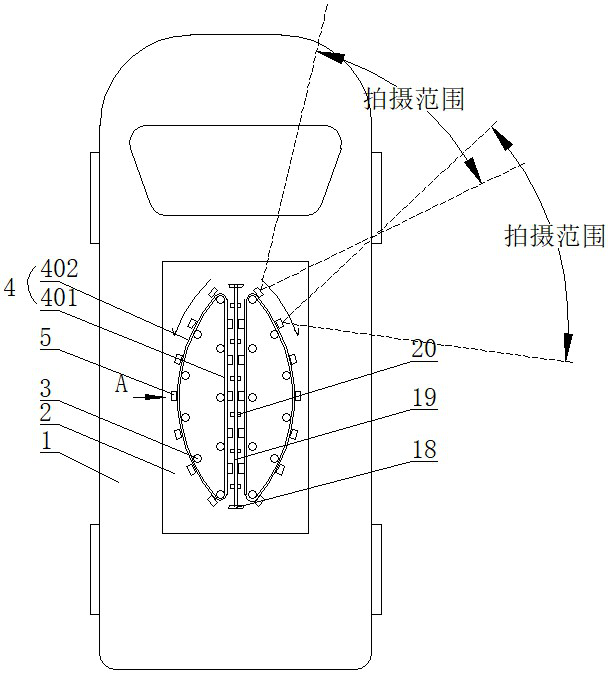

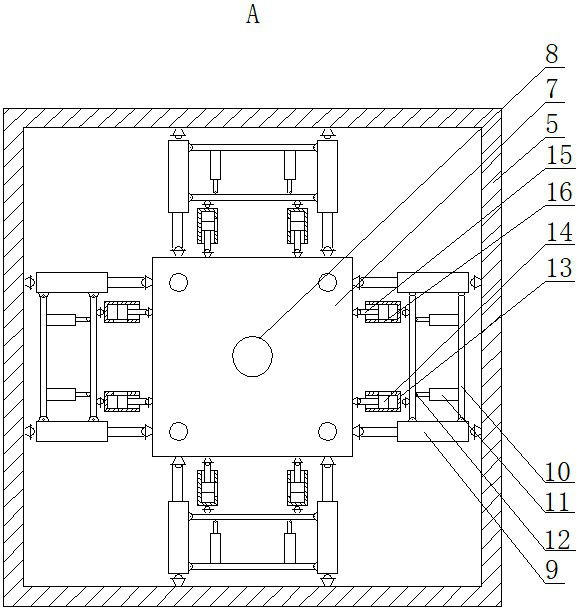

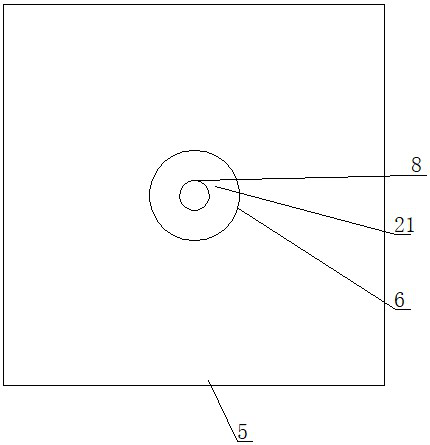

A face recognition device for intelligent investigation and patrol police vehicles

ActiveCN112511754BMeet the needs of remote controlGuaranteed Alignment LockTelevision system detailsColor television detailsPolice vehicleLeather belt

A face recognition device for an intelligent investigation and patrol police vehicle, including a vehicle, with a base on the vehicle, and two sets of belt rollers on the base, each set of belt rolls is equipped with the same belt, and the outer surface of the belt is uniformly fixed and installed along the length direction. A box body, a first through hole is opened on the side of the box body away from the belt, a mounting seat is arranged in the box body, an anti-shake device is provided between the six sides of the mounting seat and the corresponding inner wall of the box body, and the camera is fixedly installed on the side of the mounting seat away from the belt , the lens end of the camera faces the corresponding first through hole. The present invention can not only take all-round photographs of the surroundings during the running of the vehicle, but also adjust the rotation speed of the belt along with the speed of the vehicle, so as to realize the all-round view of the human body from far to near and from near to far. Shooting, at the same time, the anti-shake device can greatly reduce the impact on the camera, and the streamlined belt can reduce the impact of wind resistance on the device, further improving the anti-shake effect of the camera.

Owner:HUNAN POLICE ACAD

Modeling method of sculpture

InactiveCN102303473BTo achieve the echo effect of mutual reflectionAchieve three-dimensional effectOrnamental structuresGraphicsComputer Aided Design

The invention discloses a modeling method of a sculpture. The method is designed for solving the problems that the traditional sculpture process is complex and has long creation period and the modeled figure is not easily fused with the surrounding environment and the like. The surface of a metal plate is cut and pushed to model the sculpture in the method. The method comprises the following steps of: drawing a diagram, and amplifying the diagram according to the actual size; selecting a stainless steel plate; making a pattern vector by computer-aided design (CAD); performing laser cutting under the control of a computer; polishing the cut stainless steel plate till the mirror surface effect is polished; making a steel scaffold serving as a substrate for laser processing of the stainless steel plate, wherein the steel scaffold is used for supporting a jack to jack a cutting line; pushing the local notch of the cut stainless steel plate diagram front and back by using an upright stand as a base point and using the jack, and jacking the cutting line, so that the stainless steel plate has different reflective surfaces and the three-dimensional effect of laser is achieved. The method has the advantages that: the making period is short, the traditional sculpture representation form and technique are broken, and the positive and negative sides of works can represent different visionand figure effects of the same works; and by adopting different reflective surfaces, the three-dimensional effect of the laser is achieved.

Owner:司徒·安

Display apparatus used for displaying multiple perspective images

InactiveCN102262346BAchieve three-dimensional effectIncrease visual brightnessStereoscopic photographySteroscopic systemsComputer graphics (images)Display device

The present invention is a display device for displaying multi-view images. The display device includes a display screen and multiple projectors. Each projector includes at least one light source module, a spatial light modulation element and a lens. The display screen images the first angle of view image and the second angle of view image emitted by each projector into a first sub-view area and a second sub-view area through the first light and the second light provided by the light source module respectively. These sub-fields of machine imaging are sequentially adjacent to each other along a horizontal axis.

Owner:DELTA ELECTRONICS INC

Game special effect processing method, device and terminal

ActiveCN108379841BAchieve three-dimensional effectAchieving a three-dimensional effect on the trailVideo gamesSimulationComputer vision

The invention discloses a game special effect processing method, device and terminal. Wherein, the method includes: obtaining the current movement vector of the target object; obtaining the current transformation matrix corresponding to the sub-model of the special effect model according to the current movement vector of the target object, wherein the special effect model includes a plurality of intersecting planes; according to the current transformation matrix and / or Or the current movement vector determines the orientation and / or position of the child model; displays the updated effect model. The invention solves the technical problem of poor trail display effect in the prior art.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

A kind of whole body glazed ceramic tile with real stone effect and its manufacturing process

The invention discloses a fully polished glazed ceramic tile with a real stone effect and a production process thereof. The production process includes the following steps: (A) by means of feed modules, pigments and base adobe powder are mixed into a variety of needed colored adobe powders by a dry mixing method according to needed proportions; (B) by means of a distribution module and a press mechanism, the colored adobe powders are pressed into a fully colored adobe; (C) the fully colored adobe is dried under 120DEG C to 180DEG C for 50 to 100 minutes; (D) the surface of the fully colored adobe is decorated, so that a semifinished product is obtained; (E) the semifinished product is fired once under 1100DEG C to 1250DEG C for 40 to 90 minutes; (F) after the fired product is processed polishing, edging, waxing and filming steps, the finished product is obtained. The invention realizes the representation of the changing colors and texture of natural stone on the ceramic tile, the fully colored adobe can more embody the unique stereoscopic impression of stone, and by means of post-processing processes, such as chamfering and groove broaching, the fully polished glazed ceramic tile can show a full real stone decoration effect.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com