Surface-printed artificial stone and manufacturing method thereof

A technology of artificial stone and manufacturing method, applied in the direction of chemical instruments and methods, layered products of hydraulic substances, layered products, etc., can solve the problem of low adhesion between pigment and stone surface, unsatisfactory use effect, short shelf life, etc. problem, to achieve rich three-dimensional and perspective sense, long color preservation period, and no physiological side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

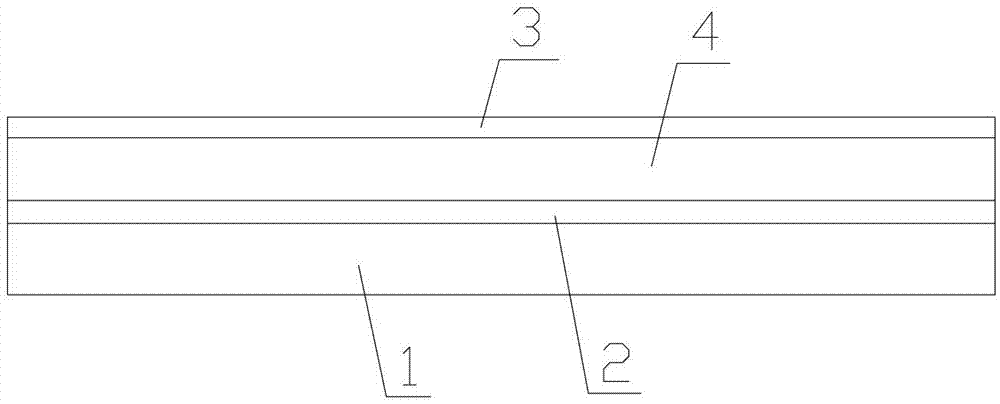

[0026] The manufacture method of surface printed artificial stone comprises the following steps: (1) epoxy resin, epoxy resin type thinner, epoxy resin type curing agent, thermosetting phenolic resin, phenolic resin type thinner, phenolic resin type curing agent, Mix and stir according to the weight ratio of 3:3:1:2:2:1 to obtain raw material A;

[0027] (2) Wash and dry the ultra-fine white quartz sand with a diameter between 0.3mm and 0.8mm and the fine white quartz sand with a diameter between 0.8mm and 1.5mm, mix them in a weight ratio of 1:3 and carry out Stir to obtain raw material B;

[0028] (3) Mix reflective sand with a diameter of 0.3mm to 0.8mm and glass powder with a diameter of 0.3mm to 0.8mm at a weight ratio of 1:4 and stir to obtain raw material C;

[0029] (4) Mix raw material A and raw material B in a weight ratio of 1:10, stir evenly, and then press it into a D-shaped sand board with a thickness of 2mm to 3mm;

[0030] (5) Mix raw material A and raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com