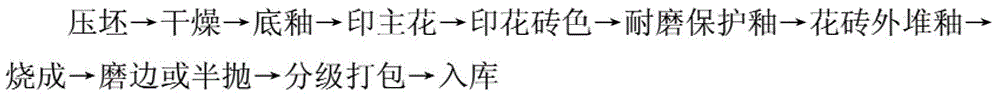

Preparation method for mono-firing embossed ceramic tile

A technology for stacking flower tiles and flower tiles, which is applied in the field of preparation of one-time-fired porcelain stacking flower tiles, can solve the problems of poor energy saving and environmental protection, large waste, tarnishing after firing, etc., achieve good economic and social benefits, enhance durability, and improve insufficient quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Blank making:

[0053] Billet formula

[0054] Table 1 Billet formula composition (wt%)

[0055] name Double water pure mud Bangsa Lisodium sand Zhou Sha 4# mud Lingwusha Billet formula 16 21 18 17 8 20

[0056] According to the ingredients, the powder is ball milled and sprayed, and pressed into shape by a press;

[0057] 2) Apply primer on the green body

[0058] The ingredients of the bottom glaze formula are shown in Table 1:

[0059] Table 1 bottom glaze formula composition (wt%)

[0060] name IL SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO MgO K 2 o

Na 2 o

ZrO 2

Undercoat 3.76 56.5 25.4 0.15 0.16 0.33 1.17 4.0 2.59 5.0

[0061] Spray the base glaze evenly on the clean green body with a high-pressure spray gun;

[0062] 3) Main brick printing

[0063] Inkjet printing with 5-color imported ink;

[0064] 4) Tile color printing

[0065] Inkjet printin...

Embodiment 2

[0080] The difference from Example 1 is that the special self-shrinking glaze formula composition is as shown in Table 4:

[0081] Table 4 Special self-shrinking glaze formula composition (wt%)

[0082]

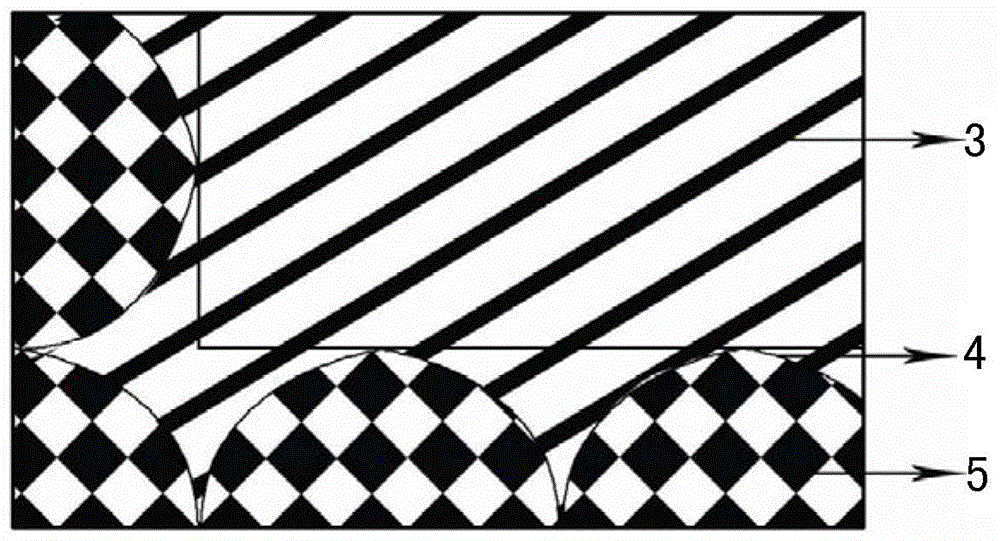

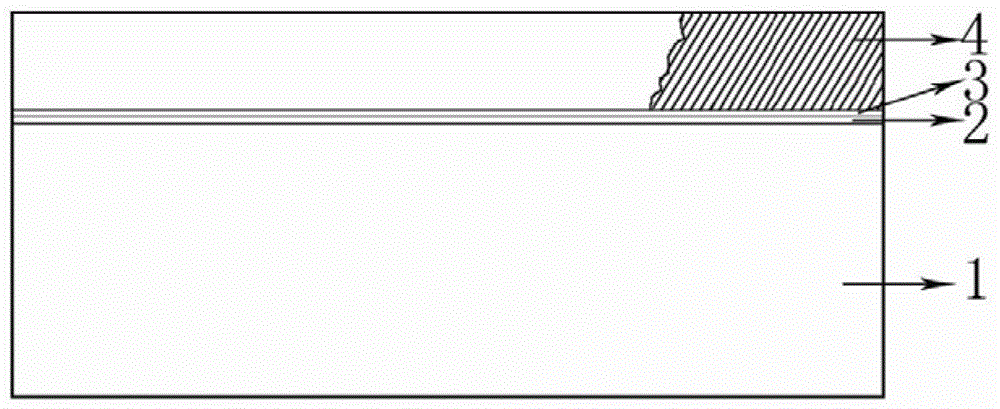

[0083] The side view of the surface of the once-fired porcelain tiles obtained in this embodiment is, for example, figure 2 and image 3 shown. The once-fired porcelain stacked pattern tiles have from bottom to top sequentially: green body 1, bottom glaze 2, main pattern 3, patterned tile piled pattern 4, protective glaze (not shown), and piled convex glaze 5 on the patterned tile. exist image 3 The tile pile pattern 4 shown includes pile convex glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com