Patents

Literature

196results about How to "Good three-dimensional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

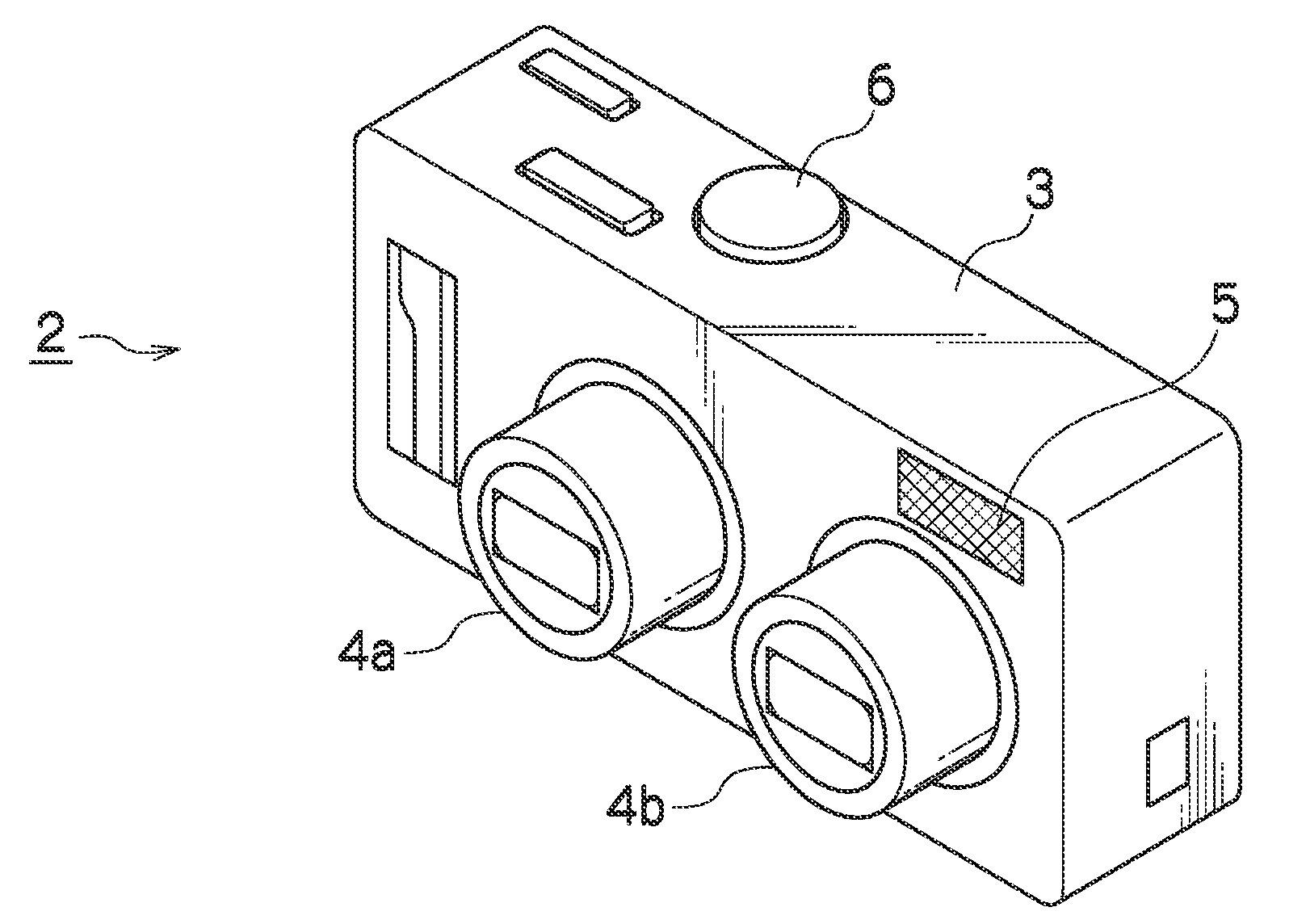

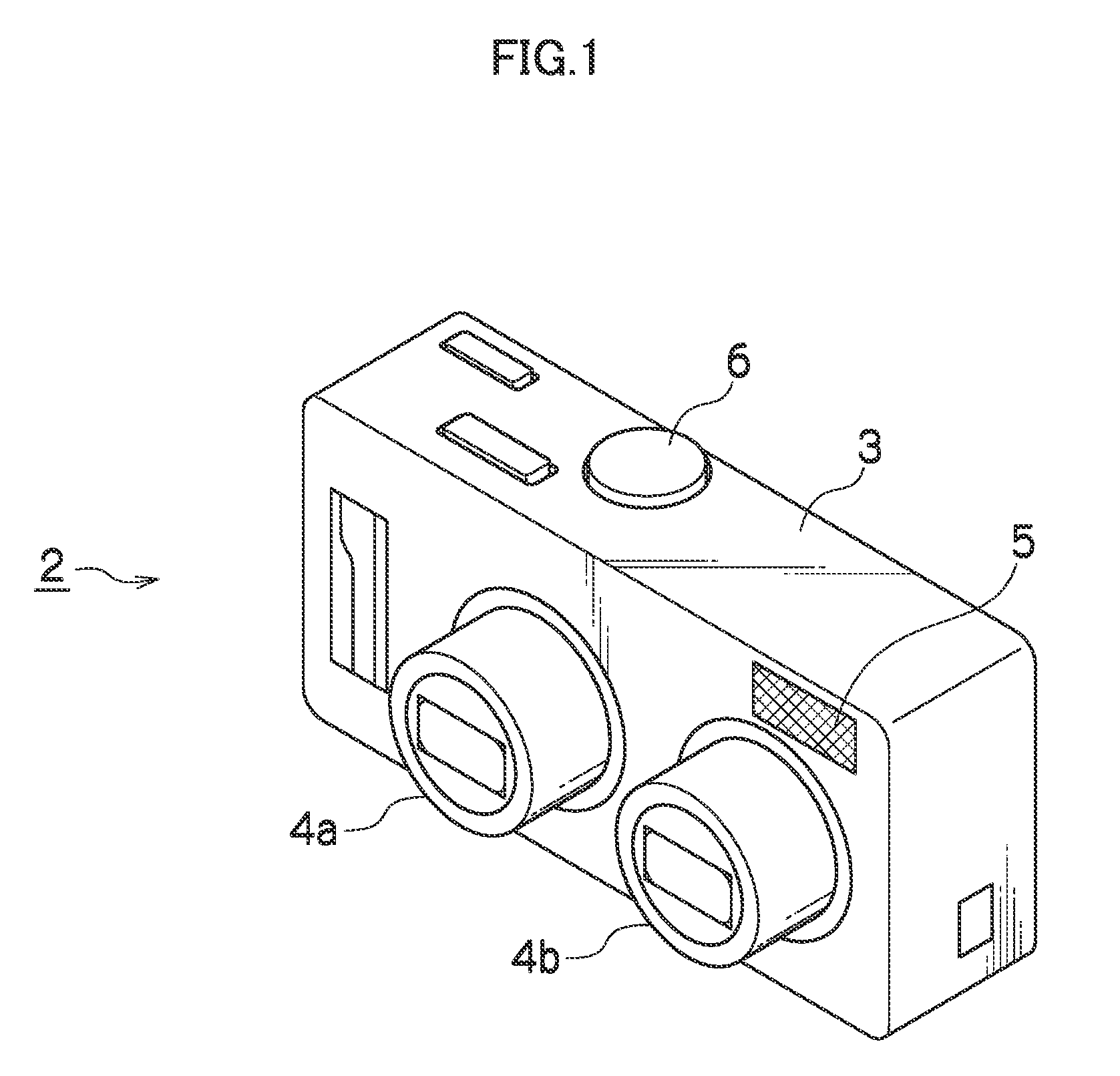

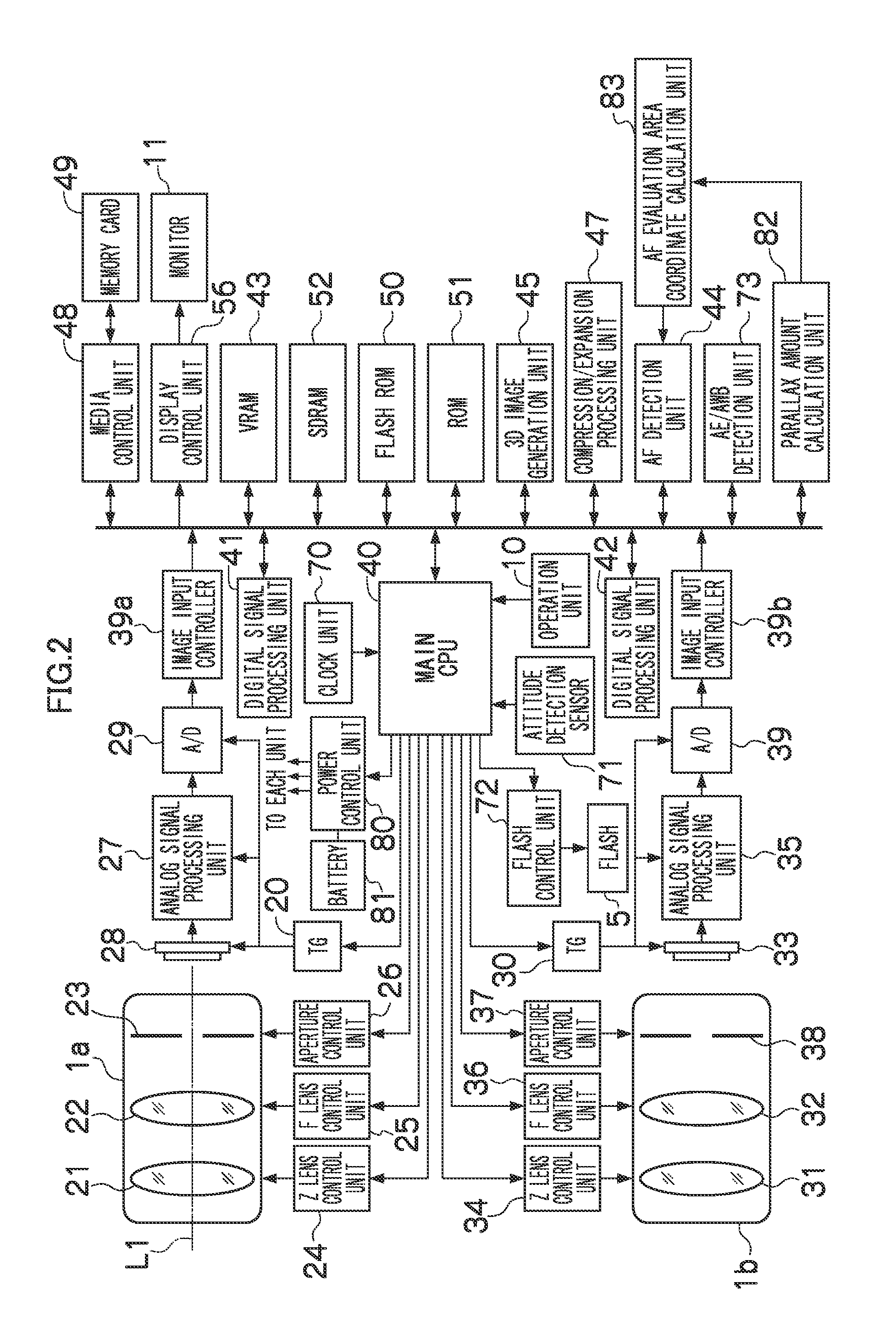

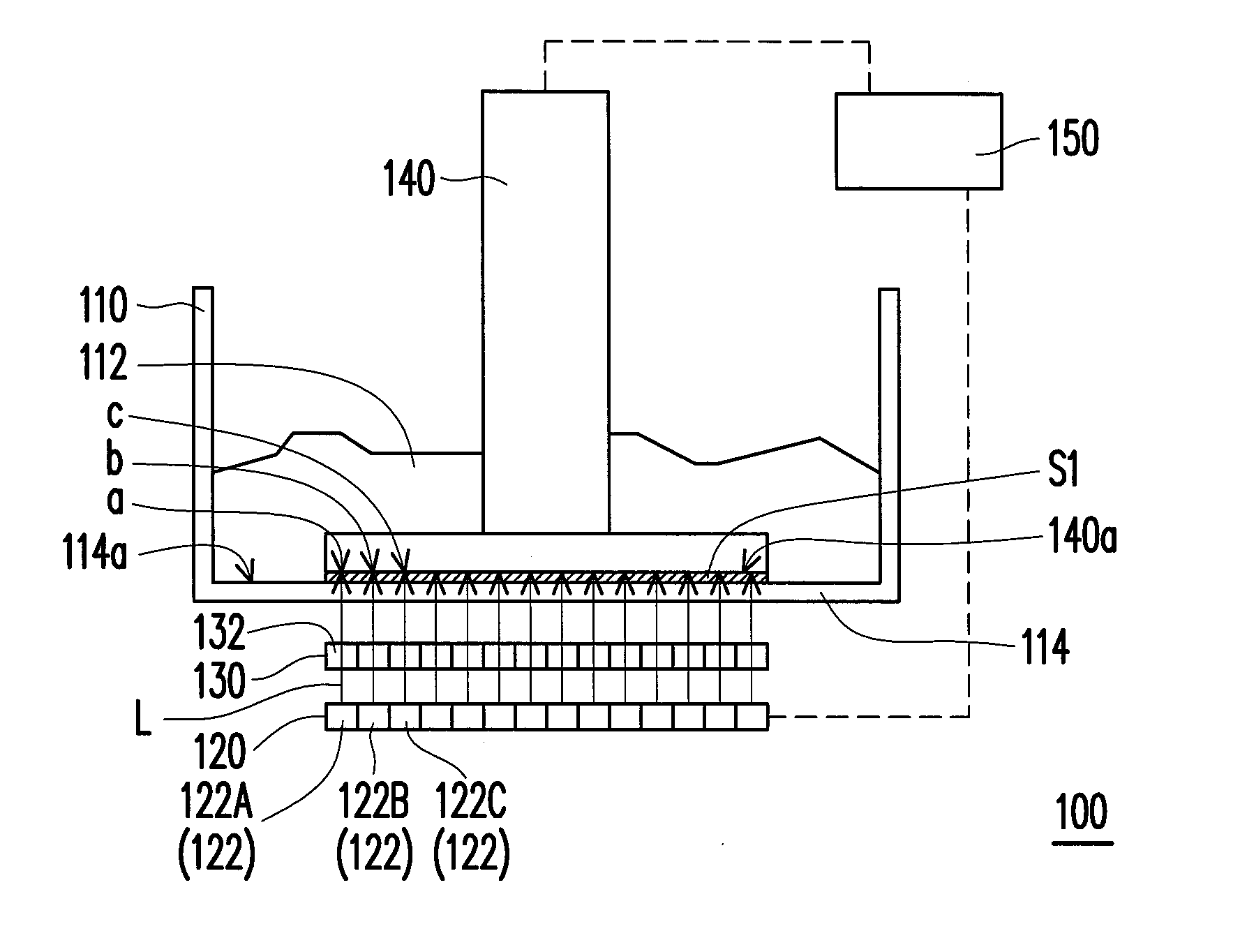

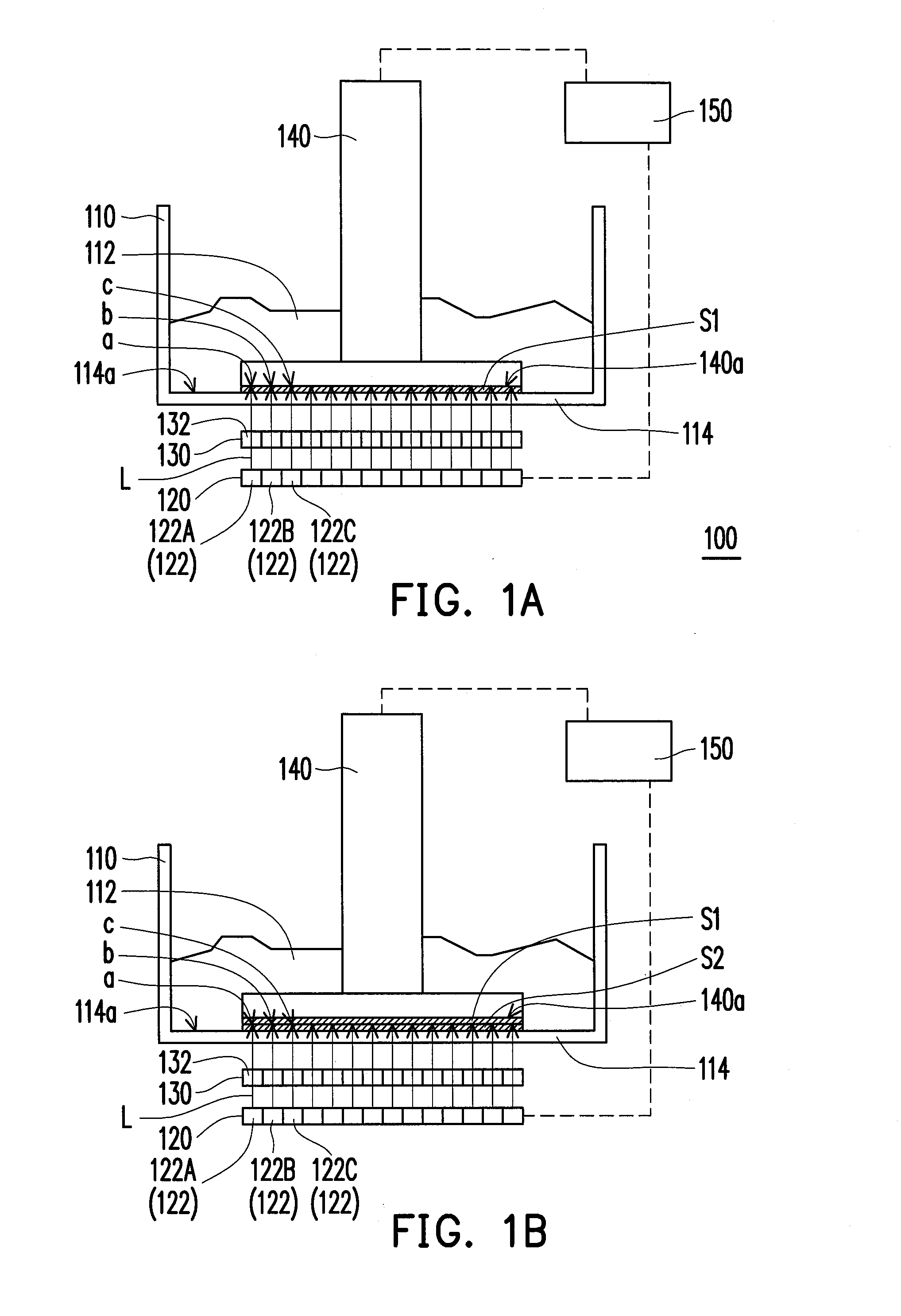

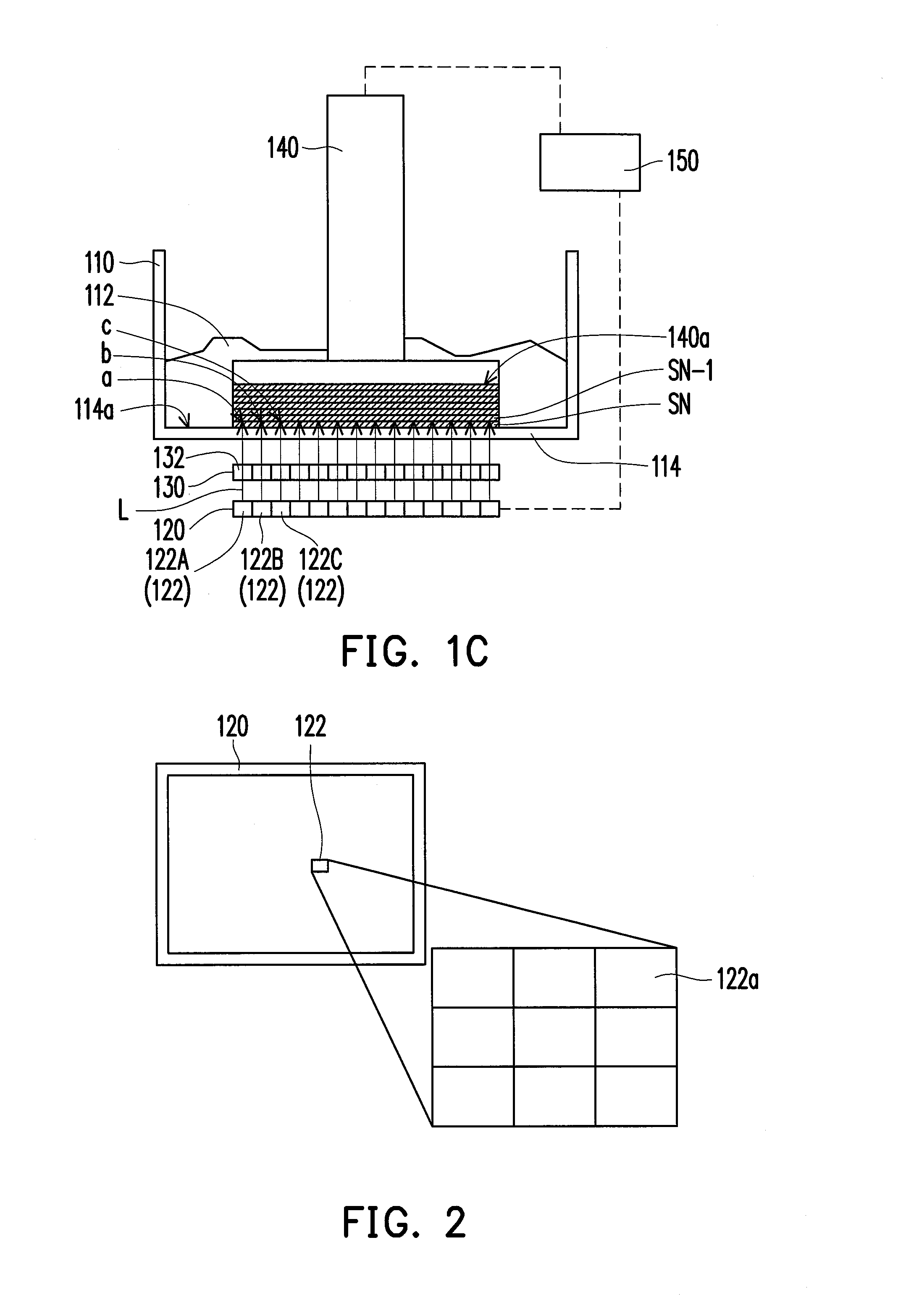

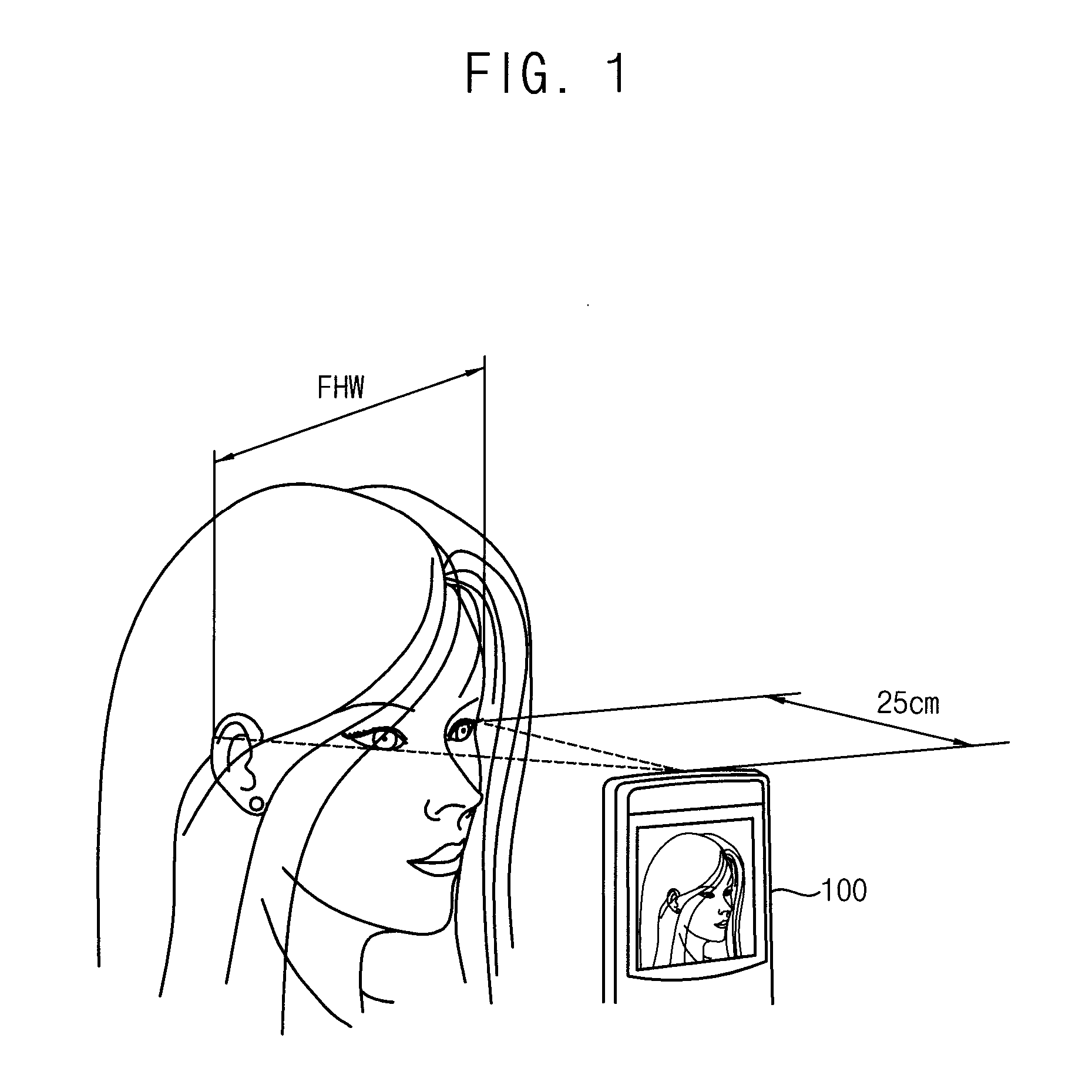

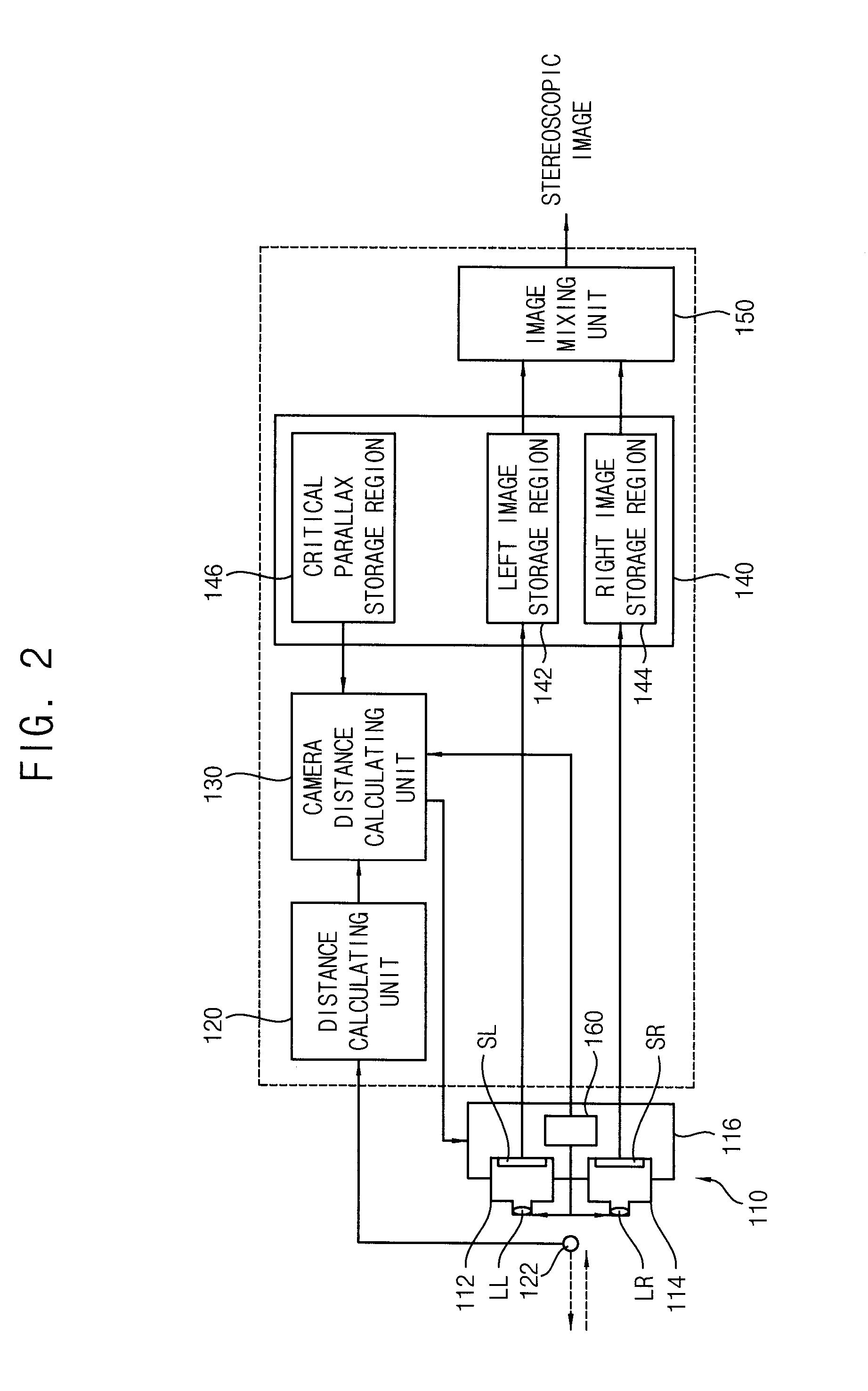

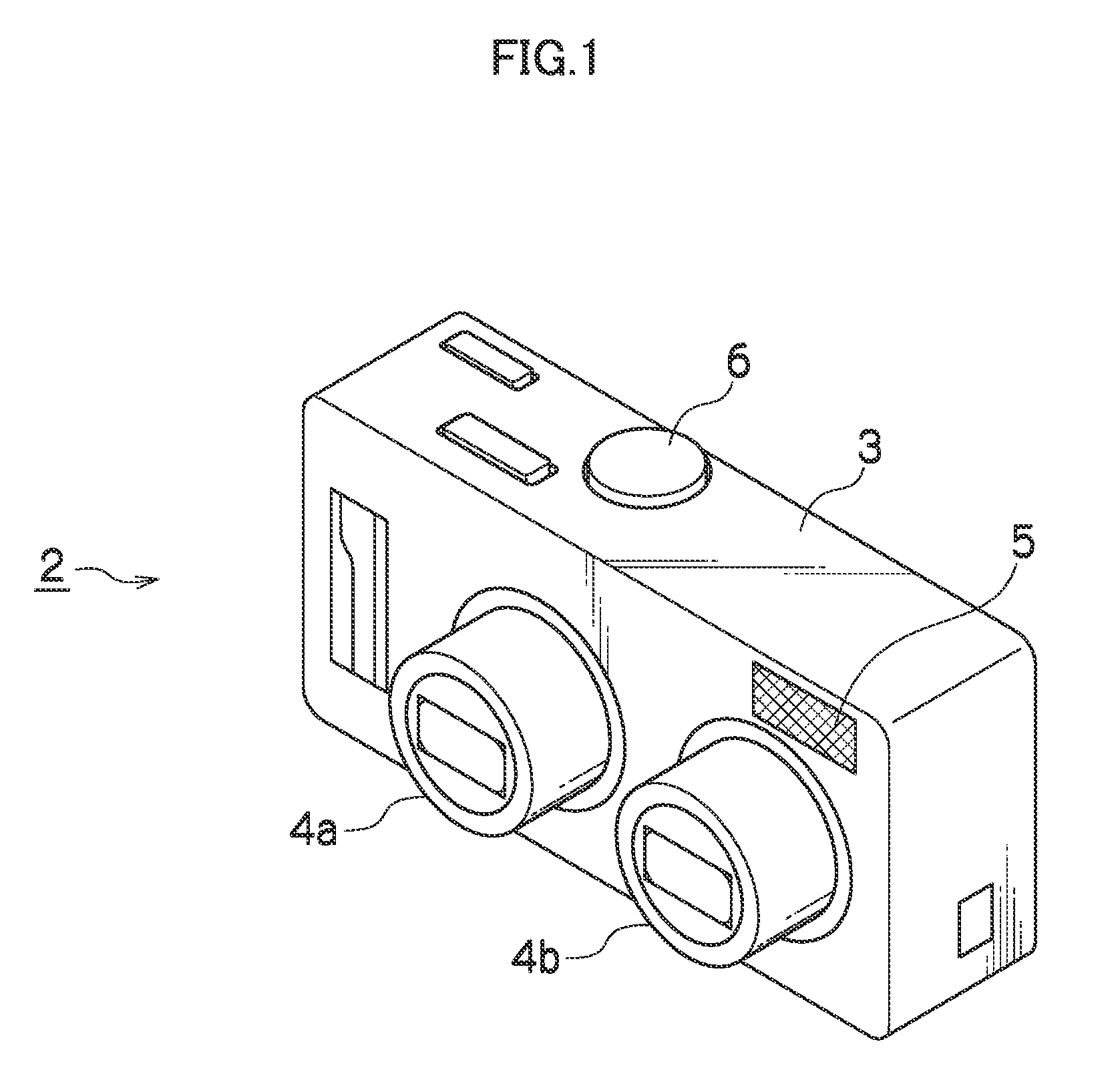

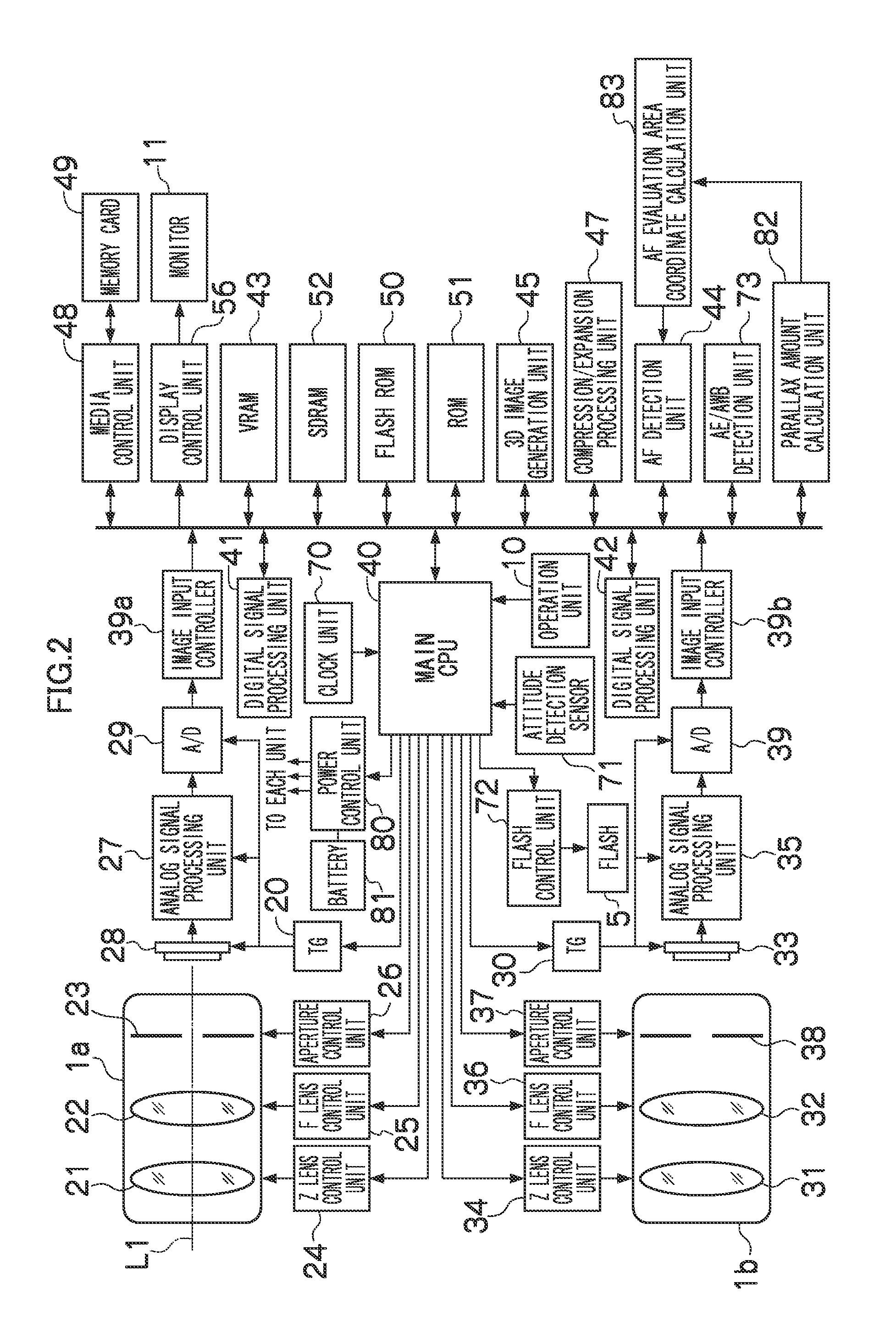

Imaging device, imaging method and recording medium

InactiveUS20110012998A1Good stereoscopic imageGood three-dimensionalTelevision system detailsPhotometryParallaxImaging condition

An imaging method includes: calculating an amount of parallax between a reference optical system and an adjustment target optical system; setting coordinates of an imaging condition evaluation region corresponding to the first viewpoint image outputted by the reference optical system; calculating coordinates of an imaging condition evaluation region corresponding to the second viewpoint image outputted by the adjustment target optical system, based on the set coordinates of the imaging condition evaluation region corresponding to the first viewpoint image, and on the calculated amount of parallax; and adjusting imaging conditions of the reference optical system and the adjustment target optical system, based on image data in the imaging condition evaluation region corresponding to the first viewpoint image, at the set coordinates, and on image data in the imaging condition evaluation region corresponding to the second viewpoint image, at the calculated coordinates, and outputting the viewpoint images in the adjusted imaging conditions.

Owner:FUJIFILM CORP

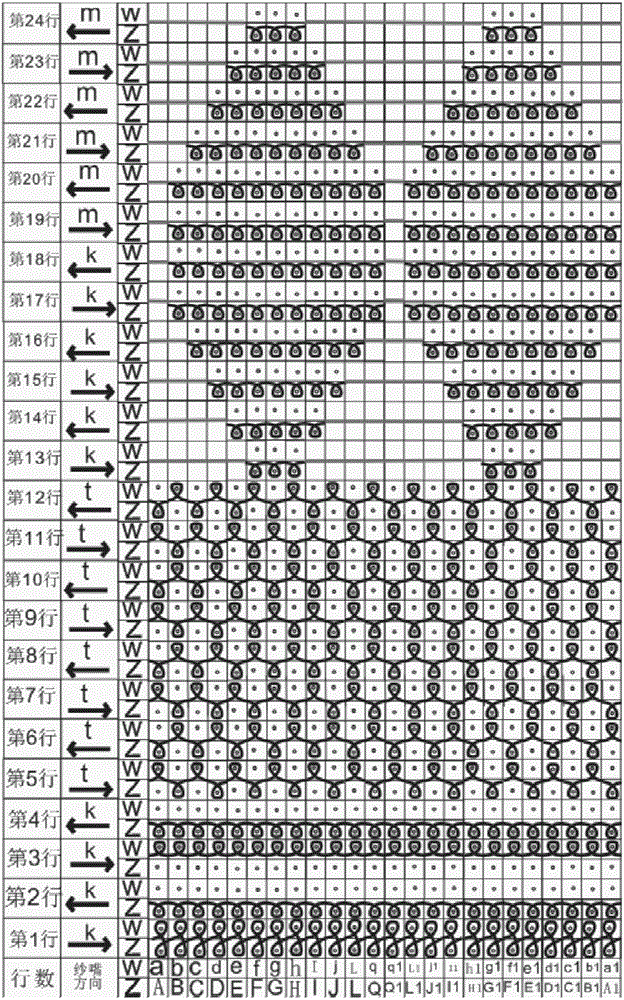

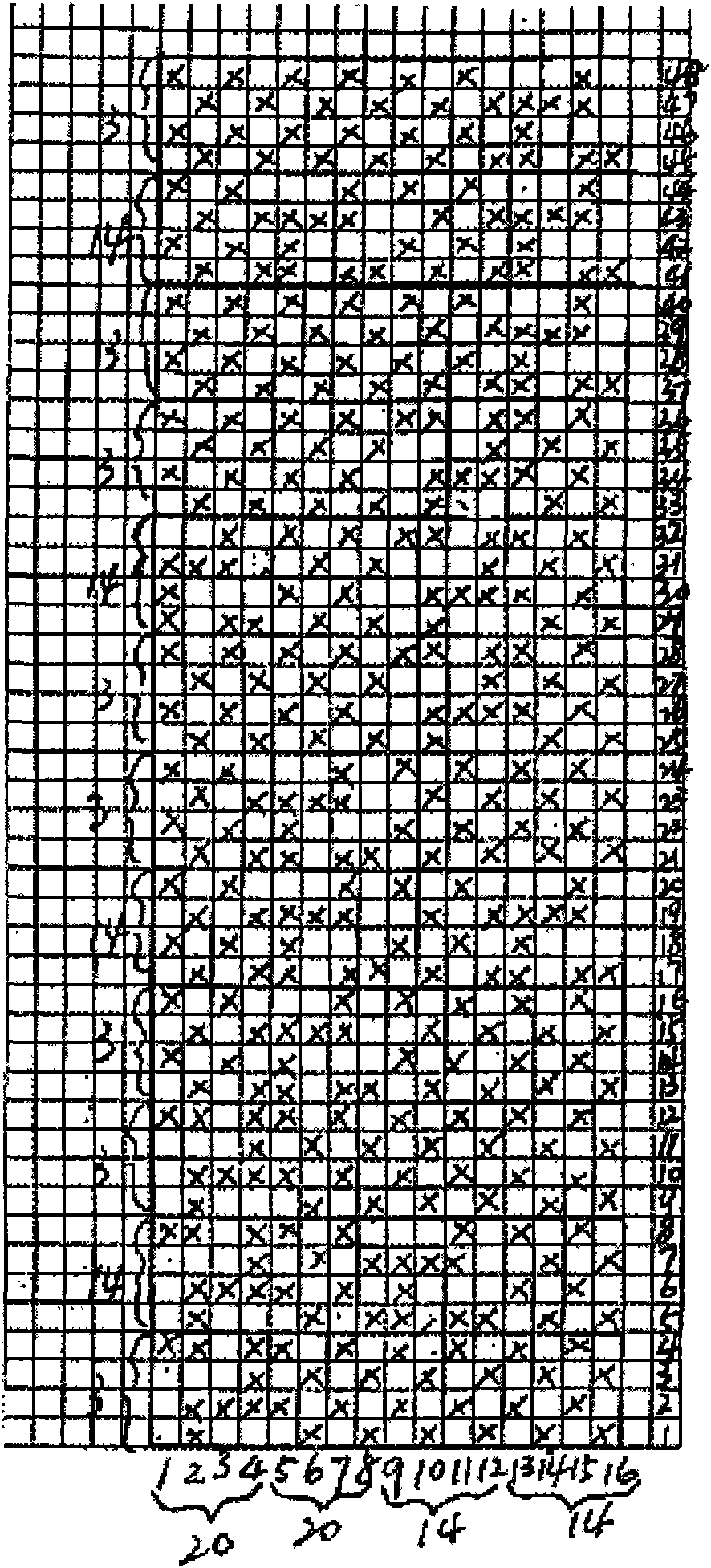

Double-faced jacquard weaving technology

The invention provides a double-faced jacquard weaving technology. A double-needle spaced fabric adopts computer-designed jacquard patterns and is woven by adopting seven guide bars, and the guide bar GB1, the guide bar GB2, the jacquard guide bar JB3.1, the jacquard guide bar JB3.2, the jacquard guide bar JB4.1, the jacquard guide bar JB4.2 and the guide bar GB5 are sequentially arranged from a front needle bed to a back needle bed. The double-faced jacquard weaving technology specifically comprises the following steps that 1, the guide bar GB1 is fully threaded to serve as a first layer of yarn to be laid to form loops on the front needle bed and used for forming the surface layer of the double-needle spaced fabric; 2, the guide bar GB2 is fully threaded to serve as a second layer of yarn to be alternated to form loops to form spaced yarn for connecting the surface layer with the bottom layer; 3, the guide bar GB5 is fully threaded to serve as a fifth layer of yarn to be laid to form loops on the back needle bed and used for forming the bottom layer of the double-needle spaced fabric. The double-needle spaced fabric made through the double-faced jacquard weaving technology is clear in pattern hierarchy and has the good stereoscopic effect in visual sense; meanwhile, the production procedures are simplified, and the cost is greatly saved.

Owner:SINCETECH FUJIAN TECH CO LTD

Three-dimensional high simulation ceramic tile with matte glaze surface and preparation method thereof

ActiveCN108727037AExtended service lifeGood three-dimensionalCeramic shaping apparatusAdobeComputer printing

The invention discloses a three-dimensional high simulation ceramic tile with matte glaze surface and a preparation method thereof, the method comprising the following steps: 1) adopting a laser four-dimensional fine carving system to finely carve a digital mold; 2) Positively pressing green body molding; 3) Controlling the water absorption rate of the ceramic tile before glazing at 15%-20% by controlling the drying temperature of the ceramic tile adobe or the biscuiting temperature of the ceramic tile adobe; 4) spraying a small amount of high-titanium impervious ground coat under high pressure; 5) spraying a small amount of matte glaze under high pressure; 6) using a digital ink jet printer to print decorative ink and functional ink; 7) decorating the dry particle frit, and adopting a controllable negative pressure absorbing dry particle frit equipment to absorb excess dry particle frit; 8) sintering to obtain the three-dimensional high imitation ceramic tile with matt glaze surface,the preparation method provided by the invention obtains the three-dimensional high simulation ceramic tile with matte glaze surface with three-dimensional simulation, 2-6 glossy units of glaze surface gloss and lifelike surface decoration effect through the collaborative and innovative preparation including mold sculpture, glaze formula control, high-pressure glaze spraying and effect decoration.

Owner:广东协进陶瓷有限公司

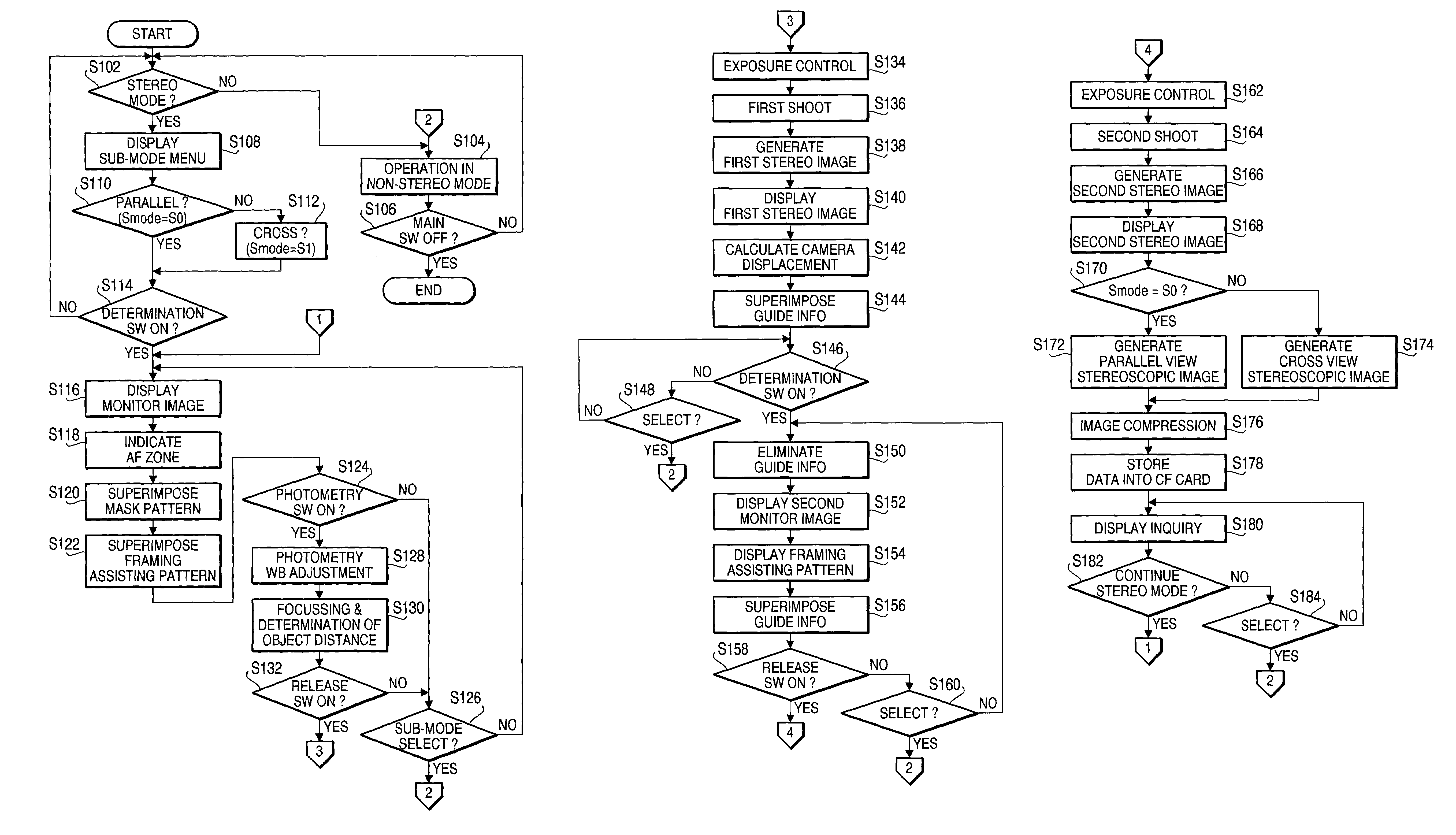

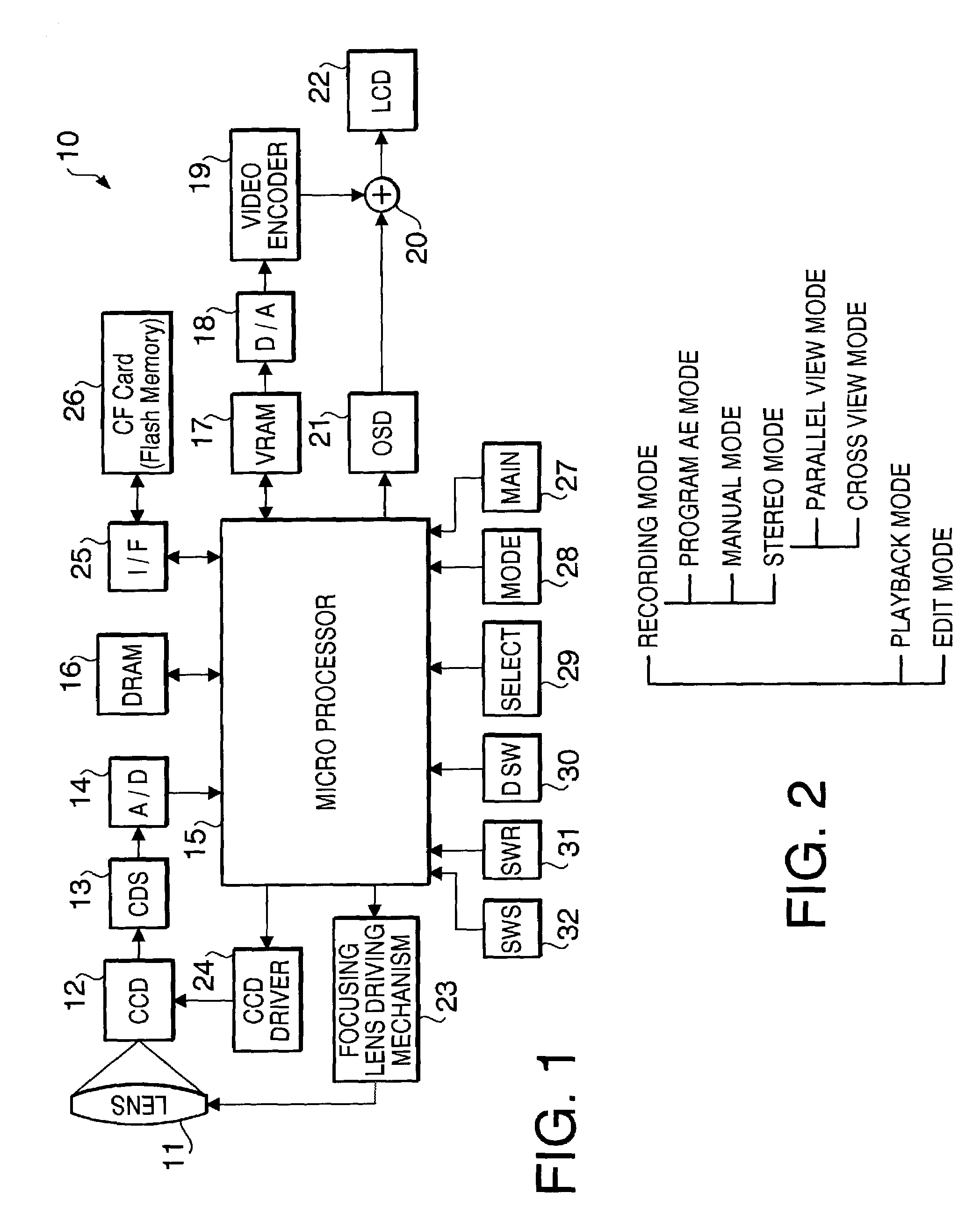

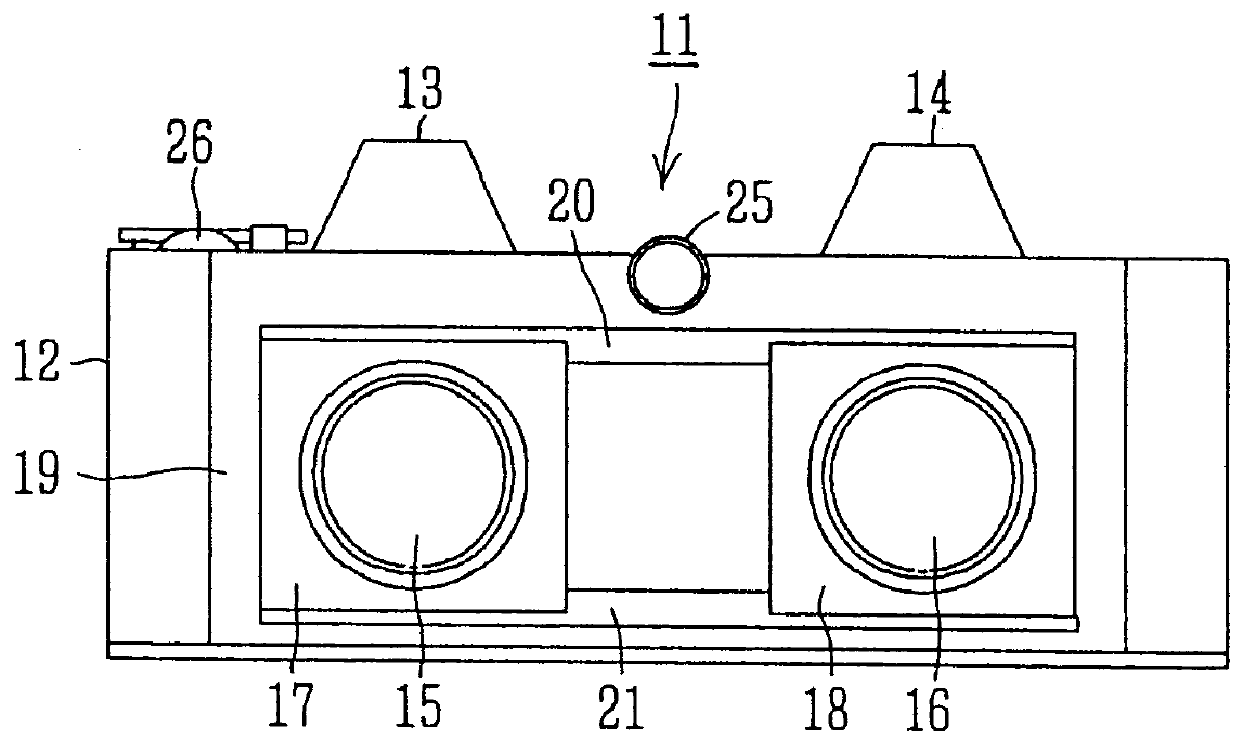

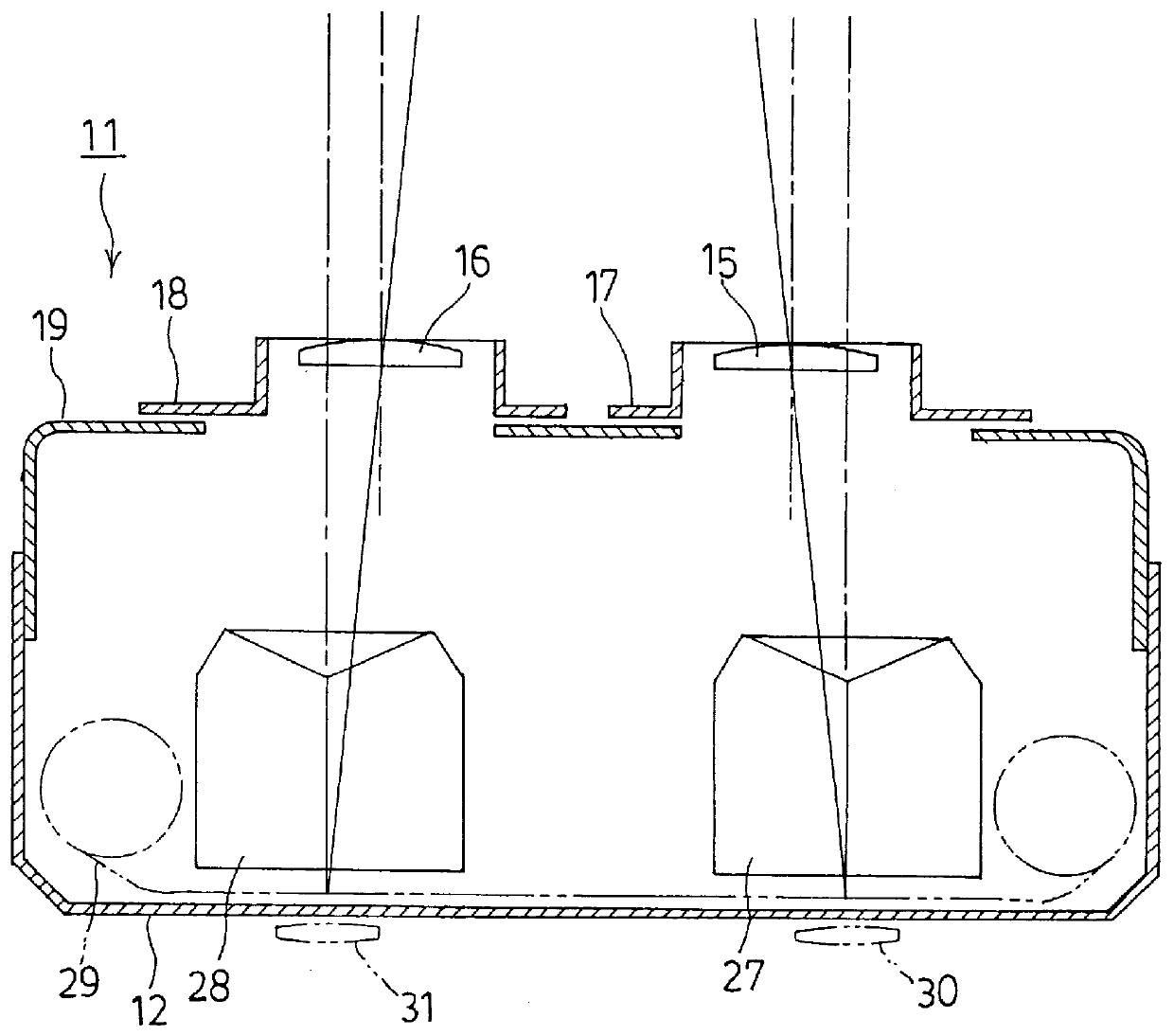

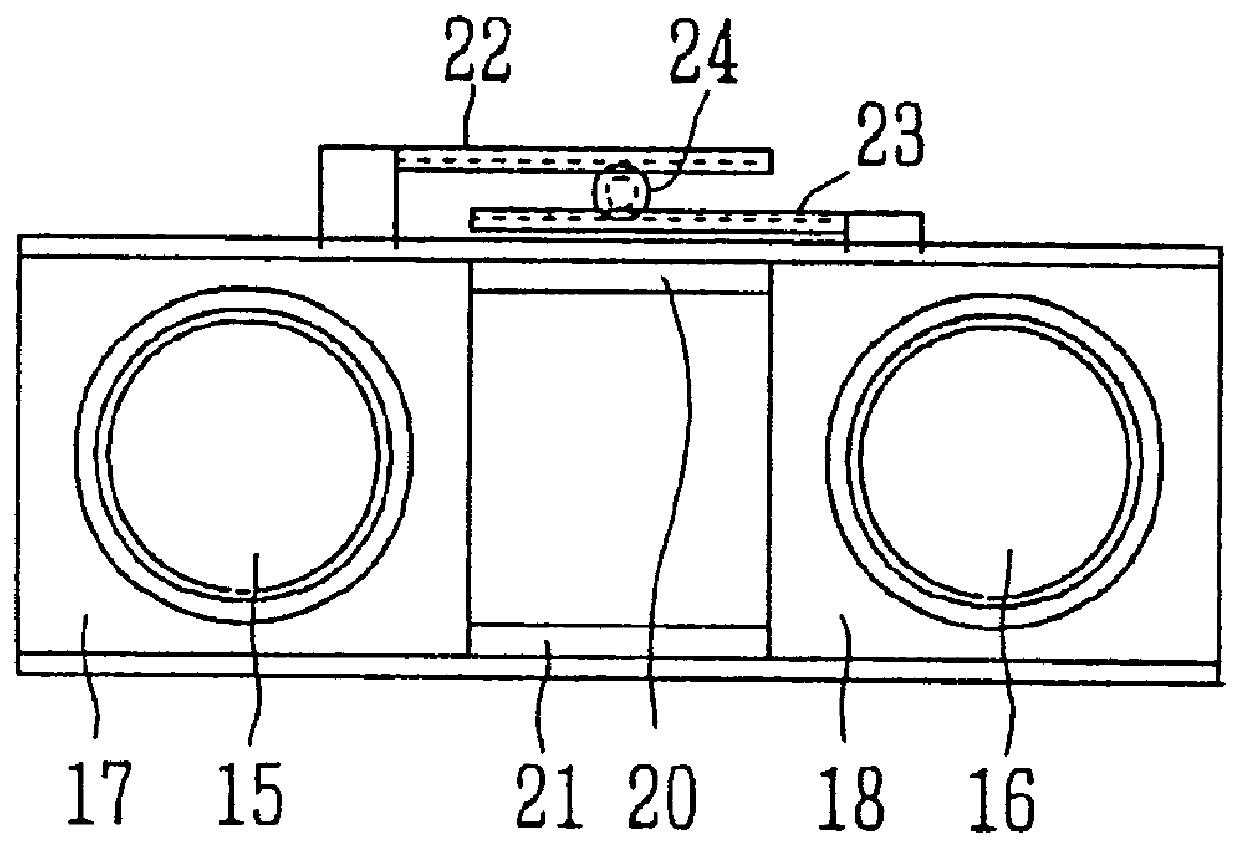

Digital camera for taking a stereoscopic pair of images

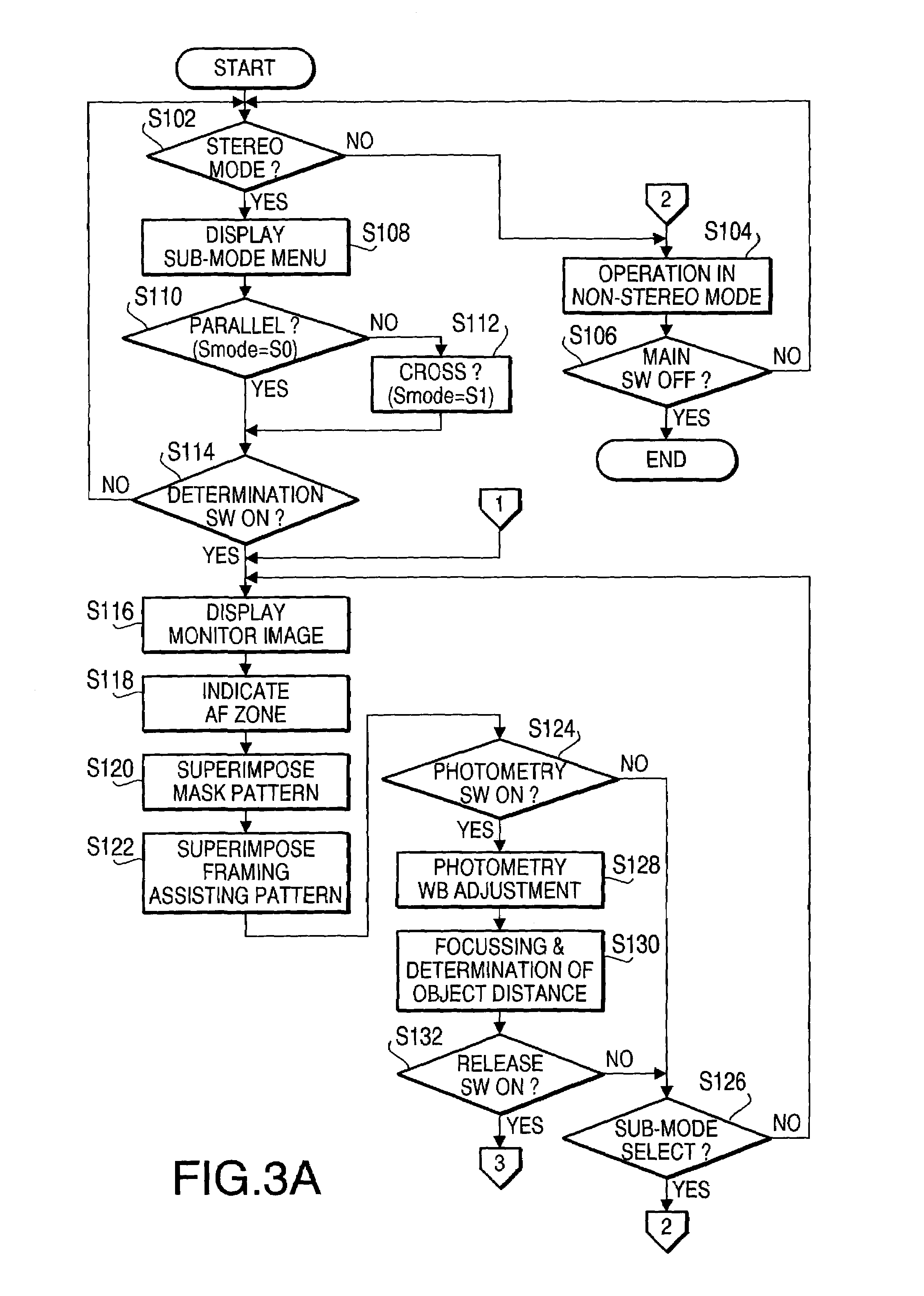

InactiveUS7181061B2Good three-dimensionalEasy to determineTelevision system detailsCharacter and pattern recognitionGrid patternImage capture

The digital camera being capable of recording stereoscopic first and second still images includes an imaging device that captures the first and second still images in this order, a display unit that displays a moving image captured by the imaging device to allow framing an image to be taken. The display unit superimpose a framing assisting pattern on the moving image to facilitate the framing of the image to be taken. A grid pattern may be utilized as the framing assisting pattern. After the first still image is captured, the display unit displays the first still image, with the framing assisting pattern superimposed thereon, besides the moving image after said first still image is captured.

Owner:ASAHI KOGAKU KOGYO KK

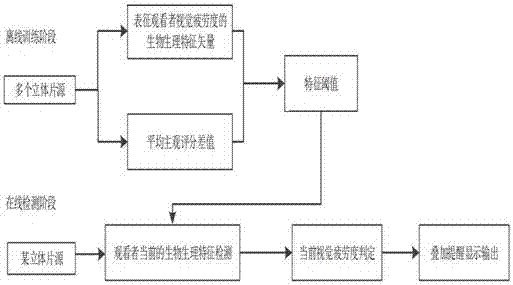

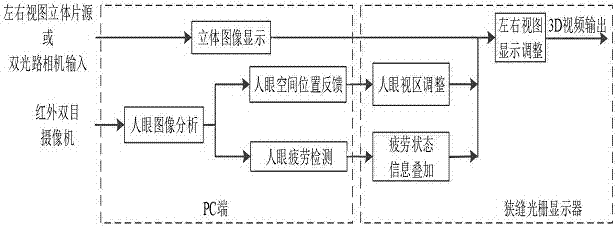

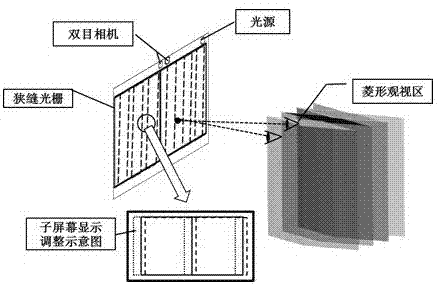

Naked eye three-dimensional display device and method through combination of visual fatigue detection

The invention relates to a naked eye three-dimensional display device and method through combination of visual fatigue detection. The device mainly is composed of an infrared binocular camera, an eye image analysis unit, an eye space position feedback unit, an eye visual area adjustment unit, a left and right view display and adjustment unit, an eye fatigue detection unit and a video output unit. According to the method, space coordinates of eyes are positioned in real time through adoption of an eyeball tracking technology; eye position movement is tracked in real time and subpixels of corresponding liquid crystal raster image are rearranged through adoption of a programmable logic array technology, thereby changing an optimum viewpoint area, the image crosstalk in an eye watching process is effectively reduced, and the viewing experience of a user is improved. Through application of the technologies, an eye fatigue state of the user in the viewing process is detected, measured and evaluated in real time, and the bad physiological reaction degree of the user is judged, thereby prompting the user to take measures to prevent or mitigate visual fatigue timely.

Owner:SHANGHAI UNIV

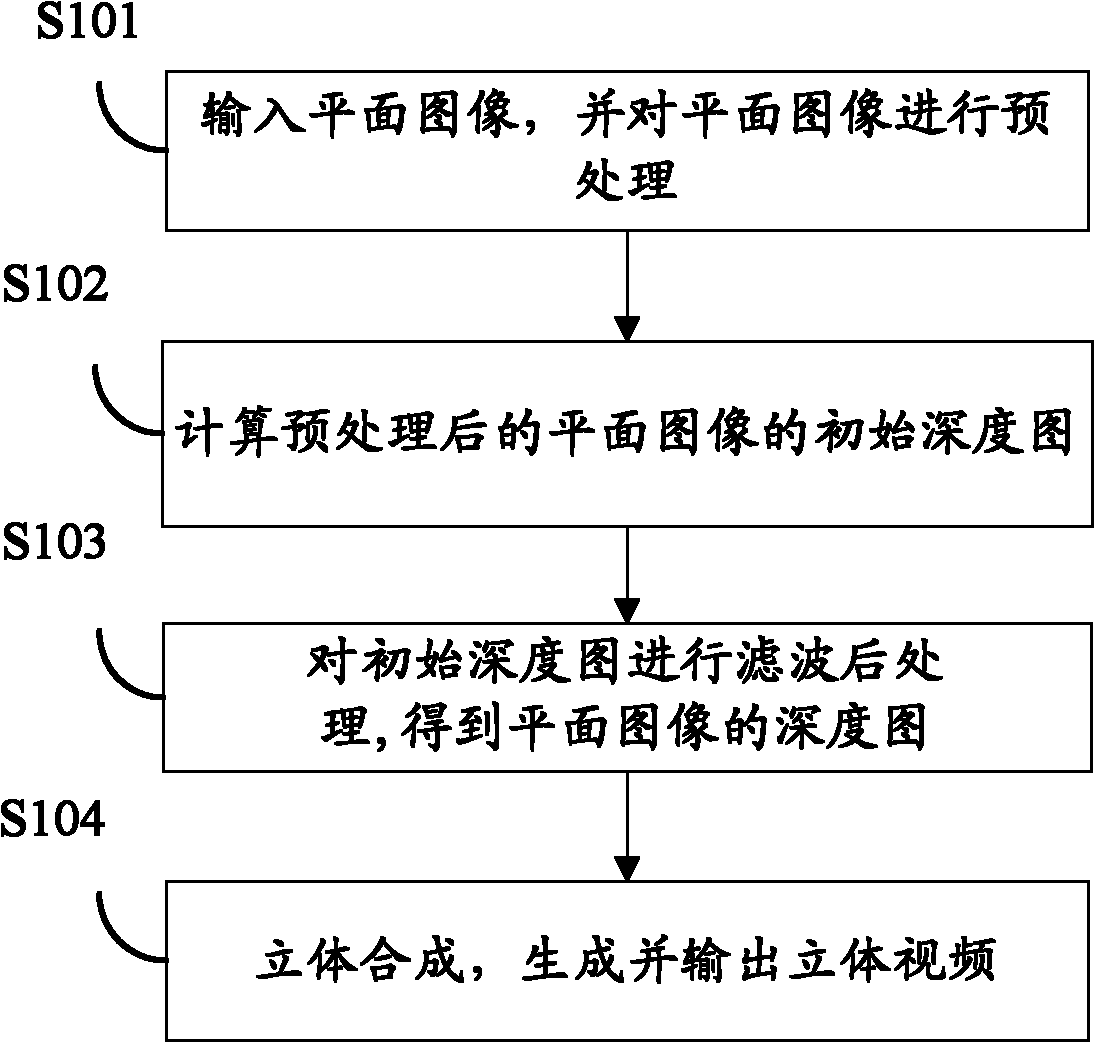

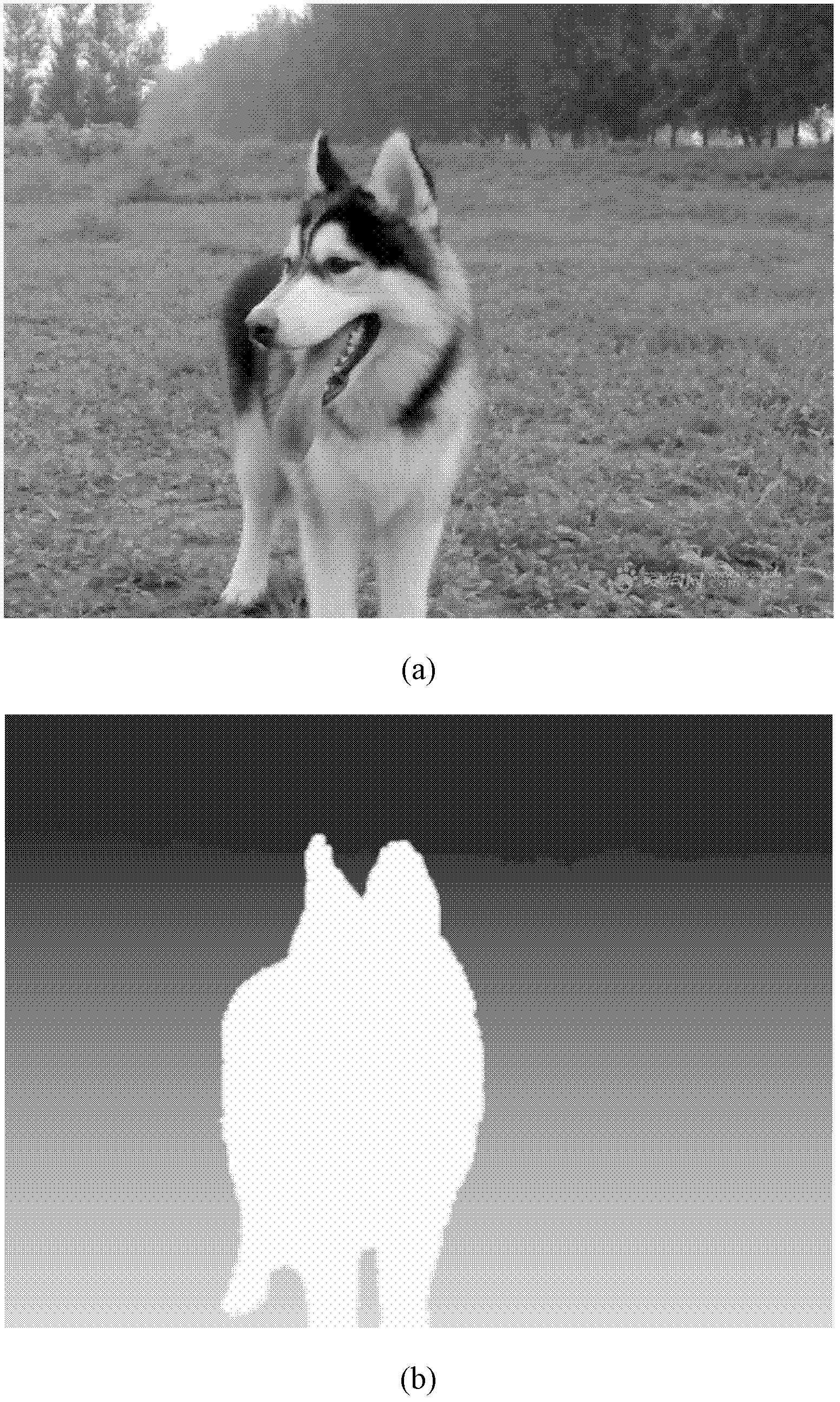

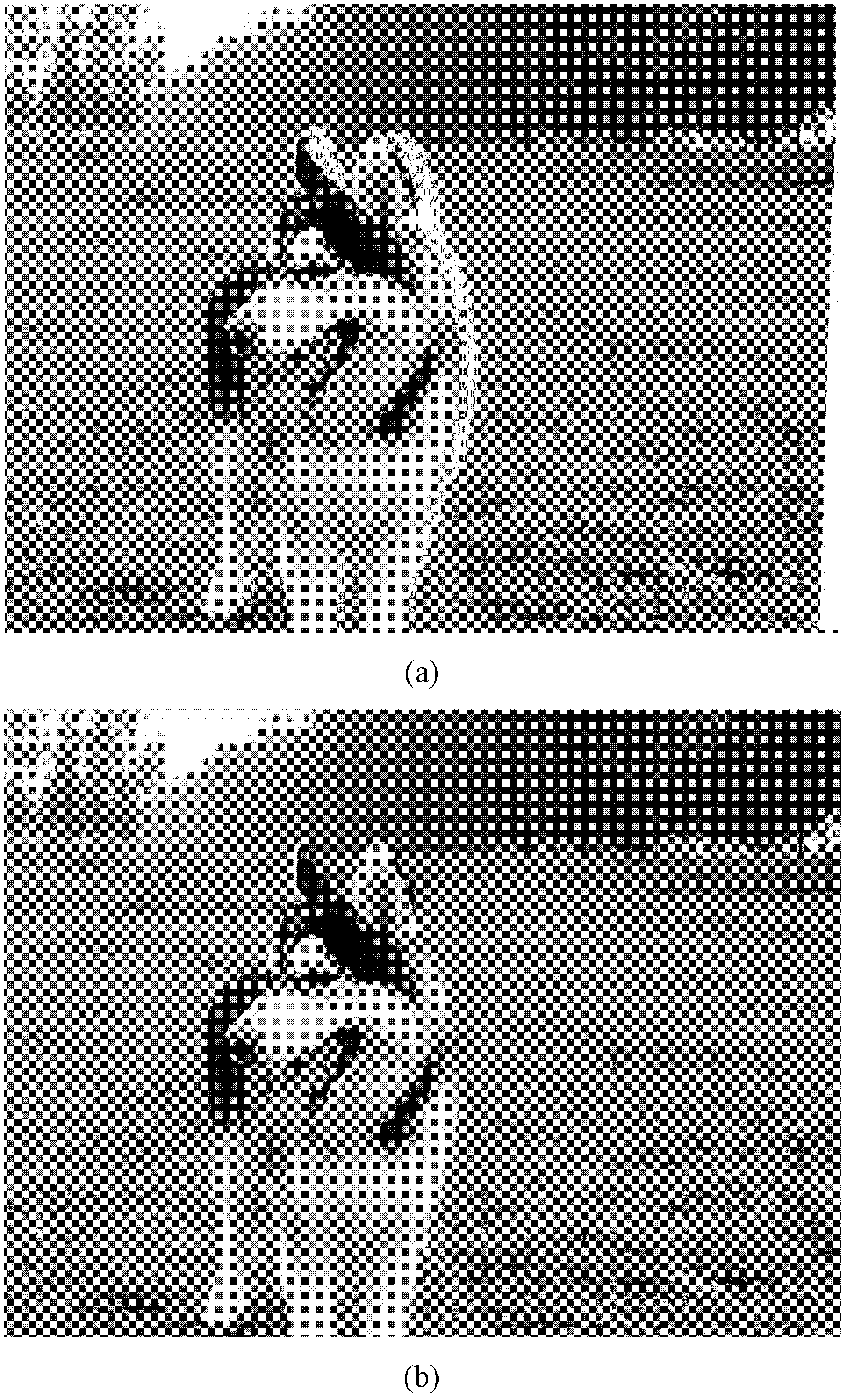

Method and device for converting planar image into stereoscopic image

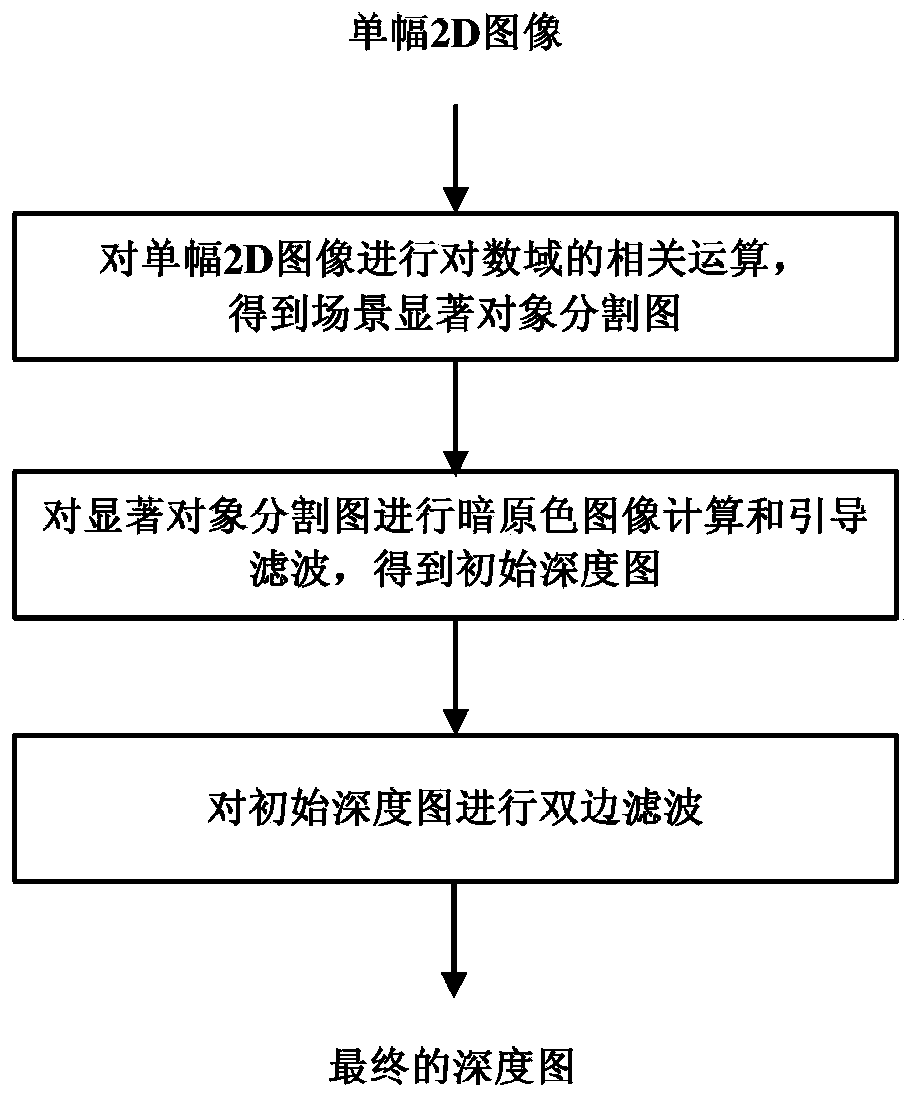

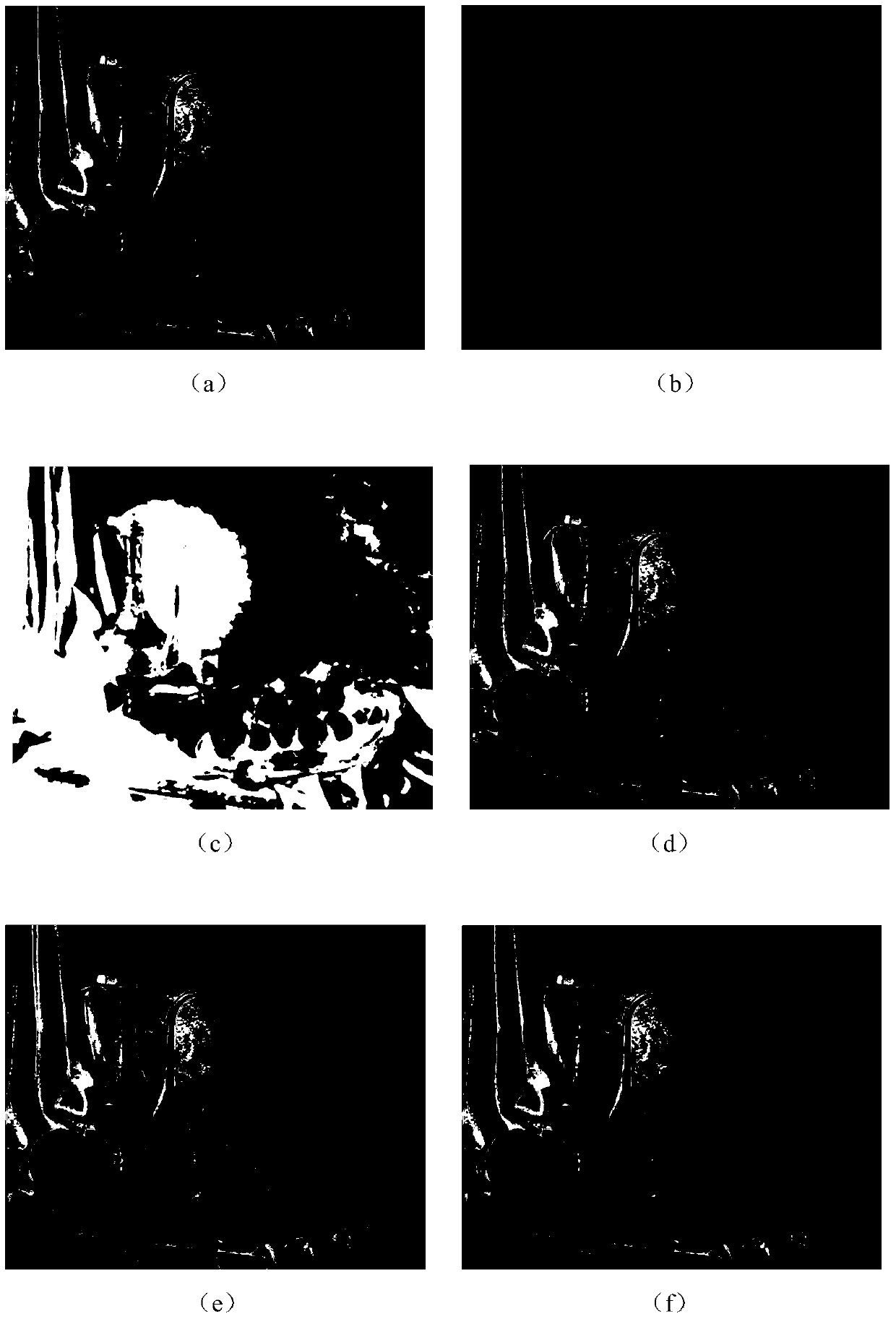

ActiveCN102098528AReal-time conversionCalculation speedSteroscopic systemsStereoscopic videoDepth map

The invention discloses a method for converting a planar image into a stereoscopic image. The method comprises the following steps of: inputting the planar image and preprocessing the input planar image; calculating the initial depth map of the preprocessed planar image; performing filtering postprocessing on the initial depth map to obtain the depth map of the planar image; and performing pixel shifting on the planar image according to the depth map of the planar image to obtain a virtual view, and synthesizing the planar image and the virtual view in a stereoscopic form so as to generate and output a stereoscopic video. The method for converting the planar image into the stereoscopic image is convenient to use, and has high processing efficiency and a good stereoscopic display effect. The invention also discloses a device for converting a planar image into a stereoscopic image.

Owner:TSINGHUA UNIV

Manufacturing method of gravure roller capable of printing three-dimensional effect

InactiveCN102529308AGood three-dimensionalStrong touch bumpy textureForme preparationComputer graphics (images)Separation technology

The invention discloses a manufacturing method of a gravure roller capable of printing a three-dimensional effect, and the method comprises the following steps that: a computer image processing technology is applied to analyze the data of an image file which is scanned from an original pattern; the image data which can highlight the three-dimensional effect can be determined according to the content of an image; an image color separation technology is adopted to extract the image data which can highlight the three-dimensional effect, and the data is made into the image file; the image is carved on the gravure roller through an electronic carving machine; and finally mesh holes which are carved on the gravure roller and lined into the pattern are etched to required depths, and the gravure roller capable of printing the three-dimensional effect is manufactured by chrome plating. After the gravure roller which is manufactured through the method prints transparent ink onto the surface of a plane pattern which is printed from an original, the pattern can show a significant three-dimensional visual effect and intense concave and convex texture for touching.

Owner:广东省南方彩色制版有限公司

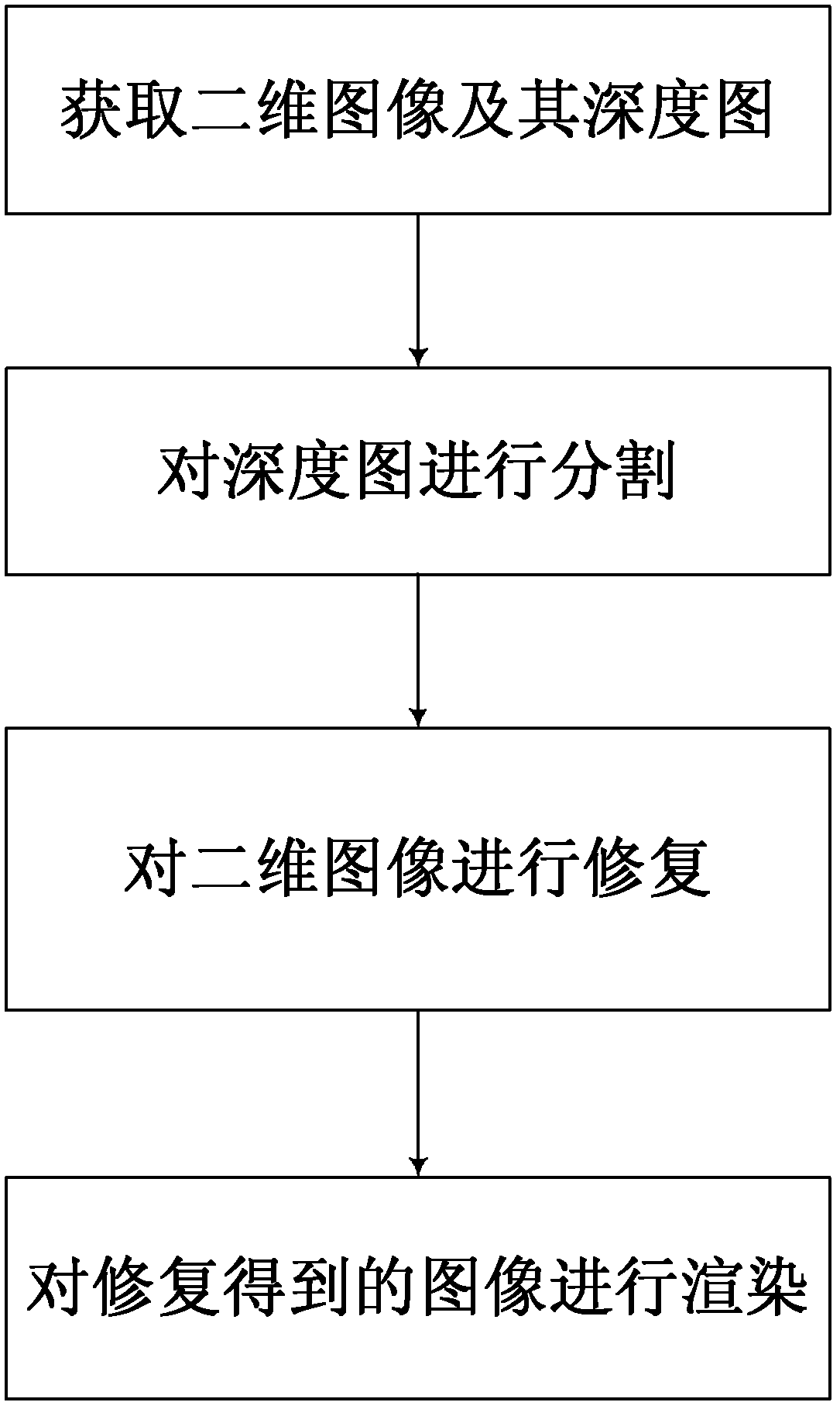

Virtual viewpoint image generation process on basis of depth map segmentation and rendering

InactiveCN102609974AEliminate voidsImprove computing efficiencySteroscopic systems3D-image renderingPersonal computerViewpoints

The invention discloses a virtual viewpoint image generation process on the basis of depth map segmentation and rendering, which includes: (1) acquiring two-dimensional images and a depth map thereof; (2), segmenting the depth map; (3), recovering the two-dimensional images; and (4), rendering the recovered images. By the generation process on the basis of depth map segmentation and rendering, virtual viewpoint images can be synthesized according to the original two-dimensional images and the corresponding depth map, and holes in the synthesized virtual viewpoint images can be eliminated thoroughly. Meanwhile, the virtual viewpoint image generation process can be implemented on hardware systems such as general PC (personal computers) or work stations and the like, higher computation efficiency can be achieved, and the virtual viewpoint images generated are obvious in stereoscopic effect.

Owner:四川和鼎昇泰信息技术有限公司

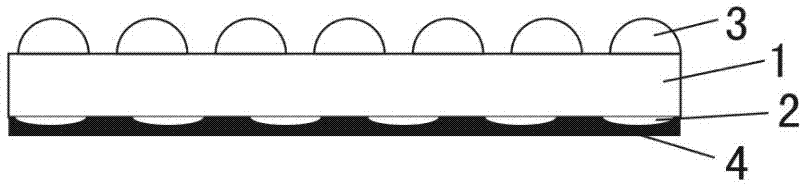

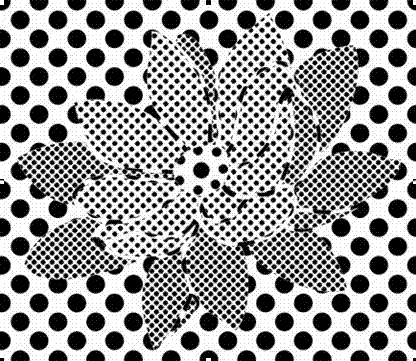

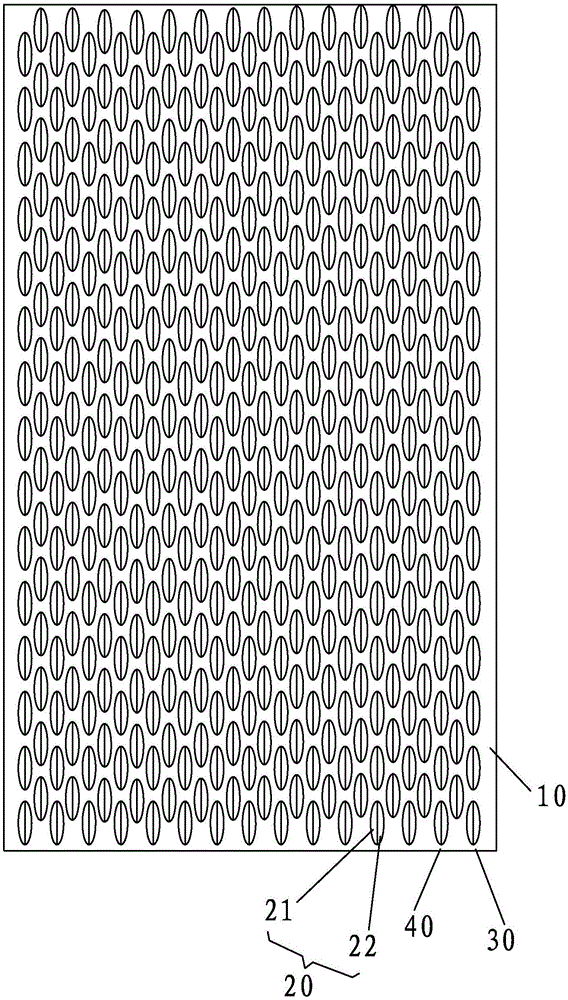

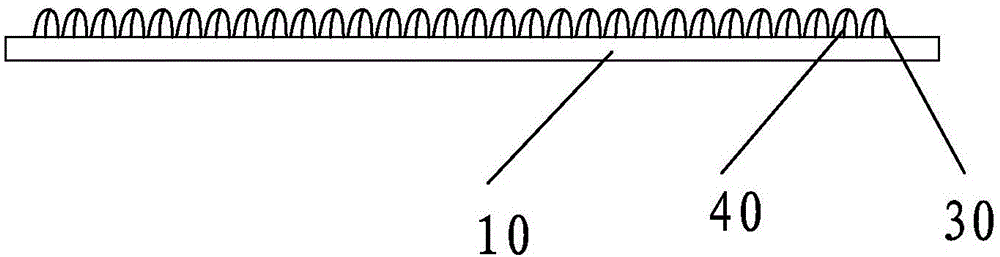

Stereograph and making method thereof

InactiveCN102398466ASimple structureLow costThree-dimensional effectsLight effect designsGratingLeft direction

The invention discloses a stereograph and a making method thereof. The stereograph comprises a transparent plate material, wherein one surface of the transparent plate material is a raster layer, and the other surface of the transparent plate material is provided with a raster image. The making method for the stereograph comprises the following steps of: (1) rasterizing a planar graph to acquire the raster image; (2) displaying the raster image on one surface of the transparent plate material; and (3) making the raster layer on the other surface of the transparent plate material and combining the raster image with the raster layer to acquire the stereograph. The making method for the stereograph is simple; and the stereograph made by the making method can clearly and completely display patterns for imaging in any direction, namely a left direction, a right direction, an upper direction and a lower direction and at any angle, has multiple stereo effects of getting into a screen, getting out of the screen, floating on the screen and the like and has an outstanding visual effect and extremely high enjoyment and artistic value.

Owner:ZHENGZHOU HENGHAO GLASS TECH

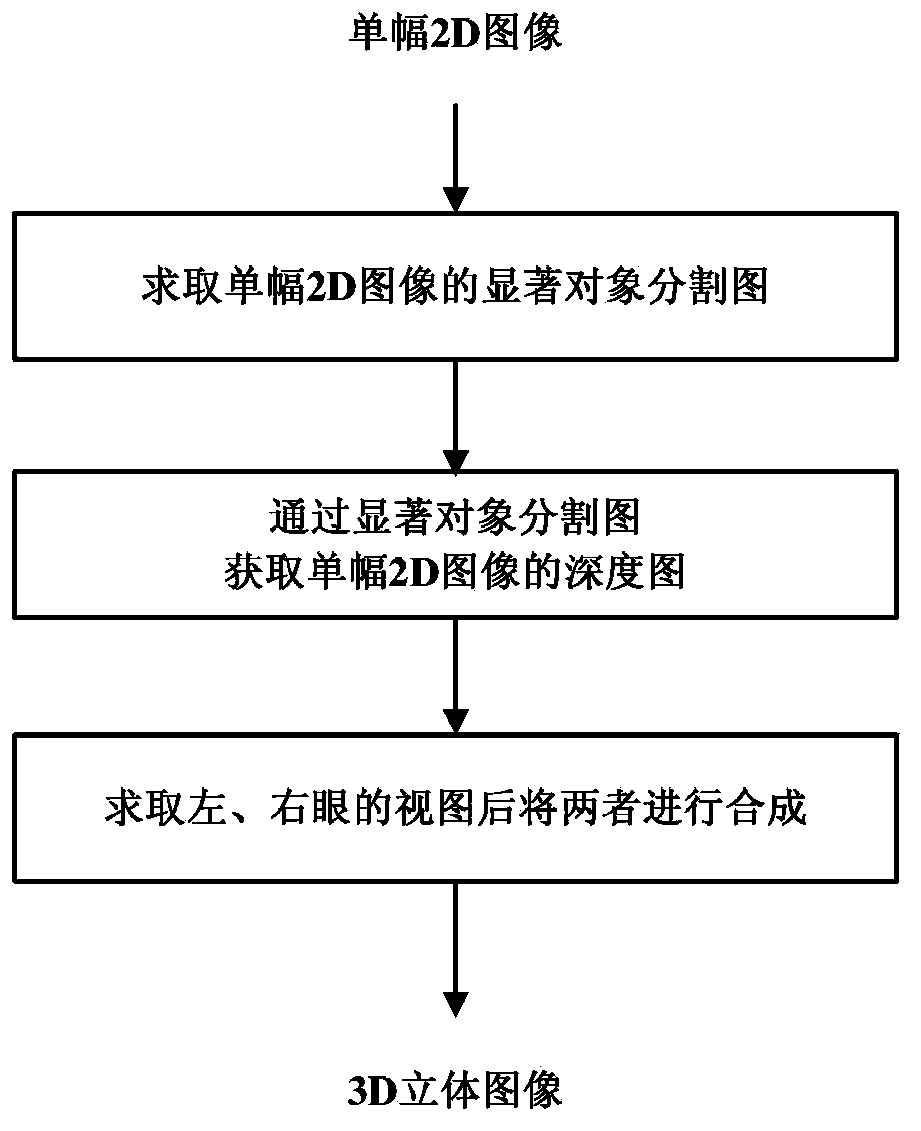

Method for obtaining 3D imaging image from single 2D image

The invention discloses a method for obtaining a 3D imaging image from a single 2D image. The method includes the following steps of firstly, obtaining a significant object segmentation image of the single 2D image; secondly, obtaining a depth image of the single 2D image through the significant object segmentation image obtained in the first step; thirdly, obtaining a left eye vision view required by 3D imaging and a right eye view required by 3D imaging through the depth image obtained in the second step, and combining the left eye view and the right eye view to obtain a 3D image corresponding to the single 2D image, wherein the produced depth image does not restore real depth information but is just a pseudo depth image which reflects the relative position relationship of an object in the image and other parts in the scene. Through a large number of experiments, the experiment result expresses that the corresponding 3D image has an obvious three-dimensional effect after the left eye view produced through the pseudo depth image is combined with the right eye view produced through the pseudo depth image.

Owner:CENT SOUTH UNIV

Three-dimensional printing apparatus

ActiveUS20130295215A1Small sizeDistanceAdditive manufacturing apparatusAuxillary shaping apparatusDisplay deviceLight beam

A three-dimensional printing apparatus is provided, including a container, a display, a control unit and an optical film. The container contains a photosensitive material. The display has a plurality of display units. Each of the display units is capable of emitting a light beam. The control unit is capable of controlling the display units. The optical film is capable of projecting the light beams emitted from the display units onto the photosensitive material, forming a plurality of projected patterns. An arranging sequence and an arranging direction of the projected patterns are substantially the same as an arranging sequence and an arranging direction of the display units.

Owner:YOUNG OPTICS

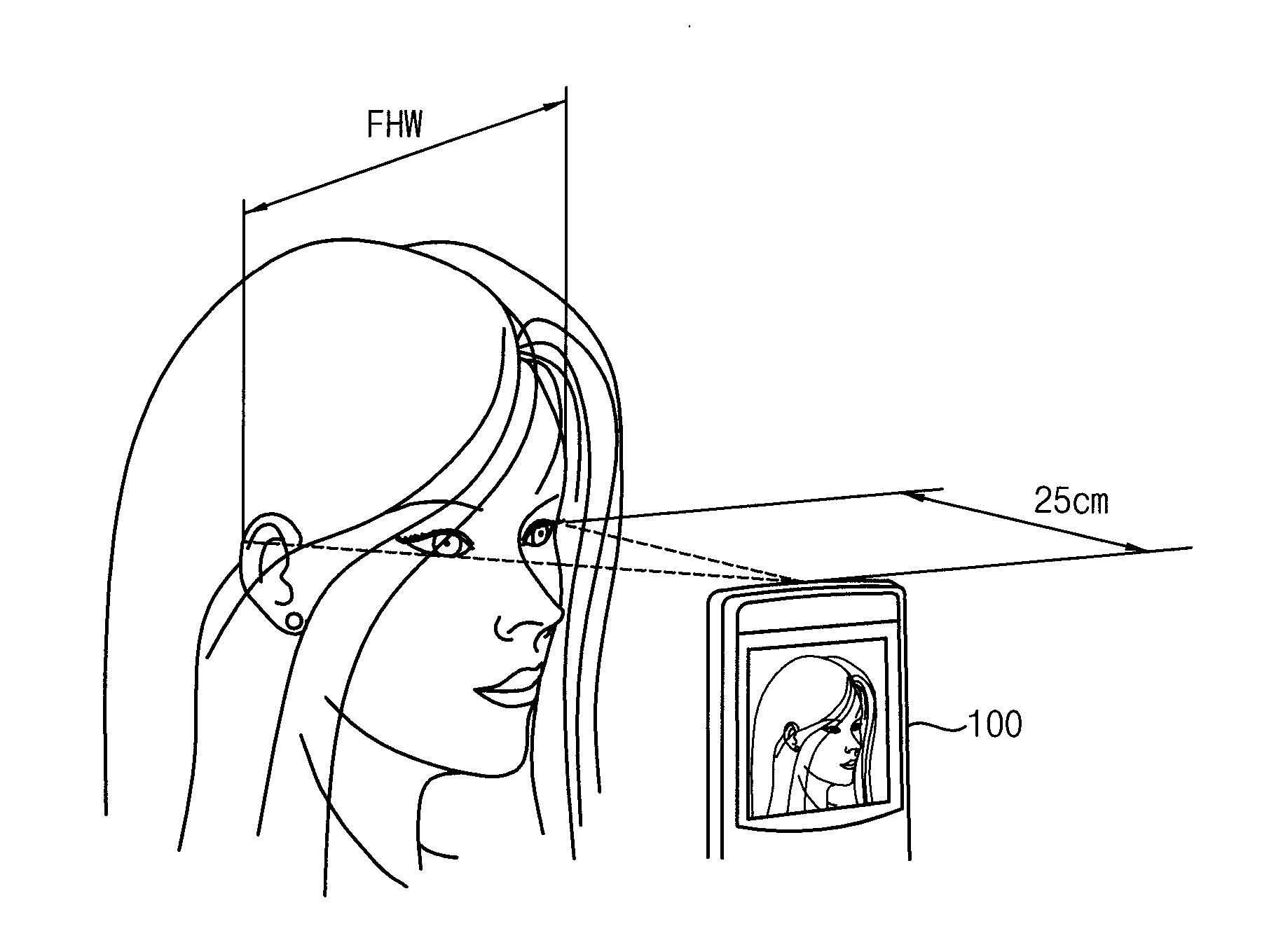

Stereo camera apparatus for a mobile device, and imaging method therefor

ActiveUS20140085423A1Simple processGood three-dimensionalImage analysisSteroscopic systemsStereo cameraMobile device

Owner:STEREOPIA CO LTD

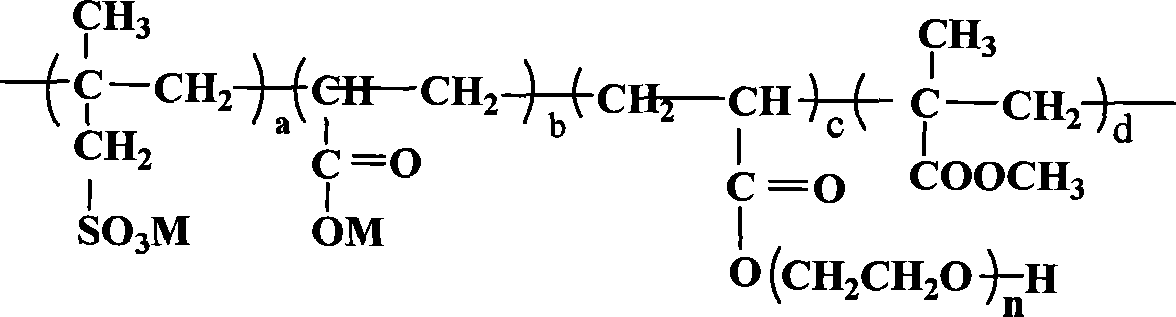

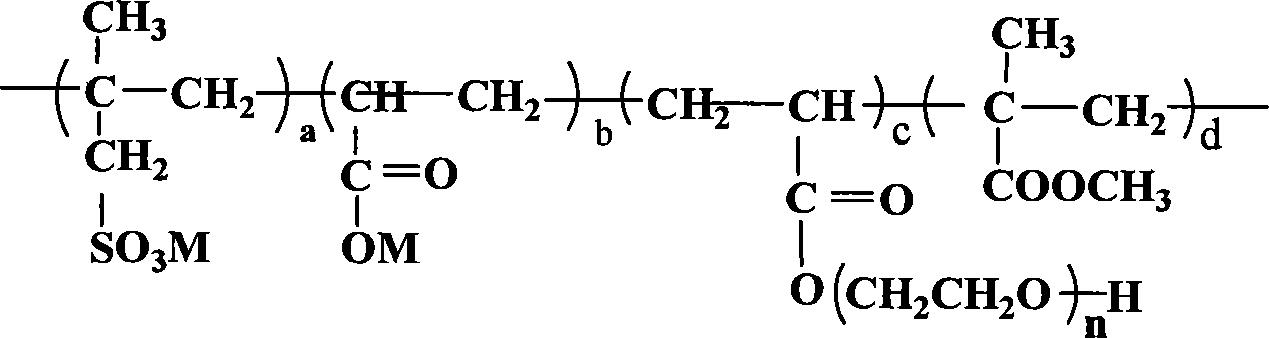

Polycarboxylic acids series water reducer and method for making same

The invention discloses a polycarboxylate type water reducer, the molecule chains of the water reducer contains two different-length polyethylene oxide side chains, the polycarboxylate type water reducer not only have high water reducing rate, but also have excellent plasticizing effect and can self-control the concrete slurry fluidity and gradual slurry fluidity variety, thereby overcoming the problems that the prior water reducer has poor cement plasticizing effect and low water reducing rate. The polycarboxylate type water reducer does not contain chloride ion and has corrosion on reinforced concrete and strong adaptability, and can applied for various specs of cements, and has stable performance and no delamination and sedimentation for long-term storage, and no crystallization in winter; the product has no toxicity and pollution, and no formaldehydel and is safe for environment. The invention also discloses a preparation method of the polycarboxylate type water reducer.

Owner:SICHUAN NORMAL UNIVERSITY

Method for manufacturing glazed tile with glaze three-dimensional effect

InactiveCN103193457AAchieve three-dimensional effectUnique effectDecorative surface effectsClaywaresTexture gradientCeramic glaze

The invention relates to a method for manufacturing a glazed tile with a glaze three-dimensional effect. The method comprises a printing process of printing on an unglazed biscuit through a relief silk screen plate with a certain thickness and a relief roller with a certain depth, so as to form texture patterns with a variable concave-convex effect, and a once-firing process, thus preparing the glazed tile with a glaze three-dimensional effect. The glazed tile manufactured by the invention can generate a concave-convex texture gradient effect, and is good in decoration effect, high in durability, good in antifouling performance, variable in patterns, and can well reflect change of the natural color of stone.

Owner:MONALISA GRP CO LTD

Simulation synchronously impressing patterns and facing artificial board production process

ActiveCN101259626AReflect completeSimple methodLamination ancillary operationsNatural patternsHigh rateEngineering

The invention discloses a manufacturing method of an emulational synchronous lines marked facing man-made panel which consists of the following steps: patterns can be obtained by shooting or according to real objects to design the patterns, and the patterns are decomposed into corresponding two parts by using the technology of computer image processing; a grounding pattern is printed on decoration paper, and a texture pattern is made to be a corresponding solid relief sculpture as a die mold; the decoration paper which is printed with the grounding pattern and other planks that are necessary to lead the facing man-made panel to be folded according to requirements; the die mold is corresponding to the decoration paper with the grounding pattern according to an original real object, and the folded planks are thermally pressed by the die mold; dye needed is coated on the surface of the sinking position of the plank pressed, and the emulational synchronous lines marked facing man-made panel can be obtained by removing the dye on the convex part and solidifying the dye. The emulational synchronous lines marked facing man-made panel uses the method to separate plane patterns on the real object patterns from the patterns which can reflect the solid effect, and the method has the advantages of low cost and high rate of finished products when the emulational man-made plate with the solid effect is made.

Owner:POWER DEKOR GROUP

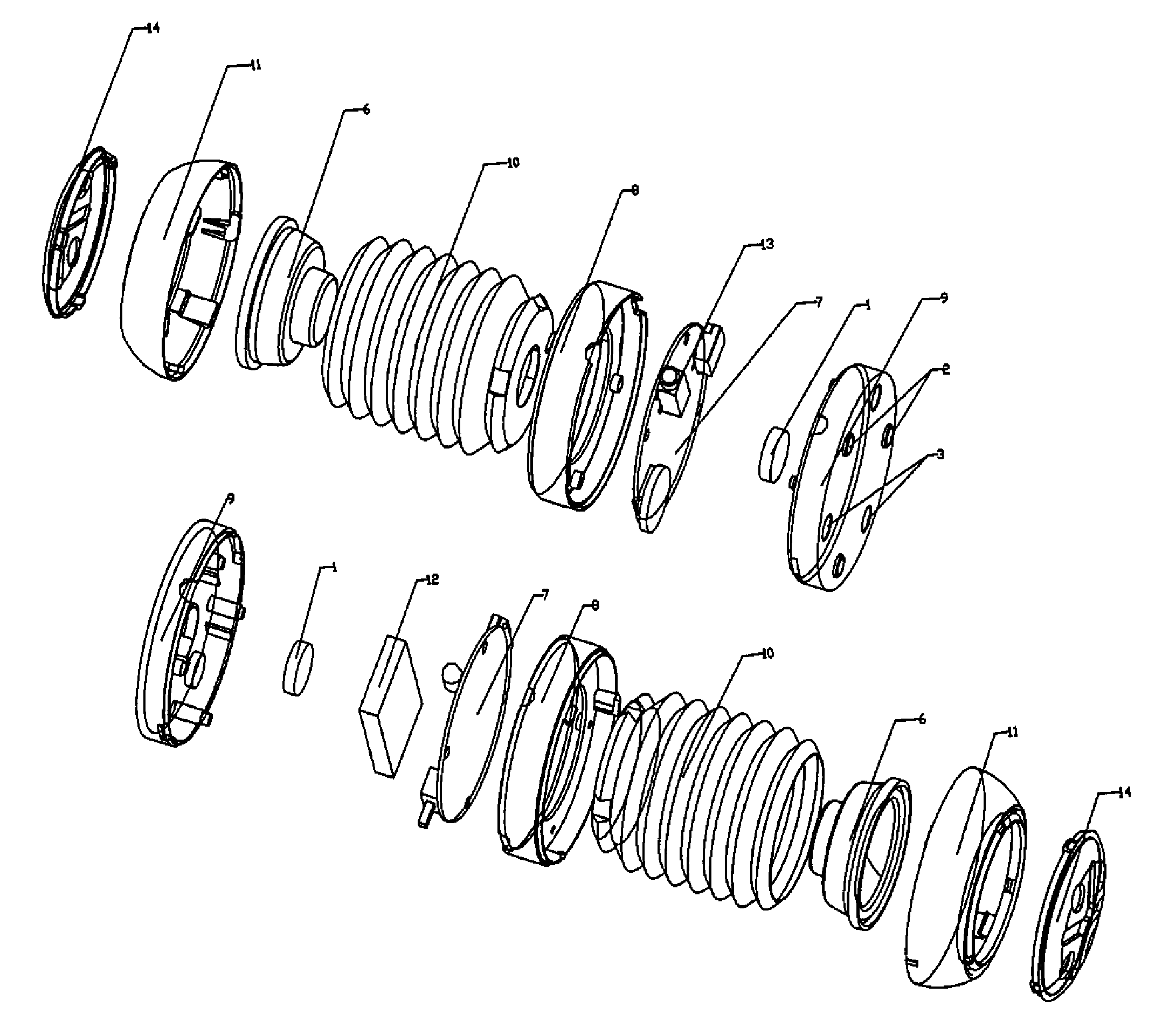

Stereoscopic camera

A stereoscopic camera for stereoscopic photography, which reduces losses in the screen when taking a picture in a close range and provides optimum stereoscopic effect without the need of adjusting the distance between the slides that are being mounted. A camera body is furnished with reflex finders constituted by a pair of right and left photographing lenses and pentaprisms. The distance between optical axes of the photographing lenses is adjusted by a horizontal shifting mechanism. Focusing plates of the right and left finders are marked with vertical lines at the centers and on the right and left sides thereof. The distance between optical axes is adjusted depending upon the distance to the subject and vertical lines of the right and left focusing plates are brought into agreement. Then, the right and left photographing areas are nearly brought into agreement on the real screen and no loss occurs on the screen.

Owner:INABA MINORU

Edge-drawing 3D embossment wallpaper and preparing method thereof

ActiveCN105220580AGood three-dimensionalHigh hardnessCovering/liningsSpecial paperSurface layerPaper based

The invention discloses edge-drawing 3D embossment wallpaper. A paper base layer, a background layer, a high-toughness, high-hardness, high-strength and high-foamed PVC layer and a edge-drawing coating are sequentially arranged from the bottom layer to the surface layer. The invention further discloses a preparing method of the edge-drawing 3D embossment wallpaper. The edge-drawing 3D embossment wallpaper and the preparing method thereof have the advantages that the edge-drawing 3D embossment wallpaper which is good in three-dimensional effect, high in hardness, strength and toughness and not likely to encounter peeling of surface decoration materials is provided, and the edge-drawing 3D embossment wallpaper can be widely applied to indoor decoration and ornament of various public and personal occasions.

Owner:ANHUI BAUHINIA WALLPAPER

Technology for engraving tridimensional wood lines in surface of aluminum profile

InactiveCN103522826AGood three-dimensionalStereo effect is realDecorative surface effectsElectrophoresisMetallurgy

The invention provides a technology for engraving tridimensional wood lines in the surface of an aluminum profile. The technology comprises the following steps of pre-processing the aluminum profile, spraying and curing solidified powder wood lines, removing powder from the surface, washing, spraying spray powder or carrying out oxidation and electrophoresis, and carrying out vacuum transfer printing. According to the technology, the limitation of the traditional aluminum profile spraying technology is broken through, the tridimensional effect of the wood lines is more obvious and authentic, and the visual effect of the tridimensional wood lines is closer to that of real raw wood.

Owner:浙江富丽华铝业有限公司

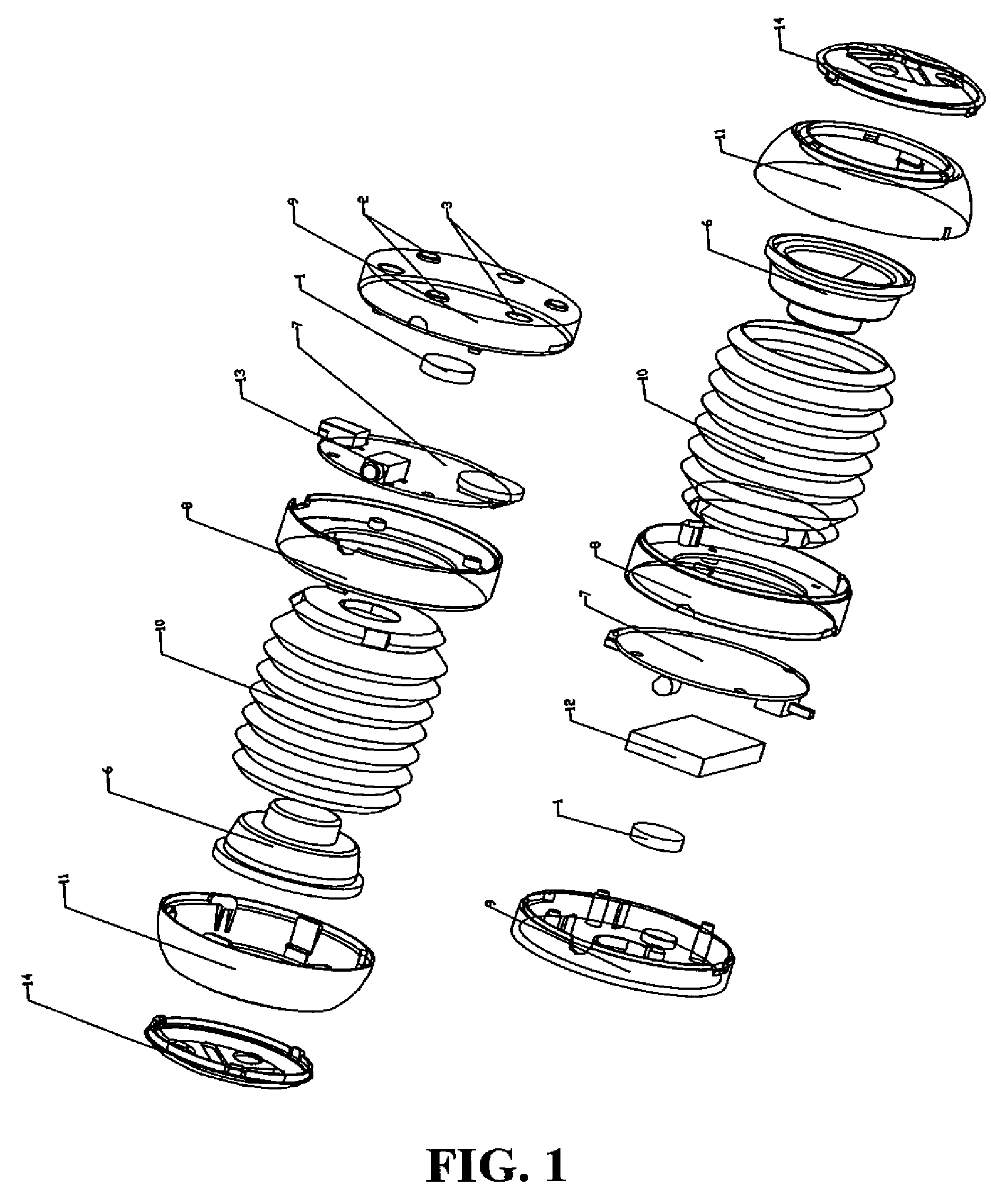

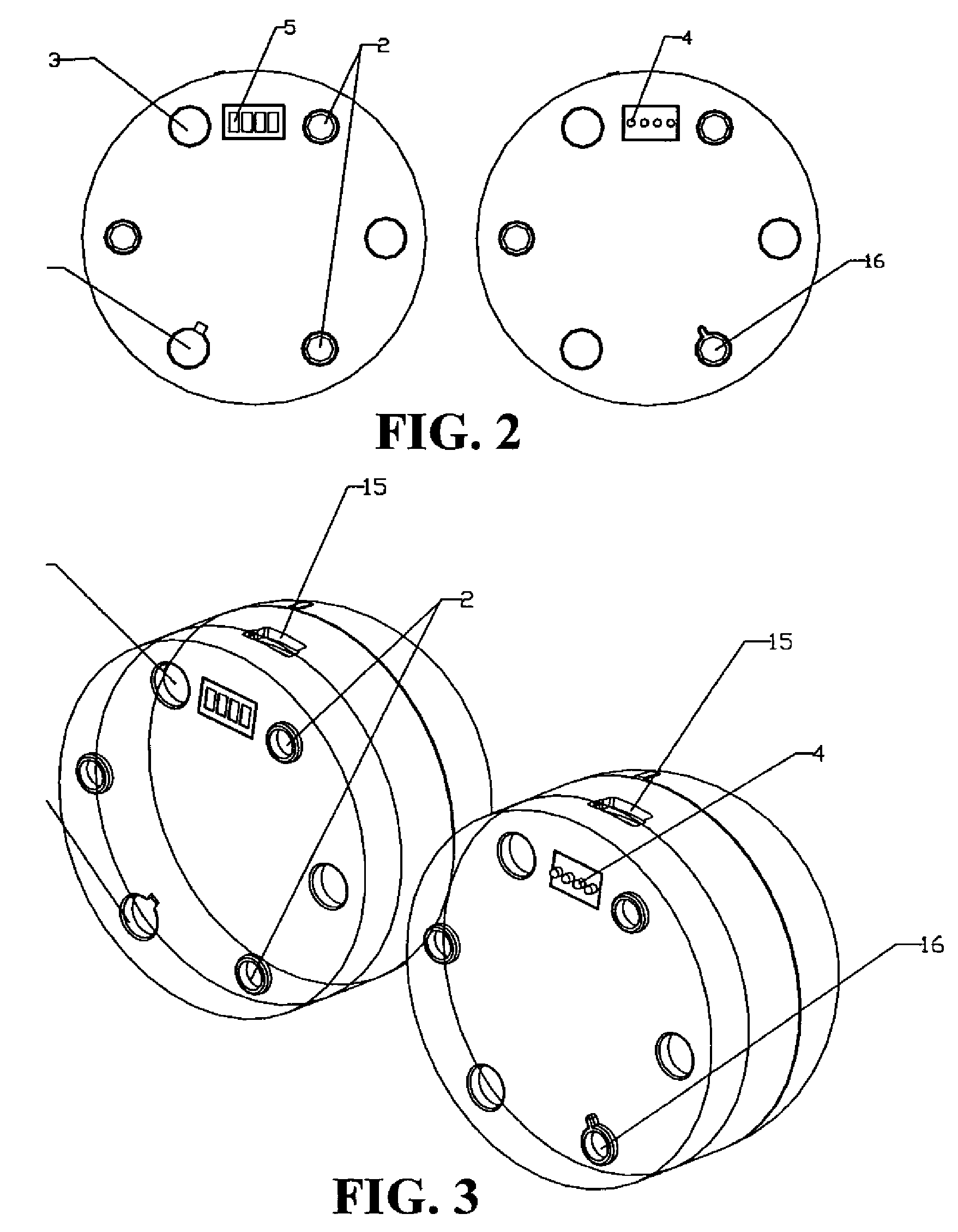

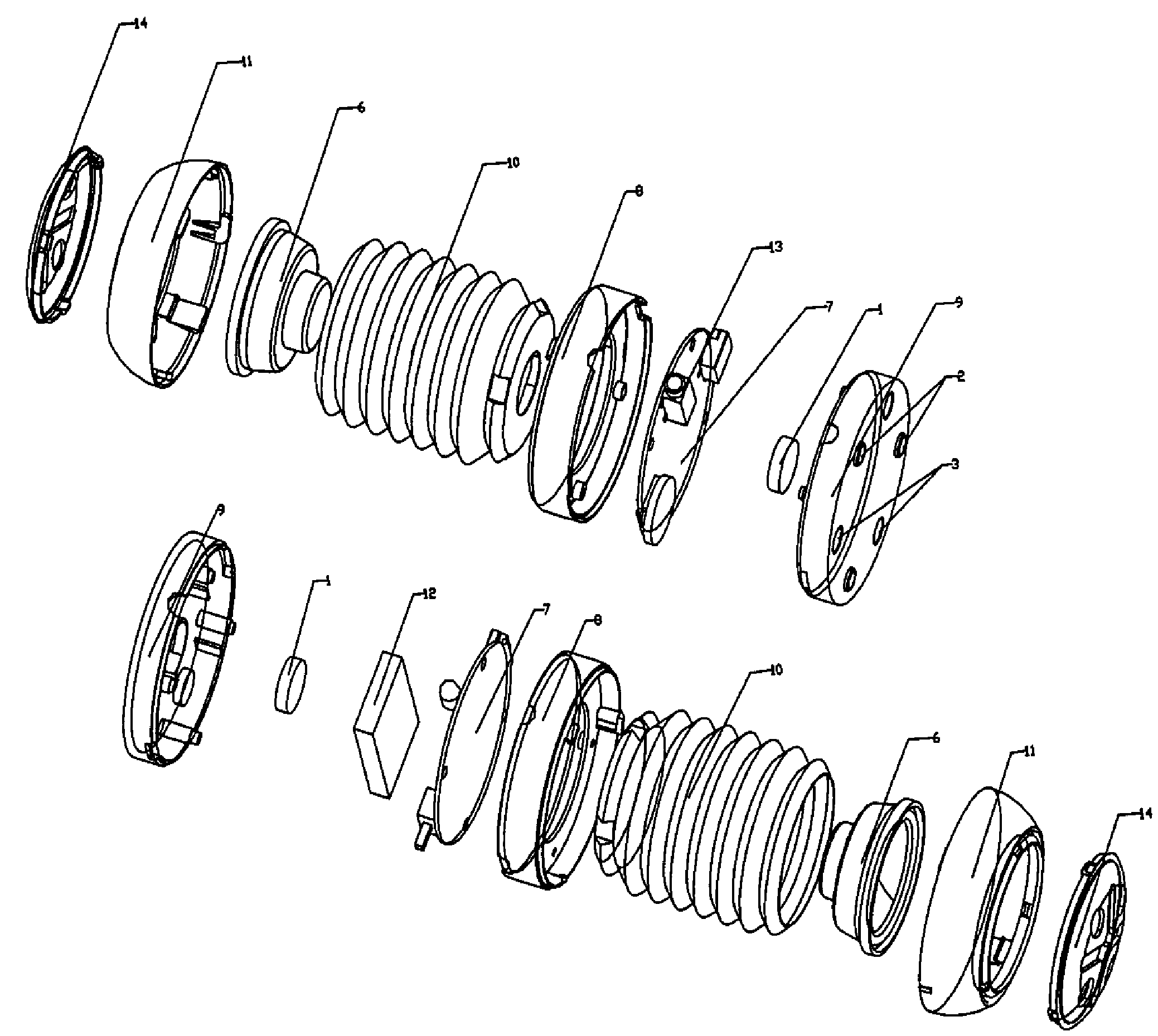

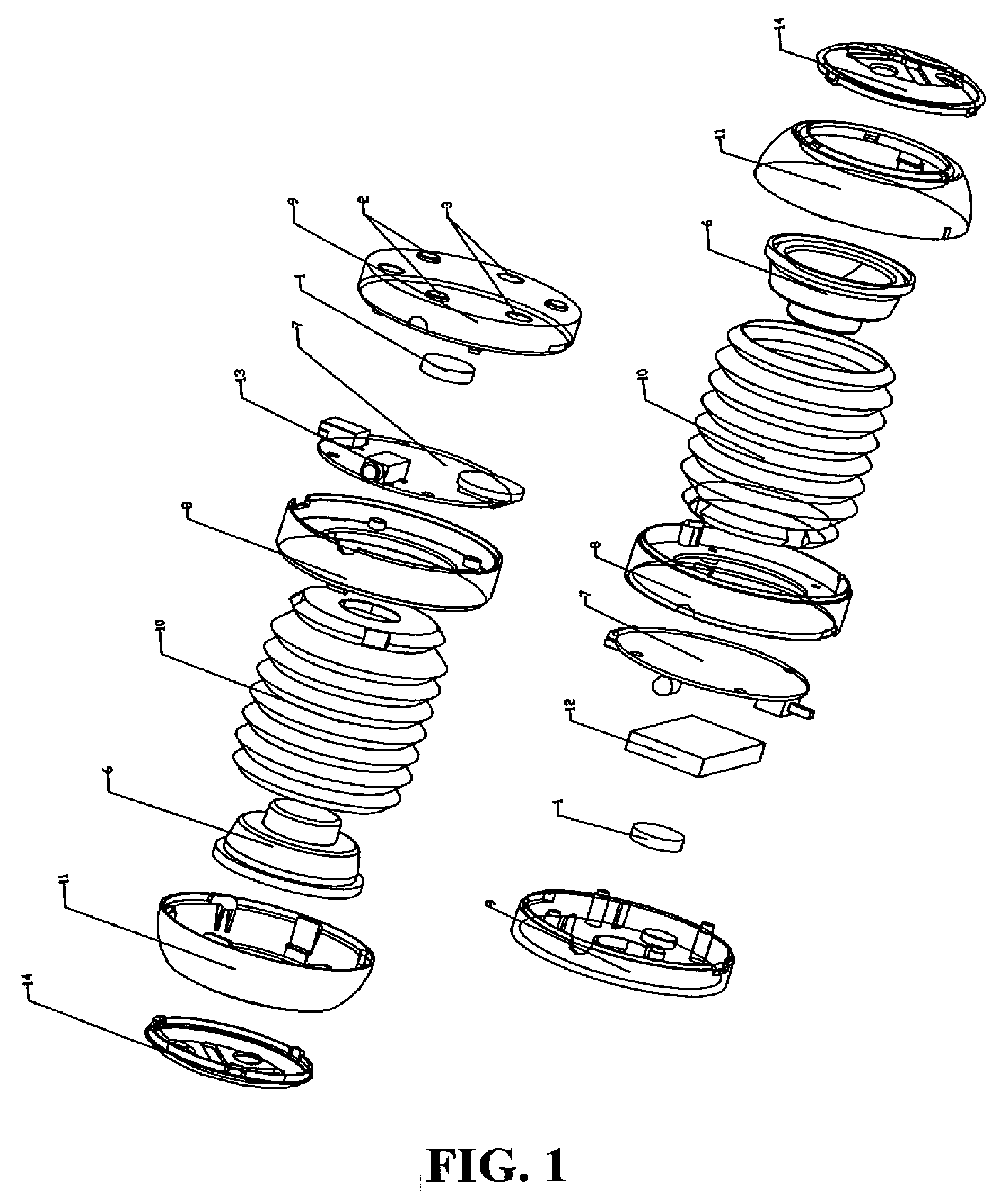

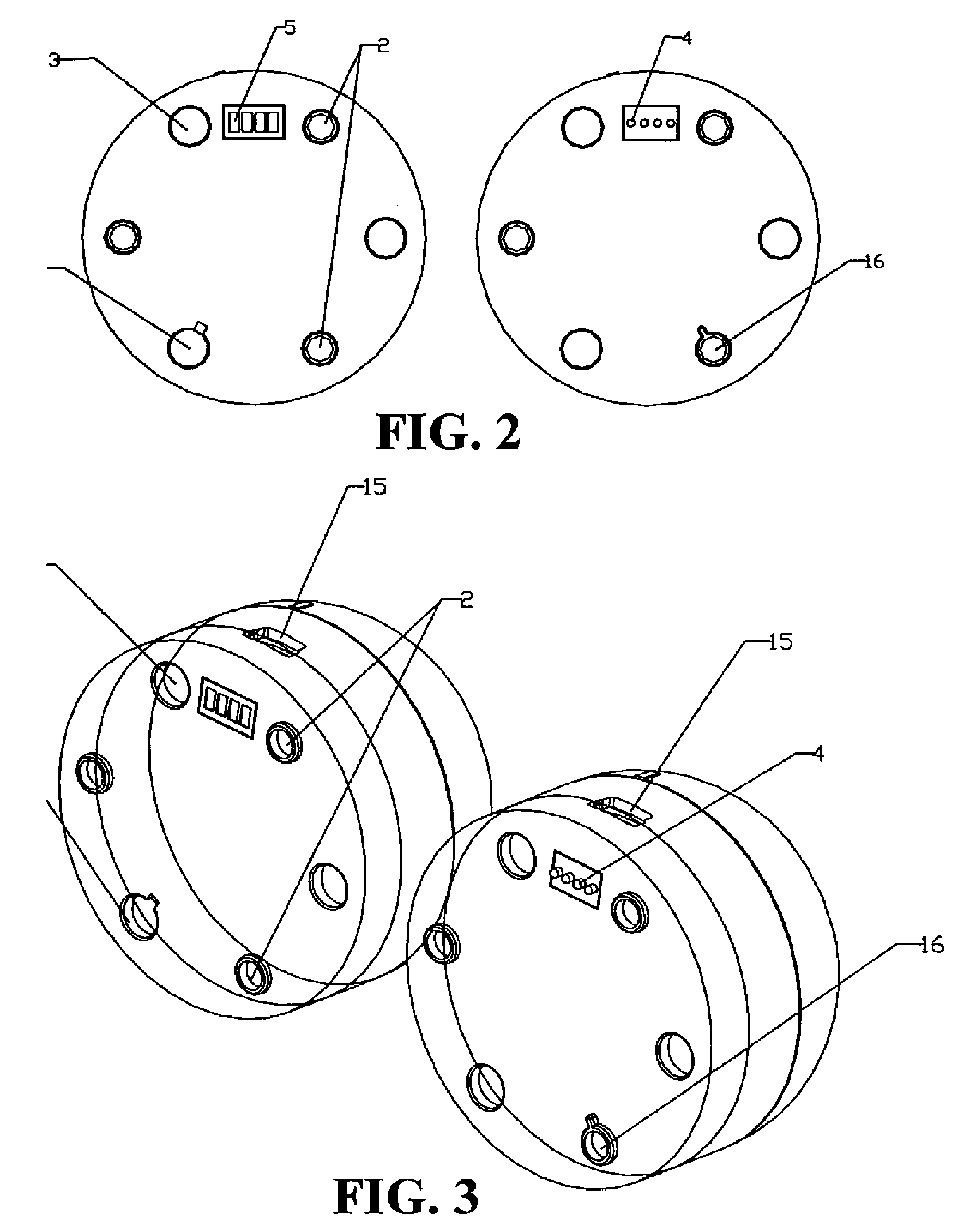

Portable sound box assembly

InactiveUS8094860B2Superior stereo soundEasy to separateLoudspeaker casing supportsCabinetsElectrical polarityEngineering

Owner:SHENZHEN YAGUAN ELECTRONICS CO LTD

Portable sound box assembly

InactiveUS20090175483A1Reliably transportConvenient to assembleLoudspeaker casing supportsCabinetsStereophonic soundMagnet

The present invention generally relates to stereo sound boxes, and more particularly to a sound box assembly containing micro stereo sound boxes joined magnetically together. The sound box assembly contains at least a pair of sound boxes with magnets of opposite polarities, respectively, so that the sound boxes could be magnetically attracted together for convenient transportation and then later could be easily detached for placing apart to achieve superior stereo sound.

Owner:SHENZHEN YAGUAN ELECTRONICS CO LTD

Environment-friendly textile pigment and preparation method thereof

The invention discloses an environment-friendly textile pigment and a preparation method thereof. The pigment is prepared from the following raw materials in parts by weight: 50.0-70.0 parts of styrene-acrylate emulsion, 10.0-20.0 parts of polyvinyl acetate emulsion, 10.0-20.0 parts of ethylene vinyl acetate copolymer emulsion, 0.2-3.0 parts of fumed silica, 0.5-3.0 parts of a polyurethane thickening agent, 2.0-3.0 parts of a film coalescing agent TXIB, 2.0-8.0 parts of glycerol, 5.0-15.0 parts of diisobutyl phthalate, 2.0-3.0 parts of phenoxyethanol, 5.0-15.0 parts of a pigment, 2.0-15.0 parts of calcium carbonate, 0.2-3.0 parts of a coupling agent KH-560, 5.0-15.0 parts of a foaming pigment, 5.0-15.0 parts of a luminous pigment, 5.0-15.0 parts of glitter powder and 0.2-3.0 parts of an emulsifying agent OP-10. The pigment can be quickly dried and has good adhesive force.

Owner:JIANGSU XINGDA STATIONERY GRP

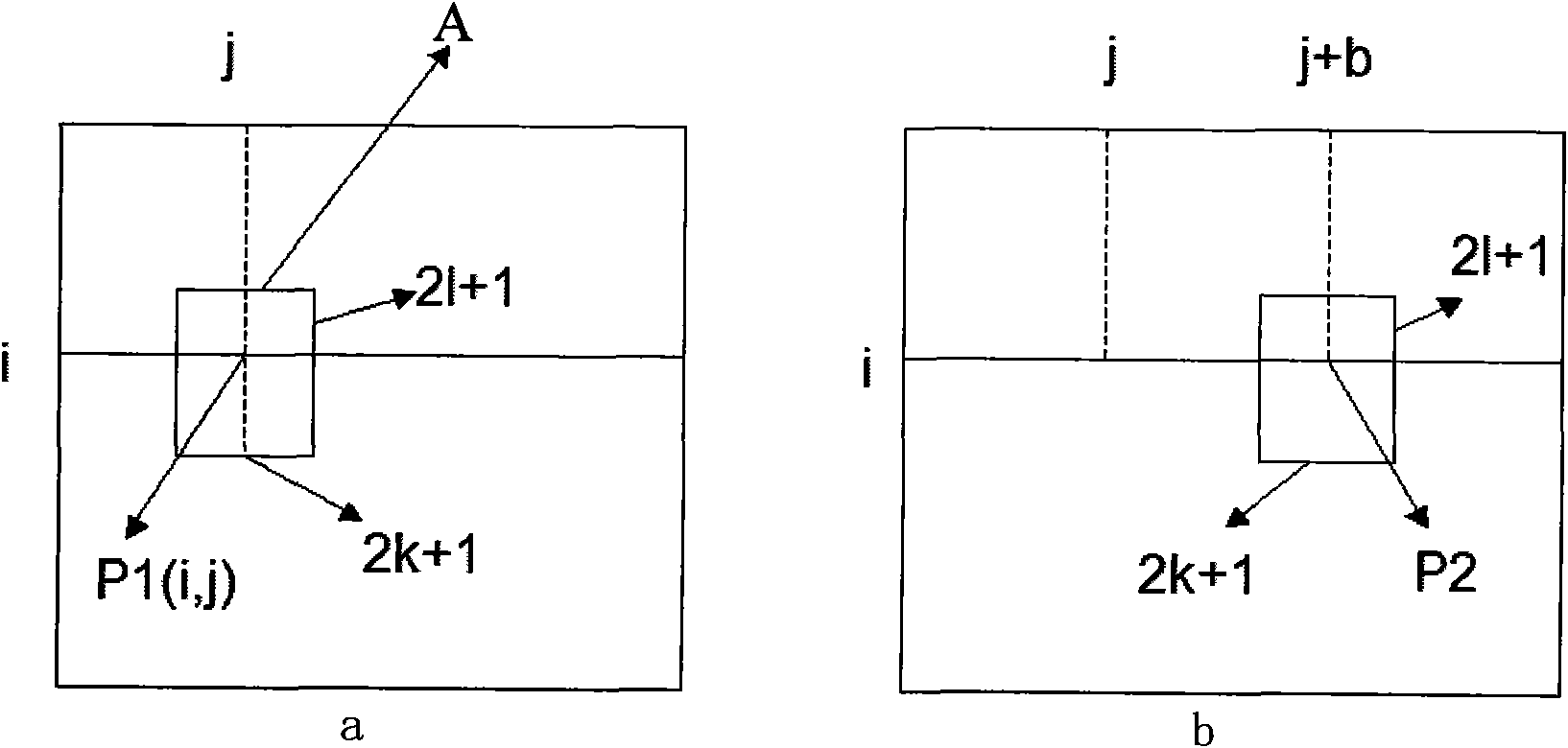

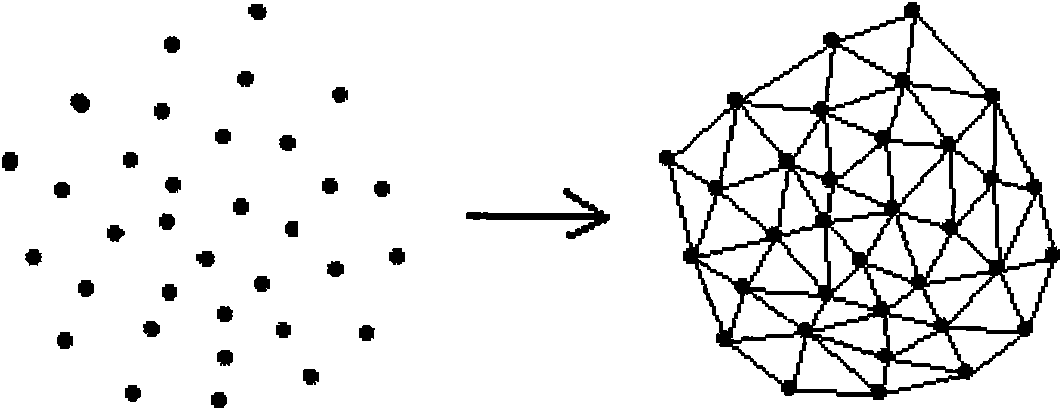

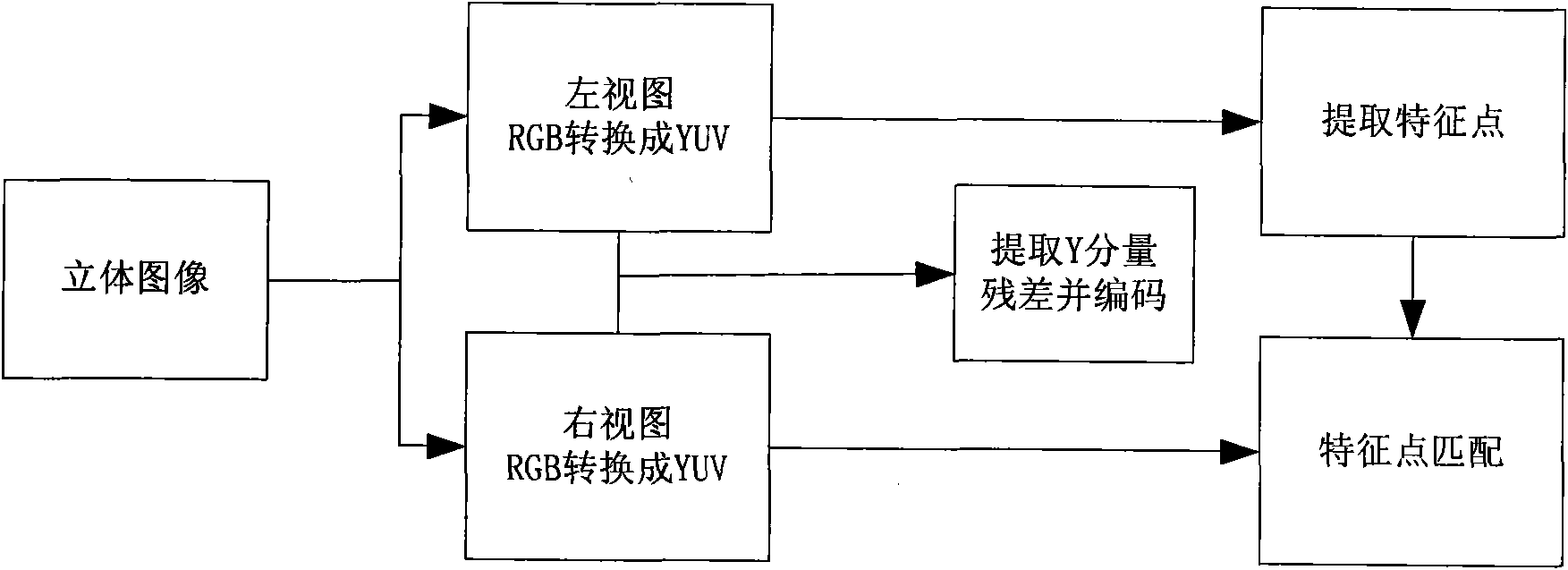

Method for compressing three-dimensional image video sequence

InactiveCN101610422AReduce data volumeGood three-dimensional effectTelevision systemsDigital video signal modificationJPEGPoint match

The invention relates to a method for compressing three-dimensional image video sequence, comprising left view L and right view R of three-dimensional image are respectively converted into YUV4:2:0; feature points of the left view L are extracted, and then the left view L is processed by Delaunay triangular mesh subdivision; points matched with the feature points of the left view L are found out in the right view R; hollow triangular mesh of the right view R is set up, and right view R' is filled out; residual information Y' of Y component between the original right view R and the filled out right view R' is then extracted; DCT transformation as well as quantization and entropy coding are carried out, and a JPEG method is used for compressing the left view L. According to the information of the matched feature point set of the left and the right views, every triangle in the left view is treated by affine transformation; the YUV information of the left view and the right view which is newly set up is transformed into RGB information, left and right three-dimensional diagram pairs can be obtained after being uncompressed and then transformed into three-dimensional image according to the display way. The method reduces the data volume of the three-dimensional image, and the three-dimensional image which is decoded and restored has good three-dimensional effect, no uncomfortable feeling and clear image. After being decoded, the image has higher similarity with the original image.

Owner:TIANJIN UNIV

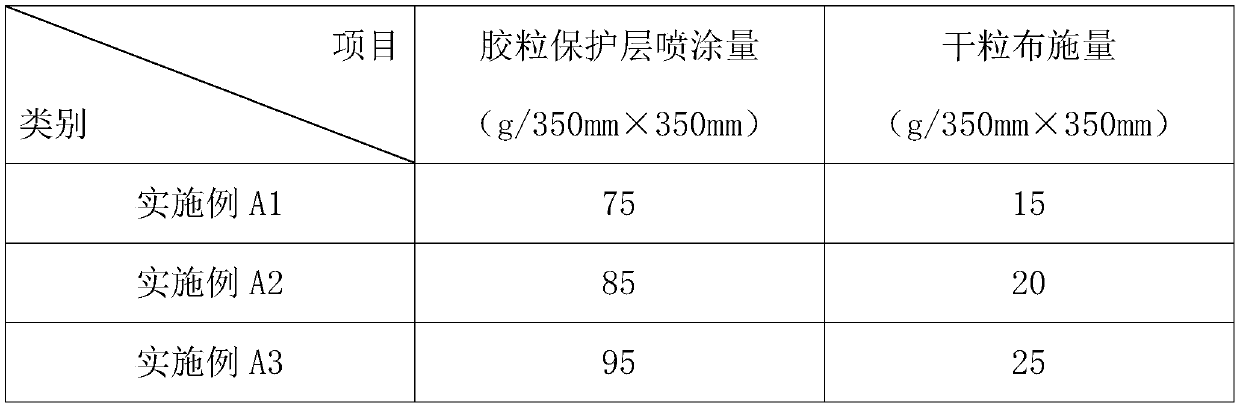

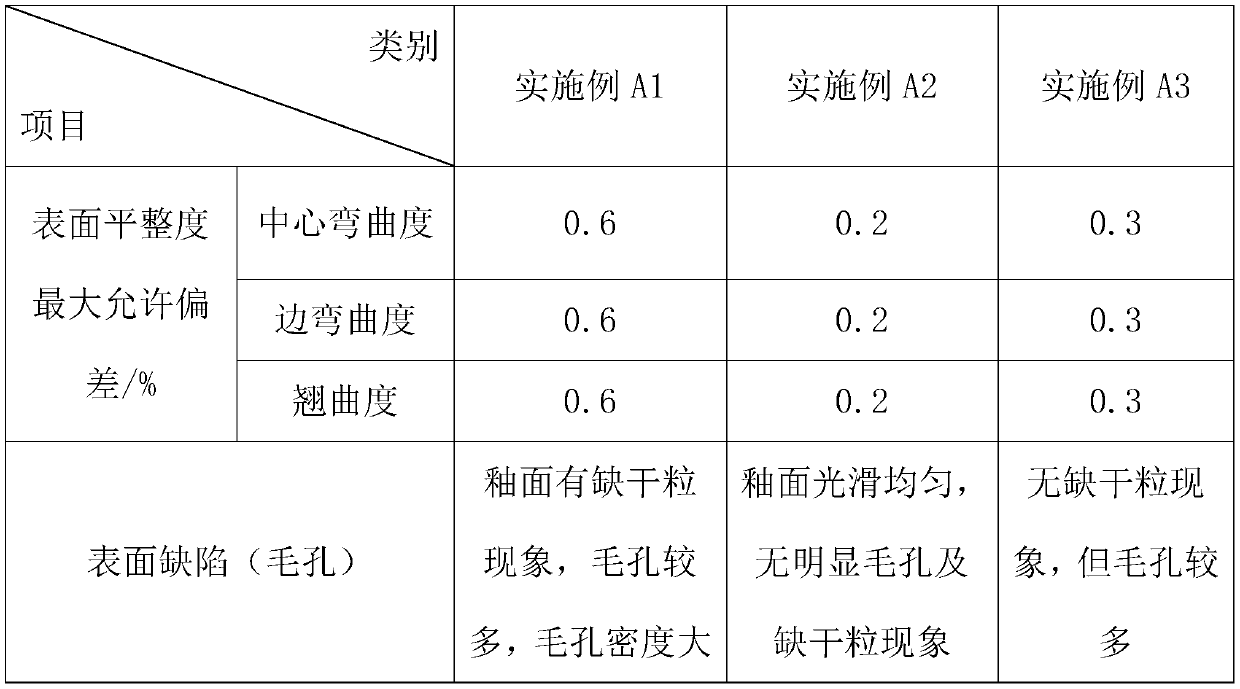

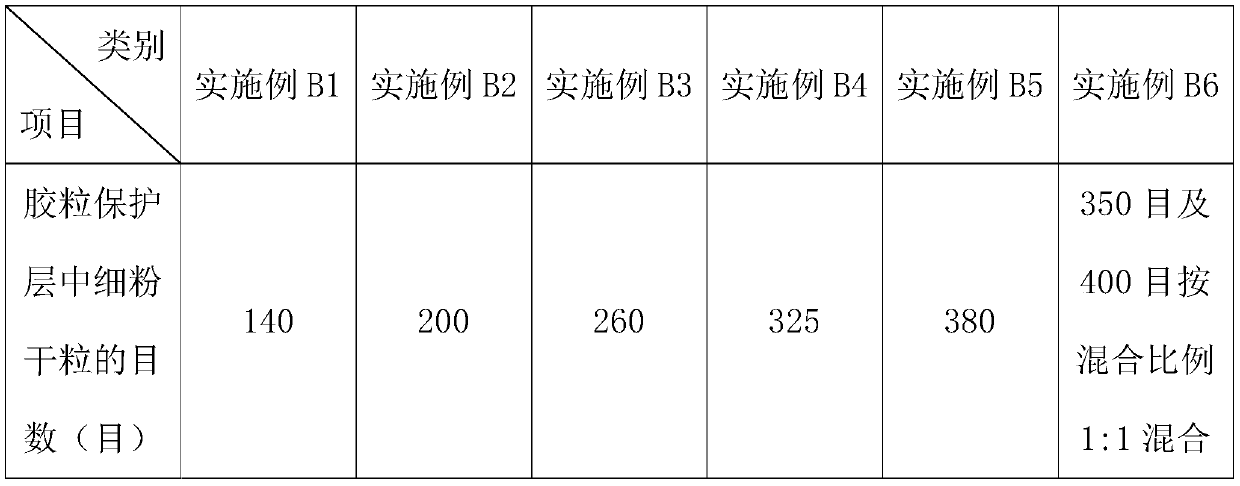

Three-dimensional multicolor dry-grain polished ceramic large plate and preparation method thereof

ActiveCN110668792AImprove adaptabilityImprove flatnessCeramic materials productionClaywaresTextile printerAdhesive glue

The invention relates to the technical field of architectural ceramics, in particular relates to a three-dimensional multicolor dry-grain polished ceramic large plate and a preparation method thereof.The three-dimensional multicolor dry-grain polished ceramic large plate sequentially comprises a green body layer, a ground coat layer, an ink-jet printing layer, a colloidal particle protection layer, a dry grain layer and a surface adhesive layer from bottom to top, wherein the colloidal particle protective layer comprises ceramic glue and fine powder dry particles, and the addition amount of the ceramic glue and the fine powder dry particles is 100: (20-40) in parts by weight; and the particle size of fine dry particles in the colloidal particle protective layer is smaller than that of dryparticles in the dry particle layer. According to the three-dimensional colorful dry-grain polished ceramic large plate and the preparation method thereof, the ceramic large plate prepared through the method is higher in surface flatness and brightness, the pattern effect of the ink-jet printing layer is more three-dimensional, and the overall decorative effect and practical performance of a ceramic large plate product can be effectively improved.

Owner:FOSHAN DONGPENG CERAMIC +3

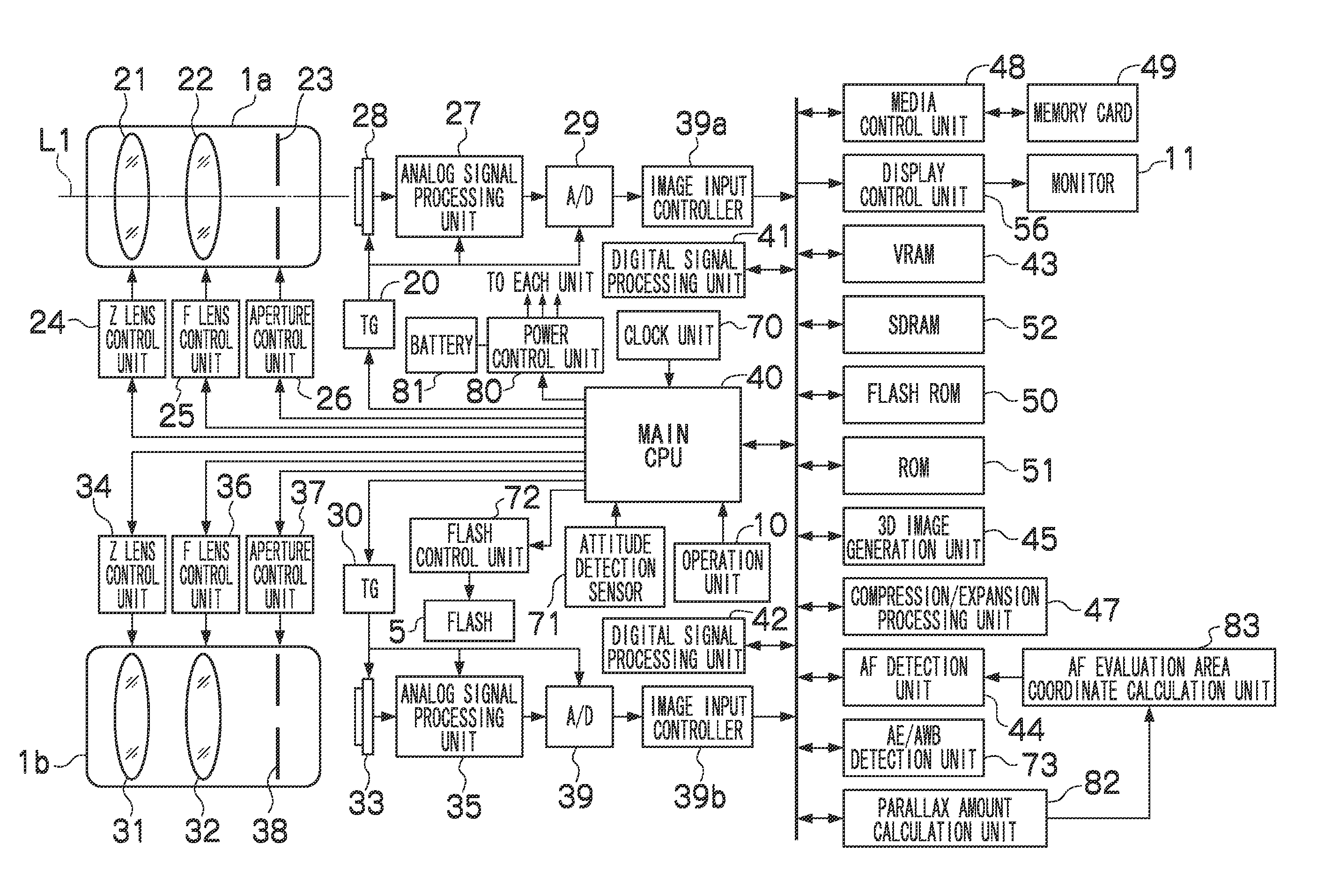

Imaging device, imaging method and recording medium for adjusting imaging conditions of optical systems based on viewpoint images

InactiveUS8773509B2Good three-dimensionalEnhance the imageTelevision system detailsPhotometryParallaxImaging condition

An imaging method includes: calculating an amount of parallax between a reference optical system and an adjustment target optical system; setting coordinates of an imaging condition evaluation region corresponding to the first viewpoint image outputted by the reference optical system; calculating coordinates of an imaging condition evaluation region corresponding to the second viewpoint image outputted by the adjustment target optical system, based on the set coordinates of the imaging condition evaluation region corresponding to the first viewpoint image, and on the calculated amount of parallax; and adjusting imaging conditions of the reference optical system and the adjustment target optical system, based on image data in the imaging condition evaluation region corresponding to the first viewpoint image, at the set coordinates, and on image data in the imaging condition evaluation region corresponding to the second viewpoint image, at the calculated coordinates, and outputting the viewpoint images in the adjusted imaging conditions.

Owner:FUJIFILM CORP

Color-changing three-dimensional fabric and manufacturing method thereof

ActiveCN106835466AGuaranteed breathabilityGood three-dimensionalWeft knittingEngineeringColor changes

Owner:SINCETECH FUJIAN TECH CO LTD +1

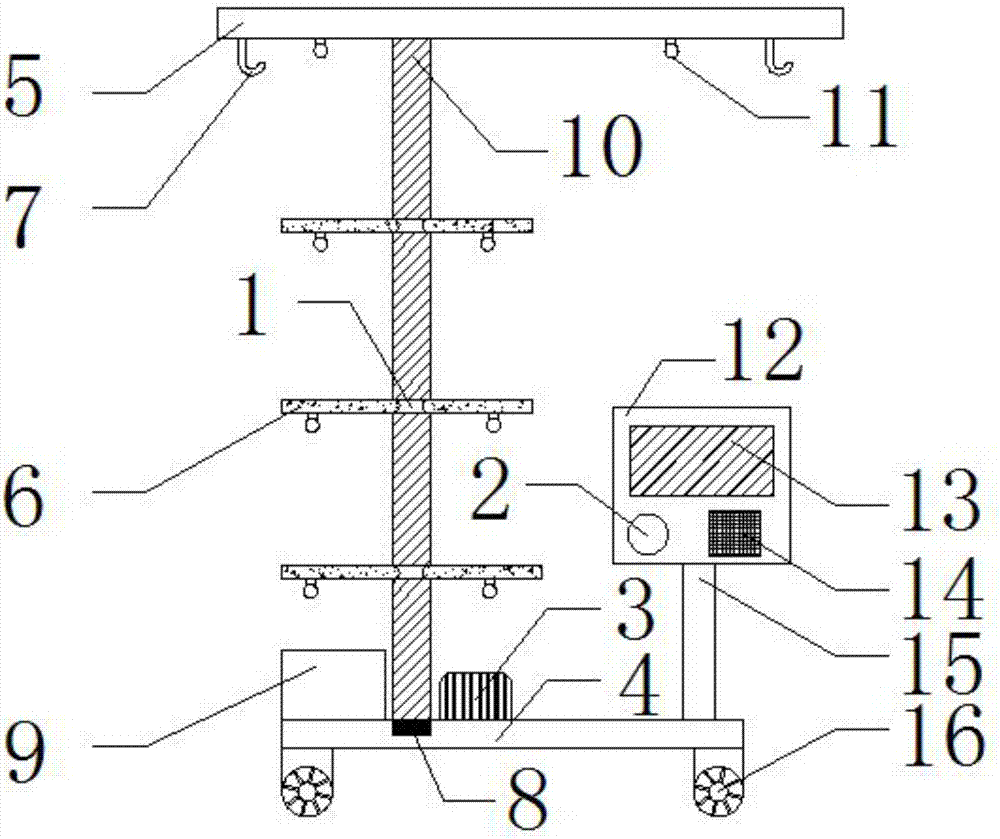

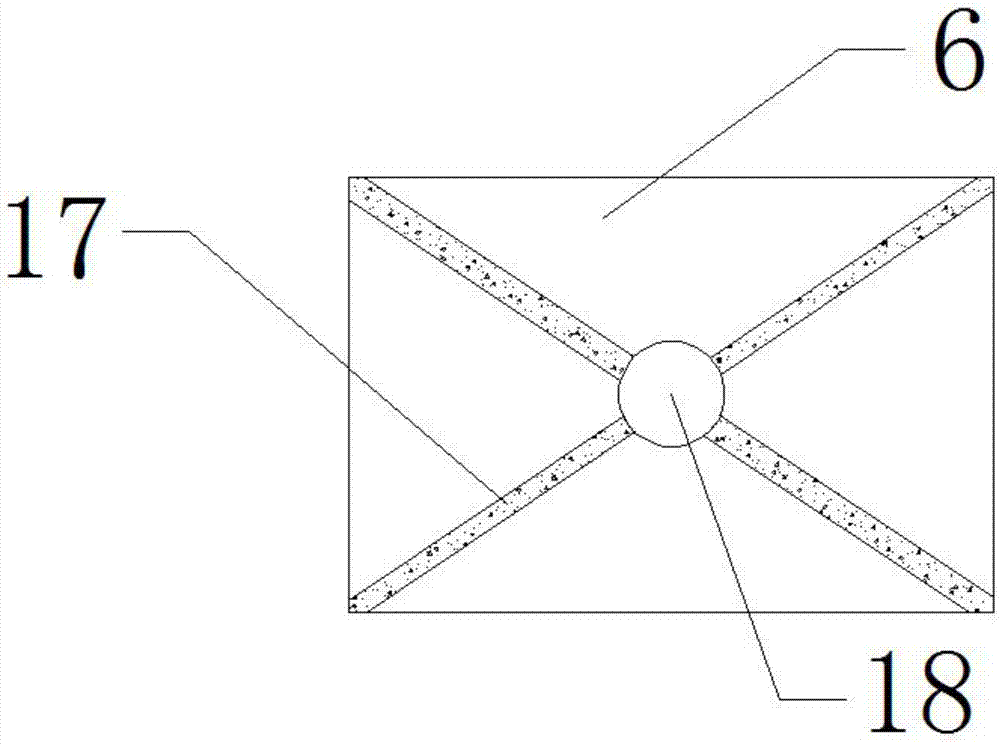

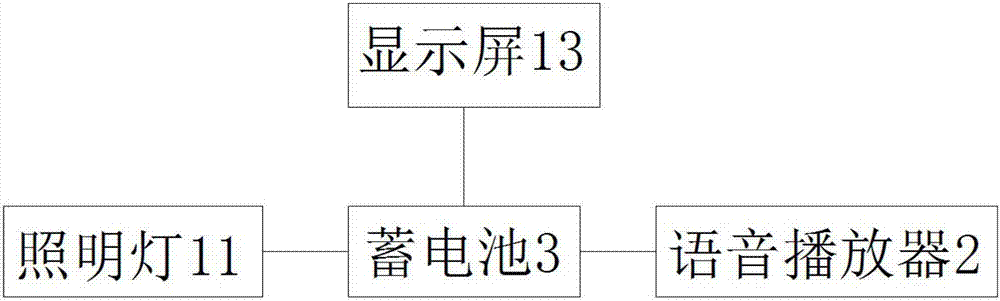

Portable exhibition showcase

InactiveCN107307686AReasonable designNovel structureAudible advertisingShow shelvesManagement science

Owner:汝州市中鼎科技有限公司

Waterproof cubic three-dimensional tweed

ActiveCN101624745AGood water and oil repellencyWith self-cleaning functionHeating/cooling textile fabricsWoven fabricsWoolMaterials science

The invention discloses waterproof cubic three-dimensional tweed which contains 92-95 percent of wool by weight and 5-8 percent of Lycra by weight. The surface material of the tweed adopts a 1 / 1 single-layer plain structure together with a 3 / 1 and 1 / 3 double-layer plain structure. The double-layer plain structure and the single-layer plain structure follow a proportion of 1:1 on the surface of the tweed. The tweed has good three-dimensional effect, bidirectional elasticity, waterproofness and oil repellency.

Owner:JIANGSU AOYANG TEXTILE IND

Production method of metal etching handicraft picture

The invention discloses a production method of a metal etching handicraft picture. The production method comprises the following steps of: exposing a black and white film on a substrate coated with metal photosensitive ink, performing developing treatment, cleaning, etching and re-cleaning in sequence, performing drying, wire drawing treatment and sealing, and storing a finished product. The production method has the advantages that an etching effect is good, especially for the handicraft picture with fine etching lines, as a side protective agent is added in etching liquid, grain marks are clear and complete when the handicraft picture is etched, the phenomenon that the grain marks are unclear caused by side corrosion cannot occur, a V-shaped structure is formed at the bottom of patterns in etching, the patterns and texts which are etched in the substrate show a stereo effect, especially the texts are etched, the stereo effect is good, and the patterns and fonts cannot discolor or deform so as to be convenient to keep for a long time. The etching method disclosed by the invention can be used for ensuring an attractive effect of the product, and is high in etching efficiency which is dozens of times that of a mechanical engraving machine, so that the working efficiency is greatly improved. The production method can be widely applied in multiple industries.

Owner:张永平

Production method of craft picture by utilizing natural river stones

InactiveCN104476974AGood three-dimensionalEasy to storeDecorative surface effectsSpecial ornamental structuresVarnishEngineering

The invention relates to a production method of a craft picture by utilizing natural river stones. The production method comprises the following steps: designing patterns; selecting a hard soleplate, and selecting raw stones, sand and stone powder, which are matched with the patterns, from a river; washing the selected stones by utilizing clean water, and screening the stones; directly drawing the design drawing on a soleplate by the hand, or printing the design drawing on the soleplate by virtue of a piece of carbon paper, or cutting paper into pieces shaped like the patterns in the design drawing, and pasting the paper pieces onto the soleplate; preparing transparent glue; drawing the outline of the patterns which are drawn by the hand on the soleplate by utilizing glue, or drawing the outlines of the patterns which are printed on the soleplate by utilizing the glue, or drawing the outlines of lines of the patterns on the soleplate by utilizing the glue, removing the paper pieces, and fully coating the patterns with the glue; adhering stone sand, stone powder and / or raw stones on the patterns; washing a combined picture by utilizing an abstergent; and coating the surface of the combined picture with varnish to obtain the craft picture. Compared with the prior art, for the production method, the three-dimensional effect of the picture is embodied by reasonably combining the river stones, the sand and the stone powder. The craft picture is attractive, firm, fadeless, difficult to drop and convenient to store.

Owner:吕珊蔚 +1

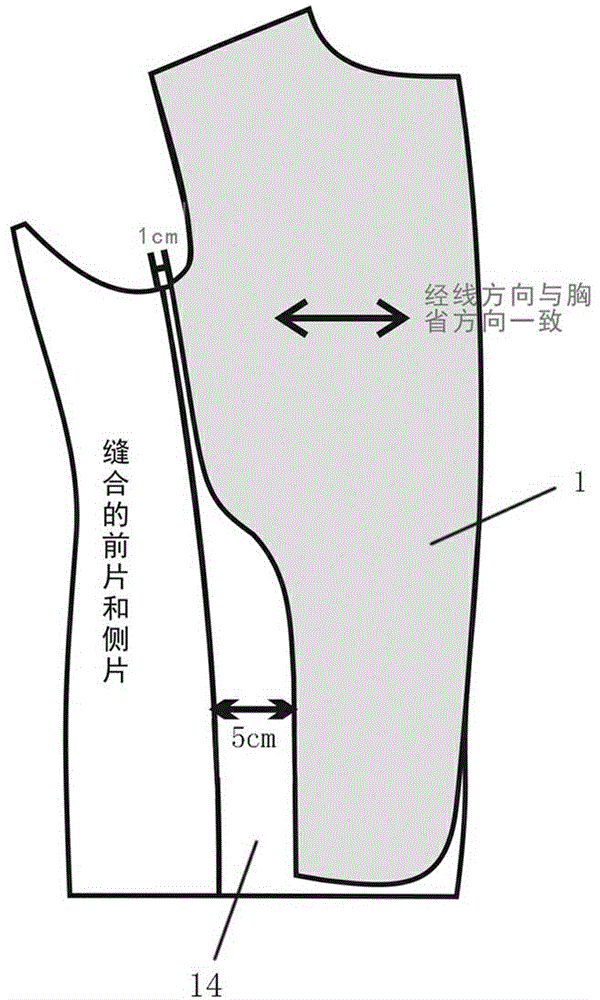

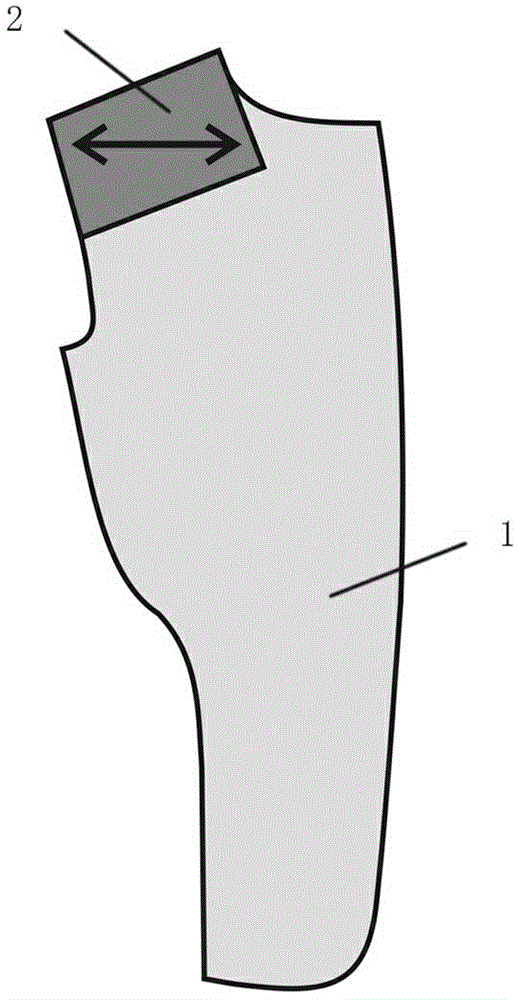

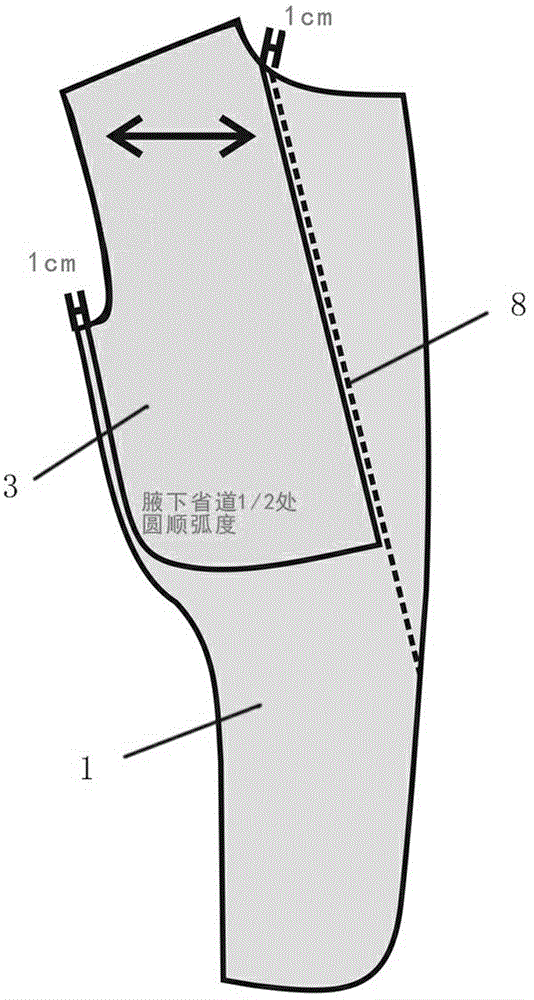

Business suit chest interlining and production method thereof

The invention relates to a business suit chest interlining and a production method thereof. The production method of the business suit chest interlining aims at solving the problem that in the prior art, men's suits are poor in shape preserving performance and comfort. According to the technical scheme, the business suit chest interlining is characterized by comprising a hair interlining with the length which is identical to that of a garment piece front part and a shoulder piece, a horse hair interlining and black chest cotton which are sequentially stacked up on the hair interlining; the hair interlining, the shoulder piece, the horse hair interlining and the black chest cotton are sewed into a whole manually. The production method of the chest interlining comprises steps of a, preparing the hair interlining, the shoulder piece, the horse hair interlining and the black chest cotton; b, fixing the hair interlining, the shoulder piece and the horse hair interlining; c, fixing the black chest cotton onto a interlining body which is obtained from the step b, diving three areas and sequentially sewing the three areas in a stitching mode as a Chinese character eight. The business suit chest interlining and the production method thereof is mainly applied to the technical field of clothing.

Owner:老合兴洋服(杭州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com