Waterproof cubic three-dimensional tweed

A cubic and three-dimensional technology, applied in the field of textile fabrics, can solve the problems of easy wrinkling, no three-dimensional effect, and no recovery, and achieve good waterproof and oil-proof effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

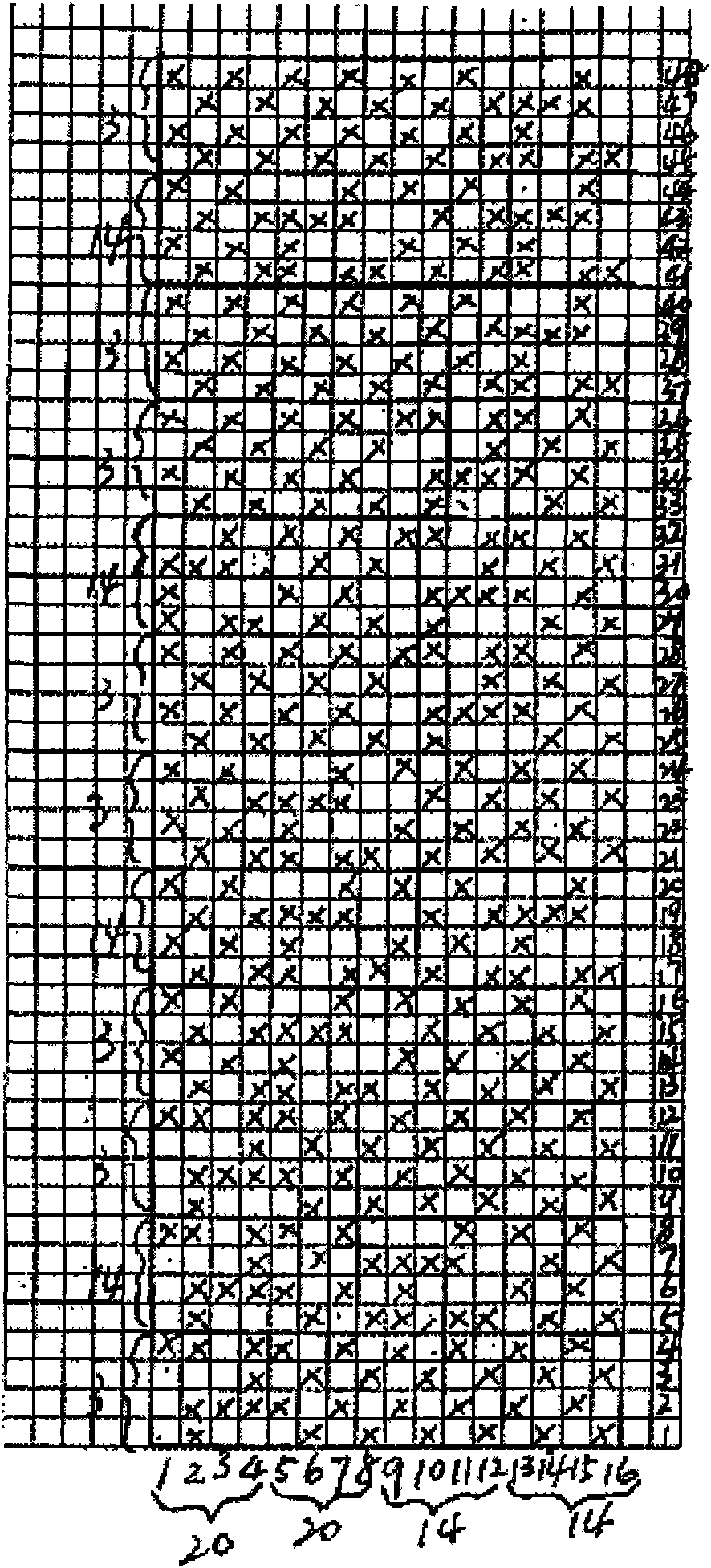

Image

Examples

Embodiment 1

[0023] Raw material: Wool / Lycra=93.78 / 6.22 (wool is 80S Australian wool, Lycra is 40D / 1 DuPont Lycra). Yarn count: 70 / 2*70 / 2, twist coefficient: 145 / 145, drafting speed ratio of wool and Lycra: 1:2.5, warp density: 287 threads / 10cm, weft density: 260 threads / 10cm, total tightness Degree: 92.5, meter weight: 310g, finished product width: 150cm.

[0024] Specific production steps: top dyeing-spinning-weaving-repair-singeing-flat washing-drying-heat setting-mud washing-double cooking-drying-cooking-brush cutting-waterproof, oil-proof finishing-baking- Intermediate inspection - wet - dry - finished product.

[0025] Among them, heat setting temperature: 190°C, speed ratio: 40m / min; waterproof, oil-proof: speed: 8m / min; temperature: 170°C, additive SL-NEW (manufactured by Ciba Essence China Co., Ltd.): added The amount is 5% of the weight of the fabric per meter. The parameters used in other steps can be realized according to the production parameters of conventional wool spinni...

Embodiment 2

[0031] Raw material: Wool / Lycra=92 / 8 (the wool is 80S Australian wool, and the Lycra is 40D / 1 DuPont Lycra). Yarn count: 70 / 2*70 / 2, twist coefficient: 145 / 145, drafting speed ratio of wool and Lycra: 1:2.5, warp density: 287 threads / 10cm, weft density: 260 threads / 10cm, total tightness Degree: 92.5, meter weight: 310g, finished product width: 151cm.

[0032] Specific production steps: top dyeing-spinning-weaving-repair-singeing-flat washing-drying-heat setting-mud washing-double boiling-drying-cooked repair-brush cutting-waterproof and oil-proof finishing-baking-middle Check-wet-dry-finished product.

[0033] Heat setting temperature: 195°C, speed ratio: 45m / min; waterproof, oil-proof: speed: 8m / min, temperature: 160°C, additive SL-NEW (manufactured by Ciba Essence China Co., Ltd.): adding amount is 5% of fabric weight per meter. The parameters used in other steps can be realized according to the production parameters of conventional wool spinning fabrics.

[0034] In the ...

Embodiment 3

[0039] Raw material: Wool / Lycra=95 / 5 (wool is 80S Australian wool, Lycra is 40D / 1 DuPont Lycra). Yarn count: 70 / 2*70 / 2, twist coefficient: 145 / 145, drafting speed ratio of wool and Lycra: 1:2.5, warp density: 285 threads / 10cm, weft density: 265 threads / 10cm, total tightness Degree: 95, meter weight: 315g, finished product width: 152cm.

[0040]Specific production steps: top dyeing-spinning-weaving-repair-singeing-flat washing-drying-heat setting-mud washing-double boiling-drying-cooked repair-brush shearing-waterproof, oil-proof finishing-baking- Intermediate inspection - wet - dry - finished product.

[0041] Among them, heat setting temperature: 190°C, speed ratio: 40m / min; waterproof, oil-proof: speed: 10m / min; temperature: 165°C, additive SL-NEW (produced by Ciba Essence China Co., Ltd.): add The amount is 4% of the weight of the fabric per meter. The parameters used in other steps can be realized according to the production parameters of conventional wool spinning fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com