Normal temperature curing solvent type two-component erasable coating and preparation method thereof

A room temperature curing, solvent-based technology, used in the field of coatings, can solve the problems of good rewritability, rewritable coatings cannot have both normal temperature film formation and high adhesion, and achieves excellent mechanical properties and weather resistance. , good rewritability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

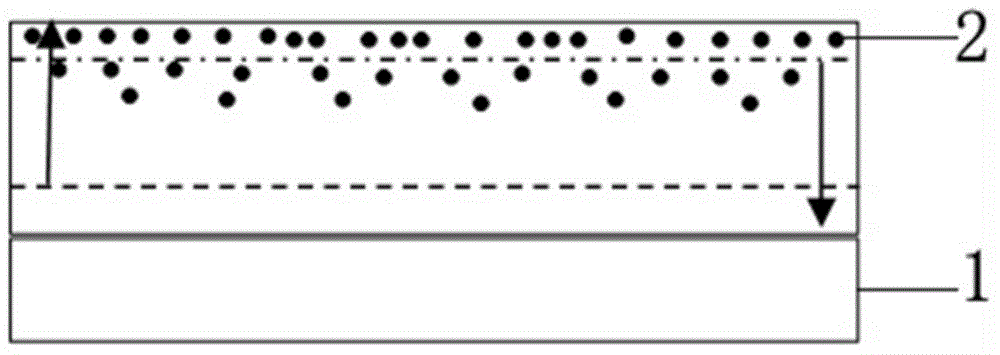

Image

Examples

preparation example Construction

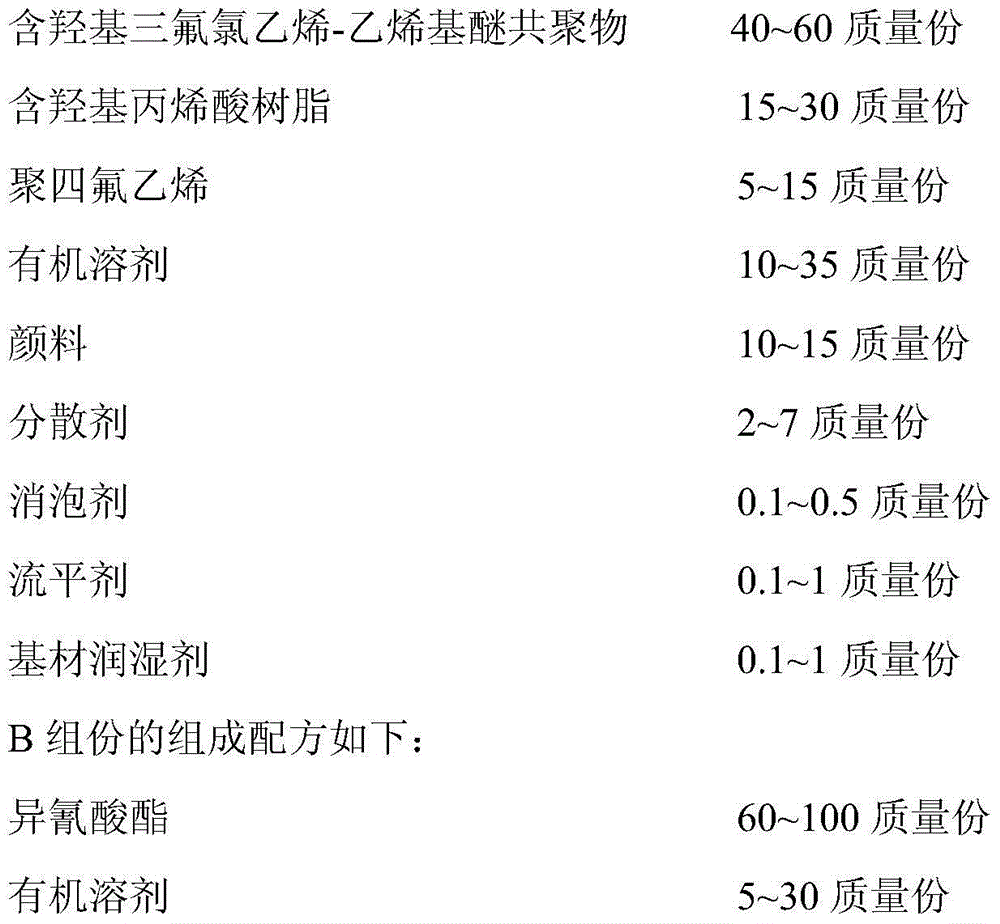

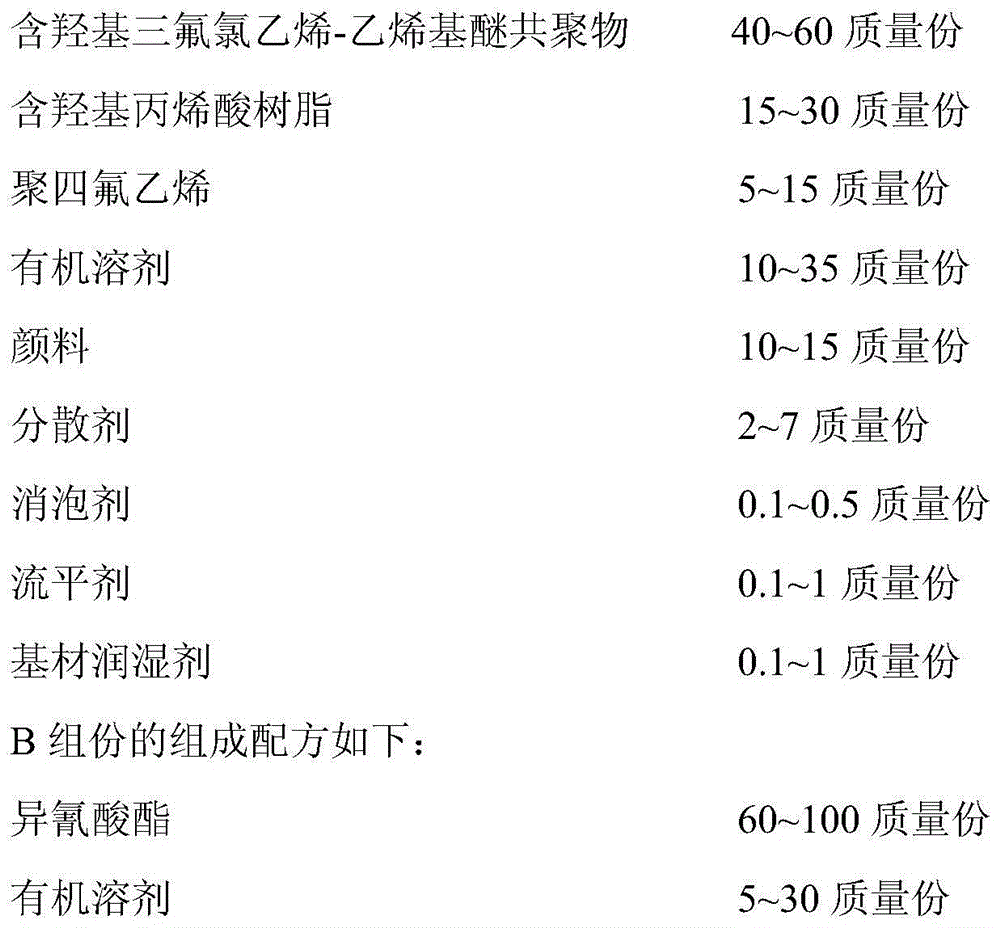

[0040] The preparation method of the two-component solvent-type rewritable coating cured at room temperature comprises the following steps:

[0041] a. Preparation of component A

[0042] Step 1. Take 30-50% of the formula amount of organic solvent, add the formula amount of pigment, the formula amount of polytetrafluoroethylene and 10-20% of the formula amount of dispersant, and use a high-speed disperser to pre-disperse to obtain a slurry, wherein , the rotating speed is 1000~3000 rpm, and the dispersion time is 30~90min;

[0043] Step 2, placing the slurry obtained in step 1 in a three-roll grinder, and grinding until the slurry has a fineness of 10-20 μm to obtain a color paste;

[0044]Step 3, mixing the hydroxyl-containing chlorotrifluoroethylene-vinyl ether copolymer of the formulation amount, the hydroxyl-containing acrylic resin of the formulation amount with the organic solvent of the remaining formulation amount, adding the color paste obtained in step 2, the dispe...

Embodiment 1

[0050] The organic solvent described in this embodiment is butyl acetate:cyclohexane:ethylene glycol butyl ether mixed in a volume ratio of 7:2:1; the pigment is rutile titanium dioxide.

[0051] A method for preparing a two-component solvent-type rewritable coating cured at room temperature, comprising the following steps:

[0052] a. Preparation of component A

[0053] Step 1. Take 8 parts by mass of organic solvent, add 12 parts by mass of pigment, 10 parts by mass of polytetrafluoroethylene and 0.75 parts by mass of dispersant, and use a high-speed disperser to pre-disperse to obtain a slurry, wherein the rotating speed is 2000 rpm. Dispersion time 60min;

[0054] Step 2, placing the slurry obtained in step 1 in a three-roll mill, and grinding until the slurry has a fineness of 15 μm to obtain a color paste;

[0055] Step 3, mix 50 mass parts of hydroxyl-containing chlorotrifluoroethylene-vinyl ether copolymer, 20 mass parts of hydroxyl-containing acrylic resin with 12 m...

Embodiment 2

[0061] The organic solvent described in this embodiment is butyl acetate:cyclohexane:ethylene glycol butyl ether mixed in a volume ratio of 6:1:1; the pigment is rutile titanium dioxide.

[0062] A method for preparing a two-component solvent-type rewritable coating cured at room temperature, comprising the following steps:

[0063] a. Preparation of component A

[0064] Step 1. Take 3 parts by mass of organic solvent, add 10 parts by mass of pigment, 5 parts by mass of polytetrafluoroethylene and 0.2 part by mass of dispersant, and use a high-speed disperser to pre-disperse to obtain a slurry, wherein the rotating speed is 1000 rpm. Dispersion time 90min;

[0065] Step 2, placing the slurry obtained in step 1 in a three-roll mill, and grinding until the slurry has a fineness of 10 μm to obtain a color paste;

[0066] Step 3, mix 40 mass parts of hydroxyl-containing chlorotrifluoroethylene-vinyl ether copolymers, 15 mass parts of hydroxyl-containing acrylic resins with 7 mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com