High hydrolysis-resistant polylactic acid fiber suitable for fishing nets and clothing and preparation method thereof

A technology of polylactic acid fiber and polylactic acid resin, applied in the field of preparation of polymer materials, can solve problems such as gel point, toxicity, human health and environmental hazards, achieve excellent decontamination and self-cleaning, improve hydrolysis resistance, Good water and oil repellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

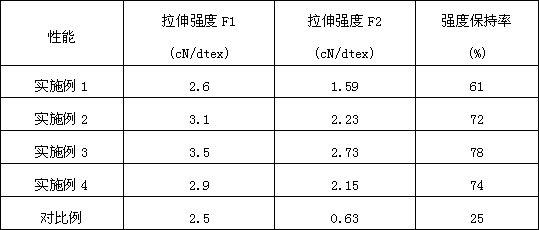

Embodiment 1

[0019] After the polylactic acid resin (the number average molecular weight Mn is 80,000) is dried, take by weight the polylactic acid resin of 99.99 parts and the fluorine-containing alcohol end-capping agent CF of 0.01 part 3 (CF 2 ) 10 CH 2 OH is mixed, and the homogeneously mixed mixture is melt-spun through a spinning machine, wherein the spinning temperature is 200° C., and the winding speed is 2000 m / min to obtain pre-oriented yarns. The pre-oriented yarn was drawn, the temperature of the first hot roll was 50°C, the temperature of the second hot roll was 80°C, and the draft ratio was 1.2 to obtain polylactic acid fibers with high hydrolysis resistance, and the performance before and after hydrolysis was tested.

Embodiment 2

[0021] After the polylactic acid resin (the number average molecular weight Mn is 150,000) is dried, take by weight the polylactic acid resin of 99.5 parts and the fluorine-containing alcohol end-capping agent CF of 0.5 part 3 (CF 2 ) 5 SO 2 NCH 3 (CH 2 ) 2 OH mixing, the uniformly mixed mixture is first granulated into slices through a twin-screw extruder, and then the slices are dried and then melt-spun through a spinning machine; the temperature of each zone of the twin-screw extruder is 150-220°C, and the screw speed 240 rpm; the spinning temperature is 210° C., and the winding speed is 2200 m / min to obtain pre-oriented yarns. The pre-oriented yarn was drawn, the temperature of the first hot roll was 70°C, the temperature of the second hot roll was 110°C, and the draw ratio was 2 to obtain polylactic acid fibers with high hydrolysis resistance. The performance before and after hydrolysis was tested.

Embodiment 3

[0023] After the polylactic acid resin (number-average molecular weight Mn is 200,000) is dried, take by weight 94 parts of polylactic acid resin and 6 parts of fluorine-containing alcohol end-blocking agent CF 3 (CF 2 ) 100 N M 2 CH 2 OH mixing, the uniformly mixed mixture is first granulated into slices through a twin-screw extruder, and then the slices are dried and then melt-spun through a spinning machine; the temperature of each zone of the twin-screw extruder is 150-220°C, and the screw speed 350 rpm; the spinning temperature is 230° C., and the winding speed is 2500 m / min to obtain pre-oriented yarns. The pre-oriented yarn was drawn, the temperature of the first hot roll was 100°C, the temperature of the second hot roll was 140°C, and the draw ratio was 5 to obtain polylactic acid fibers with high hydrolysis resistance. The performance before and after hydrolysis was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com