Patents

Literature

719results about How to "Easy to punch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

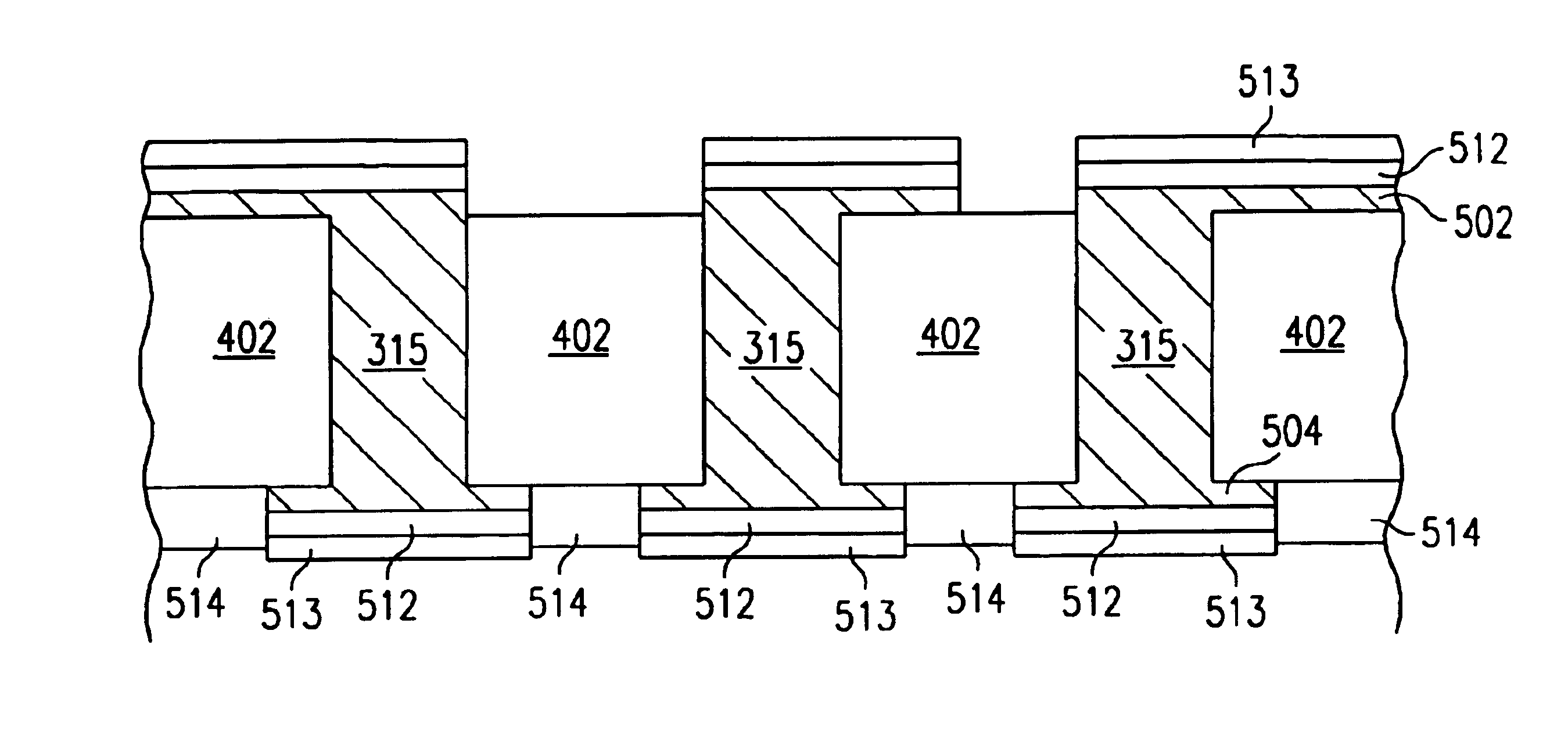

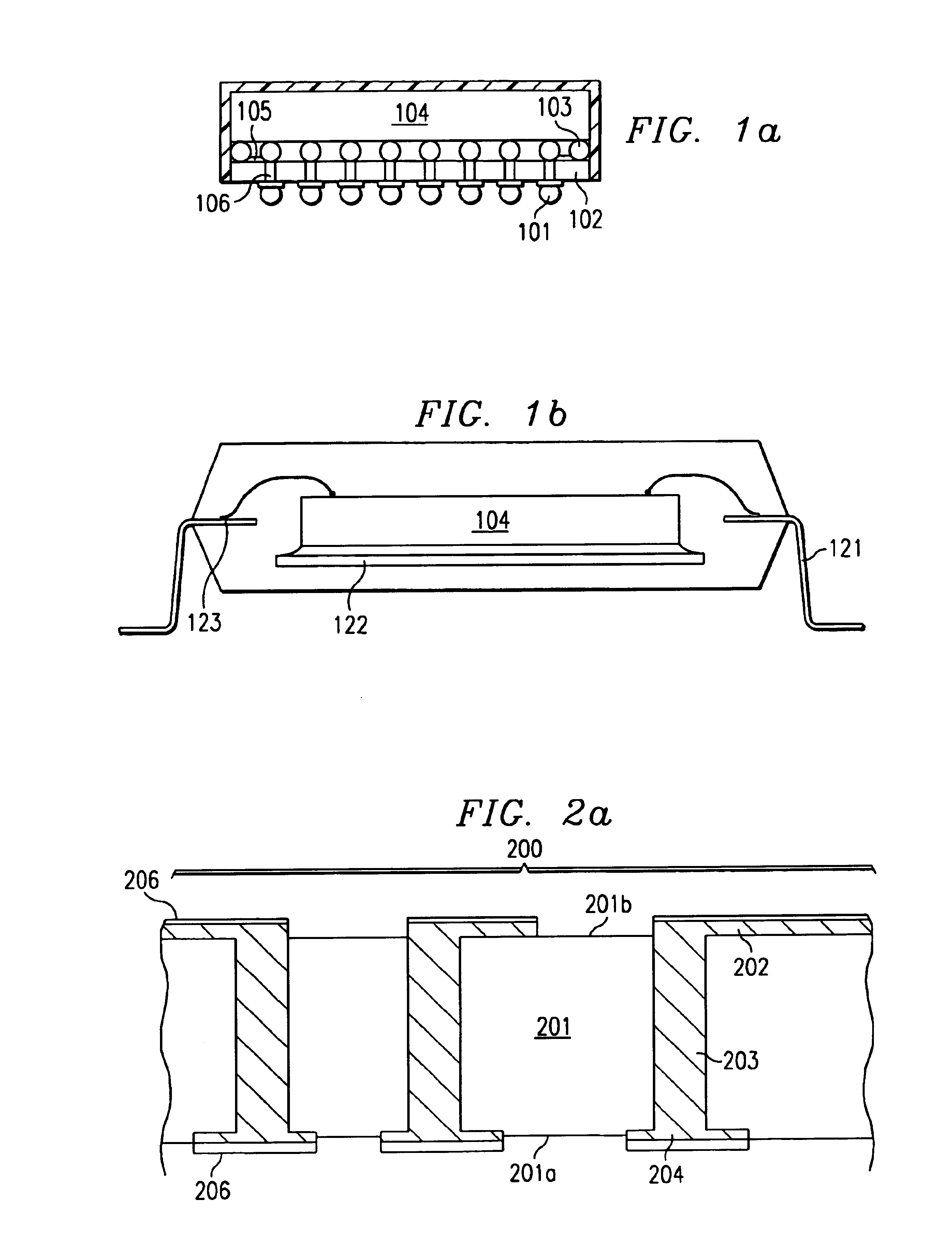

Method of fabricating flexible circuits for integrated circuit interconnections

InactiveUS6915566B2Increases conductor thicknessConnection sealPrinted circuit assemblingLine/current collector detailsIntegrated circuit interconnectFlexible circuits

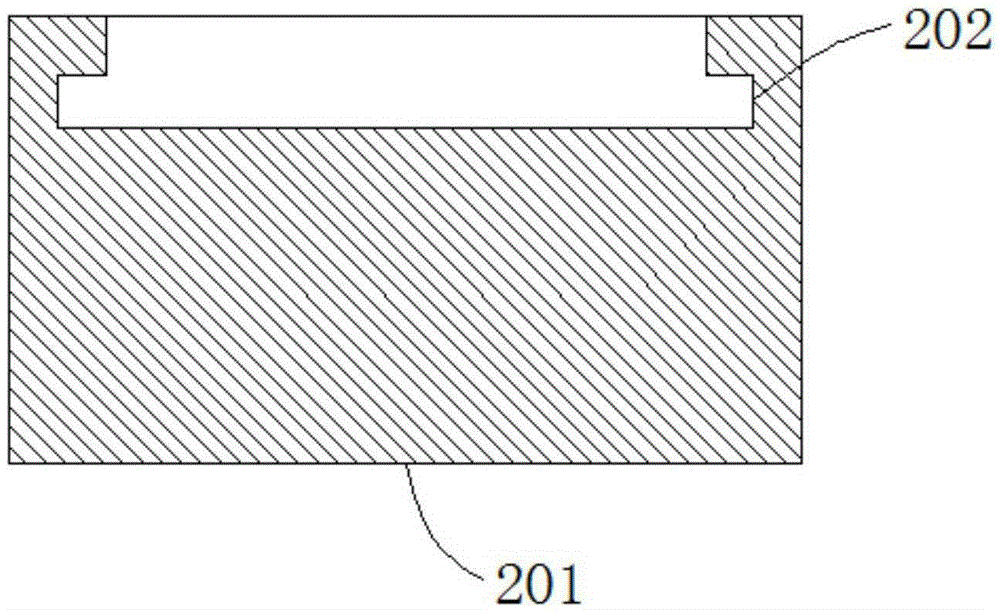

A method for the fabrication of a double-sided electrical interconnection flexible circuit (200) particularly useful as a substrate for an area array integrated circuit package. A copper matrix with studs (203) is pressed through a dielectric film (201) having a copper layer on the opposite surface, thereby forming an intermediate structure for a flex circuit with self-aligned solid copper vias in a one step process. The contacts are reinforced by plating both surfaces with a layer of copper, and conventional processes are used to complete the circuit patterning.

Owner:TEXAS INSTR INC

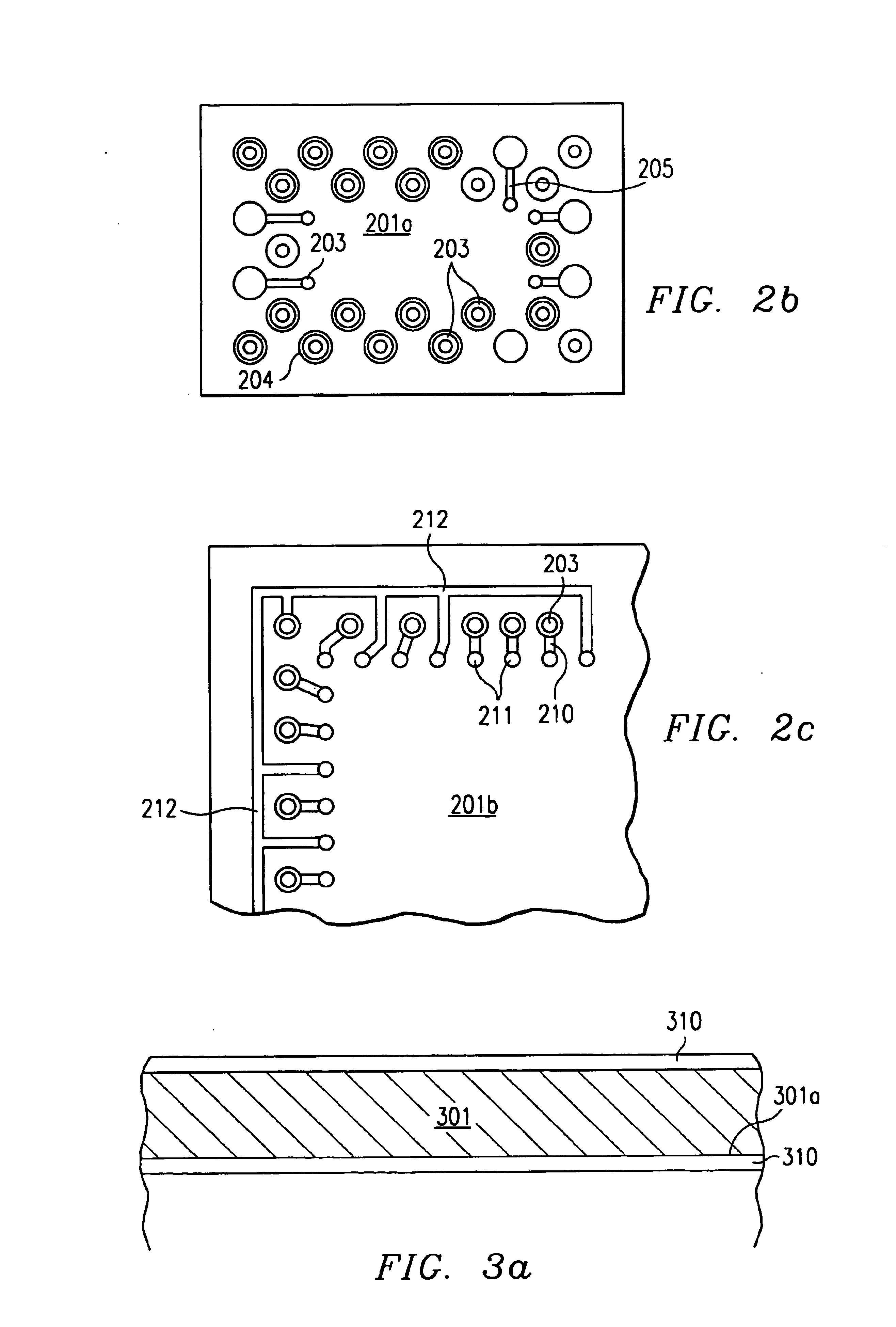

Forming method of thin-wall nut

The invention discloses a forming method of a thin-wall nut. The forming method comprises the following steps: (1) treatment of raw materials, namely aligning wires used as the raw materials by virtue of a cold upsetting machine, conveying the aligned wires to a material cutting mechanism and cutting the wires into small sections of wire blanks; (2) primary upsettig, namely putting the small sections of wire blanks into a female die, performing end surface reshaping on the wire blanks by virtue of a reshaping punch and the female die, so as to obtain a cylinder and frustum combination body; (3) pre-upsetting, namely overturning the blank subjected to primary upsetting so as to enter into a cavity of the female die, and reshaping the blank as a mushroom shape; (3) semi fine supsetting, namely forming a tray part by use of a semi fine upsetting die and forming pre-upset holes; (5) fine upsetting, namely deepening the hole by virtue of a fine upsetting die; (6) punching; (7) threading. According to the forming method disclosed by the invention, a wire upsetting process is used for replacing a sheet material deep-drawing process, area deformation is replaced by volume deformation, and various problems such as drawing breakage and wrinkling caused by area formation in the deep-drawing process can be effectively avoided.

Owner:AVIC STANDARD PARTS MFG

Double-faced jacquard weaving technology

The invention provides a double-faced jacquard weaving technology. A double-needle spaced fabric adopts computer-designed jacquard patterns and is woven by adopting seven guide bars, and the guide bar GB1, the guide bar GB2, the jacquard guide bar JB3.1, the jacquard guide bar JB3.2, the jacquard guide bar JB4.1, the jacquard guide bar JB4.2 and the guide bar GB5 are sequentially arranged from a front needle bed to a back needle bed. The double-faced jacquard weaving technology specifically comprises the following steps that 1, the guide bar GB1 is fully threaded to serve as a first layer of yarn to be laid to form loops on the front needle bed and used for forming the surface layer of the double-needle spaced fabric; 2, the guide bar GB2 is fully threaded to serve as a second layer of yarn to be alternated to form loops to form spaced yarn for connecting the surface layer with the bottom layer; 3, the guide bar GB5 is fully threaded to serve as a fifth layer of yarn to be laid to form loops on the back needle bed and used for forming the bottom layer of the double-needle spaced fabric. The double-needle spaced fabric made through the double-faced jacquard weaving technology is clear in pattern hierarchy and has the good stereoscopic effect in visual sense; meanwhile, the production procedures are simplified, and the cost is greatly saved.

Owner:SINCETECH FUJIAN TECH CO LTD

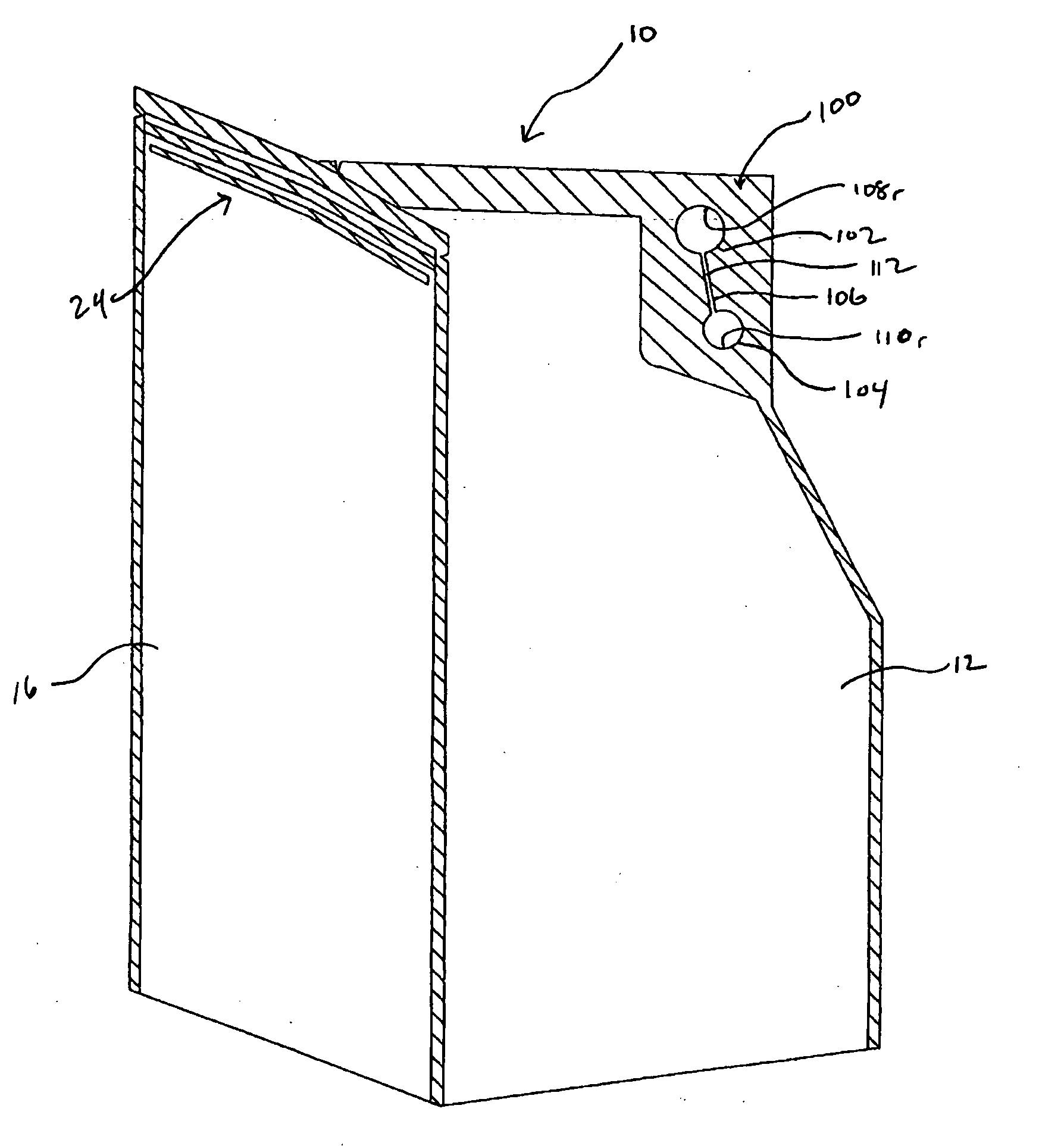

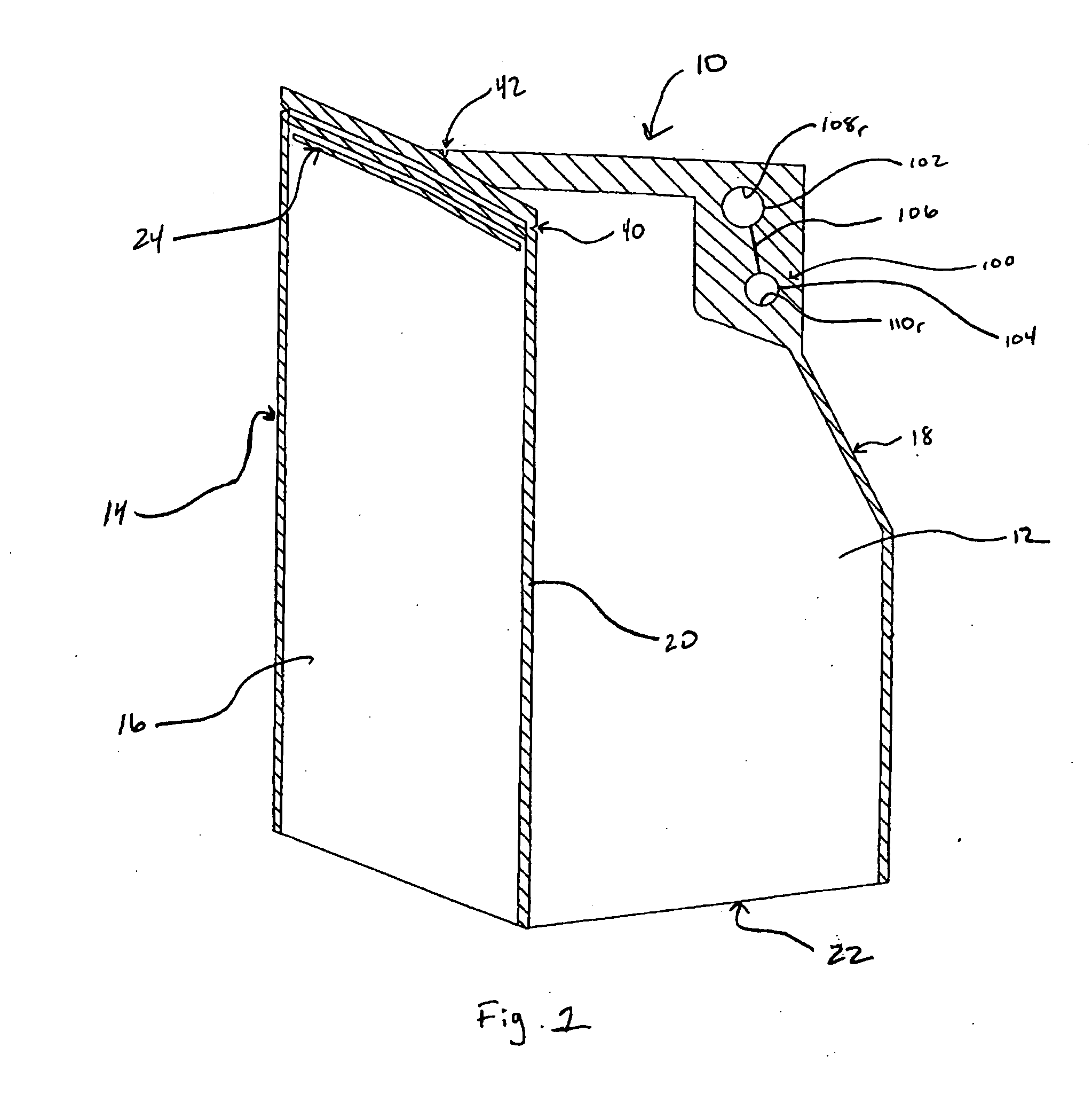

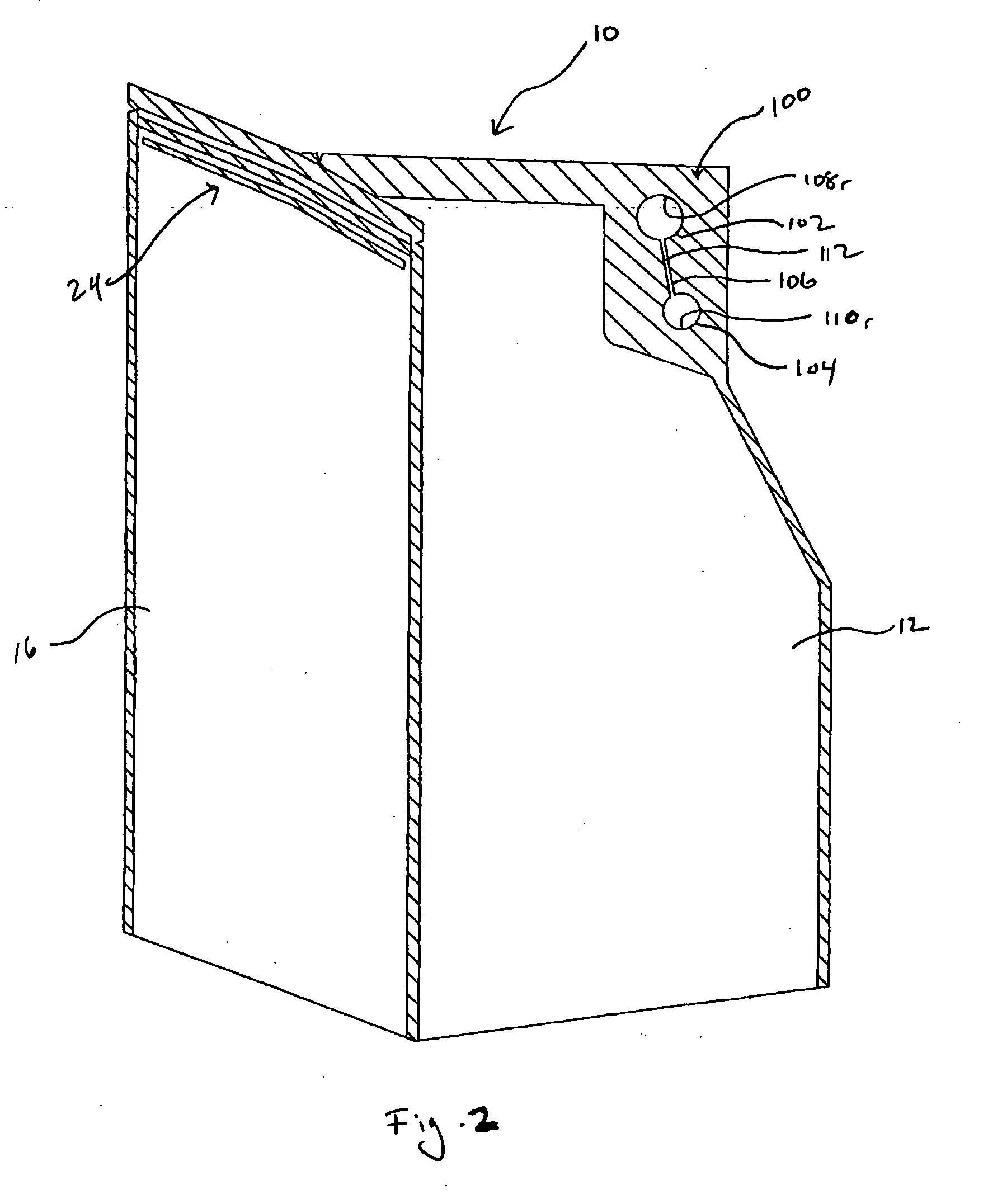

Package handle

InactiveUS20090180716A1Solve the real problemEasy to punchBagsSacksEngineeringMechanical engineering

A package having a handle portion is disclosed. The package generally includes opposing panel portions that at least partially define an interior cavity therebetween accessible through an access opening. The handle is generally formed by two or more openings or apertures punched or cut into a portion of the package. The handle can be further defined by a cut or slit line extending between and in communication with the apertures to provide a hingeable flap.

Owner:STEELE MARK

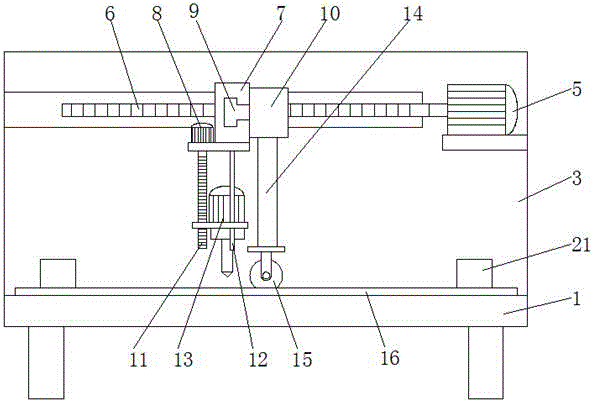

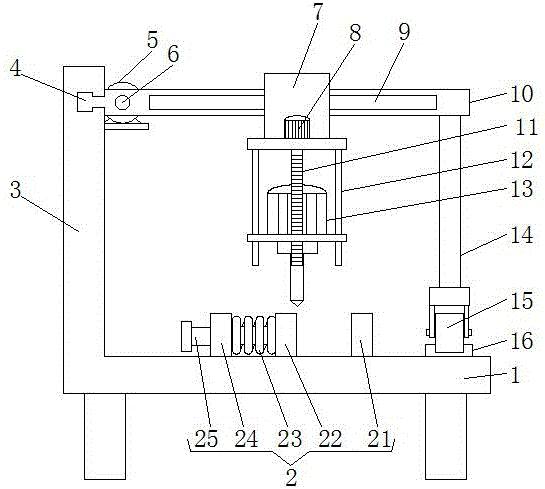

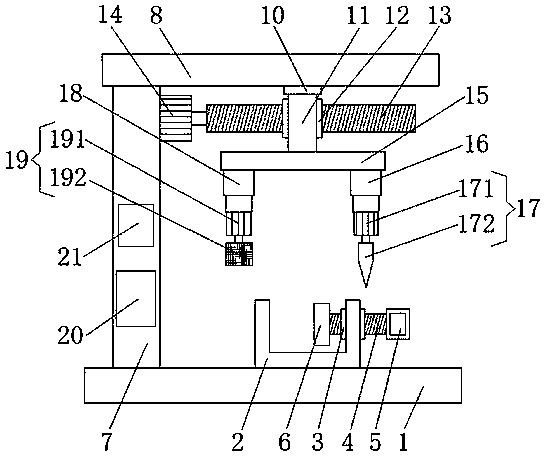

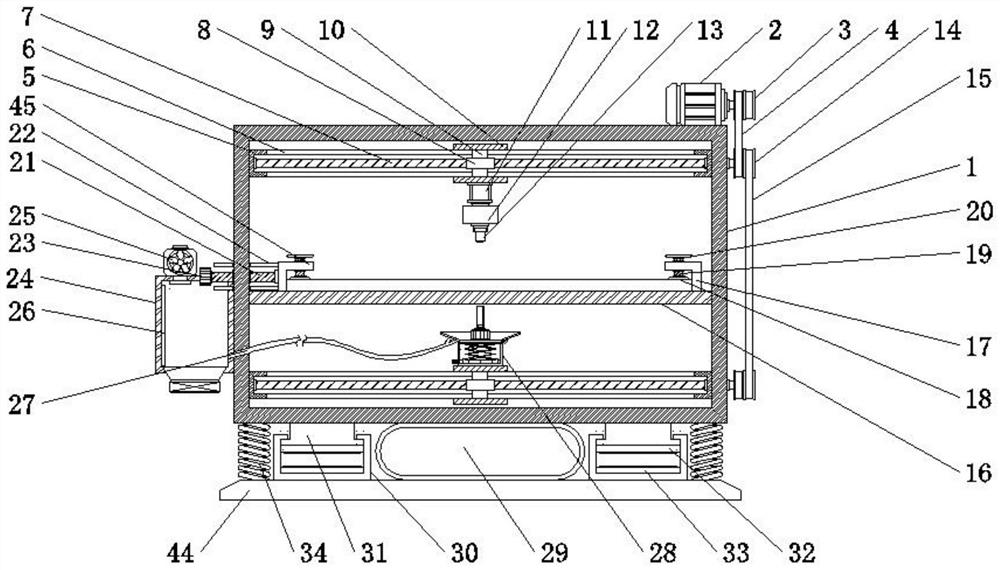

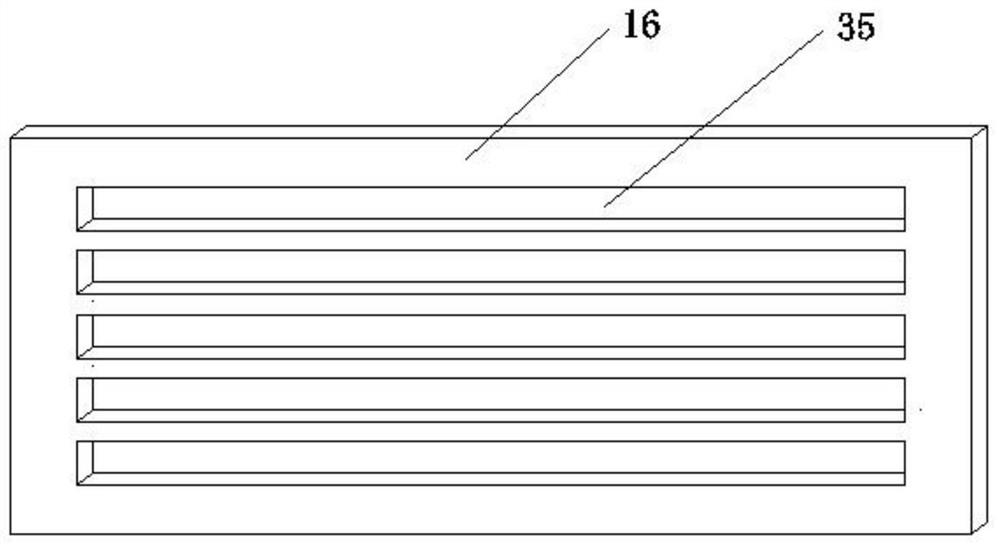

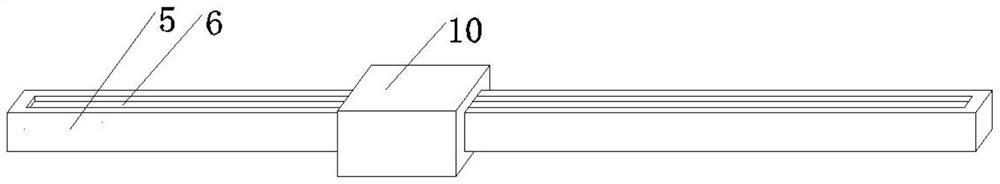

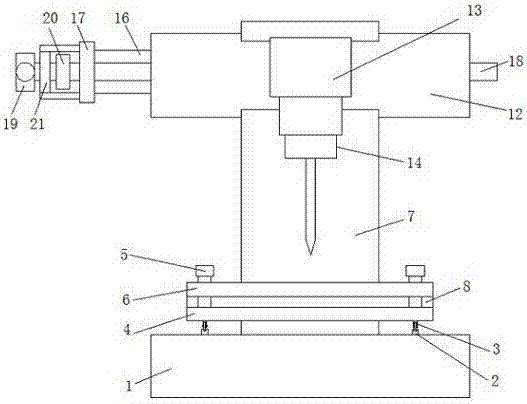

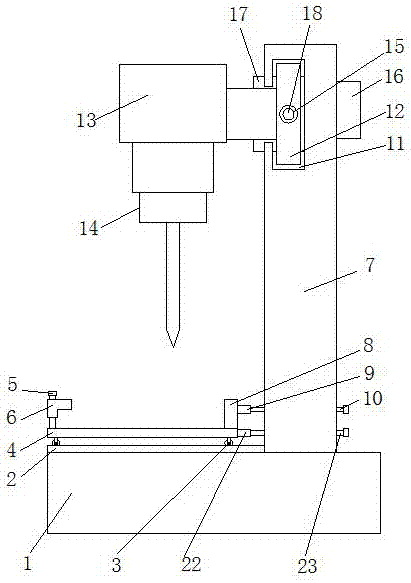

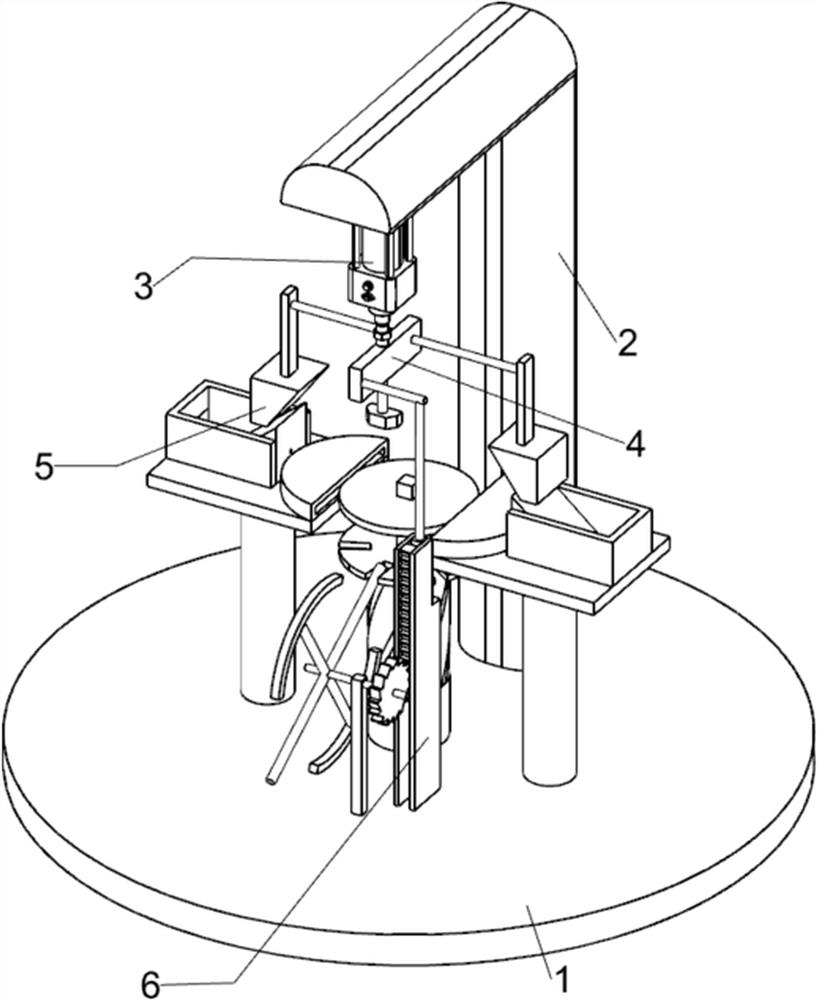

Pipe punching machine tool

ActiveCN105834474ARealize left and right adjustmentStable jobTurning machine accessoriesWorkpiecesPunchingElectric machinery

The invention discloses a pipe punching machine tool. The pipe punching machine tool comprises a working table and a cross beam; a sliding block is integrally molded at the rear end of the cross beam, and a guide rail is arranged on the left side face of the cross beam; the guide rail is sleeved with a linear motor, and a fixed plate is mounted at the bottom of the linear motor; a second drive motor is arranged on the left side of the upper surface of the fixed plate, and a second lead screw is connected to an output shaft of the second drive motor; two sliding levers are further mounted at the bottom of the fixed plate; and according to the pipe punching machine tool, through cooperation of a first drive motor, a first lead screw and the sliding block, rotation of the first drive motor is used for driving the cross beam to move, left-and-right adjustment of the cross beam is achieved, and due to cooperation of a supporting column, a pulley and a sliding rail, the front end of the cross beam is supported, so that when the cross beam works, stability is achieved. The guide rail on the cross beam is matched with the linear motor, front-and-back adjustment of a punching motor is facilitated, and through cooperation of the second drive motor, the second lead screw and the sliding lever, the punching motor can be vertically adjusted.

Owner:建湖县高新投资发展有限公司

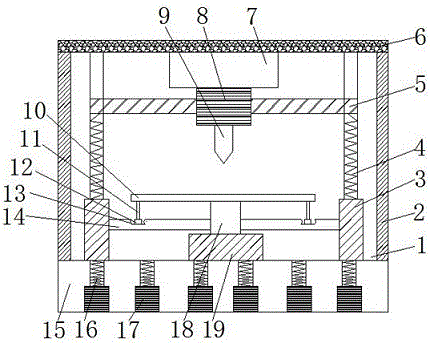

Perforating machine for auto parts

ActiveCN105946041AAvoid offsetEasy to punchPerforating toolsMetal working apparatusSlide plateEngineering

The invention discloses a perforating machine for auto parts. The perforating machine comprises a main body and a base. The two sides of the main body are fixedly connected with supports correspondingly. A top plate is mounted at the tops of the supports. A sliding seat is movably connected with the bottom of the top plate. An electric extensible rod is connected with the bottom of the sliding seat. A sliding plate penetrates through an inner chamber of the electric extensible rod. The bottoms of the two sides of the sliding plate are connected with springs correspondingly. First support plates are mounted at the bottoms of the springs correspondingly. A second support plate is connected with one sides of the first support plates. Arc-shaped slide grooves are formed in the top of the second support plate. Sliding blocks are arranged in inner chambers of the arc-shaped slide grooves correspondingly. Connection rods are connected with the tops of the sliding blocks. A holding plate is mounted at the tops of the connection rods. The bottom of the holding plate is movably connected with a rotary shaft. A rotary motor is connected with the bottom of the rotary shaft. According to the perforating machine for the auto parts, the holding plate is driven to slide in the arc-shaped slide grooves by the rotary motor and the rotary shaft, multidirectional perforating to the auto parts is facilitated, a perforating device can be driven to move by the sliding seat, and perforating positions can be conveniently adjusted.

Owner:WUXI GUOSONG ENVIRONMENTAL PROTECTION MACHINERY

Punching die

InactiveCN105251865ASimple structureEasy to processShaping toolsPerforating toolsPunchingEngineering

The invention provides a punching die, and belongs to the field of die equipment. The punching die is used for performing punching forming on multiple holes in a metal tube and comprises an upper die base, a lower die base, a die shank, a male die, a female die, guide columns and guide sleeves, wherein the male die is installed on the lower surface of the upper die base, and the female die is installed on the upper surface of the lower die base. The male die is provided with a plurality of punching parts arranged in the extension direction of the cavity of the female die at intervals. The punching die further comprises an inclined slider core-pulling mechanism. The inclined slider core-pulling mechanism comprises a core-pulling slider; the core-pulling slider is provided with a plurality of second forming holes and is pulled out of the cavity of the female die when the punching die is opened; when the punching die is assembled, the core-pulling slider is inserted into the cavity of the female die and enables the second forming holes to correspond to the punching parts in a one-to-one mode. When the punching die punches multiple holes, the metal tube is does not deform easily, the forming quality of the holes is high, the machining efficiency is improved, and the machining cost is reduced.

Owner:中山风火脚轮制造有限公司

Multifunctional suspending bucket for dry land transplanting

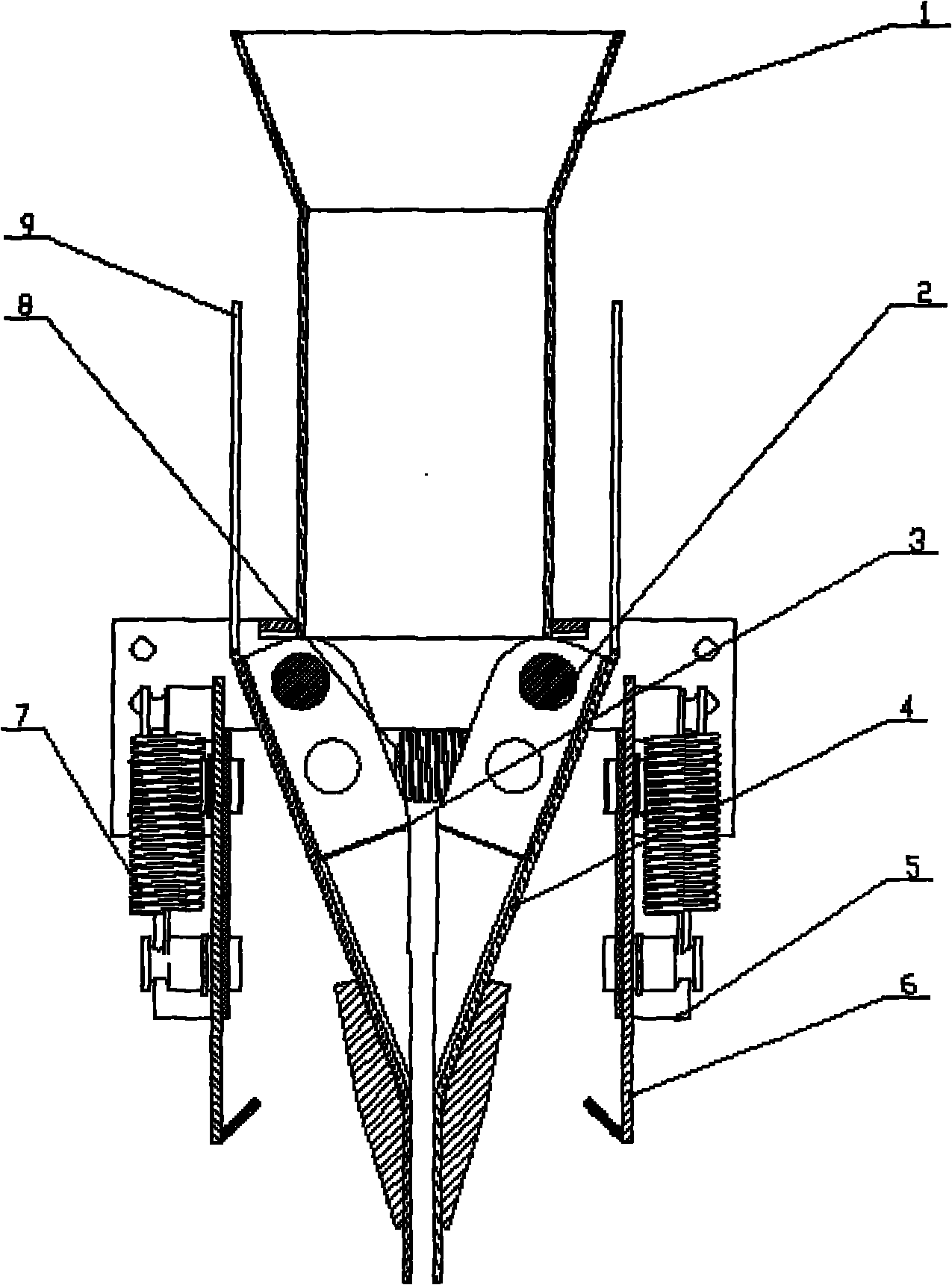

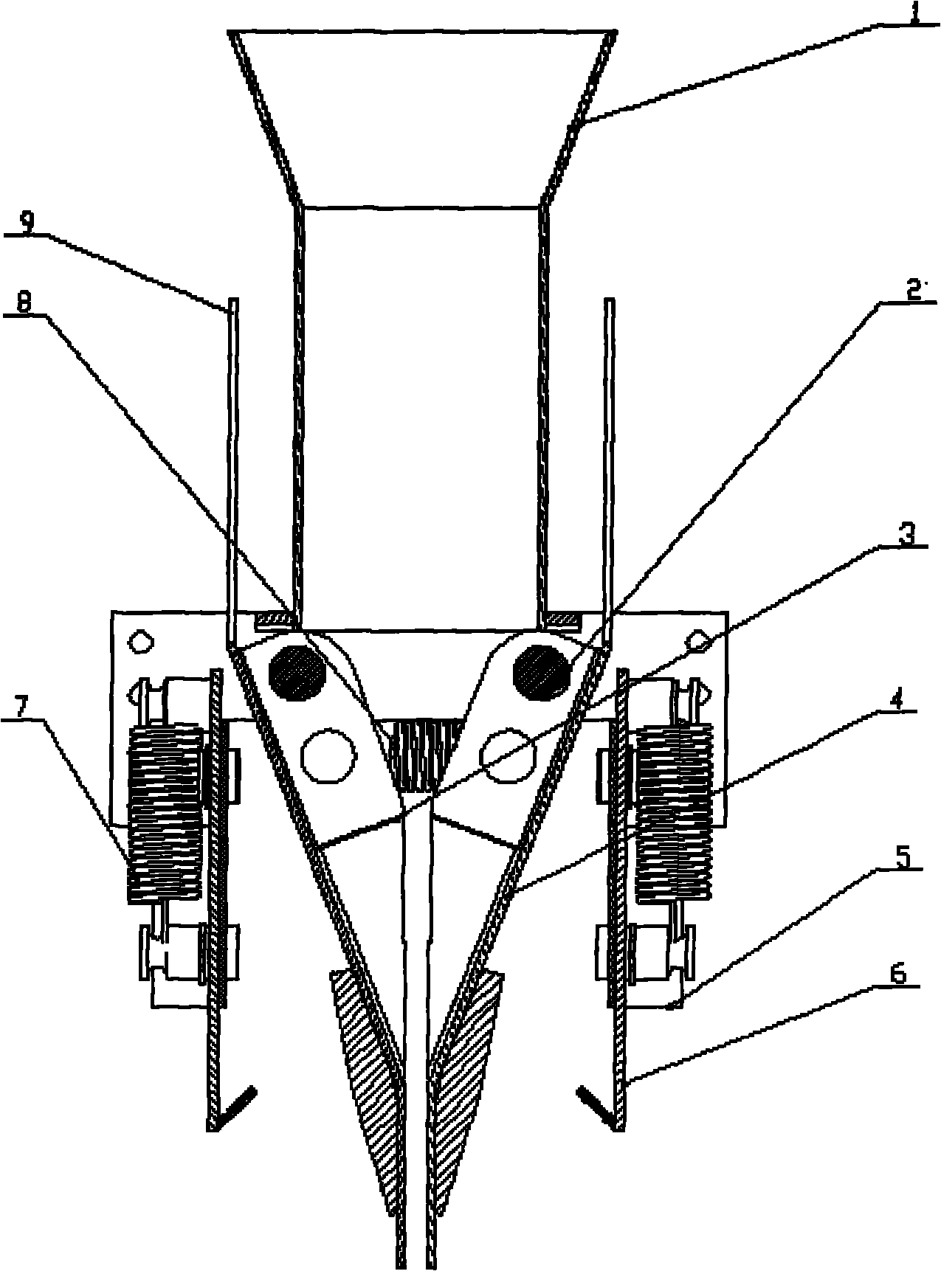

InactiveCN102077721AEnsure transplant qualityConducive to desoilingTransplantingEngineeringTransplanting

The invention discloses a multifunctional suspending bucket for dry land transplanting, which comprises a suspending bucket (1), a pin roll (2), a left duck bill (3), a right duck bill (4), a support plate (5), a rolling plate (6), an extension spring (7), an extension spring (8) and a rotating handle (9). The multifunctional suspending bucket is characterized in that the suspending bucket moves along the trochoid track, the suspending bucket moves from top to bottom when in working, the left and the right duck bills are closed under the action of the extension spring (8); when the suspending bucket is in contact with a film and soil, the film is broken and then holed, the left and the right duck bills overcome the tension of the extension spring (8) to be opened under the action of the rotating handle (9) after reaching the transplanting depth, seedlings in the suspending bucket fall down so that the seedlings are planted. The suspending bucket moves upwards under the opening state, at this time, the rolling plate is kept to be in contact with the film under the action of the spring (7) and generates a pressing action so that the earthing function is realized; and when the suspending bucket moves to the highest point, the left and the right duck bills are closed under the action of the extension spring (8) to receive the fed seedlings, so that one working circulating process is completed. An earthing function is integrated on the suspending bucket, the problem of damaging the film when a rolling wheel rolls on the film is solved, so that the earthing and the seedling transplanting operations are synchronous and the transplanting quality is favorably ensured. A plane structure is designed on the end parts of the duck bills, and is beneficial to the holing and the removal of the soil, so that the problem of holing clay on the clay is solved. The yield and the quality of agricultural products are improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Position-adjustable metal plate punching mechanism

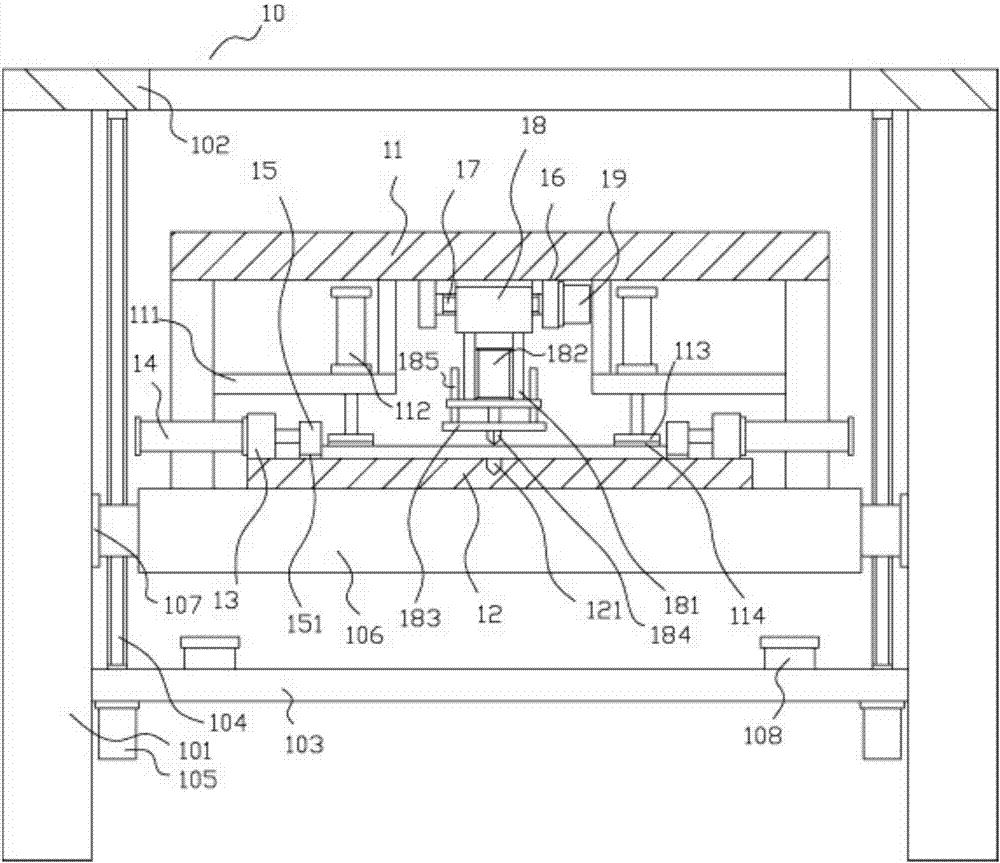

InactiveCN107511420ASimple structureFirm and convenient clampingElectric machineryArchitectural engineering

The invention discloses a position-adjustable metal plate punching mechanism, which includes a frame. The frame includes two main vertical plates and a main top plate. The top ends of the two main vertical plates are fixed on both sides of the bottom surface of the main top plate. side, the lower middle plate is fixed on the inner side walls of the two main vertical plates, the two main vertical screws are on both sides of the lower middle plate, the bottom ends of the main vertical screws are hinged on the lower middle plate, the main vertical screws The top of the main adjustment motor is hinged on the bottom surface of the main top plate, and the two main adjustment motors are fixed on both sides of the lower middle plate. The output shaft of the main adjustment motor is a spline shaft, and the spline shaft is inserted into the bottom of the main vertical screw. It is in the spline hole; it has simple structure, firm and convenient clamping, convenient punching, and is suitable for thin and small-volume sheet materials, and it can adjust the height position of the main moving plate, so as to ensure that it is compatible with the height of the conveying mechanism, so that The installation accuracy requirements are greatly reduced, and the installation is convenient.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

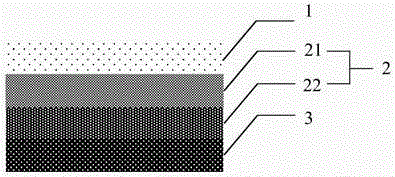

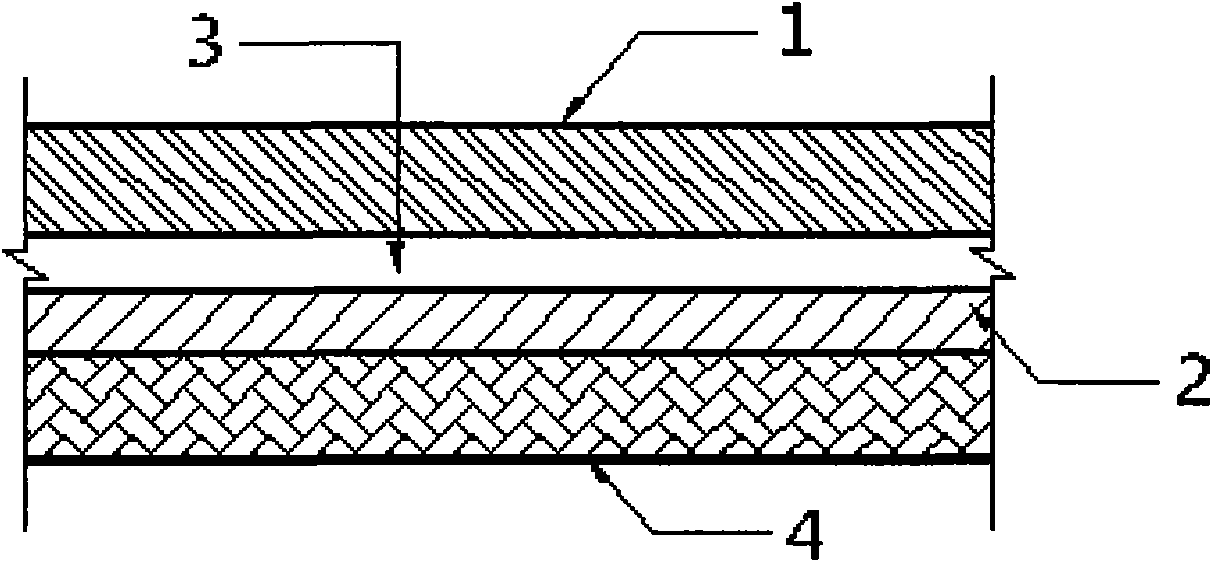

Extremely-thin flexible heat-radiation film and method for manufacturing the same

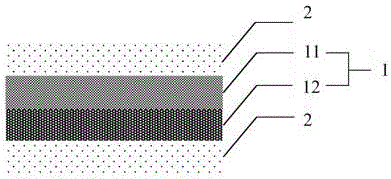

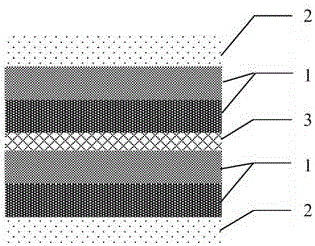

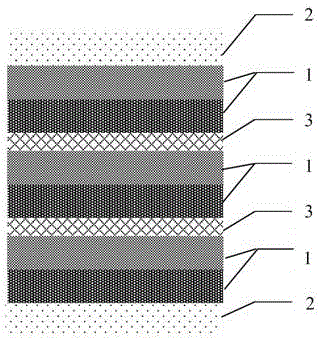

ActiveCN106531902AImprove cooling effectEasy to slimSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLayer group

The invention, which relates to the electronic material field, discloses a flexible heat-radiation film and a method for manufacturing the same. The heat-radiation film comprises a carrier film, a protection film layer, and at least one heat radiation layer group arranged between the carrier film and the protection film layer. The heat radiation layer group includes a heat-radiation adhesive film layer for horizontal heat transferring and a heat-radiation metal film layer at least being superposed on one surface of the heat-radiation adhesive film layer ad being used for longitudinal heat transferring, so that the heat radiation layer group having bidirectional heat transferring is formed. The heat-radiation adhesive film layer is made from raw materials including magnetic high-thermal-conductivity powder and resin. For the heat-radiation metal film layer, a material source is processed by a physical means to form atoms or molecules and then the atoms or molecules are deposited on the surface of the heat-radiation adhesive film layer. According to the heat-radiation film, the operation becomes simple; and the formed film layers are light, thin and compact. The flexible heat-radiation film can be applied to various electronic products and communication equipment.

Owner:广州宏庆电子有限公司

Metal hole punching device with grinding function

InactiveCN107717469AWith grinding functionReduce work intensityOther manufacturing equipments/toolsPositioning apparatusMetal machiningEngineering

The invention discloses a metal hole punching device with a grinding function. The metal hole punching device with the grinding function comprises a bottom plate; a U-shaped plate is fixedly connectedwith the upper surface of the bottom plate; a first threaded cap is connected to the right side face of the U-shaped plate in a clamped manner; a first threaded rod is connected in the first threadedcap in a threaded manner; a handle is fixedly connected to the right end of the first threaded rod; and an extruding plate is fixedly connected with the left end of the first threaded rod. Accordingto the metal hole punching device with the grinding function, by arranging a first motor, an output shaft of the first motor rotates and drives a second threaded rod to rotate, and therefore a secondthreaded cap can be driven to move left and right, and a cross plate can be driven to move left and right, and a grinding device and a hole punching device can move to replace positions; after hole punching of the hole punching device is completed, the grinding device moves rightwards to grind burrs on the metal surface, and therefore people are not needed to manually grind the burrs any more, time and physical power of workers are saved, and convenience is brought to the workers during metal machining.

Owner:无锡龙博机械有限公司

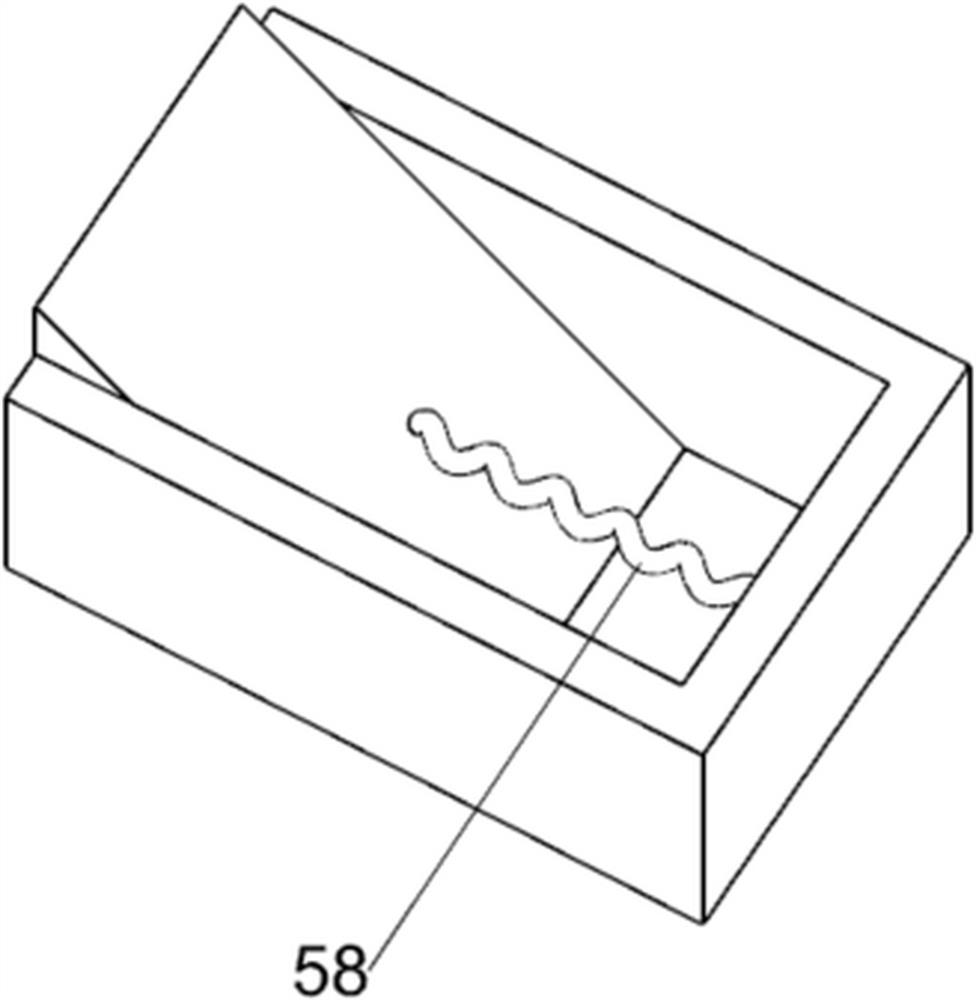

Apparatus for shaping metal sheets

InactiveUS20060230806A1Slow cool down speedSimple to executeShaping toolsPressesInsulation layerEngineering

Apparatus for shaping metal sheets including a shaping tool having an forming space for receiving a metal sheet. At least one heating element is disposed in a recess of the shaping tool for heating at least a portion of the metal sheet, whereby an insulation layer is provided to insulate the heating element from neighboring walls of the shaping tool.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

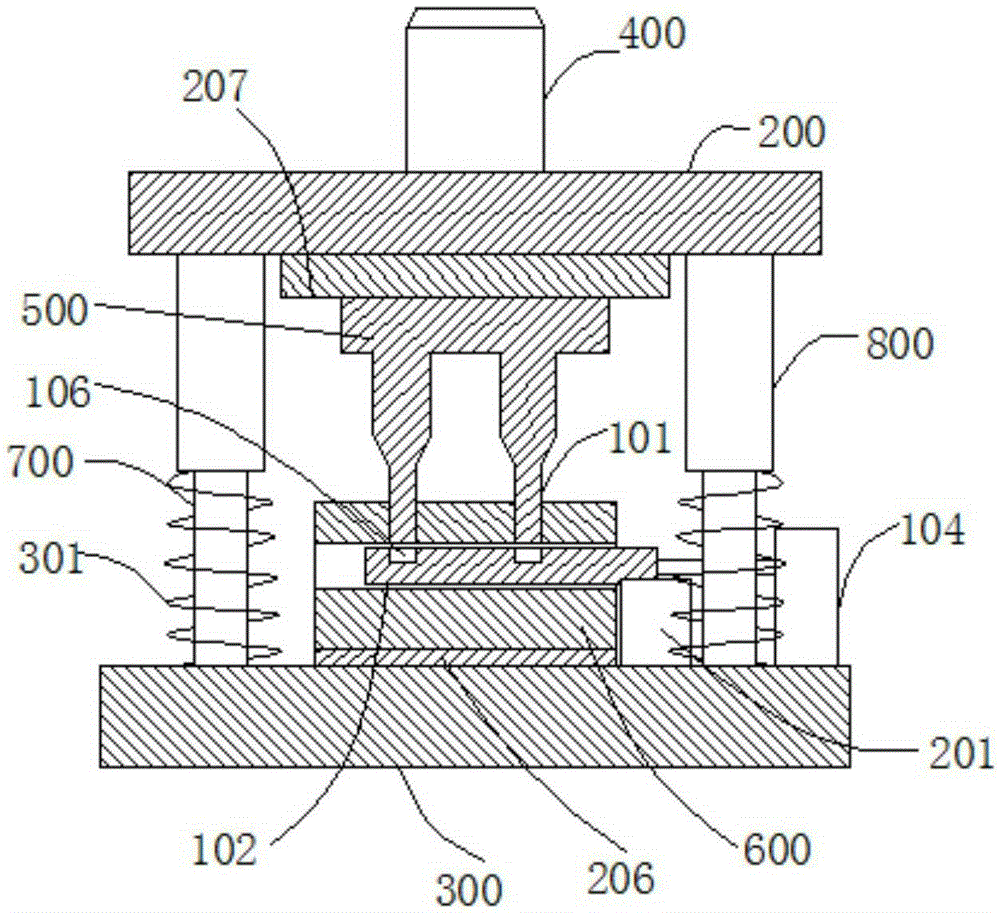

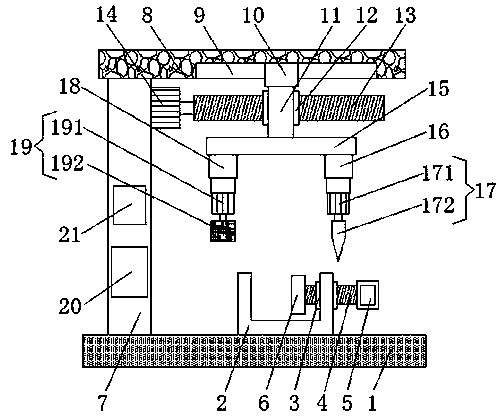

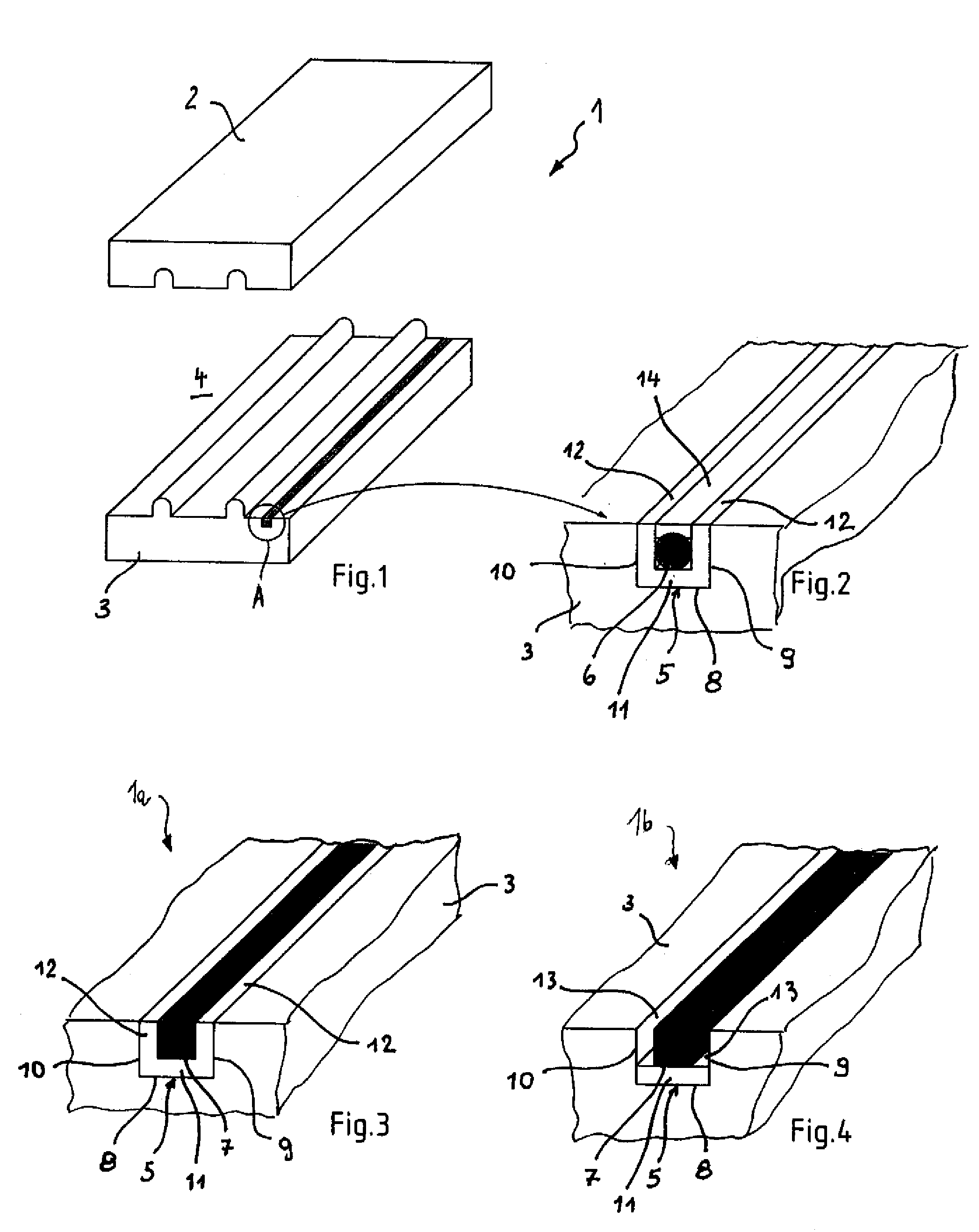

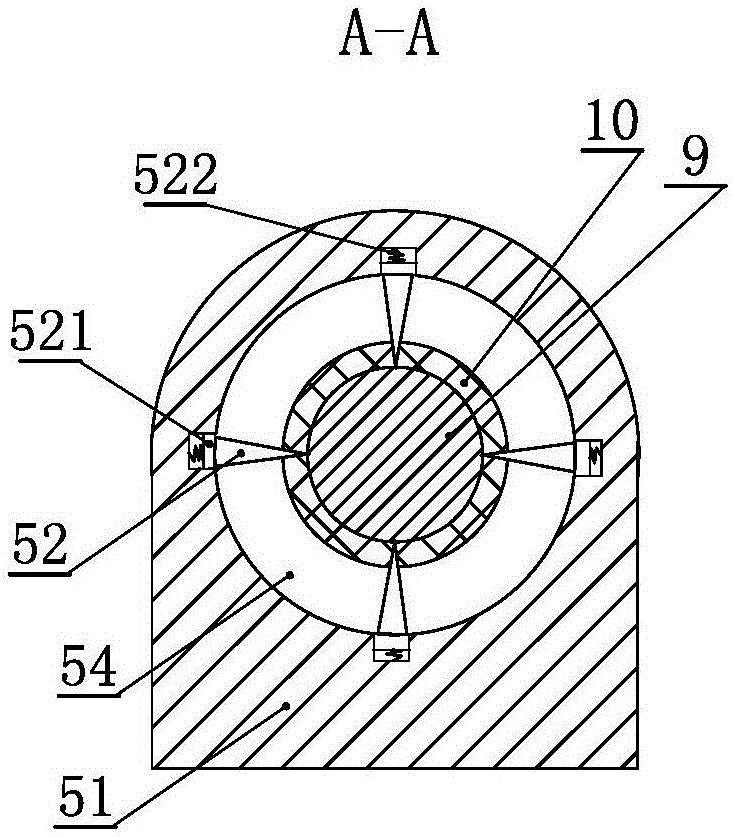

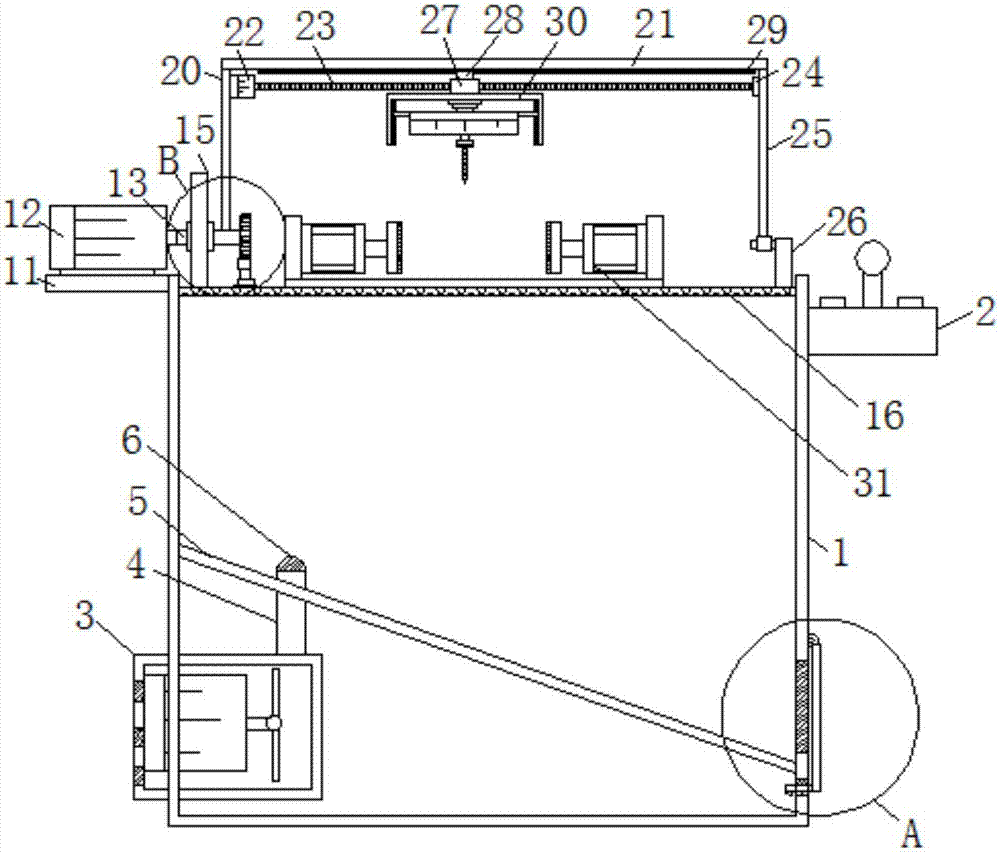

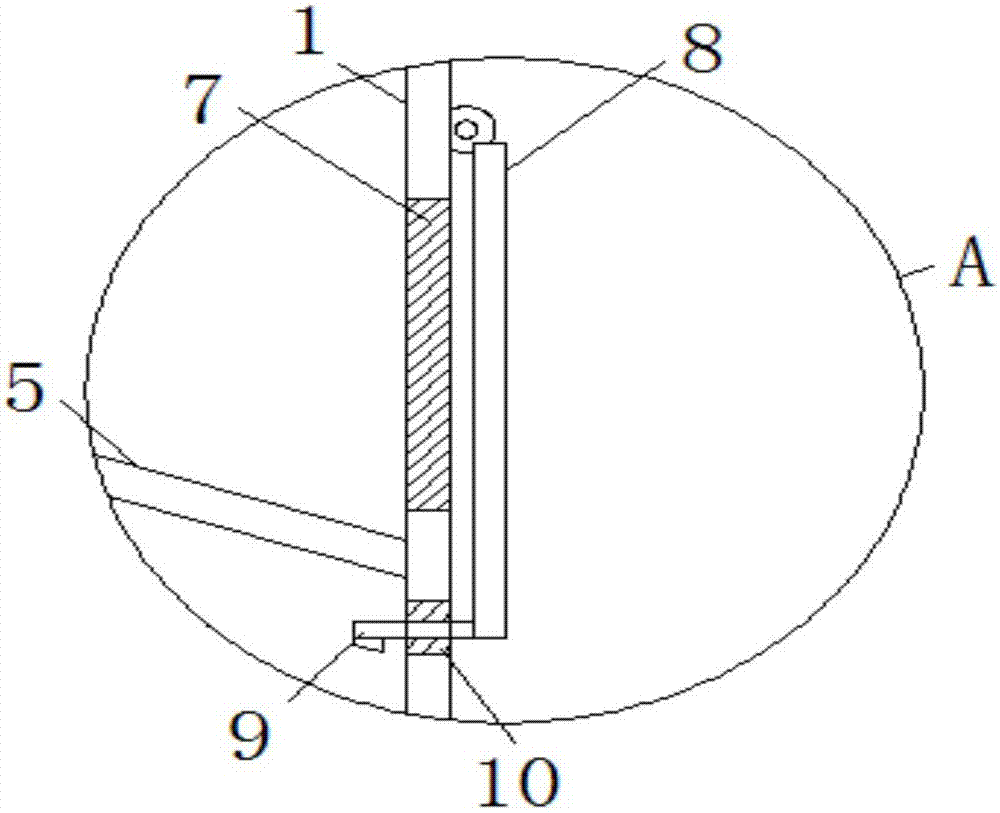

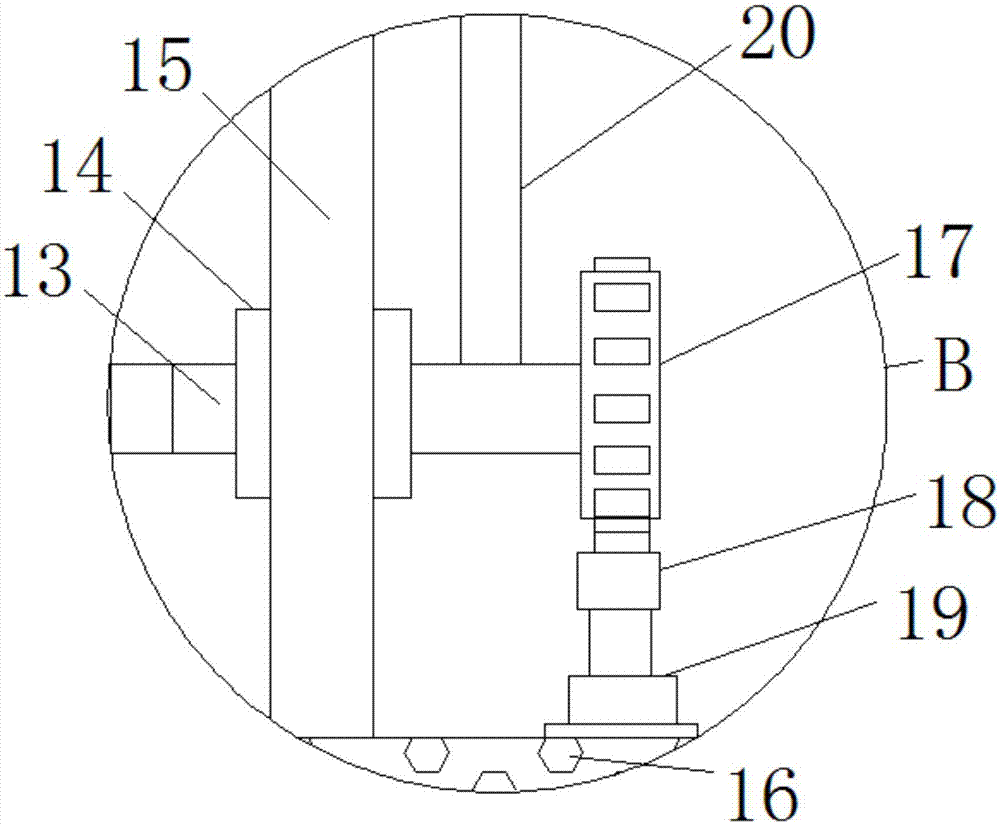

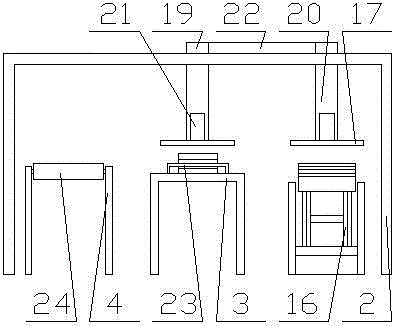

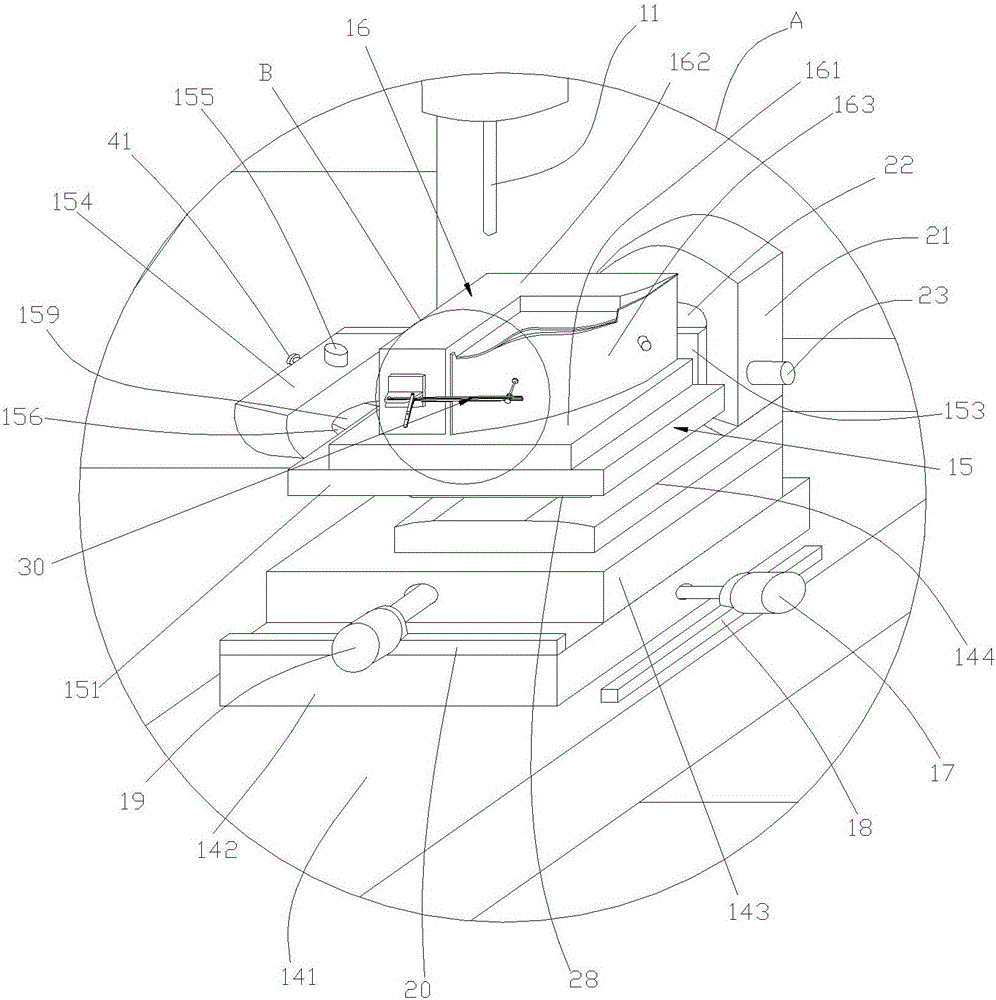

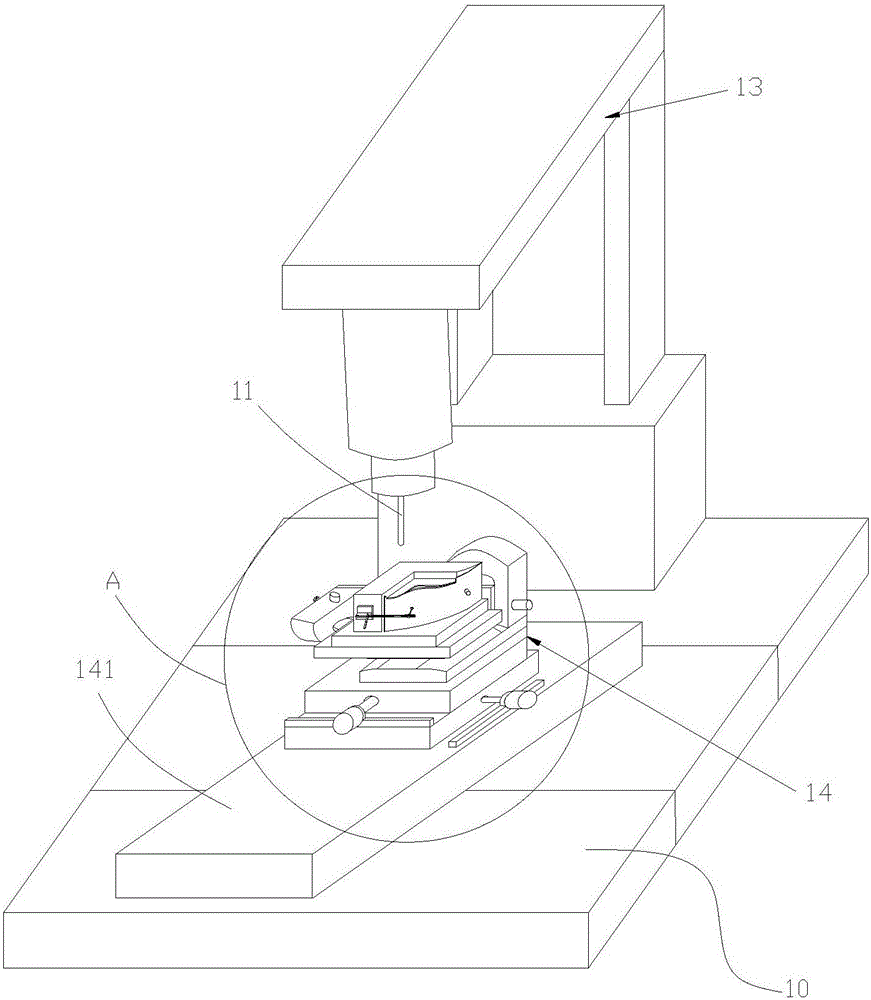

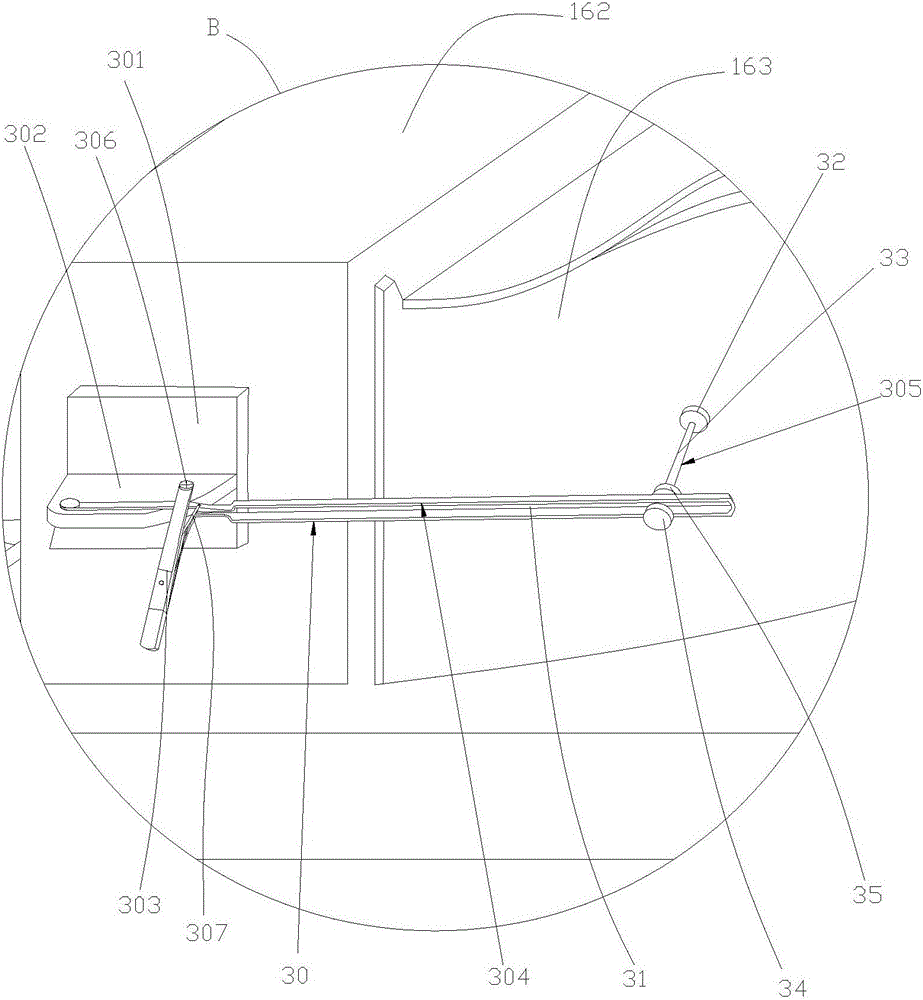

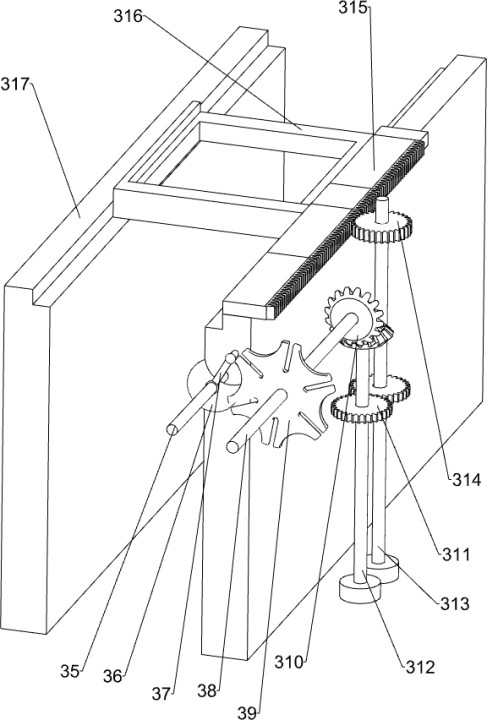

Cantilever manual punching machine for asymmetric deep groove square pipe

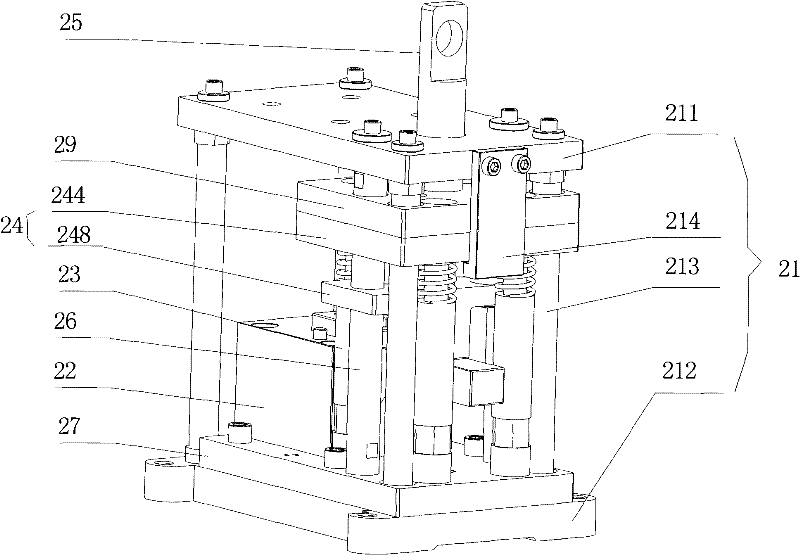

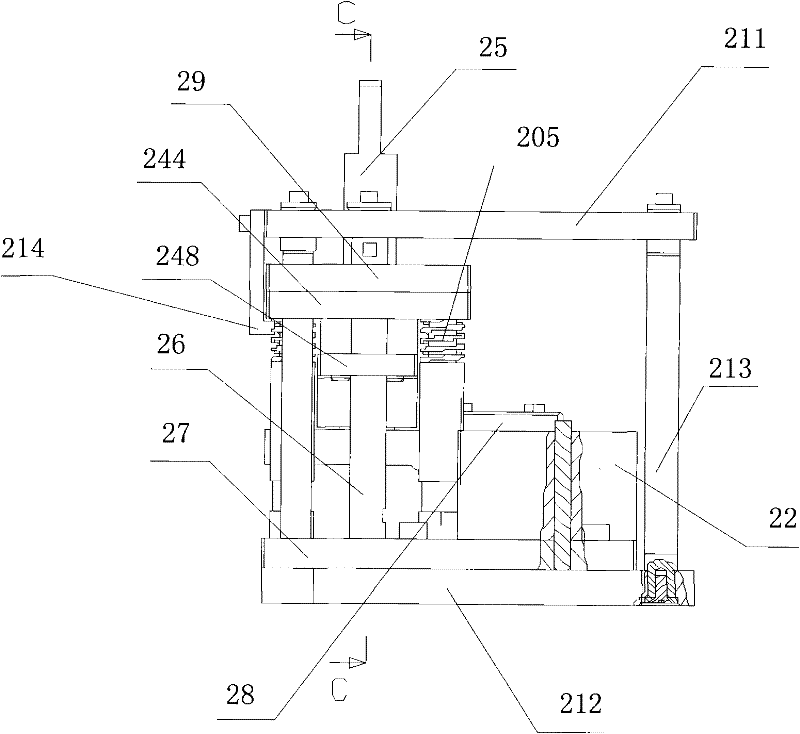

The invention provides a cantilever manual punching machine for an asymmetric deep groove square pipe. The punching machine comprises a frame (1) and a machine head (2) arranged on the frame, wherein the machine head (2) comprises a machine head frame (21), a female die (22), a plurality of elastic components (23), a punching component (24), a die handle (25), a padding plate (29) and two guide columns (26). The cantilever manual punching machine can be used for conveniently and precisely punching the pipe wall of the asymmetric deep groove square pipe on the basis of the cooperation of the punching component (24) containing a male die, the female die (22) with a cantilever and the guide columns (26).

Owner:HUNAN XINMEIGE INNOVATORY DECORATIVE MATERIAL

Metal line inner core recycle device of power supply and utilization cable

InactiveCN106205894AQuick splitEasy to separateBasic electric elementsElectronic waste recyclingMetal stripsEngineering

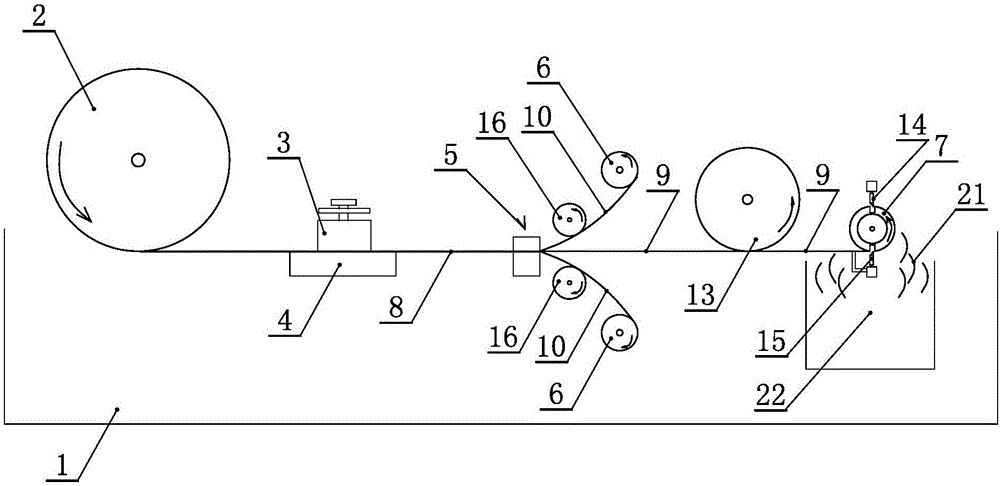

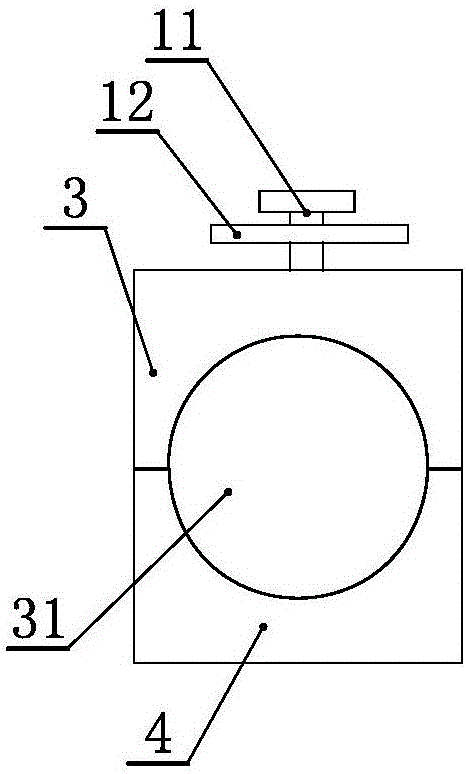

A metal line inner core recycle device of a power supply and utilization cable comprises a base, a feeding part, limitation parts, a cutting part, an outer skin recycle part, an inner core winding part, an inner core recycle part and a cut part inner core recycle box, wherein the feeding part is a feeding wheel, a cable is wound around the feeding wheel, the limitation parts are limitation rings arranged vertically, a cutting knife is arranged on the cutting part and is used for cutting the cable to a plurality of strips, an inner core and an outer skin which are cut and separated are respectively wound the inner core winding part and the outer skin recycle part, and the inner core on the inner core winding wheel is wound the inner core recycle wheel and is cut to achieve fixed length recycle of metal strips. By the device, the inner core and the outer skin of a waste cable are rapidly cut, and the fixed length mass production and recycle of the inner core of the cable become possible. The device is high in automation, a separation effect of the inner core and the outer skin is good, the inner core and the outer skin are simultaneously and orderly wound during the separation process, and subsequent utilization is facilitated.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Punching and grinding integrated equipment for intelligent manufacturing and machining of machine screen

PendingCN112355128AImprove work efficiencyPrecise positioningEdge grinding machinesGrinding carriagesPunchingAir pump

The invention discloses punching and grinding integrated equipment for intelligent manufacturing and machining of a machine screen, and relates to the field of machine screen machining. The punching and grinding integrated equipment comprises a device main body, wherein a first servo motor is installed at one side of the top of the device main body, the output end of the first servo motor is connected with a driving rotating wheel, and two sets of fixing cylinders are installed in the device main body. During punching, a dust collecting cover is located under a punching head, scraps generatedby punching can just fall into the dust collecting cover, and when a driving motor drives a grinding head to grind a hole, an air pump exhausts air in a collecting box, and under the action of negative pressure, the scraps generated during grinding and the scraps generated after punching enter the collecting box through the dust collecting cover and a dust collecting pipe, the generated scraps areadsorbed after an electromagnet plate is powered on, then the scraps can be prevented from blocking the air intake end of the air pump, and when the scraps need to be discharged after work is finished, a worker firstly powers off the electromagnet plate, and the scraps are discharged from a scrap discharging opening, so that the scrap collecting rate is improved.

Owner:岳阳市卓立机筛有限公司

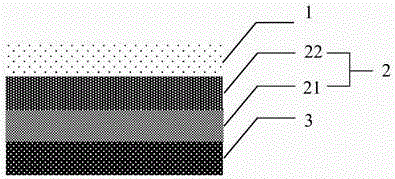

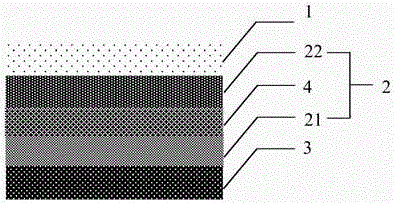

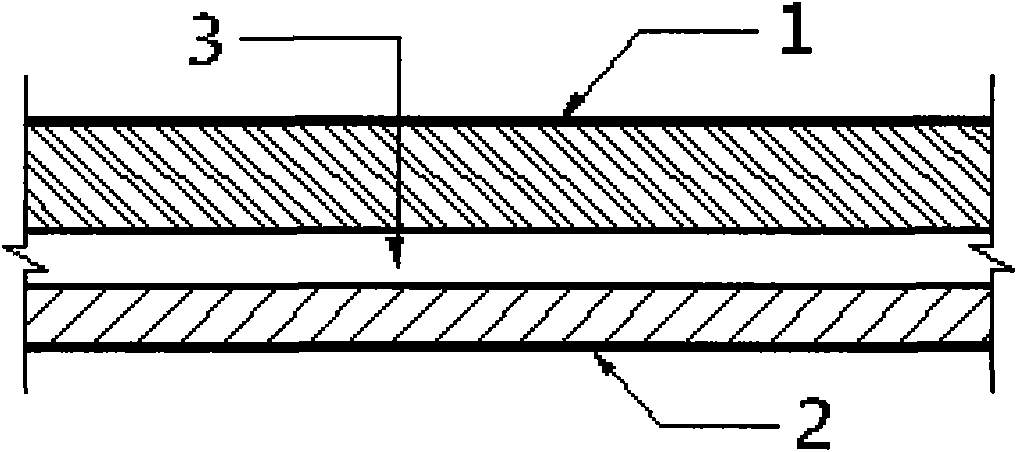

Ultra-thin heat dissipation film and preparation method thereof

ActiveCN106626583AImprove cooling effectEasy to slimLaminationLamination apparatusLayer groupElectronic materials

The invention discloses an ultra-thin heat dissipation film and a preparation method thereof, and relates to the field of electronic materials. The heat dissipation film comprises an upper protective film layer, a lower protective film layer, and at least one heat dissipation layer group positioned between the upper protective film layer and the lower protective film layer, wherein the heat dissipation layer group comprises a heat dissipation metal film layer and a heat dissipation rubber film layer which is overlaid on the heat dissipation metal film layer and is used for transferring heat transversely. The heat dissipation film provided by the invention is easy to operate, and is suitable for various electronic products and communication equipment; a formed film layer is light, thin and dense.

Owner:广州宏庆电子有限公司

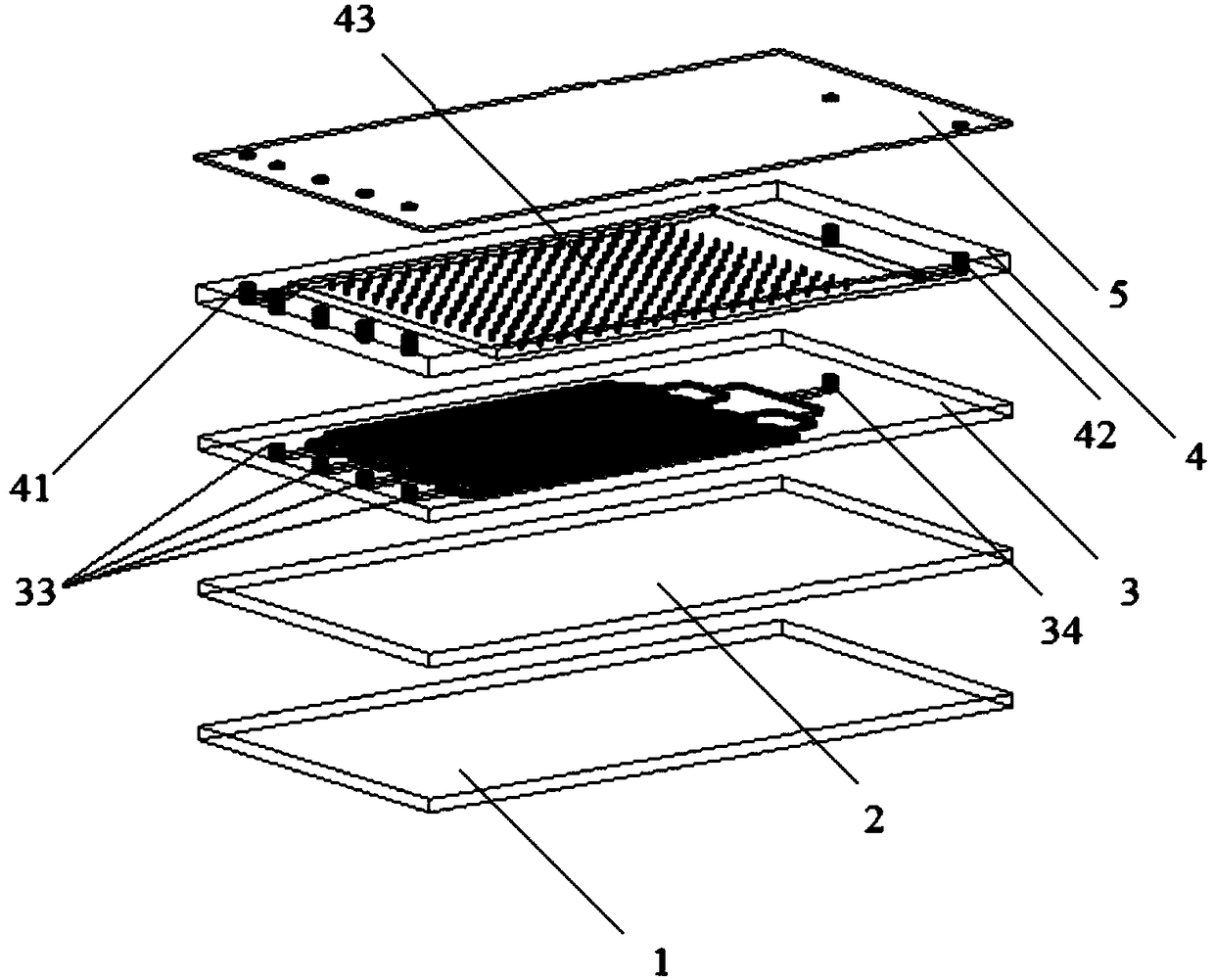

Digital PCR (polymerase chain reaction) chip and methods for preparing and applying same

InactiveCN108373969AEasy to operateAccelerateBioreactor/fermenter combinationsBiological substance pretreatmentsParyleneEngineering

The invention provides a digital PCR (polymerase chain reaction) chip and methods for preparing and applying the same. The digital PCR chip comprises a glass support layer, a seal layer, a reaction layer, a cavity layer and a waterproof layer. The glass support layer, the seal layer, the reaction layer, the cavity layer and the waterproof layer are sequentially arranged from bottom to top, the reaction layer and the seal layer are bonded to form main flow channels and a plurality of independent PCR chambers between the reaction layer and the seal layer, the PCR chambers are separated from oneanother by the main flow channels, the cavity layer and the reaction layer are bonded to form cavities between the cavity layer and the reaction layer, sample inlets and sample outlets which are sequentially perforated are further formed in the reaction layer, the cavity layer and the waterproof layer, and cavity layer inlets and cavity layer outlets which are sequentially perforated are formed inthe cavity layer and the waterproof layer; the seal layer, the reaction layer and the cavity layer are made from polydimethylsiloxane, and the waterproof layer is made from parylene. The digital PCRchip and the methods have the advantage that the digital PCR chip is easy to operate, high in speed, flux and automation degree and low in manufacturing cost.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Agricultural punching machine facilitating heat dissipation and pore diameter adjustment

InactiveCN107710981AWon't burn outImprove cooling effectPlantingFurrow making/coveringPunchingAgricultural engineering

The invention discloses an agricultural perforating device which is convenient for heat dissipation and aperture adjustment, which comprises a base and a top plate. A first through hole is arranged in the middle of the inner part of the base, and universal wheels are arranged on both sides below the base. Both sides above the base are provided with connecting pipes, and the inside of the connecting pipe is provided with a second through hole, the bottom of the connecting plate is provided with a connecting rod, and the inside of the connecting plate is provided with a fixing ring, and the connecting rod A first limit block is arranged on the four sides, a movable block is installed at the upper port of the movable rod, and a magnet block is arranged on the side of the second limit block facing the central axis of the movable rod. The agricultural punching device that facilitates heat dissipation and hole diameter adjustment can ensure that the driver will not be burned out due to excessive temperature when the device works for a long time, and the device can change the diameter of the punched hole, which is convenient for users to choose Appropriate hole diameter to drill.

Owner:南京市雨花台区创新创业法治宣传与法律服务中心

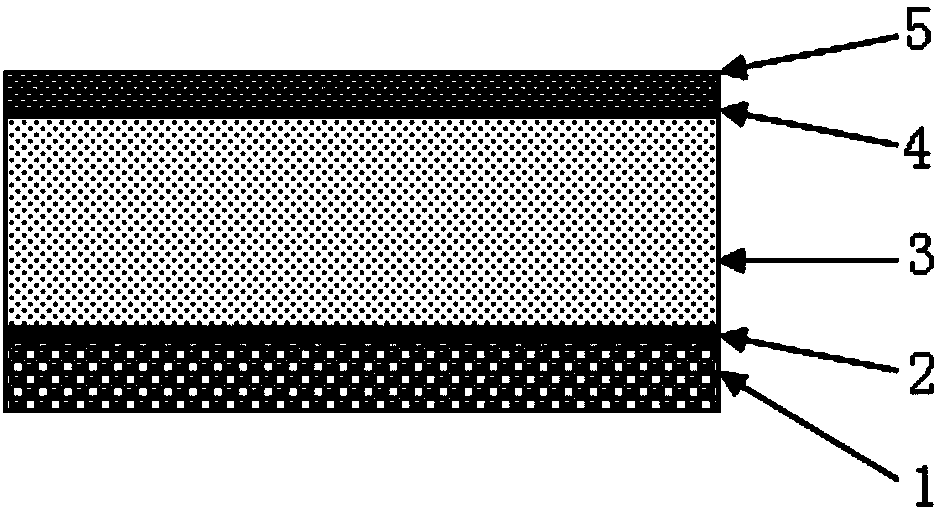

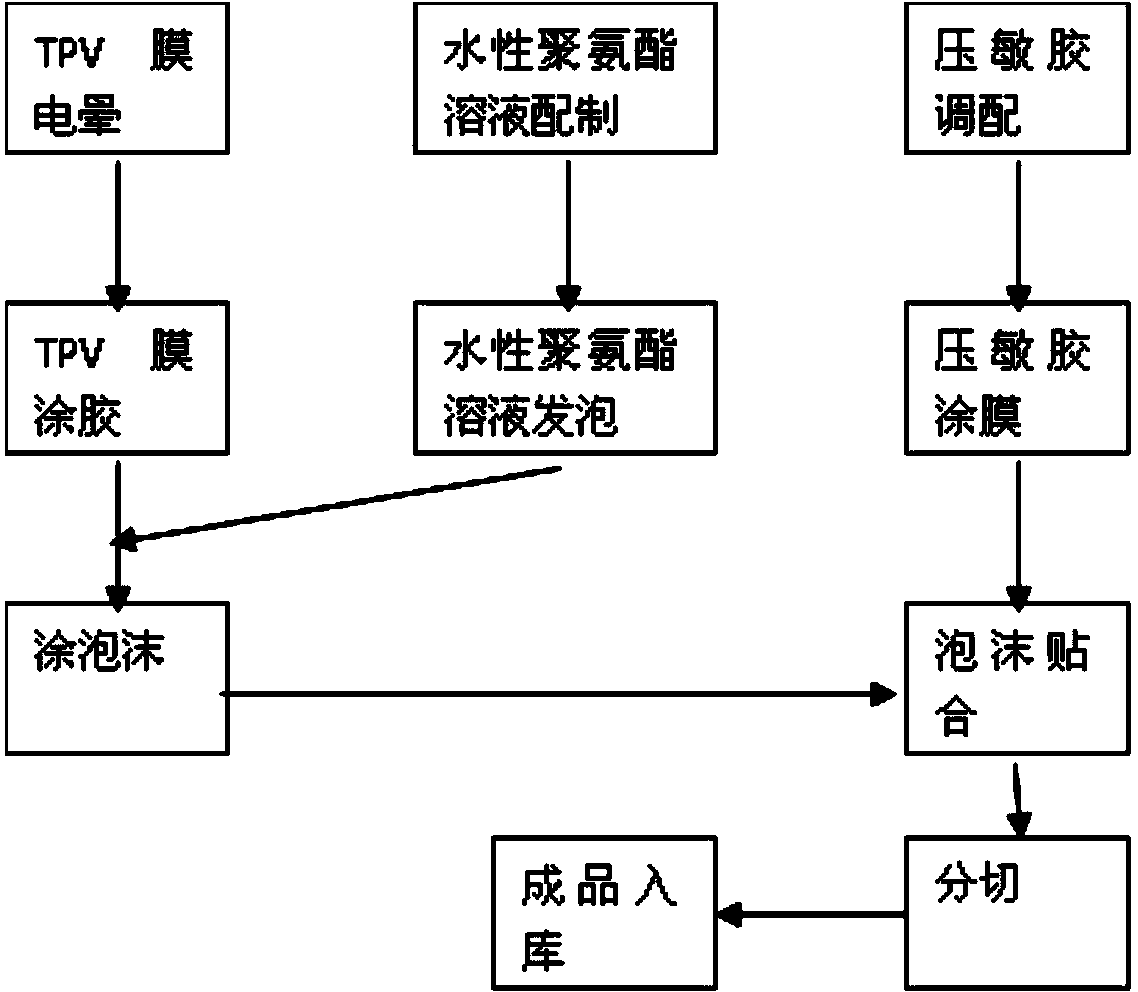

Foam adhesive tape and preparation method thereof

ActiveCN104371584AImprove sealingIncrease elasticityFilm/foil adhesivesPolyureas/polyurethane adhesivesThermoplasticPolyurethane adhesive

The invention discloses a production method of a foam tape. The foam tape comprises a TPV (Thermoplastic Vulcanizate) film, a bonding layer, a foam layer, a pressure-sensitive adhesive layer and a PE (Poly Ethylene) film. The production method comprises the following steps: a) performing polyurethane affinity treatment on the TPV film, and coating the surface of the TPV film with a single-component polyurethane adhesive to obtain the bonding layer; b) sequentially adding 10-30% of anti-hydrolysis component and 1-2% of foam regulation agent into waterborne polyurethane emulsion to form a polyurethane mixed liquid; c) performing polyurethane release treatment on the PE film; d) under a temperature condition of 100-120 DEG C, foaming the polyurethane mixed liquid to form the foam layer on the TPV film; e) coating the foam layer with the pressure-sensitive adhesive so that the PE film and the polyurethane foam are bonded. By adopting the method disclosed by the invention, the produced waterborne polyurethane foam tape has good rebound resilience, high elongation, high strength and long anti-aging time, and is environment-friendly.

Owner:SHANGHAI 3N CHEM

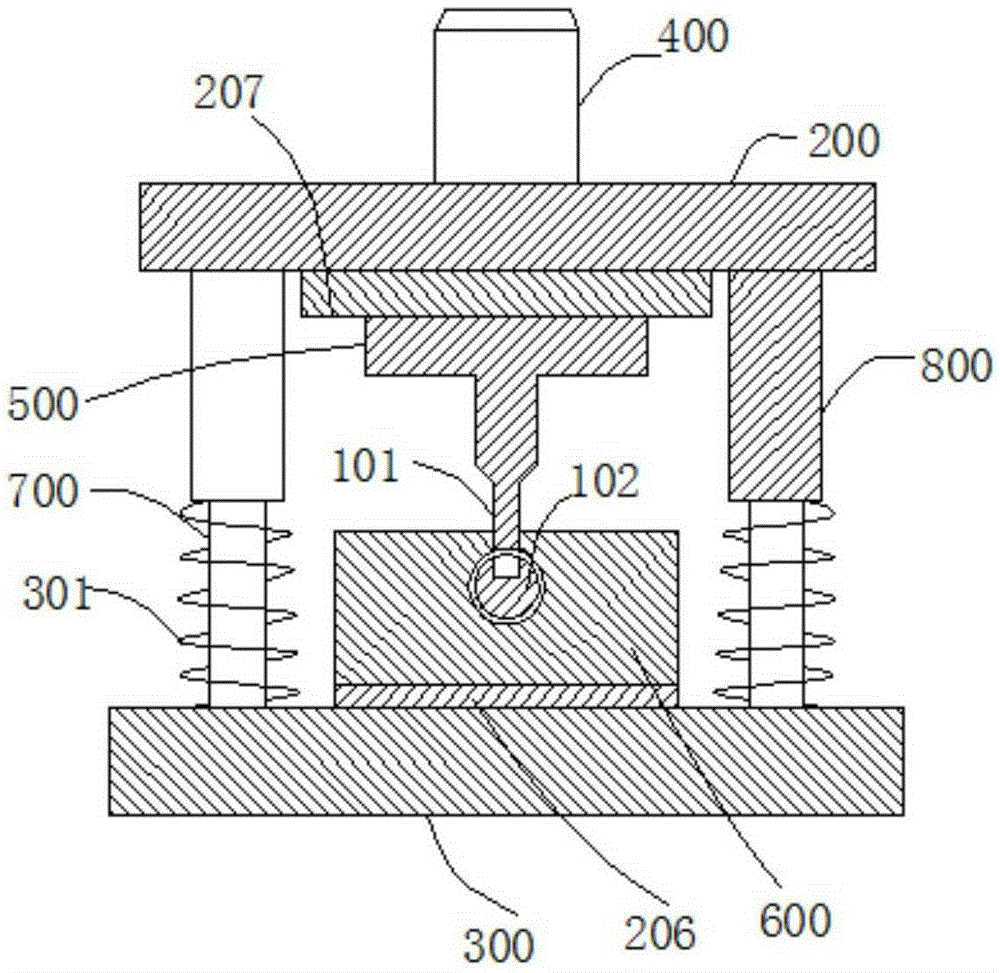

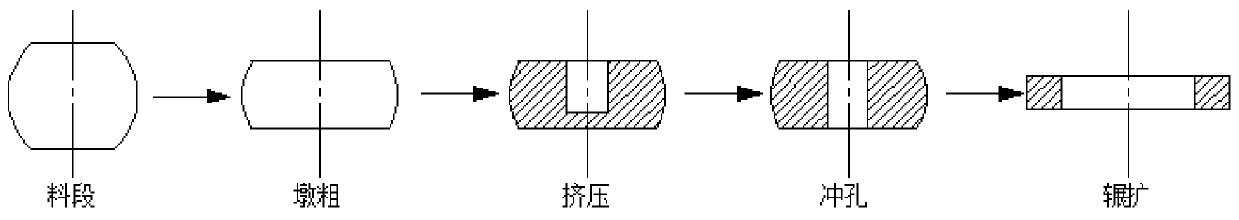

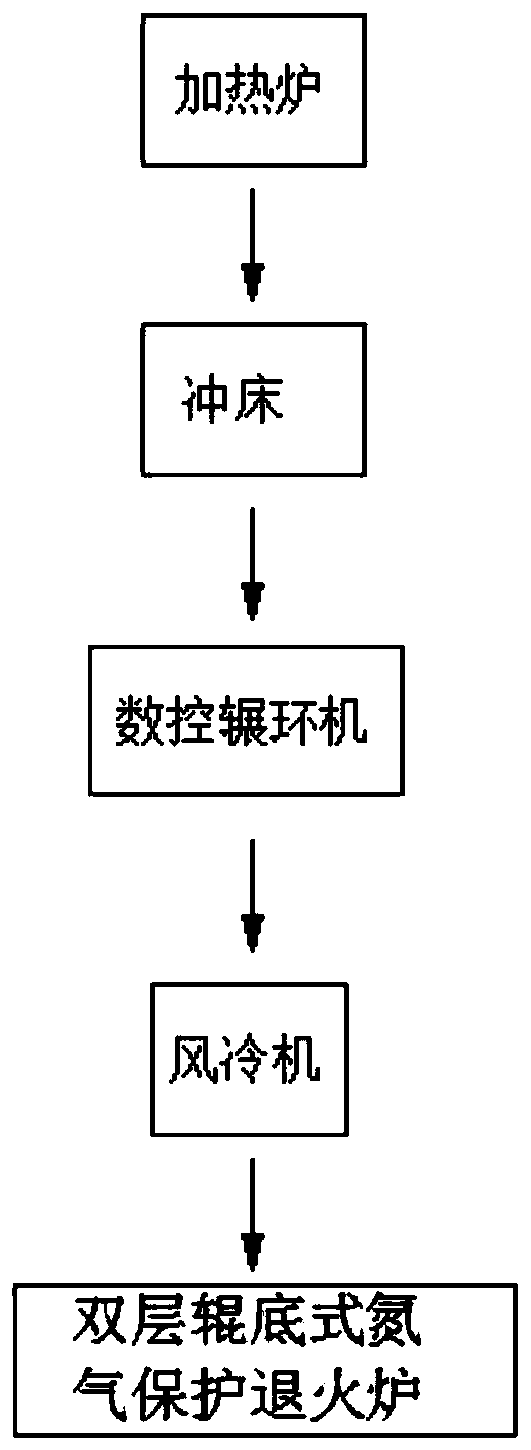

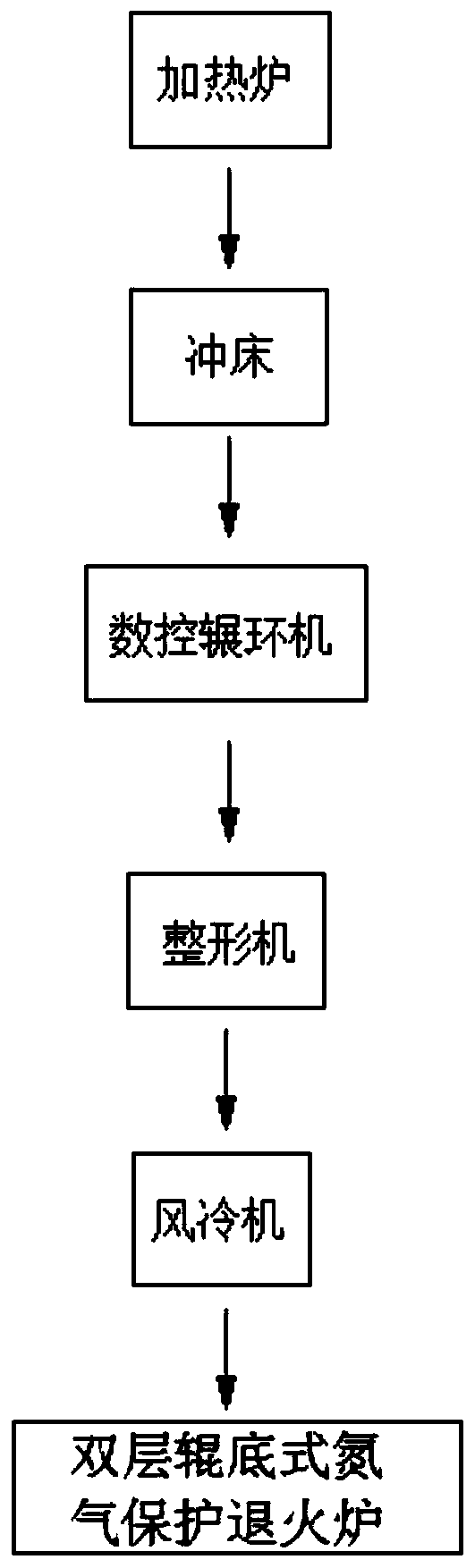

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

Puncher convenient to use

The invention relates to the technical field of mechanical equipment, and discloses a convenient punching machine, which includes a box body, one side of the box body is fixedly connected to one side of the controller, and the other side of the box body is connected to the wind turbine. One side of the chassis is plugged in, the top of the fan box is fixedly connected to the bottom of the air duct, the top of the air duct extends through the sloping plate to the outside and is fixedly connected to the bottom of the dust cover, the two sides of the sloping plate They are respectively fixedly connected to both sides of the inner wall of the box, and the side of the box away from the fan box is provided with a discharge port. The easy-to-use punching machine, through the slant plate fixedly connected on the inner wall of the box and the discharge port opened on one side of the box, cooperates with the fan box inserted on one side of the box and the leaking plate fixedly connected on the inner wall of the box, The fan box will generate suction when it is working, so that the drilling debris can be absorbed into the box when drilling. At the same time, the inclined plate and the discharge port facilitate the cleaning of the debris in the box and facilitate the use of drilling.

Owner:绍兴韵足针纺织有限公司

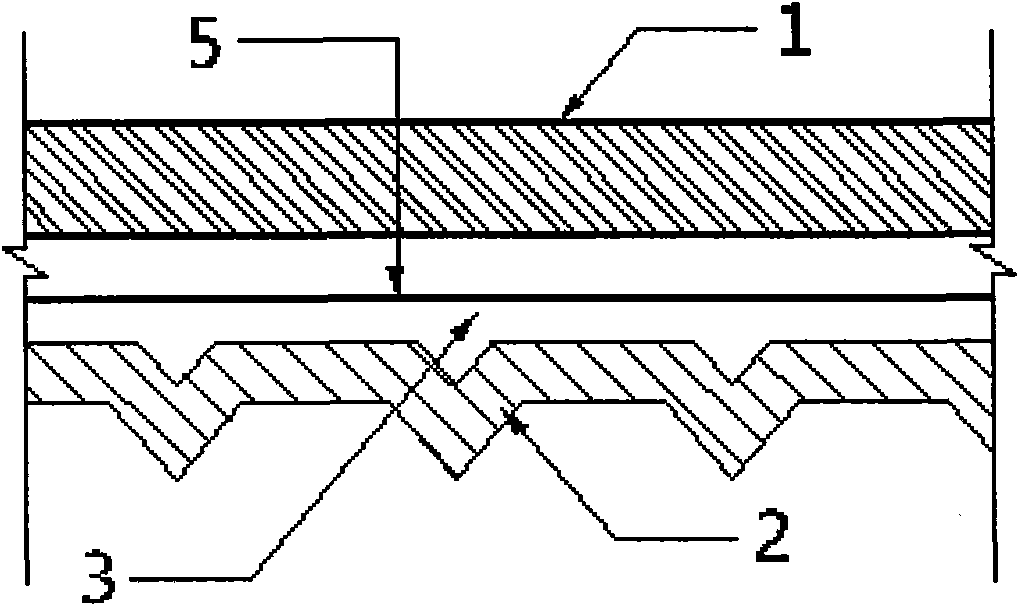

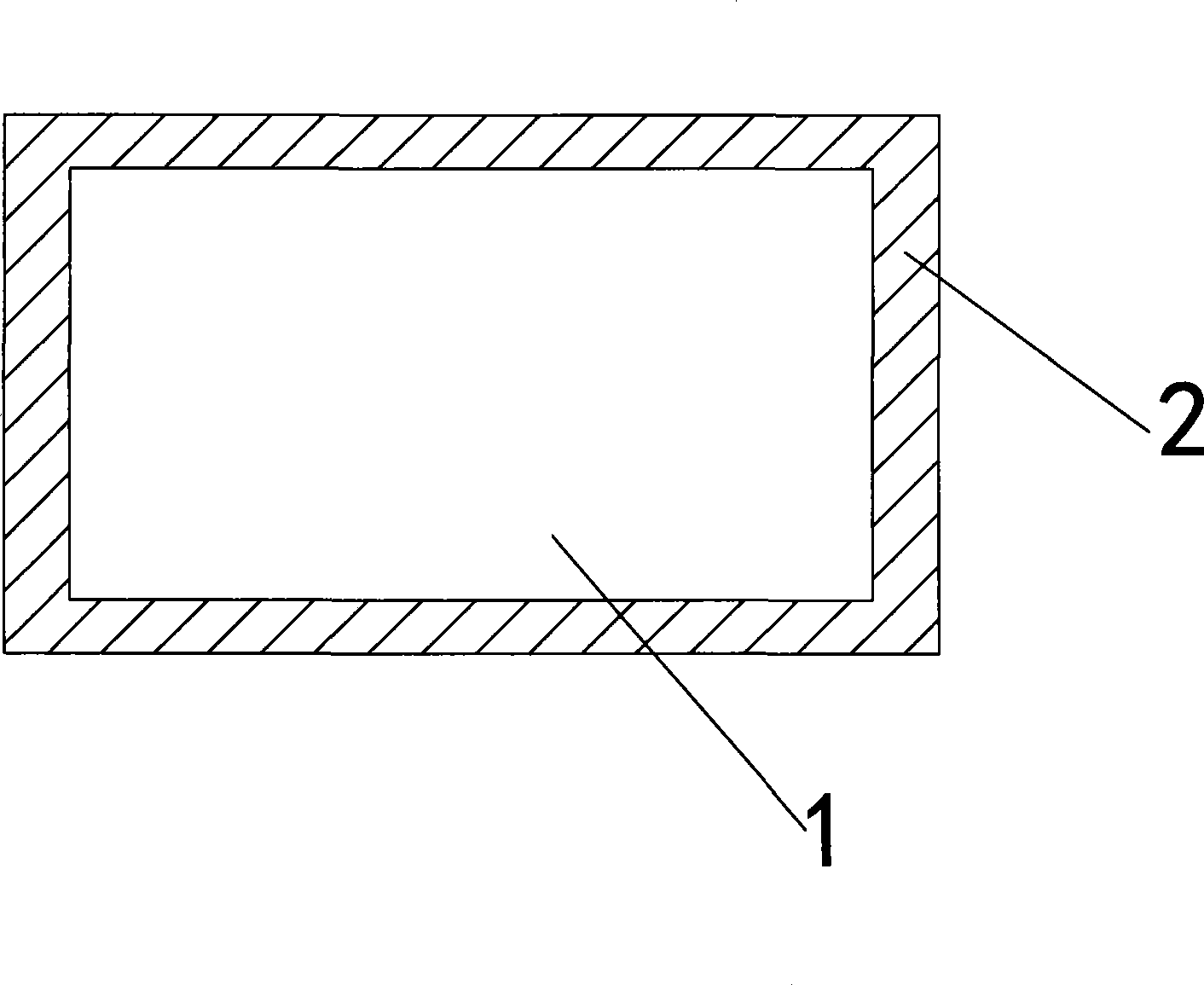

Metal-reinforced composite decorative glass plate

InactiveCN102166859ADeformation constraints are goodHigh tensile strengthSpecial ornamental structuresGlass/slag layered productsThin slabMetallic materials

The invention relates to a metal-reinforced composite decorative glass plate, wherein a glassy sheet is used as a surface layer. The decorative glass plate is convenient for cutting and punching, can be slightly cold bent when glass is relatively thin and can be conveniently fixed while decorative functions of glassy materials are maintained. The metal-reinforced composite decorative glass plate comprises a glassy sheet layer (1), a metal-reinforced layer (2) and a bonding layer (3), wherein the glassy sheet layer is bonded with the metal-reinforced layer via the bonding layer. The glassy sheet layer (1) is a sheet layer prepared from brittle glassy materials such as glass plates, tempered glass plates, glass-ceramic plates and the like. The original state of the sheet layer is in the shape of a sheet and the sheet layer is arranged by one or more sheets with the total thickness less than three millimeters. The metal-reinforced layer (2) is a structure layer prepared from metal materials which have relatively high strength and fine processing property. The metal materials mentioned above are copper, aluminum, iron, and corresponding alloy materials. And the metals can be plate-shaped, corrugated, or in the shape of engraved sheet materials, or the metals can be sheet materials which are braided or arranged in a longitudinal and a latitudinal manner, for example, copper plates, aluminium plates, aluminium alloy plates, iron plates, galvanized steel plates, steel wire sheets, stainless steel plates.

Owner:吕孟龙

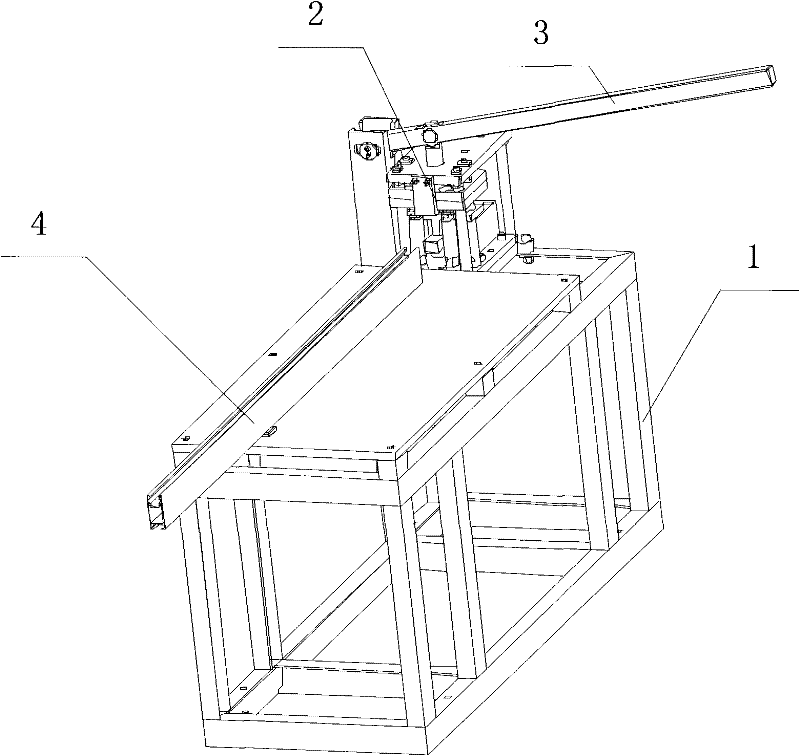

Plate perforating machine for railway transportation equipment

InactiveCN107030764AEasy to punchMetal-working feeding devicesMetal working apparatusThreaded pipeEngineering

The invention provides a plate punching machine for railway transportation equipment, which relates to the field of punching devices. The plate punching machine for railway transportation equipment includes a base, and slide rails are arranged on the left and right sides of the upper surface of the base, and a pulley block matching the slide rail is arranged on the slide rail, and the pulley block and the bottom surface of the clamping platform Fixed connection, the front side of the upper surface of the clamping platform is threaded with a clamping plate through bolts, the upper surface of the base is provided with a first connecting plate on the side away from the clamping plate, and the upper surface of the clamping platform is away from the side of the clamping plate A clamping plate is provided, the center of the back of the clamping plate is fixedly connected with the front end of the first threaded pipe, the rear end of the first threaded pipe is threadedly connected with the front end of the first threaded rod, and the rear end of the first threaded rod runs through the first The connecting plate extends to the back of the first connecting plate and is fixedly connected with a nut. The plate punching machine for railway transportation equipment can change the position of the punching device so that it is more convenient when punching the plate.

Owner:陈婷

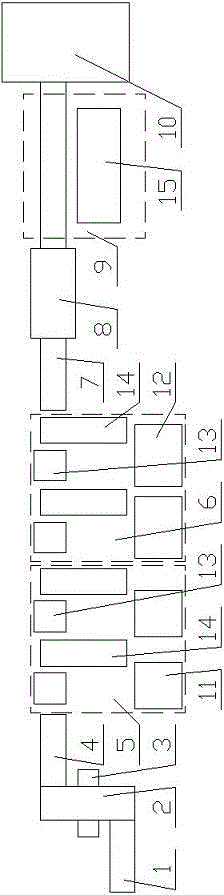

Elevator door plate production line

ActiveCN105728583AFully automatedIncrease productivityMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an elevator door plate production line. The elevator door plate production line sequentially comprises a blank feeding device, a feeding transfer rack, a punching device, a bending device, a riveting device, a rib applying area and a blanking transfer rack. A conveying rack A is disposed between the punching device and the bending device. A conveying rack B is mounted between the bending device and the riveting device. The feeding transfer rack is disposed above the feeding device, the punching device and the conveying rack A. The conveying rack B is connected with the blanking transfer rack through the riveting device and the rib applying area. According to the structure of the elevator door plate production line, automatic production of elevator door plates is achieved, the production efficiency of the elevator door plates is improved, and the labor cost is effectively reduced.

Owner:JIANGYIN FIVE STAR WELDING COPPER

Spectacle frame drilling machine capable of achieving multi-angle rotation

ActiveCN106475593AEasy to punchIngenious designSpectales/gogglesPositioning apparatusEngineeringMechanical engineering

The invention relates to a spectacle frame drilling machine capable of achieving multi-angle rotation. The spectacle frame drilling machine comprises a base, a drill bit arranged on the base and a fixing device used for fixing a spectacle frame. The fixing device comprises a mounting plate, a left-right movable block, a front-back movable block which is arranged on the left-right movable block in a front-back moving mode, a supporting block which is fixedly arranged on the front-back movable block, and a rotating device which is arranged above the supporting block. The rotating device is provided with a spectacle frame mounting base used for fixing the spectacle frame. According to the spectacle frame drilling machine capable of achieving multi-angle rotation, the left-right position of the spectacle frame can be adjusted by adjusting a first screw rod, the front-back position of the spectacle frame can be adjusted by adjusting a second screw rod, the spectacle frame drilling machine can rotate around the x-axis direction by adjusting a first adjusting knob so that fine adjustment of the spectacle frame position can be realized, and therefore the spectacle frame position can be adjusted in a multi-angle rotation mode, and the spectacle frame can be drilled conveniently. The spectacle frame drilling machine can rotate around the y-axis direction by adjusting a second adjusting knob so that fine adjustment of the spectacle frame position can be realized.

Owner:XIAMEN MINGLAI TECH CO LTD

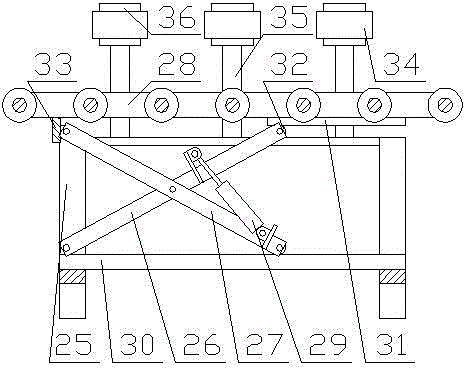

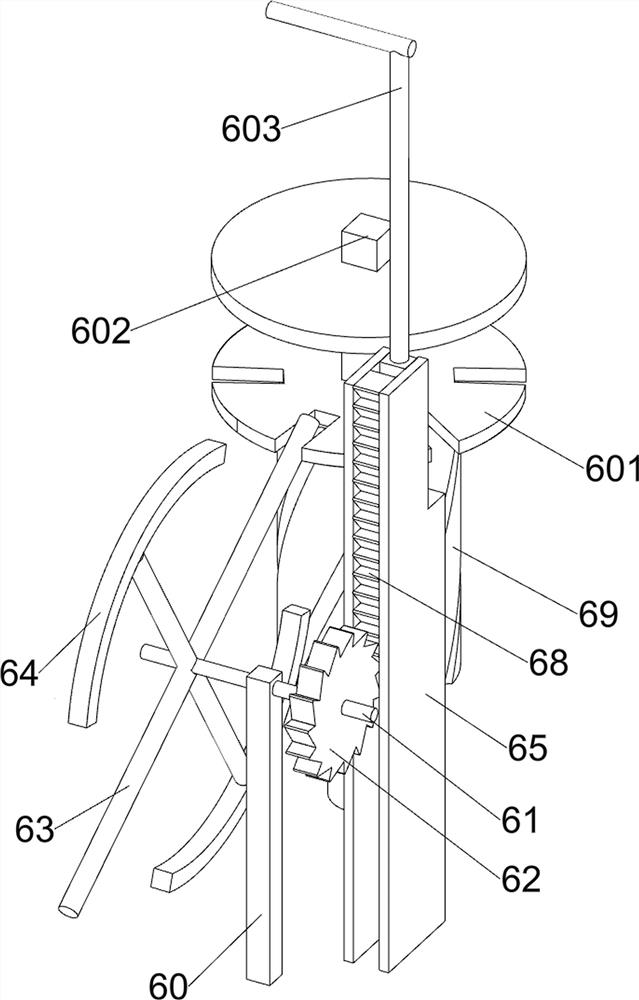

Iron sheet punching and perforating equipment

ActiveCN111957818AImprove efficiencyEasy to punchMetal-working feeding devicesPositioning devicesRatchetPunching

The invention relates to perforating equipment, in particular to iron sheet punching and perforating equipment. A robot is provided to replace human hands for fixing and perforating iron sheets, so that the iron sheet punching and perforating equipment is safe in perforating and high in working efficiency. The iron sheet punching and perforating equipment comprises a base and a support. The support is arranged on the rear side of the top of the base. The iron sheet punching and perforating equipment further comprises a connecting plate, a punching mechanism, clamping mechanisms and a rotatingmechanism. The punching mechanism is arranged on the front side of the support. The connecting plate is arranged on the punching mechanism. The clamping mechanisms are connected between the two sidesof the connecting plate and the top of the base. The rotating mechanism is arranged on the front side of the top of the base and is connected with the front portion of one side of the connecting plate. A cylinder is arranged to punch and perforate an iron sheet; a groove is then formed in a limiting disc to realize control over the iron sheet by a cross rod and an arc-shaped stirring piece; and aratchet rack and a ratchet gear cooperate to realize the intermittent rotating of the iron sheet, and the punching work can be conveniently carried out.

Owner:合肥亿昌兴智能科技有限公司

Conductive bus and manufacturing method thereof

InactiveCN101478092AImprove conductivityLow priceContact member manufacturingCoupling contact membersAluminum canCopper

The invention relates to a conducting bar and a manufacturing method thereof. The conducting bar comprises an aluminum core and a copper layer covering the aluminum core. The copper layer is closed around the aluminum core. The cross section of the conducting bar is rectangular; the area of the cross section of the copper layer accounts for 13 to 21 percent of the area of the cross section of the conducting bar. The conducting bar with copper covering aluminum can reach various parameter standards of the conducting bar. The invention further provides a new conducting material. By comparing the conducting bar with a fine copper conducting bar with equal cross section area, the price is low; the weight is light; and the conducting bar provided by the invention can be installed and transported conveniently, and is favorable for the environmental protection.

Owner:崔纪康 +1

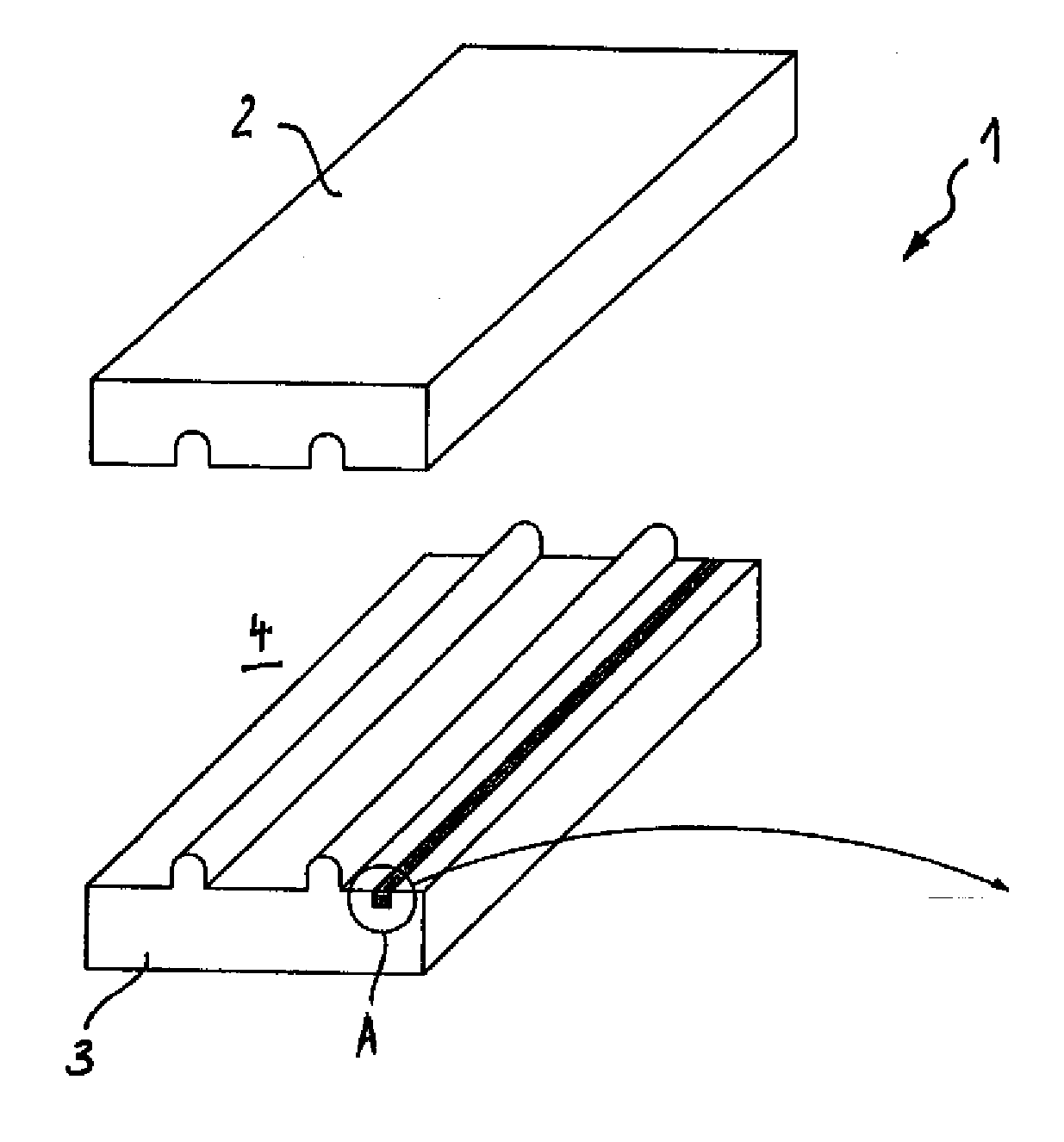

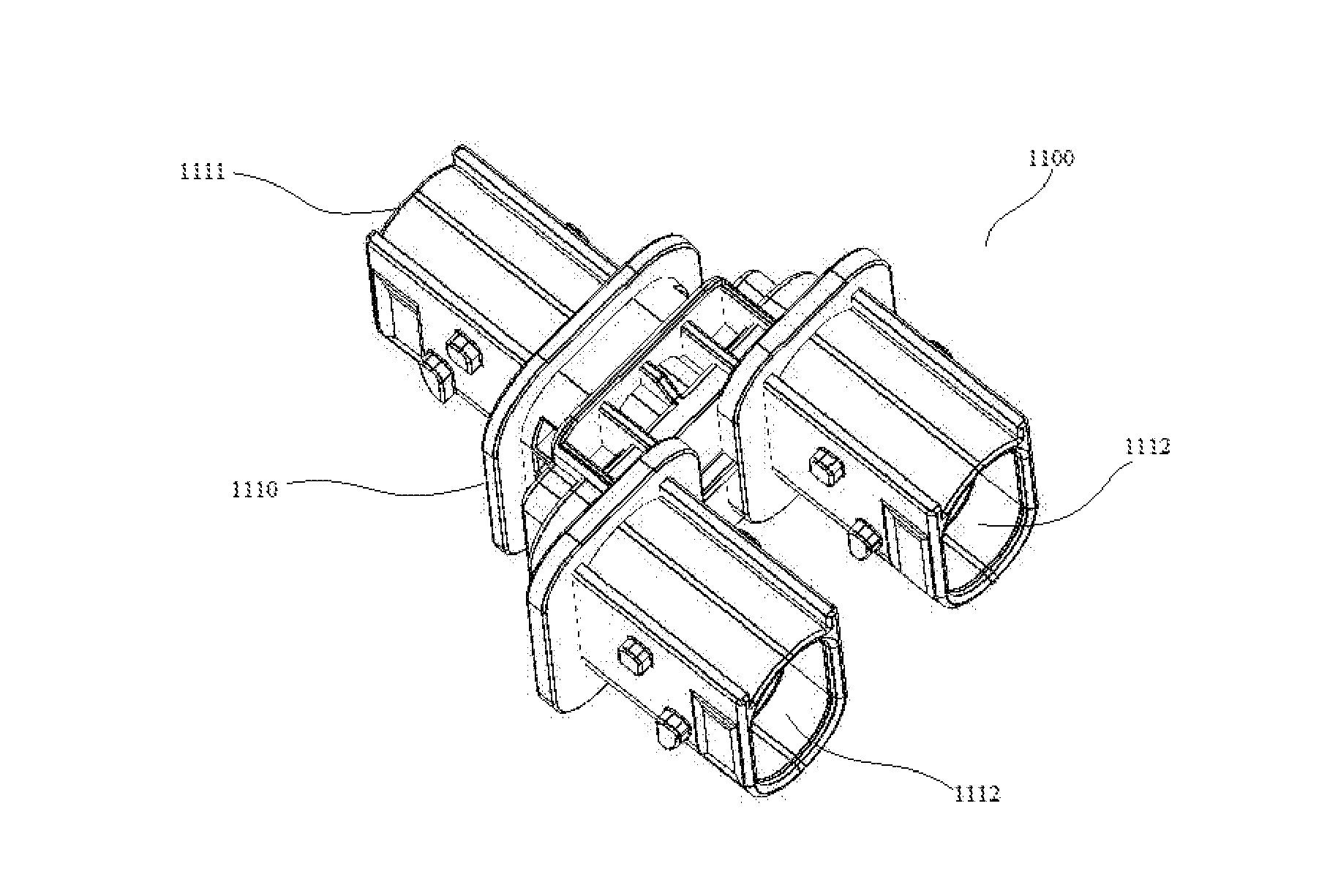

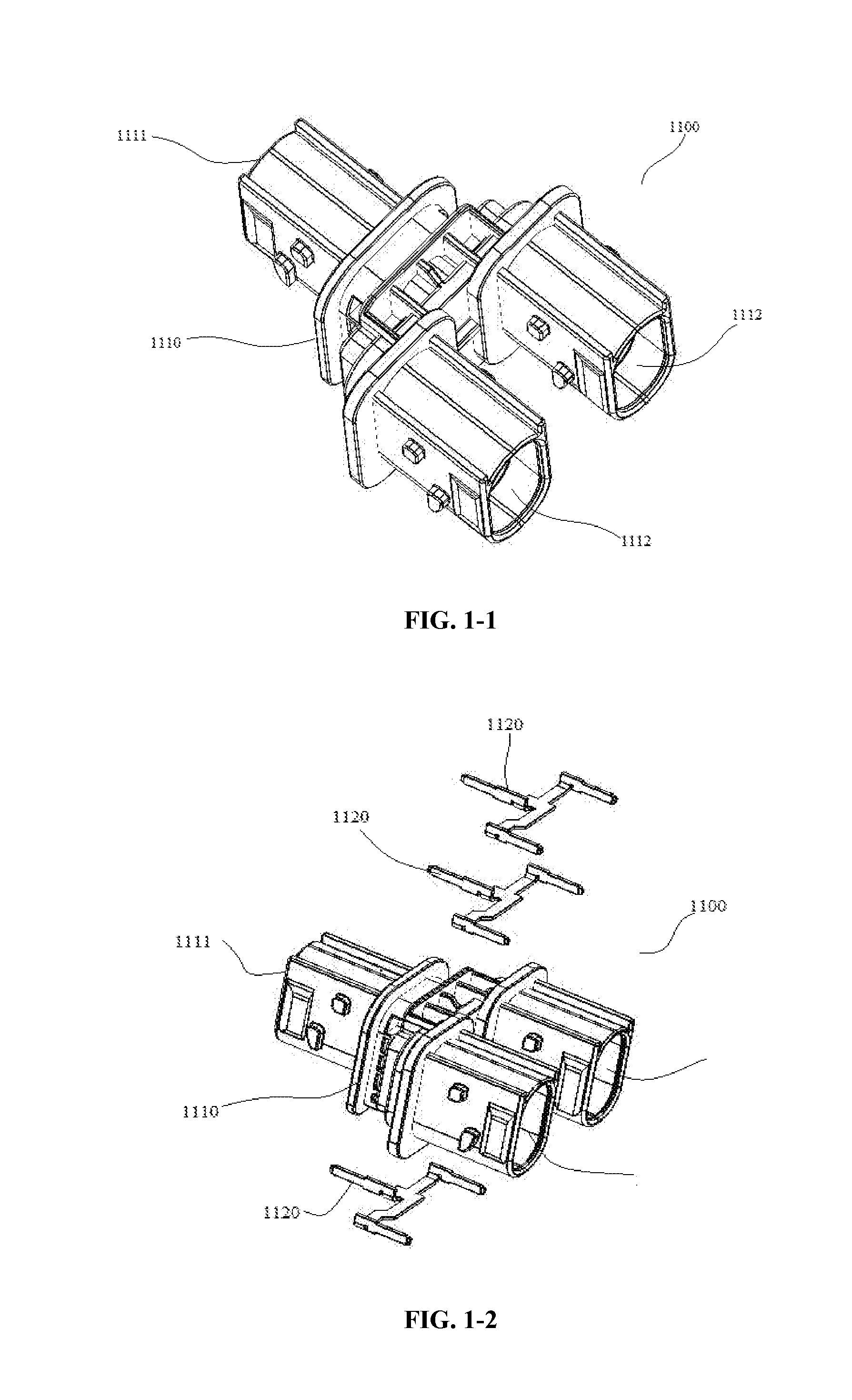

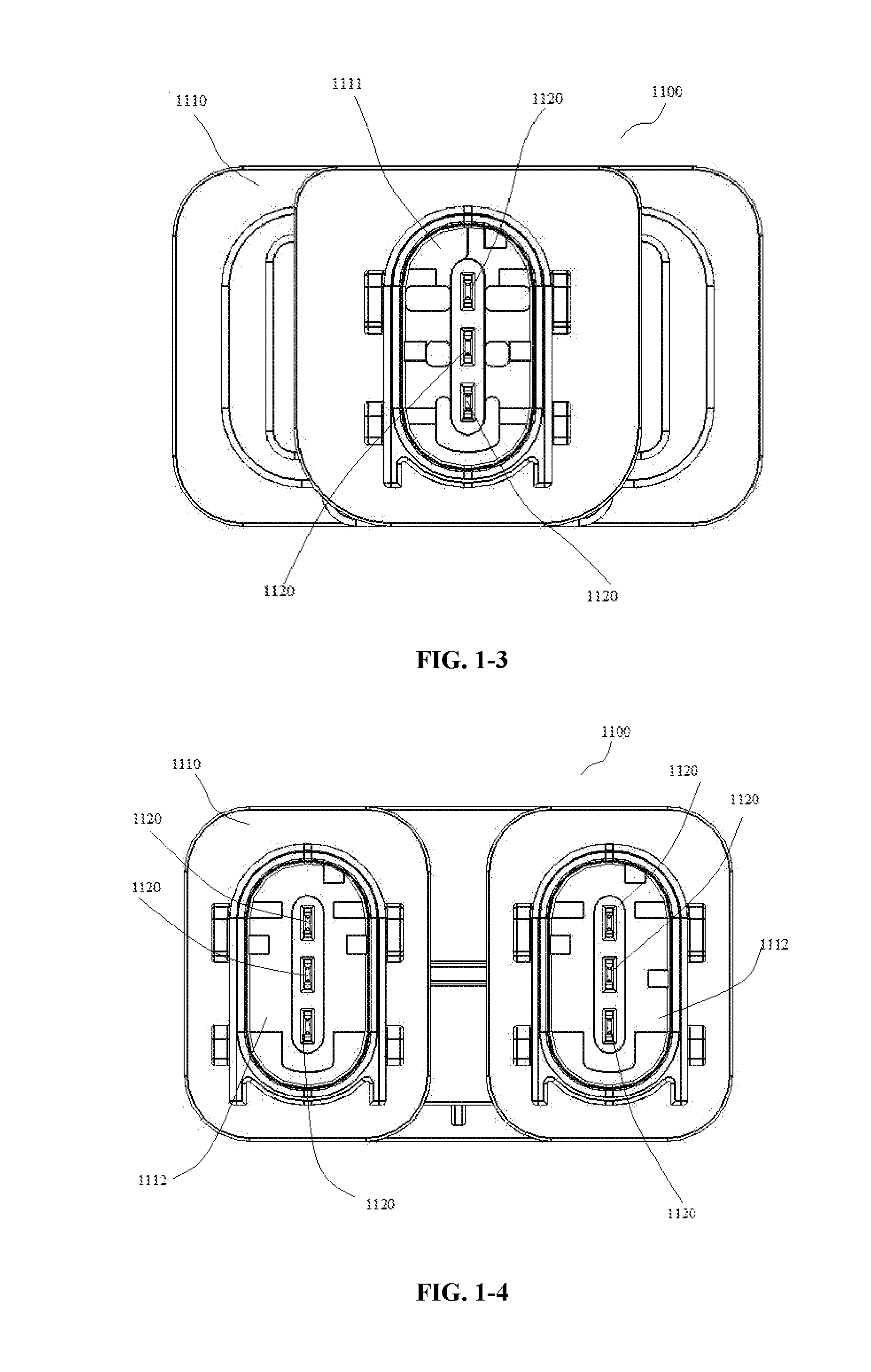

Connector, cable harness assembly, vehicle can bus connector and connection terminal

A first perspective of the invention relates to a connector, a cable harness assembly, and a vehicle CAN bus connector. The connector includes a housing and a metal connection terminal. The cable harness assembly includes multiple cables and the connector. The vehicle CAN bus connector includes the cable harness assembly. According to the invention, an input terminal and an output terminal are integrally disposed, saving the need of a printed circuit board, as such, a process of connecting terminals to a printed circuit board is eliminated. A second perspective of the invention relates to a connection terminal, a connector, a cable harness assembly, and a vehicle CAN bus connector. The connection terminal includes a terminal body and one or more shoulders, which are asymmetrically disposed on a surface of the terminal body and protrude therefrom, so that the connection terminal has an asymmetric structure in a direction perpendicular to the plug-in direction. The invention can prevent a mold from being damaged by incorrect placement of the connection terminal.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

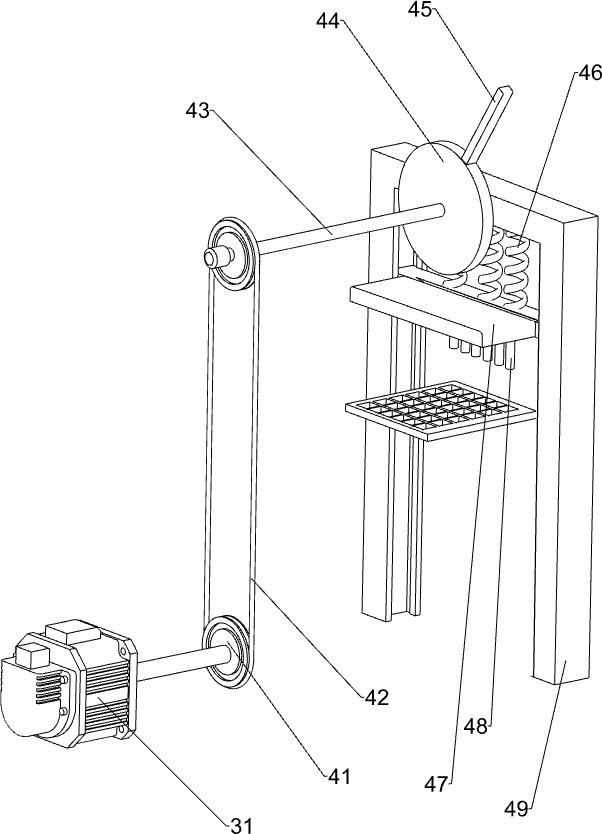

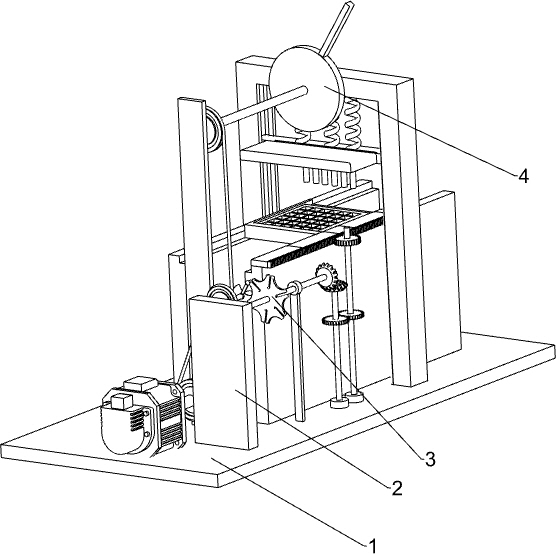

Self-moving die punching machine

InactiveCN111687291AEasy to punchImprove drilling efficiencyPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention relates to a punching machine, in particular to a self-moving die punching machine. The self-moving die punching machine can automatically punch a composite leaking plate, punch a plurality of holes at one time, and improve the punching efficiency. According to the technical scheme, the self-moving die punching machine comprises a base and a punching mechanism, wherein a support is installed on the front side of the base; a movement mechanism is arranged on the base; and the punching mechanism is installed on the base and connected with the movement mechanism. According to the self-moving die punching machine, the composite leaking plate can be driven to move intermittently through the movement mechanism, so that the different parts of the composite leaking plate are punchedconveniently; the composite leaking plate can be punched automatically through the punching mechanism; meanwhile, through the design of a plurality of punching rods, the plurality of holes can be punched simultaneously, so that the punching efficiency is improved; and waste falling in the punching process is collected through a waste collecting box instead of being swept manually.

Owner:刘建

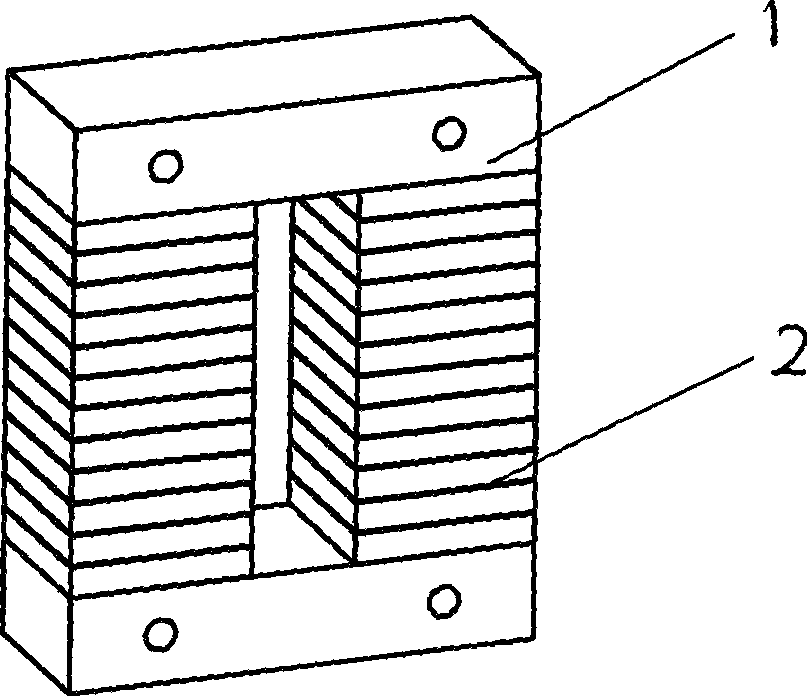

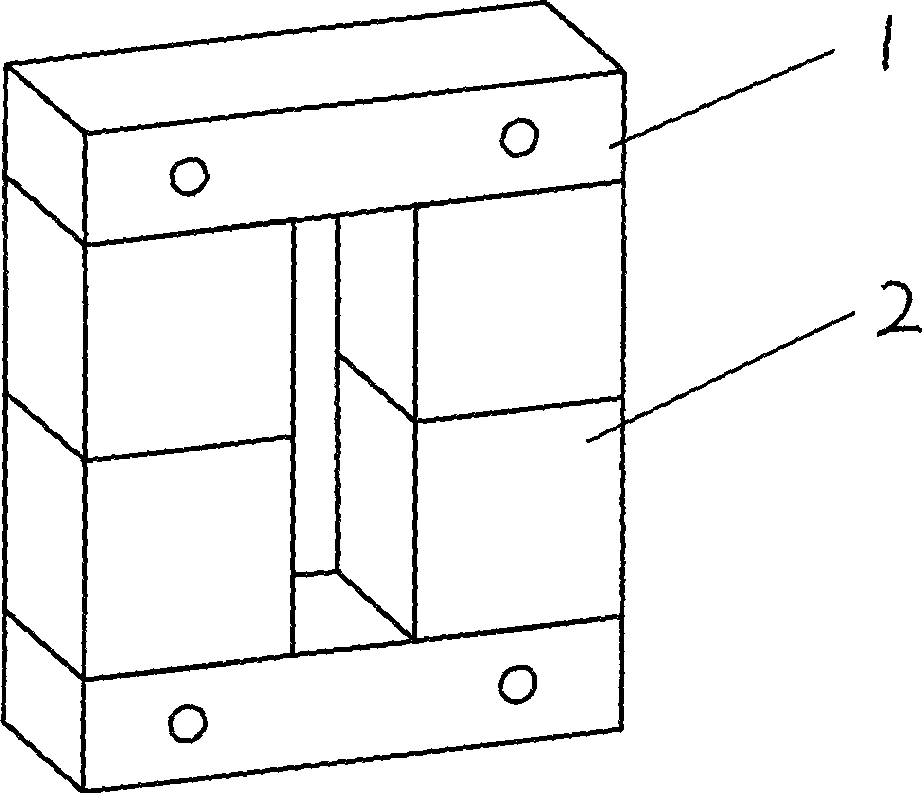

Novel inductor iron core

InactiveCN101430961AReduce additional lossReduce noiseInorganic material magnetismTransformers/inductances magnetic coresInductorUltimate tensile strength

The invention relates to a novel inductance core, consisting of a yoke iron and a core limb; the inductance core is characterized in that the yoke iron and the core limb are made of different soft magnetic materials. The novel inductance core uses different soft magnetic materials to be composed to prepare the yoke iron and the core limb of the inductance core; wherein, the yoke iron is preferably made of the soft magnetic material such as silicon steel which has greater strength, is easy to be welded and punched and is economical; the core limb is preferably made of materials such as soft magnetic ferrite or metal soft magnetic powder core which have extremely low loss during high frequency and light weight, are convenient to be processed into blocks with small dimension, can generate a plurality of air gaps during the overlapping process and are convenient for processing the air gaps at the same time. The inductance core has the advantages of simple and firm yoke iron, low loss of core limb, dispersed air gaps, extremely low loss generated by diffusion magnetic field, high efficiency, low loss, light weight, and the like.

Owner:焦海波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com