Forming method of thin-wall nut

A thin-wall, nut technology, applied in nuts, threaded fasteners, connecting components, etc., can solve the problems of affecting product quality, low production efficiency, long manufacturing cycle, etc. Lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

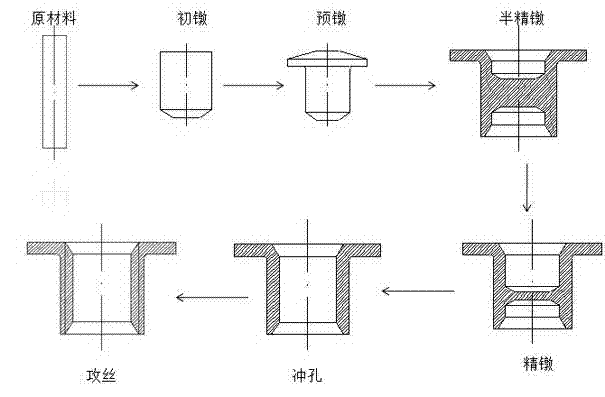

[0019] see figure 1 , a thin-walled nut forming method, comprising the steps of:

[0020] (1) Raw material: The raw material is the annealed round steel wire with phosphating and saponification on the surface. The steel wire is straightened by the cold heading machine. The straightened steel wire is sent to the cutting mechanism and cut into small pieces of blanks. The length is determined by the process volume of the part;

[0021] (2) Initial upsetting: Put the blank cut into small pieces into the female mold for end face shaping, which can avoid burrs and facilitate further deformation of the blank. Under the action of the shaping punch and the female mold, the blank is shaped into a cylinder and The combination of cone and frustum, the size of the cone angle is 90°, and the diameter of the small end of the cone is 0.5 times the diameter of the cylinder. At this time, the diameter of the cylinder is the minimum value of the diameter of this part of the part minus 0.4mm;

...

Embodiment 2

[0029] see figure 1 , a thin-walled nut forming method, comprising the steps of:

[0030] (1) Raw material: The raw material is the annealed round steel wire whose surface has been phosphated and saponified. The steel wire is straightened by an automatic cold heading machine. The straightened steel wire is sent to the cutting mechanism and cut into small pieces of blanks. The length of is determined by the process volume of the part;

[0031] (2) Initial upsetting: Put the blank cut into small pieces into the female mold for end face shaping, which can avoid burrs and facilitate further deformation of the blank. Under the action of the shaping punch and the female mold, the blank is shaped into a cylinder and The combination of cone and frustum, the size of the cone angle is 102°, and the diameter of the small end of the cone is 0.6 times the diameter of the cylinder. At this time, the diameter of the cylinder is the minimum value of the diameter of this part of the part minu...

Embodiment 3

[0039] see figure 1 , a thin-walled nut forming method, comprising the steps of:

[0040] (1) Raw material: The raw material is the annealed round steel wire whose surface has been phosphated and saponified. The steel wire is straightened by an automatic cold heading machine. The straightened steel wire is sent to the cutting mechanism and cut into small pieces of blanks. The length of is determined by the process volume of the part;

[0041] (2) Initial upsetting: Put the blank cut into small pieces into the female mold for end face shaping, which can avoid burrs and facilitate further deformation of the blank. Under the action of the shaping punch and the female mold, the blank is shaped into a cylinder and The combination of cone and frustum, the size of the cone angle is 110°, and the diameter of the small end of the cone is 0.7 times the diameter of the cylinder. At this time, the diameter of the cylinder is the minimum value of the diameter of this part of the part minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com