Conductive bus and manufacturing method thereof

A manufacturing method and a technology for conductive bars, which are applied in the manufacture of contacts, contact parts, etc., can solve the problems of increasing the manufacturing cost of power distribution equipment, inconvenient installation and transportation, and rising copper prices, achieving light weight, favorable for punching, The effect of good ductility and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

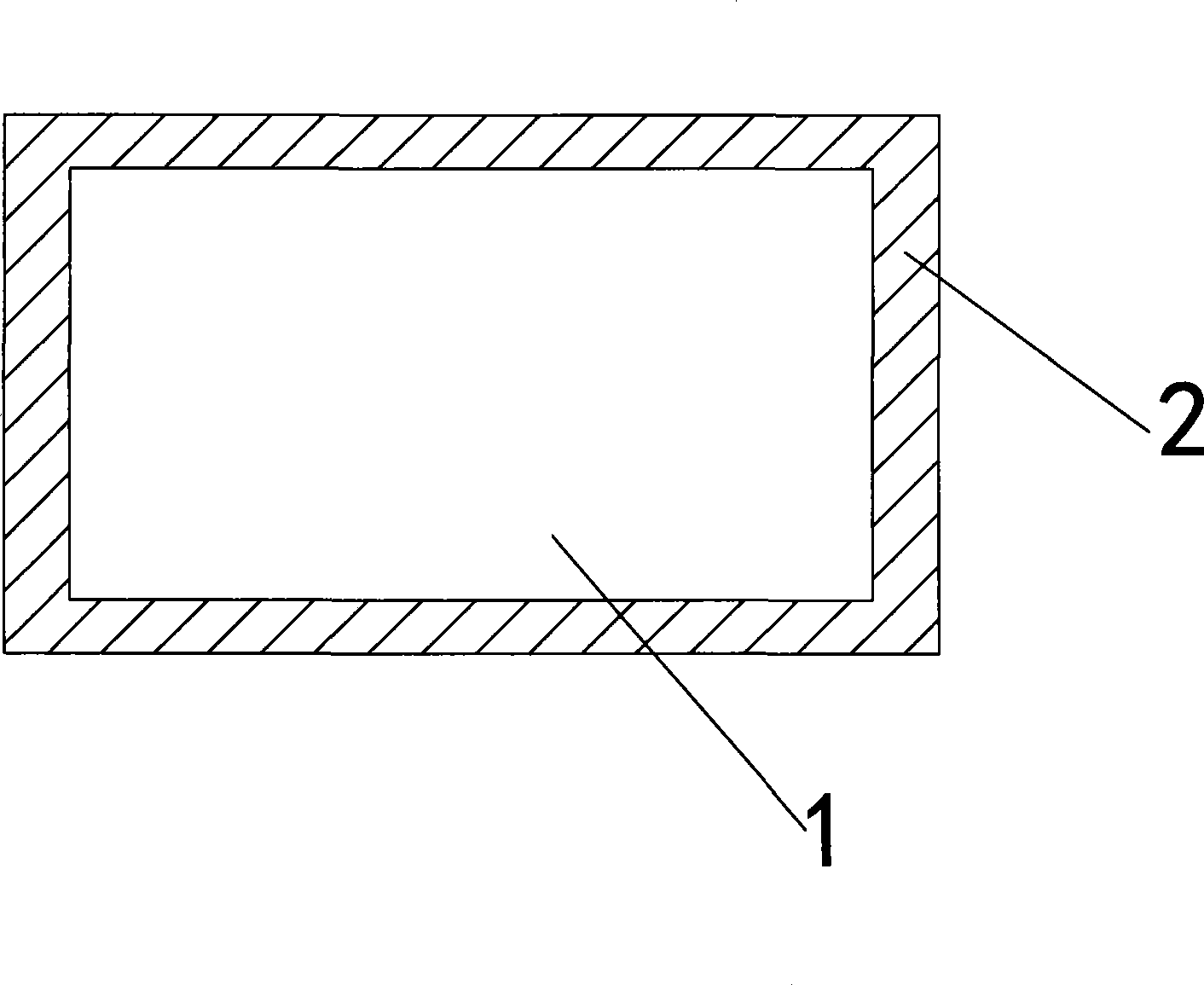

[0023] Referring to the drawings, a conductive row includes an aluminum core 1 and a copper layer 2 coated on the outside of the aluminum core 1, and the copper layer 2 is fully coated on the outside of the aluminum core 1 , a closed circle is formed on the cross section of the conductive row, and the copper layer 2 has no seams.

[0024] The cross-section of the conductive row is rectangular, and the cross-sectional area of the copper layer 2 accounts for 13-21% of the cross-sectional area of the conductive row, and the best embodiment is 15%. Experiments show that the volume of the copper layer The conductivity of the copper-clad aluminum busbar with a ratio of 15% is 85% of that of pure copper compared with pure copper busbar, and the density of copper-clad aluminum busbar is only 37%-40% of that of pure copper busbar. The length ratio of copper-clad aluminum row to pure copper row is 2.0-2.5.

[0025] A method of manufacturing the above conductive row, comprising the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com