Patents

Literature

36results about How to "With grinding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

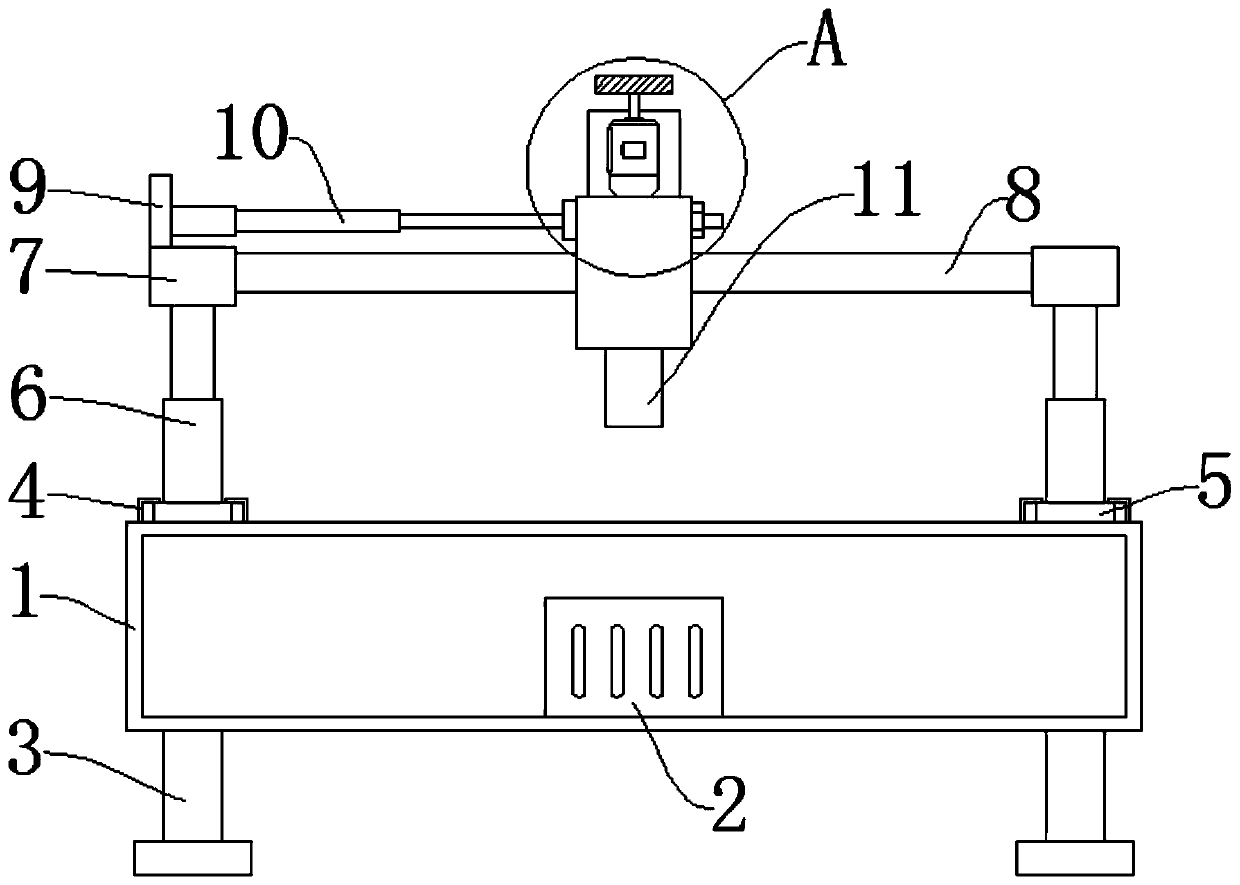

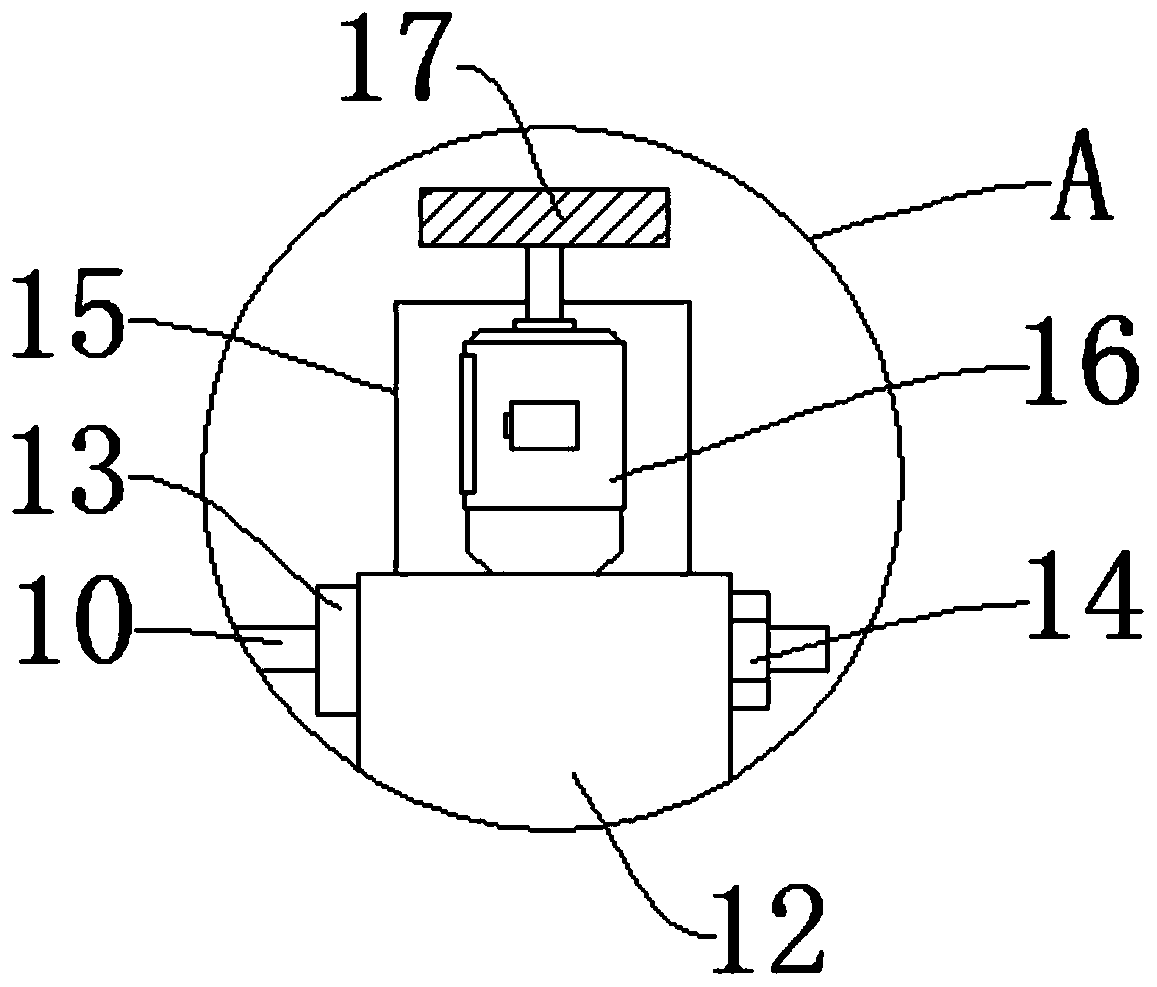

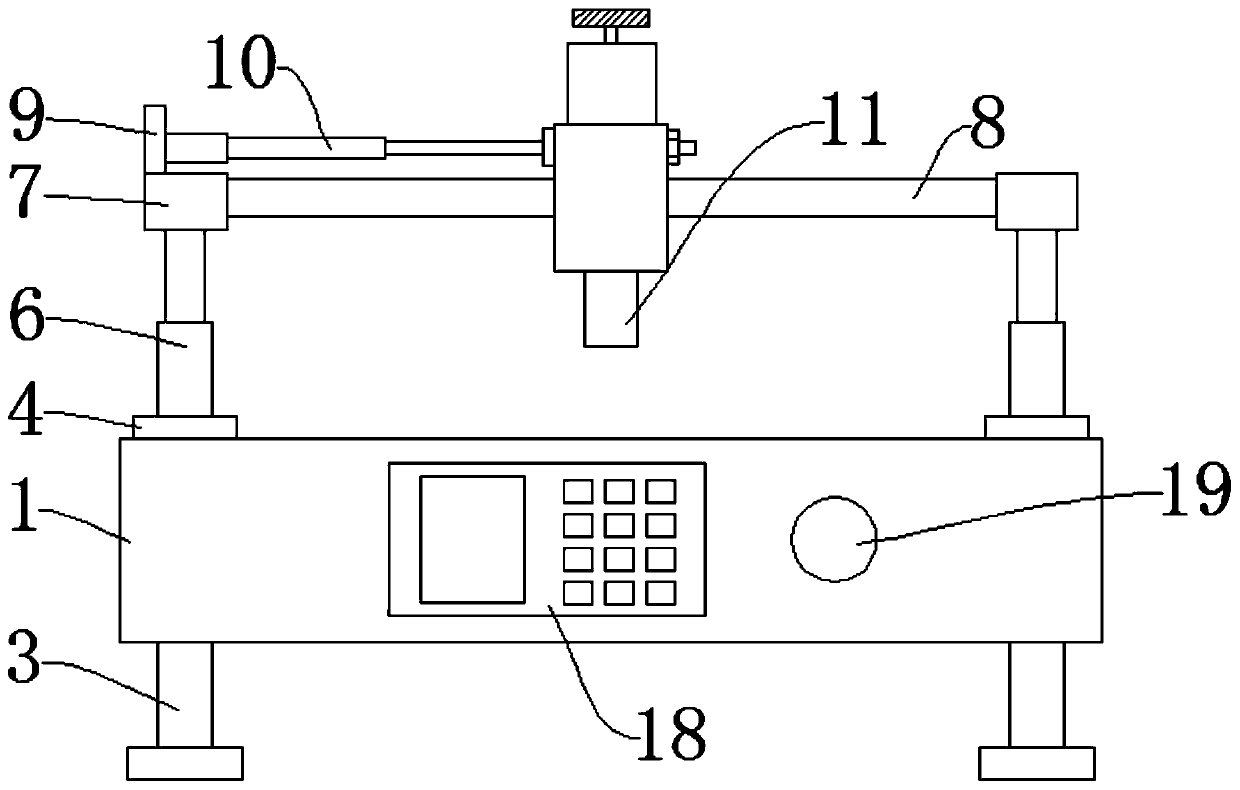

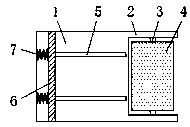

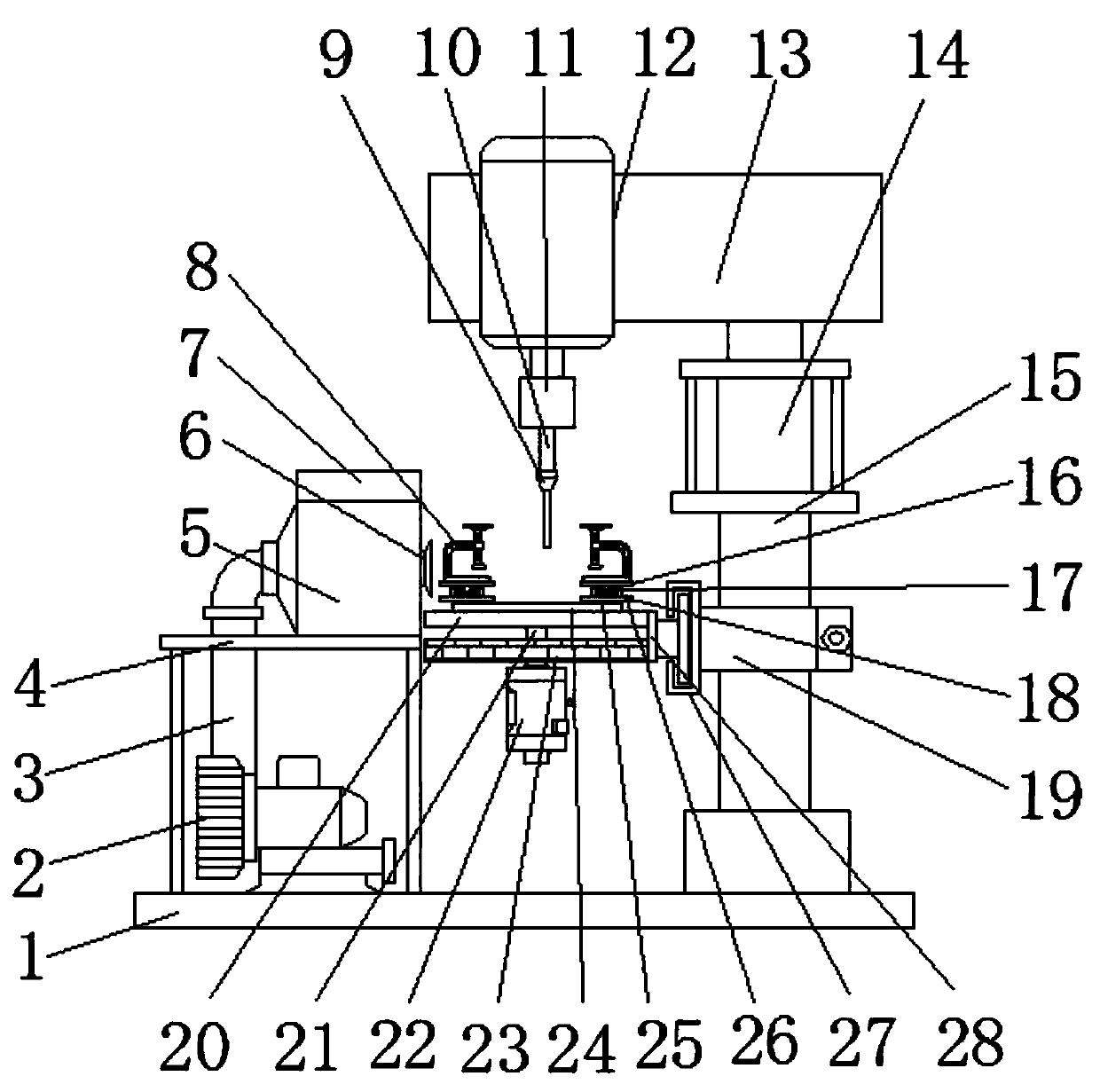

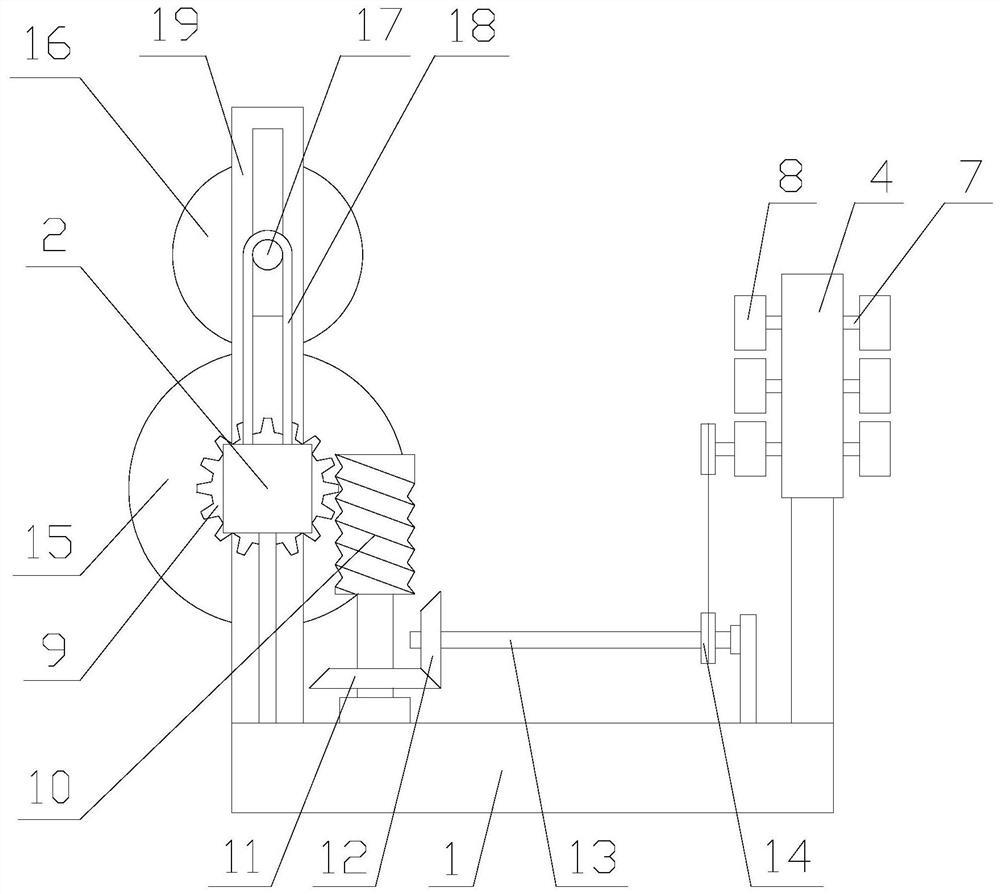

Metal hole punching device with grinding function

InactiveCN107717469AWith grinding functionReduce work intensityOther manufacturing equipments/toolsPositioning apparatusMetal machiningEngineering

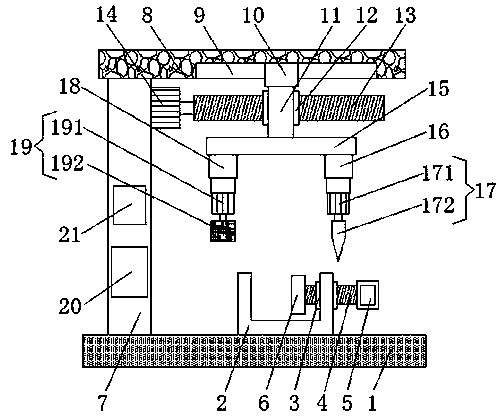

The invention discloses a metal hole punching device with a grinding function. The metal hole punching device with the grinding function comprises a bottom plate; a U-shaped plate is fixedly connectedwith the upper surface of the bottom plate; a first threaded cap is connected to the right side face of the U-shaped plate in a clamped manner; a first threaded rod is connected in the first threadedcap in a threaded manner; a handle is fixedly connected to the right end of the first threaded rod; and an extruding plate is fixedly connected with the left end of the first threaded rod. Accordingto the metal hole punching device with the grinding function, by arranging a first motor, an output shaft of the first motor rotates and drives a second threaded rod to rotate, and therefore a secondthreaded cap can be driven to move left and right, and a cross plate can be driven to move left and right, and a grinding device and a hole punching device can move to replace positions; after hole punching of the hole punching device is completed, the grinding device moves rightwards to grind burrs on the metal surface, and therefore people are not needed to manually grind the burrs any more, time and physical power of workers are saved, and convenience is brought to the workers during metal machining.

Owner:无锡龙博机械有限公司

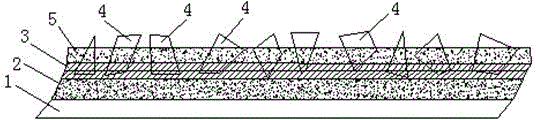

Industrial abrasive band based on chopped linen fibers

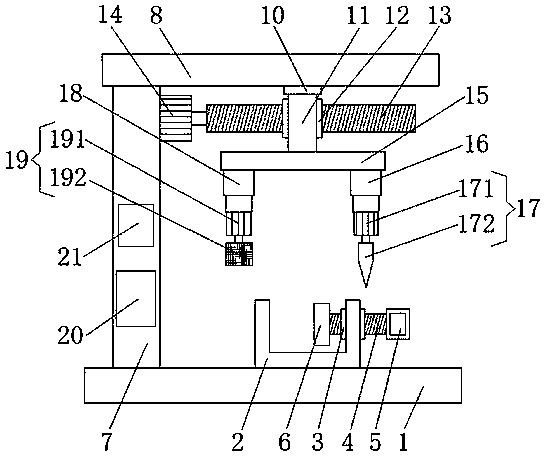

The invention discloses an industrial abrasive band based on chopped linen fibers and aims to solve the technical problems that a base material of the conventional abrasive band does not have a grinding function and is poor in mechanical performance, elasticity modulus is difficultly improved greatly and the like. The industrial abrasive band comprises a base material, wherein the base material is subjected to soaking and scraping treatment or soaked with glue which contains the chopped linen fibers or is added with sand; a layer or a plurality of layers of glue which contains the chopped linen fibers or is added with the sand is formed on one surface, namely the front side or the back side of a treated fabric base through blade coating according to requirements, then a primer containing the glue which contains the chopped linen fibers or is added with the sand is coated, then sand is planted on the primer, and the primer is coated with composite glue, wherein the composite glue can be glue which contains the chopped linen fibers or is added with relative fine grained sand. According to the industrial abrasive band, a messy structure of the chopped linen fibers is adopted, so that the shock resistance of the glue layers is improved; simultaneously, the chopped linen fibers can be synchronously consumed and has certain polishing and grinding performance; and due to certain hardness and brittleness of linen fiber, the industrial abrasive band has grinding capability, the performance is improved, and the using cost is reduced.

Owner:谢泽

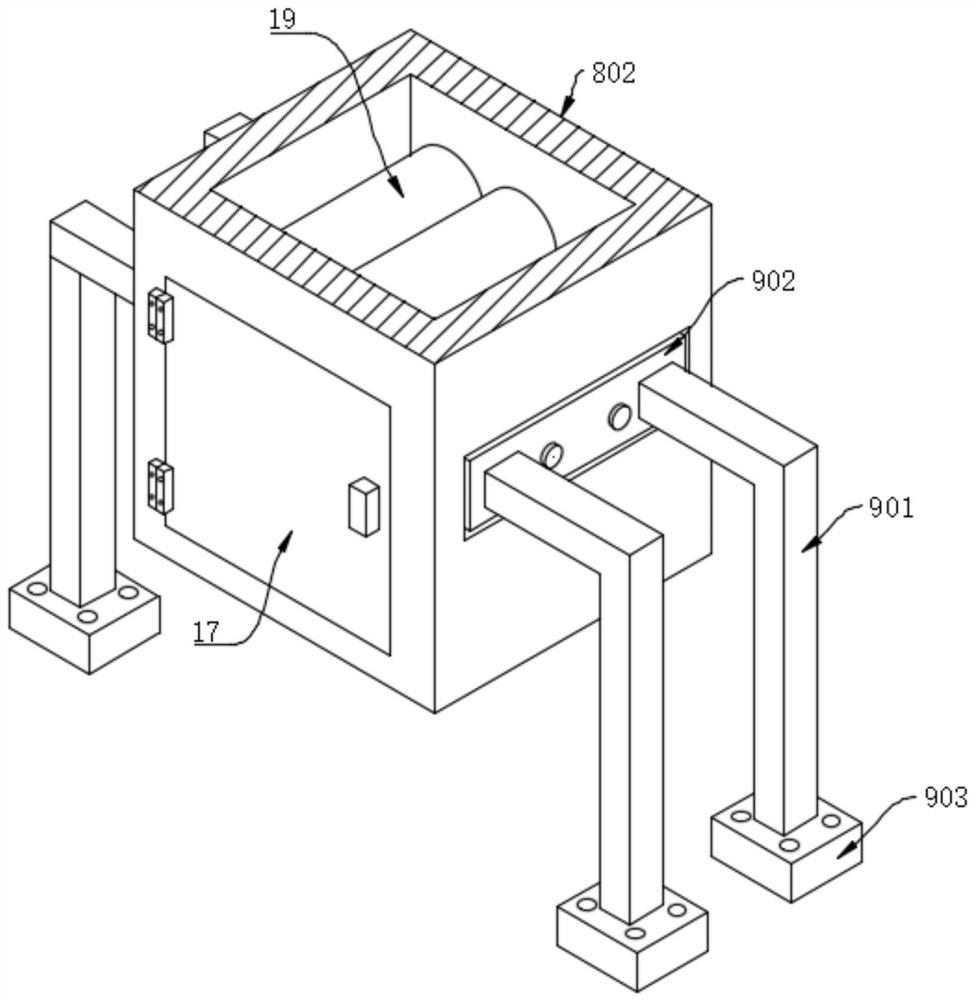

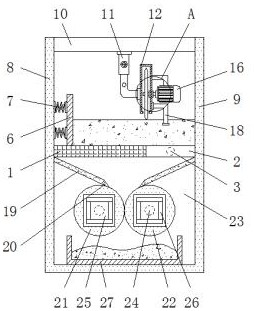

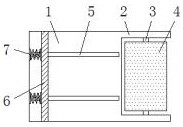

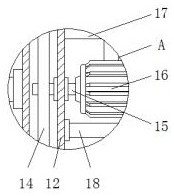

Sand blasting machine provided with polishing wheel for polishing burr

InactiveCN107717755AWith grinding functionAvoid deformationEdge grinding machinesAbrasive machine appurtenancesWater storage tankEngineering

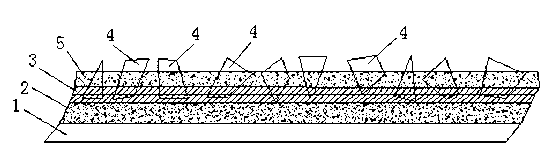

The invention discloses a sand blasting machine provided with a polishing wheel for polishing burr. The sand blasting machine comprises a rack, the polishing wheel and a sand blasting chamber, whereinthe sand blasting chamber is arranged on the rack; two elevating mechanisms are symmetrically arranged on the left side and the right side of the top end of the inside of the sand blasting chamber; the polishing wheel and a sand storage cylinder are respectively arranged at the lower ends of the two elevating mechanisms; the polishing wheel comprises a rotating motor arranged at the lower ends ofthe elevating mechanisms and a polishing piece coaxially and rotatably connected with the rotating motor; a water storage tank is arranged on one side of the polishing wheel; an air bag for extrusionis arranged at the upper end of the water storage tank in a through connection manner; a water discharge pipe is guided out of the lower end of the water storage tank; a nozzle is arranged at the lower end of the water discharge pipe and inclines to the polishing piece; a spray gun is connected with the lower end of the sand storage cylinder by a material guide hose. Through adoption of the manner, the burr on the surface of a workpiece, which cannot be removed in sand blasting, can be auxiliarily polished by the polishing wheel.

Owner:WUXI RISHENG MACHINERY FACTORY

Multifunctional fast laser cutting device

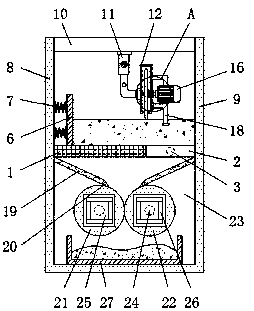

InactiveCN109807473AImprove practicalityWith grinding functionLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a multifunctional fast laser cutting device, which comprises a base, a controller, a control panel and an emergency stop button, wherein the controller is fixed inside the basethrough screws; the control panel is arranged at the front part of the base; the emergency stop button is arranged at one side of the control panel; and support feet are welded under the base. The height of a laser cutting head can be regulated through electric push rods, so that the multifunctional fast laser cutting device can be used for cutting articles at different heights; the practicability of the device is improved; when the articles need to be ground, a locking screw nut is dismounted, so that an electric telescopic rod is separated from a slide block; the slide block turns for a half cycle, so that a grinding wheel is vertically toward; then, the electric telescopic rod is inserted into the slide block; the locking screw nut is tightly screwed; next, a motor is started through the control panel; the motor is electrified to drive the grinding wheel to rotate; therefore the device has a grinding function; and the functionality of the device is improved.

Owner:孝感金致科技有限公司

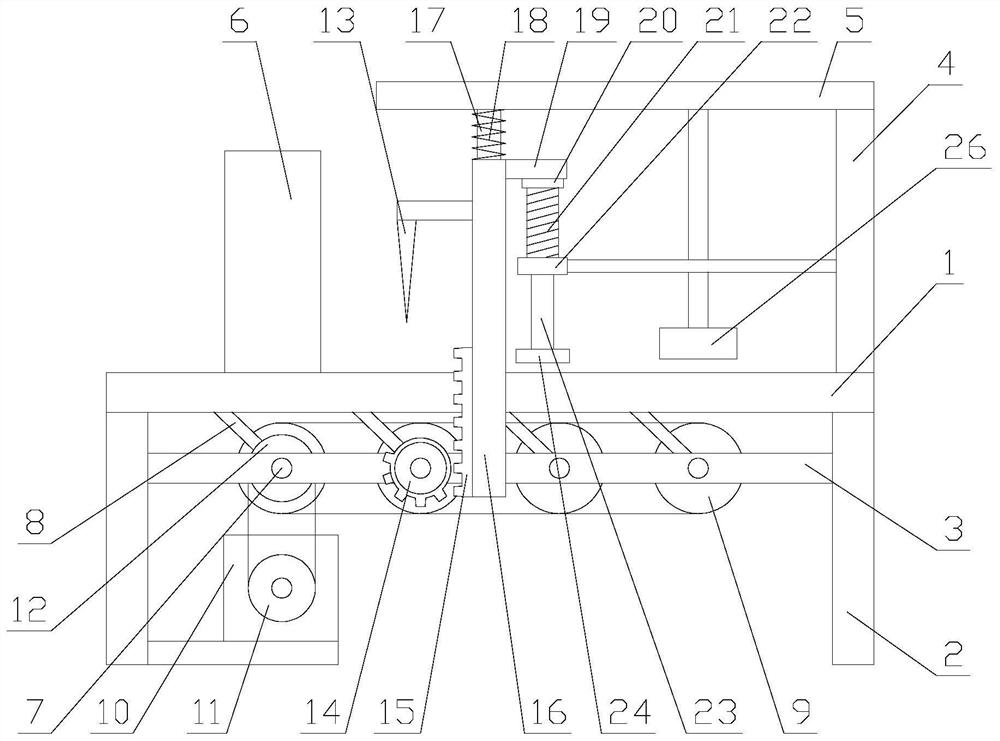

Fixed-length cutting device for Chinese herbal medicine processing and with grinding function

ActiveCN109648632AWith grinding functionGuaranteed accuracyGrain treatmentsMetal working apparatusEngineeringHolding tank

The invention discloses a fixed-length cutting device for Chinese herbal medicine processing and with a grinding function. The fixed-length cutting device for Chinese herbal medicine processing and with the grinding function comprises a workbench, a cutting blade, flow guide plates, a first grinding roller and a second grinding roller. Fixing plates are welded at the front end and the rear end ofthe right side of the workbench, and a fixing shaft is installed at the bottom of a top plate. The cutting blade is installed inside a protective cover, and the flow guide plates are fixedly arrangedat the outer ends of the bottoms of the workbench and the fixing plates correspondingly. The top of the first grinding roller and the top of the second grinding roller are connected with scraping plates, and the front end of the first grinding roller and the front end of the second grinding roller are connected with a second motor and a third motor in a rotating mode through third rotating shafts.A material holding tank is installed below the first grinding roller and the second grinding roller. By the adoption of the fixed-length cutting device for Chinese herbal medicine processing and withthe grinding function, fixed-length cutting can be conducted on the length of Chinese herbal medicine in the cutting process, and the cut Chinese herbal medicine is collected advantageously, and canalso be further ground.

Owner:LINGNAN NORMAL UNIV

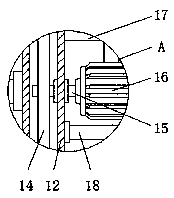

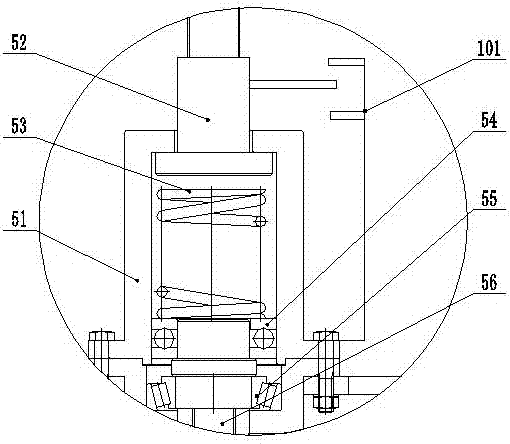

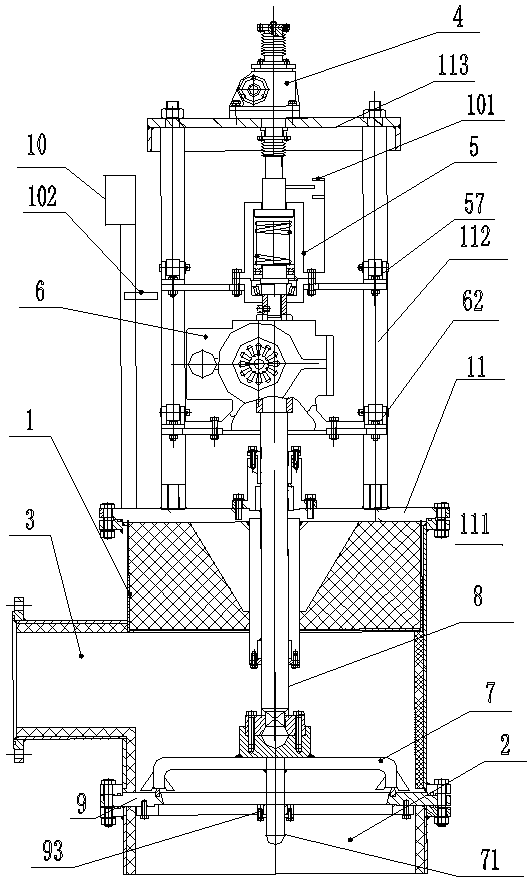

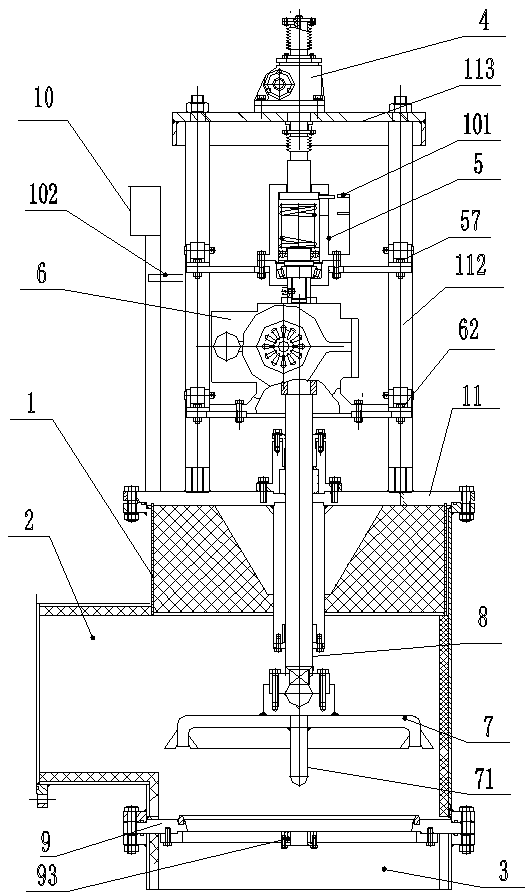

Seal valve

ActiveCN107035874ARealize their respective functionsRealize functionOperating means/releasing devices for valvesValve members for heating/coolingLinear motionIndependent motion

The invention discloses a seal valve. The seal valve comprises a valve body, an air inlet, an air outlet, a valve element opening and closing mechanism, a load control mechanism, a valve element rotating mechanism, a valve element and a valve rod, wherein the air inlet and the air outlet are formed in the valve body; a valve seat is arranged at the air inlet or the air outlet and is in contact with the valve element; the valve element is connected with the valve rod; the valve rod penetrates the valve body and is connected with the valve element rotating mechanism; the valve element rotating mechanism is connected with the valve element opening and closing mechanism through the load control mechanism; and rotary motion of the valve element rotating mechanism and linear motion of the valve element opening and closing mechanism are changed into relatively independent motions through the load control mechanism. According to the seal valve, the opening and closing force and the rotating, driving and grinding resistance are controlled by the load control mechanism, so that the seal valve has reliable leakproofness.

Owner:朱书红

Building wear-resistant material cutting device with polishing function

InactiveCN109318304AWith grinding functionAdjustable cutting angleEdge grinding machinesProfiling/shaping machinesWear resistantArchitectural engineering

The invention discloses a building wear-resistant material cutting device with a polishing function. The building wear-resistant material cutting device comprises a bottom plate, a processing plate, arotating rod and a cutting piece, wherein the left and right ends of the lower surface of the bottom plate are fixedly provided with cushion blocks, a gathering groove is formed below a pawl lever, the processing plate is located above the bottom plate, the left and right sides of the upper portion of the processing plate are in threaded connection with a fixing clamping plate, a motor is fixedlyarranged in the middle of the surface of the inner side of a side plate, the outer side of a first gear plate is connected with a conveyor chain in an engaged manner, the rotating rod is connected tothe interior of the inner surface of the upper end of the side plate in a penetrating manner, the right end of a fixing rod is symmetrically provided with fixing bolts, and the fixing bolts are in threaded connection with an outer shell, and the cutting piece is located on the inner side of the lower end of the outer shell. The building wear-resistant material cutting device with the polishing function can adjust the cutting angle, does not need repeated lifting operation, improves the processing efficiency, and is convenient to install and disassemble. The device is movably installed, and awaste collecting device is arranged.

Owner:WUHU HUANGSHANSONG IND FLOOR NEW MATERIAL CO LTD

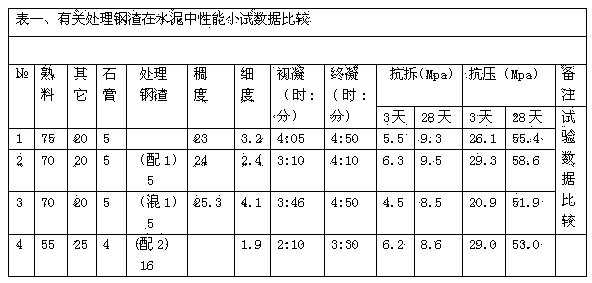

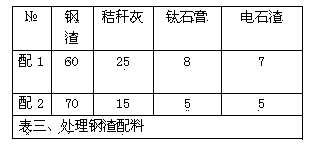

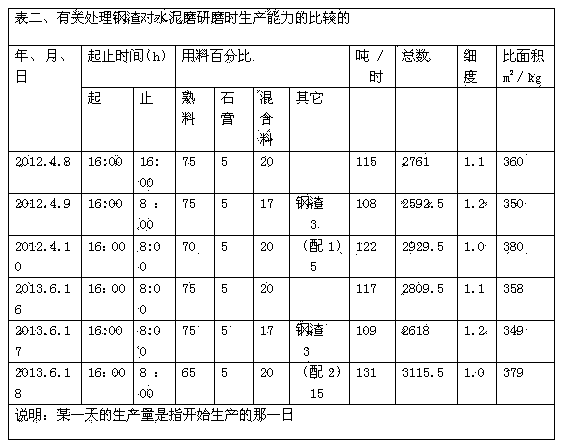

Method for stimulating early hydration activity of cement steel slags

ActiveCN103936308AIncreases hydration strengthWith grinding functionClinker productionIndustrial wasteCorrosion

The invention discloses a method for stimulating early hydration activity of cement steel slags. The method comprises the following steps: (1) selection and batching of raw materials; (2) stirring and mixing under a wet condition; (3) formation; (4) maintenance; and (5) dehydration. The method has the advantages that (1) the raw materials are all local industrial waste residues; (2) the amount of used steel slags in the batching is above 55%, and the batching of other materials satisfies a condition that the pH value of a slurry body during an early stirring stage is larger than 10, so formation of hydrated minerals can be promoted and the corrosion to steel slags can be enhanced; (3) the hydration period at normal temperature is 2-5 weeks; and (4) chemical refining is combined with mechanical grinding, the steel slags, straw ash, carbide slags and titanium gypsum are mixed and formed together in a wet environment and then dehydrated after two or more weeks, wherein the mixture-dehydrated and treated steel slags can be used for producing cement, are easy to grind, have the function of assisting grinding, are high in hydration speed, can be used for stimulating the hydration of cement clinkers and other materials used in the cement and increasing the hydration intensity of the cement, are environmentally friendly and low in cost.

Owner:江苏省建筑材料研究设计院有限公司 +2

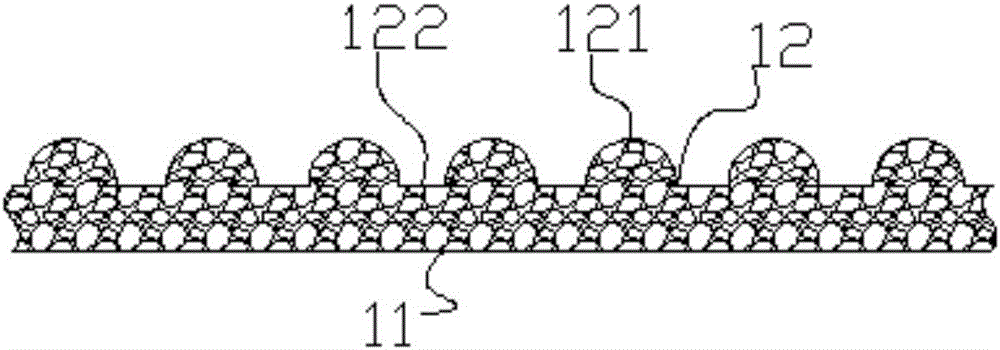

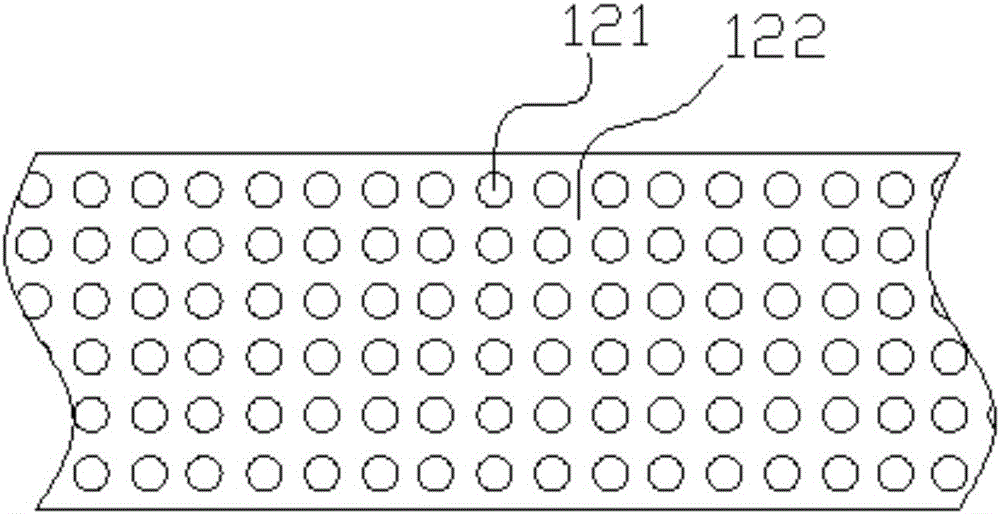

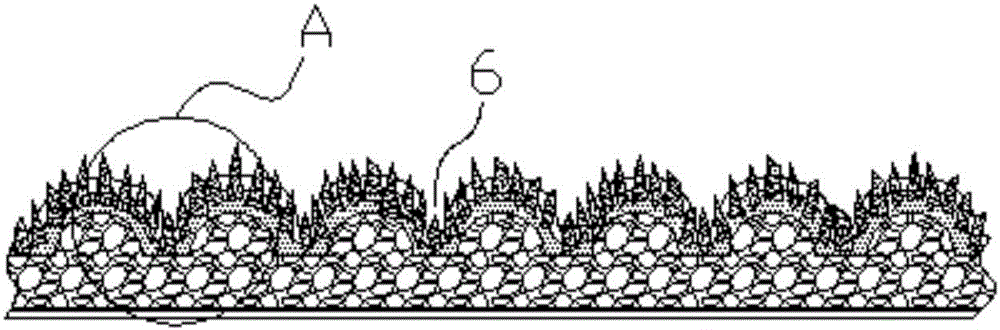

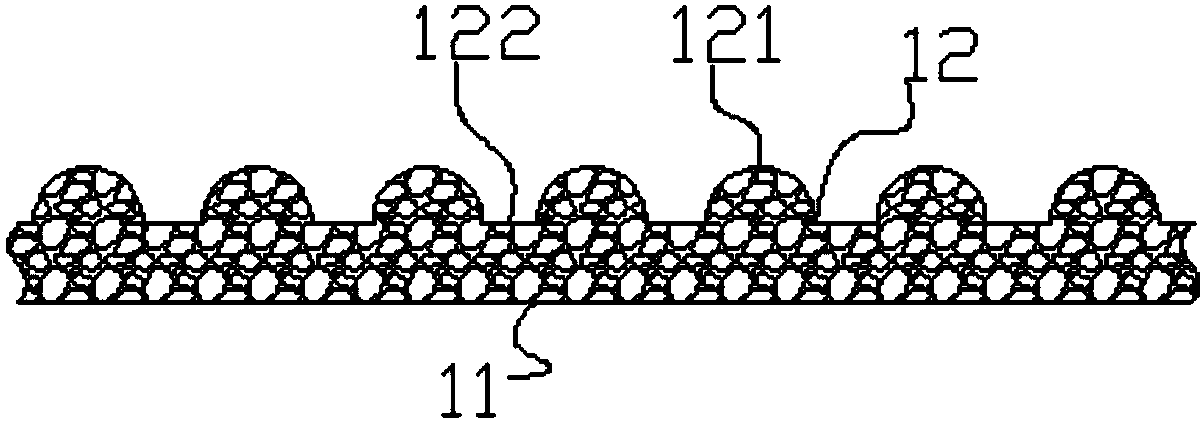

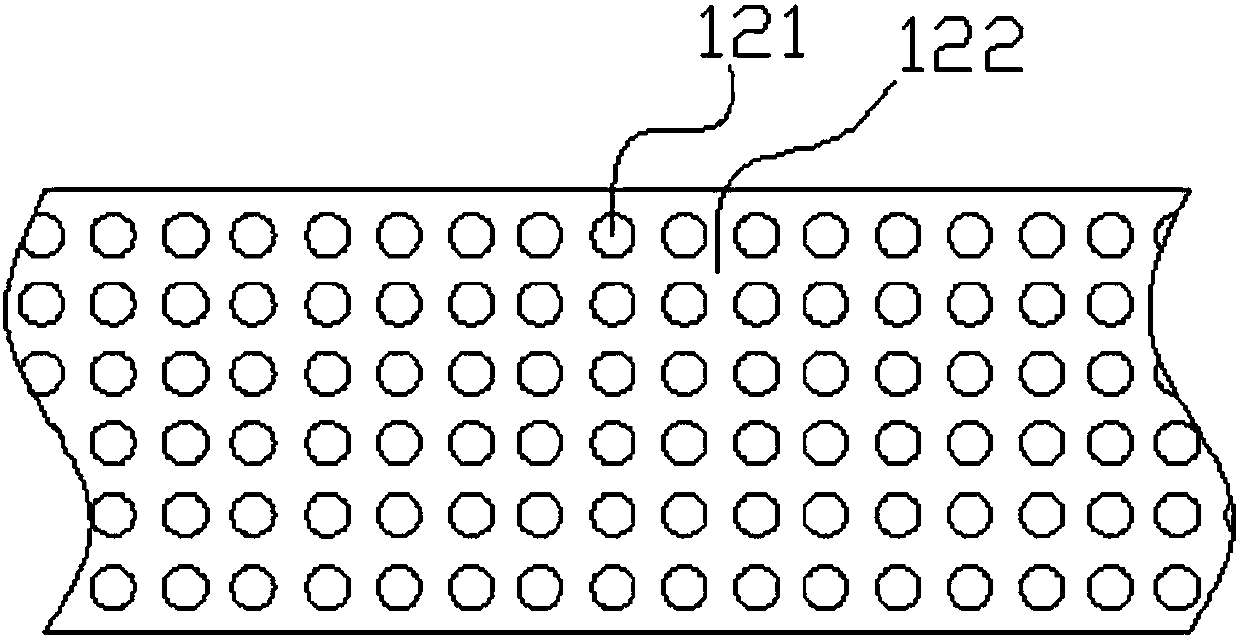

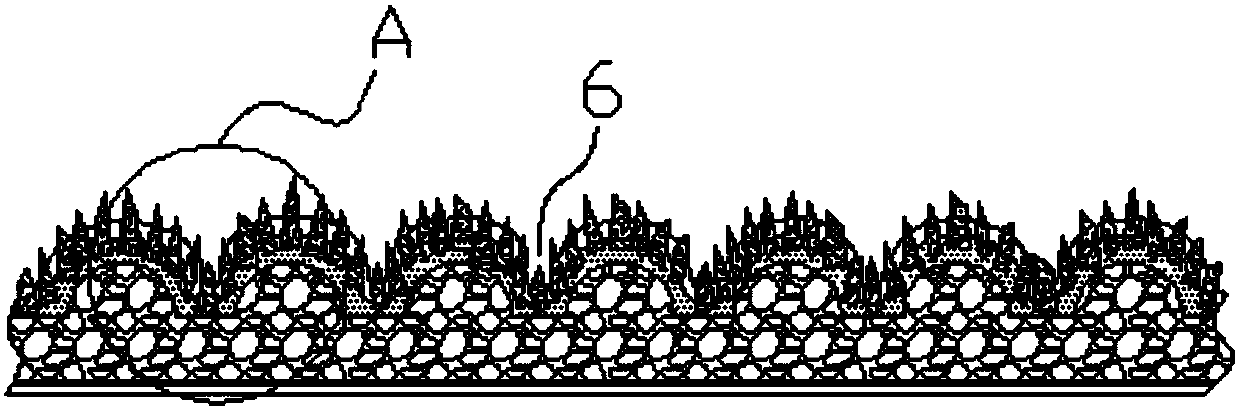

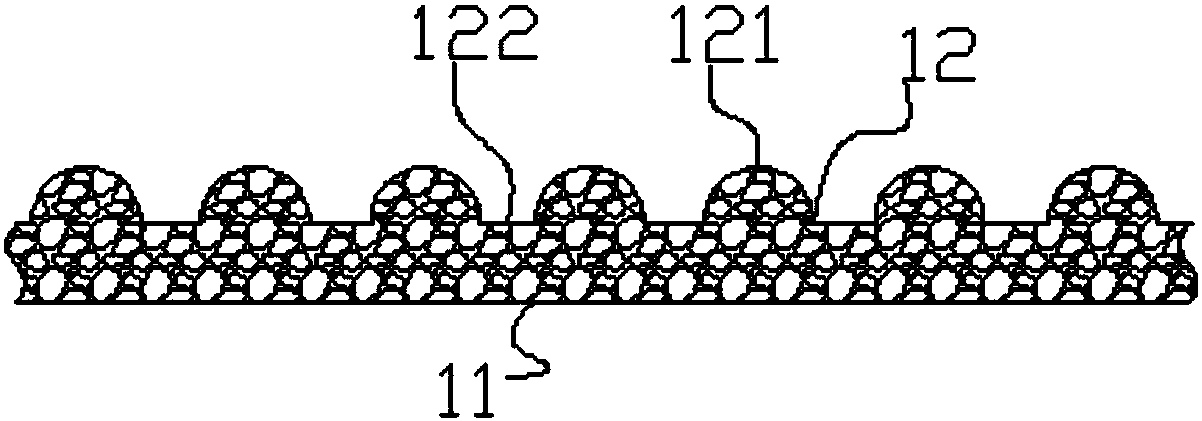

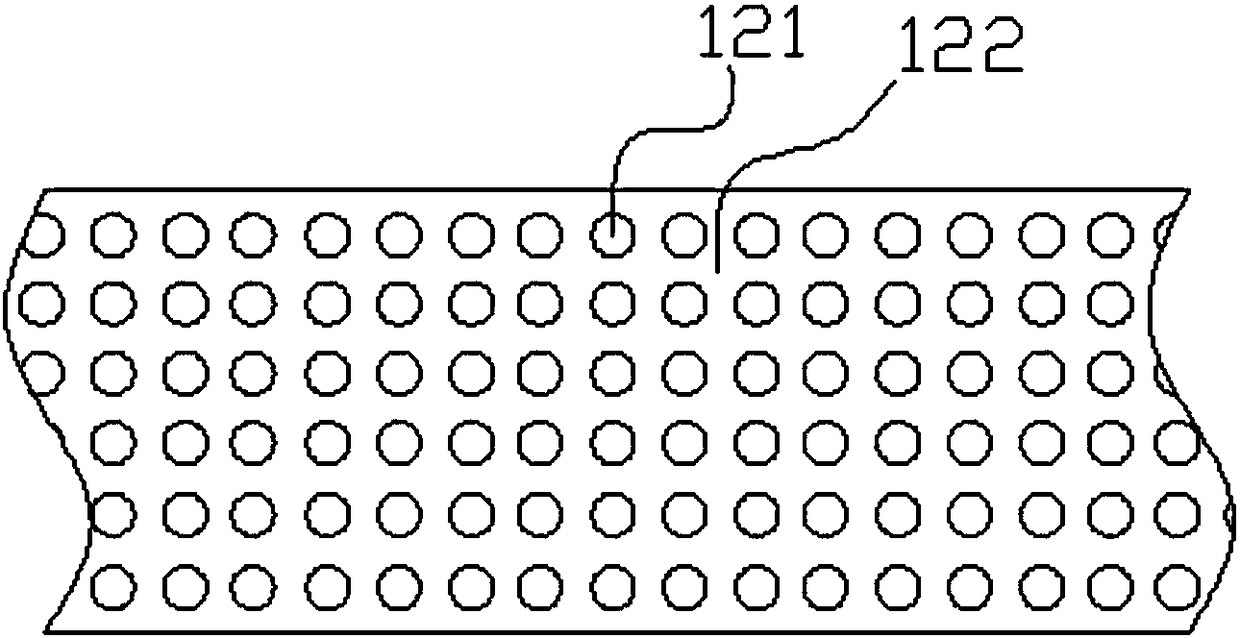

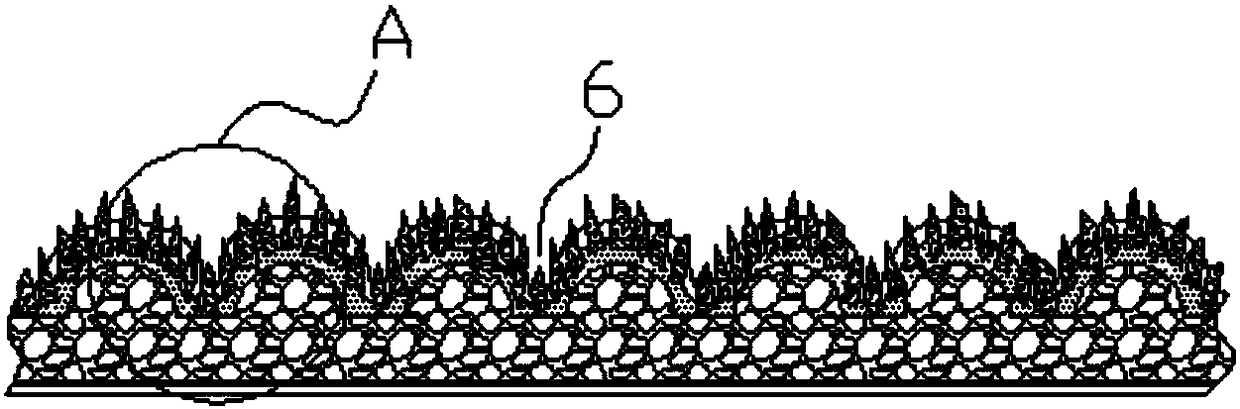

PVA elastic anti-blocking abrasive belt and manufacturing method thereof

ActiveCN106346381AWith grinding functionImprove grinding abilityAbrasion apparatusGrinding devicesAdhesive beltPolyvinyl alcohol

The invention relates to a PVA elastic anti-blocking abrasive belt and a manufacturing method thereof. The PVA elastic anti-blocking adhesive belt comprises apolyvinyl alcohol concave-convex sponge, a PVC soft film, a bottom rubber layer, a composite rubber layer and an abrasive material, wherein a front face of the polyvinyl alcohol concave-convex sponge is covered with dot patterns, namely, patterns formed by a plurality of hemispherical salient points arranged uniformly, and voids between adjacent salient points are connected to form a communicating groove; the PVC soft film is formed on the back face of the polyvinyl alcohol concave-convex sponge; the front face of the polyvinyl alcohol concave-convex sponge is coated with the bottom rubber layer; the upper surface of the bottom rubber layer is coated with the composite rubber layer; the lower end of the abrasive material is embedded into the bottom rubber layer, and the upper end of the abrasive material protrudes from the upper surface of the composite rubber layer; and recessed positions, corresponding to the communicating groove, of the surface of the abrasive belt communicate with one another to form a chip removal groove. The PVA elastic anti-blocking abrasive belt has the properties of blocking prevention and elastic grinding, and also the advantages of simple process, low equipment investment, low cost, wear resistance, long service life, no toxicity, and the like.

Owner:东莞市俊盛五金磨具有限公司

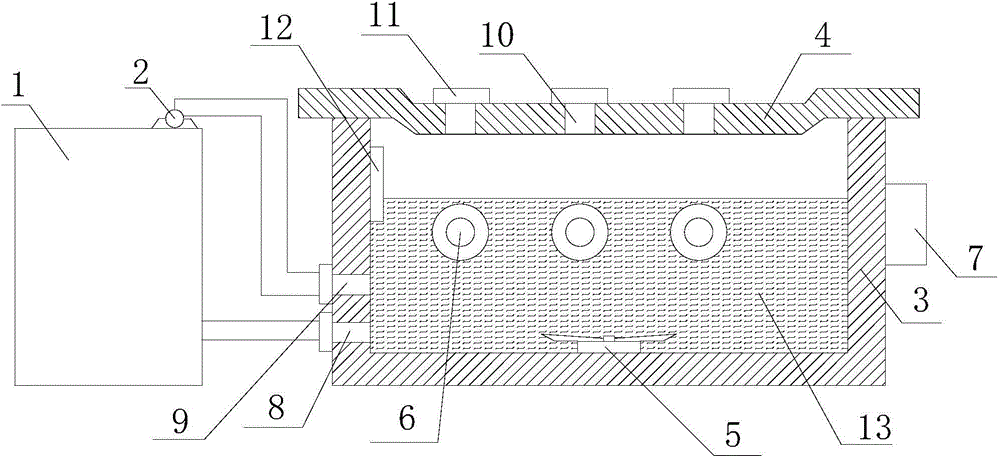

Centralized optical fiber end grinding and cleaning device

ActiveCN104816236AFacilitate subsequent processingAvoid subsequent processingLapping machinesWork carriersChinese charactersWater wheel

The invention relates to a centralized optical fiber end grinding and cleaning device which comprises a circulating water tank and a grinding chamber. The circulating water tank is communicated with the grinding chamber through a circulating pump, the grinding chamber comprises a grinding groove, an optical fiber positioning frame, a driving water wheel, at least one grinding roller and a driving device, wherein the cross section of the grinding groove is in a shape of a Chinese character 'ao', the driving water wheel is located at the bottom of the grinding groove, the grinding roller is located in the grinding groove and located under the circulating water level, the optical fiber positioning frame is embedded into the upper end face of the grinding groove, at least four optical fiber positioning holes are distributed in the optical fiber positioning frame in a rectangular array mode, optical fiber positioning clamps are additionally arranged at the positions of the optical fiber positioning holes, and the driving device is located outside the grinding grooves and is connected with the driving water wheel and the grinding rollers respectively. In addition, the centralized optical fiber end grinding and cleaning device has grinding and cleaning functions, the surface cleanness and finish degree of optical fiber ends can be greatly improved, noise and dust pollution easily caused in the optical fiber end grinding process is effectively avoided, and optical fiber machining operation environment is greatly improved.

Owner:南通鸿图健康科技有限公司

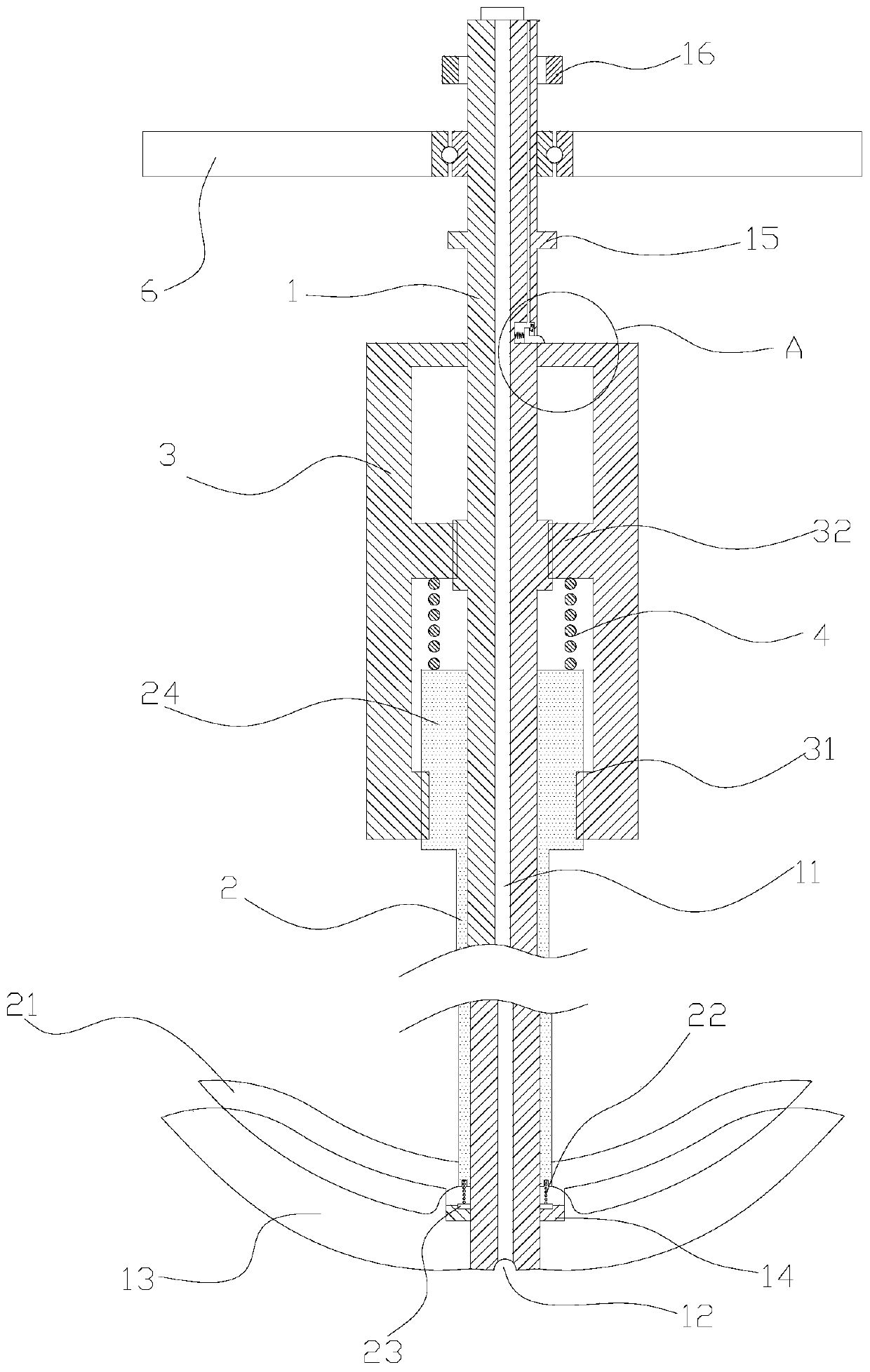

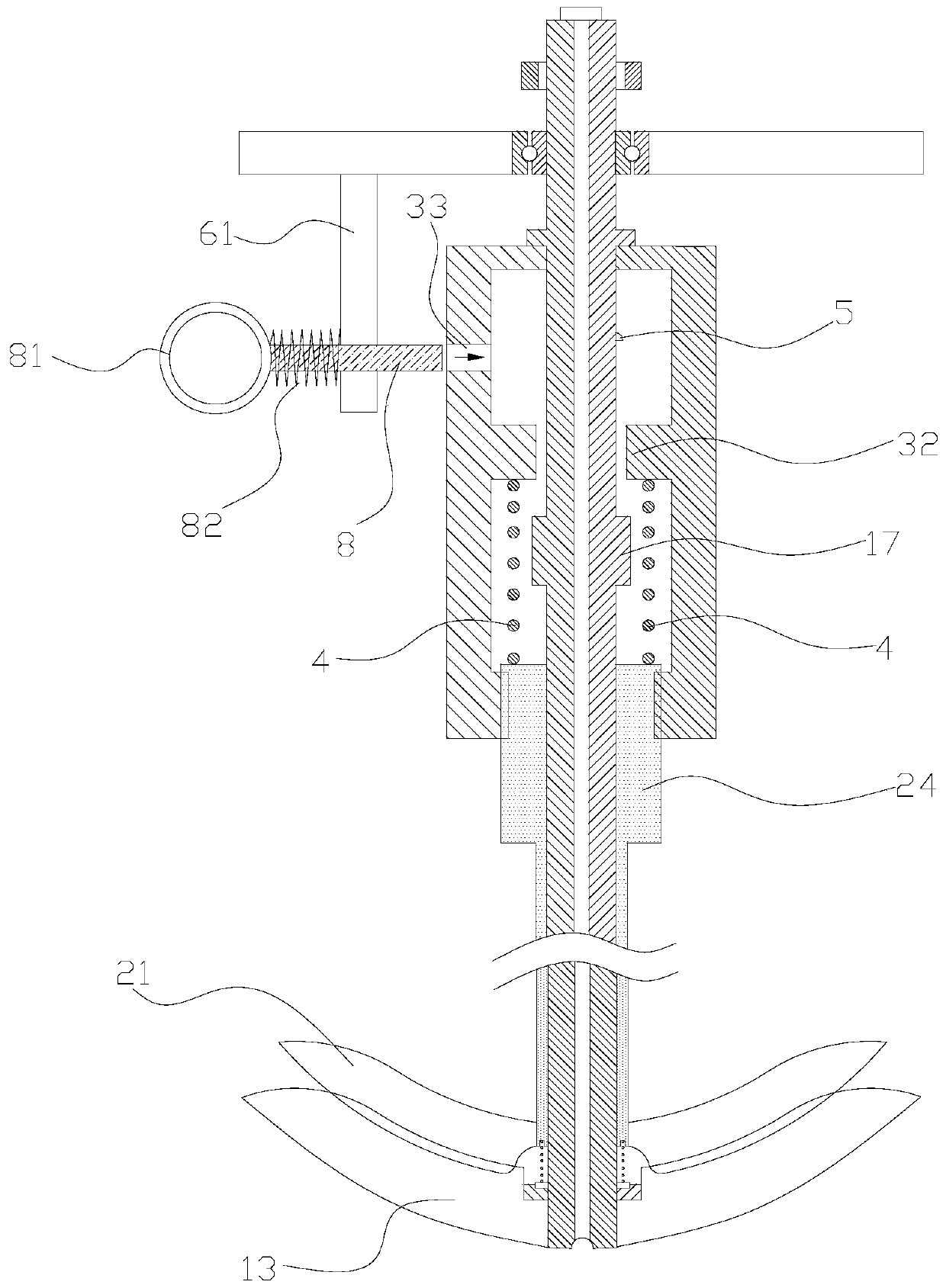

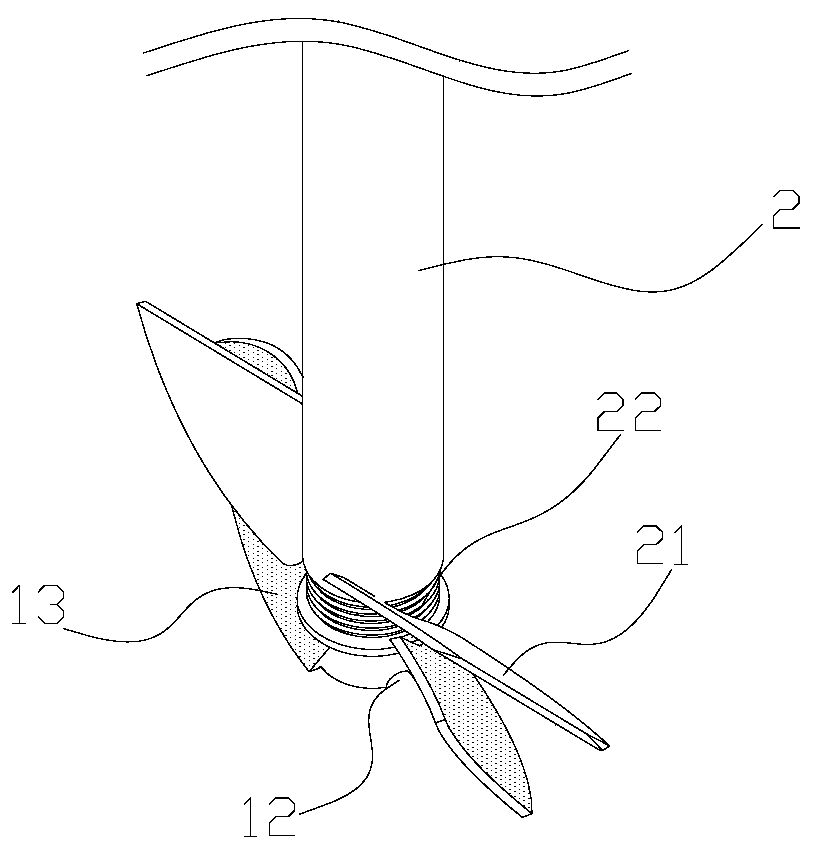

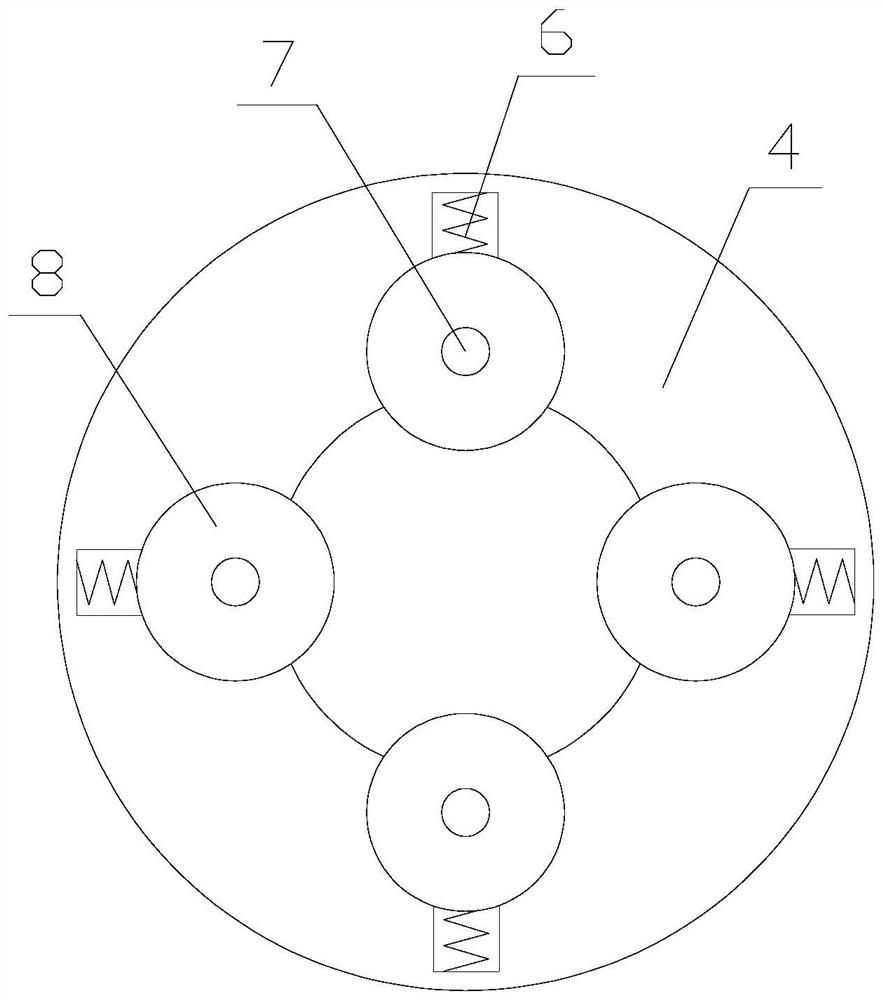

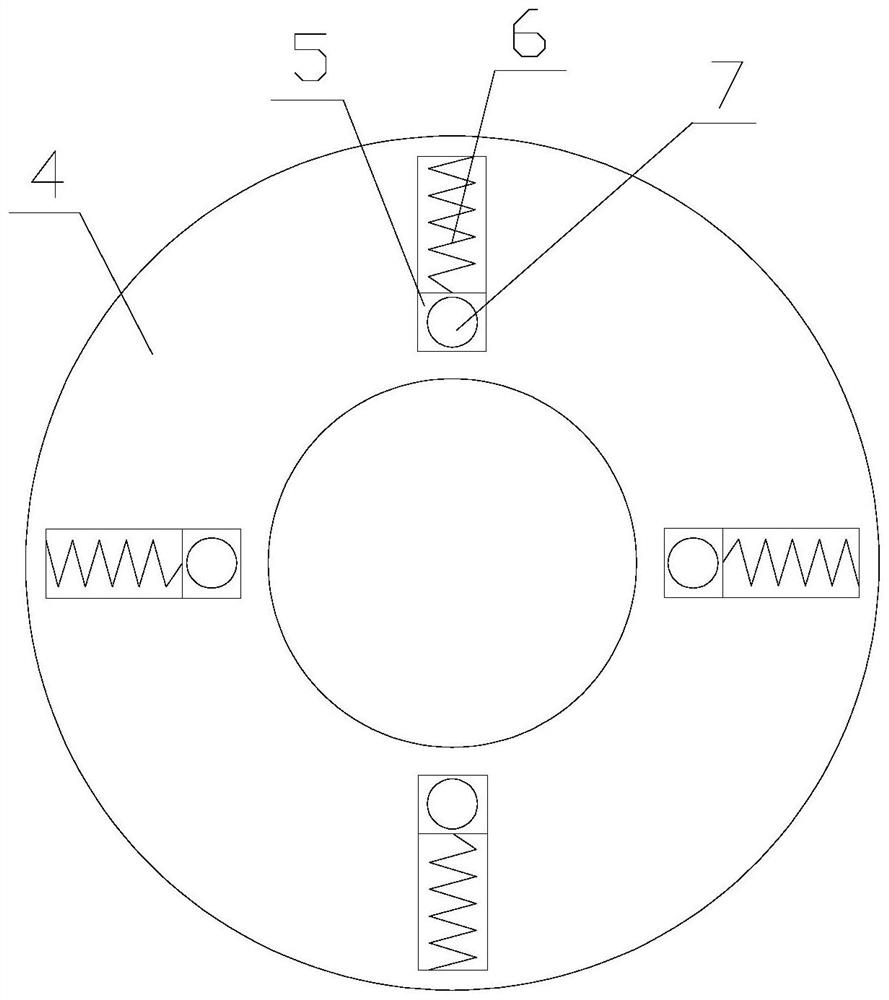

Stirring shaft with stirring and grinding functions

The invention discloses a stirring shaft with stirring and grinding functions. The stirring shaft mainly comprises an inner shaft, an outer shaft and a sleeve, the outer shaft rotatably sleeves the inner shaft, and the sleeve sleeves the outer shaft; a material discharge channel is arranged in the middle of the inner shaft, the side surface of the lower end of the inner shaft is provided with a material inlet, first stirring blades are arranged at the lower end of the inner shaft, and second stirring blades are arranged at the lower end of the outer shaft; two inner gears are arranged in the sleeve, and the inner gears include a first gear and a second gear; buffer springs are arranged between the second gear and the upper end of the outer shaft, the outside surface of the inner shaft is provided with a convex button, and an annular stopping block is arranged on the outer side of a part, above the convex button, of the inner shaft; and the upper end of the inner shaft is rotatably arranged on a support frame, and a locking mechanism is arranged on the support frame. The stirring shaft can achieve stirring, and also has the grinding function.

Owner:宜昌天仁药业有限责任公司

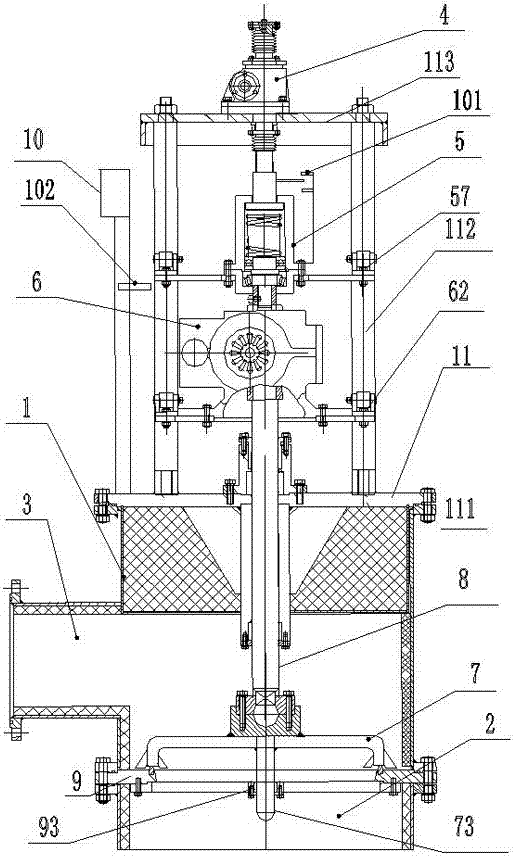

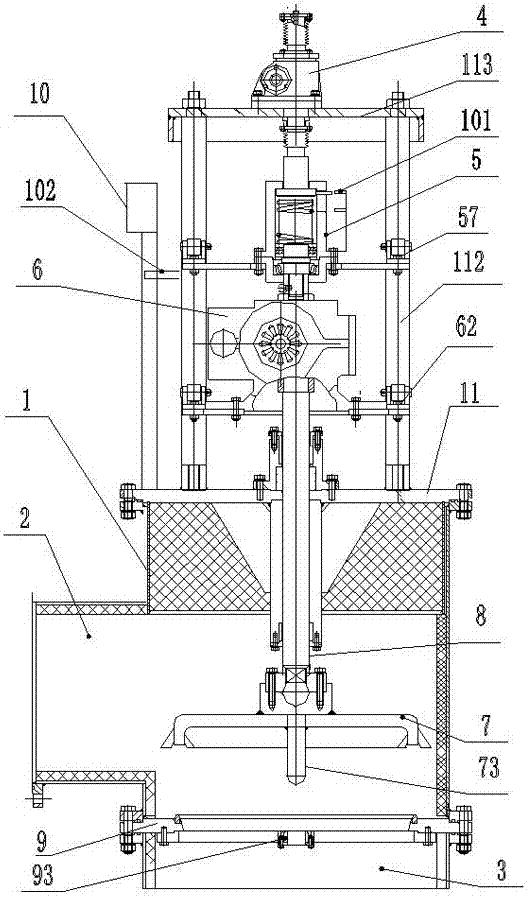

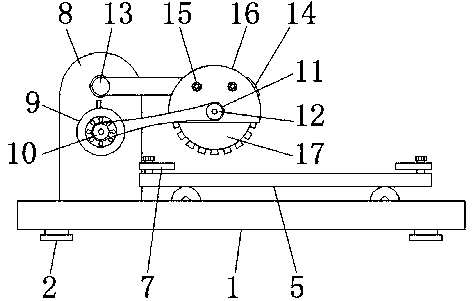

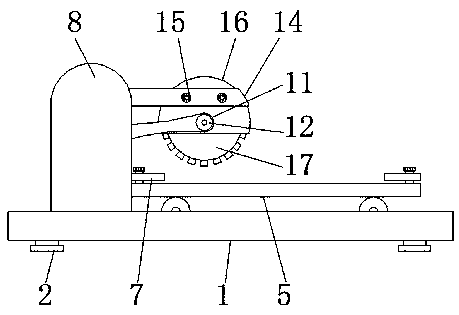

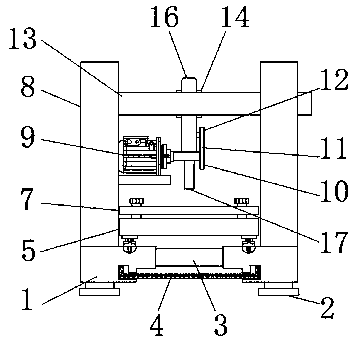

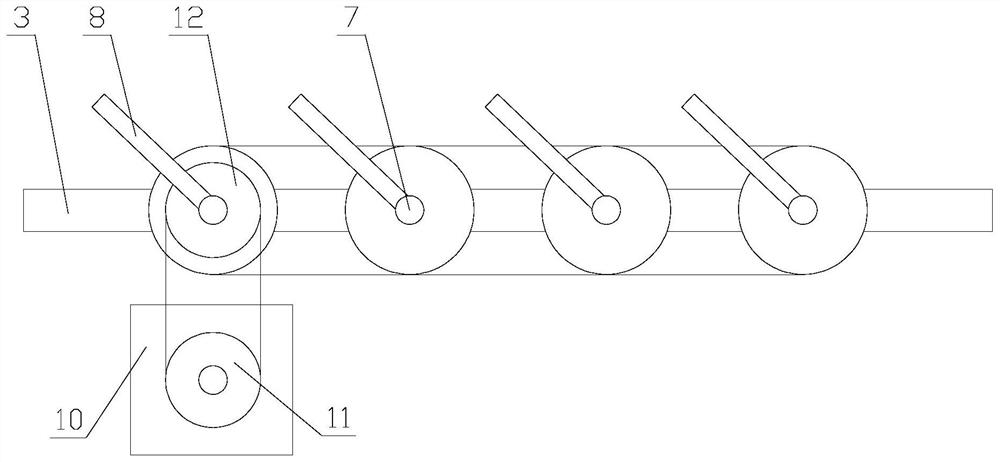

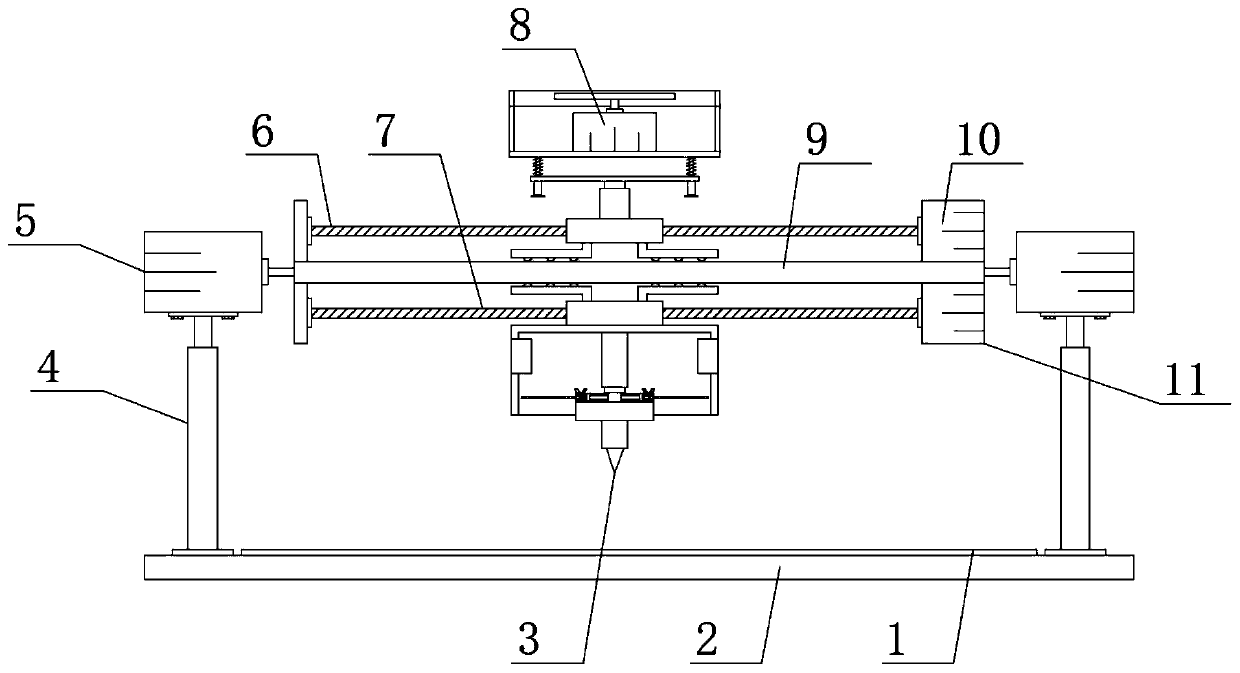

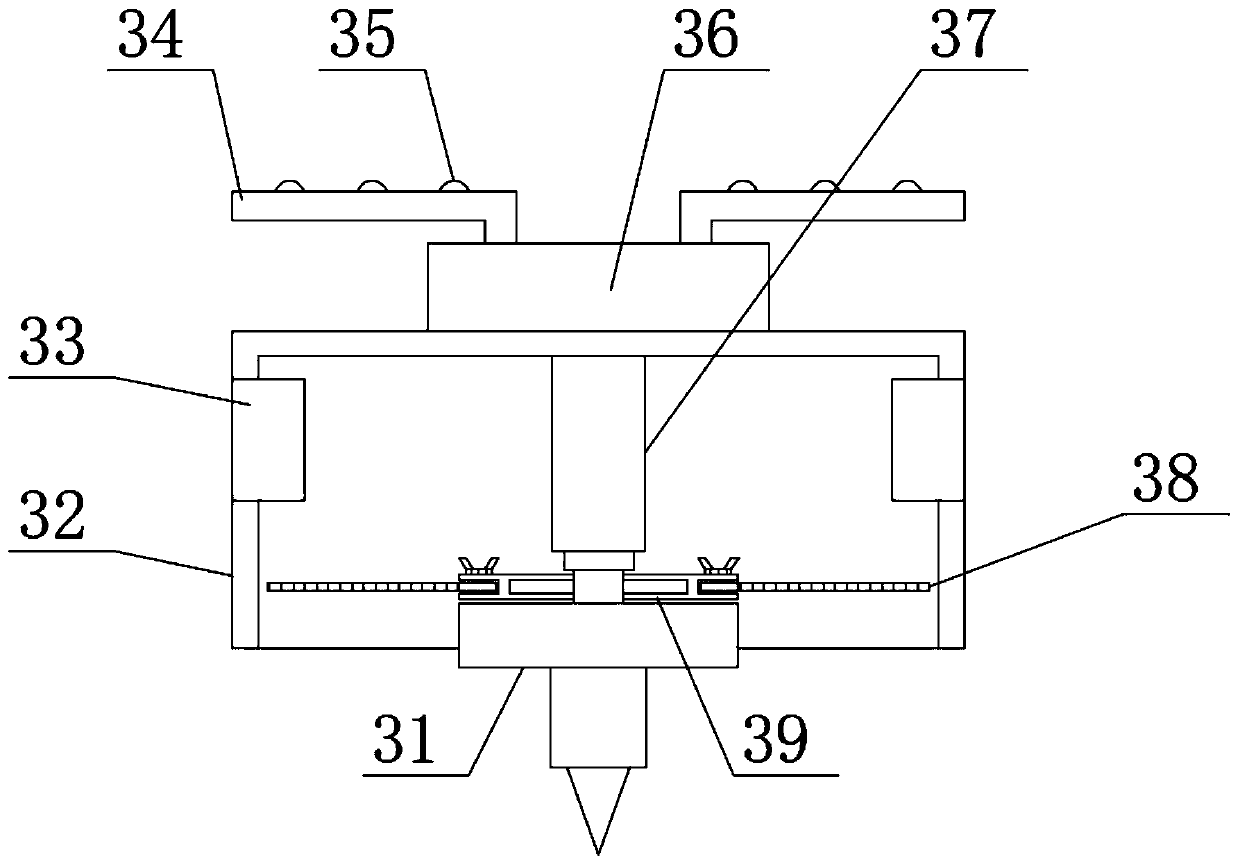

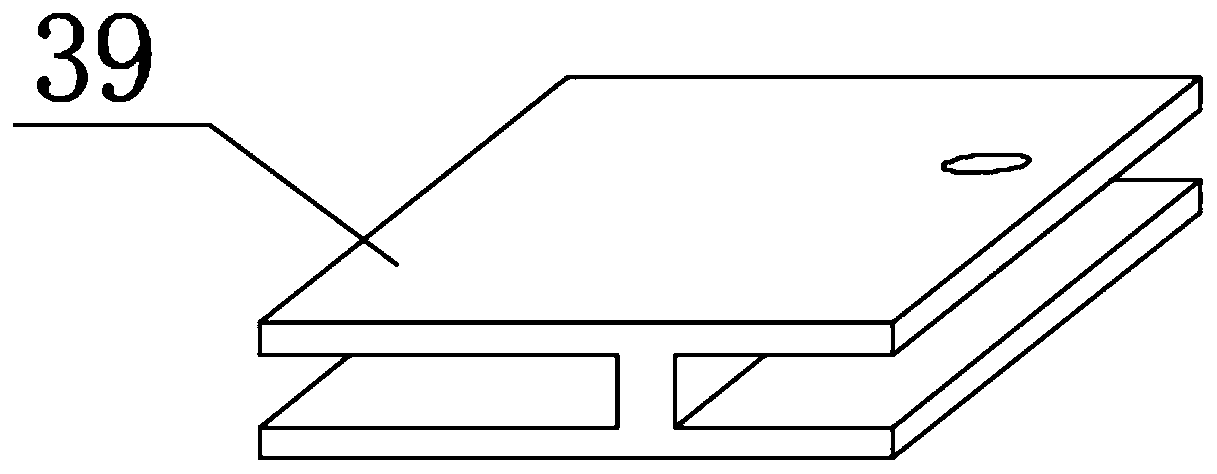

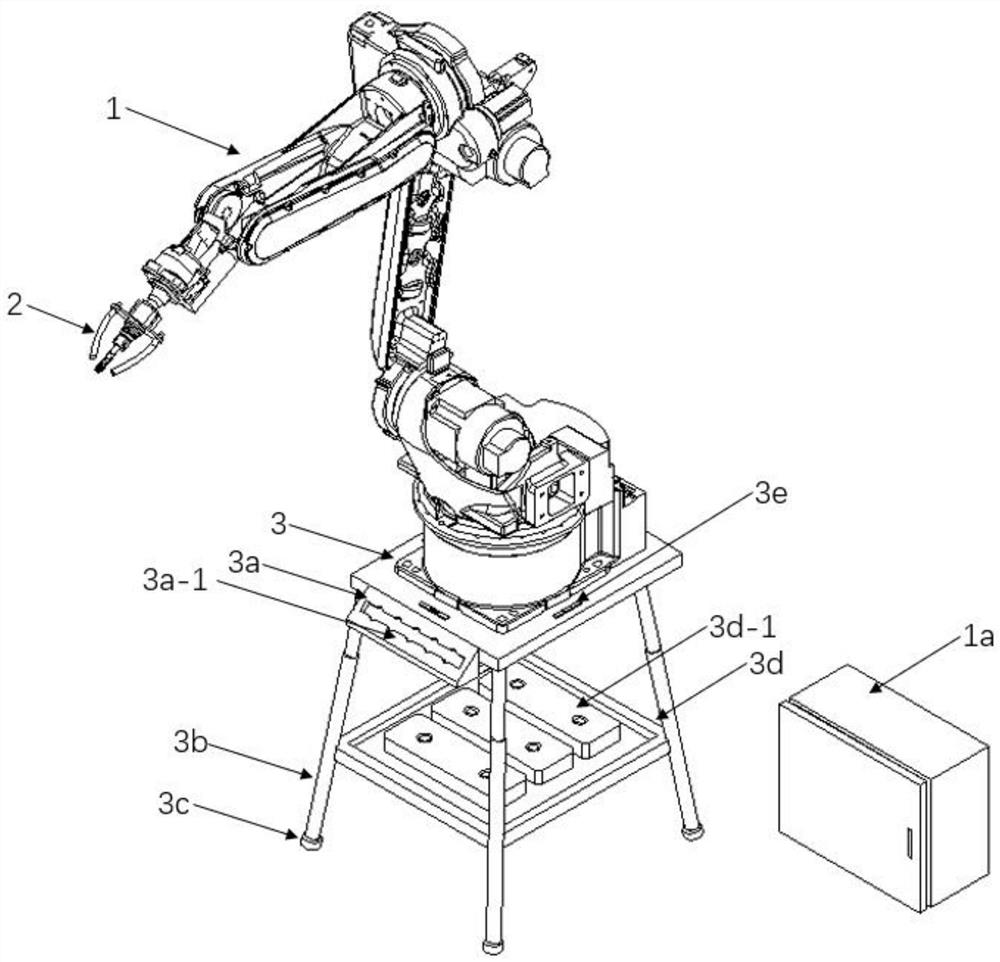

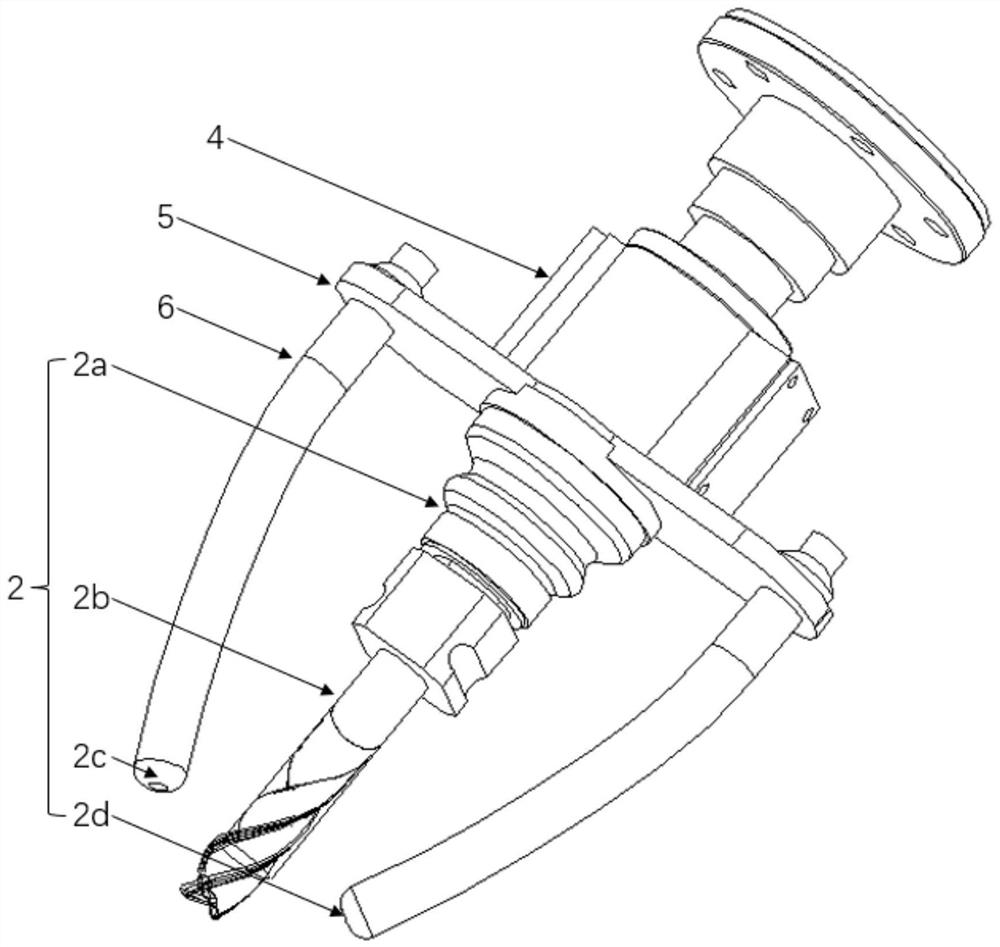

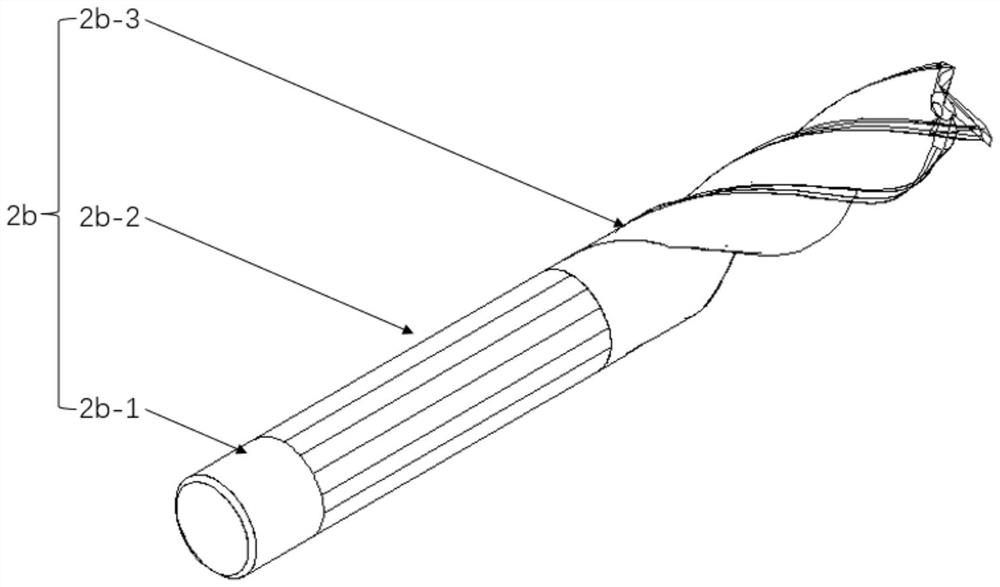

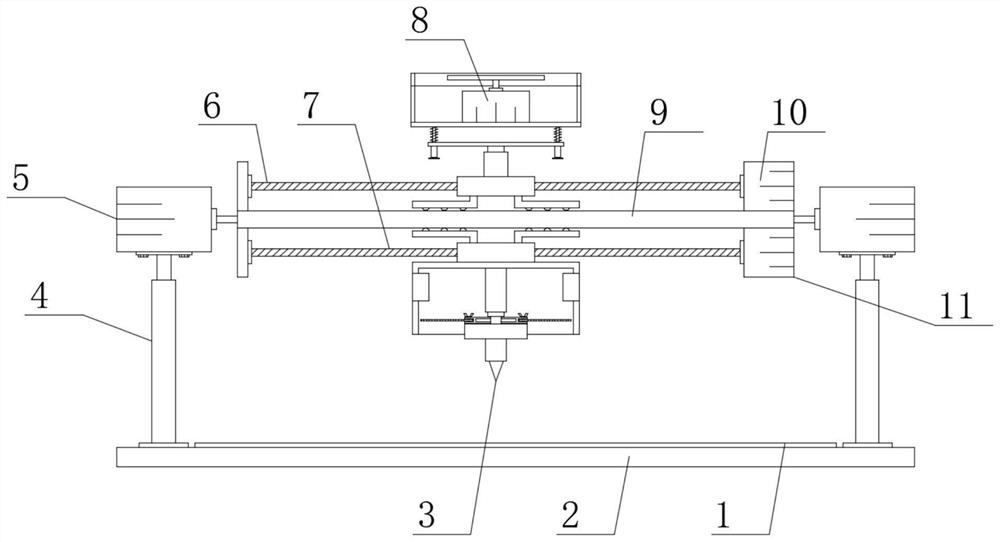

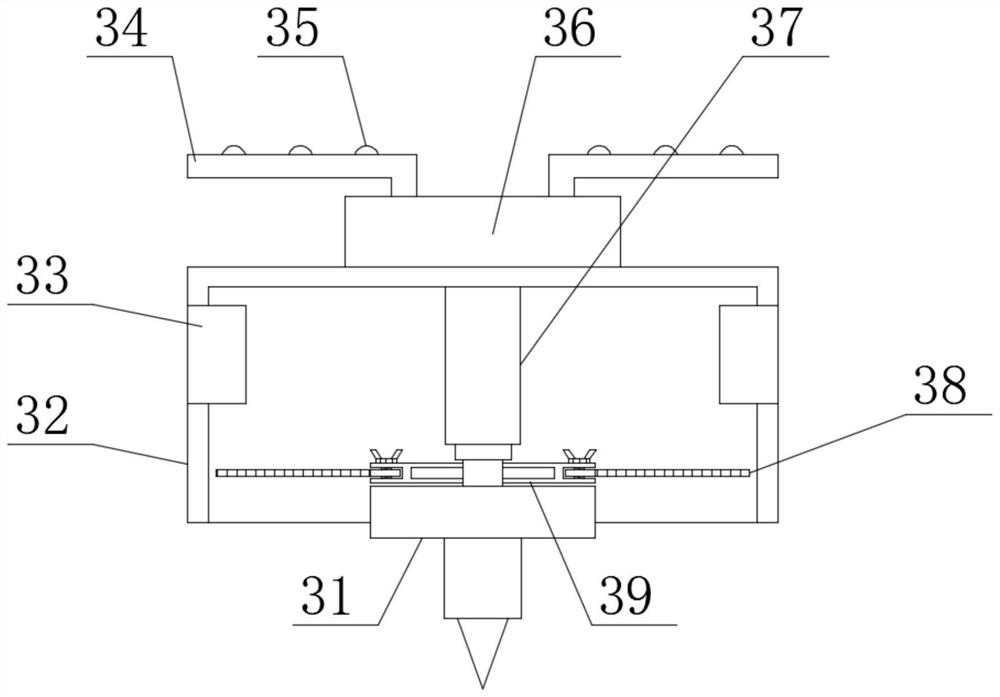

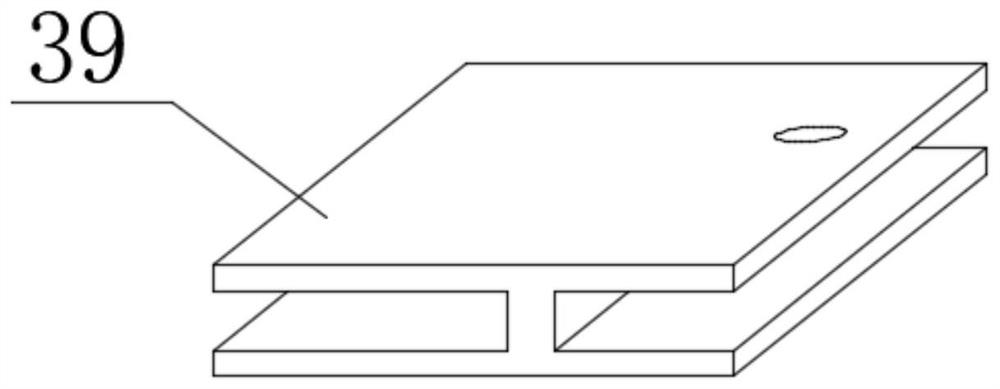

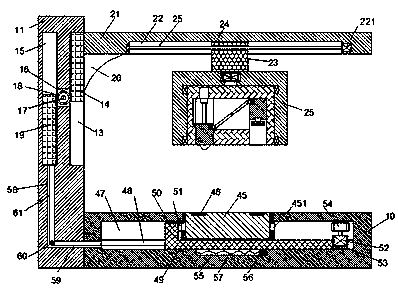

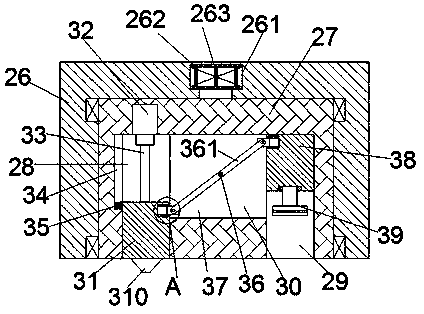

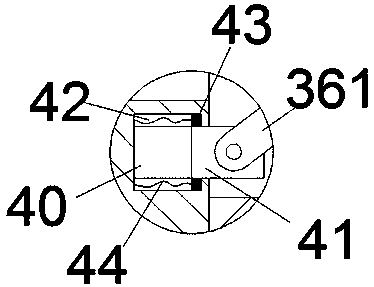

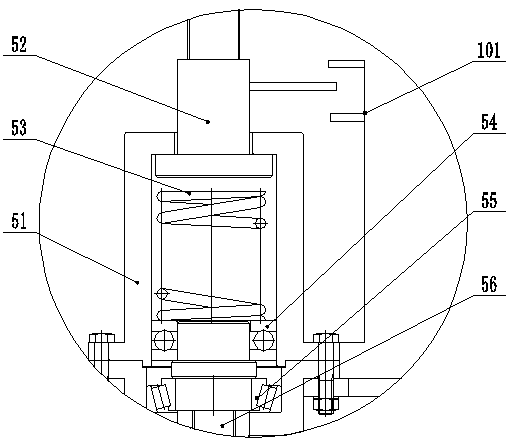

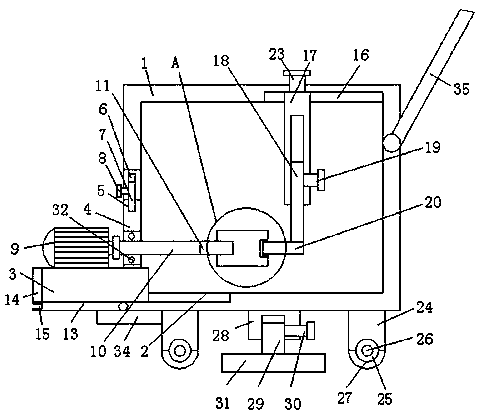

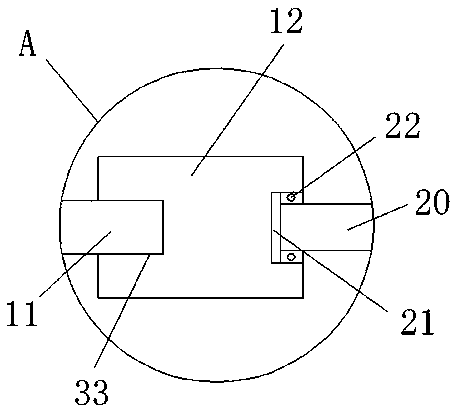

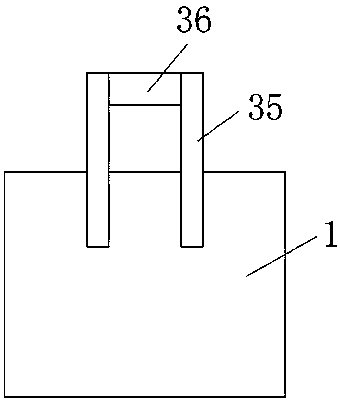

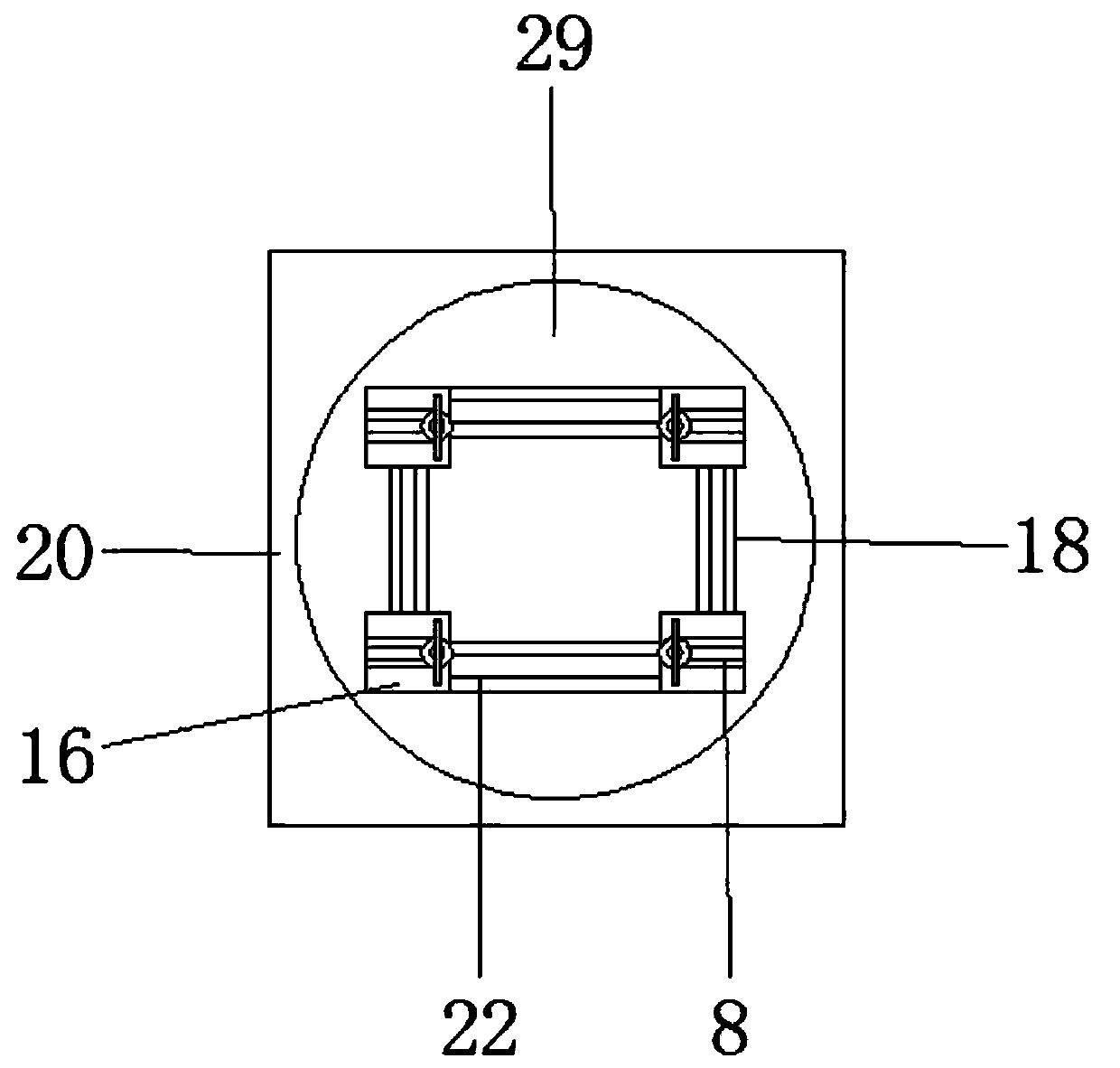

Intelligent punching robot with grinding function

ActiveCN112091634AWith grinding functionRealize online punchingOther manufacturing equipments/toolsLinkage (mechanical)Engineering

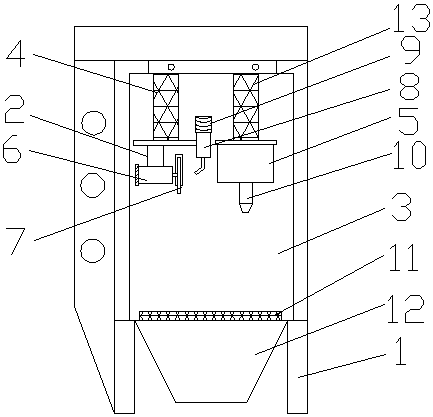

The invention relates to an intelligent punching robot with the grinding function. The robot comprises a base, a supporting column, a fixing rod, a supporting rod, a transverse rod, a feeding box, a conveying mechanism, a punching mechanism and a grinding mechanism, the transverse rod is arranged above the base through the supporting rod, the feeding box is arranged at the end, away from the supporting rod, of the base, and the conveying mechanism is arranged below the base; and the punching mechanism and the grinding mechanism are both mounted on the transverse rod. According to the intelligent punching robot with the grinding function, conveying of a workpiece is achieved through the conveying mechanism, punching is achieved through the punching mechanism, and grinding is achieved through the grinding mechanism. Compared with an existing punching device, the device has the advantages that conveying, punching and grinding of the workpiece are achieved at the same time through one output end, energy is saved, meanwhile, online punching and grinding of the workpiece are achieved through linkage of the conveying mechanism, the punching mechanism and the grinding mechanism, a pure mechanical structure is adopted in linkage, use of sensors and other electronic elements is avoided, the temperature performance of the device is improved, and the service life of the device is prolonged.

Owner:邹平颖鼎机械制造有限公司

Multifunctional metal plate welding device for building construction

ActiveCN111496420APhysical health hazardFunction increaseDispersed particle separationWelding/cutting auxillary devicesElectric machineHazardous substance

The invention discloses a multifunctional metal plate welding device for building construction, and belongs to the technical field of welding devices. The multifunctional metal plate welding device comprises a first supporting plate, wherein a second supporting plate is arranged above the first supporting plate, first driving motors are arranged at the two ends of the second supporting plate, first electric telescopic rods corresponding to the first driving motors are arranged at the two ends of the upper surface of the first supporting plate, a third driving motor is arranged at one end of the lower surface of the second supporting plate, a second limiting lead screw is arranged at the output end of the third driving motor, a welding mechanism is arranged at one end of the second limitinglead screw and comprises a collecting cover, and a first limiting sliding block corresponding to the second limiting lead screw is arranged on the upper surface of the collecting cover. The multifunctional metal plate welding device is simple in structure and convenient to use, has a purification function, and can adsorb and purify fume generated during welding, so that harmful substances in thefume are removed, and harm to the body health of workers due to the fact that the fume drifts everywhere is prevented.

Owner:抚州吉远企业管理咨询有限公司

Grinding wheel and polishing process using same

InactiveCN105479351AWith grinding functionWith mirror polishing functionAbrasion apparatusGrinding devicesGrinding wheelSilicon

The invention discloses a grinding wheel and a polishing process thereof. The grinding wheel comprises phenolic resin, a monomer for generating a polyurethane elastic material, silicon salt, white carbon black and a grinding material, wherein the dosage of the phenolic resin is 6-13 parts by weight, the dosage of the monomer for generating the polyurethane elastic material is 12-30 parts by weight, the dosage of the silicon salt is 3-10 parts by weight, the dosage of the white carbon black is 1-4 parts by weight, and the dosage of the grinding material is 50-70 parts by weight; the phenolic resin, the silicon salt and the grinding material are mixed, and then wetted with water, so as to facilitate acid-base neutralization reaction and generate a gel; after the monomer for generating the polyurethane elastic material, and the white carbon black are uniformly mixed, the gel is immediately added, the materials are uniformly stirred, and the uniformly-stirred materials are injected in a mould and moulded to obtain the grinding wheel. Compared with the prior art, the grinding wheel disclosed by the invention has a function of smoothly grinding the surfaces of workpieces, and further has the advantage of a mirror polishing function.

Owner:陈爱民 +1

pva elastic anti-blocking abrasive belt and manufacturing method thereof

ActiveCN106346381BWith grinding functionImprove grinding abilityAbrasion apparatusGrinding devicesAdhesive beltPolyvinyl alcohol

The invention relates to a PVA elastic anti-blocking abrasive belt and a manufacturing method thereof. The PVA elastic anti-blocking adhesive belt comprises apolyvinyl alcohol concave-convex sponge, a PVC soft film, a bottom rubber layer, a composite rubber layer and an abrasive material, wherein a front face of the polyvinyl alcohol concave-convex sponge is covered with dot patterns, namely, patterns formed by a plurality of hemispherical salient points arranged uniformly, and voids between adjacent salient points are connected to form a communicating groove; the PVC soft film is formed on the back face of the polyvinyl alcohol concave-convex sponge; the front face of the polyvinyl alcohol concave-convex sponge is coated with the bottom rubber layer; the upper surface of the bottom rubber layer is coated with the composite rubber layer; the lower end of the abrasive material is embedded into the bottom rubber layer, and the upper end of the abrasive material protrudes from the upper surface of the composite rubber layer; and recessed positions, corresponding to the communicating groove, of the surface of the abrasive belt communicate with one another to form a chip removal groove. The PVA elastic anti-blocking abrasive belt has the properties of blocking prevention and elastic grinding, and also the advantages of simple process, low equipment investment, low cost, wear resistance, long service life, no toxicity, and the like.

Owner:东莞市俊盛五金磨具有限公司

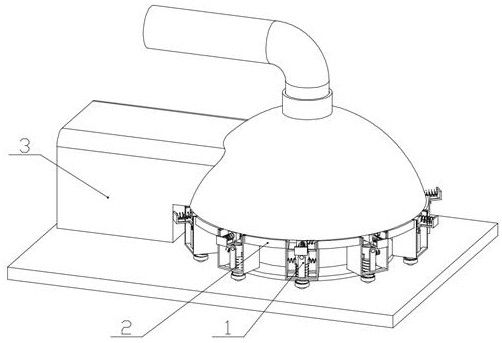

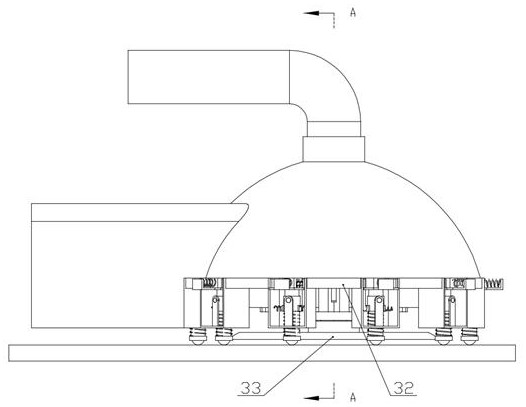

Glass fiber reinforced plastic pipeline intersecting line milling device based on industrial robot

PendingCN113714542AAvoid damageQuality improvementEdge grinding machinesBonded abrasive wheelsGlass fiberMilling cutter

The invention discloses a glass fiber reinforced plastic pipeline intersecting line milling device based on an industrial robot, and belongs to the technical field of glass fiber reinforced plastic pipeline machining. The glass fiber reinforced plastic pipeline intersecting line milling device comprises the industrial robot and a milling head, the industrial robot is controlled through a control cabinet, and the milling head is arranged at the working tail end of the industrial robot. A workbench is arranged at the bottom of the industrial robot, the milling head comprises an electric spindle, a milling cutter is arranged on the electric spindle, a vacuum dust suction inlet and a water cooling head are arranged beside the electric spindle, and the milling cutter comprises a milling blade part and a polishing blade part. The workbench is provided with a tool magazine, a gradienter is arranged on the workbench, and moving wheels are arranged at the bottom of the workbench. The industrial robot is used for driving the milling device to automatically cut the intersecting line of the glass fiber reinforced plastic pipeline, and manual milling is replaced. The milling cutter also has a polishing function, and can polish the edge of an intersecting line opening after milling, so that the roughness is reduced, and later pipeline insertion is facilitated. The milling cutter can be replaced in time, so that the cutting efficiency and quality are ensured.

Owner:JIANGSU UNIV OF TECH

Safety protection mechanism for composite material polishing machine

The invention discloses a safety protection mechanism for a composite material polishing machine. The safety protection mechanism comprises a wire drawing triggering type passive locking mechanism, an unpowered air blowing dust collecting mechanism and a driving protection mechanism. The invention belongs to the technical field of polishing safety protection mechanisms, and particularly relates to a safety protection mechanism for a composite material polishing machine. The invention creatively provides a wiredrawing triggering type passive locking mechanism which comprises a triggering type rebounding guide assembly, a triggering type locking pin assembly, a pre-tightening type swing assembly and a telescopic swing rod assembly, the mechanism is triggered through the movement of the fibers, the response can be quickly made when the fibers are pulled out, and the operation is convenient. According to the technical scheme, whether the current state is a grinding working state or not can be automatically judged, a locking mechanism cannot be triggered even if the current state is touched by mistake in a non-working state, and the technical effect of safety protection in the technical aspect is achieved only through an ingenious mechanical structure under the condition that no electric control or sensor exists.

Owner:江苏众成复合材料有限责任公司

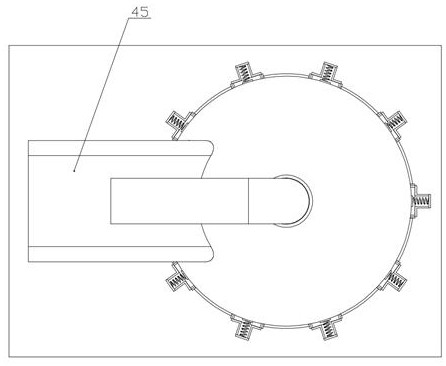

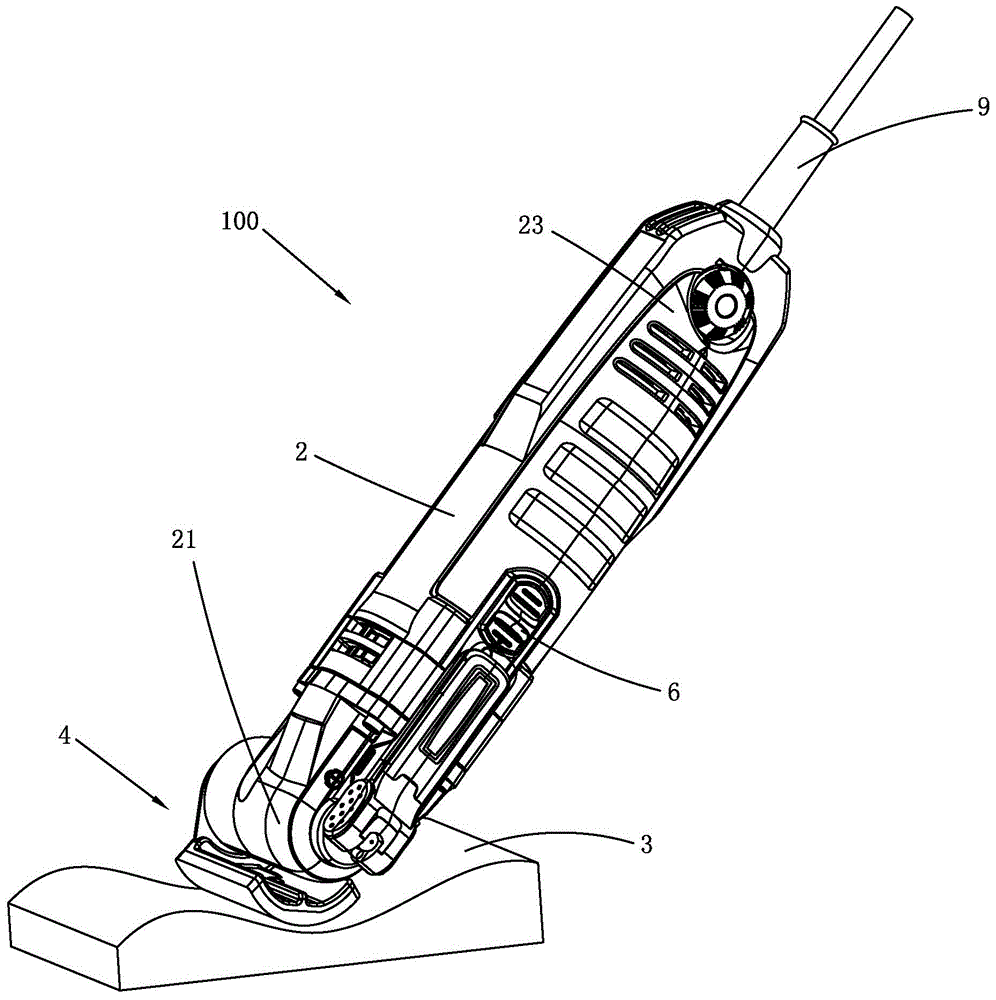

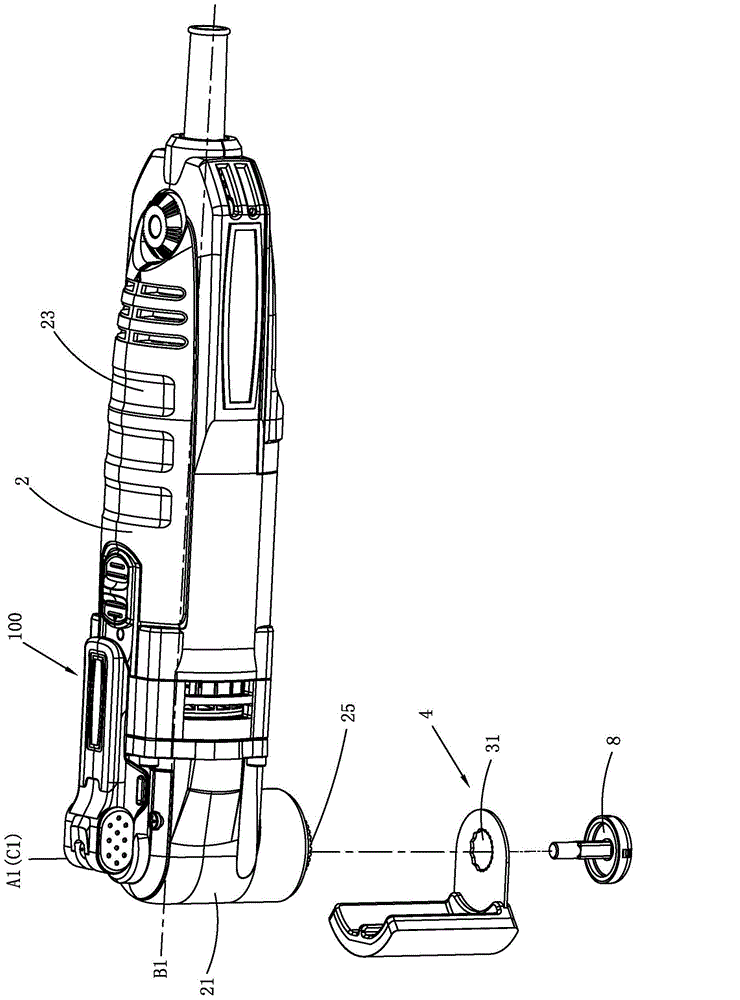

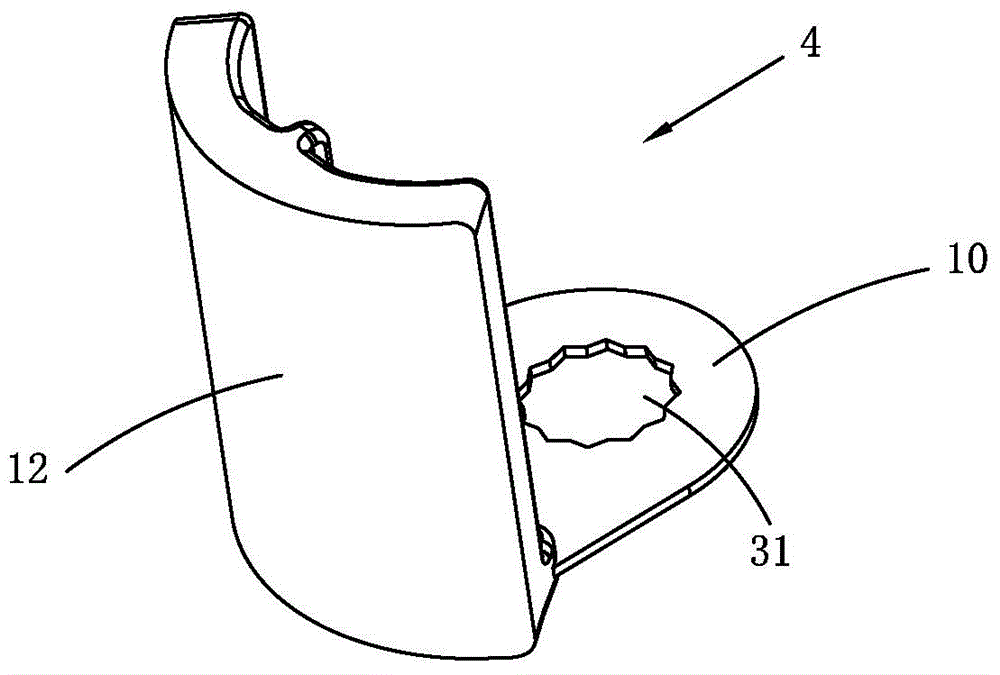

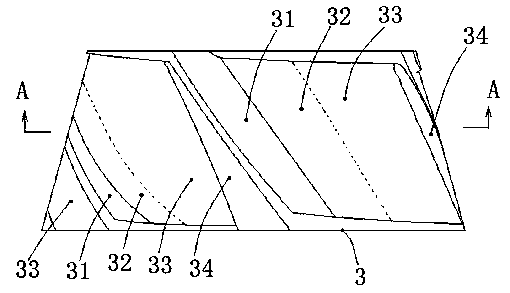

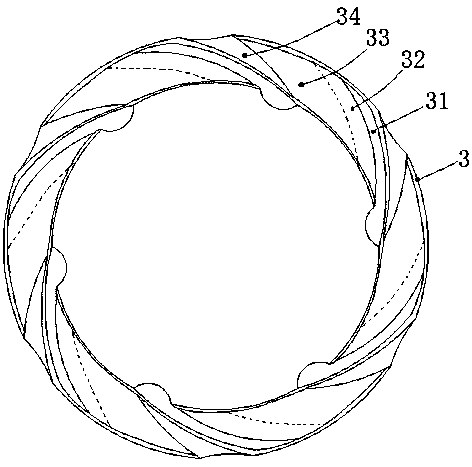

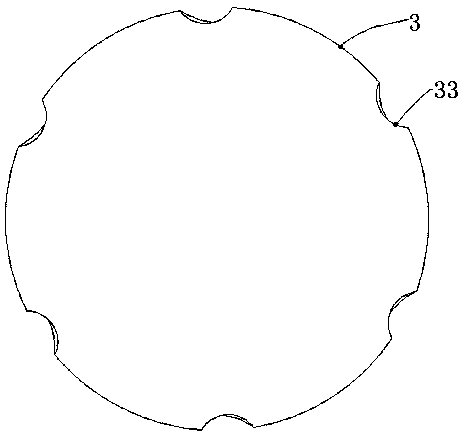

Grinding accessory, swing power tool and application thereof

InactiveCN105081960AImprove grinding efficiencyImprove fitLapping machinesLapping toolsEngineeringPower tool

The invention relates to a grinding accessory, and the grinding accessory can be installed on a swing power tool detachably. The swing power tool comprises a head casing and an output shaft which extends out from the interior of the head casing and is provided with a center axis, and the output shaft can rotate and swing around the center axis. The grinding accessory comprises a transmission portion and a grinding portion, one end of the transmission portion is connected to the output shaft, the grinding portion is connected to the other end of the transmission portion, the grinding portion is provided with an installation surface used for the installation of a grinding member, and the installation surface is a curved surface. The invention also relates to a swing power tool provided with the grinding accessory, and the application of the a swing power tool.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

A multifunctional metal plate welding device for building construction

ActiveCN111496420BPhysical health hazardFunction increaseDispersed particle separationWelding/cutting auxillary devicesElectric machineHazardous substance

The invention discloses a multifunctional metal plate welding device for building construction, which belongs to the technical field of welding devices and comprises a first support plate, a second support plate is arranged above the first support plate, and two ends of the second support plate are provided with The first drive motor, the two ends of the upper surface of the first support plate are provided with the first electric telescopic rod corresponding to the first drive motor, the lower surface of the second support plate is provided with the third drive motor, the third drive The output end of the motor is provided with a second limit screw, and one end of the second limit screw is provided with a welding mechanism. The welding mechanism includes a collection cover, and the upper surface of the collection cover is provided with a first stop corresponding to the second limit screw. A limit slider; the present invention is simple in structure, easy to use, and has a purification function, which can absorb and purify the smoke generated during welding, thereby removing harmful substances in the smoke and preventing the smoke from flying around, which is harmful to the health of the staff Harm.

Owner:抚州吉远企业管理咨询有限公司

Manufacturing method of polyvinyl alcohol embossed sponge

ActiveCN106493893BWith grinding functionIncrease elasticityAbrasion apparatusPolyvinyl alcoholMaterials science

The invention relates to a manufacturing method of polyvinyl alcohol concave-convex sponge. The polyvinyl alcohol concave-convex sponge comprises a polyvinyl alcohol concave-convex sponge body, a PVC soft glue film, a bottom glue layer, a composite glue layer and abrasive materials. Dot patterns are bestrewed on the front face of the polyvinyl alcohol concave-convex sponge body. The dot patterns are composed of a plurality of semispherical salient points arranged uniformly. Gaps between the adjacent salient points are mutually connected to constitute a communicating groove. The PVC soft glue film is formed on the back face of the polyvinyl alcohol concave-convex sponge body. The front face of the polyvinyl alcohol concave-convex sponge body is coated with the bottom glue layer. The upper surface of the bottom glue layer is coated with the composite glue layer. The lower ends of the abrasive materials are embedded into the bottom glue layer, and the upper ends of the abrasive materials protrude out of the upper surface of the composite glue layer. The concave portions of the position, corresponding to the communicating groove, of the surface of an abrasive belt communicate with one another to constitute a chip removal groove. The manufacturing method of the polyvinyl alcohol concave-convex sponge not only achieves the properties of blockage preventing and elastic grinding but also has the advantages that the process is simple, equipment investment is low, cost is low, abrasion resistance is achieved, service life is long, and toxicity is avoided.

Owner:佛山钰豪研磨材料科技有限公司

High-end intelligent tableware

The invention discloses high-end intelligent tableware. The high-end intelligent tableware comprises a machine base, a supporting column and a beam. The supporting column is fixedly arranged on the left side of the machine base and is arranged in an upward extension manner. The beam is arranged on the top of the right end face of the supporting column and extends rightwards. A first sliding grooveis arranged on the bottom end face of the beam and extends in the left and right direction. An end opening of the first sliding groove is arranged downward. A first sliding block is installed in thefirst sliding groove in a sliding manner. A screw hole is formed in the first sliding block. A threaded rod is installed in the screw hole in a matched manner. The left end of the threaded rod is rotationally arranged in the part, on the left side, of the inner wall of the first sliding groove. The right end of the threaded rod is in power connection with a first driver which is fixedly arranged in the part, on the right side, of the inner wall of the first sliding groove. An assembly rack is fixedly arranged on the bottom end face of the first sliding block. A first rotary chamber with a downward port is arranged in the top end face of the assembly rack.

Owner:朱娟红

a sealing valve

ActiveCN107035874BRealize their respective functionsRealize functionOperating means/releasing devices for valvesValve members for heating/coolingIndependent motionLinear motion

The invention discloses a seal valve. The seal valve comprises a valve body, an air inlet, an air outlet, a valve element opening and closing mechanism, a load control mechanism, a valve element rotating mechanism, a valve element and a valve rod, wherein the air inlet and the air outlet are formed in the valve body; a valve seat is arranged at the air inlet or the air outlet and is in contact with the valve element; the valve element is connected with the valve rod; the valve rod penetrates the valve body and is connected with the valve element rotating mechanism; the valve element rotating mechanism is connected with the valve element opening and closing mechanism through the load control mechanism; and rotary motion of the valve element rotating mechanism and linear motion of the valve element opening and closing mechanism are changed into relatively independent motions through the load control mechanism. According to the seal valve, the opening and closing force and the rotating, driving and grinding resistance are controlled by the load control mechanism, so that the seal valve has reliable leakproofness.

Owner:朱书红

Cart with polishing function

PendingCN108312005AWith grinding functionTo achieve the effect of grinding equipmentGrinding machinesCouplingEngineering

The invention discloses a cart with a polishing function. The cart comprises a box; a first chute is formed in the inner wall of the box; the inner wall of the first chute is slidingly connected witha base; the surface of the base is fixedly connected with a baffle plate; a first clamping groove is formed in the surface of the baffle plate; a lifting groove is formed in the inner wall of the box;a clamping rod is slidingly connected to the inner wall of the lifting groove; the surface of the box is in threaded connection with a first fixed bolt; the surface of the base is fixedly connected with a motor; and an output shaft of the motor is fixedly connected with a rotating shaft through a coupling. In the cart with the polishing function, when equipment needs to be used, the motor is started to drive rotation of the rotating shaft, the rotating shaft drives rotation of a connecting rod, and the connecting rod drives rotation of a polishing roller; the polishing process is operated through an operation hole to achieve the equipment polishing effect; and the problems of complicated structures of general polishing equipment, troublesome disassembly and assembly during carrying and influence on the working efficiency to a certain extent are effectively solved.

Owner:WUXI KONSTANT POWER TECH CO LTD

Grinding device and multifunctional flour milling machine

The invention provides a grinding device and a multifunctional flour milling machine. The grinding device comprises a circular truncated cone type inner roller, the inner roller is sleeved with an outer roller, the inner wall of the outer roller and the outer wall of the inner roller are attached and are in running fit, a plurality of functional areas are distributed on the outer wall of the innerroller along the circumference of the inner roller, and each functional area comprises a feeding area, a buffering area, a grinding area and a discharging area which are sequentially arranged along the outer circumference of the inner roller. The functional area is arranged on the inner roller, so that materials are rubbed, ground and milled in the buffer area and the grinding area of the functional area and then enter the discharging area, grinding machining of the materials is completed, the grinding efficiency is high and the finished product quality is good; due to the fact that the outerroller is in the circular truncated cone shape and matched with the functional area, the rotating speed of the inner roller is reduced while the grinding yield is guaranteed, the temperature of the inner roller and the outer roller is kept low and powder is not damaged so that the quality of finished materials is guaranteed.

Owner:李海军

Multifunctional drilling device for circuit board production

InactiveCN110524620AEasy to cleanVersatileEdge grinding machinesGrinding wheel securing apparatusHigh pressureMultiple function

The invention discloses a multifunctional drilling device for circuit board production. The device comprises a base, a high-pressure fan, a mounting shaft rod, a supporting rod and a third sliding rail, and a supporting rod is installed on one side of the upper portion of the base. A fixing buckle is mounted at the middle end of the supporting rod; a third sliding rail is installed on the inner side of the fixing buckle. Two groups of third slide blocks are mounted on the third sliding rail; a second fixed seat is mounted on one sides, far away from the third sliding rail, of the third slidingblocks; according to the invention, the high-pressure fan is installed; a dust collection bin is arranged at the joint of the air inlet pipe, so chippings generated by drilling can be cleaned away intime, cleaning is more convenient, the chippings can be prevented from influencing the drilling efficiency, through the arrangement of the universal chuck at the bottom end of the mounting shaft rod,the device can conduct drilling, meanwhile, a grinding wheel grinding head can be mounted, the drilling device can have the grinding function, and the functions are more comprehensive.

Owner:赣州市深联电路有限公司

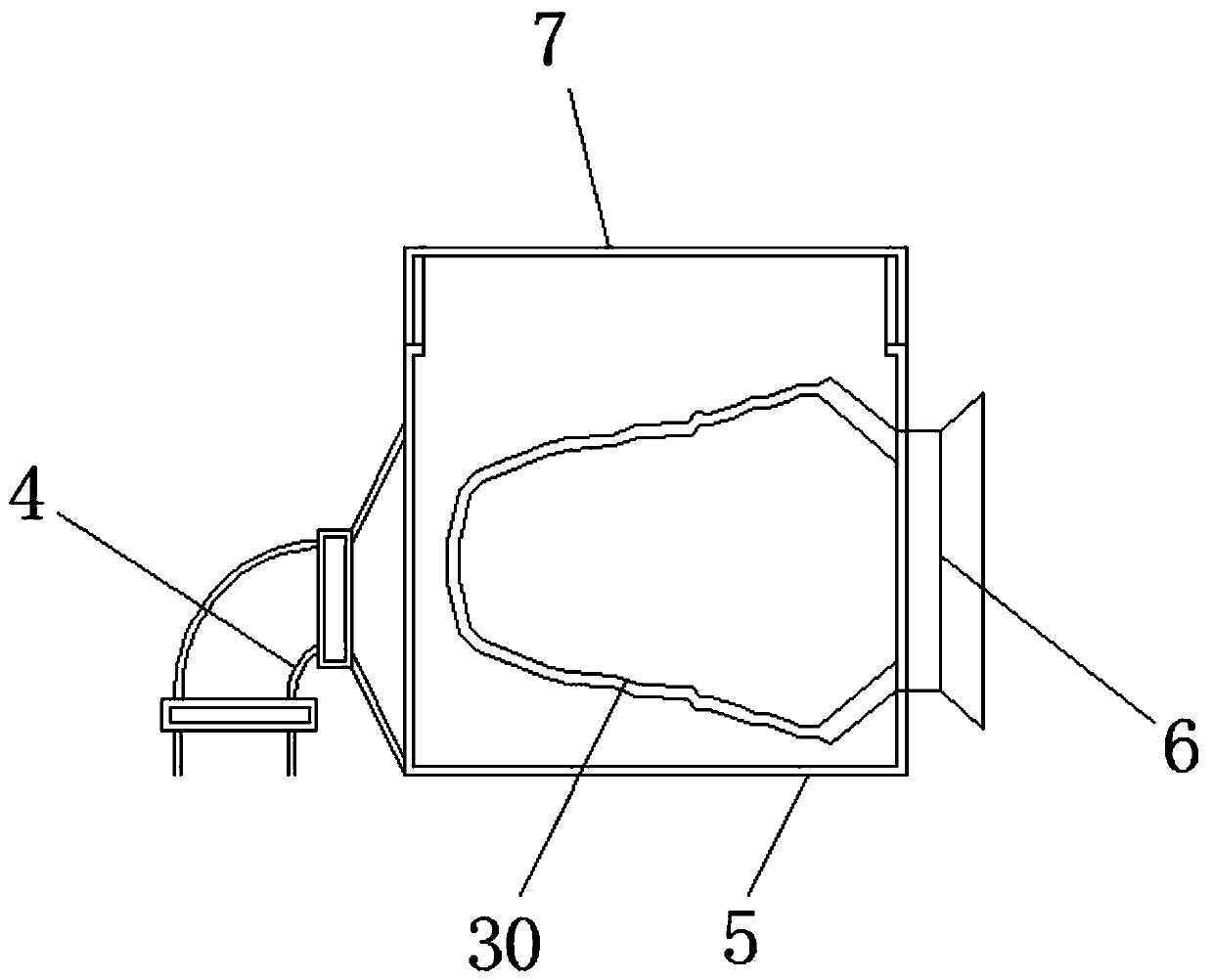

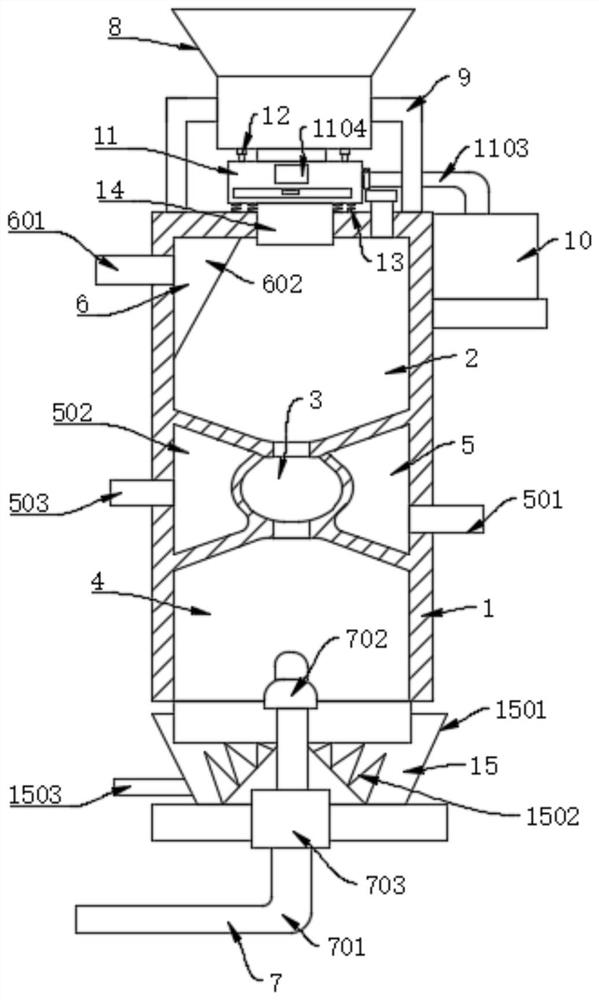

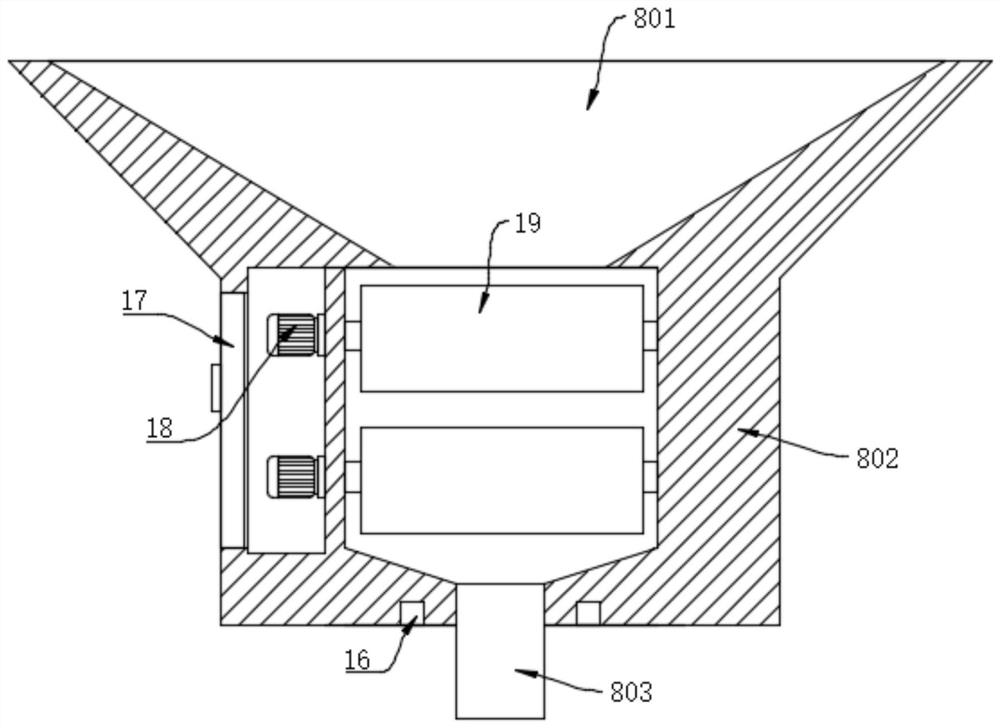

A kind of catalytic dry distillation equipment and dry distillation process of oil shale organic waste

ActiveCN113684046BEasy to installWith grinding functionDispersed particle filtrationLiquid hydrocarbon mixture productionThermodynamicsOil shale

The invention relates to the field of dry distillation of oil shale, in particular to a catalytic dry distillation equipment for oil shale organic waste and a dry distillation process, including a dry distillation furnace body, a feeding component, a filtering component, a recovery component and a rock ash collection component. The cooperation of the feeding component and the supporting component is convenient to install the feeding component on the upper end of the retort furnace body, and the feeding component has a grinding function, which can regrind the oil shale entering the feeding component, which is convenient for oil shale The large particles in the raw material are pulverized; through the cooperation of the filter assembly and the feed assembly, it is convenient to filter the oil shale after the grinding of the feed assembly, so that the smaller particles of oil shale enter the interior of the retort furnace body, shorten the oil shale Combustion time to ensure complete combustion of oil shale, and the filter assembly is detachable, which is convenient to replace filters with different mesh sizes according to actual use requirements.

Owner:宁夏回族自治区矿产地质调查院

A fixed-length cutting device for processing traditional Chinese medicinal materials with grinding function

ActiveCN109648632BWith grinding functionGuaranteed accuracyGrain treatmentsMetal working apparatusMedicinal herbsKnife blades

The invention discloses a fixed-length cutting device for Chinese herbal medicine processing and with a grinding function. The fixed-length cutting device for Chinese herbal medicine processing and with the grinding function comprises a workbench, a cutting blade, flow guide plates, a first grinding roller and a second grinding roller. Fixing plates are welded at the front end and the rear end ofthe right side of the workbench, and a fixing shaft is installed at the bottom of a top plate. The cutting blade is installed inside a protective cover, and the flow guide plates are fixedly arrangedat the outer ends of the bottoms of the workbench and the fixing plates correspondingly. The top of the first grinding roller and the top of the second grinding roller are connected with scraping plates, and the front end of the first grinding roller and the front end of the second grinding roller are connected with a second motor and a third motor in a rotating mode through third rotating shafts.A material holding tank is installed below the first grinding roller and the second grinding roller. By the adoption of the fixed-length cutting device for Chinese herbal medicine processing and withthe grinding function, fixed-length cutting can be conducted on the length of Chinese herbal medicine in the cutting process, and the cut Chinese herbal medicine is collected advantageously, and canalso be further ground.

Owner:LINGNAN NORMAL UNIV

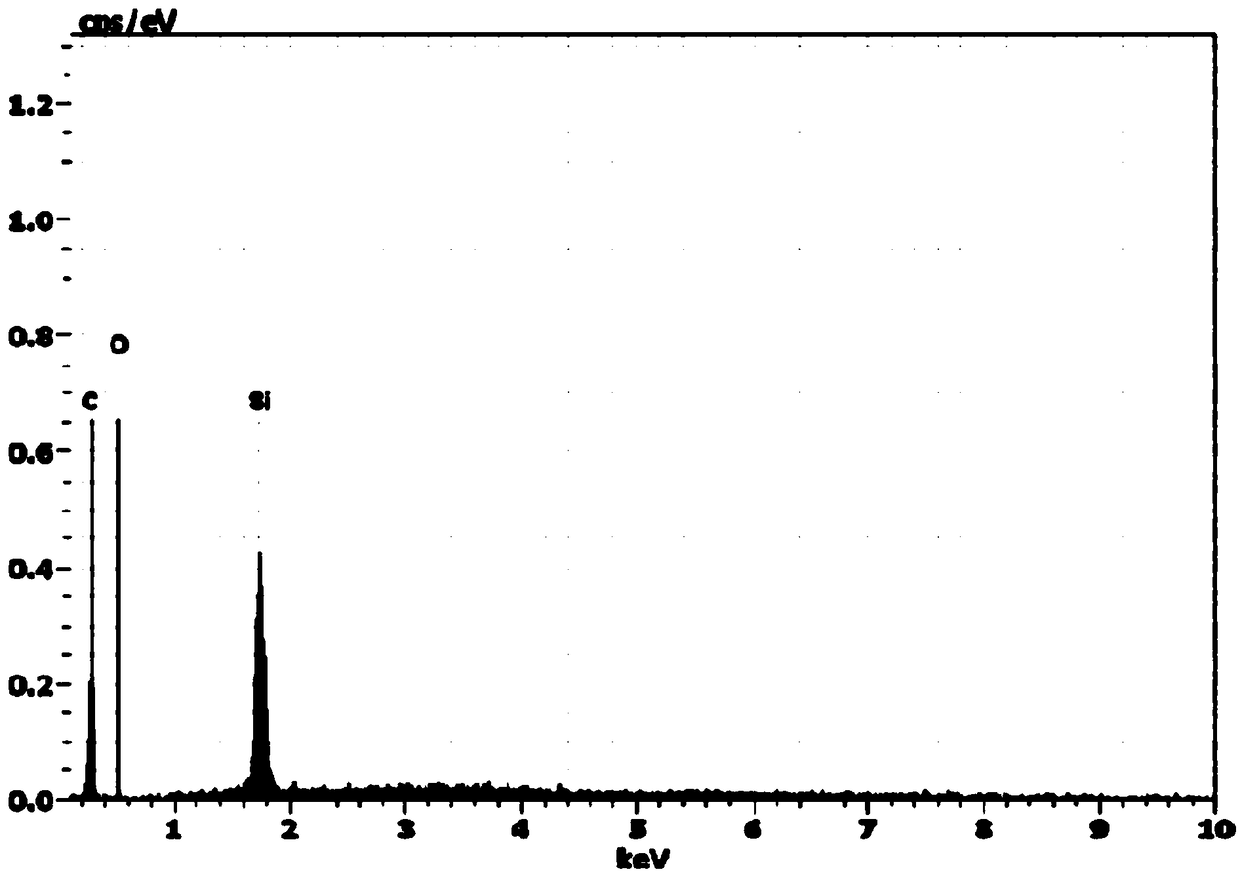

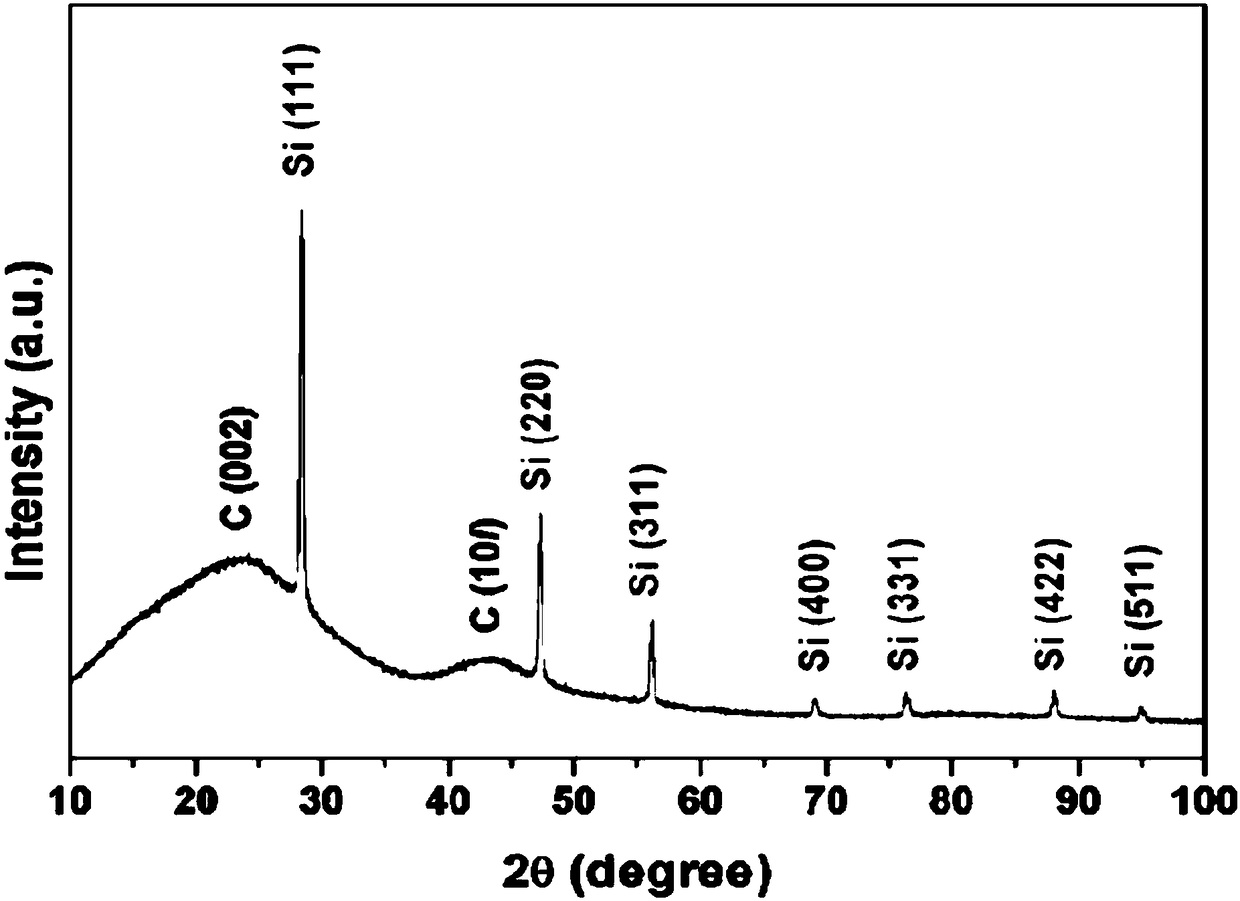

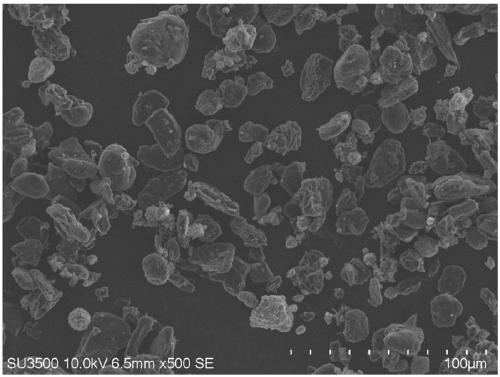

A method for preparing carbon-silicon composite materials by biological method

ActiveCN107215875BGuaranteed carbon to silicon ratioConsistent carbon to silicon ratioCell electrodesSecondary cellsGizzardCarbonization

The invention provides a biological preparation method for a carbon-silicon composite. The biological preparation method comprises the following steps: subjecting raw materials for a chicken feed and a silicon-containing material to mixing and granulation; feeding chicken flocks with the obtained silicon-containing chicken feed, allowing silicon-containing chicken feed to be fully mixed in the gizzards of chickens through digestion and allowing an organic carbon-source compound to coat the silicon-containing material in advance; allowing undigestable micro powder of the silicon-containing material and an undigested organic carbon-source compound to be discharged out in the form of chicken manure, collecting the silicon-containing chicken manure and carrying out drying and homogenization; and subjecting the homogenized silicon-containing chicken manure to high-temperature carbonization in an inert atmosphere so as to obtain the carbon-silicon composite. According to the invention, the gizzards of chickens, a biological stirrer, are made full use of for preparation of a precursor of the carbon-silicon composite, so the problem of pollution caused by the chicken manure is overcome, and the added value of the chicken manure is increased.

Owner:张绍乙

Metal rod shearing device with grinding function

InactiveCN111890059ARealize the effect of positioning and clampingEasy to moveOther manufacturing equipments/toolsDrive shaftElectric machinery

The invention relates to a metal rod shearing device with the grinding function. The metal rod shearing device comprises a base, a driving mechanism, a grinding mechanism and a shearing mechanism, wherein the driving mechanism is arranged on the base, the grinding mechanism is arranged on the driving mechanism, the shearing mechanism is arranged at one side of the grinding mechanism, the driving mechanism comprises a motor and a driving shaft, the motor is horizontally arranged above the base, and the driving shaft is installed on the motor. According to the metal rod shearing device with thegrinding function, through the driving mechanism, the grinding mechanism is driven to clamp and grind workpieces; and through the shearing mechanism, the workpieces are sheared in batch. Compared withexisting grinding mechanisms, the grinding mechanism not only grinds the workpieces, but also achieves the effect of positioning and clamping the workpieces. Compared with existing shearing mechanisms, the shearing mechanism not only achieves movement of the workpieces, but cuts the workpieces with high precision, thus batch production is achieved, grinding and cutting of the workpieces are achieved simply through one output end, and the energy sources are saved at the same time.

Owner:深圳市壹闻科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com