Manufacturing method of polyvinyl alcohol embossed sponge

A polyvinyl alcohol and manufacturing method technology, applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of reduced grinding capacity, increased abrasive belt cost, less abrasive belt surface, etc., and achieves increased water resistance and good flexibility. , The effect of high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

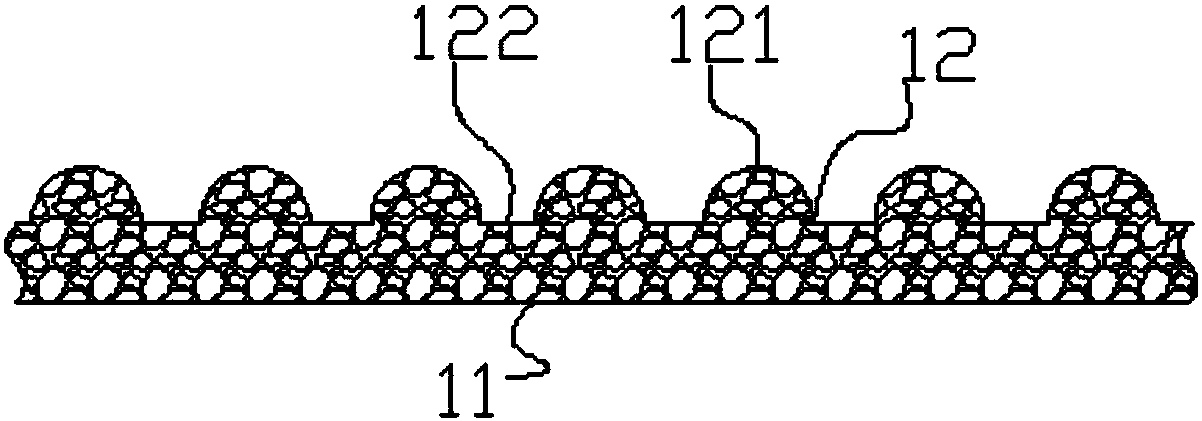

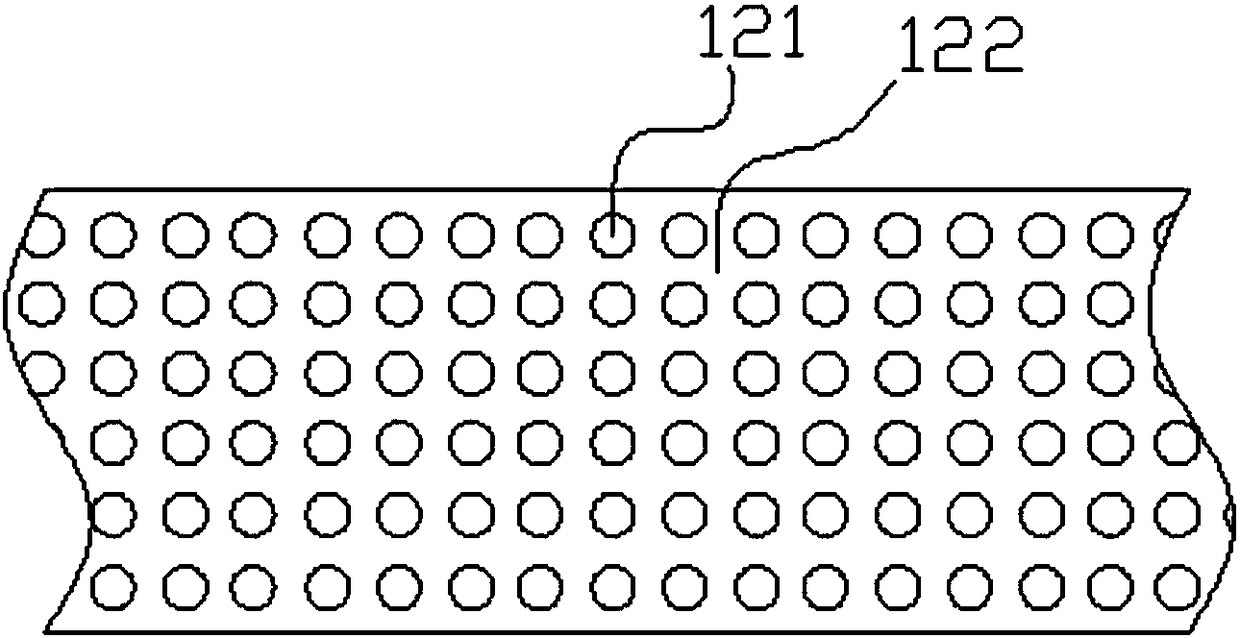

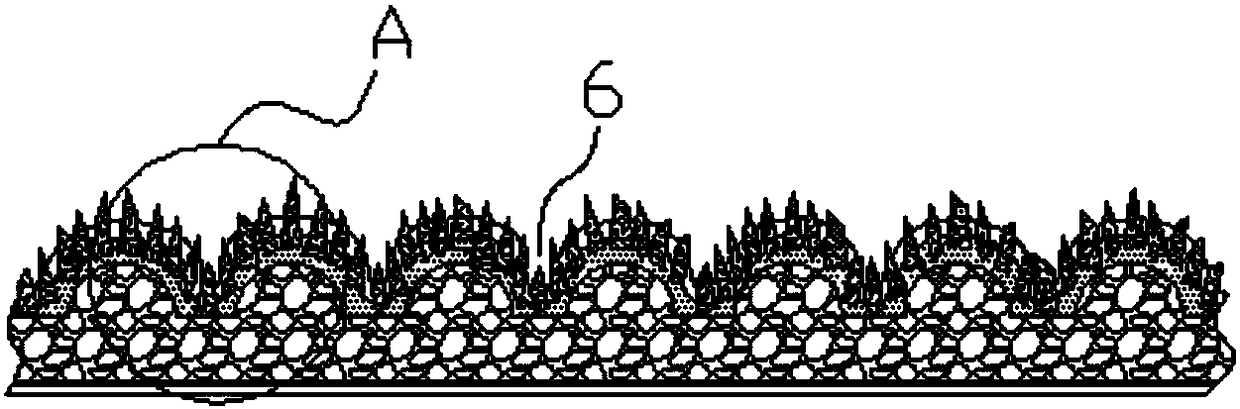

[0029] see Figure 1-4 , the manufacture method of a kind of polyvinyl alcohol concave-convex sponge described in a preferred embodiment of the present invention, comprises polyvinyl alcohol concave-convex sponge 1, PVC soft film 2, primer layer 3, compound glue layer 4 and abrasive material 5, so The polyvinyl alcohol concave-convex sponge has opposite backs 11 and fronts 12, and the front side 12 of the polyvinyl alcohol concave-convex sponge is covered with a dot pattern, and the dot pattern refers to a plurality of evenly arranged hemispherical raised points 121. The gaps between adjacent raised points are connected to each other to form a connecting groove 122, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com