Patents

Literature

94results about How to "Improve grinding ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature high-strength devitrified glass ceramics bond cubic boron nitride grinding wheel

InactiveCN101362316AHigh hardnessImprove grinding abilityBonded abrasive wheelsNumerical controlBoron nitride

The invention discloses a cubic boron nitride grinding wheel with low-temperature and high-strength microcrystalline glass ceramic binder. The cubic boron nitride grinding wheel consists of a matrix, a binding course and a grinding wheel block. The grinding wheel block is a cubic boron nitride grinding wheel block, and adopts the following raw materials (according to the weight percentage of the content): 45 to 80 percent of cubic boron nitride abrasive, 0 to 20 percent of corundum, and 20 to 35 percent of ceramic binder; the ceramic binder is the microcrystalline glass ceramic binder, and the raw material composition and the weight percentage content is as follows: 40 to 70 percent of SiO2, 5 to 25 percent of B2O3, 2 to 5 percent of Al2O3, 2 to 15 percent of Na2O, 2 to 5 percent of K2O, 2 to 4 percent of MgO, 2 to 4 percent of CaO, 1 to10 percent of Li2O, 2 to 5 percent of ZrO2 and 2 to 5 percent of Sb2O3. The invention provides a high efficiency grinding tool which has the advantages that the using linear speed of the grinding wheel can be 160 m / s, the process precision is high, the service life is long, the environment pollution is avoided, and the high efficiency grinding tool can be matched with a high speed high efficiency numerical control crankshaft grinder and is mainly used in the grinding machining of car crank shafts and various numerical control.

Owner:TIANJIN UNIV

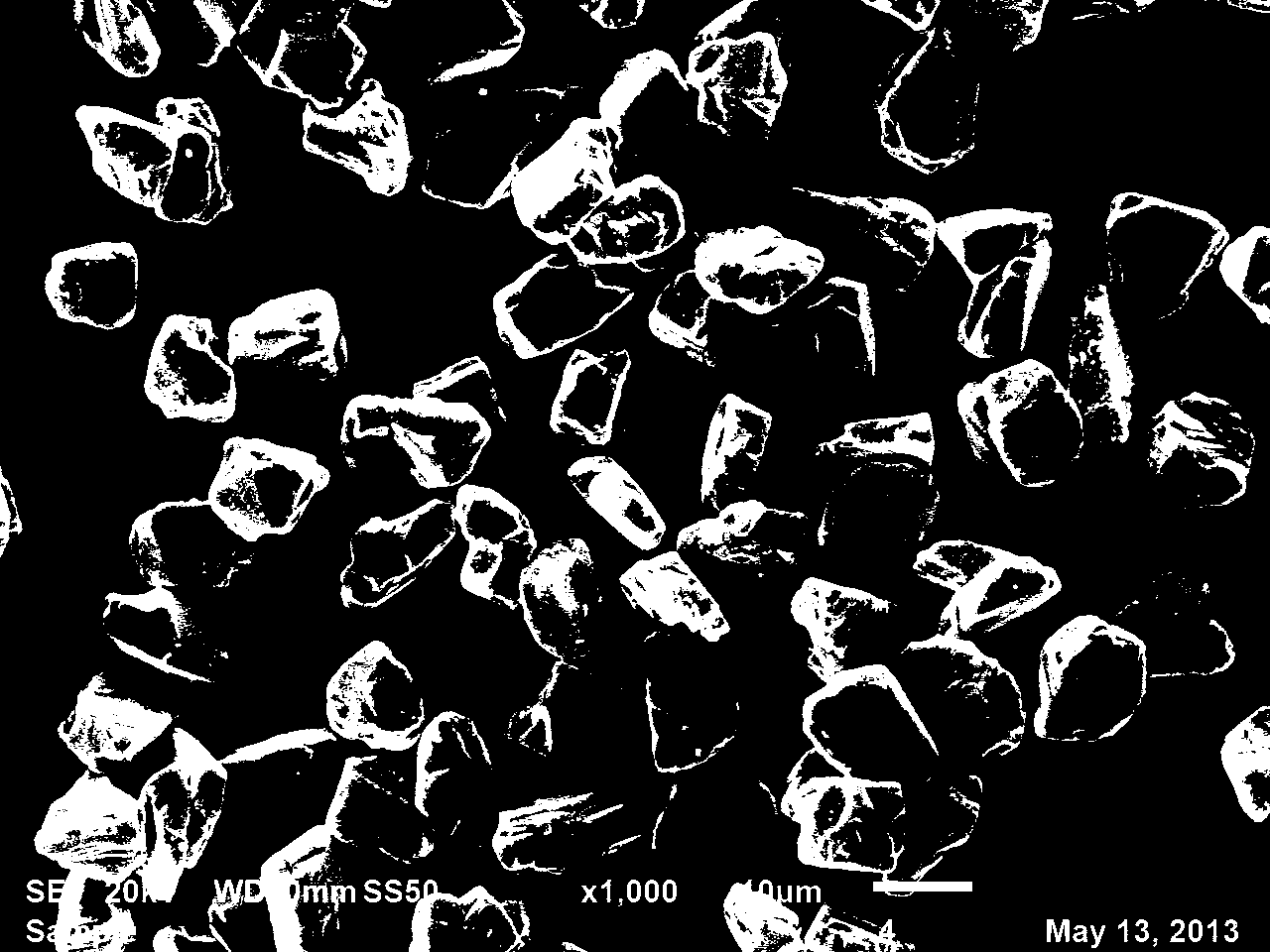

Superhard composite abrasive material and preparation method thereof

ActiveCN104293291AHigh hardnessImprove toughnessOther chemical processesGrinding devicesBoron nitrideChemical stability

The invention discloses superhard composite abrasive material and a preparation method thereof. The superhard composite abrasive material is composed of the following components by weight: 10%-90% of cubic boron nitride and / or diamond and 10%-90% of an additive, wherein the additive is any one or a combination of oxide, nitride, carbide, carbonitride, aluminium nitride, garnet and doped metal. The superhard composite abrasive material combines cubic boron nitride and / or any one or a combination of oxide, nitride, carbide, carbonitride, aluminium nitride, garnet and doped metal. The obtained composite abrasive material has relatively high hardness and toughness, high milling capacity, high efficiency, relatively good abrasive resistance, thermal stability and chemical stability, and relatively long service life. Meanwhile, little raise dust is produced in a processing process of the abrasive material, thereby preventing pollution to ambient air and being suitable for processing processes of metal cutting and polishing.

Owner:FUNIK ULTRAHARD MATERIAL

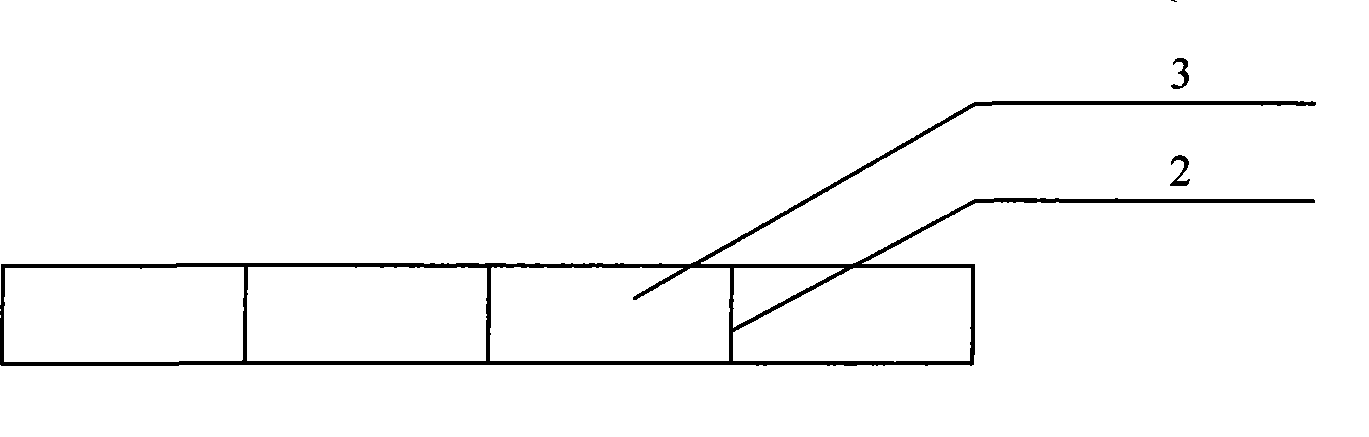

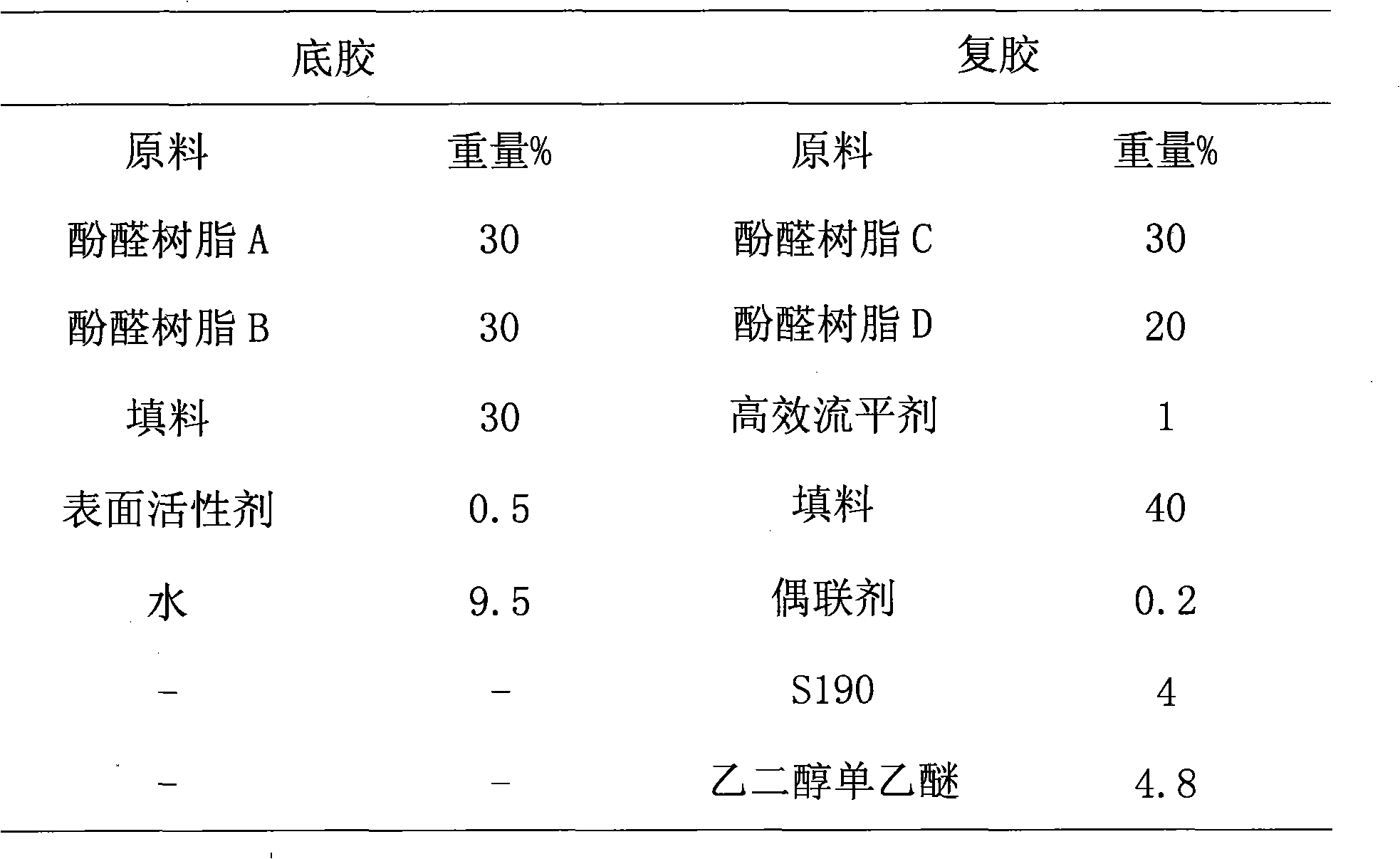

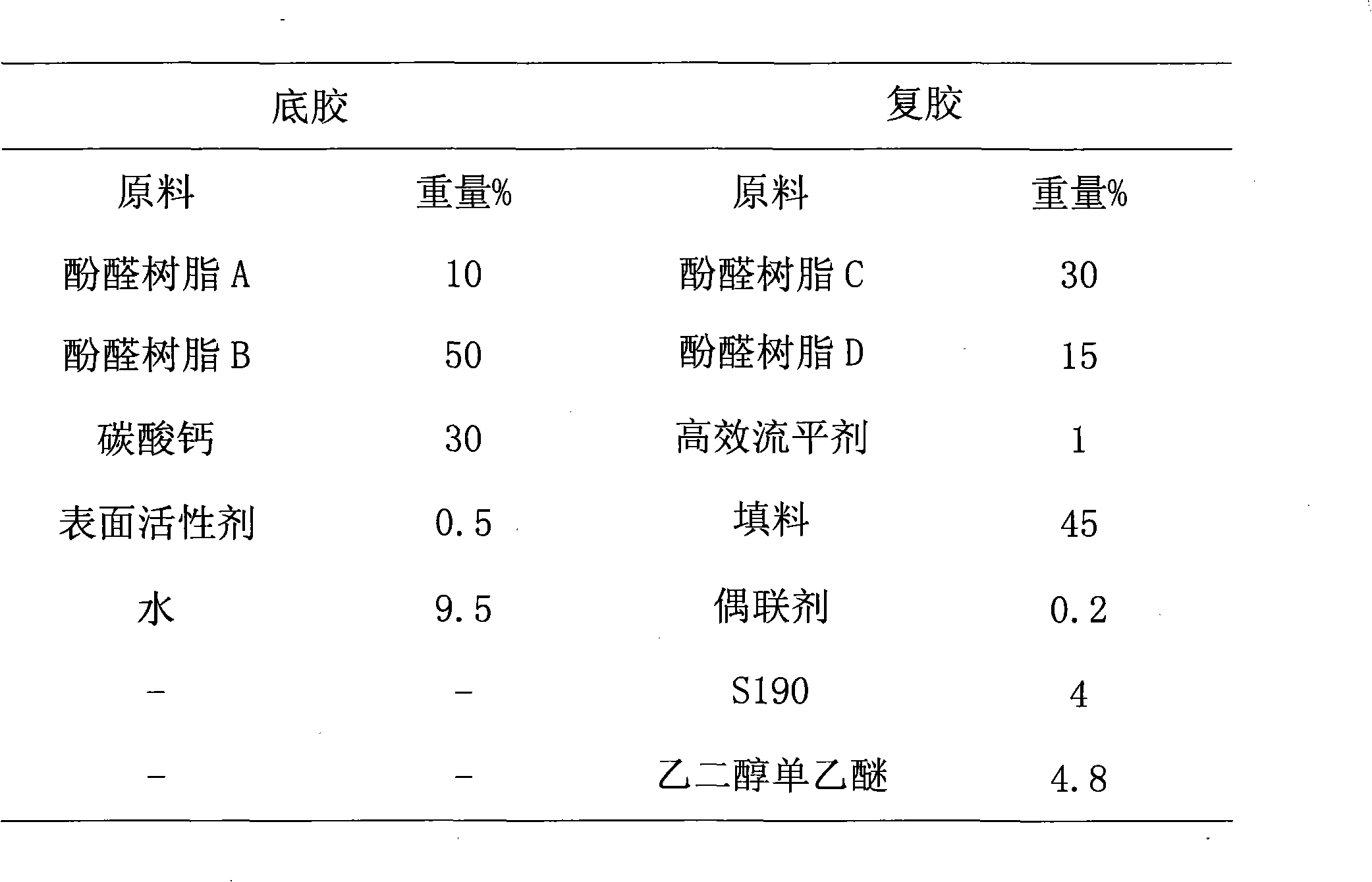

High-performance elastic composite abrasive sheet and preparation method thereof

ActiveCN101966694AAvoid deformationImprove grinding abilityAbrasion apparatusGrinding devicesLaser cuttingPhenol formaldehyde resin

The invention belongs to the field of coated abrasives, and relates to a high-performance elastic composite abrasive sheet and a preparation method thereof. The high-performance elastic composite grinding sheet comprises a vulcanized paper back base, bottom glue, abrasive and complex glue, wherein the bottom glue comprises the following compositions in percentage by weight: 25 to 40 percent of phenolic resin A, 15 to 40 percent of phenolic resin B, 30 to 58 percent of fillers, 0.1 to 1.5 percent of surfactant and 0.1 to 15 percent of diluent; and the complex glue comprises the following compositions in percentage by weight: 15 to 70 percent of phenolic resin C, 15 to 70 percent of phenolic resin D, 0.1 to 3 percent of efficient flatting agent, 5 to 60 percent of fillers, 0.1 to 1.0 percent of coupling agent, 1 to 5 percent of pigment, and 0.1 to 10 of thinner. The method for preparing the high-performance elastic composite abrasive sheet comprises the steps of bottom glue coating process, grain coating process, complex glue coating process, post curing process, curly sand surface flatting process, laser cutting process, vulcanized paper deformation preventing process and storage process, wherein in the post curing process, the sand surface is curly outwards, and after the curly sand surface flatting process, the sand surface is curly inwards so as to enable the sand surface to be flat. The invention can effectively prevent deformation, and has the advantages of strong tensile strength, good adhesive performance and strong grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

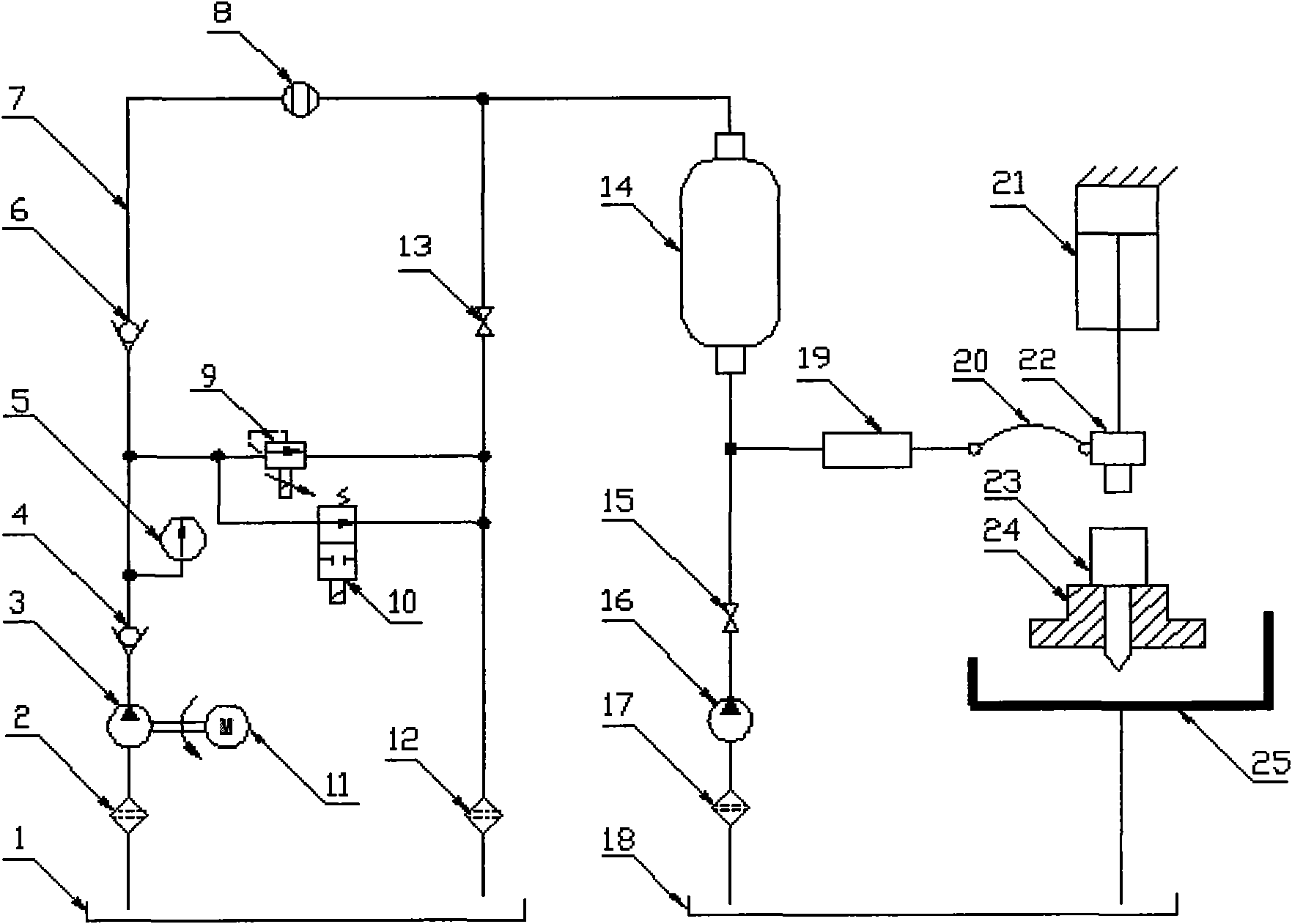

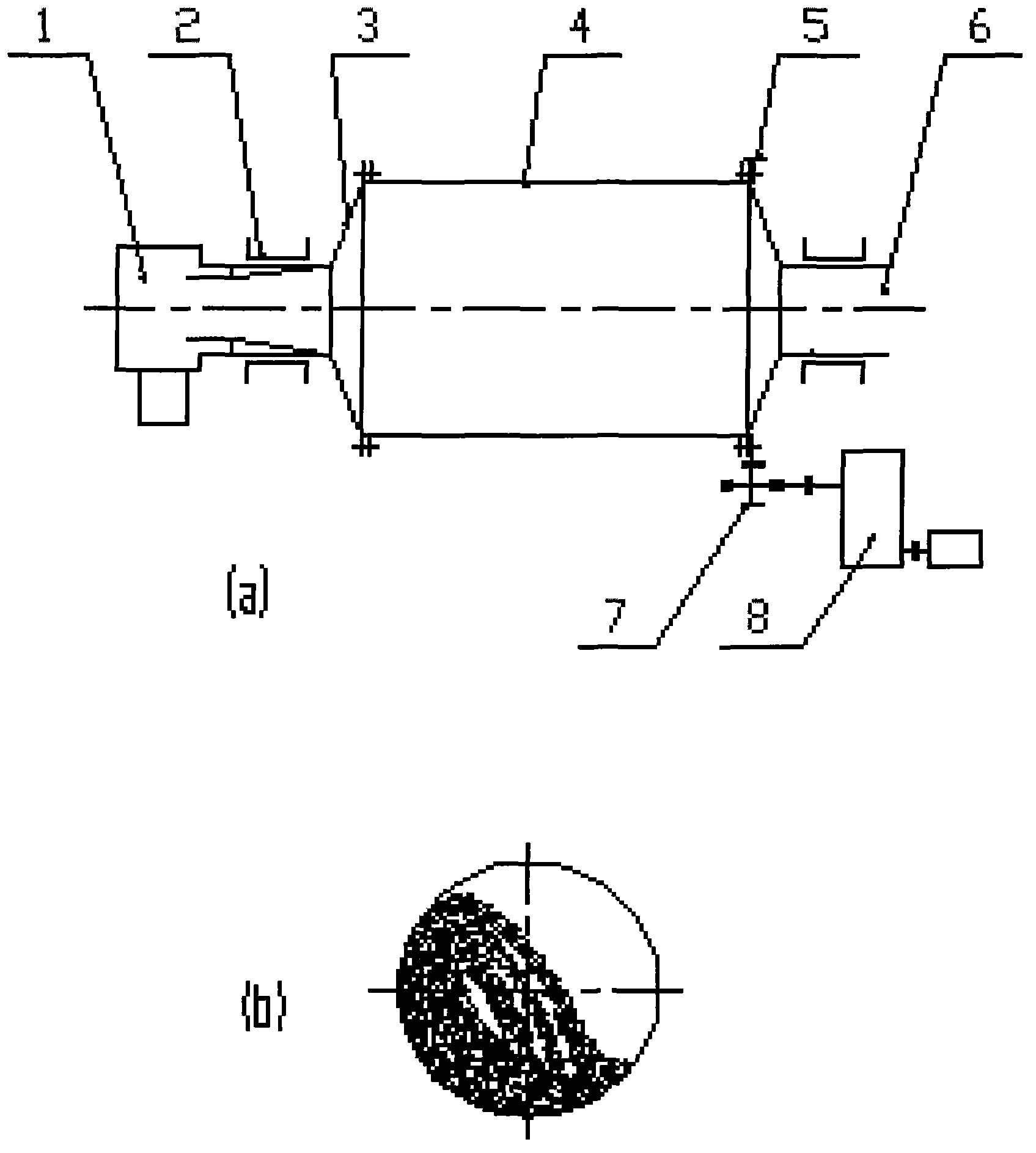

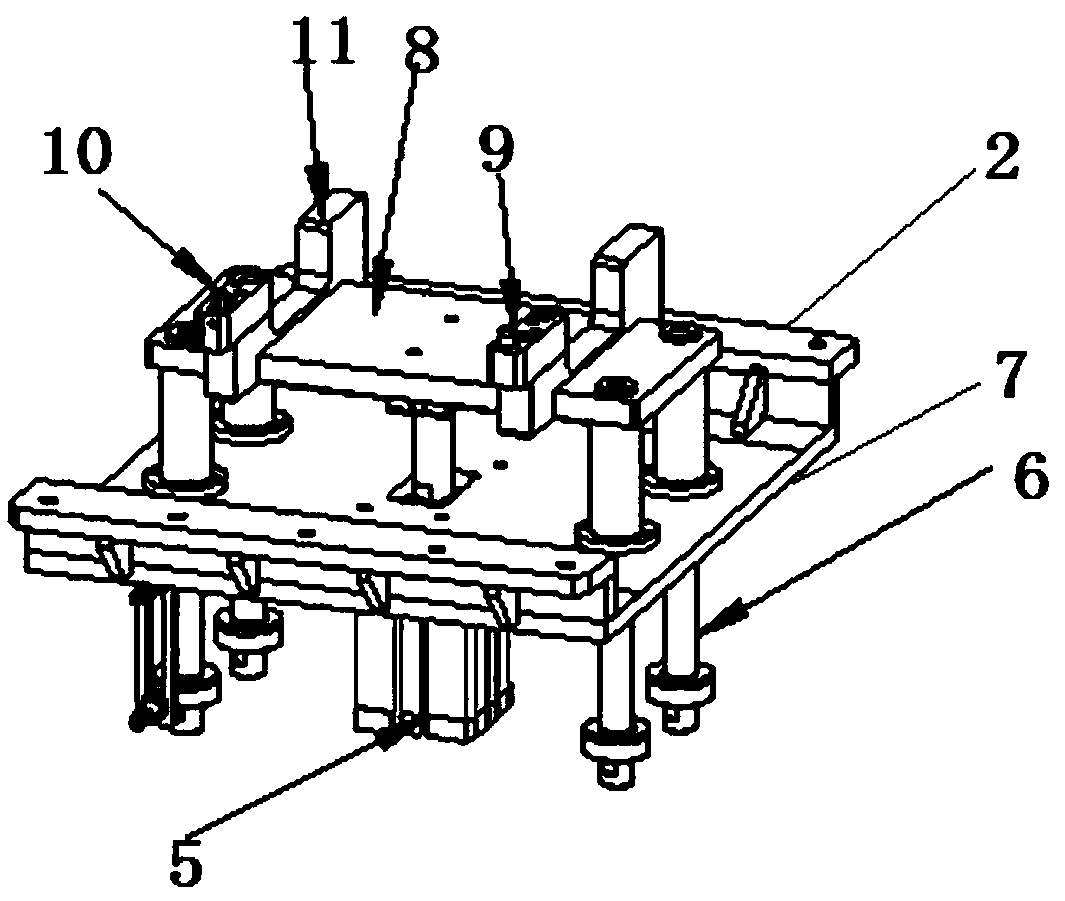

Equipment for processing abrasive slurry water-jet microporous nozzle internal runner and method for detecting and controlling real-time flux

InactiveCN101564831AIncrease the flow rate coefficientTraffic real-time detectionAbrasive feedersRelative volume flow measurementsControl signalFuel tank

The invention relates to an equipment for processing abrasive slurry water-jet microporous nozzle internal runner and a method for detecting and controlling real-time flux. The equipment comprises an oil tank, a slurry box and a high-pressure material tank; a high-pressure pipeline and an oil returning pipeline are communicated with the oil inlet of the high-pressure material tank and the oil tank; a material inlet pipe and a material supply pipe are communicated with the material inlet of the high-pressure material tank and the slurry box; the oil inlet of the high-pressure material tank is provided with a high-precision flowmeter; a processed microporous nozzle is communicated with a material supply interface; the inlet of the material supply joint is provided with a check valve; the material supply joint is arranged on a clamping device; the real-time oil inlet quantity of the high-pressure material tank, namely the real-time flux of the processing microporous nozzle, is measured by the high-precision flowmeter; the real-time slurry flux detection data is input to a controller; when the slurry flux reaches a given value, the controller outputs a control signal to close the check valve, thus stop processing. The equipment has high grinding efficiency and high precision.

Owner:SHANGHAI UNIV +2

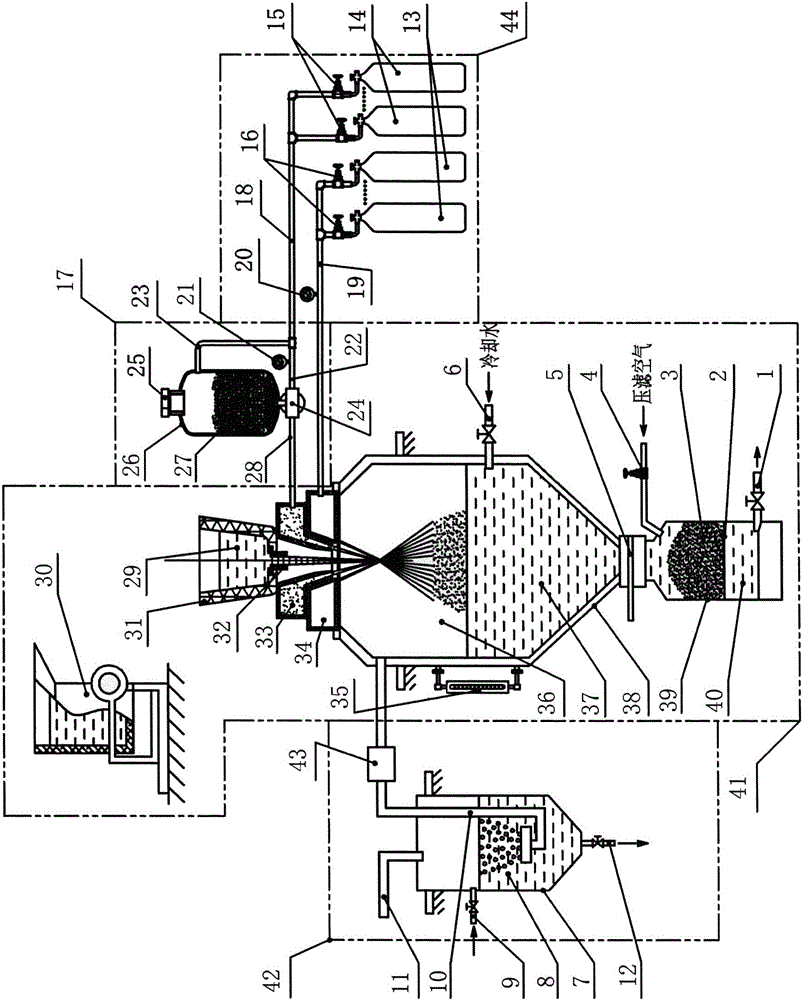

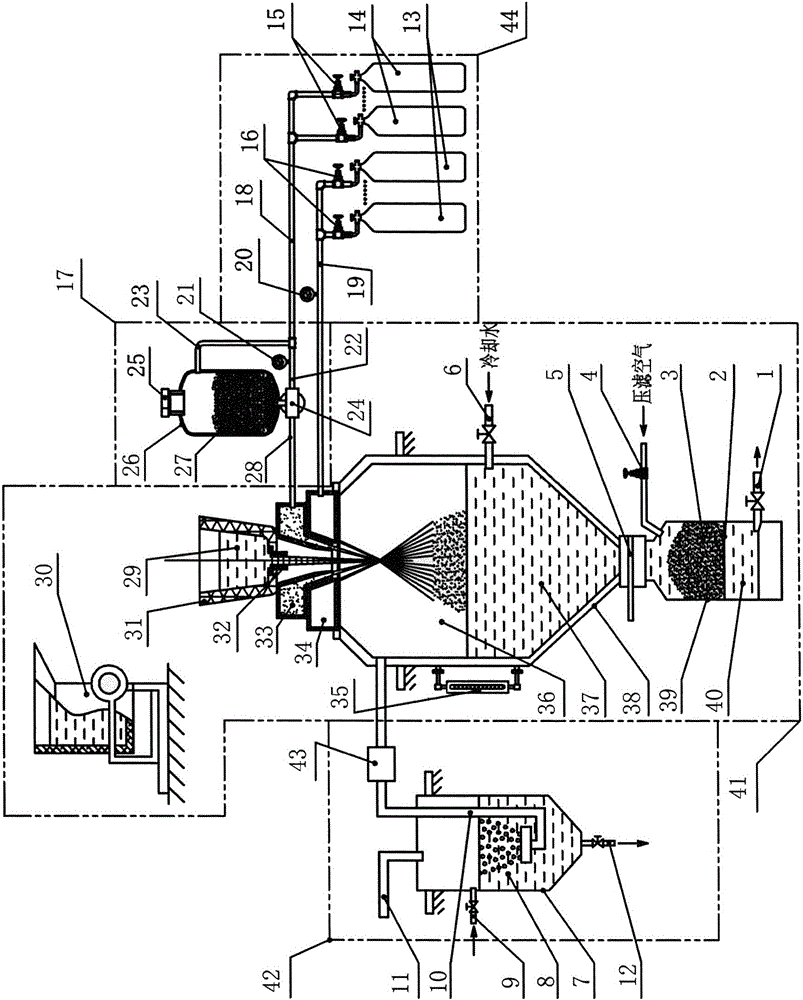

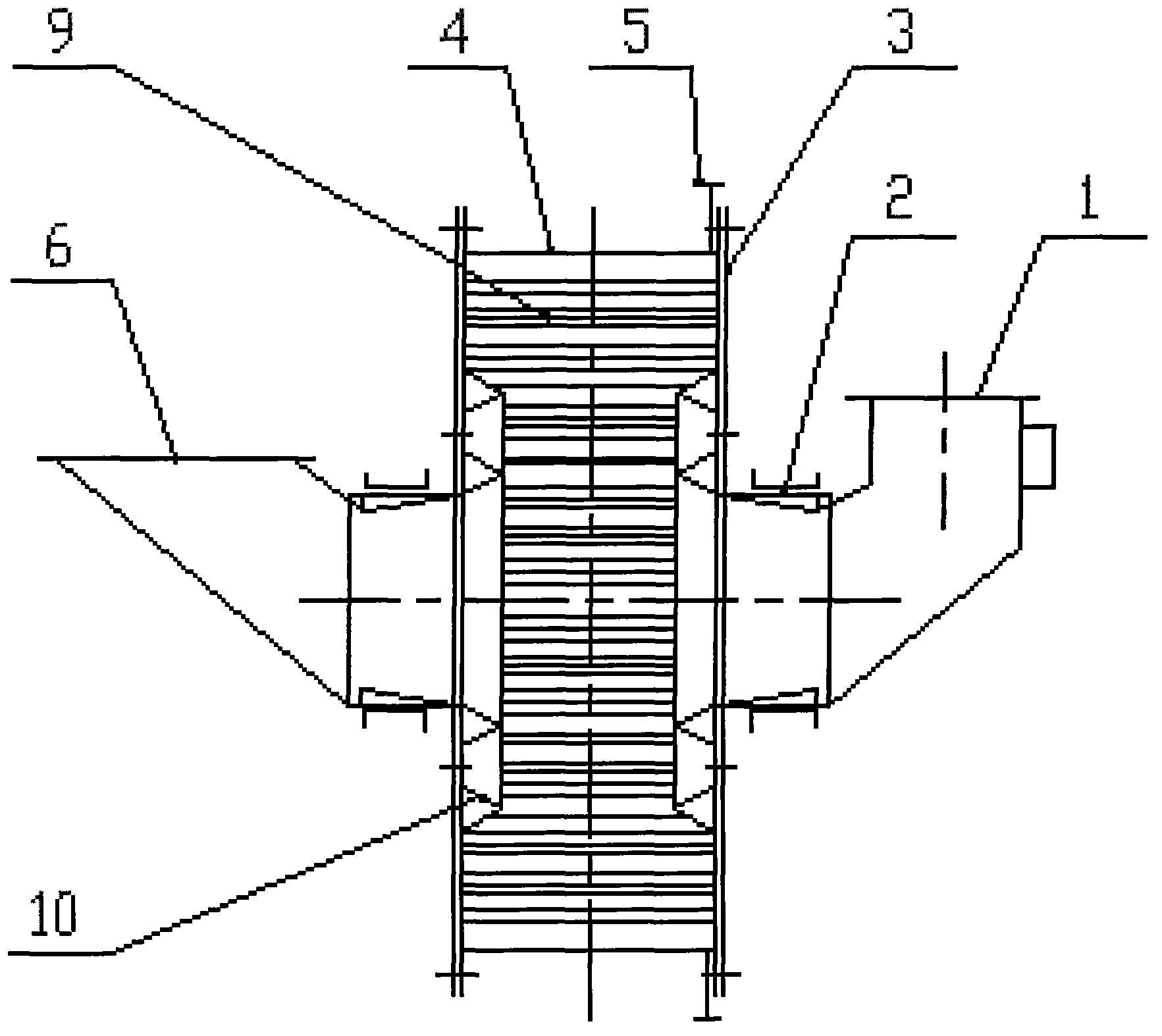

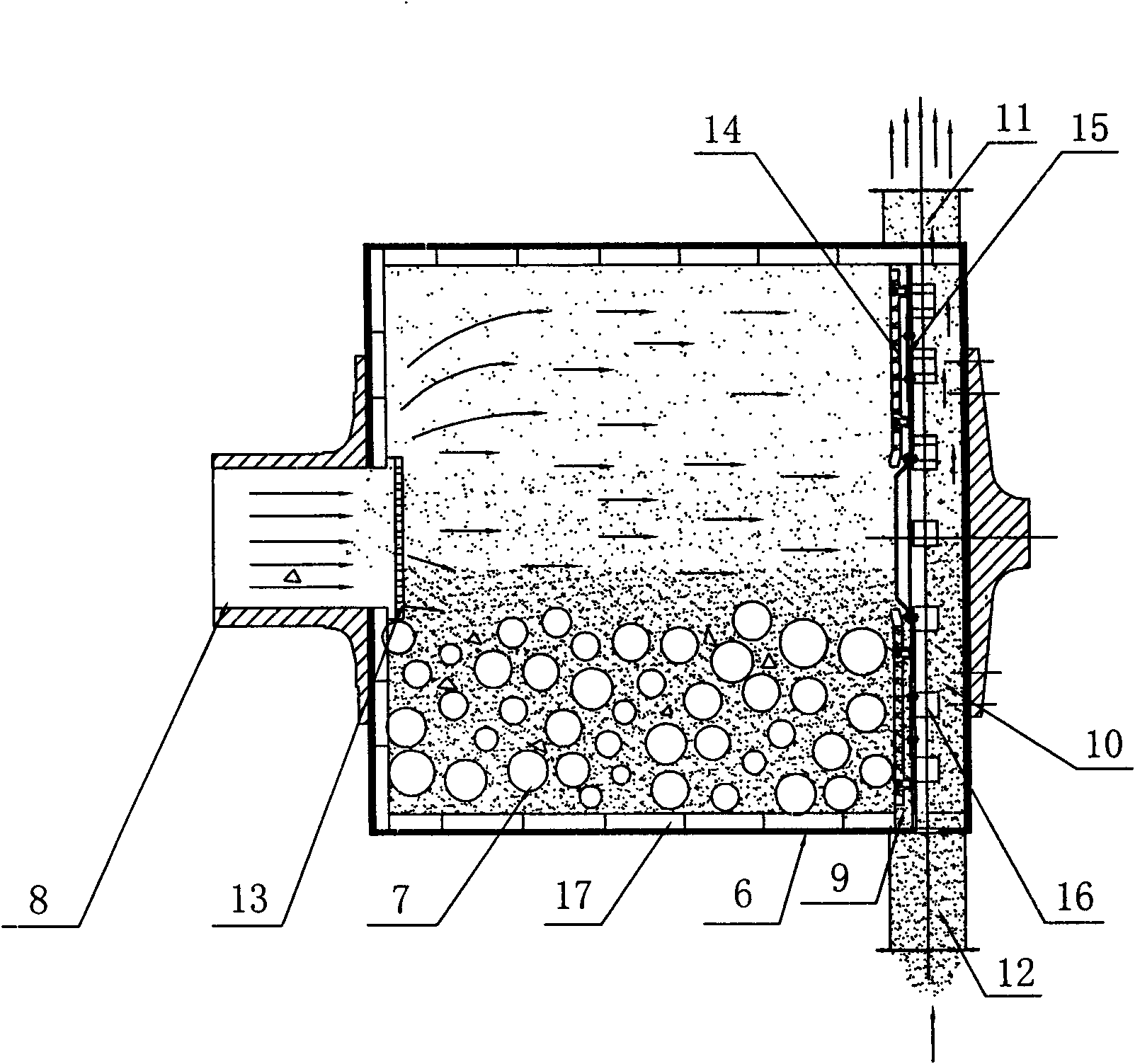

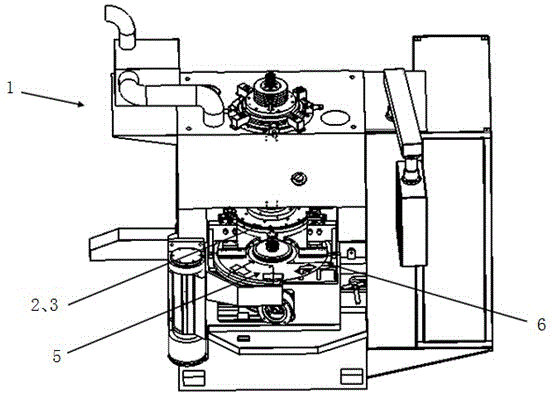

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

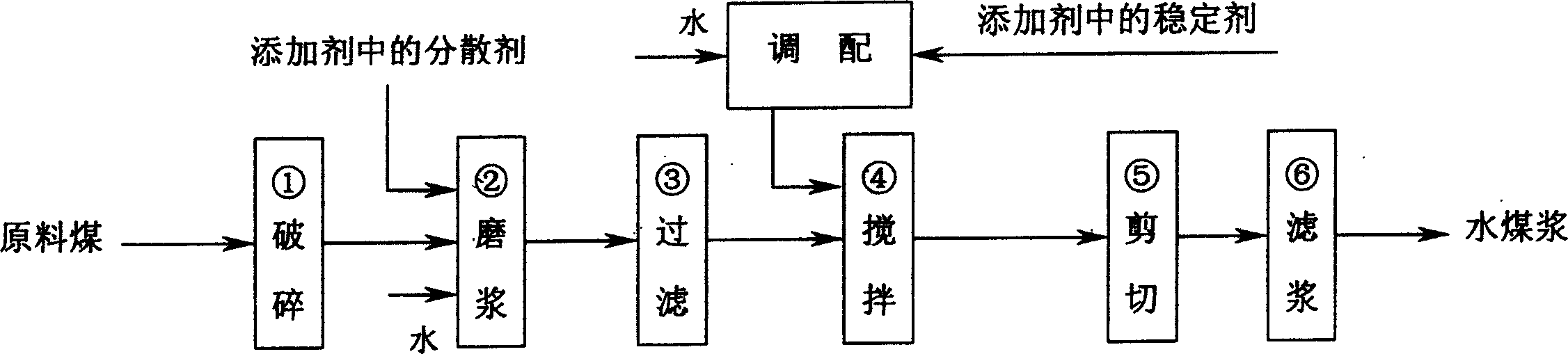

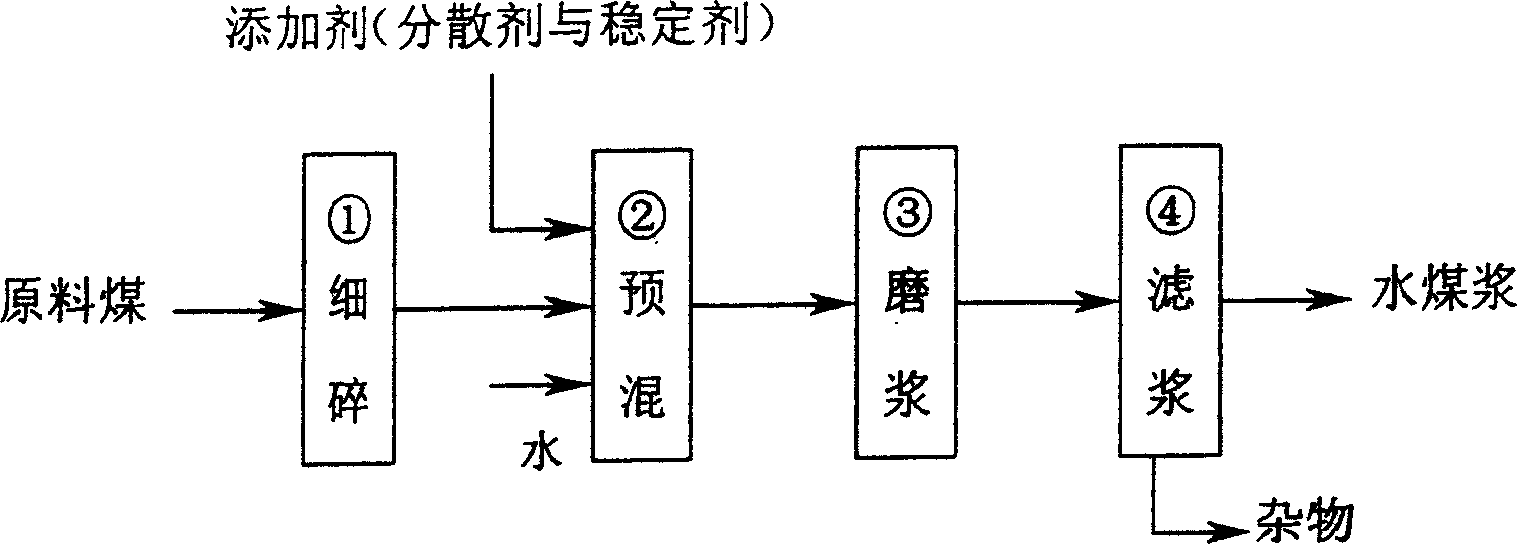

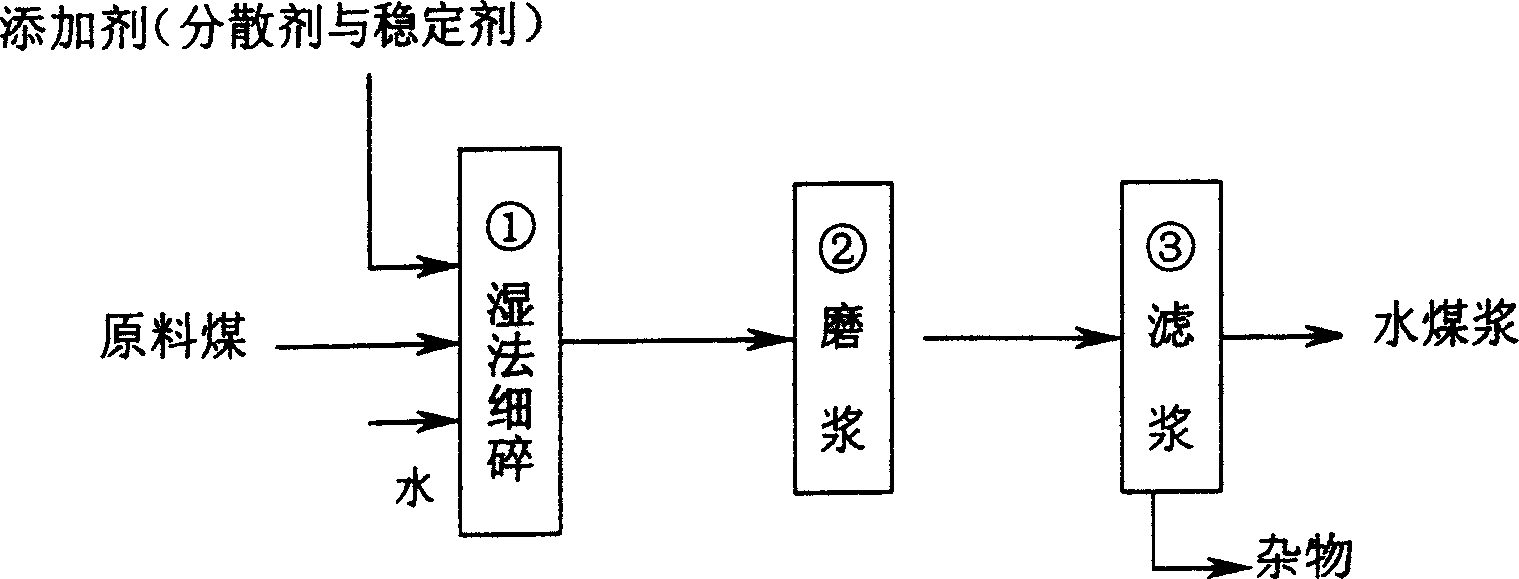

Preparation process of high producing rate, energy-saving water coal paste

InactiveCN1597878ASmall granularityAvoid efficiencyLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterFilling rate

The invention is a high-productivity energy-saving coal water fuel preparing method, relating to the ore wet-milling field, including the steps of finely crushing, premixing, pulp-milling and pulp-filtering, where the finely crushing step further reduces the particle size of raw material coal, the premixing step mixes raw material coal, coal water fuel additive and water together into a uniform strongly self-flowing pulp, the pulp-milling step has strong milling effect because of the increased filling rate of a miller, and the pulp-filtering step adopts centrifugal pulp filtering, so as to make the coal water fuel high-productivity and energy-saving.

Owner:北京柯林斯达能源技术开发有限公司

High-efficiency composite grinding sheet and manufacturing method thereof

ActiveCN103612217AHigh bonding strengthImprove acid resistanceAbrasion apparatusGrinding devicesFiberPost curing

The invention discloses a high-efficiency composite grinding sheet and a manufacturing method thereof. The high-efficiency composite grinding sheet comprises a base material, base gel, an abrasive material and composite gel. The abrasive material is attached to the base material through the base gel and the composite gel, the back of selected steel vulcanized fiber paper is coated with the base gel through at least one of the methods of roller painting, blade coating and flat coating; the selected abrasive material is ground into abrasive material particles which are evenly mixed with the composite gel, and then the back of the selected steel vulcanized fiber paper with the base gel is coated with the mixture; a semi-finished product coated with the base gel and the composite gel is detached and sequentially undergoes a post curing process, a flexure and water entrainment process, a laser cutting process, a steel vulcanized fiber paper anti-deformation processing process and a storing process so as to support a grinding sheet finished product. The grinding sheet is sharp, long in service life, resistant to high temperature after being ground, and good in moisture resistance. The manufacturing method can effectively prevent deformation, and the product is large in tensile strength, good in adhesion and strong in grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

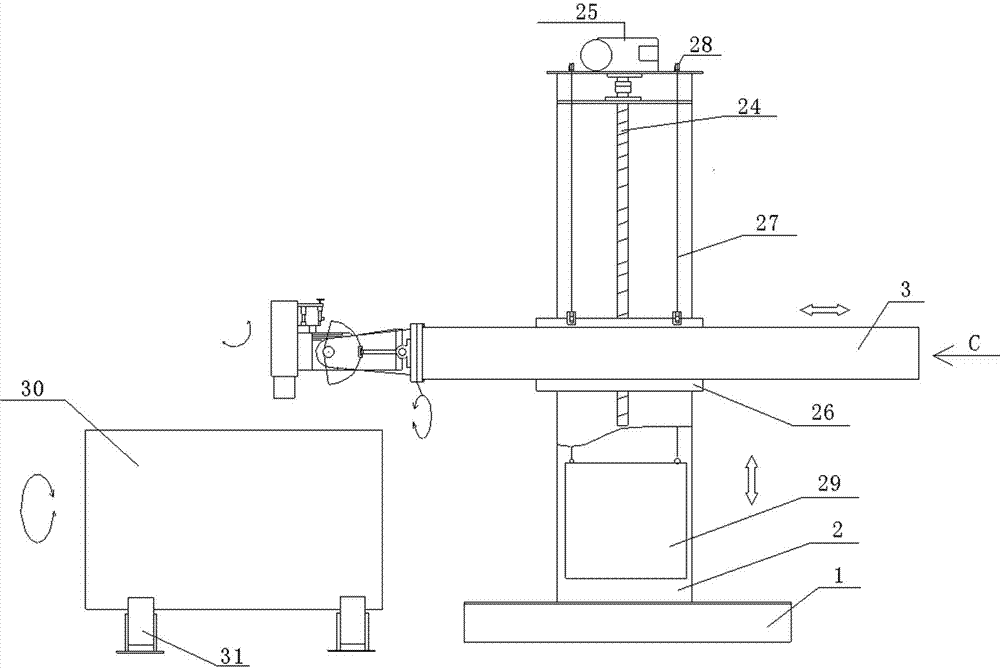

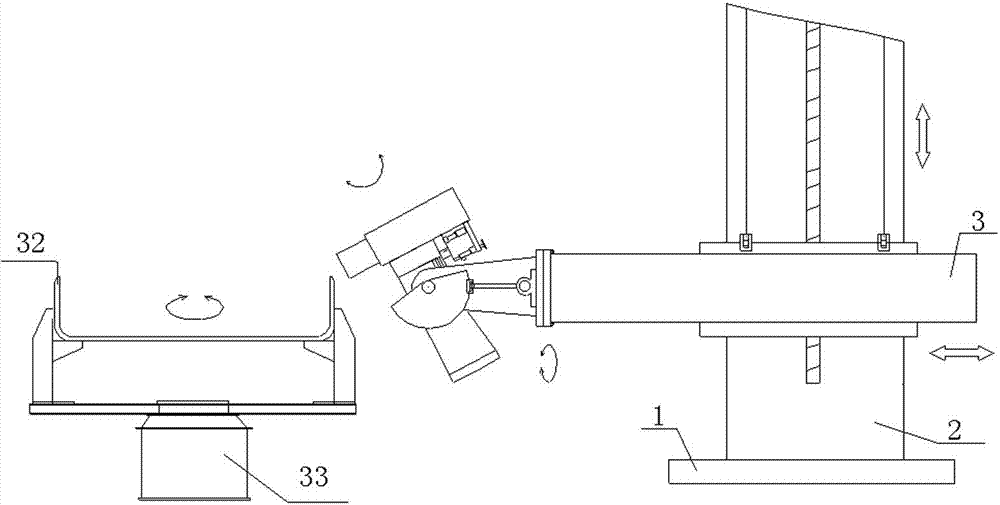

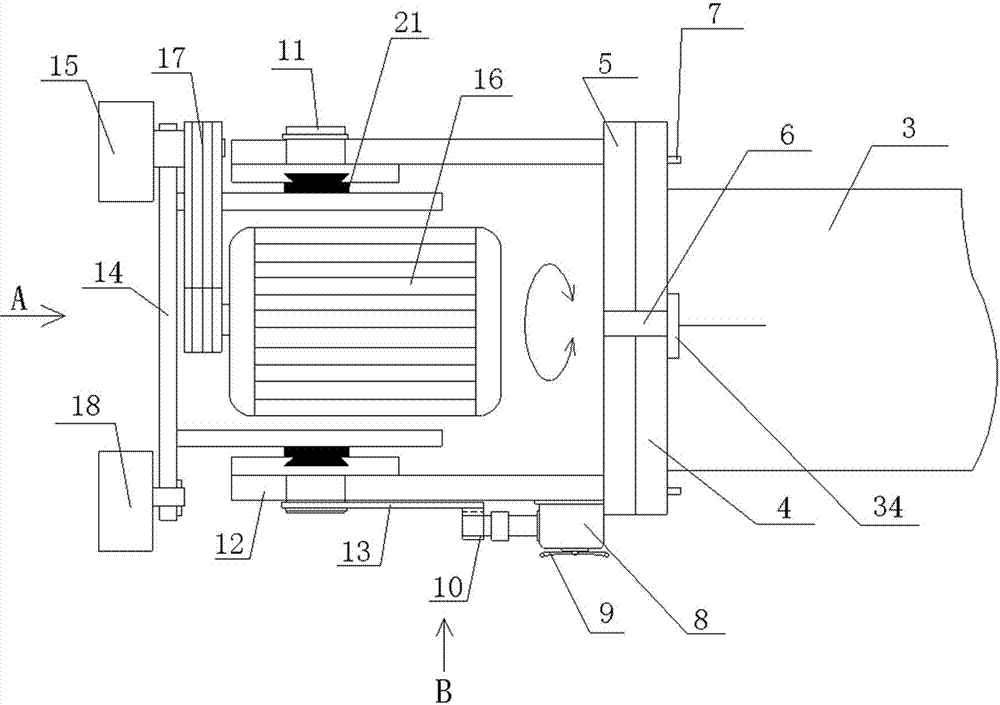

Tank body multi-angle polishing grinding machine

PendingCN106985038AImprove grinding abilityImprove toughnessBelt grinding machinesRotational axisElectric machinery

The invention discloses a tank body multi-angle polishing grinding machine. A stand column is arranged on a base. A cross arm is arranged on the stand column, goes up and down along the stand column through a lifting device and moves left and right along the stand column through a left-right movement device. An abrasive belt grinding head mounting base is arranged at the left end of the cross arm and rotationally connected with the cross arm through a first rotary shaft. The abrasive belt grinding head mounting base rotates around the cross arm. An abrasive belt grinding head is arranged on the abrasive belt grinding head mounting base and rotationally connected with the abrasive belt grinding head mounting base through a second rotary shaft peripherally. The central line of the first rotary shaft is perpendicular to the central line of the second rotary shaft. The abrasive belt grinding head swings around the second rotary shaft peripherally. The abrasive belt grinding head comprises a supporting base fixed to the second rotary shaft. An abrasive belt grinding polishing device and an abrasive belt driving device are arranged on the supporting base. A barrel and an end socket of a tank body can be ground and polished through one abrasive belt grinding head, the power of an adopted motor is low, the energy consumption is low, cost can be lowered, and the equipment investment can be reduced.

Owner:南阳龙腾专用车制造有限公司

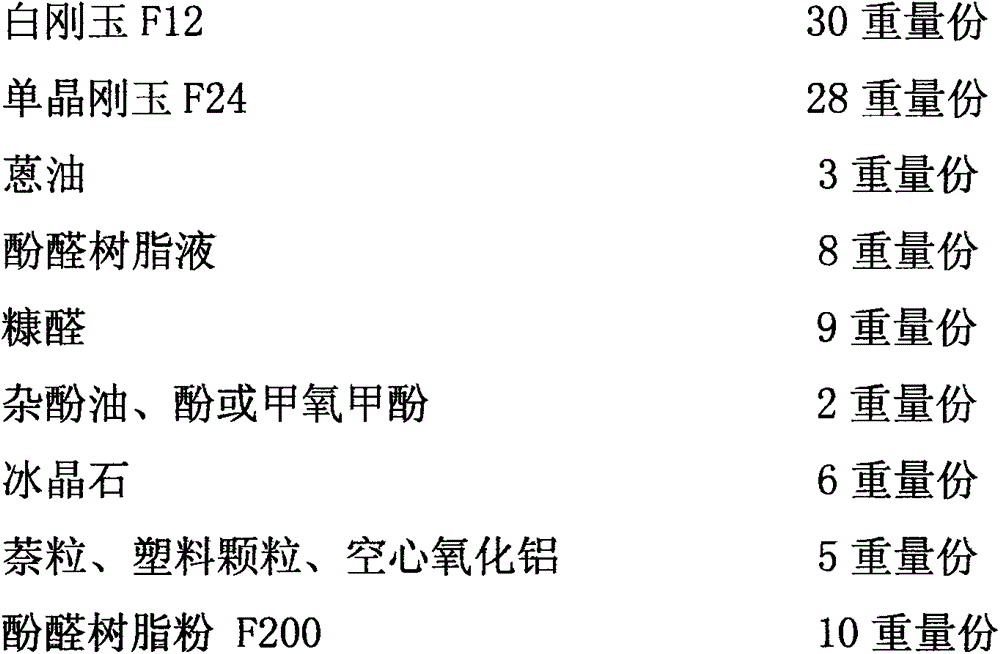

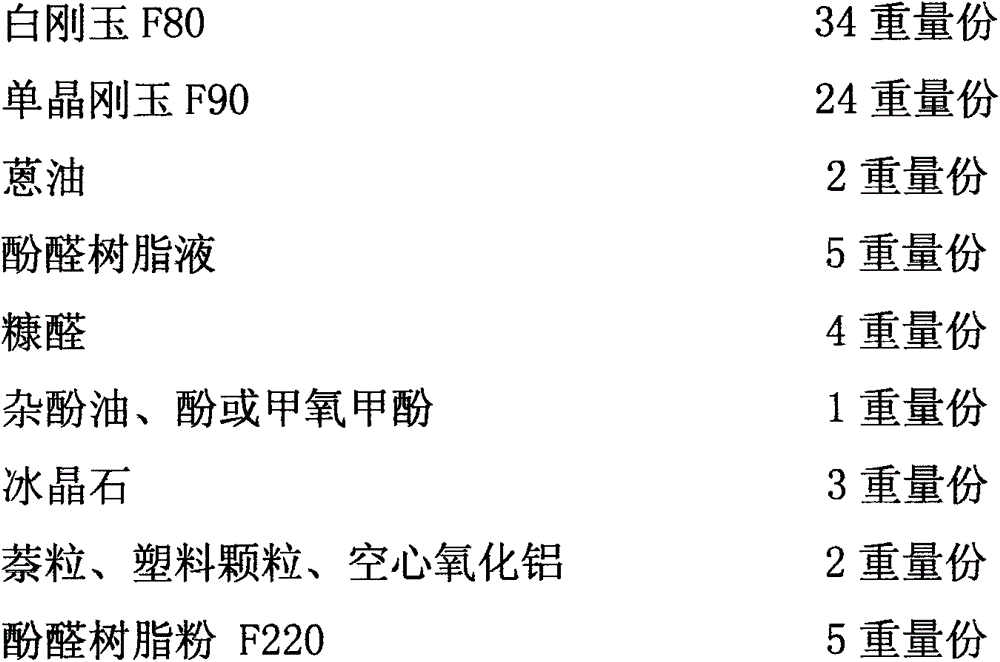

Resin grinding wheel preparation method

ActiveCN104128894AImprove production qualityGood chemical stabilityAbrasion apparatusGrinding devicesWettingPhenols

The invention provides a resin grinding wheel preparation method. A resin grinding wheel is prepared by combining multi-granularity white corundum, monocrystalline fused alumina, anthracene oil and phenolic resin liquid with furfural, kreosote, phenol or kreosol and cryolite, naphthalene grains, plastic particles and hollow alumina filling according to a certain weight ratio. By implementing the method, powder cannot be wrapped by wet materials in the process of mixing of materials, and influence on quality of a resin grinding wheel product due to the fact that the materials are not dispersed and cake is avoided. In addition, a certain weight part of silicon carbide is added in raw materials of mixed grinding materials, and grinding wheel cutting pieces different in performance can be acquired by controlling proportioning content of a silicon carbide grinding material, mixed white corundum and monocrystalline fused alumina and adjusting content of a wetting agent and phenolic resin powder within a certain range.

Owner:NINGBO DAHUA GRINDING WHEEL

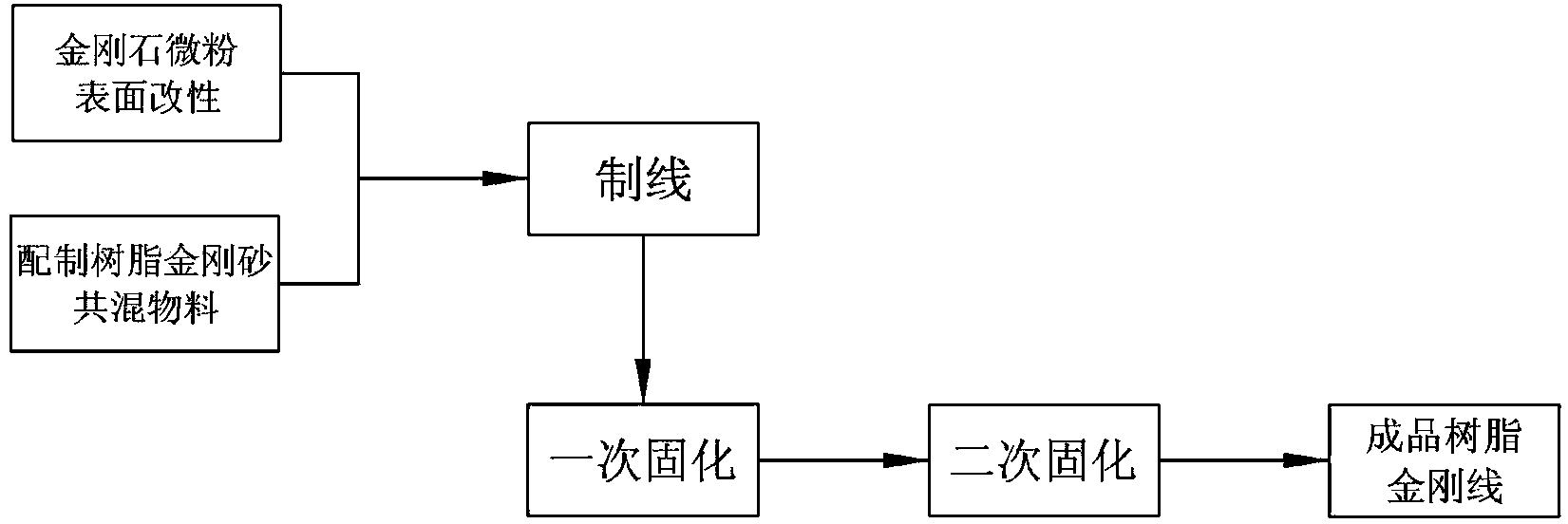

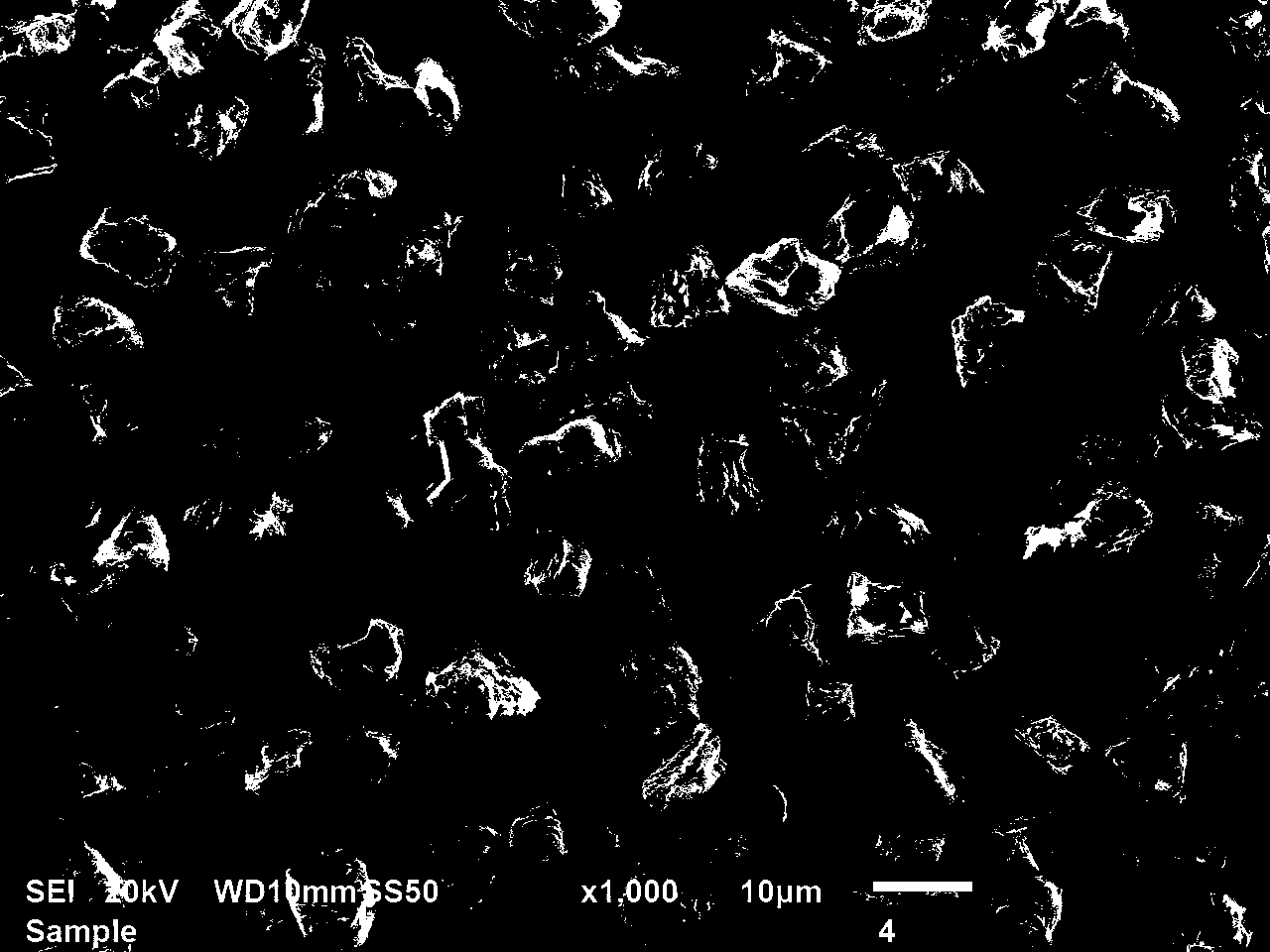

Method for manufacturing resin diamond line by non-plating diamond

InactiveCN103753720AImprove grip or adhesionImprove grinding abilityFine working devicesSurface modificationEnergy consumption

The invention discloses a method for manufacturing a resin diamond line by a non-plating diamond. The technical problems that in the prior art, when the resin diamond line is manufactured by metal plating diamond micro powder, the cost is high, energy consumption is high, and the pollution is large are solved. The method comprises the following steps that first, surface modification treatment is conducted on diamond micro powder; then resin emery blending materials are prepared; the resin emery blending materials are evenly coated on a core line; the finished resin diamond line is obtained through primary solidification and secondary solidification. According to the resin diamond line manufactured by the method, the average line diameter is small, the cutting quality is high, the efficiency is high, and cutting opening loss is small. The method is simple in technology, low in production cost, small in environmental pollution, and beneficial to large scale production.

Owner:开封恒锐新金刚石制品有限公司

Waterproof emery cloth for grinding of car industry and manufacturing method thereof

ActiveCN105415211AGood grinding effectFlat surfaceAbrasion apparatusGrinding devicesAdhesive cementMechanical engineering

The invention discloses a waterproof emery cloth for grinding of the car industry. The waterproof emery cloth comprises a base abrasive cloth, a base material reinforcing layer, abrasive particles and an adhesive, wherein the surface of the base abrasive cloth is divided into a plurality of areas; the abrasive particles attached in the same area have the different size, and the abrasive particles attached in different areas are different in size; the size of the abrasive particles attached to each area of the base material reinforcing layer gradually increases from the center of the base abrasive cloth to the side edge of a base material; the abrasive particles are compound abrasive particles and prepared by compounding nanometer cerium dioxide particles and silicon dioxide particles; the adhesive comprises a component A and a component B. The invention further designs a manufacturing method of the waterproof emery cloth for grinding of the car industry. The method comprises the following processes: coating the adhesive; pre-curing; arranging sand; post-curing; flexing with water; cutting with laser; performing anti-deformation treatment for the base material; storing. The manufacturing method is simple and easy to carry out, and low in manufacturing cost; the manufactured waterproof emery cloth for grinding is resistant to ageing, resistant to fatigue, resistant to high temperature, resistant to abrasion, and long in service life.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

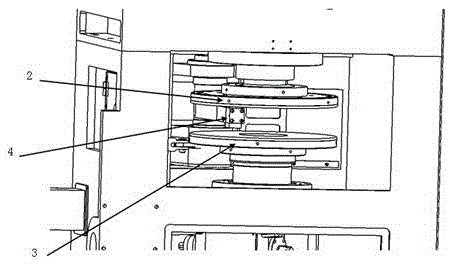

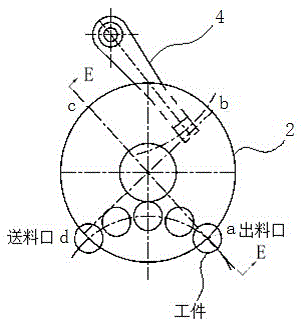

Free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method

The invention provides a free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method. The method is characterized in that double-stage free-falling nozzles are adopted, the first-stage nozzle is a low-pressure mixed powder flow jetting nozzle, the second-stage nozzle is a high-pressure gas flow nozzle, the low-pressure mixed powder flow jetting nozzle is next to the portion above the high-pressure gas flow nozzle, and by adjusting the height of the water level of cooling water in an atomizing and cooling chamber, the cooling speed of powder mixed molten metal drops is controlled, so that the hard abrasive forms the magnetic abrasive distributed on a surface shallow layer of a magnetic abrasive metal matrix. According to the method, the effect of fully mixing the hard abrasive and molten metal before atomization is achieved, waste of the hard abrasive is avoided, the proportion of the hard abrasive in the magnetic abrasive is controlled, erosive wear to a single-stage nozzle is avoided, and control over the depth of distribution of the hard abrasive on the surface shallow layer of the magnetic abrasive metal matrix is achieved; meanwhile, the flight distance of the powder mixed molten metal drops is shortened substantially, and the overall height of the atomizing chamber and equipment is reduced. The method is a new technical method for preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

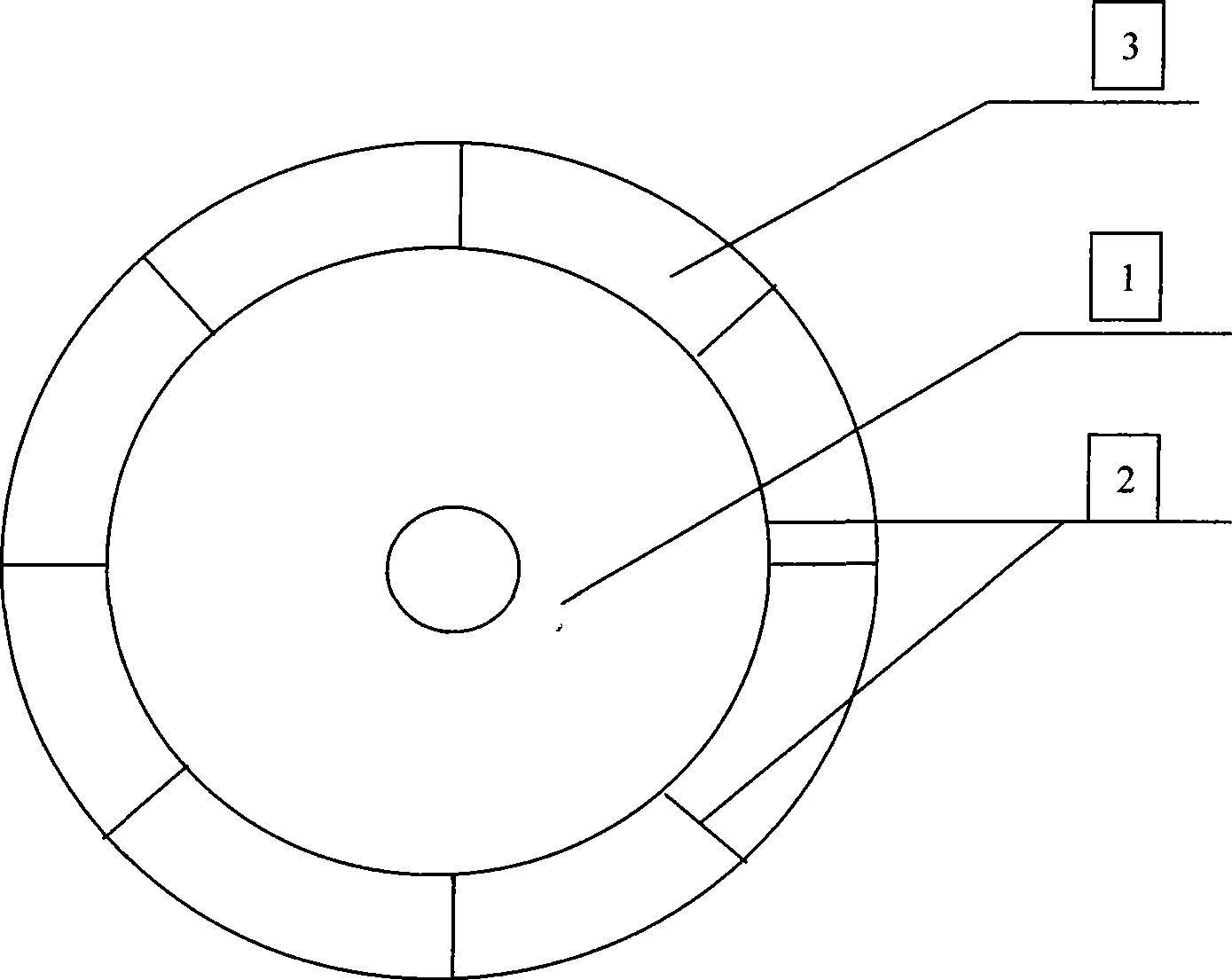

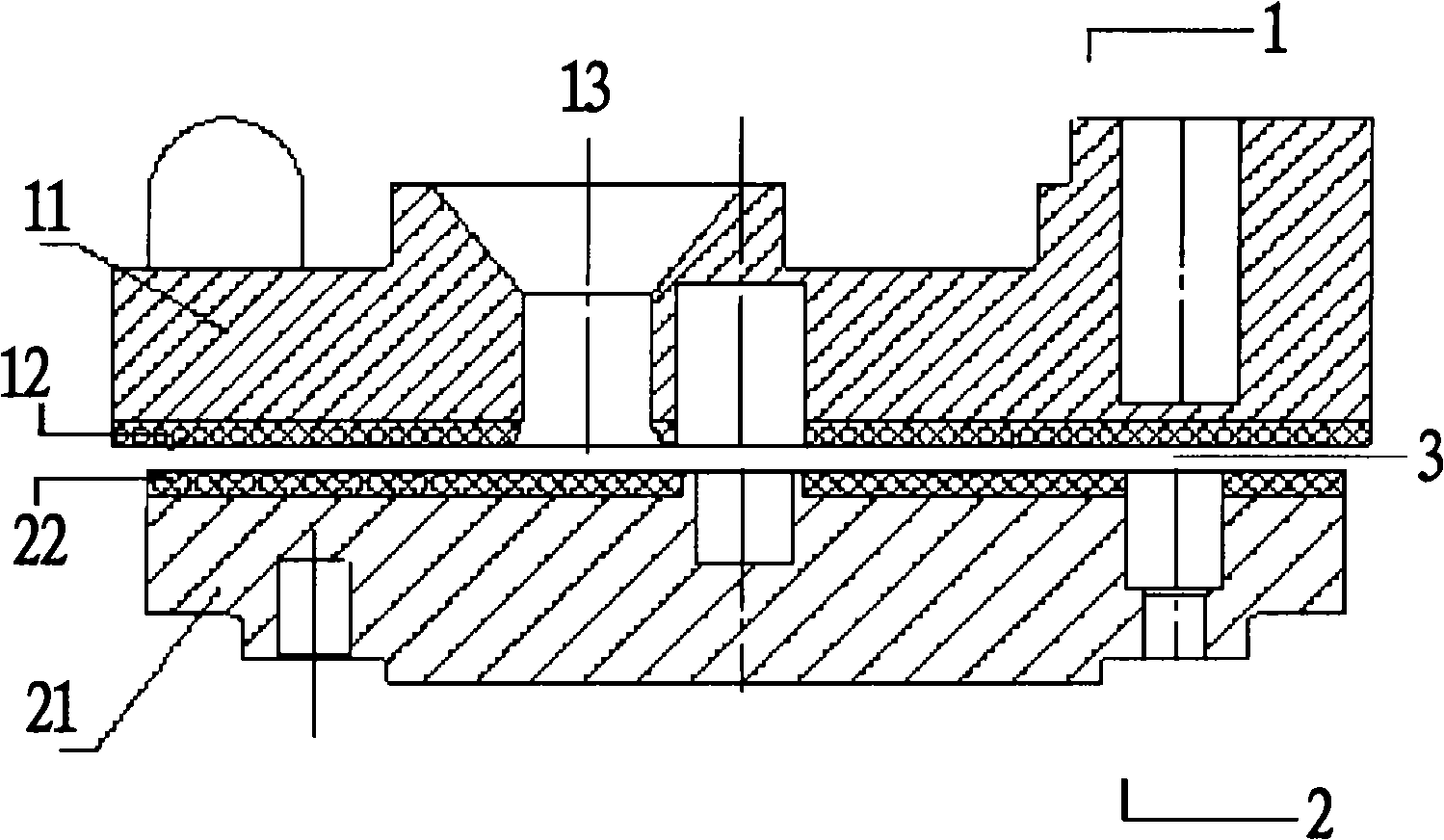

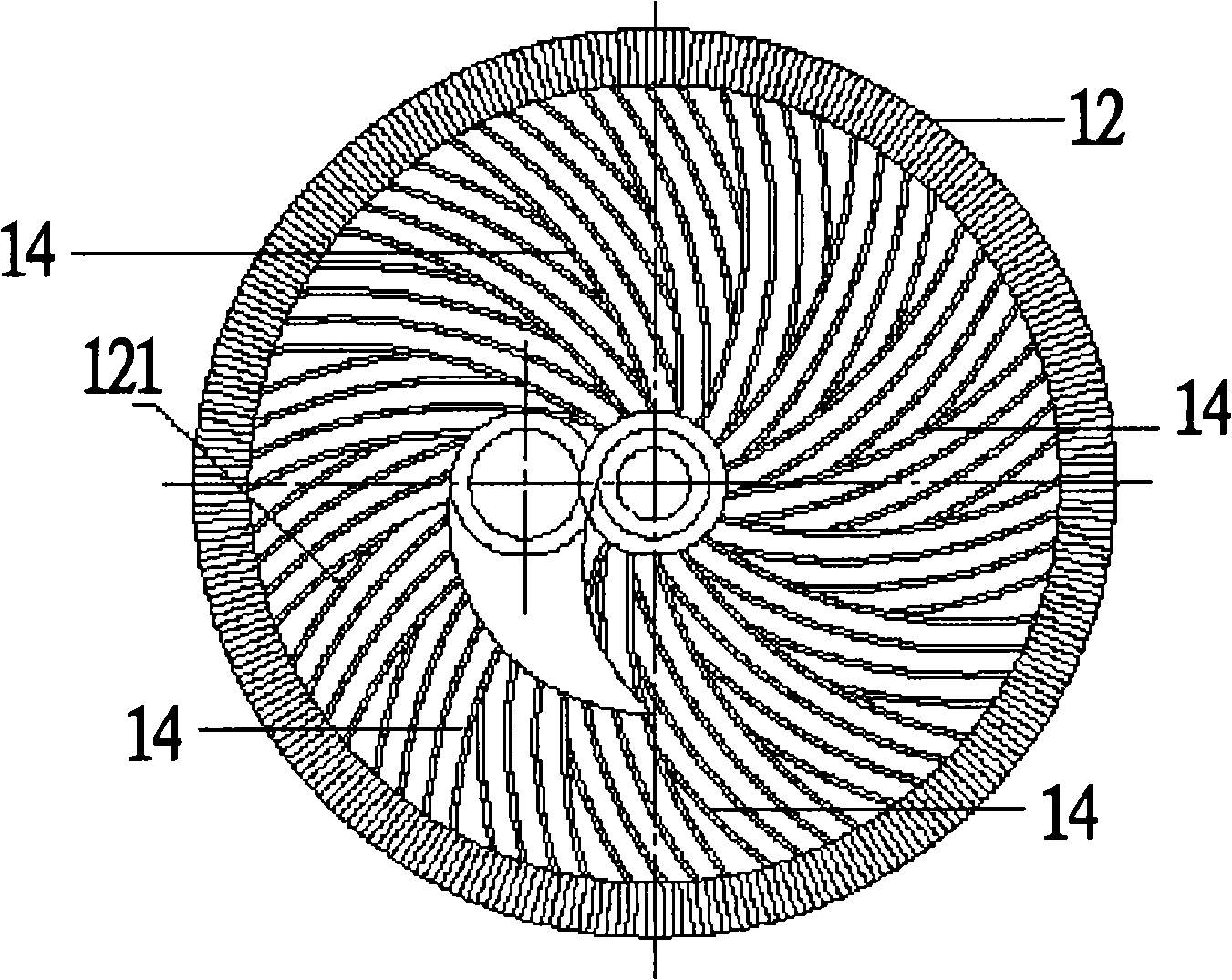

Grinding disc of high-voltage panel type grinding equipment

InactiveCN101342505AAdaptableStrong continuous extrusionCocoaGrain treatmentsEngineeringHigh pressure

The invention relates to a mill disc for a high-pressure disc grinding mill. The mill disc is capable to crush and mill the materials in the grinding mill into fine powder. The mill disc can be mounted horizontally or vertically in the milling device. The mill disc comprises an upper mill disc and a lower mill disc. A basal body is arranged on the upper mill disc, an upper milling layer is arranged under the basal body, and a plurality of milling lines are arranged on the upper milling layer. A milling cavity is formed between the upper milling layer and the lower milling layer. The basal body with high strength and sound flexibility is tightly combined with the high-performance wear-resisting layer. Various special milling line structures are applicable to various solid materials and water contents; the materials are milled into fine particles under continuous strong pressing, shearing and grinding on spots, lines and surface.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Blue ssuperindividual corundum and preparation method thereof

ActiveCN101906663AChemically stableNo pollution in the processPolycrystalline material growthSingle crystal growth detailsAluminium fluorideZirconium dioxide

The invention discloses a blue superindividual corundum and a preparation method thereof. The preparation method comprises the following steps of: carrying out mixing, smelting, temperature reduction solidification, blowing-in grinding, magnetic separation impurity removal, screening and secondary magnetic separation impurity removal on one ton of alumina powder, anatase titanium dioxide, titanium stone powder, aluminium fluoride and zirconium dioxide powder; and then carrying out magnetic separation by using a magnetic separator so as to obtain the blue superindividual corundum. Because iron ores are not used, the smelting process causes no smoke and odour, and the processing process of a product causes no hydrogen sulfide gas, therefore the whole production process causes no pollution to the environment; in addition, because a right amount of the zirconium dioxide is added, the zirconium dioxide and the alumina appear in a crystal combining way, therefore true specific weight and granularity are obviously increased, chemical property is more stable, strength achieves 33 N, density achieves 4.02 g / cm<3>, the content of Al2O3 contained in the blue superindividual corundum achieves more than 99.55 percent, and the content of various impurities is lower.

Owner:XIXIA ZHENGHONG MONOCRYSTALLINE CORUNDUM

Resin-bonded grinding wheel

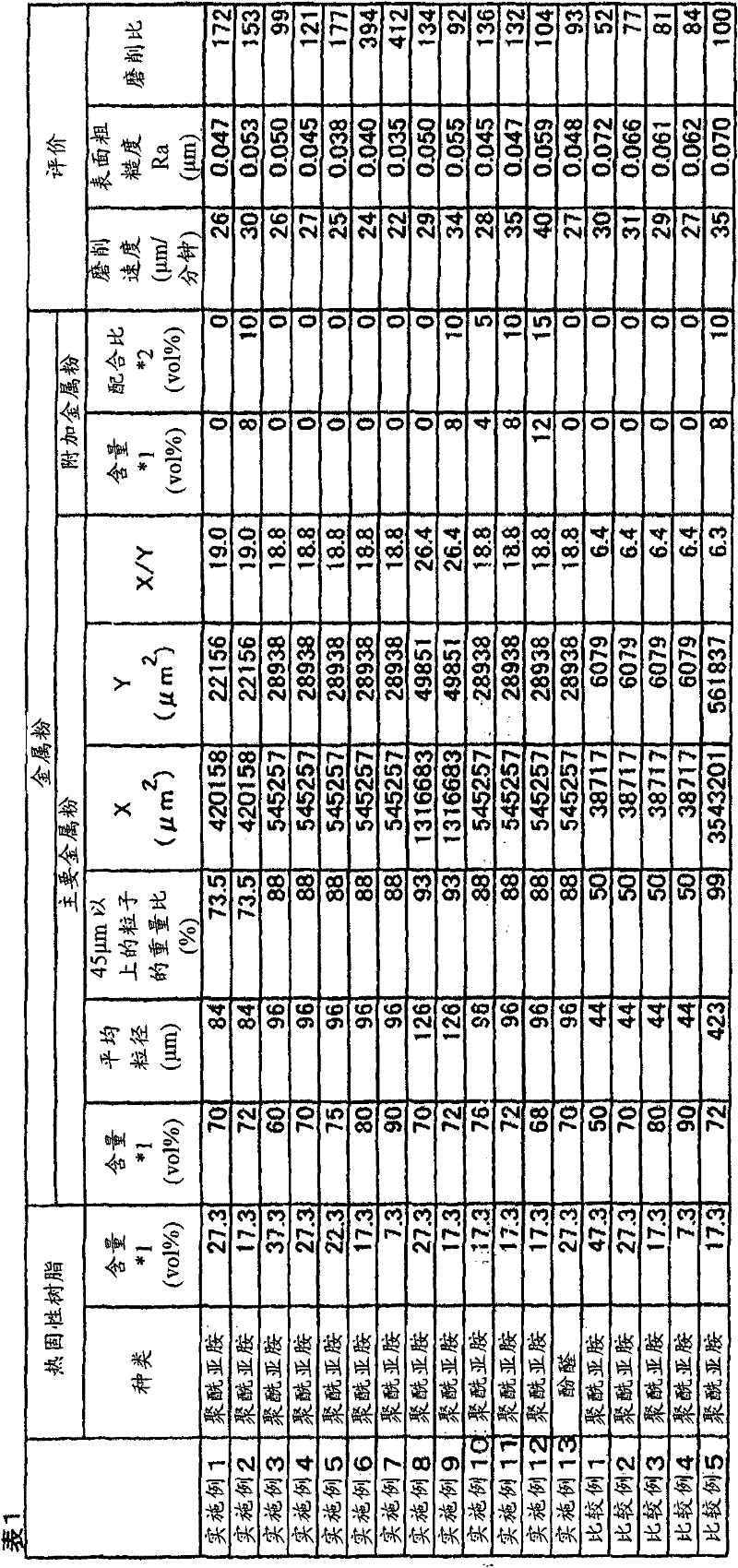

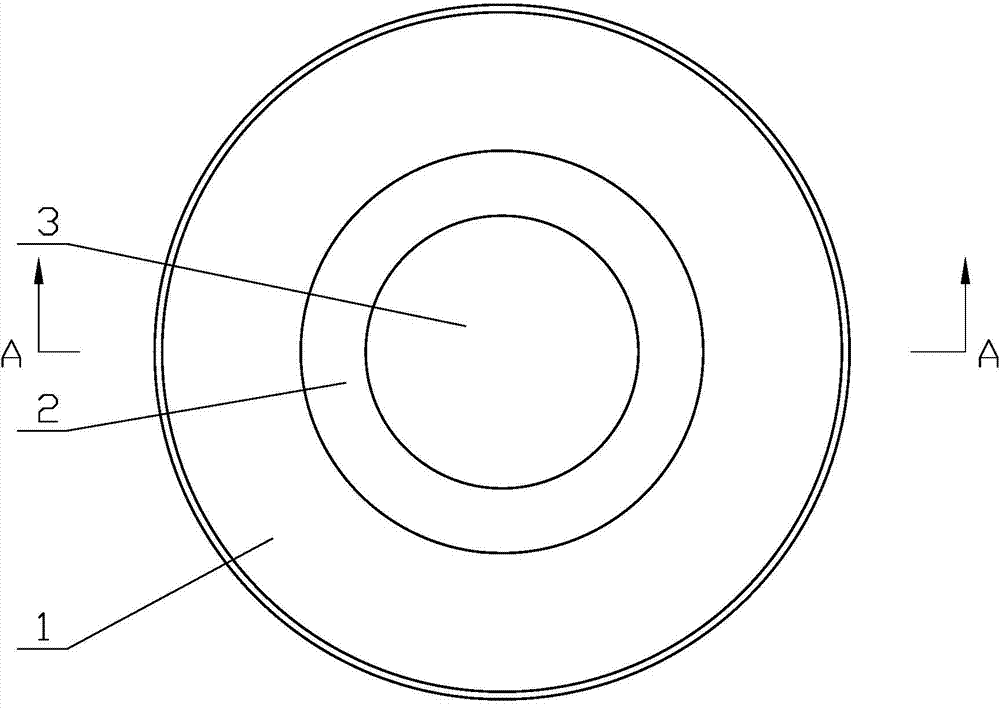

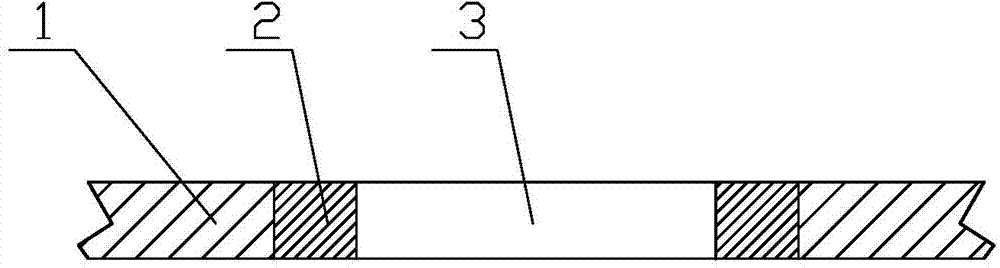

The invention provides a resin-bonded grinding wheel satisfying the requirements of high retention and excellent grinding capability of abrasive particles and highly accurate grinded surfaces, and a grinding method by using the resin-bonded grinding wheel. The resin-bonded grinding wheel has a resin-bonded layer containing thermosetting resin and abrasive particles and metallic powder scattered thereon, wherein the metallic power contains over 50% of non-spherical metallic powder particles of 45 micrometers, and the ration of surface area of each metallic particle X to the surface area of an average spherical particle of the metallic particles Y is high than 10.

Owner:FUJIMI INCORPORATED

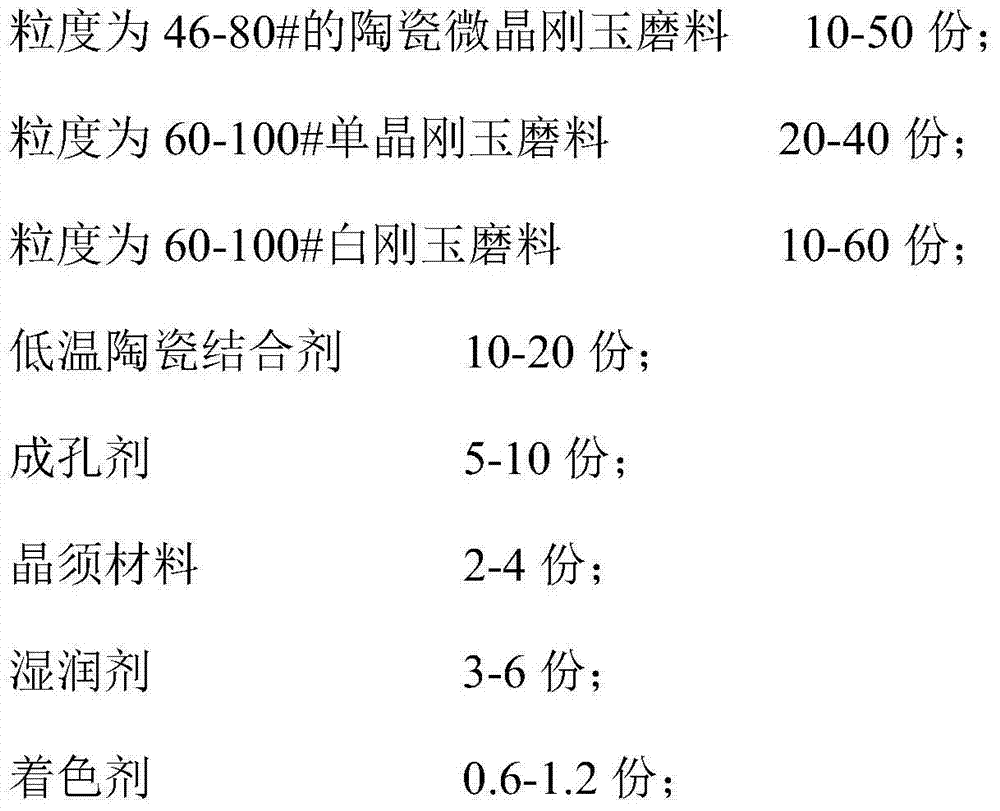

Ceramic microcrystal fused alumina grinding wheel for crankshaft grinding and manufacturing method thereof

InactiveCN104759993AGood self-sharpeningLess frequency of trimmingAbrasion apparatusGrinding devicesMetallurgyColoring agents

The invention relates to a ceramic microcrystal fused alumina grinding wheel for crankshaft grinding and a manufacturing method thereof. The grinding wheel is characterized in that a grinding portion comprises 10-50 parts of ceramic microcrystal fused alumina grinding materials with the granularity being 46-80#, 20-40 parts of monocrystal fused alumina materials with the granularity being 60-100#, 10-60 parts of white fused alumina grinding materials with the granularity being 60-100#, 10-20 parts of low-temperature ceramic bond, 5-10 parts of pore-forming agents, 2-4 parts of crystal whisker materials, 3-6 parts of wetting agents and 0.6-1.2 parts of coloring agents, and a clamping portion comprises 100 parts of white fused alumina grinding materials with the granularity being 60-100#, 10-20 parts of low-temperature ceramic bond, 2-4 parts of crystal whisker materials and 4-6 parts of wetting agents. The ceramic microcrystal fused alumina grinding wheel has the advantages of being strong in grinding capacity, high in machining precision and efficiency, long in service life, good in heat dissipation, low in finishing frequency, good in self-sharpening performance, good in processing surface roughness, long in service life and much cheaper than a superhard material grinding wheel, not burning workpieces and saving the cost.

Owner:QINGDAO SISA ABRASIVES CO LTD

High temperature wear-resistant coating for metal surface, and its preparing mand using method

ActiveCN1850917AHigh refractorinessImprove thermal conductivityLiquid surface applicatorsCoatingsWear resistantPhosphoric acid

The invention discloses a high temperature antifriction dope for metal surface and the using method. It is made up from 85% thickness phosphoric acid 22-28 portions, aluminum hydroxide 3-5 portions, water 5-8 portions, chrome 0.01-0.02 portions, thinned silica solution 6-10 portions, white steel 10-18 portions, zirconia 12-18 portions, alumina 8-12 portions, magnesia 0.03-0.05 portions, and coagulant 4-7 portions and stainless steel wire 0.3-0.6 portions.

Owner:枣庄市新达节能技术开发有限责任公司

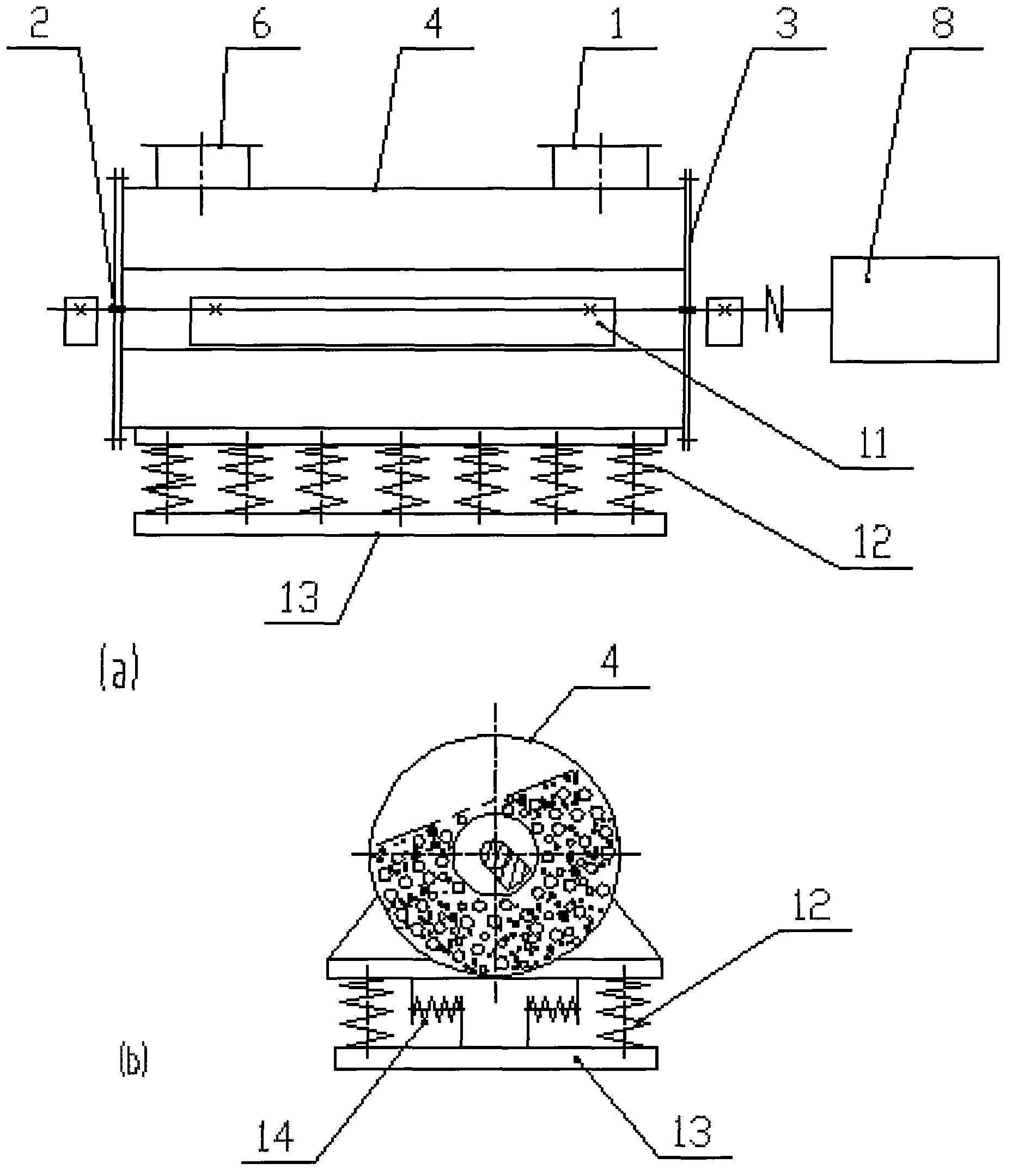

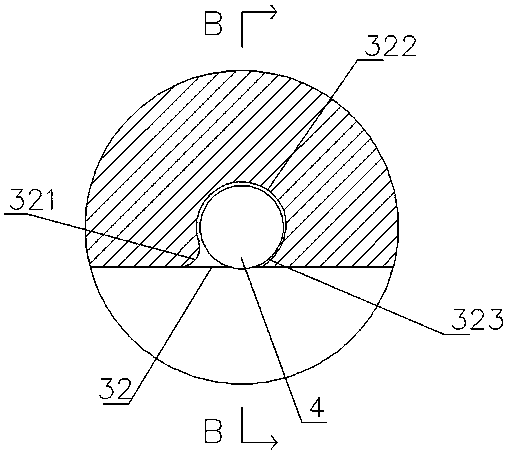

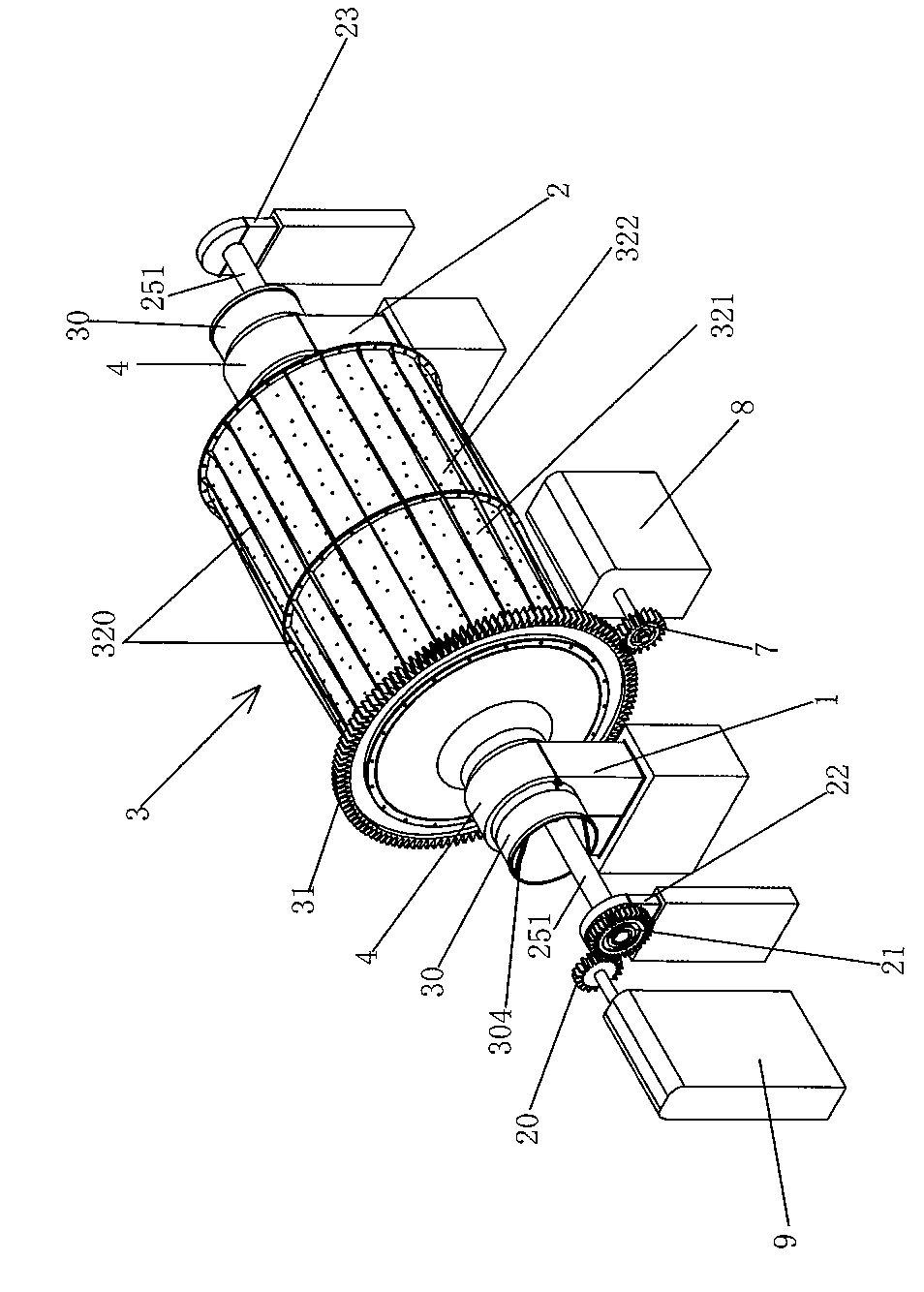

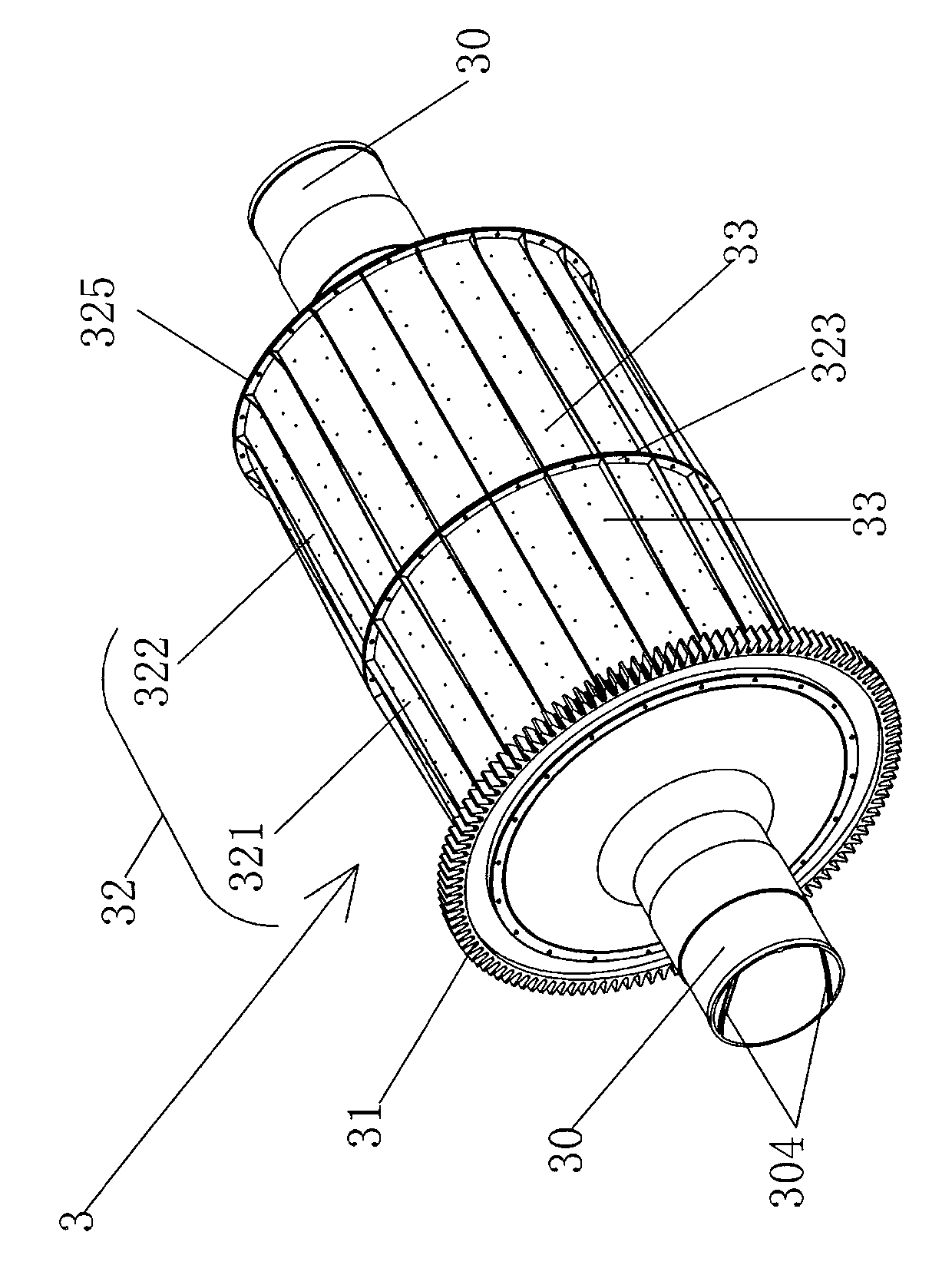

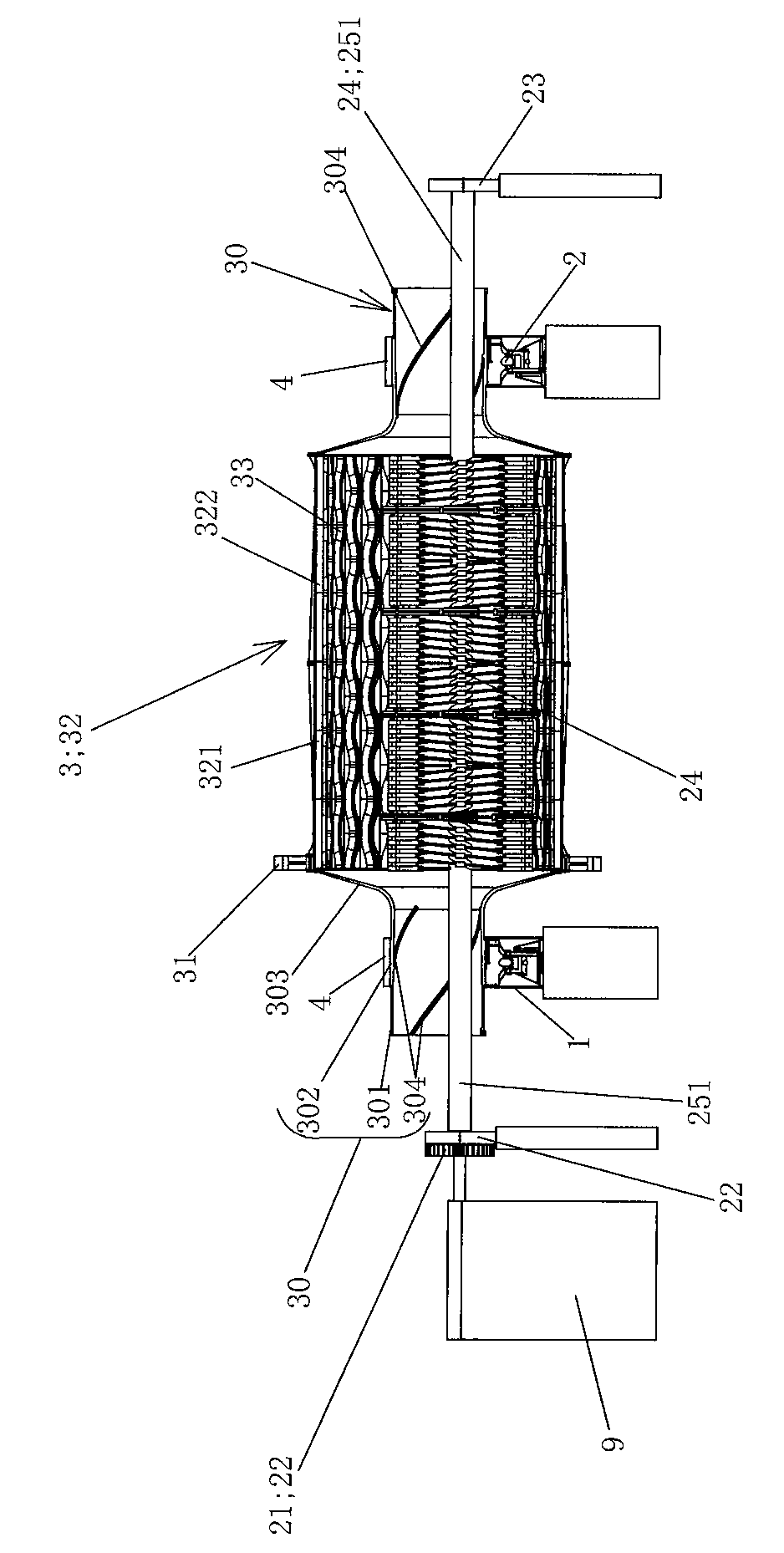

Inertial ball mill

The invention provides an inertial ball mill which is mainly applicable to operations of crushing and grinding massive or granular minerals. The inertial ball mill provided by the invention mainly comprises a moving system, wherein the moving system consists of a cylinder body, a lattice sieve plate, a classifying device, a plurality of vibrating bodies, middling rings and flexible shafts; the vibrating bodies, the middling rings and the flexible shafts are arranged in the cylinder body; the system is driven by a transmission device to perform high-speed rotational swinging movement to crush and grind materials. Through the inertial ball mill, the mill efficiency is greatly improved, and the energy consumption is reduced; the inertial ball mill is small in equipment size, light in weight, simple in structure and easy to maintain.

Owner:张学骞

Production method for blue SA (single alundum)

ActiveCN101748486AGood particle shapeImprove grinding abilityPolycrystalline material growthSingle crystal growth detailsSingle crystalProduct processing

The invention discloses a production method for blue SA (single alundum). The production method includes the following steps of: a. material mixing; b. smelting; c. temperature reduction and solidification; d. blowing-in and crushing, e. magnetic separation and impurities removing; f. screening; g. secondary magnetic separation and impurities removing. As the blue SA which is produced by the production method does not use iron ores, no smoke and smell are caused in the smelting process, no hydrogen sulphide gas is generated during the product processing, no pollution is caused to the atmosphere, no sewage is discharged, and no pollution is caused to the environment in the whole production process. The number of monocrystals produced during the later period is up to 95%, which is 50% higher than the original number of the monocrystals (the monocrystals of the original SA accounts for 65% or so); the intensity exceeds 26N; and the toughness is up to 90.5%, which is 25% higher than that of the original SA.

Owner:西峡县正弘单晶刚玉有限公司

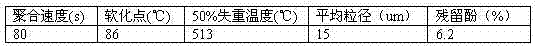

Novolak phenolic resin microspheres and preparation method thereof

The invention relates to novolak phenolic resin microspheres and a preparation method thereof, and belongs to the field of chemical synthesis. The microspheres consist of the following components in part by weight: 80 to 100 parts of absolute ethanol, 95 to 105 parts of phenol, 100 to 115 parts of formaldehyde, 6 to 12 parts of triethylenetetramine, 2 to 6 parts of boric acid and 1 to 1.75 parts of polyvinylpyrrolidone. The method comprises the following steps of: sequentially feeding the reactants with heating, reacting for a certain period of time, cooling, discharging, precipitating, performing centrifugal separation, and drying. The novolak phenolic resin microspheres prepared by the method have high dispersibility, have the particle size of 5 to 50mu m, are easily mixed with other aids uniformly, have the thermal decomposition temperature of more than 450 DEG C after being cured, and have high toughness, moisture absorption property and strength; and the preparation process is short, easy to operate and low in cost, and products can be used for an organic friction material, a molding compound, a grinding wheel bonding material, a thermal insulation material, a fireproof material and the like, so the microspheres can replace the traditional phenolic resin.

Owner:重庆阁林环保科技有限公司

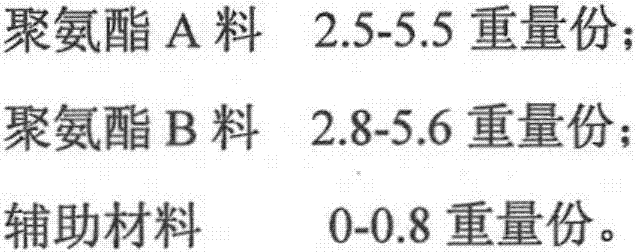

Polyurethane grinding wheel

InactiveCN106938446ALower sintering temperatureHigh energyAbrasion apparatusGrinding devicesMixed materialsGrinding wheel

The invention discloses a polyurethane grinding wheel and a production process thereof. According to the polyurethane grinding wheel, abrasive materials in raw materials are carborundum, and polyurethane is adopted as a binding agent; and the polyurethane comprises a polyurethane material A and a polyurethane material B. The production process includes the steps that material mixing is firstly carried out, wherein the carborundum and the polyurethane material A are put into a material mixing machine to be mixed, and the polyurethane material B and auxiliary materials are sequentially added to be evenly mixed; then a mixed material is screened to be placed into a die to be subject to pressing molding; and finally, a green body is sintered for 8 h to 24 h at the temperature ranging from 125 DEG C to 165 DEG C, and is cooled to be discharged out of a furnace. According to the production process, the polyurethane serves as the binding agent to produce the grinding wheel, the auxiliary materials in an existing grinding wheel recipe can be applied to the method according to the production requirement, and the manufactured grinding wheel has the beneficial effects that the sintering temperature is low, saved energy resources are many, pollution is avoided, the molding density is large, the grinding wheel balance is good, the rotating speed is high, the grinding performance is high, and the production period is short, and the quality of products in the machine tool industry, the bearing industry, the bent axle industry, the engine industry and the steel rolling industry is improved.

Owner:龙口东润砂轮有限公司

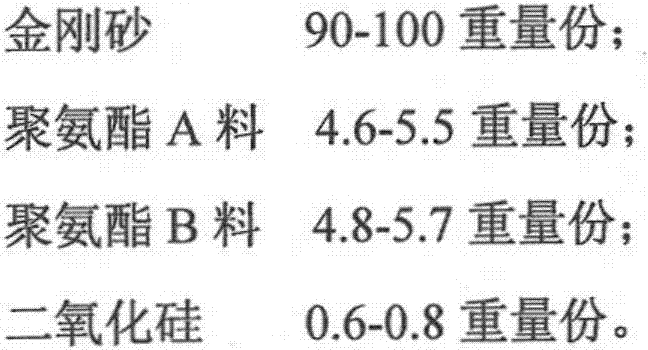

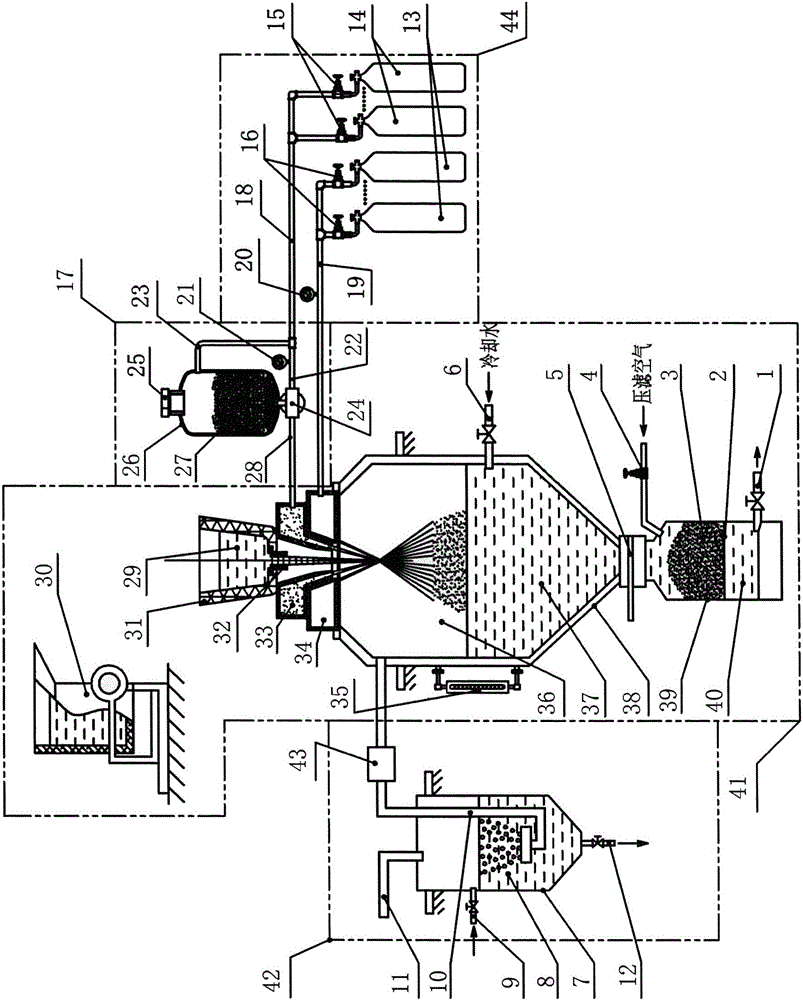

Semi-finished grinding process of cement wind selection pre-grinding and device thereof

InactiveCN101671134AReduce reactive power wasteReduce overgrindingPulp and paper industryCement grinding

The invention belongs to the technical field of cement grinding, in particular to a semi-finished grinding process of cement wind selection pre-grinding and a device thereof. The device comprises a wind selection pre-grinding machine, a dynamic powder selecting machine, a dust remover and a ball milling machine, wherein an upper outlet of the wind selection pre-grinding machine is connected with the dynamic powder selecting machine, and a lower outlet is connected with the ball milling machine; an upper outlet of the dynamic powder selecting machine is connected with a finished product collector through the dust remover, and a lower outlet is connected with the ball milling machine; a lower outlet of the ball milling machine is connected with the finished product collector, and an upper outlet is connected with the finished product collector through the dust remover. The invention can realize powder selection before grinding and collect qualified materials in advance without feed grinding for secondary grinding so as to improve the efficiency of the grinding machine and improve the utilization rate of clinker.

Owner:南京旋立重型机械有限公司

Preparing method for free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix aluminum oxide magnetic abrasive

ActiveCN105665722APrevent splashAvoid wastingTransportation and packagingMetal-working apparatusAlloyHigh pressure

The invention provides a preparing method for free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix aluminum oxide magnetic abrasive. The method is characterized in that aluminum oxide powder is adopted as hard abrasive of the magnetic abrasive, and an alloy composed of iron, silicon, aluminum and copper is adopted as a metal matrix material; upper and lower dual-layer free-falling nozzles are adopted as nozzles, the upper layer free-falling nozzle is a low-pressure mixed powder flow jetting nozzle, and the lower layer free-falling nozzle is a high-pressure gas flow nozzle; water cooling is adopted as a cooling manner, and by adjusting the height of the water level of cooling water in an atomizing and water cooling chamber, the cooling speed of molten metal drops containing aluminum oxide abrasive is controlled, so that the magnetic abrasive with the aluminum oxide abrasive distributed on the shallow layer of the surface of a magnetic abrasive metal matrix is formed; and a spiral mixed powder conveying device is adopted for conveying mixed powder, so that flow of the aluminum oxide abrasive is controlled precisely. According to the metal matrix aluminum oxide magnetic abrasive prepared from the method, aluminum oxide and the metal matrix are combined firmly, the magnetic abrasive has high magnetic abrasive performance, the production technology process is controlled in a programmed manner, the product performance is stable, and the method is suitable for scale production.

Owner:SHANDONG UNIV OF TECH

Environmentally-friendly energy-saving and high-performance composite grinding sheet

ActiveCN105500182AHigh bond strengthGood weather resistanceLapping toolsActive agentSurface-active agents

The invention provides an environmentally-friendly energy-saving and high-performance composite grinding sheet. The composite grinding sheet comprises a base, an adhesive and a grinding material, wherein the grinding material is attached to the base through the adhesive; the adhesive is formed by mixing 57 to 65 percentage by weight of a composition A and 35 to 43 percentage by weight of a composition B; the composition A comprises phenolic resin, trimethylolpropane tris-acrylate, a packing, a surface active agent, a diluent, a coupling agent, a fire retardant, an ethylene-vinyl acetate copolymer, linear low-density polyethylene and high-density polyethylene; the composition B comprises phenolic resin, polyphenylene oxide resin powder, sodium carbonate, epoxy resin, methyl methacrylate, butyl acrylate, a packing, a coupling agent, a diluent, an antistatic agent and a catalyst. The grinding sheet is sharp, quick, long in service life, resistant to high grinding temperature, and outstanding in moisture resistance; a preparation method of the grinding sheet can effectively prevent deformation; the product is high in tensile strength, high in adhering performance, and outstanding in grinding performance.

Owner:南通市锋芒复合材料科技有限公司

Ceramic grinding device for manufacturing Lei Cha (specialty food)

ActiveCN108212428AUniform amount of materialGuaranteed efficiencyGrain treatmentsSpecialty foodsMetallurgy

The invention relates to a ceramic grinding device for manufacturing Lei Cha (specialty food). The ceramic grinding device comprises a grinding bar which comprises a handheld part and a grinding partwhich are connected, a grinding face is arranged at the front end of the grinding part and comprises a grinding side face and a grinding bottom face which are connected, a plurality of grinding grooves are formed in the grinding face, grinding balls are arranged in the grinding grooves, the grinding balls cannot penetrate out of groove openings of the grinding grooves, and each grinding groove comprises a grinding section arranged at the top of the grinding groove, a feeding section and a discharging section, wherein the feeding section and the discharging section are arranged on the two sidesof the corresponding groove opening. The grinding device has the beneficial effects of being simple in structure and convenient to use; in addition, the grinding grooves are additionally arranged, the requirements are improved, and therefore the grinding efficiency, the grinding fineness and the grinding uniformity can be obviously improved; and the grinding bar made of a ceramic material is small in abrasion, and the grinding capacity is higher.

Owner:BAOJING COUNTY JINFENG CERAMIC

Novel energy-saving mixer-mill

InactiveCN103230824AReduce energy consumptionImprove carrying capacityBearing componentsGrain treatmentsLubricationTransmission system

The invention discloses a novel energy-saving mixer-mill. The novel energy-saving mixer-mill consists of a first hydrostatic bearing, a second hydrostatic bearing, a rotator, hydrostatic bearing sealing covers, a first local dust collector, a second local dust collector, a first gear, a first transmission system, a second transmission system, a third gear, a fourth gear, a first rolling bearing, a support of the first rolling bearing, a second rolling bearing, a support of the second rolling bearing, and a crushing and grinding component, wherein the shaft journals of hollow shafts at the two ends of the rotator are respectively placed on the first hydrostatic bearing and the second hydrostatic bearing and are covered by the two hydrostatic bearing sealing covers respectively; the first gear is connected with an output shaft of the transmission system; the second gear is arranged at the left end of a cylinder in a penetrating way; the first gear is engaged with the second gear; the crushing and grinding component is arranged in the rotator in the penetrating way; cage stirring shafts at the two ends of the crushing and grinding component respectively penetrate from the hollow shafts at the two ends of the rotator; and the crushing and grinding component is driven to rotate by the second transmission system. When the novel energy-saving mixer-mill works, the rotator floats, and the complete liquid lubrication is realized; the grinding effects between a grinding medium and a mineral aggregate and amoing the mineral aggregates are enhanced because of a corrugated liner plate in the rotator; and the mineral aggregate can be ground quickly by the crushing and grinding component.

Owner:KUNMING UNIV

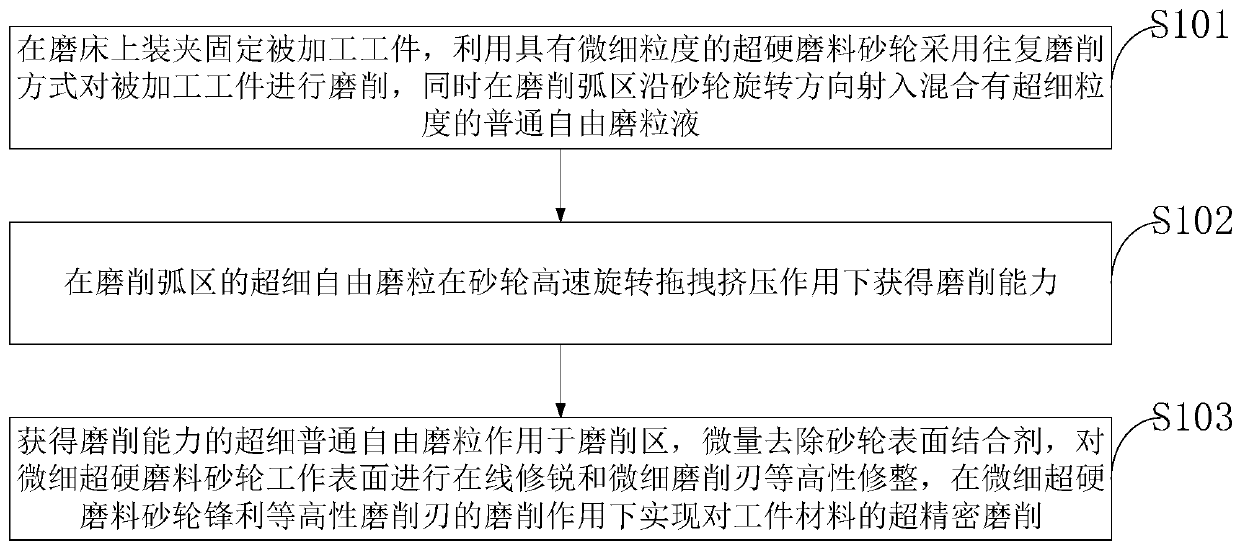

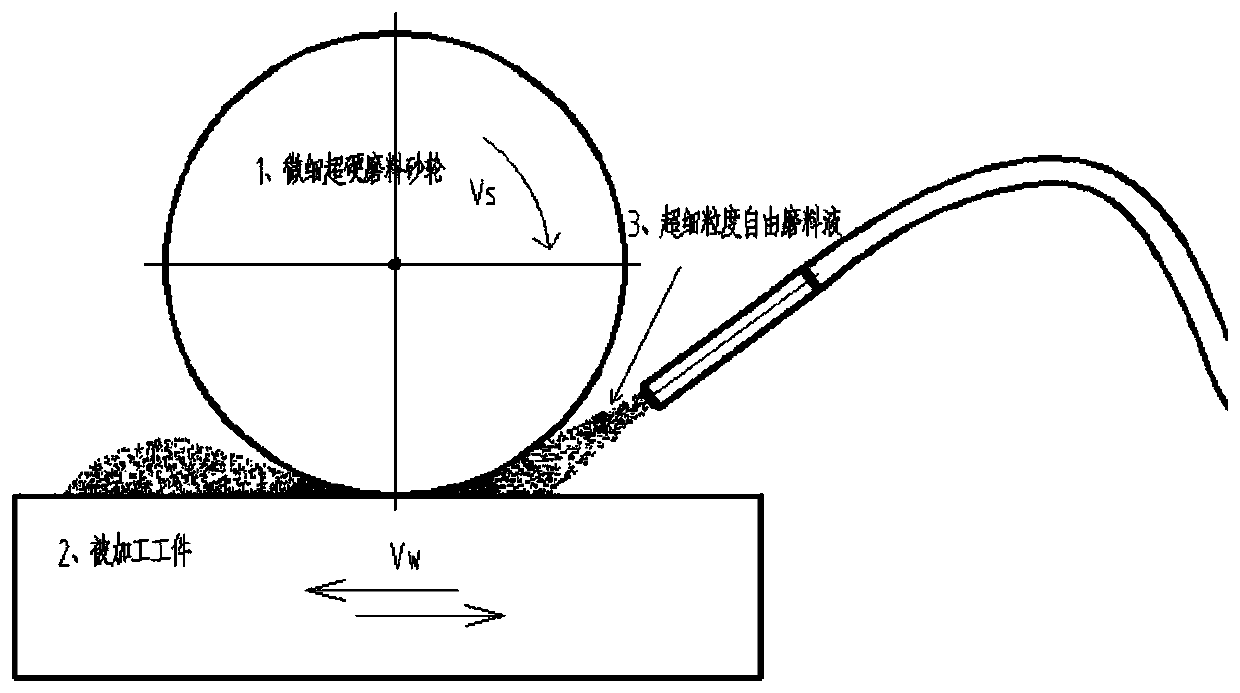

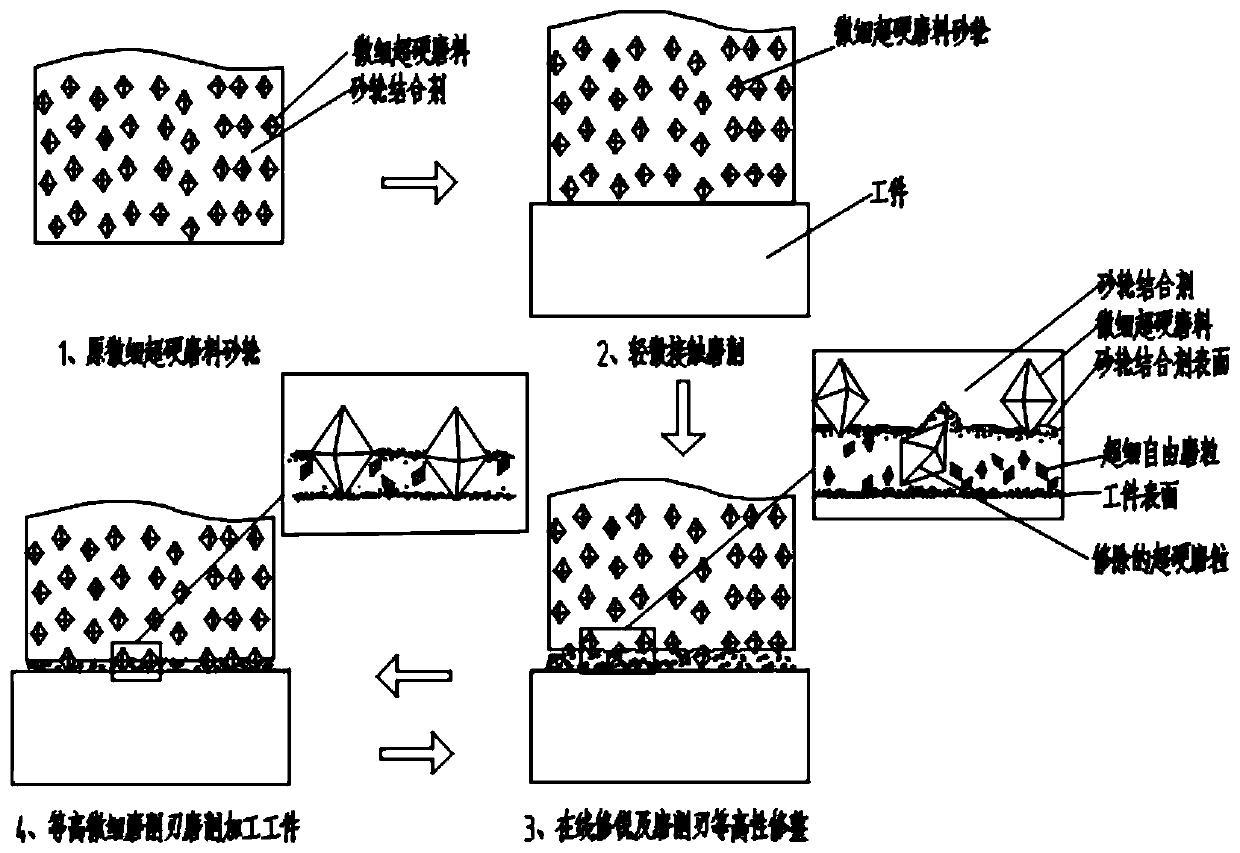

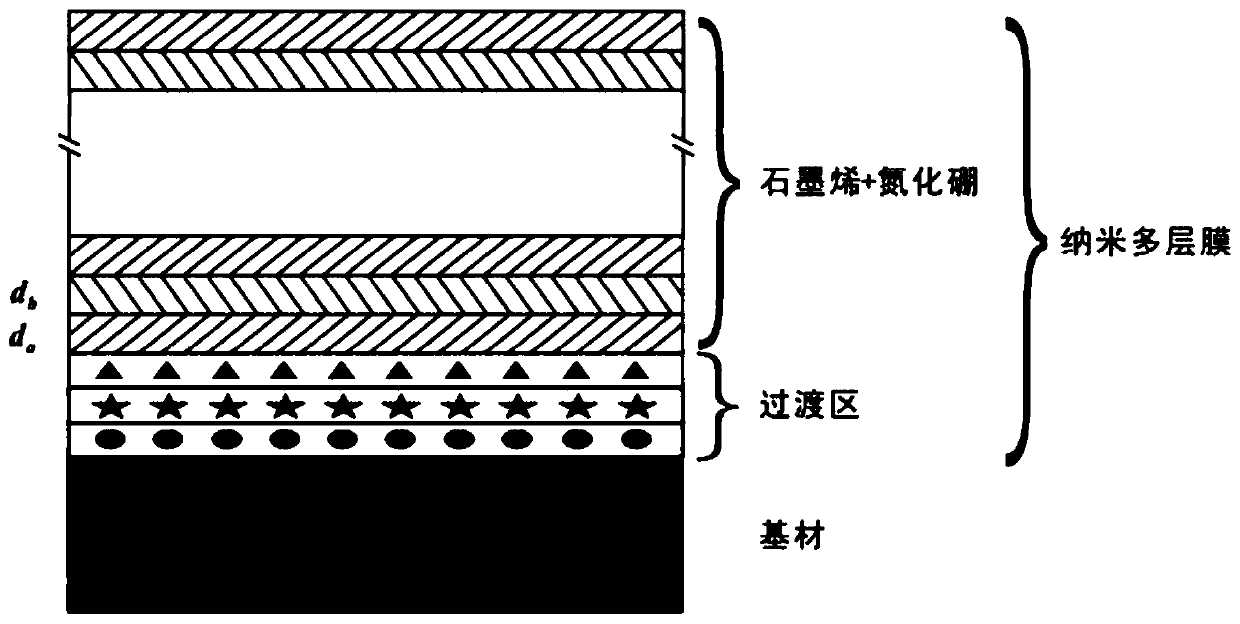

Abrasive particle jet assisted ultrahard fine abrasive material grinding wheel ultraprecise grinding method

InactiveCN110774160AAchieve sharpening and contouringSolve technical problemsEdge grinding machinesPolishing machinesTechnology developmentSurface grinding

The invention belongs to the technical field of grinding, and discloses an abrasive particle jet assisted ultrahard fine abrasive material grinding wheel ultraprecise grinding method. The precise grinding process of an ultrahard fine abrasive material grinding wheel is assisted by abrasive particle liquid jet flow with ultrafine particle size; the online sharpening and the fine grinding edge equal-height finishing are performed on the working surface of the ultrahard fine abrasive material grinding wheel in the grinding process by using the strength difference of ultrahard abrasive materials,general abrasive materials and bonding agents; and the ultraprecise grinding is realized under the grinding effect of a sharp equal-height grinding edge of the ultrahard fine abrasive material grinding wheel. The method realizes the sharpening and the equal-height finishing of the grinding edge of the ultrahard fine abrasive material grinding wheel, effectively solves the technical difficulties ofthe online sharpening and the grinding edge equal-height finishing of the surface grinding edge of the ultrahard fine abrasive material grinding wheel, and achieves an active effect on improvement ofthe grinding surface quality. The method achieves obvious advancement, and achieves prominent academic and actual application value on promotion of the grinding technology development.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

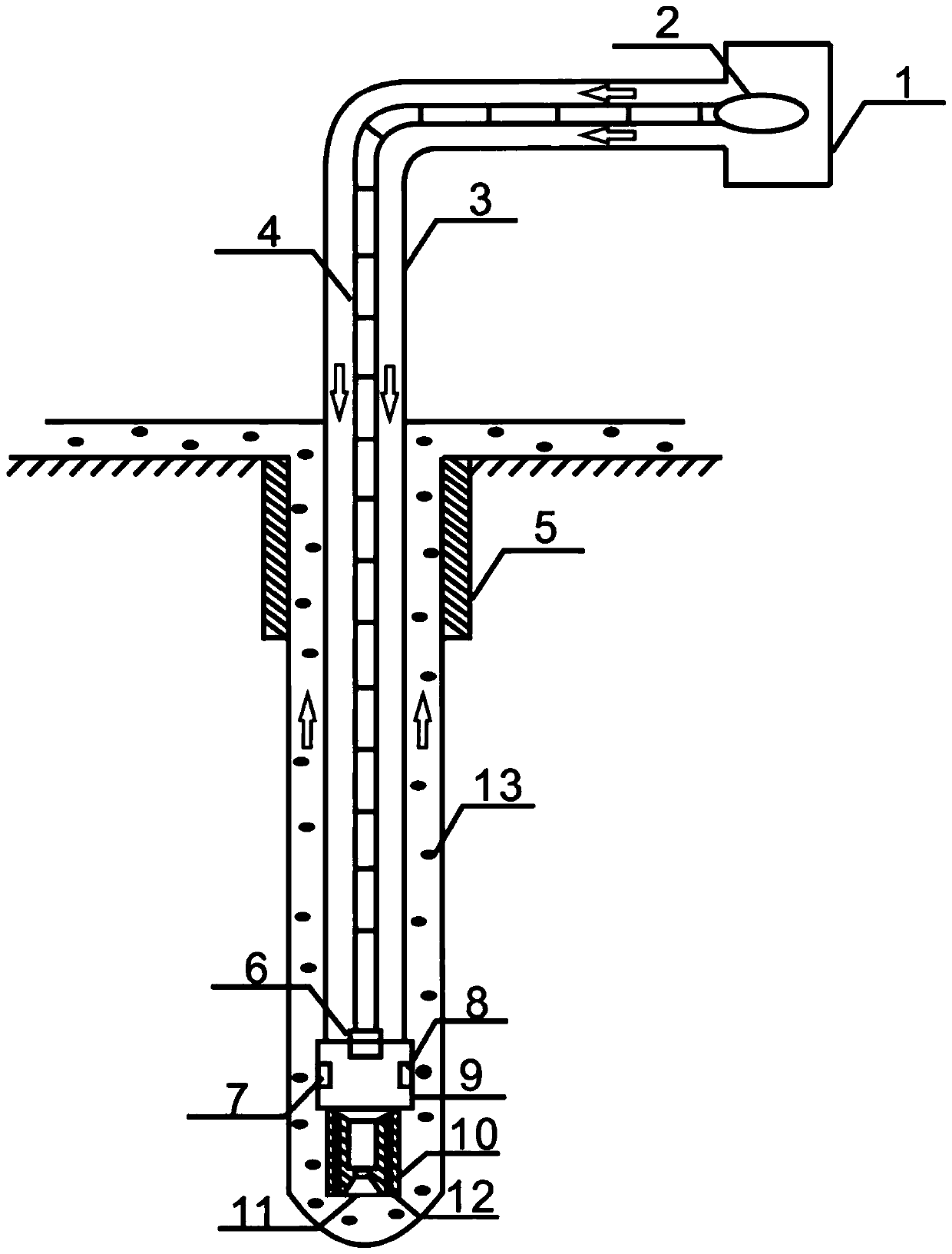

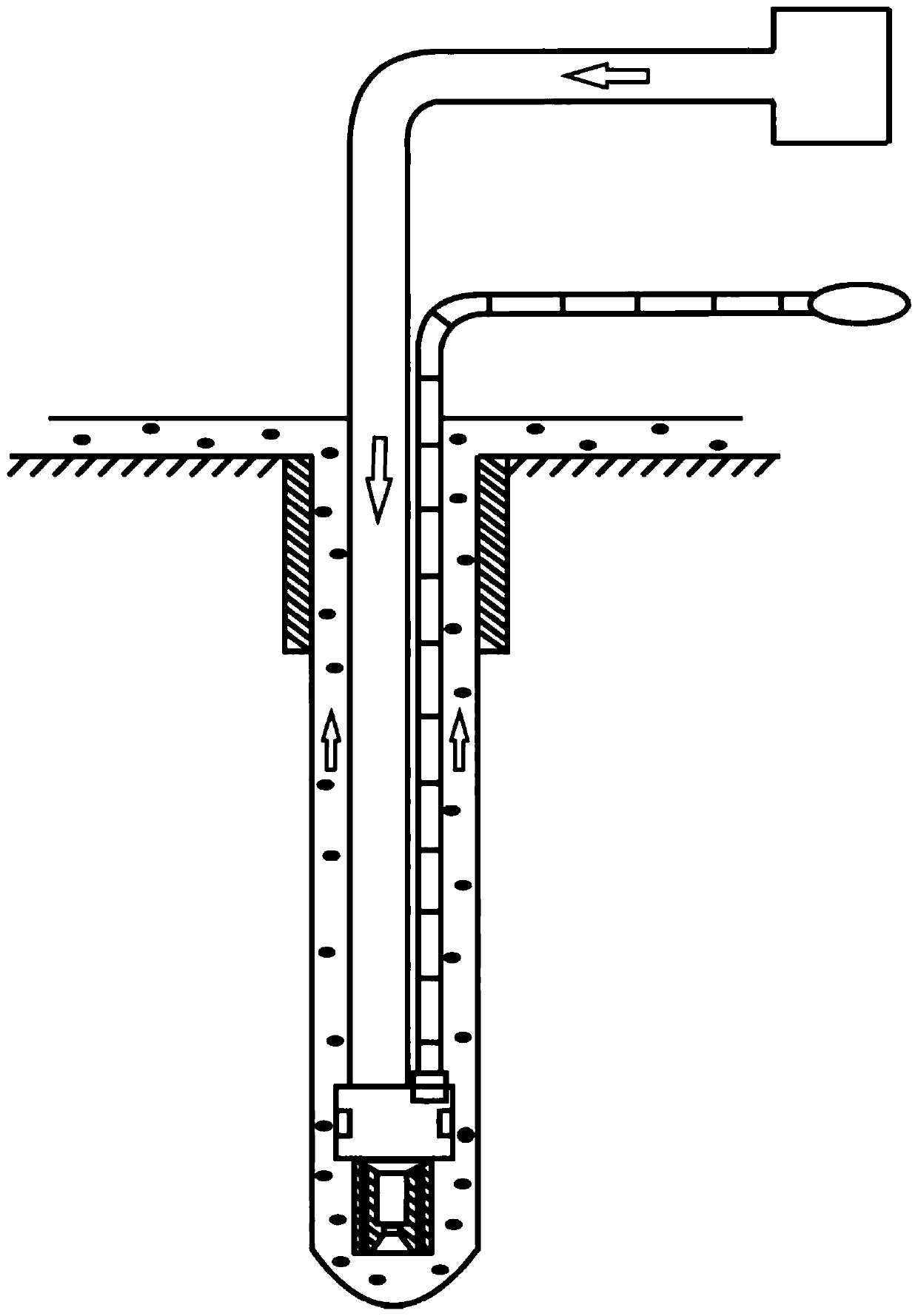

High-temperature abrasive jet drilling system and drilling method

ActiveCN111305755AHigh degree of non-uniform heatingIncrease heatBlast gunsThermal drillingThermodynamicsMicrowave

The invention relates to a high-temperature abrasive jet drilling system and a drilling method, and belongs to the field of petroleum exploration and development. The system consists of a ground pumpset, a microwave generating device, a coiled tubing, a waveguide tube, a microwave antenna, a heating cavity, a temperature sensor, a pressure sensor, a high-temperature abrasive jet device and the like. According to the drilling method, the actions of abrasive jet and rock thermal cracking are taken into comprehensive consideration, and high-temperature abrasive jet acts on shaft bottom rocks inconjunction with the principle of microwave heating, thereby realizing efficient rock breaking. Through the adoption of the method, the problems of the low rate of penetration, short service life of adrill bit, the poor rock breaking effect and the like for deep hard formation and high abrasiveness formation in the existing conventional drilling technology are solved, and strong support is provided for the efficient development of the deep oil and gas resources in China.

Owner:CHINA PETROLEUM & CHEM CORP +1

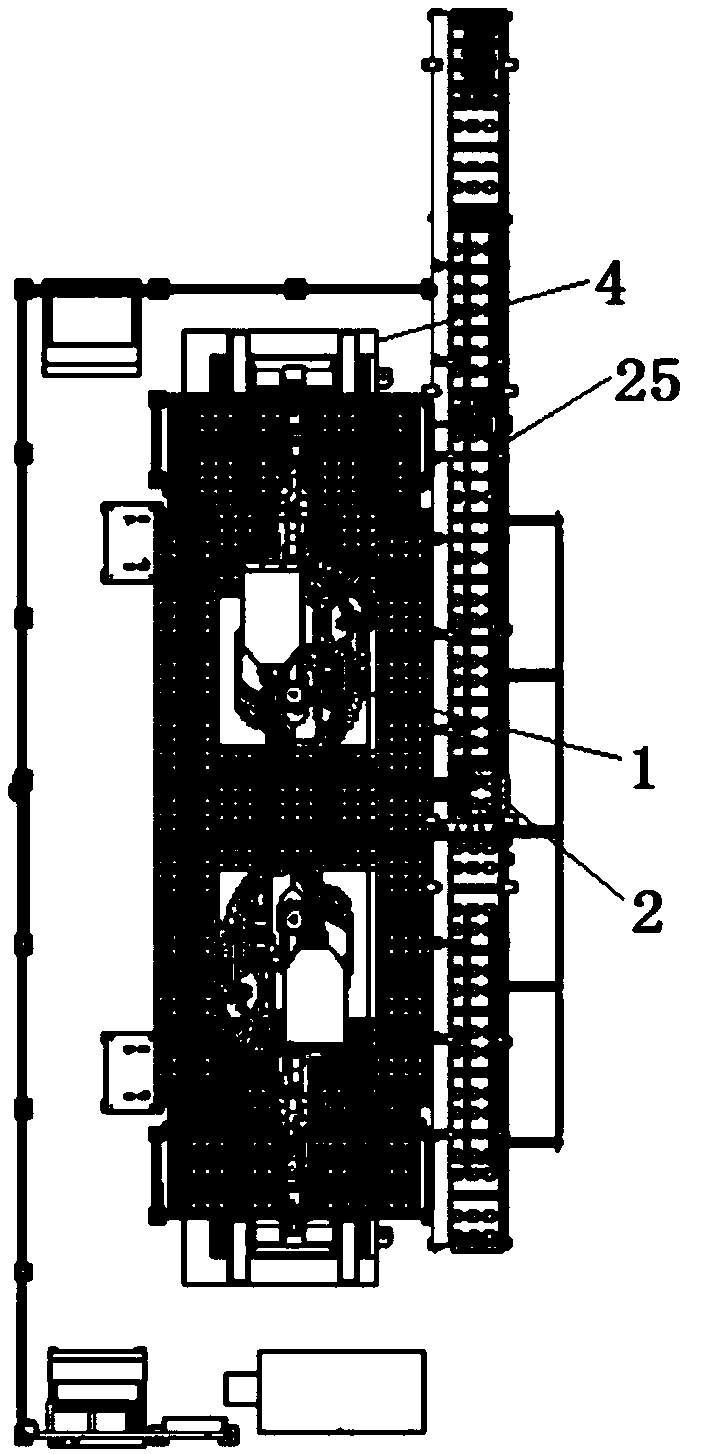

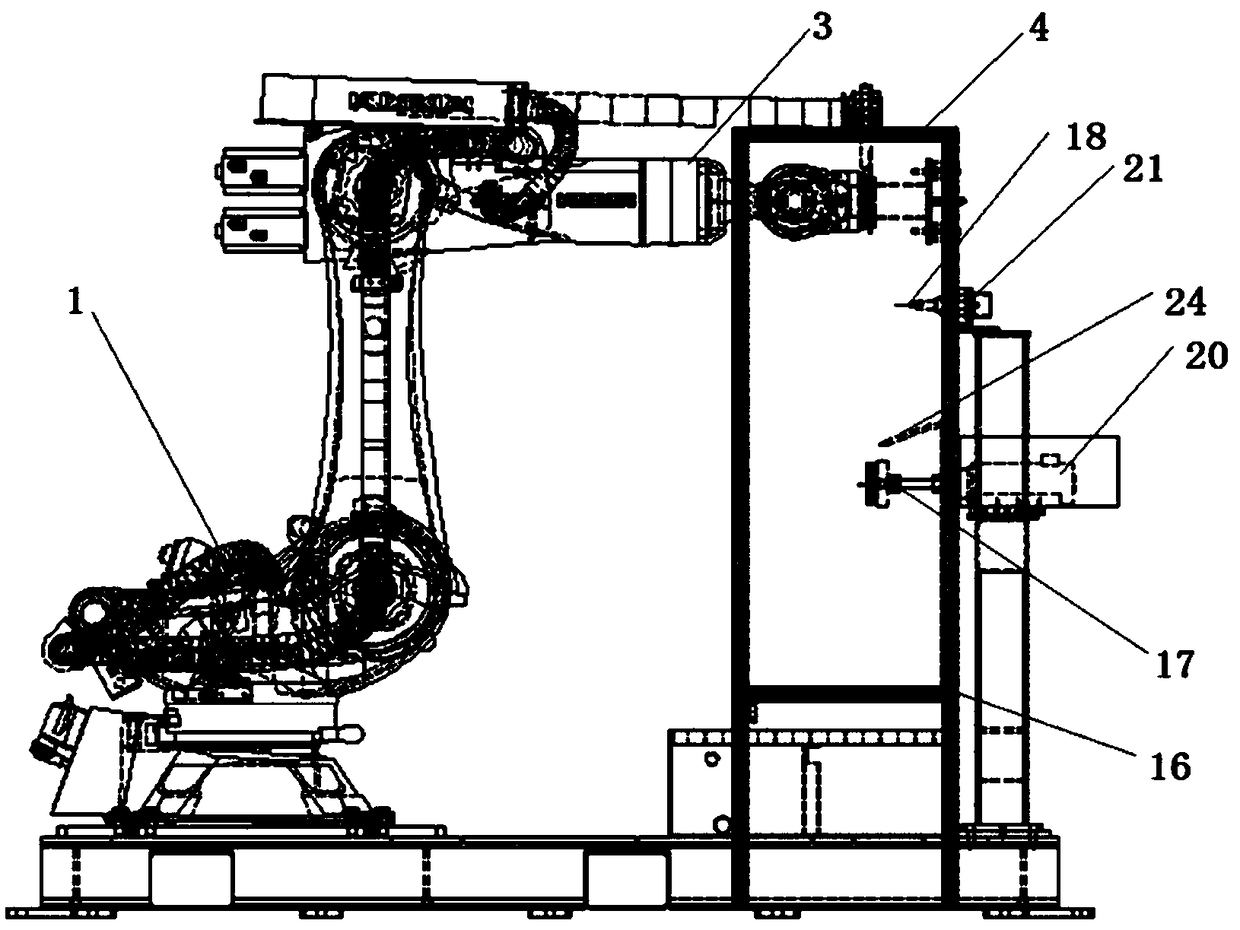

Engine cylinder head robot automatic burr removal workstation

ActiveCN108907948AHigh speedRaise the potentialEdge grinding machinesAutomatic grinding controlProduction lineControl system

The invention relates to an engine cylinder head robot automatic burr removal workstation, and belongs to the technical field of burr removal. The workstation includes a robot, a control system for controlling operation of the robot, a jacking positioning device, a cylinder head gripper assembly and a burr removal tool assembly. The workstation adopts the robot to grasp workpieces to remove burrs.After a cylinder head on an automatic roller conveyor system arrives at the gripping point of the robot, the jacking positioning device is adopted for jacking and positioning to achieve accurate positioning, the robot grabs the cylinder head to remove the burrs, and the workpieces are cleaned to ensure the cleanliness while the burrs are removed. The workstation can replace the manual burr removal operation, improves the automatic intelligent and information level of a production line, and improves the production efficiency and product quality.

Owner:KUNMING YUNNEI POWER

Grinding and thinning method for glass

ActiveCN105563261AEfficient automated productionHigh-quality automated productionLapping machinesAbrasive surface conditioning devicesWater basedLinear motion

The invention discloses a grinding and thinning method for glass. The grinding and thinning method comprises the following steps of adopting a paralleled surface grinding machine as processing equipment; taking upper and lower grinding wheels or polishing pads as cutting tools; using a water-based cutting fluid to cool and lubricate a workpiece; and placing a glass workpiece between an upper cutting tool and a lower cutting tool for grinding, wherein a feeding mode of the processing equipment is that the mode of circular motion or linear motion is adopted for feeding; end faces of the upper and lower cutting tools work by adopting a parallel or angle opening mode, and the maximum cutting thickness of the workpiece is not more than granularity values of the cutting tools. By adopting the grinding and thinning method disclosed by the invention, the time for processing mobile phone glass is about 3S; compared with a traditional method, the grinding and thinning method disclosed by the invention has the advantages that the efficiency is improved by 6 times, the thickness dimensions of the workpieces are stable and controllable, the quality and the yield of products are improved, and labor intensity is reduced; and in addition, high-efficiency and high-quality automatic production of glass (such as a mobile phone glass panel and a sapphire panel) is easily realized.

Owner:YUHUAN CNC MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com