Grinding and thinning method for glass

A technology of glass and grinding pads, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes. It can solve the problems of high labor intensity, difficult control of workpiece thickness differences, and difficulty in automation. To achieve the effect of improving product quality and yield, stable and controllable workpiece thickness and size, and high-quality automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

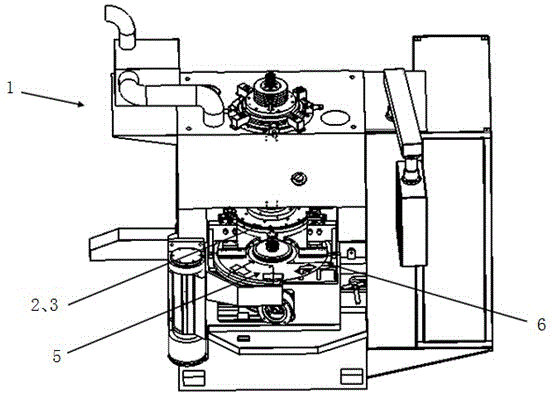

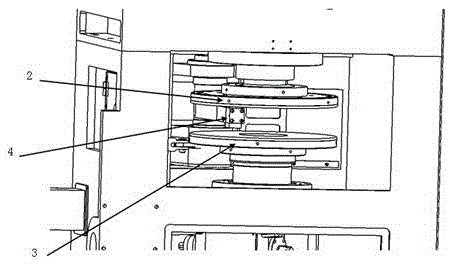

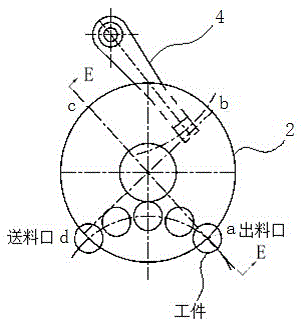

[0022] The grinding and thinning method of glass provided by the invention comprises: adopting such as figure 1 , 2 The shown double-face grinding machine 1 is used as a processing equipment, including an upper grinding wheel 2 and a lower grinding wheel 3 (or upper and lower grinding pads) as cutting tools, a swing arm repairing arm 4, a feeding tray 5, and a feeding support plate 6. The cutting fluid cools and lubricates the workpiece. Place the glass workpiece between the upper and lower grinding wheels 2 and 3; the feeding method of the double-end grinding machine 1 adopts circular motion (or linear motion) to feed; The grinding wheel 3 is set horizontally, and the upper grinding wheel 2 deflects at a certain angle θ relative to the lower grinding wheel 3. The angle θ can be selected within the range of 35.26 to 211.55 seconds. It is determined according to the thickness of the workpiece. Generally, the 4-point distance value method is used to adjust, such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com