Patents

Literature

86results about How to "Efficient automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

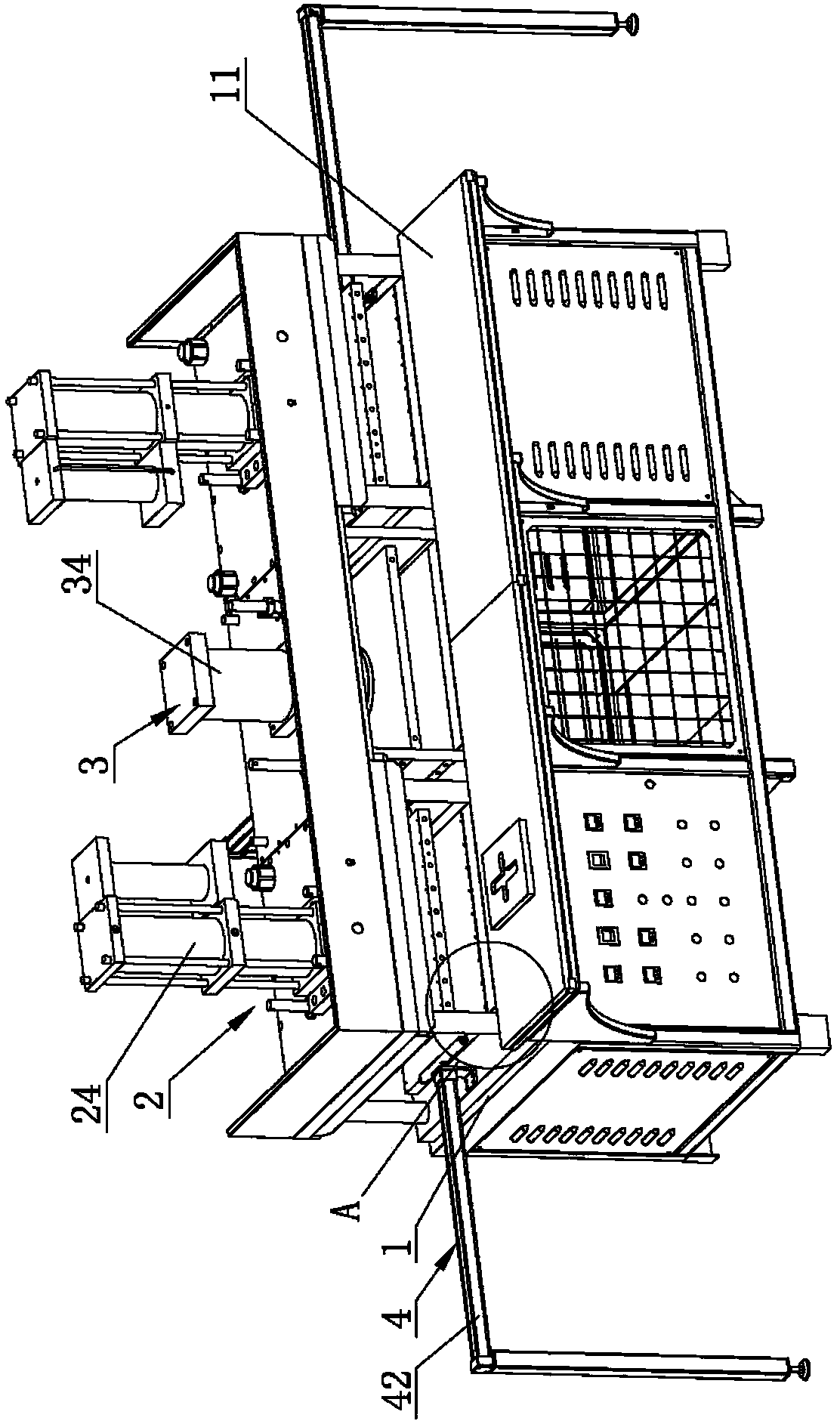

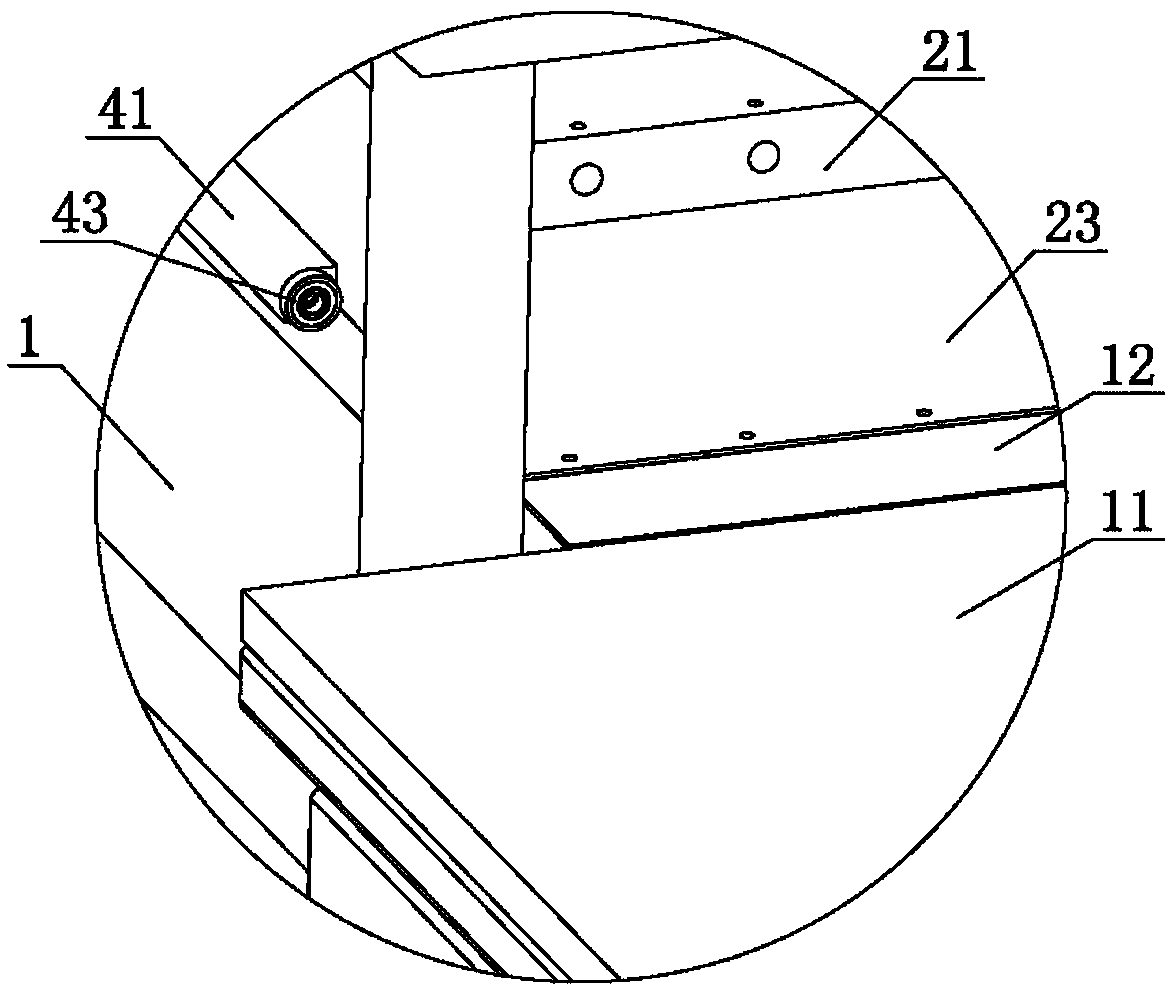

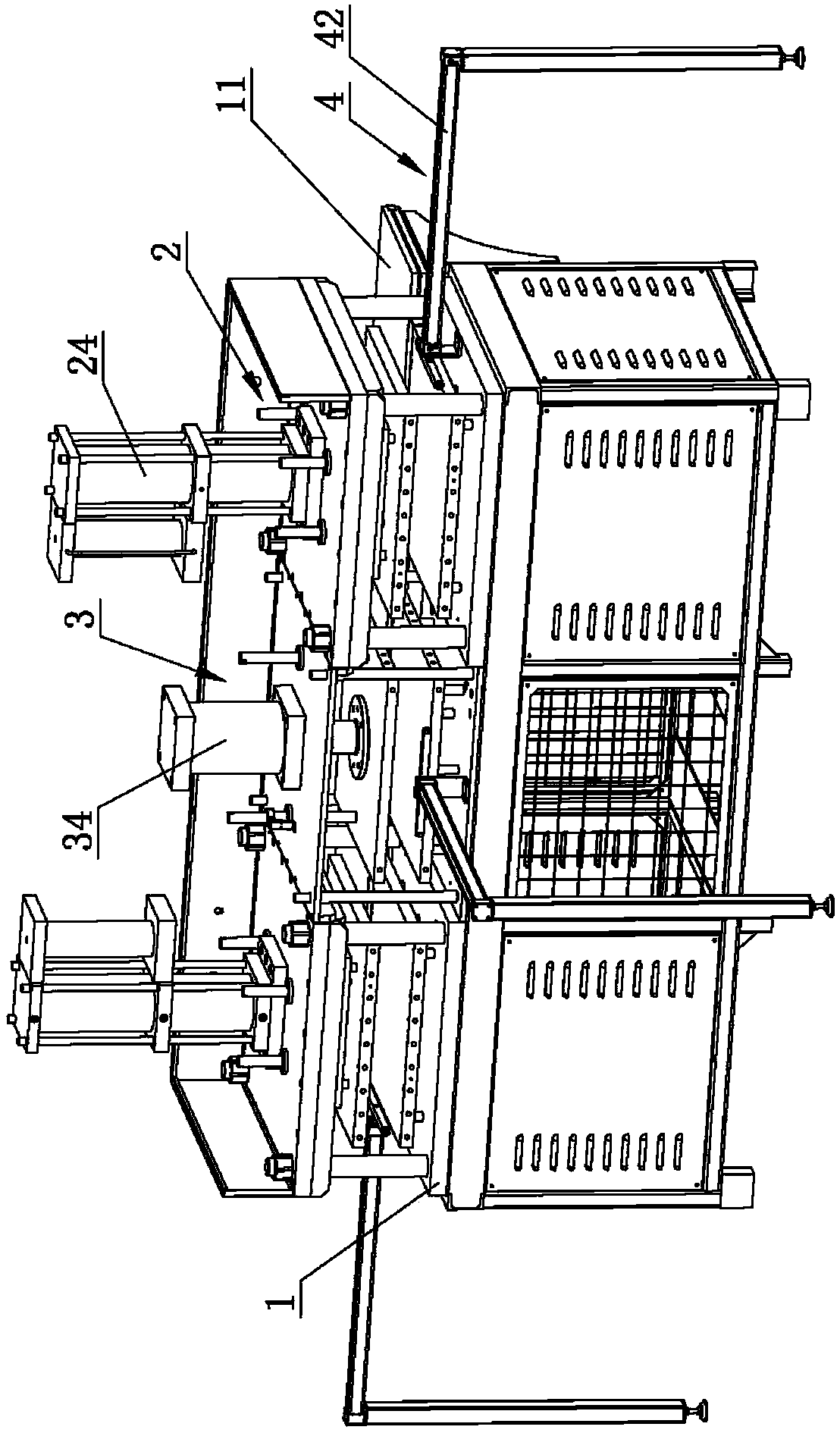

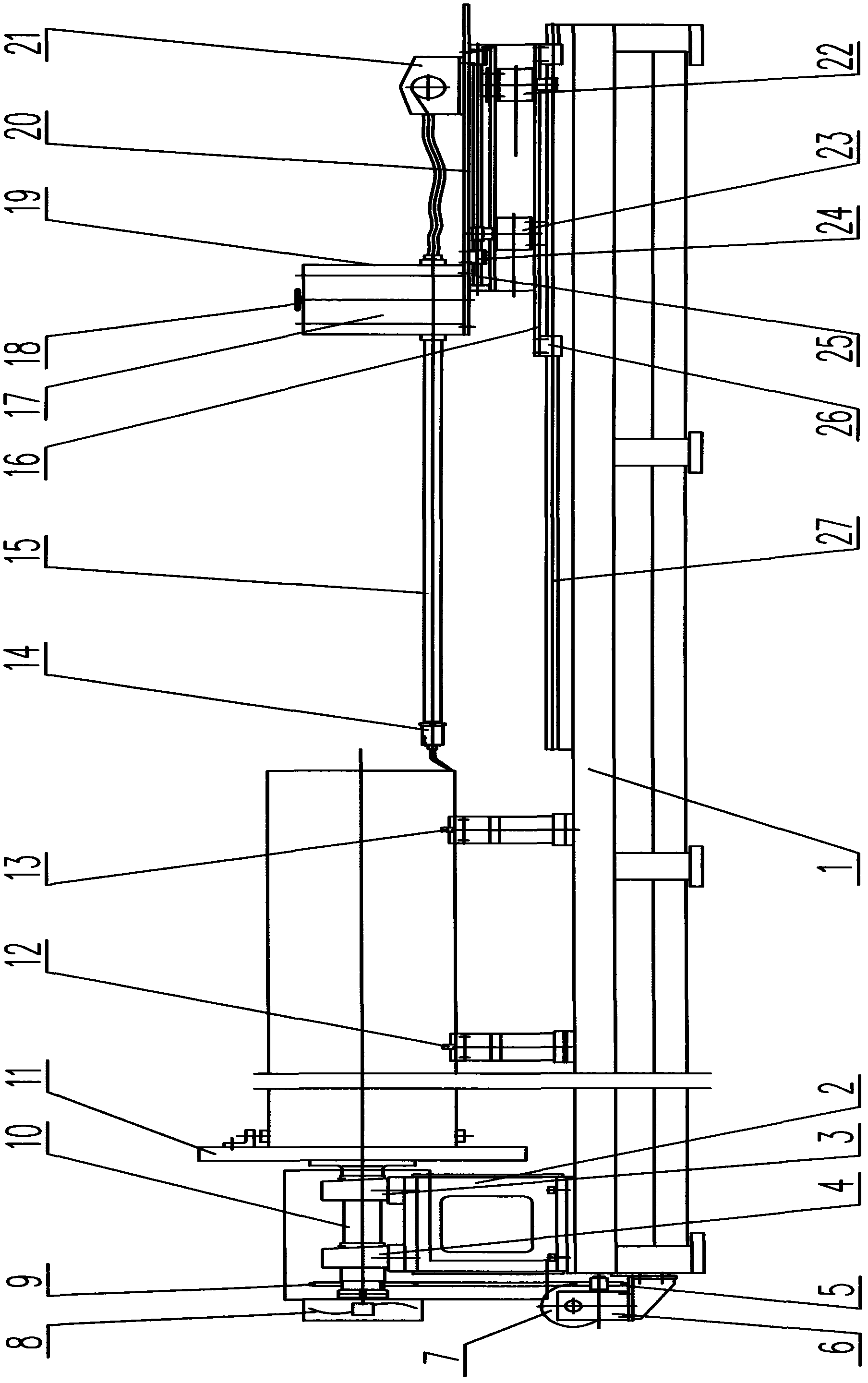

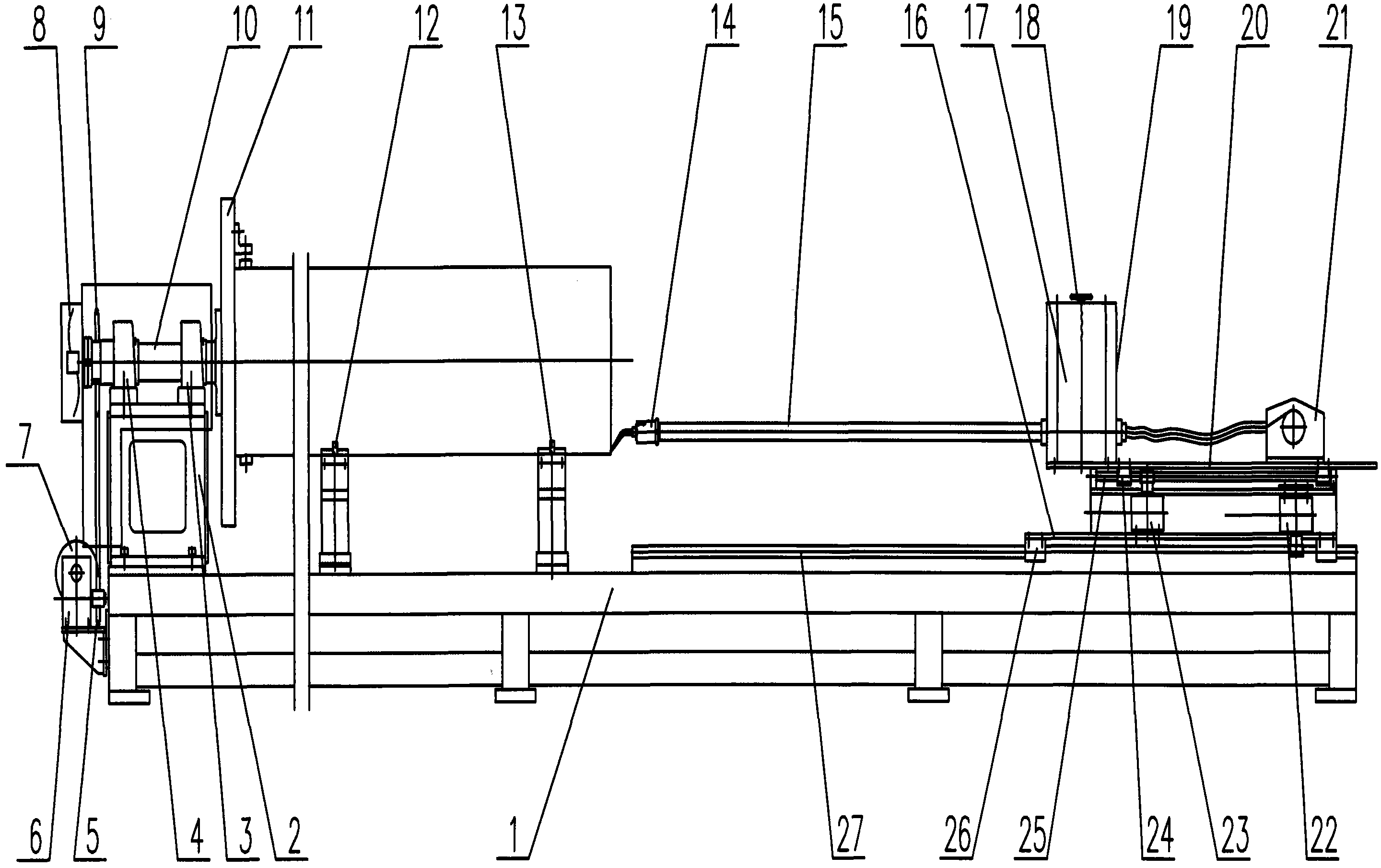

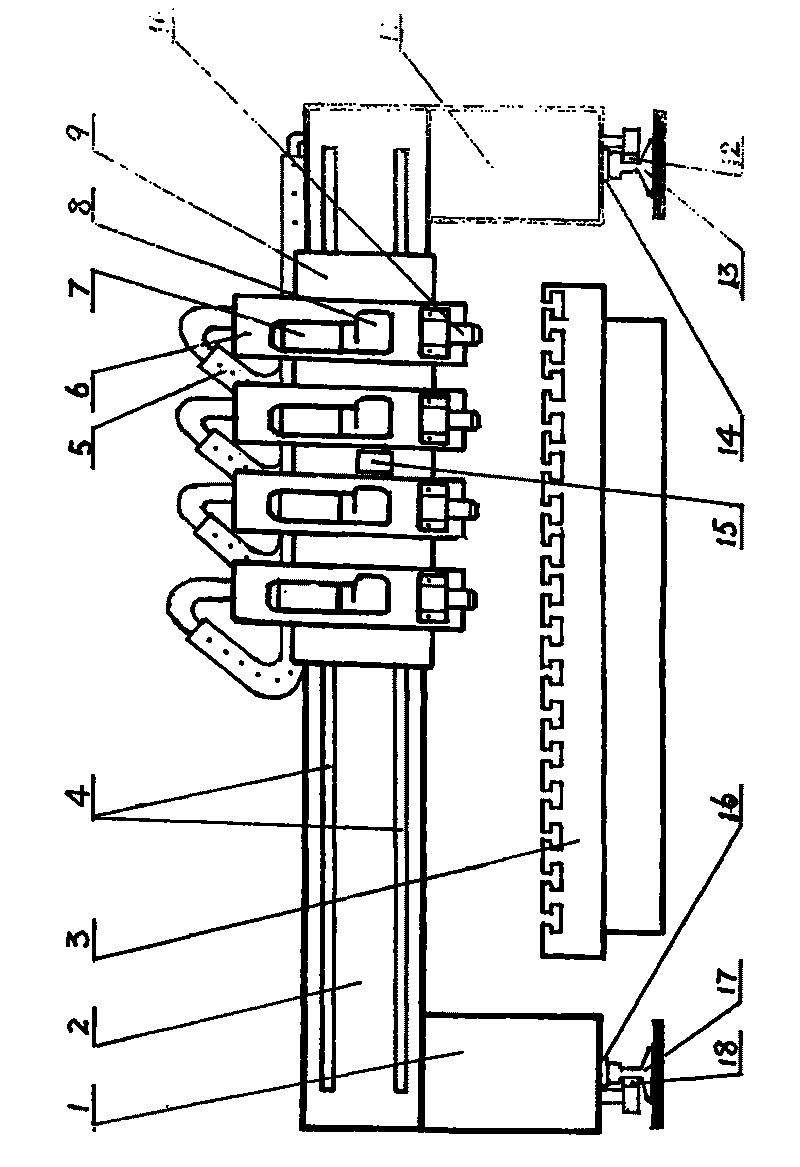

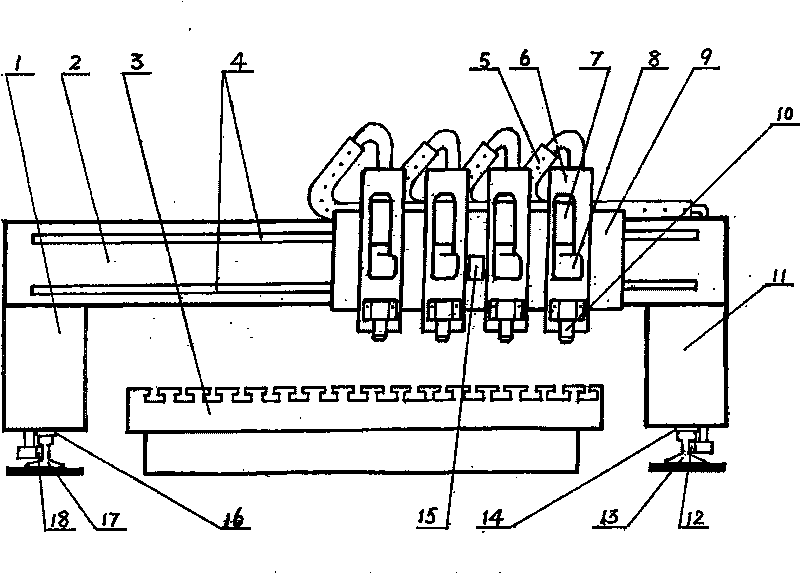

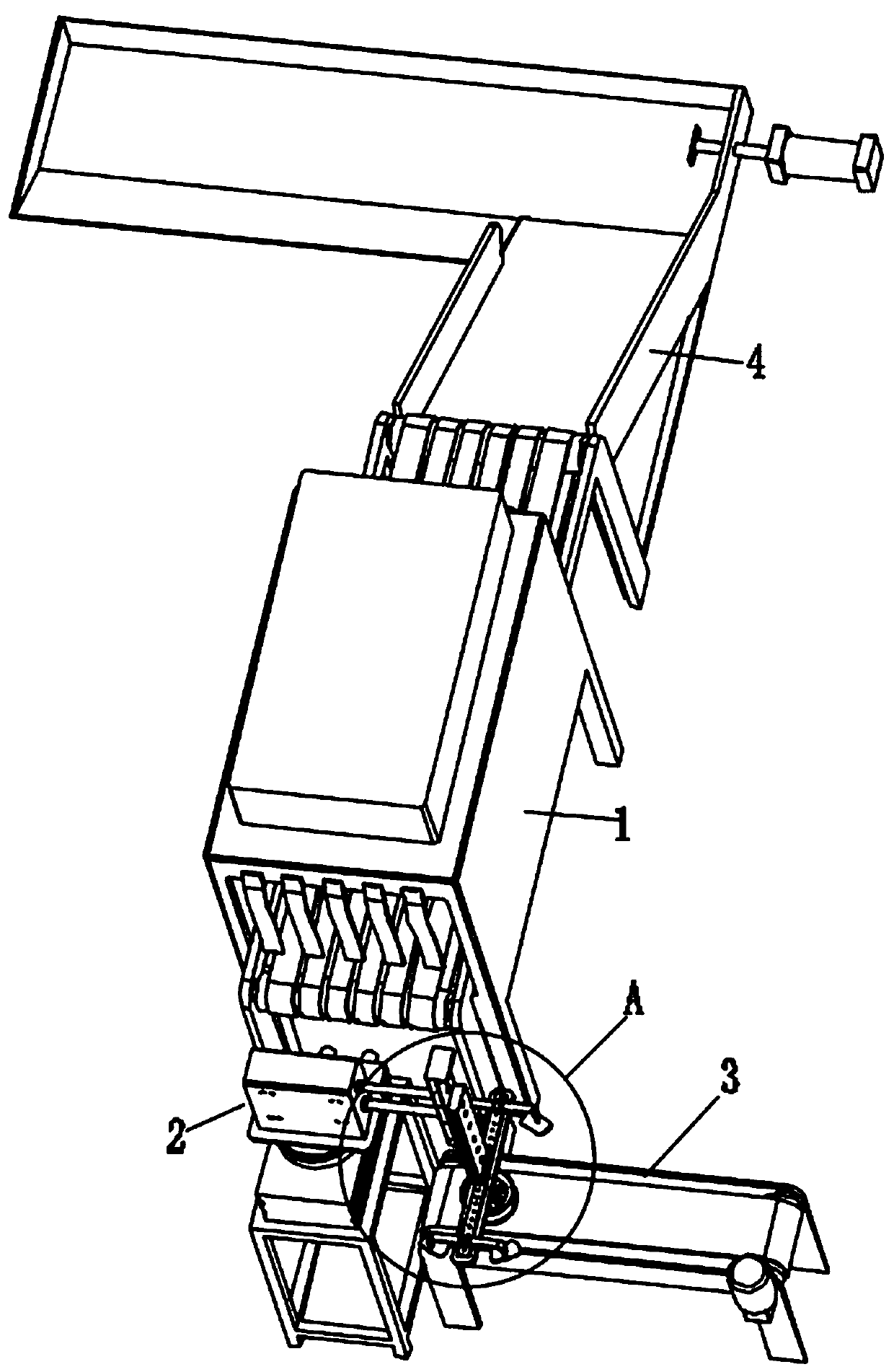

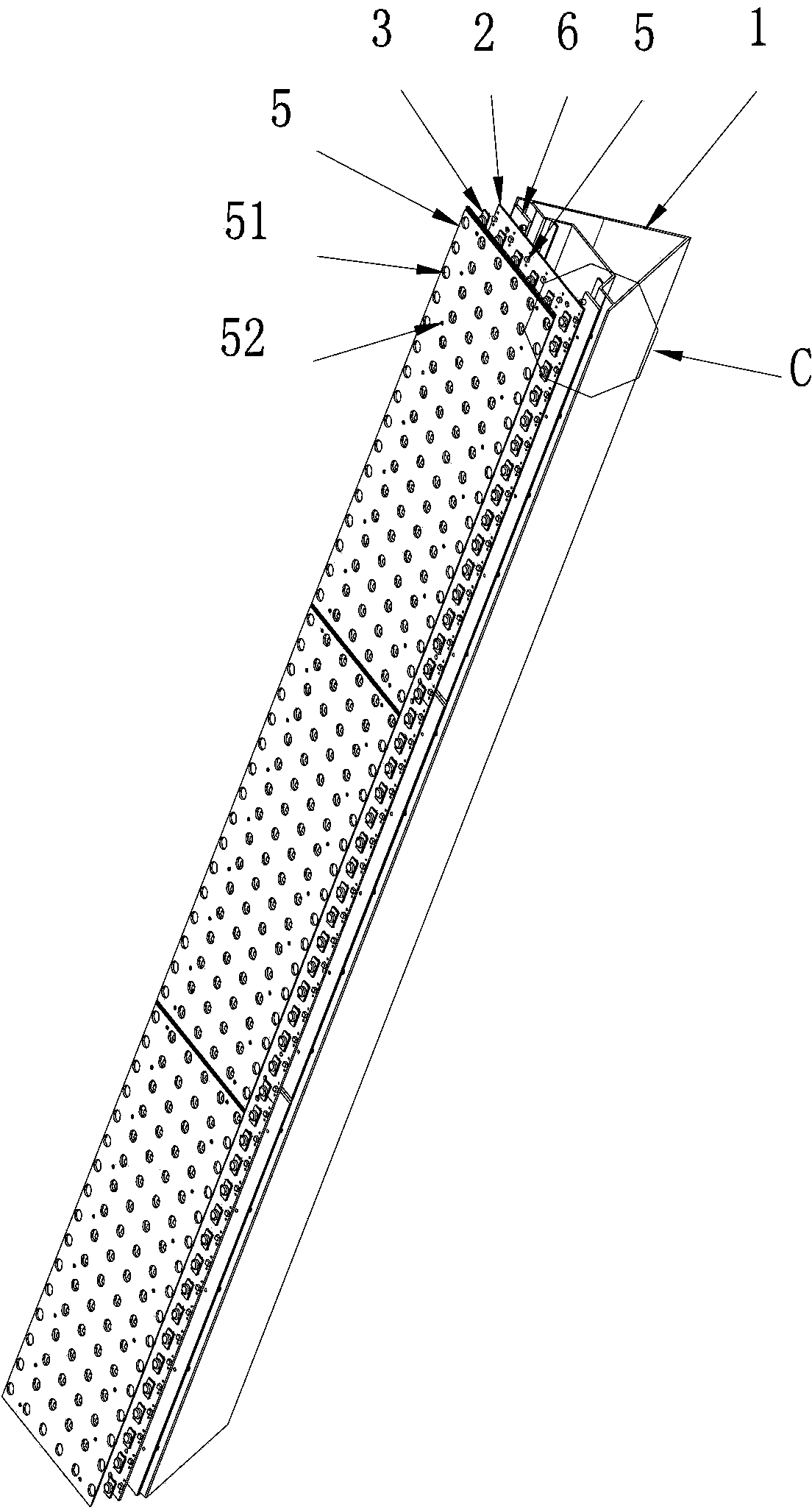

Automatic build-up welding equipment for abrasion-resistant layer on inner wall of pipeline and automatic build-up welding method

InactiveCN102049594ASmooth and reliable rotation speedGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlWelding power supply

The invention discloses automatic build-up welding equipment for an abrasion-resistant layer on an inner wall of a pipeline and an automatic build-up welding method for realizing efficient automatic production of high abrasion-resistant composite conveying pipelines. The equipment comprises a host, a direct-current gas protective welding power supply, a protective gas storage tank and a control box with a built-in automatic control device; one end of a base is provided with a head, a main shaft, a chuck and an adjustable roller bracket; the other end of the base is provided with a welding gun running execution device, and the device comprises a driving and reversing platform, a swing platform, a welding gun lifting mechanism, a wire feeder and a welding gun; the front end of the welding gun is provided with a welding torch, and a welding wire and a protective gas conveying pipe are communicated to the front end of the welding gun; the anode of the welding power supply is connected with the welding torch, and the cathode of the welding power supply is connected with a workpiece; and the moving parts are driven by a step motor through the automatic control device. The operation process comprises early preparation, parameter setting, welding and reset stopping; and by setting control parameters, the execution parts run according to the set parameters to form build-up welding layers tightly arranged and uniformly distributed in a spiral motion locus.

Owner:济南杰瑞复盛机电设备有限公司

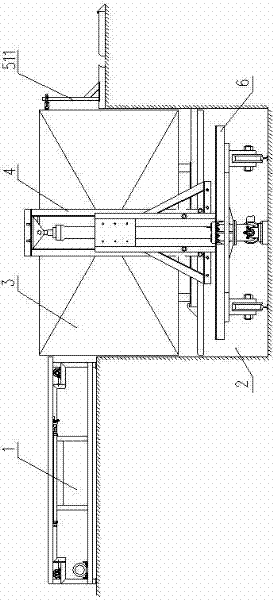

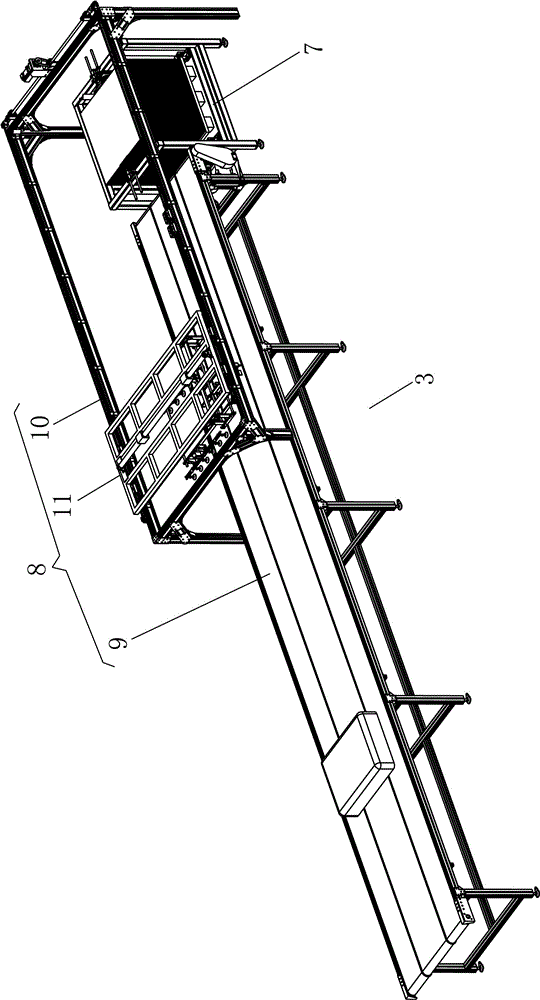

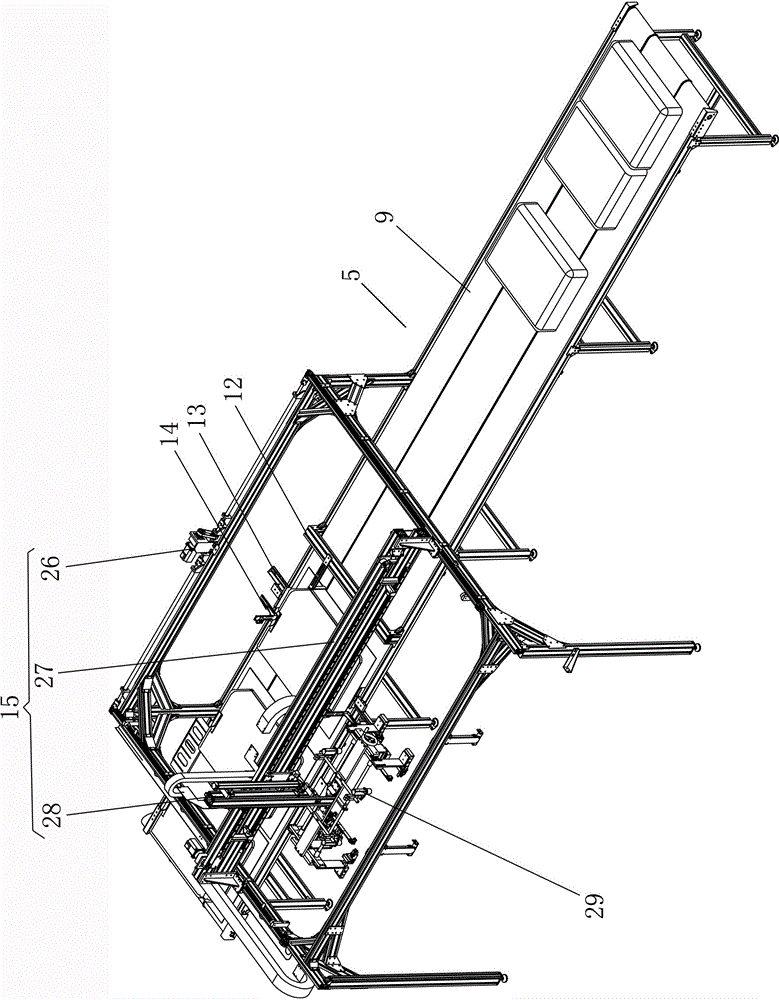

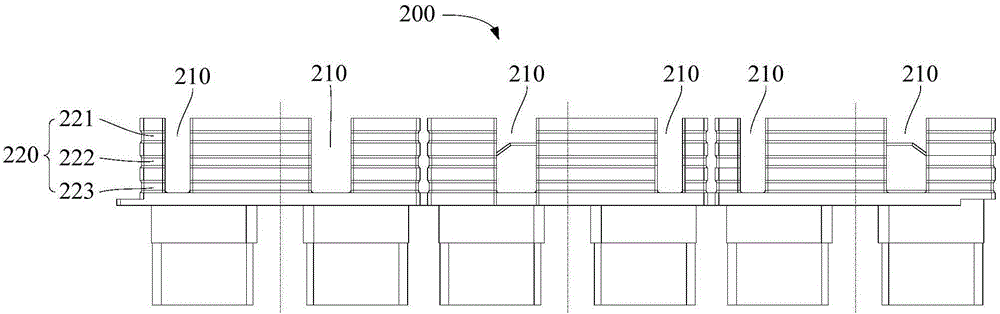

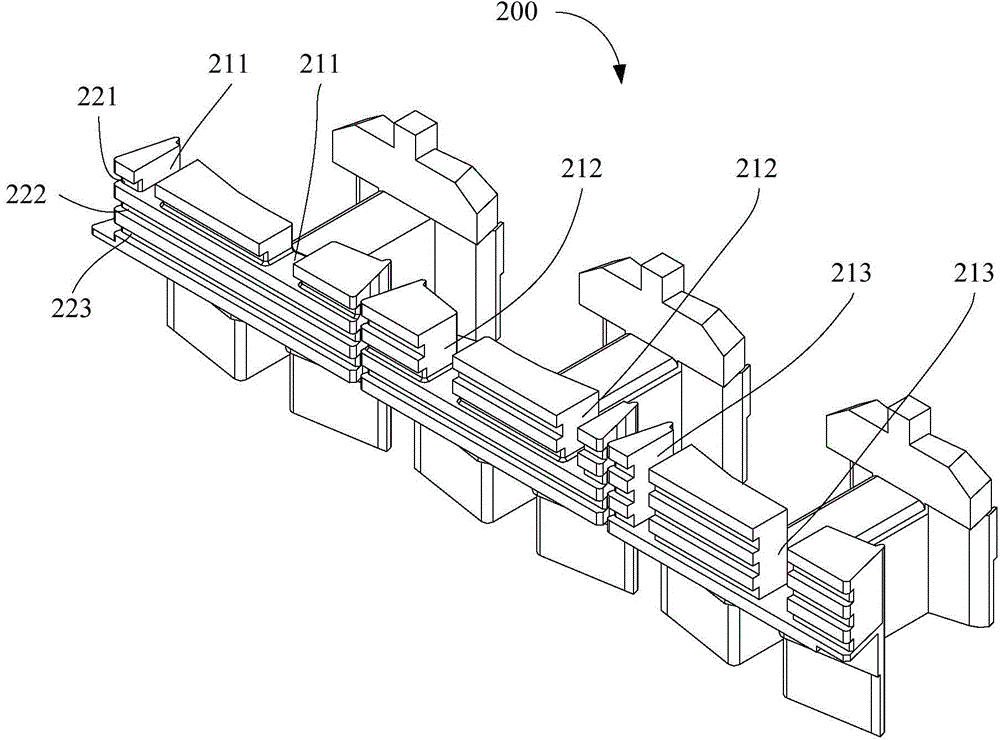

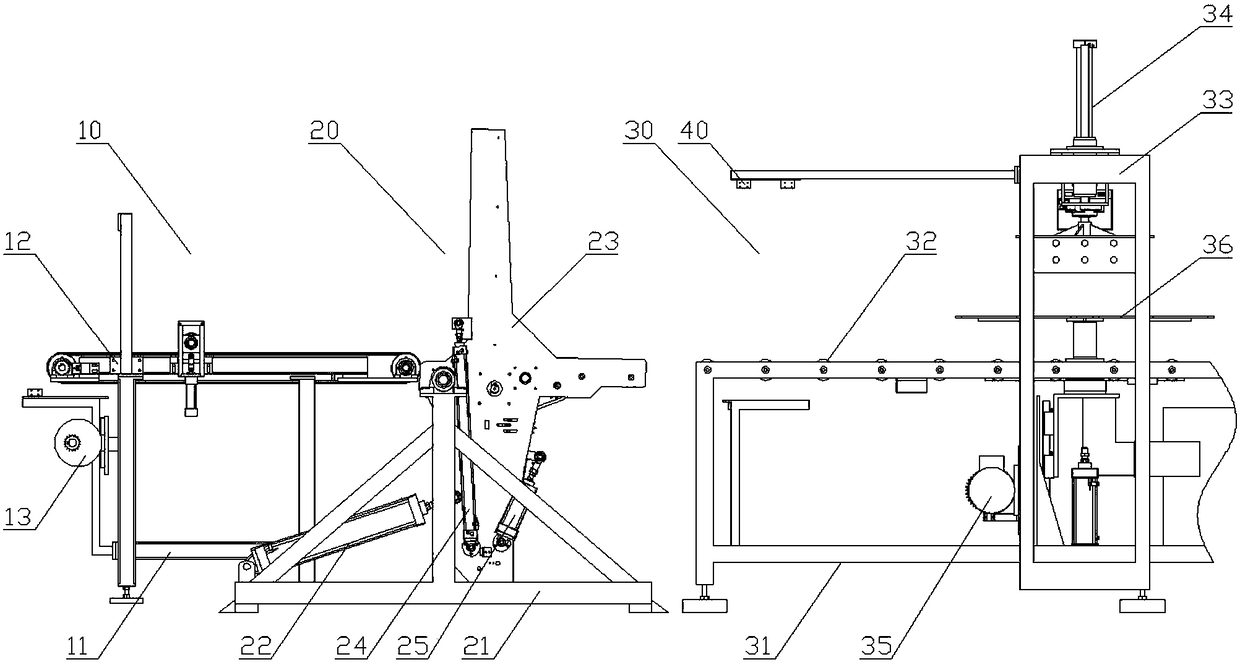

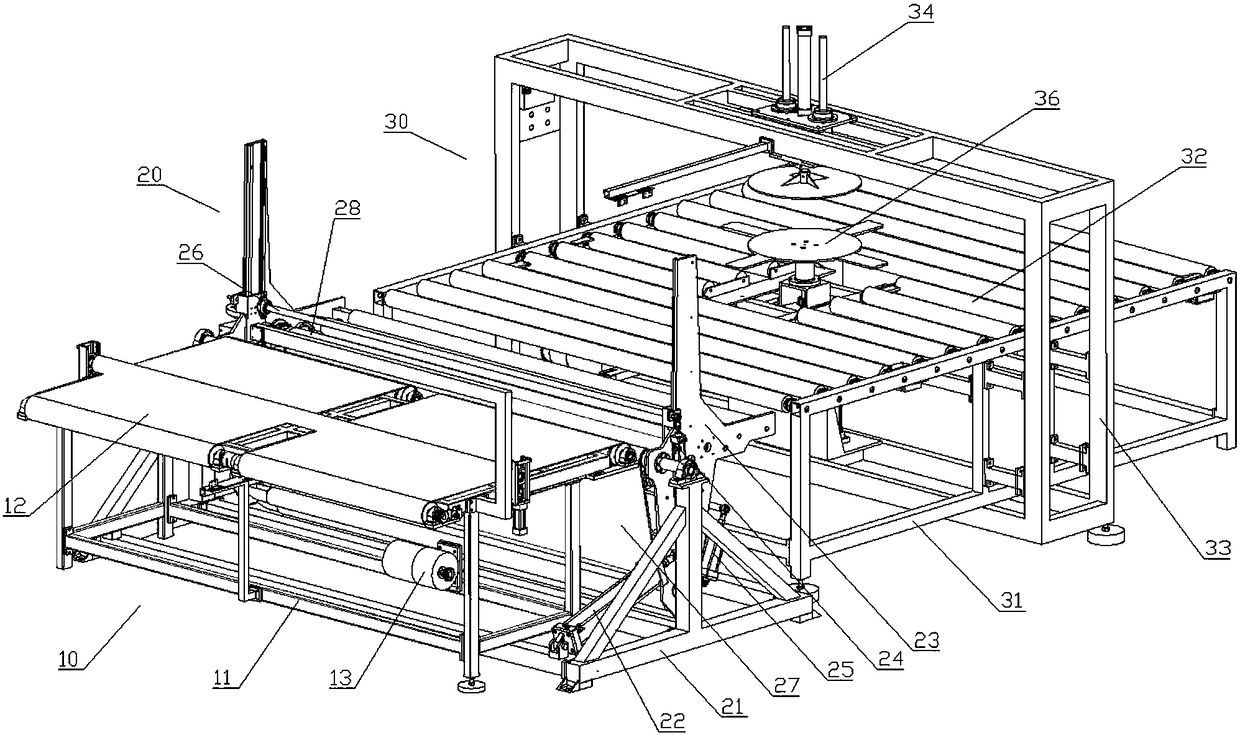

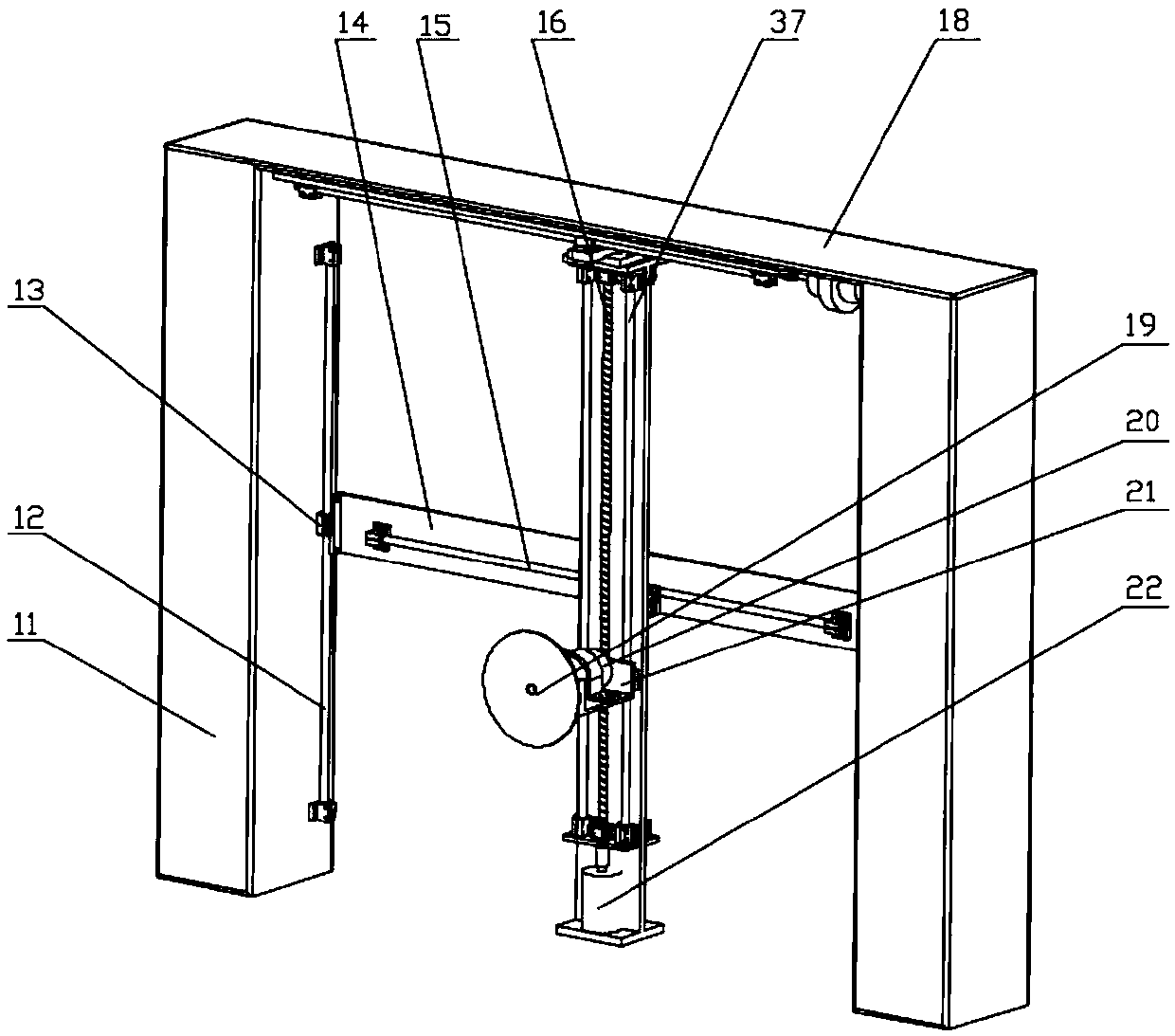

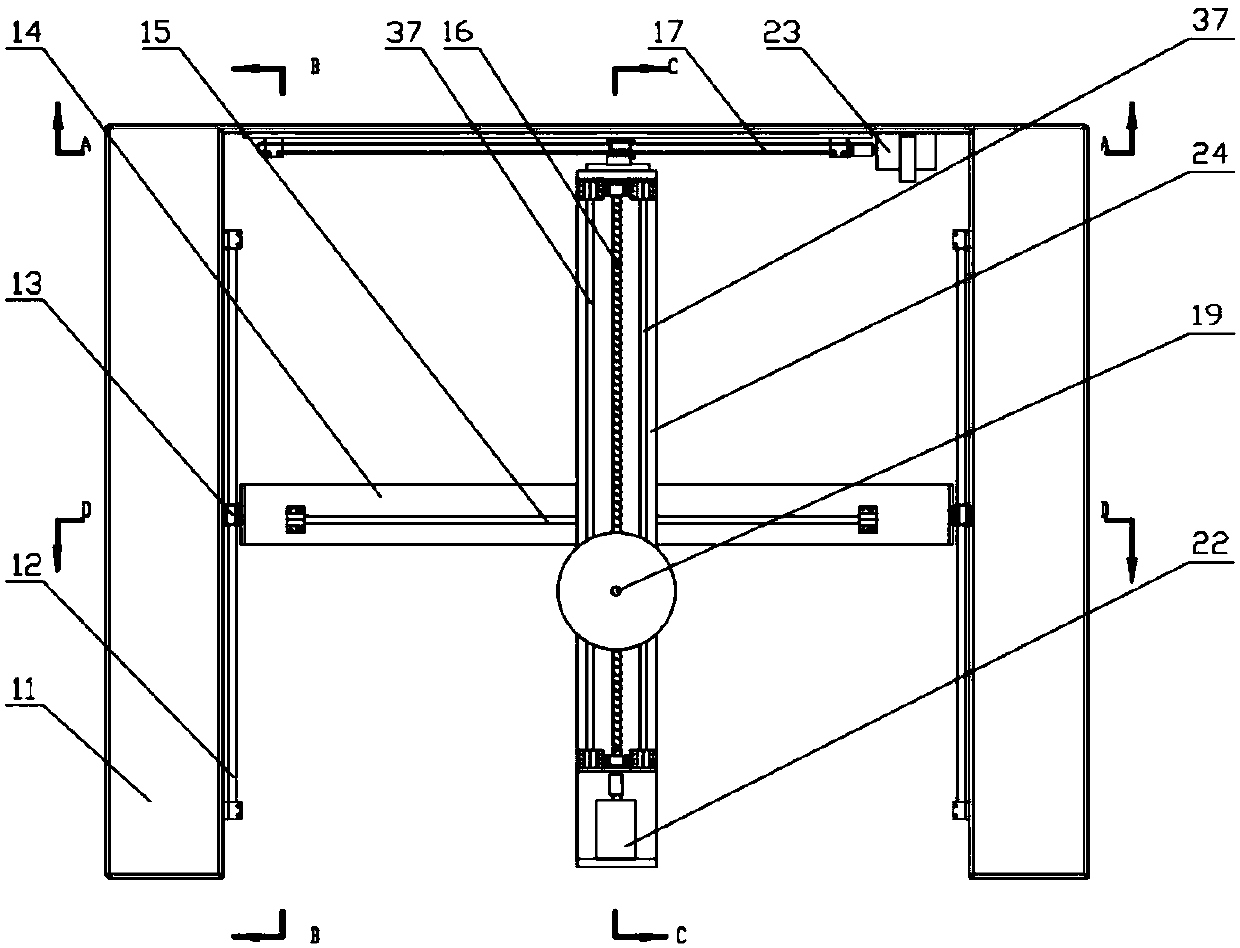

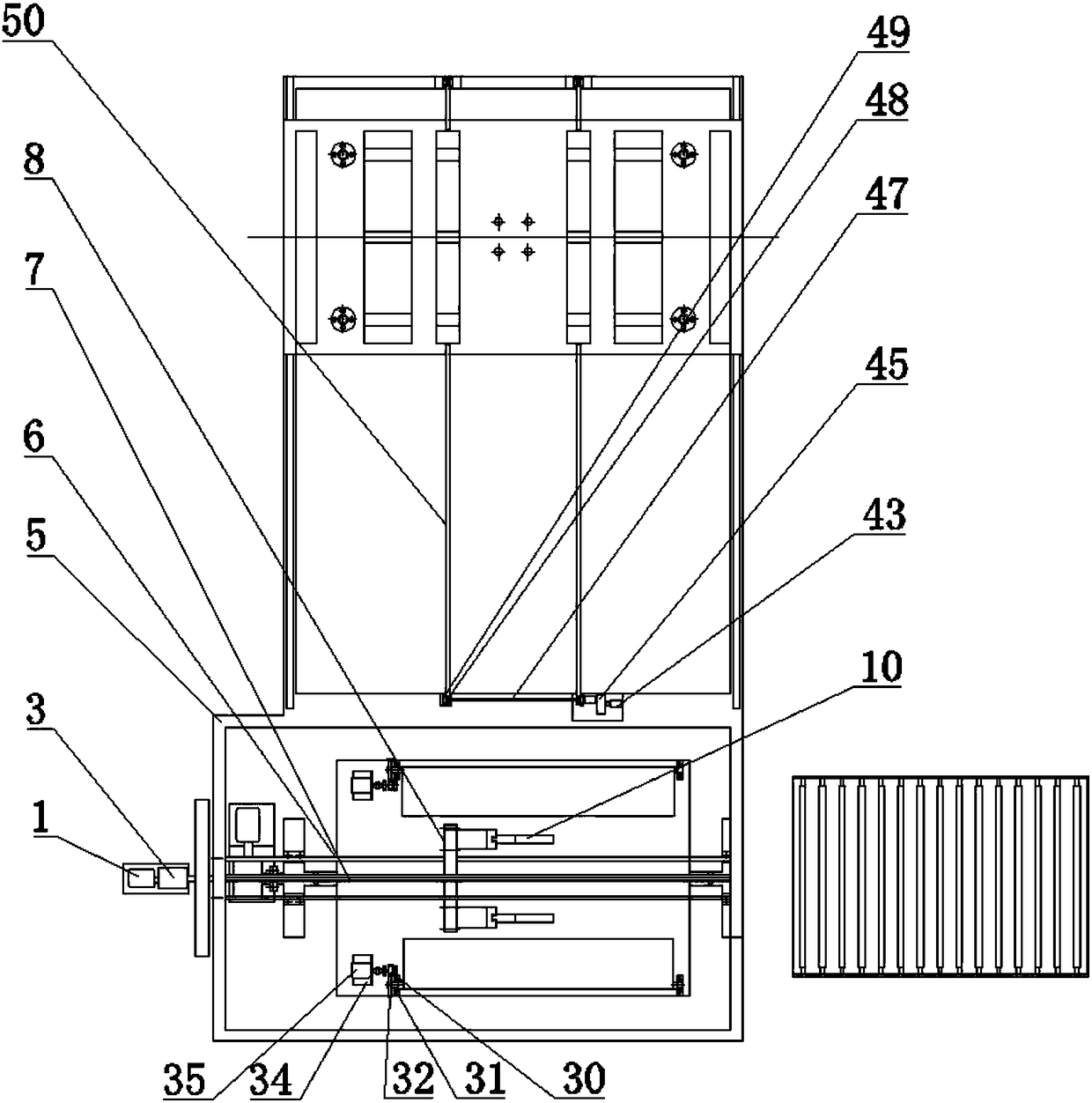

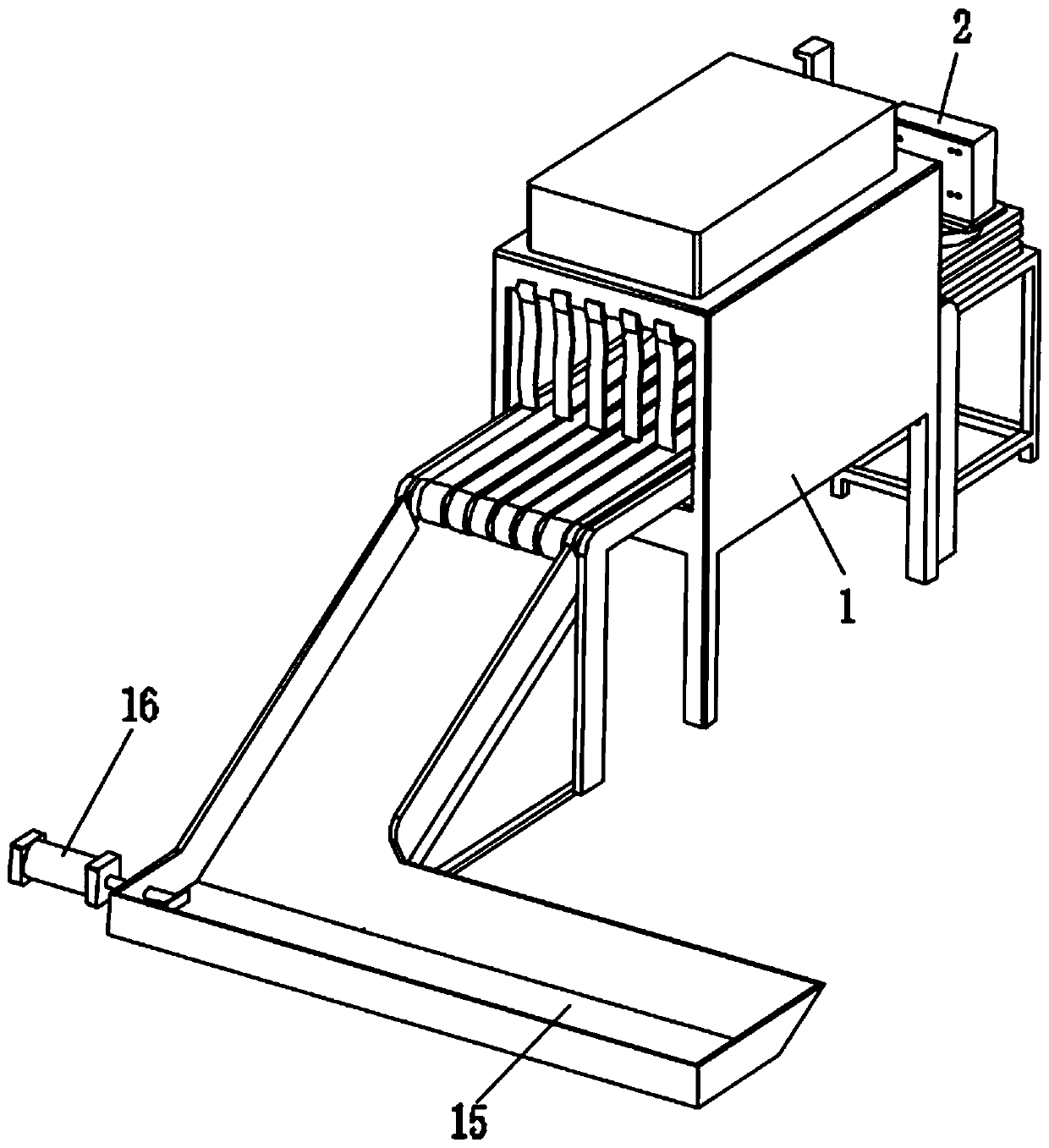

Board discharge device in glass magnesium board production line

InactiveCN102367114AGuaranteed uninterrupted productionPass smoothlyPile receiversProduction lineFlat panel

The invention discloses a board discharge device in a glass magnesium board production line. The board discharge device comprises a board material conveying device connected to the tail end of the production line, the tail end of the board material conveying device is provided with a pit capable of containing three lifting mechanisms, and the board material conveying device is dead against the middle part of the pit. The board discharge device has the characteristics that the pit is internally provided with a platform trolley mechanism of which the operating direction is vertical to the conveying direction of glass magnesium boards; two erector mechanism are fixedly arranged on a platform trolley in the platform trolley mechanism, and each erector mechanism is provided with a cage conveying trolley; a cage for containing the glass magnesium boards is arranged on each cage conveying trolley; and two ground rails by which the cage conveying trolleys can run conveniently are arranged on the ground at the other side of the pit opposite to the board material conveying device. The board discharge device has the advantages of facilitating the achievement of high-efficiency automatic production, greatly improving production efficiency and being applicable to glass magnesium board production line equipment, and is simple and convenient for operation.

Owner:张家港市玉龙科技板材有限公司

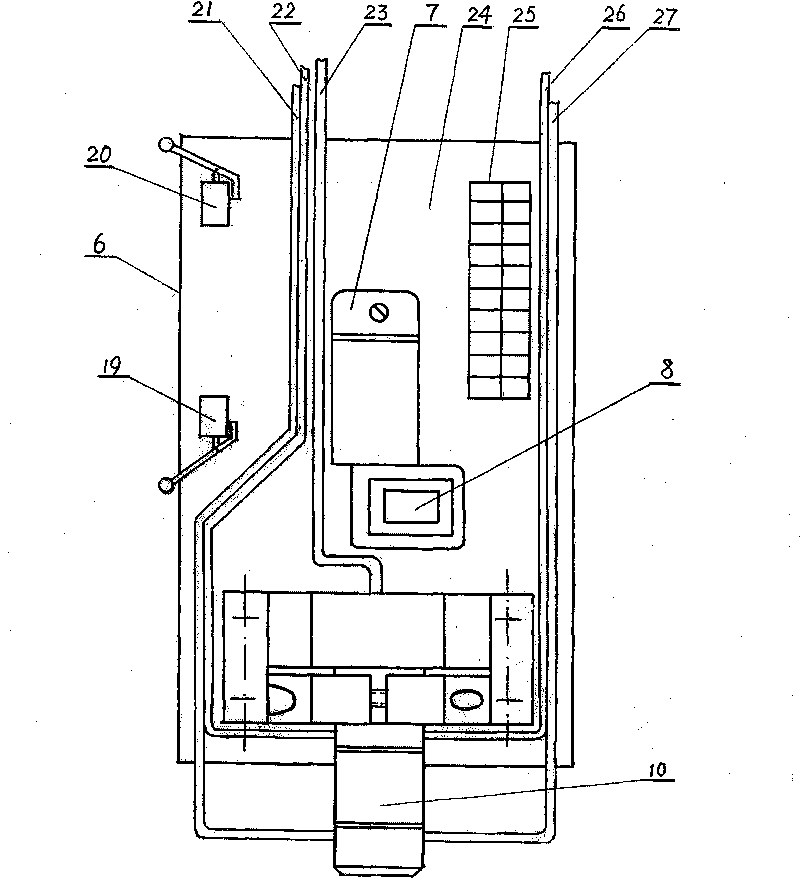

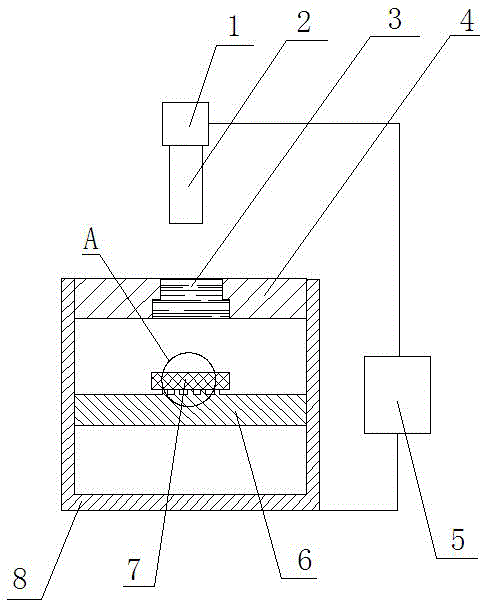

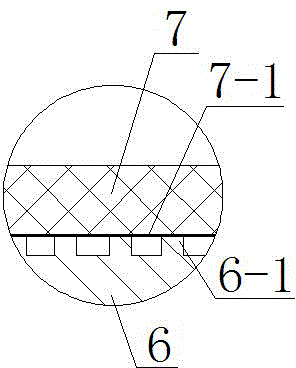

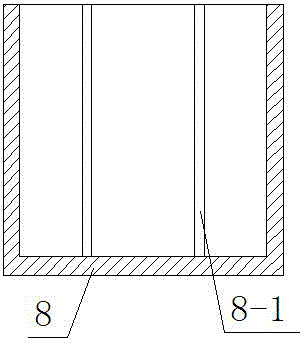

Plasma arc plane surface welding machine

InactiveCN101733535AReasonable structural designMature and reliable technologyWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlWater source

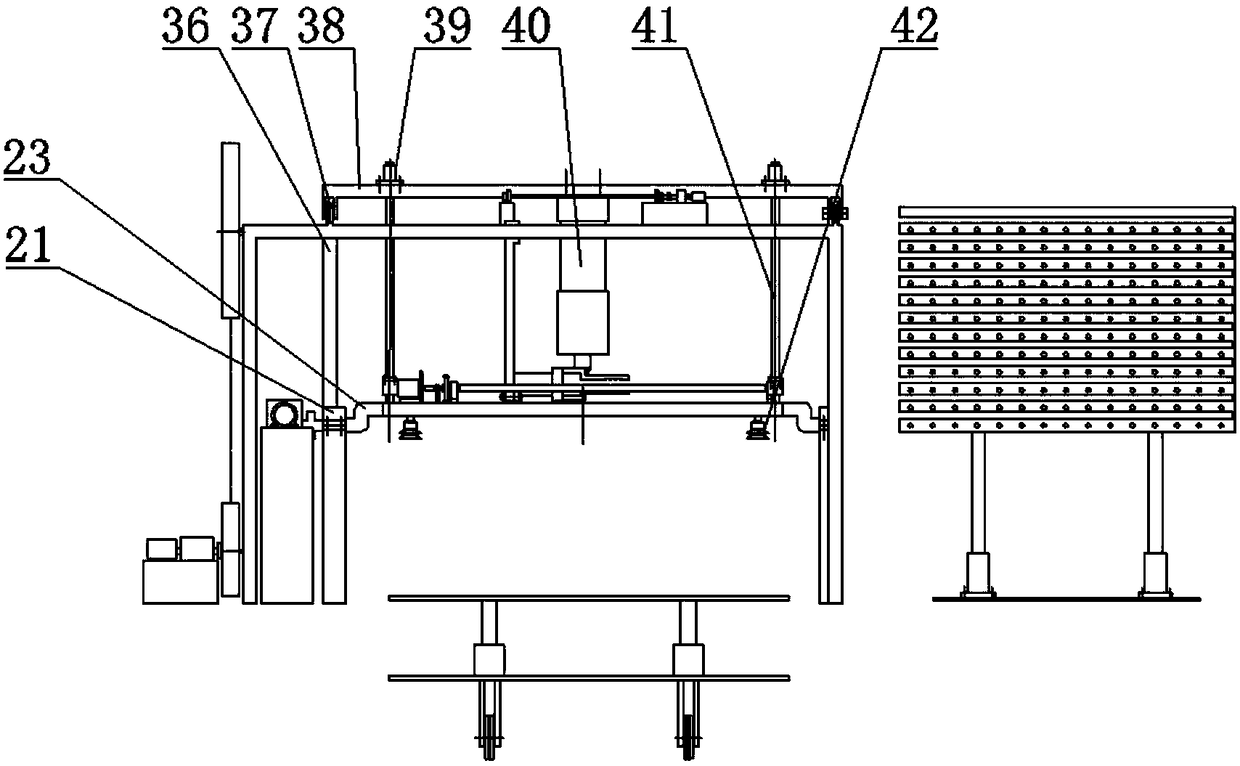

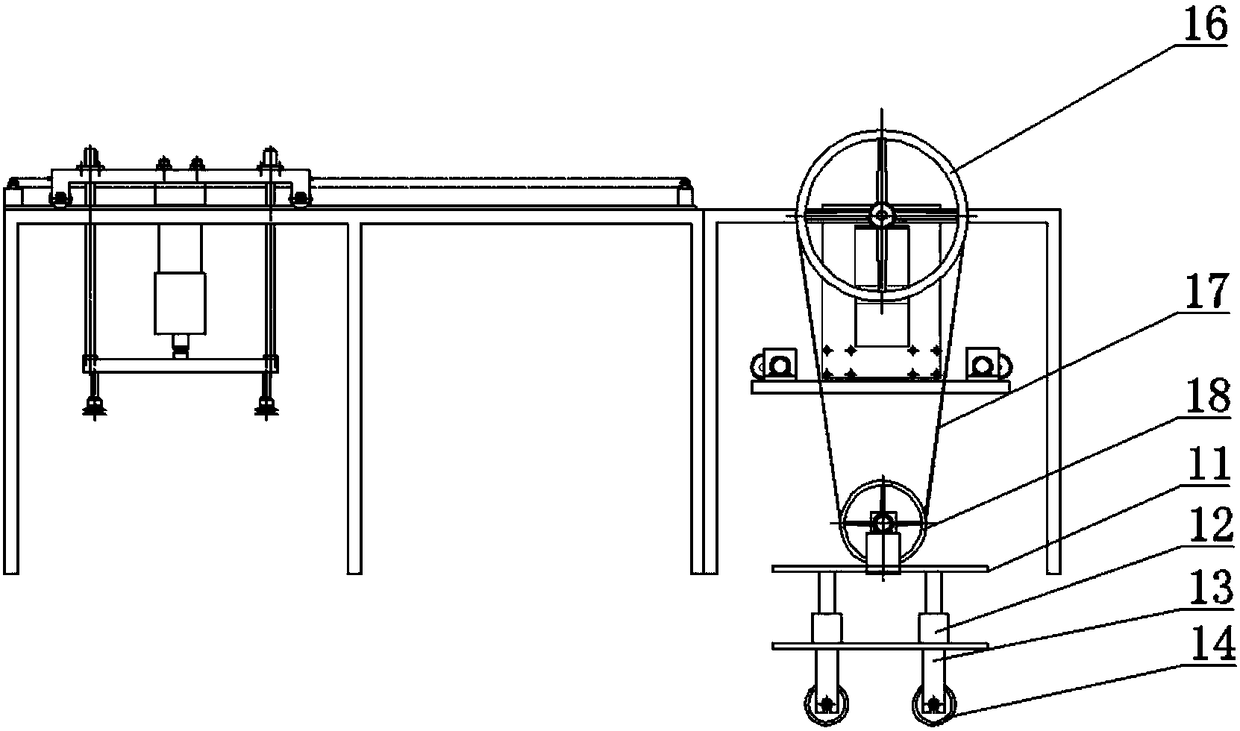

The invention discloses a plasma arc plane surface welding machine, and aims to provide plasma arc plane surface welding equipment for a plane-shaped composite material surface welding product. The plasma arc plane surface welding machine comprises a machine frame and a welding platform, wherein the machine frame is in a portal frame structure, the welding platform is correspondingly arranged, and the machine frame and the welding platform can relatively longitudinally move in parallel under the drive of a longitudinal travelling motor; a transverse sliding plate which is driven by a transverse mobile motor and can transversely move or swing is arranged at the side of a crossbeam of the machine frame, a liftable welding torch bracket is arranged at the outer side of the transverse sliding plate, a plasma welding torch pointing to the welding platform is installed on the welding torch bracket, the height position of the plasma welding torch can be adjusted under the drive of a lifting motor, and the plasma welding torch is also provided with a direct current welding power supply, a working gas and a cooling water source; and leads for connecting all motors are led to a control box and automatic control is realized through an electric automatic control system. The plasma arc plane surface welding machine has reasonable structural design and mature and reliable technology, satisfies each operational requirement for welding working, and realizes high-efficiency automatic production.

Owner:济南杰瑞复盛机电设备有限公司

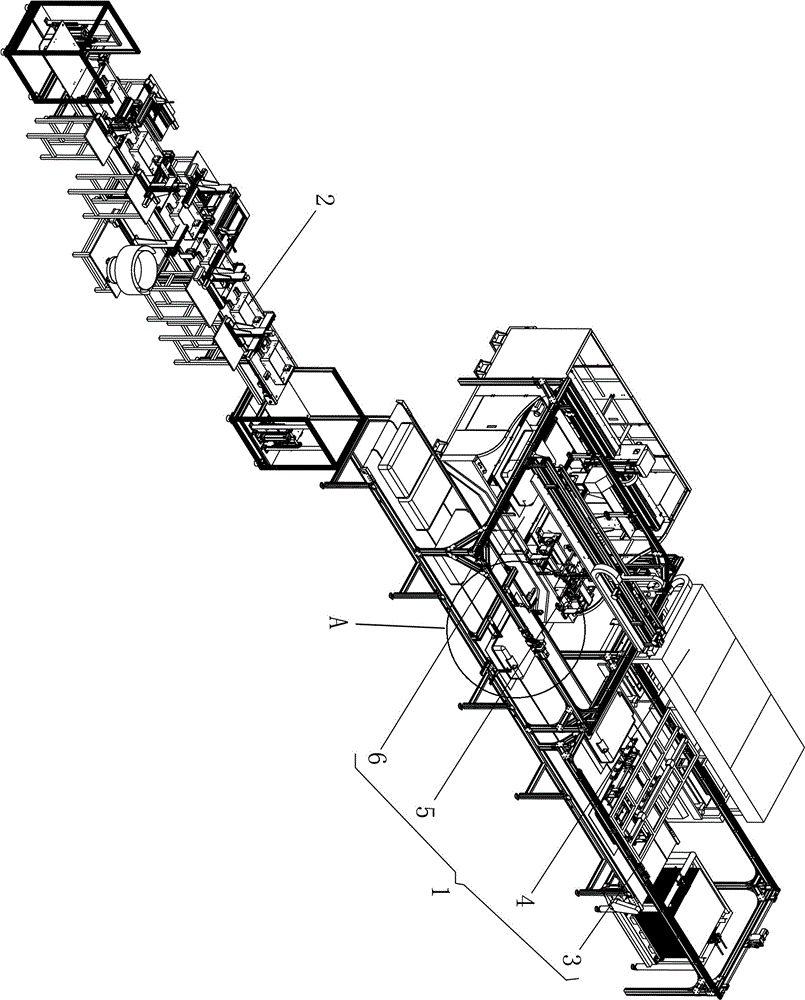

Automatic cutting assembly equipment for draw-bar box and production process of automatic cutting assembly equipment

PendingCN107521120AEfficient automated productionSimple production processDomestic articlesProcess engineeringAssembly line

The invention relates to automatic cutting assembly equipment for a draw-bar box and a production process of the automatic cutting assembly equipment. The automatic cutting assembly equipment consists of a processing part and an assembly part, wherein the processing part comprises a feeding device, a plastic vacuum forming machine, a detection device and a cutting device which are hinged and work together through an overall rack; the detection device comprises a positioning mechanism, a resetting mechanism, a detection mechanism and a transport mechanism; the positioning mechanism is fixedly arranged on a feeding table; the resetting mechanism and the detection mechanism are symmetrically mounted on two sides of the feeding table; and the transport mechanism is arranged above the feeding table in a sliding manner. The automatic cutting assembly equipment has the following beneficial effects: such processes as molding, detection, cutting and assembly of a traditional draw-bar box are combined; the integral assembly line type transport mechanism is used for taking and feeding materials, so that efficient automatic production of all the links is achieved, the overall production technological process is simplified, the production cycle is shortened, the production efficiency is effectively improved, and the production cost is lowered; and the automatic cutting assembly equipment is convenient to produce and high in practicability.

Owner:DONGGUAN RBT IND ROBOT TECH

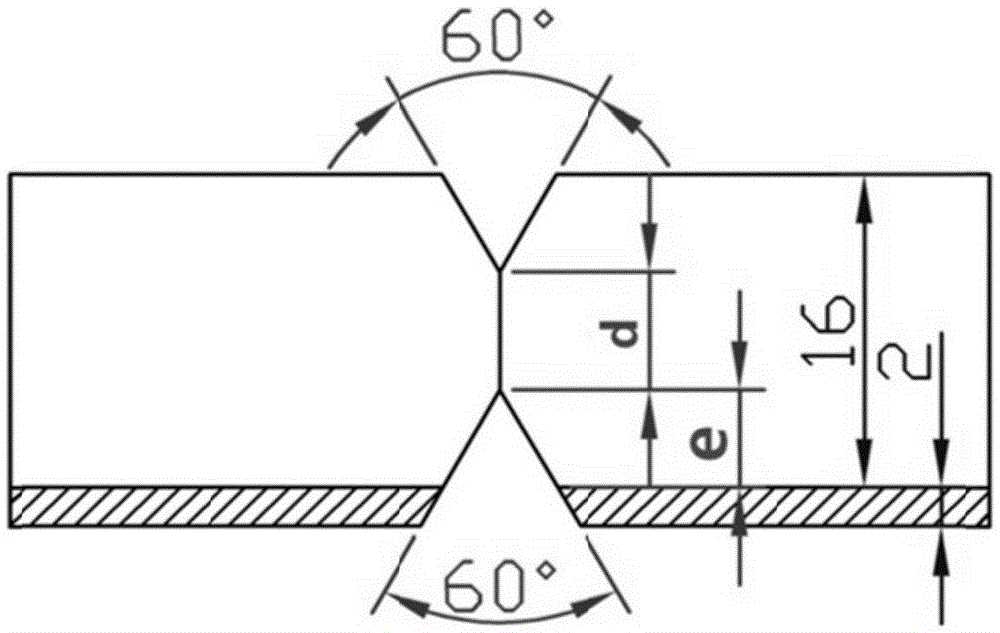

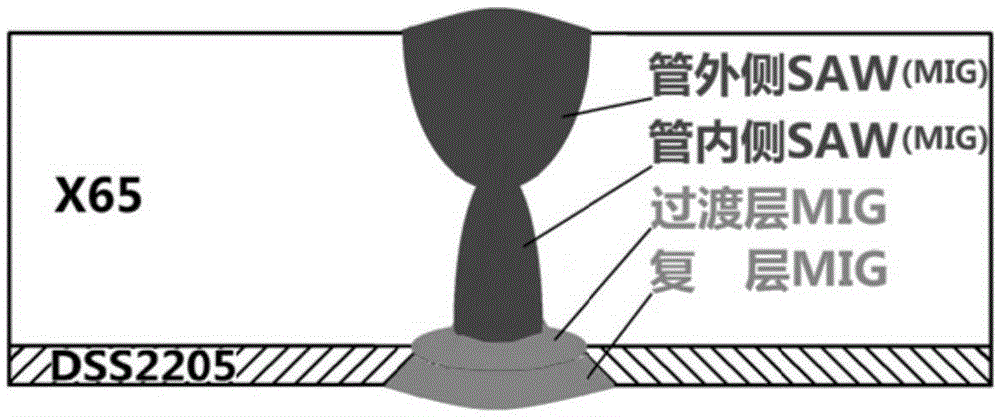

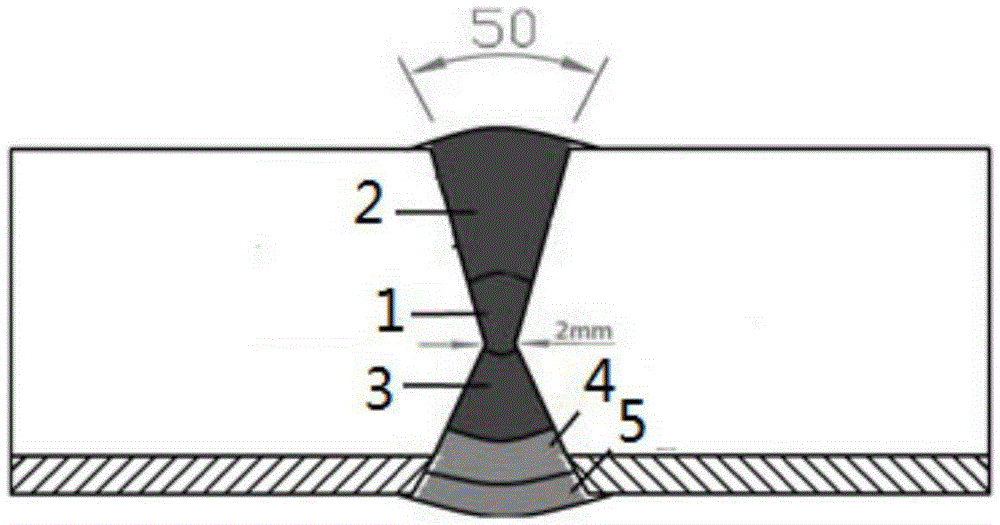

Bi-metal metallurgy composite pipe welding method

InactiveCN105252116AEfficient automated productionRealize large-scale industrial productionArc welding apparatusWelding/soldering/cutting articlesPipe weldingChemical composition

The invention discloses a bi-metal metallurgy composite pipe welding method. The bi-metal metallurgy composite pipe welding method includes the steps that (1) an X-type groove is formed in an SS2205-X65 bi-metal composite plate in a butt-joint mode; (2) metal active gas (MAG) is used for carrying out welding on the center of the X-type groove from the outer side, and a first outer side base layer welding joint is formed; (3) the MAG is used for carrying out welding on the first outer side base layer welding joint from the outer side, and a second outer side base layer welding joint is formed; (4) the MAG is used for carrying out welding on the center of the X-type groove from the inner side, and an inner side base layer welding joint is formed; (5) the MAG is used for carrying out welding on the inner side base layer welding joint from the inner side, and a transition layer welding joint is formed; and (6) the MAG used for carrying out welding on the transition layer welding joint from the inner side, and a composited layer welding joint is formed. Through reasonable section of the welding method, welding materials and the welding process, the chemical components and structure of the welding joints are controlled, and welding on a composited layer, a transition layer and a base layer are carried out respectively, so that efficient and automatic production of SS2205-X65 bi-metal composite pipes is realized.

Owner:XI AN JIAOTONG UNIV

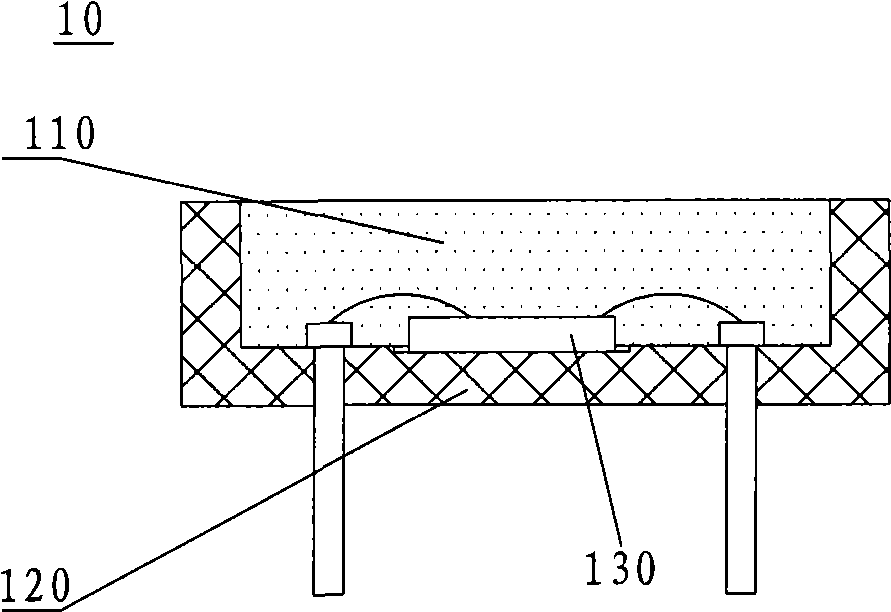

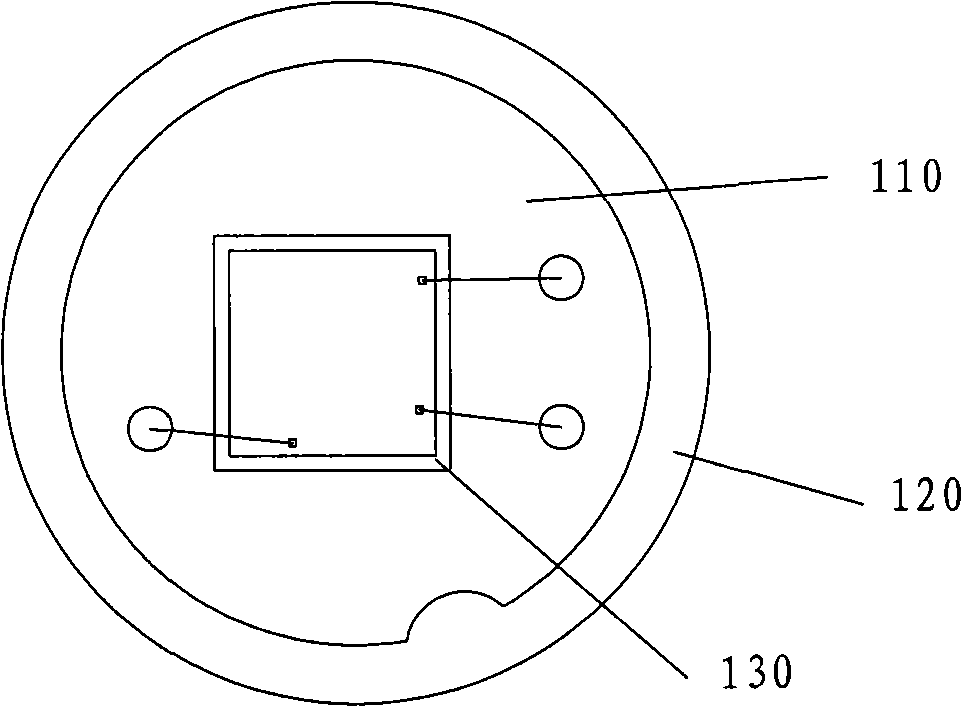

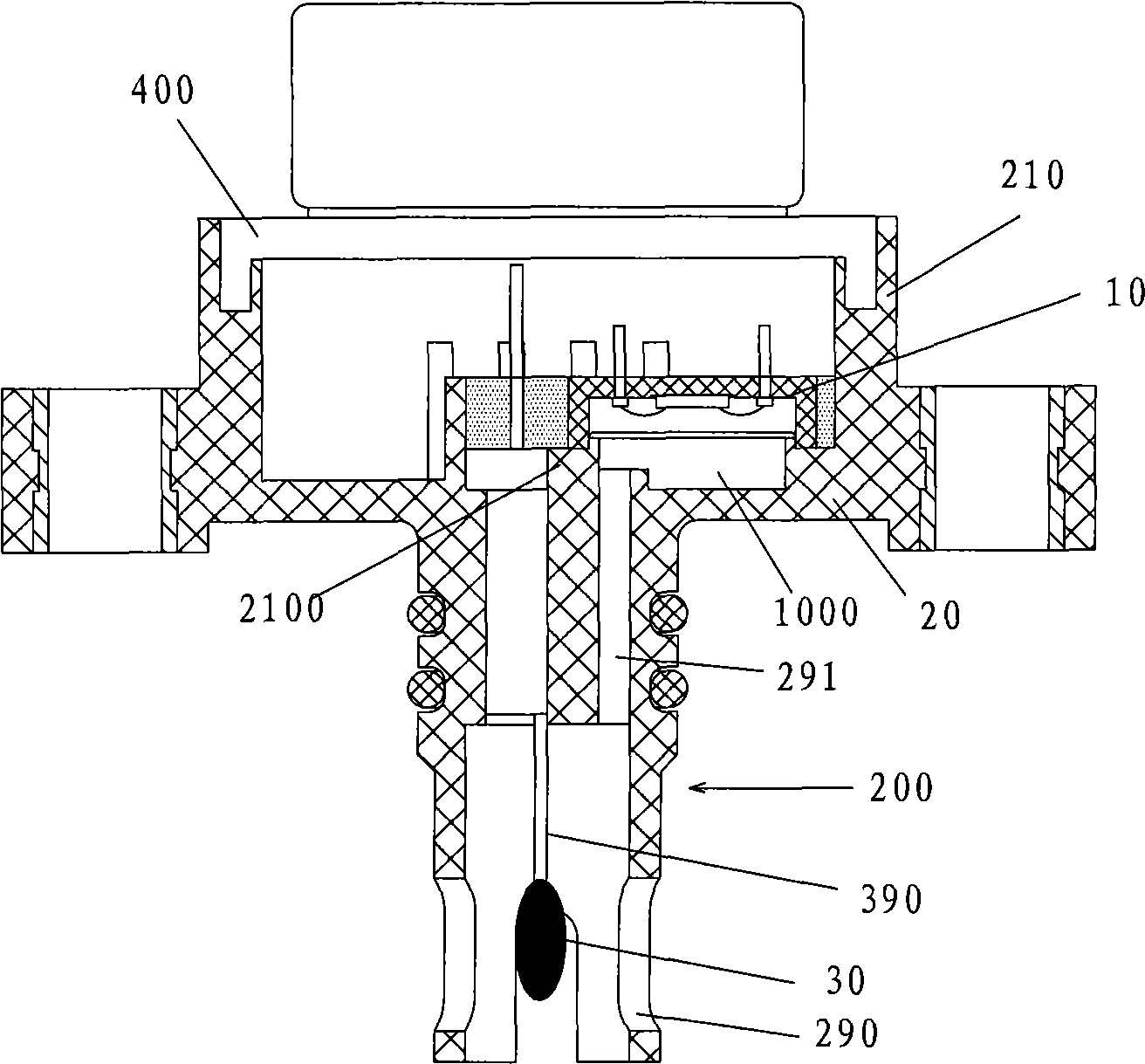

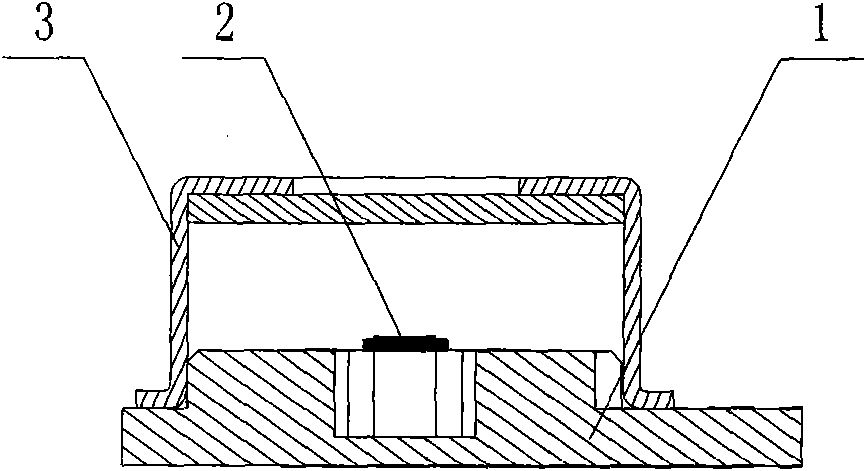

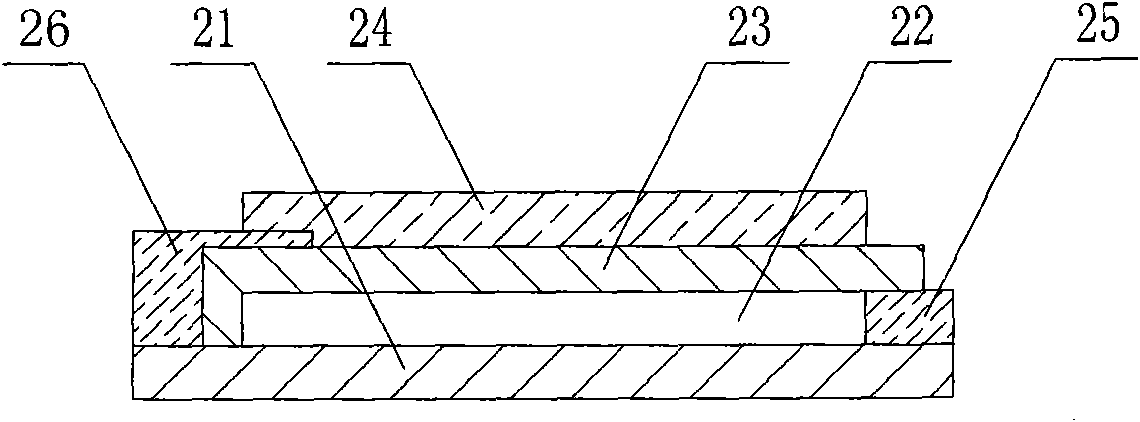

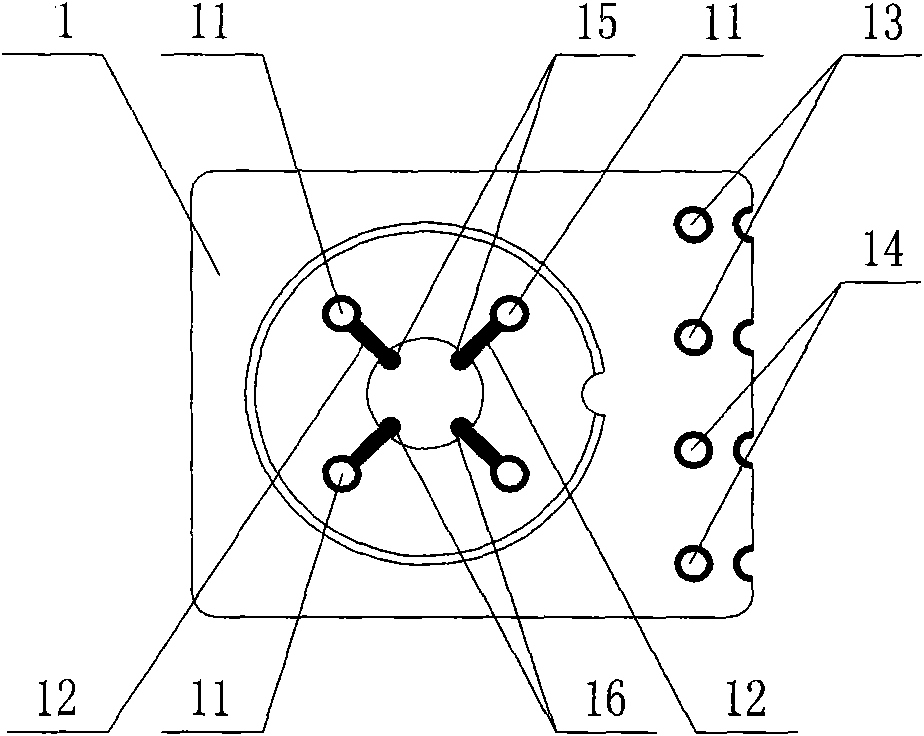

Partially sealed pressure-temperature sensor and its manufacturing process

InactiveCN101498612AEnsure consistencyReduced sealing requirementsThermometer detailsFluid pressure measurementProduction rateEngineering

The invention relates to a pressure temperature sensor which is sealed partially, comprising a pressure module, a temperature module and a shell for supporting the pressure module and the temperature module, wherein the pressure module comprises a baseplate, a chip for detecting air pressure and gel for covering the chip; the baseplate has a shape of a bowl; the chip is arranged in the bowl-shaped core space of the baseplate; and the holding part and the joining part of the shell are isolated in a sealing way. The pressure temperature sensor with the pressure module can enhance the reliability of the embedding and the sealing of gel. The invention can embed gel in a certain quantity and seal local parts of products, thereby being capable of performing supermatic production and enhancing the production efficiency and the performance stability of the products as well.

Owner:SHANGHAI HAIHUA SENSOR

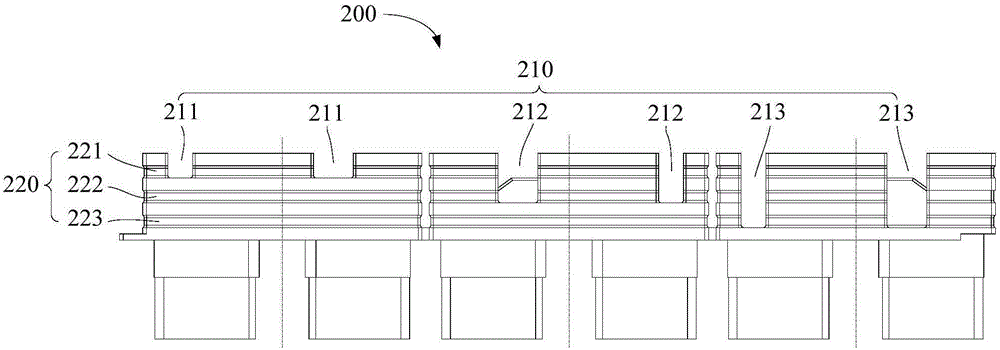

Insulated framework, stator having same and stator assembly method

ActiveCN106160275AThere will be no crossoverAvoid short circuit conditionsMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringElectrical and Electronics engineering

The invention discloses an insulated framework, which comprises a first insulated framework and a second insulated framework arranged at the two ends of a motor stator core respectively. The first insulated framework is provided with at least two line incoming ports / line outgoing ports in the place corresponding to each stator tooth of the stator core; the outer side of the first insulated framework is provided with layered line passing grooves; and the line passing grooves run through the line incoming ports / line outgoing ports. According to the insulated framework, the layered line passing grooves can provide non-crossed winding paths for phase lines, so that the case of intercrossing of the phase lines does not occur, and the case of short circuit between the phase lines can be effectively prevented. The invention also provides a stator having the insulated framework and a stator assembly method.

Owner:GREE ELECTRIC APPLIANCES INC

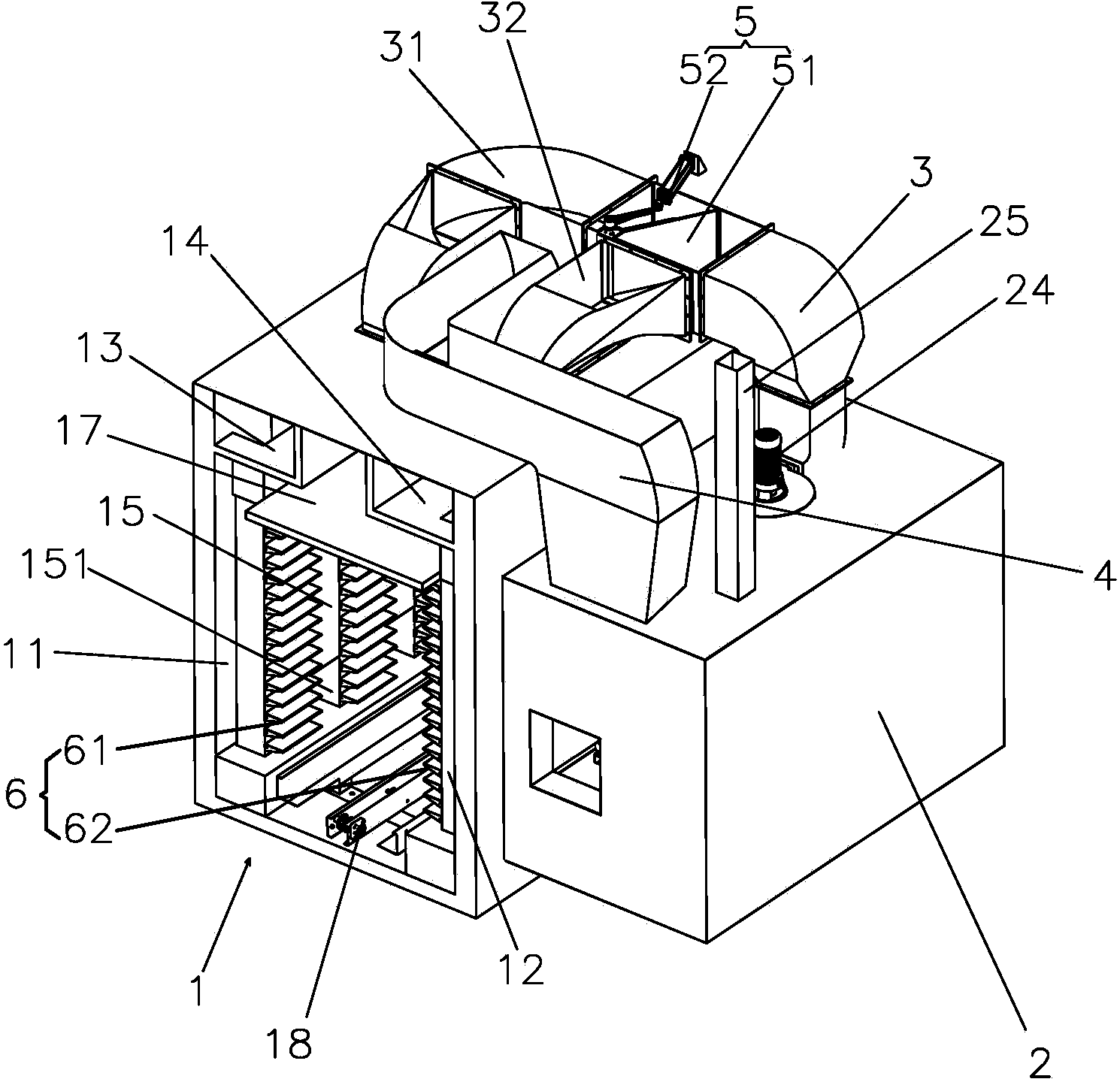

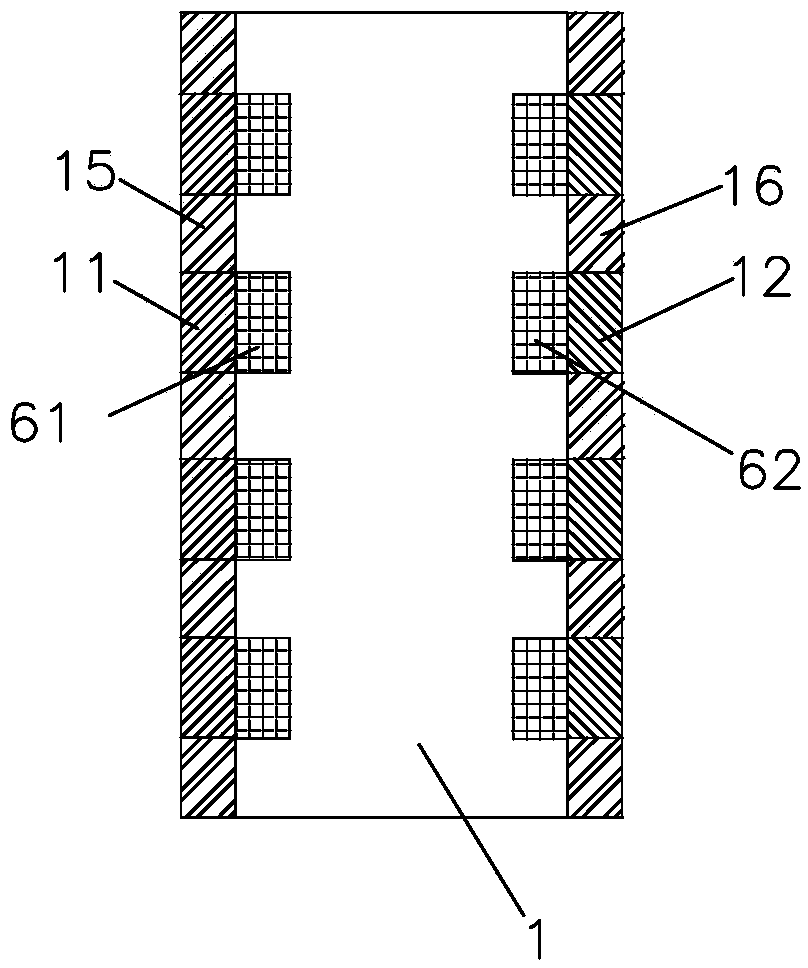

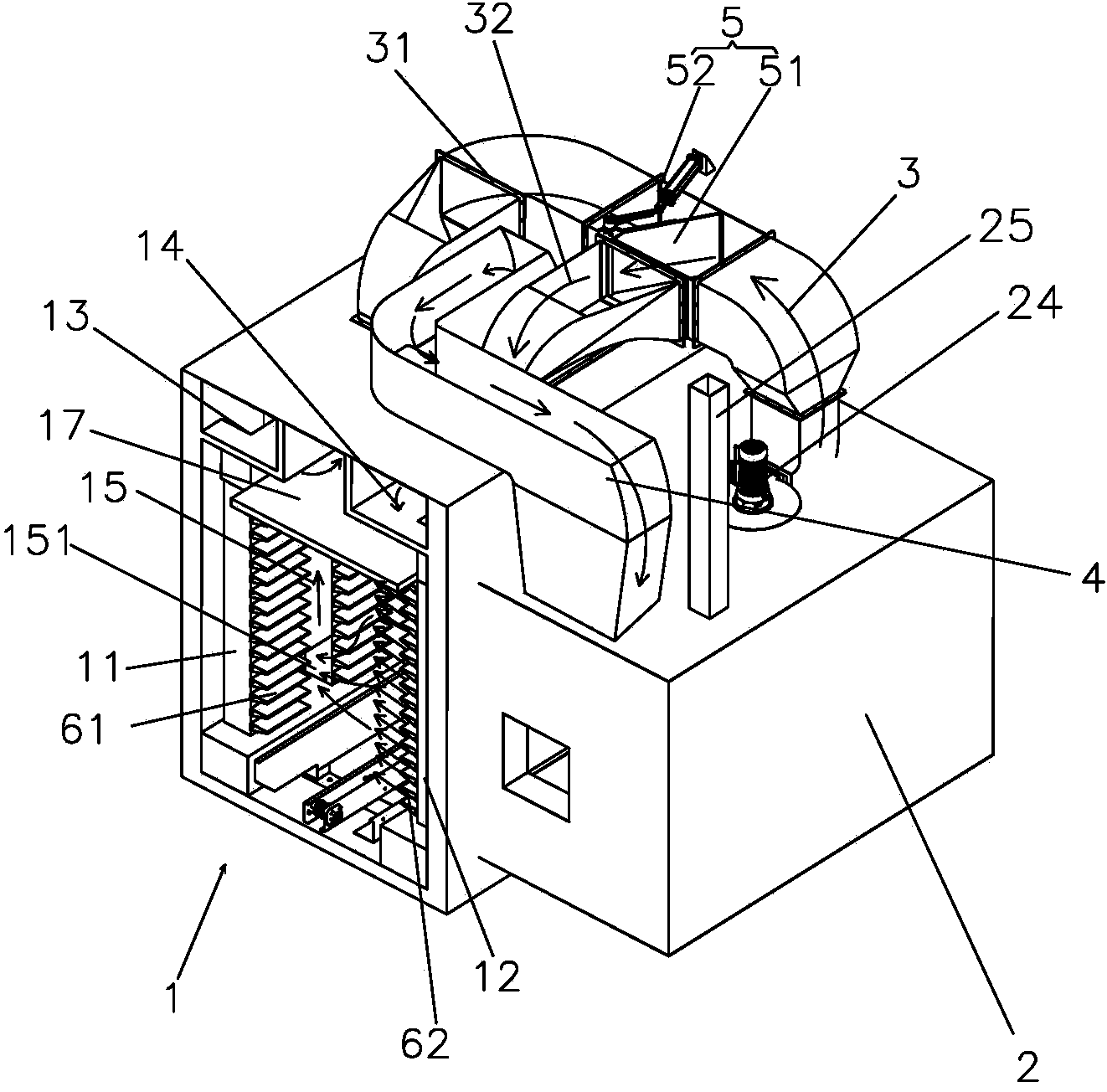

Tunneling-type food baking equipment

ActiveCN104381350ARealize switchingEasy to controlOven air-treatment devicesFood processingCooking & bakingEngineering

The present invention discloses a tunneling-type food baking equipment. In the baking chamber, there set up at least two sets of air outlets located on different side walls and the intake channel is divided into at least two sub-channels which are connected with corresponding air outlets in each group. The hot air flows into the concerted sub-channels from the intake channels through air ducting and into the baking chamber through the connected air outlets. Air outlets in each group are set up in columns and each column has vertically and parallel arranged multiple air outlets. Each air outlet stretches from side wall into the inside of the baking chamber with a gradual decreased interior diameter; at least one baking vehicle is set up in the baking chamber and the baking vehicle has vertically and parallel arranged multiple baking plates. The baking plates and the air outlets are vertically arranged in a dislocation to evenly bake the food on each baking plate.

Owner:DUOLUFA ENVIRONMENTAL PURIFY TECH FUJIAN

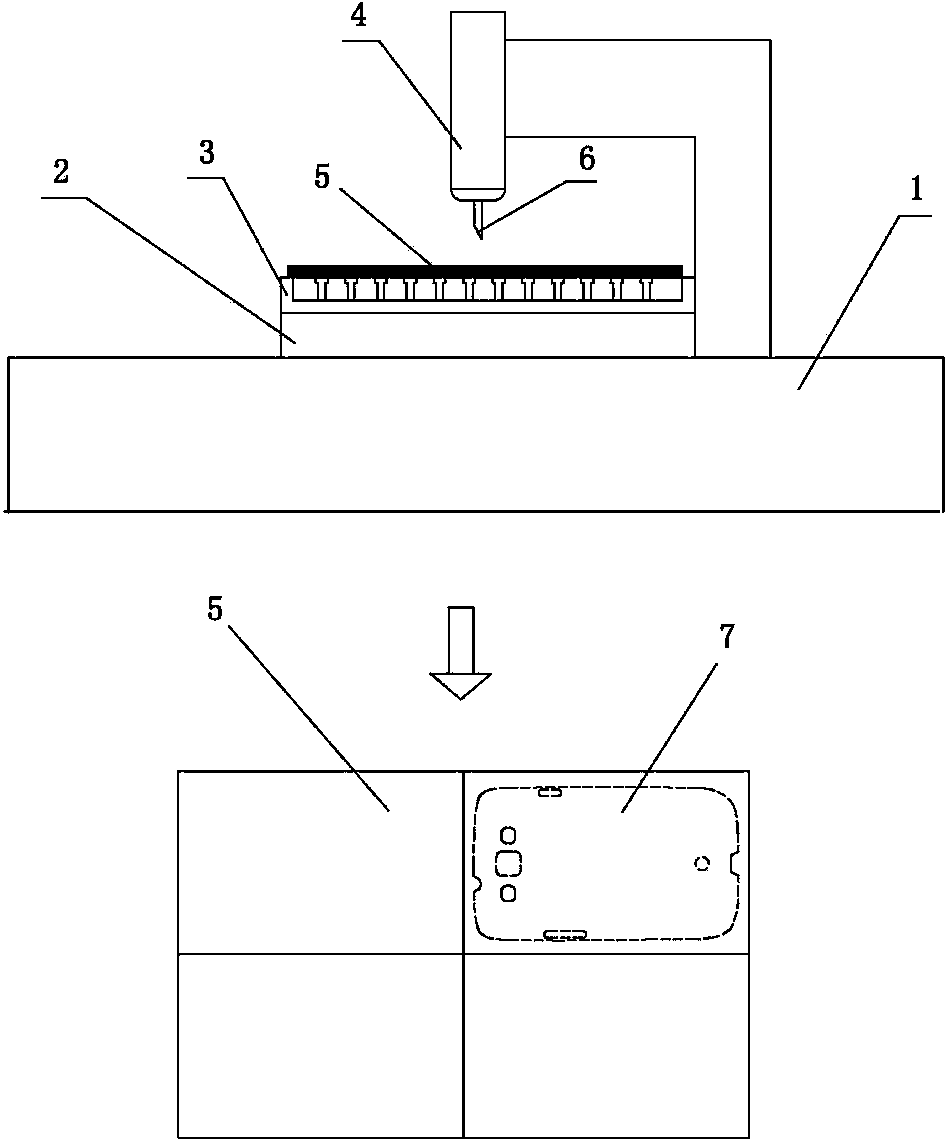

Forming process and special processing device for ultrathin protective cover sleeve

InactiveCN103465424AImprove molding efficiencyReduce material wasteMilling equipment detailsPositioning apparatusProcessing accuracyForm processing

The invention discloses a forming process and a special processing device for an ultrathin protective cover sleeve. The forming process comprises the following steps: 1, preparing a cover sleeve material and a die; 2, preparing a vacuum adsorption jig and installing the vacuum adsorption jig in an adsorption device on a working table; 3, starting the vacuum adsorption device and an engraving and milling electric spindle on the working table to prepare a semifinished sheet metal of the ultrathin protective cover sleeve; 4, carrying out surface processing process on the semifinished sheet metal of the ultrathin protective cover sleeve; and 5, using the die for carrying out pressing forming on the semifinished sheet metal of the ultrathin protective cover sleeve by a hot press so as to obtain the ultrathin protective cover sleeve. The working table of the special processing device is provided with the vacuum adsorption device and the engraving and milling electric spindle. The process disclosed by the invention enables forming efficiency of the ultrathin protective cover sleeve to be high and can be used for single plastic or various composite materials to carry out forming processing of the ultrathin protective cover sleeve; the die and equipment are not required to replace; and the special processing device has high processing accuracy and yield, adopts the simple and convenient process, and is beneficial for implementing high-efficiency automatic production and also for saving labor cost.

Owner:李建勇

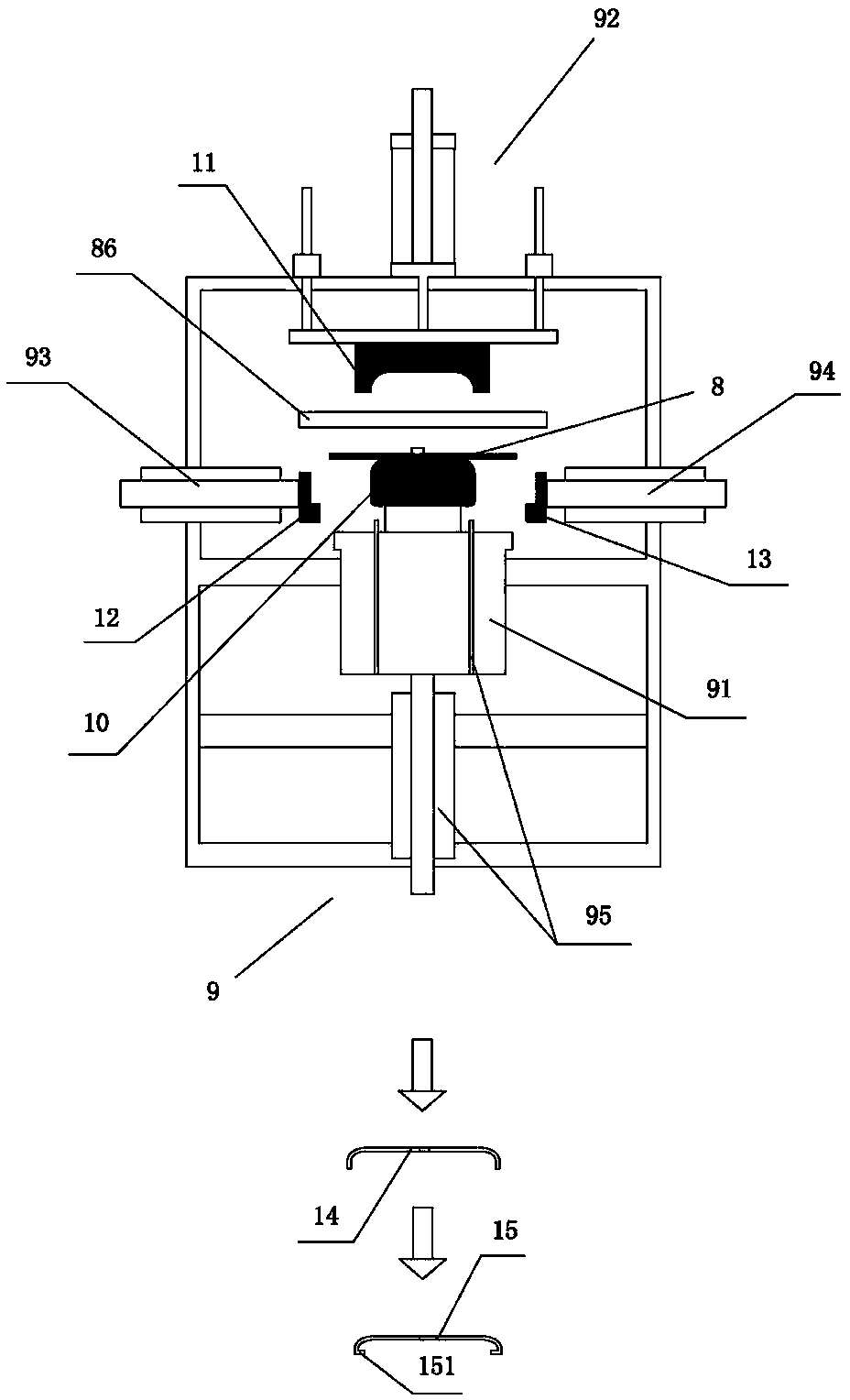

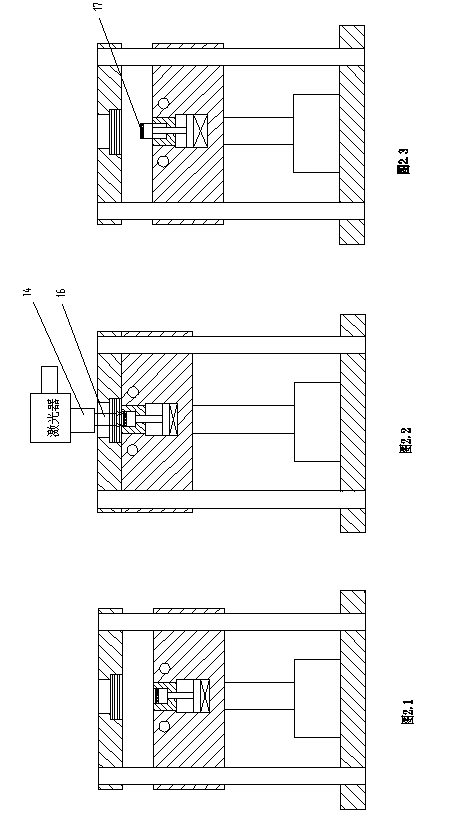

Small plastic part laser melting extrusion molding method and apparatus thereof

The invention discloses a small plastic part laser melting extrusion molding method and an apparatus thereof, relates to the high-precision small plastic part molding processing field, and especially relates to an infrared laser melting and die extrusion molding based small plastic part molding method and an apparatus thereof. Traditional high-precision small plastic parts have the disadvantages of high injection molding processing cost, difficult control of the quality of the an injection part, and severe wastes of plastic raw materials and energy. In the invention, infrared laser rapid heating melting and molding die extrusion molding processing technologies are adopted for the high-precision thermoplastic small plastic part. The small plastic part laser melting extrusion molding method and the apparatus thereof have the advantages of high molding precision, good molding quality, high efficiency and low cost, are suitable for the batch automatic molding processing of high-precision small plastic parts, and have high application values.

Owner:盐城动益汽车配件有限公司

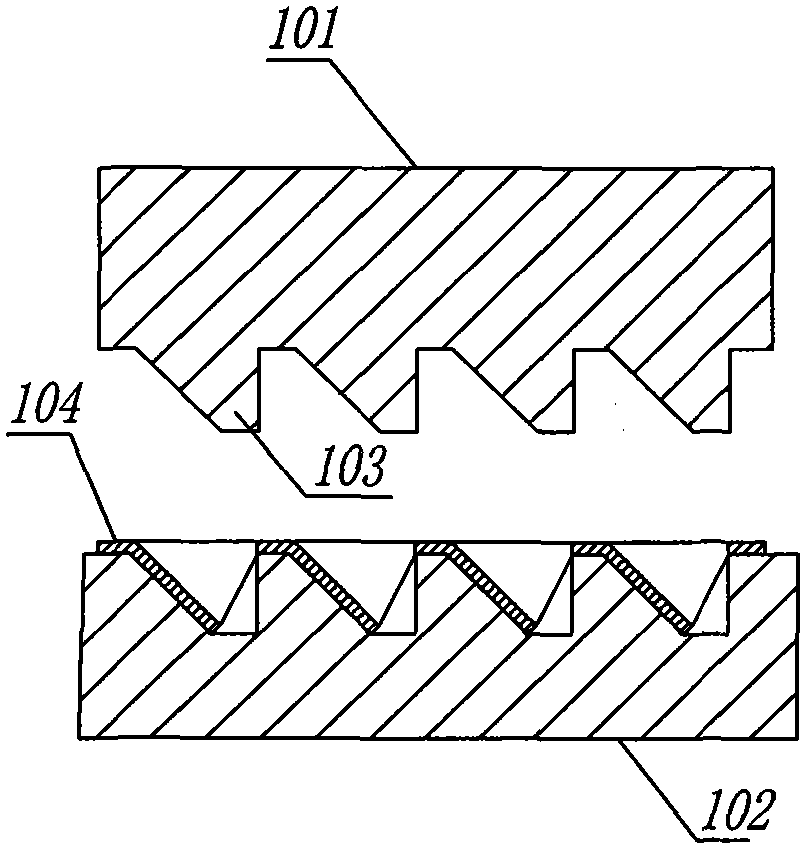

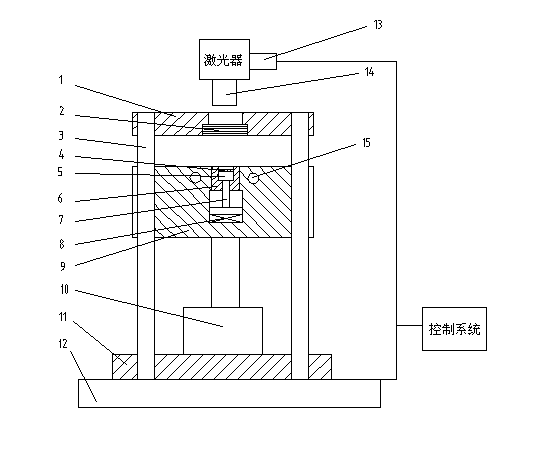

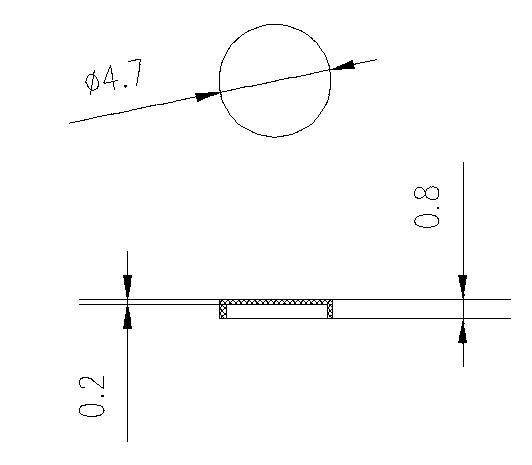

Voice diaphragm pressure bearing piece stamping and laser irradiation composite forming machining device and method thereof

InactiveCN104608185AImprove the heating effectRealize forming processMetal working apparatusPunchingBand shape

The invention relates to a voice diaphragm pressure bearing piece stamping and laser irradiation composite forming machining device and a method of the device. The device is a composite device formed by combining an automatic grading stamping forming die and a laser irradiation heating system. Strip-shaped materials are fed and located under the control of an automatic feeding device. The voice diaphragm pressure bearing piece forming machining process is divided into three continuous automatic grading steps of punching, laser irradiation heating forming and blanking. In a first station, an edge pressing mechanism, a punching male die and a fixed die plate are combined for punching, so that a voice diaphragm pressure bearing piece is punched; in a second station, a forming male die, the fixed die plate and restraint layer glass are combined to acquire a laser irradiation heating forming station, a laser unit works, the strip-shaped materials are irradiated with lasers through the restraint layer glass, the strip-shaped materials are heated and softened through laser irradiation, extrusion of the forming male die is conducted, and therefore the voice diaphragm pressure bearing piece is formed; in a third station, blanking is conducted, the voice diaphragm pressure bearing piece is blanked through a blanking male die. The voice diaphragm pressure bearing piece stamping and laser irradiation composite forming machining device is simple, practical and low in cost, the forming efficiency of the voice diaphragm pressure bearing piece is high, and the forming accuracy of the voice diaphragm pressure bearing piece is good.

Owner:GUANGZHOU YINJIE ELECTROACOUSTIC EQUIP CO LTD

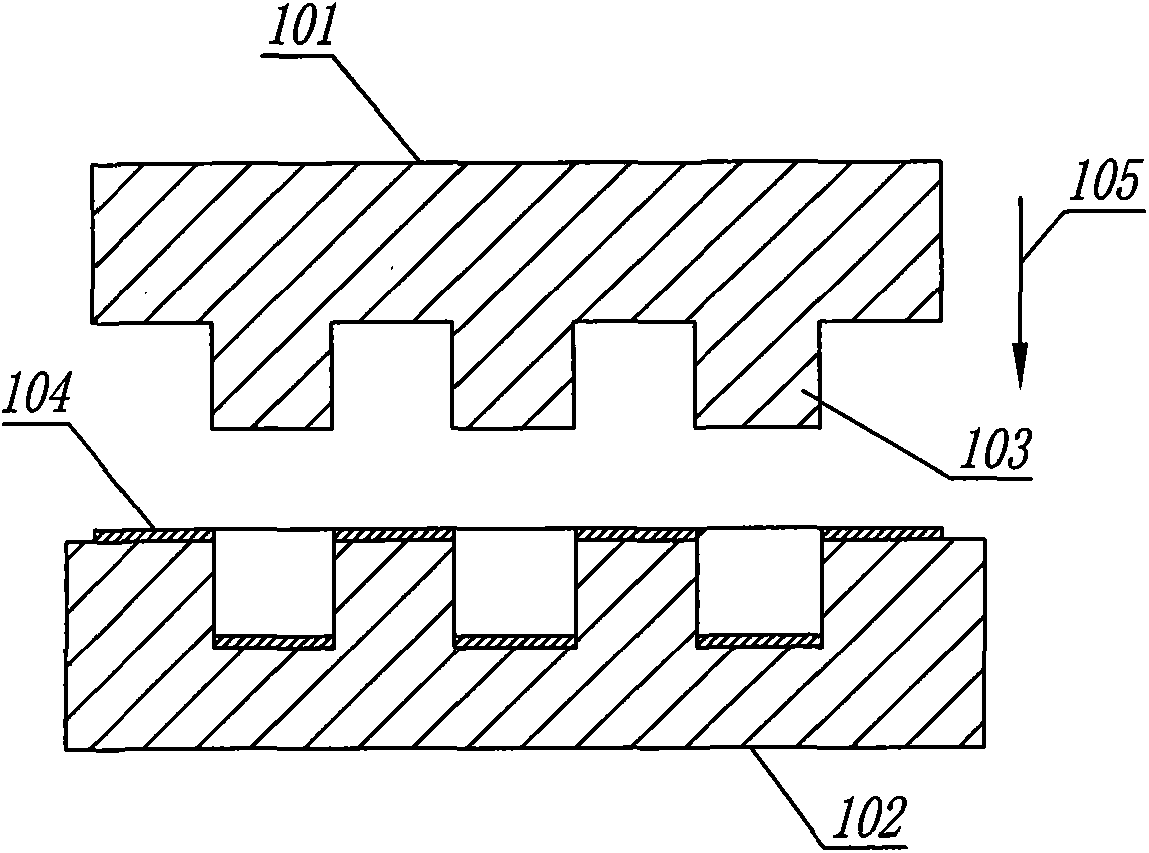

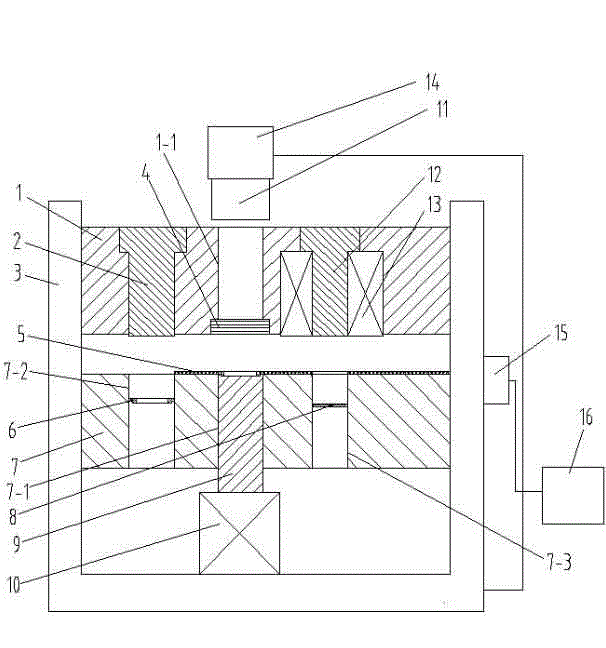

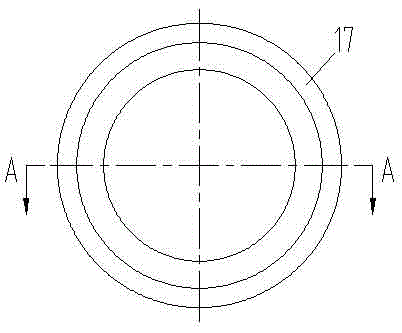

Polymer microfluidic chip microchannel compression moulding forming device and method thereof

ActiveCN104527038AAchieving a physical transformationRealize formingForm processingBiomedical engineering

The invention discloses a polymer microfluidic chip microchannel compression moulding forming device and a method thereof, relates to the field of polymer microfluidic chip forming processing, and particularly relates to a polymer microfluidic chip microchannel compression moulding forming processing method and device which are based on laser transmission heating. According to the polymer microfluidic chip microchannel compression moulding forming device and the method thereof, laser energy field is used for heat source, lasers penetrate a polymer microfluidic chip matrix, a absorbing coating absorbs the lasers, the absorbing coating heats up rapidly after absorbing the laser energy, the absorbing coating with higher temperature heats and melts the surface of the microfluidic chip matrix, a forming template with microstructural embossment is used for extruding the surface of the microfluidic chip matirx, and the polymer microfluidic chip microchannel compression moulding replication forming processing is achieved. The polymer microfluidic chip microchannel compression moulding forming device and the method thereof have the advantages that the operation is simple, the accuracy of replication is good, the efficiency is high and the cost is low. Batch forming processing for polymer microfluidic chips is applicable.

Owner:重庆大茂伟瑞柯车灯有限公司

Automatic folding device for mattress

InactiveCN108584038AImprove automatic processing efficiencyReduce intensityPackagingEngineeringDistance sensors

The invention relates to an automatic folding device for a mattress. The automatic folding device for the mattress disclosed by the invention comprises a conveying mechanism, a folding and turning mechanism and a controller, wherein the conveying mechanism comprises a first support, a conveyor belt, a first motor, a first distance sensor and an encoder; the conveyor belt is arranged on the first support and is driven by the first motor to be rotated; the first distance sensor is arranged at the feeding end of the conveyor belt, and the encoder and the conveyor belt are used for recording a movement distance of the conveyor belt; and the first distance sensor and the encoder are electrically connected with the controller. According to the automatic folding device for the mattress disclosedby the invention, by judging a central point of the mattress, the mattress is folded at the central point of the mattress, so that the automatic processing efficiency is improved.

Owner:台山市宏盛自动化机械有限公司

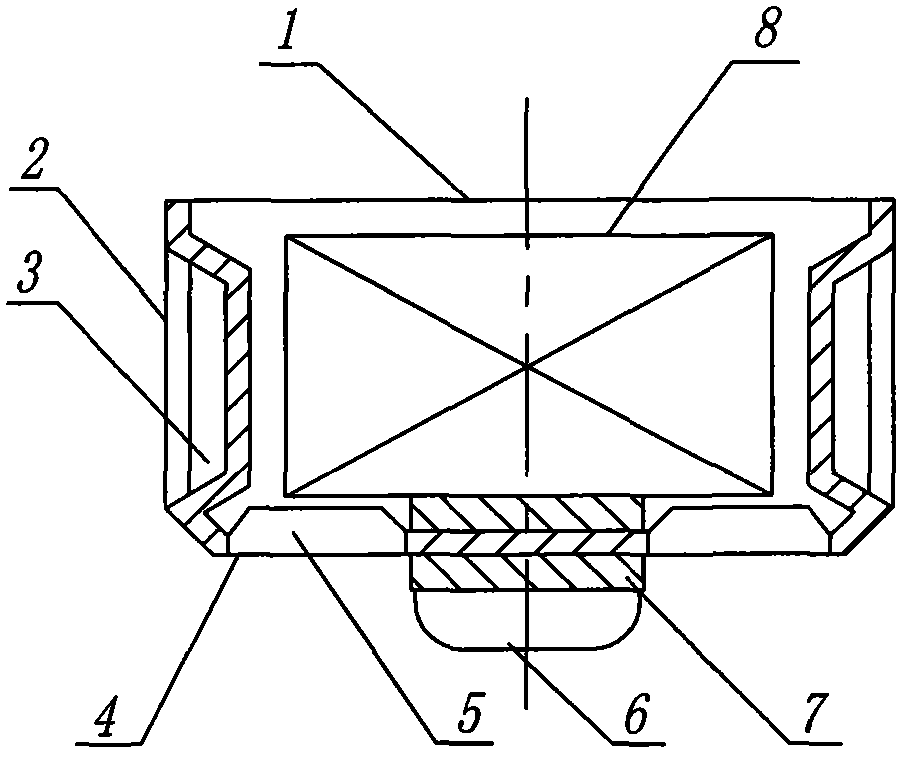

Insulation sleeve suitable for LED spherical bulb and LED spherical bulb structure

InactiveCN105674098ADifficulty of SimplificationImprove securityElectric circuit arrangementsLight fasteningsAgricultural engineeringPipe insulation

The invention provides an insulation sleeve suitable for an LED spherical bulb and an LED spherical bulb structure provided with the insulation sleeve. The insulation sleeve comprises an insulation sleeve body; a fixed clamping groove is formed in the peripheral part of the insulation sleeve body; a wire penetrating hole and a card inserting groove are recessed in the frontal end surface of the insulation sleeve body; a positioning hollow column for penetrating through an L polar lead is arranged at the back end of the insulation sleeve body; and a hollow through hole of the positioning hollow column is communicated with the wire penetrating hole. The insulation sleeve is mounted in the LED spherical bulb structure. The insulation sleeve is mounted and assembled at a high voltage end of a power supply driving circuit board, improves the safety, simplifies the process, reduces the safety difficulty, realizes automatic welding and assembly, and improves the production efficiency.

Owner:唐瑞波

Novel efficient combined additive for zinc electrodeposition

ActiveCN106676578AImprove precipitation qualityHigh cathode current efficiencyPhotography auxillary processesProcess efficiency improvementElectricityEconomic benefits

The invention discloses a novel efficient combined additive for zinc electrodeposition. The novel efficient combined additive for zinc electrodeposition is characterized in that the combined additive comprises 0.05-0.2 g / L of bone glue, 0.01-0.1 g / L of aloe gel, 0.01-0.03 g / L of cetylpyridinium chloride; during usage, bone glue, aloe gel and cetylpyridinium chloride are prepared into a solution; the required additives are molten with hot water and then are fully mixed to the fixed volume. The combined additive provided by the invention is used for the zinc electrodeposition process, has a certain creative and positive significance of solving the detail problems during production, improving the current efficiency and the electrolytic zinc quality, reducing energy consumption of zinc electrodeposition and saving the labor cost and also has the great practical production significance of realizing efficient automatic production of zinc electrodeposition, improving the production of zinc smelting, lowering the production cost, increasing the economic benefits of enterprises and other aspects.

Owner:SHENYANG RES INST OF NONFERROUS METALS

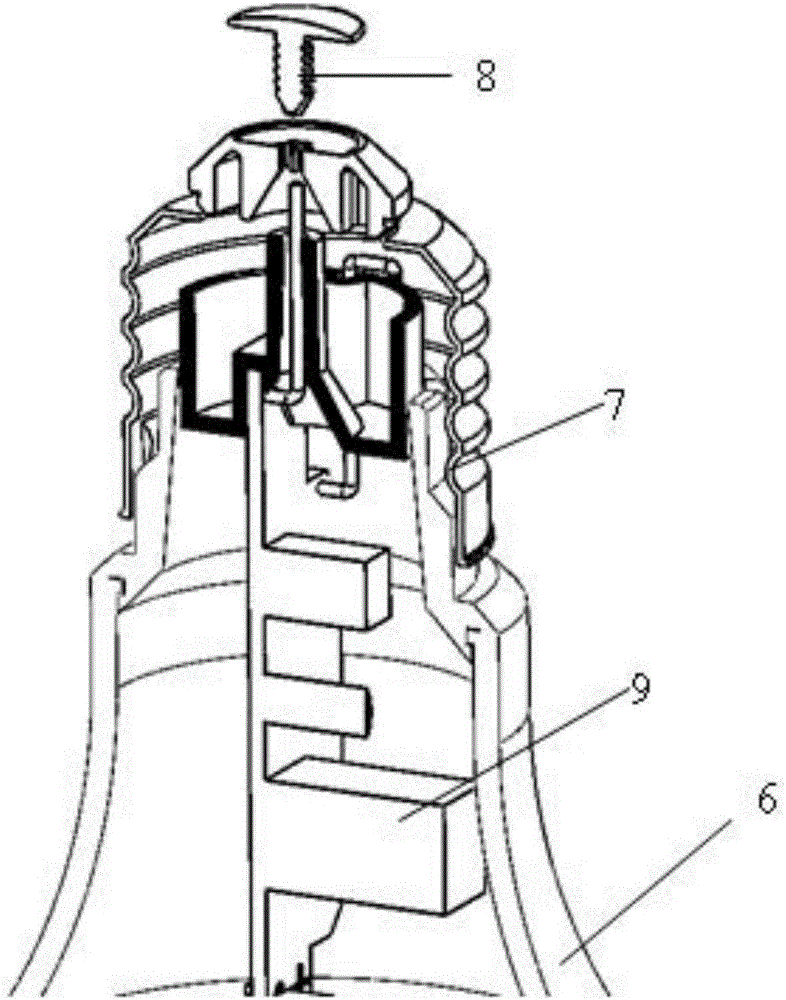

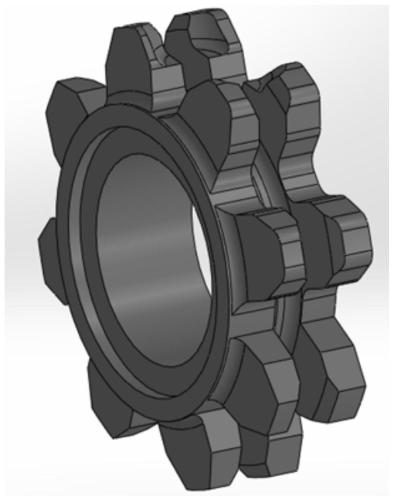

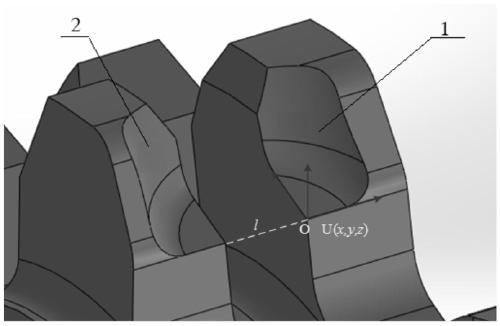

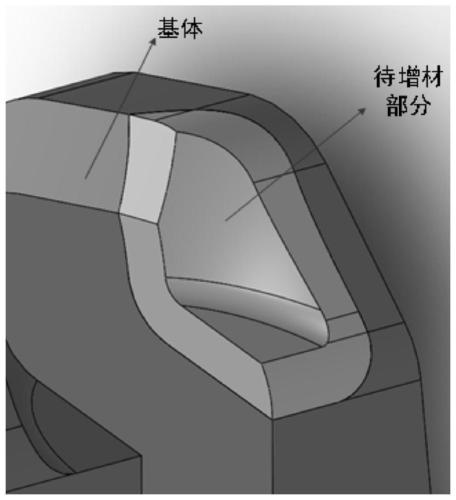

Mining chain wheel chain nest surface automatic surfacing method

ActiveCN111558758ARealize the surfacing processImprove adaptabilityForecastingWelding accessoriesControl engineeringProcess engineering

The invention provides a mining chain wheel chain nest surface automatic surfacing method and relates to the technical field of additive manufacturing. The mining chain wheel chain nest surface automatic surfacing method is provided for solving the problems that an existing chain nest surfacing process is not automated and the welding efficiency is low. The mining chain wheel chain nest surface automatic surfacing method comprises the steps of planning a welding gun traveling path; determining a user coordinate system through a line structured light sensor; obtaining the final transformationalrelation between a pixel coordinate system S and a base coordinate system B according to the transformational relation between the pixel coordinate system S and a camera coordinate system C, the relation between the camera coordinate system C and a tool coordinate system T and the relation between the tool coordinate system T and the base coordinate system B and realizing transformation of the user coordinate system U relative to the base coordinate system B; and conducting coordinate transformation to generate a final surface program. The mining chain wheel chain nest surface automatic surfacing method is used for chain wheel chain nest electric arc surfacing treatment.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

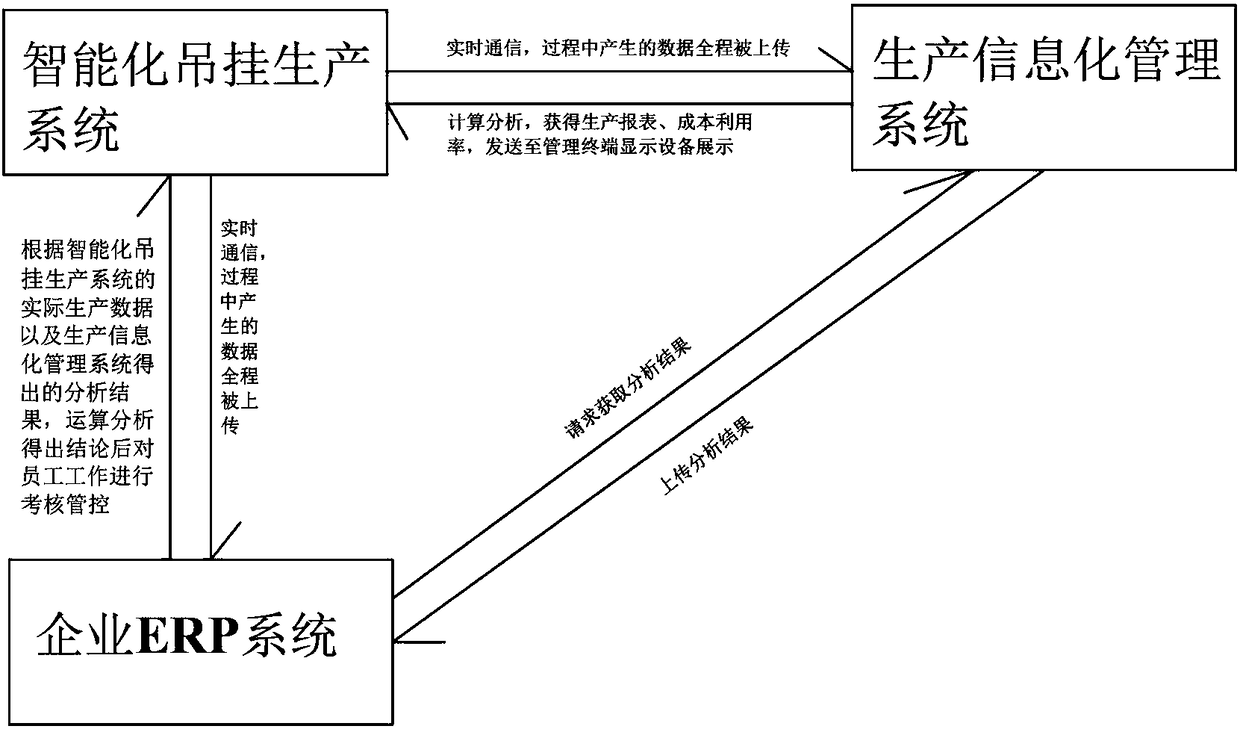

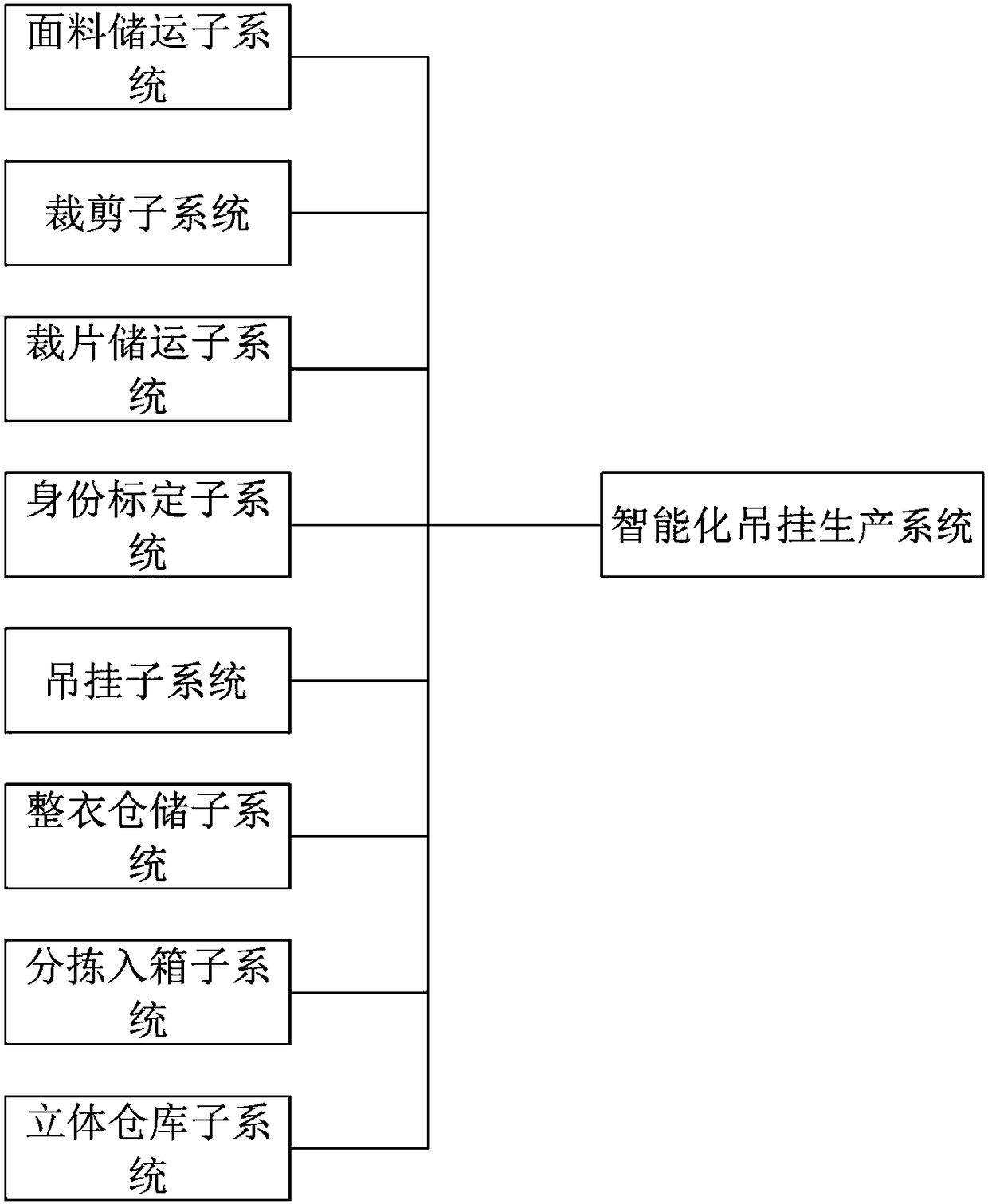

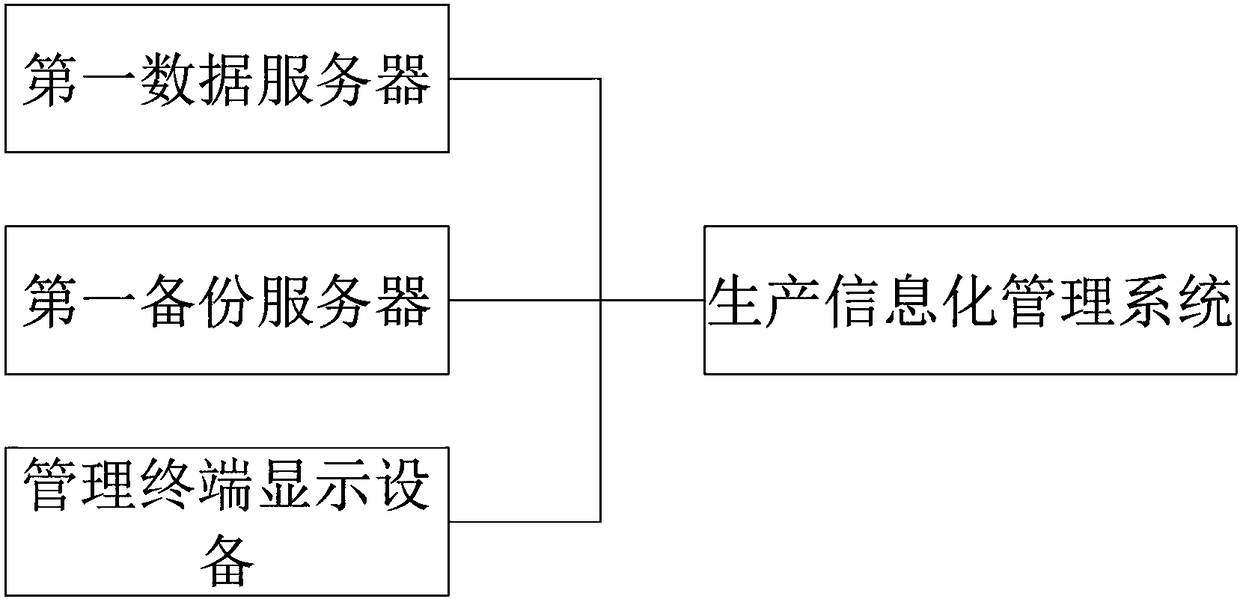

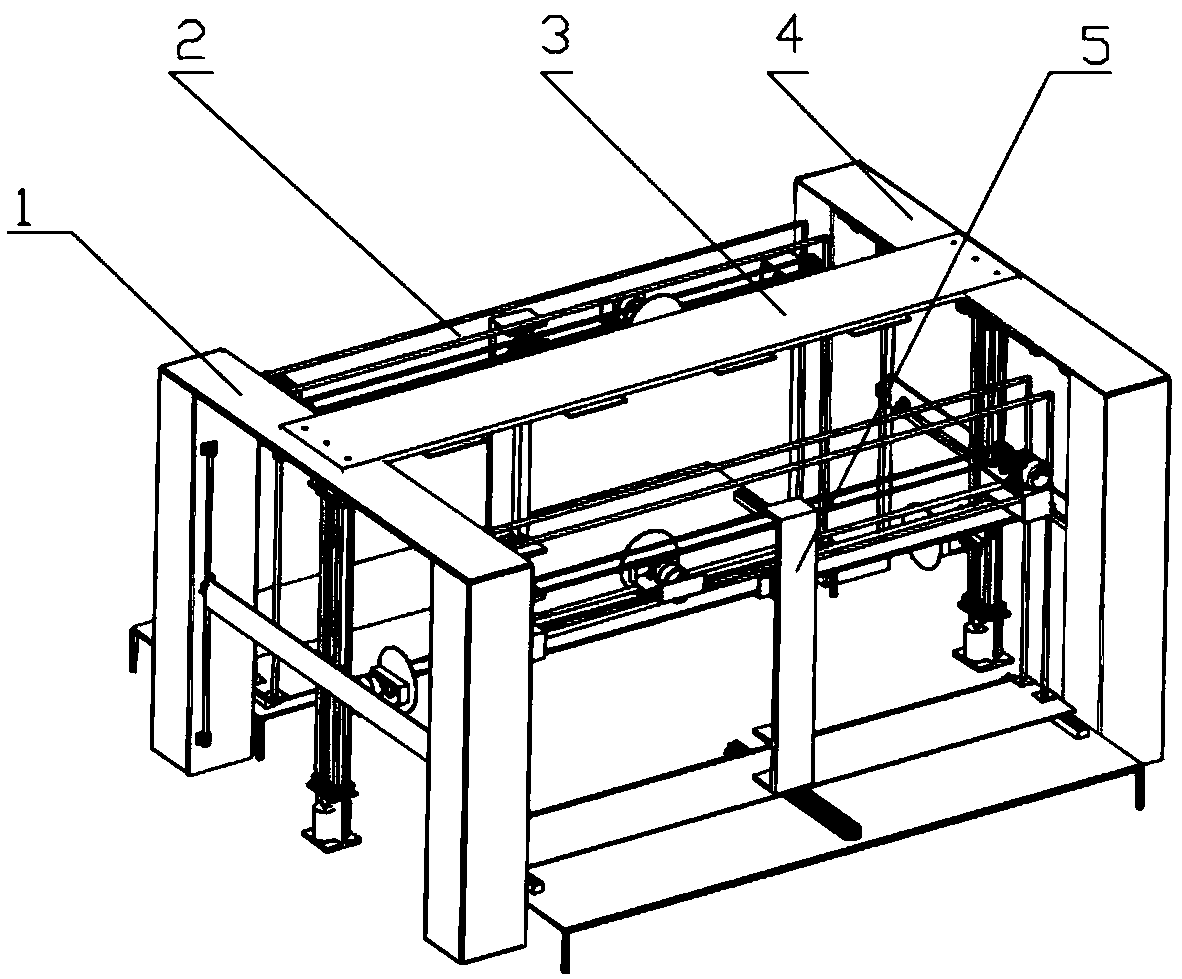

Intelligent control hanging system based on Internet of Things technology

InactiveCN108594773AScientific guidanceScientific controlTotal factory controlProgramme total factory controlInformatizationThe Internet

The invention relates to the field of big data industrialization, and in particular to an intelligent control hanging system based on the Internet of Things technology, comprising an intelligent hanging production system and a production information management system; the intelligent hanging production system is used for assisting high-efficiency industrial production and recording real-time production data based on a transportation device and an identification device; the production information management system includes a first data server, a first backup server and a management terminal display device; the production information management system communicated with the intelligent hanging production system, and is used for the whole process monitoring and tracking of the intelligent hanging production system to obtain real-time production data, performing calculation and analysis to obtain the analysis result and displaying the analysis result on the management terminal display device to assist the production management. The system combines the Internet of Things in the intelligent industrial assembly line mode, facilitates unified scheduling, optimizes resources, matches big data, optimizes production capacity and resources, reduces costs, and maximizes revenue.

Owner:水财

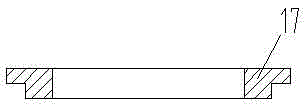

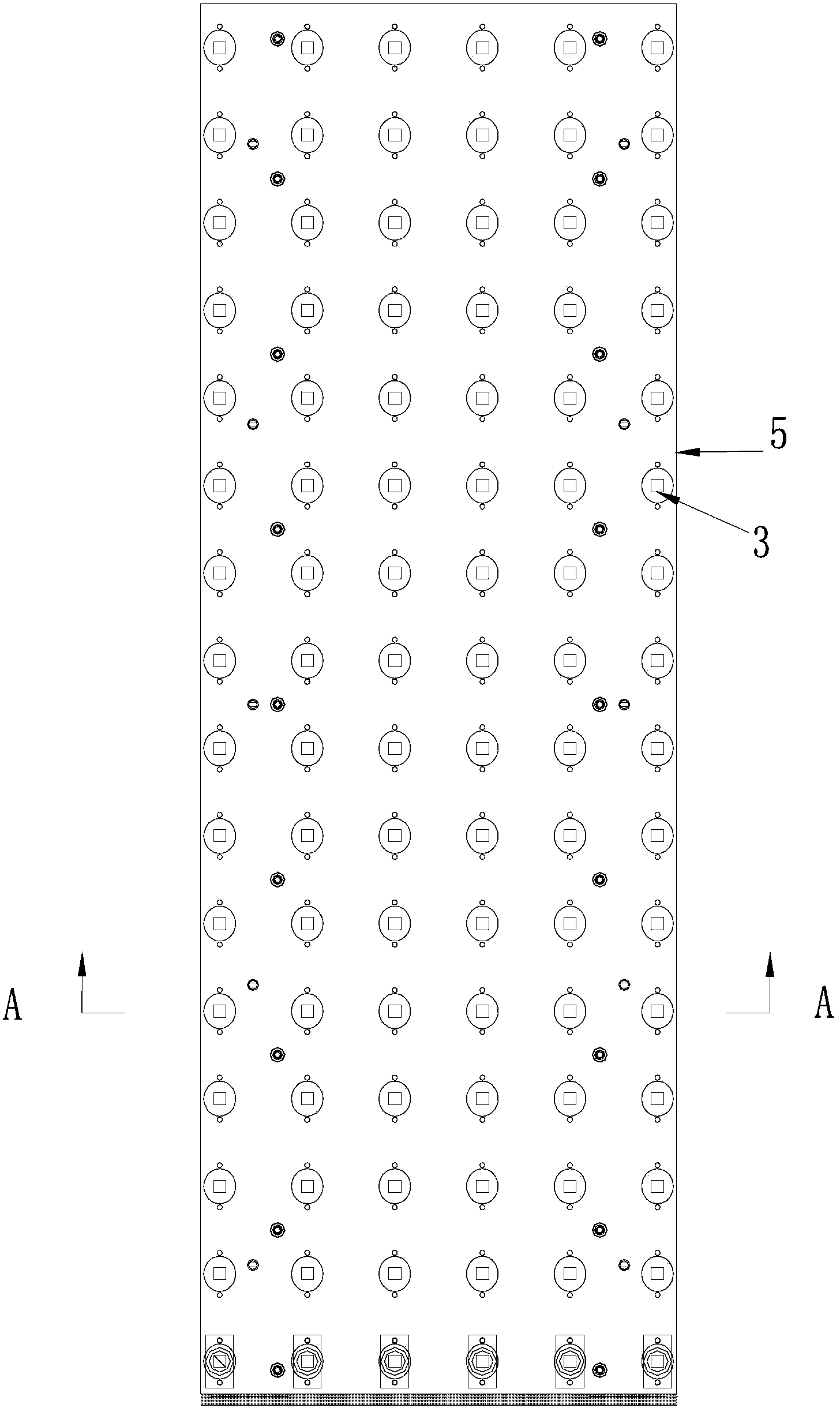

Multi-spindle glass magnesium flat plate edge cutter and edge cutting method

ActiveCN109591199AEfficient automated productionEasy to operateWorking accessoriesStone-like material working toolsCutting glassCircular saw

The invention discloses a multi-spindle glass magnesium flat plate edge cutter and an edge cutting method. The edge cutter comprises a pressing device and edge cutting devices. During edge cutting, multiple to-be-edge-cut glass magnesium flat plates are stacked and put under a pressing part, air cylinder rods of pressing air cylinders of the pressing part stretch out to drive pressing plates to move downwards, and the to-be-edge-cut glass magnesium flat plates are pressed; according to the specifications and dimensions of the to-be-edge-cut glass magnesium flat plates, by means of all-direction feeding movement, circular saw webs are close to the to-be-edge-cut glass magnesium flat plates; and meanwhile main motors are started, and edge cutting is started. Compared with the prior art, whenthe edge cutting devices and the edge cutting method are adopted for machining the glass magnesium plates, firstly, the glass magnesium plates are pressed and then cut, and the machining procedures are simple; the whole machining process is high in production efficiency, and the production cost is reduced while the labor force is saved; and edge cutting is carried out under the multi-spindle effect, the edge cutting precision is high, and the quality of the machined glass magnesium plates is uniform and stable.

Owner:合肥龙智机电科技有限公司

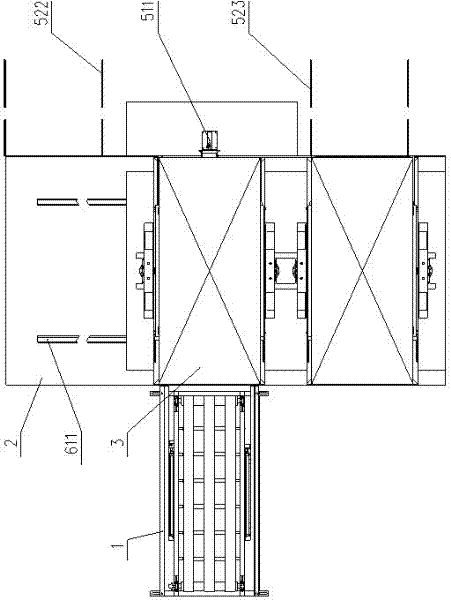

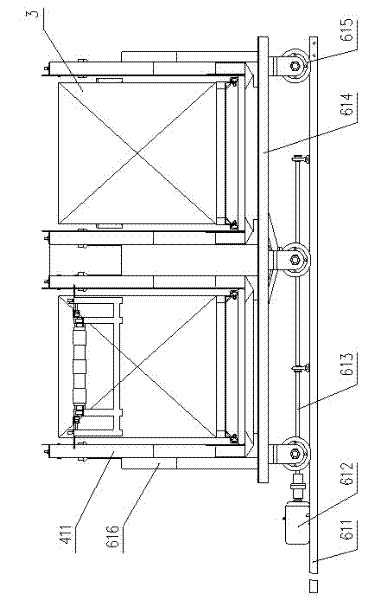

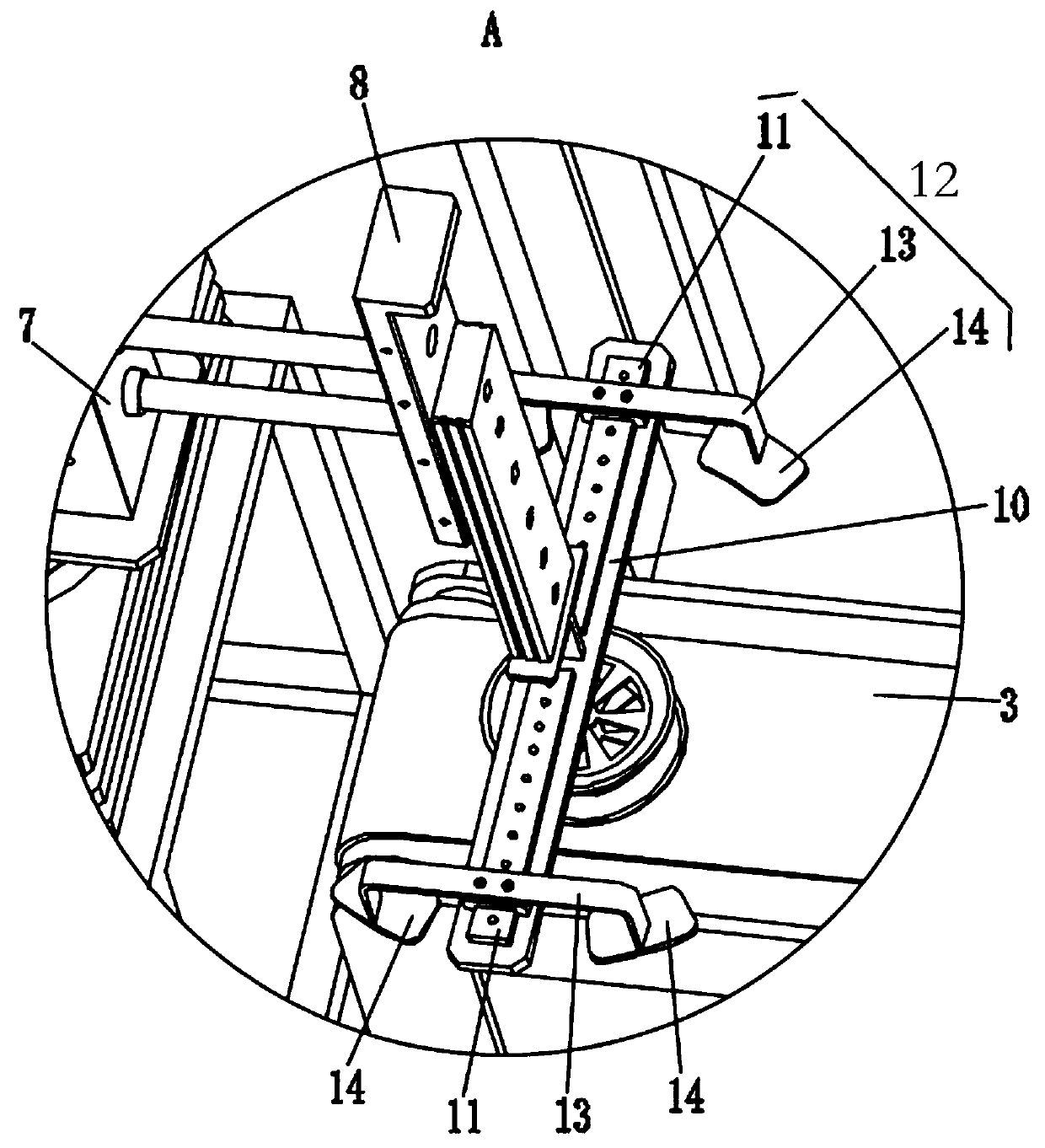

Glass magnesium board demoulding machine and demoulding method

ActiveCN108067560AEfficient automated productionEasy to operateDischarging arrangementStripping-off devicesEngineeringManipulator

The invention provides a glass magnesium board demoulding machine. The glass magnesium board demoulding machine comprises a board drawing assembly, an overturning assembly, a separation assembly, a three-dimensional board frame and a movable trolley. According to the provided glass magnesium board demoulding machine and a provided demoulding method, efficient automation production can be conveniently achieved, operation is simple and convenient, and the production efficiency is greatly improved. The glass magnesium board demoulding machine has the specific beneficial effects that firstly, a dried formed glass magnesium board is drawn out of the three-dimensional board frame without manual operation, the process is replaced with mechanical arms, efficiency is improved, and manpower is saved; secondly, the two mechanical arms are adopted in the board drawing assembly for grabbing the glass magnesium board, and the system reliability is improved; and thirdly, a pressing plate is adopted for pressing the formed glass magnesium board, the tight pressing reliability is improved, and the glass magnesium board is prevented from being damaged by pressing.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing [18f]fallypride with low base concentration

ActiveUS20120178920A1High purityHigh yieldSugar derivativesCarboxylic acid nitrile preparationIon exchangeChemistry

A method for preparing [18F]fallypride is disclosed, which comprises a first step for trapping a fluorine-18 to a polymer ion exchange cartridge; a second step for extraction of fluorine-18 by inputting low base concentrations: 5.0˜25 μL of 40% TBAHCO3 or K2.2.2. / K2CO3 (5˜25 mg / 0.5˜3.0 mg) as a phase-transfer catalyst in a mixture of alcohol / water (1.0 / 0.2 (v / v)) or alcohol as a solvent into the polymer ion exchange cartridge trapped by the fluorine-18; a third step for preparing a [18F]fallypride product by removing the solvent from the trapped fluorine-18, by inputting tosylate precursor in CH3CN as a solvent into a reactor and by reacting the same for 5˜35 minutes at 50˜120° C.; and a fourth step for preparing a pure [18F]fallypride by purifying the prepared [18F]fallypride product.

Owner:SEOUL NAT UNIV R&DB FOUND

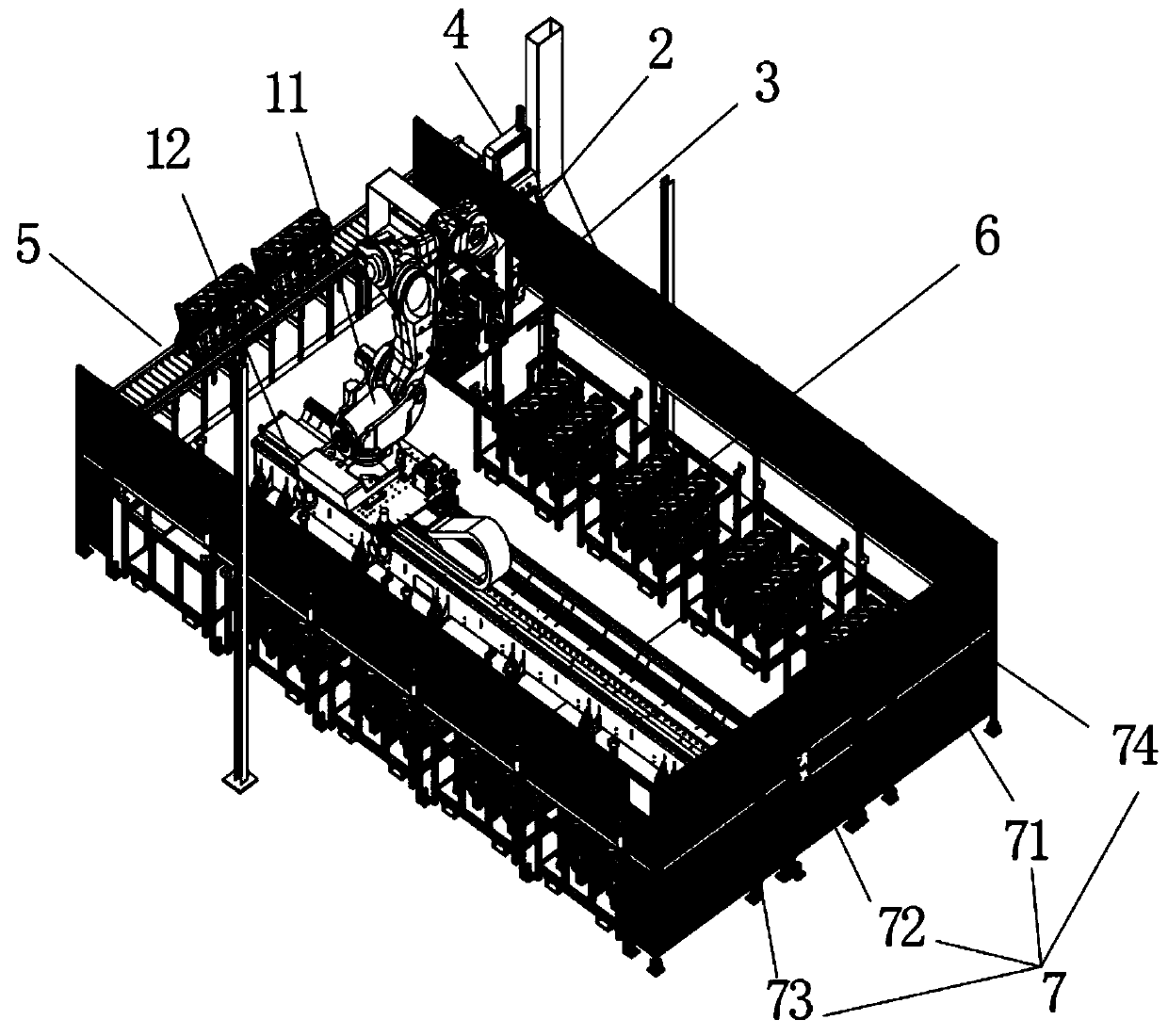

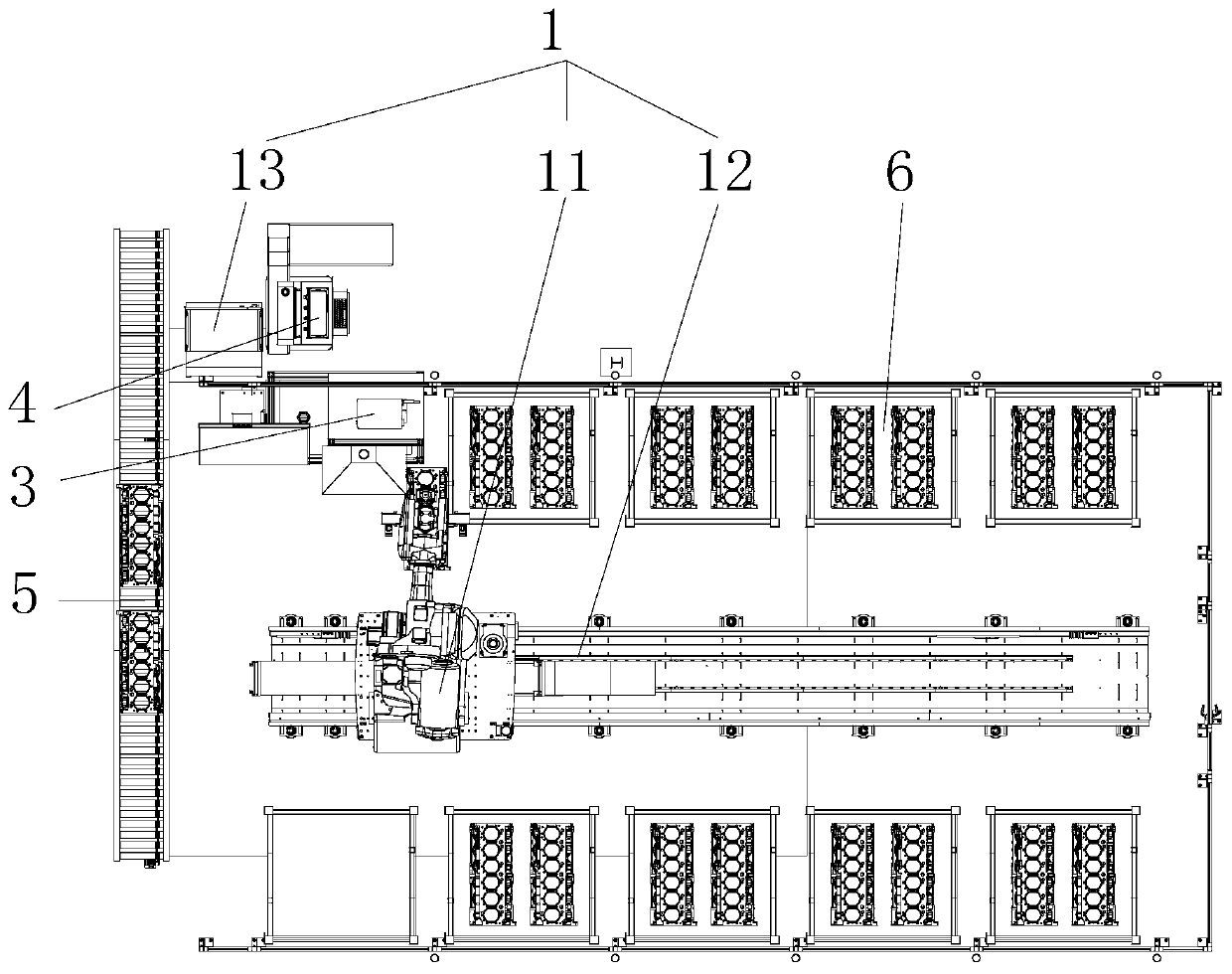

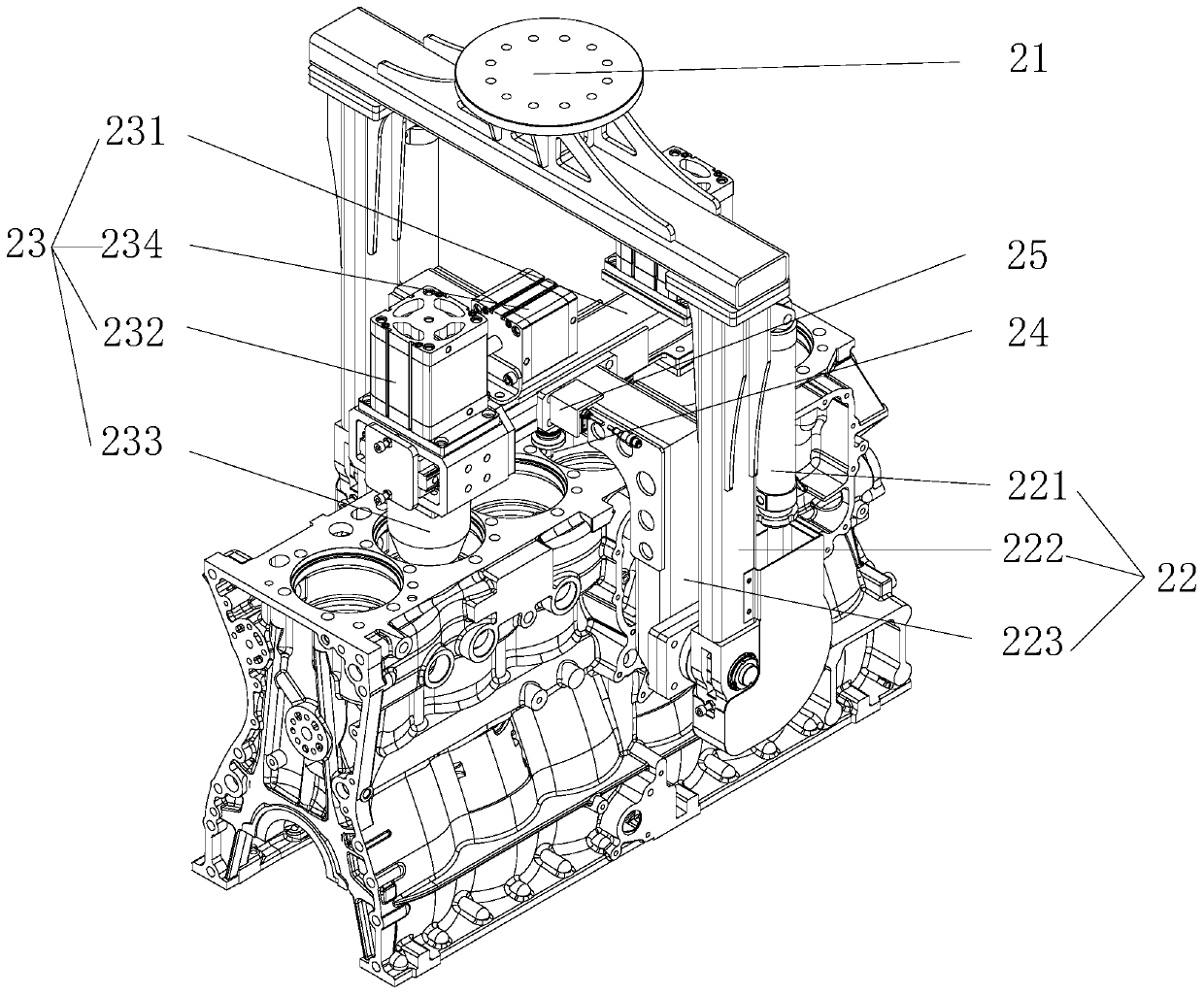

Visual guidance engine cylinder unstacking detection robot equipment and method thereof

PendingCN110877151AEasy to operateIncrease productivityProgramme-controlled manipulatorGripping headsControl systemControl engineering

The invention relates to visual guidance engine cylinder unstacking detection robot equipment and a method thereof. The equipment is provided with a joint robot system, a visual guidance engine cylinder unstacking detection robot end executor, a visual detection marking system, a control system, a conveying system and a stacking station. The equipment is provided with a joint robot system, a visual guidance engine cylinder unstacking detection robot end executor, a visual detection marking system, a control system, a conveying system and a stacking station. The equipment is convenient to operate, time-saving and labor-saving, achieves accurate carrying and automatic detection marking of engine cylinder block production unstacking and stacking, effectively improves the production efficiency, replaces the heavy carrying work of workers in cycles, reduces the ever-increasing labor cost, has very high economic benefit value, and is worthy of application and popularization. The equipment isprovided with a safety protection system, so that the safety of personnel in a workshop is guaranteed, the probability of safety accidents is reduced, and the requirements of modern safety productionare met.

Owner:无锡黎曼机器人科技有限公司

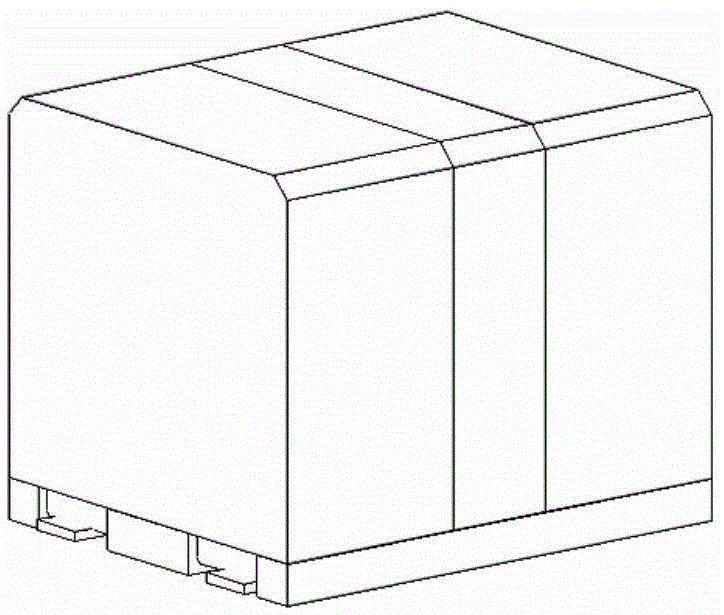

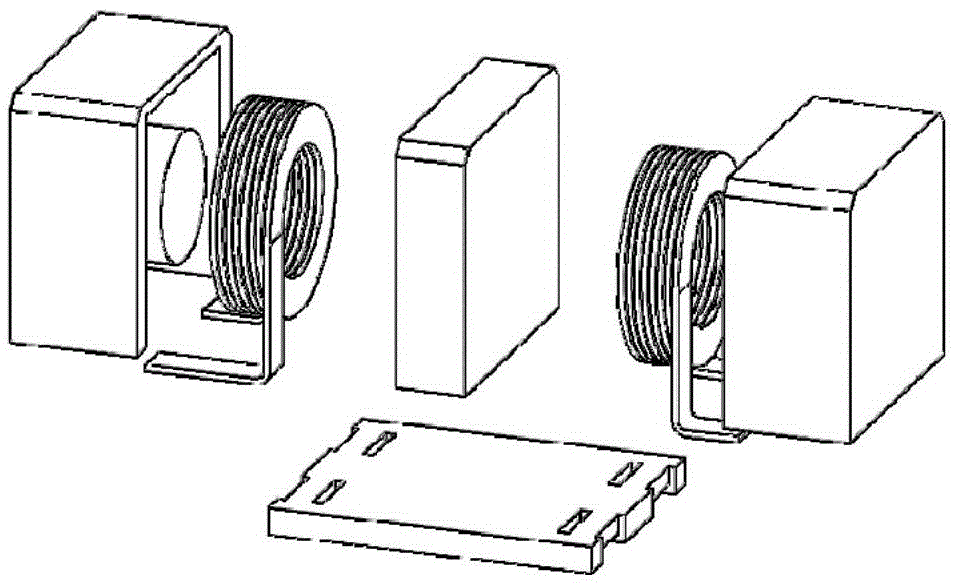

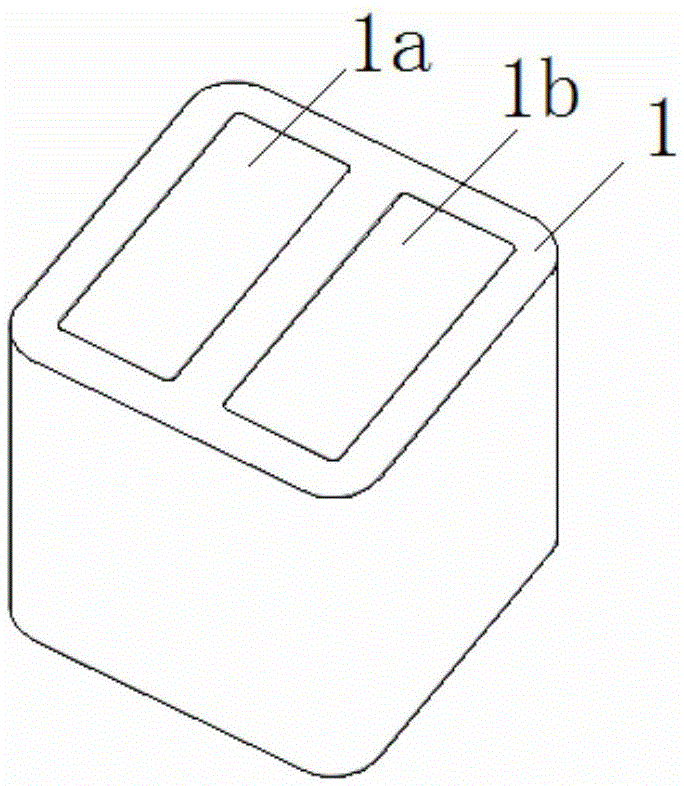

Inductor used for class D power amplifier and manufacturing method of inductor

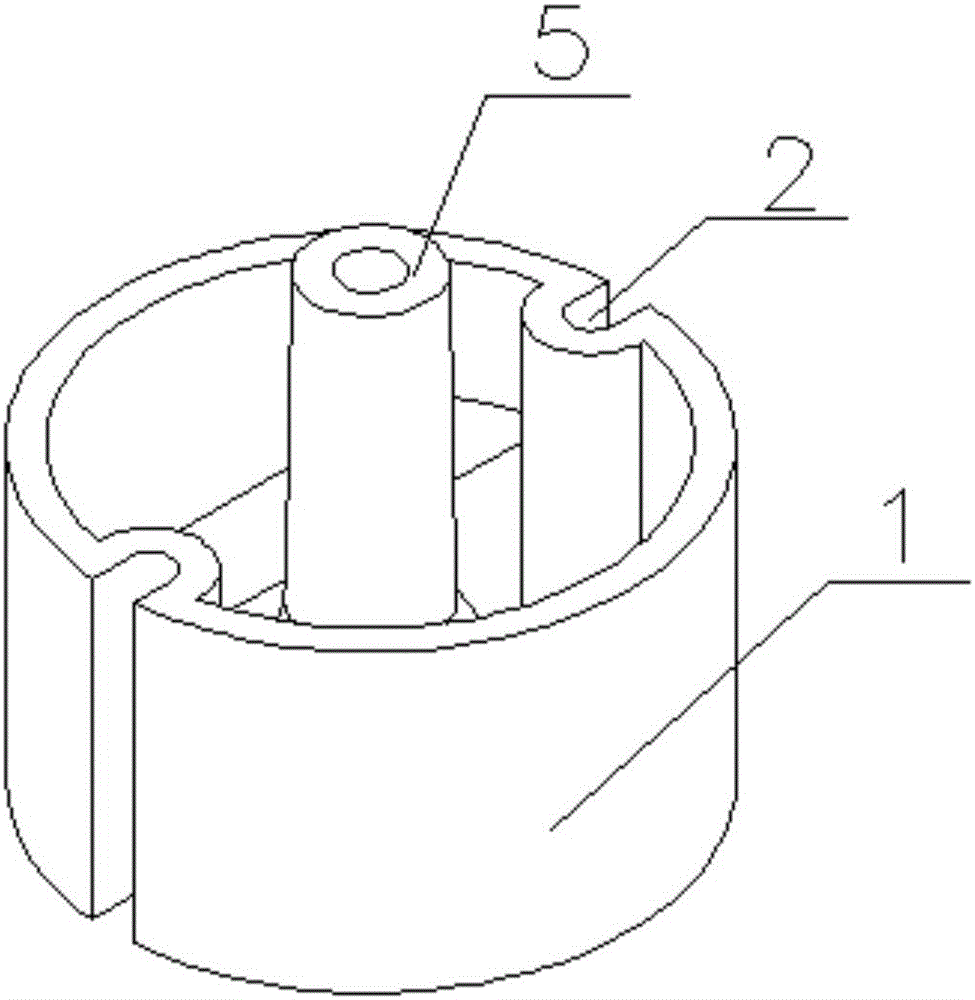

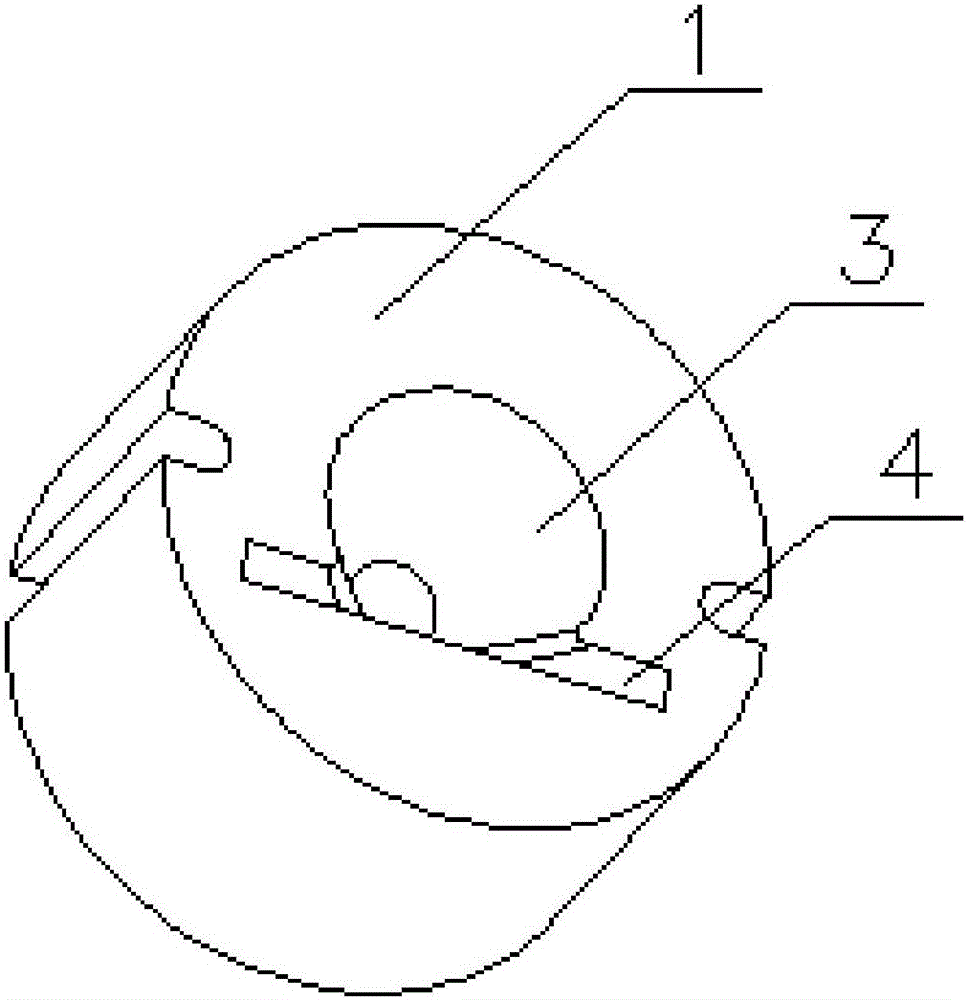

ActiveCN105489342AReduce assemblyShorten the production cycleTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorEngineering

The invention discloses an inductor used for a class D power amplifier. The inductor comprises a cap body magnetic core, two rod magnetic cores, two coil windings and a base. The top face of the cap body magnetic core is closed. An opening is formed in the bottom face of the cap body magnetic core so that two cavities can be formed. The two cavities are separated through a middle wall. The two rod magnetic cores are independent of the cap body magnetic core. The two rod magnetic cores are inserted in the two coil windings respectively and arranged in the two cavities respectively. The bottom face of the cap body magnetic core is sealed by and covered with the base. Terminals of coils are led out of electrode holes in the base. The invention further discloses a manufacturing method of the inductor. By means of the inductor, the production cycle can be effectively shortened, cost is reduced, and efficient and automatic production is achieved.

Owner:SHENZHEN SUNLORD ELECTRONICS

Automatic sand blasting device for automobile hub production

InactiveCN110757348AFacilitate automatic collectionReduce labor intensityAbrasive machine appurtenancesAbrasive blasting machinesSand blastingMotor vehicle part

The invention relates to the technical field of automobile part machining equipment, and provides an automatic sand blasting device for automobile hub production. The automatic sand blasting device comprises a sand blasting machine and a controller. The automatic sand blasting device is characterized in that an automatic feeding mechanism for automatically putting hubs in the sand blasting machineis mounted at the feeding end of the sand blasting machine, a conveyor is arranged on one side of the automatic feeding mechanism, and an automatic discharging mechanism for automatically collectingthe hubs obtained after sand blasting is mounted at the discharging end of the sand blasting machine. Automatic feeding and discharging are achieved, the time is saved, the labor intensity of workersis relieved, meanwhile, the production efficiency is improved, and efficient automatic production is facilitated.

Owner:CHINA THREE GORGES UNIV

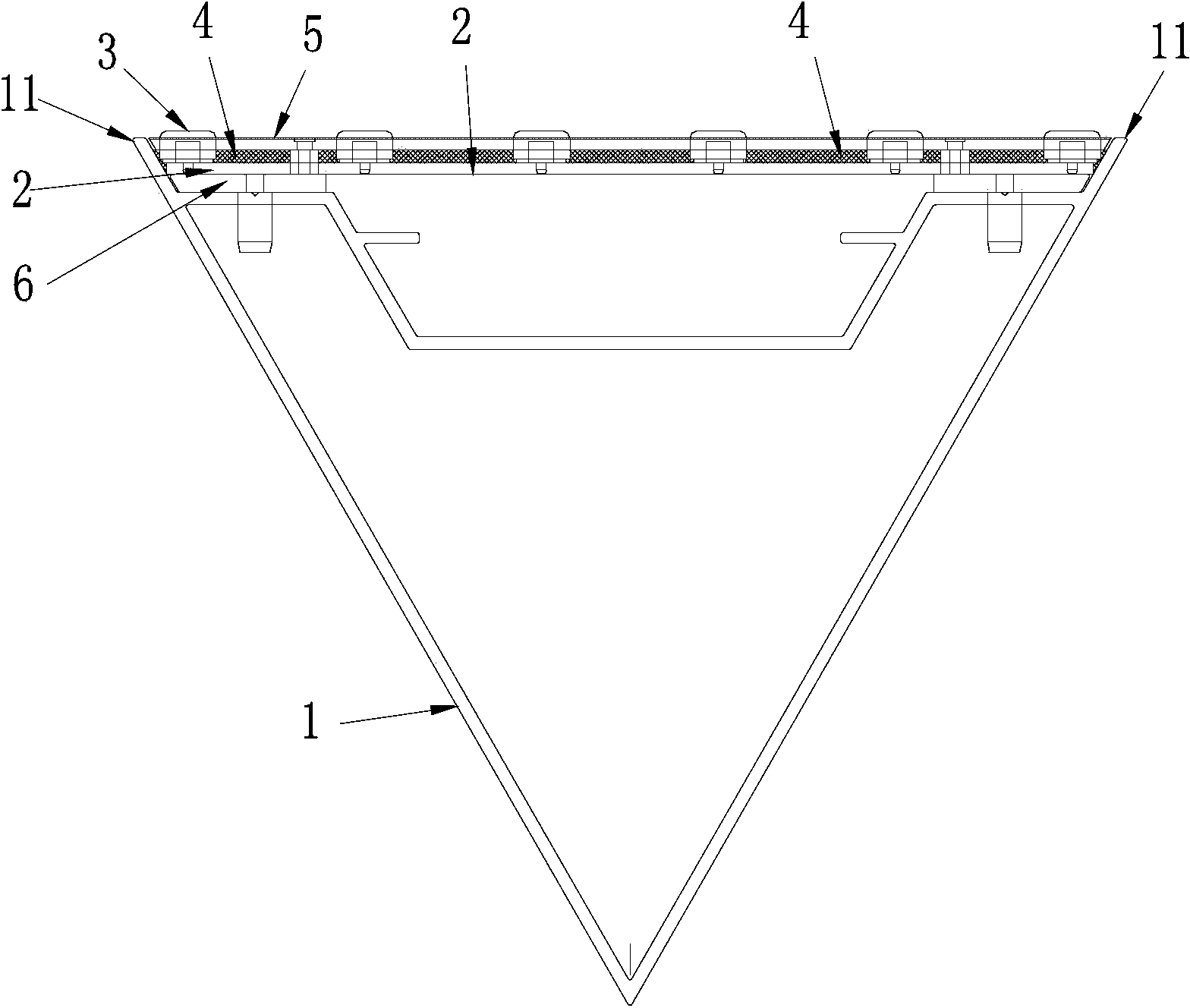

LED two-sided overturning advertisement board structure

ActiveCN102750883BEliminate the problem of leakageImprove reliabilityIdentification meansEngineeringLight head

The invention relates to an LED two-sided overturning advertisement board structure which comprises a triangular prism two-sided aluminum profile and a PCB (Printed Circuit Board) arranged on one side face of the two-sided aluminum profile from bottom to top, wherein a plurality of LED lamps are uniformly arranged on the PCB, and a plurality of independent lamp holders for covering respective LED lamps are mutually independently arranged on the PCB; and extension edges are extended from another two intersecting side faces of the two-sided aluminum profile along the opening direction of an included angle, and a sealing layer is filled in a space surrounded by the extension edges, the PCB and the independent lamp holders. In the invention, the independent lamp holders are adopted and the sealing layer is filled in the whole surface, so that uneven illumination is prevented, the problem that the LED advertisement board is soaked by rainwater in outdoor use is effectively eliminated, the quality reliability and the service life of the advertisement board are increased, and the maintenance frequency is reduced. Meanwhile, the filling amount can be accurately controlled, efficient and automatic production is realized, the processing cost is greatly lowered, and the production efficiency is increased.

Owner:SICHUAN SIMOIRE SCI & TECH CO LTD

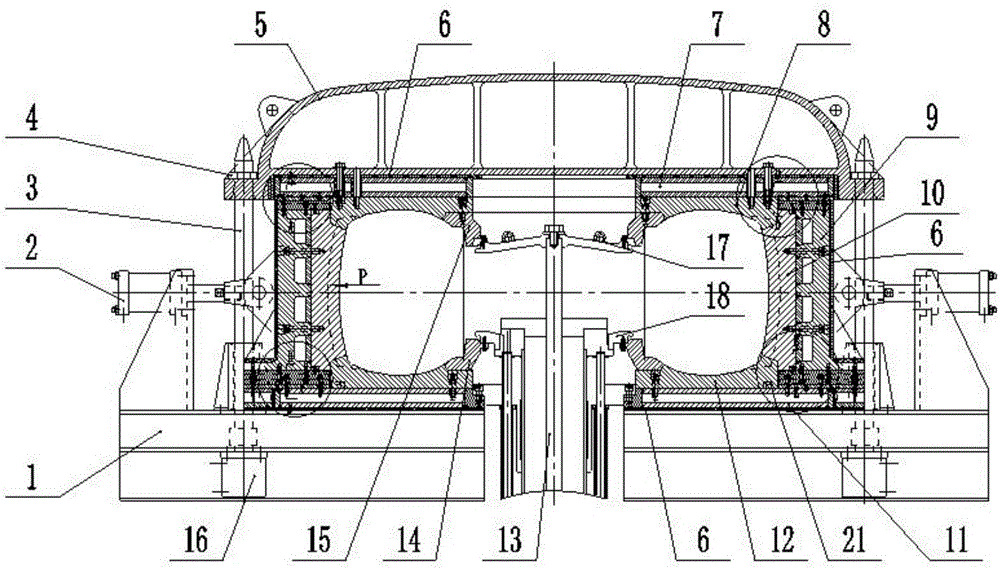

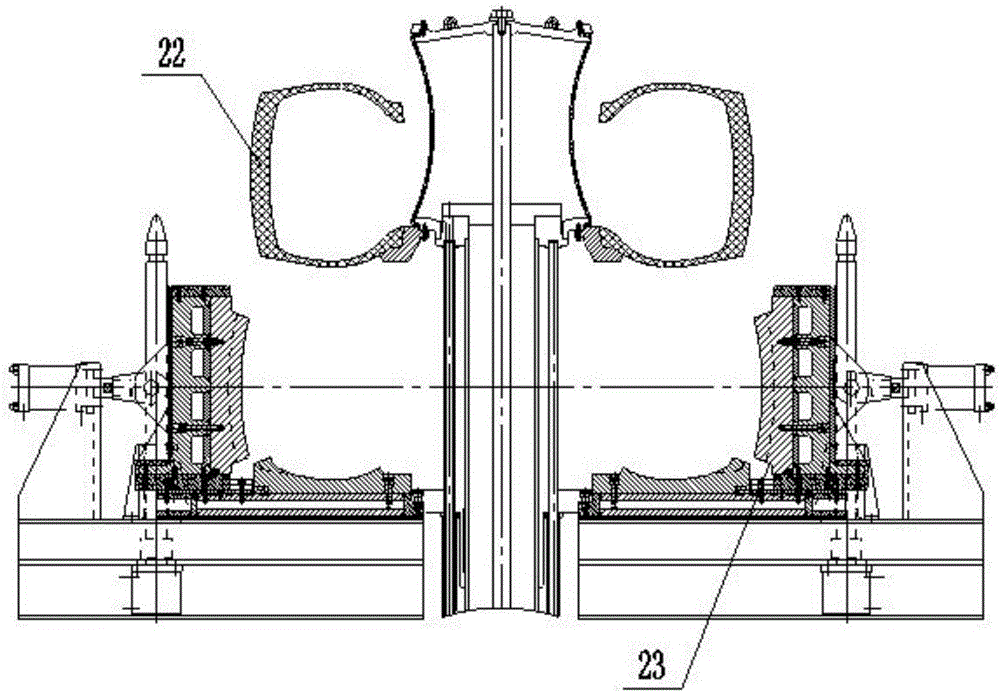

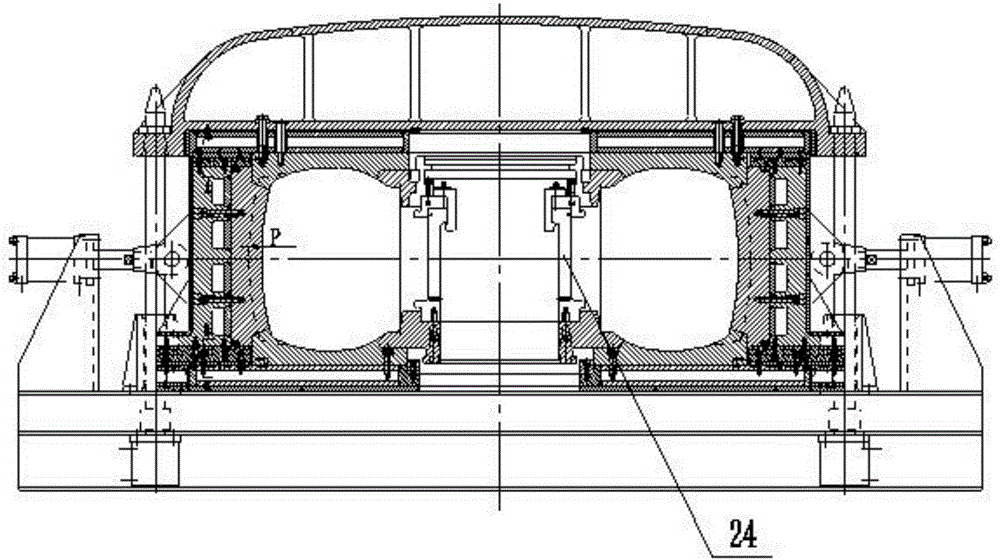

Hot plate type giant tire vulcanizing equipment

The invention discloses hot plate type giant tire vulcanizing equipment and belongs to the technical field of rubber equipment. The hot plate type giant tire vulcanizing equipment comprises a main machine and a giant tire mold. The main machine comprises a vulcanizing cavity and a base. The giant tire mold is installed in the vulcanizing cavity and comprises a plurality of pattern blocks. A sliding block is arranged on the back face of each pattern block. A pattern block mold opening-closing driving device is arranged in the position, corresponding to each sliding block, of the outer side of the base. The problems that mold opening-closing equipment of giant tire vulcanizing equipment is huge in size and complex in structure are solved, the vulcanizing heating mode is further improved, installation matching of the mold is improved, and a clamping mechanism is adopted for improving the vulcanizing efficiency.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Leadless ceramic chip type gas sensor

ActiveCN101975796AOutstanding FeaturesHighlight significant progressMaterial analysis by electric/magnetic meansIsolation layerMaterials science

The invention provides a leadless ceramic chip type gas sensor which comprises a ceramic base and a ceramic chip type gas sensitive chip; the gas sensing chip comprises a ceramic substrate, a heating resistor, a heating electrode, an isolation layer, a gas sensing material and a measuring electrode, wherein the ceramic substrate, the heating resistor, the isolation layer and the gas sensing material are sequentially printed together; a through hole and a printing electrode penetrating the through hole are arranged on the ceramic base, a heating electrode printing point and a measuring electrode printing point are arranged on the front surface of the ceramic base, an heating electrode input end and a measuring electrode output end are arranged on the back surface of the ceramic base, and the heating electrode printing point and the measuring electrode printing point are respectively connected with the heating electrode input end and the measuring electrode output end through the printing electrode; and the heating electrode and the measuring electrode are respectively connected on the heating electrode printing point and the measuring electrode printing point. The gas sensor has the advantages of scientific design, stable performance running, high sensitivity and high precision, and is applicable to industrial large-scale production.

Owner:郑州炜盛电子科技有限公司

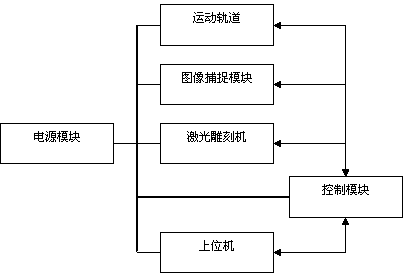

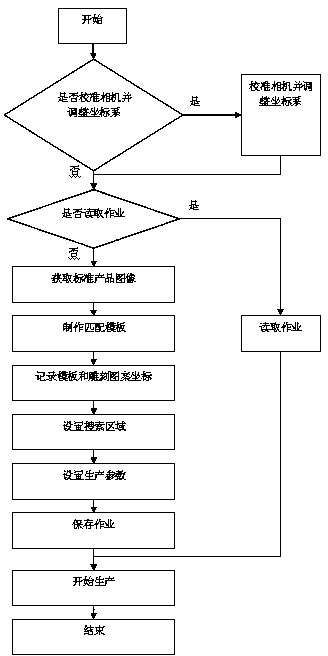

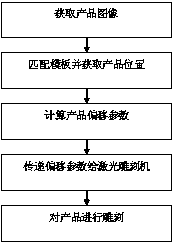

Automatic laser engraving system based on computer vision and service method of automatic laser engraving system

InactiveCN102490523BHigh precisionIncrease productivityModel makingComputer graphics (images)Laser engraving

The invention relates to an automatic laser engraving system based on computer vision and a service method of the automatic laser engraving system. The system comprises a movement track, an image capture module, a laser engraving machine, a control module, an upper computer and a power module. The service method of the automatic laser engraving system includes realizing distortion rectification and adjustment of a coordinate system for the image capture module, adjusting a coordinate system of the movement track, setting production parameters, and recording matching information related to positioning of a product during production; conveying the product to a shooting area via the movement track, shooting the product by the image capture module, matching and comparing shot image information with the matching information, obtaining position information of engraved patterns, finally conveying the product to the laser engraving machine via the movement track to realize laser engraving for the product, and completing a production cycle after the laser engraving is completed. The automatic laser engraving system and the service method thereof have the advantages that precision is greatly improved, labor cost is reduced by means of enhancing production efficiency, rejection rate of products is reduced, production success rate of the products is improved, and accordingly production cost is lowered.

Owner:WUHAN UNIV

Method for preparing [18F]fallypride with low base concentration

A method for preparing [18F]fallypride is disclosed, which comprises a first step for trapping a fluorine-18 to a polymer ion exchange cartridge; a second step for extraction of fluorine-18 by inputting low base concentrations: 5.0˜25 μL of 40% TBAHCO3 or K2.2.2. / K2CO3 (5˜25 mg / 0.5˜3.0 mg) as a phase-transfer catalyst in a mixture of alcohol / water (1.0 / 0.2 (v / v)) or alcohol as a solvent into the polymer ion exchange cartridge trapped by the fluorine-18; a third step for preparing a [18F]fallypride product by removing the solvent from the trapped fluorine-18, by inputting tosylate precursor in CH3CN as a solvent into a reactor and by reacting the same for 5˜35 minutes at 50˜120° C.; and a fourth step for preparing a pure [18F]fallypride by purifying the prepared [18F]fallypride product.

Owner:SEOUL NAT UNIV R&DB FOUND

Solid-state light source heat-dissipation metal shell as well as manufacturing method and manufacturing mold thereof

InactiveCN104048277ASimple structureEasy to shapePoint-like light sourceLighting heating/cooling arrangementsEngineeringLouver

The invention provides a solid-state light source heat-dissipation metal shell as well as a manufacturing method and a manufacturing mold thereof. In order to lower the structural member cost and improve the heat-dissipation performance of a solid-state light source, the invention provides a heat-dissipation metal shell (1) as well as a manufacturing method and a manufacturing mold, wherein a metal side wall (2) of the heat-dissipation metal shell (1) is provided with a ventilation window (3); the ventilation window (3) is of a louver-type or staggered structure with formation convex teeth for axial pushing formation; all the formation convex teeth are fixed in a concave mold; a convex mold is provided with a corresponding formation groove; the convex teeth move axially so as to push the metal shell to deform inward, so that an air vent is formed. The used mold is simple in structure, is capable of realizing multi-station continuous mold stamping forming, and is high in production efficiency.

Owner:秦彪

Large-area fabric embossing device and process

PendingCN110541316AStereotype stableImprove the pressing effectTextile decorationSoft materialsEngineering

The invention relates to the technical field of embossing devices and processes, in particular to a large-area fabric embossing device and process. A plurality of hot die pressing mechanisms are all arranged around a cold die pressing mechanism, a plurality of feeding assemblies are distributed at the side of a workbench, and the feeding assemblies correspond to the hot die pressing mechanisms andthe cold die pressing mechanism one to one; the hot die pressing mechanisms press and heat a soft material into deformation, wherein the die pressing pressure of the hot die pressing mechanisms is 15-45 tons per square meter, and the die pressing temperature is 120-300 DEG C; the cold die pressing mechanism presses, cools and shapes the soft material after hot die pressing, wherein the die pressing pressure of the cold die pressing mechanism is 0.6-3.5 tons per square meter. Through the layout of the die pressing mechanisms, by cooperating with an automatic structure, sustainable operation and production can be achieved, a standby state of the cold die pressing mechanism cannot occur, the feeding process is automatic without manual intervention, and a good press fit effect and stable shaping of the soft material are obtained in combination with specific technological parameters.

Owner:GUANGDONG LIXIN INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing [18f]fallypride with low base concentration Method for preparing [18f]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/825cb240-91fd-408c-a723-587f0921a094/US20120178920A1-20120712-D00001.png)

![Method for preparing [18f]fallypride with low base concentration Method for preparing [18f]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/825cb240-91fd-408c-a723-587f0921a094/US20120178920A1-20120712-D00002.png)

![Method for preparing [18f]fallypride with low base concentration Method for preparing [18f]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/825cb240-91fd-408c-a723-587f0921a094/US20120178920A1-20120712-D00003.png)

![Method for preparing [18F]fallypride with low base concentration Method for preparing [18F]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/e26120a8-2f51-4920-a965-35c1cc6abd65/US08624039-20140107-D00001.png)

![Method for preparing [18F]fallypride with low base concentration Method for preparing [18F]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/e26120a8-2f51-4920-a965-35c1cc6abd65/US08624039-20140107-D00002.png)

![Method for preparing [18F]fallypride with low base concentration Method for preparing [18F]fallypride with low base concentration](https://images-eureka.patsnap.com/patent_img/e26120a8-2f51-4920-a965-35c1cc6abd65/US08624039-20140107-D00003.png)