Forming process and special processing device for ultrathin protective cover sleeve

A molding process and protective shell technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large initial investment in molding equipment, high technical level of workers, complex mold structure, etc., to save labor costs , high-efficiency automated production, and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

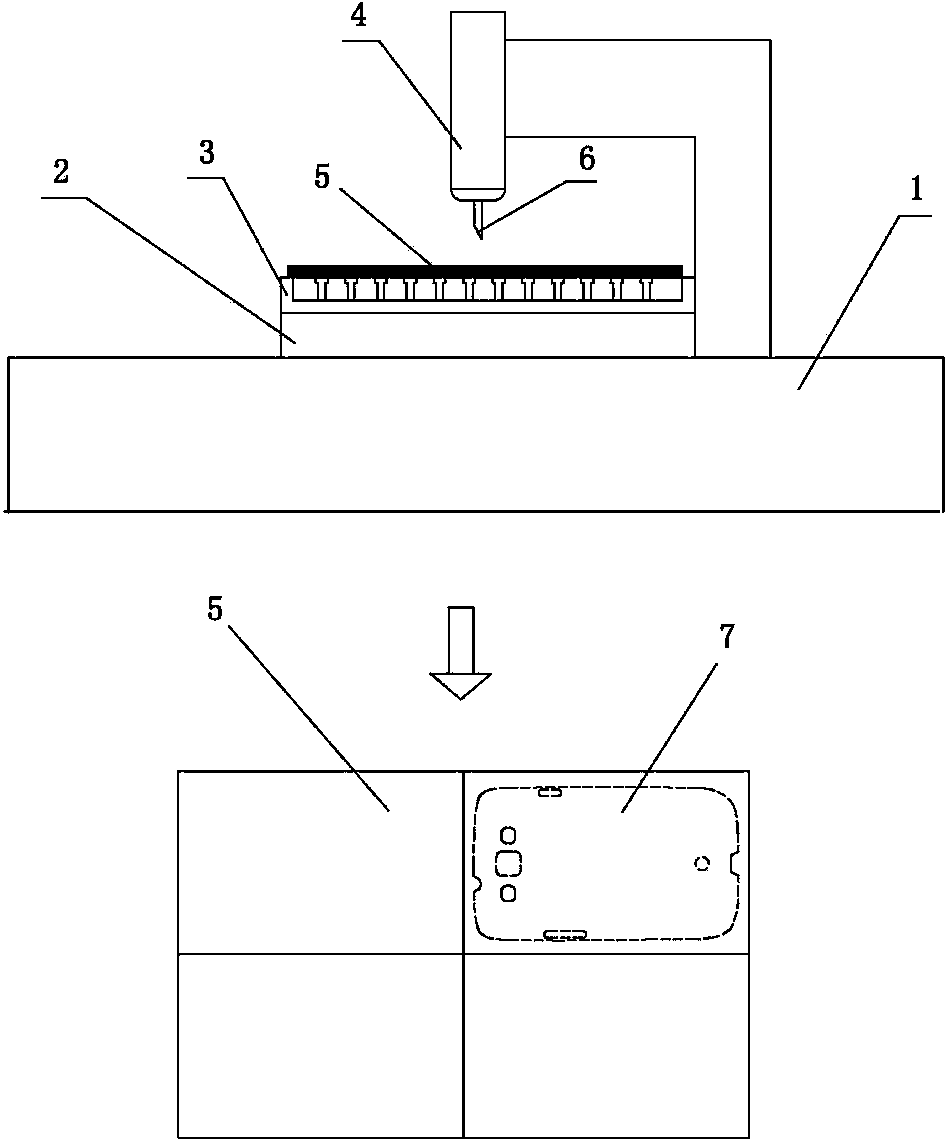

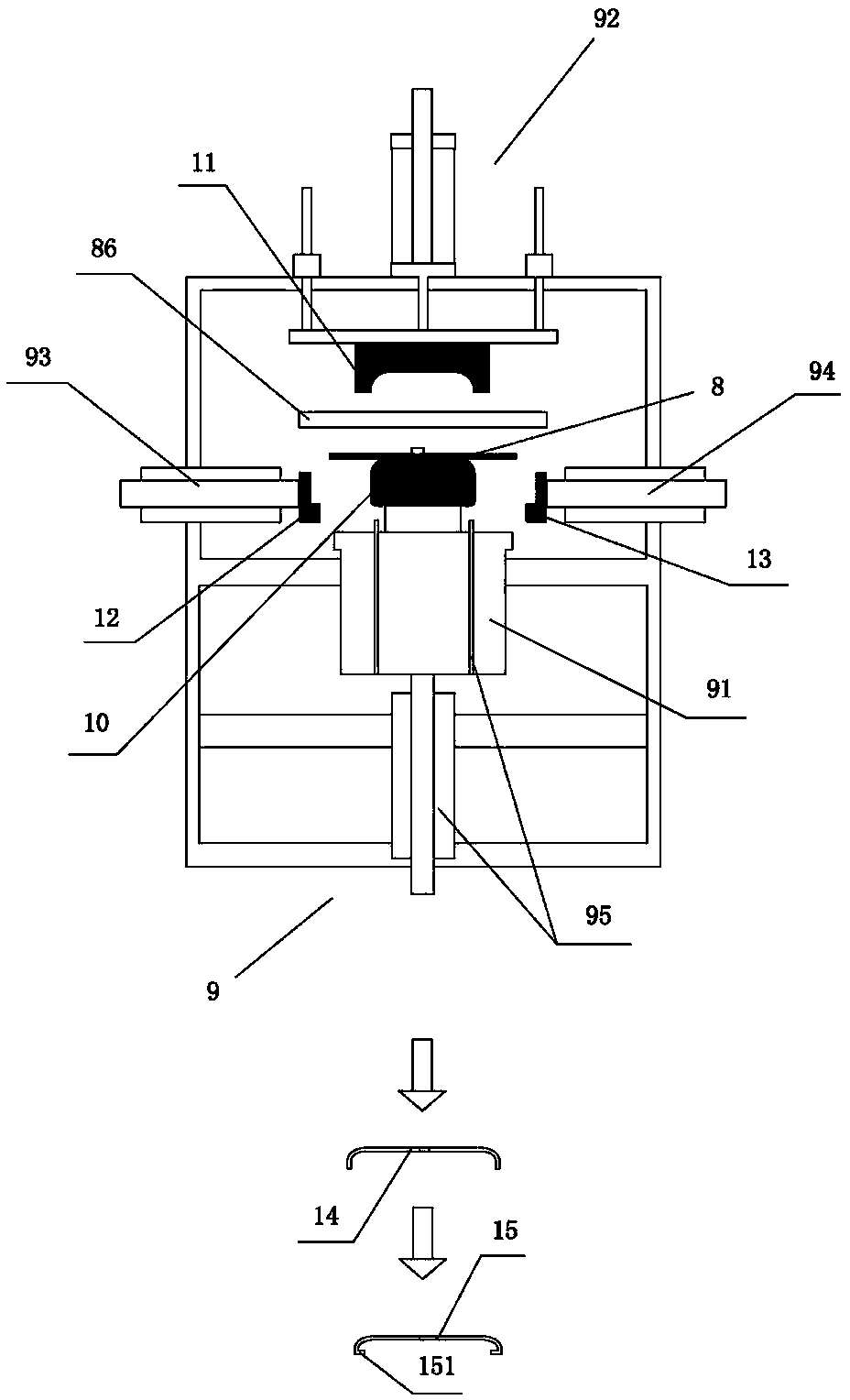

[0032] Example: see Figure 1 to Figure 2 , the forming process of the ultra-thin protective shell provided in this embodiment, which includes the following steps:

[0033] (1) Prepare the plate-shaped shell material 5 and the thermoforming mold; in the first step, polyester (PET), non-crystalline polyethylene terephthalate (APET), non-crystalline copolyester ( PETG), polyvinyl chloride (PVC), polypropylene (PP) and other materials are used as the ultra-thin protective shell material, and the shell material is made into a thin plate for use; according to needs, one of the above materials can be used as The base material is made into a thin plate, and one side is compounded with genuine leather, PU leather, leather fiber, cloth, or printing / hot stamping / water transfer printing / thermal transfer printing is performed on one side of the base material to make a composite material for use ;

[0034] The second step is to prepare a thermoforming mold. The thermoforming mold is a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com