Automatic sand blasting device for automobile hub production

A technology of sandblasting device and automobile wheel hub, which is applied to used abrasive treatment devices, abrasive jetting machine tools, abrasives, etc., can solve the problems of increasing the labor intensity of workers, unfavorable high-efficiency automated production, and reducing production efficiency. Realize the function of automatic feeding, which is conducive to efficient automatic production and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

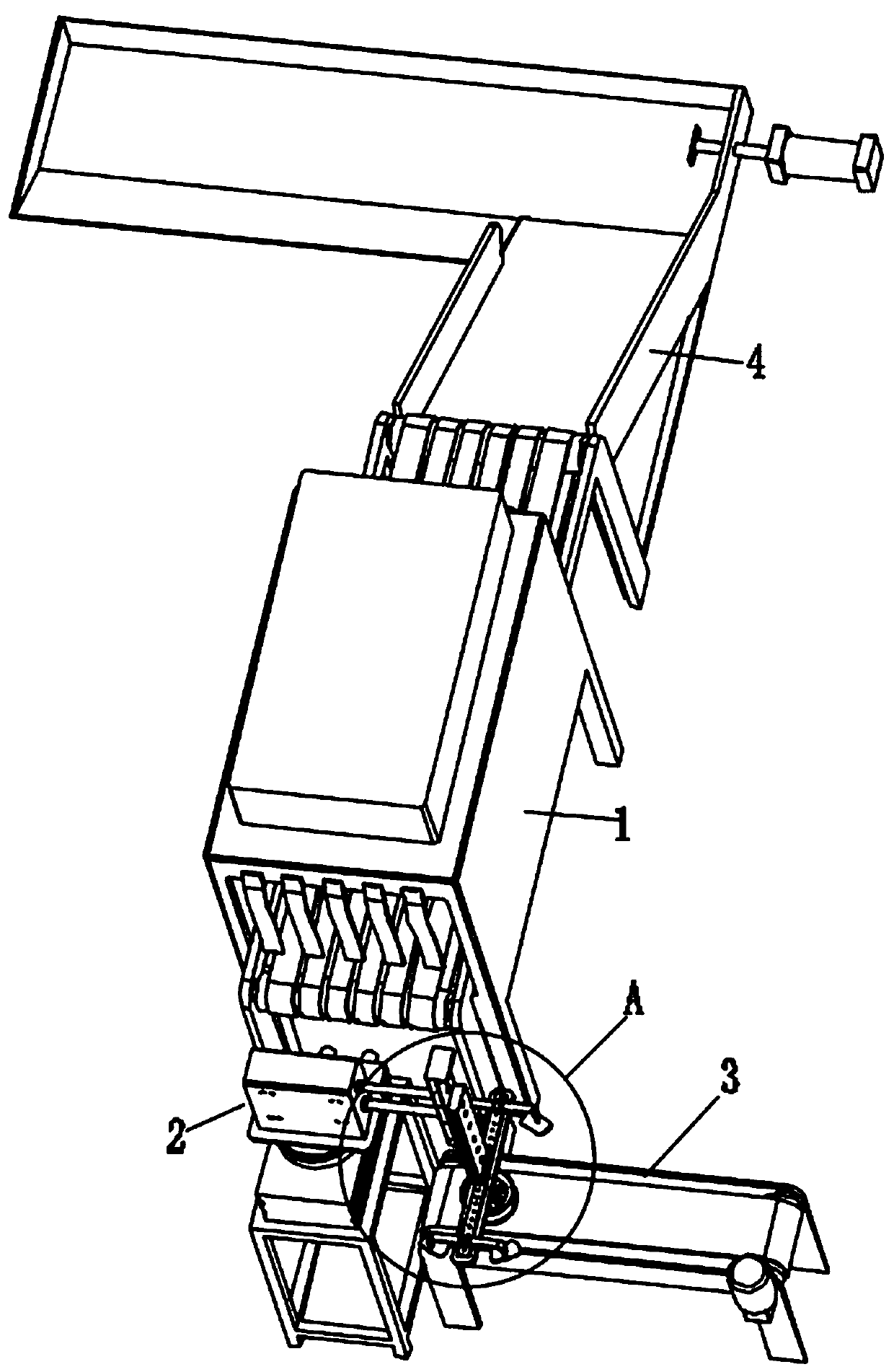

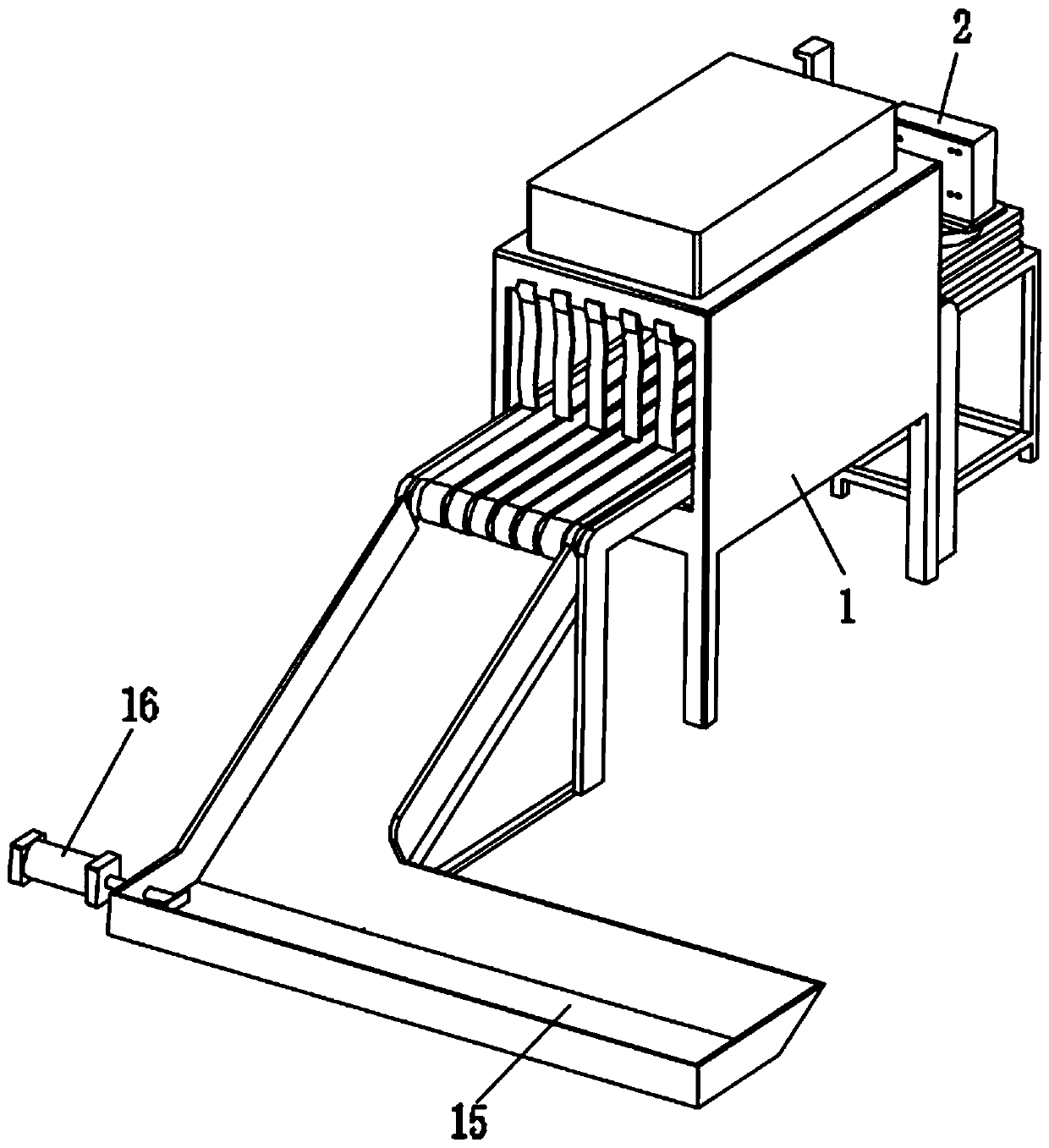

[0029] An automatic sandblasting device for the production of automobile wheels in this embodiment includes a sandblasting machine 1 and a controller. The feeding end of the sandblasting machine 1 is equipped with an automatic feeding mechanism 2 for automatically putting the wheel hub into the sandblasting machine 1 , one side of the automatic feeding mechanism 2 is provided with a feeder 3, and the feeder 3 and the sandblasting machine 1 are distributed at 90 degrees around the automatic feeding mechanism 2, and the discharge end of the sandblasting machine 1 is equipped with a Automatic unloading mechanism 4 for automatic collection of wheel hubs after blasting.

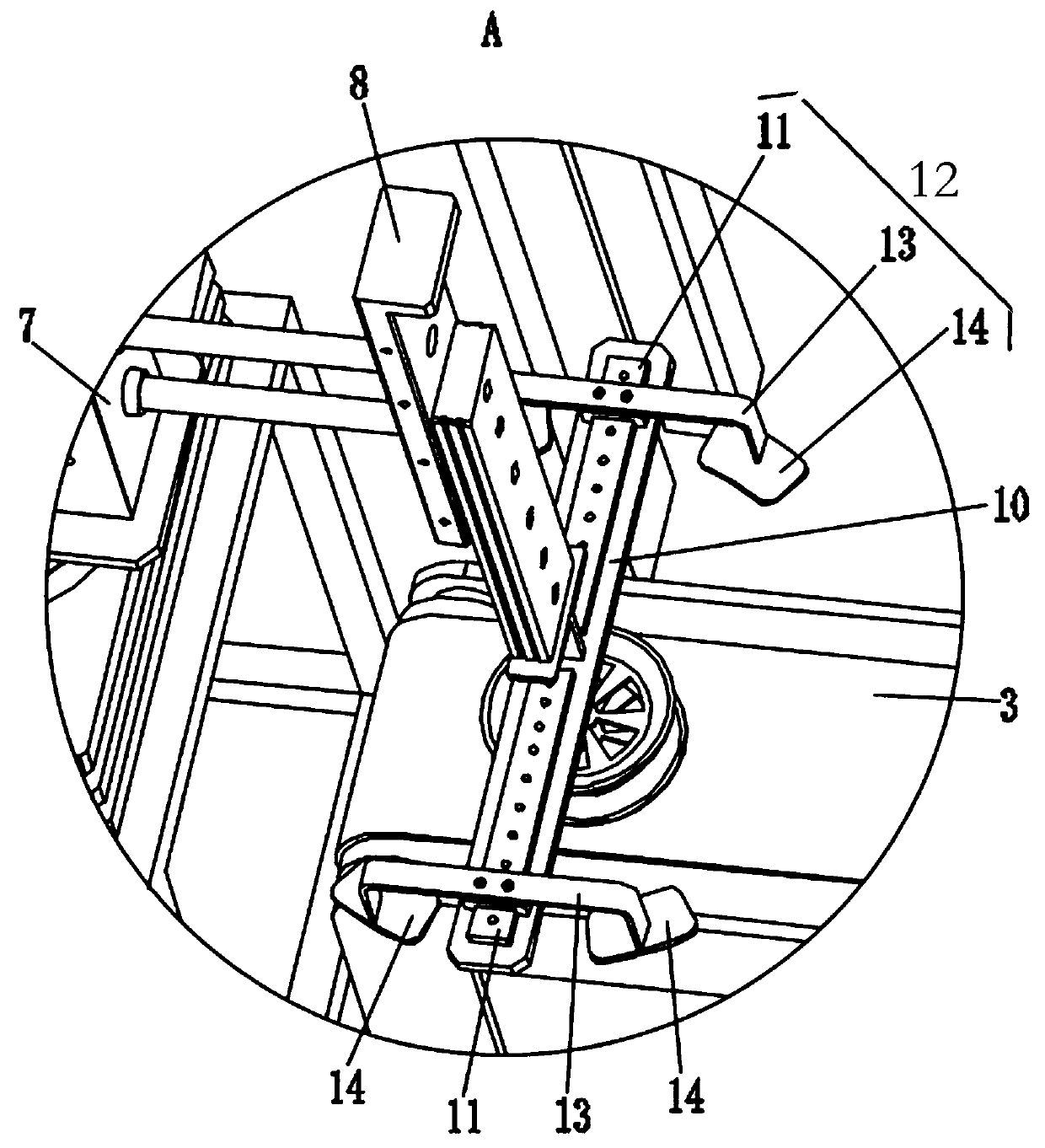

[0030] Wherein, the automatic feeding mechanism 2 includes a frame 5 placed on the front end of the sandblasting machine 1, a rotary cylinder 6 is installed on the top surface of the frame 5, and a biaxial cylinder 7 is installed on the output end of the rotary cylinder 6, and the biaxial cylinder 7 A sliding tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com