Plasma arc plane surface welding machine

A plasma arc and surfacing welding machine technology, which is applied to plasma welding equipment, welding equipment, welding equipment, etc., can solve the problems of high labor intensity for operators, difficulty in guaranteeing welding quality, and low production efficiency, so as to improve labor productivity and realize The effect of automated production and efficient automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

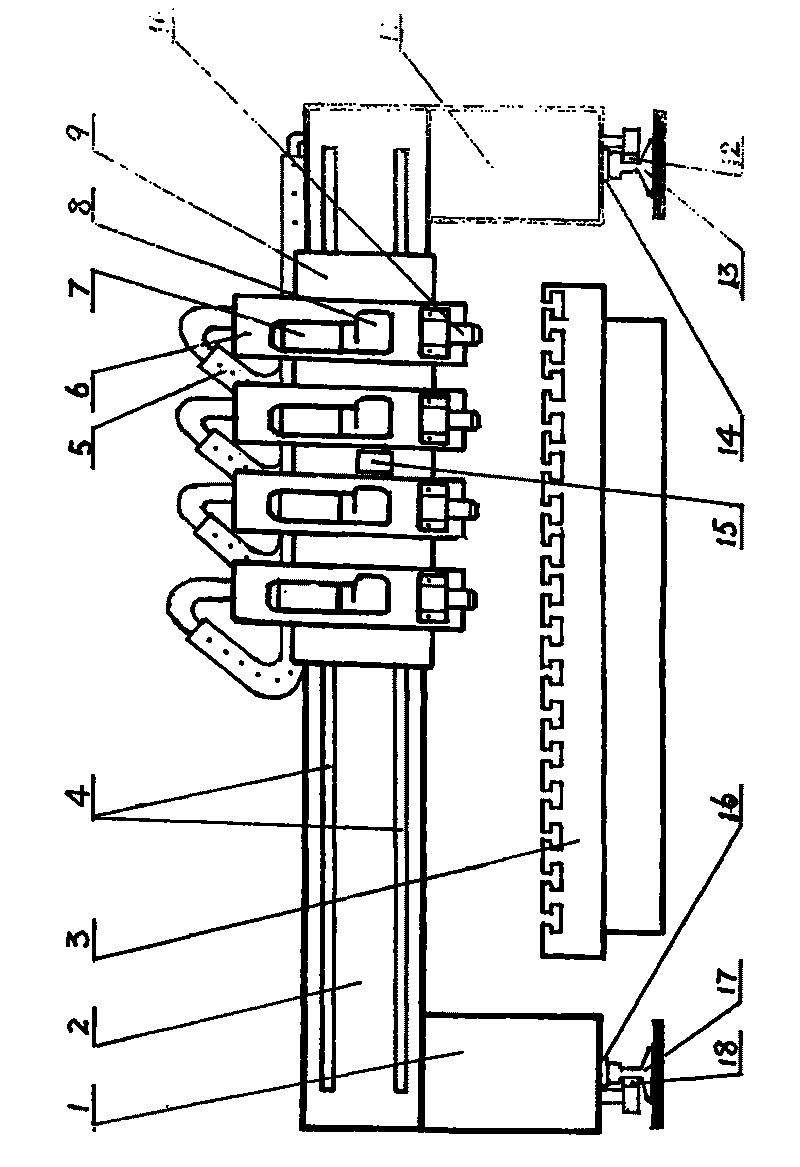

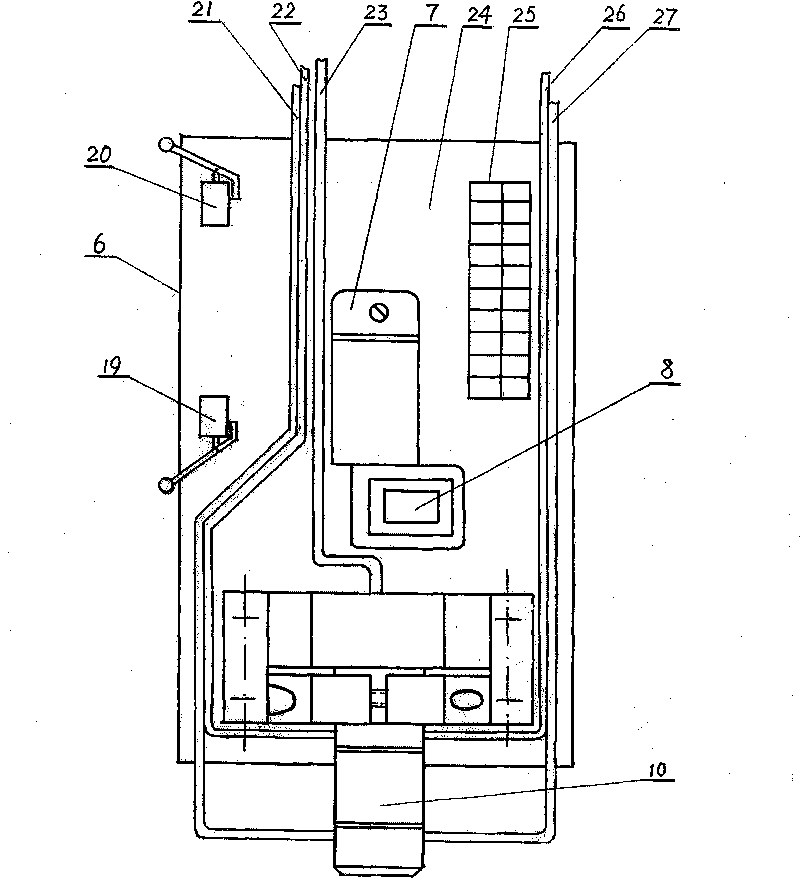

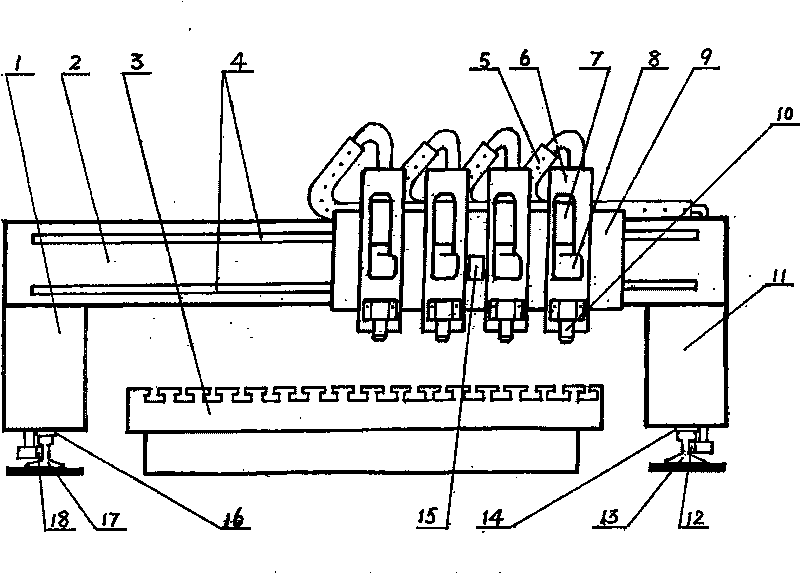

[0020] Such as figure 1 The shown plasma arc plane surfacing welding machine includes the frame of the gantry structure composed of columns 1, 11 and cross beam 2 and the welding platform 3 arranged at the corresponding position of the frame. Driven by (not shown in the figure), the frame and the welding platform 3 can move in parallel relative to the longitudinal direction, that is, advance or retreat; a lateral movement or swinging horizontal movement driven by a lateral movement motor 15 is provided on the side of the crossbeam 2 of the frame. The slide plate 9 is provided with a liftable welding torch support 6 on the outer surface of the horizontal slide plate 9, and the plasma welding torch 10 pointing to the welding platform 3 is installed on the welding torch support 6, and the height position of the plasma welding torch 10 is adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com