Partially sealed pressure-temperature sensor and its manufacturing process

A technology of pressure temperature and sensor, which is applied in the direction of temperature measurement of moving fluid, thermometer, and measurement of fluid pressure, etc. It can solve the problems of pressure module packaging structure, gel potting and sealing instability, and achieve the reduction of sealing requirements and guarantee Consistency, providing reliability and durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

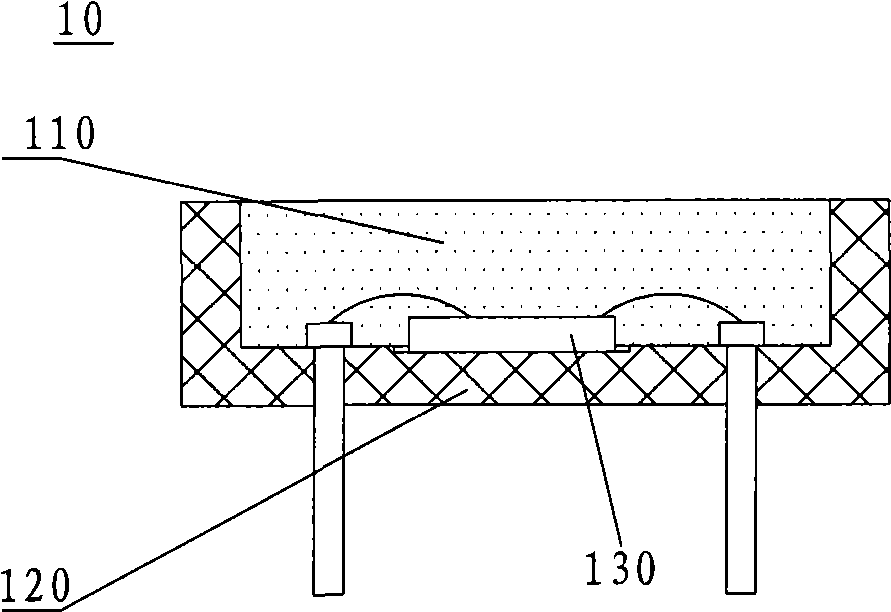

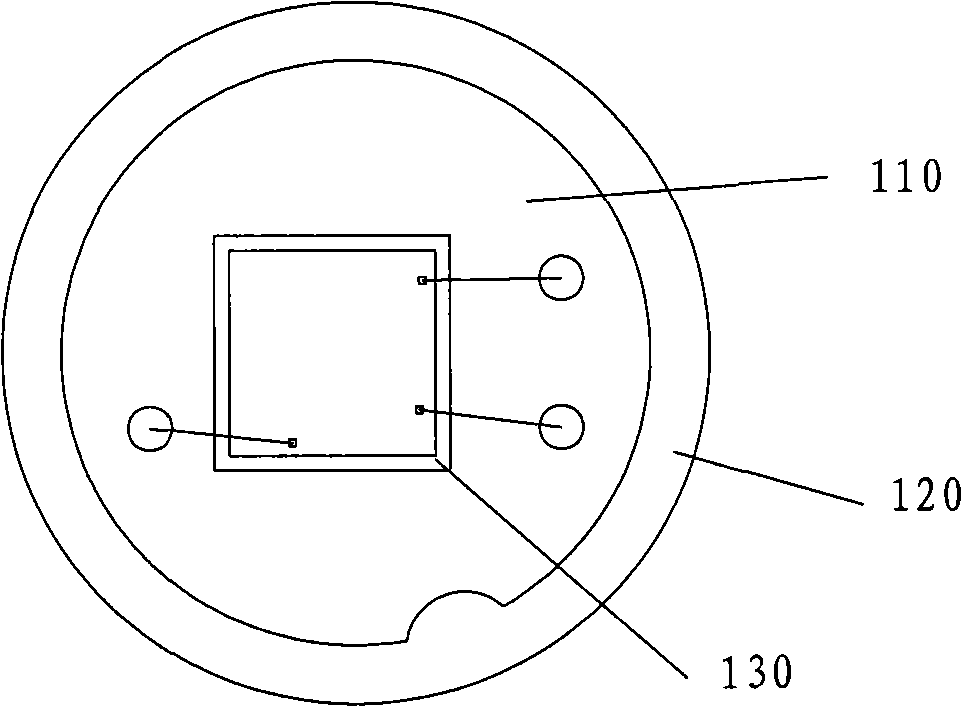

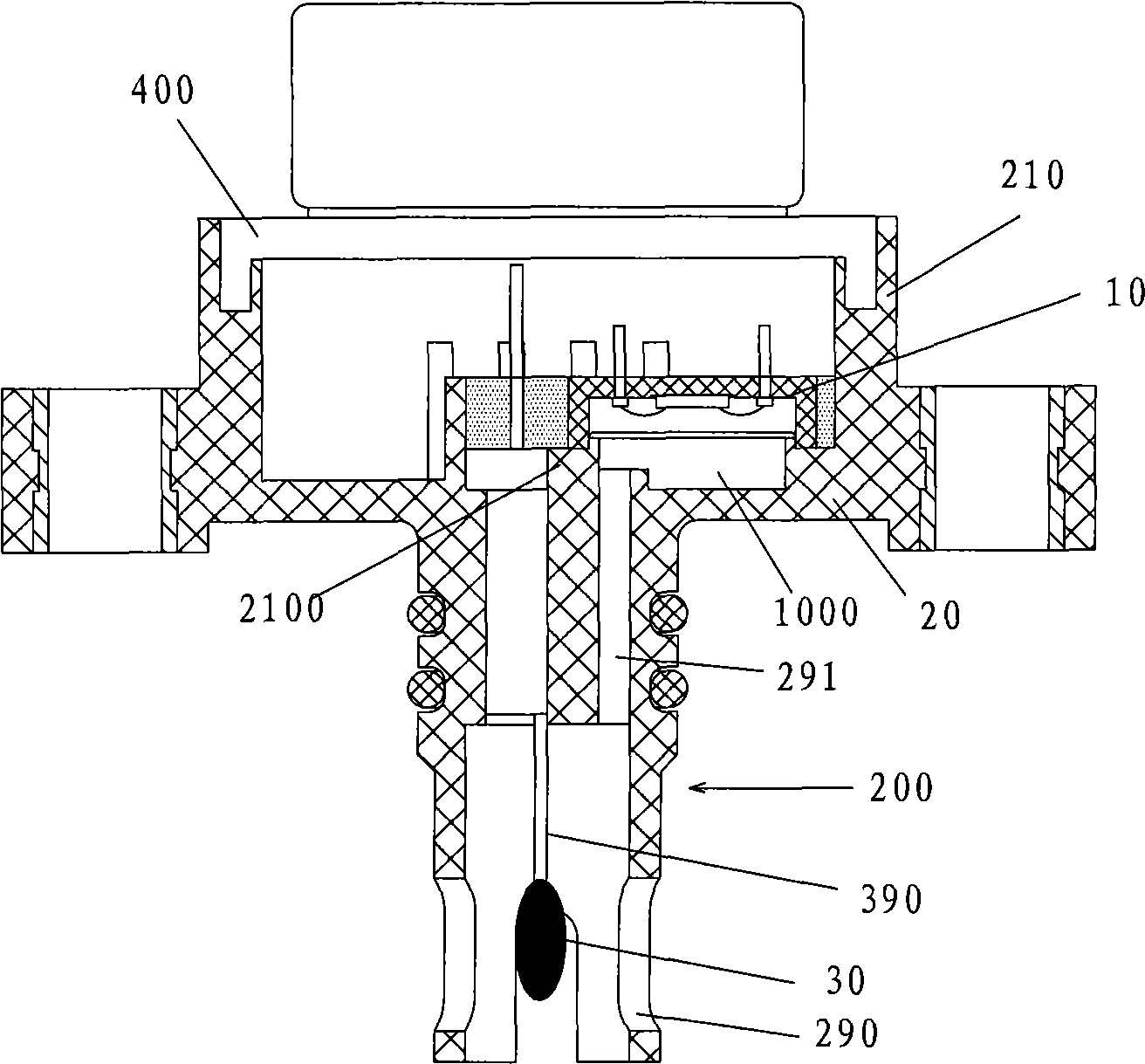

[0022] Such as figure 1 and figure 2 As shown, the pressure module 10 includes a substrate 120 , a chip 130 fixed on the substrate 120 , and a gel 110 covering the chip 130 . The substrate 120 is bowl-shaped and made of ceramic molding material. The substrate 120 provides a cavity in which the chip 130 is fixed, and the gel 110 fills the entire cavity. Both the chip 130 and the gel 110 are available in the market, and the gel 110 can completely transfer the air pressure to the chip 130 without attenuating the transferred air pressure. The chip 130 is used for measuring gas pressure, and its electrical pins pass through the bottom of the substrate 130 . Compared with the existing pressure modules, the pressure template 10 has many advantages. Since the chip 130 is accommodated in the cavity provided by the substrate 120, the chip 130 (and its binding wires) can be completely covered with a certain amount of gel 110 , even if the gel 110 has good fluidity, the cavity provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com