Patents

Literature

56results about How to "High cathode current efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

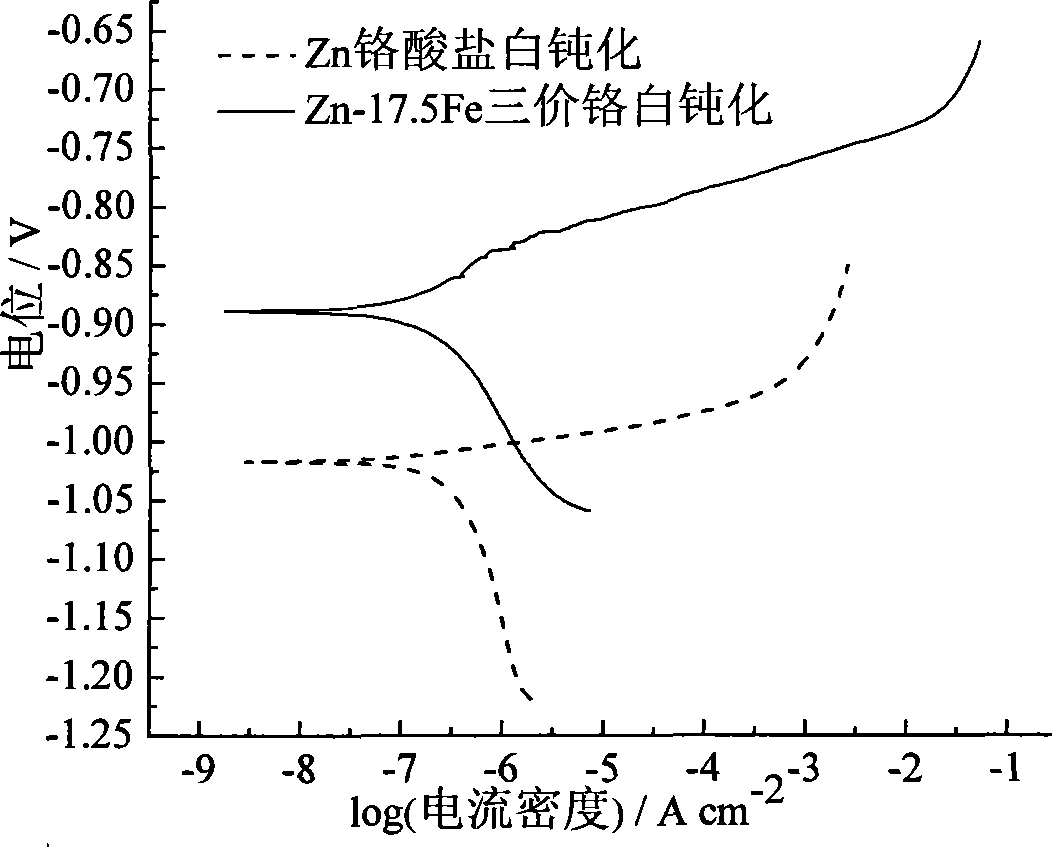

Bright corrosion resisting zinc-iron alloy plating process

The invention discloses a bright corrosion resisting zinc-iron alloy plating process which comprises the step of adding complexing agent and ferrous ion to zincate zincification solution. Zinc-iron alloy plating bath comprises 6-12g / L of ZnO, 90-150 g / L of NaOH, 20-50 mL / L of trolamine, 5-13g / L of FeSO4.7H2O, 2-8mL / L of DE, 0.5-1g / L of ethylenediamine tetracetic acid, 0.02-0.1 g / L of vanillina, 0.02-0.1 g / L of dodecyl sodium sulfate and 1-2 g / L of Zn powder. The process can reach the cathode current efficiency of 90 percent, is easy to control the alloy component and can obtain bright zinc-iron alloy plating containing 17-20 percent of iron; in addition, electrochemistry and salt-spray fog corrosion results show that the bright zinc-iron alloy plating has better corrosion resistance than pure zinc plating chromating, and the bright zinc-iron alloy plating has better protection property and decoration performance.

Owner:SOUTH CHINA UNIV OF TECH

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

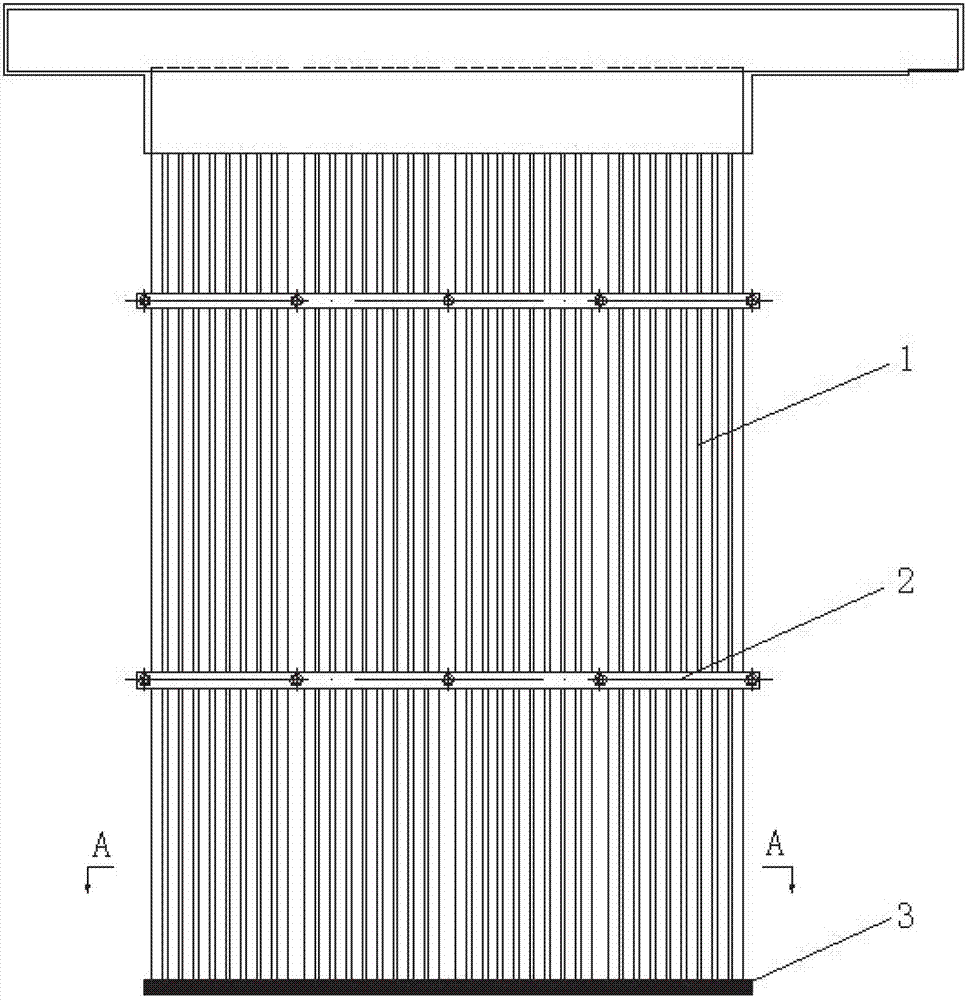

Fence type anode plate for electrodeposition of nonferrous metals

The invention discloses a fence type anode plate for electrodeposition of nonferrous metals. The fence type anode plate for electrodeposition of the nonferrous metals is characterized in that lead or lead-based complex alloy with the thickness of 2-10mm is compounded on the surface of a rod core to form a composite rod; a corrugated or sawtooth type pattern is drawn on the surface of the composite rod; a conductive ceramic composite coating layer is coated or electrodeposited on the surface of the composite rod; the fence type anode plate is formed by assembling a plurality of the composite rods; and the composite rods are fixed by insulation edge clamping strips and clamped by insulation rivets. By the fence type anode plate for electrodeposition of the nonferrous metals, fluidity of electrolyte solution is improved, concentration polarization of a cathode area is reduced, and deposition amount of cathode metals is increased, so that cathode current efficiency is improved; the fence type anode plate does not bend and deform, and therefore short circuit phenomenon of anode and cathode plates is prevented; and compared with the conventional lead-based alloy anode plate, the conductivity of the fence type anode plate is obviously improved, the tank voltage is reduced by 10%, the material cost is reduced by 20% and the current efficiency is increased by 2-5%.

Owner:KUNMING HENDERA SCI & TECH

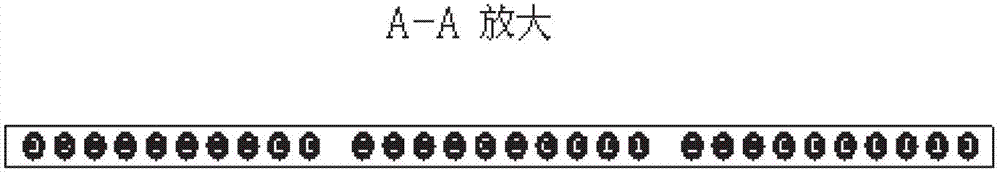

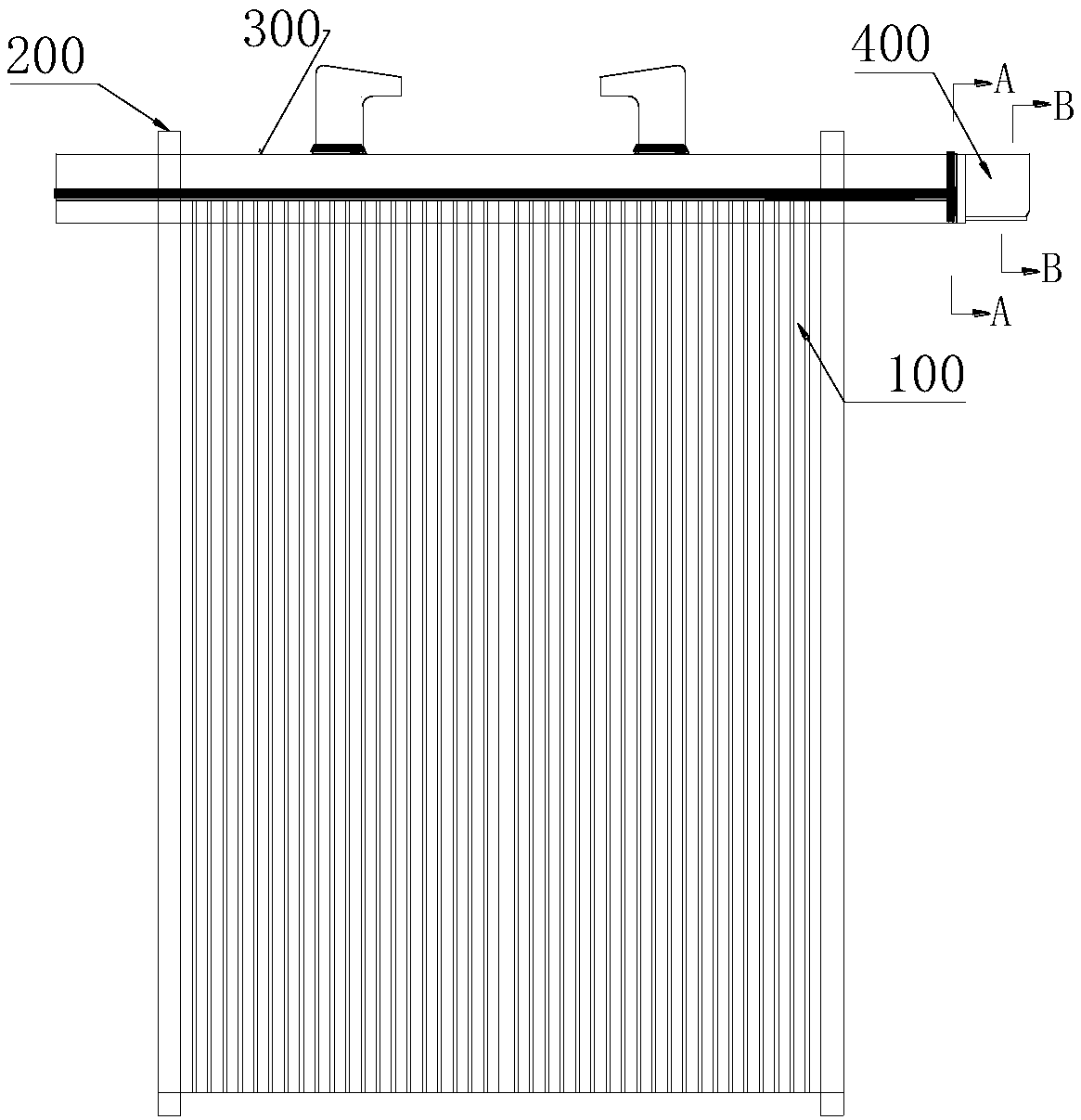

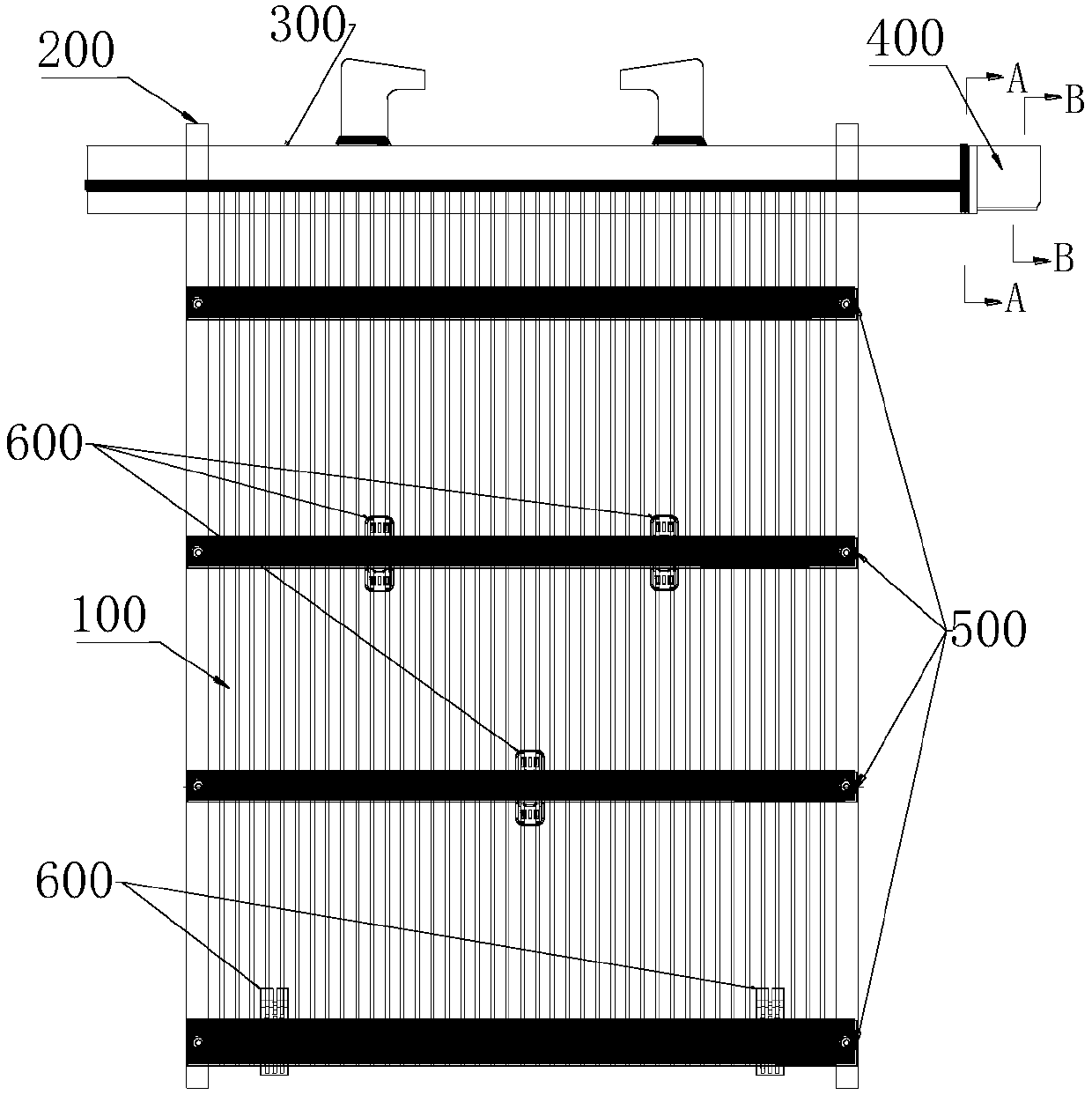

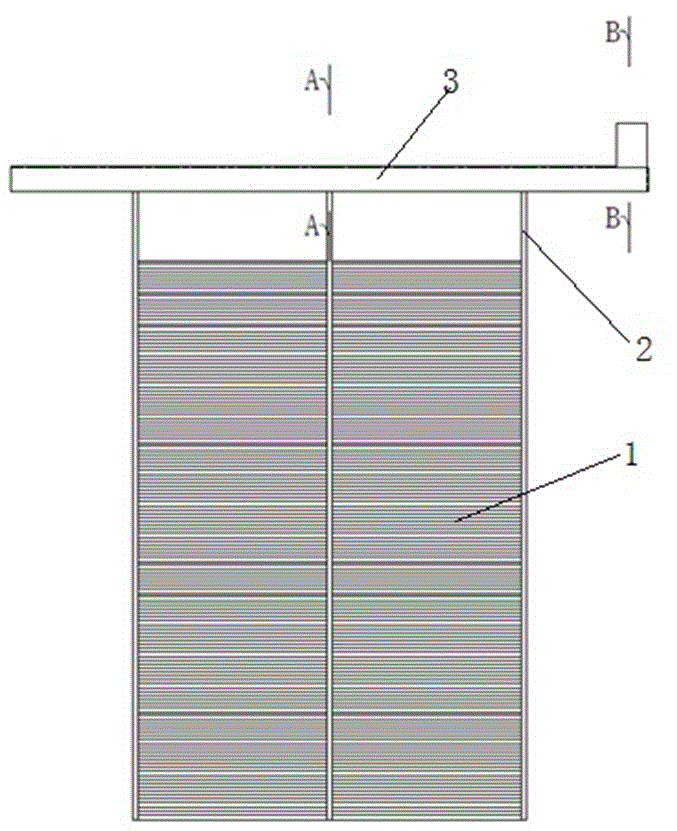

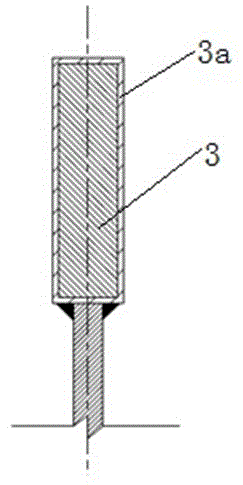

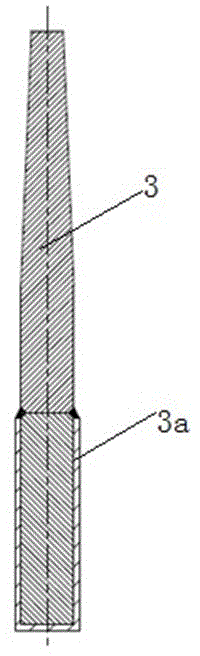

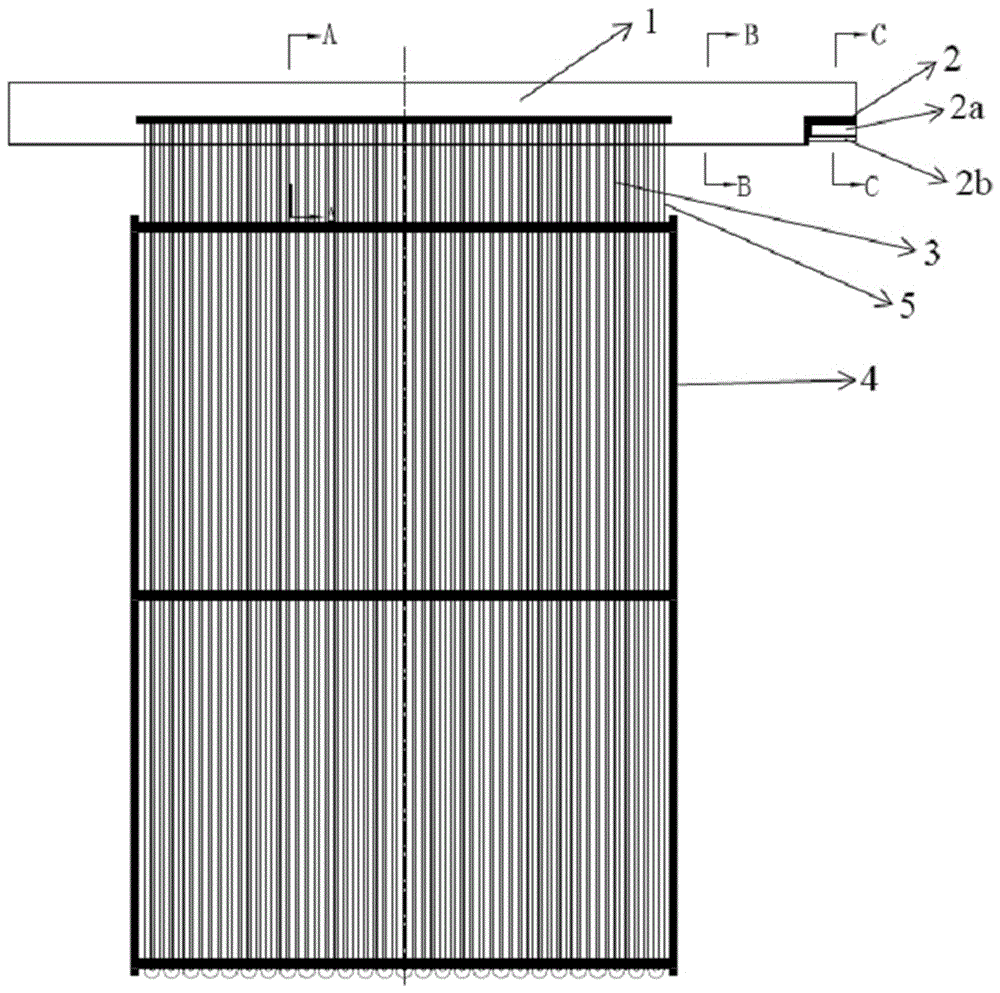

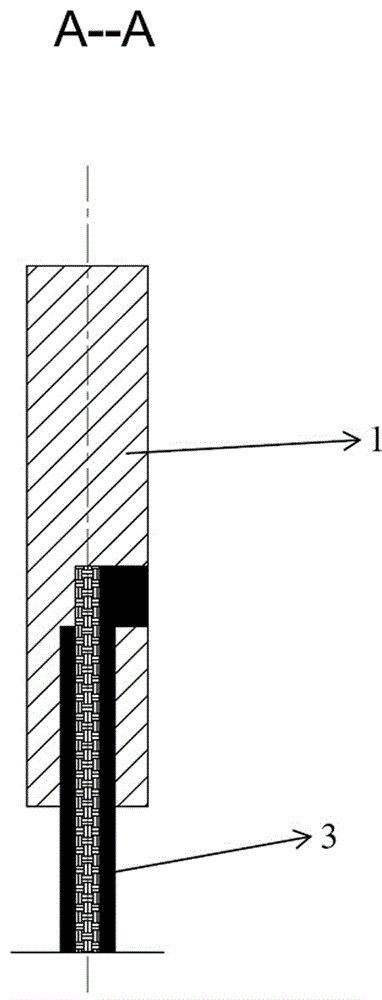

Fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition and preparation method of fence-type aluminum bar lead alloy anode plate

ActiveCN104611731AImprove mobilityIncrease depositionLiquid/solution decomposition chemical coatingElectrolytic organic material coatingCeramicLead alloy

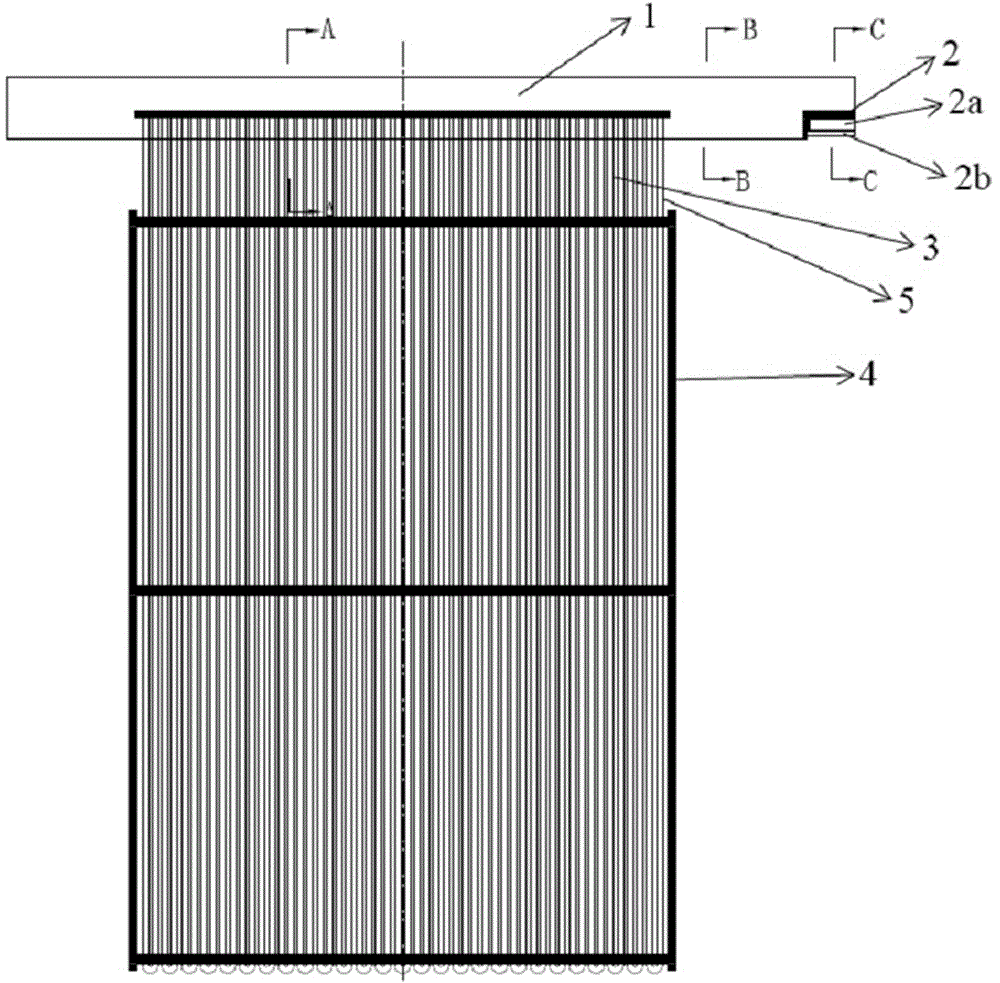

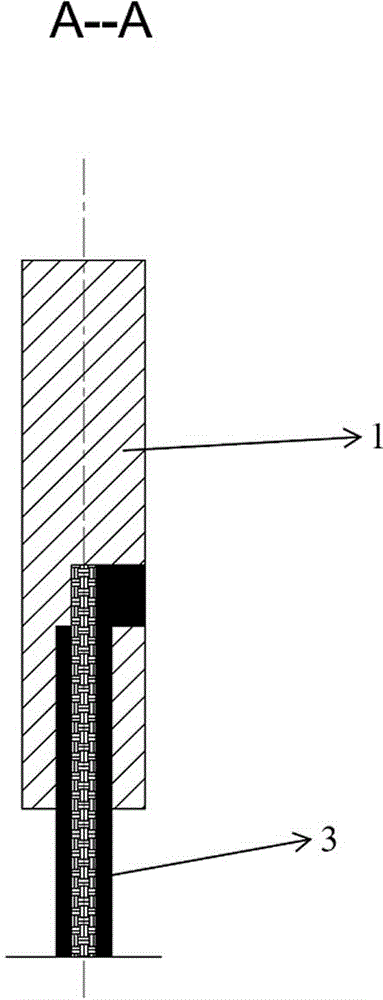

The invention discloses a fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition and a preparation method of the fence-type aluminum bar lead alloy anode plate. The fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition comprises an aluminum or aluminum alloy conductive beam (1), a copper-aluminum explosive composite conductive head (2) and a fence-type anode plate bracket (3), wherein the copper-aluminum explosive composite conductive head (2) is welded on the conductive beam; the fence-type anode plate bracket (3) is welded below the aluminum or aluminum alloy conductive beam (1), and is assembled by aluminum bar lead alloy composite anode bars; the aluminum bar lead alloy composite anode bars forming the fence-type anode plate bracket are fixed by virtue of an insulating edge-clamping strips (4); the insulating edge-clamping strips are welded with one another to form an overall frame; and a layer of beta-PbO2-polyaniline conductive ceramic (5) covers the surface of the fence-type anode plate bracket. Compared with a traditional lead-based alloy anode plate, the fence-type aluminum bar lead alloy anode plate has the advantages that the electrical conductivity is significantly improved; the bath voltage can be reduced by 12%; the material cost is reduced by 30%; and the current efficiency is improved by 2%-5%.

Owner:KUNMING HENDERA SCI & TECH

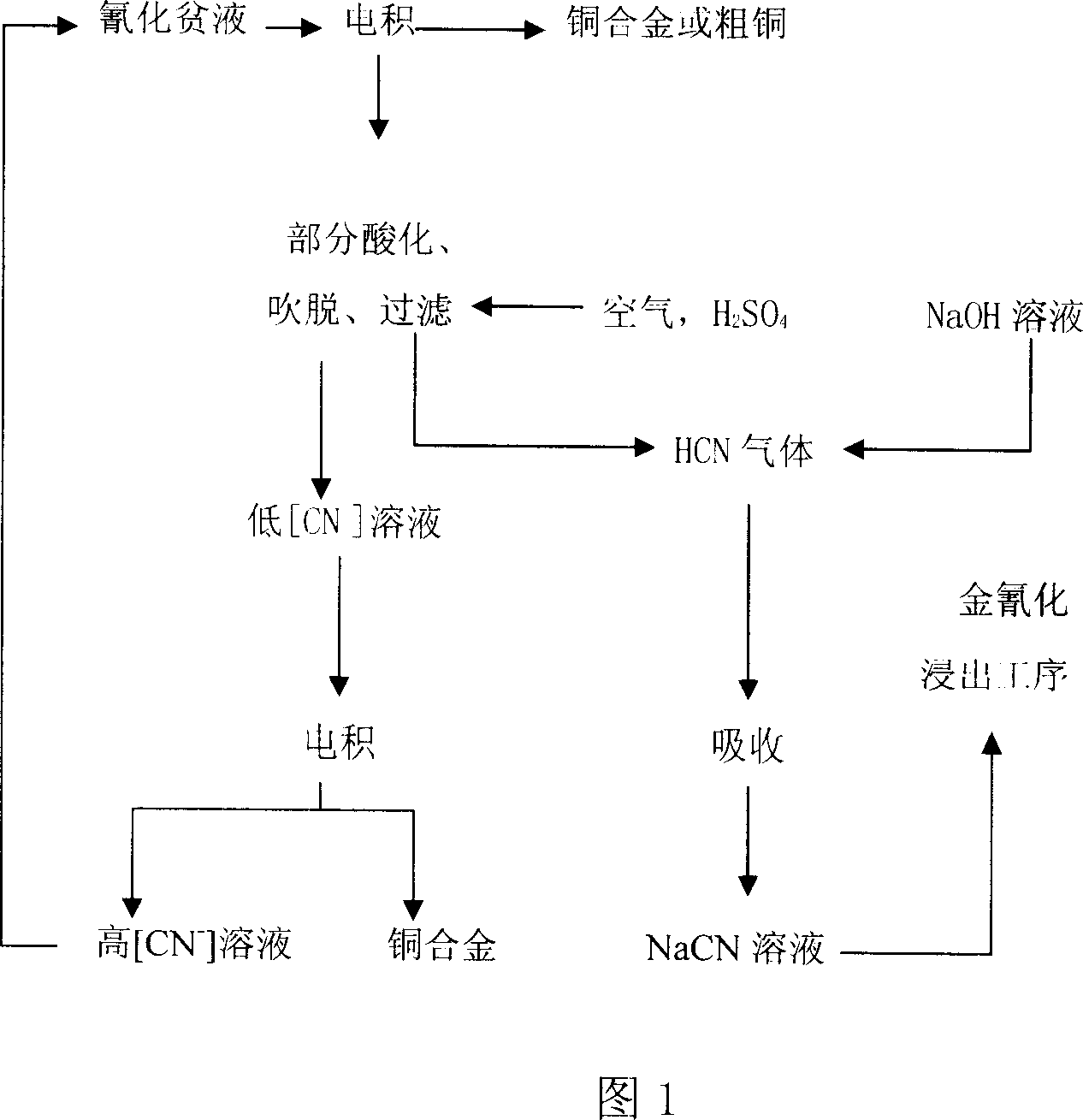

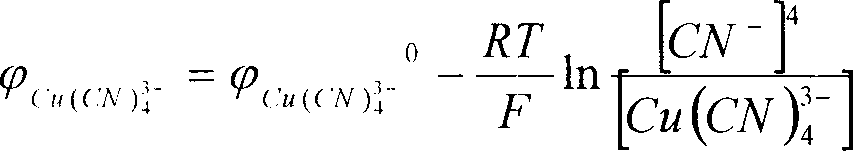

Method for recovering copper from cyanide-containing waste water and related waste water treatment method

InactiveCN101008090AHigh cathode current efficiencySolve the problem of low current efficiencyPhotography auxillary processesWater/sewage treatmentElectricityCyanide

The invention discloses a method for recovering copper from cyanic waste water and relative wastewater treatment method, belonging to non-ferrous metallurgy and environmental protection field. It is characterized in that it combines diaphragm electrodeposition with part of acidification, adds acid into electrodeposition liquid and aerates to blow off and recover free CN-, which greatly increases cathodic current efficiency; it employs diaphragm electrodeposition, that is to employ cationic exchange membrane to separate free cyanogen and metal- cyano complex from anode, to avoid cyanogen oxidation in anode; the waste electrodeposition liquid can be reused in cyanogen extraction process, or discharged after further treatment.

Owner:TSINGHUA UNIV

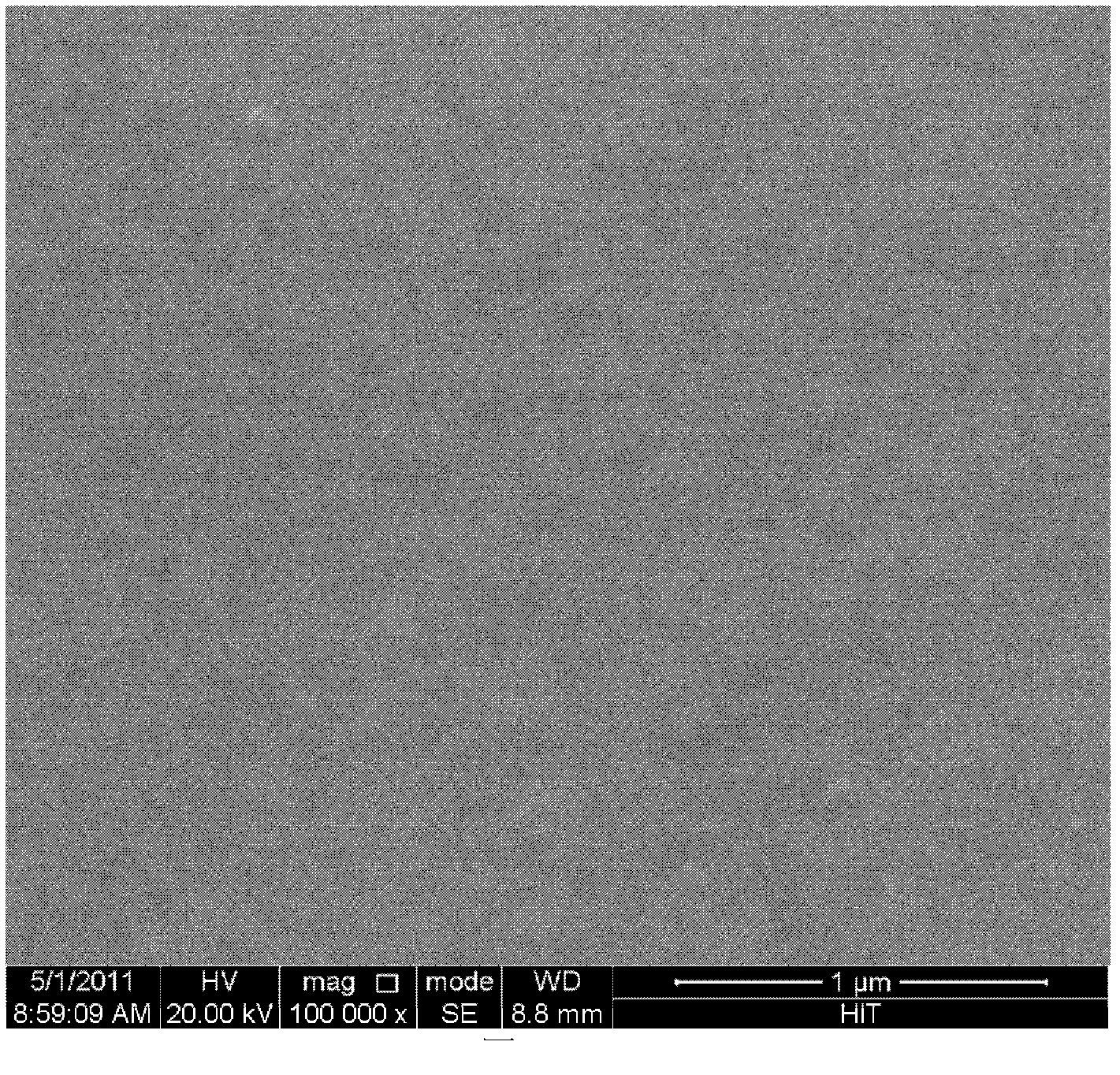

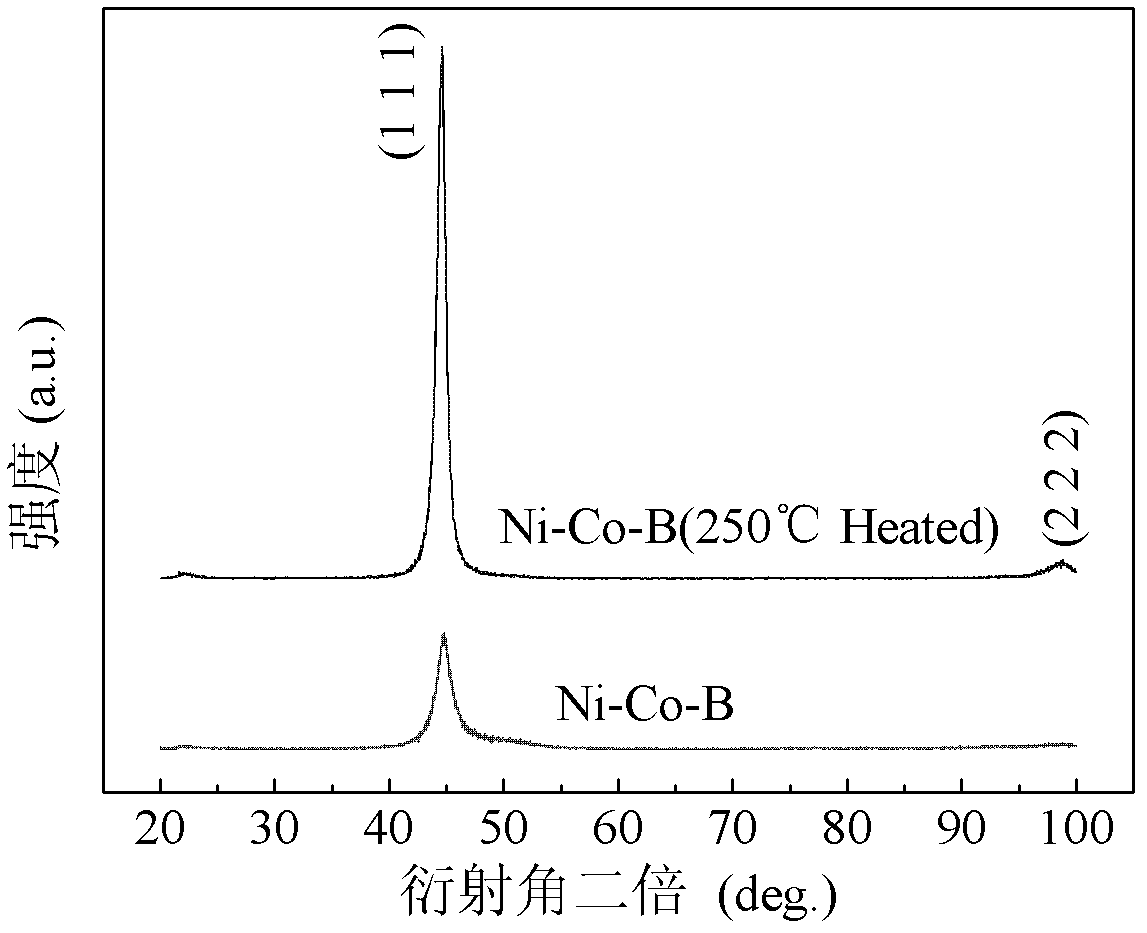

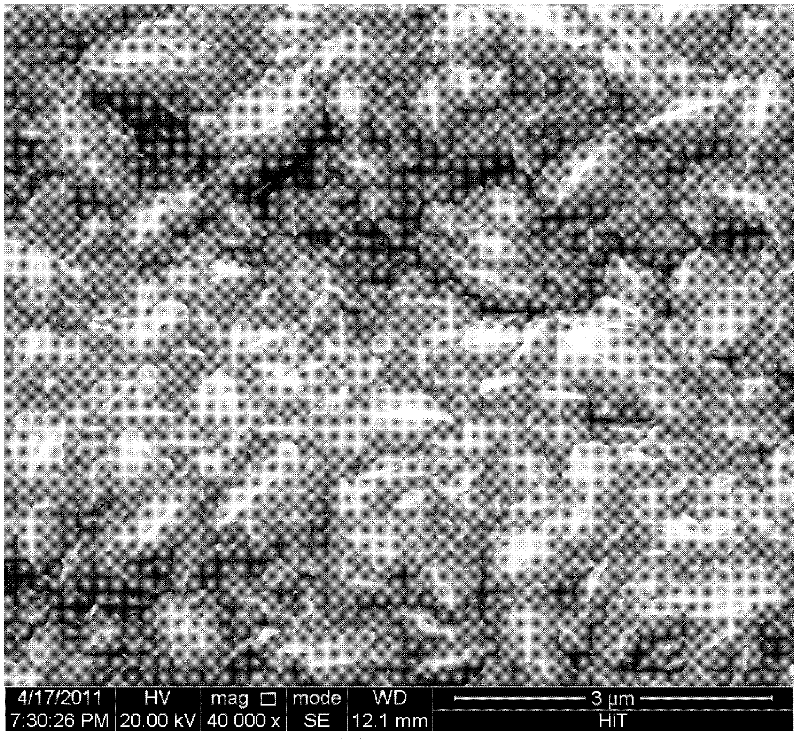

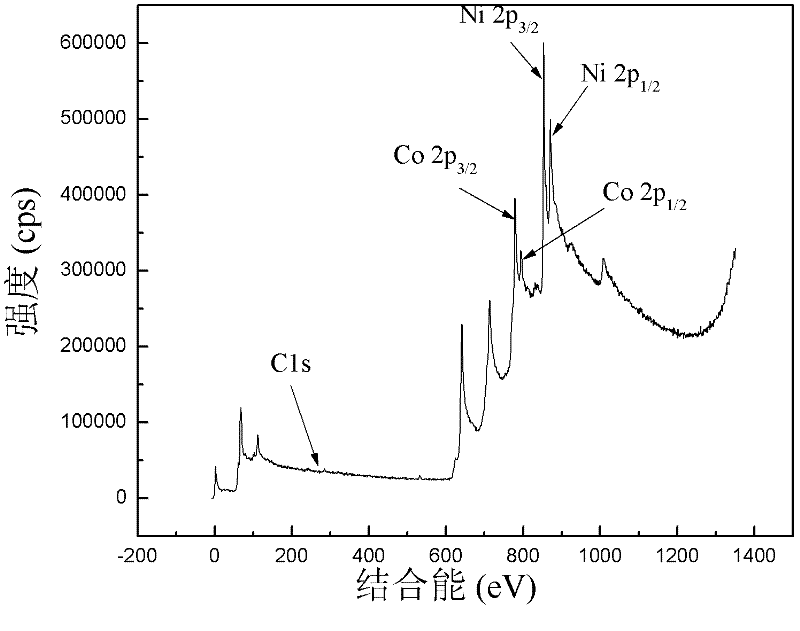

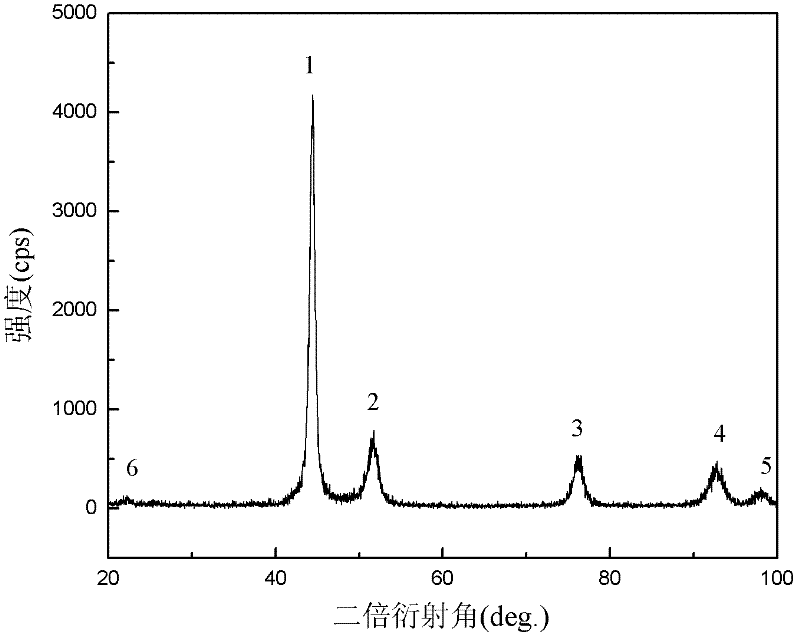

Electric deposition preparation method of Ni-Co-B alloy substituted hard chromium plating

The invention provides an electric deposition preparation method of a Ni-Co-B alloy substituted hard chromium plating, relating to a preparation method of the Ni-Co-B alloy substituted hard chromium plating. The method 1 comprises the following steps of: taking nickel salt, cobalt salt, nickel chloride, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. The method 2 comprises the following steps of: taking nickel chloride, cobalt salt, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. In the invention, a Ni-Co-B alloy plating with uniform brightness, hardness of 770-800HV50 as well as good corrosion resistance and bonding force is obtained at a deposition rate higher than 60mu m / h. In the plating process, the cathode current efficiency is higher than 96%; and after the plating is subjected to heat treatment at 150-400 DEG C for 1-3 hours, the hardness of the plating can be increased to 1055-1108HV50.

Owner:HARBIN INST OF TECH +1

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

Electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating

The invention discloses an electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating, which relates to the preparation method of Ni-Co-C alloy substitute hard chromium plating. The method one comprises the steps of: taking nickel salt, cobalt salt, NiC12.6H2O, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. The method two comprises the steps of: taking NiC12.6H2O, cobalt salt, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. In the invention, the Ni-Co-C alloy plating with uniform brightness, hardness of 690-770HV50 and favorable corrosion resistance is obtained at a deposition speed of 32 microns per hour; in the electroplating process, the cathode current efficiency is higher than 60%; and the hardness of the plating can be improved to 1000-1100HV50 after undergoing heat treatment for 1-3h at a temperature between 150-400DEG C.

Owner:HARBIN INST OF TECH +1

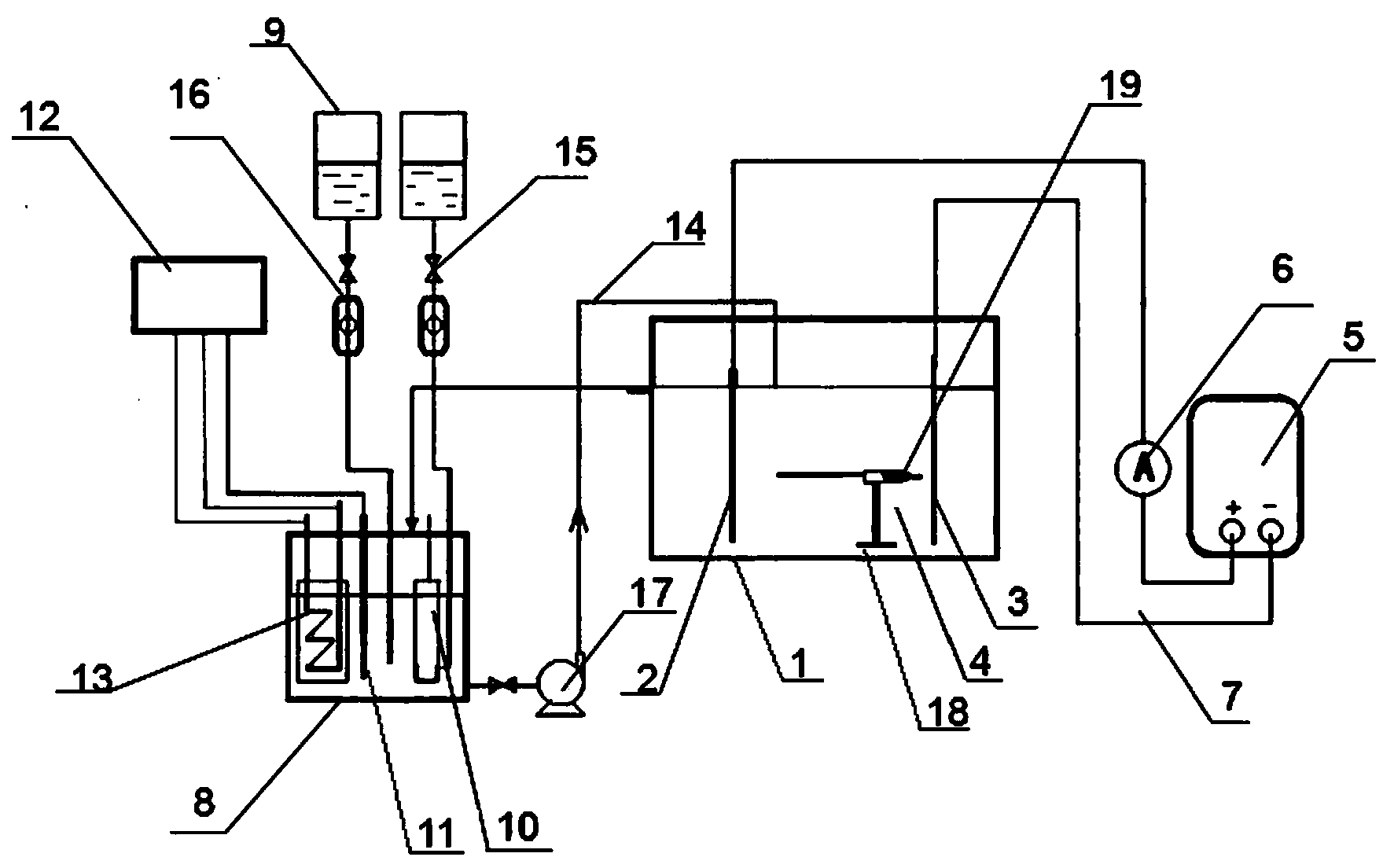

High-uniformity electroplating device for through holes of HDI (high density inverter) printed wiring board

InactiveCN104328465AHigh cathode current efficiencyInhibition of hydrogen evolution side reactionCellsPrinted element electric connection formationSide reactionEngineering

The invention relates to the technical field of through hole processing of HDI (high density inverter) printed wiring boards and particularly relates to a high-uniformity electroplating device for through holes of an HDI (high density inverter) printed wiring board. The device comprises an electroplating bath (1), an anode (2), a cathode (3) and a rectifying power supply (5), wherein the electroplating bath (1) is internally provided with a spraying mechanism (4) which can move in the electroplating bath (1) to directionally spray the surfaces of the through holes of the HDI board at a high speed. The cathode deposition currents on the surfaces of the through holes of the HDI board obtained are uniformly distributed, the copper layers are continuously distributed and are uniform in thickness, compact in organization structure, and good in conductivity, and the plating quality is improved. By using the electroplating device, the cathode current efficiency in the electroplating device is high, the hydrogen evolution side reaction is better inhibited, the efficiency of the electroplating production process is improved and the influence of hydrogen evolution on the quality of the copper layers is reduced, thereby facilitating reduction of the production cost.

Owner:ZHEJIANG ZHENYOU ELECTRONICS CO LTD

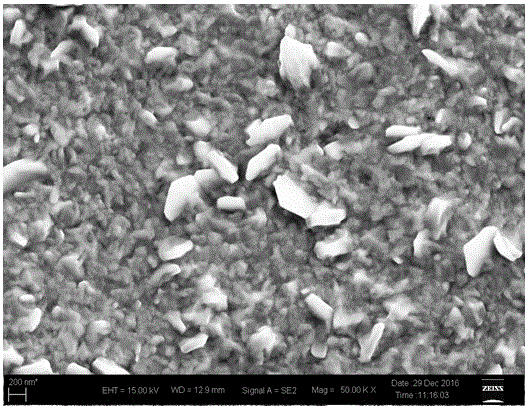

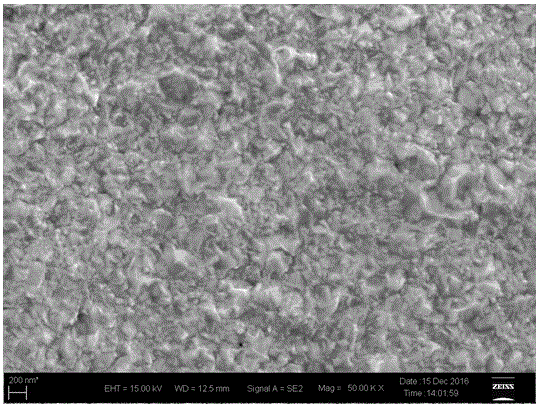

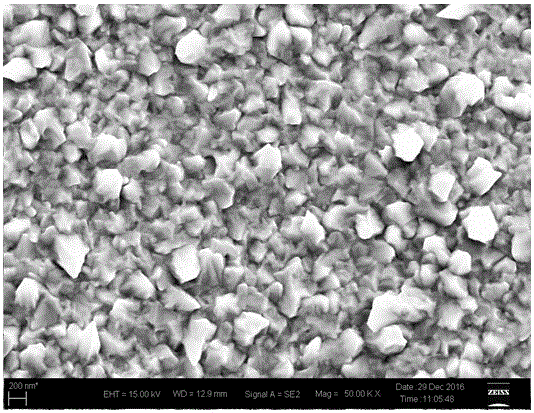

Ionic liquid gold plating solution containing coordination agent and additive and gold plating method adopting ionic liquid gold plating solution

The invention discloses an ionic liquid gold plating solution containing a coordination agent and an additive and a gold plating method adopting the ionic liquid gold plating solution and belongs to the technical field of gold electroplating. The gold plating solution is prepared from a solvent [BMIm] [BF4], main salt chloroauric acid, the coordination agent and the additive. Gold electroplating mainly includes the steps of (1) a substrate pretreatment and nickel preplating process and (2) gold electroplating. The ionic liquid gold plating solution containing the coordination agent and the additive and the gold plating method adopting the ionic liquid gold plating solution have the advantages that the added coordination agent has a certain coordination relation to gold ions, the stability of a gold complex in the plating solution can be improved, cathodic polarization can be improved in the electroplating process, and the functions of refining grains and brightening plating coatings are achieved; the added additive cooperates with the coordination agent to a certain degree so that the grains can be further refined, the coatings can be more compact and the appearance can be brighter; and to sum up, the ionic liquid gold plating solution and the gold plating method have the best characteristic that by adding the coordination agent and the additive in an ionic liquid system, the stability of the gold complex in the gold plating solution and the stability of the gold plating solution are improved, and therefore the gold plating coatings and the gold plating solution which are good in properties are obtained.

Owner:HARBIN INST OF TECH

Cyanide-free one-step rapid copper plating process for steel wire surface

The invention relates to a cyanide-free one-step rapid copper plating process for a steel wire surface. The cyanide-free one-step rapid copper plating process is characterized in that the electroplating solution is obtained by mainly mixing 150-300 g / L of copper sulfate, 5-16 mL / L of glycerol, 15-40 g / L of sulfuric acid, 50-100 g / L of a mixture of amino trimethylene phosphonic acid and 2-mercaptobenzimidazole, and 10-40 g / L of ammonium citrate, the cathode current density during electroplating is 35-50 A / dm<2>, and the temperature is 50-60 DEG C. According to the present invention, pre-plating is not required, the copper layer can be formed at a high speed, and the uniform, bright and delicate plating layer with good binding force can be obtained.

Owner:WUXI XINSANZHOU STEEL

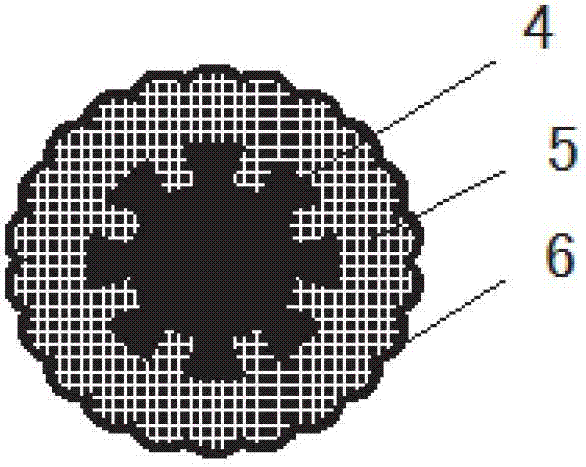

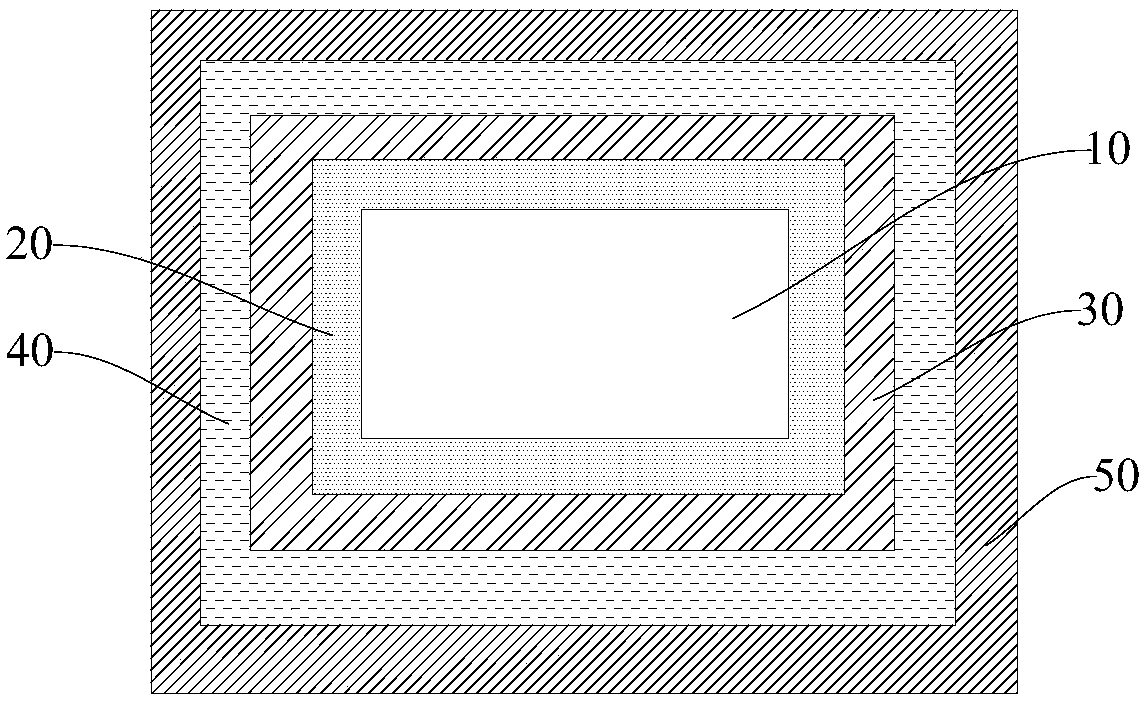

Composite anode material, preparation method of composite anode material, anode plate and preparation method of anode plate

ActiveCN107604388AImprove liquidityReduce concentration polarizationElectrolytic inorganic material coatingCeramic layered productsAlloyTitanium

The invention provides a composite anode material. The composite anode material comprises a metal bar core, a metal layer, a conductive ceramic layer and an activate ceramic layer, wherein the metal bar core is coated with the metal layer, and the metal layer adopts lead or a lead alloy; the metal layer is coated with the conductive ceramic layer, and the conductive ceramic layer comprises beta-PbO2-Al2O3 composite oxide; and the conductive ceramic layer is coated with the activate ceramic layer, and the activate ceramic layer comprises gamma-MnO2-Ti4O7 composite oxide. Compared with the priorart, according to the composite anode material, the outermost layer of the anode composite material comprises the gamma-MnO2-Ti4O7 composite oxide, wherein the gamma-MnO2 has the low oxygen evolutionpotential, the catalytic activity and corrosion resistance of an electrode can be further improved due to doped titanium, and meanwhile the intermediate conductive ceramic layer beta-PbO2-Al2O3 composite oxide has the good corrosion resistance and conductivity, so that the service life of the anode composite is longer, and the lower cell voltage is provided.

Owner:KUNMING HENDERA SCI & TECH +2

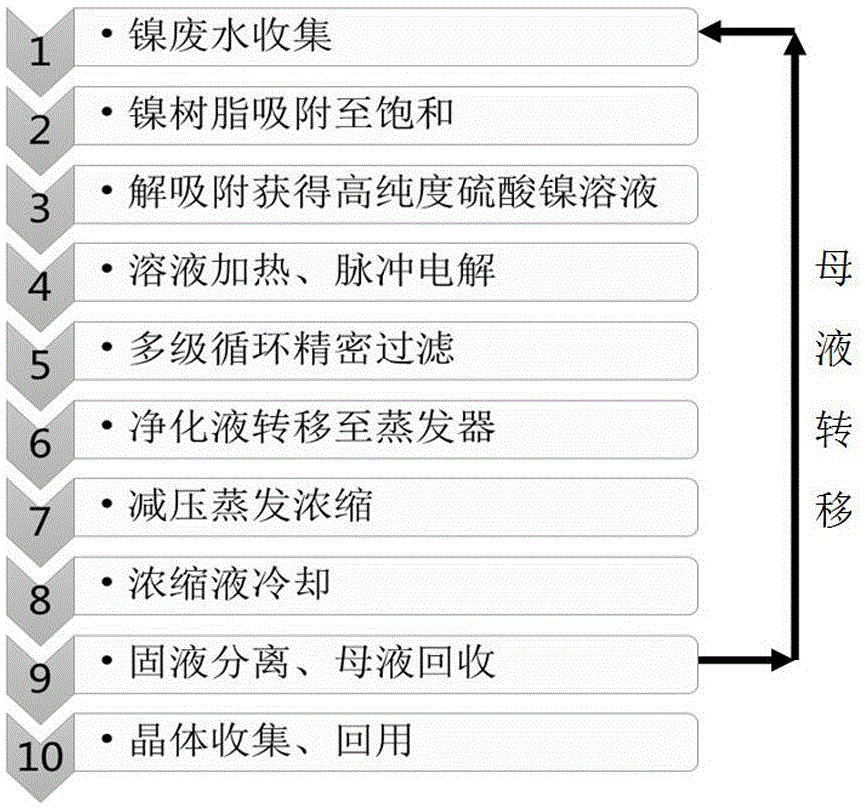

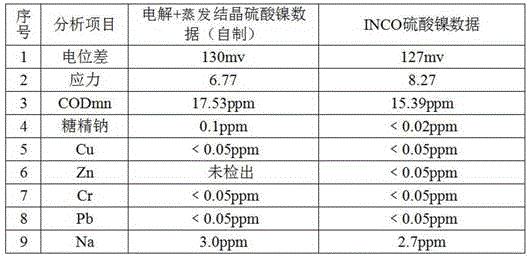

Method for preparing high-purity nickel salt by recycling industrial nickel-containing wastewater

The invention discloses a method for preparing high-purity nickel salt by recycling industrial nickel-containing wastewater. Nickel salt in the industrial nickel-containing wastewater is purified, crystallized, recycled and reused, the three-level purifying process including the steps of nickel resin adsorption primary concentration and purification, pulse electrolysis impurity removing and the third-level purification of evaporation crystallization impurity removing is adopted, nickel metal salt is recycled, obtained nickel salt is high in purity with the impurity and metal ions lower than the international standards, and the outsourcing quantity of nickel metal salt materials is greatly reduced; in addition, the method is easy to implement, low in cost, high in safety and significant in economic and social value.

Owner:XIAMEN RUNNER IND CORP

Preparation method of gradient composite anode for nonferrous metals electrodeposition

ActiveCN104562094AImprove liquidityReduce concentration polarizationElectrodesNonferrous metalTitanium

The invention discloses a preparation method of a gradient composite anode for nonferrous metals electrodeposition. The method comprises the following steps: preparing titanium bars by a drawing extrusion process; connecting a group of transverse titanium bars and three copper-coated titanium vertical bars to assemble into a fence-type titanium plate substrate; removing oil and carrying out activating treatment on the substrate by a chemical method, and preparing a nano-polyaniline-doped tin-antimony oxide by a coating method, and then carrying out argon arc welding on a fence-type titanium plate and a copper-coated titanium conductive beam; and respectively preparing an alpha-PbO2 intermediate layer and a molybdenum oxide-doped beta-PbO2 activating layer by an electrochemical codeposition method. The anode prepared by the method is good in electrocatalytic activity, low in cell voltage in electrodeposition, long in service life and low in energy consumption.

Owner:KUNMING HENDERA SCI & TECH

Copper electrolysis tail liquid purification copper removal decontaminating process method

ActiveCN106757179AHigh cathode current efficiencyImprove resource utilizationPhotography auxillary processesElectrolysis componentsElectrolysisResource utilization

The invention relates to a copper electrolysis tail liquid purification copper removal decontaminating process method. The process method includes the following steps that (1) electrolysis tail liquid is extracted at regular intervals to be fed to a liquid purification system, copper oxide ore is used for reducing acid, and normal temperature mechanical agitation leaching is carried out; (2) a sodium sulfite solution is added into a cupric sulfate solution obtained after filtering, the PH value of the solution is controlled, mechanical agitation is carried out, a leaching agent is subject to conversion and copper deposition, and copper is deposited in the form of cuprous sulfite or copper sulfite mixture; and (3) liquid obtained after deposition is subject to ferric reduction to be fed to a tailing pond, a way is opened for iron and other impurities from an electrodeposition system. According to the process method, the technology of reducing copper sulfate to deposit the cuprous sulfite through the sodium sulfite is adopted, a way is opened for copper and other impurity elements from a bath solution, the cathode current efficiency is improved, redundant acid in the bath solution is neutralized through copper oxide ore, the resource using rate is higher, and the beneficial effects of being not high in control requirement of equipment and process conditions, small in investment, simple, practical and capable of being returned to be used in the form of the cuprous sulfite or the copper sulfite are achieved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

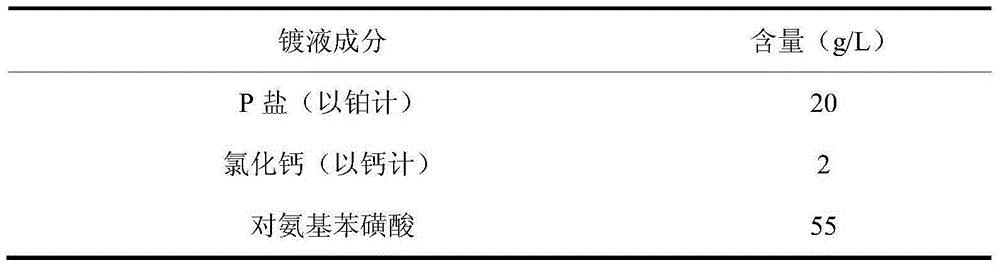

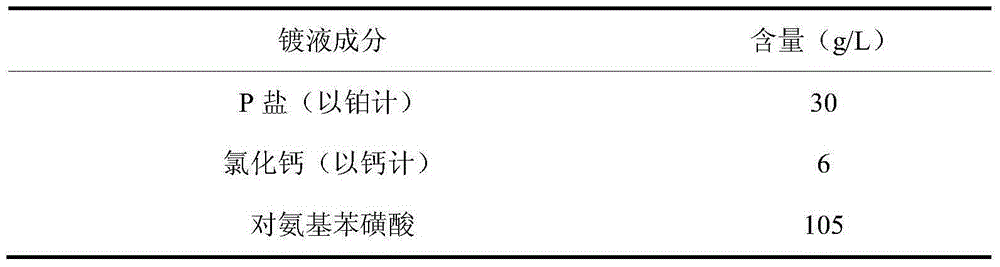

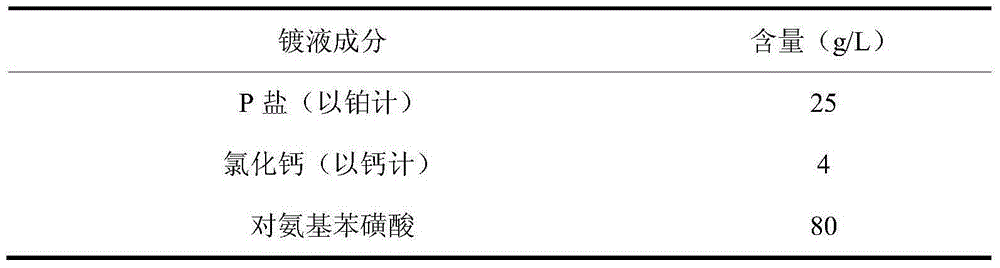

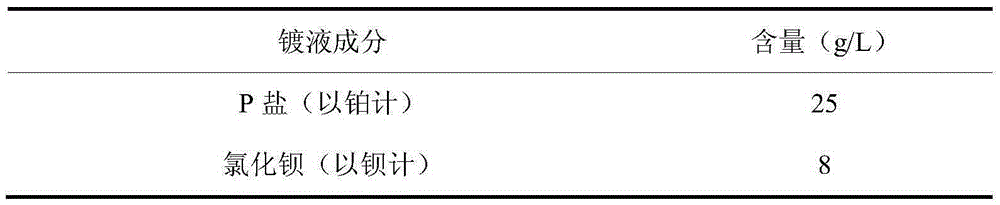

Dinitrodiammineplatinum ammoniacal electroplating solution for acidic platinum plating and electroplating method adopting dinitrodiammineplatinum ammoniacal electroplating solution

The invention discloses a dinitrodiammineplatinum ammoniacal electroplating solution for acidic platinum plating and an electroplating method adopting the dinitrodiammineplatinum ammoniacal electroplating solution. The dinitrodiammineplatinum ammoniacal electroplating solution comprises 20-30 g / L of dinitrodiammineplatinum ammoniacal which is measured by the content of platinum, 55-105 g / L of sulfanilic acid and 2-6 mg / L of calcium chloride which is measured by the content of calcium. Dinitrodiammineplatinum ammoniacal is utilized as a platinum main salt, sulfanilic acid is utilized as a complexing agent, and strontium chloride is utilized as a brightening agent, so that the obtained dinitrodiammineplatinum ammoniacal electroplating solution is relatively high in dispersion force and deep plating capability, and high in cathodic current efficiency and performance; when the dinitrodiammineplatinum ammoniacal electroplating solution is adopted for electroplating under an alkali condition, the obtained plating is low in porosity, and high in brightness and quality.

Owner:WUXI QINGYANG MACHINERY MFG

Novel efficient combined additive for zinc electrodeposition

ActiveCN106676578AImprove precipitation qualityHigh cathode current efficiencyPhotography auxillary processesProcess efficiency improvementElectricityEconomic benefits

The invention discloses a novel efficient combined additive for zinc electrodeposition. The novel efficient combined additive for zinc electrodeposition is characterized in that the combined additive comprises 0.05-0.2 g / L of bone glue, 0.01-0.1 g / L of aloe gel, 0.01-0.03 g / L of cetylpyridinium chloride; during usage, bone glue, aloe gel and cetylpyridinium chloride are prepared into a solution; the required additives are molten with hot water and then are fully mixed to the fixed volume. The combined additive provided by the invention is used for the zinc electrodeposition process, has a certain creative and positive significance of solving the detail problems during production, improving the current efficiency and the electrolytic zinc quality, reducing energy consumption of zinc electrodeposition and saving the labor cost and also has the great practical production significance of realizing efficient automatic production of zinc electrodeposition, improving the production of zinc smelting, lowering the production cost, increasing the economic benefits of enterprises and other aspects.

Owner:SHENYANG RES INST OF NONFERROUS METALS

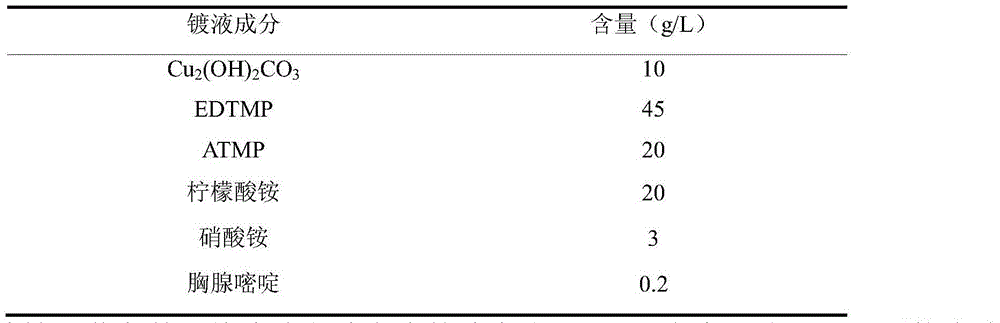

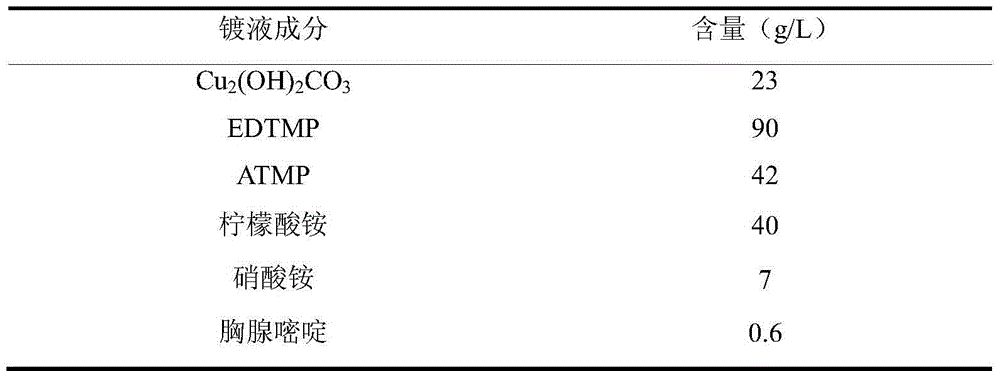

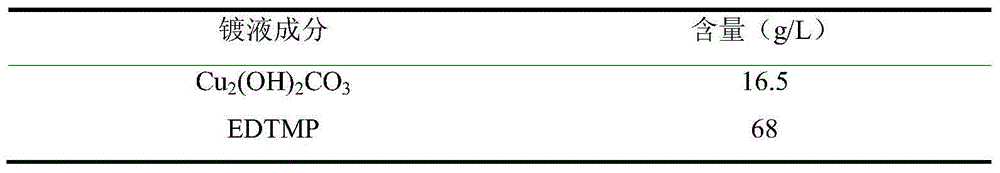

Electroplating solution for composite organic phosphonic acid cyanide-free copper plating and electroplating method

The invention discloses an electroplating solution for composite organic phosphonic acid cyanide-free copper plating and an electroplating method. The electroplating solution comprises: 10-23g / L Cu2(OH)2CO3, 45-90g / L EDTMP (ethylene diamine tetra(methylene phosphonic acid)), 20-42g / L ATMP (aminotri-(methylene phosphonic acid)), 20-40g / L citrate, 3-7g / L nitrate and 0.2-0.6g / L thymine. The electroplating solution provided by the invention adopts EDTMP and ATMP composite organic phosphonic acid as the coordination agent to improve the coordination ability of copper ions, and takes citrate as the auxiliary coordination agent, so that the electroplating solution has good dispersion force and deep plating ability, high cathode current efficiency, and excellent performance. The coating obtained by electroplating of the electroplating solution under an alkaline condition has low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

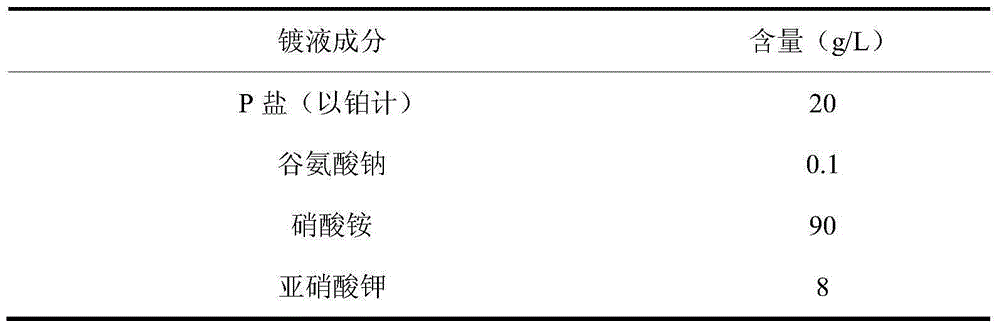

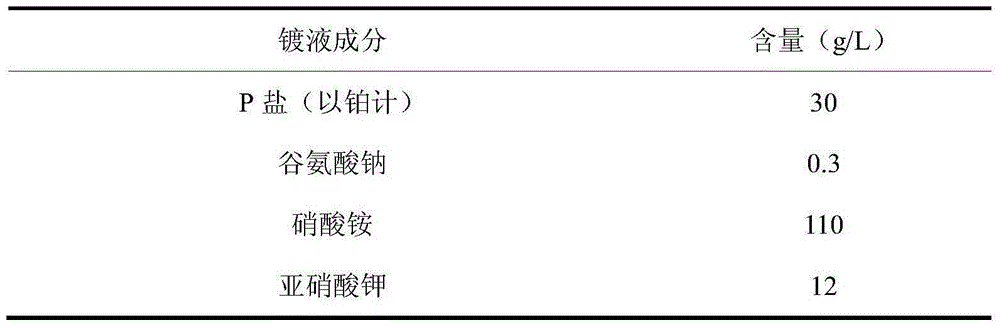

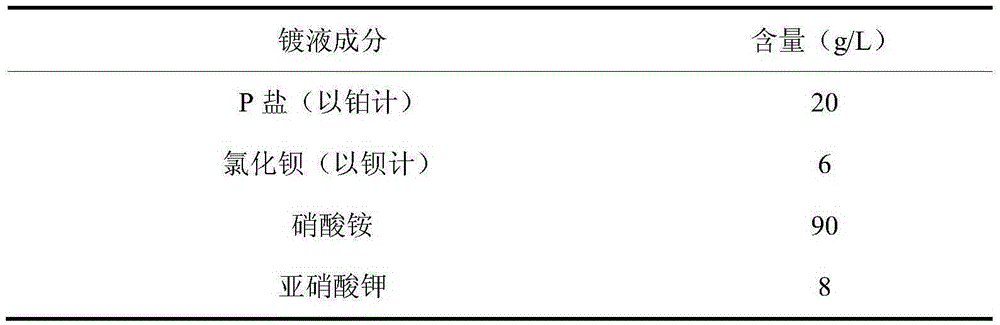

Alkaline P salt plating solution for electroplating platinum and electroplating method thereof

The invention discloses an alkaline P salt plating solution for electroplating platinum and an electroplating method thereof. In terms of platinum, the plating solution comprises 20-30g / L p salt, 90-110g / L ammonium nitrate, 8-12g / L potassium nitrite or sodium nitrite and 100-300mg / L sodium glutamate. The ammonium nitrate and the potassium nitrite or sodium are taken as auxiliary salts, and the sodium glutamate is taken as a brightening agent, so that the obtained plating solution has better dispersion force and deep plating cavity, high cathode current efficiency and excellent plating solution performance. A plating layer obtained by electroplating through the plating solution under an alkaline condition has low porosity, high brightness and good plating quality.

Owner:WUXI QINGYANG MACHINERY MFG

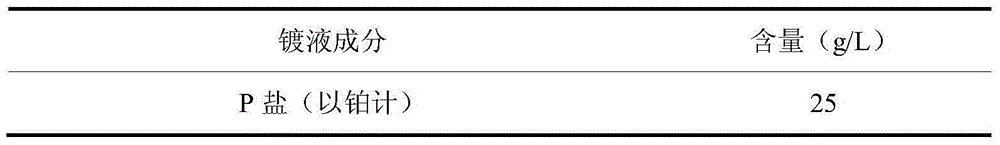

Preparation method of HEDP copper-plated non-porous thin layer

The invention belongs to the technical field of cyanide-free copper plating technology, and particularly relates to a preparation method of an HEDP copper-plated non-porous thin layer. The preparation method comprises the steps that abrasive paper is used for polishing to remove floating rust at first, then, chemical degreasing and activation are carried out, and finally deionized water is used for cleaning; a plating solution is prepared; plating is carried out, particularly, an electrolysis copper plate is used as an anode, an oxidation film on the surface of the copper plate is removed, activation treatment is carried out for 5-10 s through a 10%-20% dilute hydrochloric acid solution, a base plate which is treated is used as a cathode to be placed in the plating solution, the temperature is 50-65 DEG C, the pH value is 9-11, direct current plating is carried out, the current density is 0.5-3.5 A / dm<2>, plating is carried out under the cathode moving condition, the moving speed is 3 cm / s-5 cm / s, and the HEDP copper-plated non-porous thin layer is obtained. The HEDP alkaline plating solution is low in toxicity, environmentally friendly and quite low in corrosion to production equipment, the leveling ability, dispersing ability and deep plating ability of the HEDP alkaline plating solution can reach or even exceed those of a cyanide copper plating solution, the cathode current efficiency reaches up to 95% or above, and the plating solution is stable in performance.

Owner:SHENYANG AIRCRAFT CORP

Environment-friendly electro-coppering liquid

The invention discloses an environment-friendly electro-coppering liquid which is characterized by comprising a main binder, an auxiliary binder, a main salt, a conductive salt and a pH value conditioning agent, wherein the binder is disodium ethylene diamine tetraacetate or dipotassium ethylene diamine tetraacetate with a concentration of 100 to 150 g / L, the auxiliary binder is trisodium citrate, tripotassium citrate or potassium sodium tartrate with a concentration of 20 to 35 g / L, the main salt is copper sulphate or basic cupric carbonate with a concentration of 10 to 40 g / L, the conductive salt is sodium nitrate or potassium nitrate with a concentration of 5 to 10 g / L, and the pH value conditioning agent is sodium hydroxide or potassium hydroxide with a concentration of 25 to 50 g / L. The environment-friendly electro-coppering liquid provided by the invention has the following advantages: the electro-coppering liquid is a cyanide-free plating solution which is environment-friendly and nontoxic, easy to operate and maintain and applicable to direct electroplating on the surface of steel wires; the electro-coppering liquid has good polarization performance, high cathodic current efficiency and a wide density scope; and a coating formed by the liquid has good bonding force and is simple to maintain and low in cost.

Owner:NANTONG HUIFENG ELECTRONICS TECH

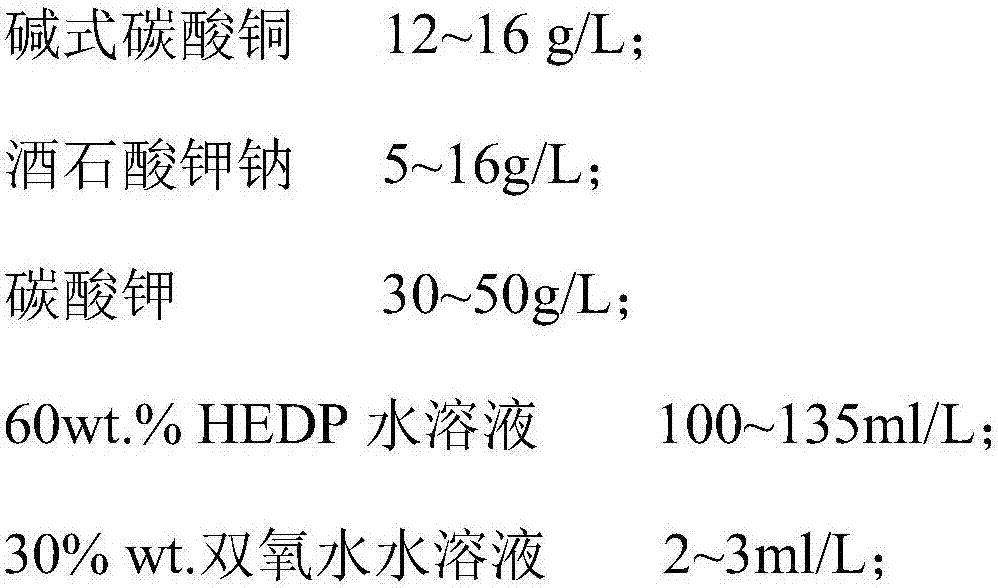

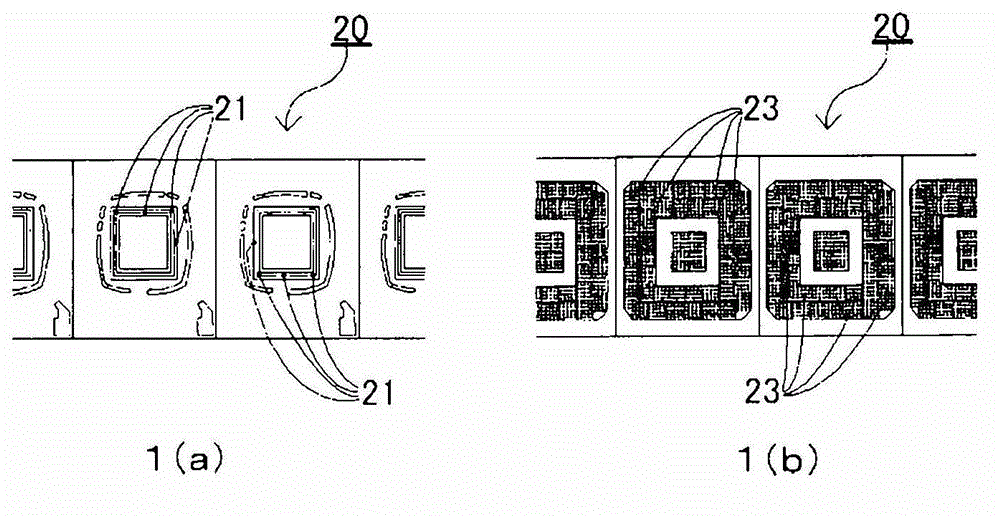

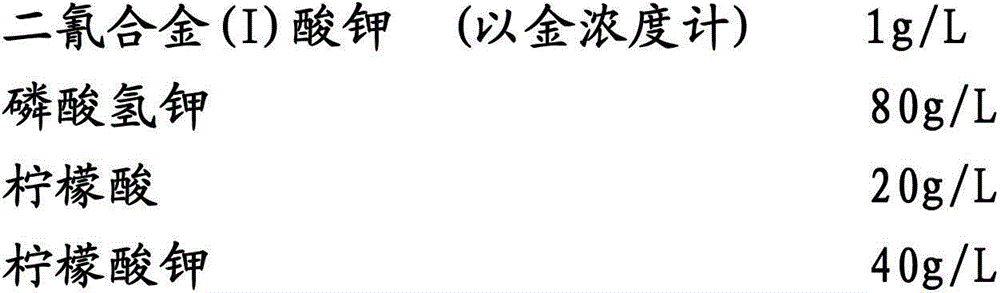

Cyanide based electrolytic gold plating solution and plating method using same

InactiveCN102753732AExcellent liquid stabilityExcellent liquid lifeConductive pattern reinforcementCyanideCrystal

Disclosed is a cyanide based electrolytic gold plating solution characterized by containing a dicyanoaurate (I) alkali salt or dicyanoaurate (I) ammonium salt such that the gold concentration is 1.0 - 5.0 g / L, crystal adjuster, conductive salt, buffer and deposition accelerator formed from one of either a sulfite alkali salt and sulfite ammonium salt such that sulfite ions amount to 0.1 mg / L - 18 g / L.

Owner:N E CHEMCAT

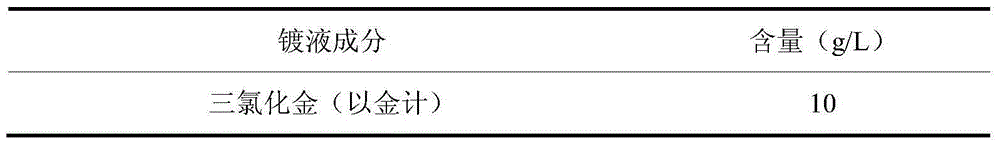

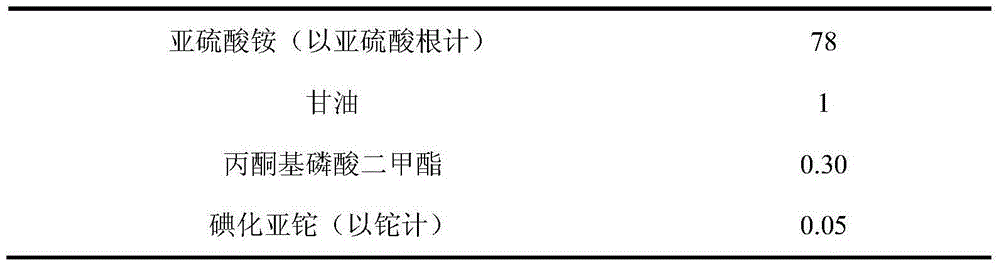

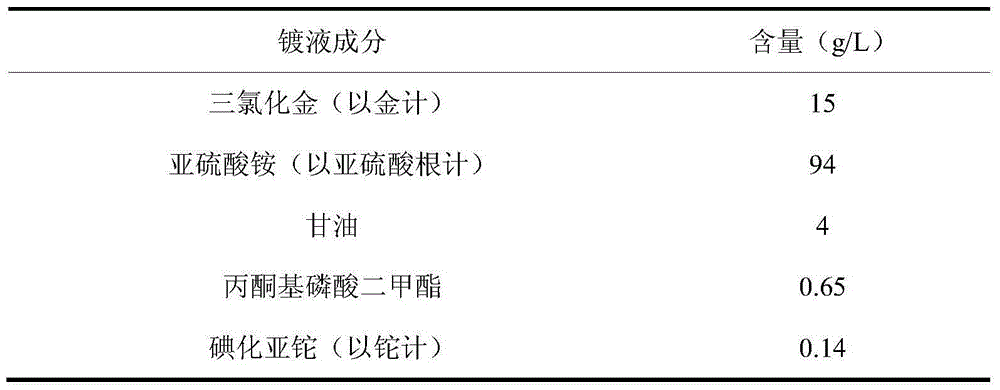

Electroplate liquid and electroplate method for cyanide-free gold plating of thallium-contained sulfite

The invention discloses electroplate liquid and an electroplate method for cyanide-free gold plating of thallium-contained sulfite. The electroplate liquid is composed of 10-15 g / L of gold chloride in terms of gold, 78-94 g / L of sulfite in terms of sulfite radicals, 1-4 g / L of glycerinum, 0.30-0.65 g / L of organic phosphorus compounds and 0.05-0.14 g / L of thallous salt in terms of thallium. According to the electroplate liquid, the sulfite serves as main coordination agents, the glycerinum serves as stabilizers, the organic phosphorus compounds serve as electron accelerators, the thallous salt serves as brightening agents, and the gold chloride serves as main gold salt, so that the obtained electroplate liquid is good in dispersion capacity and covering capacity, cathode currents are high in efficiency, and the electroplate liquid is excellent in performance. By the adoption of the electroplate liquid, plating obtained through electroplating under the alkaline condition is low in porosity, high in brightness and good in quality.

Owner:无锡永发电镀有限公司

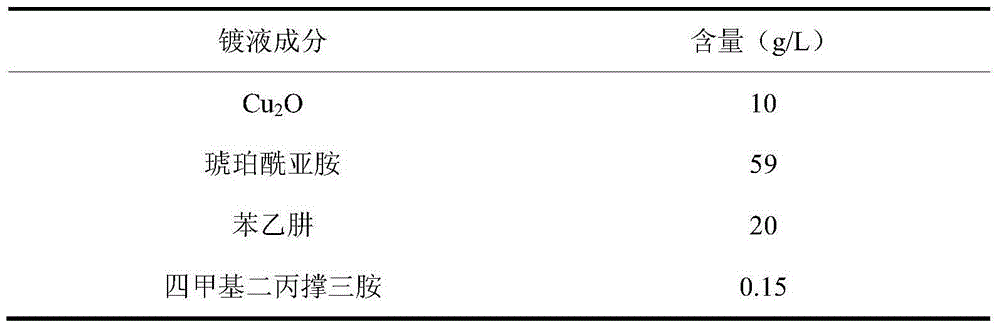

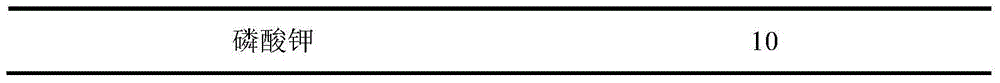

Hydrazine reducing agent cyanide-free cuprous electroplating solution and electroplating method

The invention discloses a hydrazine reducing agent cyanide-free cuprous electroplating solution and an electroplating method. The electroplating solution comprises 10-25g / L of Cu2O, 59-99g / L of succinimide, 20-40g / L of a hydrazine compound, 0.15-0.5g / L of tetramethyldipropylenetriamine and 10-20g / L of phosphate. The electroplating solution utilizes Cu2O as a copper source, a hydrazine compound as a cuprous stabilizing agent, succinimide as a cuprous ion coordination agent, tetramethyldipropylenetriamine as a brightener and phosphate as a conductive salt so that the electroplating solution has a good dispersion force, a deep plating capability, high cathode current efficiency and excellent plating solution performances. Through the electroplating solution, the plated layer obtained by electroplating under alkaline conditions has low porosity and has good quality.

Owner:WUXI HANKWANG ELECTRIC

Cyanide-free copper electroplating method for reducing porosity of copper plating layer

The present invention relates to a cyanide-free copper electroplating method for reducing porosity of a copper plating layer. According to the cyanide-free copper electroplating method, a substrate is alternately subjected to a direct current electroplating unit and a pulse electroplating unit, the pH value of the electroplating solution is controlled to 12-13, the temperature is 50-70 DEG C, the cathode current density for copper electroplating in each direct current electroplating unit is 0.5-3.0 A / dm<2>, the electroplating time is 2-3 min, the pulse average current density for copper electroplating in each alternating current electroplating unit is 0.5-3.0 A / dm<2>, the duty ratio is 15%, and the electroplating time is 2-3 min. The plating layer obtained through the method has minimal porosity when the plating layer thickness is 10-20 mum.

Owner:WUXI XINSANZHOU STEEL

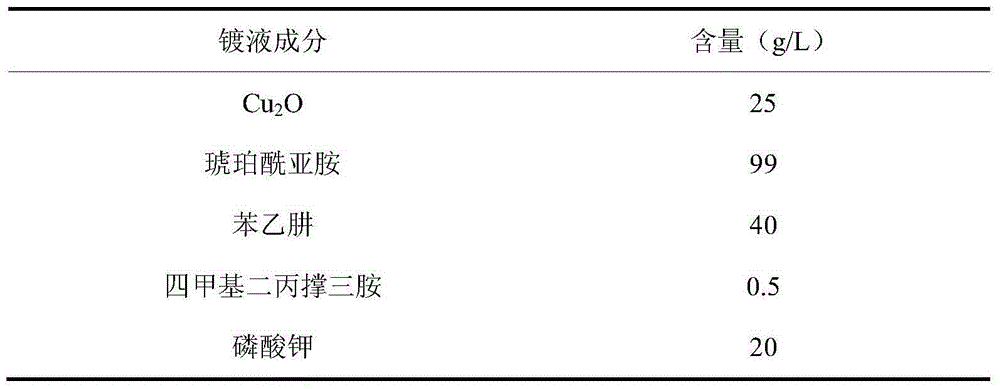

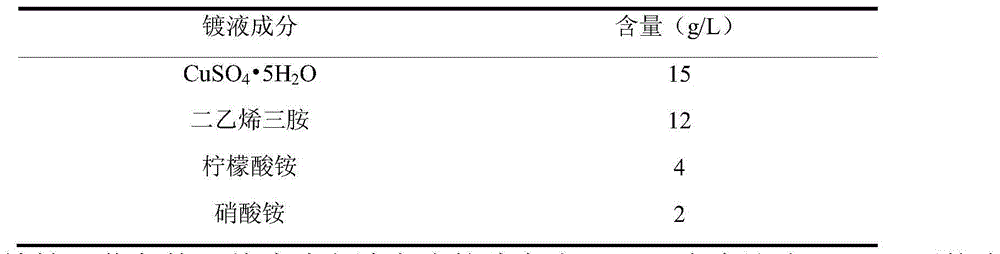

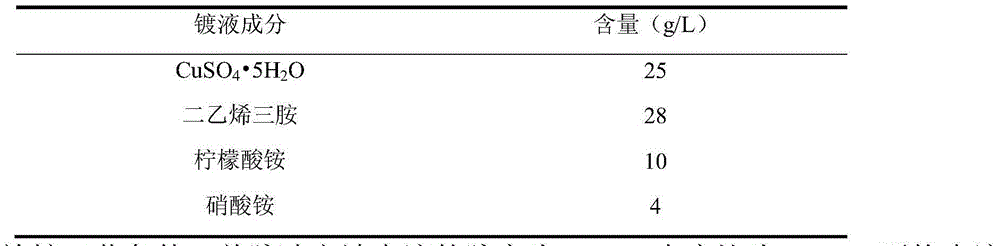

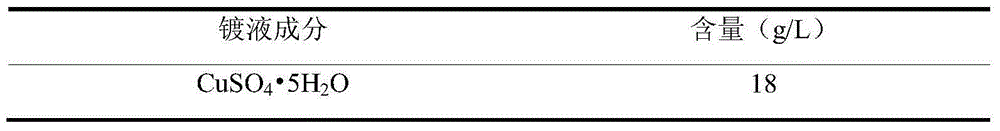

Electroplating liquid and electroplating method of diethylenetriamine cyanide-free copper plating

InactiveCN104630836AGood dispersion and depth capabilitiesHigh cathode current efficiencyChemistryCopper plating

The present invention discloses an electroplating liquid and an electroplating method of diethylenetriamine cyanide-free copper plating. The electroplating liquid comprises 15-25 g / L of CuSO4.5H2O, 12-28 g / L of diethylenetriamine, 4-10 g / L of citrate, and 2-4 g / L of nitrate. According to the electroplating liquid of the present invention, the diethylenetriamine is adopted as the coordination agent, and the citrate is adopted as the auxiliary coordination agent, such that the electroplating liquid characteristics of good dispersion, good deep plating ability, high cathode current efficiency, and excellent plating liquid performance. In addition, the plating layer obtained through electroplating under the alkaline condition has characteristics of low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

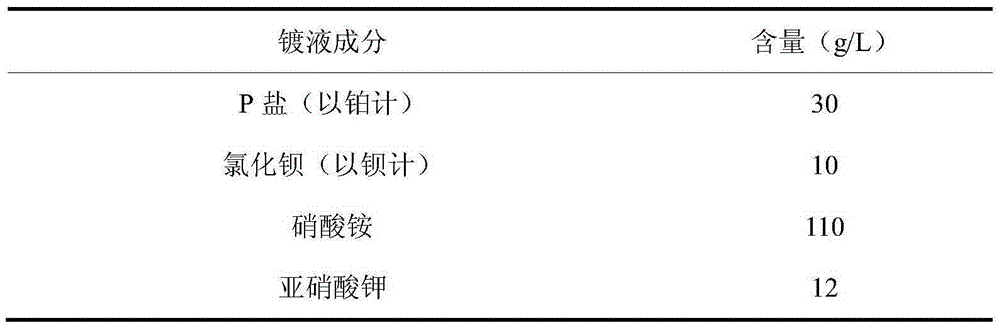

Barium-salt-contained alkaline plating Pt P salt electroplating bath and electroplating method thereof

The invention discloses barium-salt-contained alkaline plating Pt P salt electroplating bath and an electroplating method of the electroplating bath. The electroplating bath comprises, by platinum, 20-30 g / L of P salt, 90-110 g / L of ammonium nitrate, 8-12 g / L of potassium nitrite or sodium nitrite and 6-10 mg / L of barium chloride by barium. P salt serves as platinum main salt, the ammonium nitrate and the potassium nitrite or sodium are taken as auxiliary salt, and the barium chloride serves as a brightening agent, so that the obtained electroplating bath has the good dispersion force and deep plating capacity, the current efficiency of a negative pole is high, and the performance of the plating bath is excellent. A coating obtained through electroplating of the electroplating bath under the alkaline condition is low in porosity, high in brightness and good in quality.

Owner:WUXI QINGYANG MACHINERY MFG

A preparation method of a fence-type aluminum rod-lead alloy anode plate for electrowinning of nonferrous metals

ActiveCN104611731BImprove liquidityReduce concentration polarizationLiquid/solution decomposition chemical coatingElectrolytic organic material coatingCopperPolyaniline

The invention discloses a fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition and a preparation method of the fence-type aluminum bar lead alloy anode plate. The fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition comprises an aluminum or aluminum alloy conductive beam (1), a copper-aluminum explosive composite conductive head (2) and a fence-type anode plate bracket (3), wherein the copper-aluminum explosive composite conductive head (2) is welded on the conductive beam; the fence-type anode plate bracket (3) is welded below the aluminum or aluminum alloy conductive beam (1), and is assembled by aluminum bar lead alloy composite anode bars; the aluminum bar lead alloy composite anode bars forming the fence-type anode plate bracket are fixed by virtue of an insulating edge-clamping strips (4); the insulating edge-clamping strips are welded with one another to form an overall frame; and a layer of beta-PbO2-polyaniline conductive ceramic (5) covers the surface of the fence-type anode plate bracket. Compared with a traditional lead-based alloy anode plate, the fence-type aluminum bar lead alloy anode plate has the advantages that the electrical conductivity is significantly improved; the bath voltage can be reduced by 12%; the material cost is reduced by 30%; and the current efficiency is improved by 2%-5%.

Owner:KUNMING HENDERA SCI & TECH

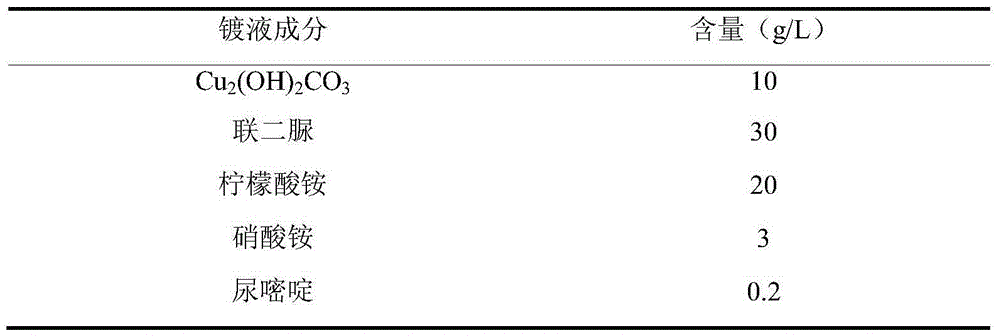

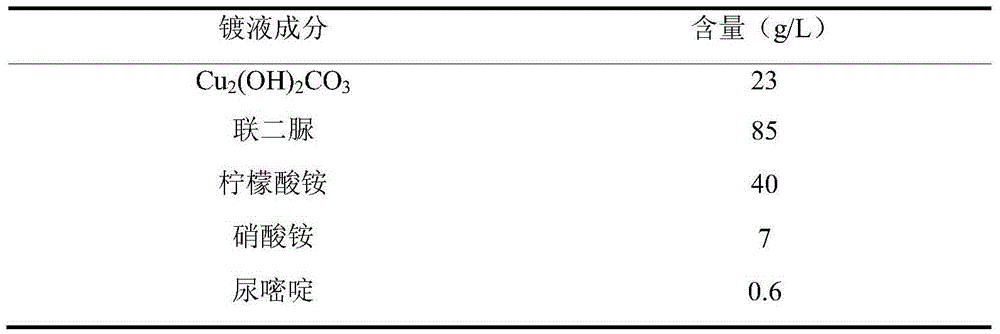

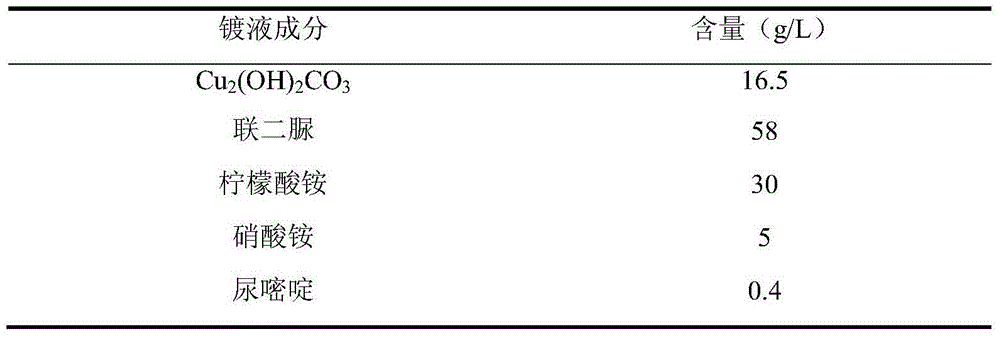

Electroplating liquid and electroplating method of biurea cyanide-free copper plating

The present invention discloses an electroplating liquid and an electroplating method of biurea cyanide-free copper plating. The electroplating liquid comprises 10-23 g / L of Cu2(OH)2CO3, 30-85 g / L of biurea, 20-40 g / L of citrate, 3-7 g / L of nitrate, and 0.2-0.6 g / L of uracil. According to the electroplating liquid of the present invention, the biurea is adopted as the coordination agent, and the citrate is adopted as the auxiliary coordination agent, such that the electroplating liquid characteristics of good dispersion, good deep plating ability, high cathode current efficiency, and excellent plating liquid performance. In addition, the plating layer obtained through electroplating under the alkaline condition has characteristics of low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

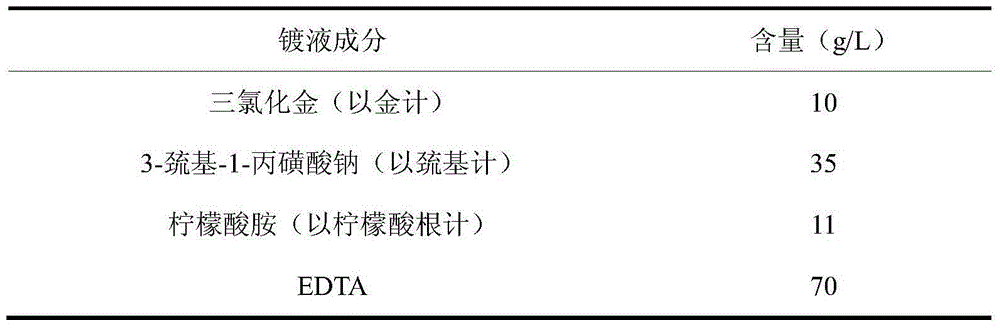

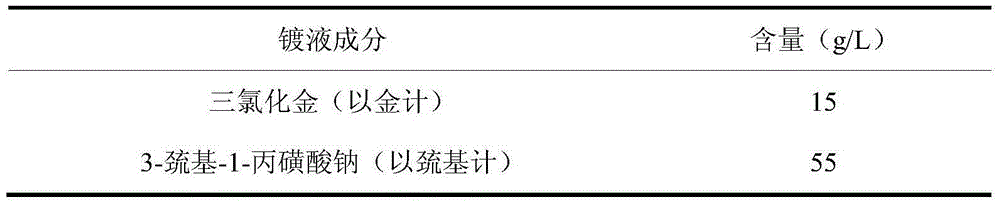

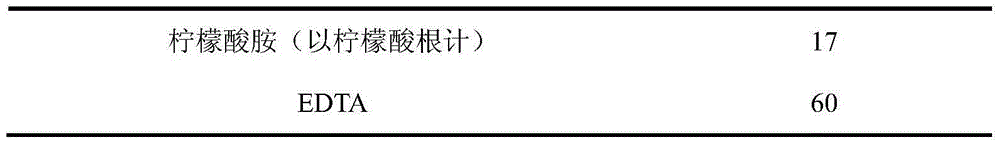

Plating solution for mercapto sulfonic acid non-cyanogen gold plating and plating method thereof

The invention discloses a plating solution for mercapto sulfonic acid non-cyanogen gold plating and a plating method thereof. The plating solution comprises 10-15g / L of gold trichloride calculated by gold, 35-55g / L mercapto sulfonic acid compound calculated by mercapto group, 11-17g / L citric acid and salts thereof calculated by citrate, and 50-70g / L EDTA. The plating solution uses mercapto sulfonic acid compound as the main complexing agent, uses citric acid and its salts, and EDTA as the auxiliary complexing agent, and uses gold trichloride as the main gold salt, so that the obtained plating solution has good dispersion force, deep plating capability power, high cathodic current efficiency, and excellent performance. The plating layer obtained under basic conditions by using the plating solution has the advantages of low porosity, high brightness and good plating layer quality.

Owner:无锡永发电镀有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com