Fence-type aluminum bar lead alloy anode plate for non-ferrous metal electrodeposition and preparation method of fence-type aluminum bar lead alloy anode plate

A technology of non-ferrous metals and lead alloys, applied in the field of electrochemistry, which can solve the problems of large loss of silver and calcium, easy peeling of the deposited layer, and low current efficiency, and achieve the effects of resisting sulfuric acid corrosion, shortening the effective diameter, and improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

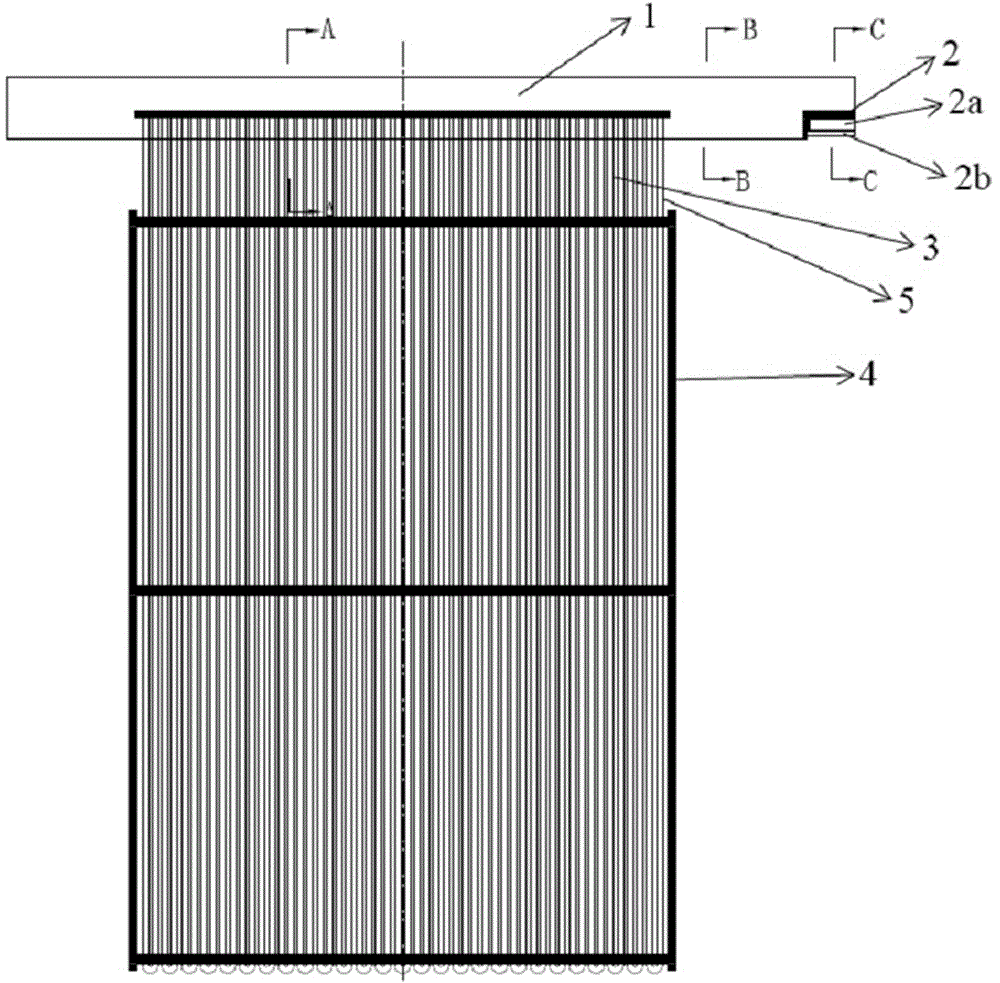

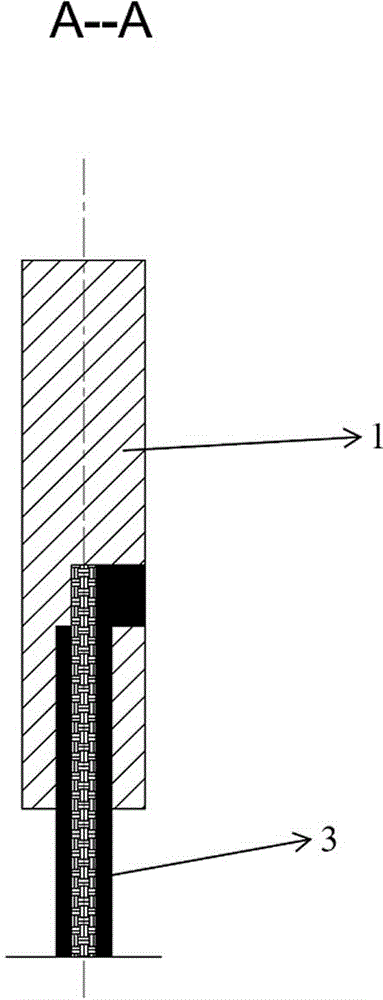

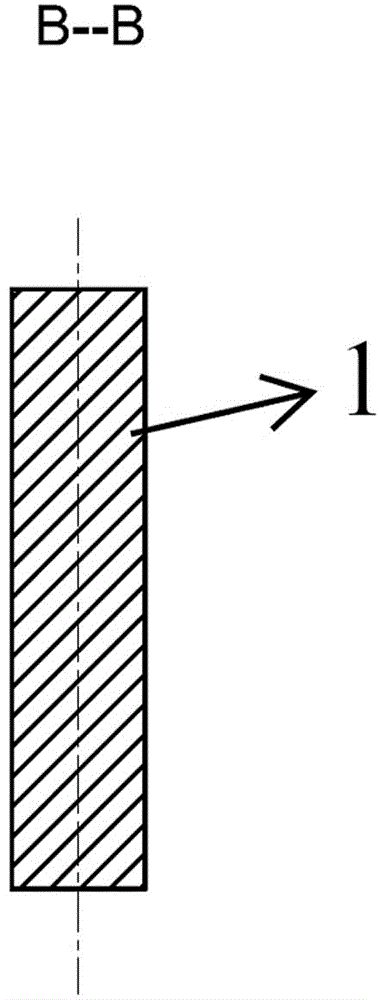

[0036] Such as Figure 1 ~ Figure 4 As shown, the fence-type aluminum rod-lead alloy anode plate for electrowinning of nonferrous metals of the present invention includes an aluminum or aluminum alloy conductive beam 1, a copper-aluminum explosive composite conductive head 2 welded on the conductive beam, and a copper-aluminum explosive composite conductive head 2 welded on the aluminum or aluminum alloy The fence-type anode plate support 3 below the conductive beam 1; the fence-type anode plate support is assembled from an aluminum rod-lead alloy composite anode rod, and the frame of the fence-type anode plate support is fixed by an insulating clamping strip 4, and the insulating clamping strip Welded with each other to form an integral frame; the surface of the fence-type anode plate support is covered with a layer of β-PbO 2 - Polyaniline Conductive Ceramic5. The aluminum or aluminum alloy rod core of the aluminum rod lead alloy composite anode rod is an elliptical rod wit...

Embodiment 2

[0043] The preparation method of the fence type aluminum rod lead alloy anode plate for electrowinning of nonferrous metals is as follows:

[0044] 1) An elliptical aluminum rod is prepared by drawing and extrusion technology, and its surface is drawn with heterogeneous tooth patterns, and then put it in sodium hydroxide with a mass volume ratio of 10% for 8 minutes, rinse with clean water, and put it in Volume ratio 20%HNO 3 Soak in tin plating solution for 0.5min, rinse with clean water, soak in tin plating solution for 2min, wash with deionized water, dry quickly with hot air, and set aside. The formula and process parameters of the tin plating solution used are: 60g / L potassium stannate, 100g / L potassium pyrophosphate, 40g / L potassium hydroxide, 40g / L sodium acetate, 30g / L ethylenediaminetetraacetic acid, OP emulsifier 0.1g / L, dipping temperature 40℃;

[0045] 2) The surface of the aluminum or aluminum alloy rod core obtained in step 1) is combined with lead-silver alloy...

Embodiment 3

[0049] The preparation method of the fence type aluminum rod lead alloy anode plate for electrowinning of nonferrous metals is as follows:

[0050] 1) An elliptical aluminum rod is prepared by drawing and extrusion technology, and its surface is drawn with a zigzag pattern, and then it is soaked in sodium hydroxide with a mass volume ratio of 10% for 10 minutes. 20%HNO 3 Soak in water for 1min, rinse with clean water, soak in silver plating solution for 4min, wash with deionized water, dry quickly with hot air, and set aside. The formula and process parameters of the silver plating solution used are: 10g / L AgNO 3 , 6g / L NaOH, 10 mL / L NH 3 ·H 2 O, 9g / L glucose, 1g / L tartaric acid, 100 mL / L ethanol, polyvinylpyrrolidone (PVP) 0.2 / L, silver plating solution pH13, immersion plating temperature 25°C. 2) The surface of the aluminum or aluminum alloy rod core obtained in step 1) is compounded with lead-silver-calcium rare earth alloy by drawing and extrusion process to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com