Method for recovering copper from cyanide-containing waste water and related waste water treatment method

A disposal method and technology for copper recovery, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of long process and low current efficiency, and achieve closed-circuit zero discharge, avoid Effects of Oxidative Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The feed liquid is a poor cyanide solution, and its composition is as follows: CNt 14.57g / L, Cu 8.1g / L, Zn 2.5g / L, CN4.0g / L, SCN- 6.56g / L, Fe trace, pH=11.9 .

[0039] When the solution temperature is 38°C, pH=9, the current density is 9.8~12mA / cm 2 Under the electrowinning conditions, brass containing 73% copper can be obtained on the cathode in the first 2 hours, and then blister copper containing 97% copper can be obtained by continuing electrowinning. Table 1 lists certain cathode blister copper compositions.

[0040] Table 1 cathode blister copper composition (%)

[0041] Cu,

Zn

Ca

Pb

Si

Fe

other

97.0

2.5

0.21

0.17

0.038

0.023

0.059

[0042]When the current efficiency drops below 40% (about 4 to 5 hours), pump the electrolytic solution into the acidification tank, and add sulfuric acid with a concentration of 50% (v / v) into the electrolytic solution at a volume rat...

Embodiment 2

[0046] The feed liquid is a high-concentration copper-cyanide solution, and its composition is as follows: CNt 64g / L, Cu 30.0g / L, Zn 4.1g / L, CN 20g / L, Fe 0.1g / L, pH=12.

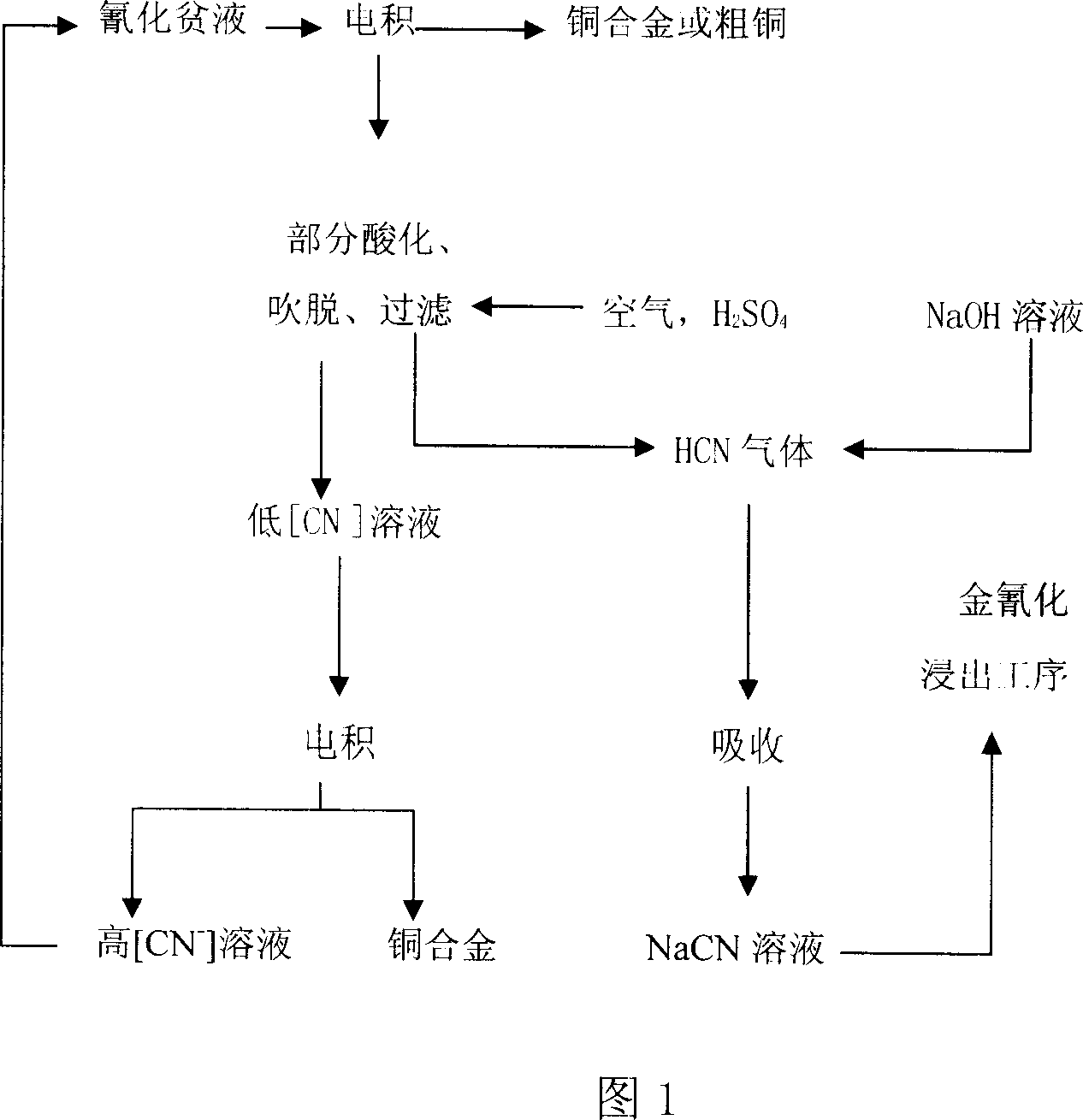

[0047] The process flow of electrowinning-partial acidification is shown in Figure 1.

[0048] At a solution temperature of 45°C, pH=10, and a current density of 20-40mA / cm 2 Brass can be obtained by electrodeposition under certain conditions; when the solution temperature is higher than 44°C, the pH is 4.5-8, and the current density is 10-25mA / cm 2 Blister copper containing copper ≥ 98.0% can be obtained by electrowinning. Table 2 lists certain cathode brass and blister copper compositions.

[0049] Table 2 Composition of cathode brass and blister copper (%)

[0050] Cu,

Zn

Ca

Pb

Fe

other

70.5

29.1

0.19

0.1

0.01

0.10

98.2

1.4

0.20

0.1

0.02

0.08

[0051] When the current ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com