Patents

Literature

58results about How to "Good deep plating ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplating solution and electroplating method for electroplating through holes and blind holes of circuit boards

The invention discloses an electroplating solution for electroplating through holes and blind holes of circuit boards. The electroplating solution comprises the following components: 160-180g / L of copper sulfate pentahydrate, 20-50g / L of sulfuric acid, 0.05-0.07g / L of chloride ions, 0.5-1.5g / L of accelerant, 7-30g / L of inhibitor, 10-30g / L of leveling agent and the balance of water. The electroplating solution provided by the present invention is applicable to electroplate through holes and blinds holes of circuit boards, and in particular capable of realizing simultaneously hole-filling electroplating of a through hole and a blind hole in one groove of a circuit board; as a result, the electroplating steps are reduced and the production efficiency is improved.

Owner:苏州禾川化学技术服务有限公司

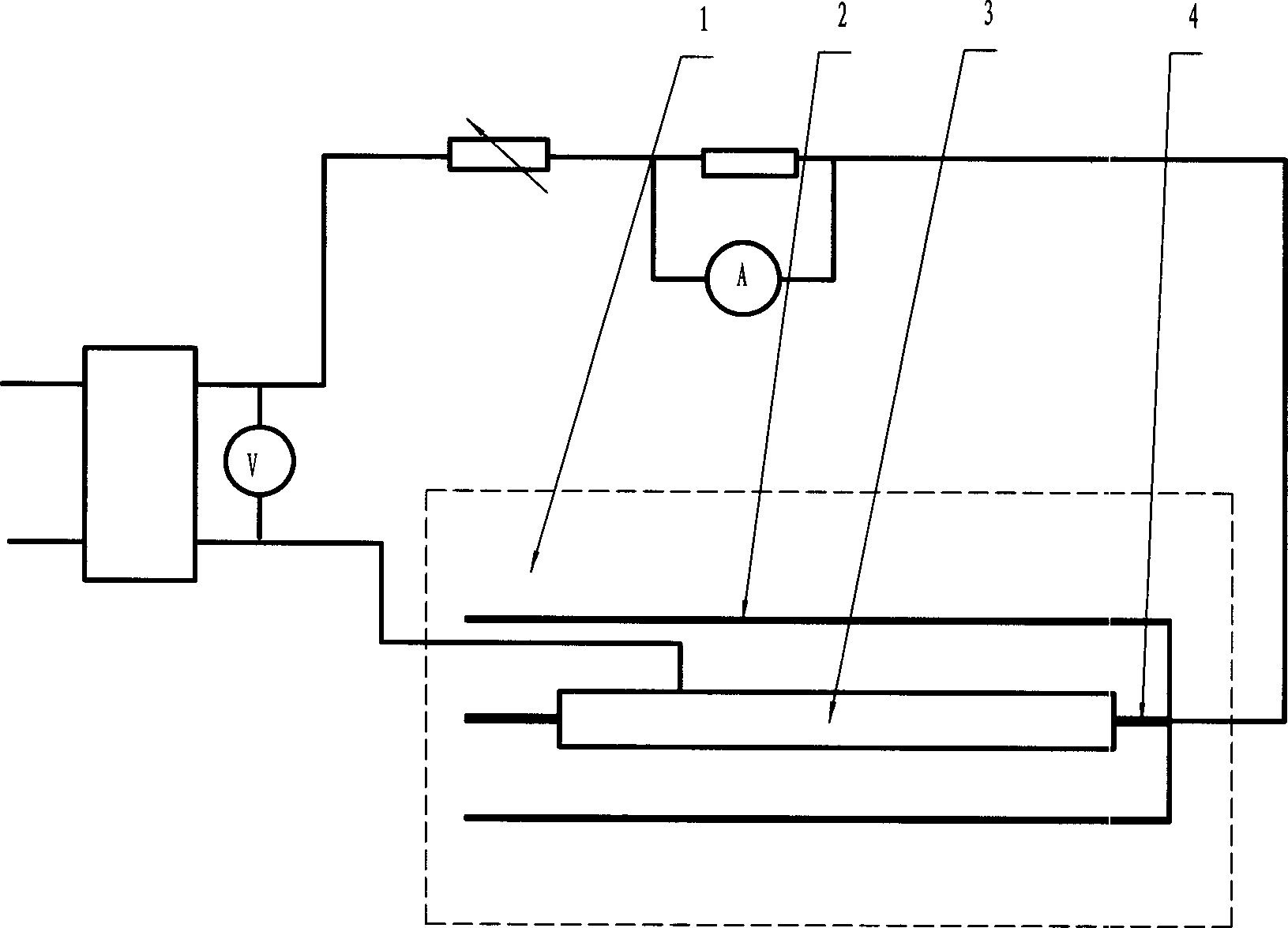

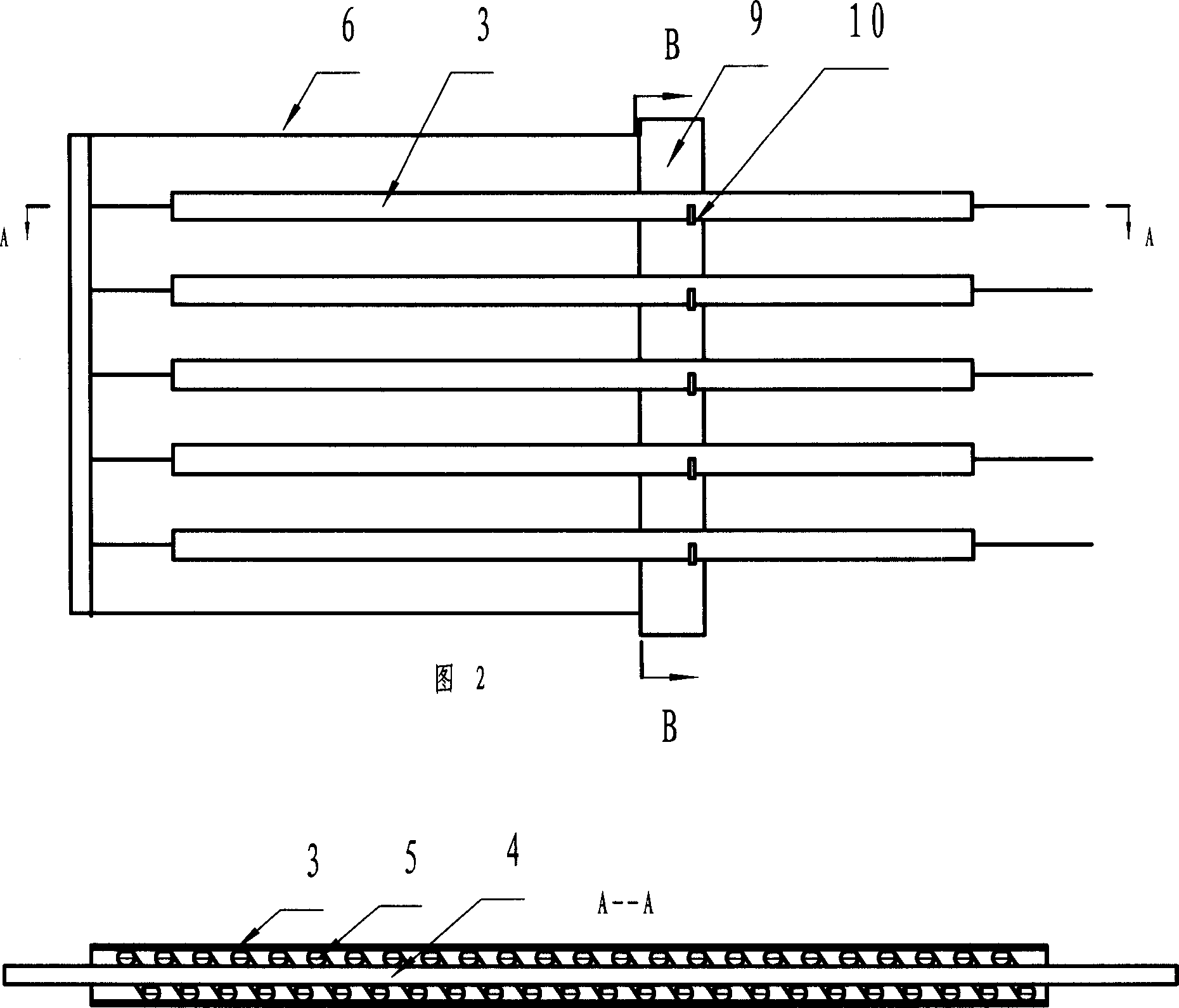

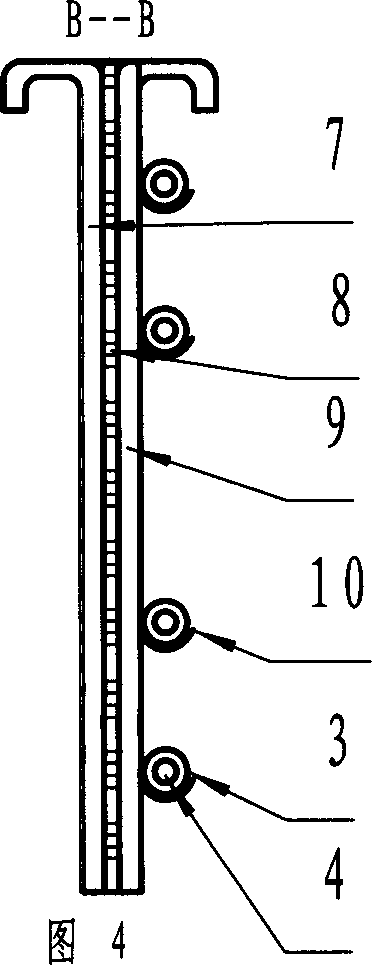

Process and special apparatus for electrogalvenizing inner and outer walls of steel pipe

InactiveCN1401823AFacilitates automatic cycle updatesImprove corrosion resistanceElectrolysis componentsElectrogalvanizationCyanide

A process for electroplating the inner and outer surfaces of steel tube with Zn is disclosed. It is characterized by that its electroplating liquid has the merits of both alkaline zincate and cyanide used for plating zinc. Its apparatus is characterized by that an auxiliary anode is additionally used inside the steel tube to be plated, that is, its hanger plays the roles of both cathode and anodes. Its advantages are high anticorrosion power of its plated layer and enough thickness of internal plated layer.

Owner:山东鲁宏塑窗机械集团总公司五金电镀厂

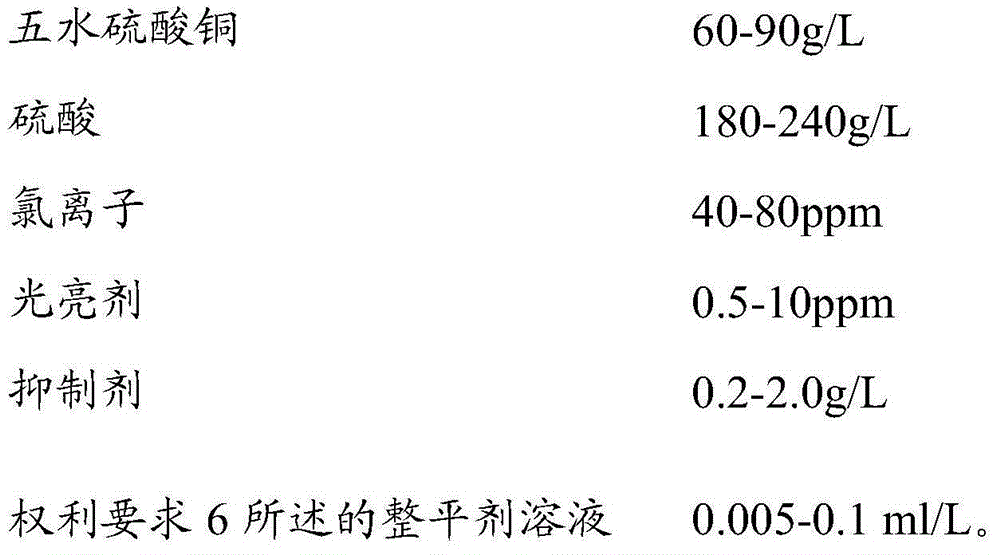

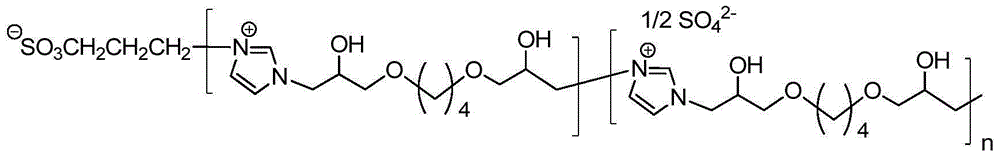

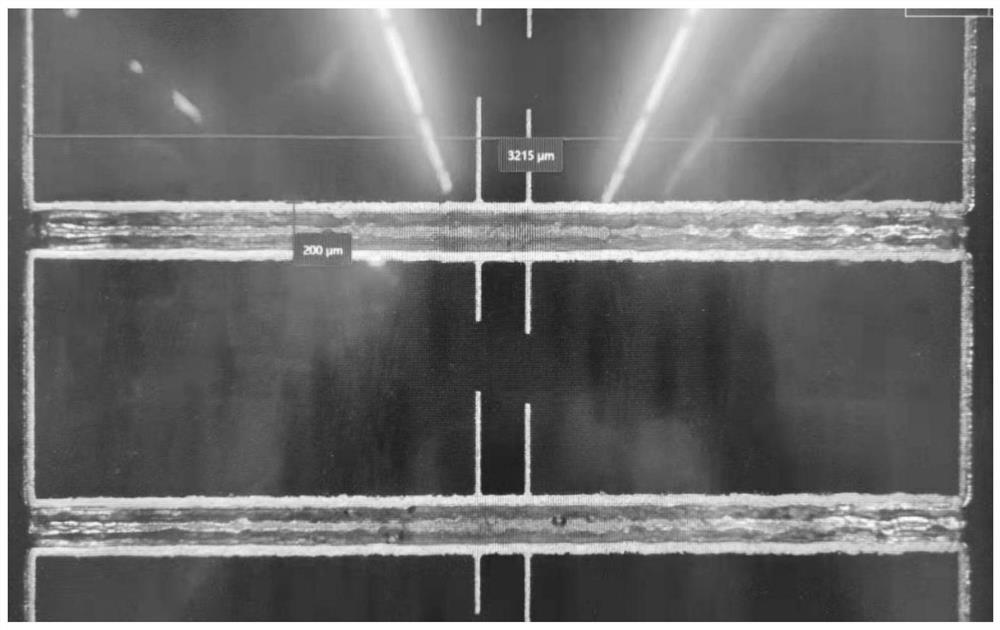

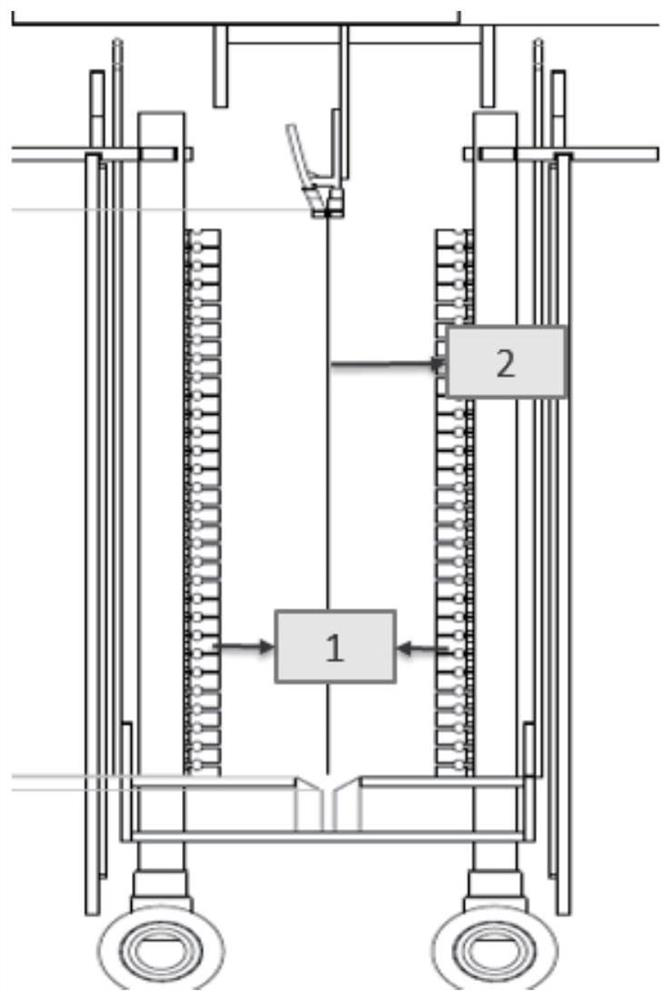

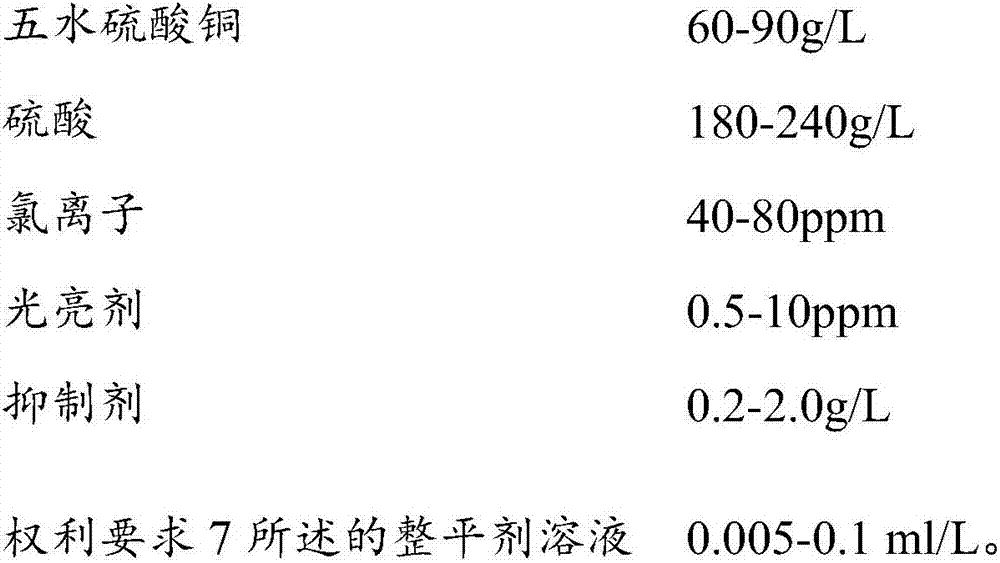

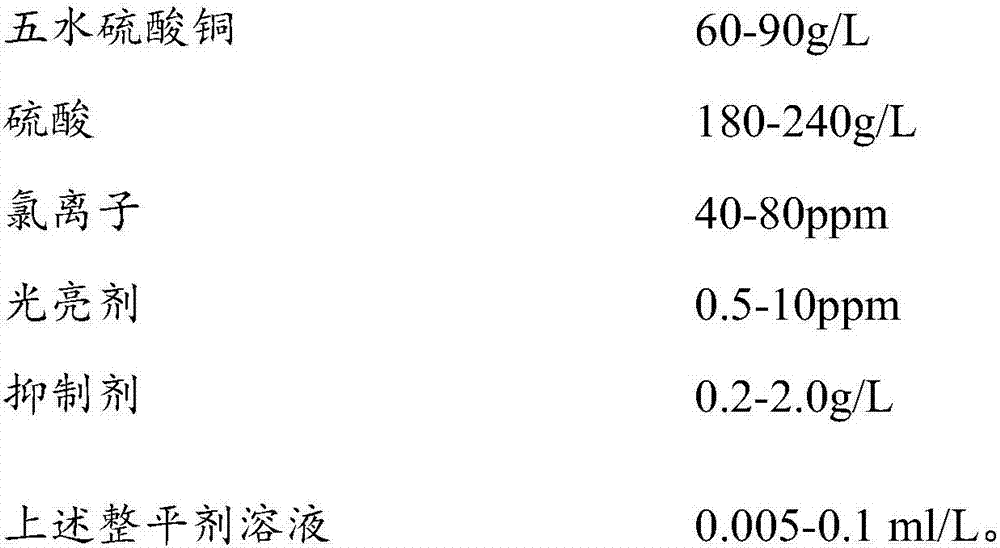

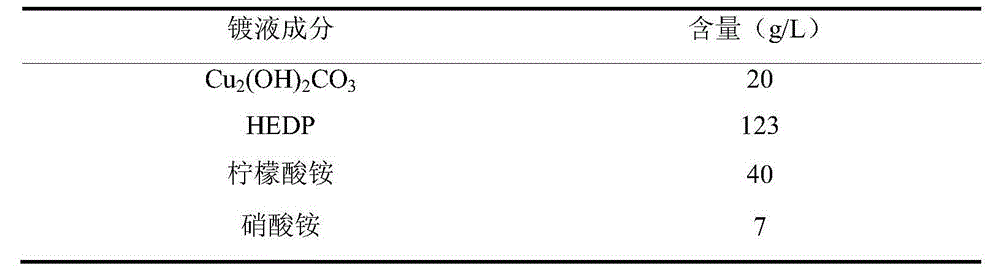

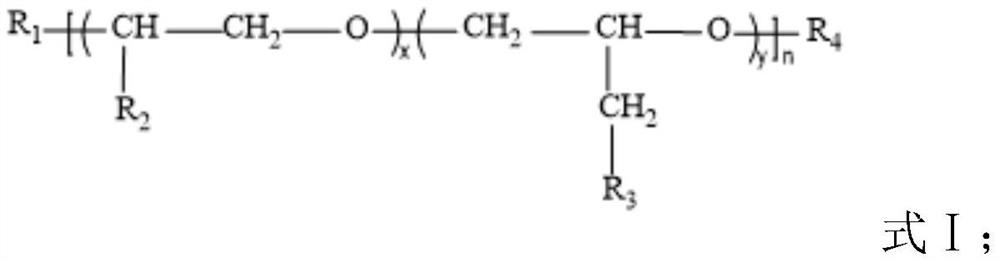

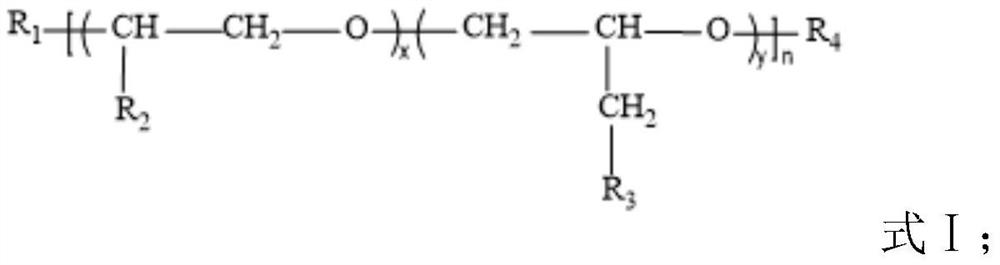

Leveling agent solution and preparation method and application thereof

ActiveCN105002527AHas a leveling effectHas a bright effectAlkyl transferNitrogenous heterocyclic compound

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

Blind hole filling electrocoppering solution for HDI plate and carrier plate

ActiveCN111945192AImprove plating lifeMaintain fill plating effectJewelleryElectrical resistance and conductanceElectrolysis

The invention discloses a blind hole filling electrocoppering solution for an HDI plate and a carrier plate. An electrocoppering solution comprises the following components of, in concentration, 150-200 g / L of copper sulfate pentahydrate, 40-80 g / L of sulfuric acid (98%), 30-70 mg / L of chloride ions, 0.5-4 mg / L of a brightening agent, 200-500 mg / L of a wetting agent, 5-30 mg / L of a leveling agent,30-100 mg / L of a new additive, and the balance deionized water. The above components are mixed according to the concentration to form the electrocoppering solution, when the electrocoppering solutionis used for electroplating, a Dummy sheet is firstly used for electrolyzing an electroplating bath to 2 AH / L, then electroplating is carried out at a current density of 1-3 A / dm<2 >, a temperature of15-35 DEG C, and a circulation rate of 2-8 TurnOver / H. According to the solution, the stability of a bath solution is improved through the method of adding the new additive, so that a blind hole plating layer is good in deepening plating ability, excellent in hole filling rate, free of voids and cracks, thin in surface copper and bright in surface, the defects of unstable signal transmission, high resistance, excessive power loss and the like caused by blind hole voids or equal-wall growth can be effectively prevented, and the reliability of an electronic product is further improved.

Owner:SHENZHEN CHENGGONG CHEM

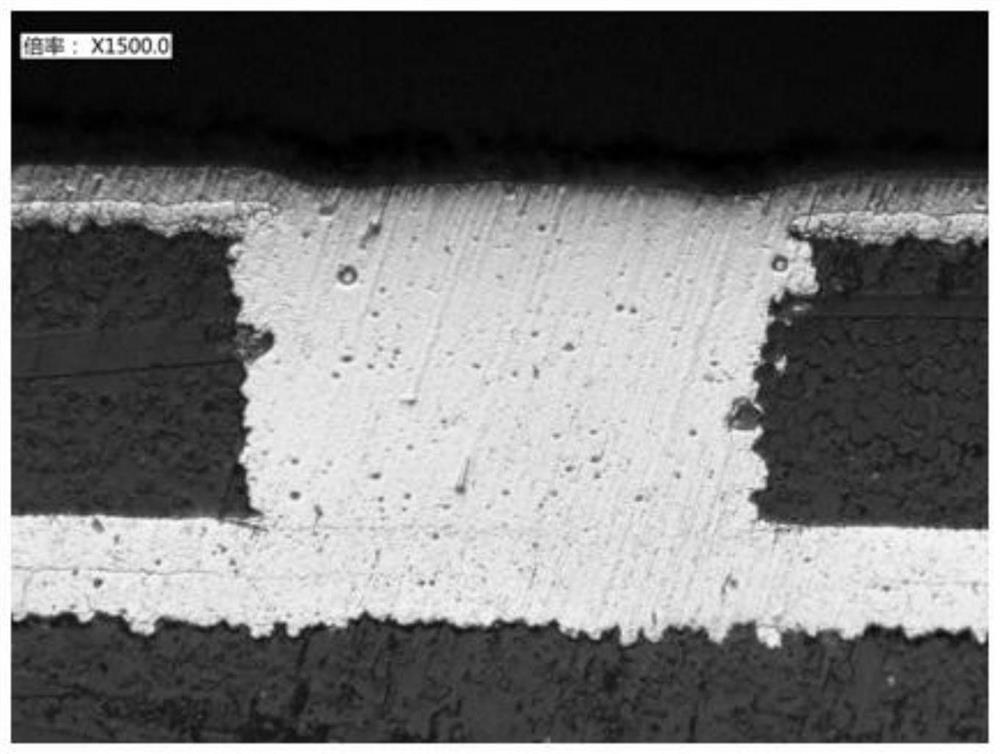

Through hole pulse electroplating solution and through hole pulse electroplating coating method

PendingCN113881983AGood deep plating abilityIncrease current densityPrinted element electric connection formationElectrodesCu2 ionsPulse electroplating

The invention provides a through hole pulse electroplating solution. The through hole pulse electroplating solution comprises 60-80 g / L of copper ions, 200-250 g / L of acid, 40-100 mg / L of chloride ions, 0.05-20 mg / L of a brightening agent and 50-4000 mg / L of a wetting agent. Through combination of the electroplating solution and the pulse electroplating technology, electroplating to a PCB through hole reaches the deep plating capacity exceeding 100%, and a circuit board with the aspect ratio exceeding 12: 1 and the board thickness exceeding 3 mm can obtain more excellent deep plating capacity.

Owner:广州市慧科高新材料科技有限公司

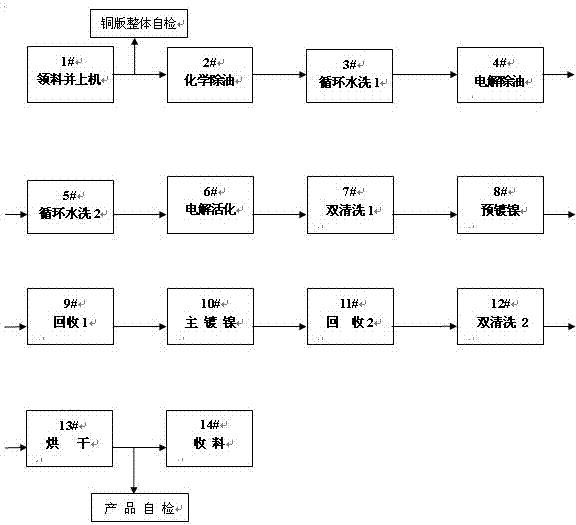

Production technology of fine bronzing plate with high precision and hardness

ActiveCN103484841AExtended service lifeIncrease productivityLiquid/solution decomposition chemical coatingSodium acetateBiological activation

The invention discloses a production technology of a fine bronzing plate with high precision and hardness. The production technology comprises the following steps : (1) loading materials; (2) chemical oil removal; (3) recycling washing; (4) electrolytic activation; (5) double cleaning; (6) nickel plating: carrying out chemical nickel plating by using a plating liquid containing 28 g / L nickel sulfate, 30 g / L sodium hypophosphite, 18 mL / L lactic acid (W = 85%), 13 g / L sodium acetate, 8 mg / L potassium iodate and purified water, adjusting the pH value of the plating liquid to 4.6-4.9, stirring at 85-91 DEG C for 3-5 min; (7) double cleaning; (8) drying; and (9) rolling. The invention employs electrolytic activation in advance and nickel preplating to substantially enhance firm combination degree of a nickel coating and a copper base and prolong service life of the bronzing plate.

Owner:青岛黎马敦包装有限公司

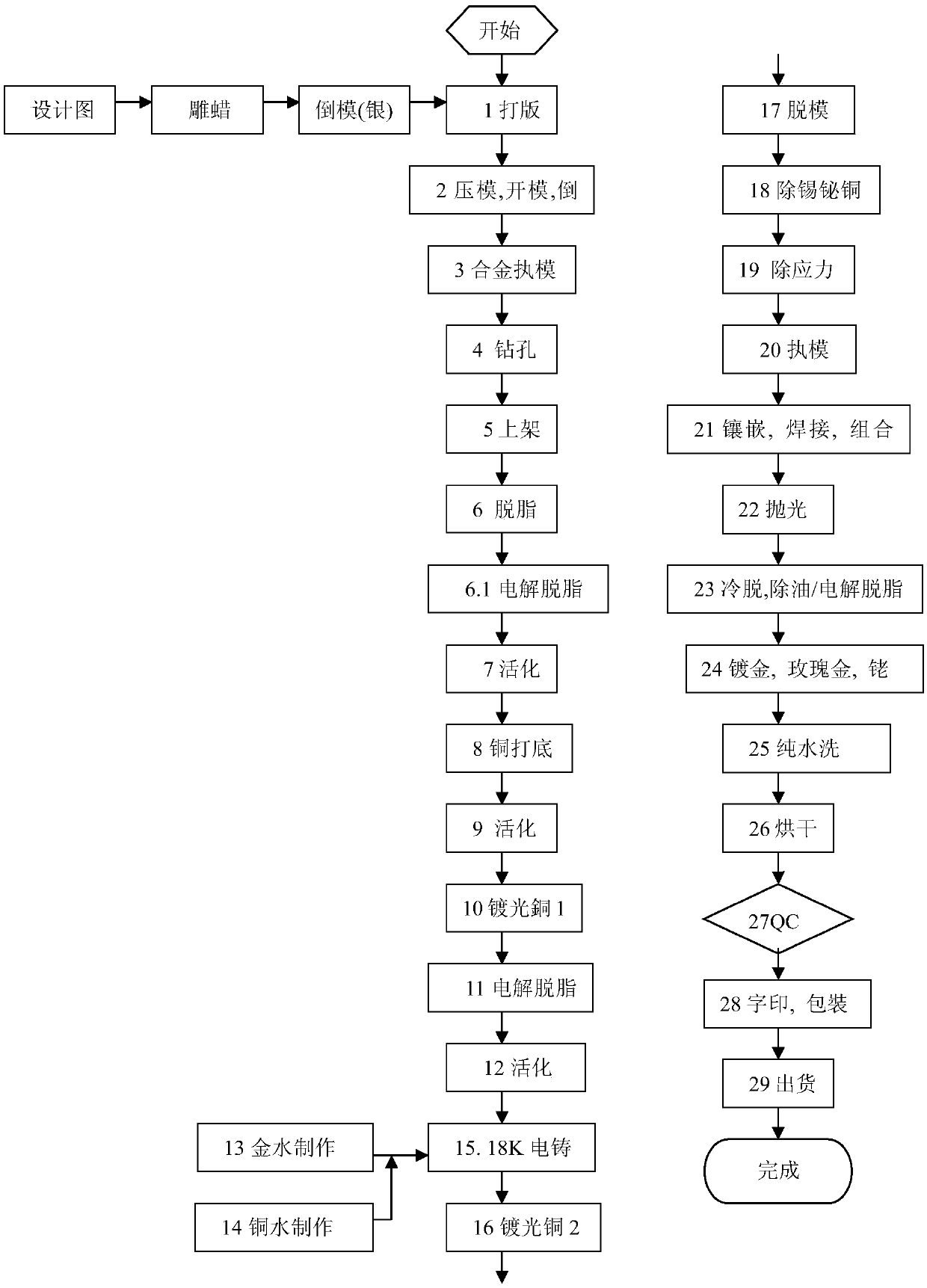

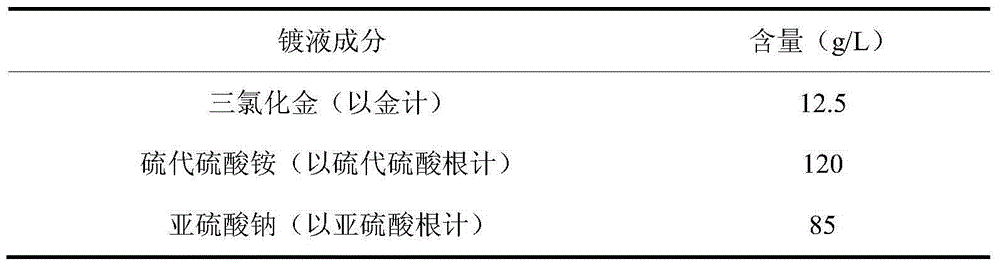

Preparation method for cyanide-free 18 k gold jewelries

The invention discloses a preparation method for cyanide-free 18 k gold jewelries. The preparation method comprises the steps of plate making, mold pressing, opening and reversing, alloy mold carrying, drilling, loading, degreasing, primary activation, copper bottoming, secondary activation, gloss copper 1 plating, electrolytic degreasing, ternary activation, gold water preparation, molten copperpreparation, 18 k electroforming, gloss copper 2 plating, demolding, tin bismuth copper removal, distressing, mold carrying, embedding, welding, combination, polishing, cooling, deoiling, electrolyticdegreasing, gold plating, pure water washing, drying, quality inspection, character printing, packing and delivery in sequence; and then, the cyanide-free 18 k gold jewelries are obtained. The preparation method is simple in process and easy to operate, obviously improves the jewelry quality, reduces the gold loss, and contains no cyanide-contained poisonous substance in the preparation process to achieve environmental protection and safety; the hardness and the toughness of the 18 k gold jewelries are prominently improved to preferably guarantee the stability of the jewelries in the wearingprocess; and further, electroforming liquid is excellent in stability, dispersibility and deep plating capacity, can be prepared beforehand for future use, and improves the production efficiency.

Owner:NANJING INST OF PROD QUALITY INSPECTION

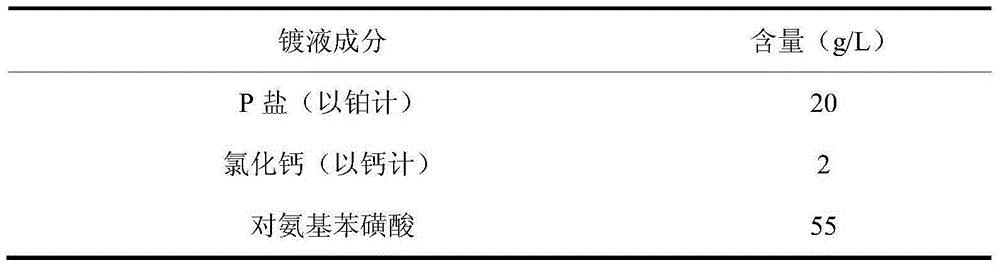

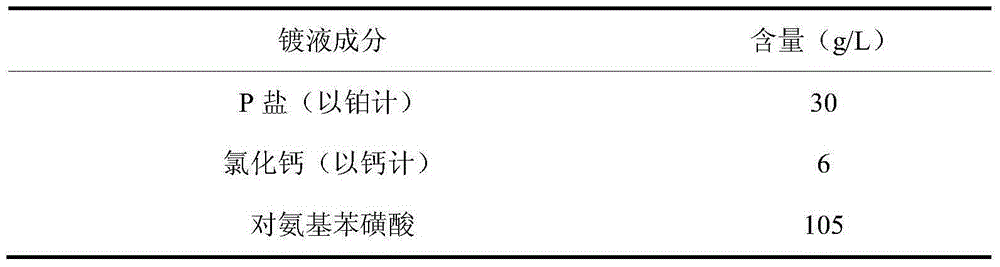

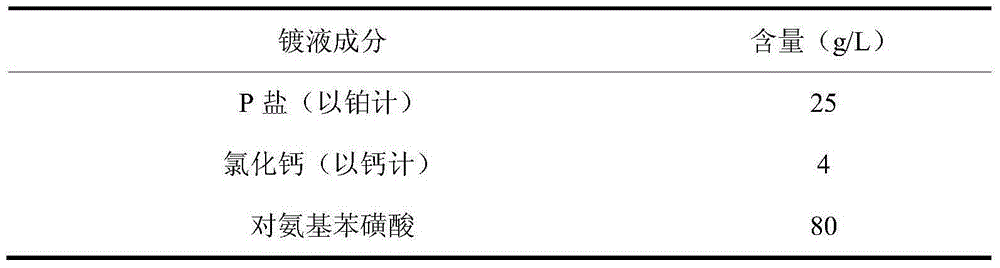

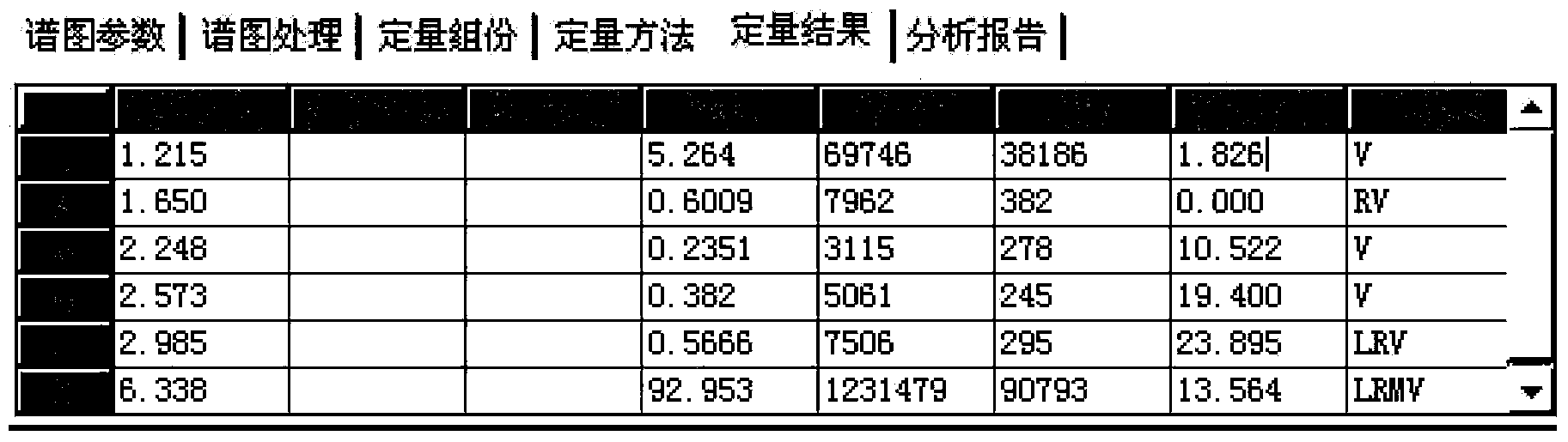

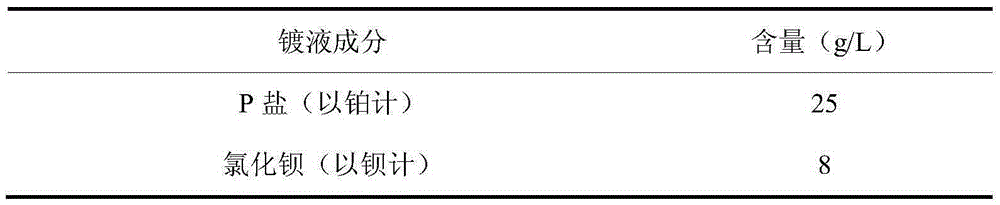

Dinitrodiammineplatinum ammoniacal electroplating solution for acidic platinum plating and electroplating method adopting dinitrodiammineplatinum ammoniacal electroplating solution

The invention discloses a dinitrodiammineplatinum ammoniacal electroplating solution for acidic platinum plating and an electroplating method adopting the dinitrodiammineplatinum ammoniacal electroplating solution. The dinitrodiammineplatinum ammoniacal electroplating solution comprises 20-30 g / L of dinitrodiammineplatinum ammoniacal which is measured by the content of platinum, 55-105 g / L of sulfanilic acid and 2-6 mg / L of calcium chloride which is measured by the content of calcium. Dinitrodiammineplatinum ammoniacal is utilized as a platinum main salt, sulfanilic acid is utilized as a complexing agent, and strontium chloride is utilized as a brightening agent, so that the obtained dinitrodiammineplatinum ammoniacal electroplating solution is relatively high in dispersion force and deep plating capability, and high in cathodic current efficiency and performance; when the dinitrodiammineplatinum ammoniacal electroplating solution is adopted for electroplating under an alkali condition, the obtained plating is low in porosity, and high in brightness and quality.

Owner:WUXI QINGYANG MACHINERY MFG

Metal surface zinc-nickel alloy electroplating solution and electroplating process

The invention discloses a metal surface zinc-nickel alloy electroplating solution. The formula of the electroplating solution comprises 20-50 g / L of zinc oxide, 10-20 g / L of nickel sulfate, 120-160 g / L of sodium hydroxide, 10-30 g / L of a complexing agent, 0.5-5 g / L of an additive and 1-5 g / L of a brightening agent, wherein the complexing agent is composed of ammonium citrate, triethanolamine and 1, 3-diamino-2-propanol according to the mass ratio of 1: (1-3): (3-5), the additive is composed of sodium phytate and hexadecyl trimethyl ammonium bromide according to the mass ratio of 1: (3-5), thebrightening agent is composed of saccharin, vanillin, 2-butyne-1, 4-diol and sodium allysulfonate according to the mass ratio of (5-10): (1-3): (3-5): 1. The electroplating solution can provide a bright zinc-nickel alloy coating with refined grains, improves the deep plating capability and dispersion performance of the coating, and is particularly suitable for electroplating of long-tube-shaped workpieces.

Owner:上海炫帝实业有限公司

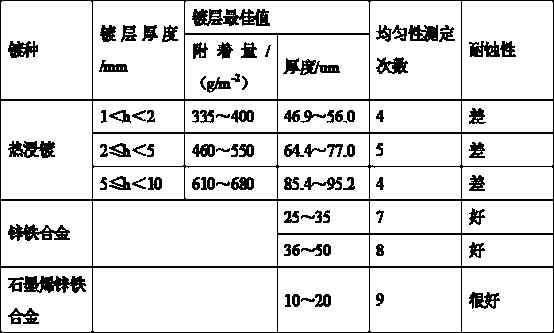

Alkaline graphene zinc-iron alloy electroplating liquid, preparation method and electroplating technology

InactiveCN109137016AEvenly dispersedPlating solution is stableElectrolytic coatingsPropylaminePyrophosphate

The invention discloses alkaline graphene zinc-iron alloy electroplating liquid, a preparation method and an electroplating technology. Each liter of the electroplating liquid comprises main salt including 80-100g of zinc chloride and 5-12g of ferrous sulfate, 200-250g of conducting salt namely ammonia chloride, 200-300ml of an ammonia solution, 20-100mg of graphene quantum dots, 25-40g of a buffering agent namely boric acid, 8-16g of a brightener namely benzotriazole, 1-2g of a reducing agent, 10-22g of a complexing agent, 3-5g of a coordination agent namely stannous pyrophosphate, 0.2-1g ofsodium dodecyl sulfate, 1-3g of alkalization tetra-isopropyl amine and the balance of water, wherein the temperature of the electroplating liquid is 20-55 DEG C, and the pH of the electroplating liquid is 9-14. According to an electroplated product obtained through the formula of the electroplating liquid disclosed by the invention, a graphene-zinc ferrum composite plating layer can be formed through a simple electrodeposition technology, the plating layer is 10-20 microns, and through a cupric sulphate maceration and corrosion test, the plating layer shows excellent corrosion resistance and has excellent combination properties.

Owner:湖州金业表面科技有限公司

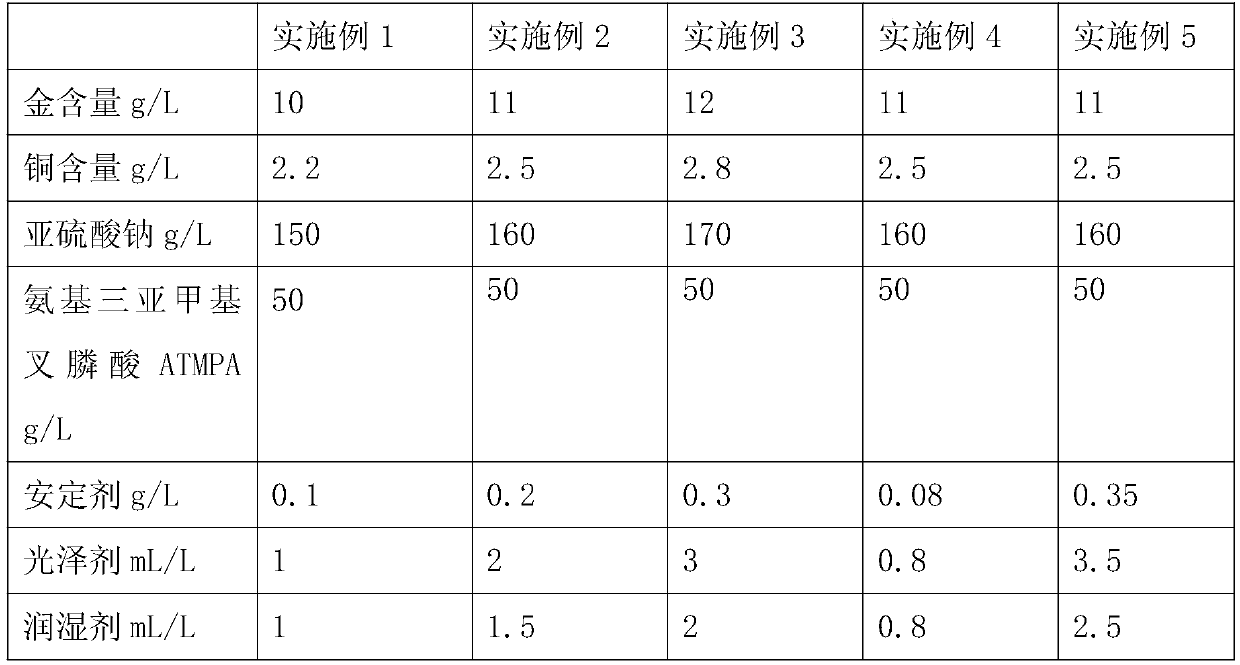

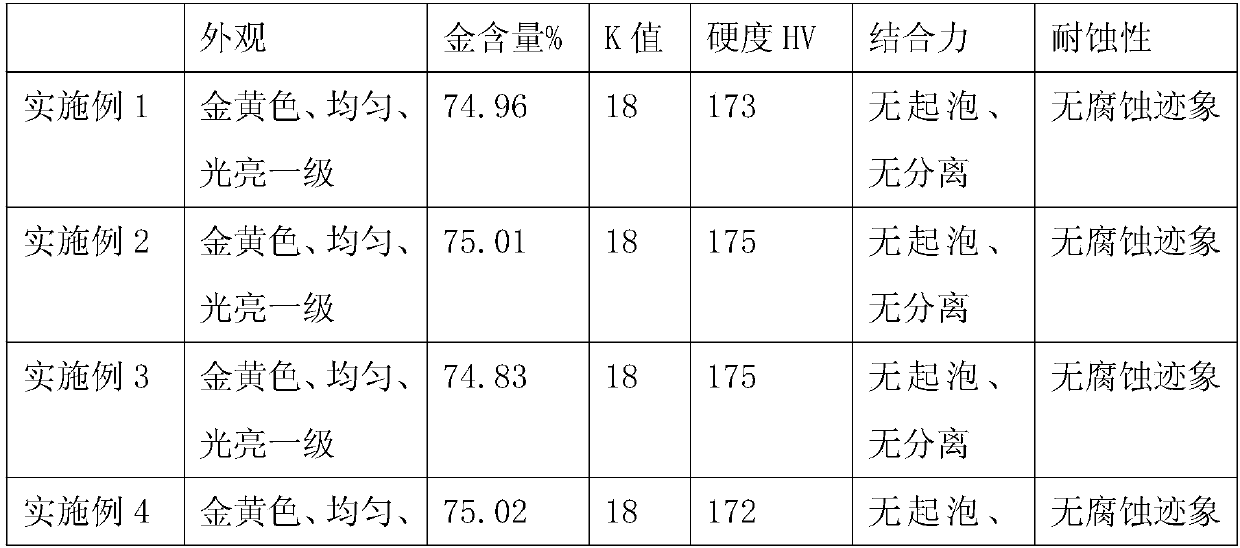

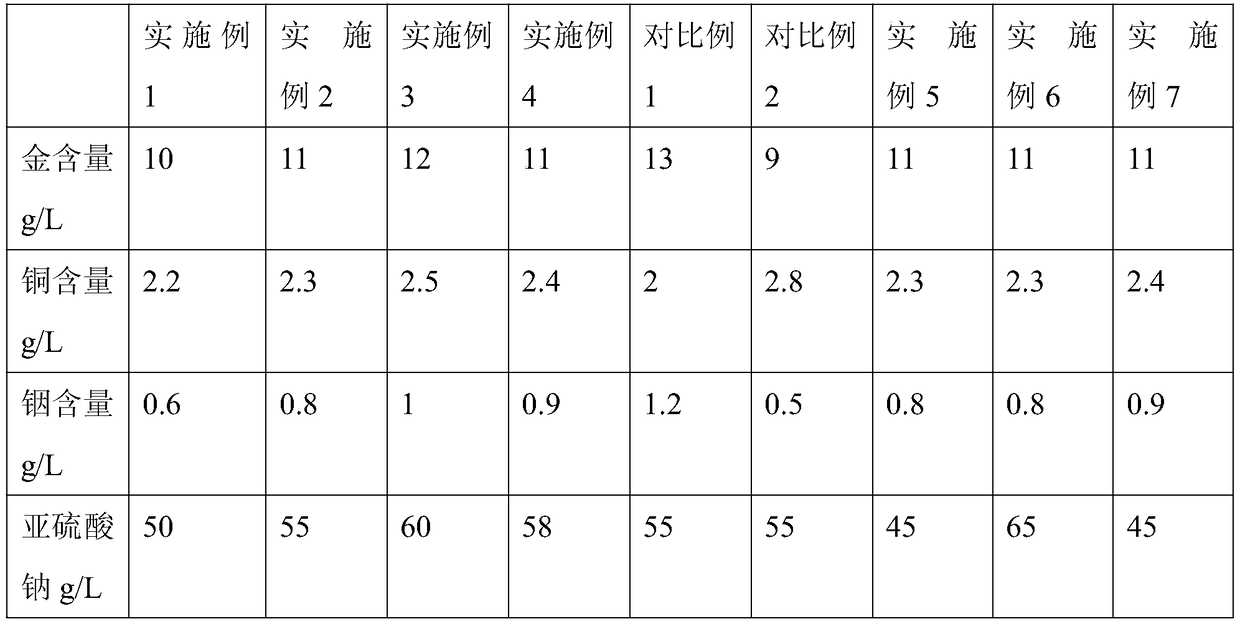

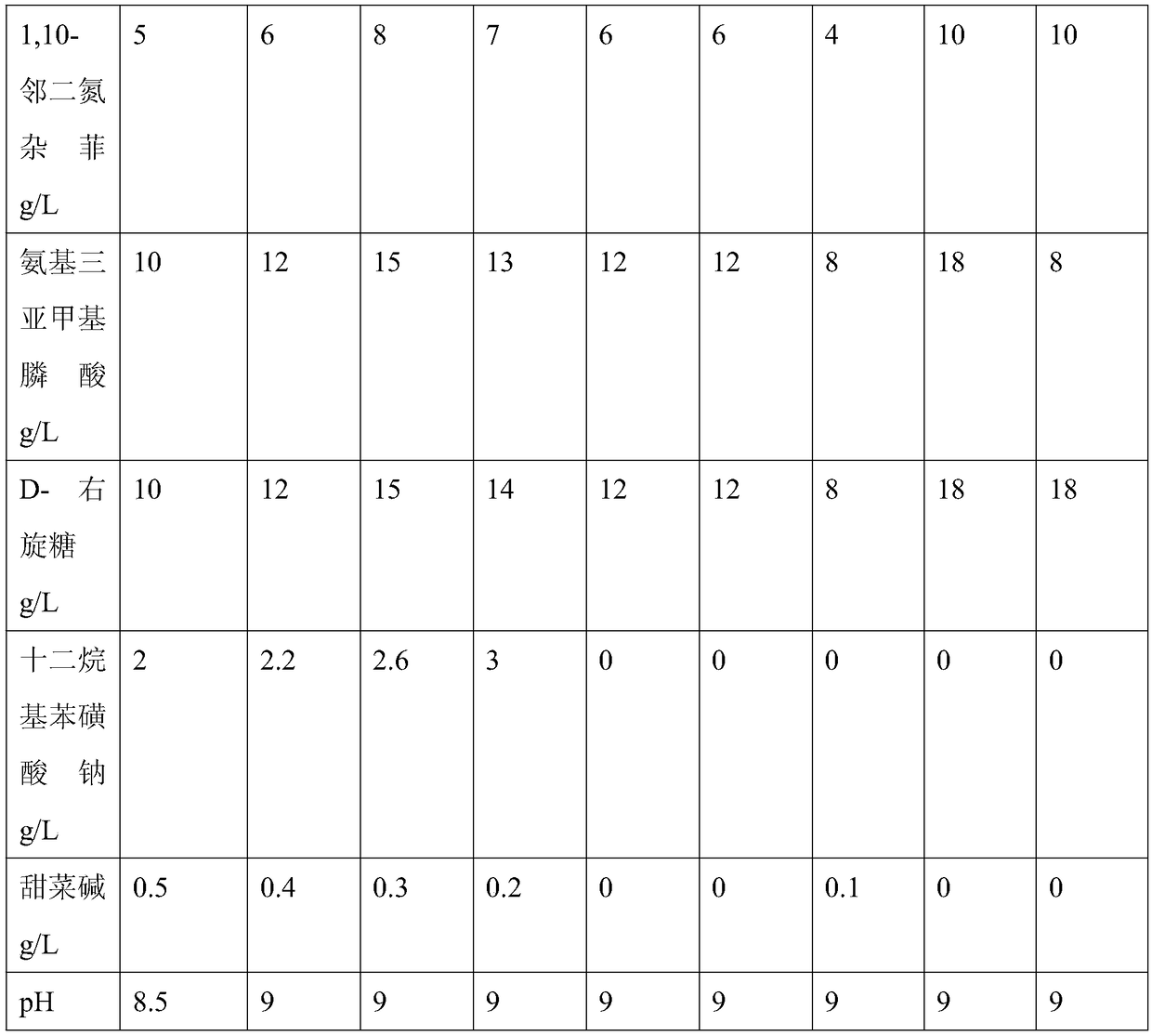

Cyanide-free 18k gold electrocasting solution and preparation method and application thereof

The invention discloses a cyanide-free 18k gold electrocasting solution and a preparation method and application thereof. The cyanide-free 18k gold electrocasting solution is prepared from the raw materials by volume: 10-12 g / L of gold, 2.2-2.5 g / L of copper, and 0.6-1 g / L of indium. The electrocasting solution is high in stability, high in dispersibility, and high in covering power. The electrocasting solution can be prepared in advance, and therefore labor intensity is lowered, production efficiency is improved, and the quality of ornaments is improved. Toxic substances containing cyanide are not adopted, and therefore security is high. The gold content is easy to control, and therefore gold loss is reduced, and yield is improved. Hardness of a 18k gold ornament is improved, and stability of the ornament during wearing is better guaranteed, and embedded gemstones are prevented from loosing. The corrosion resistance, decoloring resistance and abrasion resistance of the 18k gold ornament are obviously improved.

Owner:NANJING INST OF PROD QUALITY INSPECTION +1

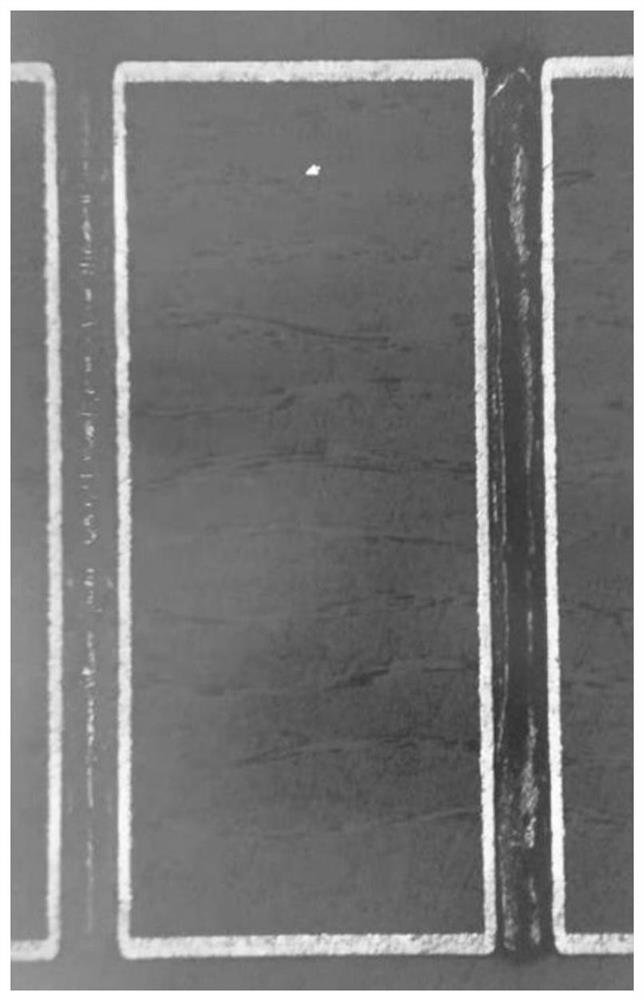

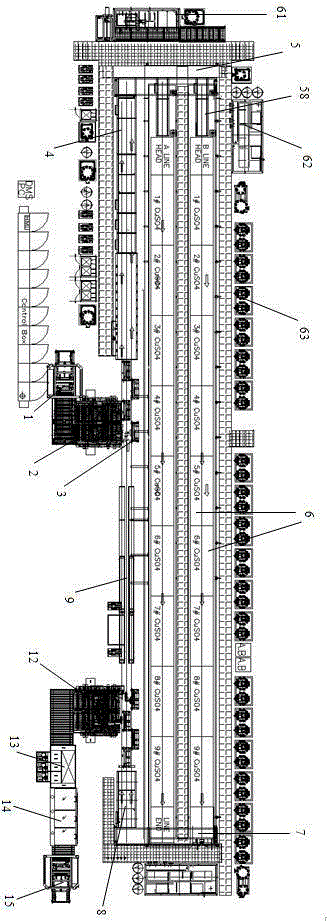

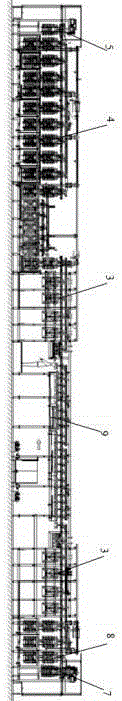

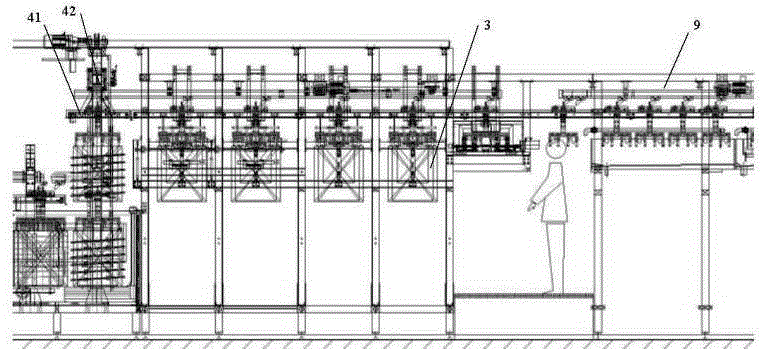

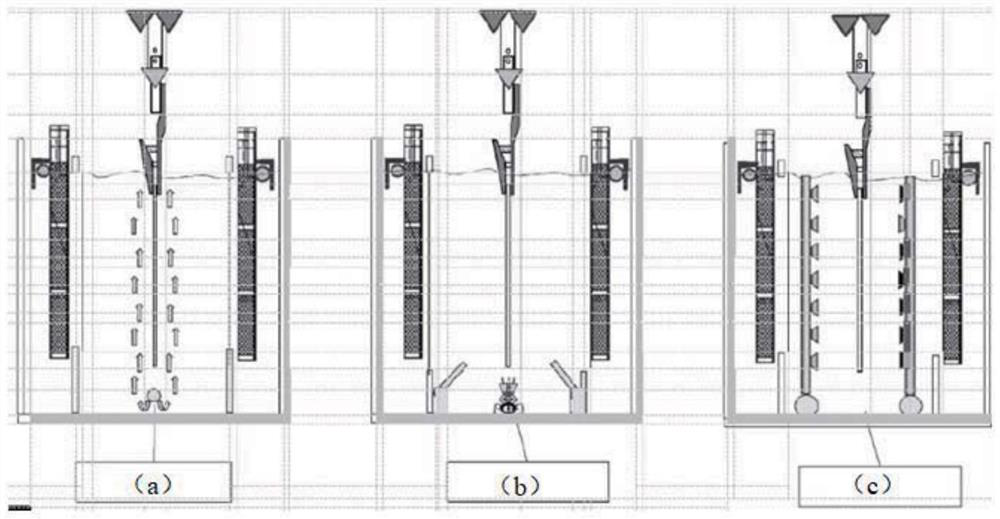

Vertical continuous electroplating hole filling line

PendingCN106637371AGood hole filling abilityGood bindingSemiconductor devicesPre treatmentEngineering

The present invention provides a vertical continuous electroplating hole filling line for PCB board processing. The vertical continuous electroplating hole filling line comprises a plurality of sub-lines arranged in a side-by-side manner, and is characterized in that each sub-line comprises a material feeding mechanism, a pretreatment device, a front shifting device, an electroplating pretreatment device, a multi-stage electroplating copper cylinder, a rear shifting device, a post-treatment device and a deplating device, wherein the material feeding mechanism, the pretreatment device, the front shifting device, the electroplating pretreatment device, the multi-stage electroplating copper cylinder, the rear shifting device, the post-treatment device and the deplating device are sequentially connected, the material inlet end of the material feeding mechanism is connected to an automatic plate feeding device, the material inlet end of the automatic plate feeding device is provided with a plate feeding conveying belt, and the material outlet end of the post-treatment device is sequentially connected to a central positioning machine, a corner turning machine, a horizontal plate drying machine and an automatic plate collection device. According to the present invention, with the vertical continuous electroplating hole filling line, the thickness uniformity of the plating layer at blind holes, buried holes and other hole filling positions of the high density circuit board, the deep plating ability, the hole filling ability and the bonding force are good, the shape is beautiful, the consistency of the hole wall plating layer and the plate surface plating layer is good, the operation, the maintenance and the repair are convenient, the structure is compact, the occupation space is small, the generated waste gas is less, and the environmental protection advantage is provided.

Owner:DONGGUAN CRAY AUTOMATION TECH

Nitrogen-leaching heat treatment processing process for chromium-plated hydraulic valve rod

InactiveCN107893248AExtended service lifePromote absorptionSolid state diffusion coatingNitrogenHydraulic equipment

The invention discloses a nitrogen-leaching heat treatment processing process for a chromium-plated hydraulic valve rod and relates to the technical field of hydraulic equipment. Aiming at the problems that a chromium-plated layer of an existing hydraulic valve rod is prone to fall off and is poor in wear resistance, the nitrogen-leaching heat treatment processing process for the chromium-plated hydraulic valve rod comprises the steps of (1) initial processing, (2) chromium-plating processing and (3) nitrogen-leaching heat treating and the like, wherein a multiple-stage type nitrogen-leachingheat treatment process of low temperature and low nitrogen-high temperature and high nitrogen-low temperature and high nitrogen-high temperature and high nitrogen-high temperature and low nitrogen isadopted in the step (3) of the nitrogen-leaching heat treating, the hardness and wear resistance of a surface layer and the chromium-plated layer of the hydraulic valve rod can be effectively improved, the fusion degree of the chromium-plated layer and the hydraulic valve rod is improved, the chromium-plated layer is made to be not prone to fall off, and the service life of the hydraulic valve rodis prolonged.

Owner:SICHUAN CHANGJIANG HYDRAULIC TIANCHENG MACHINERY

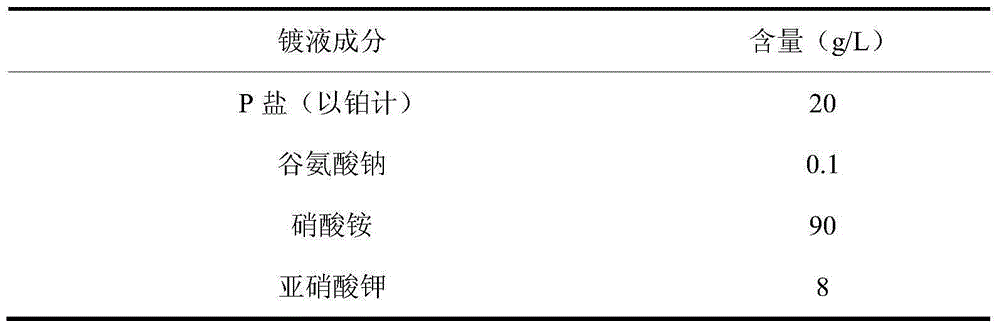

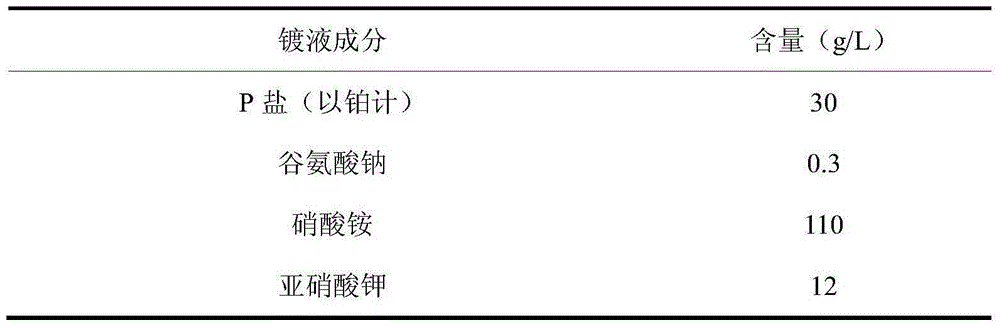

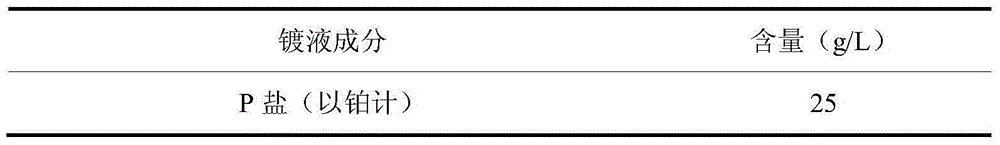

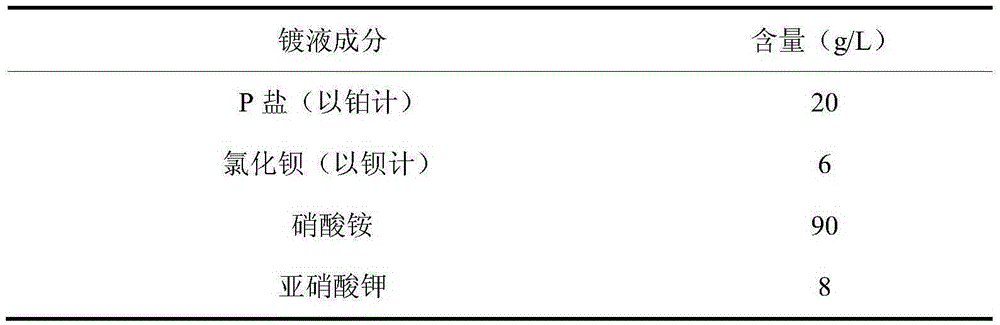

Alkaline P salt plating solution for electroplating platinum and electroplating method thereof

The invention discloses an alkaline P salt plating solution for electroplating platinum and an electroplating method thereof. In terms of platinum, the plating solution comprises 20-30g / L p salt, 90-110g / L ammonium nitrate, 8-12g / L potassium nitrite or sodium nitrite and 100-300mg / L sodium glutamate. The ammonium nitrate and the potassium nitrite or sodium are taken as auxiliary salts, and the sodium glutamate is taken as a brightening agent, so that the obtained plating solution has better dispersion force and deep plating cavity, high cathode current efficiency and excellent plating solution performance. A plating layer obtained by electroplating through the plating solution under an alkaline condition has low porosity, high brightness and good plating quality.

Owner:WUXI QINGYANG MACHINERY MFG

Compound chromium plating additive

The invention discloses a compound chromium plating additive, comprising organic matter and inorganic matter, wherein the organic matter comprises 1-20 g of alkansulfonic acid and / or alkanoic disulfonic acid in 1L of a standard chromium plating liquid or 0.01-0.1 g of nitrogen-containing organic compound in 1L of the standard chromium plating liquid, the inorganic matter comprises 0.001-0.01 g of a light rare earth fluoride in1L of the standard chromium plating liquid and / or 0.01-0.1 g of one of VA family element oxide, hydroxide or sulfate / According to the invention, the organic matter and the inorganic matter are added in the standard chromium plating liquid, thus the current efficiency is high , the coating has good brightness, the technology bright range is wide, the deep plating capability is good, the coating has high hardness, the anode has no corrosion, the technology is simple, and the cost is low.

Owner:闫瑞景

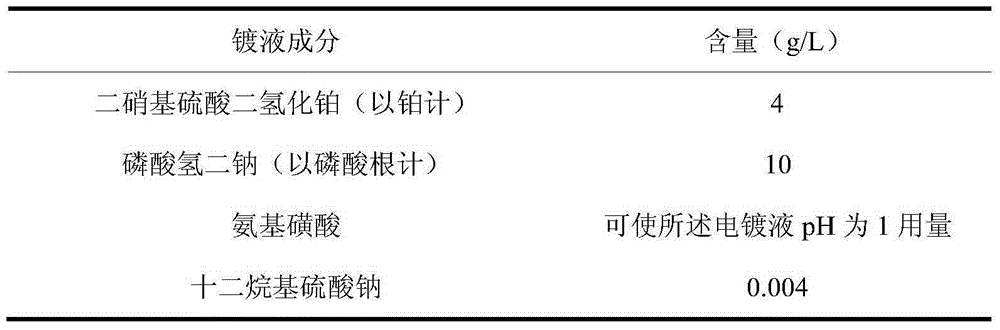

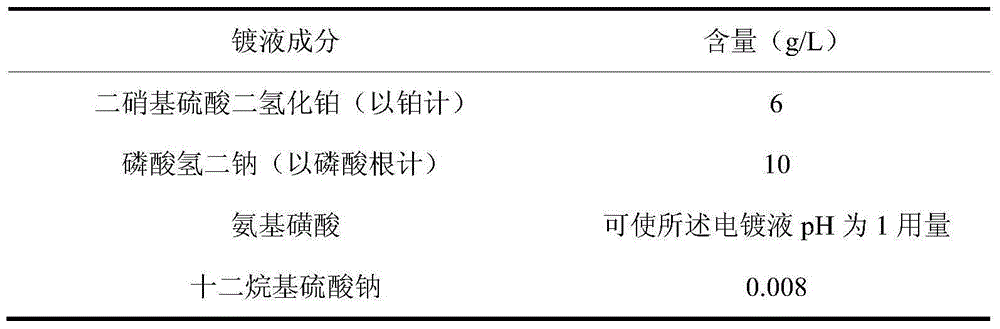

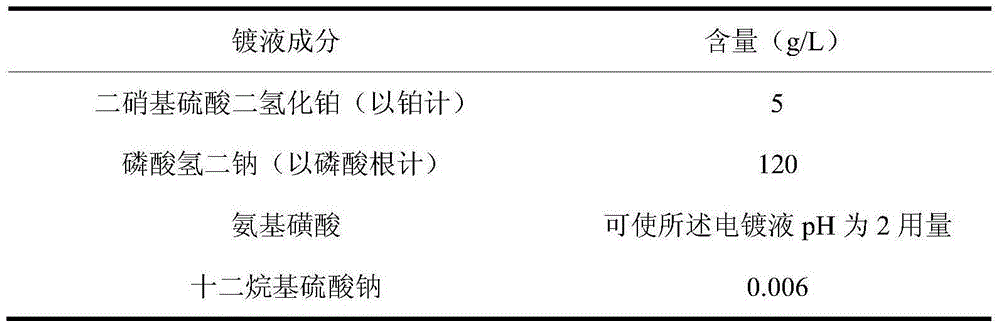

Platinum electroplating solution comprising dihydrogen dinitrosulfatoplatinate and electroplating method adopting platinum electroplating solution

The invention discloses a platinum electroplating solution comprising dihydrogen dinitrosulfatoplatinate and an electroplating method adopting the platinum electroplating solution. The electroplating solution comprises 4-6 g / L of dihydrogen dinitrosulfatoplatinate calculated by platinum, 100-140 g / L of water-soluble phosphate calculated by phosphate radicals, 4-8 mg / L of sodium dodecyl sulfate or dodecyl sulfate and sulfamic acid capable of adjusting the pH of the electroplating solution to be 1-2. According to the invention, dihydrogen dinitrosulfatoplatinate is used as platinum main salt, phosphate is used as brightener salt, dodecyl sulfate is used as an additive, and sulfamic acid is used for adjusting the pH of the electroplating solution to be acidic, so that the obtained electroplating solution has better dispersancy and deep plating capacity, and is high in cathode current efficiency and excellent in performance. A plating layer obtained by electroplating through the electroplating solution under alkaline conditions is low in porosity, high in brightness and good in quality.

Owner:WUXI QINGYANG MACHINERY MFG

Zinc-nickel alloy electroplating liquid and electroplating method

InactiveCN111876804AGood deep plating abilityImprove wear resistanceSodium GlycollateZinc Acetate Dihydrate

The invention provides zinc-nickel alloy electroplating liquid. The zinc-nickel alloy electroplating liquid comprises 30-50 g / L of zinc chloride, 10-20 g / L of zinc acetate, 30-40 g / L of nickel sulfate, 100-150 g / L of sodium hydroxide, 20-40 g / L of a complexing agent, 5-10 g / L of a brightener and water. The brightener comprises sodium glycolate, sodium sulfamate, toluenesulfonamide and propargyl alcohol in a ratio of (1-2): (1-2): (3-5): (3-5); and the complexing agent comprises sodium citrate, ethylenediamine and triethanolamine in a mass ratio of (1-2): (3-5): (3-5). According to the electroplating liquid, zinc chloride, zinc acetate and nickel sulfate are used as main salt, and the brightener and the complexing agent with specific compositions are matched, so that a plating layer obtained by electroplating not only has good deep plating capability, but also has good wear resistance, high brightness and good neutral salt mist resistance.

Owner:霸州市青朗环保科技有限公司

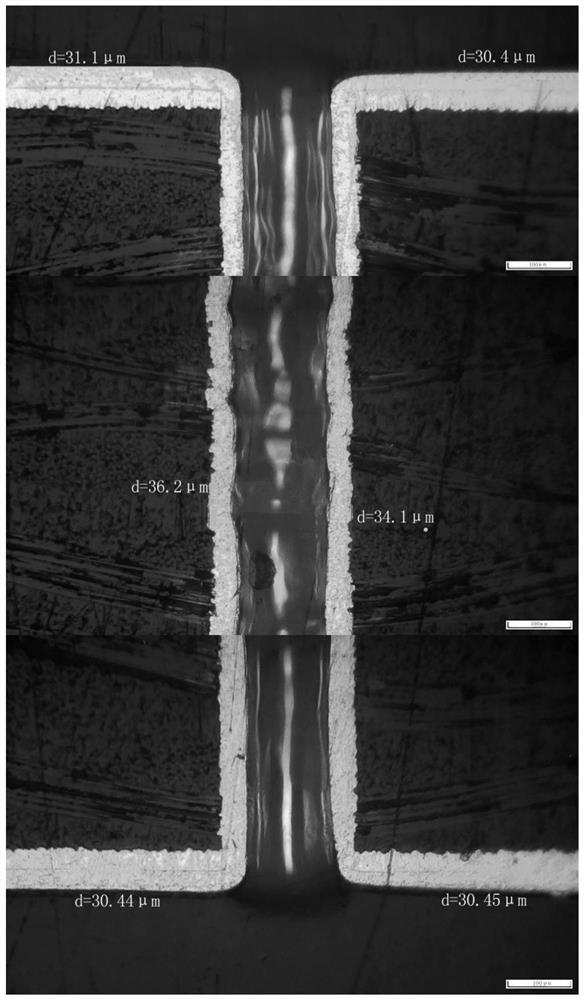

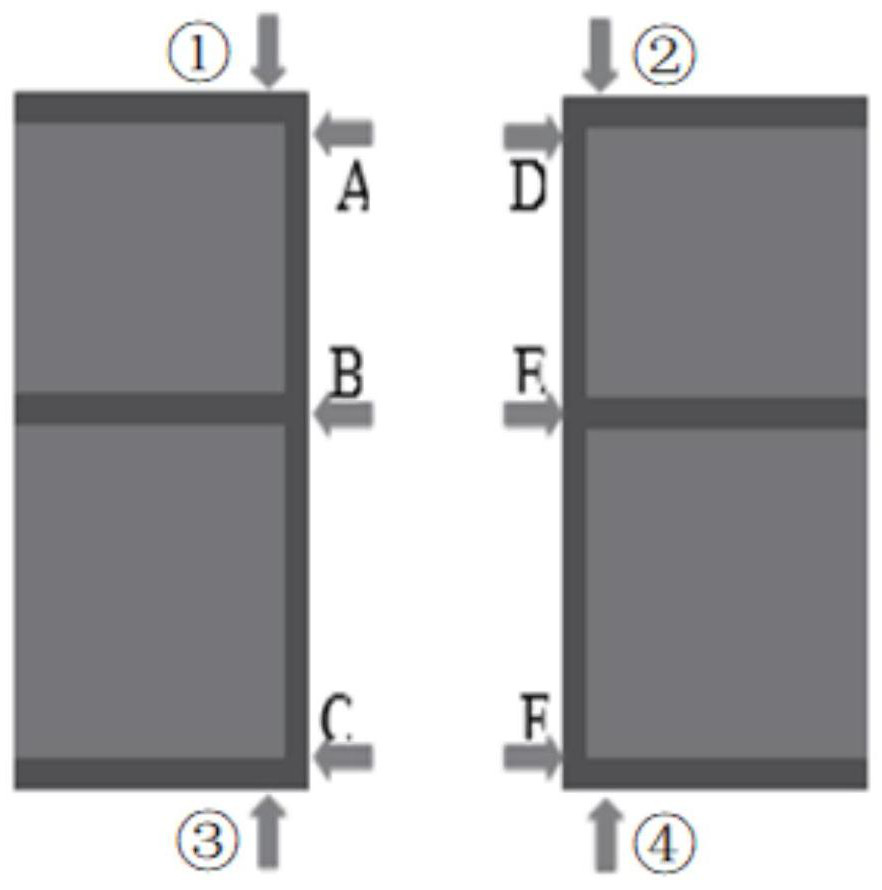

PCB electroplating method and PCB electroplating equipment

ActiveCN112501664AStrong penetrating powerGood deep plating abilityElectrolysis componentsPrinted circuit manufactureEngineeringMechanical engineering

The invention provides a PCB electroplating method and PCB electroplating equipment. The PCB electroplating method comprises the steps of S1, fixing a PCB in an electroplating tank body of the electroplating equipment, wherein a fixing assembly for fixing the PCB is arranged in the electroplating tank body of the electroplating equipment, and a first nozzle set and a second nozzle set are correspondingly arranged at the two sides of the PCB; and S2, controlling the first nozzle set and the second nozzle set to alternately execute a chemical liquid spraying operation and a chemical liquid suction operation, so that a positive pressure difference and a negative pressure difference are formed on the two sides of the PCB in the chemical liquid spraying process. According to the PCB electroplating method and the PCB electroplating equipment, the penetrability of chemical liquid flowing in holes during side spraying is improved, the good deep plating capacity is achieved, and the breakthrough that the TP value of the thickness-diameter ratio of 40: 1 is 100% can be achieved.

Owner:深圳明阳芯蕊半导体有限公司

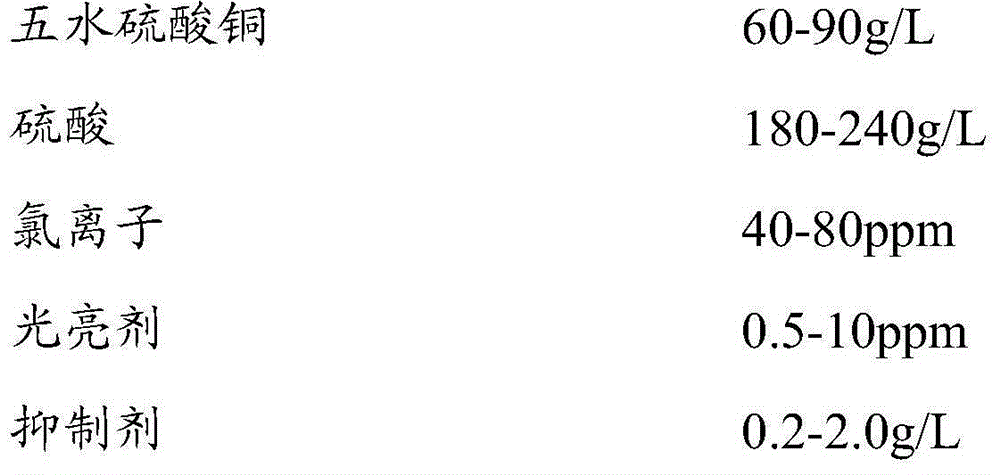

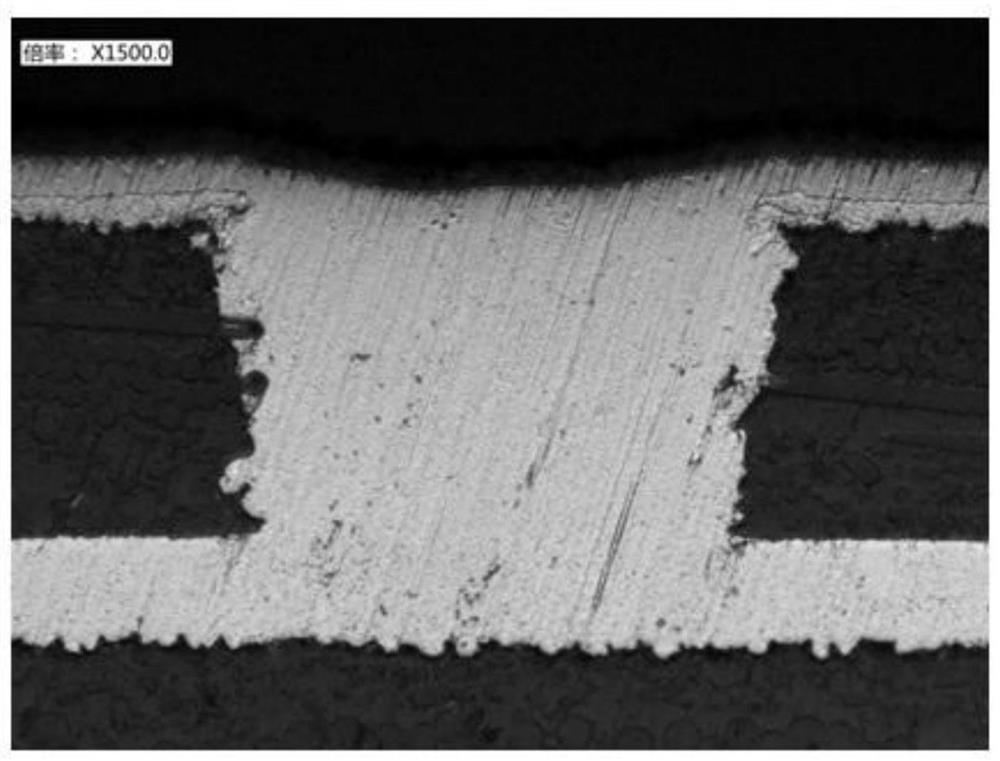

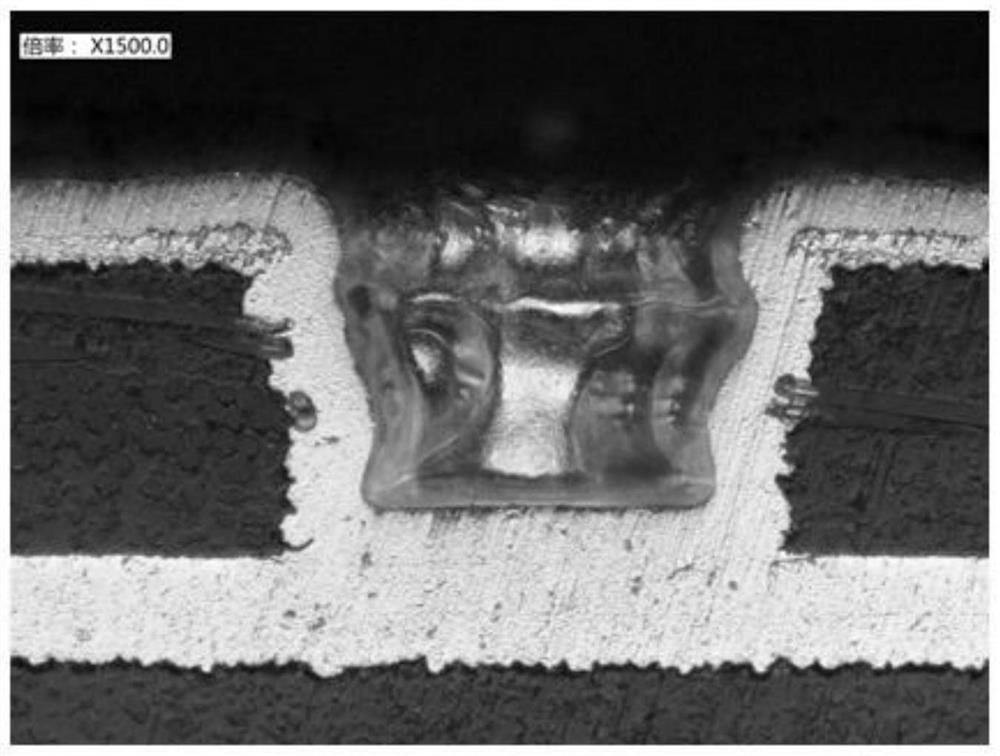

Leveling agent solution and its preparation method and application

ActiveCN105002527BGood effectGood deep plating abilityNitrogenous heterocyclic compoundCombinatorial chemistry

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

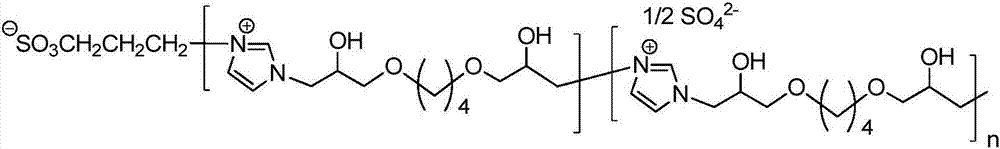

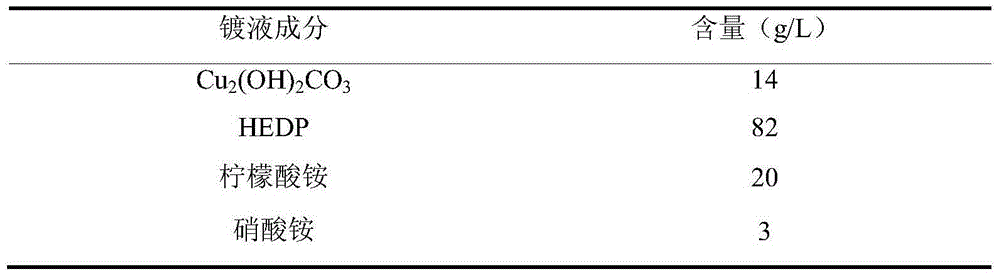

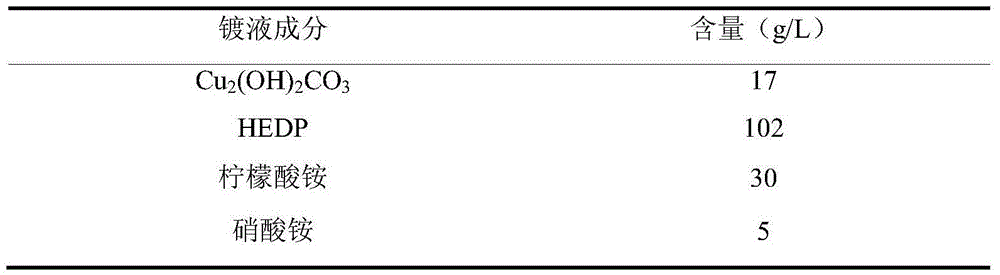

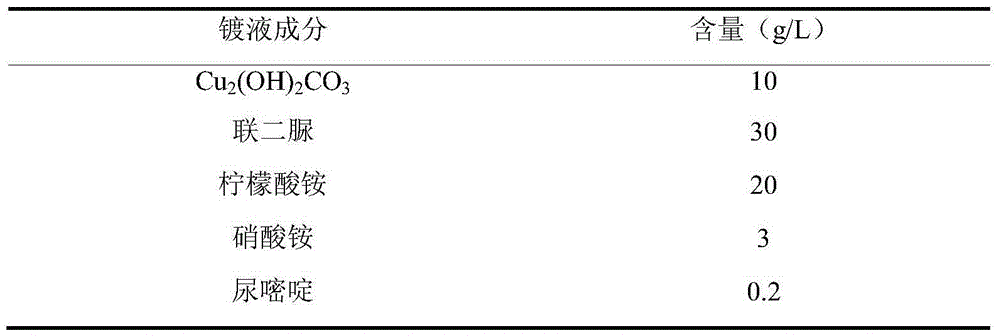

Electroplating solution for HEDP cyanide-free copper plating and electroplating method

The invention discloses an electroplating solution for HEDP (1-hydroxyethylidene-1, 1-diphosphonic) cyanide-free copper plating and an electroplating method. The electroplating solution includes: 14-20g / L Cu2(OH)2CO3, 82123g / L HEDP, 20-40g / L citrate and 3-7g / L nitrate. The electroplating solution provided by the invention adopts HEDP as the coordination agent and citrate as the auxiliary coordination agent, so that the electroplating solution has good dispersion force and deep plating ability, high cathode current efficiency, and excellent performance. The coating obtained by electroplating of the electroplating solution under an alkaline condition has low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

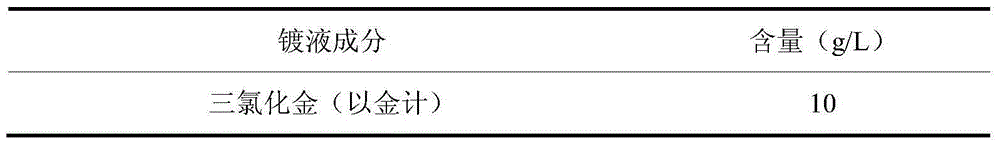

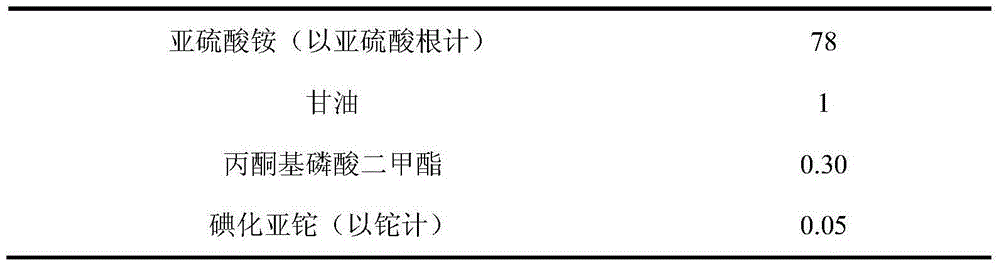

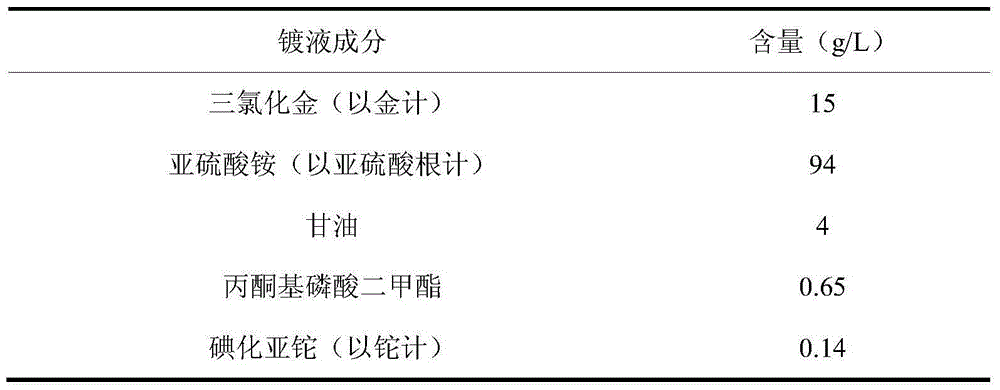

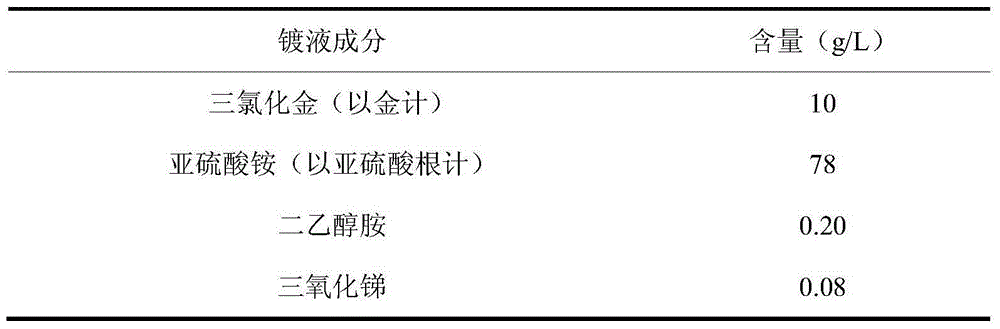

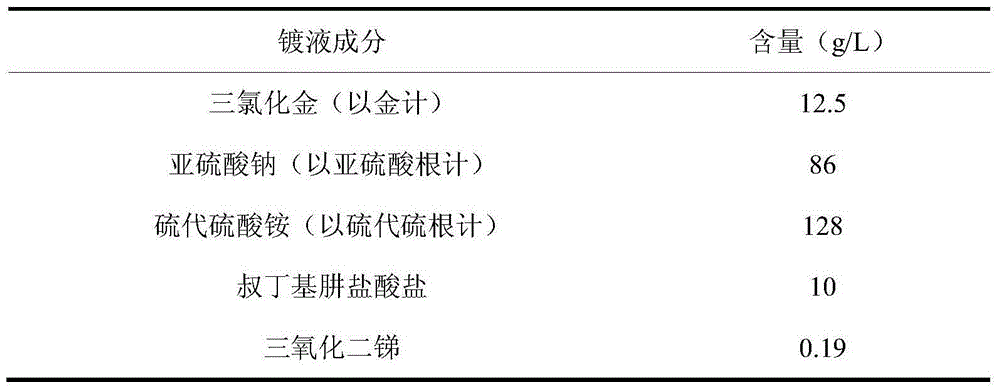

Electroplate liquid and electroplate method for cyanide-free gold plating of thallium-contained sulfite

The invention discloses electroplate liquid and an electroplate method for cyanide-free gold plating of thallium-contained sulfite. The electroplate liquid is composed of 10-15 g / L of gold chloride in terms of gold, 78-94 g / L of sulfite in terms of sulfite radicals, 1-4 g / L of glycerinum, 0.30-0.65 g / L of organic phosphorus compounds and 0.05-0.14 g / L of thallous salt in terms of thallium. According to the electroplate liquid, the sulfite serves as main coordination agents, the glycerinum serves as stabilizers, the organic phosphorus compounds serve as electron accelerators, the thallous salt serves as brightening agents, and the gold chloride serves as main gold salt, so that the obtained electroplate liquid is good in dispersion capacity and covering capacity, cathode currents are high in efficiency, and the electroplate liquid is excellent in performance. By the adoption of the electroplate liquid, plating obtained through electroplating under the alkaline condition is low in porosity, high in brightness and good in quality.

Owner:无锡永发电镀有限公司

Composite chrome plating additive

The invention discloses a composite chrome plating additive comprising an organic matter and an inorganic matter. The organic matter is alkyl-chain sulfonic acid and / or alkyl-chain disulfonic acid with a dose of 1-20g / L of standard chrome plating liquid. Or the organic matter is 0.01-0.1g / L of a nitrogen-containing organic compound. The inorganic matter is light rare earth fluoride with a dose of 0.001-0.01g / L of standard chrome plating liquid, and / or one of VA element oxides, hydroxides, and sulfates, wherein the dose of the VA element oxide or hydroxide or sulfate is 0.01-0.1g / L of standard chrome plating liquid. According to the invention, the organic matter and the inorganic matter are added into the standard chrome plating solution, such that advantages such as high current efficiency, good plating brightness, wide process brightness range, and good deep plating performance are provided. The plating has the advantages of high hardness, high current efficiency, no anode corrosion, wide process brightness range, good deep plating performance, simple operation process, and low cost.

Owner:太原特益达科技有限公司

Synthesis method of 1-benzylpyridinium-3-carboxylate

ActiveCN103435541ANo pollution in the processHigh yieldOrganic chemistrySodium acetateSodium bicarbonate

The invention discloses a synthesis method of 1-benzylpyridinium-3-carboxylate. The 1-benzylpyridinium-3-carboxylate is obtained by performing a chemical reaction on benzyl chloride, nicotinic acid and sodium hydroxide serving as raw materials; fully dissolving the sodium hydroxide in water; adding the nicotinic acid; stirring to fully dissolve; adding a composite catalyst and a buffer; dropwise adding the benzyl chloride and continuously reacting for 1-2 hours after the dropwise adding is finished so as to obtain the 1-benzylpyridinium-3-carboxylate, wherein the composite catalyst is a mixture of K2CO3 or Na2CO3 and quaternary ammonium salt; the quaternary ammonium salt is one or more of tetrabutylammonium bromide, benzyltriethylammonium chloride, dodecyl trimethyl ammonium chloride, methyl trioctyl ammonium chloride, hexadecyl trimethyl ammonium bromide and bromogeramine; the buffer is one of sodium bicarbonate, sodium carbonate, sodium acetate and boric acid. The synthesis method has the advantages of high yield, short reaction time, low cost, high product purity, no environment pollution during production and environmental friendliness.

Owner:湖北吉和昌化工科技有限公司

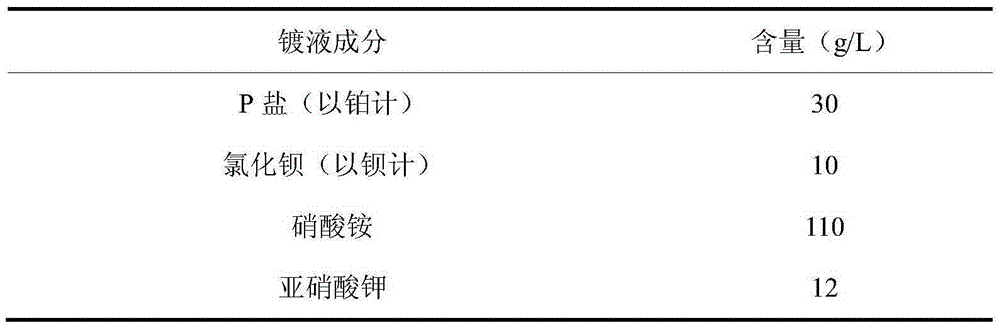

Barium-salt-contained alkaline plating Pt P salt electroplating bath and electroplating method thereof

The invention discloses barium-salt-contained alkaline plating Pt P salt electroplating bath and an electroplating method of the electroplating bath. The electroplating bath comprises, by platinum, 20-30 g / L of P salt, 90-110 g / L of ammonium nitrate, 8-12 g / L of potassium nitrite or sodium nitrite and 6-10 mg / L of barium chloride by barium. P salt serves as platinum main salt, the ammonium nitrate and the potassium nitrite or sodium are taken as auxiliary salt, and the barium chloride serves as a brightening agent, so that the obtained electroplating bath has the good dispersion force and deep plating capacity, the current efficiency of a negative pole is high, and the performance of the plating bath is excellent. A coating obtained through electroplating of the electroplating bath under the alkaline condition is low in porosity, high in brightness and good in quality.

Owner:WUXI QINGYANG MACHINERY MFG

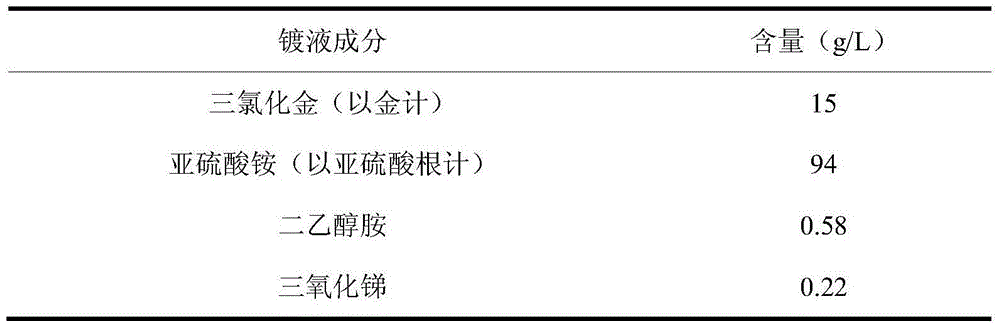

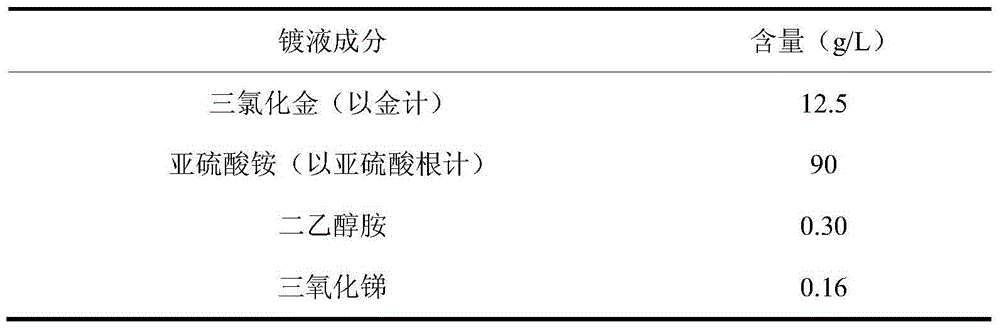

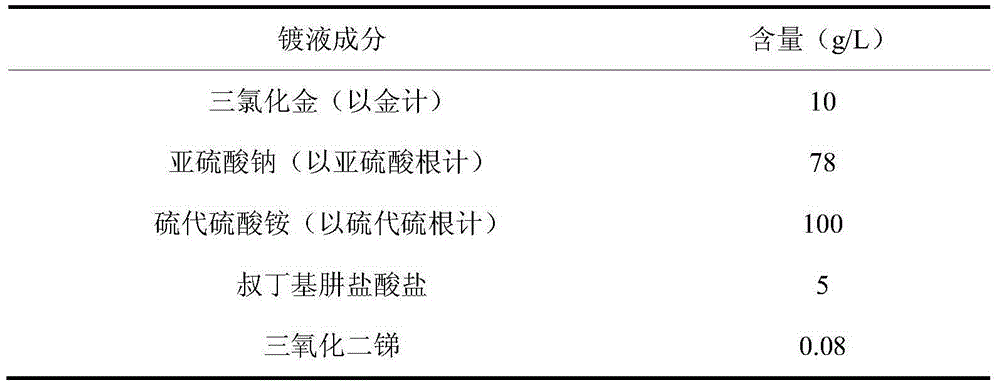

Electroplate liquid and electroplate method for cyanide-free gold plating of antimony-contained sulfite

The invention discloses electroplate liquid and an electroplate method for cyanide-free gold plating of antimony-contained sulfite. The electroplate liquid is composed of 10-15 g / L of gold chloride in terms of gold, 78-94 g / L of sulfite in terms of sulfite radicals, 0.20-0.58 g / L of alcoholamine and 0.08-0.22 g / L of antimonous oxide. According to the electroplate liquid, the sulfite serves as main coordination agents, the alcoholamine serves as electron accelerators, the antimonous oxide serves as brightening agents, and the gold chloride serves as main gold salt, so that the obtained electroplate liquid is good in dispersion capacity and covering capacity, cathode currents are high in efficiency, and the electroplate liquid is excellent in performance. By the adoption of the electroplate liquid, plating obtained through electroplating under the alkaline condition is low in porosity, high in brightness and good in quality.

Owner:无锡永发电镀有限公司

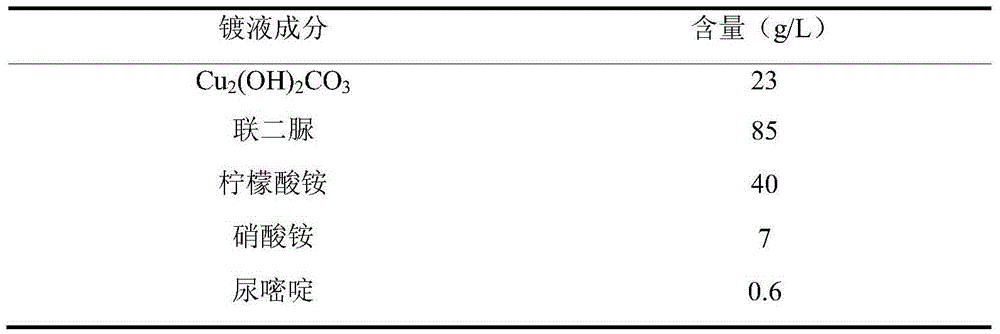

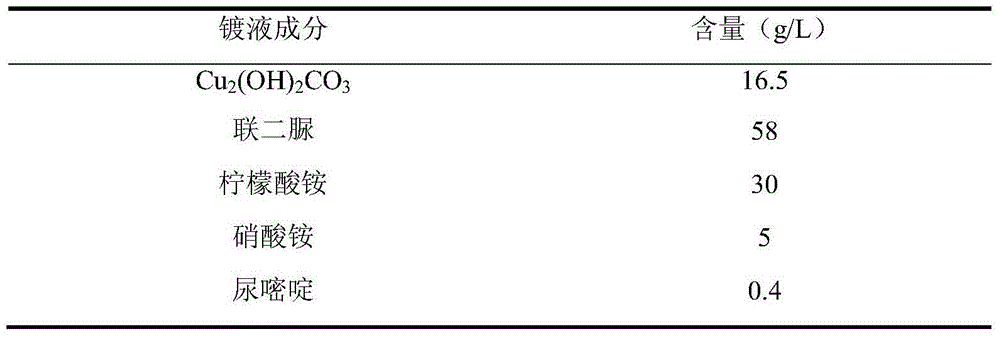

Electroplating liquid and electroplating method of biurea cyanide-free copper plating

The present invention discloses an electroplating liquid and an electroplating method of biurea cyanide-free copper plating. The electroplating liquid comprises 10-23 g / L of Cu2(OH)2CO3, 30-85 g / L of biurea, 20-40 g / L of citrate, 3-7 g / L of nitrate, and 0.2-0.6 g / L of uracil. According to the electroplating liquid of the present invention, the biurea is adopted as the coordination agent, and the citrate is adopted as the auxiliary coordination agent, such that the electroplating liquid characteristics of good dispersion, good deep plating ability, high cathode current efficiency, and excellent plating liquid performance. In addition, the plating layer obtained through electroplating under the alkaline condition has characteristics of low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

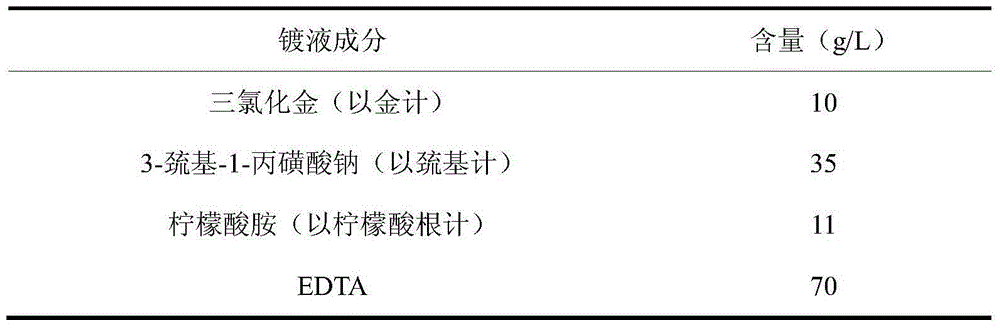

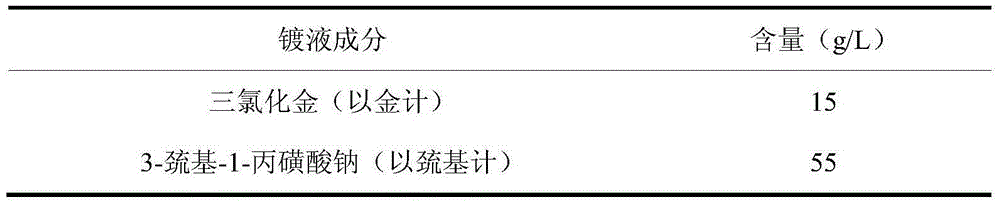

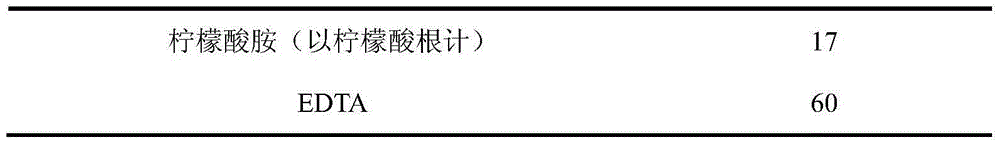

Plating solution for mercapto sulfonic acid non-cyanogen gold plating and plating method thereof

The invention discloses a plating solution for mercapto sulfonic acid non-cyanogen gold plating and a plating method thereof. The plating solution comprises 10-15g / L of gold trichloride calculated by gold, 35-55g / L mercapto sulfonic acid compound calculated by mercapto group, 11-17g / L citric acid and salts thereof calculated by citrate, and 50-70g / L EDTA. The plating solution uses mercapto sulfonic acid compound as the main complexing agent, uses citric acid and its salts, and EDTA as the auxiliary complexing agent, and uses gold trichloride as the main gold salt, so that the obtained plating solution has good dispersion force, deep plating capability power, high cathodic current efficiency, and excellent performance. The plating layer obtained under basic conditions by using the plating solution has the advantages of low porosity, high brightness and good plating layer quality.

Owner:无锡永发电镀有限公司

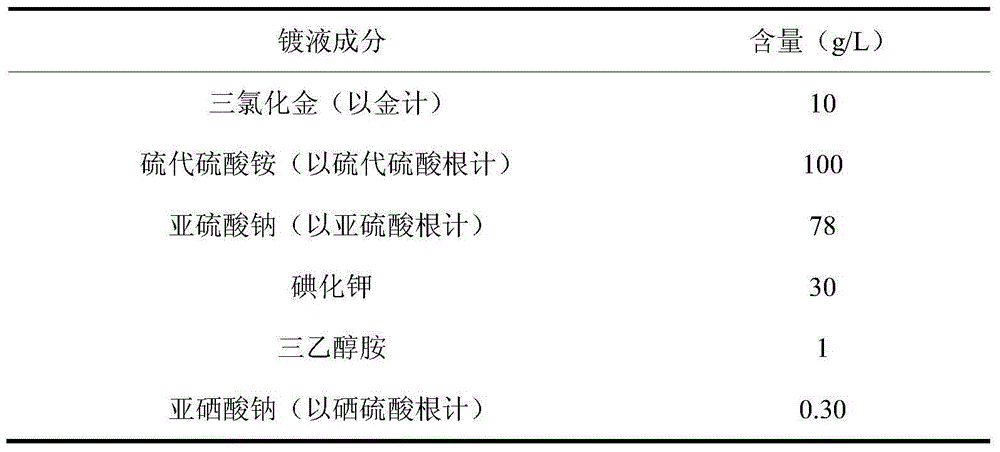

Iodide-added thiosulfate cyanide-free gold-electroplating solution and electroplating method

The invention discloses an iodide-added thiosulfate cyanide-free gold-electroplating solution and an electroplating method. The gold-electroplating solution comprises 10-15 g / L by gold of gold trichloride, 100-140 g / L by thiosulfate radical of thiosulfate, 78-94 g / L by sulfite radical of sulfite, 30-55 g / L by iodine of iodide, 1-4 g / L of an alcohol amine compound, and 0.30-0.60 g / L by selenite radical of selenite. In the gold-electroplating solution, iodide is taken as a stabilizing agent; thiosulfate is taken as a complexant; the alcohol amine compound is taken as the electron accelerant; selenite is taken as a brightener; and gold trichloride is taken as main gold salt. Therefore, the obtained gold-electroplating solution is relatively good in dispersion and deep electroplating ability, high in cathodic current efficiency, and excellent in electroplating solution performance. Through adopting the electroplating solution in an alkaline condition, a plated layer obtained through electroplating is low in porosity, high in brightness, and excellent in plating quality.

Owner:无锡杨市表面处理科技有限公司

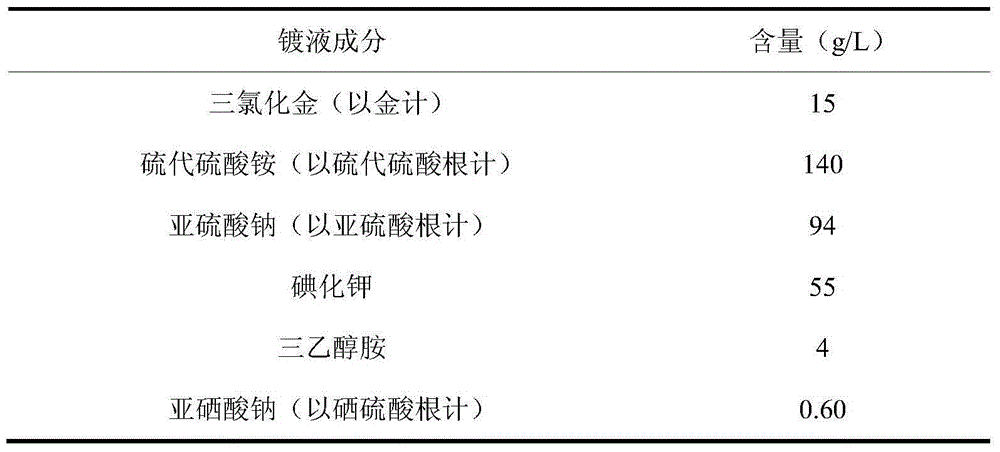

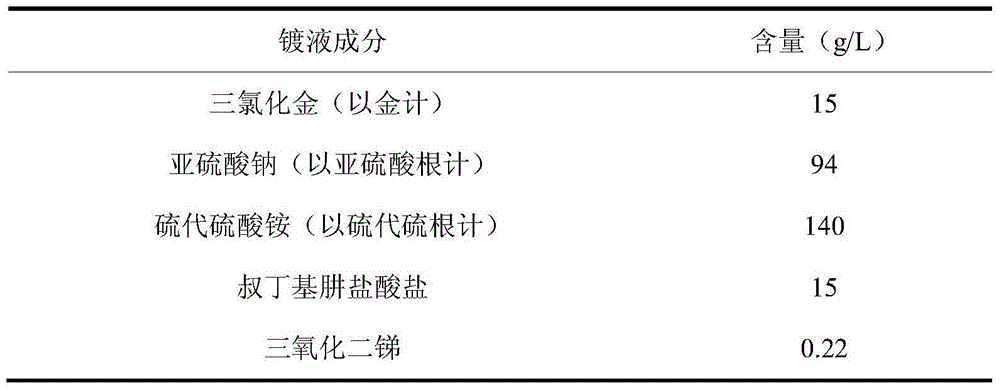

Thiosulfate cyanide-free gold-plating electroplating liquid with added hydrazine hydrochloride and electroplating method

The invention discloses a thiosulfate cyanide-free gold-plating electroplating liquid with added hydrazine hydrochloride and an electroplating method. The electroplating liquid comprises, 10-15 g / L of gold trichloride calculated based on gold, 100-140 g / L of a thiosulfate calculated based on thiosulfate radical, 78-94 g / L of a sulfite calculated based on sulfite radical, 5-15 g / L of hydrazine hydrochloride compound and 0.08-0.22 g / L of diantimony trioxide. The electroplating liquid employs the hydrazine hydrochloride compound as a stabilizing agent, employs diantimony trioxide as a brightener, employs a thiosulfate as a coordination agent and employs gold trichloride as a gold main salt, and the obtained electroplating liquid possesses relatively good dispersing force and covering power, high cathodic current efficiency and excellent performances. A plating layer obtained by employing the electroplating liquid for performing electroplating under an alkaline condition is low in porosity, high in brightness and good in plating-layer quality.

Owner:无锡杨市表面处理科技有限公司

Electroplating solution and electroplating method and application thereof

ActiveCN112877739AReduce surface tensionLow Electrical ConductivityJewelleryActive agentSurface-active agents

The invention relates to a electroplating solution and an electroplating method and application thereof. The electroplating solution comprises sulfuric acid, copper ions, chloride ions, a tetravalent vanadium compound, a pentavalent vanadium compound, a surfactant and an auxiliary agent. The surfactant comprises any one or a combination of at least two of polyoxyethylene and a derivative thereof, polyoxypropylene and a derivative thereof, a polyoxyethylene-polyoxypropylene copolymer and a derivative thereof or a fatty alcohol ethyoxyl compound. A plating layer formed after electroplating of the electroplating solution has the characteristics of fine plating layer crystals, high ductility and high electrical conduction performance.

Owner:上海天承化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com