Patents

Literature

170 results about "Thiosulfates" patented technology

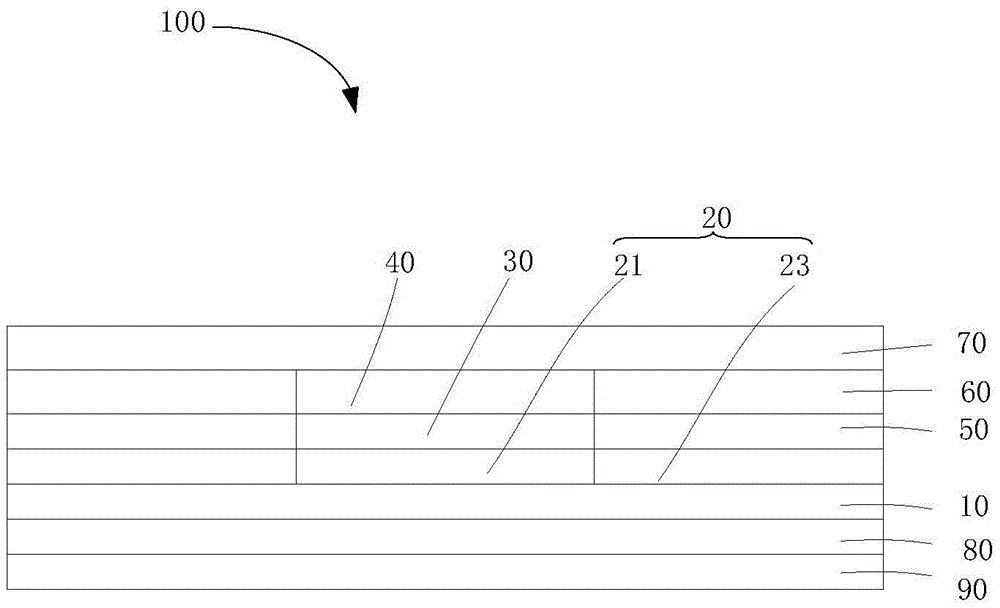

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

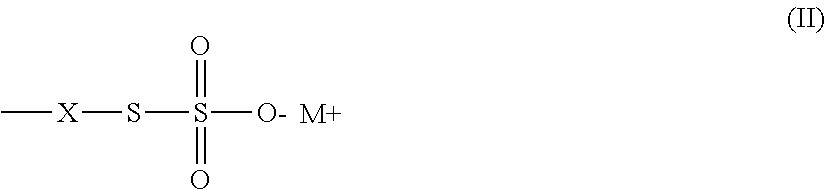

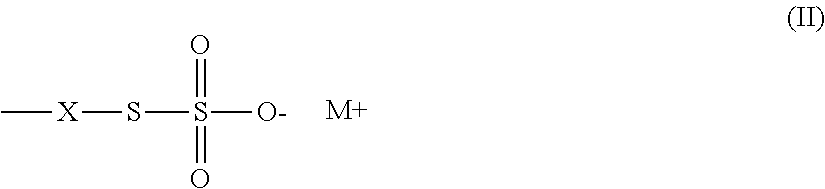

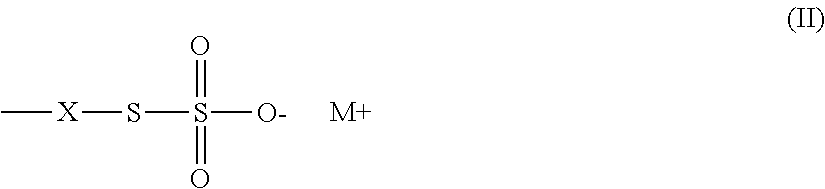

Inorganic salts of thiosulfuric acid possessing the general formula R2S2O3.

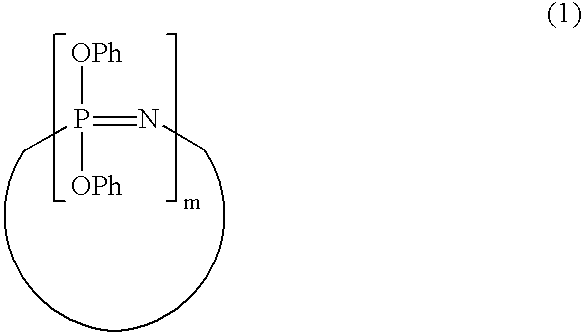

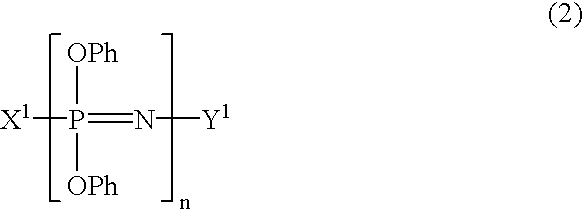

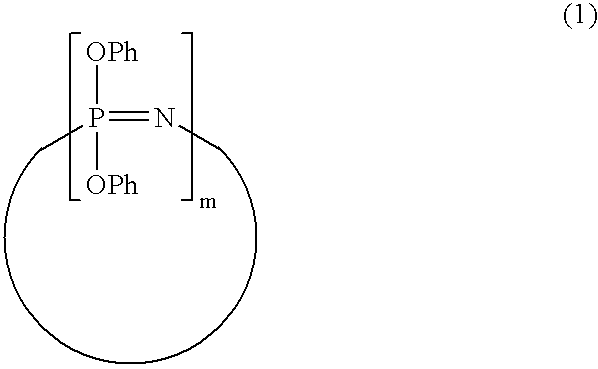

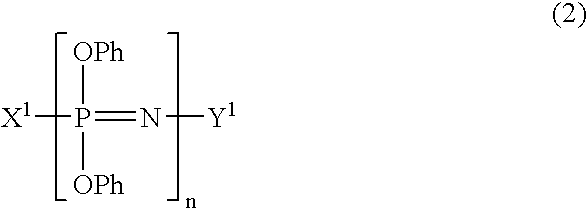

Process for producing phenoxyphosphazene compound, flame- retardant resin composition, and flame-retardant resin molding

InactiveUS20030040643A1Quality improvementIncrease resistanceGroup 5/15 element organic compoundsAlkanePolymer science

The phenoxyphosphazene compound of the present invention is prepared by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide or (c) both the adsorbent and reagent. Incorporation of the phenoxyphosphazene compound prepared by the process of the invention into a synthetic resin achives the following advantages: the synthetic resin can be prevented from discoloration; when the resultant resin composition is stored for a long time, the properties of the synthetic resin, such as heat resistance, weatherability, resistance to discoloration and chemical resistance are not deteriorated; and the resin composition gives a resin composition molded article excellent in properties such as flame retardancy, thermal stability, and moldability.

Owner:OTSUKA CHEM CO LTD

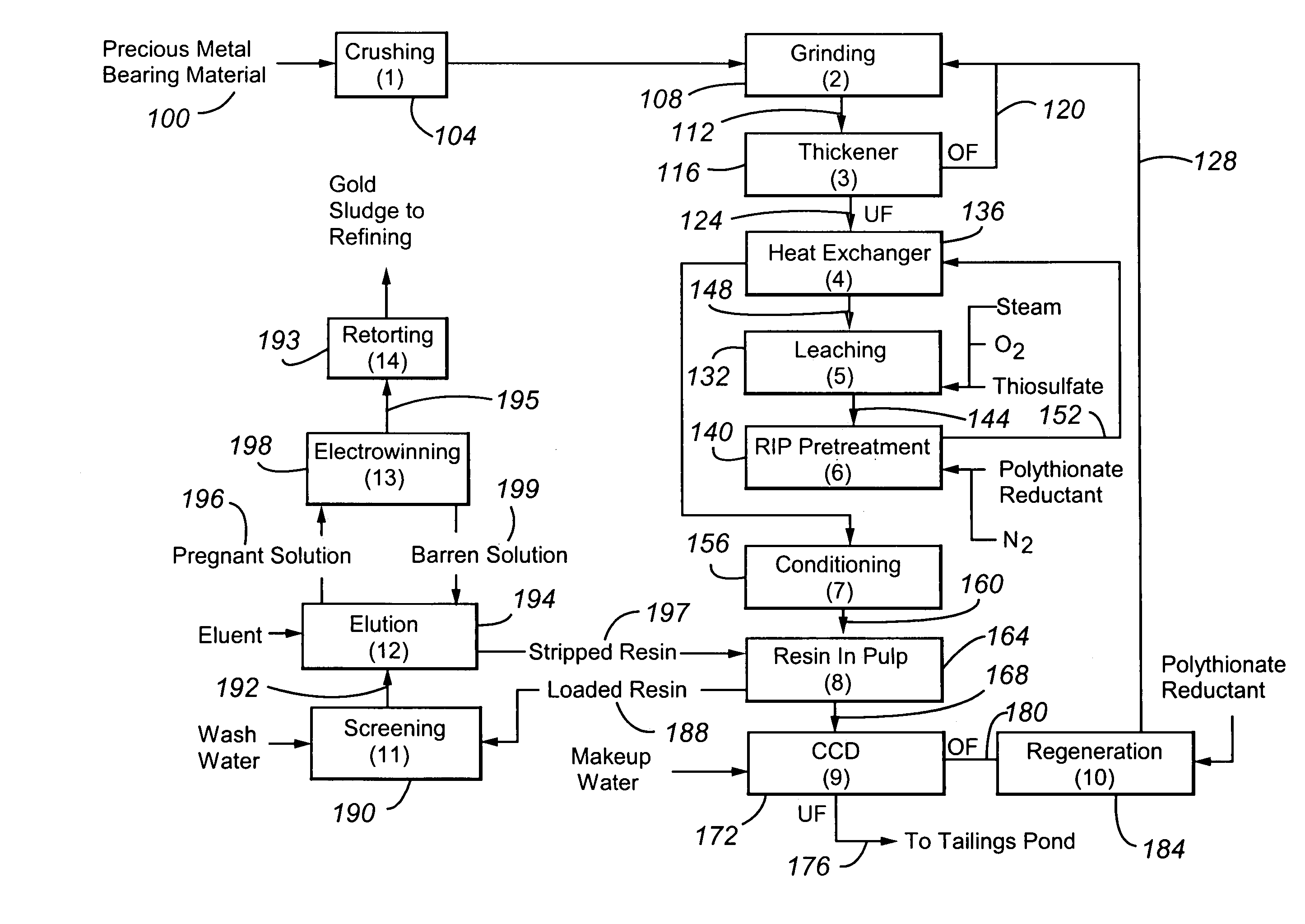

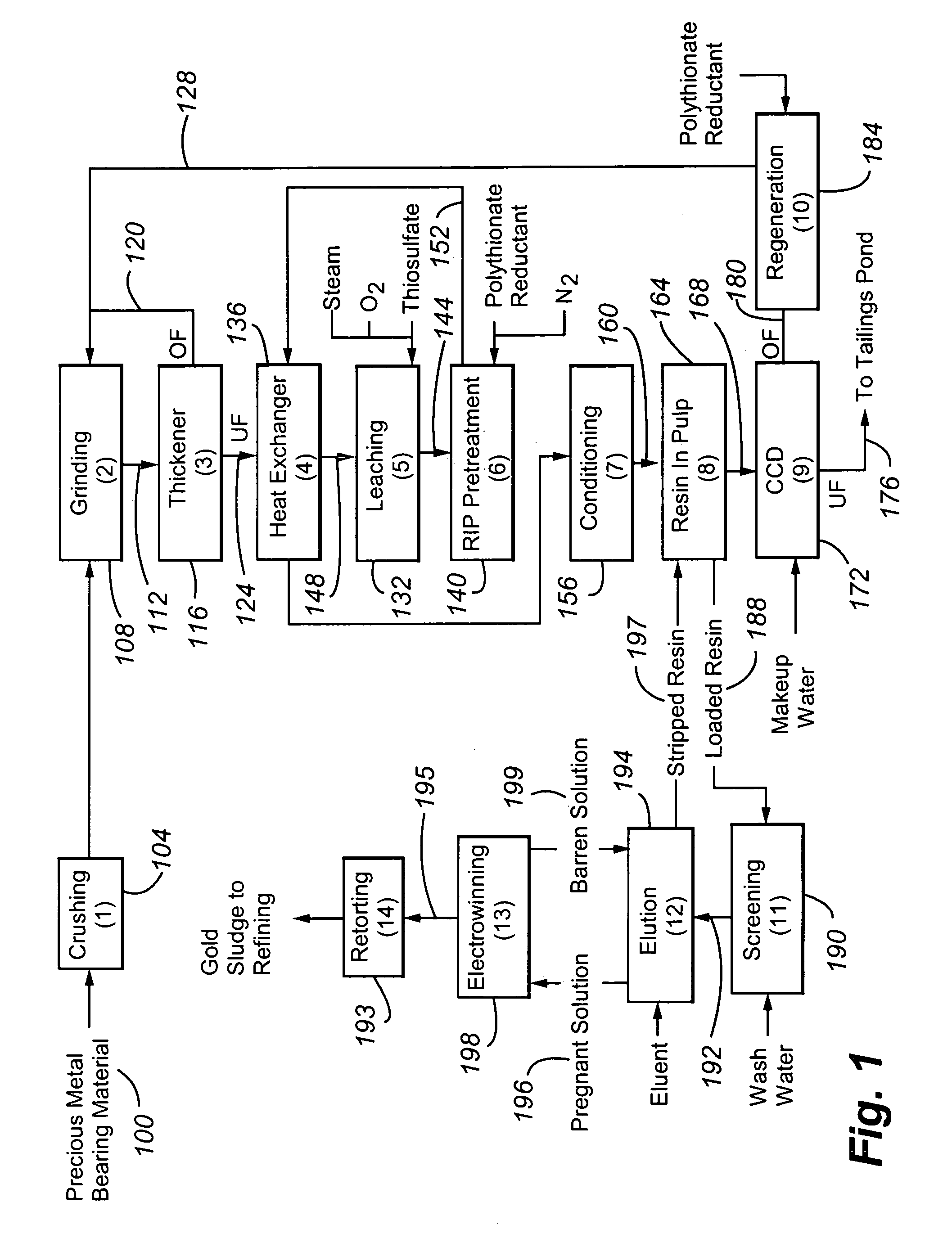

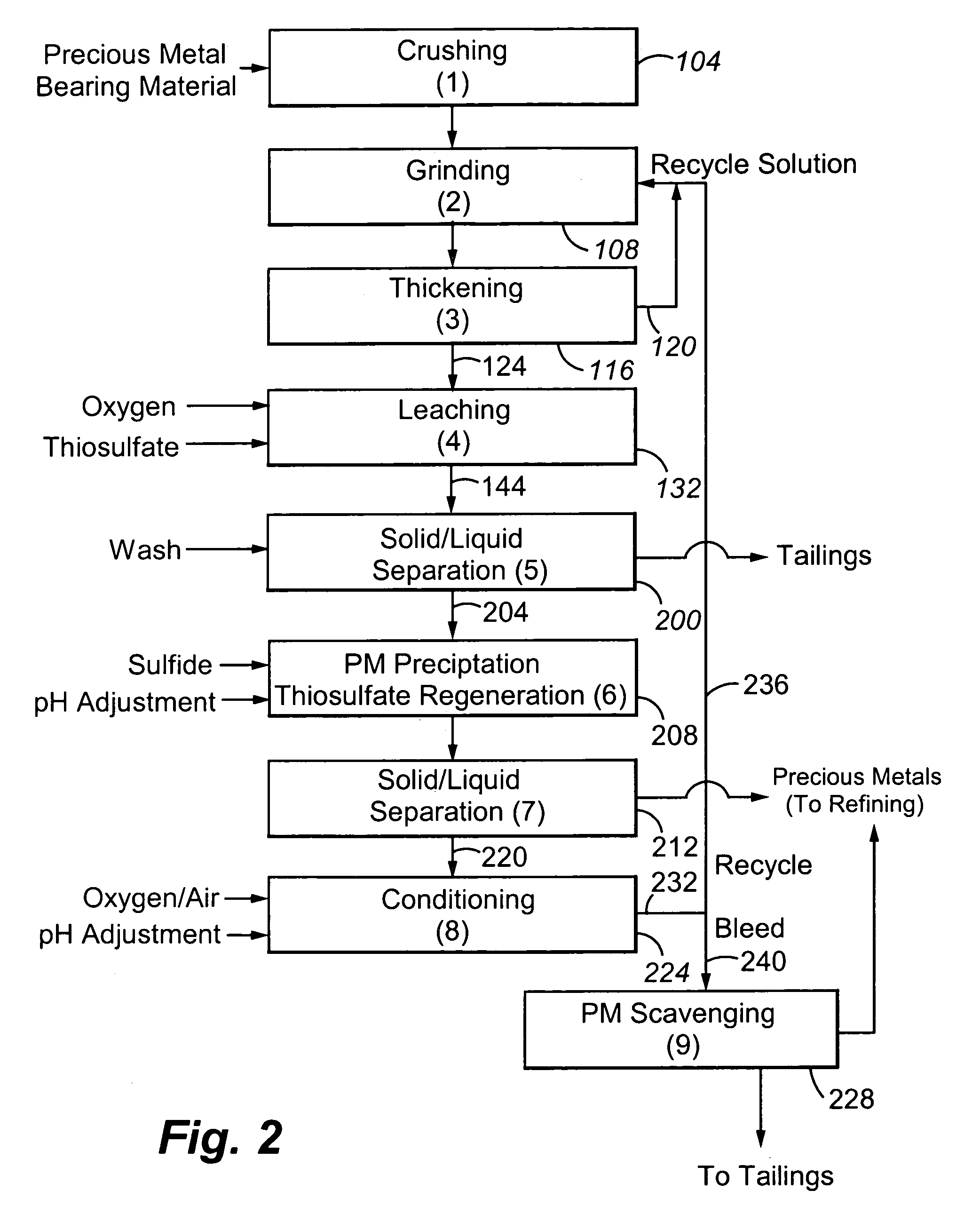

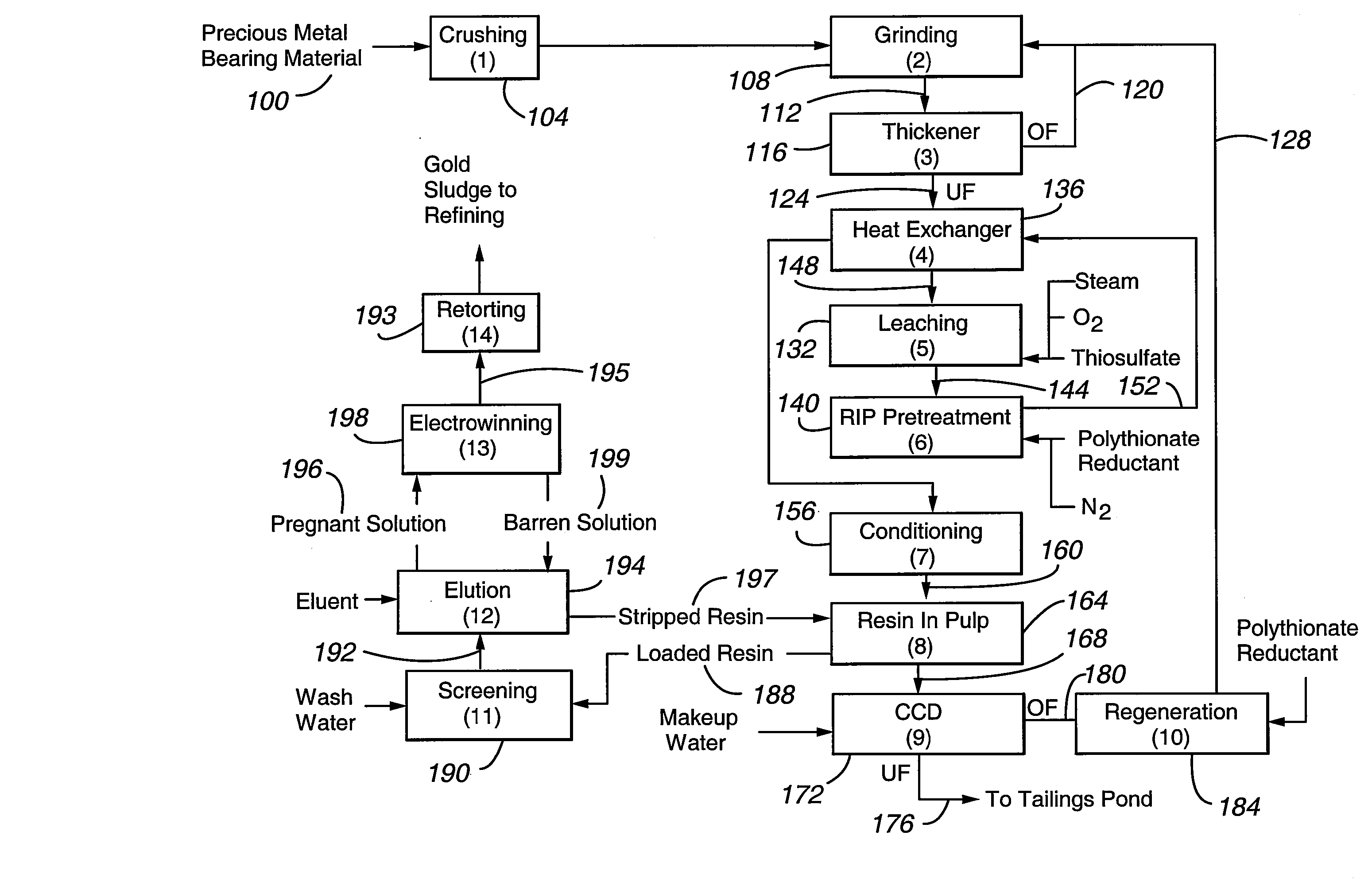

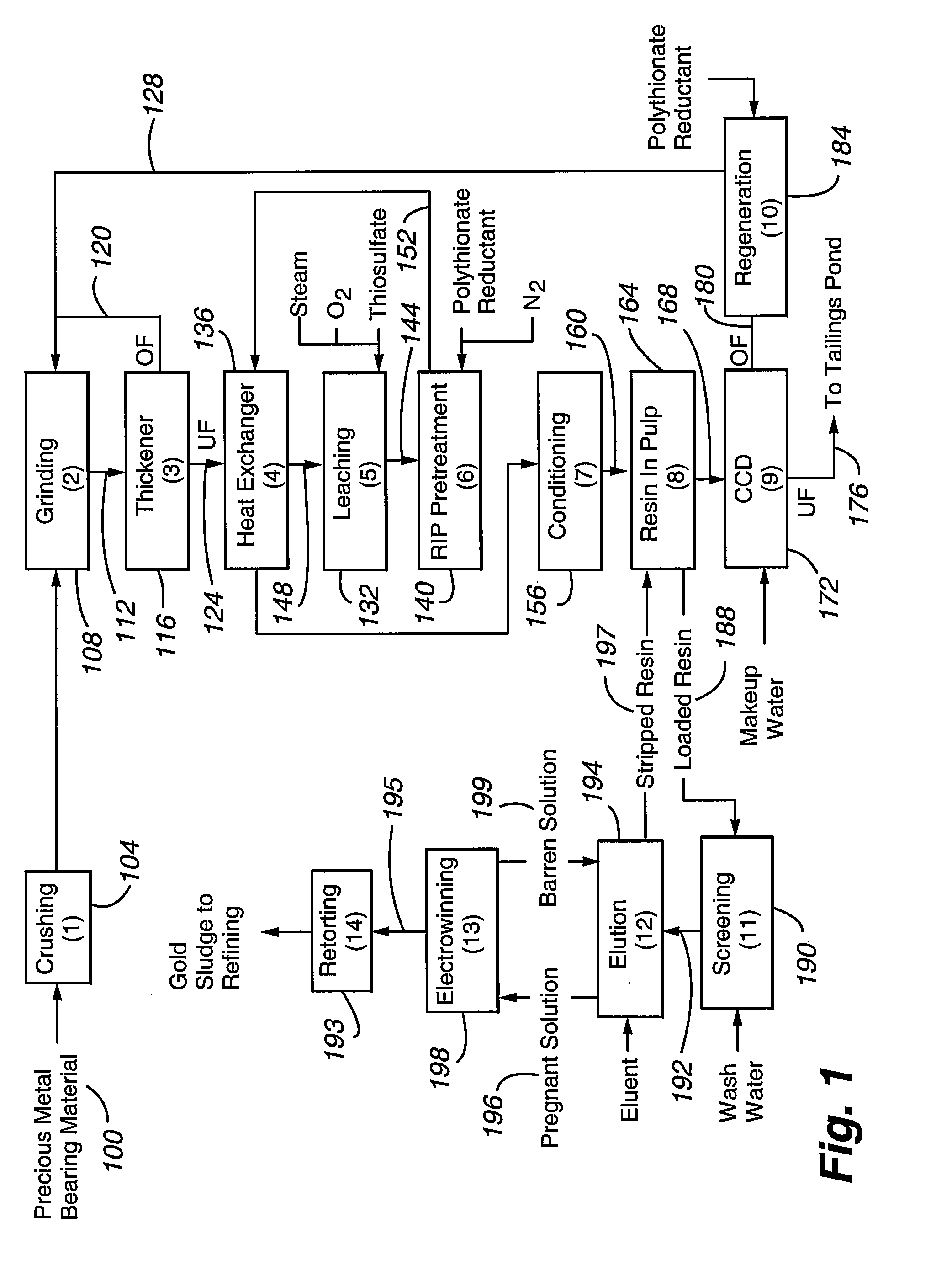

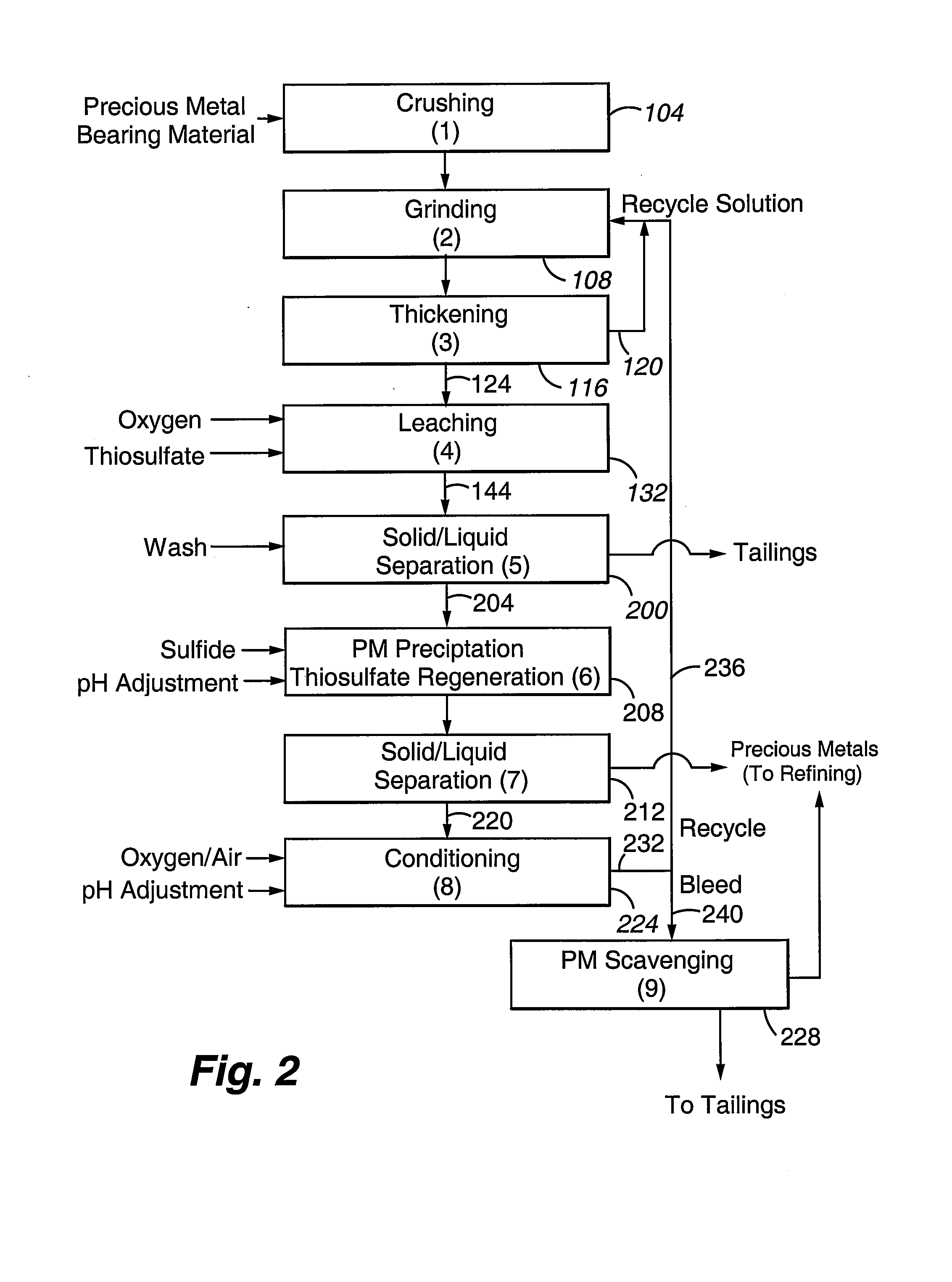

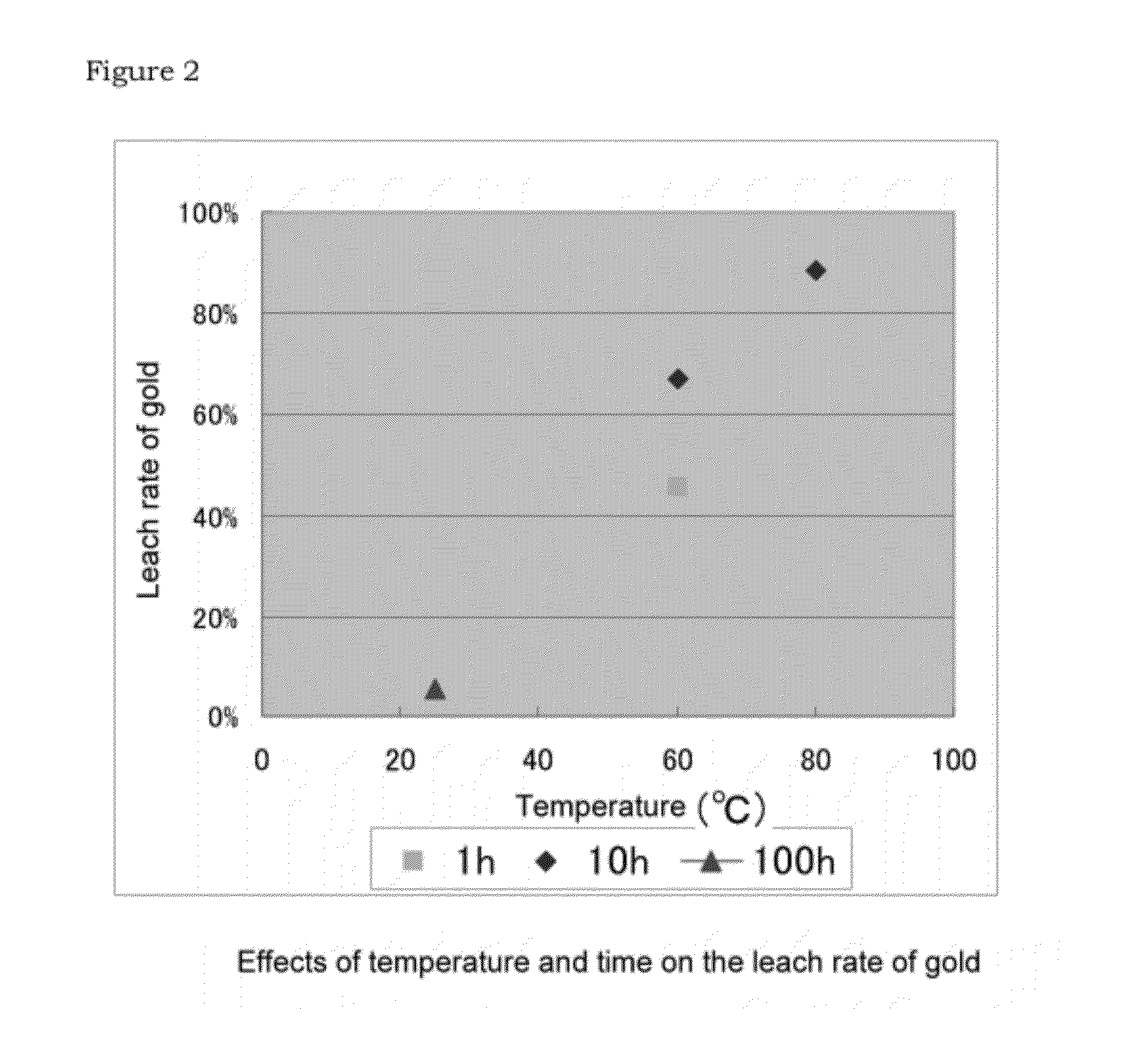

Method for thiosulfate leaching of precious metal-containing materials

InactiveUS7066983B2Improve precious metal loading capacityQuantity minimizationSolvent extractionGold compoundsLixiviantThio-

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ lixiviants that include at most only small amounts of copper and / or ammonia and operate at a relatively low pH, reduction of polythionates, inert atmospheres to control polythionate production, and electrolytic solutions which provide relatively high rates of precious metal recovery.

Owner:PLACER DOME TECHN SERVICES

Passivator for repairing mercury polluted soil, mercury polluted soil repairing method and application

InactiveCN106281332AReduce contentAvoid failureContaminated soil reclamationOrganic fertilisersSulfur containingPollution

The invention provides a passivator for repairing mercury polluted soil. The passivator is prepared from a sulfur-containing reagent and an iron-containing reagent which are stored separately in a mass ratio of 1:5-5:1, wherein the sulfur-containing reagent is one or more of sulfur, sulfide, hydrosulfide, polysulfide and thiosulfate, and the iron-containing reagent is one or more of zero-valent iron, ferrous sulfate and hydrate thereof, ammonium ferrous sulfate and hydrate thereof, ferric sulfate, ferrous chloride and hydrate thereof, ferric chloride and hydrate thereof, polyferric chloride, poly ferrous sulfate, ferroferric oxide and ferric oxide. The sulfur-containing reagent and the iron-containing reagent in the passivator for repairing mercury polluted soil are stored separately, so that invalidation of effective ingredients of mercury in soil caused by reactions generated by mixing can be avoided. The passivator is wide in raw material source and low in cost. The repairing method is simple and feasible, is not sensitive to the soil type, has a remarkable repairing effect for various forms of mercury, does not have secondary pollution, and can be used for repairing cadmium, lead, zinc, copper or nickel heavy metal polluted soil.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Ternary foaming cleaner

InactiveUS20030114340A1Process stabilityImproving efficacy of cleanerOrganic detergent compounding agentsHigh foaming compositionsThio-Active agent

A composition is provided comprising three liquids which are separately maintained prior to forming an admixture during delivery to a surface to be treated, whereupon the admixture generates a heated foam sufficient for cleaning efficacy and stability. A first liquid preferably includes a hypohalite, or a hypohalite generating agent, a second liquid preferably includes a peroxygen agent and a third liquid includes a reducing agent, such as a thiosulfate. The first liquid is thickened to a specified rheology, resulting in the generation of a highly effective foam. As the liquids are initially separated, they can be maintained in an environment free of reactants and otherwise conducive to their activity and stability up to the time of use. When the liquids are allowed to mix, for example, by simultaneously pouring into a drain, the hypohalite and peroxygen react to liberate oxygen gas, while the hypohalite and thiosulfate react to generate heat. As foam generation occurs, the escaping gas contacts surfactant in the solution, and creates foam which expands to completely fill the drain pipe. The expanded foam is hot as a consequence of athe exothermic reaction, and further contains an excess of the hypohalite, both of which act to clean the drain.

Owner:THE CLOROX CO

Process for producing phenoxyphosphazene compound, flame-retardant resin composition, and flame-retardant resin molding

InactiveUS6946578B2Reduce molecular weightChange hueGroup 3/13 element organic compoundsPhosphorus organic compoundsHypochloriteHydrazine compound

An improved phenoxyphosphazene compound is produced by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide, or (c) both the adsorbent and reagent, thereby reducing the acid value of said phosphazene compound to lower than 0.025 mgKOH / g.

Owner:OTSUKA CHEM CO LTD

Systemic Treatment of Pathological Conditions Resulting From Oxidative Stress and/or Redox Imbalance

Alterations of redox homeostasis in mammals underlie a host of symptoms, syndromes and diseases, including AIDS and cancer, which can be successfully treated by administration to a mammal of therapeutically-effective amounts of sulfide compounds and / or thiosulfate compounds and / or thionite compounds and / or sulfite compounds and / or thionate compounds and / or any organic, inorganic or organometallic precursors thereof. The unique compositions of this invention contain one or more “active sulfur compounds” in combination with each other or with other therapeutic agents. The invention also encompasses the varying modes of administration of the therapeutic compounds.

Owner:SULFAGENIX

Acetylene-hydrochlorinated low-content gold compound catalyst

ActiveCN103191760ADip evenlyImprove conversion ratePhysical/chemical process catalystsPreparation by halogen halide additionAcetyleneAlkali metal

The invention discloses an acetylene-hydrochlorinated low-content gold compound catalyst, particularly a nonmerculic catalyst which is suitable for synthesis of chloroethylene through an acetylene hydrochlorination reaction. The catalyst comprises carrier active carbon, a main catalysis element and auxiliary elements A and B, wherein the content of the carrier active carbon is 10,000 parts, the main catalysis element is thiosulfate of gold with the content of 1-120 parts, the auxiliary element A is thiosulfate of silver with the content of 50-1,000 parts, the auxiliary element B is alkali metal compound and a mixture of the alkali metal compounds with the content of 50-1,000 parts. According to the acetylene-hydrochlorinated low-content gold compound catalyst disclosed by the invention, the content of gold in the prepared gold compound catalyst is low; the cost of noble metal catalyst is remarkably reduced; the prepared gold compound catalyst is a good-activity, strong-stability and high-selectivity novel nonmerculic catalyst; and the acetylene-hydrochlorinated low-content gold compound catalyst has the advantages of simple production process, short production period and environment-friendliness.

Owner:XINJIANG TIANYE GRP +1

Method for treating alkali residue liquid waste and three-sludge of oil refineries

ActiveCN104556523AReduce moisture contentAvoid shockSludge treatment by de-watering/drying/thickeningWater treatment compoundsLiquid wasteSulfate

The invention relates to a method for treating alkali residue liquid waste and three-sludge of oil refineries. The method comprises the following steps: at first, contacting the alkali residue liquid waste of oil refineries with an oxygen-containing gas at 100-200 DEG C and at a pressure of 0.3-3 MPa to carry out a mild wet oxidation treatment, so as to convert sulfur in sulfides into sulfates and / or thiosulfates, mixing the alkali residue liquid waste experiencing the oxidation treatment with the three-sludge of oil refineries in a mixing and stirring tank, adding a coagulant, a flocculant, magnetic powder and an oxidant into the mixing and stirring tank, reacting for a period of time, and carrying out solid-liquid separation on materials at the outlet of the mixing and stirring tank in a magnetic separator, wherein the separated water can be directly drained or recycled, and the separated solid is further dewatered after the magnetic powder is recycled. According to the method provided by the invention, the COD removal rate is up to 99%, and the water content of the dewatered sludge is smaller than 60%. The method provided by the invention is simple in treatment process, little in equipment, short in dwell time, simple and convenient to operate and high in treatment efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for thiosulfate leaching of precious metal-containing materials

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ lixiviants that include at most only small amounts of copper and / or ammonia and operate at a relatively low pH, reduction of polythionates, inert atmospheres to control polythionate production, and electrolytic solutions which provide relatively high rates of precious metal recovery.

Owner:PLACER DOME TECHN SERVICES

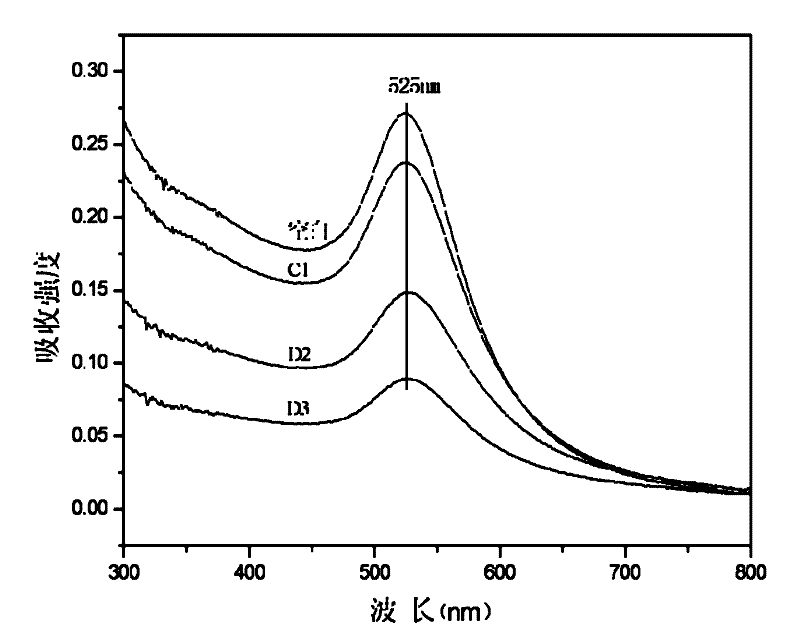

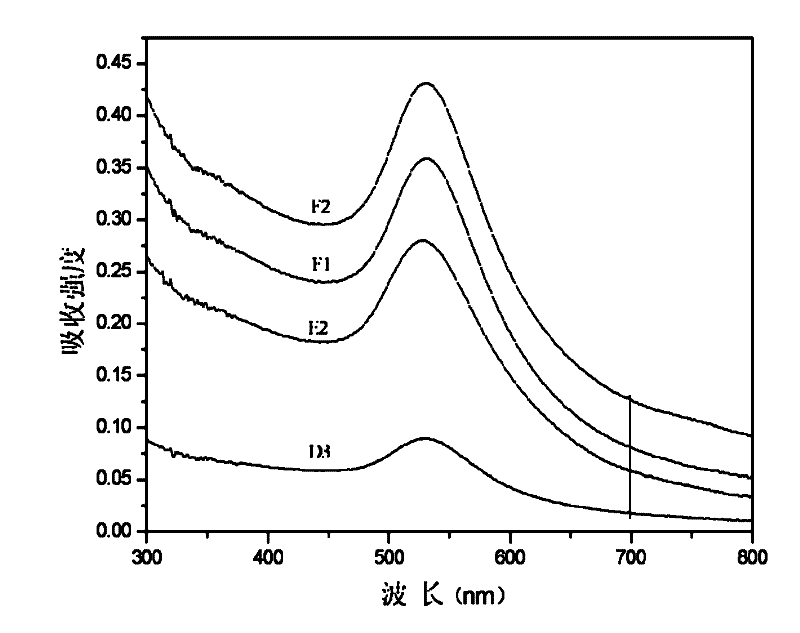

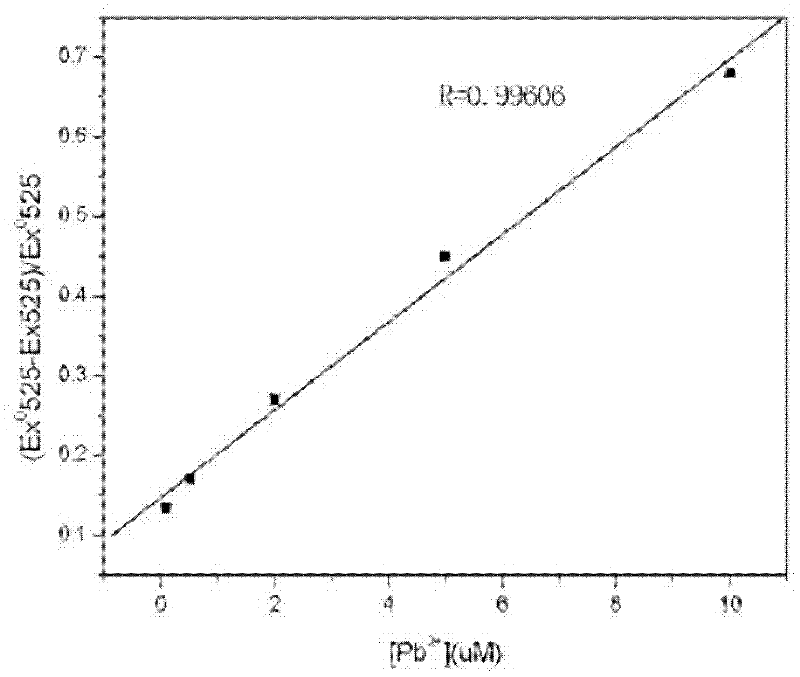

Detection method of lead ion

ActiveCN102368053AQuick checkEasy to operateMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationIonThiosulfates

The invention relates to a detection method of a lead ion. The method is characterized by comprising the steps of: adding a chloroauric acid water solution into deionized water, adding a cationic surfactant water solution under magnetic stirring, then slowly adding a newly prepared reductant water solution dropwisely, conducting magnetic stirring for 30min under room temperature, thus obtaining asurfactant modified Au nanoparticle detection liquid; taking two parts of the detection liquid in an equivalent amount; adding two parts of a thiosulfate water solution of an equivalent volume into the two detection liquids respectively, and shaking them uniformly so as to obtain a first mixed solution and a second mixed solution; adding ultrapure water and a solution to be detected in an equivalent volume into the first mixed solution and the second mixed solution respectively, mixing them well so as to form a third mixed solution and a fourth mixed solution; comparing the color change of the third mixed solution and the fourth mixed solution so as to determine whether existing a lead ion in the detected solution. The thiosulfate can be sodium hyposulfite or potassium thiosulfate. The method provided in the invention has the advantages of simple, convenient and rapid operation, low detection cost, small sampling amount and wide application scope.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nanometer vanadium catalyst for preparing sulfuric acid through oxidizing SO2 and preparation method thereof

ActiveCN102489320AReduce energy consumptionLower operating temperaturePhysical/chemical process catalystsSulfur compoundsPtru catalystThio-

The invention relates to a nanometer vanadium catalyst for preparing sulfuric acid through oxidizing SO2 and a preparation method thereof. The nanometer vanadium catalyst which uses diatomite as a carrier to load V2O5 contains cesium oxide and lanthanum oxide, and raw materials of the nanometer vanadium catalyst comprise, by mass, 4-5.5% of V2O5, 0.01-5% of a cerium-containing compound, 1-3% of a thiosulfate, 1-10% of a cesium-containing compound, 0.01-5% of a lanthanum-containing compound, and 0.5-7% of a surfactant and an organic macromolecular compound. According to the finished nanometer vanadium catalyst, V2O5 is nanometer grade V2O5; the ignition temperature is 340-350DEG C; the operation temperature of the catalytic reaction is 360-370DEG C; and the SO2 volume concentration is 3-12%, the total conversion rate is equal to or greater than 99.7% and the SO2 emptying amount is equal to or less than 400mg / m<3> when the catalytic reaction adopts a 3+2 flow of a converter. The prepared catalyst has the advantages of low ignition temperature, high activity, high use stability, good compressive strength, and low abrasion.

Owner:南京云高新型材料有限公司

Method for recycling gold in thiosulfate system

InactiveCN111004922AHigh recovery rateSimple processProcess efficiency improvementActivated carbonThio-

The invention relates to a method for recycling gold in a thiosulfate system, and belongs to the technical field of hydrometallurgy and precious metal recycling. According to the method for recoveringgold in the thiosulfate system, mercaptan is adopted as an additive, mercaptan is added into a solution containing Au(S2O3)2<3->, and then unmodified commercial activated carbon can be directly usedfor adsorbing gold. The method is simple in process, low in cost and high in gold recovery rate; the gold in the thiosulfate gold leaching solution can be adsorbed without modifying the activated carbon, so that the time and the cost are saved; potential dangers and environmental pollution possibly existing in the modifier process are avoided.

Owner:KUNMING UNIV OF SCI & TECH

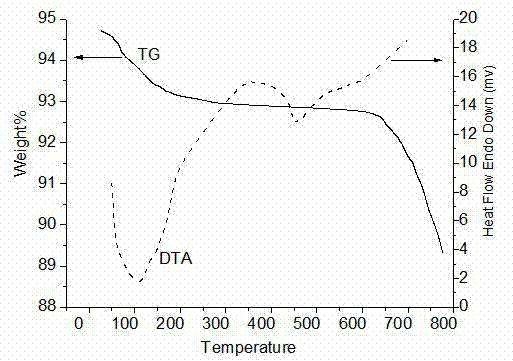

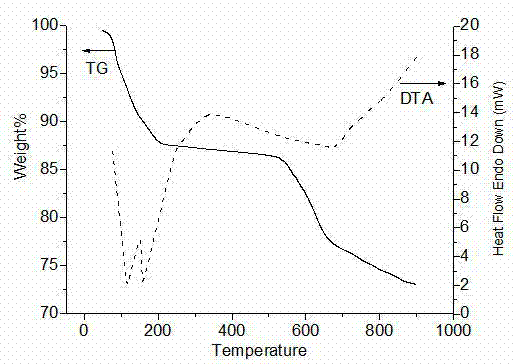

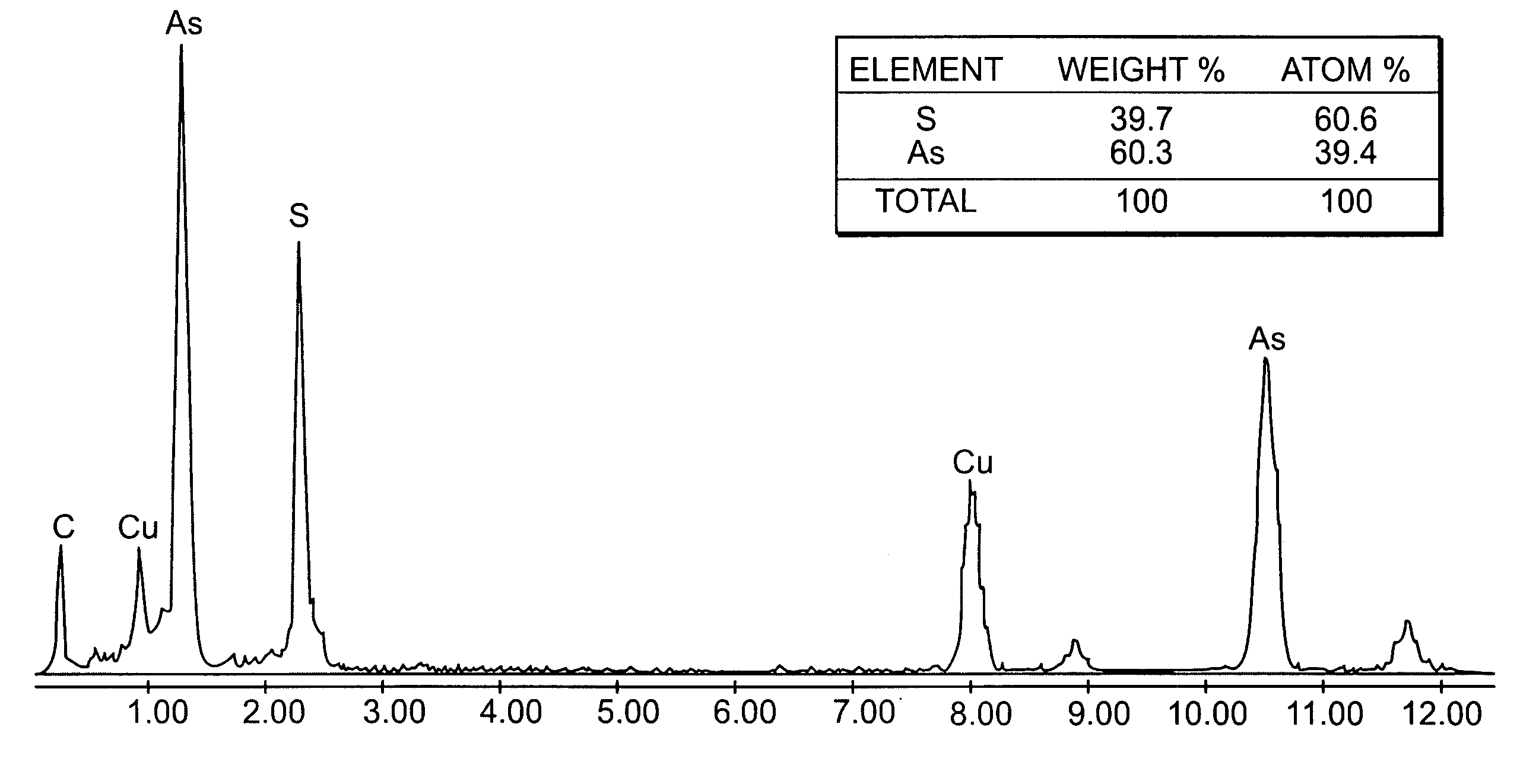

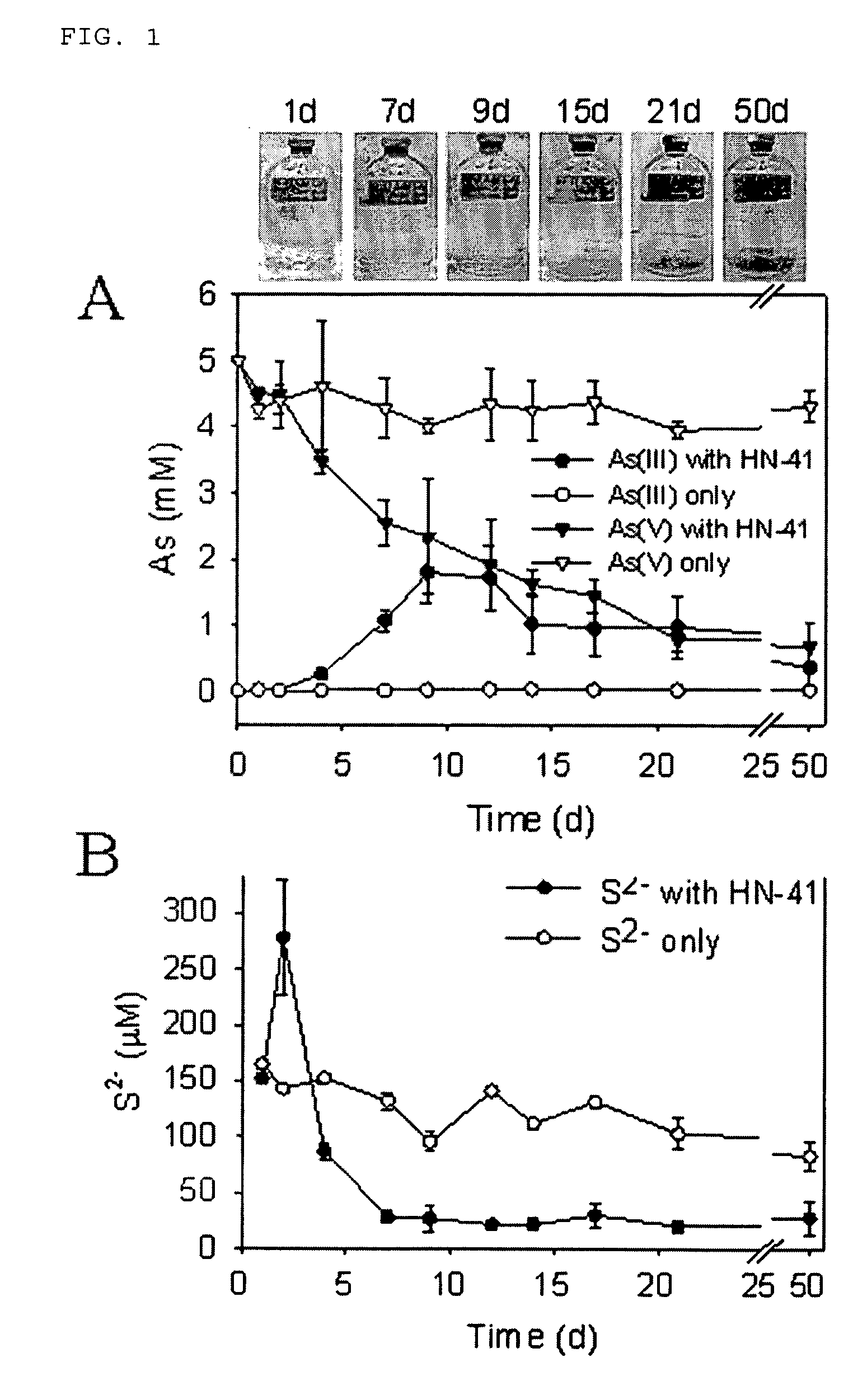

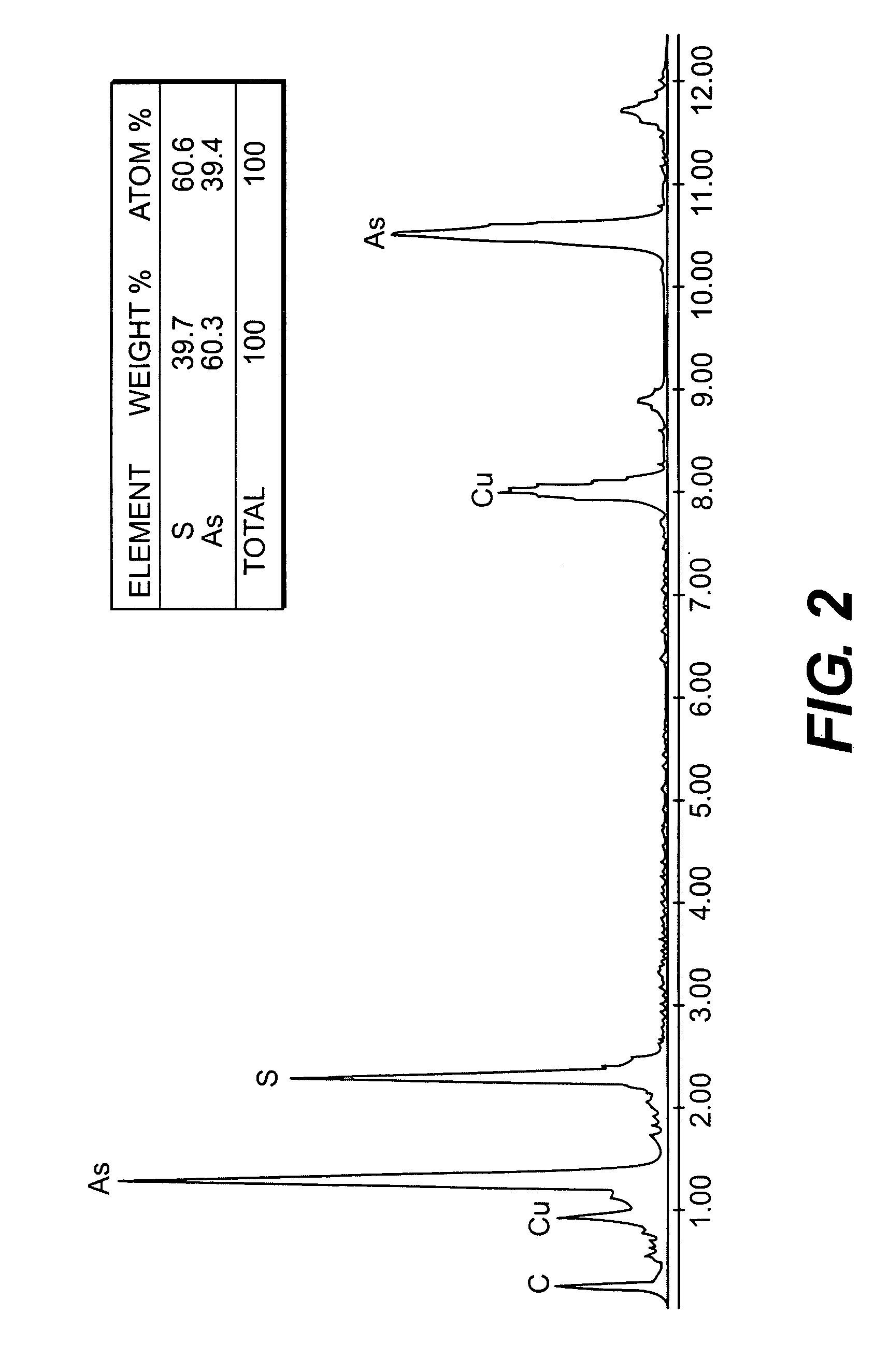

Biological production method of photoconductive arsenic-sulfide (As-S) nanotube and strain used for the same

InactiveUS20090155876A1Improve convenienceHigh potential utilityBacteriaUnicellular algaeArsenateBiochemistry

Disclosed is a biological method for preparing arsenic sulfide (As—S) compounds. More particularly, the present invention provides a method for production of nanotubes based on As—S compounds including As2S3 by reacting thiosulfate S2O32− with arsenate As5+ through mediation of Shewanella sp. strain.

Owner:GWANGJU INST OF SCI & TECH

Ternary foaming cleaner

InactiveUS6638900B2Good curative effectOrganic detergent compounding agentsHigh foaming compositionsProduct gasTime of use

A composition is provided comprising three liquids which are separately maintained prior to forming an admixture during delivery to a surface to be treated, whereupon the admixture generates a heated foam sufficient for cleaning efficacy and stability. A first liquid preferably includes a hypohalite, or a hypohalite generating agent, a second liquid preferably includes a peroxygen agent and a third liquid includes a reducing agent, such as a thiosulfate. The first liquid is thickened to a specified rheology, resulting in the generation of a highly effective foam. As the liquids are initially separated, they can be maintained in an environment free of reactants and otherwise conducive to their activity and stability up to the time of use. When the liquids are allowed to mix, for example, by simultaneously pouring into a drain, the hypohalite and peroxygen react to liberate oxygen gas, while the hypohalite and thiosulfate react to generate heat. As foam generation occurs, the escaping gas contacts surfactant in the solution, and creates foam which expands to completely fill the drain pipe. The expanded foam is hot as a consequence of the exothermic reaction, and further contains an excess of the hypohalite, both of which act to clean the drain.

Owner:THE CLOROX CO

Antibiotic wastewater degradation process

InactiveCN105502775AEffective control of concentrationLow costWater treatment parameter controlWater/sewage treatment by irradiationPersulfateUltraviolet lights

The invention relates to an antibiotic wastewater degradation process. The antibiotic wastewater degradation process comprises the steps of firstly adding persulfate into pretreatment wastewater so as to obtain a mixed solution, regulating pH of the mixed solution with an acid liquid or an alkali liquid, carrying out first illumination on the mixed solution by virtue of 200nm-300nm ultraviolet light after the pH regulation, adding a thiosulfate solution into the mixed solution, and carrying out secondary illumination by virtue of 300nm-400nm ultraviolet light, so as to obtain water in which antibiotics are removed. According to the antibiotic wastewater degradation process, the antibiotics in the wastewater are degraded, the degradation speed is high, the degradation efficiency is high, the degradation effect is good, furthermore, the raw material cost is low, by-products are toxic-free, and the concentration of the antibiotics in water can be effectively controlled. Data show that the degradation rate of the degradation process to the antibiotics in the wastewater reaches up to 91%-96%.

Owner:中华人民共和国济南出入境检验检疫局

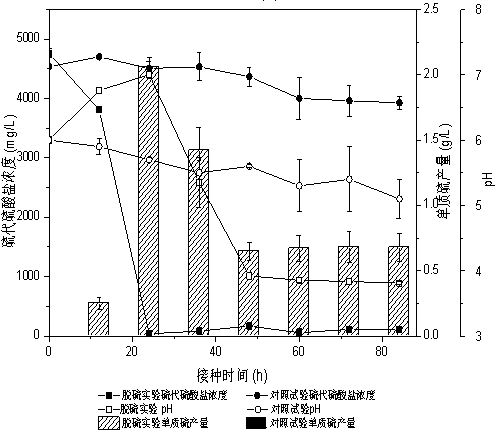

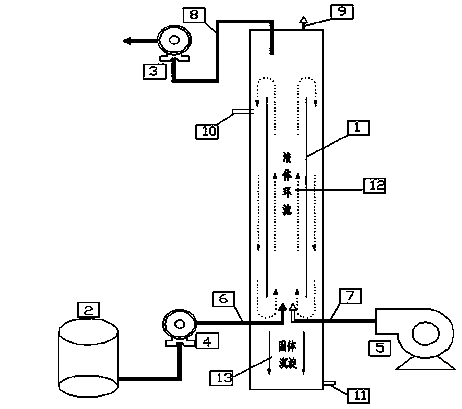

Sulfur-oxidizing bacterium and method for removing sulfide by using sulfur-oxidizing bacterium

ActiveCN103667096AImprove desulfurization efficiencyHigh yieldBacteriaMicroorganism based processesThermithiobacillus tepidariusSulfate

The invention discloses a sulfur-oxidizing bacterium and a method for removing sulfide by using the sulfur-oxidizing bacterium and belongs to the technical field of biological and environmental protection. The invention discloses the bacterium classified and named Themithiobacillustepidarius JUN-2, and the preservation number is CCTCCNO:M2013217. The bacterium has very high oxidizing efficiency for sulfur compounds, and a byproduct named elemental sulfur with high additional value is efficiently generated. The invention further relates to a method for removing the sulfur compounds in sulfur-containing waste liquid by applying the the sulfur compounds in sulfur-containing waste liquid in a gas lifting type inner circulation continuous operation aerobic reaction device; the hydraulic retention time (HRT) is 10 hours; the yield of the elemental sulfur is 0.1-gL<-1>h<-1>; the generation ratio of the elemental sulfur is about 60 percent; the oxygenation efficiency of thiosulfate is greater than 98 percent. The gas lifting type inner circulation continuous operation aerobic reaction device behaves well, and has a potential to removal of the sulfides in the sulfur-containing waste liquid on large scale.

Owner:JIANGNAN UNIV

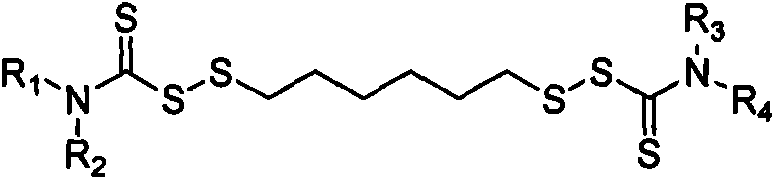

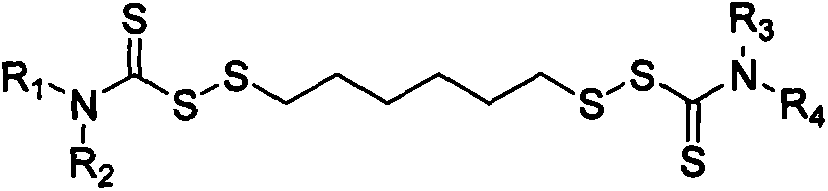

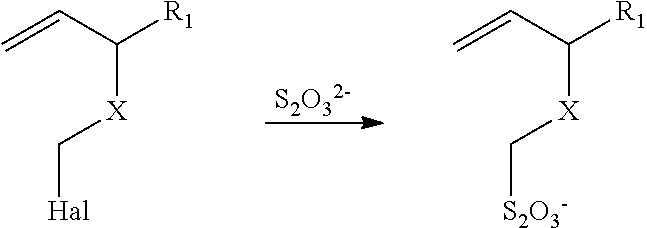

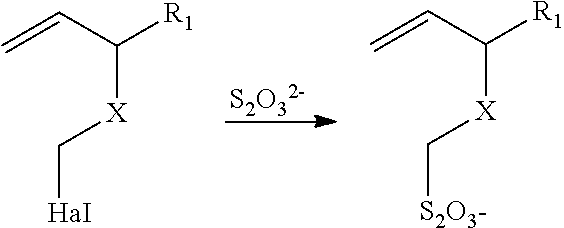

Forming patterns using thiosulfate polymer compositions

InactiveUS20140287365A1High bonding strengthLow costPhotosensitive material processingOriginals for photomechanical treatmentPolymer sciencePhotosensitizer

A thiosulfate polymer composition includes an electron-accepting photosensitizer component, either as a separate compound or as an attachment to the thiosulfate polymer. The thiosulfate polymer composition can be applied to various articles and used to form a predetermined polymeric pattern after photothermal reaction to form crosslinked disulfide bonds, removing non-crosslinked polymer, and reaction with a disulfide-reactive material.

Owner:EASTMAN KODAK CO

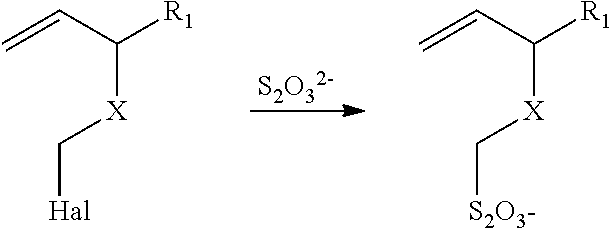

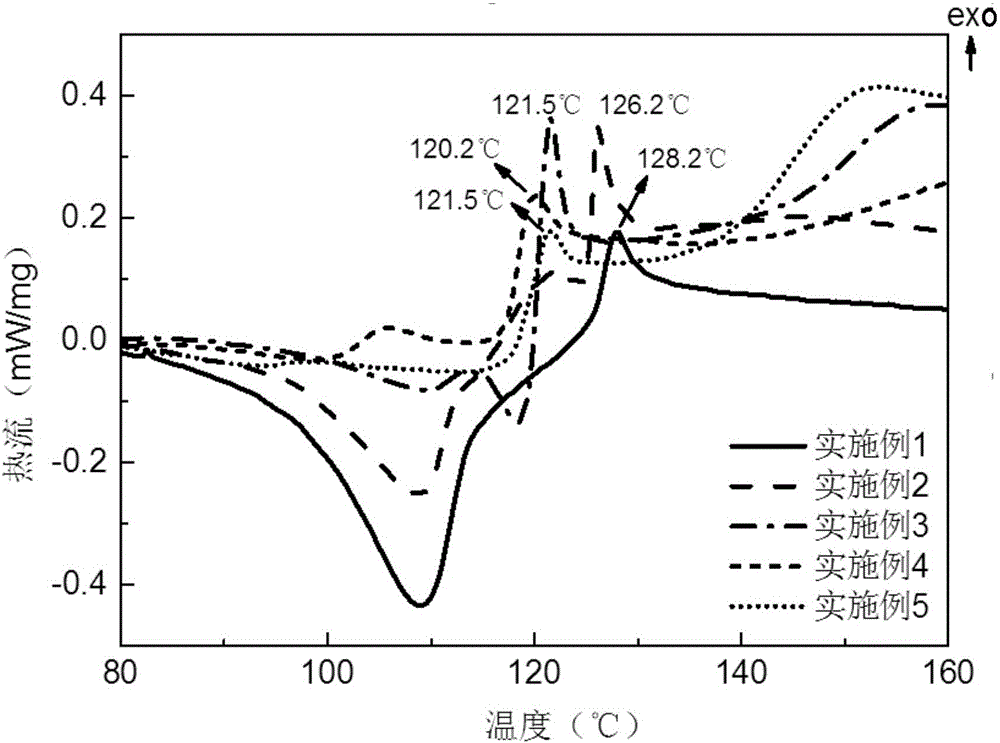

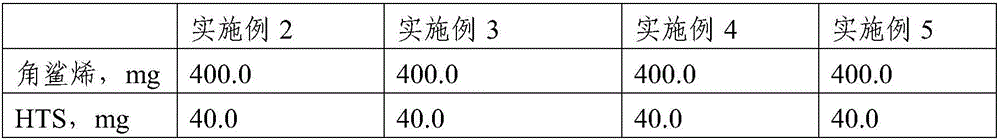

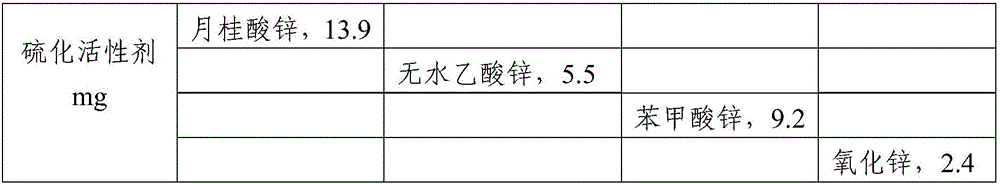

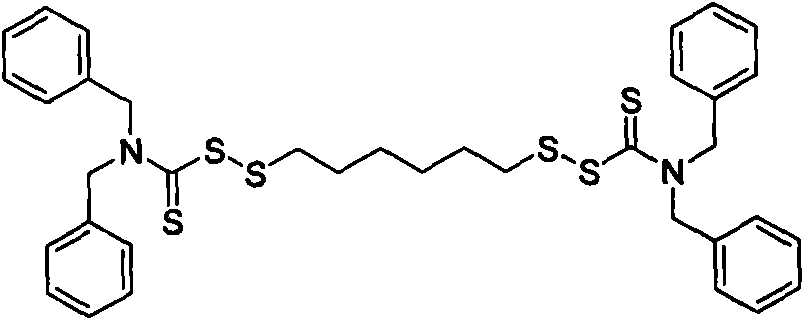

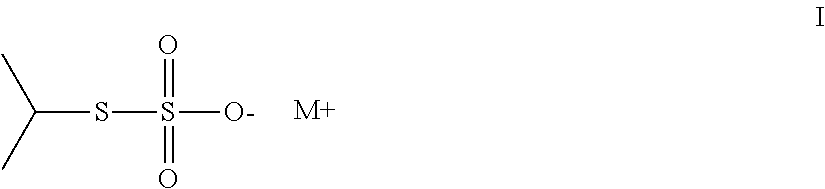

Testing method for detecting activity of vulcanizing activator

InactiveCN105842277AEasy to makeLess sample consumptionMaterial heat developmentPhysical chemistryDifferential scanning calorimetry

The invention provides a testing method for detecting activity of a vulcanizing activator. The testing method comprises the following steps: step 1, preparation of a sample: weighing an organic thiosulfate sample, adding the organic thiosulfate sample into a mortar, adding the vulcanizing activator, then adding squalene and carrying out adequate grinding so as to realize uniform mixing of the sample; step 2, differential scanning calorimetric (DSC) testing; and step 3, analysis of a DSC pattern: finding out exothermic peaks in the DSC pattern and marking temperature or time corresponding to a maximum exothermic peak. Compared with conventional methods which carry out physical property testing after mixing of natural rubber, the testing method employing DSC to testing exothermic conditions of reactions with squalene as a natural rubber analogue in the invention has the following obvious advantages: consumption of the sample is small; sample preparation is simple; and the testing method is simple and is rapid in testing speed. Meanwhile, test results of the testing method and the results of physical property testing after natural rubber mixing can confirm each other; and the testing method can prejudge the results of physical property testing after natural rubber mixing and enables physical property testing to be more targeted.

Owner:BEIJING RED AVENUE INNOVA

Multiple-effect composite additive of diesel oil and preparation method thereof

ActiveCN101812334AImprove drivabilityImprove acceleration performanceLiquid carbonaceous fuelsPhenolP-Phenylenediamine

The invention discloses a multiple-effect composite additive of diesel oil, comprising the following raw materials in parts by weight: 10-15 parts of glycol dinitrate, 12-20 parts of glycerol trinitrate, 8-16 parts of heptyl ester nitrate, 9-18 parts of diphenylamine, 1-6 parts of succinimide, 1-6 parts of p-phenylenediamine, 10-28 parts of ethylene glycol methyl ether, 16-29 parts of barium thiosulfate, 2-5 parts of naphthalin, 2-5 parts of camphor, 2-8 parts of dodecencylsuccinic acid, 2-8 parts of hexadecyl dimethyl ammonium chloride, 1-3 parts of hexadecyl phenol and 1-3 parts of polyoxyethylene hexadecyl phenol ether. The invention also discloses a preparation method of the composite additive. The composite additive can greatly enhance the combustion performance of the diesel oil and reduce the discharge amount of harmful substances, i.e. CO and hydrocarbon (CH), contained in tail gas and also has certain oil saving effect.

Owner:SHANDONG TAIDE NEW ENERGY

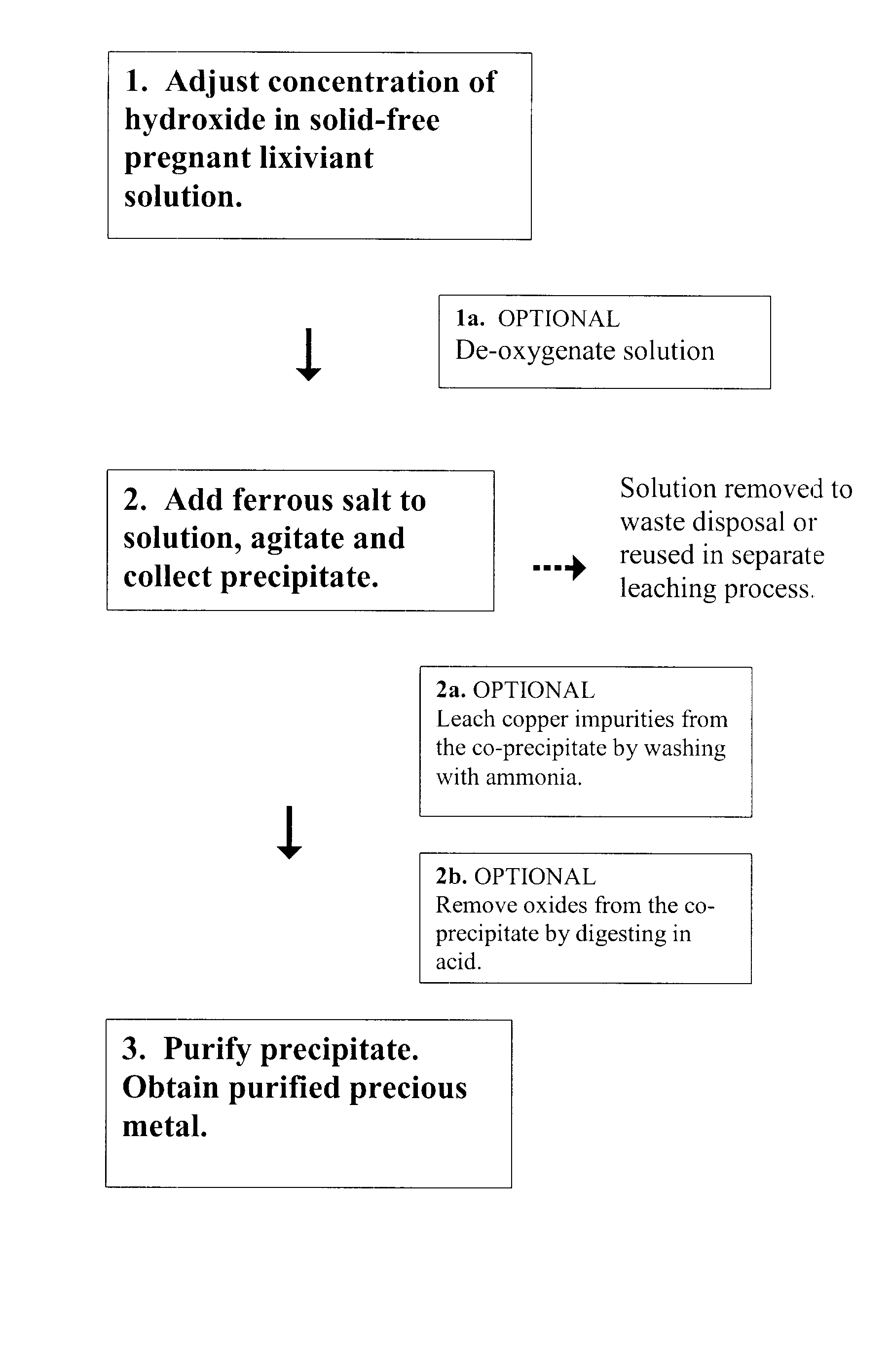

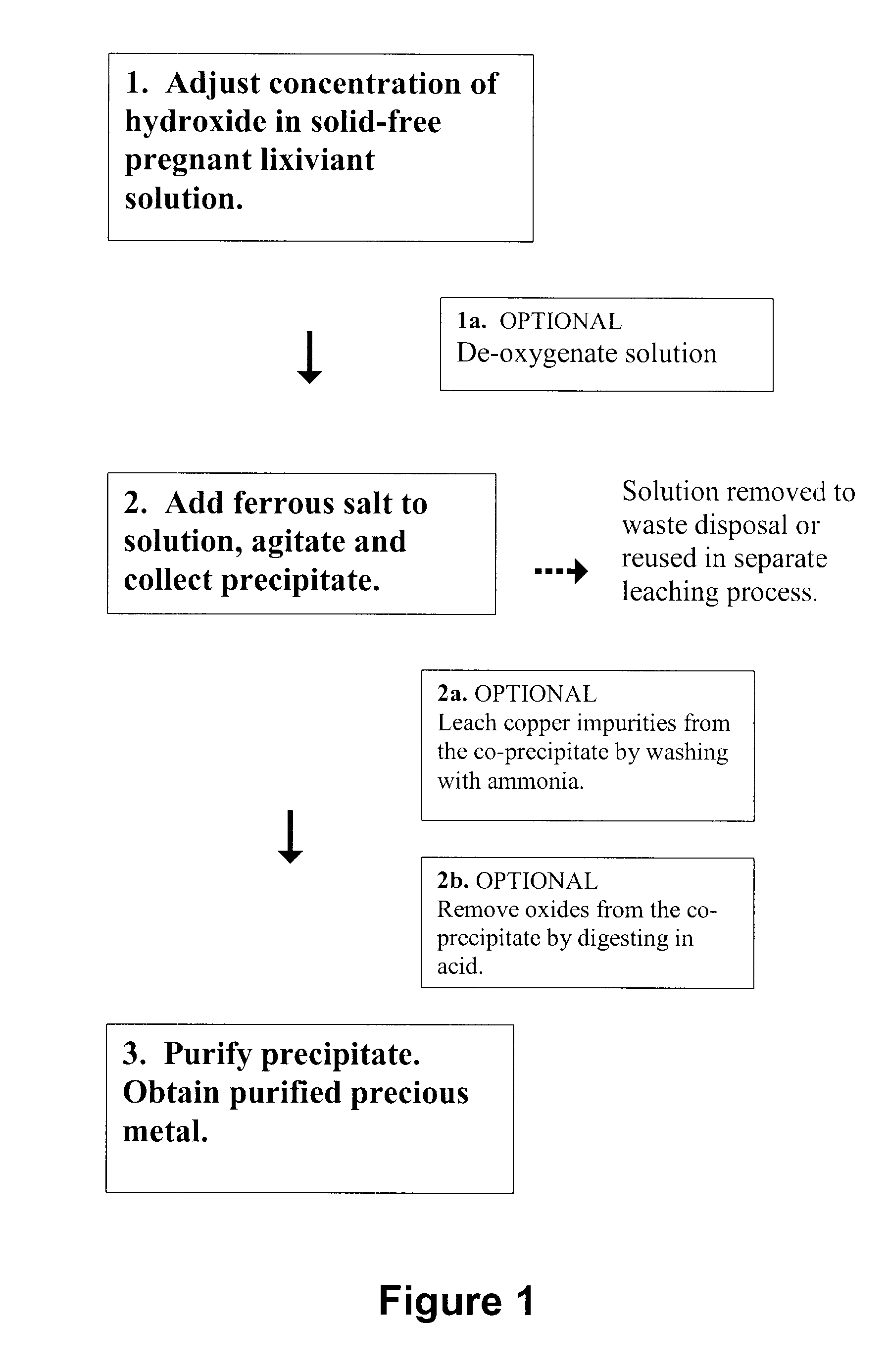

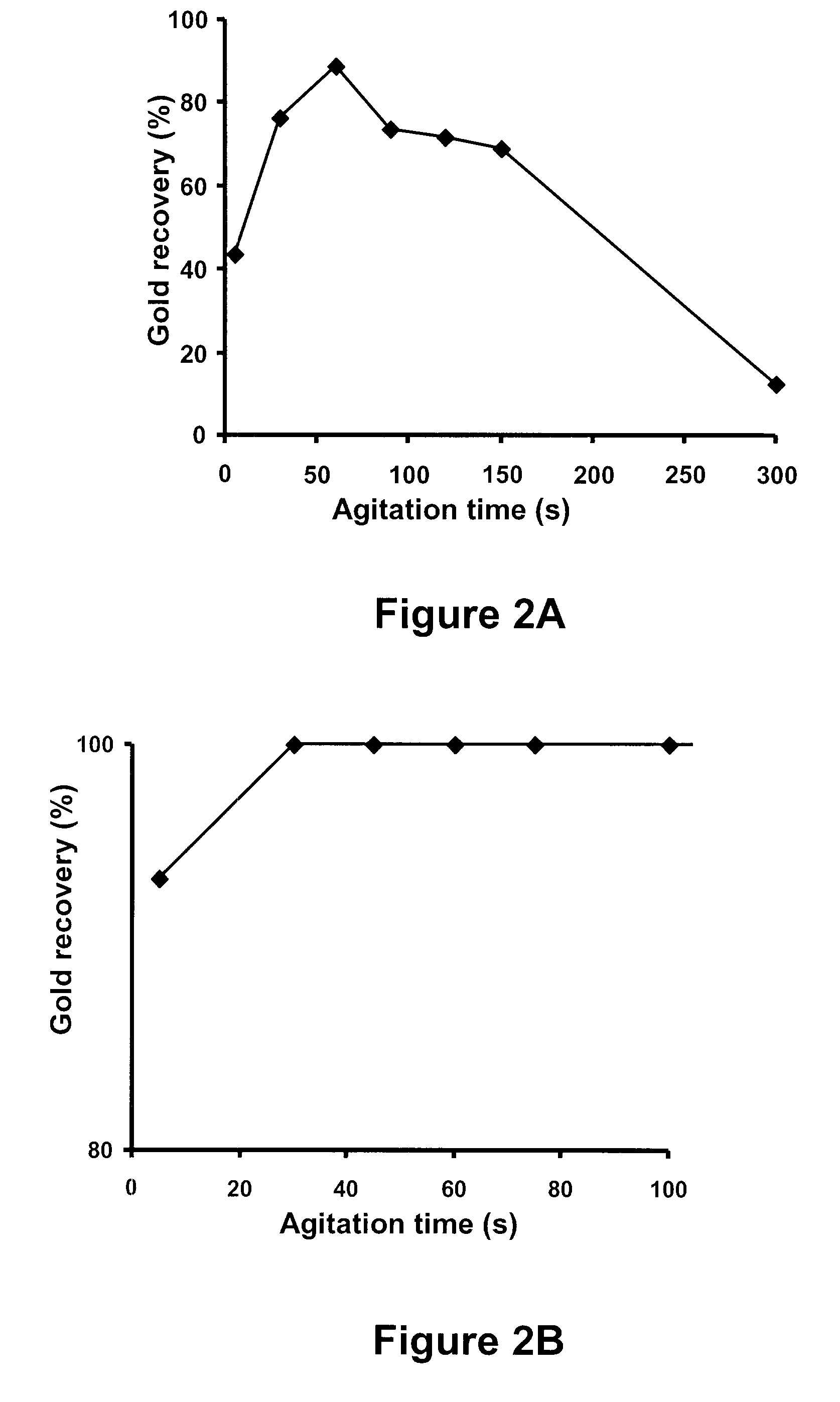

Precious metal recovery from solution

InactiveUS7972413B2Easy to separateLow cost of reagentsPhotography auxillary processesProcess efficiency improvementFerric oxide hydrateAqueous solution

A method for recovering precious metals such as gold and silver from aqueous solution as solid is described The method includes mixing an aqueous solution (e.g, thiosulfate or thiocyanate lixiviant) containing precious metals with ferrous ions in the presence of an effective amount of hydroxide ions. The precious metal ions are reduced and co-precipitate with iron hydroxides and / or hydrated iron oxides The co-precipitate is collected and purified. De-oxygenation of the reaction solution is optional. The recover / method is fast, complete and clean.

Owner:METAL ASIA INT

Thiocarbamic acid derivative and preparation method thereof

The invention provides a preparation method, which is simple in operation and is green and environment-friendly, for preparing a thiocarbamic acid derivative. According to the preparation method, organic thiosulfate and sodium thiocarbamate are used as raw materials, dichloromethane and formaldehyde can be added during reaction to accelerate the reaction, suction filtration is performed after reaction to separate out a solid product, and the filtrate can be recycled to continuously prepare the thiocarbamic acid derivative. The boiling point of the dichloromethane added during the reaction is low, so that the reaction temperature can be reduced, the energy consumption is reduced, and the dichloromethane is difficult to burn to ensure that the safety performance during production is improved.

Owner:BEIJING RED AVENUE INNOVA

Thiosulfate polymer compositions and articles

ActiveUS20140287349A1High bonding strengthLow costCosmetic preparationsHair cosmeticsPhotosensitizerSulfate

A thiosulfate polymer composition includes an electron-accepting photosensitizer component, either as a separate compound or as an attachment to the thiosulfate polymer. The thiosulfate polymer composition can be applied to various articles, or used to form a predetermined polymeric pattern after photothermal reaction to form crosslinked disulfide bonds, removing non-crosslinked polymer, and reaction with a disulfide-reactive material. Such thiosulfate polymer compositions can also be used to sequester metals in nanoparticulate form, and as a way for shaping human hair in hairdressing operations.

Owner:EASTMAN KODAK CO

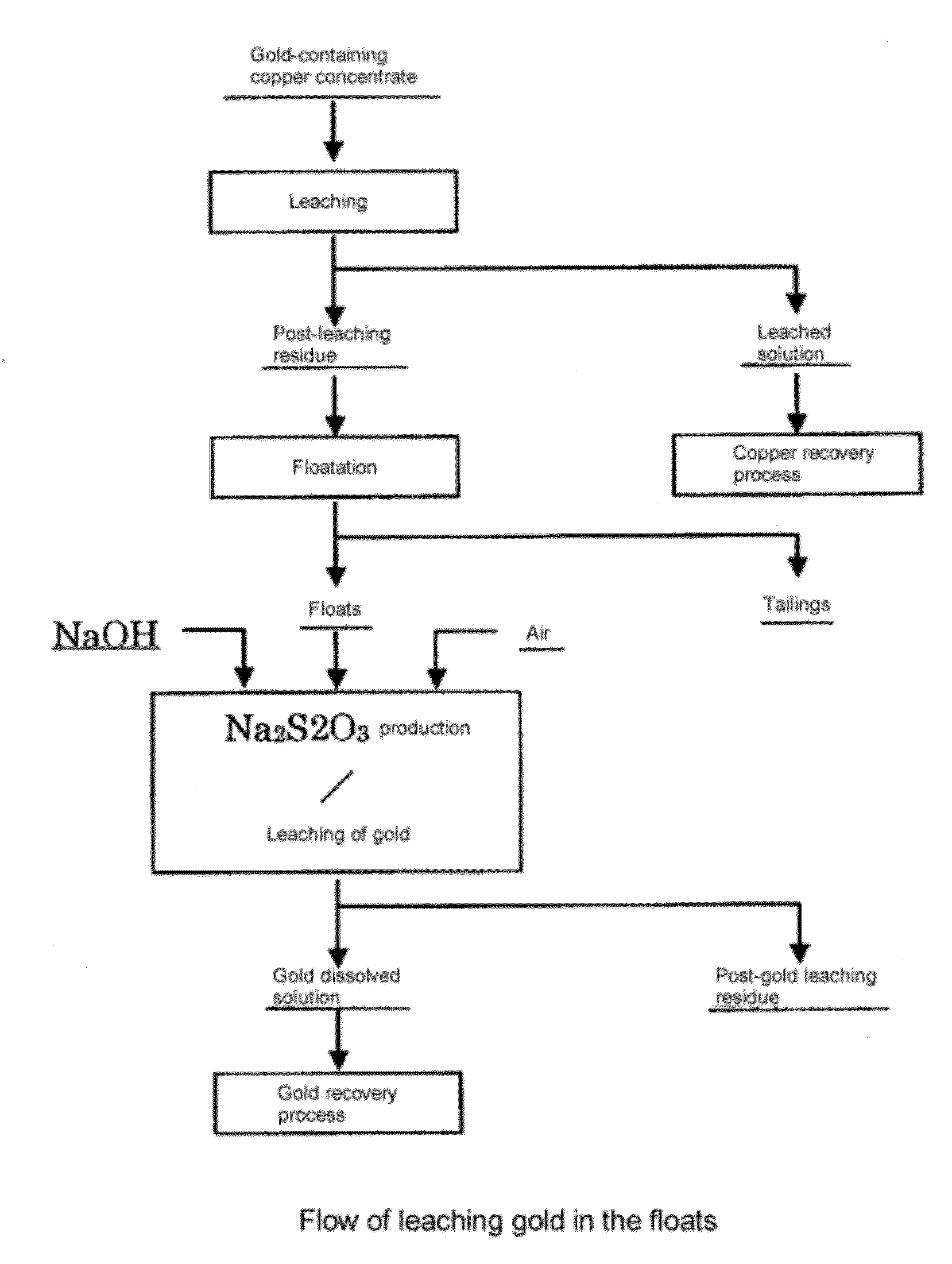

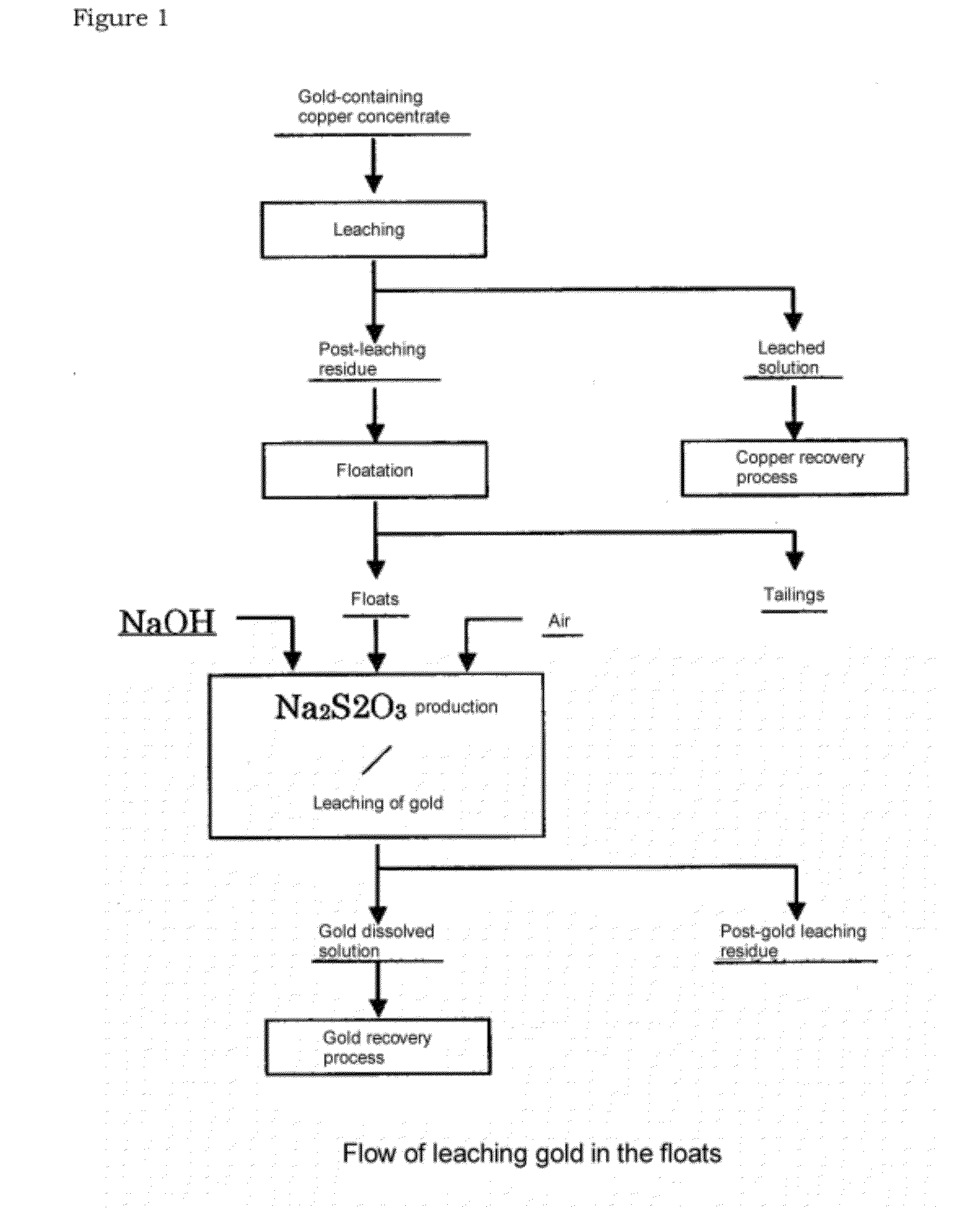

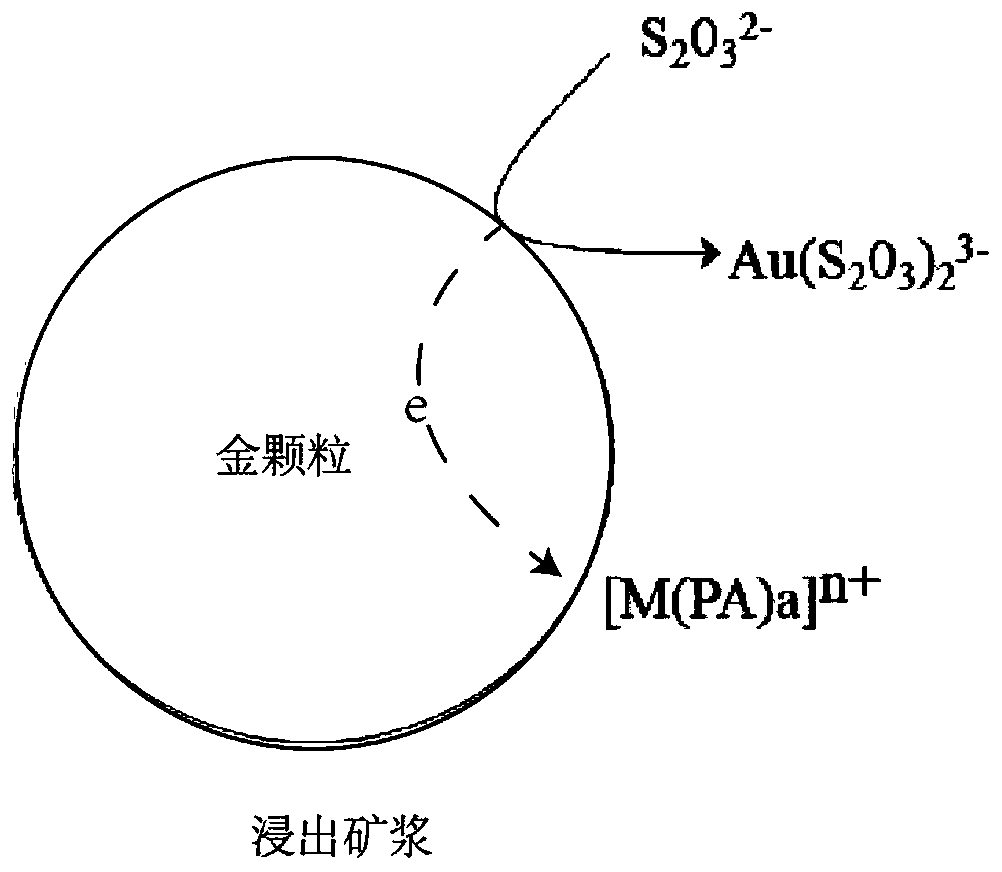

Process of leaching gold

This invention provides a process of leaching gold that can be inexpensively and efficiently carried out without using cyan from the mixture containing sulfur and gold, typically from the material which contains sulfur and gold and is an intermediate product recovered by the flotation method in the hydrometallurgical method.Specifically, this invention provides a process of leaching gold from the mixture containing elemental sulfur and gold, comprising contacting said mixture and an aqueous solution of hydroxide of one or more of metals selected from the group consisting of alkali metals and alkaline earth metals, and reacting said hydroxides and elemental sulfur so that thiosulfate of corresponding metal, and thus, gold is leached by the thiosulfate produced.

Owner:JX NIPPON MINING& METALS CORP

Hardening accelerator for hydraulic composition

Provided is a hardening accelerator for a hydraulic composition, which comprises a specific compound (1) such as glycerin and one or more inorganic salts (A ) selected from alkali metal sulfates and alkali metal thiosulfates, wherein the molar ratio of the compound (1) and the inorganic salt (A) is 5 / 95 to 45 / 55 by compound (1) / inorganic salt (A).

Owner:KAO CORP

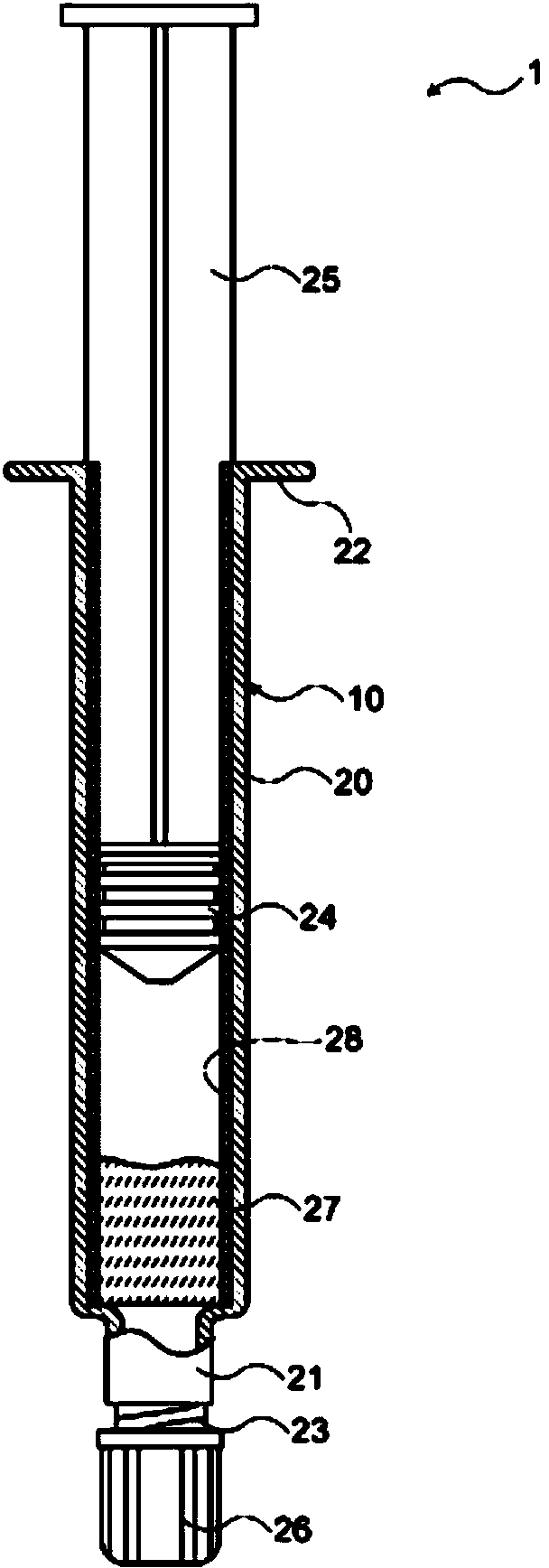

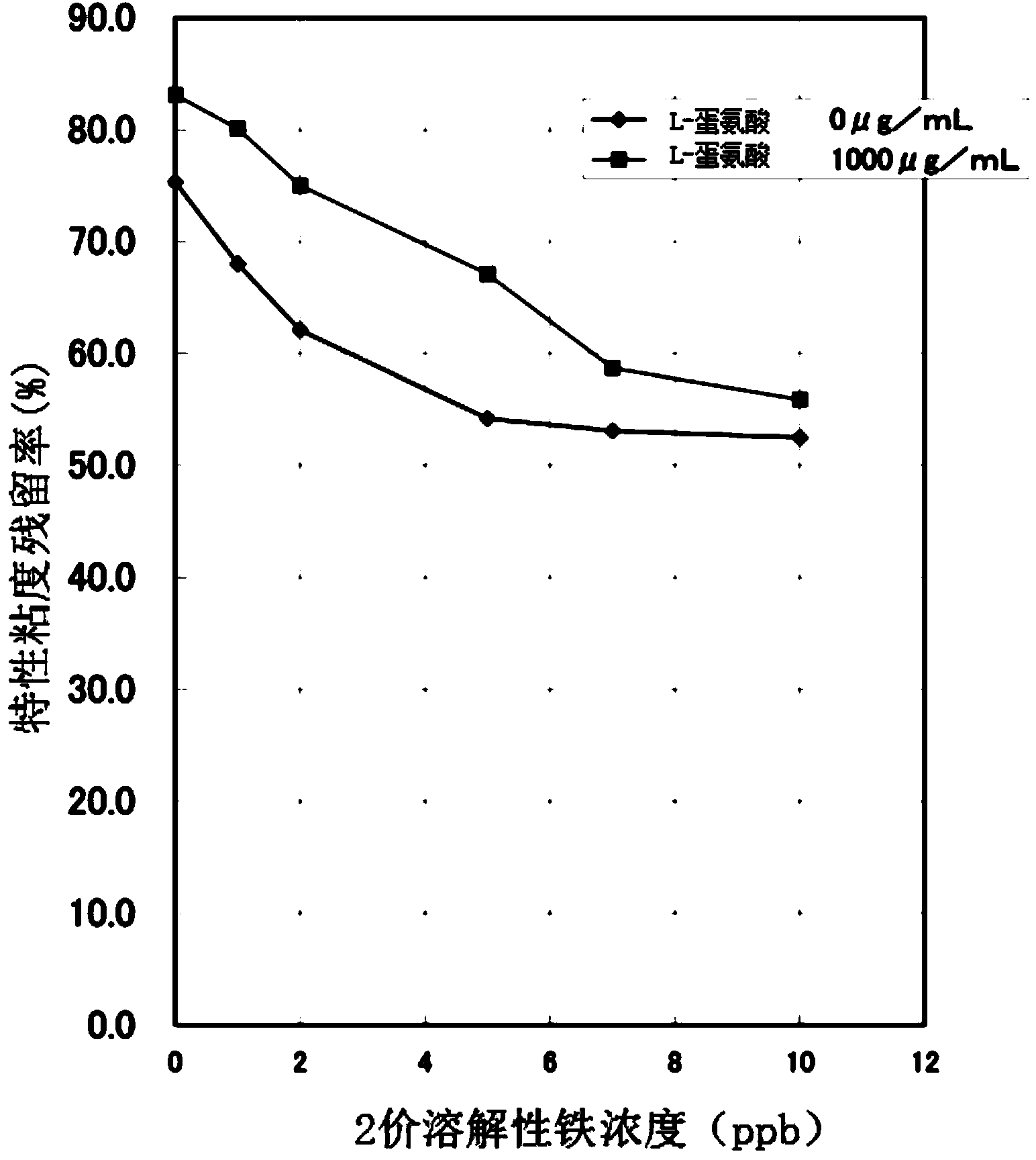

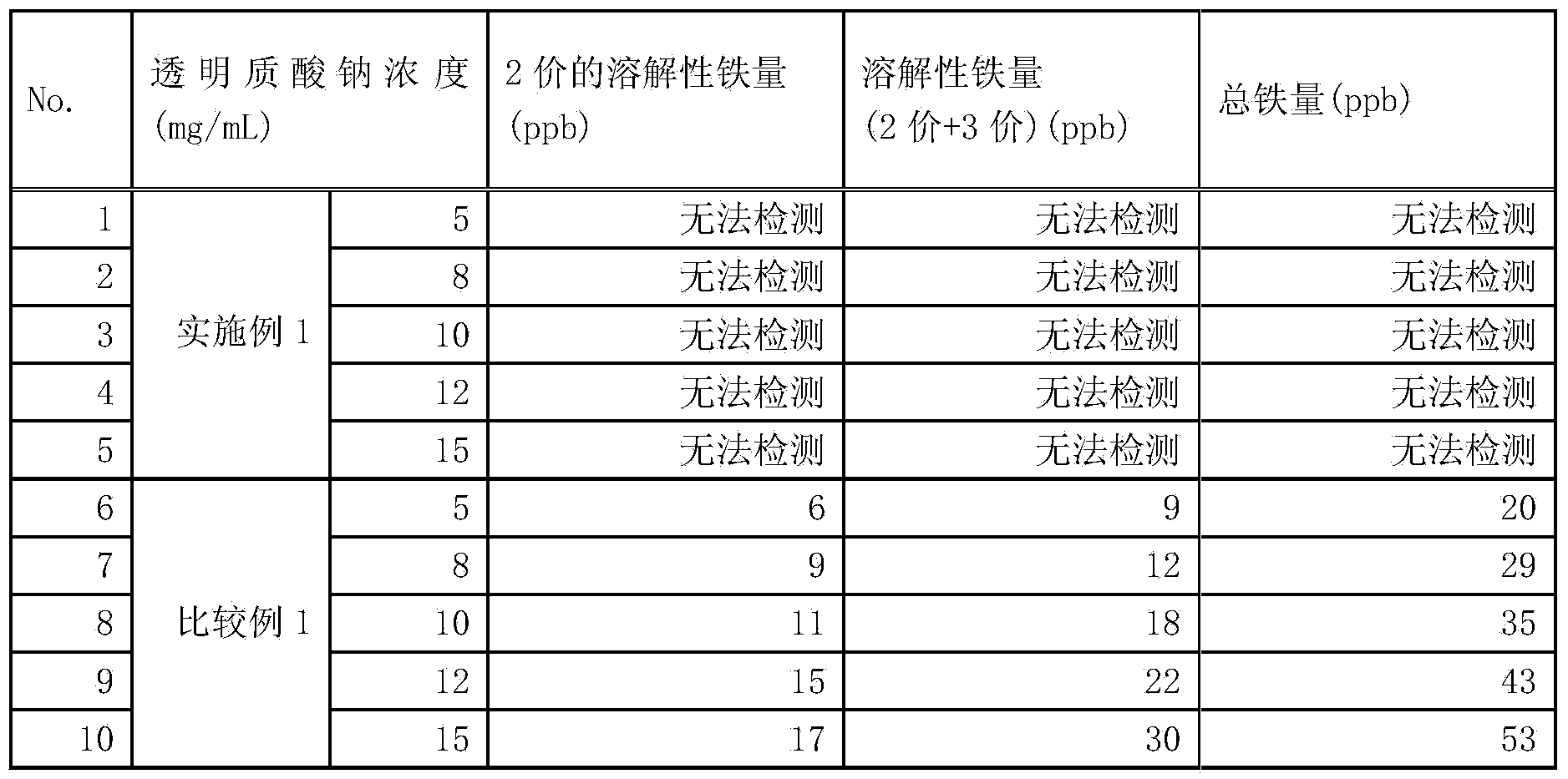

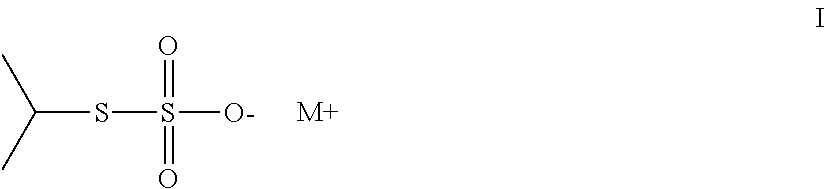

Pre-filled syringe filling syringe having resin barrel with aqueous solution containing hyaluronic acid or salt thereof

Provided is a pre-filled syringe that can stably store a highly-pure sodium hyaluronate aqueous solution that fills the inside of a resin barrel. Provided is a pre-filled syringe that fills a syringe having a resin barrel with an aqueous solution containing hyaluronic acid or a salt thereof. Moreover, the aqueous solution containing hyaluronic acid or a salt thereof contains a divalent soluble iron content of no greater than 5 ppb, and contains at least one additive selected from the group consisting of a metal thiosulfate, a metal thiocyanate, a thiourea, a thiosemicarbazide, a thioketone, and a sulfide.

Owner:DENKA CO LTD

Thiosulfate polymers

ActiveUS20140288253A1Surface energy of the photoresist can be modifiedMass productionCoatingsPolymer sciencePhotosensitizer

A thiosulfate polymer includes both an electron-accepting photosensitizer component and thiosulfate groups in the same molecule, arranged in random order along the backbone. The thiosulfate polymer composition can be formulated into compositions and applied to various articles, or used to form a predetermined polymeric pattern after photothermal reaction to form crosslinked disulfide bonds, removing non-crosslinked polymer, and reaction with a disulfide-reactive material. Such thiosulfate polymer compositions can also be used to sequester metals in nanoparticulate form, and as a way for shaping human hair in hairdressing operations.

Owner:EASTMAN KODAK CO

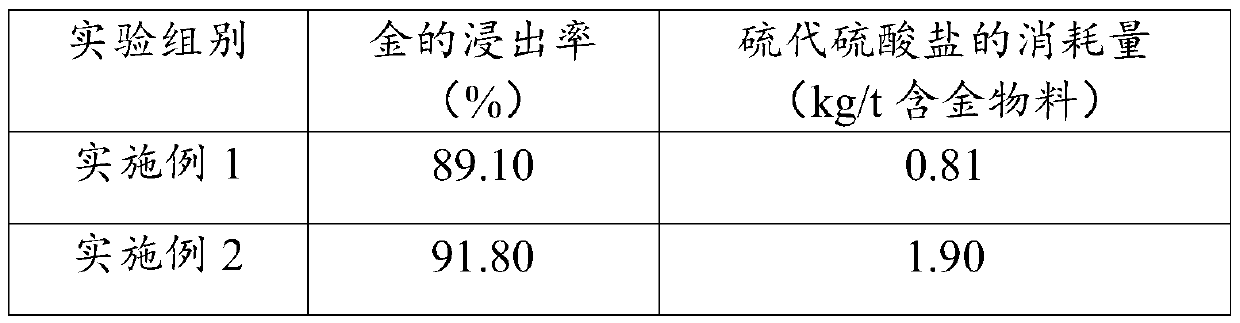

Thiosulfate gold leaching method and application

ActiveCN111471858AImprove the defect of excessive consumptionImprove gold leaching rateProcess efficiency improvementThio-Carboxylic acid

The invention provides a thiosulfate gold leaching method and application, and relates to the technical field of hydrometallurgy. The thiosulfate gold leaching method comprises the steps of adding metal salt, a polycarboxylic acid additive and thiosulfate into gold-containing ore pulp for leaching, wherein a large number of acid radical groups distributed on a hydrocarbon chain of the polycarboxylic acid additive and positive ions generated through hydrolysis of the metal salt in a solution can be subjected to a multi-tooth chelation effect to generate complex ions, thereby replacing Cu (NH3)4 < 2 + > in a traditional thiosulfate gold leaching process, and the defect of large thiosulfate consumption due to the fact that Cu (NH3) 4 < 2 + > has oxidability can be overcome on the premise that the high gold leaching rate is obtained. The concentration of harmful ions such as dithionite in decomposition products of S2O3 < 2-> in the leaching solution is remarkably reduced, and recycling ofthe leaching solution and recycling of gold in the solution are facilitated; and meanwhile, the thiosulfate gold leaching method also avoids the problems of safety and environmental influence causedby the use of ammonia water.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

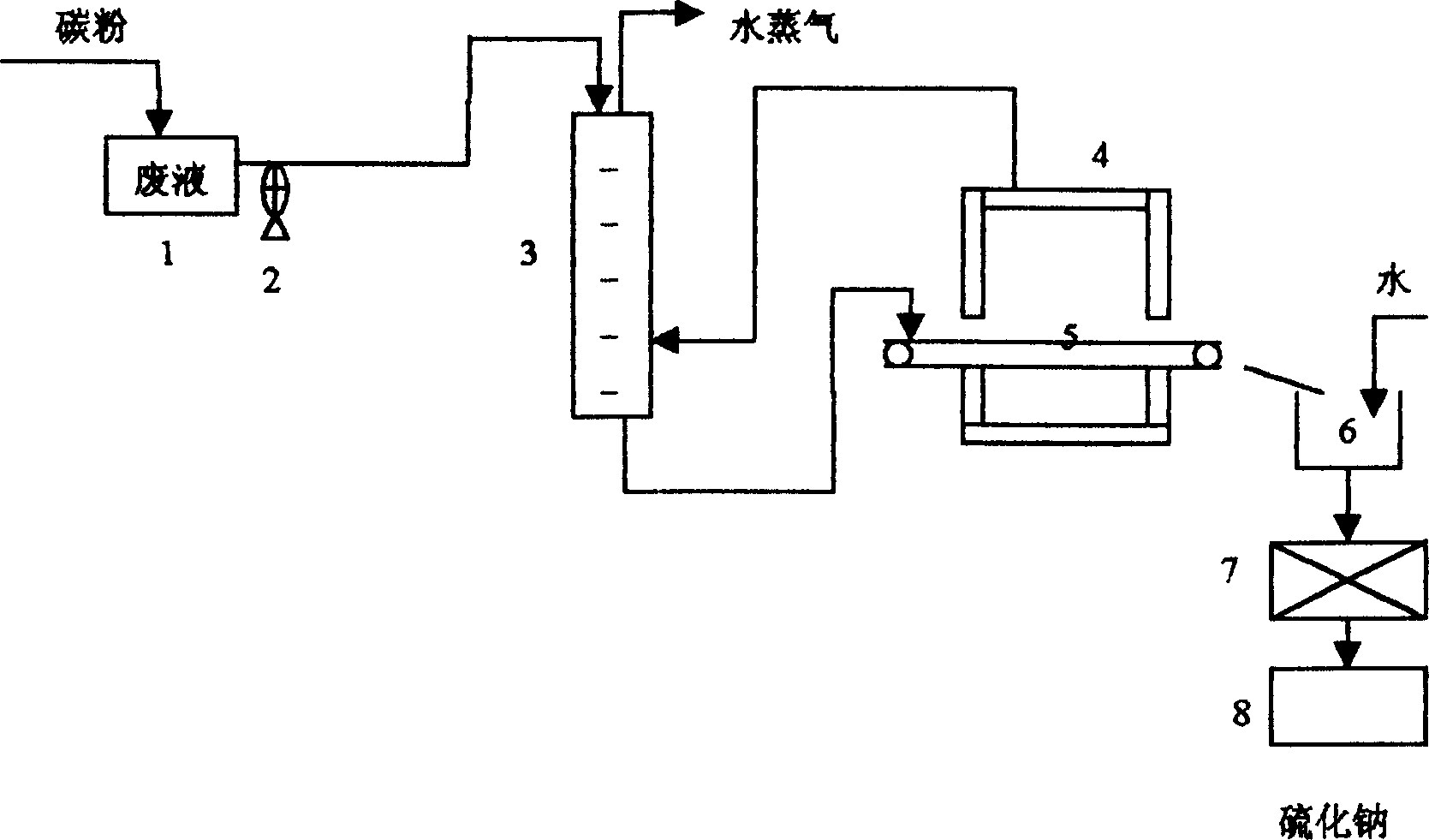

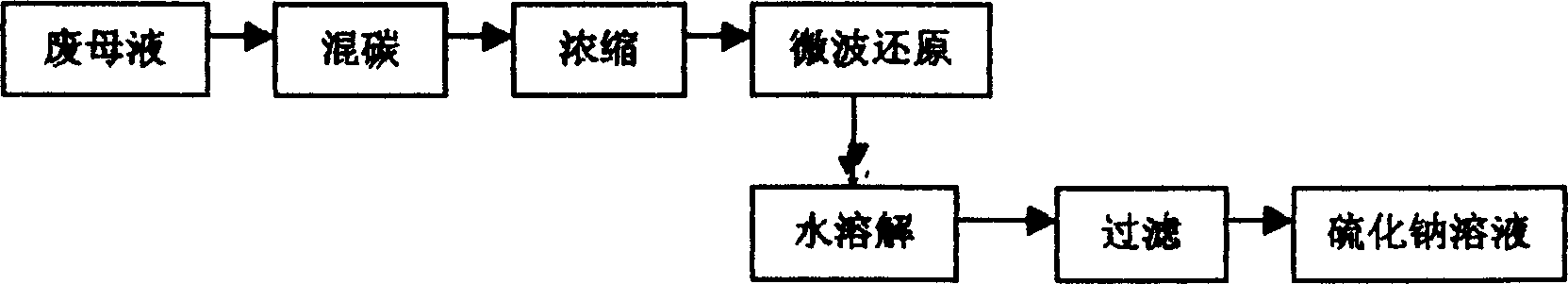

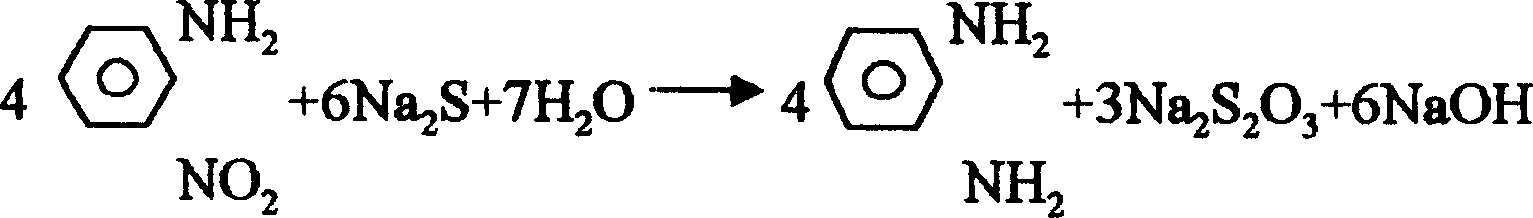

Process of preparing sodium sulfide from reducing sodium thiosulfate by microwave inducting carbon

ActiveCN1559886AEliminate pollutionLess investmentAlkali metal sulfides/polysulfidesSodium thiosulfateAmmonium thiosulfate

The invention discloses a method of preparing sodium sulphide by using microwave induced carbon to reduce sodium thiosulfate, and its characteristic: in mole ratio of sodium thiosulfate to alkali 1 to 2, mixing sodium thiosulfate with excessive carbon for concentrating or spray-drying, using microwave to act on the obtained solid for 2-3 min and completing the reaction, after cooling, adding in water for dissolving, filtering and recovering the fully unreacted carbon, and the filtrate is sodium sulphide solution. It can economically and fast reduce the waste liquids containing sodium thiosulfates into sodium sulphides, and the produced sodium sulphides contain no organic impurities and can meet the requirement of circularly using.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

Solution and method for one-step electrodeposition of Cu2ZnSnS4 (CZTS) prefabricated layer film

The invention relates to a solution and method for one-step electrodeposition of a Cu2ZnSnS4 (CZTS) prefabricated layer film, and belongs to the technical field of CZTS films. The solution for one-step electrodeposition of the CZTS prefabricated layer film comprises 0.001-0.005 mol / L of metal salt, 0.03-0.1 mol / L of thiosulfate, 0.1-0.4 mol / L of conducting salt, 0.01-0.5 mol / L of hydroxy acid, 0.01-0.5 mol / L of thiourea derivative and 1-5 g / L of stabilizer, wherein the pH value of the solution is 1-6.0. The method for one-step electrodeposition of the CZTS prefabricated layer film includes the steps that (1) the solution for preparing the CZTS prefabricated layer film is placed in a plating bath; (2) a three-electrode system is used for connecting a power controller, a reference electrode, a conducting substrate and an inertia anode, and a salt bridge is used for connecting a reference electrode solution and an electrodeposition solution; (3) a power supply is on, and a constant potential method is used for conducting codeposition on Cu, Zn, Sn and S; and (4) the deposited CZTS prefabricated layer film is taken out, washed and dried. The solution and method are simple and practical, stable in solution system, simple in technology, easy to operate, safe, environmentally friendly and suitable for large-area preparation of the CZTS films.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Color change indicating device and transparent ink

ActiveCN105542555AAvoid interferenceMeet the use requirementsMaterial analysis by observing effect on chemical indicatorInksPolyethylene oxideCellulose acetate

The invention relates to a color change indicating device and transparent ink. The color change indicating device comprises a substrate layer and an indicating layer formed on the surface of the substrate layer. The indicating layer comprises an indicating portion which is formed by printing of indicating ink sensitive to oxygen. The color change indicating device further comprises a protective layer covering the surface of the indicating portion. The protective layer is formed by printing of the transparent ink. The color change indicating device is characterized by further comprising a reducing agent, a binding agent and a solvent. The reducing agent is selected from at least one of hyposulphite, thiosulfate, hydrosulphite, sulfite, borohydride salt and ascorbic acid. The binding agent is selected from at least one of gelatin, hydroxyethyl cellulose, polyvinyl butyral, ethyl cellulose, cellulose acetate, polyvinylpyrrolidone, polyethylene oxide and polymethyl methacrylate. The pH value of the transparent ink is the same as that of the indicating ink. The color change indicating device can effectively prevent deviation of the pH value of the indicating portion.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com