Process of preparing sodium sulfide from reducing sodium thiosulfate by microwave inducting carbon

A sodium thiosulfate and sodium sulfide technology, applied in the direction of alkali metal sulfide/polysulfide, etc., can solve the problems of large equipment investment, difficult process control, and large carbon consumption, so as to reduce production costs, reduce environmental pollution, The effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

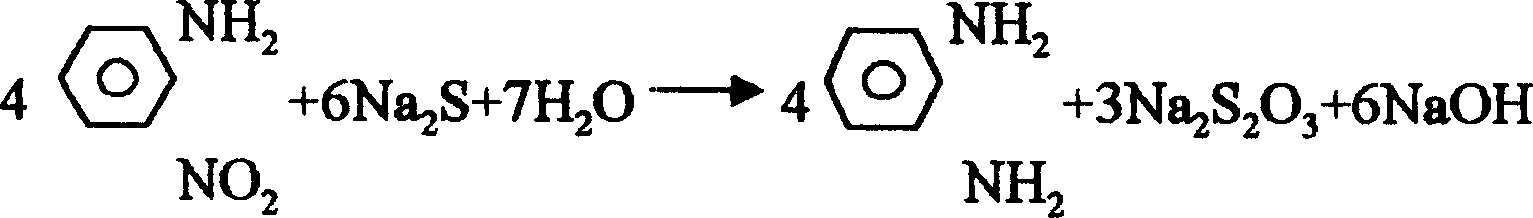

Problems solved by technology

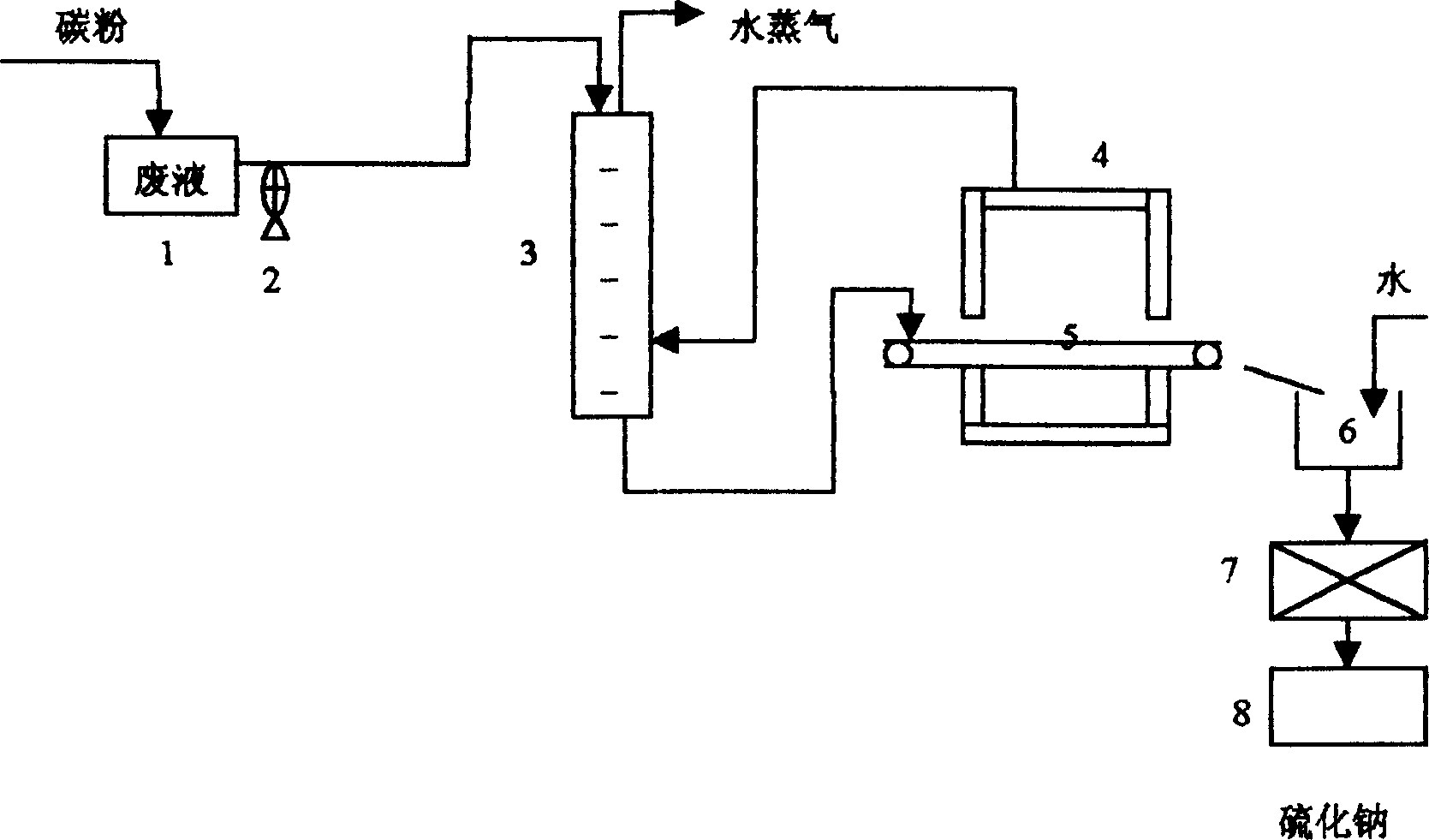

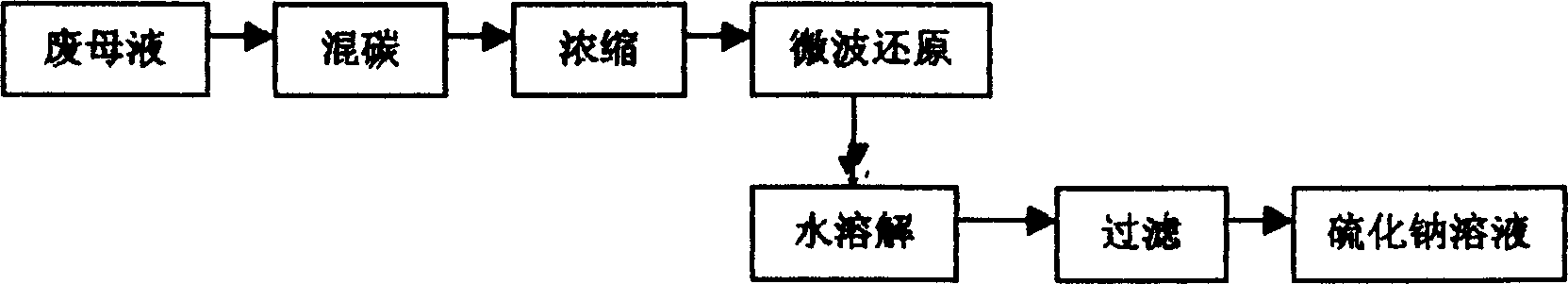

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Sodium thiosulfate 50g, charcoal powder 20g are mixed homogeneously, are placed in the crucible, add a cover, only leave air hole, in case contact with air and burn. Put it into a microwave oven with an input power of 1000W and a microwave frequency of 2450MHz, and induce heating in the microwave cavity for 3 minutes. It was found that besides the formation of sodium sulfide, sulfur was also generated. The transformation rate of sodium thiosulfate is greater than 95%, and a small amount of sodium sulfate is also generated.

Embodiment 2

[0022] Example 2: Mix 50 g of sodium thiosulfate, 25 g of sodium hydroxide, and 20 g of charcoal powder evenly, put them in a crucible, place them in a 1000W, 2450 MHz microwave oven, heat for 3 minutes, and the reduction reaction can be completed. The conversion rate of sodium thiosulfate is greater than 98%, and no sulfur and sodium sulfate exist. The reaction mixture was dissolved in 100 ml of water, and excess carbon was removed by filtration to obtain a light yellow transparent liquid with a sodium sulfide content of 32%.

Embodiment 3

[0023] Example 3: Mix 50 g of sodium sulfate and 20 g of charcoal powder evenly, put them in a crucible, place them in a 1000W, 2450 MHz microwave oven, heat for 5 minutes, and the reduction reaction ends. The transformation rate of sodium thiosulfate is greater than more than 96%, and is processed by the method for example 2, obtains almost colorless and transparent sodium sulfide, content 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com