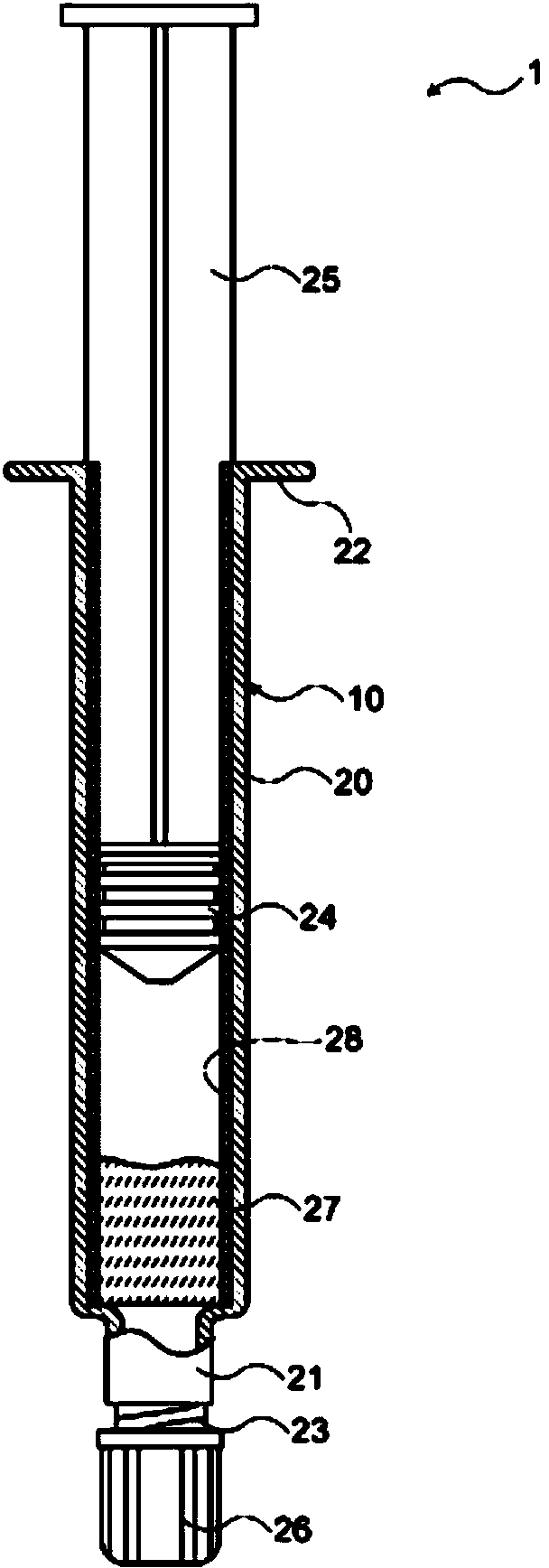

Pre-filled syringe filling syringe having resin barrel with aqueous solution containing hyaluronic acid or salt thereof

A pre-filled syringe and hyaluronic acid technology, applied in the directions of syringes, ampoule syringes, hypodermic injection devices, etc., can solve the problems of high cost, easy breakage of glass barrels, and inability to burn together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

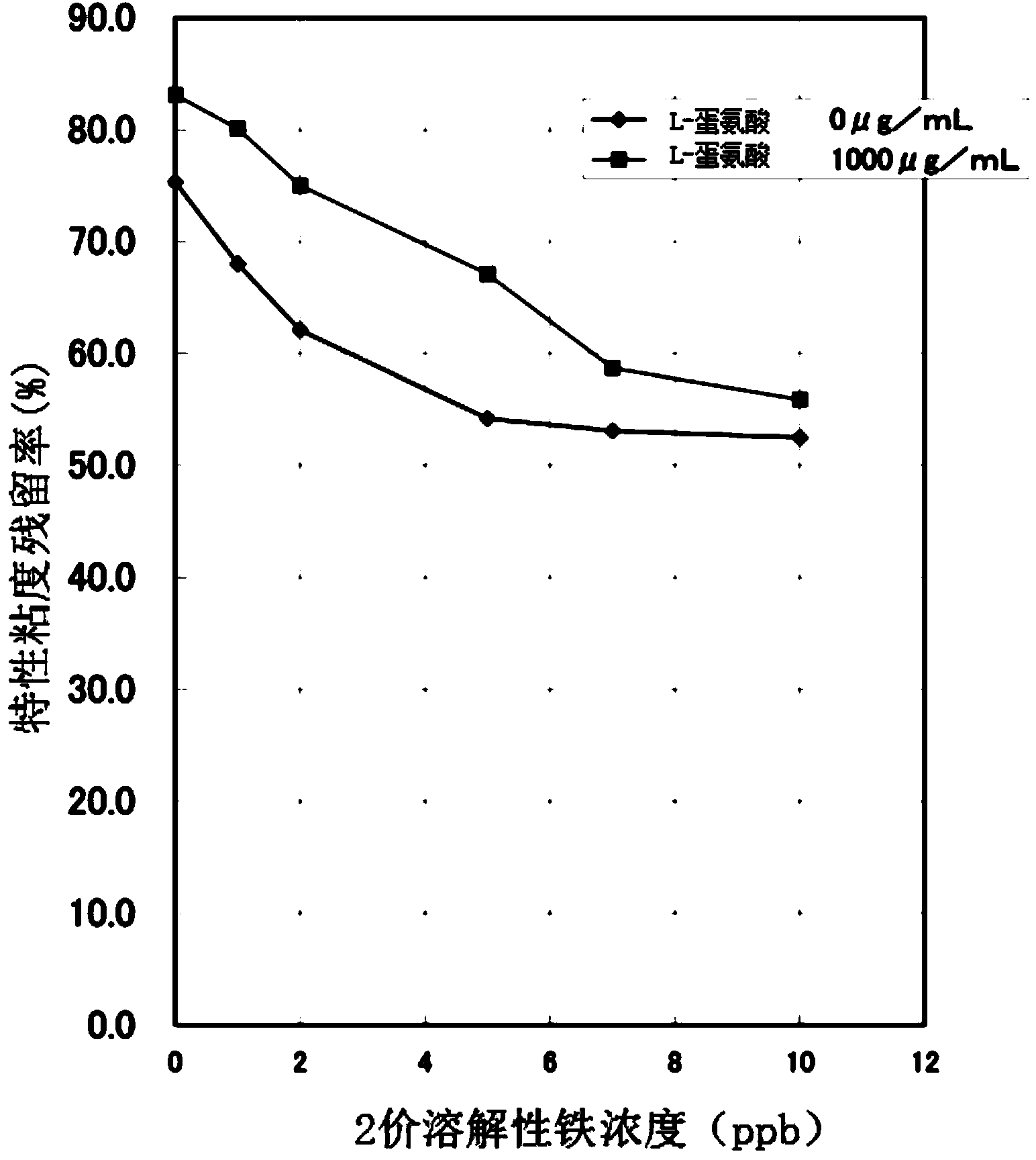

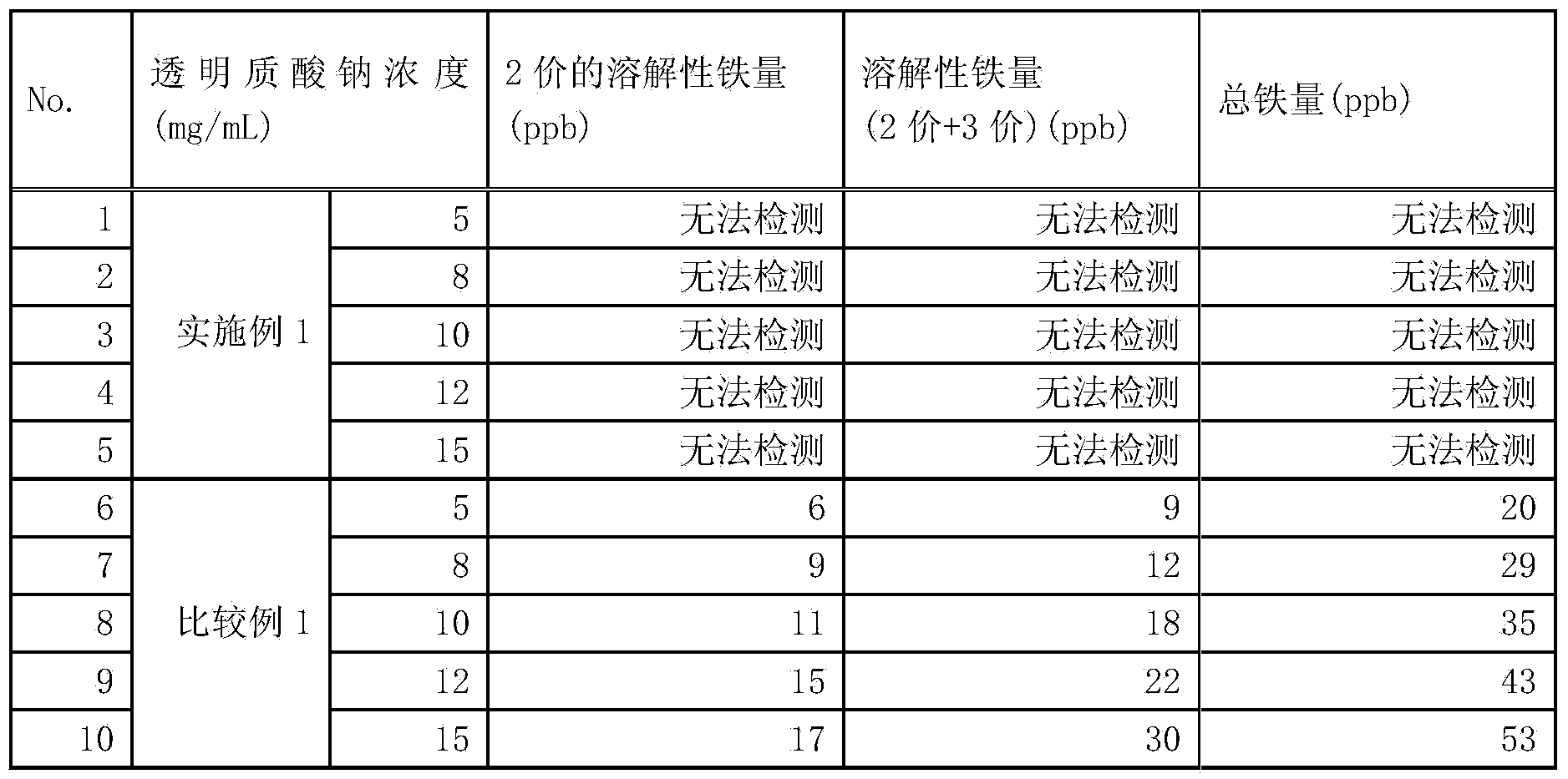

Embodiment 1

[0060] The sodium hyaluronate aqueous solution was adjusted in the following order. First, after heat-sterilizing 1 liter of a medium consisting of 5% glucose, 0.2% potassium primary phosphate, 1.0% polypeptone, and 0.5% yeast extract, Streptococcus equi ( Streptococcus equi) FM-100 (Wei Gong Yan Tiao No. 9027) for inoculation. While blowing air at 1vvm, stir at 200 rpm, and cultivate for 20 hours at a temperature of 33°C and a pH of 8.5 (controlled by automatic dropwise addition of 20% sodium hydroxide). After this solution was filtered with a bacterial filter, it was dialyzed against water for 12 hours to recover the hyaluronic acid solution in the dialysis membrane. In order to prevent the incorporation of iron, the collection container uses a container made of glass on the inner surface. Sodium chloride was added thereto so as to be 2.5%, and ethanol was added in an amount twice that of the hyaluronic acid solution to precipitate sodium hyaluronate. Wash the precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com