Sulfur-oxidizing bacterium and method for removing sulfide by using sulfur-oxidizing bacterium

A technology of sulfur-oxidizing bacteria and thermophilic Thiobacillus, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of low yield of elemental sulfur and low desulfurization efficiency, and achieve an enhanced system Effects of mixing, high-efficiency oxidation, and high-efficiency elemental sulfur production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 strain screening

[0026] In this example, the sludge from an anaerobic pond of a sewage treatment plant in Jiangsu Province was taken, and an inoculation amount of 5% was added to a 250mL triangular flask containing 100mL thiosulfate medium, pH=7, 37°C, 170r / min, Carry out enrichment culture for 4 days, repeat 3-4 times, use sodium thiosulfate medium for plate separation, after 3 days, colonies are formed, pick a single colony and insert it into sodium thiosulfate medium for culture, repeat plate separation 4 times to obtain pure bacteria.

Embodiment 2

[0027] Embodiment 2 strain identification

[0028] The whole genome of the pure culture was extracted using the bacterial whole genome rapid extraction kit, and PCR was performed with 16S rDNA universal primers to identify the strain as Thiobacillus thermophiles ( Themithiobacillus tepidarius ).

Embodiment 3

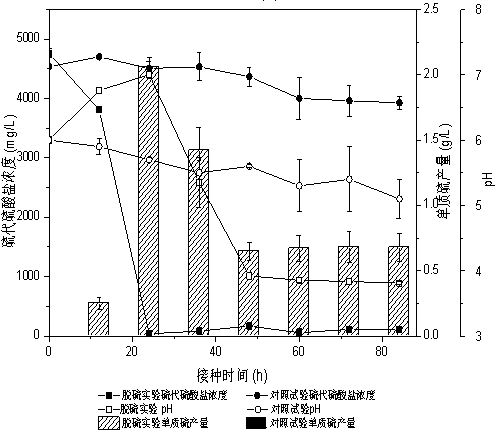

[0029] Example 3 Physiological, biochemical and batch biological desulfurization of bacterial strains

[0030] The morphology of the above-mentioned JNU-2 was observed by transmission electron microscopy as follows: figure 1. Take the strains screened at initial pH = 4.0, 5.0, 6.0, 7.0, 8.0 and 9.0 for cultivation, and determine the optimum pH for bacterial growth to be 8.0, and the optimum pH for elemental sulfur production to be 6.0; , 40°C, 43°C, 46°C and 50°C were cultivated at the optimum pH for elemental sulfur production, and the optimum temperature range for growth and elemental sulfur production was determined to be 37-43°C. Determine the optimal energy substrate (g / L) for strain JNU-2 by the following combinations: yeast extract 1.0; peptone 1.0; glucose 1.0; fructose 1.0; sucrose 1.0; lactose 1.0; galactose 1.0; maltose 1.0; glycine 1.0 ; Lysine 1.0; Methionine 1.0; Na 2 S 2 o 3 ·5H 2 O 10.0; Na 2 S 1.0; S 0 1.0; yeast extract 1.0 and Na 2 S 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com